Abstract

Cement is a globally produced building material and a crucial component of every construction project. Alternative materials, mostly agro-industrial wastes, are emerging as potential cement replacements due to high carbon dioxide emissions associated with cement manufacturing and rising cost of cement. Numerous naturally occurring materials like rice husk ash, corn cob ash, fly ash, slag, silica fume, bagasse ash (BA), and natural pozzolans are used as partial substituents for cement in concrete and mortars due to their strength, cost-effectiveness, and environmental benefits. BA is frequently used as a partial cement replacement in concrete, but most studies limit its utilization to 15%, highlighting the limitations of pozzolanic materials. This study investigates the effects of binary blended BA and calcined dolomite powder (CDP) as partial cement replacement, i.e., 0%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, and 50%, on the compressive strength of C-25 grade concrete. Additionally, the physicochemical properties of BA, CDP, and the binary mixture were studied using X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscope (SEM), X-ray fluorescence (XRF), and dynamic light scattering (DLS). Furthermore, the effects of the binary mixture on workability, setting time, compressive strength, strength activity index (SAI), water absorption, and dry density on the concrete were evaluated in detail. The compressive strength was examined by casting 66 standard cubes of 15 cm  15 cm

15 cm  15 cm size and curing them for 7 and 28 days. The compressive strength test indicates that by reducing pozzolana particle size below cement grade and blending BA with CDP, up to 30% of cement can be replaced by enhancing the compressive strength to 36.7 MPa at the end of 28 days.

15 cm size and curing them for 7 and 28 days. The compressive strength test indicates that by reducing pozzolana particle size below cement grade and blending BA with CDP, up to 30% of cement can be replaced by enhancing the compressive strength to 36.7 MPa at the end of 28 days.

Keywords: Bagasse ash, Pazzolona, Calcined dolomite, C-25 grade concrete, Compressive strength, Partial replacement

Subject terms: Materials science, Nanoscience and technology

Introduction

Concrete, a widely used construction material globally, is experiencing a significant increase in demand due to population growth, urban expansion, and infrastructure development. A significant revolution in the cement and concrete industry is needed for sustainable growth and environmental protection, particularly in reducing carbon dioxide (CO2) emissions 1. Cement is a chemical compound utilized in construction as a binder, forming bonds between materials through setting, hardening, and binding 2. Cement manufacturing contributes significantly to global environmental concerns, emitting 5–10% of CO2 and consuming up to 80% of power. Studies explore alternative waste materials to cement for CO2 reduction, highlighting the cost-effective and environmentally responsible disposal of waste in the construction industry 3. The construction sector faces threats from rising energy production prices, lower CO2 discharges, and poor-quality components, necessitating sustainable solutions to reduce environmental impact. It is crucial to explore eco-type cementations materials to replace or partially replace cement to decrease energy consumption and CO2 emissions. The need for environmentally friendly energy-building materials has led to extensive research into alternative materials that can mitigate the environmental impact of cement 4–6. Researchers have demonstrated the significance of agro-waste ash in achieving high-strength concrete by partially replacing 10–30% of cement with agro-wastes 2. Natural materials like limestone powder, marble dust, rice husk ash, corn cob ash, fly ash, slag, silica fume, bagasse ash, and natural pozzolans are partially replacing cement in concrete and mortars 7. Raj Bhosale et al. 8 studied the strength of rice husk ash and BA as partial cement replacements. They found that using 20% RHA and 20% BA, or 40%, provides the highest compressive strength. Mostafa Shaaban 5 study on a binary binder system containing calcined dolomite powder and rice husk ash found that CDP-RHA had superior mechanical properties than OPC, with a mixture containing 50% CDP and 50% RHA being optimal. Muliye Tarekegn et al. 9 conducted a study on concrete made from hybrid coffee husk ash and sugarcane bagasse ash, finding that up to 10% of the ash had superior compressive and tensile strength, thereby reducing construction costs and environmental pollution.

Bagasse ash (BA)

Sugarcane (Saccharum spp. hybrid) is a monocotyledonous crop cultivated in tropical and subtropical regions, is crucial for sugar production, bioenergy, and other derivatives. Its ability to store a high concentration of sucrose in its stem internodes makes it a significant industrial crop 10. Brazil leads the world in sugarcane production, with annual crop yields of 814.9 million tons, followed by India at 376.1 million tons and China at 138.3 million tons 11,12. In Ethiopia, the sugar industry utilizes only sugarcane and has significantly contributes to the country’s socio-economic development. Although the crop is not native to Ethiopia, it was grown in some parts of the country even before large-scale commercial plantations and the establishment of a modern sugar factory at Wonji-Shoa, Metahara, Finchaa, Tendaho, Arjo-Dedessa, and Kessem primarily for local consumption 10,13,14. On average, these companies produce 893,270 tons of sugarcane bagasse annually 15. Sugarcane bagasse (SCB), a fibrous by-product of refined sugarcane juice extraction, is utilized as a raw material for paper manufacturing. BA is a potential pozzolanic material that is a byproduct of sugar and alcohol production, is a silica-rich, readily available substance produced by calcining SCB 16. However, currently, bagasse is primarily utilized as a fuel propellant in cogeneration boilers for steam production and energy in sugar mills for sugarcane juice processing, typically burned at 500-550 °C for maximum calorific value 17. BA demonstrated superior reactivity in pozzolanic assessment tests due to its larger specific surface area, higher amorphous content, smaller particle size dispersion, and lower quartz contamination 18. Pozzolanas are naturally occurring materials composed of a very fine dispersion of aluminous and siliceous compounds, in the presence of water that react with Ca (OH)2 to form cementation materials 19–22. Numerous studies have explored the use of low-cost, agro-industrial waste and green materials to partially replace cement in the construction industry, with BA up to 10% providing the highest compressive strength value 17–19. The major reason for this limited percent replacement is primarily due to its chemical composition, which consists mainly of alumina and silica, but minimal calcium oxide 23.

Dolomite powder

Dolomite is a rock-forming mineral composed of calcium and magnesium carbonate, with a theoretical percentage of 45.7 MgCO3 and 54.3 CaCO3, making it a double carbonate 24,25. The pure dolomite powder undergoes calcination to create calcined dolomite, which is then broken down into calcium oxide (CaO) and magnesium oxide (MgO) components. In 2016, Guillaume Jauffret studied the addition of pozzolanic elements to Portland cement using thermally activated dolomite, substituting half-burned dolomite powder for 20-25% of cement and conducting a compressive strength test after 28 days. The highest compressive strength values were achieved at a substitution level of 10-15 mass% half-burned dolomite 26,27. However, before blending and partially replacing cement, BA and CDP must be fine and homogeneous to meet industry requirements 28. The optimal use of grinding and classifying equipment in mortar and concrete necessitates proper operation and regulation before they can be added to cement for optimal performance 29. This work involved grinding BA and CDP using a ball miller, controlling ball diameter and time, to produce ultrafine powder. Grinding increases powder particle surface area and reactivity, as materials are more reactive in their divided state. The pozzolanic reaction is enhanced when BA has an ultrafine particle size distribution 30–32. Therefore, this study examines the effects of binary blended BA and CDP on the compressive strength of C-25 grade concrete. Additionally, the physicochemical characteristics of BA, CDP, and its mixture were characterized by using XRD, FTIR, SEM, XRF, and DLS techniques. Furthermore, the effects of the binary mixture on workability, setting time, compressive strength, strength activity index (SAI), water absorption, and dry density on the concrete were examined in detail.

Novelty

Previous studies have examined the individual effects of BA and CDP as partial cement replacements, highlighting their significant contributions to the field. This research investigates the effects of adding binary blended BA and CDP as a partial substitution of cement on the compressive strength of C-25 grade concrete. Furthermore, this research utilized prolonged grinding to achieve nano-sized particles, enhancing pozzolanic performance. Dynamic light scattering analysis confirmed polydispersed particles, mostly within the nano-range. In addition to that, this study demonstrates the potential to replace cement by up to 30%, reducing cement consumption and carbon dioxide (CO2) emissions, contributing to its nobility.

