Abstract

Polypropylene mesh, integrated in N95 respirators and surgical masks that are widely used in the current crisis of COVID-19, filters aerosols via electrostatics in addition to the physical block. However, any contact to water such as storage under high humidity, exposure to exhaling breath, and washing in water removes its charges and thus compromises its filtering efficiency. We developed a desk top device based on a Cockcroft-Walton's voltage multiplier that can restore the electrostatic charge of surgical masks within 1 min and recover the filtering efficiency of the polypropylene mesh from 87% to 97%. The device is easy to operate and safe, thus may be applied for the reuse of surgical masks towards reducing the plastic wastes.

Keywords: Polypropylene, Static electricity, Mask, COVID-19

1. Introduction

N95 respirators and surgical masks, used by health caretakers in the current COVID-19 pandemic, filter virus-containing aerosols despite the fact that its pore size (∼10 μm) is larger than small aerosols (<1 μm) [1]. This is attributed to the static electricity of the melt-blown polypropylene fabric used in these masks [[2], [3], [4], [5], [6]], which captures small aerosols by electrostatic forces as most aerosols are electrically charged [[7], [8], [9], [10]]. Currently, 129 billion masks are estimated to be used and disposed every month worldwide [11], producing a large amount of (micro-) plastic pollution in the environment [12]. Since the onset of the pandemic in early 2020, scientific communities have proposed different strategies for their sterilization and reuse, such as heating, boiling, washing [13], exposure to UV or hydrogen peroxide vapor [14], and others [[15], [16], [17]]. A challenge in these approaches is to sterilize efficiently while maintaining the static electricity. Application of high voltage with a voltage generator [18] or treatment with corona discharge [19] have been demonstrated to recover the electrostatics after washing, yet both methods are either too expensive or too dangerous for general use. To overcome this problem, previously, we have reported that the van de Graaff generator, commonly used for the demonstration of static electricity in e.g. scientific museums, can be used as a safe, cheap and quick method to recover the polypropylene electric charges and its filtering function that are lost during the sterilization processes [20].

In this work, we developed a compact and safe “mask charger” by miniaturizing and improving the reproducibility, robustness and the user interface of our previous work [20].

First, the charge generator based on the triboelectric effect used in the van de Graaff generator was replaced with a Cockcroft-Walton's-voltage-multiplier-based static electricity gun, which allowed the device volume to be down-sized by 7 folds and improved the stability, reproducibility and robustness. Second, the flat electrode was used to accumulate charges in contrast to the spherical one used in the van de Graaff generator to increase the surface contact with surgical masks and reduce the volume. Third, the metal electrode was covered with an insulator to avoid unwanted discharge in air to improve the user comfort without sacrificing the homogenous distribution of charges thanks to the conductivity of the underlying metal plate. Forth, several strategies were implemented to avoid the charge leak from the electrode to the ground. Fifth, we made a lid that is electrically grounded to replace the counter electrode used in the van de Graaff generator. At the end, we will combine all of the elements written above to fabricate a desktop device and evaluate its performance.

2. Results and discussions

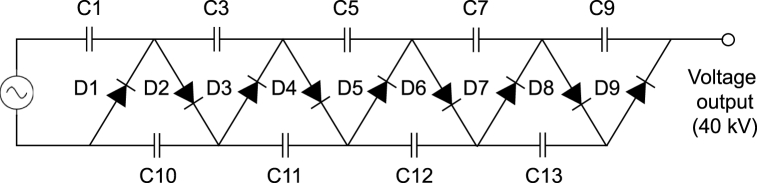

In our previous study [20], a van de Graaff generator (Fig. S1) was used to produce high voltages. However, its operational principle that employs triboelectric effect did not yield stable and reproducible voltages. Therefore, in this work, we selected an alternative method to create high voltages based on the Cockcroft-Walton's voltage multiplier (Fig. 1). This circuit, made of series of capacitors and diodes, amplifies the input voltage and generates a high voltage output at the end of the circuit. Similar to the van de Graaff generator, it creates high voltages but operates under low current condition, thus is one of the safe ways to produce several tens of kV. The goal of this work is to develop an easy-to-use mask charger by connecting an electrode to the tip of this static electricity generator based on this circuit, where a mask can be placed and a high voltage can be applied for charging the mask efficiently.

Fig. 1.

Cockcroft-Walton's voltage multiplier used in the static electricity generator.

