Abstract

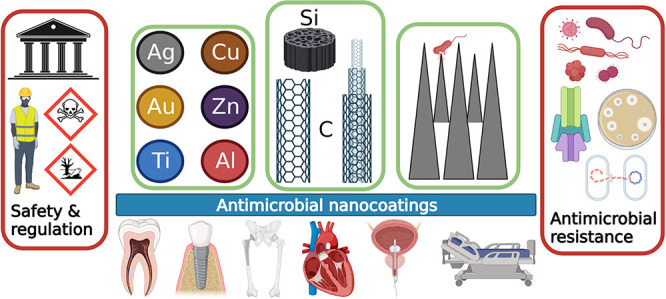

This review discusses topics relevant to the development of antimicrobial nanocoatings and nanoscale surface modifications for medical and dental applications. Nanomaterials have unique properties compared to their micro- and macro-scale counterparts and can be used to reduce or inhibit bacterial growth, surface colonization and biofilm development. Generally, nanocoatings exert their antimicrobial effects through biochemical reactions, production of reactive oxygen species or ionic release, while modified nanotopographies create a physically hostile surface for bacteria, killing cells via biomechanical damage. Nanocoatings may consist of metal nanoparticles including silver, copper, gold, zinc, titanium, and aluminum, while nonmetallic compounds used in nanocoatings may be carbon-based in the form of graphene or carbon nanotubes, or composed of silica or chitosan. Surface nanotopography can be modified by the inclusion of nanoprotrusions or black silicon. Two or more nanomaterials can be combined to form nanocomposites with distinct chemical or physical characteristics, allowing combination of different properties such as antimicrobial activity, biocompatibility, strength, and durability. Despite their wide range of applications in medical engineering, questions have been raised regarding potential toxicity and hazards. Current legal frameworks do not effectively regulate antimicrobial nanocoatings in matters of safety, with open questions remaining about risk analysis and occupational exposure limits not considering coating-based approaches. Bacterial resistance to nanomaterials is also a concern, especially where it may affect wider antimicrobial resistance. Nanocoatings have excellent potential for future use, but safe development of antimicrobials requires careful consideration of the “One Health” agenda, appropriate legislation, and risk assessment.

Keywords: antimicrobial, resistance, antibacterial, antibiofilm, antibiotics, nanoparticle, nanomaterial, nanocoating, surface, safety

Engineered nanomaterials (ENMs) are clusters of atoms forming structures that have at least one dimension in the size range of 1–100 nm and can be found in different shapes and forms including nanoparticles, nanocrystals, nanorods and nanofibers.1 The behavior of ENMs can differ significantly from that of their bulk counterparts because their properties are not determined by their mass or chemical composition exclusively, as with most macro-materials. Certain factors affect the biological interactions of ENMs including their particle size,2,3 shape and surface area to volume ratio,4,5 crystallinity6 and surface charge.7 The unique properties and behaviors of nanomaterials in comparison to their micro- and macro-scale counterparts are the driving force behind the growing body of research in nanotechnology, which allows materials to be developed with specific desired properties. A range of ENMs have been found to have potent antimicrobial properties and as such have enormous potential in medical engineering applications where inhibition of bacterial growth and colonization is important. In recent years, the mechanisms of action of ENMs have become better understood and the exact effects that ENMs can have on bacterial or eukaryotic cells are finally being described, allowing optimization of their antimicrobial performance while maintaining biocompatibility and reducing ecological impact.

This review addresses the state of up-to-date research on the development, application and testing of ENMs with intrinsic antimicrobial properties as surface coatings for medical and dental applications. There are plentiful publications examining nanomaterials as antimicrobial agents8−11 or as carriers for antimicrobial drug delivery.12,13 However, this review discusses the use of ENMs in the form of antimicrobial surface nanocoatings and modification of the surface nanotopography to achieve infection prevention and control (IPC) in medicine and dentistry. The electronic search was conducted by applying a combination of subject terms and keywords on databases including PubMed, Scopus, Google Scholar, and Web of Science. The keywords applied to the searches were: (nanomaterial OR nanoparticle OR nanocoating OR nanotechnology) AND (antimicrobial OR antibacterial OR antifungal OR antibiofilm OR infection). Quality criteria included an assessment of experimental design and appropriate controls, comparisons, and conclusions in the published and peer-reviewed English-language literature. Publications with insufficient detail or relevance, poor descriptions of methodology, lack of replication, or inadequate material characterization were excluded. Examples were also chosen to show a representative selection of materials and applications; these selected examples from the published literature are presented in Tables 1–4. Representative example images of nanocoatings are also shown in Figures 2 and 4. The aims of this review are: (a) to present and discuss the types of antimicrobial nanocoatings available where the nanomaterial itself is intrinsically antimicrobial and assess their reported efficacy, (b) to evaluate the importance and relevance of nanocoatings and surface nanotopography as alternative antimicrobial strategies in the wider context of antimicrobial resistance and infection prevention and control, and (c) to discuss the general pitfalls and safety considerations associated with clinical applications.

Table 1. Summary of Additional Selected Examples from the Published Literature Regarding Application of Metal and Metal Oxide Nanoparticles as Antimicrobial Nanocoatings.

| Nanocoating description | Aim of application | Key methodsa | Target organisms | Key resultsa | Source |

|---|---|---|---|---|---|

| Quaternary ammonium-modified gold nanoclusters | Orthodontic devices | 48 h disc immersion in bacterial suspension | Streptococcus mutans | Reduced biofilm mass (85%) and viability (95%) | (129) |

| CVSA and CLSM biofilm quantification | Good nanocoating stability | ||||

| Biocompatibility for oral keratinocytes | No hemolysis and negligible cellular toxicity found | ||||

| Nickel–titanium wires coated with ZnO NPs by an electrochemical deposition method | Orthodontic wires | Agar diffusion test | Streptococcus pyogenes, | ZOIs observed against all bacteria investigated (mean 3.57–6.25 mm), with stronger activity against Gram positives (mean 4.25–6.25 mm) | (178) |

| Staphylococcus aureus, | |||||

| Escherichia coli | |||||

| ZnO NPs (12–27 nm) applied to TiZrNb alloy by plasma electrolytic oxidation | Dental and orthopedic implants | Sample immersion in bacterial suspension | Staphylococcus aureus | >2 log reduction in biofilm after 2 h | (179) |

| Adherent cells enumerated | ZnO NPs-containing ceramic oxide coating hydrophobicity may affect eukaryotic cell attachment | ||||

| Biocompatibility tested by seeding with U2OS cells and performing Alamar blue testing | |||||

| Ti or Ti–Zr surfaces were coated with a dual layer of ZnO nanospheres and nanorods synthesized by a hydrothermal method | Dental implants to prevent peri-implantitis | Sample immersion in bacterial suspension | Escherichia coli, Staphylococcus aureus | Rapid release from ZnO nanospheres with up to 2-fold higher short-term antibacterial activity | (180) |

| Viable counts after 6 or 48 h | Slower release from ZnO nanorods with longer-term antibacterial properties | ||||

| SEM to assess antibiofilm activity on surfaces coated with bacterial suspension after 2 h | 30–70% Staphylococcus aureus biofilm inhibition after 6 h | ||||

| In vivo activity in rats measured by implantation | In vivo Staphylococcus aureus inhibition (60–80%) over 2 weeks | ||||

| Ag NPs (38 nm) from silver nitrate applied to surgical nylon threads | Antimicrobial wound dressing material | Agar diffusion test with AgNO3 solution and sterile water controls | 6 Gram positive bacteria, 4 Gram-negatives | >15 mm ZOIs against Pseudomonas aeruginosa, Bacillus subtilis, Micrococcus luteus, Bacillus megaterium, and Staphylococcus aureus | (181) |

| 3 molds | >12 mm ZOIs against Rhizopus stolonifera and Candida albicans | ||||

| 1 yeast | |||||

| Silver NPs deposited on both sides of cotton gauzes by technology based on in situ photoreduction of AgNO3 | Application to prevent wound infections | Agar diffusion tests | Staphylococcus aureus | Growth and biofilm proliferation significantly reduced (3.5–4.5 log) | (182) |

| Sample immersed in bacterial suspension and cells enumerated, CLSM and SEM | 0.5% (w/v) had little effect on cell viability and high stability | ||||

| Cytotoxicity on mouse embryonic fibroblasts and human keratinocytes with MTT assay | 4% (w/v) showed 80% reduced cell viability and several fold higher silver release | ||||

| A “simultaneous sonochemical/enzymatic process” used to apply ZnO NPs to cotton | Medical textiles | Sample immersed in bacterial suspension and bacterial enumeration after 1 h | Escherichia coli, Staphylococcus aureus | Nonwashed samples were up to 98% more efficacious against Escherichia coli | (183) |

| Durability evaluated after 10 wash cycles | Cellulase treatment improved durability of antimicrobial effect | ||||

| Coatings of ZnO (120–180 nm) or CuO (18–20 nm) NPs were applied to a teeth model | Antibiofilm coatings to improve oral health | Biofilm assays on artificial teeth | Streptococcus mutans | Biofilm formation inhibited by ZnO (85%) and CuO (70%) | (184) |

| CVSA after 24 h | Effect was solely antibiofilm | ||||

| Fixed teeth visualize with SEM | |||||

| TiO2 nanocoatings on Ti implants formed by an aqueous plasma electrodeposition technique | Photoactivated antimicrobial properties for titanium implants | TiO2-coated Ti specimen activated with infrared laser for 30 s | Staphylococcus aureus | 5 min exposure reduced viability to 23% | (185) |

| Samples immersed in bacterial suspension | 30 min exposure reduced viability to 9% | ||||

| Real time in situ imagining with live/dead-CLSM |

CVSA: crystal violet solubilization assay; CLSM: confocal laser scanning microscopy; SEM: scanning electron microscopy; ZOI: zone of inhibition.

