Abstract

Supercapacitors, designed to store more energy and be proficient in accumulating more energy than conventional batteries with numerous charge–discharge cycles, have been developed in response to the growing demand for energy. Transition metal carbides/nitrides called MXenes have been the focus of researchers’ cutting-edge research in energy storage. The 2D-layered MXenes are a hopeful contender for the electrode material due to their unique properties, such as high conductivity, hydrophilicity, tunable surface functional groups, better mechanical properties, and outstanding electrochemical performance. This newly developed pseudocapacitive substance benefits electrochemical energy storage because it is rich in interlayer ion diffusion pathways and ion storage sites. Making MXene involves etching the MAX phase precursor with suitable etchants, but different etching methods have distinct effects on the morphology and electrochemical properties. It is an overview of the recent progress of MXene and its structure, synthesis, and unique properties. There is a strong emphasis on the effects of shape, size, electrode design, electrolyte behavior, and other variables on the charge storage mechanism and electrochemical performance of MXene-based supercapacitors. The electrochemical application of MXene and the remarkable research achievements in MXene-based composites are an intense focus. Finally, in light of further research and potential applications, the challenges and future perspectives that MXenes face and the prospects that MXenes present have been highlighted.

1. Introduction

The declining use of fossil fuels and the increasing use of energy have sparked interest in renewable energy sources. Due to climatic changes, relying solely on these energy sources is impossible. Consequently, there is an urgent need for renewable and endless energy sources.1 It leads to multifunctional electrochemical energy storage devices with safety, high stability, and high power density.2 The widespread acceptance of rechargeable batteries results from their extended lifespan and increased energy density.3,4

Nevertheless, an ideal power source that stores energy and produces a sound output is practically unfeasible. In this scenario, developing energy storage systems using diverse technologies is essential. Supercapacitors (SCs) or electrochemical capacitors have emerged as a class of new-generation storage systems that can fulfill the growing demands in the high-energy field because of their high-power density and long-term stability.5,6 Supercapacitors are divided into electrical double-layer capacitors (EDLCs), pseudocapacitors, and hybrid capacitors based on how energy storage and ions move from the electrode to the electrolyte.7,8 Carbonaceous materials are frequently used for EDLCs, including carbon nanotubes (CNTs), graphene, and activated carbon.9,10 Metal oxides, nitrides, sulfides, conducting polymers, and tellurides are suitable electrode materials for pseudocapacitors.10,11Figure 1 shows the schematic representation of a supercapacitor.

Figure 1.

Schematic diagram of a supercapacitor.

High-performance electrodes with a large surface area, high electrical conductivity, a long life span, and a uniform pore size distribution are needed.9 Therefore, research on new electrode materials with high performance is ongoing and worthwhile. Among several electrodes, 2D inorganic materials are prominent due to their unique physical, chemical, optical, and electrical properties like high morphological anisotropy and a special quantum effect.12 Simultaneously, some 2D materials, such as covalent–organic frameworks, metal–organic frameworks, metal oxides, and MXenes for supercapacitors, are gaining prominence.13 Among them, MXenes were discovered by Gogotsi and Barsoum in 2011 and have been proven as effective pseudocapacitive electrode materials with high capacitance, a large surface area, and long cyclic stability.10,14,15 They successfully synthesized Titanium Carbide MXene (TiC2Tx) by the selective etching of raw Titanium Aluminum Carbide (Ti3AlC2). It became the researcher’s favorite material due to its tunable properties, like its 2D structure with atomic thickness, electrical conductivity, mechanical strength, and excellent performance in many applications, including sensors, medicine, etc.12,16,17

Despite the synthesis of over 30 MXenes and 70 MAX phases in the scientific field, the initial MXenes captured the spotlight, leading to the rapid expansion of this family of 2D materials.18−20 MXenes are currently facing challenges in attaining the desired level of flexibility for wearable technology. Despite ongoing efforts, certain issues persist in their journey toward achieving the requisite flexibility for wearable technology. The conventional etching method of MXene by hydrochloric acid has some defects and requires improvement.21 Due to their propensity for compact packing, MXene sheets hinder the movement and diffusion of electrolyte ions, particularly organic ones. It impacts the ability of MXenes to store energy in supercapacitors and limits their electrochemical performance.22 However, MXenes are readily oxidized at higher anode potentials, decreasing cycle efficiency and longevity.23 The rational design and manufacturing of composite electrodes based on MXene are considered effective solutions to the above-mentioned issues. Shao et al. conducted work to understand the pseudocapacitive behavior of Ti3C2Tx MXene in H2SO4 electrolyte.24 Shi et al. proposed a braided coaxial zinc–ion hybrid FSC with several meters of Ti3C2Tx MXene cathode as core electrodes, and the shell zinc fiber anode was braided on the surface of the Ti3C2Tx MXene fibers across the solid electrolytes and exhibited a high areal capacitance of 214 mF cm–2, an energy density of 42.8 μWh cm–2 at 5 mV s–1, and excellent cycling stability with 83.58% capacity retention after 5000 cycles.25

MXene-based Ti3C2Cl2 nanodot-interspersed MXene@NiAl-layered double hydroxide hybrid electrodes with superior pseudocapacitor storage performance have been elaborately designed and electrostatically assembled, exhibiting a super specific capacitance of 2010.8 F/g at 1.0 A/g and high energy density of 100.5 Wh/kg at a power density of 299.8 W/kg.26 Feng et al. synthesized N-doped Ti3C2Tx electrode material with an energy density of 51.1 Wh/kg at a power density of W/kg.27 MXene–carbon composites can be employed to create highly flexible supercapacitors with effective electrochemical characteristics.28 Liang et al. analyzed the cyclic voltammetry data in Na2SO4 electrolyte for Ti3C2Tx–MCNT electrodes, showing that areal capacitance of 1.93 F/cm2 is substantially higher than literature results for pure Ti3C2Tx and Ti3C2Tx composites.29 Ti3C2Tx NSs are used as the assembly unit in a coagulation bath of IPA and distilled water containing 5 wt % CaCl2 to create high-performance fiber supercapacitors with low corrosion. This results in a meter-long Ti3C2Tx fiber with exceptional electrical conductivity and mechanical flexibility.30 Liu et al. investigated the electrochemical properties of Co3O4-decorated 3D MXene/rGO hybrid aerogels with a maximum capacitance of 345 F/g at 1 A/g for the porous aerogel electrode.31 Patra et al. fabricated a two-electrode symmetric device using Ti3C2Tx MXene and passivated vertical graphene nanosheets (VGNs) as a current collector and displayed a high areal capacitance of 199 mF/cm2 at 0.08 mA/cm2 along with an excellent stability and efficiency of 90% and nearly 100% over 6000 repetitive charge–discharge cycles.32 The MXene–metal oxide composites have high electrical conductivity, greater volumetric capacitance, and electrochemical stability, making them apt electrode materials for flexible supercapacitors.33,34 The electrochemical efficiency of MXenes varies with the thickness of the electrode. One approach to overcoming this challenge is by creating composites of MXene with the polymer.35,36 Yuan et al. synthesized the MXene/CNF/PANI composite as a suitable electrode for high-performance supercapacitors.37 A novel water-free etching method has free layered Ti3C2Tx MXenes in deep eutectic solvents at room temperature and exhibits splendid specific capacitance of 320 F/g at 2 mV/s.38 The Ti3C2Tx/NiCo2S4 asymmetric device exhibits a maximum areal/gravimetric capacitance of 48.6 mF cm–2/54.57 F g–1 at 2 mA cm–2/2 A g–1 of current density within the wider potential window of 1.4 V.39 For those new to the field, a timely update on electrode material research and development, the creation of novel capacitor configurations, and a discussion of theoretical aspects would be helpful.

Due to their intrinsic conductivity, the possibility of charge transfer made possible by the transition metal M’s changing oxidation number, and their distinctive stacking structure, MXenes exhibit exceptional electrochemical properties and are desirable for energy storage applications. MXene finds application across various market segments, including supercapacitors, batteries, electromagnetic shielding, catalysts, gas sensors, water purification, etc. Many papers and reviews on MXene and its synthesis, modifications, and applications have been published. The design process for enhancing the MXene layer has advanced to date. We look forward to the ongoing evolution of fundamental concepts and technical innovation linked to MXenes, which is expected to unveil even more captivating discoveries. Herein, we review the recent research on MXenes and their noteworthy achievements in the realm of supercapacitors. We summarize the structure and properties of MXene. It covers different synthesis methods and highlights their significant advantages. The review thoroughly discusses the working principle, applications, and electrochemical properties of differently synthesized MXene. As the core part of this review, influencing factors depending on electrochemical performance are thoroughly discussed. Further, we focus on the most topical developments in MXene-based composites and their capacitance values. The development trends, problems, and possibilities of MXene composites for energy storage are collected and prospected to give direction for designing MXene for energy storage and other related applications.