Materials and methods

Materials

Bagasse’s ash (BA)

In this study, SCB was collected from the Metehara sugar factory located in the Oromia region, about 200 km away from Addis Ababa, Ethiopia. The density of BA was 1.98 gcm-3.

Dolomite

Dolomite powder (DP) was brought from Dan and Friends dolomite manufacturing factory, which was located in Addis Ababa, Ethiopia. The DP from the factory has particles passing through a 25 μm sieve. The density of the row DP used in this research was 2.68 gcm-3.

Coarse aggregate

This study uses locally accessible coarse aggregates with a maximum size of 20 mm and minimum size of 10 mm, following IS 383-1970 for testing. The 20 mm aggregates were filtered using a 20 mm sieve, and after removing dust and debris, they were cleaned and dried. The physical properties of course aggregate was illustrated in Table 1.

Table 1.

Physical property of course aggregate.

| No | Characteristic | Value |

|---|---|---|

| 1 | Type | Crushed |

| 2 | Maximum size | 20 mm |

| 3 | Minimum size | 10 mm |

| 3 | Specific gravity | 2.71 |

| 4 | Total water absorption | 0.48% |

Fine aggregate

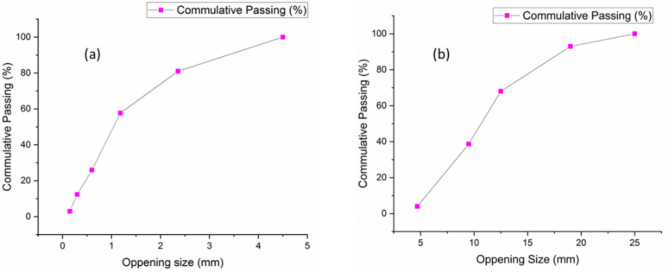

Fine aggregates comprise materials like clay, silt, and sand. The experiment utilized locally obtained sand that met IS 383-1970’s Zone-I grading standards. After cleaning, it was filtered through a 4.75 mm screen to remove larger particles, and dried until moisture was lost. Table 2 provides information on the physical properties of fine aggregate. Furthermore, the gradation graph of fine and coarse aggregate was depicted in Fig. 1a, b.

Table 2.

Physical property of fine aggregate.

| No | Characteristic | Values |

|---|---|---|

| 1 | Type | Natural |

| 2 | Specific gravity | 2.5 |

| 3 | Water absorption | 0.9% |

| 4 | Fiennes modules | 2.71 |

Fig. 1.

Gradation graph of (a) fine and (b) coarse aggregates.

Cement

The control specimens in this study were made using regular Portland cement (ASTM C150 Type I). OPC Mosobo Grade 43.

Water

Concrete cylinders were mixed and cured using water (a drinkable liquid) that was available at the campus laboratory.

Experimental study

Preparation of BA

The raw sugarcane bagasse (SCB) collected from the factory was burned in a furnace at 600 °C for 1 h to produce ash, which contains a large amount of amorphous silica with pozzolanic characteristics as shown in Fig. 2. The burned BA was ground into ultrafine particles using a ball miller, and then sieved through 300 μm sieves to separate it from other solid particles. BA, with particle sizes ranging from 0 to 100 μm, was milled using a laboratory planetary ball miller and carbon steel balls with varying diameters with a fixed milling time of 78 min 33. The ball size included 15 , 12

, 12 , 10

, 10 , 5

, 5 , and 0.75

, and 0.75 . The planetary ball miller’s speed was set at 350 rpm.

. The planetary ball miller’s speed was set at 350 rpm.

Fig. 2.

Sample preparation of bagasse ash.

Preparation of CDP

Dolomite was calcined at 925 °C for 6 h to break down into magnesium oxide (MgO) and calcium oxide (CaO) components (Fig. 3)25. After calcination, it was grinded using a planetary ball miller for 39 min to achieve a uniform particle size. The process occurs in a CO2 containing atmosphere, with magnesite breaking down at 770 °C and calcite breaking down at 915 °C 34,35. The calcination process was shown in Eqs. (1–3):

|

1 |

|

2 |

|

3 |

Fig. 3.

Calcination of dolomite powder at 925 °C.

Blending of BA and CDP

After carefully preparing, two samples of BA and CDP were blended and grinded in a ball miller for 10 min to form uniformity, with blending performed at 75% BA and 25% CDP by volume.

Concrete mix design

Concrete properties depend on many factors, such as cement, water, aggregate volume, batching, mixing, placing, compacting, and curing 36. This study followed the Indian standard (IS 10262 -1982) in designing the mix for C-25 grade concrete with the aforementioned parameters. A C-25 grade concrete mix was developed without BA and CDP, and BA and CDP were added to replace 5, 10, 15, 20, 25, 30, 35, 40, 45, and 50% of cement, respectively. The total number of cubic samples prepared for the 7th and 28th days compressive strength was 66, with 3 cubes for a single test. The mixing ratio for C-25 grade concrete was 1:1:2 in nominal volumetric mix ratio, with a constant water-cement ratio of 0.5, as shown in Table 3 37.

Table 3.

Concrete mix design of partial replacement of cement by 5% increment of (SBA/CDP) binary mixtures.

| Type | Cement (kg m− 3) | SBA/CDP (kg m− 3) | Water (kg m− 3) | Fine aggregate (kg m− 3) | Coarse aggregate (kg m− 3) |

|---|---|---|---|---|---|

| 100% OPC | 341 | 0 | 171 | 648 | 1057 |

| 95% OPC/5% (BA/CDP) | 323 | 17 | 171 | 614 | 1001 |

| 90% OPC/10% (BA/CDP) | 306 | 34 | 171 | 581 | 949 |

| 85% OPC/15% (BA/CDP) | 289 | 51 | 171 | 549 | 896 |

| 80%OPC/20% (BA/CDP) | 272 | 68 | 171 | 517 | 843 |

| 75%OPC/25% (BA/CDP) | 255 | 85 | 171 | 485 | 791 |

| 70% OPC/30% (BA/CDP) | 238 | 102 | 171 | 452 | 738 |

| 65% OPC/35% (BA/CDP) | 221 | 119 | 171 | 420 | 685 |

| 60%OPC/40% (BA/CDP) | 204 | 136 | 171 | 388 | 632 |

| 55%OPC/45% (BA/CDP) | 187 | 153 | 171 | 355 | 580 |

| 50%OPC/50% (BA/CDP) | 170 | 170 | 171 | 323 | 527 |

Concrete casting

After concrete mix design, different C-25-grade 43 concerts of size 15 cm × 15 cm × 15 cm were prepared by casting. Each concrete mix have different cement replacement ratios. 11 different C25 grade 43 concrete mixtures were cast, of which one was 100% OPC as a controlled group. While preparing the concrete mixture and casting, the slump test was also performed in order to check the workability of the samples. After soaking the concrete in a water bath, a compressive strength test was performed on the 7th and 28th days.

Characterization technique

The crystalline size and phases of BA, CDP, and binary mixture was recorded by X-ray diffraction (Drawell XRD-7000, China) with CuKα radiations (λ = 1.54 Å) at a scanning speed 0.02° s− 1 in 2θ range of 10 to 80° under 30 kV and 25 mA. The functional groups were determined by Fourier transform infrared spectrometer (FTIR, PerkinElmer, spectrum two, USA) in KBr pellet method in the 4000-400 cm− 1 with a resolution of 4 cm− 1. The chemical composition was examined using X-ray Fluorescence (XRF). The size distribution and polydispersity index (PDI) were measured by dynamic light scattering (DLS) analysis using Nano S (Malvern Instruments, UK).