Table 4. Summary of Additional Selected Examples from the Published Literature Regarding Application of Nanocomposites as Antimicrobial Nanocoatings.

| Nanocoating description | Aim of application | Key methods | Target organisms | Key results | Source |

|---|---|---|---|---|---|

| Dental resin with 70% Bis-GMA and 30% TEGDMA with SiO2 and different proportions by weight of MgO NPs | Photocurable dental resin composite with antibacterial properties | Samples seeded with bacterial suspension | Streptococcus mutans | Antibacterial activity correlated with proportion of MgO NPs - 1% MgO NP reduced viability by 67.7% and 4% MgO NP by 99.4% | (267) |

| Viable counts performed on bacteria liberated from samples into saline after 16–18 h | |||||

| A composite dental resin modified by incorporation of TiO2 NPs or a TiO2/Ag nanocomposite | Antibacterial dental restorative material | Immersion in bacterial suspension for 1 h and further broth added | Streptococcus mutans | 0.5%, 1% and 2% TiO2 and 1% and 2% TiO2/Ag NPs significantly inhibited bacterial growth | (268) |

| Nonadherent cells enumerated after 18 h | 2% TiO2 and TiO2/Ag NPs significantly reduced biofilm formation | ||||

| Biofilm established by immersion for 7 days | |||||

| Adherent cells enumerated | |||||

| ZnO quantum dots incorporated into hydroxyethyl methacrylate and mixed with Bis-GMA | Antimicrobial adhesive resins for application in tooth restoration | Immersion in bacterial suspension | Streptococcus mutans | 2.16 log reduction in biofilm in treated samples | (269) |

| Adherent cells enumerated after 24 h | No cytotoxicity observed | ||||

| Cytotoxicity evaluated against human fibroblasts | |||||

| Transbond XT pastes prepared with 1%, 5% and 10% hydroxyapatite/Ag NPs. Resins light-cured for 20 s from each side | Modified orthodontic adhesives to reduce development of caries | Immersion in bacterial suspension | Lactobacillus acidophilus | >50% reduction in biofilm formation for all bacteria | (270) |

| Adherent cells enumerated after 72 h | Streptococcus mutans | Leaching demonstrated, causing dose-dependent loss of bacterial viability | |||

| Aliquots of leached components inoculated with bacterial | Streptococcus sanguinis | ||||

| Viable cells enumerated after 24 h | |||||

| Ag NPs and amorphous calcium phosphate NPs incorporated into the Scotchbond multipurpose bonding system | Dental adhesives with antibacterial properties to reduce development of caries | Dental plaque microcosm model | Saliva microbes from healthy donors | Damaged bacteria in treatment group and >50% less live staining vs controls | (271) |

| Immersion in saliva combined with broth | Significant reduction of biofilms vs controls | ||||

| Live/dead staining and enumeration of adherent cells after 2 days | 50% reduction in cell viability (MTT) and lactic acid production vs controls | ||||

| Metabolic activity (MTT assay) and lactic acid production measured | |||||

| Orthodontic composite paste blended with TiO2 NPs | Antibacterial orthodontic composites | Immersion in bacterial suspension | Streptococcus mutans | >8-fold lower bacterial recovery from experimental specimens versus controls | (272) |

| Viable cells enumerated after 48 h | Antibacterial effect lasted 30 days after curing |

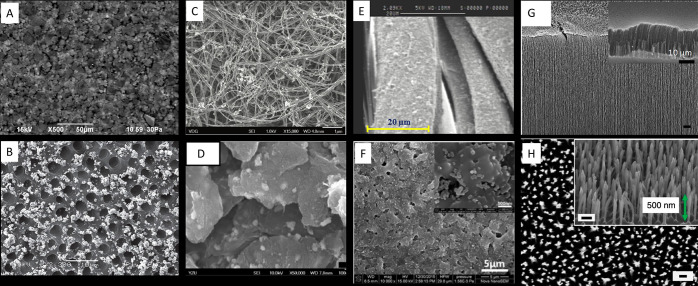

Figure 2.

Representative scanning electron micrographs of antimicrobial nanocoatings. (A) Poly(methyl methacrylate) and silver nanoparticles desposited on silicon wafers. Reprinted with permission from ref (76). Copyright 2017 Elsevier. (B) Dentine coated with silver nanoparticles. Reprinted with permission from ref (77). Copyright 2014 Taylor & Francis Ltd. (C) Multiwalled carbon nanotubes decorated with silver nanoparticles. Reprinted with permission under a Creative Commons CC BY 3.0 License from ref (78). Copyright 2014 Hindawi Publishing Corporation. (D) Silver nanoparticles and zinc oxide nanoparticles embedded on graphene oxide. Reprinted with permission under a Creative Commons CC BY 4.0 License from ref (79). Copyright 2019 MDPI. (E) Fabric coated with poly(styrenesulfonate), chitosan and silver nanoparticles. Reprinted with permission from ref (80). Copyright 2020 Elsevier. (F) Silica nanoparticles applied to a titanium substrate by a microarc oxidation technique. Reprinted with permission from ref (81). Copyright 2017 Elsevier. (G) High aspect ratio (30 μm) vertically aligned carbon nanotubes. Reprinted with permission from ref (82). Copyright 2018 American Chemical Society. (H) Upper surface of black silicon with the green arrow indicating the relative height of the nanoprotrusion on the surface. Reprinted with permission from ref (83). Copyright 2013 Springer Nature.

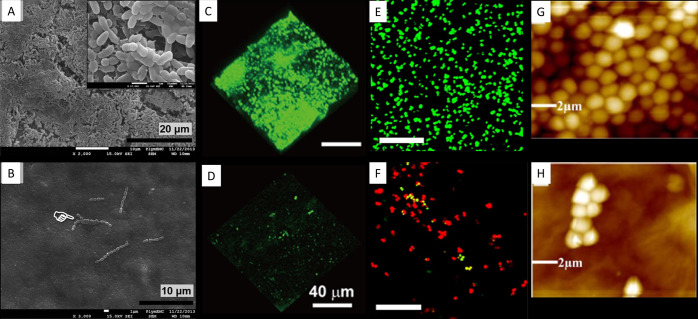

Figure 4.

Representative examples of nanocoated surfaces showing antimicrobial activity compared to uncoated controls. (A) Streptococcus sanguinis biofilm on the surface of uncoated control titanium alloy implants compared to (B) absence of biofilm formation on those implants following application of a dual layer silver-hydroxyapatite nanocoating. Reprinted with permission from ref (69). Copyright 2017 Taylor & Francis Ltd. (C) Confocal laser scanning microscopy live/dead image of Streptococcus mutans biofilm on uncoated Invisalign aligners compared to (D) reduced biofilm formation on gold nanocluster-coated aligners. Reprinted with permission from ref (129). Copyright 2020 American Chemical Society. (E) Confocal laser scanning microscopy live/dead image of Staphylococcus aureus biofilm on control surfaces compared to (F) surfaces coated with stearic acid nanostructures where fewer live bacteria and far more dead bacteria were present. Reprinted with permission from ref (130). Copyright 2017 Elsevier. (G) Atomic force microscopy image of Staphylococcus aureus biofilm on a control surface compared to (H) limited biofilm formation on surfaces coated with graphene oxide. Reprinted with permission from ref (131). Copyright 2017 American Chemical Society.

Antimicrobial Mechanisms of Nanoparticles

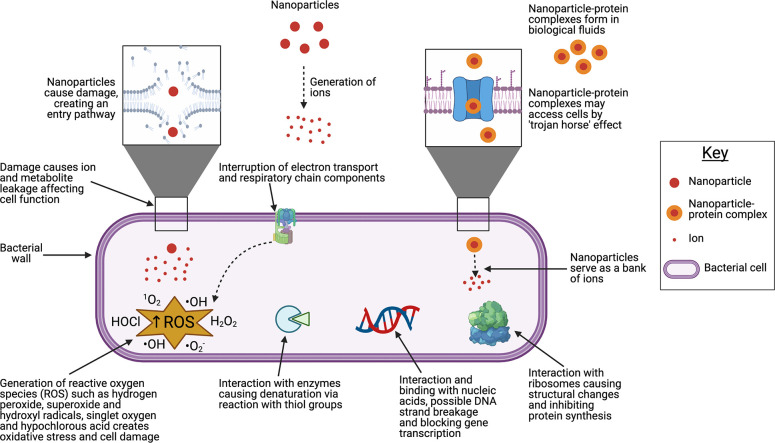

The antimicrobial mechanisms of nanoparticles (NPs) are increasingly being understood in detail and are summarized in Figure 1. Generally, these mechanisms can be classified as direct contact-mediated killing and ion-mediated killing. Direct contact-mediated killing involves NP anchorage to and infiltration of the bacterial cell wall; this leads to membrane damage, leakage of cellular contents and ultimately may alone result in bacterial death.14−17 In this way, large NPs that cannot translocate the bacterial cell wall can still exert bactericidal effects by adsorption and thereby causing mechanical deformation leading to cell rupture and death.18 Upon penetration of the cell wall, NPs gain access to the cell interior and interfere with the function of intracellular biomolecules or structures such as proteins, organelles, and DNA either by direct interactions or by generation of ions. It is possible that NPs may also gain access to the cell without causing membrane damage by way of the protein corona effect, in which NPs in biological environments become modified by adsorption of biomolecules to their surface.19,20 Protein-occluded NPs become akin to a “trojan horse” and gain easier entry into the cell; however, while this has been shown to occur in eukaryotic cells,21,22 it is not known whether the mechanism can be generalized to include bacteria.