2.1. Insulator/metal double layer as a charging surface suppressed unwanted discharge in air and improved the usage comfort without compromising the homogenous voltage distribution

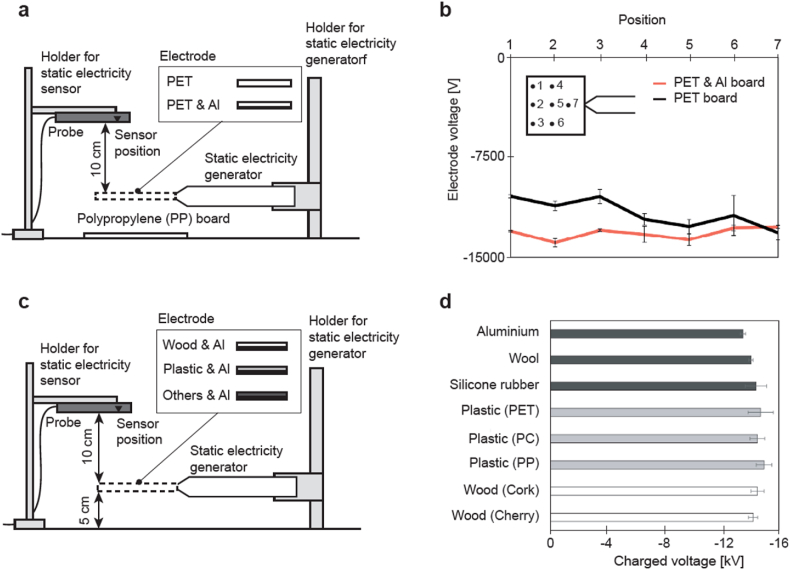

Metal electrodes such as the ones used in the van de Graaff generators enable homogenous voltage distribution in the electrode. However, they promote discharge in air that often associates with uncomfortable sounds and sparks. To reduce this sounds and sparks for improving the user friendliness, first, we studied whether use of insulator as an “electrode” suppresses the air discharge. Fig. 2a depicts the setup of this experiment, where either a polyethylene terephthalate (PET) or a PET/aluminum double layer board is being attached to the tip of the static electricity generator.

Fig. 2.

a, A scheme showing the setup used to measure the voltages of PET or PET/aluminum double layer electrode. b, Measured voltage vs the position of the electrode (n = 3). Inset shows the position numbers. c, A scheme showing the setup used to measure the voltages of double layer electrodes with different insulators as a covering material. d, The measured voltages of the double layer electrodes with different insulators (n = 31); polyethylene terephthalate (PET), polycarbonates (PC), polypropylene (PP).

The static electricity generator is supported by a holder, whereas a static electricity sensor is placed above the electrode. The static electricity sensor measures the surface voltage right underneath the probe head via the mirror charge of the capacitor in the sensor. When PET board was attached, the air discharge was suppressed. However, the voltage distribution was not homogenous, where the voltage became lower as the distance from the point contact to the static electricity generator increased (Fig. 2b). This problem was solved by placing an aluminum plate below the PET (PET/Al double layer), to which an electrical contact was taken from the tip of the static electricity generator. This assured the homogenous voltage distribution thanks to the conductivity of the metal (Fig. 2b).

2.2. The material of the insulator covering the metal electrode did not significantly affect the electrode voltages

Next, we replaced PET with different types of insulators (e.g. wood, plastic, silicon) to study the material dependence on the electrode voltages (Fig. 2c). Overall, all of the materials presented comparable voltages (Fig. 2d). The result implies that the type of the insulator is not a critical factor for the electrode voltage.

