Abstract

In the recent years, packaging made of conventional plastics has been increasingly replaced by materials believed to be more sustainable. However, perceived sustainability must align with scientific assessments, such as life cycle assessments (LCAs). This review analysed 53 peer-reviewed studies published in the time range 2019–2023, aiming at understanding the state of the art in LCA about the environmental impacts of packaging by focusing on the comparison between plastics and alternative materials. The literature showed that consumer perceptions often differ from LCA findings and revealed that, frequently, conventional plastics are not the least environmentally friendly choice. Bioplastics typically show benefits only in the climate change and the fossil resource depletion impact categories. The heavy weight of glass turns out to affect its environmental performances with respect to the light plastics, with reuse being an essential strategy to lower the burdens. The comparison between plastics and metals is more balanced, leaning more towards plastics for food packaging. Similarly, paper resulted often preferable than plastics. Finally, for the other materials (i.e. wood and textiles), the picture is variable. To be competitive with plastics, the alternative materials require improvements like the optimisation of their production processes, their reuse and enhanced end-of-life options. At the same time, recycled polymers could boost the eco-performance of virgin plastics.

Keywords: Life cycle assessment, plastics, bioplastics, glass, metals, paper, packaging, systematic review

Introduction

Packaging plays a vital role in preserving product quality, ensuring safety and communicating valuable details, making it an integral part of modern life and commerce. The overall global packaging production in 2020 reached 3.8 trillion units, and a further 2.3% annual growth rate is forecasted until the year 2025 (Euromonitor International, 2021), with a significant growth expected in Asia and Africa (Euromonitor International, 2021). The main estimated growth sectors will be soft drinks, dairy and confectionery (Packmedia, 2021). Furthermore, the recent COVID-19 pandemic influenced the packaging sector, increasing the demand for packaging protecting against contamination (Kitz et al., 2021) and leading to a significant growth of packaging for the food delivery market and for the e-commerce (Euromonitor International, 2021; Kochańska et al., 2021; Oppaca, 2022). Plastic packaging, accounting for 64% of the global sales of grocery packaging in the year 2020, still have a pivotal role in several sectors such as food, beverage, beauty and home care industries (Euromonitor International, 2021). Nevertheless, because of the increasing environmental awareness among citizens and companies, where this is technically feasible, conventional plastics are being more and more substituted with other materials that are perceived as being more sustainable (Grosso, 2022; United Nations, 2023). Accordingly, the current circular economy policies support the introduction of packaging made of materials alternative to plastics (Michaliszyn-Gabryś et al., 2022). For example, bioplastics are generally perceived as more sustainable than conventional plastics, since they derive from renewable resources and/or are biodegradable (Atiwesh et al., 2021; Madival et al., 2009). The same for paper, with the big limitation of packaging for liquid products, that requires at least the coating with a waterproof film, that can be manufactured of bioplastics (Kunam et al., 2022; Mujtaba et al., 2022). Glass also has a much greener image in the public perception (Boesen et al., 2019; De Feo et al., 2022), but its weight and fragility make it less flexible in terms of possible applications as alternative to plastics.

Nevertheless, the perception of greater sustainability of alternative materials, such as glass, paper or bioplastics, needs to be supported and confirmed by robust scientific assessments that include the complete life cycle of packaging. Life cycle assessment (LCA) is a scientific methodology standardised in the ISO 14040 and ISO 14044 technical standards, developed for assessing and quantifying the potential environmental impacts associated with entire product and services life cycles (Rigamonti and Mancini, 2021). According to the aforementioned standards, the LCA methodology is composed of four main stages: (i) goal and scope definition (definition of analysed scenarios, functional unit, system boundary, impact categories and characterisation methods, data quality and methods used for handling multifunctionality); (ii) inventory analysis (quantification of the most important inputs and outputs from the system boundary of the studied system/s); (iii) impact assessment and (iv) results interpretation. Through the LCA methodology, it is possible, thus, to analyse the overall performances of a given product and sometimes to debunk some wrong perceptions about the environmental friendliness of packaging materials (Boesen et al., 2019). Otto et al. (2021) investigated the relationship between the consumer perception and the scientific sustainability of packaging materials (plastics, glass, metals and paper), considering aspects such as the carbon footprint, the recycling and reuse rates and the biodegradability. The outcomes demonstrated that the perception of the environmental sustainability of plastics resulted underestimated, whereas for glass and biodegradable plastics, it was overestimated. Boesen et al. (2019) found that bioplastics and glass are typically perceived as being more environmentally sustainable than plastics. Moreover, consumers underestimate the sustainability of plastics compared to aluminium (Boesen et al., 2019). Nevertheless, the sustainability of packaging determined through LCA resulted different from the consumers’ perception, which may be swayed by emotional and pleasurable responses, natural looking packaging and supposed recyclability. Concerning glass, Borghesi et al. (2022) and De Feo et al. (2022), thanks to an additional sociological survey, demonstrated that the consumer perception in favour of single-use glass was unfounded. Globally, these researches outlined a misperception of sustainability by consumers deriving from a lack of connection with the scientific community (De Feo et al., 2022).

Among the previous works trying to assess the environmental performances of plastics, Gomes et al. (2019) reviewed LCAs of polyethylene terephthalate (PET) and alternative materials (glass or aluminium) for carbonated beverages and concluded that PET shows better environmental performances. Moreover, Kakadellis and Harris (2020) reviewed 19 LCAs comparing food packaging made of conventional plastics and of bioplastics. The outcomes showed that bioplastics generally reduce the environmental impacts for the climate change and the use of non-renewable resources (if biogenic), but there is no general benefit from an environmental point of view.

The novelty of this review, compared with previous reviews addressing similar questions, is the environmental comparison of plastics with all the materials typically used for packaging (i.e. bioplastics, glass, metals, paper, wood and textiles). In detail, the LCAs (published between 2019 and 2023) reporting at least one comparison between a packaging made of plastics and another made of alternative materials were selected. Their review was performed with the aim to understand the state of the art in LCA about the environmental impacts of packaging and the plastics performances when compared to alternative materials from the environmental point of view. The outcomes could be helpful to support the behaviour of decision-makers, companies and consumers with scientific research findings, in order to further promote the development, the choice and the use of more sustainable packaging.

Through the review, it was also possible to analyse the presence of assessments for evaluating aspects other than the environmental sustainability, such as social or economic impacts.

Materials and methods

This review followed the Standardized Technique for Assessing and Reporting Reviews of Life Cycle Assessment Data (STARR-LCA), developed by Zumsteg et al. (2012). This technique provides many recommendations for making systematic, transparent and standardised reviews. A nine-point checklist assists in the conduction and reporting of systematic reviews of LCA data, with regard to: (i) document title, structured summary and keywords; (ii) rationale of the review; (iii) review questions and objectives; (iv) description of review protocol; (v) findings and features of individual studies in the review; (vi) assessment of bias; (vii) synthesis methods; (viii) limitations of the review and (ix) summary of findings and conclusions. The STARR-LCA checklist was filled in Supplemental Material.

Studies selection

The selection of LCA studies available in the scientific literature was done through a search within article title, abstract and keywords, in the Scopus database (Elsevier BV, 2023). The chosen string search was ‘“life cycle assessment” OR LCA AND packaging AND plastic’. The search, carried out in May 2023, revealed 210 studies published in the last 5 years (between 2019 and 2023), which is the time framework defined for the review. An analysis of the abstracts allowed to select 43 studies that reported at least one comparison between a packaging made of plastic and another made of a different (alternative) material. Other 10 studies were identified via backward snowballing, leading to a total of 53 studies. The selection included some studies evaluating items that are not packaging (i.e. cutlery), when considered useful for the discussion.

The research questions of the current review are: (i) what is the state of the art in LCA practice about the environmental impacts of plastic packaging compared with other materials? (ii) How does plastics compare with the alternative materials (bioplastics, glass, metals, paper, wood and textiles)? (iii) Is the recent emphasis on the need to replace plastics with other more sustainable alternatives supported by scientific evidence?

Reviewed aspects

The discussion on the selected LCAs is divided in two parts.

