Abstract

Chocolate is a widely consumed product with high levels of polyphenols; unfortunately, it is reduced during the process. Adding other components allows for counteracting the polyphenols lost during chocolate processing and reducing the content of unsaturated fatty acids, affecting its physical properties. This study identified the conching time, concentration of sauco by-products, and levels of sacha inchi oil to produce enriched dark chocolates. For this study, sauco by-products in percentages of 2, 6 and 10%, sacha inchi oil in levels of 1, 3, and 5%, and three conching times of 16, 20, and 24 h were added to 75% dark chocolates, and the process conditions were optimized through the response surface methodology (RSM). The physicochemical properties of the dark chocolates were studied, observing that the sauco by-product, sacha inchi oil, and conching time significantly affected (p < 0.05) the variables of antioxidant activity, total phenol content, rheology, hardness, and particle size. The R2 correlation of the factors declared against the variables indicated the model's reliability as it was close to 1. The results suggest that incorporating sauco by-products allows for obtaining chocolates with good chemical properties; however, high percentages of sacha inchi oil and shorter conching time cause a negative effect on the chocolate affecting the physical properties.

Keywords: Fortification, CBE, Sauco by-products, Sacha inchi oil, Polyphenols

1. Introduction

Chocolate is one of the most popular foods worldwide due to its unique taste and aroma, characteristics that make it an object of temptation, as well as its anti-ulcer, anti-carcinogenic, anti-thrombotic, antimicrobial properties in the health of consumers, thanks to the high levels of polyphenols [1,2]. However, the phenolic content and antioxidant activity of chocolate decrease at each stage of the manufacturing process as fermentation, drying, roasting, conching, and storage [3]; being the conching a critical stage due to the exposure of the mass to high temperatures for prolonged times that drastically reduce the phenolic compounds; affecting viscosity, texture, particle size, aroma and the final quality of the chocolate [4]. For chocolate manufacturing, cocoa butter (CB) is the central component of the liquid block of the continuous phase, providing a network structure that gives stability to the components found in the dispersed phase, such as cocoa paste, sugar, lecithin, mainly; which together give it attributes such as smoothness, slow melting in the mouth, and snapping [5,6]. However, the high saturated fatty acid content of CB leads to health problems such as atherosclerosis and cardiovascular disease, creating the need to use vegetable fats as cocoa butter substitutes (CBS), not exceeding 5% of the total product ([1,7].

Studies on the effects of conching time on phenolic compounds, antioxidant activity, and physical properties are underway. According to Pedan et al. [8], the longer the conching time, the smoother the chocolate is during consumption, but the greater the loss in sensory and nutritional attributes. Generally, periods can vary from a few hours to days; in this sense [9] studied four different conching periods; 8, 12, 16, and 20 h, suggesting that the 20-h conching period yielded better quality chocolates and an acceptable range of particle size between 20 and 30 μm. In addition to this, Gültekin-Özgüven et al. [3] suggested that choosing cocoa beans rich in phenols, reducing the temperature and the roasting and conching time will preserve the bioactive compounds, as confirmed in the study of [10] where the conching process decreased the content of total phenols and antioxidant activity significantly (p < 0.05). However, there is limited information on the influence of the conching process on the content of bioactive compounds.

On the other hand, it has been reported that incorporating bioactive substances such as phenolic acid, flavonoids, polyphenols, and vitamins, among others, counteract the losses of phenolic compounds that occur during the processing of dark chocolate. These substances are found naturally, improving the value of the food chain [11] and thus the product's nutritional value, maintaining its functionality and chemical structure during the shelf life [12]. Studies suggest that the incorporation of natural additives such as fruits, by-products, nuts, salts, and herbal extracts, among others, can improve the functional characteristics of chocolate [13]; this is why a good alternative is the incorporation of elderberry by-products, known to be a rich source of polyphenolic compounds, mainly flavonols, phenolic acids, and anthocyanins that protect the human body against oxidative stress and lipid peroxidation processes [14]. On the other hand, using elderberry residues strengthens the circular economy, giving added value to the initial product and favoring producers [15]. Unfortunately, there is little information on the metabolic profile, bioactive properties, and physicochemical characteristics of sauco (Sambucus peruviana) and its by-products (peels and seeds). Several reports indicate that total phenolic compounds and antioxidant activity are higher in the fruits' peel than in the pulp [16]. In addition, some studies have been carried out on the antioxidant activity of berry seeds, indicating that their use as a source of additives and natural ingredients would be beneficial [17]. Studies on the content of total polyphenols have been generated in various fruits, as reported by Ref. [18], who found that the total polyphenol content in grape skins and seeds was higher than in whole fruit pulp; this can be explained by the presence of pressed seeds and skins, similar to the results reported in another study where the highest values in radical scavenging activity, antioxidant capacity, and ferric reduction were recorded in blackcurrants, blackberries, and blueberries, with blueberries and blackberries having the highest concentration of polyphenols [19].

The trend towards healthy food consumption has created the need to produce low-saturated fat chocolates, with the challenge of maintaining their physical and functional characteristics [20]. As alternatives, there is the incorporation of BC substitutes (CBS) such as Sacha Inchi, reported by Refs. [21,22]. Sacha inchi (Plukenetia huallabambana. sp.nov.), grown only in the Peruvian Amazon, contains high concentrations of phenolic compounds and antioxidant capacity [23]. Therefore, its use as an equivalent of CB in chocolate production is plausible. Given the growing demand for natural CBS, it is necessary to propose alternatives to the existing ones. In addition, given that there are few CBS in the Peruvian market for the manufacture of chocolates, it is necessary to use other vegetable oils from local raw materials [21]. Likewise [24] mentioned that there are predominant phenolic compounds in sacha inchi husk extracts (an underutilized by-product in oil processing), such as 3,4-dihydroxy-benzaldehyde, hydroxy-4-chromone and their derivatives. In the research of [21], due to the loss of total phenolic content and antioxidant capacity during the production of dark chocolate, sacha inchi oil was used as a substitute for cocoa butter, showing that as the percentage of sacha inchi oil increased, the antioxidant capacity and phenolic content also increased, demonstrating that it is a potential substitute for CB.

The studies report that it is possible to improve not only the physicochemical properties of chocolates by using fruit by-products but also by incorporating SCB, such as sacha inchi oil, as well as by improving the manufacturing process, such as conching. However, these studies were conducted separately. Therefore, this study has focused on identifying the optimal values of conching time, the concentration of sauco by-products, and sacha inchi oil levels for dark chocolate manufacturing using Response Surface Methodology (RSM) (see to Fig. 1).

Fig. 1.

Workflow for identifying the conching process time, sauco by-product concentration, and sacha inchi oil levels for the enrichment of dark chocolate.