2. Introduction to MXenes

MXenes are two-dimensional inorganic compounds that contain transition metal carbides, nitrides, or carbonitrides and are indicated by the chemical formula Mn+1XnTx (n = 1, 2, 3), where M denotes early transition metals such as Zr, Ti, Sc, V, Mo, and Nb, and x represents carbon or nitrogen. T means the functional group such as −O, −H, and −Cl.40,41Figure 2 shows a periodic table illustrating the MAX phase and MXene elements. Due to their negatively charged surface groups, MXenes are hydrophilic and can be dispersed in an aqueous medium without the support of any surfactants.42 These surface groups can provide many active sites, which maintain the potential for surface modification and high-efficiency loading of active material.43 It is proven that the energy storage capacity of MXene is powerfully dependent on surface terminal functional groups. F and OH surface terminals decrease energy storage capacity by blocking electrolyte ion transport.44 Hu et al. inspected the structural characteristics of oxidized Ti3C2Tx and pointed out the importance of surface-terminated groups in electrochemical behavior.45 MXenes are synthesized from their parent, known as the MAX phase, a family member of the layered hexagonal with P63/mmc space group.46 It has a formula of Mn+1AXn (n = 1, 2, 3), where M denotes early transition metals; A denotes group IIIA or IVA elements; and X represents carbon or nitrogen or both.47 In most MAX phases, the M–X bond is ionic or covalent, and the M–A bond is metallic. As a result, the M–X bond is more reactive and durable than the M–A bond. Layers were selectively etched from MAX phases using suitable chemicals because of their high reactivity. The M atoms on the surface are terminated with surface groups referred to as Tx. The chemically stable and closely packed MXene (Mn+1XnTx) highlights its properties similar to graphene.47,48,42,49,50

Figure 2.

Periodic table illustrating the elements of the MAX phase and MXene.

3. Synthesis of MXene

3.1. Top-up Method

The top-down approach can be divided into 5 categories41 based on the etchant. The vital principle to achieve a 2D structure MXene from its respective 3D MAX phase is to fade the interlayer bonds of the 3D structure. The mechanical and chemical etching methods can exfoliate the 3D system for a 2D design.49 However, this method is not valid for MXene since the MAX phase’s M–A bond is a solid metallic bond that stops the mechanical shearing and hinders the formation of the 2D structure MXene.8 Hence, MXene can be synthesized by selective etching or temperature treatment.42

3.1.1. HF Etching

According to reports, Naguib et al. synthesized the first MXene by HF etching.51 The submerging of MAX phase material accomplishes the exfoliation of A layers from the MAX phase by immersing MAX phase material into an aqueous solution of HF acid, the most widely used etchant.8 This process of etching results in the replacement by surface termination groups like −F, −O, and −OH and multilayered flakes of MXene with 2D layers that van der Waals and hydrogen bonds organize. Then, sonication facilitates the delamination of distinct MXene layers into multilayered MXene.8,52,53 The properties of MXene depend on the HF concentration. A high HF concentration leads to ternary fluoride development, which delays the etching process. Also, it causes structural imperfections and a drop in lateral size.54 A low concentration of HF holds more high-mobility water molecules between the interspaces of MXene and gives additional interlayer space and higher capacitance.55 Hu et al. synthesized MXene using high and low concentrations of HF and revealed a vast interlayer area and high capacitance for low HF concentrations compared to high HF concentrations.19 A vacancy-ordered Mo1.3CTx MXene is formed from (Mo2/3Sc1/3)2 AlC by the selective etching of Al and Sc using suitable etchant HF and shows excellent supercapacitor properties.56

3.1.2. Fluoride Salt Etching

Some of the etchants include fluorine and difluoride-containing salts like LiF, NaHF2, NH4F, NH4HF2, CaF2, NaF, and KF that are friendly to their surroundings and are used to etch MAX precursors by the intercalation of metal cations and molecules of water and have some advantages over HF.57 A mild etchant solution of lithium fluoride (LiF) and hydrochloric acid (HCl) can still be used for the in situ production of a less toxic etching solution containing traces of HF in addition to the HF etchant.58,59Figure 3 shows a schematic representation of lithium fluoride etching.

Figure 3.

Schematic representation of etching.

In 2014, Ghidiu et al. reported the first successfully synthesized Ti3C2 by a LiF/HCl solution at 40 °C and obtained a conductive clay with strong plasticity.22 This MXene can be used as an electrode in a supercapacitor with a specific capacity of 900 F cm–3 and a minimum capacity loss after 10,000 cycles.60,22 An advantage of LiF/HCl etching is that the interlayer spacing of MXene is more extensive than that of HF-etched MXene. It allows faster intercalation of ion movement, resulting in more pseudocapacitive redox sites.42,61 Zhang et al. fabricated mesoporous MXene using the LiF etching method, which has an excellent volumetric capacitance of 2079 F/cm3 and excellent environmental stability.62 Sun et al. synthesized Ti3C2Tx MXene by the LiF etchant from the Ti3AlC2 MAX phase for an ideal electrode in a supercapacitor.63 Liu et al. synthesized Mo2CTx by LiF etching with Mo2Ga2C as the MAX phase.64

3.1.3. Alkali Etching

The alkali-etching method is acid-free and uses a low alkali concentration to obtain good-quality MXenes. In Mn+1AXn, a stronger etchant and longer etching time are needed for higher values of n. Ghidiu et al. and colleagues demonstrated that Nb4AlC3 (n = 3) requires twice the etching time of Nb2AlC (n = 3) under identical etching conditions.65 Zhang et al. and Li et al. suggested a NaOH solution as the etchant for an alkali-assisted hydrothermal etching method at a high temperature of 270 °C to synthesize Ti3C2Tx MXene.66,67 The high concentration of NaOH and high reaction temperature enable the dissolution of aluminum hydroxides in NaOH and hinder the oxidation of Ti. There are qualitative changes in the reaction between the MAX phase and alkali. Because of the low water containment in this reaction system, −O and −OH groups can bind on the surface of Ti3C2 MXene except for −F groups.68 The fluorine-free MXene can provide more −OH and −O surface terminations that enhance the electrochemical properties of supercapacitors.60 Feng et al. conveyed the selective etching of Al layers from Ti3AlC2 using an aqueous electrolyte of 1 M ammonium chloride (NH4Cl) and 0.2 M tetramethylammonium hydroxide (TMAOH), which yields single or bilayer Ti3C2Tx MXene that can be used as an electrode.69 The etching reaction in an alkaline solution leads to an increase in interlayer spacing and a size reduction, which causes an increase in the active sites of Ti3C2Tx MXene and enhancement in cation diffusion. As a result, the e-Ti3C2Tx MXene can attain a gravimetric capacitance of 368.1 F/g at a current density of 2 A/g.70

3.1.4. Molten Etching Method

In this process, the reactant and molten salt are arranged into a uniform mixture based on a specific ratio. Heating causes the molten salt to melt, and the reactant completely reacts with the dissolved molten salt.71 The first 2D transition metal nitride was created by Gogotsi et al. using a fluoride-containing molten salt etching method.72 Talapin et al. synthesized and verified Cl/Br-terminated MXene by molten salt etchants cadmium chloride (CaCl2) and cadmium bromide (CaBr2), respectively.73

3.1.5. Temperature Etching

The etching process can be more straightforward by the temperature at which metallic bonding of M–A layers can break at high temperatures. The following equation depicts the MAX phase’s response under high point temperatures.8

Scale-up is difficult due to the acute toxicity of HF, and the management of surface composition and grafting techniques is challenged by competing surface hydrolysis. So, Jawaid et al. present a productive room-temperature etching approach for producing MXenes from Ti3AlC2 using halogens (Br2, I2) in anhydrous conditions.74 V2CTx MXene is synthesized by temperature etching methods at different temperatures, including room temperature.75 The synthesis of MXene by temperature etching has been the least explored.

3.1.6. Electrochemical Etching

The electrochemical process for preparing the MXene includes the selective exclusion of A layers from the MAX phase at a particular voltage. The M–A bond’s break allows the A layer to be removed in the MAX phase, and MXene is rapidly synthesized at room temperature. It was confirmed that the capacitance of MXene-based supercapacitors after electrochemical etching was greater than that of LiF/HCl-etched MXene.76 Yang et al. introduced an efficient fluoride-free etching method based on the anodic decomposition of Al atoms, Ti3AlC2, in a binary aqueous electrolyte followed by in situ intercalation of ammonium hydroxide. The exfoliated sheets show high volumetric capacitances of 439 F/cm3 at a scan rate of 10 mV/s, more remarkable than LiF/HCl-etched MXene.69 Chen et al. devised a facile and time-saving electrochemical method to synthesize −F-free and −Cl-containing Ti3C2Tx in a mixed LiOH and LiCl solution with a specific capacitance of 323.7 F/g for supercapacitors.77 The comparison of the synthesis techniques is shown in Table 1.