Results and discussions

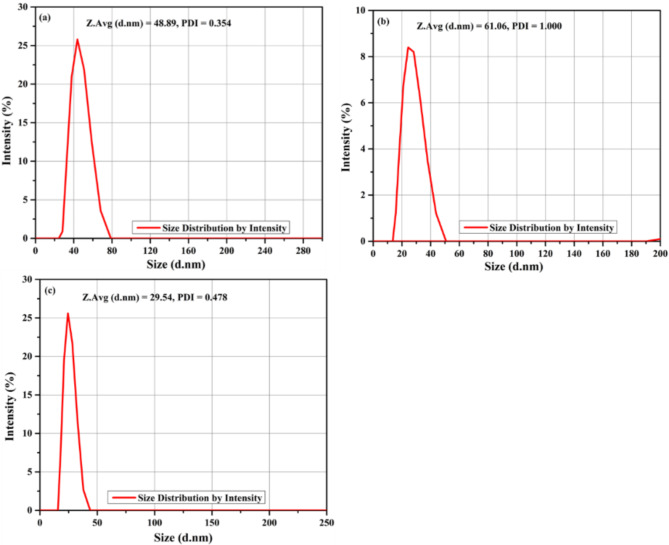

DLS analysis

Particle size distribution (PSD) is a crucial physical property influencing the reactivity of pozzolanic materials in concrete mixes, with larger and finer particles generally increasing mix reactivity, thereby optimizing concrete pore structure. Hence, the filling effect of pozzolanic particles has reduced the void between cement and aggregate particles, resulting in improved density and strength 38. The PSD of BA, CDP, and a binary mixture were depicted in Fig. 4a-c. The average PSD of CDP was 61.06 nm after fine grinding (Fig. 4a), while the average particle size of BA (Fig. 4b) and their binary mixture (Fig. 4c) was 48.89 nm and 29.54 nm, respectively. Therefore, the result revealed that the pozzolanic activity of grined powders were directly linked to its fineness, with BA and CDP exhibiting good pozzolanic activity 39–42.

Fig. 4.

DLS analysis of (a) bagasse ash, (b) calcined dolomite powder and (c) mixture of BA and CDP.

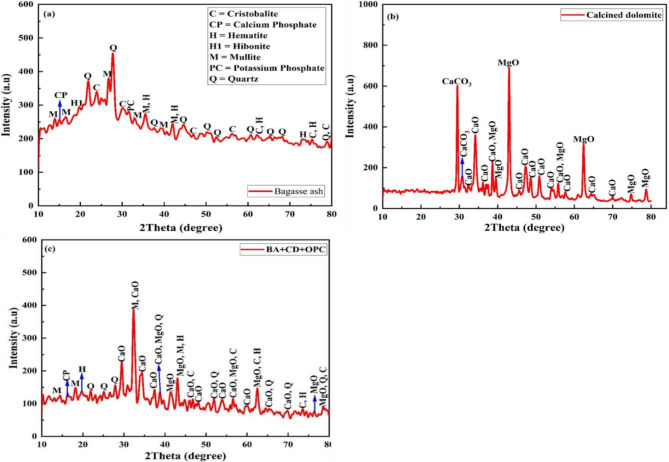

XRD analysis

XRD was used to analyze the crystallographic properties of BA and CDP, as shown in Fig. 5a-c. The diffraction pattern of BA was depicted in Fig. 5a. The diffraction peaks of BA were identified as quartz and cristobalite at 2θ values of 20.21 (4.44Å), 22.30 (3.98 Å), 28.10 (3.16Å), 44.98 (2.03Å), 51.27 (1.78Å), 66.81(1.39Å), 25.28 (3.49Å), 30.40 (2.91Å), and 57.15 (1.61Å), respectively. BA has a high concentration of quartz and cristobalite silica, as indicated by the intensity of phase diffraction peaks, which were proportional to the concentration of the component producing it. The oxide composition of BA consists of a cumulative sum of silicon, alumina, and iron oxides, respectively, meeting the chemical requirement of pozzolan as per ASTM standard C618 43–46. On the other hand, XRD pattern of CDP (Fig. 5b) shows sharp picks primarily linked to the presence of CaO and MgO 47,48. The XRD pattern of a binary blended mixture revealed the chemical compositions of both BA and CDP, which indicate successfully nixed as a binary system and demonstrated in Fig. 6c.

Fig. 5.

XRD analysis of (a) bagasse ash, (b) calcined dolomite, (c) mixture of BA,CDP andOPC.

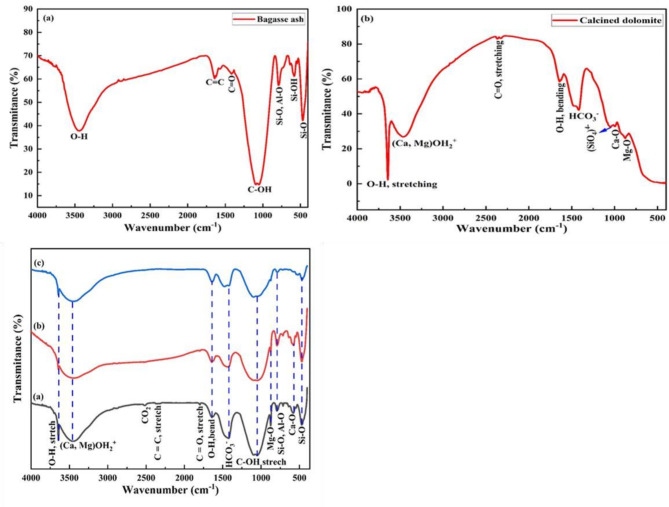

Fig. 6.

FTIR analysis of (a) bagasse ash (b) calcined dolomite powder (c) mixture of BA, CDP and OPC.

Fourier transform infrared analysis (FTIR)

Fig. 6a-c shows the FTIR spectra of BA, CDP, and their ternary mixtures. Fig. 6a depicts the FTIR spectrum of BA. The broad peaks at 3447 cm−1 and a strong absorption band between 500 and 1400 cm−1 correspond to OH and Si-O symmetric stretching vibration. The SiO₄ symmetric stretching vibration was observed at 820 cm−1 and 620 cm−1, with the lowest bending mode at 500 cm−1. The peak at 1100 cm−1 revealed the tetrahedral asymmetric stretching vibration of quartz crystal, as reported by previous work 49–52. The absorption peaks observed in CDP were displayed in Fig. 6b. The peak at around 550 cm−1 was due to MgO stretching vibration, while the absorption bands observed at 720 cm−1, 870 cm−1, and 1420 cm−1 were due to CaO stretching bonds, and 820 cm−1 peaking due to silica impurity. Fig. 6c depicts the presence of various functional groups in the mixture of BA, CDP, and OPC. Water bond (O-H stretching and bending) with hydrated gels of the BA/CDP-OPC reaction was observed at a broad absorption band of around 3460 cm−1 and a weak band of 1640 cm−1. The O-H broad absorption band intensity of the mixture was found to be lower and broader than BA and CDP due to increased gel formation.