2. Materials and methods

2.1. Raw materials

The main raw material is the Criollo cocoa variety, obtained from the APROCAM cooperative (Bagua, Amazonas), which contained 7.5% humidity. The sauco (Sambucus peruviana) belonged to a local producer (Chachapoyas, Amazonas) and was harvested from the plantations when it was ripe. The seeds and skins were separated from the pulp and freeze-dried. Sacha Inchi oil was of the variety (Plukenetia huallabambana. sp.nov.) and was obtained from the local market in processed form. The chocolates were made in the Laboratorio de Investigación de Ingeniería de Alimentos y Poscosecha and evaluated at the Laboratorio de Biotecnología Agroindustrial of the Universidad Nacional Toribio Rodríguez de Mendoza de Amazonas.

2.2. Freeze-drying of sauco by-products

The ripe sauco was pressed into juice using a blender. The skin and seeds were collected during pressing and taken to an ultra-freezer (New Brunswick, United Kingdom) at −86 °C for 72 h; then taken to a freeze dryer (LABCONCO, Canada) for 72 h, at a pressure of 0.360 mbar and −75.8 °C. At the end of the freeze-drying process, the samples were ground in a ball mill (Retch, MM200, Germany) at 25v for 5 min, with a final moisture content of 2.7%.

2.3. Chocolate manufacturing

The process followed [25,26] method with some modifications; the cocoa beans were cleaned, sorted, and graded before processing, then taken to a tray dryer at 130 °C for 25 min and then taken to a dehuller (IMSA, Peru) to separate the husk from the nibs. The cocoa nibs were passed through a bean mill (Prosol, Peru) to obtain cocoa liquor. Cocoa liquor, sugar, CB, aceite de sacha inchi, and freeze-dried sauco by-products were added to a two-roller conching and refining machine (Premier, India) for the time required for the research. Subsequently, the chocolate was tempered (Revolation, U.S.A) at 45, 29, and 33 °C to form the desired crystals. Then, they were placed in 45 g-plastic molds, packed in aluminum foil, and stored at 7 °C.

2.4. Chocolates antioxidant activity

One gram of the chocolate sample was weighed to obtain the extracts, and 10 mL of methanol-water (80:20, v/v) was added, as described by Ref. [27]. Subsequently, the extract was taken to the centrifuge at 5000 rpm for 10 min, then filtered, and the supernatant was kept refrigerated. The prepared extract was used to analyze total phenolic content and antioxidant capacity.

2.4.1. DPPH assay

According to de Souza et al. [28], the following procedure was performed, the DPPH solution (600 μM) was diluted with ethanol to obtain an absorbance of 0.7 ± 0.02 units measured at 517 nm with a spectrophotometer (Emelab, Germany). The extracts (0,1 mL) were left to react with 3,9 mL of the DPPH radical solution for 30 min in the dark, and the decrease in absorbance of the resulting solution was monitored. The absorbance of the reaction mixture was measured at 517 nm. The results were expressed in μmol Trolox equivalent per gram sample (umol of TEs/g). Each sample was analyzed in triplicate.

2.4.2. ABTS·+ assay

For the ABTS assay, the procedure followed the method of de Souza et al. [28] with some modifications. The ABTS radical cation is generated by 5 mL of aqueous ABTS solution (7 mM) reaction with 88 μL of 140 mM (final concentration of 2.45 mM) potassium persulphate. The mixture was kept in the dark for 16 h before use and then diluted with ethanol to get an absorbance of 0,7 ± 0,02 units measured at 734 nm with a spectrophotometer (Emelab, Germany). The extracts and Trolox standard (30 μL) were reacted with 3 mL of the resulting blue-green ABTS radical solution in the dark. The absorbance was measured after 6 min. Results are expressed as micromoles of Trolox equivalents (TEs) per gram sample (umol of TEs/g).

2.5. Total phenol content

Total phenolic content was determined following the procedures of de Souza et al. [28] with some modifications. The extract (0.1 mL) was mixed with 2.5 mL of Folin-Ciocalteu reagent, then 2 mL of sodium carbonate solution was added. The reagents were mixed by vigorous shaking for 10 s with a vortex. The mixture was left to stand in the dark for 2 h before absorbance measurement at 760 nm using a spectrophotometer (Emelab, Germany). A standard curve of gallic acid in 70% methanol was diluted (10–100 μg/mL) to create a calibration curve. Total phenolic content is expressed as mg gallic acid equivalents per gram sample (mg GAE/g). All samples were run in triplicate.

2.6. Rheological characterization

The Casson plastic viscosity (Pa. s) and the Casson yield stress (Pa) were measured by a Rheometer (Anton Paar, Model MCR 92, Austria) equipped with a concentric cylinder geometry measured the flow properties of the chocolate; for this, the chocolate was melted at 45 °C in a water bath for 10 min prior to the measurement and placed in a concentric cylinder. The measurement procedure was based on method 209 [29] with minor modifications. The temperature of the rheometer was adjusted to 40 °C; each measurement was repeated in triplicate.

2.7. Texture evaluation

According to Ma et al. [30], the force-time curve and hardness of the chocolates were measured using a Texture Analyzer. The measurement in a penetration cycle was performed with a probe (TA2/1000, 30 mmd Cone, 60°, 5 kg load cell) coupled to the texture analyzer. The test was performed on 55 × 50 x 0.7 (cm) specimens at a 10.0 mm/s speed.

2.8. Particle size distribution

According to Afoakwa et al. [7], a particle size analyzer (Anton Paar, Austria) was used for this procedure. An amount of 200 mg of defatted sample was placed in the disperser of the analyzer, using water as a solvent. The distribution curves characterized the particle size in specific surface areas small D [10], middle D [50], and large D [90].

2.9. Experimental design and data analysis

The present research employed a response surface methodology (RSM) with a three-level composite central rotating design (CCD) used for the studies. Experimental scenarios were generated with three factors: sauco by-product concentration (2, 6, and 10%), sacha inchi oil concentration (1, 3, and 5%), and conching time (16, 20, and 24 h). Twenty runs with three central points were carried out in triplicate. The dependent variables (responses), antioxidant activity, total phenols contents, rheology, hardness, and particle size distribution were analyzed, and the fitted models were subjected to variance analysis (ANOVA) to specify significance (P < 0.05), determination coefficient (R2), and lack of fit. The lack of fit value confirms the applicability of the model. After removing the non-significant terms, the best-fit equations for all the responses were established. Multiple response optimizations were conducted to recognize the combination of experimental factors, simultaneously optimizing the responses; data analysis was done with Statistica v10 software.

