Abstract

The European Commission asked EFSA to provide an opinion according to Article 23(6) of Regulation (EC) No 1107/2009, in conjunction with Article 29 of Regulation (EC) No 178/2002, regarding the approved plant protection uses of chitosan and chitosan hydrochloride as basic substances. The Panel on Plant Protection Products and their Residues (PPR) was not provided with new dossiers but collated available scientific and technical knowledge and used a weight of evidence approach and experts' judgement for its appraisal. The statement has considered the possibility for extrapolation of the toxicological properties between chitosan and chitosan hydrochloride, and whether both substances can be expected to be of no toxicological concern; a comparison between the estimated levels of chitosan and chitosan hydrochloride resulting from the approved uses as basic substances and the level of chitosan expected to naturally occur in the environment. This last comparison served to verify whether the approved uses as basic substances might lead to an exceedance of the expected natural background levels in any of the environmental compartments (quantitative for the soil compartment and (semi)quantitative for the freshwater compartment); and accordingly, whether there was a need to advise on the safety of chitosan and chitosan hydrochloride to non‐target species occurring in the impacted environmental compartments. Overall, the PPR Panel concluded that toxicological properties can be extrapolated between chitosan and chitosan hydrochloride and that no toxicological concerns were identified. The estimated levels of chitosan and chitosan hydrochloride in the environment following application in accordance with their approved uses as basic substances would be within the same range, or below, the expected natural background exposure levels in soil and freshwaters. Considering the available ecotoxicological data and the environmental fate assessment, further consideration in relation to the safety to non‐target organisms was considered not necessary. Missing information alongside related uncertainties have been identified and considered in the overall weight of the evidence.

Keywords: chitin, basic substances, chitosan, chitosan hydrochloride, mammalian toxicology, environmental fate, natural waters, pesticide, soil

SUMMARY

Chitosan and Chitosan Hydrochloride are approved as basic substances for use in plant protection as laid down in Commission Implementing Regulation (EU) 2022/456 and Commission Implementing Regulation 563/2014, respectively.

EFSA evaluated these substances previously, in accordance with Article 23(4) of Regulation (EC) No 1107/2009, and issued the results of its work in the form of a Technical Report first for chitosan hydrochloride (in 2013) and then for chitosan (in 2020).

In 2022, following the request of two Member States to review the approvals of chitosan and chitosan hydrochloride, as in their view there was an insufficient level of information to conclude that the uses as basic substances would not lead to any risks for human or animal health, nor any unacceptable risk to the environment, EFSA was requested by the European Commission to provide an opinion according to Article 23(6) of Regulation (EC) No 1107/2009, in conjunction with Article 29 of Regulation (EC) No 178/2002. The request concerned specifically:

to verify whether the toxicological properties can be extrapolated between chitosan and chitosan hydrochloride and, consequently, advise whether it can be expected that there is no toxicological concern as indicated in the EFSA Technical Report of 2020 for chitosan hydrochloride (Term of Reference, ToR 1);

to advise to which extent it could be expected that the estimated levels of chitosan and chitosan hydrochloride resulting from the approved uses as basic substance would exceed the level expected to occur in the environment, either naturally or derived from other uses (ToR 2);

in addition, in cases the environmental levels of chitosan and chitosan hydrochloride resulting from the approved uses as basic substance would exceed significantly the levels expected to occur in the environmental compartments, to advise on the safety of chitosan and chitosan hydrochloride to non‐target species occurring in these compartments (ToR 3).

By using a weight of evidence approach and experts' judgement, the PPR Panel derived the following overall conclusions:

For the ToR 1, the PPR Panel concluded that considering the chemical structures of chitosan and chitosan hydrochloride, the history of safe use of chitosan and its salts, the poor absorption in the gastrointestinal tract of these molecules independent of their chemical form (salt or free) and the absence of toxicological concern from the available and recent literature, the two molecules are similar and the toxicological properties can be extrapolated between chitosan and chitosan hydrochloride. Overall, based on the evidence considered to address the current mandate, a toxicological concern was not identified. However, different uncertainties have been considered in the overall weight of the evidence.

For the ToR 2, the PPR Panel concluded that the estimated levels of chitosan and chitosan hydrochloride in the environment following application in accordance with their approved uses as basic substances, conservatively calculated as predicted environmental concentrations (PECs) for soil and freshwater 1 compartments, would be within the same range or below the expected natural background exposure levels of chitosan 2 in soil and natural freshwaters. A quantitative comparison for the soil compartment was carried out by the PPR Panel, while for the freshwater compartment only a semi‐quantitative comparison was possible. Moreover, the PPR Panel took note of the extensive body of knowledge of the uses of chitosan and chitosan hydrochloride other than the use as basic substance, in the first instance, uses falling under the Regulation (EU) 2019/1009 on fertilising products. The PPR Panel acknowledged that these uses shall be considered as constituting a major potential input for the overall environmental exposure, even though these uses could not be accounted for in the comparison PECs vs expected natural background exposure level due to a lack of accurate quantitative data applicable at the EU‐level. 3

For the ToR 3, the PPR Panel concluded that based on the available information in ecotoxicology and the environmental fate properties of chitosan, no further assessment in relation to the safety to non‐target soil, and surface water and sediment organisms was deemed necessary since the exposure levels resulting from the use of chitosan and chitosan hydrochloride as basic substances, in comparison to the natural background exposure levels, are not considered sufficient to trigger any risk for non‐target organisms.

1. INTRODUCTION

Chitosan was approved as a basic substance for use in plant protection by Commission Implementing Regulation (EU) 2022/456, 4 following the submission of an application by the company Kitozyme on 19 December 2018, on the basis of a Technical Report published on 22 July 2020 by the European Food Safety Authority (EFSA, 2020b). This application originally concerned an extension of use of chitosan hydrochloride, however, based on the Technical Report by EFSA and the documentation provided by the applicant, the scope of the application was re‐defined and the subsequent approval was granted for the basic substance ‘chitosan’.

Chitosan hydrochloride was approved as a basic substance by Commission Implementing Regulation (EU) 563/2014, 5 on the basis of a Technical Report published in 2013 EFSA (EFSA, 2013). In 2021, the Commission review report for chitosan hydrochloride was amended to include, in its Appendix II, additional uses as a basic substance. 6 Furthermore, later in 2020 and following years, other applications for extension of use of chitosan hydrochloride have been submitted. 7

In March 2022, two Member States requested the Commission to review the approvals of chitosan and chitosan hydrochloride in accordance with Article 23(6) of Regulation (EU) No 1107/2009. 8 In their view, the available level of information did not allow to conclude that the uses as basic substances would not lead to any risks for human or animal health, nor any unacceptable risk to the environment.

Considering the request for a review of the approval, the arguments discussed at the Standing Committee on Plants Animals, Food and Feed, and the EFSA Technical Reports from 2013 and 2020, the European Commission considered that there were indications that chitosan and chitosan hydrochloride no longer satisfy the criteria provided for in paragraphs 1 to 3 of Article 23 of Regulation (EU) No 1107/2009. Accordingly, in accordance with Article 23(6) of Regulation (EU) 1107/2009, the European Commission invited the applicants to submit any relevant information or comments on the eligibility of chitosan and/or chitosan hydrochloride to be approved as basic substances. Two applicants submitted their comments. These comments were made available to the Member States and EFSA, who were then also invited to comment. EFSA submitted its comments on 17 April 2023, and one Member State submitted its comments on 3 May 2023.

On 23 January 2024 EFSA was requested by the European Commission to provide an opinion according to Article 23(6) of Regulation (EC) No 1107/2009, in conjunction with Article 29 of Regulation (EC) No 178/2002, concerning the basic substances chitosan and chitosan hydrochloride taking into account: (i) already existing European and other regulatory or governmental assessments; 9 (ii) the dossiers of both substances submitted for their approvals 10 as well as the dossiers for the subsequent extensions of use, (iii) information submitted by the applicants in the context of the current review of approval, (iv) other scientific and technical knowledge.

The specific requests of the present mandate are presented in the following section.

1.1. Terms of Reference (ToR) as provided by the requestor

In accordance with Article 23(6) of Regulation (EC) No 1107/2009 in conjunction with Article 29 of Regulation (EC) No 178/2002, EFSA is requested to provide an opinion regarding the approved use(s) 11 of the substances chitosan and chitosan hydrochloride as basic substances.

Specifically, by using a weight of evidence approach and under consideration of expert judgement regarding the occurrence in the environment of chitosan and chitosan hydrochloride, the Commission asks EFSA to:

-

–

verify whether the toxicological properties can be considered similar and extrapolated between chitosan and chitosan hydrochloride and, consequently, advise whether it can be expected that both substances are of no toxicological concern as indicated in the EFSA Technical Report of 2020 for chitosan hydrochloride;

-

–

advise to which extent it could be expected that the estimated levels of chitosan and chitosan hydrochloride resulting from uses as basic substance 12 (currently approved at application rates 100–800 g/ha) would exceed levels expected to occur in the environment, either naturally or derived from other uses, also taking into account the structural similarity between chitin and chitosan (and its hydrochloride), the natural abundance of chitin 13 in the environment, the route of degradation of chitin which can be the precursor of chitosan 14 as well as the degradation/persistency of chitosan and chitosan hydrochloride;

-

–

In addition, in cases the environmental levels of chitosan and chitosan hydrochloride resulting from the conditions of use as defined by the existing approvals as basic substance would exceed significantly the levels expected to occur in the environmental compartments (see previous point), advise on the safety of chitosan and chitosan hydrochloride to non‐target species occurring in these compartments.