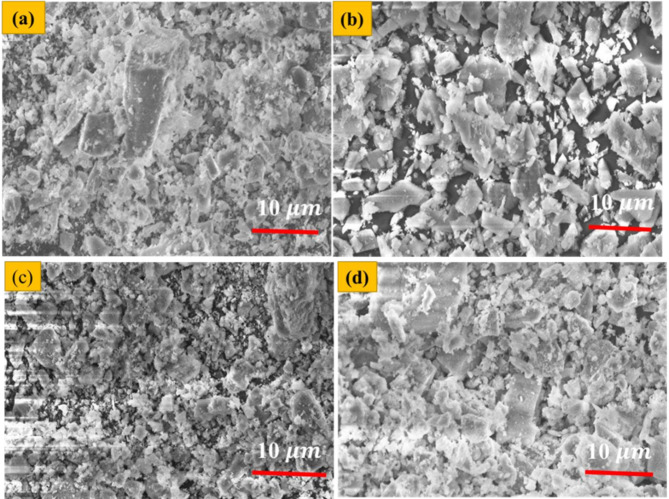

SEM analysis

Fig. 7a-d displays SEM images of BA, CDP, binary mixture of BA and CDP, and tertiary mixture of BA, CDP, and OPC. SEM micrographs of BA showed agglomerated, tubular, prismatic, spherical, irregular, porous, and fibrous particles with various shapes (Fig. 7a). The study reveals that the regular shaped particles of BA were silica-rich and have similar morphological features to those reported in the literature regarding their pozzolanic activity 53. The silica and alumina present in the BA will react with calcium hydroxide from cement hydration in order to produce additional set of calcium silicate hydrate (Ca-Si-H) or aluminum silicate hydrate which strengthen the concrete 54. The efficiency of this reaction depends on the shape and fines of this silica and alumina particles. The SEM image of CDP shows non-uniformly distributed granular structures, as depicted in Fig. 7b. The granular and angular shape of CDP will also contribute for mechanical interlocking within the concrete matrix. CDP is reach in CaO, which will react with silica and alumina in the presence of water to produce Ca-Si-H products. Those the shape and size of CDP also influences the rate this pozzolanic reaction. The binary mixture of BA and CDP (Fig. 7c) display irregularly shaped particles uniformly dispersed, with a small amount of space or void compared to pure CDP, as shown in the SEM image. Fig. 7d, demonstrating the SEM image of the mixture containing BA,CD and OPC, shows the particles are arranged more compactly, leaving fewer voids or empty space between them. This densely packed mixture of BA, CD, and OPC with numerous direct contact points with neighboring particles significantly contributes to the final strength of the concrete.

Fig. 7.

Secondary electron SEM image of (a) bagasse’s ash, (b) calcined dolomite powder, (c) binary mixture of BA and CDP (d) mixture of BA, CDP and OPC.

XRF analysis

Table 4 displays the chemical compositions of BA, CDP, and the binary mixture. As depicted in Table 4, BA with a significant chemical composition of 42.22% SiO2, 15.65% Al2O3, and 16.90% Fe2O3 constitutes over 74.77% of the reactive compounds, crucial for its effective pozzolanic activity. Pozzolan’s lower CaO content (1.97%) and OPC’s higher calcium content (62.90%) effectively facilitate successful secondary Ca-Si-H formation during pozzolanic reactions. Furthermore, BA was found to have high alkali content, such as K2O (14.62%), thus implying high potential for alkali silica reaction when used in concrete with silica reach aggregates. More importantly, the XRF analysis result of row BA concedes with ASTEM C-618-03 which puts standard specifications for coal fly ash and raw or calcined natural pozzolans for use in concrete. On the other hand, CaO (48.25%) of CDP was greater than BA (1.97%) and binary system (12.60%). This revealed that CDP has the required chemical requirement of raw materials for cement production.

Table 4.

Chemical composition of BA, CDP, blended mixture and grade 43 OPC.

| S. no. | Composition | BA | CD | 75%BA/25%CDP | OPC |

|---|---|---|---|---|---|

| 1 | SiO2 | 42.22 | 3.47 | 38.54 | 21.86 |

| 2 | Al2O3 | 15.65 | 2.79 | 15.70 | 5.76 |

| 3 | K2O | 14.62 | 0.10 | 10.98 | 0.34 |

| 4 | Fe2O3 | 16.90 | 0.95 | 11.30 | 4.14 |

| 5 | MgO | 1.43 | 44.17 | 10.74 | 1.19 |

| 6 | CaO | 1.97 | 48.25 | 12.60 | 62.90 |

| 7 | TiO2 | 0.63 | 0.09 | 0.49 | 0.21 |

| 8 | MnO | 1.29 | 0.10 | 0.54 | 0.03 |

| 9 | Cr2O3 | 0.76 | – | 1.90 | 0.02 |

| 10 | P2O5 | 3.57 | – | 0.22 | 0.41 |

| 11 | SO2 | 0.31 | – | 0.11 | – |

| 12 | SO3 | – | – | – | 2.93 |

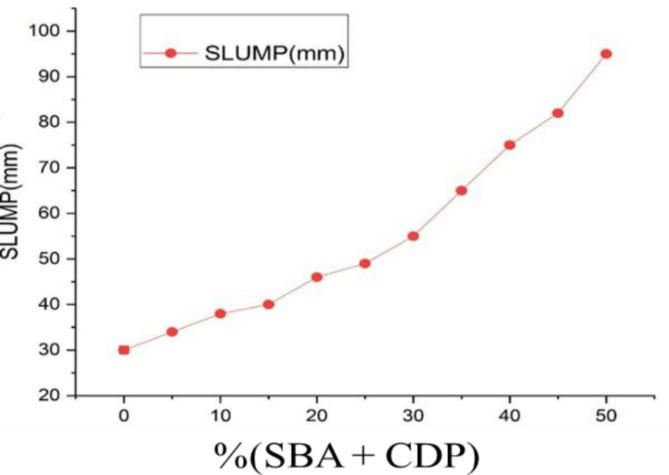

Workability

The slump value of the concrete mixture with a partial replacement of cement was performed according to ASTM 143 to evaluate the workability of the concrete mix 55. The value indicated the workability of the concrete mix gradually increased as the percent replacement of cement was increased. The fineness of the BA and CDP particles causes them to occupy a space inside the cement, which reduces the quantity of water needed for a given mixing. Consequently, there was a high level of workability and relative free water, which aligns with previous findings 56–58. Fig. 8 shows the slump value of the different percent replacement of cement.

Fig. 8.

Slump value as the percent of BA and CDP increase.

The highest slump obtained was 95 mm, which was for 50% replacement. The lowest slump recorded was 30 mm, which belongs to the 100% OPC. The slump value of concrete mixture increases with the addition of ultrafine BA and CDP due to the small PSD of the binary mixture. The nanoparticles of BA and CDP, due to their small PSD, have a higher surface area than their cement counterparts, thereby improving particle packing and reducing water demand in the mixture. The low water demand leads to a higher slump value for a given mixing.

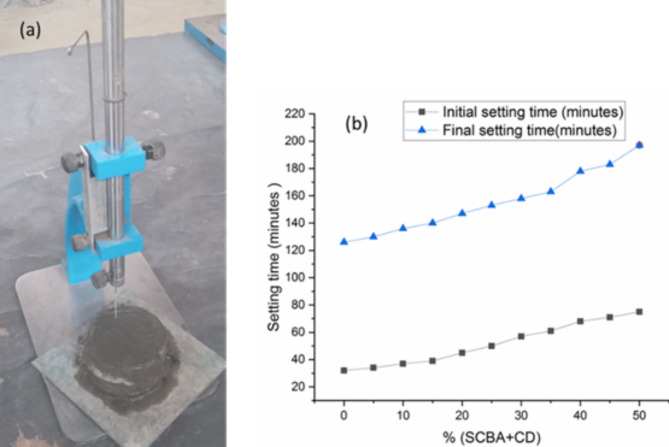

Setting time

The Vicat needle test method, as per ASTM C191, was used to determine the initial and final setting time of cement with varying percent replacements, ranging from 0 to 50%, as depicted in Figs. 9a and b. The result reveals that mixtures containing BA and CDP have higher initial and final setting times compared to a controlled mixture with 100% OPC. This was due to the decrease in OPC available for immediate hydration as the percent replacement increases, as OPC hydrates quickly, leading to shorter setting times (Fig. 9b). This indicates that the initial and final setting times increase with cement replacement 59,60. BA, a pozzolanic material, reacts with calcium hydroxide from cement hydration, causing a slower setting process than OPC hydration. CDP, while improving workability and strength, does not set as quickly as OPC, contributing to longer setting times. This trend was similar to previous research on partial cement replacement with BA, indicating a longer setting time 61–63.

Fig. 9.

(a) The Vicat needle test method (b) initial and final setting times for the mix.