3. Results and discussions

3.1. Antioxidant activity

In this study, the antioxidant capacity of the samples was measured by DPPH and ABTS assays. Values from 30.60 to 53.10 (μmol Trolox/g) were found for DPPH and 12.22 to 22.21 (μmol Trolox/g) for ABTS (Table 1.) [31]. evaluated dark chocolates containing zinc lactate, enriched with sauco extracts, obtaining values of 1911.6 (μmol TE/g) for Dpph and 2337.1 (μmol TE/g) for Abts; likewise, they evaluated dark chocolates that obtained a value of 144.2 (μmol TE/g) in Dpph and 433.9 (μmol TE/g) in Abts, values below those of the enriched chocolates. We can say that sauco increased the antioxidant capacity of dark chocolate since these fruits are rich in terpenoids, vitamins, polyphenols, flavonoids, anthocyanins, carotenoids, and other minority compounds, which favors the antioxidant capacity of the final product [32]. Moreover, the freeze-drying method allowed the maintenance of the bioactive properties of sauco after processing as husk and seed. In our study, the freeze-dried sauco by-product contributed to the bioactive properties of the chocolate [33]. Furthermore, in our work, it is shown that, with the percentages close to the maximum concentration of sauco by-products, low percentages of sacha inchi oil, and shorter conching time, the antioxidant activity reached optimal values (54.53 and 23.28 for DPPH and ABTS; respectively) (Table 2.). In the study of [21], the antioxidant properties of dark chocolates increased with the partial use of sacha inchi oil CBS when added at the final conching stage. However, in our study, sacha inchi oil was added at the initial conching stage and could affect the antioxidant contribution. Therefore, we believe that sacha inchi oil properties are affected by the conching time and temperature (Fig. 2 a; Fig. 2b) due to its chemical nature, presenting a high susceptibility to oxidation due to high temperatures, limiting its shelf life, causing a loss in its nutritional value, and forming undesirable compounds [34]. The correlations between the results obtained with the two antioxidant assays were positively high in DPPH (R2 = 90.50) and ABTS (R2 = 81.94); consequently, both conching time, sacha inchi oil and sauco by-product contributed significantly (p < 0.05) to the antioxidant activity of chocolate.

Table 1.

Experimental design with factors and responses.

| CT (h) | SP (%) | SIO (%) | AA-DPPH (μ mol Trolox/g) | AA-ABTS (μ mol Trolox/g) | TPC (mg GAE/g) | CPV (Pa. s) | CEL (Pa) | Hardness (N) | PSD- [D10] (μm) | PSD- [D50] (μm) | PSD- [D90] (μm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 2 | 1 | 43.63 ± 0.08 | 17.31 ± 0.08 | 22.72 ± 0.01 | 2.14 ± 0.02 | 40.35 ± 0.58 | 4.70 ± 0.19 | 5.12 ± 0.10 | 12.26 ± 0.08 | 29.33 ± 0.12 |

| 16 | 10 | 5 | 50.32 ± 0.13 | 20.53 ± 0.12 | 25.27 ± 0.02 | 1.77 ± 0.02 | 32.69 ± 1.60 | 4.27 ± 0.05 | 8.18 ± 0.01 | 21.21 ± 0.03 | 42.23 ± 0.20 |

| 24 | 10 | 1 | 40.24 ± 0.21 | 19.87 ± 0.05 | 23.96 ± 0.02 | 1.97 ± 0.03 | 35.29 ± 0.45 | 6.98 ± 0.12 | 7.65 ± 0.11 | 18.39 ± 0.04 | 37.69 ± 0.03 |

| 24 | 2 | 5 | 36.79 ± 0.08 | 17.53 ± 0.08 | 22.35 ± 0.02 | 1.85 ± 0.03 | 36.09 ± 0.74 | 4.75 ± 0.05 | 2.75 ± 0.09 | 4.27 ± 0.07 | 24.49 ± 0.38 |

| 20 | 6 | 3 | 44.40 ± 0.13 | 19.24 ± 0.02 | 22.61 ± 0.03 | 1.86 ± 0.02 | 23.43 ± 0.99 | 4.58 ± 0.42 | 2.87 ± 0.04 | 4.69 ± 0.05 | 26.76 ± 0.01 |

| 20 | 6 | 3 | 44.40 ± 0.21 | 19.25 ± 0.06 | 22.57 ± 0.01 | 1.87 ± 0.03 | 25.58 ± 1.93 | 4.49 ± 0.19 | 2.80 ± 0.08 | 4.62 ± 0.01 | 26.72 ± 0.11 |

| 20 | 6 | 3 | 44.40 ± 0.13 | 19.18 ± 0.03 | 22.58 ± 0.01 | 1.83 ± 0.02 | 22.36 ± 1.69 | 4.47 ± 0.40 | 2.95 ± 0.06 | 4.72 ± 0.15 | 26.76 ± 0.09 |

| 20 | 6 | 3 | 44.40 ± 0.22 | 19.28 ± 0.07 | 22.59 ± 0.02 | 1.83 ± 0.03 | 23.74 ± 1.16 | 4.49 ± 0.46 | 2.81 ± 0.04 | 4.56 ± 0.12 | 26.73 ± 0.09 |

| 20 | 6 | 3 | 44.40 ± 0.13 | 19.22 ± 0.09 | 22.60 ± 0.02 | 1.87 ± 0.02 | 23.43 ± 0.67 | 4.81 ± 0.39 | 3.04 ± 0.16 | 4.47 ± 0.06 | 26.73 ± 0.03 |

| 20 | 6 | 3 | 44.40 ± 0.05 | 19.13 ± 0.08 | 22.59 ± 0.02 | 1.82 ± 0.02 | 23.71 ± 0.60 | 4.14 ± 0.07 | 2.49 ± 0.33 | 4.29 ± 0.18 | 26.58 ± 0.12 |

| 16 | 10 | 1 | 53.10 ± 0.13 | 22.18 ± 0.07 | 24.09 ± 0.02 | 2.80 ± 0.02 | 34.20 ± 0.51 | 5.88 ± 0.56 | 9.85 ± 0.07 | 19.54 ± 0.10 | 40.69 ± 0.11 |

| 16 | 2 | 5 | 35.35 ± 0.13 | 16.54 ± 0.05 | 22.72 ± 0.02 | 1.73 ± 0.09 | 32.53 ± 0.22 | 3.35 ± 0.21 | 3.66 ± 0.07 | 7.61 ± 0.06 | 26.72 ± 0.04 |

| 24 | 2 | 1 | 42.21 ± 0.08 | 19.89 ± 0.05 | 22.62 ± 0.02 | 1.89 ± 0.03 | 45.36 ± 0.79 | 6.08 ± 0.24 | 2.55 ± 0.07 | 4.40 ± 0.06 | 24.48 ± 0.04 |

| 24 | 10 | 5 | 45.46 ± 0.17 | 18.73 ± 0.05 | 24.22 ± 0.03 | 2.32 ± 0.03 | 37.82 ± 0.36 | 3.44 ± 0.40 | 6.50 ± 0.05 | 17.91 ± 0.03 | 39.60 ± 0.03 |

| 20 | 2 | 3 | 30.60 ± 0.13 | 12.22 ± 0.06 | 22.15 ± 0.02 | 1.51 ± 0.08 | 30.29 ± 0.19 | 4.37 ± 0.15 | 2.36 ± 0.04 | 3.79 ± 0.03 | 23.63 ± 0.03 |