1.2. Interpretation of the Terms of Reference

EFSA deemed it appropriate to request the PPR to provide its opinion, in the form of a statement, to the European Commission regarding the approved uses of chitosan and chitosan hydrochloride as basic substances, according to Article 23(6) of Regulation (EC) No 1107/2009. Accordingly, a Working Group (WG) was established under the PPR Panel 15 to elaborate this assessment.

The PPR Panel interpreted that the ToR required the Panel to provide advice on:

- the comparison of chitosan and chitosan hydrochloride chemical structures, and whether the mammalian toxicological properties can be extrapolated between them. The Panel will also indicate whether both substances can be expected of being of no mammalian toxicological concern.

- estimates of the expected natural background exposure levels of chitosan in soil and, possibly, freshwaters, by considering chitosan and chitin abundance and their route of degradation in the environment.

- the possibility of comparing the estimated levels of chitosan/chitosan hydrochloride resulting from the approved uses as basic substance (with a maximum yearly application rate of 8 × 800 g/ha) against the expected natural background exposure levels in soil and, possibly, freshwaters.

- the collection of qualitative/quantitative information on uses of (chitin)/chitosan and chitosan hydrochloride, other than the use as basic substances, in particular as improvers of the quality of soil and as animal feed material(s).

If triggered by the outcome of ToR 2, (b), the Panel would present, if possible, a risk assessment and/or ecotoxicological consideration for the non‐target species occurring in the pertinent environmental compartments in which the exposure to chitosan/chitosan hydrochloride following application in accordance with their approved uses as basic substances is judged to significantly exceed the expected/estimated natural background exposure levels and thus, whether that possible exceedance could impact non‐target organisms in any possible way.

The PPR Panel also noted that the outcome of the consultation process organised by EFSA 16 and EFSA's scientific views on the individual comments received for the application dossiers on chitosan hydrochloride and its extension of use had been presented in the EFSA Technical Reports issued in 2013 (EFSA, 2013) and 2020 (EFSA, 2020b) respectively. Accordingly, these applications were not intended to be reassessed by the PPR Panel in this output.

2. PROBLEM FORMULATION

In line with the ToRs and the draft framework for protocol development for EFSA's scientific assessments (EFSA, 2020a), the following tasks were addressed:

For the ToR 1, in order to verify whether the toxicological properties can be extrapolated between chitosan and chitosan hydrochloride and that there is no toxicological concern:

1a. A comparison of the chemical structures of chitosan and chitosan hydrochloride.

1b. Verification of the availability of chitosan salt products to the general public (e.g. medicines and cosmetics) and their presence in foods as food constituents.

1c. Evaluation of the available absorption, distribution, metabolism and excretion (ADME) and toxicological data from basic substance applications and their extension of uses, of the relevant studies from other regulatory frameworks and of the evidence retrieved on chitosan hydrochloride from public literature and any other evidence regarding chitosan (review only).

For ToR 2:

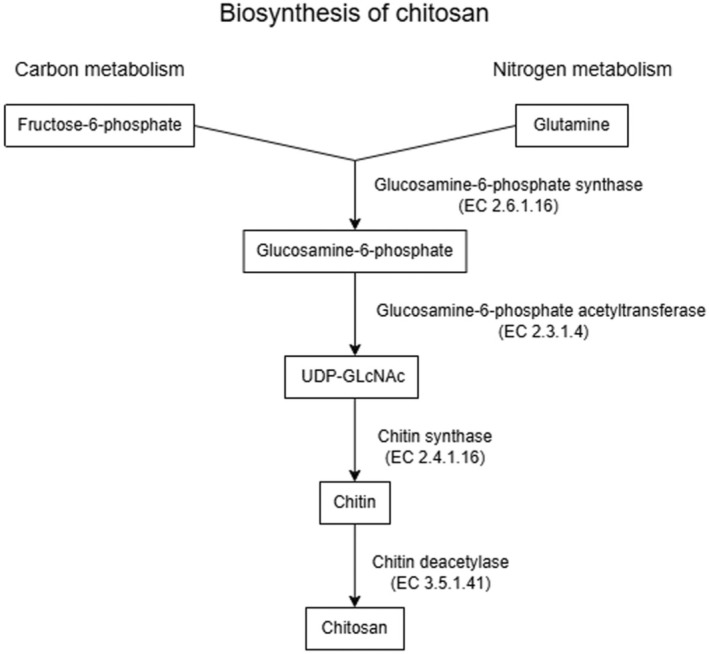

2a. It was considered that the compound of environmental interest would be chitosan in its dry (free) or eventually ‘cationic’ form, depending on the environmental conditions, and not any possible ‘anionic’ counterions (e.g. chlorides, acetates) usually employed to get the salt form, such as chitosan hydrochloride. Accordingly, an estimation of the expected natural background exposure levels of chitosan only in soil and, possibly, freshwaters would be performed by considering:

-

–

the natural abundance of chitin and chitosan: their average occurrence in biomass found in fungi, insects, nematodes and crustaceans;

-

–

the route of degradation of chitin into chitosan: chitosan derived from the microbial degradation of chitin by considering the metabolism process and the related enzymes involved;

-

–

chitosan degradation: degradation and biodegradability of chitosan and its behaviour under environmental conditions.

2b. Possible semi‐quantitative comparison of the estimated levels of chitosan/chitosan hydrochloride following application in accordance with their approved uses as basic substances (up to a max application rate of 8 × 800 g ha−1) against the estimated natural background exposure levels of chitosan in soil and possibly in freshwaters (see bullet point 2a above). Accordingly, to enable this semi‐quantitative comparison, a direct comparison by using the application rates and the PECs for the selected environmental compartments (i.e. soil, surface water and sediment) resulting from the approved uses as basic substances will be carried out by the Panel. The estimation of the PECs will be made based on the available evidence and the parameters reported in the respective Good Agricultural Practice (GAP) tables as available in the respective EC Review reports for chitosan and chitosan hydrochloride (European Commission, 2023a, 2023b; see also Appendix E).

A comparison for the groundwater compartment will not be provided considering the expected natural biodegradation of chitosan, and because chitosan is insoluble at the pH relevant for groundwater used for potable uses (Drinking Water Directive, 2020 17 ).

2c. Collection of quali−/quantitative information on uses of (chitin)/chitosan and chitosan hydrochloride other than the uses as basic substances, mainly as improvers of the quality of soil and as animal feed materials, to better understand the potential contribution of these additional uses to the overall environmental exposure of these substances. However, a total environmental load taking into account these additional uses will not be considered, and the comparisons under task 2b will not take into account the potential exposure derived from the environmental load of chitosan by these other non‐natural sources, including uses as fertilisers/soil improvers or feed materials.

For ToR 3:

3a. Should the semi‐quantitative comparison and further environmental fate and behaviour considerations conducted under task 2b trigger the need for ecotoxicological consideration for certain taxa/non‐target species, a risk assessment would be made based on the available evidence.

3. DEFINITION OF THE METHODS

The following methodology was identified by the PPR Panel to address the problem formulation questions:

- Tools for data collection:

- –

-

–Available regulatory and/or governmental assessments pertinent to and/or supporting the present assessment of chitosan/chitosan hydrochloride were investigated by EFSA staff from Pesticides Peer Review (PREV) unit and Environment, Plants & Ecotoxicology (PLANTS) unit.

-

–EFSA staff from PREV and PLANTS units collated the available evidence from application dossiers and information submitted in the context of the former evaluations of chitosan and chitosan hydrochloride to support their approval as basic substances or in the context of peer‐review processes of chitosan‐based active substances (see Section 4.1).

-

–Hearing expert with academic and regulatory experience in chitosan research and EFSA staff from PLANTS unit with predominant expertise in (micro)biology were consulted.

-

–Papers provided by the PPR Panel WG experts.

-

–Collaboration with EFSA Panel on Food Additives and Flavourings (FAF) and Panel on Nutrition, Novel Foods and Food Allergens (NDA) and their related WGs dealing with cross‐cutting chitosan applications. 18

- Tools for data validation and evidence appraisal:

-

–Distiller SR and EndNote for title and abstract screening of the retrieved papers from the literature search (see Appendix A).

-

–Environmental fate and exposure modelling in use at European level for the estimation of the predicted environmental concentrations of pesticides in soil, surface water and sediment (see Appendix E).

-

–

- Tools for uncertainty analysis:

-

–listed sources of uncertainties (qualitative only), following the principles of the EFSA Guidance on Uncertainty Analysis in Scientific Assessments (EFSA Scientific Committee, 2018).

-

–

4. DATA AND METHODOLOGIES

The current assessment was performed by the EFSA PPR Panel in accordance with Article 23(6) of Regulation (EC) No 1107/2009 and in conjunction with Article 29 of Regulation (EC) No 178/2002. The PPR Panel collected and selected available data and information, appraised the relevant evidence, and analysed and integrated the evidence in a weight of evidence approach and under consideration of experts' judgement to enable drawing conclusions forming the basis for the present statement.

4.1. Data

The PPR Panel was not provided with newly submitted application dossiers 20 for chitosan and chitosan hydrochloride.

The Panel based its assessment on relevant information submitted to EFSA in the context of:

the evaluation, in accordance with Article 23 of Regulation (EC) No 1107/2009, of an application for approval of chitosan hydrochloride as a basic substance (EFSA, 2013);

the evaluation, in accordance with Article 23 of Regulation (EC) No 1107/2009, of an application for extension of use of chitosan hydrochloride as a basic substance (EFSA, 2020b);

the call to applicants to submit any relevant information or comments on the eligibility of chitosan and/or chitosan hydrochloride to be approved as a basic substance;

additional applications for extension of use(s) of chitosan/chitosan hydrochloride submitted by applicants 21 ;

peer‐review processes on chitosan‐based active substances COS‐OGA (EFSA, 2014) and hydrolysed chitosan, hydrochloride (polimerisation degree n = 25–55; average acetylation degree 0%–20%) (also named ‘OptiCHOs’) 22 .

