Abstract

Novel and improved biocatalysts are increasingly sourced from libraries via experimental screening. The success of such campaigns is crucially dependent on the number of candidates tested. Water-in-oil emulsion droplets can replace the classical test tube, to provide in vitro compartments as an alternative screening format, containing genotype and phenotype and enabling a readout of function. The scale-down to micrometer droplet diameters and picoliter volumes brings about a >107-fold volume reduction compared to 96-well-plate screening. Droplets made in automated microfluidic devices can be integrated into modular workflows to set up multistep screening protocols involving various detection modes to sort >107 variants a day with kHz frequencies. The repertoire of assays available for droplet screening covers all seven enzyme commission (EC) number classes, setting the stage for widespread use of droplet microfluidics in everyday biochemical experiments. We review the practicalities of adapting droplet screening for enzyme discovery and for detailed kinetic characterization. These new ways of working will not just accelerate discovery experiments currently limited by screening capacity but profoundly change the paradigms we can probe. By interfacing the results of ultrahigh-throughput droplet screening with next-generation sequencing and deep learning, strategies for directed evolution can be implemented, examined, and evaluated.

1. Introduction

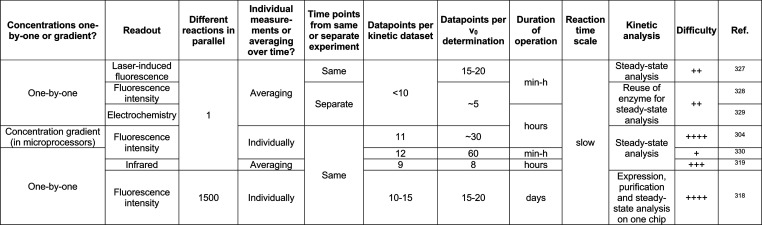

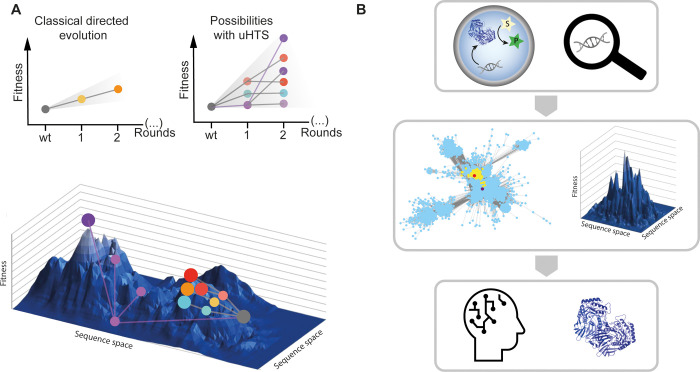

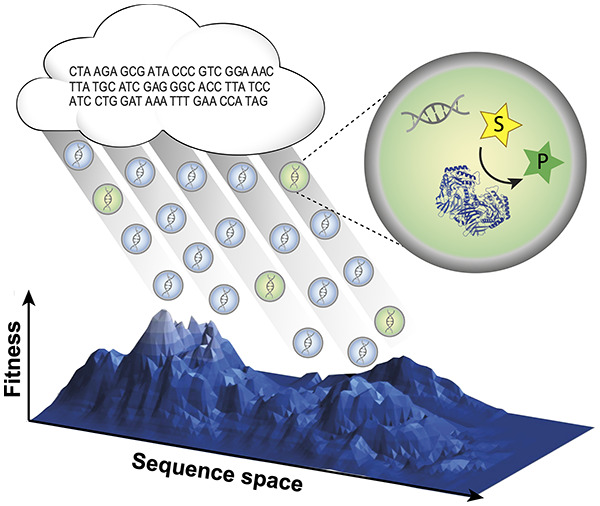

Protein engineering by directed evolution relies on combinatorial experiments that explore how amino acids are best arranged to bring about functional molecules. New functional proteins are in high demand in applications ranging from affinity reagents or antibodies in medical research and therapy to biocatalysts for “green”, energy efficient and sustainable processes. Finding these molecules is difficult because the total combinatorial diversity generated from 19 amino acid alternatives in every position of a protein is enormous and efficient methods for its exploration are required to find catalysts on a useful time scale. To increase the chances of success and to accelerate library screening, the throughput should be as high as possible (Figure 1).

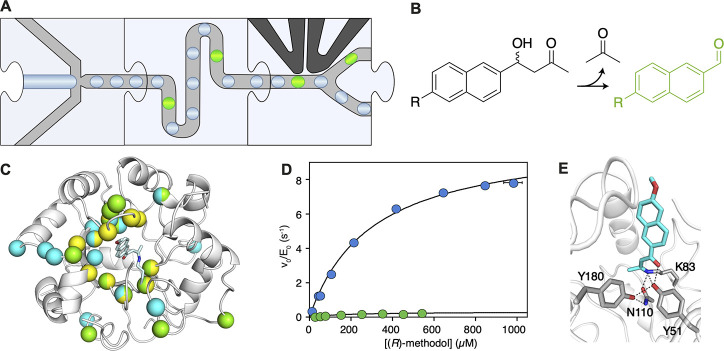

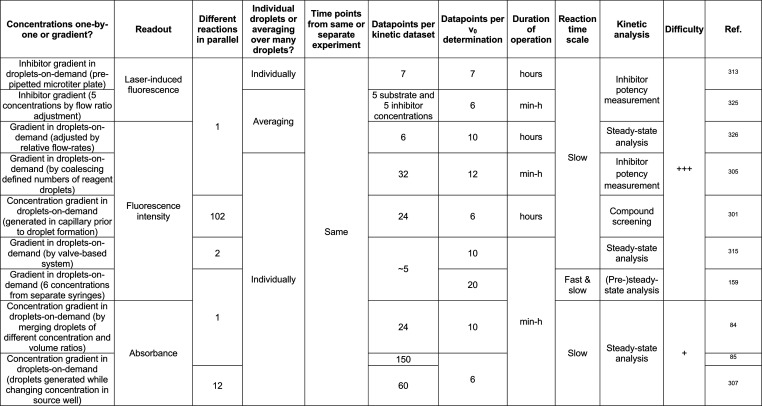

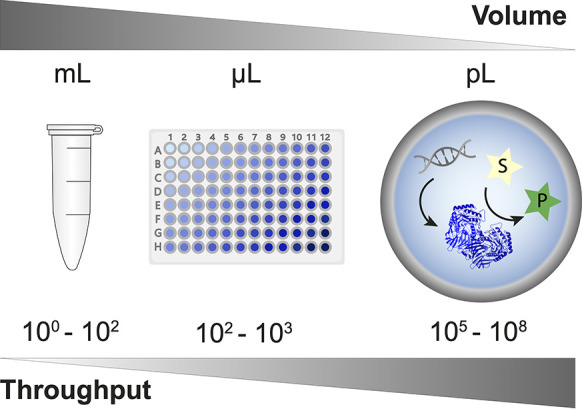

Figure 1.

Droplet microfluidics enables a massive scale-down of reaction volumes from milliliters in test tubes, beyond microliters used in plate formats (and robotic liquid handling systems) to picoliters in in vitro compartments. This miniaturization format is highly economical, so access to ultrahigh-throughput screening of enzymes (here shown as generated by in vitro expression, but see Figure 8 8 for other formats) becomes possible at relatively low cost. This review provides an overview of the use of droplet compartmentalization in protein discovery and engineering.