| 20 | 10 | 3 | 46.24 ± 0.13 | 19.21 ± 0.05 | 24.65 ± 0.01 | 1.75 ± 0.03 | 35.83 ± 0.47 | 5.32 ± 0.25 | 2.47 ± 0.01 | 11.19 ± 0.05 | 35.56 ± 0.03 |

| 20 | 6 | 1 | 44.93 ± 0.13 | 18.82 ± 0.07 | 22.15 ± 0.03 | 1.85 ± 0.05 | 29.19 ± 0.57 | 6.71 ± 0.29 | 2.24 ± 0.02 | 5.23 ± 0.11 | 24.79 ± 0.04 |

| 20 | 6 | 5 | 49.43 ± 0.13 | 21.03 ± 0.02 | 22.61 ± 0.01 | 1.80 ± 0.04 | 32.88 ± 0.68 | 5.90 ± 0.04 | 2.78 ± 0.02 | 8.29 ± 0.07 | 24.32 ± 0.11 |

| 16 | 6 | 3 | 48.85 ± 0.13 | 22.21 ± 0.08 | 22.85 ± 0.02 | 2.10 ± 0.02 | 25.05 ± 0.62 | 4.43 ± 0.11 | 3.45 ± 0.02 | 10.17 ± 0.07 | 29.73 ± 0.10 |

| 24 | 6 | 3 | 43.26 ± 0.25 | 19.92 ± 0.07 | 22.41 ± 0.02 | 1.96 ± 0.02 | 27.21 ± 0.43 | 6.06 ± 0.26 | 2.39 ± 0.02 | 7.27 ± 0.04 | 25.62 ± 0.07 |

CT: conching time; SP: sauco by-products; SIO: sacha inchi oil; AA-DPPH: Antioxidant activity (2,2-diphenyl-1-picrylhydrazyl); AA-ABTS: Antioxidant Activity (2,2′-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid); TPC: total phenolic content; CPV: Casson plastic viscosity; CEL: Casson yield strength; PSD: particle size determination.

Table 2.

Optimum response values of factors in dark chocolate samples.

| Samples | Variables | Predicted values | CT (h) | SP (%) | SIO (%) | Desirability Compound |

|---|---|---|---|---|---|---|

| Dark Chocolates | AA-DPPH (μ mol Trolox/g) AA-ABTS (μ mol Trolox/g) TPC (mg GAE/g) CPV (Pa. s) |

54.53 23.28 25.25 2.61 |

16 16 16 16 |

7.66 7.58 10 10 |

1 1 5 1 |

1.0000 1.0000 0.9881 0.6610 |

| CEL (Pa) | 43.52 | 24 | 2 | 1 | 0.8947 | |

| Hardness (N) | 7.24 | 24 | 7.25 | 1 | 1.0000 | |

| PSD- D [10] (μm) | 8.92 | 16 | 10 | 1 | 0.8699 | |

| PSD- D[50] (μm) | 20.28 | 16 | 10 | 5 | 0.9454 | |

| PSD- D[90] (μm) | 41.57 | 16 | 10 | 3.6 | 0.9588 |

CT: conching time; SP: sauco by-products; SIO: sacha inchi oil; AA-DPPH: Antioxidant activity (2,2-diphenyl-1-picrylhydrazyl); AA-ABTS: Antioxidant Activity (2,2′-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid); TPC: total phenolic content; CPV: Casson plastic viscosity; CEL: Casson yield strength; PSD: particle size determination.

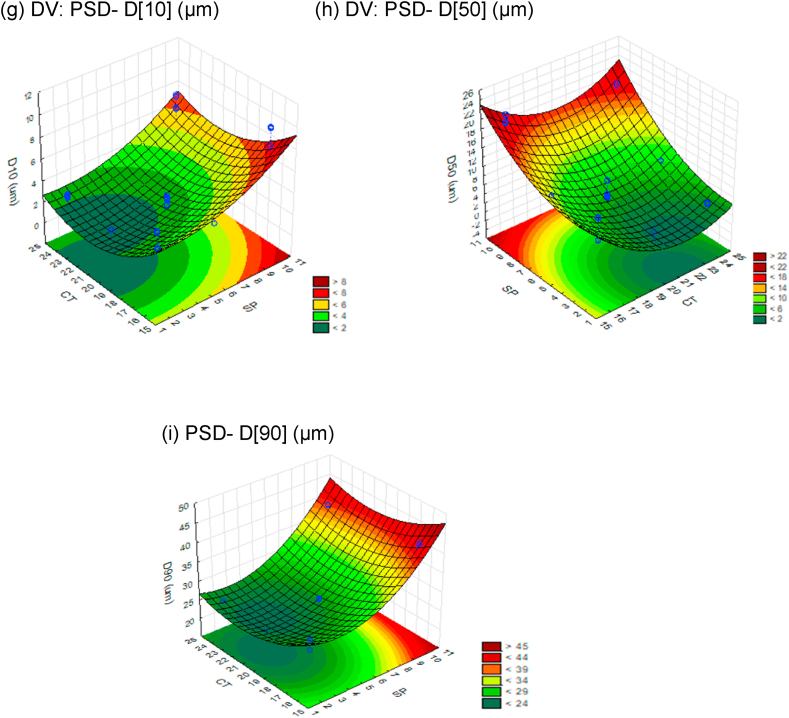

Fig. 2.

Response surface of AA-DPPH (a), AA-ABTS (b), TPC (c), CPV (d), CEL(e), Hardness (f), PSD- D [10] (g), PSD- D[50] (h) and PSD- D[90] (i) as a function of CT: conching time; SP: sauco by-products; SIO: sacha inchi oil.

3.2. Total phenols content

The results show that the total phenols content ranged from 22.15 to 24.65 mgGAE/g (Table 1.) [35]. reported values of 19.80 mg/gGAE in 75% dark chocolates with raspberry and 15.02 mg/gGAE in 75% dark chocolates, both of which were lower than the results obtained in this study; at the same time, a significant increase in total phenols content (p < 0.05) is observed with the addition of raspberry to the chocolate and corroborated by Ref. [31] where they obtained values of 32.5 mgGAE/g in chocolates with sauco extracts. However, the total polyphenol content varies according to the variety of cocoa beans and the conditions during fermentation, drying, roasting, processing, and storage [36].

On the other hand, it was observed that the lower the concentration of sauco by-products and sacha inchi oil and the longer the conching time, the lower the total phenol content (p < 0.05). Faccineto-Beltrán et al. [37] mentioned that, during the chocolate-making process, the content of total phenols decreases due to the high temperatures and the presence of oxygen, which is why, in our work, we used high concentrations of sacha inchi oil and freeze-dried sauco by-products to recover the values of total phenol content that could be lost during conching (Fig. 2c). Moreover [38], found that the total phenol content is negatively affected (p < 0.05) by high temperatures (60 °C) and long conching times (over 24 h), while a combination of low temperatures (45 °C) and long conching times, the reduction of total phenol content was minor. On the other hand [10], reported that the antioxidant activity and total phenol content in raspberry-enriched chocolates are not affected by the conching time and temperature, similar to the study reported by Ref. [3] were nor did the conching time and the temperature significantly decreased the total phenol content (p < 0.05). Other studies suggest that higher conching temperature requires short conching times; however, there is still limited information.