In addition, the Panel also considered available EU/non‐EU regulatory or governmental assessments and other scientific and technical knowledge. All references and information considered in the present assessment are summarised in Appendices B and C along with an indication of the respective sources.

4.2. Methodologies

Based on the latest available knowledge and pertinent risk assessment methodologies when weighing the available evidence, the PPR Panel addressed the topics as presented and discussed in Section 2 Problem formulation. In this respect, an evidence‐based approach for the data retrieval, compilation and integration in a weight of evidence (WoE) was used. The PPR Panel collected the data as reported in Section 3.

The internal validity of the study design was included as part of the expert judgement while evaluating the evidence retrieved. No pre‐defined critical appraisal tools were applied for the studies included.

For task 1c, a targeted literature review was performed. New evidence from the years 2013–2024 on chitosan hydrochloride was retrieved from bibliographic databases using a fit‐for‐purpose search strategy (see Appendix A.1, search #1). The selection of the scientific studies for inclusion or exclusion was carried out by two WG experts by following these steps: (1) Title & Abstract (Ti&Ab) screening and (2) full‐text screening to further identify references to be excluded or included based on criteria related to test item and study type (i.e. whether the reference is informative of toxicological properties). Distiller SR has been used for title and abstract screening of the retrieved papers. The studies that passed the full‐text screening (see Appendix A.1.1) are reported in tables and excel spreadsheets (Appendix B) and, when relevant, discussed in the corresponding sections of the statement (Section 5.3).

New evidence from the years 2019 to 2024 on chitosan was retrieved from bibliographic databases using a fit‐for‐purpose search strategy (see Appendix A.1, search #2). Due to the large number of papers available in the public domain (more than 10,000 references), only review papers were selected for informing the assessment and the search period was limited to 5 years also considering the year of the submission of the application on chitosan (December 2018). The selection of the scientific studies for inclusion or exclusion was conducted by two WG experts by following these steps: (1) Ti&Ab screening and (2) full‐text screening to further identify references to be excluded or included based on criteria related to test item and study type (i.e. whether the reference is informative of toxicological properties). Distiller SR has been used for title and abstract screening of the retrieved papers. The studies that passed the full‐text screening (see Appendix A.1.2) are reported in tables and excel spreadsheets (Appendix B) and, when relevant, they are also discussed in the corresponding section of the statement (Section 5.3).

The evidence identified was appraised through a structured review and collegial discussion within the WG and it was synthesised and integrated using a qualitative approach.

For tasks 2a and 2c, evidence on chitin and chitosan was retrieved from bibliographic databases using three different search strategies targeted for specific purposes (see Appendix A.2):

natural occurrence and environmental fate (degradation) of chitin/chitosan,

agricultural uses of chitosan/chitosan hydrochloride other than the use as basic substances (e.g. to improve the quality of agriculture soils),

use of chitosan/chitosan hydrochloride as feed additive/material.

For all three searches, the selection of the scientific studies for inclusion or exclusion was conducted by the WG experts by following these steps: (1) Ti&Ab screening 23 and (2) full‐text screening to further identify references to be included or excluded based on criteria related to test item and study type. The studies that passed the full‐text screening are reported in Appendix C and, when relevant, they are also discussed in the corresponding section of the statement (Section 5.4).

For search #1, due to the large number of papers available in the public domain even after an optimised targeted search (more than 5000 references), only review papers, without limitation as to year of publication, 24 were selected for the first screening (Ti&Ab). Moreover, specifically for addressing task 2a, a targeted estimation of the chitosan content from natural biological sources, based on the findings of the Scientific Report on chitin estimation in agricultural soils (EFSA, 2025), was provided. Accordingly, this estimation enabled, at least for the soil compartment, a quantitative estimation of chitosan natural background exposure levels. However, chitin/chitosan ‘natural loads’ occurring in the freshwater compartments could not be quantitatively investigated. This was due to a lack of necessary information to perform a quantitative assessment considering the different variables (mainly seasonal) that play a key role in estimating concentrations in small edge‐of‐field water bodies.

For search #2 and #3, the search was extended to reviews and individual original papers and limited to the timeframe 2018–2024 (see Appendix A.2).

For task 2b, the estimation of chitosan concentrations in the selected environmental compartments, i.e. soil, surface water and sediment, was provided by the calculation of predicted environmental concentrations (PECsoil, PECsw and PECsed) following the guidance documents and using the pesticide fate models currently employed for regulatory purposes in line with the applicable legislation 25 and Commission Communications. 26 The input parameters for the PEC modelling were selected by the PPR Panel from the relevant evidence collected from the literature and available dossiers (see Section 5.4.2 and Appendix E). The PECs were calculated for both a single application at the highest rate of application and for the maximum number of applications at the shortest interval and highest rates of application (see GAP tables in Appendix E). The exposure assessment was not conducted for each approved use available in the GAP tables, but only for the worst‐case exposure scenarios, which are assumed to also cover scenarios with lower exposure (risk envelope approach 27 ). The PECsw and PECsed were estimated acknowledging the difficulties encountered obtaining reliable values, mainly due to the lack of substance property data needed as input parameters for the aquatic compartments (see details in Appendix E).

The comparison between the estimated levels of chitosan/chitosan hydrochloride resulting from the approved uses as basic substance with the expected natural background exposure levels was provided quantitatively for the soil compartment. Whereas for the aquatic compartments, the comparison was made semi‐quantitatively based on an evidence‐based approach and by using experts' judgement.

For all tasks described above, an overall qualitative uncertainty analysis was carried out to address the main sources of uncertainty identified across the scientific assessment process (see Section 7).

5. ASSESSMENT

5.1. Identity of the basic substances

Chitin & Chitosan (and its salts)

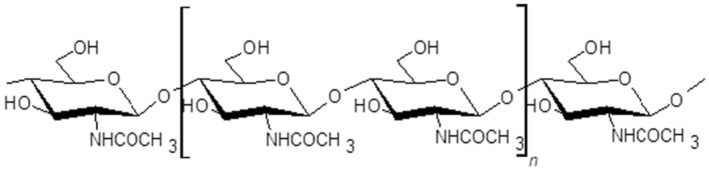

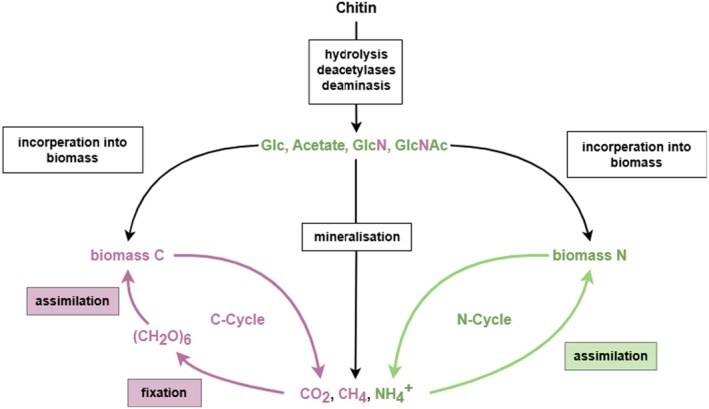

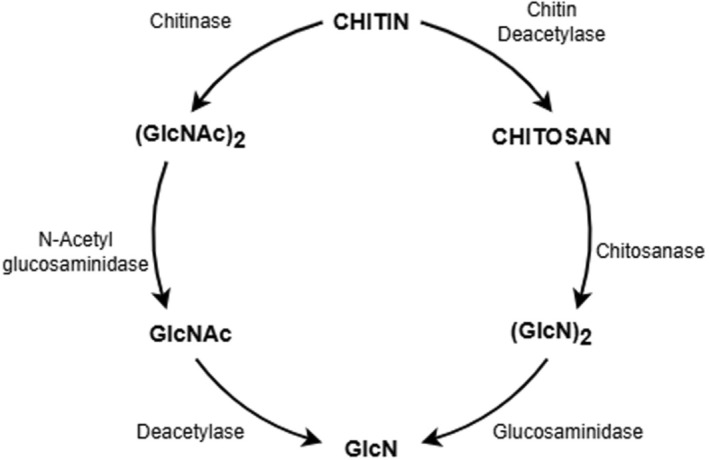

Chitin is a linear polymer (polysaccharide) of N‐acetyl‐d‐glucosamine. Chitin is the second most abundant natural polymer in the environment, after cellulose and it is found in organisms belonging to the Kingdoms Fungi, Animalia and, to a lesser extent, Protista (e.g. certain protozoans) and Chromista (e.g. some algae). It is not found in vertebrate animals and higher plants (Kurita, 2006; Sharp, 2013); but it is a basic component of the exoskeleton of arthropods (including crustaceans, insects and arachnids) and of the cell walls of fungi. (see further information on chitin sources in Section 5.4.1) (Figure 1).

FIGURE 1.

Chitin chemical structure (CAS number: 1398‐61‐4) (fully acetylated).

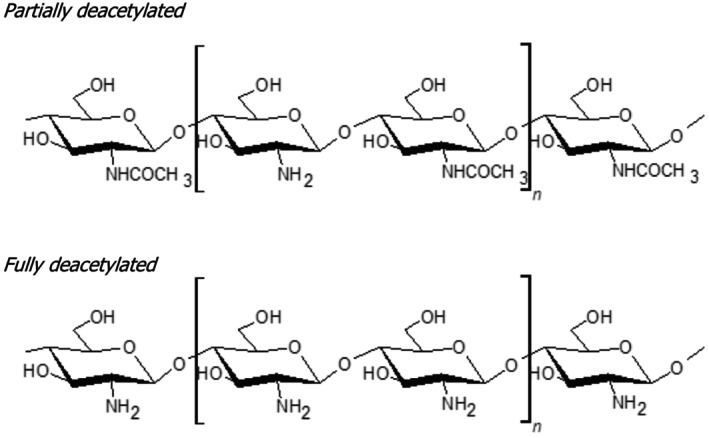

Commercially produced chitosan is a linear polysaccharide derived from the (partial or total) deacetylation of chitin (i.e. deacetylation of its amino groups) and it is composed of two units of randomly distributed d‐glucosamine (GlcN) and N‐acetyl‐d‐glucosamine (GlcNAc), linked by β (1,4) glycosidic bonds. Chitosan is also naturally occurring, produced mainly by certain fungi belonging to the phyla Zoopagomycota and Mucoroycota. 28 The latter phylum, contains various moulds which, notably, produce considerable amounts of chitosan (see further information on chitosan sources in Section 5.4.1).