Water-in-oil emulsion droplets, made and handled in microfluidic devices, provide a relatively recently established experimental format for screening and selection of functional proteins. The droplet compartment replaces the classical test tube (or multiwell plate), and lab-on-a-chip devices automatize and miniaturize liquid handling operations—carried out by one’s own fair hands or by large robots—so that experiments can be conducted more quickly, with minimal consumption of reagents and plasticware (tubes, plates, and tips). The micrometer dimension of droplet compartments achieves a scale-down of reaction volumes to the picoliter range (corresponding to a >107-fold volume reduction compared to the regular 96-well plate format with a ∼200 μL volume).1,2 This is necessary because the possible combinations of amino acids - even in a focused protein library - easily exceed the screening capacity (e.g., a library in which only 5 residues are fully randomized almost matches the throughput of droplet microfluidics; 205 = 3.2 × 106 combinations).

For screening of protein libraries in directed evolution or functional metagenomics, each droplet compartment needs to contain a code for the identity of the library member: the droplet boundary thus links genotype and phenotype by compartmentalizing the gene, enzyme, and reaction product. The criterion for selecting individual variants is a readout of the successful progress of the reaction of interest (ideally directly reporting quantitatively on product concentration), so an analytical interface is necessary to evaluate the reaction progress.

In the future, protein engineering campaigns may go beyond the “black box” lottery that combinatorial screening experiments currently are: one can never be sure whether a library contains initial hits that can be evolved later—and why. When next-generation sequencing will be applied to the output of rounds of screening, one will produce large data sets that describe ensembles of genes satisfying an experimentally set threshold. These correlations of sequence to function could help to describe “fitness landscapes”. When trajectories through sequence space are visualized, directed evolution ceases to be a “black box”. Instead “fitness landscape” maps may help to steer directed evolution by evaluating whether navigation into more or less interesting sections of sequence space is possible. Ideally long trajectories familiar from natural evolution should be emulated in laboratory experiments. Machine-learning algorithms and artificial intelligence3−5 will be helpful to obtain insight into multiparameter spaces and in all likelihood be necessary to provide meaningful extrapolations from experimentally explored sequences to further improved proteins.

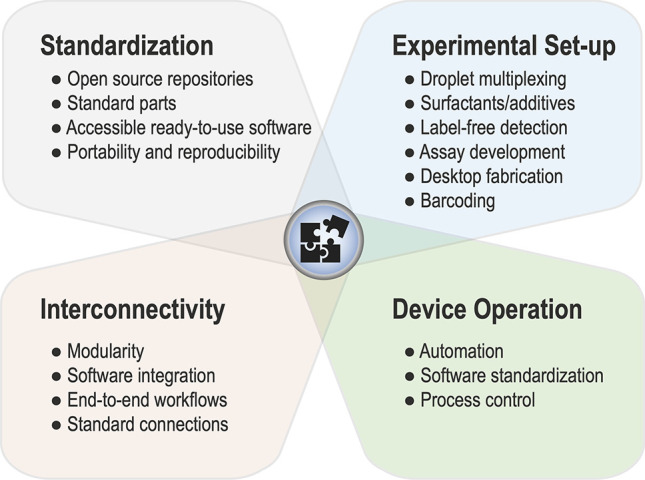

A large number of excellent reviews describe technical aspects of in vitro compartmentalization and droplet microfluidics, along with various applications.6−19 The objective of this review is to take stock of the steps that have been established as the basis for the discovery of functional enzymes in large libraries, to showcase studies that have integrated droplet technologies with protein discovery campaigns, to provide a guide for newcomers into this area faced with everyday issues of practical implementation, and finally to extrapolate where this technology will find its most powerful uses.

2. Types of In Vitro Compartments

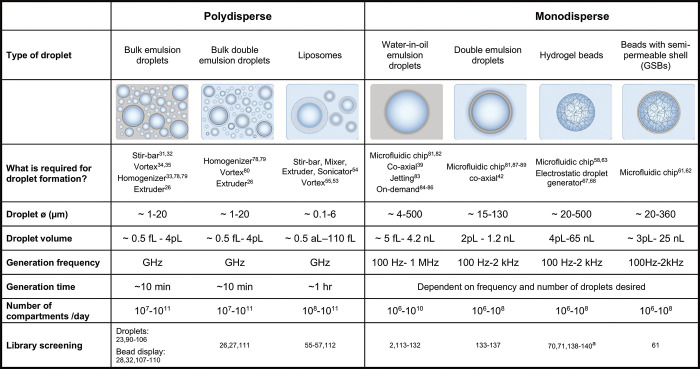

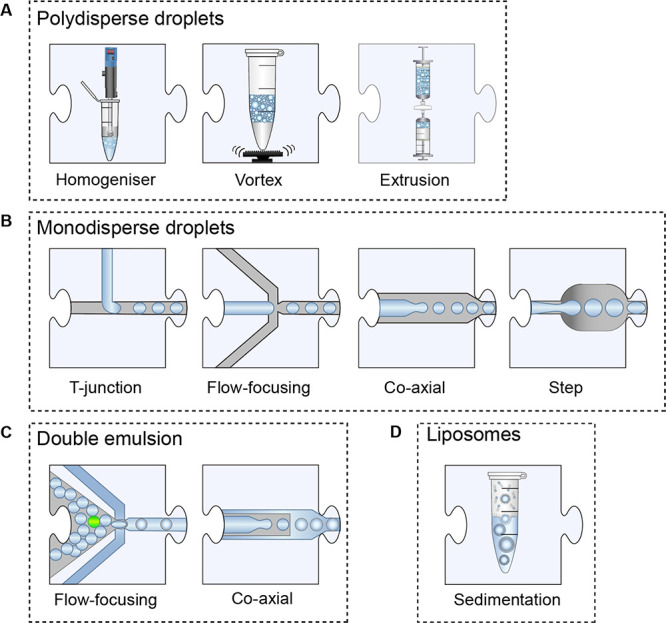

Conceptually the idea of isolating a single library member from all others by a droplet boundary is embodied by a large number of formats (Table 1). These in vitro compartments differ in size, ease of production, stability, and the rate at which they can be generated. Historically, water-in-oil (W/O) emulsion droplets were first produced in a polydisperse format (for single-cell20,21 and single-enzyme22 experiments), where droplets are generated very quickly. However, while the droplet boundary restricts crosstalk, droplet sizes vary considerably and the assay quality may be less than uniform, as differently sized droplets will contain different amounts of reagents. Nevertheless, polydisperse emulsions still are used today for protein engineering.23−28 1010–1011 compartments are produced in minutes: (i) with a stirring bar,29,30 (ii) with an emulsifier or homogenizer,18,27,31 (iii) by vortexing,32,33 or by extrusion through a filter26,34 (Figure 2A).

Table 1. Polydisperse and Monodisperse Droplet Compartments Used for Protein Engineering.

Self-encapsulation of cells by hydrogel formation: “fur-shell”.

Figure 2.