3.3. Rheology

Rheology studies the flow and deformation of matter and is quantified with plastic viscosity and yield strength parameters. In our research, the plastic viscosity values increased as the concentration of sauco by-products and sacha inchi oil increased and also decreased as the conching time increased (p < 0.05); the longer the conching time, the smaller the particle size (Table 1.) (Fig. 2 d) [7,39].

The yield strength is related to the energy required to initiate the flow of chocolate and is important in keeping small solid particles in suspension and coating solid surfaces [7]. The results of our research indicate values from 1.51 to 2.80 Pa. S (Table 1.). using Casson's model, similar to that reported by Mongla & Ziegler [40], who reported reference values for dark chocolate of 2.1 and 3.9 Pa. S. Likewise [4], identified the Casson model of chocolate samples in the range of 1.83–2.31 Pa. S. For their part [41], show that the incorporation of solid particles (sugar, fruits, and flours) leads to an increase in viscosity and yield stress due to the interactions between the suspended particles and the increase in the surface area of the particles in contact with the cocoa butter (Fig. 2 d; Fig. 2e). Our study achieved the optimal Casson plastic viscosity value (2.61 Pa. s) with the highest concentration of sauco by-products, the lowest concentration of sacha inchi oil, and the shortest conching time. On the other hand, the optimum value of the Casson yield strength (43.52 Pa) was obtained with the lowest concentration of sauco by-products and sacha inchi oil and the longest conching time (Table 2), corroborated by the study of [39] where both conching time and temperature significantly influence the Casson viscosity of the chocolate milk mass based on cocoa liquor with unfermented beans.

3.4. Texture

Table 1 Shows the values of the breaking strength of the dark chocolates ranging from 3.35 to 6.98 N. Hardness in the chocolate industry for bars or tablets is associated with the snap or cracking sound of the product [42], which in physical terms is associated with the breaking strength. This characteristic results from formulation, tempering, and cooling; it is higher in dark chocolates than in milk or white chocolates. In our enriched chocolate, hardness was affected (p < 0.05) by conching time, sauco by-products, and sacha inchi oil (Table 3). We observed that obtaining an optimized hardness value requires a longer conching time, an intermediate concentration of sauco by-products, and a minimum concentration of sacha inchi oil (Table 2).

Table 3.

Regression coefficient and p-value for significant response for dark chocolates.