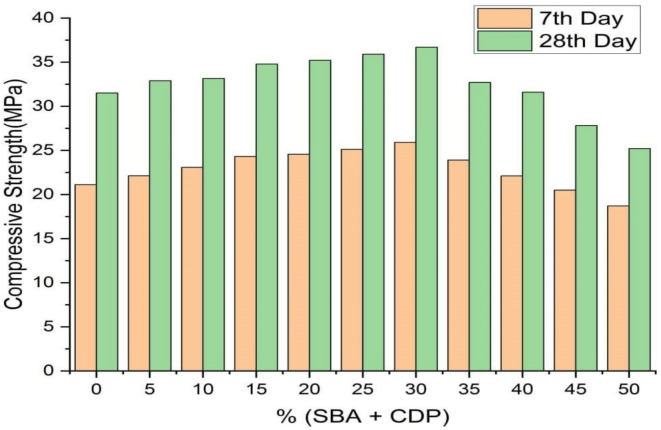

Compressive strength

The results of compressive strength tests were shown in Fig. 10. The 30% partial replacement of cement achieved the highest compressive strength, reaching 25.9 at the 7th day and 36.5 at the 28th day from ten different partial replacements. The value of the compressive strength increases as the percent replacement of the cement by the binary mixtures increases until 30% percent. The compressive strength value decreases after 30% due to the increased use of agro-industrial wastes in the mixture of ultrafine CD and BA. Table 5 demonstrates consistent reliability in compressive strength measurements, with low variability and small standard deviation, indicating material stability across cubic samples.

Fig. 10.

The 7th and 28th days compressive strength value for a partial replacement of OPC with 5% increment of (BA + CDP).

Table 5.

The 7th and 28th days compressive strength value for a partial replacement of OPC with 5% increment of (SBA + CDP) together with the resulting standard deviation and coefficient of variation.

| Cement replacement | Weight of concrete (kg) | 7th day Compressive strength value (MPa) |

SD (MPa) | COV (%) | 28th days Compressive strength value (MPa) |

SD (MPa) | COV (%) |

|---|---|---|---|---|---|---|---|

| 100% OPC | 8.955 | 21.12 | 0.176 | 0.83 | 31.5 | 0.424 | 1.35 |

| 95%OPC + 5% (SBA + CDP) | 8.895 | 22.11 | 0.23 | 1.04 | 32.9 | 0.041 | 0.124 |

| 90%OPC + 10% (SBA + CDP) | 8.98 | 23.08 | 0.241 | 1.04 | 33.14 | 0.206 | 0.618 |

| 85%OPC + 15% (SBA + CDP) | 8.368 | 24.31 | 0.49 | 2.01 | 34.79 | 0.071 | 0.204 |

| 80%OPC + 20% (SBA + CDP) | 8.77 | 24.56 | 0.5 | 2.05 | 35.2 | 0.46 | 1.31 |

| 75%OPC + 25% (SBA + CDP) | 8.674 | 25.11 | 0.134 | 0.53 | 35.9 | 0.0943 | 0.263 |

| 70%OPC + 30% (SBA + CDP) | 8.799 | 25.9 | 0.093 | 0.36 | 36.7 | 0.318 | 0.866 |

| 65%OPC + 35% (SBA + CDP) | 8.667 | 23.9 | 0.47 | 1.97 | 32.7 | 0.216 | 0.66 |

| 60%OPC + 40% (SBA + CDP) | 8.777 | 22.1 | 0.212 | 0.96 | 31.6 | 0.285 | 0.9 |

| 55%OPC + 45% (SBA + CDP) | 8.432 | 20.5 | 0.416 | 2.03 | 27.82 | 1.47 | 5.29 |

| 50%OPC + 50% (SBA + CDP) | 8.754 | 18.7 | 0.532 | 2.84 | 25.2 | 0.78 | 3.04 |

The result also demonstrates the impact of blending BA and CDP on the compressive strength of C-25 grade concrete. The binary mixture results in a higher compressive value than other similar studies using only BA as a cement replacement material, in which the maximum amount of replacement was found up to 15% 64–66. The improved compressive strength of a binary mixture of CDP and BA was primarily due to the reduced particle size distribution and appropriate calcination. The compressive strength data shows a 35% replacement of cement, nearly equivalent to 100% OPC with 31 MPa. However, the optimal cement replacement depends on factors like workability, durability, and other performance. A binary system of BA and CDP can replace cement to 30% without affecting concrete performance.

Strength activity index (SAI)

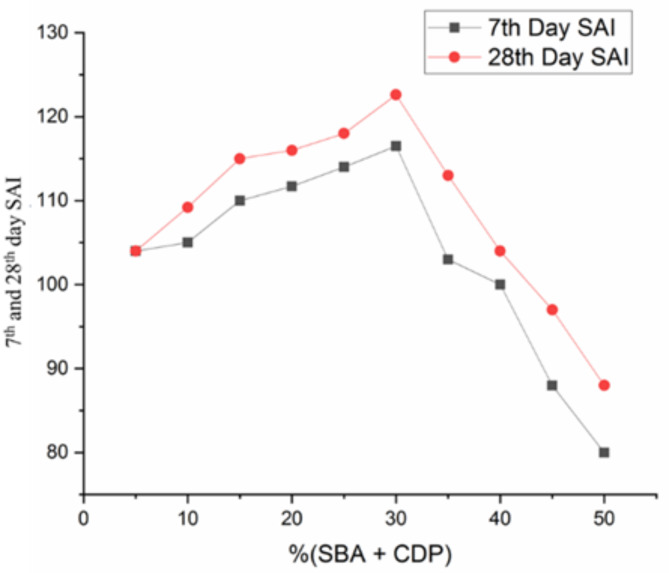

The strength activity index (SAI) was determined using compressive strength results from the 7th and 28th days, following ASTM C311, to assess the pozzolanic activity of the binary binder 67,68. Fig. 11 shows the strength activity index for the 7th and 28th days, with 30% replacement achieving the highest at 116 and 122, while 50% replacement had the lowest at 80. The activity index indicates that a binary mixture of bagasse ash and calcined dolomite powder is an effective pozzolanic material that surpasses the control mix. The study also reveals that BA blended with CD exhibits high pozzolanic activity, meeting ASTM C311 standards, with a strength activity index above 75 indicating good pozzolanic activity 69.

Fig. 11.

7th and 28th days strength activity index.

Water absorption

The Belgian standard NBN B15-215 (1989) measures a material’s water absorption capacity when submerged. This test involves drying and saturating the material with water, assessing concrete’s durability and water resistance, making it a common technique in testing materials as shown in Table 6. The water absorption test revealed that the lowest value was 3.94 for 5% replacement, while the highest was 7.68 for 50% replacement. Concrete mixtures should have a water absorption value between 4 and 6% for longer durability 70,71. As cement replacement percentage increases, the water absorption value of the mixture also increases, possibly due to the development of pores due to rising ash content. This increase in ash content also increases the level of specific oxides, such as magnesium and potassium oxide, which are controlled in cement formulations. Magnesium oxide was hydrated to produce magnesium hydroxide, a less dense and higher volume form. This increases the volume of magnesium oxide, causing pours, voids, and micro cracks in concrete structures, resulting in increased porosity and water absorption 72. Additionally, excess potassium oxide can cause an alkali-silica reaction between potassium oxide and reactive silica in certain aggregates, leading to disruption, increased porosity, and water absorption due to the expansion of the compound 73. This study found that at 30% replacement, maximum compressive strength is achieved due to a balance between packing density and concrete porosity. The optimal packing density and additional C-S-H gel from the pozzolanic reaction resulted in a denser concrete microstructure. However, the increased volume of binary replacement material may have increased overall porosity, affecting water absorption slightly.

Table 6.