In nature, chitin can have various degrees of deacetylation and therefore the distinction from chitosan is not strict (Mouyna et al., 2020). In this regard, it is noted that polymers with a degree of deacetylation of 50% or higher, are generally termed as ‘chitosan’, while those with lower deacetylation levels are commonly referred to as ‘chitin’. For instance, the PPR Panel noted that the commercial preparations of chitosan, assessed by the EFSA Panel of Dietetic Products, Nutrition and Allergies (NDA) for the substantiation of health claims (EFSA NDA Panel, 2011), had a degree of deacetylation (DD) ranging from 60% to 100% (EFSA NDA Panel, 2011).

Accordingly, it is acknowledged that the term ‘chitosan’ does not refer to a single polymer with a strict molecular definition, but to a family of molecules with differences in their composition, size and monomer distribution (Aranaz et al., 2021). Overall, the PPR Panel observed that the terms chitin, chitosan and chitosan oligomers are often used interchangeably in literature (see Uncertainty No. 1, Section 7).

The pattern of acetylated/amino moieties in the polymer chains of chitin/chitosan affects the physical–chemical properties of these polymers, including their solubility. Chitin, as a result, is insoluble in water and in most organic solvents due to its amino acetylated groups. Conversely, chitosan, having free (deacetylated) primary amino groups, is a weak basic cationic polyelectrolyte, which is soluble in aqueous acidic solutions (pH < 6.5), with higher solubility as the pH of the aqueous media decreases due to the protonation of the amino group. The transition between more soluble and insoluble polymers occurs around the value of the pKa that is typically between 6.0 and 6.5 (Aranaz et al., 2021) according to the degree of deacetylation, which is one determinant of this property of the polymer. The best solvent for chitosan is considered to be aqueous formic acid, while the most commonly used ones are aqueous acetic acid (1% with a pH close to 4; see also Table 2), hydrochloric acid (1%), lactic acid and nitric acid (Romanazzi et al., 2009). The solubility decreases when pH rises (from physiological values, i.e. those typically occurring in organism tissues) to alkaline values, with the increase of ionic strength of the media, with the molecular weight, with the degree of deacetylation and with the degree of polymerisation (Casadidio et al., 2019).

TABLE 2.

Identity and biological properties of chitosan as reported in the EC review report (SANTE/10594/2021 Rev. 2, European Commission, 2023a).

| Common name (ISO) | Chitosan |

| Chemical name (IUPAC, not CA) | poly[4‐O‐(2‐acetamido‐2‐deoxy‐β‐d‐glucopyranosyl)‐2‐amino‐2‐deoxy‐β‐d‐glucopyranose] |

| Common names | poly‐d‐glucosamine, Poliglusam |

| CAS No | 9012‐76‐4 |

| CIPAC No and EEC No | 618‐480‐0 (EC) |

| FAO SPECIFICATION | None |

| Minimum purity |

≥ 85% chitosan Heavy metals: max. 20 mg/kg Food grade, meeting the specifications for ‘chitosan extract from fungi’ as set out in Commission Implementing Regulation (EU) 2017/2470. |

| Molecular mass and structural formula | polycationic polysaccharide |

| Origin |

Aspergillus niger The strain of Aspergillus niger used in production of chitosan for plant protection purposes must be the strain that is used in food production and not produce mycotoxins, in particular ochratoxin A. |

| Mode of Use |

Low‐medium volume sprayer Post‐harvest treatment by immersion/dipping |

| Preparation to be used |

Soluble powder (SP) to be diluted in compliance with rate of application reported in Appendix II. 30 Preparation 1: chitosan powder should be added to a half‐filled water tank, making sure the powder is evenly distributed over the water surface to avoid aggregation. The mixture should be stirred vigorously while adding the remaining water. The mixture should be used as soon as possible. Preparation 2: Chitosan powder can be dissolved in water with pH < 5. The pH of water should be regulated by adding 7 mL vinegar (8% of acetic acid) per 1 L of water). |

| Function of plant protection | Plant elicitor |

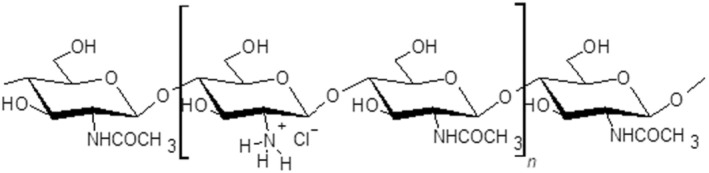

Overall, the PPR Panel took note that as ‘chitosan materials’ are typically not water soluble at basic/neutral pH, chitosan needs to be in an acidic media or transformed into its soluble salt variant (e.g. chitosan hydrochloride or acetate) to dissolve in water, thus to enable a dilution to be prepared for making applications for plant protection purposes (see Figure 3, Tables 1 and 2 below, entry ‘Preparation to be used’).

FIGURE 3.

Chitosan hydrochloride chemical structure (CAS number: 70694‐72‐3).

TABLE 1.

Identity and biological properties of chitosan hydrochloride as reported in the EC review report (SANCO/12388/2013– rev. 5. European Commission, 2023b).

| Common name (ISO) | Not relevant |

| Chemical name (IUPAC) | Not relevant |

| Chemical Name (CA) | Not relevant |

| Common names |

Chitosan hydrochloride Hydrochloride of linear polysaccharide composed of randomly distributed 1–4 linked d‐glucosamine and N‐acetyl‐d‐glucosamine produced by deacetylation of chitin. |

| CAS No | 70694‐72‐3 |

| CIPAC No and EEC No | Not relevant |

| FAO SPECIFICATION | Not relevant |

| Minimum purity |

European Pharmacopeia Chitosan hydrochloride being a product of animal origin must be in compliance with the requirements of Regulation (EC) No 1069/2009 and Commission Regulation (EU) No 142/2011. |

| Molecular formula | Not relevant |

| Relevant impurities | Max content of heavy metals: 40 ppm |

| Molecular mass and structural formula | Not relevant |

| Mode of Use | Chitosan hydrochloride to be used in water solution for application on various crops or for seed treatment. |

| Preparation to be used | Chitosan hydrochloride to be diluted in compliance with rate of application reported in Appendix II. 29 |

| Function of plant protection | Elicitor, having a fungicide and bactericide effect via the stimulation of natural defence mechanisms. |

5.2. Specifications for chitosan and chitosan hydrochloride as approved basic substances

5.2.1. Chitosan hydrochloride

Chitosan hydrochloride was approved as a basic substance as laid down in Commission Implementing Regulation (EU) No 563/2014 of 23 May 2014. A summary of the identity and biological properties of the basic substance chitosan hydrochloride is presented in Table 1.

5.2.2. Chitosan

Chitosan was approved as a basic substance as laid down in Commission Implementing Regulation (EU) No 456/2022 of 21 March 2022. A summary of the identity and biological properties of the basic substance chitosan is presented in Table 2.

5.2.3. Overview of identity properties and conditions of use of chitosan and chitosan hydrochloride

Chitosan (from KytoZyme application, see Documentation provided to EFSA Nr: (1) and chitosan hydrochloride (from ChiPro application, see Documentation provided to EFSA Nr: (2) approved as basic substances and subjects of the current statement, are produced in the form of a SP and a water‐soluble powder for seed treatment (SS):

chitosan hydrochloride is soluble in neutral aqueous environment, and it is added as such by the end user in water at 1% w/w.

chitosan has to be dissolved in acidic solution (e.g. by adding natural vinegar) prior to application.

As outlined in Section 5.1, chitosan, when used for plant protection purposes, either needs to be in the dissociated form dissolved in acidic aqueous solution or in the form of a salt (e.g. chitosan hydrochloride or acetate) that following dilution in water dissociates to the cation chitosan and related counterions in the water including the chloride anion.

5.3. Human health

5.3.1. Toxicological consideration based on chemical structure of chitosan and chitosan hydrochloride (task 1a)

The PPR Panel has performed a comparison of the chemical structures of chitosan and chitosan hydrochloride (reported in Sections 5.1 and 5.2) to verify whether the toxicological properties can be extrapolated between the two basic substances.

The chemical structure of the two basic substances differs for the chloride ion. The addition of hydrogen chloride to the chitosan molecule has the technological function to improve the water solubility of chitosan. In fact, chitosan, when used for plant protection purposes, either needs to be in the dissociated form (e.g. dissolved in acidic aqueous solution) or in the form of a salt (e.g. chitosan hydrochloride or acetate) that following dilution in water dissociates to the cation chitosan and related counterions (including the chloride anion).

To further support the comparison between chitosan and chitosan hydrochloride and to clarify the toxicity of hydrochloride per se, the PPR Panel considered the pharmaceutical experience in drug development where hydrochlorides and chlorides have been by far the most frequent choice for salts of basic drugs due to their easy availability and physiological tolerability.