| Response | Factors | coefficient | p-value | Model fitting |

|---|---|---|---|---|

| AA-DPPH (μ mol Trolox/g) | SP(L) | 4.678 | 0.000 | R2 = 90.50% |

| SP(Q) | −5.845 | 0.000 | F = 41.58 | |

| SIO(L) | −0.675 | 0.045 | P = 0.000 | |

| SIO(Q) | 2.919 | 0.008 | ||

| CT(L) | −2.328 | 0.000 | ||

| CT(Q) | 1.794 | 0.000 | ||

| SP*SIO | 2.017 | 0.000 | ||

| SP*CT | −2.219 | 0.000 | ||

| SIO*CT | 1.358 | 0.000 | ||

| Interceptor | 28.66 | |||

| Lack-of-fit | 0.000 | |||

| AA- ABTS (μ mol Trolox/g) | SP(L) | 1.703 | 0.000 | R2 = 81.94% |

| SP(Q) | −3.253 | 0.000 | F = 19.80 | |

| SIO(L) | −0.372 | 0.045 | P = 0.000 | |

| SIO(Q) | 0.958 | 0.008 | ||

| CT(Q) | 2.097 | 0.000 | ||

| SP*CT | −0.961 | 0.000 | ||

| Interceptor | 7.71 | |||

| Lack-of-fit | 0.000 | |||

| TPC (mg GAE/g) | SP(L) | 0.9619 | 0.000 | R2 = 98.36% |

| SP(Q) | 0.163 | 0.000 | F = 262.05 | |

| SIO(L) | −0.2093 | 0.000 | P = 0.000 | |

| SIO(Q) | 0.8898 | 0.006 | ||

| CT(L) | −0.1269 | 0.006 | ||

| CT(Q) | 0.1231 | 0.007 | ||

| SP*SIO | 0.213 | 0.000 | ||

| SP*CT | −0.088 | 0.001 | ||

| SIO*CT | −0.1472 | 0.000 | ||

| Interceptor | 38.65 | |||

| Lack-of-fit | 0.000 | |||

| CPV (Pa. s) | SP(L) | 0.1497 | 0.000 | R2 = 93.42% |

| SP(Q) | −0.1321 | 0.000 | F = 61.95 | |

| SIO(L) | −0.1163 | 0.024 | P = 0.000 | |

| SIO(Q) | 0.0612 | 0.000 | ||

| CT(L) | −0.0533 | 0.024 | ||

| CT(Q) | 0.2662 | 0.000 | ||

| SIO*CT | 0.2187 | 0.000 | ||

| Interceptor | 70.97 | |||

| Lack-of-fit | 0.000 | |||

| CEL (Pa) | SP(L) | −0.880 | 0.000 | R2 = 90.68% |

| SP(Q) | 7.416 | 0.000 | F = 42.47 | |

| SIO(L) | −1.237 | 0.003 | P = 0.000 | |

| SIO(Q) | 5.396 | 0.000 | ||

| CT(L) | 1.694 | 0.000 | ||

| SP*SIO | 2.263 | 0.000 | ||

| Interceptor | 42.50 | |||

| Lack-of-fit | 0.000 | |||

| Hardness (N) | SP(L) | 0.264 | 0.003 | R2 = 83.00% |

| SP(Q) | −0.422 | 0.013 | F = 21.30 | |

| SIO(L) | −0.8647 | 0.000 | P = 0.000 | |

| SIO(Q) | 1.035 | 0.000 | ||

| CT(L) | 0.4680 | 0.000 | ||

| SP*SIO | −0.3088 | 0.002 | ||

| SP*CT | −0.3146 | 0.002 | ||

| SIO*CT | −0.2379 | 0.015 | ||

| Interceptor | 9.35 | |||

| Lack-of-fit | 0.000 | |||

| PSD- D [10] (μm) | SP(L) | 1.822 | 0.000 | R2 = 87.88% |

| SP(Q) | 0.722 | 0.021 | F = 31.64 | |

| SIO(L) | −0.354 | 0.029 | P = 0.000 | |

| SIO(Q) | 0.821 | 0.009 | ||

| CT(L) | −0.841 | 0.000 | ||

| CT(Q) | 1.232 | 0.000 | ||

| Interceptor | 1.23 | |||

| Lack-of-fit | 0.000 | |||

| PSD- D[50] (μm) | SP(L) | 5.589 | 0.000 | R2 = 97.25% |

| SP(Q) | 2.732 | 0.787 | F = 154.20 | |

| SIO(Q) | 2.000 | 0.000 | P = 0.000 | |

| CT(L) | −1.854 | 0.000 | ||

| CT(Q) | 3.966 | 0.000 | ||

| SP*SIO | 0.748 | 0.001 | ||

| SP*CT | 0.844 | 0.000 | ||

| Interceptor | 9.69 | |||

| Lack-of-fit | 0.000 | |||

| PSD- D[90] (μm) | SP(L) | 6.712 | 0.000 | R2 = 99.14% |

| SP(Q) | 4.375 | 0.000 | F = 500.62 | |

| SIO(Q) | −0.664 | 0.003 | P = 0.000 | |

| CT(L) | −1.683 | 0.000 | ||

| CT(Q) | 2.455 | 0.000 | ||

| SP*SIO | 0.754 | 0.000 | ||

| SIO*CT | 0.373 | 0.005 | ||

| Interceptor | 15.74 | |||

| Lack-of-fit | 0.000 |

L: Linear, Q: Quadratic.

CT: conching time; SP: sauco by-products; SIO: sacha inchi oil; AA-DPPH: Antioxidant activity (2,2-diphenyl-1-picrylhydrazyl); AA-ABTS: Antioxidant activity (2,2′-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid); TPC: total phenolic content; CPV: Casson plastic viscosity; CEL: Casson yield strength; PSD: particle size determination. Statistically significant at (p < 0.05).

On the other hand [43], mention that the use of illipe butter and medium palm fraction in dark chocolate does not affect the rheological properties and texture, maintaining the same characteristics as chocolate made with only CB, possibly due to the chemical properties of the substitutes used. Likewise, when comparing white and dark chocolate made with CBS, white chocolate has a lower breaking strength than dark chocolates, possibly due to the absence of cocoa solids. Similarly, in the study of [44], the hardness decreased when increasing sunflower oil as a substitute for CB; the triacylglycerol composition of CBS explains this, as it contains more saturated oleoyl-oleyl which leads to softening of the cocoa butter and consequently the chocolates.

In addition, adding solid ingredients such as sauco by-products (large particles) could increase the hardness of the chocolate and thus require longer conching time to reduce and disperse the particles (Fig. 2f). However, further research is required.

3.5. Particle size

It can be seen from Table 1 That the particle size of the chocolates in our research is in the range of 2.36–42.23 μm, with the particle size distribution of the chocolates enriched with sauco by-products and sacha inchi oil increasing proportionally to the concentrations added. Furthermore, we observed that to obtain an optimized value of particle size D [10], D [50], and D [90]; the shortest conching time, the highest percentage of sauco by-product, and a level of sacha inchi oil ranging from the lowest to the highest, respectively, is required (Table 2 Y Fig. 2 g, Fig. 2 h, and Fig. 2i). Other studies have shown that dark chocolates with CBS have similar values for D 10, D 50, D 90 [25,43], corroborated by the rheology and texture results; because the average particle size influences the yield strength, plastic viscosity and hardness [45].

3.6. Response surface methodology

Statistica v10 software generated optimal formulations for conching time, sauco by-products, and sacha inchi oil. Table 2 And Fig. 2 Summarize the predicted values, optimal formulations and composite desirability. The results show that at the shortest conching time (16 h), concentrations close to the highest value of sauco by-products (10%) and the lowest level of sacha inchi oil (1%) exhibited the maximum values under optimal conditions for antioxidant activity, Casson's plastic viscosity and particle size D [10], but increasing sacha inchi oil to the highest level (5%) gives the maximum result for total phenolic content and particle size D [50] and D [90]. Furthermore, increasing the conching time from 16 to 24 h showed the optimal values for the Casson hardness and yield strength, being the variables requiring long conching times; however, the rest required short conching times. At the same time, the experimental scores were satisfactorily close to the values predicted by the model. Finally, the desirability function was used to optimize all responses simultaneously.

4. Conclusions

The addition of sauco by-products, sacha inchi oil and conching time in dark chocolate showed significant changes (p < 0.05) in antioxidant activity, total phenol content, rheology, hardness and particle size. Particularly, sauco by-products and sacha inchi oil significantly increased the values of antioxidant activity and total phenol content in the dark chocolates; conversely, sacha inchi oil significantly decreased the rheology and hardness of the chocolate. Conching times of (20 and 24 h) significantly affected the chemical and physical properties of the dark chocolate, except for hardness which does require a conching time of 24 h to have the optimum value. Optimum values were generated and conditions were determined using the RSM experimental model. The scores were satisfactorily close to the values predicted by the model, which confirms the validation of the model. However, it is necessary to report the exact moment of incorporation of the sacha inchi oil in order not to lose its bioactive compounds, as well as to elaborate the dark chocolates with the values optimized by the model, and to carry out a sensory analysis and reproduce it on an industrial scale.

Funding statement

This research was funded by the Consejo Nacional de Ciencia, Tecnología e Innovación Tecnológica-Concytec (Project: Cristalización y polimorfismo de la manteca de cacao en granos de diferentes orígenes geográficos y su impacto en la calidad de chocolates finos, contract Nº PE501077920-2022-PROCIENCIA) of the Peruvian Government.

Author contribution statement

Marleni Medina-Mendoza: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper. Efraín M. Castro-Alayo: Conceived and designed the experiments. César R. Balcázar-Zumaeta, Jorge L. Maicelo-Quintana, Ilse S. Cayo-Colca: Performed the experiments; Analyzed and interpreted the data; Wrote the paper. Miguelina Z. Silva-Zuta: Contributed reagents, materials, analysis tools or data.

Data availability statement

Data will be made available on request.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Marleni Medina-Mendoza, Email: marleni.medina@untrm.edu.pe.

Efrain M. Castro-Alayo, Email: efrain.castro@untrm.edu.pe.

Cesar R. Balcazar-Zumaeta, Email: cesar.balcazar@untrm.edu.pe.

Miguelina Z. Silva-Zuta, Email: miguelina.silva@untrm.edu.pe.

Jorge L. Maicelo-Quintana, Email: jorge.maicelo@untrm.edu.pe.

Ilse S. Cayo-Colca, Email: icayo.fizab@untrm.edu.pe.

