ABSTRACT

Objective:

The study aims to evaluate the impact of chemical disinfection using ozone water and glutaraldehyde on the surface detail reproduction (SDR) of vinyl polyether silicone (VPES) impression material at different time intervals.

Methodology:

VPES impressions were categorized into light-body and heavy-body groups and further divided based on the disinfectant used (ozone water or glutaraldehyde) and the time interval of disinfection (T1: 15 minutes and T2: 24 hours). A total of 80 impressions (40 light-body and 40 heavy-body) were prepared and subjected to the respective disinfection protocols. The SDR was evaluated using a standard scoring system to determine the quality of detail reproduction.

Results:

Ozone water demonstrated superior performance in preserving surface detail compared to glutaraldehyde at both T1 and T2 for both light-body VPES and heavy-body VPES. Light-body VPES showed better SDR scores compared to heavy-body VPES across all conditions. Specifically, for light-body VPES, the mean SDR scores at T1 were significantly better for ozone water compared to glutaraldehyde (mean scores: 1.00 vs. 1.27, P = 0.046). For heavy-body VPES, ozone water also performed better at T1 compared to glutaraldehyde (mean scores: 1.27 vs. 1.67, P = 0.034). Disinfection at T1 resulted in better SDR scores compared to T2 for both light-body VPES and heavy-body VPES.

Conclusion:

Ozone water is a more effective disinfectant than glutaraldehyde for preserving the surface detail of VPES impressions, especially when disinfection is conducted for a shorter duration (15 minutes).

KEYWORDS: Dental impressions, disinfection, glutaraldehyde, heavy-body VPES, light-body VPES, ozone water, surface detail reproduction, vinyl polyether silicone

INTRODUCTION

Elastomeric impression materials, like vinyl polyether silicone (VPES), are crucial in dentistry for their high accuracy, dimensional stability, and tear resistance, which are essential for creating precise dental prostheses.[1,2] Despite their effectiveness, these impressions need disinfection to prevent cross-contamination, as they can harbor pathogenic microorganisms. However, disinfection must not compromise the impression’s surface detail reproduction (SDR), which is vital for accurate restorations.[3,4] Glutaraldehyde and ozone water are commonly used disinfectants, with glutaraldehyde known for its broad-spectrum efficacy but the potential to alter impression surface characteristics, and ozone water offering a safer alternative due to its oxidative properties and minimal residue.[5,6]

By examining the effects of ozone water and glutaraldehyde on VPES impressions at different time intervals, this study aims to provide evidence-based guidelines for clinicians. These guidelines will help balance effective disinfection with the preservation of impression integrity, ultimately ensuring the successful fabrication of dental prostheses. Understanding the optimal disinfection protocol is crucial for improving patient outcomes and maintaining high standards in dental practice.

This study aims to evaluate the impact of these two disinfectants on the SDR of VPES, considering two time intervals (15 minutes and 24 hours) for both light-body and heavy-body materials. Prior research indicates that disinfectants can cause dimensional changes or surface alterations in elastomeric materials, affecting the accuracy of dental restorations.

MATERIALS AND METHODS

The study will utilize a customized stainless steel (SS) mold designed according to revised ADA specification no. 19 to test the surface detail reproduction (SDR) of nonaqueous elastic dental impression materials. The mold consists of three sections: Section A with scribed lines as the base, Section B containing a 3-mm-thick SS ring for the impression material, and Section C with a perforated plate for uniform pressure application and mechanical retention. The impression materials tested are PVES (EXA’lence™) in heavy- and light-body consistencies. A total of 30 specimens will be prepared, with any containing bubbles or irregularities being discarded.