Figure 1.

Antimicrobial mechanisms of nanoparticles. Nanoparticles gain entry by damaging the cell wall. Damage to the cell wall by nanoparticle entry may itself lead to leakage of ions and metabolites, conferring an antimicrobial effect. Nanoparticles act as a reservoir of ions which go on to interact intracellularly with ribosomes, nucleic acids, and enzymes, disrupting normal function. Interruption of the respiratory chain leads to generation of reactive oxygen species which create oxidative stress and damage cell components. Figure was created using BioRender.com.

The generation of ions (e.g., Ag+ or Cu2+) is broadly correlated with NP surface area, with greater surface area leading to greater ion production and thus greater antimicrobial activity.23 NPs may function as a “bank” of ions once inside the cell, continuously releasing them and prolonging or strengthening the antibacterial effect. Liberated metal cations can interact with thiol (sulfhydryl) groups in bacterial enzymes, forming stable bonds and disrupting function in essential molecules involved in transmembrane energy generation and electrolyte transport.24 Metal cations such as Ag+ can uncouple the respiratory electron transport chain from oxidative phosphorylation and interfere with penetration of H+ and phosphate into membranes.25−27 Within the bacterial cell, metal cations can form complexes with nuclear material by intercalation between base pairs, disrupting hydrogen bonds and ultimately preventing effective cell division.28,29 The production of reactive oxygen species (ROS), either by disruption of the thioredoxin system30 or by interaction with the respiratory chain and interruption of intracellular O2 reduction,31 is a major ion-mediated killing mechanism.

Generally, the mechanisms mentioned above overlap and cumulatively contribute to an antimicrobial effect. In some cases, however, certain mechanisms are considered to be more prominent for specific nanomaterials than for others. For example, nanosilver binds to the thiol groups of cysteine residues, which are frequently crucial for many proteins to maintain their integrity and function.32 Meanwhile, for nanomaterials consisting of oxides, such as TiO2, ZnO, CuO and Al2O3, toxicity to bacteria is predominantly the result of ROS generation.33−35 However, it is also clear that nonoxide NPs such as Se NPs36 and NPs composed of Ag, Cu, Fe, Mn, Co, Au, or Pt also generate ROS.37

Biofilm Development and Antimicrobial Resistance

Biofilms are communities of bacteria organized into localized, heterogeneous and sessile aggregations that form when bacteria accumulate and adhere to surfaces, forming a thin but robust layer. The bacteria in biofilms are embedded within and secrete a mixture of biomolecules making up a dynamic matrix collectively termed extracellular polymeric substances (EPS). The EPS is composed of a complex assembly of protein, polysaccharide, and extracellular DNA, resulting in a three-dimensional architecture.38,39 The EPS has several roles including physical protection from shear forces, antimicrobials, and immune responses, enabling the diffusion of nutrients through the biofilm, and facilitating horizontal transfer of genes.40,41 The EPS layer confers a level of hydrophobicity which prevents permeation by most extraneous molecules and makes the biofilm very resilient, with some authors even referring to it as “omniphobic” – i.e., repelling all substances.42 Experiments conducted in vitro have demonstrated that bacteria residing in mature biofilms can be between 10–1,000 fold more resistant to antibiotics than their equivalent planktonic cells, demonstrating the extremely robust nature of biofilms once formed.43,44 In this way, biofilm formation represents a major strategy allowing bacteria to defend against antimicrobial attack, facilitating resistance. Biofilms are ubiquitous in the environment, increasingly being considered the predominant means by which microbes thrive in their niche,45 including in the human body, but can present particular health concerns due to their ability to harbor pathogens and resist disinfectants46,47 and antibiotics.48−51

Antimicrobial resistance (AMR) is the outcome of microorganisms changing over time to be able to survive exposure to antimicrobial medicines such as antibiotics which are designed to kill them or inhibit their growth. The recent repeated warnings regarding the rise of AMR in bacteria, the major clinical challenges that this imposes,52 and the various national and international efforts to develop novel antimicrobials in order to maintain our ability to fight bacterial infections underscore the importance of antimicrobial nanomaterials to biomedical research, engineering, and clinical practice. One study found that the burden of antibiotic-resistant infections is comparable to the cumulative burden of influenza, tuberculosis, and HIV, most seriously affecting children aged <1 year and the elderly aged >65 years.53 Furthermore, it was reported that about 75% of the total antibiotic-resistant infection burden was associated with healthcare and 39% of all antibiotic-resistant infections are caused by bacteria with resistance to last-line or last-resort antibiotics, indicating that they are very difficult or even potentially impossible to treat. The UK government-commissioned O’Neill review54 on drug-resistant infections reported that at current rates, by 2050, AMR will lead to 10 million deaths a year, a 2.0–3.5% reduction in gross domestic product and will cost the world up to US$100 trillion. A study of the global AMR burden in 2019 estimated that 4.95 million deaths were associated with bacterial AMR, with 1.27 million deaths directly attributable to AMR.55 Unfortunately, the discovery and development of new antibiotics is not straightforward; no majorly impactful classes of antibiotics were introduced between 1962 and 2000,56 although the approval of daptomycin57 by the US Food and Drug Administration (FDA) in 2003 is often cited as one example of success. The global antibiotics market is dominated by classes introduced half a century ago56 and the majority of the pharmaceutical industry has dismantled or scaled back its antibiotic research laboratories, leaving an inadequate antibiotic pipeline and lack of industry infrastructure and expertise.58,59 The divestment in antibiotic R&D by the pharmaceutical industry is largely driven by poor returns on investment and it is now widely acknowledged that reimbursement for antibiotic development needs to be delinked from sales volumes.60 There are several international initiatives now in place that aim to “fix” the antibiotic R&D funding model: a UK scheme is being trialed where the Government will pay manufacturers a fixed fee for access to new antibiotics; similar approaches are being adopted in Germany and Sweden with a premium being paid for selected antibacterial agents; and in the US the PASTEUR Act will ensure annual revenues for new antibiotics meet a minimum level that is acceptable to industry.61

To address the recommendations of the O’Neill report, and ultimately reduce the global burden of AMR, both new antibiotics and new alternative antimicrobial strategies are urgently needed. As biofilms–once formed–provide such an effective barrier against antimicrobial attack, novel strategies which inhibit biofilm formation must be sought.

Use of Nanocoatings as a Strategy for Infection Prevention and Control

As the effectiveness of currently available antibiotics is being undermined by rising AMR, nanotechnology seems to be a promising alternative strategy for treatment or IPC. Certain types of free NPs suspended in solutions have been found to be highly effective antimicrobials under in vitro conditions.62−64 However, their application in an immobilized form, such as nanocoatings, is a way to maximize their antibacterial efficacy while minimizing material loss (see representative examples in Figure 2). Regarding surface application of antimicrobials, the ideal scenario for IPC would be inhibition of initial biofilm formation, which requires interruption of bacterial adherence to substrates or early toxicity to bacteria. A “race for the surface” effect has been suggested, in which the first cells colonizing a surface tend to be the ones to successfully develop a community on that surface.65,66 An experimental setup investigating the “race for the surface” between eukaryotic U2OS osteosarcoma cells and Staphylococcus epidermidis demonstrated realistic competition between cells, which can be affected by conditions such as medium flow rate and initial bacterial inoculum.67 This antagonistic effect between eukaryotic cells and bacteria could be the key to a successful strategy relying on the use of antimicrobial nanocoatings; preventing bacteria from initially establishing dominance on surfaces while allowing cells (e.g., host cells in the case of implanted biomaterials) to adhere.