Firstly, the general aspects, the characteristics of the assessments and the methodological choices are reviewed to understand the completeness and the accuracy level of the studies. The following aspects are evaluated: (i) geographical scope, (ii) definition of the system boundary, (iii) choice of the impact categories and of the impact assessment methods, (iv) completeness and clarity of the inventory and data sources, (v) end-of-life modelling, (vi) execution of a sensitivity analysis, (vii) implementation of an uncertainty analysis, (viii) modelling principle and (ix) presence of assessments for evaluating aspects other than the environmental sustainability. The correct implementation of these aspects is in fact relevant to assure the reliability of the outcomes of comparative LCAs. Moreover, some key aspects arisen from the reviewed studies and that can have significant effects on the outcomes of the comparison between plastics with other materials are listed and debated.

The second part of the review is focused on the comparison between plastics and each of the other materials (bioplastics, glass, metals, paper, wood and textiles). The aspects relevant for each specific material are firstly addressed. Moreover, according to the goal of this work, the results of the comparison between conventional plastics and each of the other materials are reviewed highlighting which is the most favourable option from an environmental point of view. When the comparison did not consistently favour either plastics or the alternative material, with different results for the assessed impact categories, a material was assumed to be preferable when confirmed by at least 75% of the considered impact categories.

Results and discussion

General discussion of the reviewed studies

Table 1 lists the 53 reviewed studies and the materials involved in the related comparisons. The most assessed material alternative to plastics were bioplastics (21 times), followed by glass (17), multilayer and composite materials (11), paper and cardboard (10), metals (9) and other materials (11) mainly represented by not only wood and textiles but also ceramic, beeswax, banana fibres and a mineral filler. About 34% of the studies assessed more than one alternative for plastic packaging.

Table 1.

List of the reviewed studies and compared materials.

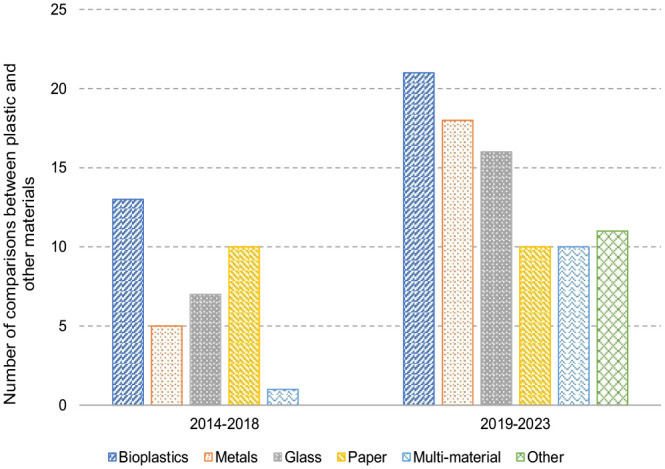

The number of comparisons between plastics and other materials is shown in Figure 1. To track the evolution of the scientific publications, Figure 1 was also integrated with the studies published in the previous 5 years (2014–2018), which resulted 27, according to the same selection method of the review. Beyond the doubling of scientific publications that happened in the last 5 years, the interest towards multimaterial and other alternative materials has certainly increased. This is the result of ongoing technological innovation, as well as of the growing focus on sustainability, especially when wood and textiles are considered.

Figure 1.

Number of comparisons between plastic and alternative materials for packaging in the scientific literature, in two different time range of publication.

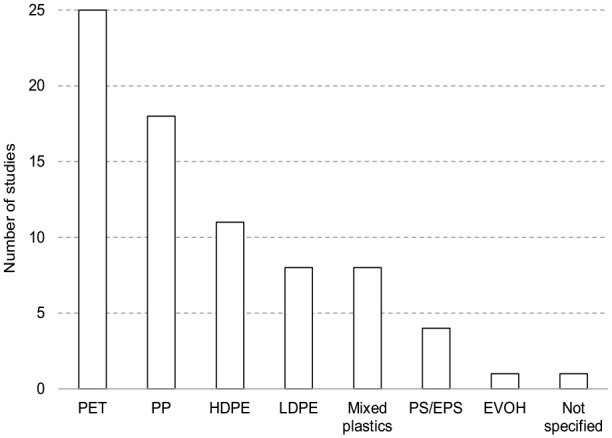

The selected 53 studies did not focus on a single polymer, but instead assessed several types of plastics, reflecting the variability in the structural properties of different packaging. Figure 2 shows that the most assessed plastic was PET (25 studies), followed by polypropylene (PP) (18) and high-density polyethylene (HDPE) (11).

Figure 2.

Number of reviewed studies assessing the different plastic polymers.

PET: polyethylene terephthalate; PP: polypropylene; HDPE: high-density polyethylene; LDPE: low-density polyethylene; PS: polystyrene; EPS: expanded polystyrene; EVOH: ethylene vinyl alcohol.

Geographical scope

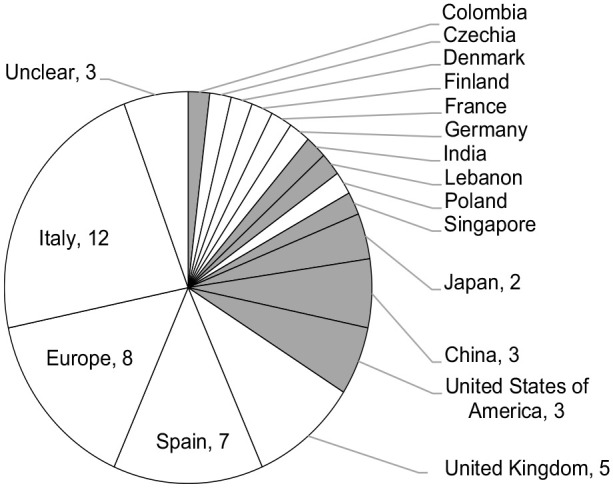

Several aspects of the modelling are strictly dependant on the geographical scope (e.g. electricity or energy mix, waste management scenarios), thus influencing results. Figure 3 reports the geographical context of the examined works. The outcomes indicate a good representativeness of different context, including 30 studies for 9 different European countries, 8 generically related to the European context and 12 studies of non-European countries.

Figure 3.

Geographical context considered in the reviewed studies. For each country or geographical area considered in more than one study, the number of studies is reported. Non-European countries are highlighted (grey colour).

System boundary

The system boundary of an LCA is the definition of a ‘set of criteria specifying which unit processes are part of a product system’ (ISO 14040:2006, 2006). In 87% of the analysed studies, the system boundary was cradle-to-grave, including all the activities from the raw materials extraction to the end-of-life stage. This is certainly positive since a comprehensive system boundary is essential to a fair and credible comparative assessment. Five studies started from the cradle and stopped at the gate of the packaging production plant, whereas one study adopted a gate-to-grave system boundary. Lastly, one study only focused on the production process (gate-to-gate).

Among the stages to be included in the system boundary of LCAs focused on packaging, additives life cycle deserves a specific focus. They are often employed in packaging manufacturing, being essential ingredients for plastics items (Rikhter et al., 2022). Additives include dyes, plasticisers, flame retardants, stabilisers, fillers, slip agents, lubricants, antioxidants, acid scavengers and antistatic agents (Hahladakis et al., 2018; Rikhter et al., 2022). Their importance is related to the fact that they can significantly alter the products and its management options at the end-of-life with an important influence on cradle-to-grave environmental assessments (La Mantia and Morreale, 2011). Although additives life cycle is often not included in the system boundary, in order to avoid uncertain and misleading outcomes, it should be excluded only when contributing less than 1% to all the impact categories, possibly reducing this threshold when multiple additives are used (Bishop et al., 2021a). Furthermore, their end-of-life and their influence on the end-of-life of the products need to be considered (Bishop et al., 2021a).

Six of the examined studies specifically indicate the exclusion of additives life cycle from the system boundary due to the low amount (Ahamed et al., 2021; Stefanini et al., 2021), low impacts according to the literature (Ponstein et al., 2019) or lack of modelling data (Ahamed et al., 2021; Fetner and Miller, 2021). Among the others, details about additives are generally missing with only four studies specifying their inclusion (Abejón et al., 2020; Accorsi et al., 2022; Civancik-Uslu et al., 2019b; Maga et al., 2019).

Impact categories and impact assessment methods

Among the examined studies, 45 included only midpoint impact categories or indicators, four evaluated only endpoint impacts and four included both.

Focusing on the midpoint impact assessment methods, the ReCiPe 2016 was the most used (14 studies), followed by the CML 2001 (10 studies). Six studies applied the Environmental Footprint scheme (Fazio et al., 2018; Saouter et al., 2020) derived from the International Life Cycle Data System (ILCD) scheme, developed since 2007 by the European Commission to select the recommended model and associated characterisation factors for each impact category. The ILCD is still used in six studies.