Table 1. Comparison of the Different Synthesis Methods of MXene.

| MAX phases | Etchants | Etching condition | MXene | Delaminating condition | ref |

|---|---|---|---|---|---|

| Ti3AlC2 | HF | 50 wt %, 36 h, 60 °C | Ti3C2Tx | DMSO, 18 h | (81) |

| Ti3AlC2 | HF | 50 wt %, 2 h | Ti3C2Tx | centrifugation | (82) |

| (Mo2/3Y1/3)2AlC | HF | 25 wt %, 120 h | Mo1.3CTx | TBAOH | (56) |

| Nb2AlC | HF | 50 wt %, 48 h | Nb2C | Isopropylamine | (83) |

| Mo2C | HF | 50 wt %, 3 h | Mo2Ga2C | (84) | |

| V2AlC | HF | 48 wt %, 92 h | V2CTx | TBAOH | (85) |

| Ti3AlC2 | LiF, 9 M HCl | 45 °C, 24 h | Ti3C2Tx | sonication | (22) |

| Ti3AlC2 | LiF, 6 M HCl | 45 wt %, 45 h | Ti3C2Tx | centrifugation | (63) |

| Ti3AlC2 | LiF, 6 M HCl | 40 °C, 45 h | Ti3C2Tx | centrifugation | (58) |

| Ti3AlC2 | 1 M NH4HF2 | Sputtering, 780 °C | Ti3C2Tx | (86) | |

| Ti3AlC2 | 27.5 M NaOH | Hydrothermal, 270 °C | Ti3C2Tx | (66) | |

| Ti3AlC2 | NaOH | Hydrothermal, 100 h | Ti3C2Tx | (87) | |

| Ti3AlC2 | KOH | 180 °C, 24 h | Ti3C2(OH)2 | (88) | |

| Ti3AlC2 | TMAOH | Ti3C2Tx | (89) | ||

| Ti3AlC2 | aqueous electrolyte | Ti3C2Tx | (69) | ||

| 1 M NH4Cl and 0.2 M TMAOH | |||||

| Ti4AlN3 | Molten salts-KF, LiF, NaF | 59, 29, 12 wt % | Ti4N3Tx | sonication | (90) |

| 550 °C, 30 min | |||||

| Ti2AlC | 2 M HCl aqueous electrolyte | Ti2C2Tx | (91) | ||

| Ti3AlC2 | 1 M NH4HF2 | 2.5 V, 2 h | Ti3C2Tx | (92) | |

| Ti3AlC2 | 1 M NH4Cl | Ti3C2Tx | (69) | ||

| 0.1 M TMAOH |

3.2. Bottom-up Method

The bottom-up method can overcome the significant drawbacks of top-down approaches, such as their small size and irregularity. This process can grow MXenes with different heterostructures and free-of-F terminations, which is challenging to compete with the top-down method. MXenes with various heterostructures and free-from-F terminations can be grown by this process, which is hard to achieve with the top-down method. Beyond the top-down approach, bottom-up techniques such as chemical vapor deposition, physical vapor deposition, and the template method are also reported. It is the method to synthesize 2D defect-free monolayer crystals with an excellent area for different applications in electronics and optoelectronics.60

Chemical vapor deposition is a method for directly synthesizing 2D transition metal carbides, allowing for coatings via reactions on the target material. The MXene grown by the CVD method has a larger size, fewer defects and disorders, a lower concentration of impurities, and higher crystallinity than the wet chemical etching method.68 Xu et al. reported the fabrication of a large area of high-quality 2D ultrathin α-Mo2CTx crystals by CVD at a high temperature of 1085 °C with good superconducting properties.78

Along with the chemical vapor deposition technique, the template method is also beneficial for synthesizing MXenes with a greater output. The synthesized MXene depends on the structure of transition metal oxides, which are used to carbonize or nitridize to form MXenes.8 Xiao et al. synthesized MoN films by the salt-templated method, displaying a very high volumetric capacitance of 928 F/cm3 with a better rate performance in sulfuric acid electrolytes.79 Zhang et al. experimentally demonstrated the ultrathin Mo2C single-crystalline films by plasma-enhanced pulsed-laser deposition at 700 °C.80

In summary, many preparation techniques have been developed, which is the result of both the diversity of carbides that can be used as raw materials and the substantial increase in demand for MXene. These techniques may narrow down the potential applications of MXene but are still in an exploratory stage. Certain challenges are associated with various MXene preparation methods; yet, they are currently under investigation to address these concerns. MXenes can be designed with high gravimetric capacitance by using different etching processes to maximize their potential for use in energy-storage applications and other areas.

4. Structure of MXene

MXenes are structurally similar to graphene, so they are suffixed as “enes” with high structural and electronic adaptabilities. They have accordion-like structures for high electrical conductivity, and decreasing ion diffusion distance for electron transfer shows potential in high-performance supercapacitors.93 The MAX phase has a lamellar structure with M atoms that are hexagonally close-packed, X atoms filling their octahedral spaces, and the A layer acting as a mirror plane.55 The MAX structures are anisotropic with the space group P63/mmc.94,95 The etching treatment at high temperatures removes A atoms and obtains the rock salt structure of carbide layers, similar to graphene.14 After etching A layers, 2D close-packed hexagonal structured Mn+1Xn layers were obtained with the terminations O, H, F, and Cl atoms.96 Wang et al. and their co-workers documented that the titanium carbide MXene is a crystal structure through the valence electron density distribution of the particle, and its space group is P3m1.97 The XRD patterns of the MAX phase and MXene are shown in Figure 4. The distinguishing sharp peak of “Al” (104), at 2θ = 38.8°, can be seen in Ti3AlC2. This“Al” totally desires to be etched out from Ti3AlC2 to attain high-quality MXene with greater separation of layers. The characteristic (104) peak of “Al” in Ti3AlC2 almost vanished in the case of MXene by HF treatment. The morphological structure is shown in Figure 5.98 The accordion-like morphology of MXene is obtained after the HF treatment. The surface of MXene is responsible for the energy storage mechanism. Overall, the layered structure and tunability of surface functional groups of MXene make them a versatile class of materials with the potential for numerous technological advancements.

Figure 4.

XRD pattern of (a) MAX powder (Ti3AlC2) in comparison with MXene, indicating the peak shift and (b) magnified image showing the peak shift after MXene formation. Reproduced from ref (89). Copyright 2021 American Chemical Society.

Figure 5.

Scanning electron micrographs of the (a) MAX phase (Ti3AlC2) and (b) accordion-like structure of exfoliated MXene. Reproduced from ref (89). Copyright 2021 American Chemical Society.

5. Properties of MXene

The transition metal atoms of MXene possess abundant electrons responsible for surface interactions of MXene and are accountable for their properties. The energy bandgap and electronic conductivity of MXene depend on the surface function, which shows different applications in electronic devices based on the energy bandgap values. Khazaei et al. deliberately studied the electronic properties of M2X with functional groups (−F, −OH, −O) and included that the MXenes are metallic without surface terminations.99 To increase the conductivity of MXene, which can be made into a metal-like, semi- or full-insulating material, including the choice of M and X and the modification of their surface terminal groups.5 Due to variations in the surface functionalities, defect concentration, d-spacing between MXene particles, delamination yield, and lateral dimensions brought about by the etching process, the electrical conductivities of Ti3C2Tx varied from 850 to 9870 S/m.74 Mechanical properties influence the electrochemical properties of MXene. Gogoti et al. experimentally proved that the polymer (PVA) confinement between the MXene flakes increases flexibility and cationic intercalation with a capacitance of 530 F/cm3 for MXene/PVA–KOH composite film at 2 mV/s. It was found that the diverse microstructures of the Ti3C2Tx-based samples led to significant differences in their dielectric properties. Conductive and polarization loss are two types of dielectric loss; flake area and flaws disturb dielectric properties.100

Temperature and environment strongly influence the MXenes’ surface chemistry and phase stabilities. The specific heat, thermal conductivity, and thermal expansion coefficient control the electrochemical performance of MXene.100 The introduction of heat affects the thermal properties of MXene and has led to a wide range of applications. Li et al. described that Ti3C2Tx MXene was stable up to 800 °C under an argon atmosphere.101 Mo2CTx MXene is immersed in numerous solvents such as ethanol, HCl, and isopropanol and annealed in air at 200 °C for 2 h. Still, no significant structural changes were observed, indicating its thermal and chemical stability.102 Ti3C2Tx MXene has thermal stability of around 108 W/mK.103

In MXene, the transition metal’s band structure and electronic transitions amid them impact its optical properties.8 Thin MXene-based films with outstanding optoelectronic properties, mechanical flexibility, and electric conductivity can be prepared by drying solution-processed films.20 Ying et al. reported the first study on the optoelectronic properties of V2CTx and its processing into flexible transparent films.104 The chemical stability of MXenes influences the composition, reaction conditions, and colloidal solution, which affect the applications due to their sensitivity to the outer environment. The oxidation state of the M element in MXene is much lower than the oxidation states of the termination groups. Redox oxidation can control the oxidation state, in which MXene acts as a reducing agent.105,106 The MXene Ti3C2Tx synthesized from Ti3AlC2 shows high stability in aqueous solutions, oxidation resistance properties, and crystallinity and more significant electronic conductivity up to 20,000 S/cm. It can provide different methods to fabricate highly stable MXene.93 Organic electrolytes can offer broader electrochemical stability than aqueous electrolytes.107 Zhang et al. presented that freezing MXenes prevents the development of TiO2 nanoparticles at the edges of the MXene flakes and holds the morphology for up to 650 days, while freshly prepared MXene displays flake edge ruining within 2 days at room temperature. The results suggested that the freezing delayed MXene oxidation.108 By adjusting the stoichiometric ratios of the M and X components, it is possible to tailor the exceptional properties of the MXene. The distinct and adaptable characteristics of MXene make them potential candidate materials for developing high-power and high-energy-density capacitors while also making them appealing for various applications. Research on MXenes is an ongoing process, and current studies are continuously revealing new properties and expanding the realm of potential applications.