Stahl (2011) investigated the safety of salts‐forming ions used for pharmaceutical purposes and classified them in first‐class, second‐class and third‐class. The first‐class are the salts that can be used without restriction because they form physiologically ubiquitous ions or because they occur as intermediate metabolites in biochemical pathways. The hydrochloride salts, as well as chlorides and sodium salts, are falling under this first‐class being of substances of very low toxicity (no acceptable daily intake (ADI) specified and having generally recognised as safe (GRAS) notifications granted by the US Food and Drug Administration (21 CFR 182.1057).

Stahl (2011) also reviewed the impact of salt formation on the safety of the pharmaceutical product, underlining that the relative toxicity of the different salts reflects their aqueous solubility as long as the unwanted action of the parent compound is limited to local effects (irritation) e.g. lower solubility will exhibit less irritative effects. However, the relationship between increased solubility and toxicity cannot be generalised. It is also reported by the same authors that hydrochloride salts of active pharmaceutical ingredients (APIs) frequently exhibit less than desirable solubility in gastric and other physiological fluids because of the abundance of Cl− ion in such media due to the law of mass action (common‐ion effect).

Other information on MW and DDA have been considered. However, the available specifications provided in the applications presented for the basic substance approval as well as in the literature considered for the current mandate are too sparse to allow a direct comparison of these properties for the two basic substances (see Uncertainty No. 1, Section 7).

5.3.2. Use of chitosan salts, including hydrochloride, under other regulatory frameworks with relevance for toxicological considerations (task 1b)

Chitosan has a wide range of agricultural, biopharmaceutical, biomedical, cosmetic, textile and food additive uses (reviewed by Bellich et al., 2016; reviewed by Hamed et al., 2016; US EPA, 2007).

Chitosan derivatives have been produced aiming to improve chitosan's properties, such as solubility or biodegradability, or to introduce new functions or properties. For instance, solubility has been improved in aqueous media by deacetylation, de‐polymerisation or quaternisation among other processes (Aranaz et al., 2010).

In the various regulations authorising the uses reported above, the chemical form of chitosan is rarely clearly mentioned. In fact, it is reported that even if the two molecules i.e. chitosan and chitosan hydrochloride, are identified by different CAS numbers, in their industrial use they are seen as interchangeable (Romanazzi et al., 2009). Also, in registration dossiers, studies with chitosan and/or chitosan salts (including chitosan hydrochloride) are used often mutually, or no clear information is provided on the salt used in the studies. For example, medical devices known to have therapeutic and osteoarthritis preventing abilities are commercially available in form of hydrochloric and sulfate salts (Crolle & D'este, 1980; Kajimoto, 1998) as well as the European Pharmacopoeia (EP) monograph having been prepared for the hydrochloride salt of chitosan (European Pharmacopoeia, 2019) . The 29th edition of the United States Pharmacopeia (USP) 34‐NF that included chitosan as is, was almost 10 years later.

As polymers for human use, both chitosan hydrochloride and chitosan‐valeric acid‐hydrocolloid are reported in IRIS, 32 the online platform of the European Medicines Agency (EMA).

In other cases (e.g. medical devices, biomedical and tissue‐engineered medical product applications), the use is regulated, more generically, either for chitosan and chitosan salts/derivatives (see Appendix B for the uses of chitosan/chitosan salts under other regulatory framework with relevance for the toxicological assessment).

5.3.3. Toxicological properties (task 1c)

General considerations

Chitosan and chitosan hydrochloride were previously assessed in the respective EFSA technical reports (EFSA, 2020b, 2013) pursuant to Article 23 (4) of Regulation (EC) No 1107/2009.

Papers from the different sources (see Section 4.1), were included in the current assessment. In addition, a targeted literature review of the recent literature on chitosan hydrochloride and chitosan, as explained in Section 4.2, was conducted by the PPR Panel.

The list of all the studies considered in the current assessment is available as Appendix to this statement (see Appendix B); in the following paragraphs only a summary of relevant evidence and/or information is reported.

It is noted that the specifications of chitosan and chitosan hydrochloride include polymers ranging from 10 to 1500 kDa MW and with a DD in the range of 70%–100% (see Table 3), therefore papers testing chitosan/chitosan hydrochloride with similar specifications were considered relevant in the current evaluation. In the open literature, information on chitosan oligomers with a MW < 10 kDa is also available, and this is also considered in the current assessment due to the possible degradation of longer chitosan polymers into smaller oligomers. Moreover, the PPR Panel took note that the possible presence of nanoparticles in chitosan materials, or its other derivatives, cannot be excluded. Further considerations in this regard may be addressed in the context of the other ongoing EFSA assessments on chitosan 33 (see also Section 7).

TABLE 3.

Overview of identity properties and conditions of use of chitosan and chitosan hydrochloride (European Commission, 2023a, 2023b; documentation provided to EFSA nr: 1 and 2).

| Chitosan | Chitosan hydrochloride |

|---|---|

|

Chemical structure of Poly‐d‐Glucosamine (Chitosan), shown as dimer. Picture as provided in the KitoZyme Basic Substance Application (2020). |

Chemical structure of Poly‐d‐Glucosamine Hydrochloride (Chitosan Hydrochloride), shown as dimer. Picture as provided in the ChiPro Basic Substance Application (2011). |

| Degree of deacetylation (DDA) = 70–100% |

Degree of deacetylation (DDA) = 80–95%; Degree of acetylation (DA) = 19% |

| Molecular weight (MW): 10kDa‐1500kDa |

MW = 182–207 kDa Mn 31 = 47,000 to 65,000 g/mol |

| Solubility = water must have a pH < 6 | Solubility = 100% in water leading to an acidic pH |

| Maximum concentration of chitosan in the product = 0.6 g/L. | Maximum concentration of chitosan hydrochloride in the product = 10 g/L in aqueous solution. |

Absorption, Distribution, Metabolism, Excretion (ADME)

Chitosan's systemic absorption and distribution is largely dependent on its MW, DD and on the water solubility of the polysaccharide. It is generally recognised that molecules above 1 kDa are poorly absorbed in the gastrointestinal tract and therefore are not considered to present a toxicological risk (EFSA CEF Panel, 2016).

Zeng et al. (2008) studied the absorption profiles of fluorescein isothiocyanate (FITC)‐labelled chitosans with different MW after single oral (gavage) administration of 500 mg/kg chitosan in mice (strain not reported). The absorption of chitosan increased with decreasing MW (see Table 4). Water‐soluble chitosan (WSC, MW = 39.1 kDa) is absorbed in a greater amount compared to non‐water‐soluble counterparts with similar MW (Zeng et al., 2008). The results of the study suggested that the absorbed chitosan might consist of water‐soluble small molecules that could be degraded (chemically or enzymatically) before absorption in the intestine. Computational assessment also supports that smaller and deacetylated chitosan oligomers could be better absorbed at gastrointestinal level (Roman et al., 2019); however, the scientific validity and the reliability of this study cannot be assessed due to the paucity of data reported in the publication.

TABLE 4.

Maximum plasma concentration (Cmax, mg/g) achieved after single oral administration of 500 mg/kg of chitosan (with different MW) in female mice (adapted from Zeng et al., 2008).

| Chitosan MW | C max (mg/g) |

|---|---|

| WSC 39.1 kDa | 0.28 |

| COS 0.99 kDa | 0.68 |

| MCS 32.7 kDa | 0.15 |

| HCS 760 kDa | 0.08 |

Abbreviations: COS, chitosan‐oligosaccharides; HCS, high‐MW chitosan; MCS, mid‐MW chitosan; WSC, water‐soluble chitosan.

The water solubility of chitosan depends on the pH of the solution; high‐molecular weight chitosan (HCS) almost precipitates at pH > 6.2 but could be degraded in the stomach, where hydrogen ions (H+) bind with the amino group (–NH2) forming a cationic tertiary amino group (–NH3+). Thus, chitosan becomes a soluble salt in the stomach environment where it interacts with hydrochloric acid to form a cationic gel (Ahmadi et al., 2015). These soluble chitosan molecules could be degraded by the enzymes in the upper intestine; however, macromolecules would gradually precipitate with increasing pH in the lower intestine, which makes the chitosan, especially the HCS proportion, less well degraded by the enzymes and so probably less well absorbed by the intestine. Therefore, chitosan polymers with higher molecular weights behave like other dietary fibre and are excreted unchanged in faeces (Zeng et al., 2008).

The study author reported that chitosan oligomers can be absorbed in a certain amount, and since the definition of oligomers varied between the different publications, it was not possible to precisely define MW ranges for what would be absorbed. However, overall chitosan oligomers have a MW in the range between 1 and 32 kDa.

Due to its use as a drug carrier and its uses in wound healing processes, there are different studies where the in vitro and in vivo (after intraperitoneal and intravenous administration) biotransformation of chitosan was investigated (see Appendix B). In vitro studies showed that chitosan is transformed mainly by lysozymes and other enzymes normally produced by bacteria in the colon. In mammals, chitinases hydrolyze the β‐1, 4 glycoside bonds of chitin. In humans, two distinct chitinases belonging to glycosyl hydrolase family 18 (GH18), i.e. chitotriosidase (CHIT1) and acidic mammalian chitinase (AMCase) and one belonging to the GH22, i.e. human lysozyme, have shown chitinolytic activity against chitin and chitosan polymers (Hellmann et al., 2025). It is reported that these enzymes play a major protective role against chitin/chitosan‐containing pathogens (Hellmann et al., 2025). The process of degradation provides shorter chitosan polymers and/or chitosan monomeric residues, i.e. d‐glucosamine (GlcN) and N‐acetyl‐d‐glucosamine (GlcNAc), that are quickly absorbed and distributed into other body compartments. GlcN and GlcNAc are synthesised in the body from glucose and are present at high concentrations in joint tissues, moreover they have an approved use in the treatment of osteoarthritis (Houpt et al., 1999). It is reported that glucosamine of exogenous origin is transported into cells by glucose transporters. The safety in animals and humans of this monosaccharide component: of chitosan was reviewed by Anderson et al. (2005), who concluded that the lethal dose (LD)50 in animals (rats, mice, rabbits) is ~8000 mg/kg with no adverse effects up to 2700 mg/kg bw per day when glucosamine is administered in different species, including rats, mice, dogs and rabbits, and in studies of variable duration i.e. up to 12 months. Safety concerns have not been reported in humans when the substance was administered in clinical trials.