Other less applied methods are Impact 2002+ (three studies), Ecoindicator 99 (two) and LIME 2 (two). One study considered selected categories from a relevant operational guide to the ISO Standards (Guinee et al., 2001). It is worth observing that 13 studies included more than one method.

Several studies assessed only selected impact categories or indicators. In detail, eight studies evaluated the potential impact on climate change according to the Intergovernmental Panel on Climate Change (IPCC) method. Water consumption was assessed by means of the available water remaining (AWARE) indicator (two studies), of the water scarcity index (two studies), and with the corresponding category of the ReCiPe 2016 method (one study).

Moreover, the energy performances in the examined systems were evaluated by means of the cumulative energy demand indicator (eight studies) and with the corresponding category of the Impact 2002+ method in one study.

Finally, in two studies, the considered method was not clearly specified.

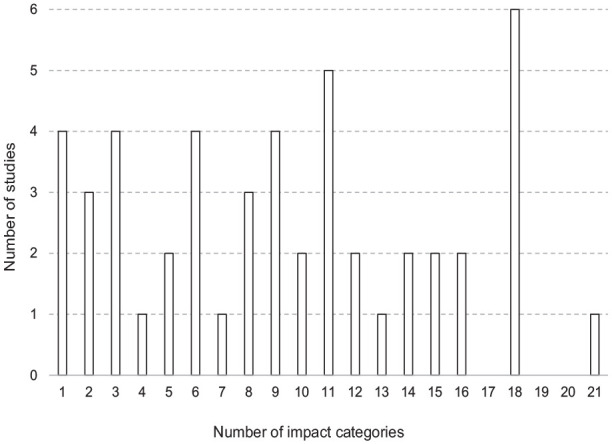

Another relevant aspect is the number of assessed impact categories. They should be enough to perform comprehensive analyses that include the widest range of environmental issues potentially connected to the compared systems. Figure 4 reports the number of midpoint impact categories assessed in the reviewed studies.

Figure 4.

Number of midpoint impact categories assessed in the reviewed studies.

More than 20% of the studies included less than four impact categories; therefore, examining only a very limited number of issues potentially affected. Among them, four studies included only the climate change impact category. When the selected impact categories were two, the climate change was always evaluated, together with energy/water consumption. When the impact categories were three (four cases), three out of four studies assessed climate change, energy demand and water consumption.

Inventory

The use of high-quality inventory data is pivotal when performing an LCA. Primary data are the ones to be preferred, as they are site-, company- or supply chain-specific. Unfortunately, they are not always disclosed by the companies and their obtainment can be time demanding. In lack of primary data, secondary data from a third-party source are necessary for the impact calculation. Primary data are typically used for the foreground system, whereas secondary data for the background system. Sixty-two percent of the reviewed studies reported the use of primary data, often in combination with non-primary data. In some circumstances, primary data were used to model the materials to be compared with plastics, while secondary data were used to model plastics. This can be related to the conventional nature of plastics, which often is the business-as-usual reference upon which the comparison is based.

Regardless of their source, inventory data should be always reported in a transparent way, in order to allow anyone to check the results and reuse data. Since LCA studies are based on a scientific methodology, they should be fully reproducible (Hauschild et al., 2018). The life cycle inventory (LCI) was detailed in 31 out of 53 studies, whereas in 13 was reported in less detail. Lastly, the LCI appeared limited in the remaining 9.

End-of-life modelling

Another aspect with a relevant influence on the results and on the comparison is the choice of the end-of-life options that greatly influence the sustainability of plastics (Banerjee and Ray, 2022). Indeed, impacts of different waste management options can greatly differ, as shown, for example, by Asadollahi et al. (2022). They compared the impacts of different end-of-life management options (modelled according to two databases) for aluminium, glass, PP, HDPE, PET and steel employed for packaging. The outcomes indicated waste prevention as the best option (from the environmental perspective). On the contrary, landfilling and incineration can show relevant negative impacts. Furthermore, Zhang et al. (2021), reviewing 45 LCAs focused on waste management systems, highlighted the significant environmental benefits of an integrated waste management system replacing the disposal in landfill.

In some of the reviewed studies, only a single potential end-of-life treatment is considered. This choice allows for a better comparison between scenarios but does not provide a realistic result when comparing different materials. In other studies, several possible treatments are individually analysed. Finally, some papers consider the realistic management scenarios in a certain geographical context (current or expected in the future).

With regard to the methodological choices in the modelling of the end-of-life management, the multifunctionality associated with the waste management (i.e. the production of energy or secondary materials) is solved with the expansion of the system boundary (with the inclusion of the avoided production) in most of the studies. Nevertheless, in many studies the applied approach is not clearly described. When including benefits of material recovery, it is important to consider the market in which the secondary material is used for and its quality with respect to the substituted material. Indeed, the technical properties of a material can unfavourably change in the recycling process (downcycling phenomenon). As an example, recycled plastics typically show downcycling due to the remaining content of additives and fillers, polymer cross contamination, presence of non-polymer impurities and degradation (Morici et al., 2022).

All the details on the modelling of the end-of-life management are reported in the Section ‘Comparison between plastics and other materials’ for the different compared materials.

Sensitivity analysis

Sensitivity analysis is a procedure in which the input data/parameters are modified to verify the effects on the output values, both in the LCI and LCIA phases (Laurent et al., 2020). Sensitivity analysis is an important check to determine the results robustness and was included in 55% of the examined studies. The most addressed data concerned the end-of-life and the production of packaging. Different end-of-life treatments, mix of treatments and related efficiency/performance were analysed in 14 studies. Data related to the production process were object of sensitivity analyses in 12 studies. The following aspects were evaluated: (i) packaging weight reduction, (ii) packaging recycled content, (iii) efficiency of processes, (iv) energy consumption, (v) energy sources. Other input data/parameters subjected to sensitivity analyses in the reviewed studies were the number of reuses, the transport distances and the geographic contexts (especially for the energy production mix).

Uncertainty analysis

For arguing that an LCA is reliable, uncertainties should not become too large and their influence on the results should be analysed (Laurent et al., 2020). Only four studies included an uncertainty analysis. In detail, Fetner and Miller (2021), Helmes et al. (2022) and Ponstein et al. (2019) included a Monte Carlo simulation. Through this method the authors iterated the life cycle impact assessment for 10,000 times after having specified a distribution function for each inventory data. One study used a discernibility analysis to confirm the robustness of results (Boutros et al., 2021). A discernibility analysis, by combining the uncertainty analysis and the comparative analysis (Klöppfer and Grahl, 2014), produces the percentage of Monte Carlo runs in which one alternative outperforms the other one.

Modelling principle

The system modelling approach in an LCA study can be classified as attributional or consequential (Sonnemann and Vigon, 2011). An attributional LCA estimates what share of the global environmental burdens belongs to a product; the system is hence modelled as it is, was or is forecasted to be, providing a static representation based on average data, which represent the actual physical flows (Ekvall et al., 2016). A consequential LCA gives, instead, an estimate of how the global environmental burdens are affected by the production and use of the analysed product (Ekvall et al., 2016).

Although it is argued that a consequential modelling is more appropriate when evaluating changes to product systems or performing a comparative analysis (Bishop et al., 2021a), only two of the reviewed studies (Bishop et al., 2021b; Helmes et al., 2022) clearly stated to use a consequential approach, while other two studies (Moretti et al., 2021; Vural Gursel et al., 2021) were supposed to be consequential based on the applied modelling choices in the goal and scope and inventory stages. All the four above-mentioned studies performed a comparison between petrochemical and bio-based plastics. Three of them purposed to assess, along the entire life cycle, the environmental consequences of replacing petrochemical plastics with biopolymers. Helmes et al. (2022) performed, instead, an anticipatory consequential LCA, adopting a use-to-grave system boundary, with the scope to compare reuse, mechanical recycling and chemical recycling options for both bio-based and petrochemical plastics.

All the three cradle-to-grave studies included in their analysis the calculation of the indirect land use change impact, calculated based on the deterministic model presented by Tonini et al. (2016), or on the update of such model, proposed by the European Commission (2019a). Furthermore, when possible, in the handling of multifunctional systems, the three studies avoided allocation by applying the substitution through boundary expansion method and they considered marginal technologies for heat and electricity production or for the modelling of the avoided production due to the recovery of secondary materials.