References

- 1.Sadowska-Rociek A. Monitoring of monochloropropanediol esters and glycidyl esters in different types of chocolates using the modified sample preparation approach. Lebensm. Wiss. Technol. 2022;165 doi: 10.1016/j.lwt.2022.113692. [DOI] [Google Scholar]

- 2.Zugravu C., Otelea M.R., Chocolate Dark. To eat or not to eat? A review. J. AOAC Int. 2019;102:1388–1396. doi: 10.5740/jaoacint.19-0132. [DOI] [PubMed] [Google Scholar]

- 3.Gültekin-Özgüven M., Berktaş İ., Özçelik B. Influence of processing conditions on procyanidin profiles and antioxidant capacity of chocolates: optimization of dark chocolate manufacturing by response surface methodology. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2016;66:252–259. doi: 10.1016/j.lwt.2015.10.047. [DOI] [Google Scholar]

- 4.Toker O.S., Palabiyik I., Konar N. Chocolate quality and conching. Trends Food Sci. Technol. 2019;91:446–453. doi: 10.1016/j.tifs.2019.07.047. [DOI] [Google Scholar]

- 5.Żyżelewicz D., Budryn G., Oracz J., Antolak H., Kręgiel D., Kaczmarska M. The effect on bioactive components and characteristics of chocolate by functionalization with raw cocoa beans. Food Res. Int. 2018;113:234–244. doi: 10.1016/j.foodres.2018.07.017. [DOI] [PubMed] [Google Scholar]

- 6.Sun P., Xia B., Ni Z.-J., Wang Y., Elam E., Thakur K., Ma Y.-L., Wei Z.-J. Characterization of functional chocolate formulated using oleogels derived from β-sitosterol with γ-oryzanol/lecithin/stearic acid. Food Chem. 2021;360 doi: 10.1016/j.foodchem.2021.130017. [DOI] [PubMed] [Google Scholar]

- 7.Afoakwa E.O., Paterson A., Fowler M. Effects of particle size distribution and composition on rheological properties of dark chocolate. Eur. Food Res. Technol. 2008;226:1259–1268. doi: 10.1007/s00217-007-0652-6. [DOI] [Google Scholar]

- 8.Pedan V., Fischer N., Bernath K., Hühn T., Rohn S. Determination of oligomeric proanthocyanidins and their antioxidant capacity from different chocolate manufacturing stages using the NP-HPLC-online-DPPH methodology. Food Chem. 2017;214:523–532. doi: 10.1016/j.foodchem.2016.07.094. [DOI] [PubMed] [Google Scholar]

- 9.Beckett S.T. Royal Society of Chemistry; 2019. The Science of Chocolate. [Google Scholar]

- 10.Di Mattia C., Martuscelli M., Sacchetti G., Beheydt B., Mastrocola D., Pittia P. Effect of different conching processes on procyanidin content and antioxidant properties of chocolate. Food Res. Int. 2014;63:367–372. doi: 10.1016/j.foodres.2014.04.009. [DOI] [Google Scholar]

- 11.Biesalski H.-K., Dragsted L.O., Elmadfa I., Grossklaus R., Müller M., Schrenk D., Walter P., Weber P. Bioactive compounds: definition and assessment of activity. Nutrition. 2009;25:1202–1205. doi: 10.1016/j.nut.2009.04.023. [DOI] [PubMed] [Google Scholar]

- 12.Botelho P.B., Galasso M., Dias V., Mandrioli M., Lobato L.P., Rodriguez-Estrada M.T., Castro I.A. Oxidative stability of functional phytosterol-enriched dark chocolate. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2014;55:444–451. doi: 10.1016/j.lwt.2013.09.002. [DOI] [Google Scholar]

- 13.Konar N., Toker O.S., Oba S., Sagdic O. Improving functionality of chocolate: a review on probiotic, prebiotic, and/or synbiotic characteristics. Trends Food Sci. Technol. 2016;49:35–44. doi: 10.1016/j.tifs.2016.01.002. [DOI] [Google Scholar]

- 14.Domínguez R., Zhang L., Rocchetti G., Lucini L., Pateiro M., Munekata P.E.S., Lorenzo J.M. Elderberry (Sambucus nigra L.) as potential source of antioxidants. Characterization, optimization of extraction parameters and bioactive properties. Food Chem. 2020;330 doi: 10.1016/j.foodchem.2020.127266. [DOI] [PubMed] [Google Scholar]

- 15.Grinberga-Zalite G., Zvirbule A. Analysis of waste minimization challenges to European food production enterprises. Emerg Sci J. 2022;6:530–543. doi: 10.28991/ESJ-2022-06-03-08. [DOI] [Google Scholar]

- 16.Kunradi Vieira F.G., da Silva Campelo Borges G., Copetti C., Valdemiro Gonzaga L., da Costa Nunes E., Fett R. Activity and contents of polyphenolic antioxidants in the whole fruit, flesh and peel of three apple cultivars. Arch. Latinoam. Nutr. 2009;59:101–106. [PubMed] [Google Scholar]

- 17.Soong Y.-Y., Barlow P.J. Antioxidant activity and phenolic content of selected fruit seeds. Food Chem. 2004;88:411–417. doi: 10.1016/j.foodchem.2004.02.003. [DOI] [Google Scholar]

- 18.Garzón G.A., Soto C.Y., López-R M., Riedl K.M., Browmiller C.R., Howard L. Phenolic profile, in vitro antimicrobial activity and antioxidant capacity of Vaccinium meridionale Swartz pomace. Heliyon. 2020;6 doi: 10.1016/j.heliyon.2020.e03845. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Zorzi M., Gai F., Medana C., Aigotti R., Morello S., Peiretti P.G. Bioactive compounds and antioxidant capacity of small berries. Foods. 2020;9:623. doi: 10.3390/foods9050623. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Tirgarian B., Yadegari H., Bagheri A., Neshagaran E., Mardani M., Farmani J. Reduced-fat chocolate spreads developed by water-in-oleogel emulsions. J. Food Eng. 2023;337 doi: 10.1016/j.jfoodeng.2022.111233. [DOI] [Google Scholar]

- 21.Medina-Mendoza M., Rodriguez-Pérez R.J., Rojas-Ocampo E., Torrejón-Valqui L., Fernández-Jeri A.B., Idrogo-Vásquez G., Cayo-Colca I.S., Castro-Alayo E.M. Rheological, bioactive properties and sensory preferences of dark chocolates with partial incorporation of Sacha Inchi (Plukenetia volubilis L.) oil. Heliyon. 2021;7 doi: 10.1016/j.heliyon.2021.e06154. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Quispe-Chambilla L., Pumacahua-Ramos A., Choque-Quispe D., Curro-Pérez F., Carrión-Sánchez H.M., Peralta-Guevara D.E., Masco-Arriola M.L., Palomino-Rincón H., Ligarda-Samanez C.A. Rheological and functional properties of dark chocolate with partial substitution of peanuts and sacha inchi. Foods. 2022;11:1142. doi: 10.3390/foods11081142. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Chirinos R., Zuloeta G., Pedreschi R., Mignolet E., Larondelle Y., Campos D. Sacha inchi (Plukenetia volubilis): a seed source of polyunsaturated fatty acids, tocopherols, phytosterols, phenolic compounds and antioxidant capacity. Food Chem. 2013;141:1732–1739. doi: 10.1016/j.foodchem.2013.04.078. [DOI] [PubMed] [Google Scholar]