Droplet generation units. (A) Polydisperse water-in-oil droplets are generated via a homogenizer, simply by vortexing or by extruding an emulsion across a filter. For the production of double-emulsion droplets, the process is repeated with the first emulsion in an aqueous carrier phase. (B) Monodisperse droplets are generated in microfluidic devices of varying designs: (1) a T-Junction, (2) a flow-focusing junction, (3) the coaxial flow of the two fluids, or (4) a step device. (C) Double emulsions are generated by flowing water-in-oil droplets into an aqueous carrier phase by using the same geometries that are used for generating monodispersed droplets. (D) Liposomes are generated by the sedimentation of an emulsion through a lipid monolayer and into a second aqueous phase.

The ease of setup makes polydisperse formats attractive, but the difference in droplet size within one experiment may often preclude screening based on relatively small activity differences. On the other hand, a larger number of droplets can be generated in an instant using the polydisperse format. Especially for reactions in which the product is amplified (as in polymerase selections23−25), rendering them quasi-binary yes/no selections, polydisperse emulsions are particularly suitable.35 Nevertheless, quantitative screenings for reactions that generate an optically active product are also possible,27 and an even subdivision of a screening output into bins has been successful, despite some noise in the sequencing readout.28

The microfluidic production of monodisperse emulsions allows a more stringent quantification of the reaction product based on the optical readout.500,501,80 There is also an additional level of control in microfluidics: multistep workflows can be constructed; the timing of lysis, reaction, and incubation, and other steps can be precisely governed. The production of monodisperse water-in-oil emulsions36 is not instantaneous, even if it occurs at kHz frequencies, with a output of >108 compartments (with diameters of a few μm) per day. A large number of microfluidic device designs that achieve near-ideal monodispersity (0.2 to 3% coefficient of variation of the droplet radius)37−42 are available (Figure 2B), e.g., flow-focusing devices,36 T-junctions,43−45 coaxial/capillary,37,46,47 or step48−50 designs.

Monodisperse as well as polydisperse droplets can be emulsified once again to produce water-in-oil-in-water (W/O/W) “double emulsions” that overall have rheological and electrostatic properties of an aqueous solution, which means that they can be analyzed in widely used commercial devices that are optimized e.g. for cell sorting in flow cytometers (see below).

Liposome compartments can be generated by vortexing a mixture of amphiphilic lipids (e.g., phospholipids such as phosphocholines (POPCs), phospho-glycerol (POPG), phospho-serine (POPS) or a cholesterol mixture) with an aqueous phase to generate a W/O emulsion, which is placed on top of the final outer solution followed by centrifugation (Figure 2D).51 Alternatively, stirring followed by extrusion and sonication52 can bring about vesicle compartments. Despite being generally less stable than emulsions, vesicles can be sorted by fluorescence-activated cell sorters (FACS). This method of “liposome display” has been used to evolve membrane proteins that benefit from being anchored in the hydrophobic ring around the vesicle53,54 as well as an aminoacyl-tRNA synthetase.55

An alternative to liquid compartments is to turn the droplet into a microsphere made of a soft material: gel-shell beads (GSBs) “immortalize” the compartmentalization by generating an agarose microsphere with a selectively permissible boundary from a droplet. After encapsulation of all reaction components in monodisperse droplets together with additional components (agarose and alginate), the droplet contents solidify to form a gel upon lowering the temperature,56−58 and thus bead microspheres (Ø ∼ 25 μm) are generated. Subsequent to the removal of the droplet boundary, the deposition of layers of polyelectrolytes on the surface of these microspheres (based on charge interactions between negative alginate in the gel and positive polyammonium electrolyte) creates a size-selective shell (with permeability only for molecules < 2 kDa). Thus, reaction products (when tagged e.g. to an oligonucleotide) can be captured together with enzyme and its encoding plasmid DNA, creating a genotype–phenotype linkage. Such GSBs have been sorted by FACS in a directed evolution campaign.59 Hollow-core polyelectrolyte-coated chitosan alginate microcapsules (HC-PCAMs) have been similarly endowed with selective permeability and used to demonstrate enrichment of a sortase (employing a large particle sorter (COPAS, complex object parametric analyzer and sorter) instead of FACS).60 Alternative materials provide routes to producing hydrogel beads as microspheres: alginate can be solidified with cations on-chip (Figure 3)61−64 or by laminar jetting into a bath,65−69 and polyacrylamide can be cross-linked.70,71 Beads based on hydrogels and other materials (e.g., polystyrene or paramagnetic composites) can also be used as a template to generate near-monodisperse droplets that tightly wrap around the bead via vortexing72−74 or pipetting through filter tips28,75 into an oil phase, avoiding microfluidic devices altogether.

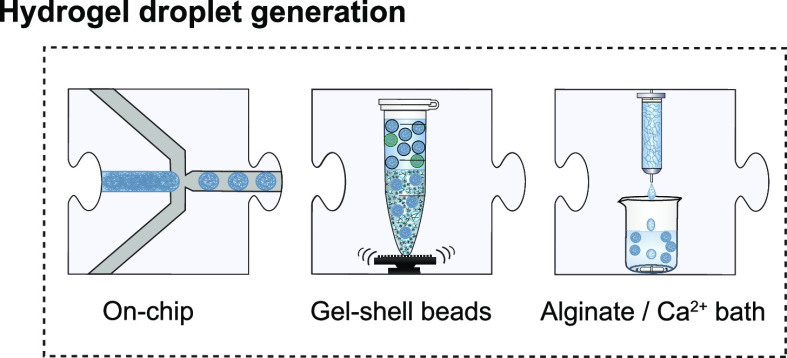

Figure 3.

Nanoliter hydrogel bead generation. Hydrogels can be used as the aqueous phase for water-in-oil droplet generation on a chip employing the various generation designs (Figure 2). When agarose and alginate droplets are de-emulsified into a positively charged polymeric solution, a layer-by-layer semipermeable shell is formed around the hydrogel. Similarly, the laminar-jet breakup of an alginate solution into a calcium bath generates monodisperse hydrogel beads.

3. Modular Workflows and Their Operation

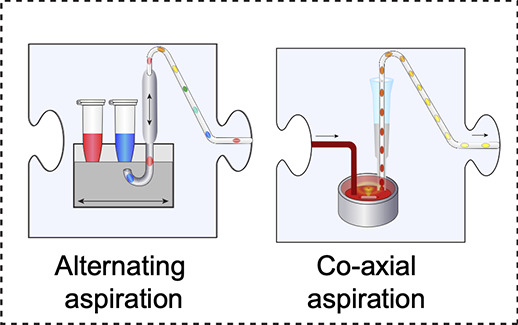

In conventional laboratory work, our hands (or liquid handling robots) carry out the basic tasks that an experiment entails. For scaled-down experiments in microdroplets, samples have to be processed in an entirely different way. In the last decades, a number of chip designs have emerged from the “lab-on-a-chip” community that provide a repertoire of “units of manipulation”. Workflow design would “translate” each manipulation carried out manually in a large-scale experiment (e.g., adding or removing reagents by hand, carrying out an optical measurement as the basis for a sorting decision) into its on-chip equivalent and combine multiple unit operations into a sequence of steps. This modularity can be conveniently represented as jigsaw pieces. For example, Figure 2 shows multiple designs for ten alternatives for the first step of a microfluidic workflow, droplet formation (and three more for the formation of hydrogels can be found in Figure 3).