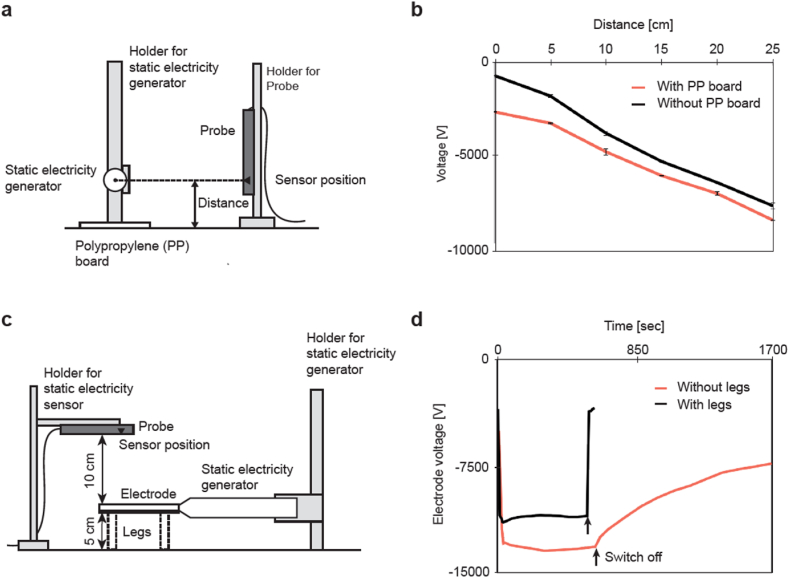

2.3. Voltage drain during charging was suppressed by inserting an insulator between the electrode and the table and by retracting the electrode several cm away from the surface

To design a table-top device, the electrode has to be placed on a table surface. We found that this causes a voltage drain to the ground, which hinders the generation of more than ten kV at the electrode that is required for charging masks. The voltage at the tip of the voltage gun depended on the distance from the table surface (Fig. 3ab). This suggests that simply taking a distance from the surface efficiently minimizes this voltage drain. In addition, it was further suppressed by inserting a polypropylene board between the tip of the gun and the table surface (Fig. 3ab).

Fig. 3.

a, A font view of the setup used to measure the voltages of the tip of static electricity generator at different heights between 6 cm and 25 cm b, Measured voltage vs the distance of the electrode from the ground (n = 3). Note that only relative values should be considered in Fig. 3b as the measurement was performed at a larger distance from the tip of the gun than the one that is used to read accurate values for avoiding breaking the probe (see materials and methods for the details). c, A scheme showing the setup used to measure voltages with a double layer electrode with or without ceramic legs. d, The measured voltages with or without legs vs time.

2.4. Voltage drain after switching off the generator was suppressed by supporting the electrode just by the tip of the gun

We found that the way the electrode is supported also affects the voltage drain. When the electrode was supported by additional four legs made of ceramic (Fig. 3c), the voltage at the electrode rapidly decreased as soon as the static electricity generator was switched off (Fig. 3d).

This is due to the short circuit to the ground. On the other hand, if the entire system is supported just by the rear of the static electricity generator, this voltage drain was less severe (Fig. 3d). This is because the rear of the static electricity generator corresponds to the input side of the Cockcroft-Walton's circuit that is electrically disconnected from the high voltage output by capacitors and diodes (Fig. 1), thus helped with suppressing the voltage drain.

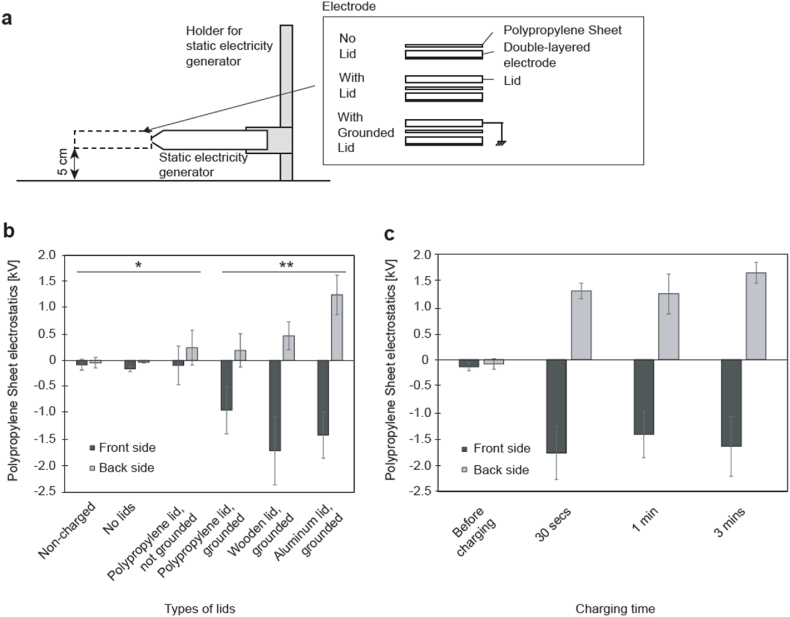

2.5. Sandwiching polypropylene with an electrically-grounded counter electrode (a grounded lid) improved the charging efficiency

Next, we placed a polypropylene sheet, extracted from N95 masks and prewashed in hot water to remove the static electricity, onto the PET/Al double layer electrode and applied voltages for 30 s with or without different types of lids (Fig. 4a). After this operation, these polypropylene sheets were moved onto a wooden board and their charge was measured by the static electricity sensor.