All the other studies seem to follow an attributional approach, but only 6 out of 49 clearly declared to use this modelling approach (Abbate et al., 2022; Boschiero et al., 2019; Boutros et al., 2021; Leivas et al., 2020; Michaliszyn-Gabryś et al., 2022; Rybaczewska-Blazejowska et al., 2020).

Analysis of aspects other than the environmental sustainability

The review was based on the evaluation of the environmental performance of the examined materials. Nevertheless, the choice of the best packaging should also address aspects other than the environment, as performed by few of the reviewed studies. In particular, Wei et al. (2022) evaluated the use of reusable tableware in aviation catering. In this study, 13 criteria are employed to select the best alternatives (before the environmental comparison): ease of assembly and transport, cost of production, reusability, cost of waste treatment, toxicity, hygiene, environmental impacts of production, environmental impacts of disposal and treatment, appearance, decency, strength, convenience for passengers and sharpness.

When it comes to the hygienic aspects, Tamburini et al. (2021), in the comparison of single-use and reusable bottles for drinking water, evaluated the microbiological quality of the contained water, underlining that the level of contamination significantly increases with the refilling of reusable bottles, especially if they are washed without the use of soap. Moreover, López-Gálvez et al. (2021) evaluated the possible contamination of fresh cauliflowers with Salmonella enterica. The outcomes of the study revealed that the risk of contamination for reusable PP crates is higher than that of single-use wooden and corrugated cardboard. Finally, Rodríguez et al. (2021) integrated LCA, life cycle costing (LCC) and technical analyses evaluating the design of a bottle lid.

Globally, almost all the articles did not include any assessment of the social or economic impacts of the products considered. This could be due to the lack of a widely accepted methodology for conducting such analyses, but this limitation should not hinder the application of these approaches.

The importance of addressing aspects other than the environmental sustainability is supported by the outcomes of a survey conducted on a sample of over 1000 European citizens in order to better understand preferences and drivers of buyers. In addition to environmental issues, people are influenced by aspects such as social responsibility for the future generation, safety to human health, comfort combined with aesthetics and low complexity of the product (Kochańska et al., 2021).

Key aspects

This section lists and discusses some aspects, arisen from the reviewed studies, with potentially significant effects on the environmental performances of items made of plastics or other materials.

Recycled content in packaging

The amount of items made of recycled plastics introduced in the market has been rapidly increasing in recent years (more than 8% of the plastic produced in the world in the year 2021 is post-consumer recycled plastic; Plastics Europe, 2022) in parallel with the amount of polymers sent to recycling (a 32% increase of plastic packaging sent to recycling was observed in Europe between 2010 and 2020; Eurostat, 2022). Several packaging can be totally or partially made of recycled polymers. Among the examined studies, this possibility is considered in 14 papers about bottles (5 studies), crates (2), trays (2) or other items (5). In detail, seven studies consider only items partially or totally made of recycled polymers (PET, HDPE or PP) with a recycled content ranging between 10% and 100%. The remaining seven studies made a comparison between virgin and recycled plastics including one of the scenarios that considers recycled plastics (five studies) or evaluating this aspect in the sensitivity analysis (two). Among these studies, five studies deal with the consequences of employing recycled polymers on the environmental performances of plastics.

Civancik-Uslu et al. (2019c) underlined that the recycled HDPE employed for the cosmetic packaging allowed for an impact reduction up to 29% for two-thirds of the examined impact categories. According to Stefanini et al. (2021), recycled PET bottles showed lower impacts than virgin PET ones for all the examined categories. Similarly, according to Rybaczewska-Blazejowska and Mena-Nieto (2020), the recycled PET is preferable to the virgin polymer.

Furthermore, two studies debated the influence of recycled plastics on the comparison between materials. In detail, according to Grisales et al. (2021), a 50% recycled PET improved the comparison with glass, with the latter resulting better than plastic for only five impact categories out of 14, even if reused 30 times. In the carbon footprint performed by Tonini et al. (2021) recycled PP and HDPE performed better than the fossil polymers. Moreover, the recycled HDPE resulted preferable to the bio-HDPE under some conditions.

It is important to underline that there is not a purely natural science-based approach to separate the different products in a system including recycling (Allacker et al., 2017). Moreover, different methodologies can model recycling and recovery processes in different ways, leading to non-homogeneous results. As an example, in Dolci et al. (2020) the production of recycled plastic was modelled with two approaches: the approach applied in the International Environmental Product Declaration (EPD) system (EPD International, 2021) and the one applied in the Product Environmental Footprint (PEF) methodology (European Commission, 2013). The former is based on the polluter pays principle: in case of recycling, ‘the user of the waste shall carry the environmental impact from the processing and refinement of the waste but not the environmental impact caused in the earlier life cycles’ (EPD International, 2021). The approach applied in the PEF methodology in case of multifunctionality in recycling considers the Circular Footprint Formula for materials introduced in the Guidance for the Development of PEF Category Rules (European Commission, 2018). These different approaches led to significantly different impacts of the production of recycled plastics (Dolci et al., 2020).

Littering

The problem of littering of waste in the environment is currently widely discussed and typically mainly associated to plastic items. Although the real scale of the problem and the ultimate fate of plastics are not clear, microplastics deriving from plastics degradation can affect both waters and soils (Ruggero et al., 2021; Shruti and Kutralam-Muniasamy, 2019).

Some examined articles, such as Ahamed et al. (2021), Moretti et al. (2021), Pragati and Maeda (2022) and Vural Gursel et al. (2021), debated about this topic. Although littering has a significant environmental relevance, these studies underline that it is generally not included in LCA due to lack of data and of a specific methodology to evaluate impacts associated to this phenomenon. Nevertheless, a littering potential should be more and more included among the assessed aspects of LCAs due to its relevance in determining the sustainability of materials and products.

To this purpose, Civancik-Uslu et al. (2019b) reported that marine littering has substantial ecological consequences, encompassing impacts on marine organisms and their coral habitats, as well as social implication such as bioaccumulation leading to human health issues. Economic effects such as the cost of ocean clean-up efforts and disruptions to fishing and tourism were also highlighted. Subsequently, Civancik-Uslu et al. (2019b) developed an assessment method for the calculation of a littering indicator (land and marine) for bags made of plastic, paper or bioplastic. It is based on four aspects: (i) the quantity of bags (i.e. the number of bags required to meet the functional unit); (ii) the bag release into the environment (related to the price of the bag); (iii) the bag dispersion in the environment (function of its weight) and (iv) the environmental persistence of the bag in the environment (related to its biodegradability). The risk is directly proportional to the quantity of bags and inversely proportional to the price, the weight and the biodegradability. This indicator allowed to identify the bags with an increased risk of causing littering, identified in those made of HDPE; in addition to be single-use, they are lightweight, cheap and non-biodegradable. For the other compared bags, the risk of littering resulted significantly lower: (i) reusable low-density polyethylene (LDPE) bag (3.3% compared to single-use HDPE), (ii) Mater-Bi bag (0.6%), (iii) paper bag (0.1%) and (iv) reusable PP bag (0.1%). Accordingly, plastic reusable bags showed a littering potential comparable to other materials.

Starting from the approach introduced by Civancik-Uslu et al. (2019b), Stefanini et al. (2021) made a proposal for a marine litter indicator for bottles. It is based on four aspects: (i) the quantity of bottles dispersed in the environment (calculable according to dispersion data for each material); (ii) the incentives for returnable bottles; (iii) the bottle weight and (iv) the bottle degradation time. The risk is directly proportional to the quantity of dispersed bottles and to the degradation time and reversely proportional to the incentives given for the returnable bottle and to the bottle weight. The single-use glass bottle resulted worse than the PET bottle, while the risk of littering of the returnable glass bottle was 24% of the risk of the PET bottle.

Key aspects determining the environmental performances of packaging

Michaliszyn-Gabryś et al. (2022) underlined four aspects with a relevant influence on the environmental performances of packaging.

The first is the design; it is well known that the maintenance of the properties required for a packaging can be satisfied with different weights, depending on the material. Accordingly, a specific item is characterised by different weights when made of different materials. Instead of considering the weights of the items found on the market, Moretti et al. (2021) suggested to estimate, for a specific item made of a certain material, the weight necessary to guarantee a specific property (e.g. stiffness). This choice allows for comparisons based on the same functionality performance; on the contrary, the weights of items found on the market can be caused by the limitation of the processing equipment and techniques rather than by the specific properties of the materials (Moretti et al., 2021).