6. Electrochemical Applications of MXene

MXene attained great importance in exploring electrode materials with good electrochemical energy storage properties, excellent electrical conductivity, hydrophilic surfaces, mechanical stability, and an intercalation effect.109 The unique accordion-like design decreases the ion diffusion path, and the high electrical conductivity for electron transfer shows the application of high-performance supercapacitors.93 The fluoride-free etching process not only allows for a safer MXene preparation but also results in excellent electrochemical performance due to the elimination of −F terminations.3 The functional group −F-terminated MXenes have lower insertion–desertion potentials and a large capacity for charge storage.110 The intercalation method can influence the terminal surface groups, which has an effect on the electrochemical performance of MXenes.111 The electrochemical properties of MXene strongly depend on the surface chemistry and transition metal layers. Surface groups on the MXene surface provide functionalization through covalent or noncovalent bonding.112

Chen et al. synthesized glycine-functionalized MXene with increased interlayer spacing for charge storage.113 The selection of etchant strongly influences the surface functional group, which results in the adsorption and diffusion of metal ions on the surface.114 The chemical etching method enables the simultaneous growth of MXenes retentive to their active surfaces for improved ion diffusion pathways, structural stability, and charge storage dynamics.115 The chemical action on the surface of the MXene provides capacitance. Capacitors store charges by adsorbing and desorbing electrolyte ions on the surface of electrodes.116

Electrostatic double-layer capacitors follow a nonfaradaic reaction because there is no charge transformation, and the energy is stored between the electrode interface and electrolyte.117,118 Since pseudocapacitor electrodes are made of redox-active materials, they can store energy through faradaic redox processes.6 The charges are transferred between the electrode and electrolyte when an external potential is applied.47 The energy storage mechanism operates simultaneously with one as notable as the hybrid supercapacitor, which combines non-Faradaic EDLC and a Faradaic pseudocapacitor.119,7 It can accept both the benefits and drawbacks of EDLC and pseudocapacitors.120 The energy storage is either by electrostatic charge accumulation at the electrode–electrolyte interface or by charge transfer by the Faradaic reaction. It is attributed to the large surface area of electrodes and pseudocapacitor stores by fast surface redox reaction at the surface of the active materials by ion intercalation.121Figure 6 shows the schematic representation of EDLC, pseudocapacitor, and hybrid capacitor. In an aqueous electrolyte, metal ions are combined with a water molecule to form an electric double-layer structure on the surface of MXene, and oxidation–reduction can occur to enhance capacitance. The organic electrolyte is influential in deciding the electrochemical charge storage mechanisms.122 The PC/Ti3C2 composite has efficient desolvation during charging, impacting high volumetric charge storage capacity and fast charge transport.123 In nonaqueous electrolytes, significant potential differences on the surface of MXene cause the electric double-layer structure. The electrolyte can control ion transport and intercalation with interlayer spacing. MXenes with layered structures will deposit ions during cyclic charge and discharge, but their energy density may be incomplete, affecting the supercapacitor applications.12 Ions are absorbed on the external adsorption sites at the edges of the layers and the deep adsorption sites with higher activation energy. At high scan rates, ions are rapidly adsorbed at external adsorption sites, resulting in a good rate performance of MXene. Also, the desorption of ions from deep adsorption sites at a higher voltage window results in high Faradaic efficiency and a long life cycle. The larger cations and smaller cations with higher charges expand and contract the interlayer spaces of MXene, respectively.8 The ionic transport medium (electrolyte), electronic transport medium (electrode), and their interfaces play a vital role in the electrochemical capacitance of supercapacitors.121 It is crucial to remember that the oxidation process primarily improves the effectiveness of ion transport. However, once the efficiency of ion transport reaches a certain point, electronic conductivity will become the dominant factor influencing the electrochemical performance of Ti3C2Tx. Therefore, preserving or improving Ti3C2Tx’s electrical conductivity is essential while developing the oxidation process.124

Figure 6.

Diagram of (a) EDLC, (b) pseudocapacitor, and (c) hybrid capacitor.

Flexible devices, such as flexible displays, electronic skin, human–machine interfaces, intelligent monitors, etc., have demonstrated significant utility in several fields. It has significantly increased the need to develop efficient power sources for these wearable electronics. Supercapacitors must have mechanical properties compatible with human skin for use as wearable electronic power sources. It necessitates that the supercapacitors be able to provide continuous power under the varying deformations caused by human motions and be pleasant to wear. Developing solid-state supercapacitors with high mechanical flexibility has received considerable attention, but they are not yet suitable for wearable applications. Due to the rigidity of the electrodes, the freezing of the electrolyte, and problems with interfacial contact, it is still challenging to create a flexible, all-solid supercapacitor that can function under various deformations and in severe environments.74 The microstructure of MXene can be improved by increasing its surface area and active site outcomes for the electrochemical performance. Ti3C2Tx has been demonstrated to be the most ideal for energy storage due to its multiple ions, faster ion diffusion, low intercalation potentials, and higher theoretical capacities.40

The restacking of the MXene film confines the high energy density of supercapacitors. The addition of conducting polymer PEDOT and metal oxide Fe2O3 into MXene results in an increase in capacitance value up to 541 F/g, due to many active sites on the surface of MXene and its excellent hydrophilicity.125 CNTs can effectively bind the restacking of MXene nanosheets, utilizing the MXene’s surface active sites and enabling fast ion and electron transport.126 The CNT in the Ti3C3Tx/CNT/CuS composite avoids the restacking of MXene sheets and allows large electroactive sites to become available for the electrolyte ions.41 Gandla et al. demonstrated that Mo2Ti2C3 MXene with larger interlayer spacing is more beneficial in ionic liquid electrolytes than conventional Ti3C2Tx MXene with high specific capacitance, cycle stability, and superior energy.127

Microsupercapacitors (mSCs) are an essential power source for portable devices. They can provide vital energy and power in a short amount of time. Optimizing and enhancing their constituent parts can alter the device’s capability.5 The fabrication of PANI@rGO/Mxenes as electrodes for a lightweight, thin, stretchable, and wet-adhesive all-hydrogel microsupercapacitor (mSC) and its first implantation onto the heart of living mice provided a practical application of MXene electrode-based supercapacitors.128 Utilizing significant ion intercalation between the multilayers of MXene-based electrodes, enhanced metallic conductivity can improve the charge storage capacity quickly, thus positioning them as a prime choice for applications involving mSC electrode materials.77,129

The high electrical conductivity of MXenes enables rapid charge and discharge cycles. This characteristic is beneficial when a quick energy supply is necessary, such as in power backup devices and regenerative braking systems. The electrical conductivity of MXenes makes them suitable for electromagnetic interference (EMI) shielding. MXene films with a thickness ranging from 40 nm to many micrometers show promise as thin EMI shielding coatings.130 MXene-based electrodes can provide excellent cycle stability because of their sturdy construction and mechanical strength. Therefore, they are ideal for long-term reliable applications, including energy storage in remote locations and wearable electronics.131 MXene-based supercapacitors can be integrated with energy-harvesting technologies to store energy from sources like vibrations, light, and thermal gradient.132 MXenes can be combined with other substances to make hybrid supercapacitors, such as conducting polymers or transition metal oxides. These hybrids can combine the advantages of many materials, improving the performance in terms of cycling stability and energy density. These applications demonstrate the adaptability of MXenes and their potential to transform numerous sectors. It is important to remember that MXenes are still a topic of active research and that many of these fields may require additional development and optimization before they can be used practically.