The use of implanted biomaterials and medical devices continues to increase year upon year mainly because of the aging population and advancement of medical engineering. Implants may include joint replacements, internal fixation orthopedic implants (e.g., screws, pins, plates), bone cements, dental and maxillofacial implants, tissue engineering scaffolds, artificial heart valves, pacemakers, stents, catheters, and wound dressings. Despite their high success rate, implants can still fail because of lack of biocompatibility and immunological rejection. However, development of peri-implantitis, which is caused by infection, remains the most common reason for implant failure.68 Infections caused by colonization of medical or dental implants can result in patient morbidity and mortality, as well as the need for repeated surgeries with associated financial cost, patient distress and wasted resources. Application of suitable nanocoatings to the surface of implants could offer IPC through inhibition of bacterial colonization and biofilm formation.69 Around half of all nosocomial infections are associated with indwelling medical devices,70 and in addition to the medical devices that come in direct contact with human tissues, there are a wealth of other surfaces in a clinical environment which can serve as reservoirs of pathogenic microbes. Examples include high-touch surfaces such as preparation surfaces in hospital kitchens and operating theaters, door handles, bedrails, taps, bedding, patient gowns, and scrubs. Detergents and disinfectants are currently used to improve hospital cleanliness but clearly have failed to eliminate the problem,71−73 and resistance is emerging.74,75 Applying durable antimicrobial nanocoatings to those surfaces could reduce the spread of infection since they could offer a long-lasting effect.

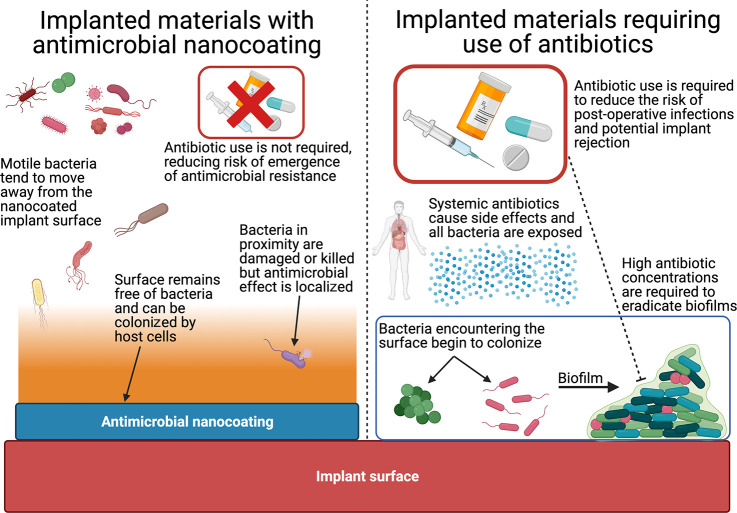

In the context of implanted biomaterials, antimicrobial nanocoatings offer advantages over antibiotics (Figure 3). One advantage is the exertion of effects locally rather than systemically, as the immediate surface is protected by the nanocoating while other tissues distant from the implant site are not exposed to the antimicrobial. Related to this, nanocoatings may improve the patient experience by avoiding the side effects84 and complications85 of antibiotics. Furthermore, antimicrobial nanocoatings would facilitate a reduction in antibiotic usage, allowing them to be reserved for other essential therapeutic applications, and may thereby reduce the opportunity for selection of antibiotic resistant bacteria.

Figure 3.

Advantages of implanted materials incorporating antimicrobial nanocoatings over those without. Implanted materials without antimicrobial nanocoatings become colonized by bacteria encountering the surface and forming biofilms. Prophylactic antibiotics are often given systemically, bringing side effects to the patient and exposing all bacteria to antibiotics, raising the risk of antimicrobial resistance. High doses of antibiotics are also required to eradicate mature biofilms. When antimicrobial nanocoatings are incorporated on the surfaces of implanted materials, the surface remains uncolonized and antibiotic use may not be required, leading to fewer patient side effects and less exposure of bacteria to antibiotics. While the antimicrobial effects of nanocoatings are local compared to systemic antibiotics, nanocoatings exert an antimicrobial effect beyond the immediate surface and cause bacteria nearby to move away or become damaged. Figure was created using BioRender.com.

Factors Affecting Antimicrobial Activity of ENMs

The activity of nanoparticulate metals differs from that of their bulk counterparts with factors such as NP size, shape, surface charge and elemental composition, playing a pivotal role in not only their physical and chemical characteristics but also their antimicrobial behavior. Due to the differing dimensions among published research and frequent lack of a systematic or easily comparable approach, it can be difficult to determine which properties confer the most potent antimicrobial effects. In some cases, it is difficult to conclude which properties are optimal given that different authors tend not to compare the same conditions, and thus there is generally a lack of direct replication of studies. It is clear though that there are complex interactions between size, shape, method of production and exposure conditions which affect overall antimicrobial activities. A greater understanding and appreciation of these properties and their combined effects on ENM antimicrobial activity will allow better fine-tuning of effects and improve suitability of ENMs to their applications.86

Size

Baker et al.87 investigated the effect of size on antibacterial activity in silver NPs and found that NPs with a mean size of 15 nm exhibited higher antibacterial activity against Escherichia coli compared to those of 75 nm. Bactericidal properties against other Gram-negative bacteria including Pseudomonas aeruginosa, Vibrio cholerae, and Salmonella Typhi have also been found to be optimal for particles having a diameter of approximately 1–10 nm.88 The trend of antimicrobial activity increasing with decreasing NP size has been confirmed by multiple other studies.89−91

Shape (Particle Morphology)

In general, spherical NPs are the most common, but other shapes including rods, cubes, flakes, and tubes are available. Some authors suggest that triangular nanoplates have the strongest biocidal activity,92 while others suggest cubic NPs are the most effective due to the exposed planes.93 The differences in activity related to particle shape or morphology appear to be due to variations in ionic release as an expression of the total surface area.94 Thus, particle morphology could be a valuable variable used to tune nanoparticle effects for intended applications, facilitating a controlled design.86

Surface Charge

Zinc oxide NPs with a positive surface charge have been shown to exhibit antimicrobial activity against both Gram positive and Gram-negative bacteria, while NPs of the same size but with negative surface charge did not exhibit any inhibition of bacterial growth. This is hypothesized to be due to the positive surface charge of the NPs enhancing ROS production and applying mechanical stress on the negatively charged bacterial membrane.95 Zwitterion-modified silver NPs have been shown to be designed to shift their surface charge in response to differing pH conditions, allowing more targeted antimicrobial activity. This is achieved by NPs responding to physiological pH in healthy tissues while adhering to negatively charged bacteria at infectious sites with lower pH values.96

Types of Nanocoatings

Nanomaterials can vary significantly in shape, size, elemental composition, synthesis, presentation, and surface modifications, which means that there is a wide range of different types of nanocoatings available or currently under development. In this review, nanocoatings have been classified according to the family of materials they consist of: metal and metal oxide NPs (Table 1), ceramic, and nonmetallic NPs, including carbon-based nanomaterials (Table 2). Representative example images from studies describing antimicrobial nanocoatings can be seen in Figure 4.

Table 2. Summary of Additional Selected Examples from the Published Literature Regarding Application of Nonmetallic Nanomaterials as Antimicrobial Nanocoatings.

| Nanocoating description | Aim of application | Key methodsa | Target organisms | Key resultsa | Source |

|---|---|---|---|---|---|

| Dual layer cotton coated with chitosan nanofibers incorporating Agrimonia eupatoria extract | Therapeutic wound dressings | Agar slurries of bacteria spread on surfaces | Pseudomonas aeruginosa, Staphylococcus aureus | Coatings with and without extract inhibited bacterial growth | (214) |

| Slurries released and bacteria enumerated | Inhibition was greater (>98%) in extract-containing group | ||||

| MTT used for in vitro cytotoxicity against human dermal fibroblasts | No cytotoxicity seen against human dermal fibroblasts | ||||

| Graphene nanoplatelets incorporated in polyurethane by melt blending and dip coating | Catheters | Bacterial culture deposited on surfaces | Staphylococcus epidermidis | Dip-coated surfaces caused 50–100% decrease in metabolic activity and 57–82% decrease in viability | (215) |

| Nonadherent bacteria enumerated after 24 h | Bactericidal activity upon contact not shown toward adherent or planktonic cells for melt blended samples | ||||

| Adherent bacteria visualized by FM | |||||

| Composite of graphite nanoplatelets and low-density polyethylene produced with graphite nanoplatelets oriented in a controlled manner, exposed by etching | Antibacterial surfaces for biomedical devices | Surfaces seeded with bacteria | Escherichia coli, Staphylococcus epidermidis | Bactericidal activity against S. epidermidis (95%) and E. coli (90%) was dependent on nanoflake orientation and density - in one group viability loss was >99.99% for both bacteria | (216) |

| Bacteria enumerated after 24 h | Reduced bacterial adhesion and surface colonization seen with live/dead staining | ||||

| Surfaces investigated with SEM, live/dead and reactive oxygen staining and FM | No toxicity against SH-SY5Y or HUH-7 cells | ||||

| In vitro cytotoxicity evaluated against SH-SY5Y and HUH-7 cells | |||||

| Graphene coating developed using a one-step laser-induced method | Antibacterial coatings for water robots | Samples placed on agar plates inoculated with bacteria followed by 10 min solar treatment | Escherichia coli | >99.8% reduction in viable bacteria | (217) |

| Bacteria enumerated after 12 h | SEM showed no bacteria on graphene-coated glass samples but dense ones on untreated surfaces | ||||