Fig. 4.

a, A scheme showing the setup with different types of lids. b, Electrostatics of polypropylene sheets before charging, after charging with no lid, with a non-grounded lid, with grounded lids made of different materials (n = 3–8). c, Charging time dependence on the polypropylene electrostatics (n = 3–4).

Neither application of voltages without a lid nor with a lid that is electrically floated (not grounded) charged polypropylene sheets (* in Fig. 4b). Surprisingly, electrically grounding the lid dramatically improved the charging effect (** in Fig. 4b). This is because the grounded lid functioned as a counter electrode in the van de Graaff generator, where its presence generated a strong field across the polypropylene. The material of the grounded lid (polypropylene (PP), wood, and aluminum) seems to have a slight effect on the charging capability. For aluminum, the size of the lid was also a key parameter, where large lids performed worse because of the discharge in air and the voltage leak to the bottom electrode (Fig. S2).

2.6. 30 s was enough for charging masks

In addition, to determine the minimum duration required for charging, we measured the static electricity of polypropylene sheet after charging 30 s, 1 min, and 3 min with the grounded 10 mm × 10 mm sized aluminum lid. The voltages saturated roughly at - 1.5 kV and 1.3 kV for the front and the backside of the polypropylene sheet, respectively, already after 30 s. Application of longer durations did not seem to have an advantage (Fig. 4c).

2.7. A desktop mask charger recovered the electrostatics to a few hundred volts and improved the filtering efficiency by 5–10%

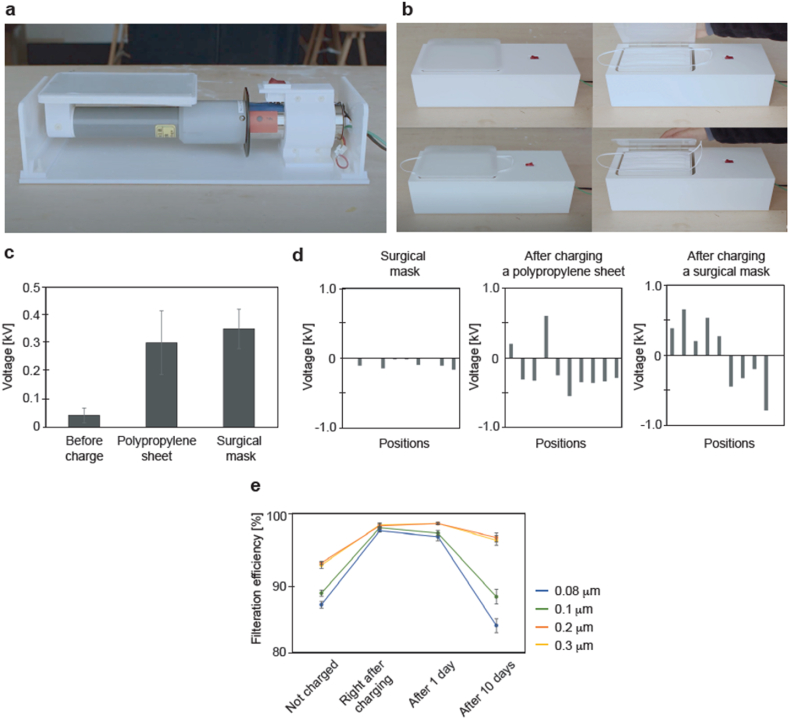

Finally, based on all of the information we have acquired above, we fabricated a desktop mask charger (Fig. 5). The static electricity generator was fixed inside a plastic box made of polypropylene, and only supported at the rear to avoid the voltage leak. The PP/Al double layer electrode was distanced from the desk and other components of the device just enough to hold over 10 kV, so that the device volume becomes reasonable. A simple grounded lid was incorporated together with a main switch for a friendly user interface (Fig. 5ab). The standard surgical masks consist of three layers (a polypropylene sheet sandwiched between two sheets of protective layers) [20]. Either these polypropylene sheets or the entire surgical masks were prewashed in hot water for removing the charges. Once they were completely dried, they were placed on top of the electrode and charged for 1 min. Both polypropylene sheets and the entire masks were successfully recharged by the device (Fig. 5c). Note that the voltage values were averaged after taking an absolute value from each measurement point, because the polarity of the voltage was not uniform in this experiment (Fig. 5d). The results from the Particle Filtration Efficiency (PFE) test (see Materials and Methods for details) proved that these added charges successfully improved the filtering efficiency by 5–10%, depending on the particle size, compared to the polypropylene sheets without charges (Fig. 5e). This effect was larger for smaller particles and lasted less than 10 days. Such correlations between charges and the filtering efficiency have been also reported previously [20,21].