Chitosans WSC, MCS and HCS are distributed in liver and kidney after oral administration in mice (Zeng et al., 2008) and HCS polymers accumulate in liver. Similarly, chitosan (hydrochloride) with MW > 10 kDa accumulates in liver after intravenous administration (Richardson et al., 1999).

Only one study (Chae et al., 2005) investigated the intestinal absorption of a chitosan salt i.e. chitosan lactate. FITC‐labelled water‐soluble chitosan (WSC i.e. chitosan lactate) with low MW 3.8 kDa (88.4% degree of deacetylation ‐ DD) had the greatest plasma concentration after administering 20 mg/kg chitosan lactate via oral (gavage) in Sprague Dawley rats (see Table 5). At increasing MW the plasma concentration, reflecting the intestinal absorption of the compound, decreased. In addition, the WSC transport through the CaCo2 cell layer is also dependant on the MW. Higher apparent permeability coefficient (Papp) and transepithelial electric resistance (TERR) values were measured with oligomeric forms of chitosan (WSC; MWs = 3.8 kDa and 7.5 kDa), whereas mid‐ and high‐MW chitosan (≥ 13 kDa) showed a time‐dependent reduction of TEER values. Chitosan was bound at intestinal cell surfaces, opened the cell membrane tight junctions and increased paracellular permeability. This characteristic of chitosan was also studied by Schipper et al. (1996, 1997) in the context of the intestine absorption‐enhancing properties of chitosan (chloride salt). The MW and the degree of acetylation (DA) also influenced the absorption‐enhancing properties of chitosan i.e. under the condition of Schipper's study, low DA and high‐MW seems to be necessary to increase epithelial permeability. This is because the positive charge of chitosan makes a charge interaction possible between chitosan and the negatively charged surface of the epithelial layer.

TABLE 5.

Maximum plasma concentrations (C max, μg/mL) and the areas under the curve (AUC, μg/mL h) values achieved after single oral administration of 20 mg/kg of chitosan (with different MWs) in Sprague Dawley male rats. The apparent permeability coefficient (Papp, cm/sec) is calculated after exposing human intestinal CaCo2 cells to chitosan lactate (adapted from Chae et al., 2005).

| Chitosan lactate MW | C max (μg/mL) | AUC (μg/mL h) | Papp (cm/s) |

|---|---|---|---|

| 3.8 kDa | 20.23 | 24.13 | 3.306*10−6 |

| 7.5 kDa | 9.30 | 11.55 | 1.825*10−6 |

| 13 kDa | 5.86 | 8.71 | 1.363*10−6 |

| 22 kDa | 4.32 | 5.59 | 0.870*10−6 |

| 230 kDa | < 0.5 | 0.97 | 8.290*10−8 |

Information on the ADME properties of chitosan and chitosan hydrochloride after dermal or inhalation exposure was not found in the applications, or in the subsequent literature searches. However, on the basis of information on the chemical characteristics of the substances (polymers), internal exposure through these compartments is not expected and if there was any dermal or inhalation exposure these are not expected to have an impact on the assessment based upon the oral route of exposure.

Acute toxicity

The table below reports an overview of the oral lethal dose (LD) 50 from the available studies relevant to this statement (Table 6).

TABLE 6.

Oral LD 50. Summary of the acute toxicity of chitosan, chitosan oligomers and chitosan derivatives following oral administration:

| Test item | MW | DD a | Species | LD50 | Reference b |

|---|---|---|---|---|---|

| Chitosan free, chitosan acetate, chitosan formate | N/R | N/R | Mice | 16,000 mg/kg | Arai et al. (1968) c |

| Chitosan | 350 kDa | 96.2% | SD b Rats M | 10,000 mg/kg | Zhang et al. (2012) |

| Chitosan | 309 kDa | 83% | Wistar Rats F | > 2000 mg/kg | Lagarto et al. (2015) |

| Water‐soluble chitosan | 210 kDa | 85% | SD Rats M | 10,000 mg/kg | Zhang et al. (2012) |

| Low‐molecular weight chitosan | 110 kDa | 84% | SD Rats F | > 5000 mg/kg | Chang et al. (2014) |

| Chitosan | N/R | N/R | SD Rats F | 2000 mg/kg | KitoZyme (2008) |

| Chitosan oligosaccharide | N/R | N/R | Wistar Rats F | 1500 mg/kg | Eisa et al. (2018) |

| Chitosan oligosaccharide | 1.2 and 5.3 kDa | 80–85% | Balb/c Mice M | > 1000 mg/kg | Fernandes et al. (2010) |

| Chitosan oligosaccharide | 1.86 kDa | 85% | Kunming Mice M,F | > 10,000 mg/kg | Qin et al. (2006) |

| Chitosan catechol | 50–190 kDa | N/R | Swiss albino Mice M,F | > 2000 mg/kg | Kaur et al. (2020) |

Abbreviations: F, female; M, male; N/R, not reported; SD, Sprague Dawley.

Degree of deacetylation.

Complete reference available in Appendix B.

Paper in Chinese, only abstract available in English.

For what concerns the other potential exposure routes i.e. dermal and inhalation, in the study conducted by Rao and Sharma (1997), chitosan showed no skin or eye irritating potential 34 when tested in guinea pigs and rabbits, respectively. Moreover, chitosan is used in cosmetics applications (review by Aranaz et al., 2018), in wound dressings and as a drug delivery system in the treatment of eye diseases (review by Shariatinia, 2019) and no adverse effects were reported in the recent literature (see Appendix A.1 and Appendix B). No local damage to pulmonary tissue was observed in rats after intratracheal administration of chitosan (MW: 31kDa, DD: ≥ 75%; de Jesús Valle et al., 2008) and chitosan oligomers (MW range: 0.340–96 kDa, DD: 87%–100%; Yamada et al., 2005).

Chitosan hydrochloride (MW: 160 kDa; DD% 87%) is well tolerated after topical administration onto the corneal surface of rabbits (Felt et al., 1999).

Genotoxicity

There is no indication of chromosomal aberration in the in vitro study conducted by Chang et al. (2014) (Chitosan from crab shell; MW: 1100 kDa, DD: 84%). The in vivo micronucleus assay conducted by the same authors and reported in the same paper confirmed this finding; however, it was not reported whether the bone marrow was sufficiently exposed.

Other studies conducted with low‐molecular weight chitosan (Fernandes et al., 2011), chitosan oligosaccharides (Fernandes et al., 2011; Nam et al., 2001; Qin et al., 2006; Yoon et al., 2005) and on the monosaccharide glucosamine (the monomer of chitosan) (review by Anderson et al., 2005) were already considered as part of the basic substance applications. It is noted that the absence of genotoxic potential of these compounds is considered a sufficiently conservative approach for addressing the concern for genetic toxicity of chitosan polymer with larger MW (Bolognesi et al., 2017; EFSA CEF Panel, 2016).

Developmental toxicity

In a prenatal developmental toxicity study (Cheng et al., 2013), high‐molecular weight chitosan was administered via single dose intraperitoneal injection in pregnant ICR mice at gestation day (GD) 6. In F0 dams, signs of maternal toxicity i.e. reduced body weight and food consumption, diarrhoea, vaginal bleeding and clinical adverse effects, were observed at doses above 500 mg/kg bw per day, the development of F1 and F2 animals was not affected. Statistically significant reduced numbers of live foetuses and increased number of early resorptions have been observed at 500 and 2000 mg/kg bw per day in F0 dams, in addition, also reduced body weights of F1 and F2 was observed and statistically significant at the top dose. The author concluded that the study had limitations, among which were the unclear mode of action leading to vaginal bleeding and diarrhoea in dams. Moreover, the route of exposure i.e. intraperitoneal, is not considered relevant to the current evaluation.

Repeated‐dose toxicity

Most of the repeated‐dose toxicity studies on chitosan and its salts or derivatives were aimed at evaluating the beneficial effects of chitosan, especially in animal models of hyperlipidaemia and obesity, therefore findings were limited to effects on body weight, behavioural signs, when reported, triglycerides and cholesterol levels and histopathology of mainly the liver and kidney.

In a few cases, a LOEL or LOAEL/NOAEL were identified for chitosan (see Table 7) from oral toxicity studies. No adverse effects have been reported for chitosan acetate and chitosan lactate.

TABLE 7.