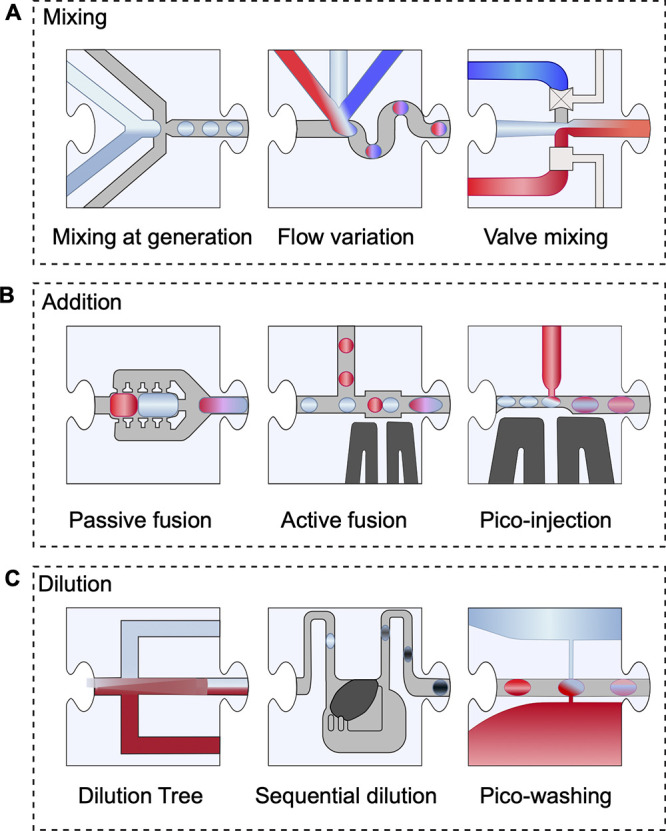

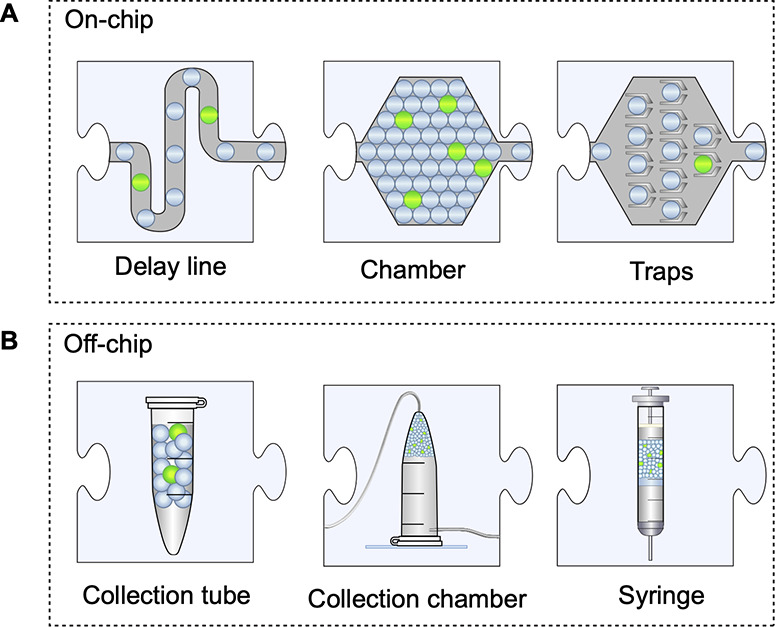

The workflow designer would pick one droplet formation module and combine it with the next unit of operation that replaces pipetting in classical experimentation: (i) mixing of reagents occurs by chaotic advection at the point of droplet formation,44,139 (ii) addition of reagents is achieved by droplet merging in passive fashion,140 by electrocoalescence of two droplets,141−144 or by picoinjection of an aqueous stream,1,121,145,146 and (iii) dilution of reagents (Figure 4). A recent addition to the toolkit is the “picowasher”, which enables simultaneous addition and subtraction of fluid from droplets, allowing washing of the droplet contents with or without solid particles inside.147 Once a biochemical reaction is set up with all of its components, the experimenter typically has to allow time for the reaction to proceed, and there are multiple on-chip solutions for this incubation step (Figure 5). Delay-lines keep the droplets in a predefined order (e.g., allowing time tracking of the incubation period), either in device microchannels,117,148,149 in long tubing,122 or in a capillary150 that connects two devices. Incubation times in the region of up to an hour are possible.117,128,149

Figure 4.

Droplet manipulation for mixing, adding, or diluting reagents. (A) Mixing of reagents can be accomplished on chip at the time of generation or by addition of reagents to droplets at a later stage. (B) Merging or fusion of droplets can be done either passively using various device designs or by electrocoalescence. (C) Dilution of the droplet content can be done directly on chip by varying the flow rates of the mixed aqueous phases during generation, controlling the flow and mixing via valve systems, separating a laminar flow in a tree-like design, fusing varying proportions of droplet pairs, simultaneously adding and removing reagents or generating droplets from sequentially diluting a concentrated initial reagent.

Figure 5.

Droplet incubation. (A) Droplets can be incubated on a chip within a channel, packed in a chamber, or held in position by trapping features. (B) Droplets can be collected into any collection tube, or in chambers or directly into syringes for easy re-injection into other microfluidic devices for further manipulation, analysis, or sorting.

For longer incubation times, the channels become so long that back-pressure typically builds up and challenges device stability (e.g., stability of droplet generation or delamination of the PDMS from the glass support). When delay-line incubation becomes impractical, incubation chambers or traps provide an on-chip opportunity to store droplets, albeit at the price of losing the rank order of the droplets. Such cavities can contain millions of droplets, and their size can be expanded when support pillars are included in the design.151−153 Droplets can also be hydrodynamically captured into traps501,154−157 or sink wells49,158 for longer-term analysis of droplet contents. While the order is still not easily controlled, time courses for individual droplets can be recorded as the basis for precise characterization of the reaction occurring in a sample of droplets.

Often it is more straightforward to carry out incubations offline instead: in standard Eppendorf tubes, in custom-built collection chambers,121,131,159 or in syringes2,87 up to 108 droplets can be stored. After incubation, droplets are reinjected into a chip to be presented for sorting (see Section 5) or any other downstream modules. Re-injection is optimal when the droplets are tightly packed upon entry into the device because diluted droplets lead to an unequal spacing between droplets. Subsequent sorting devices operate with higher quality when the droplets are uniformly spaced.

When directed evolution for higher enzyme activity is successful, the timeframes in one experimental campaign will change: obviously depending on the intrinsic activity of an enzyme, but in addition also when the enzyme becomes faster from one selection round to the next. In such a case the chip design will have to be adjusted to raise the bar for selection by making the conditions more stringent. For example, Schnettler et al.117 started with an off-chip incubation/re-injection workflow but in subsequent stages of evolution, ended up with an integrated device. Here droplet generation, incubation, and sorting were combined, to take account of the ∼360-fold improvements that reduced the reaction times from 2–3 h to less than one hour. It is tempting to think that ultimately there will be one “directed evolution machine”, but the shifting timescales in directed evolution experiments make it necessary to customize workflows to accommodate the stage of proficiency and set the selection threshold according to the evolutionary strategy chosen. Rapid prototyping of chip devices is, therefore, necessary to accommodate enzymes with different activity levels and to keep up with evolutionary improvements, may they be large or small.