7. MXene-Based Composites

7.1. MXene–Carbon Composites

Carbon nanomaterials such as carbon nanotubes and graphene are considered suitable materials to compound with MXene to manufacture highly flexible SCs.133,117 Li et al. fabricated flexible Ti3C2Tx MXene and electrochemically exfoliated graphene with a greater volumetric specific capacitance of 216 F/cm3 and admirable flexibility and conductivity.134 Kumar et al. grew graphene on Ni foil and fabricated an electrode of Ti3C3Tx/graphene/Ni, achieving a high specific capacitance of 542 F/g at a 5 mV/s scan rate. This higher capacitance is credited to the higher surface area, proper interlayer spacing, and intercalated faradaic reaction between MXene layers.135 Sikdar et al. developed 3D hydrogel hybrids of MXene and graphene as suitable electrodes for pseudocapacitors, showing a high specific capacitance of 357 F/g at a 10 mV/s scan rate. The interconnected hydrogel structure of this composite keeps excellent electrical connections throughout the electrode and helps electron transfer, which is responsible for this specific capacitance value.136 Nie et al. formulated a scalable spray-coating and dip-coating strategy to construct an rGO/MXene composite, which displays a specific capacitance of 383.3 F/g. It is attributed to the synergetic effects between rGO and MXene and the high surface area.137 An electrolyte-mediated method is used to compound rGO/MXene composite films as self-supporting electrodes. It shows a volumetric capacitance of 454.9 F/cm3 at a high mass ratio of MXene because the electrolyte layer between rGO and MXene promotes unceasing ion transport channels in composite films.138

CNTs are cast off to compound with an MXene because they can prevent MXene films from adhering.139 Kim et al. and colleagues fabricated a CNT/MXene electrode of an asymmetric supercapacitor by the biscrolling method with high mass loading of MXene, which showed a suitable capacitance of 35.5 F/cm3 and increased energy and power densities of 100 μWh/cm2 and 260 μWh/cm2, respectively.140 Luo et al. fabricated a new compact, flexible microsupercapacitor based on CNT/MXene, indicating that the interaction of electrolyte ions with Ti3C2Tx results in the superior electrochemical performance shown in Figure 7.141 The triangular GCD curves at current densities ranging from 0.5 mA/cm2 to 5 mA/cm2 (Figure 7B) further support these capacitive behaviors. At a current density of 0.5 mA/cm2, a Ti3C2Tx-CNT-based mSC exhibits areal and volumetric capacitance of 61.38 F/cm2 and 87.68 F/cm3, shown in Figure 7C. In comparison, 67.2% capacitance is retained at a high density of 5 mA/cm2 (Figure 7D). The Ragone plot of the Ti3C2Tx-CNTs and Ti3C2Tx-based mSCs’ energy density and power density is shown in Figure 7E. After 5000 charge/discharge cycles, cycling stability shows that Ti3C2Tx-CNTs and Ti3C2Tx-based mSCs preserve 85.5% and 70.7% of their initial capacitance, respectively (Figure 7F). MXene/CT@Ni is synthesized by exhibiting a maximum specific capacitance of 990.8 F/cm3 at 1 A/g.142 Liang et al. constructed an asymmetric device of Ti3C3Tx/MCNT negative electrodes and Ppy-coated MCNT positive electrodes with a relatable capacitance of 22 for the first time. Wang et al. formed a free-standing, flexible, and structurally 3D-interconnected MXene/graphyidne nanotube composite for a high-performance flexible electrode with a significantly improved capacitance of 337.4 F/g. The authors concluded that it is a novel approach to solving the stacking problem for excellent supercapacitors. The specific effects of adding carbon to MXenes depend on a variety of variables including the type of carbon used (such as graphene or carbon nanotubes), the synthesis method used, the amount of carbon added, and the intended application. Researchers delve into these factors to precisely engineer the properties of carbon-infused MXenes, tailoring them to fulfill the specific requirements of the desired functionalities. The effects include enhanced electrical conductivity, charge storage capacity, cycling stability, ion intercalation behavior, and electrocatalytic activity. This adaptability of MXenes, combined with their ability to synergize with carbon, widens the scope for creating novel materials with improved attributes, thereby offering diverse solutions for a broad spectrum of technological applications.

Figure 7.

Electrochemical testing of Ti3C2Tx-CNTs and Ti3C2Tx-based single mSC devices. (A) CV curves at 10 mv/s, (B) GCD curves at 0.5 mA/cm2, (C) rate capacity, (D) EIS, (E) Ragone plots, and (F) cycling stability for 5000 times. Reproduced from ref (127). Copyright 2021 American Chemical Society.

7.2. MXene–Metal Oxide Composites

Compared with bimetallic transition metal oxides, transition metal oxides have a higher electrical conductivity potential, a synthetic effect, and multiple valence changes. Transition metal oxides such as MnO2, NiO, RuO2, etc., keep an ultrahigh pseudocapacitance compared to carbon materials, which is advantageous for restructuring the low energy density and improving the cycle stability of supercapacitors.143 The ex situ method is the least used to synthesize MXene–metal oxide composites among different synthesis methods. Torelli et al. prepared Ti3C2Tx/Co3O4 by this method.144 Gong et al. successfully fabricated hexagonal nickel cobalt-oxide nanosheets on MOF and MXene composites with high specific capacitance and better cycle stability. It can afford more active sites to speed up the reaction rate of redox reactions and accelerate ion diffusion due to their hexagonal structure.145 Zhu et al. and co-workers successfully synthesized the TiO2–Ti3C2Tx nanocomposite through in situ hydrolysis and heat treatment. They fabricated it as an electrode with greater specific capacitance and ultralong cycle life. TiO2–Ti3C2Tx displays a higher specific capacitance of 143 F/g at 5 mV/s, 1.5 times that of pristine Ti3C2Tx. It is because the TiO2 nanoparticles increase the interlayer distance of Ti3C2Tx to enable the pull-out of cations and maintain a diffusion path for the electrolyte ions.146

V2O5/Ti3C2Tx is prepared by the combination of minimal delamination, vacuum-assisted filtration technique, and redox method and shows considerable cyclic stability and gravimetric capacitance.147 The vacuum-assisted filtering of a mixture of MXene nanosheets and V2O5 nanofibers successfully produced MXene/V2O5 films, contributing to the expansion and stabilization of the MXene interlayer gap, which is advantageous for charge diffusion or ion diffusion and transfer. Compared to pure MXene films, MXene/V2O5 films’ flexibility and electrochemical capabilities are improved. The electrode also has better specific capacitance and cycling stability.70 Rakhi et al. reported for the first time that depositing ε-MnO2 whiskers on the surface of MXene to form electrodes for aqueous pseudocapacitors with increased surface area improved electrochemical performances in an aqueous electrolyte.148 Zou et al. developed a self-assembly method to synthesize MXene/α-Fe2O3 having a high specific capacitance of 405.4 F/g at the current density of 2 A/g.149 It is proved that TM-doped samples with MXene as a second electrode can enhance the performance of the supercapacitor.150 Yuan et al. proposed a hydrothermal technique for self-assembling MXene–Co3O4 composites for a supercapacitor electrode. This fabricated electrode exhibits a larger gravimetric capacitance of 1081 F/g because Co3O4 nanoparticles avoid self-restacking and decrease the electron transport path.151 Ying et al. synthesized the Ti3C2Tx–NiO composite by vacuum freeze-drying for electrodes with improved electrochemical performance.152 Co–Ni oxides were decorated on the surface of Ti3C2Tx through the atomic layer deposition method and used as a pseudocapacitive electrode material, showing a higher specific capacitance of up to 1960 F/g with good cycle stability.153 Bin et al. synthesized nitrogen-doped Ti3C2Tx decorated with MoO3–x (N-d-Ti3C2Tx/MoOx) to attain high-performance flexible electrodes for supercapacitors carrying an ultrahigh capacity of 487 F/g at the current density of 5 A/g, as shown in Figure 8.154 The CV and GCD curves of the d-Ti3C2Tx and N-d-Ti3C2Tx/MoOx films with various mass loadings of MoOx nanoparticles are shown in Figure 8a,b. The N-d-Ti3C2Tx/100-MoOx film maintains a more stable specific capacity than the N-d-Ti3C2Tx/50-MoOx and N-d-Ti3C2Tx/70-MoOx films with increasing scan rate, as shown in Figure 8c,d with different mass loadings of MoOx nanoparticles. Sui et al. synthesized Ti3C2Tx/MoO3–x composites with a high volumetric capacitance of 1893.2 F/cm3 in 1 M H2SO4 electrolyte.155 Pan et al. fabricated Ti3C2Tx/WOx on a carbon cloth by a facile electrochemical deposition method to deliver gravimetric capacitance of 164 F/g under the high mass loading of WOx.156 Darmiani et al. synthesized porous, wire-shaped Ni(OH)2–Ni-Ti3C2@CW electrodes with a high surface area for the first time. Many active sites show excellent capacitance of 1704.50 F/cm3 due to the high conductance between active sites and CW.157 It is important to note that the specific effects of incorporating metal oxides into MXenes can vary depending on factors such as the type of metal oxide, the synthesis method, the ratio of components, and the intended application. Researchers often study these factors to tailor the composite’s properties of MXenes, and the functional properties of metal oxides make MXene–metal oxide composites highly versatile and valuable for a wide range of electrochemical applications.

Figure 8.

D-Ti3C2Tx and N-d-Ti3C2Tx/MoOx films with different mass loadings of MoOx nanoparticles: (a) CV curves at 20 mV s–1, (b) GCD curves at 5 A g–1, and (c,d) gravimetric and volumetric capacity at different scan rates. Reproduced from ref (140). Copyright 2021 Elsevier.