| SEM to visualize samples | |||||

| Hydroxyapatite coating on titanium by microarc oxidation followed by loading of chitosan by dip-coating | Titanium implants | Surfaces seeded with bacteria and enumerated after 24 h | Escherichia coli | Up to 65% antibacterial activity demonstrated and improved with increasing chitosan but decreased over time | (218) |

| Agar diffusion and UV spectrophotometry | No cytotoxicity or morphology differences found | ||||

| Biocompatibility and osteogenic properties evaluated with MC3T3-E1 cells | Cells proliferated faster on surfaces lacking chitosan and cell numbers decreased as chitosan content increased | ||||

| Titanium implants coated with chitosan and alginate by spin coating | Titanium implants | Bacterial viability quantified following surface contact | Escherichia coli | Antibacterial activity of >36% demonstrated and improved with chitosan and alginate | (219) |

| In vitro cytotoxicity against L929 fibroblasts | No cytotoxicity and biocompatibility demonstrated | ||||

| Graphene oxide (GO) applied to polyvinylidene fluoride by vacuum filtration | Antibiofouling coatings in wastewater treatment technologies | Bacterial cultures filtered through GO-modified membranes | Escherichia coli, Staphylococcus aureus | >70% bactericidal activity against both target bacteria with effects increasing over time | (220) |

| Cell morphology observed by SEM | Bactericidal activity S. aureus ≫ E. coli | ||||

| Surfaces seeded with bacterial suspensions for biofilm assays | SEM showed bacteria on coated membranes had compromised cellular integrity | ||||

| CVSA quantification after 24 h | Reduced biofilm biomass on coated versus uncoated membranes | ||||

| GO applied to polyetheretherketone by dipping method | Bioactive implant material for bone tissue engineering | Immersion in bacterial culture and adhered cells enumerated after 24 h | Escherichia coli, Staphylococcus aureus | Changes in morphology and suppressed colonization for E. coli by 54–77% but not for S. aureus | (221) |

| Fixed samples viewed with SEM | GO coating may enhance cytocompatibility as osteogenesis markers upregulated | ||||

| CCK-8 kit and CLSM for in vitro cytotoxicity toward human osteoblast-like MG-63 cells | |||||

| Polycarbonate urethane was coated with a thin film of GO | Medical implants | Immersion in bacterial culture and adhered cells enumerated after 24 h | Pseudomonas aeruginosa, Staphylococcus aureus | No GO leaching detected | (222) |

| GO leaching and hemolysis (ISO 10993–4) measured | Reduced adhesion of S. aureus (86%) and P. aeruginosa (64%) | ||||

| In vitro adhesion and proliferation measured with L929 fibroblasts by FM and MTT assay | GO coating induced hemolysis more than controls (0.055% vs 0.02%), but was <5% (ISO 10993–4) | ||||

| L929 cell proliferation unaffected compared to control | |||||

| GO-coated surfaces were prepared by Hummers’ method and an “improved” method | Antimicrobial surface coatings for biomedical applications | Immersion in bacterial culture for 24 h with viable cell enumeration | Escherichia coli, Staphylococcus aureus | Antibacterial activity seen in all treatment groups | (223) |

| Biofilm assays in GO plated 96 well plates CVSA and microscopic visualization and quantification after 24 h | Smoother surface in “improved” method–fewer pores and less E. coli biofilm inhibition | ||||

| Increasing GO content increased E. coli biofilm inhibition by up to 150% but not S. aureus, remaining around 75% |

CVSA: crystal violet solubilization assay; CLSM: confocal laser scanning microscopy; SEM: scanning electron microscopy; FM: fluorescence microscopy; UV: ultraviolet; MTT: 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide; CCK: cell counting kit.

Metal and Metal Oxide Nanocoatings

Metal compounds have been used as antimicrobial agents since antiquity with silver, zinc, titanium, copper and gold having received the most interest, each showing different properties and antimicrobial efficacy.97

Silver Nanocoatings

Bulk metallic silver (Ag) has been known for its inherent antimicrobial properties since 4000 BCE,98,99 well before the introduction of the first antibiotics. More recently, Ag has been used in medical devices such as wound dressings and catheters to restrict or impede bacterial growth and biofilm formation.100−102

Silver nanoparticles (Ag NPs) applied as nanocoatings have been investigated in the context of medical implants and prostheses. In the oral cavity, bacteria must adhere to surfaces and form biofilms to survive and proliferate; nutrients in aqueous environments tend to accumulate on surfaces, and adhesion allows bacteria to resist the shear forces of salivary fluid movement and passage to the gastrointestinal tract beyond.103 As such, prevention of initial bacterial adherence and biofilm formation or reducing the rate of biofilm development and maturation appear to be the major goals of antimicrobial surface coatings in dentistry. Ag NPs have been applied in the form of nanocoatings directly to the surface of dentine.77 The Ag nanocoatings were found to be stable in biological fluids, prevent biofilm formation, and inhibit bacterial growth in the surrounding media. Ag NPs in this form were also found to be more bactericidal toward the oral pathogen Streptococcus mutans when compared to the oral disinfectant chlorhexidine. Despite Ag NPs being equally as bactericidal as silver nitrate (AgNO3), they did not cause dentine discoloration. Similar nanocoatings were later studied following application to titanium alloy orthopedic medical implants; silver-plated discs exhibited the highest antibacterial activity and strongest antibiofilm activity while experiencing very little material loss as a result of silver dissolution from the nanocoatings.69 Ag nanocoatings applied to the surface of silicone maxillofacial prostheses were found to prevent fungal infection caused by Candida albicans in vitro, while being highly biocompatible with dermal fibroblasts.104 These studies have demonstrated that application of silver nanocoatings to medical implants and tissues is a promising alternative antimicrobial strategy that also addresses potential biocompatibility issues. However, it should be noted that these studies were exclusively performed in vitro.

Meran et al.104 suggested good compatibility between Ag NPs and eukaryotic cells, a critical issue in nanomaterial development for clinical applications. A major advantage of Ag NPs is their low toxicity to mammalian cells relative to their bactericidal concentration. This means that although it is possible for them to be toxic to mammalian cells, this can only be possible at concentrations higher than those required to demonstrate bactericidal activity. The minimum inhibitory concentration (MIC) or minimum bactericidal concentration (MBC) of Ag NPs can be difficult to reliably determine using visual methods alone and turbidity corrections must be made because turbidity caused by NP dispersions can mask absorbance caused by bacterial growth at NP concentrations above 12.5 μg mL–1.62 Corrections are particle-specific as NP properties such as size, shape and crystallinity affect measurements of absorbance. Reported MIC values for Ag NPs include 67 μg mL–1 against a 6 × 105 CFU mL–1 inoculum of Streptococcus mutans(105) or 4.9 ± 2.7 μg mL–1 against a 1.5 × 105 CFU mL–1 inoculum of the same bacterium and an MBC of 6.25 μg mL–1.106 These findings highlight the extent to which seemingly similar studies can provide quite varying results, with proteins present in different growth media and the resulting protein corona effect being responsible for those differences.107,108 An MBC of 6.25 μg mL–1 has also been reported for the pathogens Listeria monocytogenes, Escherichia coli O157:H7, Salmonella Typhimurium, and Vibrio parahemolyticus.109 The minimum concentration having damaging effects on eukaryotic cells has consistently been found to be above 5 μg mL–1 in different cell lines.110−112 Other studies on Ag NPs have reported much higher values as minimum cytotoxic concentrations: 30 μg mL–1113 or even 61 μg mL–1.114 These data suggest that there is likely to be a sufficient window of concentration within which to design nanocoatings with appropriate nanoparticle release profiles. A balance must be achieved, generating a high enough concentration of Ag NPs in the local environment to have sufficient effect on bacteria without causing such a high material release as to lead to host cell toxicity or local tissue damage.

The balance of robust antibacterial efficacy with minimal toxicity to eukaryotic cells has been investigated using a porous poly(methyl methacrylate) (PMMA) substrate, a biomaterial highly susceptible to bacterial colonization, combined with a coating of immobilized Ag NPs.76 The Ag NP thin film was applied using pulsed laser deposition, a process optimized by varying the total laser pulses to alter the thickness of the film. The study showed that it was feasible to develop a manufacturing process to apply the optimal amount of Ag NPs to a PMMA medical implant, minimizing the risk of bacterial colonization while simultaneously reducing the risk of a patient adverse reaction.

Agnihotri et al.115 investigated Ag NPs immobilized on a functionalized silica surface. Their findings underscored contact killing as the predominant bactericidal mechanism in this context, and showed that immobilized (i.e., surface-coated) NPs demonstrated greater efficacy than colloidal NPs of the same size and morphology. The tested Ag NP-glass surface was shown to be bactericidal for all three bacterial strains (two of Escherichia coli and one of Bacillus subtilis) investigated at both initial bacterial densities (103 and 105 CFU mL–1), and complete disinfection (quantified by viable counts of zero in duplicate) was achieved within 2 h for all test conditions. As would be expected, a higher initial bacterial load resulted in a longer time to disinfection, highlighting the importance of standardizing and reporting this value in future work. It was also found that coated surfaces could be reused many times without loss of antibacterial activity; complete disinfection of an initial bacterial load of 103 CFU mL–1 of Escherichia coli was achieved within 50 min, even when the surface was used for the 11th time. Disinfection was still achieved even when ionic silver release from the surface was very low (0.0109 μg mL–1).115 It would be valuable to investigate how more relevant physiological media containing proteins and other solutes can affect the efficacy of this type of coating; it is well-known that exposure of Ag NPs to physiological media containing proteins and other biomolecules compared to deionized water tends to cause greater agglomeration and more pronounced loss of antimicrobial activity,116 though this effect may potentially be circumvented by surface coating treatments aiming to prevent NP agglomeration. The relevance of this effect also depends upon the intended application of the nanocoating; it would be less relevant in a setting where nanocoatings are applied to clinical environmental surfaces (e.g., bed rails, hospital fabrics, and door handles) compared to implanted medical devices that are exposed to high concentrations of biomolecules.