4. Chip Devices

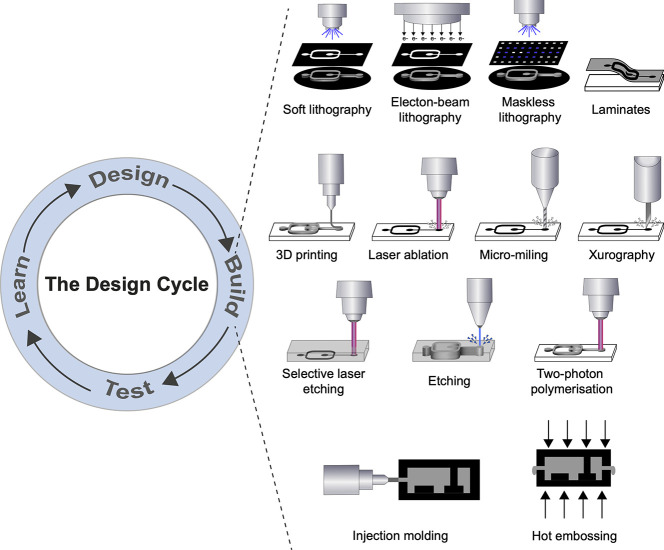

Devices for generation capable of the key modular processes can be made by soft lithography in polydimethylsiloxane (PDMS) using standard protocols for rapid prototyping, i.e., iterative testing of designs in cycles (Figure 6) that take a few days, followed by an experimental test (and redesign in response to failures). The soft lithography process is split into two steps: creating the master mold and forming the polymeric device. To create the “master”, several lithographic techniques involve the deposition of a thin layer of SU-8 photoresist onto a silicon wafer by spin-coating and “soft baking”. Ultraviolet light is then passed through a photomask (glass or plastic etc.) to pattern the photoresist that is subsequently “post baked”. The unpolymerized photoresist is dissolved using propylene glycol monomethyl ether acetate (PGMEA).160 Finally, the wafer can then be coated with a fluorinated silane to adjust channel hydrophobicity.161 In the second step, PDMS is poured into the master mold, baked to form the polymerized device, bonded onto glass (or another PDMS surface) via oxygen plasma treatment, and coated with fluorinated silane for hydrophobicity.161,162 The silanization of the PDMS devices serves to reduce “wetting effects” or friction at the channel walls,163 and various surface modifications for hydrophobic or hydrophilic coating are available to match the carrier phase, allowing choices of different oils.15

Figure 6.

The design cycle for microfluidic chip devices and the main types of available current and future fabrication methods. Rapid design and redesign of prototypes that translate workflows from the macro- to the microscale on chips are necessary to establish new assays for a wider circle of reactions but also within one directed evolution campaign to adjust the design to the increasing proficiency of the evolved catalyst (that requires modified timings or expression, incubation, and/or different selection thresholds). Soft lithography: the most commonly used method; a photomask patterns the UV curing of a photoresist resin. Electron-beam lithography: relies on the deposition energy of the accelerated electrons to the resist film on the substrate using a photomask. Maskless lithography: similar to soft lithography; however, dynamic micron-sized apertures (e.g., DMDs, LCoS) replace a photomask to project the UV onto the photoresist resin. Laminates: several sheets of material are bonded together to form a total device, such as an interface layer, a flow layer, and a bottom layer. 3D printing: an additive manufacturing technique whereby devices are formed from polymerized layers. Laser ablation: a laser removes material through vaporization; typically it is pulsed to reduce surface damage (e.g., cracking). Micromilling: uses an endmill (typically in the hundreds of microns) to drill away material in order to form channels. Xurography: uses a knife plotter to cut patterns out of thin films. Selective laser etching: a laser creates a pattern inside a glass-like material, which is then removed using an etchant. Etching: removes material from the surface using an etchant to create a pattern. Injection molding: prepolymerized pellets of a thermoplastic are heated and injected under pressure into a mold cavity and then cooled to solidify the material. Two-photon polymerization: a high-resolution technique whereby a localized area polymerizes at the focus of laser beam. Hot embossing: similar to injection molding, a thermoplastic is heated up in a mold and the pressure of two plates compresses the polymer into the desired shape.

So-called “2.5D” designs (i.e., varying channel depth within the device) can be created by patterning several layers on the master in an iterative process. In this way, areas of the mask can have an additional buildup of material, leading to varying channel depths within the device. The channel system can be connected to pumps and reservoirs via tubing that is inserted into holes made with biopsy punches. Such devices are perfectly suitable for directed evolution campaigns, although delamination and the soft nature of the material mean that the devices have a limited lifetime.

Many other harder materials (e.g., glass, poly(methyl methacrylate) (PMMA)) can be used analogously, and devices can be bought “off-the-shelf” from several companies (e.g., microfluidic ChipShop, Dolomite, and Darwin Microfluidics). Briefly, the choice of device material depends on the application. Inorganic materials (e.g., glass) are durable and rigid, making them very reusable but also more difficult and costly to fabricate. Elastomers (e.g., PDMS) are flexible and can be fabricated more rapidly through soft lithography, but they suffer from delamination issues at high pressures. Thermoplastics are easier to scale-up in production (using hot embossing and injection molding) but become more difficult to manufacture at a smaller scale due to the need for expensive micromachining tools (for an extensive review see ref (15)).

Microfluidic designs are generated with AutoCAD, Fusion360, or other computer-aided design software, and the resultant designs are converted into a mask for soft lithographic fabrication (or an STL file for 3D printing). The open access availability of AutoCAD templates (e.g., deposited in DropBase,164 Grabcad,165 or Metafluidics166) makes previously tested designs accessible. It should be noted that ab initio design and complex fluid modeling are not prerequisites for working chips. Rapid prototyping of PDMS devices facilitates design–build–test–learn cycles within a few days that are often equally instructive (and readily accessible even for neophytes). Figure 6 summarizes alternative prototyping methods used by companies and in academic settings, and Table 2 profiles their scopes.

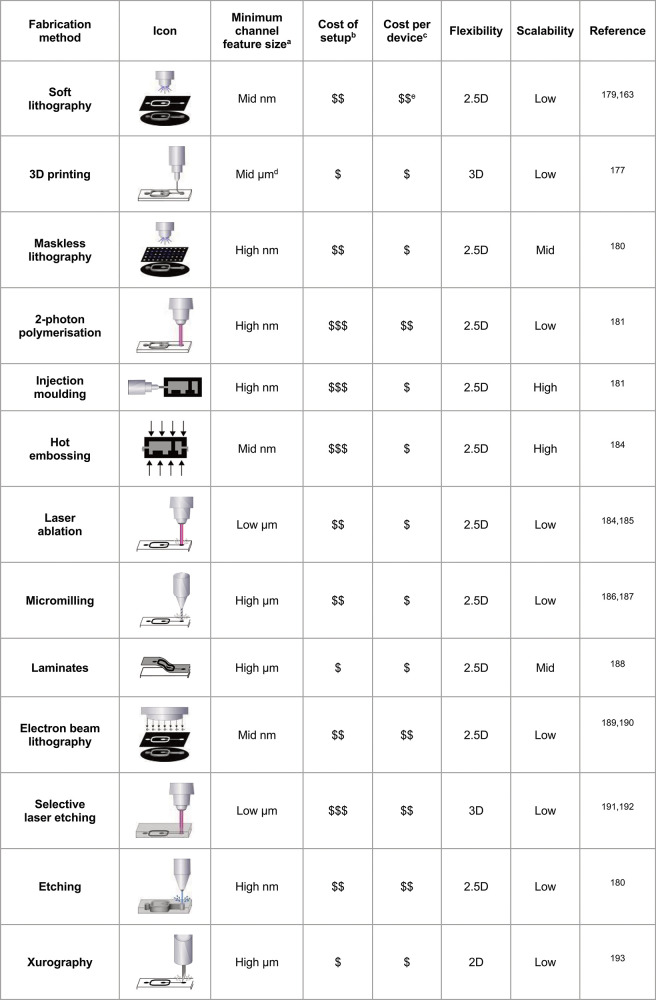

Table 2. Benchmarks for Common Microfluidic Fabrication Technologies That Provide Criteria for Choosing Which Method Suits the Desired Features and Costs of a Chip Device.