7.3. MXene–Polymer Composites

The polymer’s electrical, mechanical, and thermal properties can boost the stability of MXene flakes in MXene/polymer composites.158,159 The intercalation of polymers into MXene layers benefits the molecular level coupling between MXene and polymer molecules, which helps to improve the strength and flexibility of MXene/polymer composites.160 Poly(vinyl alcohol) (PVA) is the best candidate among various polymers to fabricate MXene/polymer composites as electrodes because of its high solubility in water and abundance of hydroxyl groups.160 Ling et al. synthesized single-layered MXene/PVA film by vacuum-assisted filtration followed by mixing the colloidal solution of Ti3C2Tx films with PVA aqueous solution, which had enhanced tensile strength and high electronic conductivity.161In situ polymerization and ex situ mixing can create MXene/polymer composites. Three processes obtain in situ polymerization: mild physical agitation, electrodeposition, and UV radiation, whereas the ex situ mixing method includes solution mixing and filtration.12 To improve the electrochemical properties of the MXene-based electrode, Yan et al. tested the electrochemical deposition of conducting polypyrrole on the surface of the MXene electrode with a specific capacitance of 343.20 F/g.162 Naguib et al. described the synthesis and characterization of MXene/polyacrylamide (PAM) composites with greater flexibility, and conductivity increased to 3.3 × 10–2 S/m.163 Through the intercalation of polypyrrole (PPy) into layered Ti3C2Tx MXene, Zhu et al. found a new approach with a capacitance of about 406 F cm–3. The porous structure of Ppy/Ti3C2Tx is the reason for excellent electrochemical output which stops the dense stacking of polypyrrole during polymerization and is advantageous to the infiltration of electrolyte into this electrode during the charging and discharging process.164 Zhang et al. reported a conductive MXene/poly(3,4-ethylenedioxythiophene):polystyrenesulfonate (MXene/PEDOT:PSS) coating for an electrode in an ultrafast supercapacitor.165 Ti3C3Tx and polyaniline (PANI) hybrid electrode materials with an excellent volumetric and gravimetric capacitance of 1682 F/cm3 and 503 F/g were created by oxidant-free in situ polymerization of PANI on the MXene.166 The authors concluded that the PANI deposition on MXene increases the ion transport; as shown in Figure 9, the capacitance value is less thickness dependent. A freestanding Ti3C2Tx/PANI electrode with a thickness of 4 μm and cyclic voltammetry (CV) profiles that were obtained at scan rates ranging from 5 to 1000 mV/s are displayed in Figure 9a. At a scan rate of 20 mV/s, Figure 9b contrasts the CV curves of two Ti3C2Tx/PANI electrodes with thicknesses of 4 and 13 μm with the CV curves of two pristine Ti3C2Tx electrodes with thicknesses of 3.5 and 10 μm. The rate dependence of the gravimetric capacitance of Ti3C2Tx/PANI electrodes with various thicknesses and mass loadings is depicted in Figure 9c. Figure 9d and e show charge–discharge profiles of the 4 μm thick Ti3C2Tx/PANI electrode at current densities ranging from 5 to 50 A/g. The electrochemical impedance spectroscopy (EIS) results for Ti3C2Tx/PANI electrodes of various thicknesses, a pure Ti3C2Tx electrode, and an electrode constructed from Ti3C2Tx crumpled by HCl treatment are shown in Figure 5f. Zheng et al. fabricated interconnected polyaniline nanoarrays and MXene networks on the fiber with high specific capacitance and energy density.167 Ye et al. synthesized MXene/PANI@cotton for flexible supercapacitors with excellent electronic properties.168 A flexible MXene/polypyrrole composite with adjustable thickness presents a gravimetric capacitance of 563.8 F/g at 0.5 A/g in 1 M H2SO4.147 Chang et al. used a hydrothermal method to create Ti3C2Tx MXene with cellulose nanofiber and sodium lignosulfonate, which has a high conductivity and volumetric capacitance of 748.96 F cm–3.169Table 2 summarizes the electrochemical performance of MXene–carbon composites, MXene–metal oxide composites, and MXene polymer composites. By preventing MXene sheets from being restacked and adding functionalization, the synthesis of MXene polymer composites presents a ground-breaking strategy that improves the material’s electrochemical performance. Overall, the combination of MXenes with polymers creates synergistic effects that capitalize on the strengths of both materials. This hybrid approach allows for the creation of composite materials with enhanced performance, durability, and functionality, making them suitable for a wide range of electrochemical applications, including energy storage, sensors, and other electronic devices.

Figure 9.

(a) CV curves of a Ti3C2Tx/PANI electrode. (b) Comparison of the CV Ti3C2Tx/PANI and Ti3C2Tx electrodes. (c) Gravimetric capacitance of electrodes with different thicknesses and mass loadings. (d) Galvanostatic charge/discharge profiles of the Ti3C2Tx/PANI electrode. (e) Specific capacitances of the Ti3C2Tx/PANI electrode. (f) EIS of Ti3C2Tx/PANI electrodes. Reproduced from ref (151). Copyright 2018 Royal Society of Chemistry.

Table 2. Summary of Electrochemical Performance of Different MXene-Based Composites.

| MXene-based composites | Capacitance (F/cm3)/(F/g) | Cyclic stability (cycles) | ref | |

|---|---|---|---|---|

| MXene–carbon composite | MXene/CNT | 990.8 F/cm3 | 5000 (78%) | (142) |

| SWCNT/MXene | 390 F/cm3 | 10000 | (170) | |

| Graphene/MXene | 216 F/cm | 2500 (82%) | (134) | |

| Graphdiyne/MXene | 337.4 F/g | 10000 (88.2%) | (171) | |

| MXene–metal oxide composites | TiO2/MXene | 143 F/g | 6000 (92%) | (137) |

| MnO2/MXene | 212 F/g | 10000 (88%) | (148) | |

| M-NC@NCM/NF | 118.5 F/g | 5000 (75.3%) | (145) | |

| Co3O4/MXene | 1081 F/g | 8000 (83%) | (151) | |

| Ti3C2Tx/MoO3–x | 733.8 F/g | (155) | ||

| Fe2O3/MXene | 405.4 F/g | 2000 (97.7%) | (149) | |

| Ni(OH)2–Ni–Ti3C2@CW | 1704.5 F/cm3 | 7000 (89.3%) | (157) | |

| MXene polymer composites | PVA/MXene | 528 F/cm3 | 10000 | (161) |

| Ppy/MXene | 343.20 F/cm3 | (162) | ||

| Ppy/MXene | 406 F/cm3 | 20000 (100%) | (164) | |

| PANI | 1682 F/cm3 | (166) |

MXene-based composites are increasingly used in SC manufacturing due to their exceptional properties. MXene oxidation is close to the anodic limit of aqueous electrolytes, and proton reduction at a low voltage is restricted in symmetric supercapacitors. Combining MXene-based materials with electroactive materials that exhibit high pseudocapacitance and high operating potential in aqueous electrolytes is one method that might be used to boost the energy density of the SC device. According to these findings, a practical method for creating high-performance MXene-based composites as symmetric capacitors can be suggested, and an efficient method for enhancing the design of MXene-based electrodes is provided.

8. Factors Influencing the Electrochemical Performance of MXene-Based Supercapacitors

8.1. Dependency on the Synthesis Method

The electrochemical performance of MXene varies with the synthesis procedure. The intercalation with cations of MXene increased the interlayer spacing and the capacitance in sulfuric acid.172 The fluorine terminations, more significant Fe cations, and water intercalation among the FeF3/HCl etchant layers can improve the electrochemical properties of the MXene electrode.173 The hydrazine-treated material has an enhanced capacitance of 250 F/g in acidic electrolytes with an outstanding cycling stability for electrodes as thick as 75 μm. Some studies have revealed that adding materials and other heterostructures weakens the volumetric capacitance of MXene electrodes.174 The specific capacitance of MXene synthesized through various rate performances of the MXene/C electrodes obtained under three different temperatures were compared, as shown in Figure 10.175 The LiF/HCl etchant in H2SO4 solution shows greater capacitance than the HF etchant because of the intercalation of Li+ ions and water molecules, which avoids restacking MXene layers.176 Tang et al. fabricated Ti3C2Tx film by concentrated H2SO4 etching with probe sonication to reach high electrochemical performance at high mass loadings. It indicates that reduced flake size, holes on the nanosheets, and increased interlayer spacing are three vital factors for MXenes to crack the restacking issue and attain high electrochemical performance at high rates without losing volumetric capacitance.177 The electrochemical performance of Ti3C2Tx film is efficiently optimized after laser writing at a high capacitance of 322 F/g at 10 mV/s.178 The carbon-intercalated Ti3C2Tx MXene (Ti3C2Tx/C) synthesized by annealing long-chain fatty amines to form carbon interlayers in MXene displays an increased interlayer spacing due to the amine interaction. The Ti2C2Tx/C heterostructure unveiled improved electrical conductivity and electrochemical performance with a gravimetric capacitance of 364.3 F/g.175 The fractional elimination of Al can simultaneously solve the restacking issue and poor conductivity. The remaining layers provide space for ion diffusion and improve interlayer conductivity upgrades to higher capacitance.55 In summary, the synthesis method plays a pivotal role in determining the electrochemical performance of the MXene-based supercapacitors. Researchers must carefully select or design a synthesis approach that aligns with the desired electrochemical properties and device requirements. A comprehensive understanding of how different synthesis parameters impact the resulting material properties is essential for tailoring MXene-based electrodes to achieve high-performance supercapacitors with enhanced energy and power densities.

Figure 10.