Copper Nanocoatings

Similar to Ag, copper (Cu) has been known to have biocidal effects since antiquity, with some more recent applications testing its use for high-touch surfaces (e.g., door handles, bathroom fixtures, and hospital bed rails)117 and fabrics.118 Despite the encouraging evidence on antimicrobial activity, concerns about the toxicity and ecological impact of Cu NPs are likely to be the reason preventing further investigation of their use as antimicrobial nanocoatings. There is evidence that Cu NPs are toxic to mammalian somatosensory neurons, with greatest toxicity resulting from smaller NP size and higher concentrations.119 This is a significant finding as nanomaterials can be transported in a retrograde manner from nerve endings in skin to neurons in the dorsal root ganglion.120 Additionally, Cu NPs have been reported to be acutely toxic to zebrafish (Danio rerio), with the gill being the primary target,121 and cause retardation of zebrafish embryonic development and morphological malformation of larvae.122 The fate of Cu NPs in the environment is also different to that of other nanomaterials. For instance, sulfidation of CuO NPs to form Cu2S or CuS in environments with augmented sulfide levels, such as in wastewater treatment plants, increases solubility rather than decreasing it (as is the case with Ag and ZnO NPs) and leads to greater Cu2+ release,123 therefore resulting in increased toxicity to aquatic organisms.124

Despite the ecotoxicity concerns around Cu nanomaterials, there have been reports on their use as part of antimicrobial strategies. In order to combine and maximize the effects of the high surface area to volume ratio of NPs and the high aspect ratio of MWCNTs, CuO NPs have been investigated as an application to MWCNTs in contact with eukaryotic cells. Additionally, decoration of CuO NPs onto MWCNTs was anticipated to limit absorption of NPs by the human body as well as reduce the loss of NPs to the environment, addressing the ecological concerns to some extent. Mean average sizes of both cupric (CuO) and cuprous (Cu2O) NPs were <10 nm, which is generally at the smaller end of the spectrum for NPs. Cytotoxicity to human dermal fibroblasts only occurred at a relatively high concentration of 150 μg mL–1, while at 100 μg mL–1, some changes to cell morphology were observed but the proportions of live and dead cells remained unaffected. Comparatively, marked antibacterial activity was observed at 60 and 50 μg mL–1. Biofilm development by Methylobacterium spp. was inhibited at biocompatible concentrations, and furthermore the CuO/MWCNTs effectively managed to remove preformed biofilms. This study invokes optimism for the synergistic bactericidal and antibiofilm properties of CuO NPs decorated on MWCNTs.

Other studies have confirmed the potent antibacterial activity of CuO NPs when applied as coatings against Escherichia coli,125Staphylococcus aureus,126 and Pseudomonas aeruginosa(127) as well as antibiotic resistant bacteria such as methicillin-resistant Staphylococcus aureus.128 LewisOscar et al.127 demonstrated that CuO NPs had a strong antibiofilm effect, with a maximum of 94% biofilm inhibition against clinical strains of Pseudomonas aeruginosa, at a concentration of only 0.1 μg mL–1. This relatively low concentration demonstrating such potent antibiofilm effects makes CuO NPs an attractive option for antimicrobial nanocoating development. In addition, CuO NPs at that concentration inhibited the production of EPS by up to 93%, complementing the principal antibiofilm properties by preventing the formation of a protective EPS layer by the proportion of bacteria able to form a biofilm. These findings highlight the potent antibiofilm properties that CuO NPs have and which would be highly relevant to antimicrobial nanocoatings.

Gold Nanocoatings

Gold (Au) has been used as an anti-inflammatory agent for the chronic inflammatory disease rheumatoid arthritis, specifically as a disease-modifying antirheumatic drug. However, use of Au salts was replaced by alternative drugs in the 1990s due to adverse effects, limited efficacy and slow relief of symptoms.132 While this was a setback for the use of Au in modern medicine, more recently Au has been reconsidered for use in nanomedicine.133 Research suggests Au NPs have potentially reduced relative toxicity and lower masses required to achieve therapeutic efficacy, which makes them an attractive option. However, other studies have exhibited opposing results disputing their potential for clinical use.

Au NPs have been reported to lack inherent antibacterial properties altogether134,135 or to inhibit biofilm formation without having toxic effects against pathogens.136 Other studies have suggested that they do have an antibacterial effect, but this is weak, with high MIC values measured (e.g., 197 μg mL–1 against Streptococcus mutans).106 Another study found no concentration-dependent effects of Au NPs against Escherichia coli, but did report that Au NPs affected cell division.137 There is evidence that Au NPs have antifungal effects, with one study reporting excellent size-dependent antifungal activity against Candida isolates.138

Presumably due to their lack of clear potent antibacterial effects, there is little evidence in the published literature describing the use of Au NPs in antimicrobial coatings. Adsorption of Au NPs on a silica surface tested against Escherichia coli and Staphylococcus aureus did not demonstrate any bactericidal properties.139 Au NPs can be applied as a shell around a dielectric core to produce an Au nanoshell, while these structures are physiologically inert, they can have photothermal effects and generate significant heat by their strong surface plasmon resonance. The plasmon resonance can be tuned to different wavelengths by varying the relative size of the dielectric core and the thickness of the Au layer.140 These Au nanoshells were applied to a silicone catheter surface and tested for antimicrobial activity against a drug-resistant strain of Enterococcus faecalis using a near-infrared diode laser to produce heat with potentially bactericidal effects. Application of the laser for 5 and 10 min resulted in severely diminished surviving bacterial numbers, with scanning electron microscopy showing thermally induced rupturing of bacterial cell walls.141 The success of the nanoshell coating becoming antimicrobial upon exposure to the near-infrared laser suggests a possible mechanism where segments of silicone catheter or other materials could be coated and subsequently sterilized on a regular basis. The comparative effects on bacteria in biofilms should also be investigated, though due to the physical method of bacterial killing, it is unlikely that biofilm formation alone would protect bacteria from the relatively high local temperatures (73 °C) encountered.

There is another field of research examining the use of Au NPs in combination with other molecules to deliver an antimicrobial effect, for example, by doping Au NPs with a tRNA analogue,142 loading them with 5-fluorouracil, an anticancer drug,143 or by coating them with the antibiotic amoxicillin.144 This type of application has previously been reviewed145 and is beyond the scope of this review because in those cases, the nanomaterial itself was not the active antimicrobial but acted as a carrier for drug delivery.

Zinc Nanocoatings

Zinc NPs are most used as antimicrobials in the form of zinc oxide (ZnO). A proposed benefit for ZnO nanocoatings applied to orthopedic or dental implants is the effect of zinc in augmenting bone formation by stimulation of osteoblast activity and cell proliferation.146,147 Zinc also has a role as a cofactor for collagen synthesis, and supports bone mineralization via alkaline phosphatase.148 This strong association with bone formation and mineralization makes ZnO NPs ideal candidates for use in antimicrobial nanocoatings near calcified tissues, such as bone scaffolds and joint replacement implants. The antimicrobial effects of ZnO NPs appear to be high, albeit potentially dependent on the morphology of the nanocoating. The strongest antimicrobial effect has been observed for nanomaterials with rod-like morphology and a high degree of crystallinity.149 These findings were contradicted by another study150 showing that ZnO nanocoatings had strong antibacterial activity toward Escherichia coli and Staphylococcus aureus, but no significant differences between particle morphologies were observed. Light-producing biosensor versions of the bacterial cells acting as reporters (constitutively expressing the Lux operon and emitting a light signal correlating with cell numbers) allowed real-time measurement of the antibacterial effect, demonstrating that a long incubation was not necessary; the antibacterial effects of ZnO nanocoatings were apparent even after short exposure times. Antibacterial effect also increases with thicker films of NPs, affecting the bacterial generation time and essentially retarding growth and leading to fewer bacterial cells present.151 Thicker films consist of larger quantities of NPs and presumably result in higher local concentrations of ions following NP dissolution.