Fig. 5.

Functional prototype of a desk-top mask charger. a, The cross section, and b, the operation of the device. c, Polypropylene sheet electrostatics before and after charging (n = 10). In “polypropylene sheet”, the polypropylene sheet was extracted from surgical masks and the sheet was charged with the device. In “surgical mask”, the entire mask was charged. d, Examples of data used in c before averaging. e, The results from the Particle Filtration Efficiency (PFE) Test (n = 9).

3. Conclusion

We developed a desk-top mask charger that operates with the standard Japanese electrical outlet (100 V, 50 Hz) and confirmed that this device can recharge surgical masks up to several hundreds of volts. Brand-new surgical masks (if stored correctly by avoiding humidity) hold static electricity in the range of 300–1000 V. Therefore, our mask charger is at least able to recover the charges back to the original level of the masks. The results from the Particle Filtration Efficiency (PFE) test proved that these added charges successfully improved the filtering efficiency by 5–10%, depending on the particle size, compared to the polypropylene sheets without charges. The presented device may be applied to reuse surgical masks to reduce the plastic waste and thus microplastic pollution in the land and the ocean in future.

4. Materials and methods

4.1. Instrument

We used a static electricity generator based on the Cockcroft-Walton's voltage multiplier purchased from Green Techno Co. Ltd, Japan. Digital low voltage static meter KSD-3000 (Kasuga, JP) was used for the static electricity measurements. This instrument measures the static electricity in terms of the voltage when the probe is placed 1 cm away from the sample surface. For Fig. 2b, d and Fig. 3d, we fixed the probe at a larger distance than 1 cm to avoid breaking the probe, whereas the values in the figures were corrected by calibration using another device. For Fig. 3b the values are not corrected because the device is meant for measuring charged surfaces, therefore there was no calibration method for the point charge measurement like in this experiment.

4.2. Materials

For the experiment in Fig. 2, the double layer electrode was fabricated by combining pieces of boards made of different materials (thickness of roughly 10 mm) and an aluminum foil with a home-made holder. The contact to the tip of the static electricity generator (the gun) was assured either by a metal wire or by an aluminum ribbon. For the experiment in Fig. 3c, the legs were made of a ceramic supporter (S-20-4, Shinohara Electronic Co., Ltd.). For the experiment in Fig. 4, a lid was made of a piece of either a polypropylene board, a wood board, or an aluminum board at 100 mm × 100 mm. Only for aluminum, other sizes of boards 50 mm × 50 mm and 10 mm × 10 mm were examined and the results are shown in the supplementary information. For the fabrication of the mask charger, polypropylene was used as the main material for the box, the lid and the static electricity generator holder etc. The lid was connected to the ground via a wire. N95 were purchased from 3 M, USA (8210). Surgical masks were purchased from BMC Co., Ltd., JP (Yawaraka Rich Mask). To remove their original charges, either the entire masks or the polypropylene sheets inside the masks were immersed in hot water for several to 30 min and dried. This procedure was repeated twice to remove the charge.

4.3. Experimental setup

Setups shown in Fig. 2a, c and Fig. 3a, c, and Fig. 4a were constructed using the above mentioned static electricity generator, the static electricity sensor and home-made holders made of woods and metals. All of the measurements were performed at room temperature (25 °C) at relative humidity of around 50%–60% [22,23].

4.4. Particle Filtration Efficiency (PFE) test

Polystyrene particles at 0.08 μm, 0.1 μm, 0.2 μm, 0.3 μm were passed through the polypropylene sheets at 28.3 l/min flow rate with the filter area of 49 cm2. 3 measurements per sample from 3 samples (9 data in total) were averaged and plotted with the standard deviation as the error bars.

Author contribution statement

Kaori Sugihara: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Taisuke Ikawa: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Kaito Fujita; Shota Kiuchi; Atsuhito Kushima; Hayato Takase; Megumi Morita; Bratati Das

Muhang Li: Performed the experiments.

Hiroyuki Todo: Conceived and designed the experiments.

Miles Pennington: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Data availability statement

Data will be made available on request.

Declaration of interest’s statement

The authors declare that the following related patent is under review.