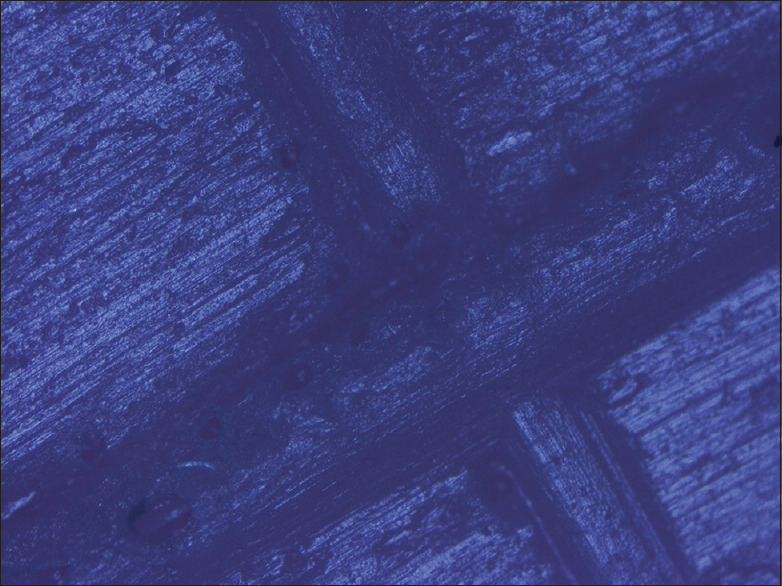

The specimens will be divided into two groups: glutaraldehyde (2.45%) and ozonated water, with each group having 15 specimens. Each specimen will be immersed in the disinfectant for 10 minutes and then tested at two intervals: T1 (15 minutes) and T2 (24 hours). The SDR for the control group will be evaluated by observing the reproduction of a 50 μ line on the impressions at ×10 magnification, with scores ranging from 1 (sharp, continuous lines) to 4 (failure to reproduce the line). This scoring system will also be applied to assess SDR for the test specimens [Figure 1].

Figure 1.

Stereomicroscope image of light-body specimen

RESULTS

The results show that ozone water significantly preserved the surface detail reproduction (SDR) better than glutaraldehyde for both light-body and heavy-body VPES impressions. As shown in Table 1, ozone water resulted in significantly lower mean SDR scores for light-body specimens at T1 (15 minutes) compared to T2 (24 hours) (P = 0.025). Table 2 further highlights that ozone water at T1 performed significantly better than glutaraldehyde at T1 for light-body specimens (P = 0.046). For heavy-body VPES [Table 3], ozone water at T1 also showed better SDR scores than glutaraldehyde (P = 0.034), although the difference was not significant at T2 (P = 0.096). Overall, these findings suggest that ozone water is more effective in maintaining the surface detail of VPES impressions shortly after disinfection, especially for light-body materials.

Table 1.

Comparison of mean surface detail reproduction scores in different groups and time intervals

| Group name | Time interval | Mean | SD | Test statistic | P |

|---|---|---|---|---|---|

| Ozone water | T1 (15 min) LB | 1.00 | 0 | -2.236 | 0.025 |

| T2 (24 Hrs) LB | 1.33 | 0.488 | |||

| Glutaraldehyde | T1 (15 min) LB | 1.27 | 0.458 | -2 | 0.046 |

| T2 (24 Hrs) LB | 1.53 | 0.516 | |||

| Ozone water | T1 (15 min) HB | 1.27 | 0.458 | -1.732 | 0.083 |

| T2 (24 Hrs) HB | 1.33 | 0.516 | |||

| Glutaraldehyde | T1 (15 min) HB | 1.67 | 0.488 | -1.414 | 0.157 |

| T2 (24 Hrs) HB | 1.8 | 0.414 | |||

| Ozone water | T1 (15 min) LB | 1.00 | 0.00 | -2 | 0.046 |

| T1 (15 min) HB | 1.27 | 0.458 | |||

| Ozone water | T2 (24 Hrs) LB | 1.33 | 0.488 | -0.707 | 0.48 |

| T2 (24 Hrs) HB | 1.47 | 0.516 | |||

| Glutaraldehyde | T1 (15 min) LB | 1.27 | 0.458 | -2.121 | 0.034 |

| T1 (15 min) HB | 1.67 | 0.488 | |||

| Glutaraldehyde | T2 (24 Hrs) LB | 1.53 | 0.516 | -1.414 | 0.157 |

| T2 (24 Hrs) HB | 1.8 | 0.414 |

Table 2.

Comparison between different disinfectant groups after disinfection of light-body specimen at T1 and T2

| Light body | Mean | SD | Test statistics | P |

|---|---|---|---|---|

| Ozone water T1 (15 min) LB | 1 | 0 | -2 | 0.046 |

| Glutaraldehyde T1 (15 min) LB | 1.27 | 0.458 | ||

| Ozone water T2 (24 Hrs) LB | 1.33 | 0.488 | -0.905 | 0.366 |

| Glutaraldehyde T2 (24 Hrs) LB | 1.53 | 0.516 |

Table 3.