Overview of NOAEL/LOAEL from oral repeated‐dose toxicity studies.

| Test item, MW, DD | Study design | NOAEL/LOAEL | Effect (as reported by the study author) | Reference a |

|---|---|---|---|---|

| Chitosan | ||||

|

Chitosan – C 309 g/mol, 83% Chitosan Acetate – CA (48.9%) Chitosan Lactate ‐ CL (57.1%) |

28‐days oral Wistar Rats/F n = 7 animals/group DOSES: C: 0, 100, 300, 1000 mg/kg bw per day CA: 0, 700 mg/kg bw per day CL: 0, 1000 mg/kg bw per day |

C: 1000 mg/kg bw per day CA and CL: N/R |

No signs of toxicity | Lagarto et al. (2015) |

| LMW Chitosan 110 kDa, 84% |

28‐days oral Wistar Rats/M‐F n = 10 animals/sex/group DOSES: 0, 0.2, 0.5, 1.0 g/kg bw per day |

1000 mg/kg bw | No signs of toxicity | Chang et al. (2014) |

|

Chitosan 82 kDa, 86.5% |

6 months oral Sprague Dawley Rats/M‐F n = 10 animals/sex/group DOSES: 0%, 1%, 3% or 9% corresponding to M/F: 450/650, 1500/1800, 5200/6000 mg chitosan/kg bw per day. |

LOEL: 450 mg/kg bw per day (M); 6000 mg/kg bw per day (F) | ↓ levels of serum vitamin A and serum and hepatic vitamin E and increased levels of serum 1,25 (OH)2 vitamin D. | NTP (2017) |

| Other test items | ||||

|

N‐acetylglucosamine MW and DD not reported |

52 and 104 weeks, oral Fisher Rat/M/F n = 10 animals/sex/group DOSES: Chronic > 0% (control), 1.25%, 2.5% or 5% equivalent to M/F: 580/647, 1159/1269, 2323/2545 mg/kg bw per day. Carcinogenic: 0; 2.5%, 5% equivalent to M/F: 964/ 1106 1935/2244 mg/kg bw per day. |

2323 (M)/2545 (F) mg/kg bw per day No carcinogenic potential was found in male and female. |

No signs of toxicity | Takahashi et al. (2009) |

| Chitosan oligosaccharide 1.86 kDa, 85% |

30‐day, oral Sprague Dawley Rat M/F (N = 10 animals/sex/group) DOSES: 0.75, 1.5, 3.0 g/kg bw per day |

No systemic toxicity up to 3.0 g/kg bw per day. | No signs of toxicity | Qin et al. (2006) |

|

Chitosan oligosaccharide < 1 kDa, DD not reported |

28‐day, oral Sprague Dawley Rat (N = 36 animals/sex) DOSES: 0, 500, 1000 and 2000 mg/kg bw per day |

NOAEL > 2000 mg/kg bw per day. | No signs of toxicity | Kim et al. (2001) |

|

OAG (oligo‐N‐acetyl‐glucosamine) < 1 kDa, DD not reported |

90‐day, oral Fisher Rat/M/F n = 10 animals/sex group DOSES: 0.2%, 1%, 5% equivalent to: not determined, 0.6411, 3.64 g/kg bw per day |

641 (M)/3640 (F) mg/kg bw per day | No signs of toxicity | Tago et al. (2007) |

|

Oligoglucosamine (OG) MW and DD not reported |

90‐day, oral Fisher F344 Rats M/F N = 20 animals/group DOSES: 0, 0.04, 0.2 or 1.0 (w/w)% equivalent to 0, 24.5/26.6, 124.0/142.0, 653.1/719.8 mg/kg bw per day |

124.0/142.0 mg/kg bw per day 653.1/719.8 mg/kg bw per day |

↑ plasma creatinine, proteinuria, abnormal testes. Additionally, several changes due to systemic malnutrition | Naito et al. (2007) |

|

Chitosan oligomers 5 kDa, > 90% |

50d, oral C57BL/6 male mice N = 15 animals/group DOSES: 0, 20, 100, 500 mg/kg bw/day |

// | No systemic toxicity up to 500 mg/kg bw per day | Mattaveewong et al. (2016) |

|

N‐acetylglucosamine (GlcNAc); MW and DD not reported |

90‐days, oral F344/DuCrj rats (n = 10 animals/sex/group) DOSES: M/F:: 0, 301.7/350.9, 587.8/694.9, 1218.0/1412.1, 2475.6/2833.6 mg/kg bw per day |

2476 and 2834 mg/kg bw per day for male and female rats | No signs of toxicity | Lee et al. (2004) |

complete reference available in Appendix B.

Repeated‐dose toxicity studies were also available on chitin‐glucan and chitin/chitosan oligosaccharides, showing no or low toxicity for chitosan oligosaccharides. Only in one oral toxicity study in Fischer F344 Rats (Naito et al., 2007), conducted with oligoglucosamine (i.e. chitosan oligosaccharide) (permitted as Food Additive in Japan 35 ), were increased plasma creatinine, proteinuria and abnormal testes reported; changes due to systemic malnutrition were also reported, with a decrease of 36% of body weight at the highest dose tested. Therefore, clinical chemistry and testicular effects are considered secondary to the poor systemic condition and not the expression of target organ toxicity.

In the study by Minami et al., 1996, mongrel dogs exposed via the subcutaneous route to chitosan (mean particle size 5 μm) suffered from severe pneumonia symptoms; the correlation between chitosan exposure and the observed effect was not clearly investigated in the study and a number of flaws were identified in the study i.e. local effects at the injection site were not reported and this could have been relevant for the systemic response of the animals (clinical chemistry and haematology). Therefore, this repeated‐dose toxicity study conducted via subcutaneous (Minami et al., 1996) route of administration was not considered relevant for the current evaluation.

Human studies

Although the main aim of the available studies in humans was to investigate the efficacy of chitosan as a dietary supplement to improve weight loss and reduce cholesterol levels, there was no evidence of adversities when chitosan was administered as a dietary supplement up to 6.75 g/day in a healthy population and up to 3 g/day in subjects with clinical conditions associated with obesity (e.g. hypercholesterolemia, hyperlipidaemia, type 2 diabetes) (see Appendix B). In the available studies (n = 28, see Appendix B) the test item was always referred to as chitosan, and there is no information on whether a salt had been used.

It is noted that chitosan and its salts, including hydrochloride, due to their absorption‐enhancing properties, are widely used as drug carriers in different medical treatments without safety concerns having been reported in pharmacovigilance. In addition, chitosan is subject to ongoing evaluations as a novel food 36 and food additive, 37 and it is frequently consumed as a dietary supplement.

Other studies– In vitro toxicity and allergenicity

In vitro toxicity

Chitosan and chitosan salts are used in biomedical applications, therefore there are several studies that have evaluated cell viability as an initial screening test for biocompatibility.

The toxicity of chitosan and its derivates (chitosan oligosaccharides and chitosan salts) on different cell types from mice (i.e. murine melanoma cell line – B16F10 and murine macrophages cell lines – RAW 264.7 and J774), chicken (i.e. ganglion neurons) and humans (i.e. immortalised cell line of human colorectal adenocarcinoma (CaCo2), human embryonic lung (L132), human lung cancer (A549), human lymphoblastic leukaemia (CCRF‐CEM), human pancreatic carcinoma (COLO‐357), human kidney carcinoma (KCC853)) was investigated in a number of studies. Also, studies on the effect of chitosan on cell morphology (in CaCo2 cells) and haemocompatibility properties of chitosan (red blood cells (RBC) from rats) were available.

The available studies underlined that the toxic effect of chitosan on the cells is highly dependent on the concentration of chitosan used, on its MW, on its deacetylation degree (DD) and finally on the salt form, modifications or derivatives. From the available in vitro evidence, Carreno‐Gomez and Duncan (1997) found chitosan hydrochloride salt to be cytotoxic (inhibitory concentration (IC50) 0.21 ± 0.04 mg/mL) against B16F10 (murine melanoma) cells. All the chitosan salts tested (chitosan hydrochloride CL110 and CL210, chitosan hydroglutamate G110, and G210 and chitosan hydrolactate L110 and L210) caused/showed concentration‐dependent cytotoxicity. Chitosan cytotoxicity could be ranked in the order as follows: chitosan hydrochloride > hydroglutamate > glycol chitosan > hydrolactate. Polymer MW also influenced the cytotoxicity, and all chitosans that had MW of > 100 kDa were more cytotoxic towards B16F10 cells. When tested on red blood cells, all the chitosans had a lytic effect in a time‐ and molecular weight‐dependent manner. At 1 h, relatively little lysis was seen, except for the hydroglutamate chitosans, G 110 (75% lysis), G 210 (60% lysis) and hydrochloride CL210 (12%). However, this study appears to have used solutions of the chitosan salts at the pH formed when dissolved, for chitosan hydrochloride in phosphate buffered saline (PBS) (10 mg/mL), pH = 5.8. At this pH the 3‐[4,5‐dimethylthiazol‐2‐yl]‐2,5‐diphenyl tetrazolium bromide (MTT) assay is not appropriate, and cell viability is compromised (reviewed by Kean & Thanou, 2010).

Richardson et al. (1999) found chitosan (probably chitosan hydrochloride, as reported in one picture but not confirmed in the text) of low MW to be slightly cytotoxic against CCRF‐CEM and L132 cells (IC50 > 1 mg/mL). However, chitosan is not haemolytic (15% lysis after 1 and 5 h).

According to Schipper et al. (1996), the toxicity of chitosan chloride salts appears to be related to the positive charge density of the polymer, and this is in line with the well‐known cell lytic and toxic properties of cationic polymers such as poly‐L lysine. In fact, the results of the study showed that the higher the MW (large molecule with high charge density) and the lower the DA, the more toxic chitosan is to cells (CaCo2 cells). The IC50 was not calculated by the authors; however, from the graphical representation (Figure 2 in Schipper et al., 1996), it seems that enzyme activity decreases by 50% when cells are treated with chitosan chloride salt concentrations between 0.01 and 0.1 mg/mL. Chitosans with low degree of acetylation (DA) (1%) also lead to change in number of microvilli and organisation of the terminal web. However, it has to be noted that the test system does not fully represent physiological conditions, i.e. the absence of mucus on the gastrointestinal epithelium, that could be relevant for the biological and/or toxicological effects of chitosan (binding to mucus may be important).

FIGURE 2.

Chitosan chemical structure (CAS number: 9012‐76‐4).

Chae et al. (2005) showed that CaCo2 cell viability is highly dependent on the concentration and on the MW of chitosan (WSC = Chitosan Lactate). With increasing concentrations of chitosan lactate, the cytotoxic effect is affected by the MW. EC50 (effective concentration for 50% cell viability) values of each chitosan were evaluated. EC50 of 3.2 and 4.5 mg/mL were measured after treating CaCo2 cells with high and middle MW water‐soluble chitosan, respectively (i.e. 230 kDa and 22 kDa).