Moreover, the packaging production process is also relevant, in particular with respect to the consumption of energy.

Strictly related to the type of energy, and also to transportations, is the location where the different life cycle stages are performed (e.g. production of raw materials, manufacturing of the item, end-of-life management).

Finally, the choice of the waste management scenario resulted fundamental in determining the environmental performances (Michaliszyn-Gabryś et al., 2022).

Comparison between plastics and other materials

This section is focused on the comparison between plastics and each of the other materials (bioplastics, glass, metals, paper, wood and textiles).

Plastics versus bioplastics

Although representing still only 1% of more than 390 million tonnes of plastics annually produced in the world (European Bioplastic, 2023), the amount of bioplastics items introduced on the market is constantly growing. Almost half of the examined studies (21) compared plastic items with bioplastics, which appear to be more and more chosen as the substitutes of conventional fossil plastics in the packaging sector. Since they are intended to be environmentally friendlier than conventional plastics, their comparison with a life cycle thinking perspective is essential.

In detail, 16 out of the 21 studies analysed biodegradable and compostable bioplastics irrespective of their fossil or biogenic origin, 2 studies examined only non-biodegradable bio-based plastics, whereas 3 studies included in the comparison both typologies. Globally, only four studies compared more than one type of bioplastics.

Concerning the studies focused on biodegradable and compostable items, the polylactic acid (PLA) was always included, except for one case. The other analysed polymers were starch-based bioplastics, poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and polybutylene succinate. These outcomes are in agreement with the diffusion of bioplastics: according to European Bioplastic (2023), PLA is the most common compostable bioplastic introduced in the market in the year 2022, with a 40.2% share.

Focusing on the packaging type, plastic and bioplastic bottles containing different liquids such as water, milk or shampoo were compared in six studies. Other considered items were films or bags (five), trays (three) and other rigid items (five), whereas three studies did not consider specific applications of bioplastics.

End-of-life modelling

Table 2 reports the end-of-life management options for the plastics and the bioplastics in the comparative examined studies. In addition to the traditionally listed treatments, Bishop et al. (2021b) also considered the option of insect feed production for the PLA, whereas Helmes et al. (2022) examined the reuse of PET and HDPE bottles (both fossil and bio-based).

Table 2.

End-of-life management options for the plastics and the bioplastics in the examined studies.

| Bioplastic type | Study | Plastics | Bioplastics | ||||||

|---|---|---|---|---|---|---|---|---|---|

| R | W | L | R | W | L | C | A | ||

| Biodegradable and compostable | Abbate et al. (2022) | X | X | X | X | X | |||

| Ahamed et al. (2021) | X | X | |||||||

| Bala et al. (2022) | X | X | X | ||||||

| Bałdowska-Witos et al. (2020) | End-of-life not included | ||||||||

| Benavides et al. (2020) | X | X | X | ||||||

| Bishop et al. (2021b) | X | X | X | X | X | ||||

| Cappiello et al. (2022) | X | X | |||||||

| Civancik-Uslu et al. (2019b) | X | X | X | X | X | ||||

| David et al. (2021) | X | X | X | X | X | X | |||

| Desole et al. (2022) | X | X | X | X | X | X | X | ||

| Gallo et al. (2022) | End-of-life not included | ||||||||

| Maga et al. (2019) | X | X | X | X | X | ||||

| Michaliszyn-Gabryś et al. (2022) | X | X | X | ||||||

| Moretti et al. (2021) | X | X | X | X | X | X | X | ||

| Rodríguez et al. (2021) | X | X | |||||||

| Rybaczewska-Blazejowska and Mena-Nieto (2020) | X | X | |||||||

| Tamburini et al. (2021) | End-of-life not included | ||||||||

| Tonini et al. (2021) | X | X | X | X | X | X | |||

| Wei et al. (2022) | X | X | X | ||||||

| Non-biodegradable | Abbate et al. (2022) | X | X | X | X | X | X | ||

| Benavides et al. (2020) | X | X | |||||||

| Helmes et al. (2022) | X | X | |||||||

| Tonini et al. (2021) | X | X | X | X | X | X | |||

| Vural Gursel et al. (2021) | X | X | X | X | X | X | |||

R: mechanical recycling; W: waste-to-energy; L: landfill; C: composting; A: anaerobic digestion.

Focusing on biodegradable and compostable bioplastics, four of the studies considered only one end-of-life option. On the contrary, seven studies assessed different realistic end-of-life scenarios. In detail, Civancik-Uslu et al. (2019b) examined the Spanish waste management scenario, whereas Moretti et al. (2021) evaluated the plastics waste management in Europe (adding the composting for the PLA). Similarly, other studies analysed the average management scenario for plastic waste in Europe (Tonini et al., 2021; Vural Gursel et al., 2021) or in selected European countries (Maga et al., 2019).

With regard to the examined options, three studies included the mechanical recycling of PLA. Tonini et al. (2021) considered this as one of the possible end-of-life options. Desole et al. (2022) considered a 30% recycling rate for PLA in the current scenario and assumed a 55% recycling rate for the year 2030. Nevertheless, it is important to underline that this treatment does not currently take place at the industrial scale, although PLA is technically recyclable. Moretti et al. (2021) considered a 15% recycling rate for the PLA packaging, underlining that the current European waste management system is not ready for PLA recycling. Firstly, in order to recycle a specific biopolymer, it must be separately collected or sorted out from the mixed plastic/bioplastic waste. Moreover, the amount of the different biopolymers is still too low to be mechanically recycled at the industrial scale. Despite these issues, according to Desole et al. (2022), this could be the best management option for PLA from an environmental point of view; therefore, the possibility of mechanical recycling of compostable bioplastics should be explored, as an alternative to composting.

Focusing on the current situation, the fate of compostable bioplastics is generally the collection together with food waste and the subsequent management in a biological treatment plant, either aerobic (composting) or anaerobic (anaerobic digestion). The composting was examined in 9 out of the 16 studies, whereas only one included the anaerobic digestion.

To this purpose, it is important to underline that compostable bioplastics, when sent to anaerobic digestion facilities, are generally removed before the digestion itself. This is because it is not possible to separate them from conventional plastics (still delivered together with the organic waste) by means of the typical pre-treatments and because their handling can cause operational problems, especially in wet or semi-dry processes. Moreover, due to their shape, when bioplastic films are removed, they drag into the residues a non-negligible amount of embedded food waste that will not reach the digester (Dolci et al., 2021b, 2023; Utilitalia, 2020).

It is also important to underline that the behaviour of compostable bioplastics subjected to biological treatment is strongly related to the process typology and its features (e.g. temperature and residence time) and to the polymer type, with a final degradability that can be very limited, especially under anaerobic conditions (Dolci et al., 2021b, 2022; European Environment Agency [EEA], 2020; Narancic et al., 2018). All these criticalities should be assessed when bioplastics waste is assumed to be managed by means of biological treatments. Only two of the reviewed studies dealt with this issue: Cappiello et al. (2022) pointed out that not all the composting plants accept compostable packaging, whereas Moretti et al. (2021) underlined that the conditions required for the PLA biodegradation are not met in several composting plants.

Finally, all the five studies comparing the same polymers (fossil and bio-based) correctly considered the same end-of-life options for both.

Land use change and carbon storage

When conventional plastics and bioplastics are compared by means of LCA, two other aspects are fundamental to come to correct conclusions: the inclusion of the emissions associated with the land use change and the modelling of the carbon storage.

These aspects are deeply evaluated in Bishop et al. (2021a) that underline their influence on LCA results.

Land use change can have relevant effects on the carbon cycle, causing significant greenhouse gas emissions by altering the carbon stored in soil and vegetation, which vary with different land use (Bishop et al., 2021a). These changes are related to the land on which the biomass (used to manufacture bio-based bioplastics) grows. With regard to the reviewed studies concerning bioplastics, 13 included impact categories related to the land use.

Additionally, the direct changes may cause the need for changes elsewhere, potentially with cascading effects (Bishop et al., 2021a), that is, the indirect land use change, a well-known aspect related to the biofuel industry (European Commission, 2019b; Puricelli et al., 2021). At this purpose, only three studies included the indirect land use change. It must be observed that the evaluation of indirect variations is not simple to be performed and therefore it is not mandatory in any international LCA standard (Bishop et al., 2021a).