Low: 1–10; mid: 10–100; high: 100–1000.

Cost of setup: “$”: $1000s; “$$”: $10,000s; “$$$”: $100,000s.

Cost per device: “$”: $1–10; “$$”: $10–100; “$$$”: >$100.

Microprojection lithography is much smaller but also more costly and time-intensive.

This is the cost of fabricating a new master mold; replicating a design from the mold is much less expensive. Ranges for b and c are the authors’ best estimates.

The device design depends on turnover rates: fast reactions require integrated modules on a chip,128 while slower reactions invite discontinuous processes with off-chip storage for incubation. However, the experimental time scales of different enzyme reactions (and mutants with increasing activities in one experiment) mean that device designs must be frequently adjusted. Soft lithography remains an option for these iterations, but alternative chip manufacturing technologies may soon replace this method. Table 2 gives a breakdown of the advantages and disadvantages of different fabrication techniques. 3D printing has seen a rise in popularity due to the decreasing costs of 3D printers, a decrease in minimum feature size, and the ability to create true 3D channels,167−172 and it would conveniently automate chip manufacture. A race is on for miniaturizing the channel features to match the μm resolution of the masks used for making PDMS chips. Fused deposition modeling (FDM) 3D printing involves injection of a heated, liquified polymer through a nozzle onto an XYZ stage to “paint” a device design (i.e., build up a three-dimensional structure layer-by-layer).173 Here the minimal channel dimensions have been shown to be just 58 × 65 μm.174 SLA/DLP (stereolithography/digital light processing) or projection micro-stereolithography 3D printing builds up material through the polymerization of a photopolymer using a guided laser beam or a configurable mask.175 When light is guided or projected through a mask to a photopolymer (which then is cured), features are created to achieve flow channel cross sections down to 18 × 20 μm.176 The benefits of 3D printing are the flexibility of the materials used, increased fabrication speed, ease of use, and ability to rapidly share designs globally.173 However, more development is required to develop inexpensive systems that produce smaller channels.

The lab around the chip is crucial for the operation of a microfluidic device. A standard instrumental setup includes a pump (syringe or pressure pumps), an inverted microscope, a high-speed camera, a computer with control software, syringes, and tubing. Pressure is provided to the syringes through the action of pumps, generally using syringe pumps or vacuum pumps. Due to the high speeds that are used in droplet microfluidics, typically, droplets flow in the kHz range, and a high-speed camera is needed to look at the functioning and routing of the droplets in a human-accessible time scale. Computer control is provided as proprietary software (e.g., for pump operation) or is custom-built using several programs such as LabView or custom-written software (e.g., Python-based). Concerted efforts to share software would be highly beneficial for the user community, helping to avoid reinventing the wheel and making an interdisciplinary research area easier to navigate for newcomers. Sharing software or code is possible via OpenWetWare or GitHub (see e.g. our repositories164,177).

5. Detection and Sorting

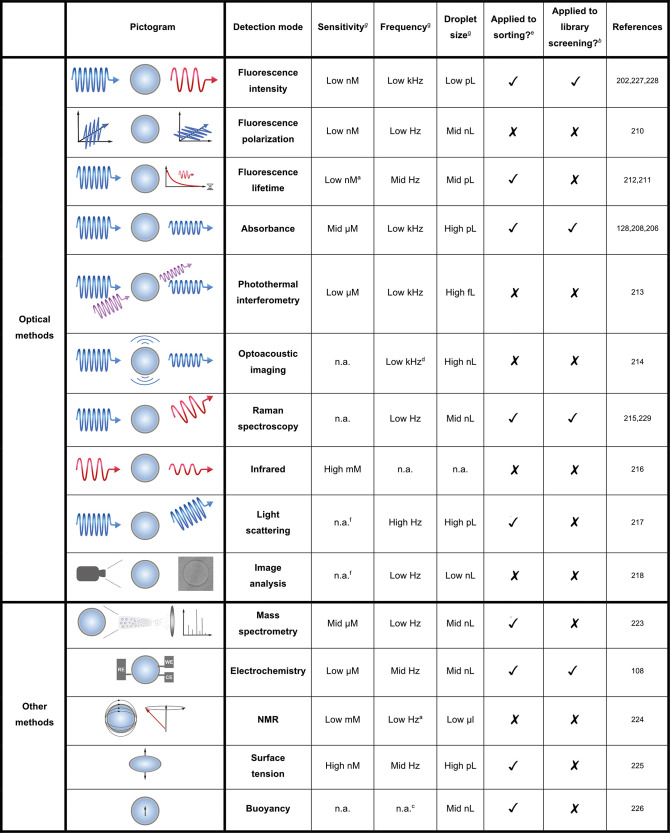

The optical transparency of the device material makes interrogation of droplet contents possible when an optical probe is integrated into the biological assay carried out in a droplet (Table 3). An optical signal reporting on the concentration of reaction product is then translated into a sorting decision.

Table 3. Overview of Detection Modes Currently Available for Microfluidic Setups.

Estimated from graphs provided or related literature.

Applied in a screening of enzyme activity from a functional metagenomic or directed evolution library.

Passive selection: in theory the throughput is only limited by the droplet generation frequency.

Only the B-scan rate is shown, not how quickly droplets can be measured.

Referring to any sorting experiment, i.e. an enrichment experiment or a library screening (not necessarily of enzyme activity and not necessarily monoclonal).

Used for cells, no molar detection limit available.

Low, 1–10; mid, 10–100; high, 100–1000; n.a. not applicable or available.

Fluorogenic assays are the most sensitive: when fluorescein is a reaction product, as little as 3000 molecules can be detected per droplet (corresponding to a low nanomolar concentration in picoliter droplet volumes),118 based on laser-induced fluorescence. The small reaction volume means that the enzyme concentration can easily be higher than the detectable fluorescein product concentration: >40,000 copies of GFP can be generated from one template molecule by in vitro expression151 or >106 copies of an enzyme from lysis of a single cell:126 this means that fewer than a single turnover per enzyme molecule is comfortably detectable. Paradoxically the extreme miniaturization in droplets thus increases sensitivity compared to plate-based screens. While finding a highly efficient enzyme is the ultimate goal of a discovery campaign, early stages of directed evolution or metagenomic screening often involve low-activity catalysts (with an initially weak, promiscuous activity as a springboard for improvements)193−195 that are inefficiently expressed in a heterologous host. For these targets, fluorescence provides access to crucial starting points for evolutionary campaigns.