- 24.Sanchez-Reinoso Z., Mora-Adames W.I., Fuenmayor C.A., Darghan-Contreras A.E., Gardana C., Gutiérrez L.-F. Microwave-assisted extraction of phenolic compounds from Sacha Inchi shell: optimization, physicochemical properties and evaluation of their antioxidant activity. Chemical Engineering and Processing - Process Intensification. 2020;153 doi: 10.1016/j.cep.2020.107922. [DOI] [Google Scholar]

- 25.Afoakwa E.O., Paterson A., Fowler M. Factors influencing rheological and textural qualities in chocolate – a review. Trends Food Sci. Technol. 2007;18:290–298. doi: 10.1016/j.tifs.2007.02.002. [DOI] [Google Scholar]

- 26.Samanta S., Sarkar T., Chakraborty R., Rebezov M., Shariati M.A., Thiruvengadam M., Rengasamy K.R.R. Dark chocolate: an overview of its biological activity, processing, and fortification approaches. Curr. Res. Food Sci. 2022;5:1916–1943. doi: 10.1016/j.crfs.2022.10.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Brand-Williams W., Cuvelier M.E., Berset C. Use of a free radical method to evaluate antioxidant activity. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 1995;28:25–30. doi: 10.1016/S0023-6438(95)80008-5. [DOI] [Google Scholar]

- 28.de Souza V.R., Pereira P.A.P., da Silva T.L.T., de Oliveira Lima L.C., Pio R., Queiroz F. Determination of the bioactive compounds, antioxidant activity and chemical composition of Brazilian blackberry, red raspberry, strawberry, blueberry and sweet cherry fruits. Food Chem. 2014;156:362–368. doi: 10.1016/j.foodchem.2014.01.125. [DOI] [PubMed] [Google Scholar]

- 29.Abdul Halim H.S., Selamat J., Mirhosseini S.H., Hussain N. Sensory preference and bloom stability of chocolate containing cocoa butter substitute from coconut oil. Journal of the Saudi Society of Agricultural Sciences. 2019;18:443–448. doi: 10.1016/j.jssas.2018.02.005. [DOI] [Google Scholar]

- 30.Ma X., Hu Z., Mao J., Xu Y., Zhu X., Xiong H. Synthesis of cocoa butter substitutes from Cinnamomum camphora seed oil and fully hydrogenated palm oil by enzymatic interesterification. J. Food Sci. Technol. 2019;56:835–845. doi: 10.1007/s13197-018-3543-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Poliński S., Kowalska S., Topka P., Szydłowska-Czerniak A. Physicochemical, antioxidant, microstructural properties and bioaccessibility of dark chocolate with plant extracts. Molecules. 2021;26:5523. doi: 10.3390/molecules26185523. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Umdale S., Ahire M., Aiwale V., Jadhav A., Mundada P. Phytochemical investigation and antioxidant efficacy of wild, underutilized berries of economically important Indian Sandalwood (Santalum album L.) Biocatal. Agric. Biotechnol. 2020;27 doi: 10.1016/j.bcab.2020.101705. [DOI] [Google Scholar]

- 33.Saqueti B.H.F., Alves E.S., Ponhozi I.B.S., Castilho P.A., Castro M.C., Souza P.M., Favetta P.M., Visentainer J.V., Santos O. de O. vol. 10. Research, Society and Development; 2021. (Viabilidade da obtenção de polpa de acerola (malpighia spp) microencapsulada e liofilizada: Uma revisão). [DOI] [Google Scholar]

- 34.Chasquibol N.A., Gallardo G., Gómez-Coca R.B., Trujillo D., Moreda W., Pérez-Camino M.C. Glyceridic and unsaponifiable components of microencapsulated sacha inchi (plukenetia huayllabambana L. And plukenetia volubilis L.) edible oils. Foods. 2019;8:671. doi: 10.3390/foods8120671. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Jaćimović S., Popović-Djordjević J., Sarić B., Krstić A., Mickovski-Stefanović V., Pantelić N.Đ. Antioxidant activity and multi-elemental analysis of dark chocolate. Foods. 2022;11:1445. doi: 10.3390/foods11101445. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Wollgast J., Anklam E. Review on polyphenols in Theobroma cacao: changes in composition during the manufacture of chocolate and methodology for identification and quantification. Food Res. Int. 2000;33:423–447. doi: 10.1016/S0963-9969(00)00068-5. [DOI] [Google Scholar]

- 37.Faccinetto-Beltrán P., Gómez-Fernández A.R., Santacruz A., Jacobo-Velázquez D.A. Chocolate as carrier to deliver bioactive ingredients: current advances and future perspectives. Foods. 2021;10:2065. doi: 10.3390/foods10092065. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Alzate L.K.A., Díaz D.P.M., Otálvaro E.V.A., Gallego W.G.V., Vélez L.P. Efecto de la TEMPERATURA del CONCHADO sobre los POLIFENOLES en UN chocolate semi-amargo. Alimentos Hoy. 2017;25:31. [Google Scholar]

- 39.Urbańska B., Kowalska H., Szulc K., Ziarno M., Pochitskaya I., Kowalska J. Comparison of the effects of conching parameters on the contents of three dominant flavan3-ols, rheological properties and sensory quality in chocolate milk mass based on liquor from unroasted cocoa beans. Molecules. 2021;26:2502. doi: 10.3390/molecules26092502. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Mongia G., Ziegler G.R. The role of particle size distribution of suspended solids in defining the flow properties of milk chocolate. Int. J. Food Prop. 2000;3:137–147. doi: 10.1080/10942910009524621. [DOI] [Google Scholar]

- 41.Fernandes V.A., Müller A.J., Sandoval A.J. Thermal, structural and rheological characteristics of dark chocolate with different compositions. J. Food Eng. 2013;116:97–108. doi: 10.1016/j.jfoodeng.2012.12.002. [DOI] [Google Scholar]

- 42.Beckett S.T., Fowler M.S., Ziegler G.R. John Wiley & Sons; 2017. Beckett's Industrial Chocolate Manufacture and Use. [Google Scholar]

- 43.Bahari A., Akoh C.C. Texture, rheology and fat bloom study of ‘chocolates’ made from cocoa butter equivalent synthesized from illipe butter and palm mid-fraction. Lebensm. Wiss. Technol. 2018;97:349–354. doi: 10.1016/j.lwt.2018.07.013. [DOI] [Google Scholar]

- 44.Kadivar S., De Clercq N., Mokbul M., Dewettinck K. Influence of enzymatically produced sunflower oil based cocoa butter equivalents on the phase behavior of cocoa butter and quality of dark chocolate. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2016;66:48–55. doi: 10.1016/j.lwt.2015.10.006. [DOI] [Google Scholar]

- 45.Afoakwa E.O., Paterson A., Fowler M., Ryan A. Matrix effects on flavour volatiles release in dark chocolates varying in particle size distribution and fat content using GC–mass spectrometry and GC–olfactometry. Food Chem. 2009;113:208–215. doi: 10.1016/j.foodchem.2008.07.088. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.