With regard to the carbon storage, bio-based materials such as bioplastics store the biogenic carbon in the biomass during its growth. Two main approaches for the management of this aspect can be observed in the LCAs: considering the temporary storage or considering the carbon neutrality because in any case in the future the carbon stored in bioplastics will be released into the atmosphere (Bishop et al., 2021a). The best practice is the complete modelling of the uptake, the storage and the release of biogenic carbon across the entire life cycle of the bioplastics. However, such modelling can be complex and requires a careful representation of biological processes (Bishop et al., 2021a). To this purpose, a specific attention must be given to the modelling of the end-of-life management. For example, when a bioplastic is incinerated, the stored carbon is released; on the contrary, when bioplastics are sent to landfill or composted, part of the stored carbon is not immediately released. The choices must be then calibrated based on the considered time horizon. Only 5 out of the 21 articles dealt with the biogenic carbon sequestration into bioplastics and the subsequent release in the end-of-life management.

The conservative approach (carbon neutrality) was instead clearly applied in three reviewed articles. In all the remaining 13 studies, the modelling approach was not detailed or resulted unclear. The worst approach (to be avoided) is the attribution of carbon sequestration to bioplastics based on biomass uptake without considering the fate of that carbon at the end of their useful life. Indeed, most of the carbon is likely to be released back into the atmosphere within the 100-year time horizon typically considered in LCAs (Bishop et al., 2021a).

Results of the comparison

According to the methodology defined in the Section ‘Reviewed aspects’, only 2 studies out of 19 found compostable bioplastics as environmentally preferable to the conventional plastics. However, one only evaluated the impacts on the climate change and the fossil energy, two of the categories (together with the resource depletion) where the bioplastics typically show lower impacts than the conventional plastics, whereas the other one was characterised by a low clarity in the methodology.

Six studies showed a more favourable outcome for conventional plastics. In the remaining 11 articles, the comparison was less straightforward: 6 articles showed variable results strongly depending on the impact categories, whereas in 4 studies the outcomes changed based on the different polymers. Finally, no conclusions were underlined in one study.

According to these outcomes, although perceived as more sustainable, on average bioplastics do not allow for environmental benefits with respect to conventional plastics when a life cycle perspective is considered.

Focusing on PLA, that is both bio-based and compostable, the environmental impacts of bio-based plastics are typically affected by the biomass cultivation stage, as confirmed by several of the examined studies. The use of pesticides, fertilisers and water significantly affects the terrestrial eutrophication and the water resource depletion (Cappiello et al., 2022), the ecotoxicity, the eutrophication and the acidification (Desole et al., 2022). Globally, a large part of bioplastics impacts is related to the agricultural phase as also suggested by Tamburini et al. (2021). Moreover, non-negligible burdens are related to the heat and the electricity required for fermentation, purification and polymerisation in PLA production (Moretti et al., 2021). Finally, Cappiello et al. (2022) underlined that PLA impacts depend on the production technology, the crop type, the climate and the geography. All these aspects have a relevant influence on the results.

In the five studies related to non-biodegradable bioplastics, once again the only one in which they resulted preferable evaluated only the impacts on the climate change and the fossil energy. The conventional plastic resulted the best option in another study, whereas results were variable depending on the impact categories in two studies and depending on the considered scenario in another study. Among these studies, Vural Gursel et al. (2021) confirmed the relevant magnitude of biomass production impacts due to the use of fertilisers, especially in the land use and in the terrestrial eutrophication.

Plastics versus glass

A comparison between plastics and glass was performed by 17 studies; 15 of them focused on the beverage packaging, 1 on the packaging of a diary product and 1 on the material for drinking straws. In particular, 11 studies analysed a specific category of beverage (wine and spirit – 4; mineral water – 3; milk – 3 and carbonated drinks – 1), 2 included different beverage categories, whereas 2 did not specify the beverage sector.

The analysed plastic polymer is PET, except for three analyses related to the distribution of milk where a HDPE container is considered. In most of the analyses, the packaging is produced by virgin plastic granulate. Only in three studies (Błażejewski et al., 2021; Grisales et al., 2021; Stefanini et al., 2021), the partial use of secondary plastic granulate was investigated. In detail, Stefanini et al. (2021) and Grisales et al. (2021) considered the use of a bottle with 50% recycled PET in the Italian context, where a recent decree (Italian Parliament, 2020) has introduced the possibility to use up to 100% recycled PET for the manufacturing of beverage bottles.

With regard to glass, nine articles evaluated only a single-use glass bottle, whereas five articles considered only refillable glass bottles with a very variable number of uses (Table 3). In three studies, both options were analysed.

Table 3.

Studies including a refillable glass bottle system, number of reuses and main results in the comparison with single-use plastics.

| Study | Number of reuses of glass bottle | Inclusion of recycled plastic | Main outcomes |

|---|---|---|---|

| Błażejewski et al. (2021) | 280 | Yes (30% recycled HDPE) | This study compared a milk supply chain based on a mix of reusable stainless steel churns and reusable glass bottles with the current supply chain based on single-use HDPE bottles. With 280 reuses for glass bottles and 1000 for churns, the supply chain based on refillable containers was recommended. |

| Boesen et al. (2019) | Not clearly indicated | No | For soft drink packages, the 0.2-L PET bottle resulted the best option if compared to a refillable glass bottle (0.25 L). On the other side, the 0.5-L PET bottle showed a performance comparable to glass. For beer (0.33 L), the PET bottle generally showed worse performances than the refillable glass bottle. |

| Boutros et al. (2021) | 20 (sensitivity up to 50) | No | A returnable glass bottle (for carbonated beverages) presented higher impacts than a single-use PET bottle in nine out the 15 impact categories for 20 uses and 6 categories for 50 uses. |

| Ferrara and De Feo (2020) | 15 | No | Compared to a refillable glass bottle for wine packaging, the three multilayer PET bottle was a worse alternative for all the categories except two. |

| Ferrara et al. (2021) | 7 | No | The PET bottle packaging system resulted generally better than the system based on refillable glass bottles in case of natural water distribution (12 out of 18 impact categories). For the sparkling water, the comparison was more balanced (the PET system is better in eight out of the 18 impact categories). |

| Fetner and Miller (2021) | 1 (260 in 1 year) | No | In the three impact categories, the single-use plastic straw showed a lower impact if the glass straw is used once, but it was outperformed by glass for 260 uses. |

| Grisales et al. (2021) | 1–30 | Yes (50% recycled PET by mass of the bottle) | For a distribution distance of 200 km, the glass distribution system of drinking water (25 uses) resulted better than the one-way virgin PET bottles system only for 6 out of 14 impact indicators. When a recycled PET bottle was considered, results were heavily in favour of the single-use PET system. |

| Stefanini et al. (2021) | 8 (sensitivity 30) | Yes (50% recycled PET by mass of the bottle) | A glass bottle (for pasteurised milk) used eight times showed lower impacts than a virgin PET system only for two categories (4 for 30 uses). Neither with 30 uses, a returnable glass bottle had lower impacts than the system based on recycled single-use PET bottles. |

Firstly, focusing on the comparison between single-use plastic and glass packaging (12 studies), the results of the reviewed studies are always in favour of plastic apart from two, where the performances of plastic and glass are comparable. Such a conclusion is valid for a wide spectrum of impact categories, ensuring a completeness of results.

The high environmental impacts of a glass packaging are due to the intrinsic characteristics of this material: on an equal volume of contained food or beverage, a glass container is much heavier than a plastic one and this impacts not only the production but also all the transports.

These results are in contrast with the consumers’ perception. Some sociological surveys (Boesen et al., 2019; De Feo et al., 2022) showed how glass is commonly perceived as a very sustainable option, whereas plastics as the least favourable.

Turning to the comparison between refillable glass and single-use plastic, it is difficult to define univocally which material is better, since the comparison depends on the analysed scenarios. In detail, the following four parameters play a key role in determining the optimal choice between the two alternatives: (i) number of reuses of the refillable glass container (Table 3); (ii) type of waste treatment at the end-of-life of the plastic container; (iii) content of recycled plastic granulate in the container and (iv) distribution distance between the bottling facility and the local distributor.