Rate performance of the TH-800, TD-800, and Ti3C2Tx-800 electrodes. Reproduced from ref (160). Copyright 2018 Royal Society of Chemistry.

8.2. Dependency on the MXene Precursor

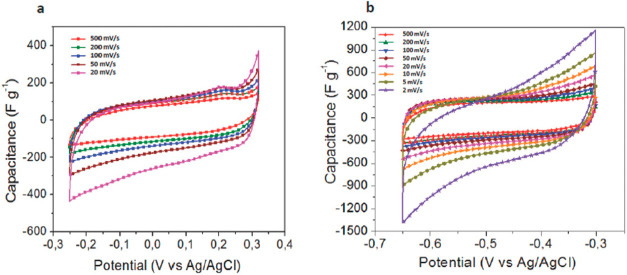

Besides the synthesis method, the electrochemical properties depend on the MXene precursors. The ball milling treatments on the precursor V4AlC3 and HF-etched V4C3Tx MXene electrode in 1 M H2SO4 exhibited a higher capacitance of 209 F/g at a scan rate of 2 mV/s with long cyclic stability. It approved the role of the valence state of vanadium along with the greater interlayer spacing, good conductivity, and sizable porous surface of MXene.179 MXene produced by two different etching protocols converted the (Mo2/3Y1/3)2AlC i-MAX phase into either (Mo2/3Y1/3)2C with in-plane elemental order after Al removal or Mo1.33C with in-plane vacancy ordering after Al and Y removal. The electrochemical properties of these materials show a different result. (Mo2/3Y1/3)2C MXene exceeded a volumetric capacitance of 1500 F/cm3 at 2 mV/s in KOH electrolyte, and Mo1.33C exceeded 1100 F/cm3 at 2 mV/s in H2SO4,180 as is shown in Figure 11. Halim et al. noted that Mo1.33C etched from the (Mo2/3Sc1/3)2AlC delivered a high capacitance of about 1308 F/cm3 in 1 M H2SO4 electrolyte, which is superior compared to (Mo2/3Y1/3)2AlC i-MAX phase precursors. The rate of capability improved by changing the electrolyte to 3 M H2SO4.56 In conclusion, the choice of MXene precursor material significantly influences the electrochemical performance of the MXene-based supercapacitors. Careful selection of the precursor material is pivotal in determining the resulting MXene’s chemical composition, layered structure, surface chemistry, and overall properties. These precursor-dependent characteristics subsequently impact the accessible surface area, pseudocapacitive behavior, conductivity, and stability of the MXene as an electrode.

Figure 11.

Scan rate dependence of volumetric capacitance of a 1.2 μm (Mo2/3, Y(1–x)/3)2C) film and a 2 μm Mo1.33C film in 1 M H2SO4 and 6 M KOH. Reproduced from ref (165). Copyright 2018 American Chemical Society.

8.3. Dependency on the Electrolyte

The electrolyte is an essential component of supercapacitors and has attracted many concerns, and the electrochemical properties of MXene-based materials can be modified by varying electrolytes. The potential window selected by the electrolytes generates a free path for the diffusion of ions between the electrodes, and the electrolytes increase interlayer spacing by cation intercalation.181 Sulfuric acid is a common aqueous electrolyte; its cation is a small-sized hydrogen ion responsible for high ionic conductivity.182 The 3 M KOH alkali electrolyte of Ti3C2Tx MXene exhibits excellent electrochemical capacitor application compared to the 3 M Na2SO4 neutral electrolyte.183 The PAA-NHEA-MXene with an organic gel electrolyte of organic electrolyte solution (4 mol/L of LiCl/EG) is a better solid capacitor for energy storage applications.184 Ti3C2Tx MXene exhibited a high volumetric capacitance of about 1500 F/cm3 with a 90 nm thick electrode in an acid electrolyte (1 M H2SO4) and the primary electrolyte (KOH), and it disclosed a volumetric capacitance of 340 F/cm3 at 2 mV/s and exhibited almost no degradation after 10000 cycles at A/g.185 Acidic- or basic-type electrolytes may leak into other parts of the system, so some gel-type electrolytes, such as poly(vinyl alcohol) (PVA/H2SO4 and PVA/H3PO4), are used to overcome this problem.186 Most work follows acid electrolytes to accomplish high performance from MXene because of the factors contributing to its high volumetric capacitance such as its high conductivity for electron transport and its layer structures for ionic intercalation.

O-terminations for redox-active sites direct the pseudocapacitive nature of MXene in acidic electrolytes.187 Fangfang et al. investigated an ionic–electronic coupling strategy for converting inactive surface functional groups into electrochemically active sites.188 A reversible electrochemical reduction/oxidation is demonstrated by the anodic and cathodic peaks in the CV profile of Ti3C2Tx/GCE which in 3 M H2SO4 are at −0.79 and −0.82 V with a slight potential difference of 0.03 V, respectively, as shown in Figure 12. The peak currents are 0.18 and 0.19 mA with a ratio of approximately 1. The CV curve of (Mo2/3, Y(1–x)/3)2C electrodes was 1.2 m thick, and the scan speeds were 20–500 mV/s in 1 M H2SO4 and 2–500 mV/s in 6 M KOH, as shown in Figure 13.180 Gogotsi et al. and co-workers experimented with different solvents to understand the effect of electrolytes on capacitance performance.123 Jackel et al. tested the volume changes of Ti3C2Tx in ionic liquid electrolytes by using the electrochemical tracing method. They verified that when the electrode attaches to electrolytes the volume expansion is irreversible due to spontaneous ion intercalation.189 To sum up, the electrolyte choice holds a key role in shaping the electrochemical performance of MXene-based supercapacitors. It is imperative to comprehend how diverse electrolyte properties impact device behavior, enabling the optimization of the energy storage capacity, power delivery, and overall robustness. Therefore, researchers need to select electrolytes thoughtfully, taking into account the desired electrochemical characteristics and operational prerequisites of the supercapacitor setup.

Figure 12.

CVs of 1.7-IL-Ti3C2Tx/GCE at 2 mV s–1 in 3 M H2SO4 and 3 M H2SO4–0.8 M [Emim]H2SO4. Reproduced from ref (173). Copyright 2020 Royal Society of Chemistry.

Figure 13.

Electrochemical performance of a 1.2 μm thick film of (Mo2/3, Y(1–x)/3)2C: (a) 1 M H2SO4 and (b) 6 M KOH. Reproduced from ref (165). Copyright 2018 American Chemical Society.

8.4. Dependency on the Design Architecture of the Electrode

The electrochemical performance of MXene-based electrodes can be of better quality by increasing the specific surface area of the electrodes. Researchers proved that the low conductivity of transition metal oxides, the low density of carbon-based materials, and the unstable structure of conducting polymers prevent them from attaining ideal capacitance performance.190,191Figure 14 shows the areal capacitance of the Ti3C2Tx film and Ti3C2Tx/PDA191 at different scan rates. MXene-based electrodes are created by coating an MXene solution (slurry) on current collectors like Ni foam. The thickness depends on the solution concentration, which affects the supercapacitor’s electrochemical performance.29 The electrode’s capacitance impacts its thickness; when thickness increases, the capacitance declines, which is credited to the electrode morphology.22 Lukatskaya et al. demonstrated how different electrode design strategies could push the capacitance value of MXene nearer to its theoretical value. Macroporous electrode architectures show capacitance retention of about 210 F/g at charge–discharge rates above 1 V/s and 100 F/g at 40 V/s.185 Huang et al. fabricated a high-performance MXene hydrogel electrode by freezing the MXene slurry, followed by a designed thawing of sulfuric acid electrolyte, and the macrostructure of the hydrogel electrode provided plentiful active sites for the storage of ions and diffusion of the electrolyte.192 Su et al. detected that the ball milling procedure results in higher carbon content and a large electrode surface area, which upgraded the capacitance.193 Tang et al. reported a controlled oxidation method for improving the electrochemical properties of titanium carbide MXene electrodes in acidic electrolytes by incrementally increasing the interlayer spacing and familiarizing defects without disturbing the electrochemically active sites.194 In conclusion, the electrochemical properties of MXene-based materials are linked to the design architecture of the electrode. Researchers must carefully engineer electrode structures to optimize the surface area, porosity, thickness, and overall configuration. A well-designed electrode contributes to the enhanced energy storage capacity, power performance, and cycling stability in various MXene-based electrochemical devices.

Figure 14.

Areal capacitances of the Ti3C2Tx film and Ti3C2Tx/PDA-2, 5, and 10 composite film electrodes as a function of the scan rate. Reproduced from ref (176). Copyright 2019 Elsevier.