Despite ZnO NPs showing good bactericidal efficacy, their biocompatibility and cytotoxic effects must also be considered. It has been reported that ZnO nanofilms significantly decrease cell viability (as confirmed by MTT assay) of cultured macrophages by 54% and 65% depending on NP size (100 and 20 nm, respectively) after a 48 h incubation, although no cytotoxicity was measured after 24 h.152 This initial lack of cytotoxic effect suggests a gradual release of material which accumulates over time to produce a more cytotoxic concentration, or alternatively could suggest a time-dependent cytotoxic effect. This contrasts with the alternative toxicokinetics where most material is released faster in the short term, causing higher toxicity in the early stages. A later report highlighted that direct exposure of cells to ZnO nanofilms could cause apoptosis and necrosis, two forms of both controlled and uncontrolled eukaryotic cell death, in a murine macrophage cell line.153 Depending on the type of bioassay employed (MTT versus LDH), cells grown on ZnO nanofilms showed a 43–68% loss of viability following a 24 h exposure compared to controls, with cells separately exposed to undiluted extracts from the coatings showing even greater viability loss. Two diluted coating extracts, 25% and 50% (corresponding to concentrations of 3.03 and 6.07 μg mL–1, respectively) showed no cytotoxic effects against macrophages, indicating a tolerable concentration of ZnO NPs, but it was unclear whether these concentrations would have an antimicrobial effect. Petrochenko et al.153 highlighted the importance of using both direct-exposure and extract-based methods to assess toxicity, as nanocoatings show gradual material release which can accumulate to a toxic level over time and extracts can simulate the result of this accumulation. It is difficult to draw wide conclusions based on these individual studies, but there are indications that ZnO nanocoatings could have inherent biocompatibility issues. Research efforts to address the biocompatibility of ZnO nanocoatings have been scant, with most studies looking at ZnO coatings at particle sizes greater than the nanoscale. A more recent study investigating the in vitro biocompatibility of ZnO nanofilms at the nanoscale found that direct exposure to ZnO nanofilms reduced cell viability of mouse fibroblasts due to inhibition of cell adhesion, regardless of ZnO crystallinity.154 This study appears to agree with that published by Petrochenko et al.153 and provides further evidence of the adverse effects of ZnO nanocoatings on eukaryotic (i.e., host) cells, leading to concerns over the safety and biocompatibility of ZnO nanocoatings in vivo.

Titanium Nanocoatings

Titanium (Ti) and its alloys are the industry standard for implanted biomaterials due to their inherent biocompatibility, inert chemistry, strength, corrosion resistance, and lack of toxicity.155 Ti NPs have also been the subject of extensive research due to their well-established photocatalytic properties,156 further enhanced by the high surface area of NPs, providing antimicrobial properties.157 Titanium dioxide (TiO2) is most associated with this application, and exists in three main forms: anatase, rutile, and brookite. Anatase is the most photochemically active phase of TiO2, though combinations of different phases may show heightened activity compared to anatase alone.158,159 The high photoactivity and stability of TiO2, along with its relatively low cost and lack of toxicity has led to its consideration as a potentially self-disinfecting or self-sterilizing surface coating.160,161 An advantage of a photocatalytic self-disinfecting surface is that there is no necessity to add other chemical reagents; the only requirements would be oxygen, water and light.162 The band gap energy of anatase TiO2 is approximately 3.2 eV, corresponding to activation by photons with wavelength shorter than 385 nm and therefore to UVA light.163 However, since only 8% of solar radiation is UV, there is a need to develop photocatalysts which can be activated predominantly by visible light (42% of solar radiation), especially if a surface is intended for environmental use with activation by sunlight.164 The extent to which activation by sunlight is a relevant mechanism will depend on the intended application of TiO2 nanocoatings; activation of antimicrobial properties by the ambient lighting on a hospital ward or similar environment would be highly beneficial.

The nature of the antimicrobial mechanism based on ROS production suggests that TiO2 nanocoatings can be hostile to both bacterial cells and eukaryotes, limiting their use in vivo. Several studies have reported that TiO2 NPs exhibit toxicity, including evidence of genotoxicity, in both light and dark conditions.165−168 The production and toxicity of ROS are indiscriminate, and therefore there is a presumption that ROS are likely to damage all cells within the vicinity.163 Despite this, TiO2 nanocoatings have been investigated in a dental context, applied to orthodontic brackets.169 Brackets coated with nitrogen-doped TiO2 nanofilms were shown to cause significant CFU reductions over 90 days compared to uncoated brackets when tested with the oral pathogen Streptococcus mutans. To date, there is little robust evidence regarding safety of TiO2 nanocoatings to oral cells, but additional research exposing eukaryotic cells to these coatings and their associated ROS, over relevant time periods, will be crucial prior to clinical testing. However, it should also be remembered that TiO2 is already heavily used as an additive (E171) in the food industry170 as a mixture of micro- and nanosized particles for food coloring purposes. E171 has been found to induce ROS generation in a cell-free environment but not in exposed Caco-2 cells, induce single-strand DNA breaks and cause chromosome damage.171 However, no acceptable daily intake is currently defined in the European Union (EU) due to TiO2 bioavailability being found to be low and independent of particle size, the vast majority of TiO2 being eliminated unchanged in feces, and a maximum of 0.1% being absorbed by gut-associated lymphoid tissue and distributed to organs.172

Equally important to the development of implanted biomaterials utilizing a TiO2 photocatalytic surface is the longevity of antibacterial activity following cessation of UV irradiation. While environmental surfaces can be suitable for continuous or repeated photocatalytic activation where antibacterial effects are immediate but short-lived following cessation, this model may not be suitable for implanted biomaterials which are inaccessible. A nanocomposite of resin and TiO2 NPs demonstrated detectable antibacterial effects for 30 min following cessation of UV irradiation.173 The post-UV treatment effect was tested against five bacterial strains: Escherichia coli, Staphylococcus epidermidis, Streptococcus pyogenes, Streptococcus mutans and Enterococcus faecalis. Although UV treatment did not affect bacterial adhesion to coated specimens, the viability of bacteria was reduced by 37%. This finding is particularly relevant because the highest risk of bacterial colonization for implanted biomaterials is prior to or during implantation. Maintaining a UV-induced antibacterial effect for even 30 min following cessation of irradiation may allow enough time for implant surfaces to self-disinfect following implantation and reduce the possibility of biofilm development and subsequent infection, which can in certain cases result in implant failure.

Aluminum Nanocoatings

Aluminum oxide (Al2O3, also termed alumina) NPs have been shown to have some antimicrobial effects, albeit at very high concentrations (1000 μg mL–1) when tested against Escherichia coli.174 It was postulated that while they exhibit toxicity to bacteria through surface charge interactions with cell membranes and walls, their free radical scavenging properties may limit intense antimicrobial action and disruption of the cell wall. Essentially, they may simultaneously exhibit antimicrobial properties by one mechanism while reducing that antimicrobial effect by another. A similar MIC in the range of 1700—3400 μg mL–1 was reported for a multidrug-resistant strain of Staphylococcus aureus.175 More recent work has demonstrated antibacterial activity at a concentration 1 order of magnitude lower (100 μg mL–1) against both Escherichia coli and Staphylococcus aureus.176 The EC50 (half maximal effective concentration) of Al2O3 NPs against Pseudomonas putida has even been reported at 0.5 μg mL–1 over 16 h.177 The differences in values between these reports demonstrate the confounding factors of NP size, shape and synthesis method and suggest that they could be as important as concentration in terms of antimicrobial activity. Nevertheless, most studies investigate alumina NPs in the form of nanosolutions with very little evidence in the literature where they have been used as nanocoatings.

Nonmetallic Nanomaterials

Carbon-Based Nanocoatings

There are a number of unique carbon-based nanomaterials (CBNMs), primarily allotropes of carbon such as graphene, with intrinsic antimicrobial properties and distinct material properties which make them useful for a range of applications in medicine and dentistry. A key property of CBNMs is their excellent biocompatibility, resulting in their testing in a range of biomedical applications including drug delivery, biosensor development, diagnostics and therapeutics.186 The various types of CBNMs available, in addition to graphene, include single- and multiwalled carbon nanotubes, fullerenes, and nanodiamonds.187

Graphene. Graphene consists of a single layer of carbon atoms arranged hexagonally and is the base component of materials including carbon nanotubes (CNTs), diamond, charcoal, graphite, and fullerenes (collectively referred to as graphene-based materials, GBMs). GBMs have intrinsic antimicrobial properties and appear to exert stronger effects if presented as coatings.188 Graphene can disrupt the bacterial cell membrane, most likely due to its physically sharp structure, interfering with the membrane potential and inducing membrane stress.189,190 While graphene in free-floating form exerts its bactericidal effect through both biomechanical interactions and ROS-mediated biochemical responses, surface-immobilization of graphene as a coating appears to limit the mechanism to primarily physical interactions causing cell membrane damage.191 Superoxide ion-induced ROS production does not appear to occur; however, oxidative stress can be produced by oxidation of glutathione, a redox mediator in bacteria.192,193 Like some other nanomaterials, the direct biomechanical mechanism of bactericidal activity offers the potential to be effective against drug-resistant pathogens, helping to protect surfaces from colonization. It has been suggested that graphene has antibacterial activity due to its ability to transfer electrons away from bacteria, as they maintain a negative resting membrane potential and require proper electron movement for the functioning of the respiratory chain.194 As graphene is an excellent electron acceptor, physical contact between bacteria and graphene may be sufficient to cause the bacteria to steadily lose electrons, interrupting the electron transport chain and leading to bacterial cell death. This effect also depends on the properties of the underlying substrate, in particular the substrate’s electrical conductivity.195 Research into the use of GBMs as antimicrobial coatings is still at a comparatively early stage, with relatively few publications available compared to the other groups of nanomaterials presented in this review; however, multiple methods of GBM application to relevant substrates have been reported.