Regarding the number of uses for the refillable glass container, when this was lower than 10 the single-use plastic option turned out to be better from an environmental point of view (Table 3). For example, Ferrara et al. (2021) concluded that the single-use PET bottle (for natural mineral water) was a preferable packaging alternative when compared to a refillable glass bottle with seven uses. However, with a higher number of reuses for glass, the environmental performances of the two alternative packaging can be considered comparable (Table 3). For example, Grisales et al. (2021) recommended a minimum of 25 uses of glass containers for the water supply, and similarly Boutros et al. (2021) concluded that 50 uses of a refillable glass bottle for carbonated beverages make it perform generally better than a PET single-use one.

In addition to the presence of organised reusable glass packaging systems, to achieve the environmental benefits given by the reuse (and more in general by waste prevention measures), the willingness of consumers is crucial (Nessi et al., 2014). Greenwood et al. (2021) reported an online survey performed in the United Kingdom on which types of packaging consumers are willing to reuse. According to the outcomes, the recycling of packaging waste was more preferred than the reuse. Moreover, the willingness to reuse was mostly driven by the material and type of the packaging and not by the kind of product contained in the packaging, with the packaging made of glass (jars and bottles) showing the best results.

In relation to the end-of life of plastics, most of the analysed studies were related to the European context, and the packaging plastic waste was modelled to be sent mainly to recycling or incineration with energy recovery. However, Boutros et al. (2021) focused their analysis on the Lebanese context, where the waste management techniques also involved open-dumping and open-burning. In such study, when the open-burning was added to the scenario of plastic packaging as an end-of-life alternative, results became in favour of the returnable glass bottle (it resulted better in 11 out of the 15 assessed impact categories).

Focusing on the third parameter, the origin of plastic granulates, two studies (Grisales et al., 2021; Stefanini et al., 2021) related to the Italian context underline that a glass returnable bottle always shows higher impacts than a recycled PET bottle (50% of secondary granulate by mass) even with 30 reuse cycles. For example, Grisales et al. (2021) found that a returnable glass system, based on a 200 km distribution distance and 30 uses, is never convenient compared to plastic, except for only two environmental impact categories. This example shows how a life cycle approach should be used to complement the waste hierarchy to make sure that the best option is identified. In the comparison between reuse of glass and closed-loop recycling of plastic, LCA demonstrates that it is clearly better to move towards the latter, although the reuse stands at a higher level of the waste hierarchy.

With regard to transportations, the importance of the distribution stage in the comparison between refillable glass and single-use PET containers was also underlined. Ferrara and De Feo (2020) and Grisales et al. (2021) concluded that a reuse programme of glass bottles was a convenient alternative only when considering a local market (i.e. a 100–200 km distance between bottling facilities and local distributors). At greater distances, the environmental burdens of the transportation would make the refillable glass bottle not environmentally convenient due to the higher weight of the container (about one order of magnitude compared to plastic).

Finally, when comparing a single-use plastic system with a reusable glass one, it is important to consider that the refillable packaging implies a washing and sanitation stage after each use, which inevitably causes additional environmental burdens.

All the studies related to beverage bottles (focusing on organised reusable glass packaging systems) except for Boesen et al. (2019) clearly included the washing stage of the refillable glass in the system boundary. In the discussion of the results, Grisales et al. (2021) underlined the non-negligible environmental impacts of the glass sanitation step. Depending on the indicators, the main burdens of the reconditioning process are associated to the electricity consumption, to the heating of the washing water and to the replacement of the single-use aluminium caps. Similar indications were given by Stefanini et al (2021) for the global warming indicator and by Błażejewski et al (2021), which underlined the high impact contribution of the sanitation stage in the glass reuse scenario (more than 40% in 16 out of 18 impact categories), due to the use of chemicals and to the electricity consumption. In contrast to the above-mentioned literature sources, Ferrara et al. (2021) indicated that the glass bottling plant operations provided a negligible contribution. When referring to the environmental impacts associated with the energy (electricity or heat), the specific energy production pathways are of great relevance. Some of the environmental impacts linked to energy production (e.g. on the climate change) are expected to progressively decrease, thanks to the legislative actions towards decarbonisation and energy efficiency. The results of LCAs are expected to evolve as well.

Focusing on the domestic handling of a refillable product, Fetner and Miller (2021) concluded that the impact of the washing stage (manual or automatic) of a reusable kitchenware product could be even greater than the life cycle impacts of a single-use product.

Plastics versus metals

The nine reviewed LCAs that compare plastics and metals can be roughly subdivided into two categories: beverage and food. PET was the most studied plastic type, appearing in five studies, whereas aluminium was the most studied metal, featuring in seven studies. Plastic bottles were the subject of the majority of the LCAs, whereas cans and bottles were the most assessed types of metal packaging. According to the methodology defined in section ‘Reviewed aspects’, only two studies indicated a clear result about the comparison between plastic (PET) and metal (aluminium), and these two results were opposite. Another study showed that plastic was better than tin, but only the climate change category was assessed. The remaining seven studies presented variable results depending on the scenarios. Therefore, in this section, it is necessary to delve deeper into the assessed scenarios to draw general outcomes.

Beverage packaging was the most assessed topic among the LCAs comparing plastics and metals. There was not a clear winner between the two types of materials. Some studies reported plastic as less impactful than metal (Boesen et al., 2019; Fetner and Miller, 2021; Pragati and Maeda, 2022), whereas other studies reported the opposite (Brock and Williams, 2020; De Feo et al., 2022; Tamburini et al., 2021). This discrepancy can be attributed to various reasons, including differences in the modelling choices made by the authors. For example, Brock and Williams (2020) and De Feo et al. (2022) reported outcomes (PET bottle less impactful than aluminium can) that were opposite to those of former studies (Amienyo et al., 2013; Boesen et al., 2019; Franklin Associates, 2009). The reasons for the discrepancies in results included: (i) the exclusion of transportations from the system boundary; (ii) different energy mixes in the production of plastics or metals; (iii) different recycled aluminium content in packaging and (iv) different end-of-life management scenarios. In summary, the results for PET and metal bottles did not seem incontrovertible and did not offer a clear verdict.

Key aspects in the LCA of a beverage container are its mass and volume, which were reported in five out of nine articles. Based on the assessed studies, a 0.33 L PET bottle had the highest range of weight-per-volume ratio: 80–115 g L−1, higher than that of a single-use 0.33 L aluminium bottle or can (47 g L−1). The 0.5 L PET bottle had an average ratio of 46 g L−1 and ranged from 38 to 57 g L−1, whereas the single-use aluminium bottle had a similar ratio (55 g L−1). Lastly, the 2 L PET bottle had the lowest weight-per-volume ratio: 22 g L−1. From these results, it can be inferred that aluminium beverage packaging is not always heavier than plastic, contrary to what one might think. The variability in inventoried weights leads to variability in statements. In fact, Brock and Williams (2020) indicated the lightness of the aluminium can as an advantage over the PET bottle. On the contrary, Pragati and Maeda (2022) stated that an advantage of PET bottles is their lightness compared to aluminium ones. Another hint provided by the list of weight-per-volume ratios is the awareness that the results of an LCA referring to a packaging designed to hold a certain volume of beverage (e.g. 0.33 L) may not remain valid proportionally for a different capacity (e.g. 0.5 L). In fact, the packaging components do not uniformly grow in mass with a growth in capacity. De Feo et al. (2022), in their study about single-use packaging, showed that aluminium cans were less impactful than the 0.33-L PET bottle but similarly impactful to the 0.5-L PET bottle. It can be concluded that scaling up a LCI of a packaging with a certain capacity to a different capacity is a simplification that could significantly affect the results.

A special mention is worth for expanded polystyrene (EPS). In fact, the single-use EPS-based coffee cup had comparable impacts with a 5-year-old reusable steel cup (Fetner and Miller, 2021). Moreover, an EPS-based single-use takeaway food container outperformed the single-use aluminium one (Gallego-Schmid et al., 2019). The lightness of EPS is a strong point since EPS is made by 95% of air. On the contrary, due to its tendency to crumbling, EPS shows a high risk of littering.