In addition to practical shortcomings (e.g., photobleaching), limits of fluorescence detection emerge when precise fine-tuning of enzymes for substrates that do not have a fluorogenic group is required. Fluorescein is bulky and hydrophobic, so it is potentially very different in terms of molecular recognition from natural functional groups. As a leaving group it is much more reactive (pKa 6.4) than natural leaving groups (e.g. sugars, pKa 12–14). Often improvements for a fluorescein-containing model substrate translate into a concomitant increase in the activity of substrates that e.g. have a different leaving group.117,196 However, this improvement is typically smaller due to specialization for the fluorogenic substrate—following directed evolution’s basic law, “you get what you screen for”.197

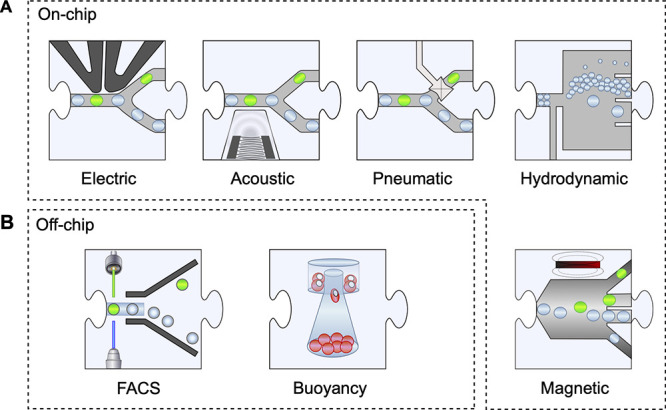

Most cases of successful library selections on-chip (see Figure 7, Table 3) were based on coupling fluorescence detection with dielectrophoresis,198−201 in which an electrode (0.5–2 kV) is triggered by the optical signal (FADS, fluorescence-activated droplet sorting). kHz screening rates can be achieved (routinely with rates similar to a flow cytometer of 1–8 kHz,117,118,123,127,128,196 but even achieving up to 30 kHz202). Most screens are based on a single fluorophore, but selection based on multiple color detection has also been demonstrated.203 Other sorting methods are shown in Figure 7.

Figure 7.

Sorting. Following analysis of the contents of individual droplets for product formation (using the methods listed in Table 3) sorting decisions are taken and droplets are steered into a collection bin for positive hits (whereas without intervention they would move into an outlet). In two cases of self-sorting, the content of the droplets causes the physical properties of the entire droplet to change, so that hydrodynamics or buoyancy becomes indicative of reaction progress.

It is important to note that water-in-oil emulsions cannot be sorted in most flow cytometers (FACS, fluorescence-activated cell sorters) because the majority use an aqueous sheath fluid as a carrier phase and are incompatible with an oil phase carrying water-in-oil emulsion droplets. However, alternative droplet formats exist to replace the on-chip sorter with a FACS. Single emulsions are emulsified again to produce water-in-oil-in-water “double emulsions” that overall have rheological and electrostatic properties of an aqueous solution and are amenable to FACS (Figure 2C).87 The multistep processes described in the preceding section can still be carried out when the second emulsification step is performed last. Polydisperse single emulsions can be converted into double emulsions using a homogenizer,27,76 by vortexing,78 or by filter extrusion.26 When the monodispersity is to be retained, on-chip re-emulsification of monodisperse single emulsions is possible.40,86,87 Liposomes behave as double-emulsion droplets and can be sorted in FACS.54,55 Likewise, formats in which a bead is carrying genotype and phenotype can be sorted by FACS, which has been employed for the selection of protein binders,75,204 kinases,28 or triesterases.30

FACS and on-chip sorters operate with similar throughputs, >107 per day, so both methods are similarly powerful. On-chip workflows allow setting up more complex processes (see below, Figure 9), but FACS sorting of double emulsions removes a technical complication and, with only a droplet-formation step performed on-chip, will be much easier to implement in nonspecialist laboratories. For widening the circle of users, a sorting step that only requires access to a walk-in instrument, e.g. in a centralized facility, will be highly attractive and help to popularize droplet approaches to a broader audience. However, FACS is limited to fluorogenic assays and serves only a relatively narrow range of target reactions. Also current multistep workflow protocols (see below, Figure 9) are only feasible while the droplets are on the chip, but when converted to double emulsions, microfluidic on-chip processing ceases to be an option.

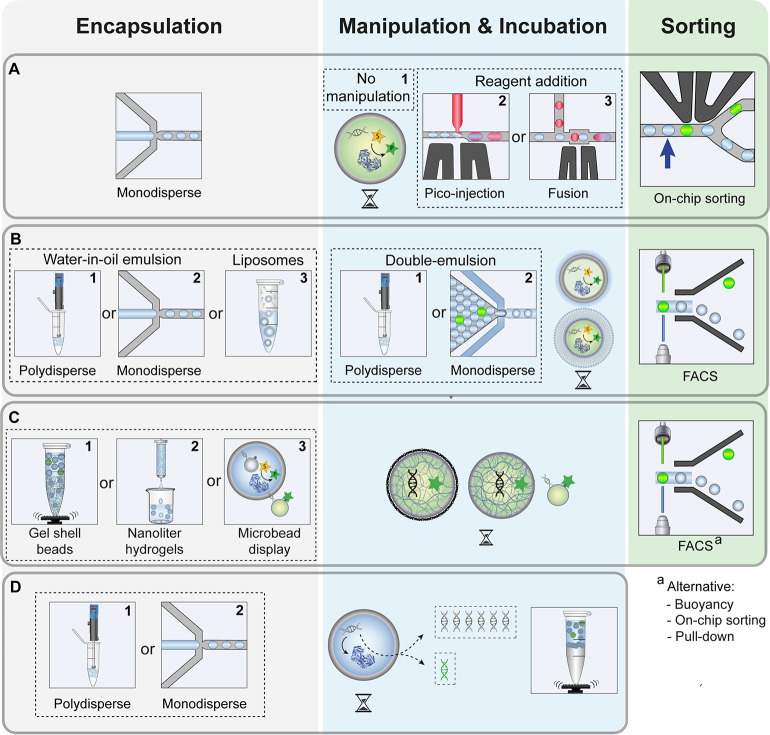

Figure 9.

General workflows to screen for enzymatic activity in droplets. Subfigure numbering indicates workflows assigned in Tables 5 and 6. (A) Reaction in monodisperse droplets and droplet sorting. Monodisperse droplets are produced, incubated and analyzed either without manipulation (1) or manipulated by picoinjection (2) or droplet fusion (3). After analysis, droplets are sorted on-chip. (B) Double emulsions and liposomes sorted by FACS. Polydisperse (1) or monodisperse (2) droplets are produced and incubated. In a second step, a polydisperse (1) or monodisperse (2) double emulsion is formed and then sorted by FACS. An alternative to double emulsions is direct encapsulation in polydisperse liposomes (3) which can be incubated and sorted by FACS. (C) Solid-particle-based genotype–phenotype linkage. Gel-shell beads (1), nanoliter hydrogels (2) or microbeads (3) are produced, incubated, and sorted by FACS. Sorting has also been performed by buoyancy, pulldown, or on-chip droplet sorting if the solid particle remains encapsulated. (D) Selection of nucleic acid-manipulating enzymes by encapsulation without sorting. DNA libraries are compartmentalized in a polydisperse (1) or monodisperse (2) emulsions, and a readout is directly achieved by manipulation of the encoding gene (e.g., amplification). The droplet emulsion is broken and the activity of variants is represented by the quantity of its encoding gene.