Graphene was applied in the form of immobilized graphene nanoplatelets (i.e., stacked graphene sheets with thickness of 2–10 layers) to the surface of silicone rubber to offer antimicrobial protection against Staphylococcus epidermidis. Independent of application methodology, the oxidized form of graphene had augmented bactericidal properties versus the nonoxidized form which may be explained by additional exertion of oxidative stress and production of ROS, leading to lipid peroxidation, mitochondrial dysfunction and protein inactivation.196,197 Graphene nanoplatelets have also been applied by spray coating onto a segment of silicone catheter.198 Spray coating has the advantage of simple adjustment of coating thickness by altering the number of passes of the nozzle over the sample surface. Dybowska et al.198 found that the graphene nanoplatelet coating was an effective antibiofilm agent preventing mature biofilm formation. However, graphene nanoplatelets decorated with Ag NPs were found to be even more effective indicating possible graphene-nanosilver synergism.

Other studies have investigated the potentially higher antimicrobial efficacy of graphene oxide (GO) nanocoatings. GO coatings have been applied to a polymeric substrate by immersion of plasma activated silicone films in a GO dispersion.199 Both colony counting and live/dead assay results showed considerable antibacterial activity against Escherichia coli and Staphylococcus aureus, with stronger activity against the former. That study concluded that the majority of bactericidal activity was the result of oxidative stress mechanisms, rather than physical or mechanical cell damage, due to the “edge-free” nature of the coating. However, this would not seem to eliminate possible antibacterial mechanisms involving interruption of electron transport. In a different study, GO-coated surfaces were prepared by two different methods, and effective inhibition of biofilm formation was reported for both Escherichia coli and Staphylococcus aureus.131 The synthesis method was a major factor affecting antibacterial efficacy, as different methods resulted in variations in functional groups present as well as nanosheet size, roughness, porosity, and thickness. These factors were significant as confirmed by the increased bacterial adhesion on the rougher nanocoating with less uniform thickness. In addition to GO coatings, reduced GO (rGO) coatings have been synthesized using the whole cell biomass of the fungus Rhizopus oryzae, coated on aluminum.200 Both the GO and rGO coatings showed excellent bactericidal activity against Escherichia coli (72% and 93% respectively), although their activity was lower than that shown for the same nanomaterials in a dispersed phase (80% and 97%); potentially because immobilization as a coating prevented access of the nanomaterials to intracellular compartments. Findings regarding bactericidal activity of the coatings were confirmed by live/dead assay, which also revealed reduced bacterial adherence to the rGO coatings and suggested that its more hydrophobic nature prevented cell attachment in addition to direct bactericidal activity. These findings indicate that GO and its variants have impressive potential to be used as antimicrobial nanocoatings, combining relatively facile and eco-friendly synthesis with potent antibacterial and biocompatible properties.

Carbon Nanotubes. CNTs are forms of graphene arranged in a cylindrical structure and can be structured with a single wall (SWCNTs) or multiple walls (MWCNTs). The single versus multiwalled nature is one of the variable properties of CNTs, along with diameter, length, surface functionalization (e.g., addition of chemical groups), and chirality. There is a strong evidence base to support the antibacterial properties of CNTs,201 but only a few reports of applications as surface coatings. CNTs have been reported to be compatible with photodynamic antimicrobial chemotherapy, where light is used to activate or tune the antimicrobial effects. This approach has been shown to be effective against both Staphylococcus aureus(202) and Escherichia coli.203 Antimicrobial and antibiofilm activity have been suggested to be the result of ROS generation which allows antimicrobial photodynamic inactivation via cell membrane damage.

Carbon nanotubes have been applied as an antimicrobial coating to paper, which can widen the range of surfaces that can be coated to protect against bacterial colonization and transmission in healthcare settings.204 Direct interaction of bacteria with paper coated with acid functionalized SWCNTs for 1 h resulted in substantial morphological changes with loss of shape and integrity, explained by damaged cell walls leading to osmotic swelling. Both Staphylococcus aureus and Escherichia coli experienced these morphological changes, but those were more severe for Staphylococcus aureus; probably because of the greater rigidity of the Escherichia coli cell wall.

The mechanical properties of CNTs can also be useful in producing an antibacterial effect. Vertically aligned carbon nanotubes (VACNTs) have a very high aspect ratio with extreme flexibility, meaning that they deform in contact with bacteria before releasing their stored elastic energy. Arrays or “forests” of VACNTs with gaps smaller than the size of bacterial cells have been found to have potent bactericidal activity against Pseudomonas aeruginosa and Staphylococcus aureus.82 The proposed mechanism of action involves CNTs retracting and stretching in response to cell attachment, with release of the stored elastic energy resulting in tearing of the adsorbed bacterial cell. This mechanical killing mechanism is an attractive complement to other mechanisms involving oxidative stress or disruption of biomolecules, with the additional benefit of killing both Gram positive and Gram-negative bacteria.

Silica Nanocoatings

Silica nanoparticles (SiO2 NPs) have exhibited potent antibacterial effects expressed by high killing efficacy (>99%) against Pseudomonas aeruginosa and Escherichia coli biofilms, while demonstrating good clinical biocompatibility by inhibiting fibroblast proliferation less than conventional antiseptics.205 Attachment of SiO2 NPs to tissue culture polystyrene has been shown to reduce the attachment and growth of Candida albicans,206 and SiO2 NPs have also been found to be useful as abrasives for tooth polishing when tested on human teeth ex vivo.207

SiO2 NPs have been deposited as a coating on titanium substrates by an electrophoretic-enhanced microarc oxidation technique and tested against Staphylococcus aureus and Escherichia coli.81 The coated substrate showed slightly reduced bacterial growth, but cell morphology was the same when compared to uncoated substrates. Results showed that coated surfaces slightly inhibited bacterial adhesion and growth, but this effect was greatly enhanced by addition of octenidine, a cationic surfactant and antiseptic. The authors attributed the antibacterial properties of the SiO2 coating without octenidine to the highly porous structure of the surface, suggesting that bacteria became physically trapped which resulted in restricted movement and proliferation. This is analogous to the “trap-killing” previously reported against Staphylococcus aureus on Ag nanocoatings applied to titanium.208

Coatings of SiO2 NPs have been applied to tiles and tested for antifungal activity against Acremonium kiliense, Acremonium strictum, and Fusarium solani. Measurements of the fungal growth showed a reduction by 27.5%, 21.5% and 37.5%, respectively.209 Antifungal activity was also found to be higher for silica–titania core–shell NPs when compared to pure SiO2 NPs, suggesting that it was the layer of titania enhancing their antimicrobial performance.

Chitosan Nanocoatings

Chitosan is a polycationic polymer obtained commercially from shrimp and crab shell chitin by alkaline deacetylation, usually by sodium hydroxide.210 Both chitin and chitosan are biocompatible, biodegradable and nontoxic, though chitosan is favored due to its higher solubility and enhanced antimicrobial activity.211

A hybrid nanomaterial incorporating chitosan and silica was applied to the surface of titanium implants and tested as an antibacterial coating.212 Chitosan was the intended antibacterial component, whereas silica was selected for its osteogenic properties. The nanocoating was synthesized following the sol–gel process with chitosan covalently bonded to the silica network. Work using human fibroblasts demonstrated that the hybrid nanocoating was not cytotoxic, and cell proliferation was supported on the nanocoated surfaces, suggesting good biocompatibility. Significant antibacterial performance against Staphylococcus aureus was demonstrated for 5–10% chitosan, with antibacterial activity increasing with chitosan content. It is important to be aware of the hydrophilicity or hydrophobicity of any nanocoating, as this can impact directly upon interactions with the biological environment and dictate cell attachment.213 Palla-Rubio et al.212 found that adding chitosan decreased hydrophilicity of the coatings and reported contact angles for optimal biological interactions from 60 to 80°.

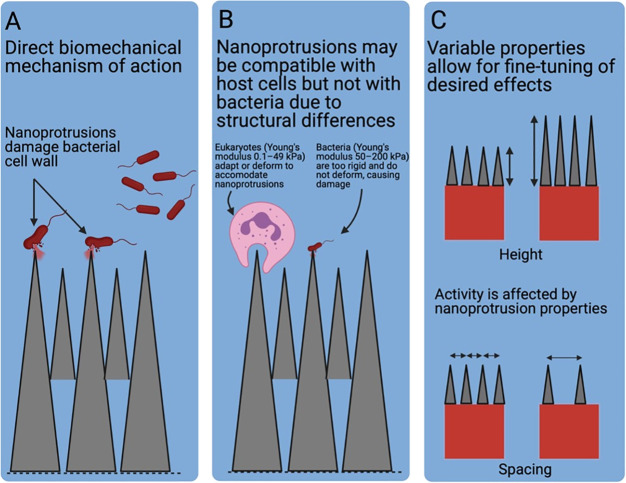

Surface Nanotopography