In the case of food packaging, the results remain variable but lean more towards plastics. For instance, a sandwich should be wrapped with a plastic wrap or a plastic bag instead of an aluminium foil (Fetner and Miller, 2021). Furthermore, a takeaway single-use food container must preferably be made of EPS rather than aluminium, but aluminium should be preferred to PP (Gallego-Schmid et al., 2019). However, if a reusable PP container was considered, it would equal the impacts of the aluminium one. Regarding cutlery, those made of stainless steel are preferable to the plastic ones, but only after a reasonable number of uses (Fetner and Miller, 2021; Wei et al., 2022). Interestingly, a reusable plastic fork is, overall, more favourable than a reusable metal fork (Fetner and Miller, 2021).

The literature clearly suggests that the reusability of an item is a factor that can become more important than the choice of the material itself. The reusability of metal packaging, such as churns for milk, drinking straws and cutlery was proven to be a strong point that single-use plastic alternatives do not have (Boesen et al., 2019; Fetner and Miller, 2021; Wei et al., 2022). Similarly, reusable plastics takeaway food containers performed better than a single-use aluminium one (Gallego-Schmid et al., 2019). Interestingly, when a reusable plastic item was compared with a reusable metal one, as in the cases of forks and coffee cups, the plastic turned out to be better than the metal. However, it is not always true that a reusable item is the best option. A single-use coffee cup made of polystyrene and EPS is potentially better than all the reusable alternatives because the impact of washing can be significant (Fetner and Miller, 2021). Additionally, Tamburini et al. (2021) demonstrated that a refillable aluminium bottle had worse environmental performance than a single-use PET bottle due to the everyday washing with hot water. It is worth noting, however, that the assumed everyday washing with 3 L of hot water seems overly cautious compared to the habits of a typical user.

The end-of-waste stage was included in eight out of nine LCAs, although the different disposal methods were not always described in detail. Metals were generally more recycled than plastics, with recycling rates of 50% for aluminium lids (Błażejewski et al., 2021) and 54–70% for aluminium cans (De Feo et al., 2022; Gallego-Schmid et al., 2019). The plastic recycling rates were 11% for PP and 50% for EPS (Gallego-Schmid et al., 2019), 43% for HDPE, PE films and PET (De Feo et al., 2022) and 50% for HDPE (Błażejewski et al., 2021). One study, due to a lack of data, considered the same recycling rate (89%) for aluminium cans and PET bottles (Boesen et al., 2019). Another study chose to dispose in landfill all the packaging types (Pragati and Maeda, 2022), but this seems a rather simplistic choice.

Plastics versus paper and cardboard

The comparison between plastics and cellulosic materials was addressed in a total of 10 publications. Studies related to multilayer or composite materials including paper such as the aseptic carton (paperboard, polyethylene and aluminium; De Feo et al., 2022; Ferrara and De Feo, 2020), multilayer carton (Cappiello et al., 2022), beverage carton (Ponstein et al., 2019) or milk carton (Brock and Williams, 2020) are excluded from this comparison. Many of these materials are in fact composed of layers of paper and other materials to tailor their performance to specific requirements; thus, it would be difficult to provide a consistent comparison. The 10 compared studies shed light on the utilisation of these materials across various applications, allowing the identification of common characteristics. By categorising the comparison into specific areas, insights into the advantages, disadvantages and overall suitability of plastics, paper and cardboard can be drawn. In order to provide a comprehensive analysis, two main groups of papers according to the different type of packaging were considered: crates for food transportation and bags.

The comparison for fruit and vegetables transport crates was analysed in five papers. The types of packaging taken into account are reusable plastic crates mainly made of PP, single-use crates also made of PP and HDPE and single-use corrugated board crates. On average, 10 impact categories were analysed in the studies considered, ensuring completeness of results. Upon analysing the results and conclusions of the five studies, three aspects play a crucial role in determining the optimal choice among the various materials: number of reusable crate cycles, travel distance and end-of-life assumptions. Abejón et al. (2020) stated that reusable plastic crates presented a better environmental performance than the cardboard boxes for all the impact categories, which was directly related to a lower consumption of materials from renewable and non-renewable sources. In general, the option of reusing plastic crates, as long as a minimum level of reuse cycles is ensured, is the most favourable one. Accorsi et al. (2022) suggested that reusable plastic crates were generally preferable to other single-use solutions (considering e.g. the climate change impact category) after 15 rotations. Del Borghi et al. (2021) considered a cycle of 50 reuses, whereas López-Gálvez et al. (2021) accounted for 150 rotations of the plastic crates. The dependence of the results on the number of reuse cycles is therefore crucial in determining the best solution. The second relevant parameter that is highlighted from the reviewed studies is the transportation. If on the one hand heavier crates contribute to increase specific impacts such as the climate change, on the other hand the demand for specific types of cardboard for long distances, which require higher performance in terms of resistance, contributes to increase the relative environmental impacts. For this reason, Accorsi et al. (2022) proposed the use of a digital tool to virtualise the logistic flows of containers, food and auxiliary materials and evaluated greenhouse gases emissions and fuel consumption outputs for each shipment. Lastly, the definition of end-of-life scenarios is one of the aspects to which studies paid particular attention to correctly evaluate the resulting impacts.

Three studies, instead, analysed the comparison between paper and plastic carrier bags. The average of the categories analysed for the comparison is 9. For all the studies, paper carrier bags performed worse than plastic ones. According to Civancik-Uslu et al. (2019b), paper performed worse than HDPE and LDPE in all the analysed categories, and in the case of the comparison with PP, paper was better for only three out of eight categories. Similarly, Pragati and Maeda (2022) asserted that grocery bags composed of HDPE outperformed paper in 15 out of the 16 examined categories.

Finally, two studies analysed the comparison between plastic and paper for packaging for food consumption. Both, however, only consider the category of climate change for their evaluations.

Plastics versus other materials

In addition to the most traditional materials, packages or other items made of textiles or wood were examined in seven and three studies, respectively.

In detail, three types of textile bags made of cotton or jute were compared to the corresponding plastic one. Results were conflicting. Ahamed et al. (2021) indicated plastic bags (either disposable or reusable) as the most preferable option when compared to reusable (50 uses) cotton bags. Pragati and Maeda (2022) underlined that textile bags need to be reused at least 41 times to show impacts similar to those of disposable plastic bags. Finally, Singh et al. (2023) indicated that jute bags reused at least 30 times caused lower environmental impacts than single-use LDPE bags.

With regard to wood, the potential impacts of several items were assessed: three of the studies considered tableware (i.e. forks, knives, spoons, containers and drinking straws), whereas two items were focused on crates for food distribution, one on bags and one on sheets typically used to separate loaded pallets during storage. In addition to bamboo (three studies), typically considered for the tableware, also kenaf and eucalyptus were included in the studies. Concerning crates, solid wood, particle wood and medium-density fibreboard were considered. Examining their features, wooden items can be disposable (crates, forks, knives, spoons and containers) or reusable (straws, sheets for pallets and bags). Concerning the results, according to three studies, wood was the most environmentally friendly solution. According to Chen et al. (2023), single-use bamboo containers performed better than the compared single-use plastic items. Comparing bamboo and plastic tableware (both disposable), the first showed lower environmental impacts because the bamboo processing required only small amounts of energy and materials (Wei et al., 2022). Finally, the kenaf reusable bag resulted better than the single-use plastic alternative (Singh et al., 2023). The remaining four studies indicated plastic as the best solution. According to López-Gálvez et al. (2021) and Del Borghi et al. (2021), single-use wooden crates performed worse than reusable plastic crates. Moreover, Civancik-Uslu et al. (2019a) indicated that the sheets for pallets reusable three times show higher environmental impacts than similar plastic items reusable 35 times (and with a significantly lower weight). According to the outcomes of the sensitivity analysis, plastic sheets resulted better than wood sheets for most of the impact categories even if disposed of after one use. It is also important to underline that this is the only study that examines a biological process (composting) for the management of wood at the end of its useful life. Finally, reusable bamboo straws performed worse than single-use plastic items, due to the burden of their washing (Fetner and Miller, 2021).

As shown, the comparison seems to underline the benefits of the reusable items, irrespective of their material.

Limitations of the review

A limitation of the study could be the short time range of the reviewed studies (5 years). However, the high number of found studies was deemed sufficient and suitable for capturing the recent state of LCA methodology, which rapidly evolves and, consequently, rapidly makes outdated the related studies. Furthermore, materials such as bioplastics still show rapid changes and evolutions in their characteristics and also in their production processes. Accordingly, the selected articles are believed to give a representative description of the current scenario. There was no financial conflict of interest that could have influenced the work.

Conclusions