Water absorption value of a concrete with partial replacement of cement with binary system of Bagasse’s Ash and calcined dolomite powder.

| Sample name | Initial wait of the dry concrete (g) | Final weight after soaking for 24 h (g) | Water absorption value (%) |

|---|---|---|---|

| 95%OPC + 5% (BA + CDP) | 2301 | 2431.5 | 3.94 |

| 90%OPC + 10% (BA + CDP) | 2435.5 | 2531.5 | 4.128 |

| 85%OPC + 15% (BA + CDP) | 2337.5 | 2439.41 | 4.36 |

| 80%OPC + 20% (BA + CDP) | 2366.5 | 2477.48 | 4.69 |

| 75%OPC + 25% (BA + CDP) | 2367 | 2497.89 | 4.95 |

| 70%OPC + 30% (BA + CDP) | 2360.6 | 2484.29 | 5.24 |

| 65%OPC + 35% (BA + CDP) | 2335.5 | 2489.0 | 6.481 |

| 60%OPC + 40% (BA + CDP) | 2332.5 | 2485.5 | 6.53 |

| 55%OPC + 45% (BA + CDP) | 2260 | 2447 | 7.64 |

| 50%OPC + 50% (BA + CDP) | 2270.5 | 2445 | 7.68 |

Dry density

The dry density of the concrete mix was determined using a 10 cm x 10 cm x 10 cm cubic metallic mold with a volume of 0.001 m³. The mass of the dry concrete sample was divided by the concrete volume, as shown in Table 7. The dry density values indicate that the concrete mixture with a partial cement replacement is well-balanced and meets the typical density requirement. The controlled mix has a density of 2357 kgm-³, while partial replacement mixtures have a density of 2301 kgm-³ for 5% and 2275 kgm-³ for 50%. All dry density values fall within the normal acceptable range of 2200 kgm-³-2600 kgm-³74. The 30% replacement of BA and CDP in the concrete mixture resulted in a slight increase in dry density, indicating effective material interaction and packing 75. The density of concrete slightly decreases as replacement percentages increase beyond optimum, primarily due to a higher percentage of BA, which may increase porosity, reducing overall density and mechanical performance 76,77.

Table 7.

Dry density values of concretes.

| Sample name | Wait of the dry sample (kg) | Dry density (kgm-3) |

|---|---|---|

| 100% OPC | 2.357 | 2357 |

| 95%OPC + 5% (SBA + CDP) | 2.301 | 2301 |

| 90%OPC + 10% (SBA + CDP) | 2.435 | 2435 |

| 85%OPC + 15% (SBA + CDP) | 2.337 | 2337 |

| 80%OPC + 20% (SBA + CDP) | 2.366 | 2366 |

| 75%OPC + 25% (SBA + CDP) | 2.367 | 2367 |

| 70%OPC + 30% (SBA + CDP) | 2.36 | 2360 |

| 65%OPC + 35% (SBA + CDP) | 2.335 | 2335 |

| 60%OPC + 40% (SBA + CDP) | 2.332 | 2332 |

| 55%OPC + 45% (SBA + CDP) | 2.26 | 2260 |

| 50%OPC + 50% (SBA + CDP) | 2.275 | 2275 |

Conclusion

This research involved preparing 11 concrete mixtures and analyzing their compressive strength and freshness, resulting in a major conclusion. The binary mixture of BA and CDP shows superior potential as a pozzolanic material for partial cement replacement, showing more promising results than individual effects. The 30% binary mixture of BA and CDP, when partially replaced with cement, demonstrated superior compressive strength and other properties compared to other mixes, including the controlled mix with 100% OPC. The slump value and initial and final setting time of concrete increased with a 5 to 50% replacement of OPC by the binary blend. The concrete’s performance decreases with a 30% replacement, while increasing it beyond this level results in increased water absorption, negatively impacting its performance. The key parameters contributing to improved concrete performance include grinding techniques for ultra-fine particle size distribution of BA and CDP, calcination temperature, and material blend.

Recommendation

The research yielded promising results, but further research is needed to expand the field based on the progress made. The study focuses on the compressive strength of concrete, and future researchers should investigate the impact of ultrafine BA and CDP on other mechanical properties. The durability of a concrete mixture containing the binary system also needs further study.

Acknowledgements

The authors acknowledge to the ASSURE SI project, “A Sustainable Construction for Ethiopia: Integrating Local Resources for Affordable, Resilient and Sustainable Housing”, with a Reference No. ET2023SIN384A104 financed by the general financial framework for VLIR-UOS-funded projects of the Five-Year Programme 2022–2027 (FYP2) and Jimma University for their financial support for conducting this research. The financial support we received enabled us to gather the necessary raw materials and conduct the necessary tests.

Author contributions

(1) Dereje Tesfaye Woldesenbet: Conceptualization, data Curation, formal analysis, investigation, methodology, validation, visualization, writing-original draft; (2) Solomon Dimiss Negedu: Conceptualization, supervision, visualization; (3) Jemal Jibril Muhammed: Funding acquisition, project administration, supervision, writing-review and editing; (4) Jose Henriques: Funding acquisition, resource, writing-review and draft; (5) Endrias Adane Bekele: Conceptualization, investigation, methodology, software, visualization, writing-original draft, writing-review and draft, improved the overall manuscript.

Funding

This research is funded by Assure SI project and Jimma University.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding authors on reasonable request.

Declarations

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Change history

7/19/2025

The original online version of this Article was revised: In the original version of this Article Dereje Tesfaye Woldesenbet was incorrectly affiliated with Affiliation 3 and Solomon Demiss Negedu was incorrectly affiliated with Affiliation 2. The correct Affiliation for Dereje Tesfaye Woldesenbet is Affiliation 1 and the correct affiliation for Solomon Demiss Negedu is Affilaition 3. The original Article has been corrected.

Contributor Information

Dereje Tesfaye Woldesenbet, Email: dereje.tesfaye@ju.edu.et.

Solomon Demiss Negedu, Email: solomondemiss@gmail.com.

Endrias Adane Bekele, Email: endrias.adane@ju.edu.et, Email: seniendu7@gmail.com.

References

- 1.Fadi Althoey, W. S. A., Muhammad Sufian, A. F. & Deifalla. Advancements in low-carbon concrete as a construction material for the sustainable built environment developments. Built Environ.16, 100284. 10.1016/j.dibe.2023.100284 (2023). [Google Scholar]

- 2.Jing He, S. K. V. A. The utilization of agricultural waste as Agro-Cement in concrete: A review. Sustainability12, 6971. 10.3390/su12176971 (2020). [Google Scholar]

- 3.Yasong Zhao, J. G., Liu, C. & Chen, X. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod.242, 118521. 10.1016/j.jclepro.2019.118521 (2020). [Google Scholar]

- 4.Oluwafemi, E., Ige, O. A. O., Kevin, J., Duffy & Collins, O. C. Environmental impact analysis of Portland cement (CEM1) using the midpoint method. Energies15, 2708. 10.3390/en15072708 (2022). [Google Scholar]

- 5.Shaaban, M. Properties of concrete with binary binder system of calcined dolomite powder and rice husk Ash. Heliyon7, e06311. 10.1016/j.heliyon.2021.e06311 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Yaseen, D. A. Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: a critical review. 16(2). 10.1007/s13762-018-2130-z (2019).

- 7.Tareg, A., Abdalla, A. A. E. H., Ahmed, Y. H. & Semmana, O. Strength, durability, and microstructure properties of concrete containing Bagasse ash – A review of 15 years of perspectives, progress and future insights. Results Eng.21, 101764. 10.1016/j.rineng.2024.101764 (2024). [Google Scholar]

- 8.Prof, R., Bhosale, A. N. & More, P. Partial replacement of cement by using rice husk Ash and sugarcane Bagasse Ash. IJARSCT3, 2581–9429. 10.48175/IJARSCT-11454 (2023).

- 9.Muliye Tarekegn, K. G. & Kenea, G. Experimental investigation of concrete characteristics strength with partial replacement of cement by hybrid coffee husk and sugarcane Bagasse Ash. Adv. Mater. Sci. Eng. Volume. 10.1155/2022/5363766. 12 (2022). [Google Scholar]

- 10.Belete Desalegn, E. K. & Legesse, H. Sugarcane productivity and sugar yield improvement: selecting variety, nitrogen fertilizer rate, and bioregulator as a first-line treatment. Heliyon9, e15520. 10.1016/j.heliyon.2023.e15520 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Bordonal, R. O. et al. Sustainability of sugarcane production in Brazil. A review. Agron. Sustain. Dev.38, 13. 10.1007/s13593-018-0490-x (2018).