8.5. Dependency on the Size and Structure of MXene

The structure and morphology affect the capacitance properties of the MXene. Structure stability has an impact on the cycling performance of a supercapacitor. Maleski et al. showed that the smaller flakes of MXene have more pathways for ions to move through. It leads to high ionic conductivity and makes it easier for the electrolyte to reach more active sites of the electrode, which increases the electrochemical performance. The larger flake size of MXene has a minor interface contact resistance, resulting in a better electron conductivity. MXene films of about 1 μm show a larger capacitance of 288 F/g, and 4.4 μm sized films show 270 F/g.195 To overcome this, Kayali et al. fabricated an electrode with a mixture of 1:1 M ratios of small flakes (below 1–2 μm) and large flakes (about ∼15 μm) and conveyed superior gravimetric and volumetric capacitances of 435 F/g and 1513 F/cm3. A pair of anodic and cathodic peaks with tiny peak separations were seen for both electrodes at a low scan rate of 2 mV s–1, and as predicted, the peaks grew wider as the scan rate was raised, as shown in Figure 15.196,166 Xinghua et al. experimentally proved that the ball milling of MXene can decrease particle size and enhances its electrochemical properties.193 The size of MXene nanosheets can be controlled by fine-tuning power and the ultrasonic exfoliation time. The high ultrasonic time and power outcomes are due to the smaller size of MXene nanosheets, which positively increases active sites for ion diffusion.197

Figure 15.

CV curves of (a) electrodes made using large flakes (average size of ∼3 μm) and (b) small flakes (average size of ∼0.18 μm). Reproduced from ref (181). Copyright 2018 American Chemical Society.

Postsynthesis methods like heat treatment, intercalation, etc., can alter the features of the terminal surface group. According to many studies, F-terminated Ti3C2Tx MXene has a lower capacitance than O/OH-terminated MXene and is more susceptible to surface redox reactions because the chemical stability of −F reduces electrolyte ion transfer and degrades electrochemical performance.198 Surface terminations with lower electronegativity (Cl, O, F) are expected to push pseudocapacitance, and the presence of −Cl increases interlayer spacing due to chlorine’s large ionic size, resulting in a larger capacitance than without chloride termination.199 In short, the size and structure of MXene play critical roles in determining its electrochemical behavior. Scientists need to carefully consider and control these factors to optimize the energy capabilities of MXene and make it more effective in various applications.

9. Conclusion: Challenges and Future Perspectives

MXenes are promising materials for energy storage devices among 2D materials due to their unique properties. There are abundant notable studies to explore MXenes, and it has become the researchers’ favorite electrode in supercapacitors. The improved properties and enhanced electrochemical performance of MXene can be used in diverse fields for energy storage applications. However, several hidden challenges delay MXene’s applications in supercapacitors. Among different kinds of MXenes, Ti-based MXene is the most explored compared to other MXenes. MXenes can show higher electrochemical performance due to their properties, such as good surface chemistry, hydrophilic nature, and metallic conductivity, and the synthesis methods influence these properties. Selected etchants are used for etching A elements from the MAX phase, such as Al and Si, leading to MXenes. Surface termination groups are challenging to identify precisely using XRD and EDS. This article reviews different etching methods, but fluoride etching is still the most widely used method since it is less expensive and easier to operate than F-free. Due to fluorine surface terminations, fluoride etchants are risky and lessen the electrochemical properties, and there is a need for inexpensive, ecofriendly green etchants without sacrificing their quality. The fluorine-free etching methods simplify the effect of the pressure and temperature on the preparation of MXene. The molten salt etching method is the best method for MXene preparation and has the same features and applicability as the HF method. By an increase in the lateral size of MXene and its interlayer structure by intercalation caused by etchants, more ions can pass through it, and more faradaic charges can be stored. This type of delamination occurs without the application of a delamination agent.

Investigating novel MXene preparation methods requires significant research and is both crucial and challenging. It is necessary to develop safe, effective, and high-quality synthesis methods. The main obstacles to the production of MXene are the cost and availability of MAX phase powders and the usage of a significant amount of intrinsically dangerous high-concentration HF. These issues will continue to be barriers to the growth of the industry. The etching of MXene is time-consuming and cannot achieve mass production, which is challenging. There is a poor understanding of the surface termination effect on the MXenes’ functional characteristics. It is a complex task that needs careful thought to functionalize MXene surfaces with particular groups while preserving stability and preventing degradation. Surface flaws in MXene caused by chemical etching are related to the oxidation of MXene. The aggregation of the synthesized MXene and the effects of the structural features of MXenes, such as basal spacing, surface chemistry, etc., have significantly impacted the electrochemical charge storage mechanism of MXene-based electrode materials. Many MAX phases and precursors are theoretically proven through computation; however, preparation methods and studies are not explored, and experimental evidence is still necessary. Only a few reports are found on nitride-based MXene, leaving it to be barely studied.

Aqueous solutions of HF are used to synthesize nitride-based MXene, and it is imperative to design a synthesis method for nitride-based MXene. To encourage commercialization, consider safer fabrication methods without compromising the quality or controlling the interaction of exfoliated MXene nanosheets with different solvents. It is still challenging to manufacture high-quality MXenes on a wide scale while keeping their stable characteristics. For practical applications, scalability without sacrificing the material’s characteristics is essential. The diversity of MXene would be more prosperous.

MXenes with high energy and power density are very important, and MXene-based composite materials enhance the electrochemical capacitance as electrodes in a supercapacitor. The transition-metal-oxide–MXene composite is the best combination for high electrochemical properties because the porous structure with a large surface area contributes to the fast faradaic reaction. Since most polymers are hydrophobic, incorporating MXene into the polymer is a challenge faced by research. So, developing a suitable method for comprising MXene and hydrophobic polymer will benefit novel applications in the future. MXenes have been used in composites, coatings, and other sectors; thus, it is crucial to comprehend and optimize their mechanical and thermal properties. Attaining the desired thermal conductivity, stability, and mechanical strength under various conditions is an ongoing challenge. It is crucial to guarantee the long-term stability of MXenes, especially in practical applications and in diverse settings. It is still challenging to stop oxidation, degradation, or other undesirable changes from happening over time.

Aqueous electrolytes increase ionic conductivity, but in some cases, the leakage of aqueous electrolytes has an unfavorable effect on the device’s electrochemical performance. Also, dissolved oxygen in the aqueous electrolyte hinders the electrochemical capacitance by surface oxidation. Hence, reports are needed for solid and nonaqueous electrolytes to achieve high electrochemical performance. Transparent and highly flexible electrodes are crucial for the next generation, and MXene looks to have a vast potential for this. It will upgrade the quality of the MXene research field to the next level. The goal of this review is to contribute favorably to the development of MXene-based electrodes for supercapacitors.

Acknowledgments

We thankfully acknowledge the University of Kerala for its financial support. We also thank the Centralized Common Instrumentation Centre (CCIF), Kerala Government Project Performance Linked Encouragement for Academic Studies (PLEASE), and Government College for Women, Thiruvananthapuram, Kerala, India, DST-FIST, for executing this work.

Biographies

Anu Mini Aravind is a physics Ph.D. student under Dr. Xavier Thankappan Suryabai at the Government College for Women, University of Kerala, Thiruvananthapuram. She received her M.Phil. in physics from the University of Kerala in 2021. Currently, her activity research is focused on the field of energy storage.

Merin Tomy graduated with a Master’s degree in physics from Mahatma Gandhi University in 2018. Currently, she is a doctoral candidate in material science at the Government College for Women, University of Kerala, Thiruvananthapuram, under the direction of Dr. Xavier Thankappan Suryabai. Her research focuses on the field of energy storage.

Anupama Kuttapan is a postgraduate from St. Thomas College (Autonomous), Thrissur, in 2017. Currently, she is a research scholar in the Department of Physics at St. Thomas College (Autonomous), Thrissur, under the guidance of Dr. Ann Mary K. A. Her research primarily focuses on the optical and electrochemical analysis of specific selenium-based nanocomposites.

Dr. Ann Mary K. A. is an Assistant Professor & Research Supervisor in the Department of Physics, St. Thomas College (Autonomous), Thrissur, University of Calicut. She obtained her Master’s degree in physics from Mahatma Gandhi University Kottayam in 2010 and received her Ph.D. in 2015 from the same university. Her research interests include material science, especially carbon-based quantum materials, biophotonics, nonlinear optics, and electrochemical energy storage studies. She has more than 20 publications in these areas to her credit.

Xavier Thankappan Suryabai is an assistant professor of physics at the University of Kerala, Thiruvananthapuram. He graduated in physics from Madurai Kamaraj University, Tamil Nadu, and received his Ph.D. in physics in 2011 from the University of Kerala, Thiruvananthapuram. His research is focused on density functional studies of materials. His research interests include nanomaterials, drug design, energy materials, spectroscopy, and physics education. He has published more than 35 scientific articles on these topics.

Author Contributions

Anu Mini Aravind: Data collection, Writing–review and editing. Merin Tomy: Review and editing. Anupama Kuttapan: Review and editing. Ann Mary Kakkassery Aippunny: Coordination, review, and editing. Xavier Thankappan Suryabai: Conceptualization, supervision, review, and editing.

The authors declare no competing financial interest.

References

- Gu T.-H.; Kwon N. H.; Lee K.-G.; Jin X.; Hwang S.-J. 2D Inorganic Nanosheets as Versatile Building Blocks for Hybrid Electrode Materials for Supercapacitor. Coord. Chem. Rev. 2020, 421, 213439. 10.1016/j.ccr.2020.213439. [DOI] [Google Scholar]