Comparison between different disinfectant groups after disinfection of heavy body specimen at T1 and T2

| Heavy body | Mean | SD | Test statistics | P |

|---|---|---|---|---|

| Ozone water T1 (15 min) HB | 1.27 | 0.458 | -2.121 | 0.034 |

| Glutaraldehyde T1 (15 min) HB | 1.67 | 0.488 | ||

| Ozone water T2 (24 Hrs) HB | 1.47 | 0.516 | -1.667 | 0.096 |

| Glutaraldehyde T2 (24 Hrs) HB | 1.8 | 0.414 |

DISCUSSION

This study evaluated the impact of ozone water and glutaraldehyde on the surface detail reproduction (SDR) of vinyl polyether silicone (VPES) impression materials at two time intervals, 15 minutes (T1) and 24 hours (T2). Results showed that ozone water outperformed glutaraldehyde in preserving surface details for both light-body VPES and heavy-body VPES at both intervals, aligning with previous findings that ozone water’s oxidative properties effectively eliminate microorganisms without compromising the material’s properties.[1,2] Specifically, light-body VPES disinfected with ozone water at T1 had a significantly better mean SDR score compared to glutaraldehyde (1.00 vs. 1.27, P = 0.046), indicating ozone water’s potential for maintaining impression quality shortly after disinfection.

The study also found that the disinfection duration affected SDR, particularly for light-body VPES. Shorter disinfection times (T1) resulted in better SDR scores for both disinfectants, suggesting that prolonged exposure to disinfectants, like glutaraldehyde, might lead to absorption and surface changes that affect detail reproduction.[3,4] For example, light-body VPES had mean SDR scores of 1.00 at T1 and 1.33 at T2 with ozone water, indicating better detail preservation at the shorter interval (P = 0.025). In contrast, heavy-body VPES was less affected by the disinfection duration, possibly due to its higher viscosity and reduced susceptibility to chemical alteration.

Clinically, these findings underscore the importance of selecting appropriate disinfection methods and times to preserve the accuracy of dental impressions. Ozone water is a preferable choice for disinfecting VPES impressions, particularly for short turnaround times, due to its ability to maintain surface detail better than glutaraldehyde.[5,6] Additionally, light-body VPES should be considered when high precision is necessary, but clinicians should be mindful of potential degradation in detail with prolonged disinfection, especially when using glutaraldehyde.

CONCLUSION

This study underscores the efficacy of ozone water over glutaraldehyde in preserving the surface detail of VPES impressions, especially when disinfected for shorter periods (15 minutes). Light-body VPES consistently outperformed heavy-body material in detail reproduction, suggesting its preferable use for high-precision impressions. These findings provide valuable guidance for dental practitioners in selecting appropriate disinfection protocols to ensure the highest quality of dental impressions.

Conflicts of interest

There are no conflicts of interest.

Funding Statement

Nil.

REFERENCES

- 1.A SR, Reddy N, Dinapadu S, Reddy M, Pasari S. Role of ozone therapy in minimal intervention dentistry and endodontics - A review. J Int Oral Health. 2013;5:102–8. [PMC free article] [PubMed] [Google Scholar]

- 2.Amin WM, Al-Ali MH, Al Tarawneh SK, Taha ST, Saleh MW, Ereifij N. The effects of disinfectants on dimensional accuracy and surface quality of impression materials and gypsum casts. J Clin Med Res. 2009;1:81–9. doi: 10.4021/jocmr2009.04.1235. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Rueggeberg FA, Beall FE, Kelly MT, Schuster GS. Sodium hypochlorite disinfection of irreversible hydrocolloid impression material. J Prosthet Dent. 1992;67:628–31. doi: 10.1016/0022-3913(92)90160-c. [DOI] [PubMed] [Google Scholar]

- 4.Pratten DH, Covey DA, Sheats RD. Effect of disinfectant solutions on the wettability of elastomeric impression materials. J Prosthet Dent. 1990;63:223–7. doi: 10.1016/0022-3913(90)90109-p. [DOI] [PubMed] [Google Scholar]

- 5.Azarpazhooh A, Limeback H. The application of ozone in dentistry: A systematic review of literature. J Dent. 2008;36:104–16. doi: 10.1016/j.jdent.2007.11.008. [DOI] [PubMed] [Google Scholar]

- 6.Savabi O, Nejatidanesh F, Bagheri KP, Karimi L, Savabi G. Prevention of cross-contamination risk by disinfection of irreversible hydrocolloid impression materials with ozonated water. Int J Prev Med. 2018;9:37. doi: 10.4103/ijpvm.IJPVM_143_16. [DOI] [PMC free article] [PubMed] [Google Scholar]