- 12.Pathak, A. K. Sugarcane production and productivity growth scenario in India. Indian Farming. 67 (02), 64–68 (2017).

- 13.Medhanit Mamaye, Z. K., Feleke, S., Anuradha, S. & Yimam, J. A. Valorization of Ethiopian Sugarcane Bagasse To Assess its Suitability for Pulp and Paper Production. Sugar Tech.10.1007/s12355-019-00724-x.

- 14.Gashaw, E. T. & Ayana, A. F. M. Sugarcane Landraces of Ethiopia: Germplasm Collection and Analysis of Regional Diversity and Distribution. Adv. Agric. 7920724, 18. 10.1155/2018/7920724 (2018).

- 15.Samuel Tegene, H. T., Dejene, M. & Tegegn, G. Esayas Tena & Amare ayalew, Survey of sugarcane Smut (Sporisorium scitamineum) and association of factors influencing disease epidemics in sugarcane plantations of Ethiopia. Trop. Plant. Pathol.46, 393–405. 10.1007/s40858-021-00437-1 (2021). [Google Scholar]

- 16.Cordeiro, G. C. & Lemos, B. D. F. L. Production of a highly pozzolanic sugarcane bagasse ash via densimetric fractionation and ultrafine grinding. Ambiente Construído4, 49–58. 10.1590/s1678-86212022000400627 (2022).

- 17.Thomas, B. S. et al. Sugarcane Bagasse Ash as supplementary cementitious material in concrete – a review. Mater. Today Sustain.15, 100086. 10.1016/j.mtsust.2021.100086 (2021). [Google Scholar]

- 18.Guilherme, C., Cordeiro, P. V. A., Luís, M. & Tavares. Pozzolanic properties of ultrafine sugar cane Bagasse Ash produced by controlled burning. Heliyon5, e02566. 10.1016/j.heliyon.2019.e02566 (2019). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Ying Lin, U. J. A. & Ibrahim, Z. Effect of treated and untreated rice husk Ash, palm oil fuel Ash, and sugarcane Bagasse Ash on the mechanical, durability, and microstructure characteristics of blended concrete – A comprehensive review. J. Building Eng.78 (1), 107500. 10.1016/j.jobe.2023.107500 (2023). [Google Scholar]

- 20.Behailu Zerihun, M. D. Y. & Vo, D. H. Effect of agricultural crop wastes as partial replacement of cement in concrete production. Adv. Civil Eng., 5648187, 31. 10.1155/2022/5648187 (2022).

- 21.Wang, H. & Zhang, X. L. Z. Pozzolanic activity evaluation methods of solid waste: A review. J. Clean. Prod.402, 20. 10.1016/j.jclepro.2023.136783 (2023). [Google Scholar]

- 22.Alexandre Lopes Borges, S. M. S. et al. Evaluation of the pozzolanic activity of glass powder in three maximum grain sizes. Mater. Res.24 (4), e20200496. 10.1590/1980-5373-MR-2020-0496 (2021).

- 23.Yadav, A. L., Muruganandam, V. S. L. & Srinivasan, K. An overview of the influences of mechanical and chemical processing on sugarcane Bagasse Ash characterisation as a supplementary cementitious material. J. Clean. Prod.10.1016/j.jclepro.2019.118854 (2019). [Google Scholar]

- 24.Yash Agrawal, T. G., Siddique, S. & Sharma, R. K. Potential of dolomite industrial waste as construction material: a review. Innovative Infrastructure Solutions. 6, 205. 10.1007/s41062-021-00570-5 (2021). [Google Scholar]

- 25.Resio, L. C. Dolomite thermal behaviour: A proposal to Establish a definitive decomposition mechanism in a convective air atmosphere. Open. Ceram.15, 100405. 10.1016/j.oceram.2023.100405 (2023). [Google Scholar]

- 26.Glasser, J. Thermally activated dolomite as pozzolanic addition to Portland cement. Adv. Cem. Res.28 (6), 378–388. 10.1680/jadcr.15.00110 (2016). [Google Scholar]

- 27.Jeon, I. K., Jakhrani, H. G. K. S. H. & Ryou, J. S. Evaluation of the microstructure, mechanical, and durability properties of alkali-activated slag-based mortar with light-burnt dolomite powder. J. Mater. Res. Technol.13, 2220–2228. 10.1016/j.jmrt.2021.06.024 (2021).

- 28.Amaresh Tripathy, P. K. A. Characterization of Bagasse Ash and its sustainable use in concrete as a supplementary binder – A review. Constr. Build. Mater.322, 126391. 10.1016/j.conbuildmat.2022.126391 (2022). [Google Scholar]

- 29.Jagadesh, P. Processing of sugar cane bagasse ash and properties of processed sugar cane bagasse ash blended cements. Sådhanå. 47, 187. 10.1007/s12046-022-01963-7Sadhana (2022).

- 30.Onesippe Potiron, C. e al. Enhancement of the reactivity of sugarcane bagasse ash for 2 pozzolan-lime paste: effect of particle size. Constr. Build. Mater.350, 128561 (2022).

- 31.Guilherme, C. & Cordeiro, K. E. K. Effect of mechanical processing on sugar cane Bagasse Ash pozzolanicity. Cem. Concr. Res.97, 41–49. 10.1016/j.cemconres.2017.03.008 (2017). [Google Scholar]

- 32.Emerson Carlos Mansaneira, N. S.-C., Barreto-Sandoval, G. F., & Martins-Toralles, B. Sugar cane bagasse ash as a pozzolanic material. DYNA84(201), 163–171. 10.15446/dyna.v84n201.61409 (2017).

- 33.Junaid, M. F. et al. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater.319 (14), 126061. 10.1016/j.conbuildmat.2021.126061 (2022).

- 34.Yimin Deng, J. L. et al. The steam-assisted calcination of limestone and dolomite for energy savings and to foster solar calcination processes. J. Clean. Prod.363, 132640. 10.1016/j.jclepro.2022.132640 (2022).

- 35.Winny Wulandari, S. et al. Performance of Dolomite Calcination in a Bench-Scale Rotary Kiln MATEC Web of Conferences 156, 06008. 10.1051/matecconf/201815606008 (2018).

- 36.Subh Naman, S. S. & Baldi, A. Identification of spices and their adulterants by integrating machine learning and analytical techniques: A representative study. Int. J. Pharm. Sci. Drug Res. May - June. 16 (Issue 3), 359–369. 10.25004/IJPSDR.2024.160307 (2024). [Google Scholar]

- 37.Kazeem, A. D. E. et al. Determination of appropriate mix ratios for concrete grades using Nigerian Portland-limestone grades 32.5 and 42.5. Leonardo Electron. J. Pract. Technol.26, 79–88 (2015).

- 38.Mohsen, M. O. et al. Fly Ash and natural Pozzolana impacts on sustainable concrete permeability and mechanical properties. Buildings13 (1927). 10.3390/buildings13081927 (2023).

- 39.Hussein, M., Hamada, F. A., Zaid, A., Al-Sadoon, A. & Alashkar Enhancing pozzolanic activity of fly Ash via dry and wet milling: A comparative study for sustainable construction material enhancement. J. CO2 Utilization. 83, 102811. 10.1016/j.jcou.2024.102811 (2024). [Google Scholar]

- 40.Pakawat Pormmoon, A. A., Charoenwaiyachet, C. & Tangchirapat, W. Effect of cut-size particles on the pozzolanic property of bottom Ash. J. Appl. Res. Technol.10, 240–249. 10.1016/j.jmrt.2020.12.017 (2021).

- 41.Abdul Qudoos, H. G. K., Atta-ur-Rehman, J. S. & Ryou Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw Ash blended cement composites. Constr. Build. Mater.193, 481–490. 10.1016/j.conbuildmat.2018.10.229 (2018). [Google Scholar]

- 42.Yasong Zhao, J. G., Liu, C., Chen, X. & Xu, Z. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod.242 (1). 10.1016/j.jclepro.2019.118521 (2020).