A comprehensive overview of the IC50 of chitosan, chitosan salts and chitosan derivatives was reported in the review by Kean and Thanou (2010) (Table 8). It has to be noted that a number of studies were not submitted as part of the basic substance applications. Among these, the study by Opanasopit et al. (2007) investigating the cytotoxic effect of different chitosan salts, including chitosan hydrochloride, on CaCo2 cells. The results reported by Opanasopit are in line with the ones from Carreno‐Gomez and Duncan (1997); chitosan hydrochloride has higher cytotoxicity compared to the other salts with an IC50 of 0.22 ± 0.06 mg/mL (for chitosan hydrochloride with MW 45 kDa).

TABLE 8.

Summary of cytotoxicity (IC50) of chitosan and chitosan derivatives to different cells (adapted from Kean & Thanou, 2010).

| Chitosan details (DD, MW) | Modification | Assessment | IC50 | Reference |

|---|---|---|---|---|

| 95% DD, 18.7 kDa | Steric acid conjugation micelle | In vitro, A549 cells | 369 ± 27 μg/mL | Ye, Y. Q., Chen, F. Y., Wu, Q. A., Hu, F. Q., Du, Y. Z., Yuan, H., and Yu, H. Y. (2009). Enhanced cytotoxicity of core modified chitosan‐based polymeric micelles for doxorubicin delivery, Journal of Pharmacology Science, 98, 704–712. |

| 95% DD, 18.7 kDa | Steric acid conjugation and entrapment in micelle | In vitro, A549 cells | 234 ± 9 μg/mL | |

| 97% DD, 65 kDa | N‐octyl‐O‐sulfate | In vitro, primary rat hepatocytes | > 200 mg/mL | Zhang, C., Qu, G., Sun, Y., Yang, T., Yao, Z., Shen, W., Shen, Z., Ding, Q., Zhou, H., and Ping, Q. (2008). Biological evaluation of n‐octyl‐o‐sulfate chitosan as a new nano‐carrier of intravenous drugs. European Journal of Pharmacology Science, 33, 415–423. |

| 87% DD, 20, 45, 200, 460 kDa | None, aspartic acid salt | In vitro, Caco‐2 cells, pH 6.2 | 0.67 ± 0.24, 0.61 ± 0.10, 0.65 ± 0.20, 0.72 ± 0.16 mg/mL | Opanasopit, P., Aumklad, P., Kowapradit, J., Ngawhiranpat, J., Apirakaramwong, A., Rojanarata, T., and Puttipipatkhachorn, S. (2007). Effect of salt forms and molecular weight of chitosans on in vitro permeability enhancement in intestinal epithelial cells (caco‐2), Pharmaceutical Development & Technology, 12, 447–455. |

| 87% DD, 20, 45, 200, 460 kDa | None, glutamic acid salt | 0.56 ± 0.10, 0.48 ± 0.07, 0.35 ± 0.06,0.46 ± 0.06 mg/mL | ||

| 87% DD, 20, 45, 200, 460 kDa | None, Lactic acid salt | 0.38 ± 0.13, 0.31 ± 0.06, 0.34 ± 0.04, 0.37 ± 0.08 mg/mL | ||

| 87% DD, 20, 45, 200, 460 kDa | None, hydrochloride salt | 0.23 ± 0.13, 0.22 ± 0.06, 0.27 ± 0.08, 0.23 ± 0.08 mg/mL | ||

| 78% DD, < 50 kDa | None, lactic acid salt | In vitro B16F10 cells | 2.50 mg/mL | Carreño‐Gómez, B., and Duncan, R. (1997). Evaluation of the biological properties of soluble chitosan and chitosan microspheres. International Journal of Pharmaceutics, 148, 231–240. |

| 82% DD, 150–170 kDa | None, lactic acid salt | In vitro B16F10 cells | 2.00 ± 0.18 mg/mL | |

| > 80% DD, 60–90 kDa | None, glutamic acid salt | In vitro B16F10 cells | 2.47 ± 0.14 mg/mL | |

| 77% DD, 180–230 kDa | None, lactic acid salt | In vitro B16F10 cells | 1.73 ± 1.39 mg/mL | |

| 85% DD, 60–90 kDa | None, hydrochloric acid salt | In vitro B16F10 cells | 2.24 ± 0.16 mg/mL | |

| 81% DD, 100–130 kDa | None, hydrochloric acid salt | In vitro B16F10 cells | 0.21 ± 0.04 mg/mL | |

| 100% DD, 152 kDa | Glycol chitosan | In vitro B16F10 cells | 2.47 ± 0.15 mg/mL | |

| 100% DD, 3–6 kDa | 20, 44, 55% Trimethyl chitosan, chloride salt | In vitro, MCF7 and COS7 cells, 6 and 24 h | > 10 mg/mL | Kean, T., Roth, S., and Thanou, M. (2005). Trimethylated chitosans as non‐viral gene delivery vectors: Cytotoxicity and transfection efficiency. Journal of Control Release, 103, 643–653. |

| 100% DD, 3–6 kDa | 94% Trimethyl chitosan, chloride salt | In vitro, MCF7, 6 h | 1.402 ± 0.210 mg/mL | |

| 100% DD, 3–6 kDa | 94% Trimethyl chitosan, chloride salt | In vitro, COS7, 6 h | 2.207 ± 0.381 mg/mL | |

| 100% DD, 100 kDa | 36% Trimethyl chitosan, chloride salt | In vitro, MCF7, 6 h | 0.823 ± 0.324 mg/mL | |

| 100% DD, 100 kDa | 36% Trimethyl chitosan, chloride salt | In vitro, COS7, 6 h | > 10 mg/mL | |

| 84.7% DD, 400, 100, 50, 25,5 kDa | 40% Trimethyl chitosan | In vitro, L929 cells, 3 h | 30, 70, 90, 270, > 1000 μg/mL | Mao, S., Shuai, X., Unger, F., Wittmar, M., Xie, M., and Kissel, T. (2005). Synthesis, characterisation and cytotoxicity of poly(ethylene glycol)‐graft‐trimethyl chitosan block copolymers, Biomaterials, 26, 6343–6356. |

| 84.7% DD, 1.89 MDa | 12% PEG modified 40% trimethyl chitosan | In vitro, L929 cells, 3 h | 220 μg/mL | |

| 84.7% DD, 3.6 MDa | 25.7% PEG modified 40% trimethyl chitosan | In vitro, L929 cells, 3 h | 370 μg/mL | |

| 84.7% DD, 300 kDa | 6.44% PEG modified 40% trimethyl chitosan (and all PEG modified TMC with lower M w) | In vitro, L929 cells, 3 h | > 500 μg/mL | |

| 97% DD, 65 kDa | N‐octyl‐O‐sulfate | In vivo, IV, mice | 102.59 mg/kg | Zhang, C., Qu, G., Sun, Y., Yang, T., Yao, Z., Shen, W., Shen, Z., Ding, Q., Zhou, H., Ping, Q. (2008). Biological evaluation of n‐octyl‐o‐sulfate chitosan as a new nano‐carrier of intravenous drugs. European Journal of Pharmaceutical Sciences, 33, 415–423. |

| 97% DD, 65 kDa | N‐octyl‐O‐sulfate | In vivo, IP, mice | 130.53 mg/kg |

Zubareva et al. (2017), showed that unmodified chitosan is slightly toxic (5%–10% at 100 μg/mL) to cells compared to the quaternised chitosan. The cytotoxicity of chitosan (2% w/v in 6% v/v CH3COOH, 100 mL) on A549 Cells was investigated by Huang et al. (2004), who reported that cell viability (A549 Cells) was not affected at concentration lower than 0.741 mg/mL. Wiegand et al. (2010) found that chitosan (MW: 120 kDa, DD: 85%, source and manufacturing process not reported) and chitosan oligosaccharide lactate (MW: 5 kDa, DD: > 90%) caused MW‐dependent cytotoxicity, measured as intracellular ATP content, on human keratinocytes when tested in vitro (at 0.5% and 1% w/v), no positive control was included in the study.

Allergenicity

Chitosan and chitosan hydrochloride are not included in the list of substances or products causing allergies or intolerances (Annex II, Regulation (EU) No 1169/2011); however, since chitosan may derive from sources included in the list (e.g. crustaceans), a dedicated chapter has been included in the current evaluation.

Chitosan is unlikely to pose allergenicity concerns when industrially processed, provided that all animal proteins are removed during extraction and purification processes. The manufacturing process, involving demineralisation with hydrochloric acid, protein removal with sodium hydroxide and extraction with organic solvents is considered effective in removing or denaturing proteins, fats and other potentially allergenic or toxic contaminants (US EPA, 2019). Since strong acid/alkali are used to obtain chitosan from chitin, it is reasonable to assume that no protein will remain that can induce an allergenic reaction.

While there has been research into other methods of manufacturing chitosan, this process is understood to be the industry standard and other methods have not been shown to be viable on the scale required to produce chitosan at its current level of demand.

Waibel et al. (2011) investigated the safety of ‘HemCon®’ bandages that were introduced in 2005 for US soldiers. Patients who reported shellfish allergy were recruited. Initial assessment included a detailed history, IgE skin prick testing (SPT) and serum testing to shellfish allergens. Participants who demonstrated specific shellfish IgE underwent a bandage challenge. It was reported that of the 19 participants who were enrolled, 10 completed the study. No participant had a positive SPT to chitosan powder or experienced an adverse reaction during bandage challenges (Waibel et al., 2011).

5.4. Environmental fate and behaviour