Acknowledgments

Part of the research leading to these results has received funding from UTEC-UTokyo FSI Research Grant Program, the FY 2020 University of Tokyo Excellent Young Researcher, Takeda Science Foundation, Mitsubishi Foundation, Inoue Foundation for Science, Naito Foundation, Fuji Seal Foundation, JSPS KAKENHI Grant Number JP22K03544, JP22H04525, JST FOREST Program Grant Number JPMJFR211Q, and JPNP20004, subsidized by the New Energy and Industrial Technology Development Organization (NEDO).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2023.e15359.

Contributor Information

Miles Pennington, Email: miles@designlab.ac.

Kaori Sugihara, Email: kaori-s@iis.u-tokyo.ac.jp.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Tcharkhtchi A., Abbasnezhad N., Seydani M.Z., Zirak N., Farzaneh S., Shirinbayan M. Bioact. Mater. 2021;6:106. doi: 10.1016/j.bioactmat.2020.08.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Ding H. P Soc Photo-Opt. Ins. 1991;1519:847. [Google Scholar]

- 3.Tsai P.P., Schreuder-Gibson H., Gibson P. J. Electrost. 2002;54:333. [Google Scholar]

- 4.Shambaugh R.L. Ind. Eng. Chem. Res. 1988;27:2363. [Google Scholar]

- 5.Lee K.H., Ohsawa O., Watanabe K., Kim I.S., Givens S.R., Chase B., Rabolt J.F. Macromolecules. 2009;42:5215. [Google Scholar]

- 6.Kilic A., Shim E., Pourdeyhimi B. Aerosol Sci. Technol. 2015;49:666. [Google Scholar]

- 7.Konda A., Prakash A., Moss G.A., Schmoldt M., Grant G.D., Guha S. ACS Nano. 2020;14:6339. doi: 10.1021/acsnano.0c03252. [DOI] [PubMed] [Google Scholar]

- 8.Guha S., McCaffrey B., Hariharan P., Myers M.R. J. Occup. Environ. Hyg. 2017;14:214. doi: 10.1080/15459624.2016.1237029. [DOI] [PubMed] [Google Scholar]

- 9.Zhang Y. J. Phys. Conf. Ser. 2020;1622 [Google Scholar]

- 10.Pierlot A.P., Alexander D.L.J., Schutz J.A. Int. J. Environ. Res. Publ. Health. 2022;19 [Google Scholar]

- 11.Prata J.C., Silva A.L.P., Walker T.R., Duarte A.C., Rocha-Santos T. Environ. Sci. Technol. 2020;54:7760. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- 12.Tesfaldet Y.T., Ndeh N.T. Sci. Total Environ. 2022;814 doi: 10.1016/j.scitotenv.2021.152859. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Juang P.S.C., Tsai P. J. Emerg. Med. 2020;58:817. doi: 10.1016/j.jemermed.2020.04.036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Schwartz A., et al. Appl. Biosaf. 2020;25:67. doi: 10.1177/1535676020919932. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Sharma N., Hasan Z., Velayudhan A., Emil M.A., Mangal D.K., Gupta S.D. J. Health Manag. 2020;22:157. [Google Scholar]

- 16.Wang J., Pan L.J., Tang S., Ji J.S., Shi X.M. Environ. Pollut. 2020;266 doi: 10.1016/j.envpol.2020.115099. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Wang D., et al. Eng. Plast. 2020;6:1115. [Google Scholar]

- 18.Hossain E., Bhadra S., Jain H., Das S., Bhattacharya A., Ghosh S., Levine D. Phys. Fluids. 2020;32 doi: 10.1063/5.0023940. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Bandi M.M., Ishizu N., Kang H.B. P Roy. Soc. a-Math. Phy. 2021;477 doi: 10.1098/rspa.2021.0062. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Sugihara K. Soft Matter. 2021;17:10. doi: 10.1039/d0sm02004d. [DOI] [PubMed] [Google Scholar]

- 21.Takahashi T. エアロゾル研究. 1988;3:283. [Google Scholar]

- 22.Chang D.Q., Chen S.C., Fox A.R., Viner A.S., Pui D.Y.H. Aerosol Sci. Technol. 2015;49:966. [Google Scholar]

- 23.Yang S.H., Lee W.M.G., Huang H.L., Huang Y.C., Luo C.H., Wu C.C., Yu K.P. J. Environ. Sci. Heal. A. 2007;42:51. doi: 10.1080/10934520601015651. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.