- 43.Torres, S. M. et al. Assessing the pozzolanic activity of sugarcane Bagasse Ash using X-ray diffraction. Constr. Build. Mater.264, 120684. 10.1016/j.conbuildmat.2020.120684 (2020).

- 44.Imran, M. et al. Characterization of agricultural waste sugarcane bagasse ash at 1100 C with various hours. Mater. Today Proc.5, 3346–3352 (2018).

- 45.Batool, F., Masood, A., & Ali, M. Characterization of sugarcane bagasse ash as pozzolan and influence on concrete properties. Arab. J. Sci. Eng.10.1007/s13369-019-04301-y.

- 46.Yogitha Bayapureddy, K. M. & Mutukuru, M. R. G. Sugarcane Bagasse Ash as supplementary cementitious material in cement composites: strength, durability, and microstructural analysis. J. Korean Ceram. Soc., 10.1007/s43207-020-00055-8.

- 47.Miriam Arabiourrutia, G. B., Maider Bolaños, M. & Olazar, A. Catalytic pyrolysis of date palm seeds on HZSM–5 and dolomite in a pyroprobe reactor in line with GC/MS. Biomass Conversion. Biorefnery14, 2799–2818. 10.1007/s13399-022-02493-2 (2024).

- 48.Valverde, S. M. C. J. M. In situ XRD analysis of dolomite calcination under CO2 in a humid environment. CrystEngComm10.1039/d0ce00974a.

- 49.Ahmad, S. & W.a.K, Y. C. Sugarcane Bagasse powder as biosorbent for reactive red 120 removals from aqueous solution. IOP Conf. Series: Earth Environ. Sci.140, 012027. 10.1088/1755-1315/140/1/012027 (2018). [Google Scholar]

- 50.Prabhu, P. Adaptability of sugar cane Bagasse Ash in mortar. J. Inst. Eng. India Ser. A, 10.1007/s40030-019-00359-x.

- 51.Yadav, A. L., Srinivasan, V. S. K. & Muruganandam, L. Synthesis and characterization of geopolymer from Metakaolin and sugarcane Bagasse Ash. Constr. Build. Mater.258, 119231. 10.1016/j.conbuildmat.2020.119231 (2020). [Google Scholar]

- 52.Leila Nóbrega Sousa, P. F. F., et al. Effect of non-calcined sugarcane Bagasse Ash as an alternative precursor on the properties of alkali-activated pastes. Molecules27, 1185. 10.3390/molecules27041185 (2022). [DOI] [PMC free article] [PubMed]

- 53.Hasnain, M. H., Ali, U. J. A. & Zafar, M. S. Eco-friendly utilization of rice husk ash and bagasse ash blend as partial sand replacement in self-compacting concrete. Constr. Build. Mater.10.1016/j.conbuildmat.2020.121753.

- 54.Amin, M. N. et al. Mechanical and microstructural performance of concrete containing high-. Bagasse Ash Silica Fume. 12 (1), 5719 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Standard, A. Standard Test Method for Slump of hydraulic-cement Concrete (ASTM Annual Book of ASTM Standards, 2015).

- 56.Teltayeva, B. B., Izmailova, C. O. R. G. G., Amirbayev, E. D. & Elshibayev, A. O. Evaluating the effect of asphalt binder modification on the low-temperature cracking resistance of hot mix asphalt. Case Stud. Constr. Mater.11, e00238. 10.1016/j.cscm.2019.e00238 (2019). [Google Scholar]

- 57.Waqas Ahmad, A. A., Ostrowski, K. A., Aslam, F., Joyklad, P. & Zajdel, P. Sustainable approach of using sugarcane Bagasse Ash in cement-based composites: A systematic review. Case Stud. Constr. Mater.15, e00698. 10.1016/j.cscm.2021.e00698 (2021). [Google Scholar]

- 58.Falk, G., Teixeira, G. P. S. L. B., Moraes, E. G., Novaes de, A. P. & Oliveira Synthesis of silica nanoparticles from sugarcane Bagasse Ash and nanosilicon via magnesiothermic reactions. Ceram. Int., 10.1016/j.ceramint.2019.07.157.

- 59.Beaudoin, J. & Odler, I. Hydration, Setting and Hardening. Lea’s chemistry of cement and concrete: p. 157.

- 60.Marchon, D. & Flatt, R. J. Mechanisms of Cement hydration. In Science and Technology of Concrete Admixtures. Elsevier. pp. 129–145.

- 61.Akkarapongtrakul, A., Julphunthong, P. & Nochaiya, T. Setting time and microstructure of Portland cement-bottom ash sugarcane bagasse ash pastes. Monatshefte Chemie-Chem. Mon.148, 1355–1362.

- 62.Ainomugisha, S. et al. Effect of sugarcane bagasse ash on eco-friendly blended cement production: Physicochemical, mechanical, and microstructure properties. Case Stud. Constr. Mater.22, e04141.

- 63.Hailu, B. & Dinku, A. Application of sugarcane Bagasse Ash as a partial cement replacement material. Zede J.29, 1–12.

- 64.Dineshkumar, R. Behavior of high–strength concrete with sugarcane Bagasse Ash as replacement for cement. Innov. Infrastruct. Solut.. 6, 63. 10.1007/s41062-020-00450-4 (2021). [Google Scholar]

- 65.Sabir Ali, A. K., Rizvi, S. H., Ali, M. & Ahmed, I. Effect of Sugarcane Bagasse Ash as Partial Cement Replacement on the Compressive Strength of Concrete. Quest Res. J.18(2), 44–49. 10.52584/QRJ.1802.07 (2020).

- 66.Kiran, K. & Kishore, I. S. x. and An experimental study on partial replacement of cement with bagasse ash in concrete mix. Int. J. Civ. Eng. Technol.8(1), 452455 (2017).

- 67.Dunstan, E. R. Jr An enhanced procedure to measure strength and durability of Pozzolans. ACI Mater. J., 116, 183–192.

- 68.Patil, C., Manjunath, M., Hosamane, S., Bandekar, S. & Athani, R. Pozzolonic activity and strength activity index of bagasse ash and fly ash blended cement mortar. Mater. Today Proc.42, 1456–1461.

- 69.Kasaniya, M. Pozzolans: Reactivity test method development and durability performance. (2019).

- 70.Zhuang, S., Wang, Q. & Zhang, M. Water absorption behaviour of concrete: novel experimental findings and model characterization. J. Building Eng.53, 104602 (2022). [Google Scholar]

- 71.Golewski, G. L. Assessing of water absorption on concrete composites containing fly Ash up to 30% in regards to structures completely immersed in water. Case Stud. Constr. Mater.19, e02337. 10.1016/j.cscm.2023.e02337 (2023). [Google Scholar]

- 72.Fengze Cao, M. M., Peiyu & Yan Hydration characteristics and expansive mechanism of MgO expansive agents. Constr. Build. Mater.183, 234–242. 10.1016/j.conbuildmat.2018.06.164 (2018). [Google Scholar]

- 73.Zhengqi Li, K. A., Rao, P. & Rangaraju Effect of alkali content of cement on properties of high performance cementitious mortar. Constr. Build. Mater.102, 631–639. 10.1016/j.conbuildmat.2015.10.110 (2016). [Google Scholar]

- 74.Iffat, S. Relation between density and compressive strength of hardened concrete. Concrete Res. Lett.6(4), 182–189.

- 75.Neto, J. S. A. et al. Effects of adding sugarcane bagasse ash on the properties and durability of concrete. Constr. Build. Mater.266, 120959.

- 76.Thomas, B. S. et al. Sugarcane Bagasse Ash as supplementary cementitious material in concrete review. Mater. Today Sustain.15, 100086.

- 77.Quedou, P. G., Wirquin, E. & Bokhoree, C. Sustainable concrete: potency of sugarcane Bagasse Ash as a cementitious material in the construction industry. Case Stud. Constr. Mater.14, e00545.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding authors on reasonable request.