Absorbance detection has more recently emerged as an alternative detection mode to enlarge the reactions of interest to chromogenic assays and can be coupled with dielectrophoretic sorting, named absorbance-activated droplet sorting (AADS) in analogy to the FADS described above. Practically, AADS is attractive: the setup is more straightforward and less expensive than FADS, as no lasers or photomultiplier tubes are needed. On the other hand, detection is not as sensitive as fluorescence detection (high μM vs nM detection limits, respectively). Absorbance is directly proportional to path length; therefore, droplets with a larger diameter (and therefore larger volumes) are needed. Consequently, the amount of reagent required for each droplet is larger, and the throughput of sorting is reduced because a higher electric field is needed to sort larger droplets.

In current enzyme screening campaigns, FADS was at least ∼20-fold faster than AADS (1–3 kHz198,201 vs 100 Hz).126 Attempts to increase the sensitivity and sensitivity of absorbance sorting have been made: (i) Duncombe et al.205 introduced UVADS (UV–Vis Spectra Activated Droplet Sorter) in a channel design with increased path length (by installing a right-angled turn at the detection interface) and by recording entire spectra (200–1050 nm) as unique signatures in UV–Vis Spectra-Activated Droplet Sorting. (ii) Richter et al.206 have shown kHz sorting throughput in a model separation based on removal of droplet trace artifacts by using a combination of surface acoustic waves and microlenses in the form of an optical air cavity. (iii) Medcalf et al.207 overcame the scattering caused by droplet edges in an improved microfluidic design (i.e., with a single-layered inlet leading to enabling more even spacing), refractive index matching, and faster sorting algorithms (compared to ref (126)), so sorting around 1 kHz became possible.

Fluorescence anisotropy (or fluorescence polarization) is a similarly sensitive detection technology to distinguish between bound and unbound forms of the fluorescently labeled analyte. Here, the fluorophore—attached away from the place of binding or catalysis—is excited using linearly polarized light, and the ratio between vertically and horizontally polarized emission light provides information about the rotational lifetime or tumbling of the fluorescently labeled substrate. This effectively provides a size measurement that has been used on droplets for assessment of binding processes.208,209 Extending this approach to catalysis (e.g., of size-changing protease or glycosidase reaction) will be useful to assay biopolymer-degrading or -assembling enzymes, but the integration into a sorter is necessary.

Fluorescence lifetime assays require a longer measuring time than the above-mentioned fluorescence assays (>ms instead of <μs), but in recent experiments fluorescence lifetime-activated droplet sorting (FLADS) has been shown to operate with frequencies in the 60–100 Hz range.210,211

Many other optical detection techniques have been developed: photothermal interferometry,212 optoacoustic imaging,213 Raman,214 infrared imaging,215 light scattering,216 and image analysis.217 While opening the option for different screening modalities, they all have reduced sensitivity, with the highest, photothermal interferometry, being at a low μM concentration. Methods to increase sensitivity and enable screening214 have been developed and successfully used in sorting a diacylglycerol acyltransferase library.218 The frequency of these techniques varies, with photothermal interferometry and optoacoustic imaging managing kHz speeds, while the others are at 1–100 Hz speeds.

A very attractive detection method is mass spectrometry (MS), because it is label-free, potentially possible with any ionizable product, and also provides information on multiple product candidates (and their ratios) emerging from an enzymatic reaction. Electrospray ionization has been used in several studies, after phase separation,219 directly from biphasic systems (double emulsions)220 or from plugs in segmented flow.221 In one case, an enzyme activity screening has been demonstrated: Holland-Moritz et al.222 enabled this by splitting droplets on-chip into two queues, one to be analyzed by ESI-MS and the other for dielectrophoretic sorting in response to the MS result (with addition of marker droplets for synchronization). Now sequences and functional readout could be matched, albeit with a throughput of <1 Hz. In these seminal experiments, >106 copies of the DNA template had to be supplied in the droplets. Library selections would require droplets to be monoclonal (at least initially); therefore, integration with DNA amplification may be necessary. It will also need to be checked whether in vitro expression produces enough protein to yield detectable quantities of product if its ionization is difficult.

Other non-optical methods have been developed: electrochemistry106 and NMR.223 These methods both work at a much lower frequency (1–10 Hz) due to the need for a longer interrogation time and the need for a large droplet volume. Surface tension-224 and buoyancy-based225 detection have also been applied to droplet sorting, with potentially very high throughputs possible for buoyancy screening due to passive selection.

We envision more progress on label-free detection methods to be developed to match conventional microfluidic sorting speeds due to the obvious advantage of not needing a labeled substrate or product. This circumvents lengthy assay development times and prevents evolving enzymes that are not specific to the target of interest but to the label itself. However, sensitivity issues and the length of the interrogation time need further development.

Additionally, other sorting mechanisms are in exploration, e.g. (i) hydrodynamic “self-sorting” of differently sized droplets229−231 or of droplets with different buoyancy;225 (ii) magnetic sorting232 based on the encapsulation of magnetic particles that enable pulling droplets into a sorting channel; and (iii) sorting with pneumatic valves (via actuation of a valve that opens or closes a channel).233−,235

6. Expression Systems

The identity of library members is defined by a DNA identifier—a gene or a plasmid or fosmid in a cell—depending on whether an in vitro or in vivo expression is used to generate protein. The DNA is supplied at the start of an experiment into emulsion droplets in a Poisson distributed fashion. Here, Poisson’s equation describes the probabilistic likelihood of the occupation of a droplet compartment with 0, 1, or more. Ideally, droplets are monoclonal, i.e., initially containing just one library member, so a Poisson distribution, in which single compartmentalization dominates (while the majority of droplets is typically empty), is chosen, e.g., in directed evolution experiments.

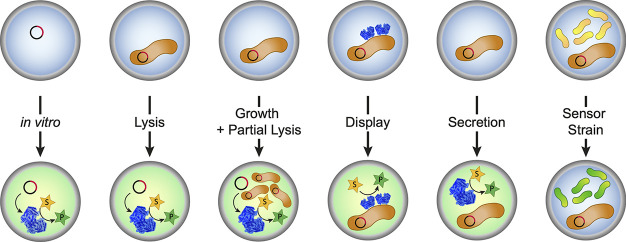

The practical challenges for the expression system include the following: (i) monoclonality, expression from single variants, while also having to recover enough DNA for decoding to avoid the loss of hits (Figure 8); (ii) access, the need for the target enzyme to reach its substrate, i.e., not be physically separated by, e.g., a cell membrane; (iii) sensitivity, sufficient amounts of protein to turn over enough substrate to product to exceed the detection threshold; so expression systems have to be efficient.

Figure 8.

Expression systems used in droplets. Single library members are encapsulated in droplets according to Poisson distributions where they encounter the reaction substrate. For in vitro systems DNA library members are compartmentalized and expressed using cell-free expression systems. Alternatively, cells representing library members (and containing the genotype) are compartmentalized: while the encounter with substrate is straightforward for display systems (e.g., yeast or E. coli display), for intracellularly produced enzymes, full or partial cell lysis or secretion of the enzyme is necessary. Finally, intracellularly expressed protein can be screened without lysis when the substrate is transported in and the product out of the cell to be detected by a cocompartmentalized sensor strain.

6.1. In Vivo Expression

Bacterial lysates have been used most often for making protein available in droplets:2,236−238 the protein is produced, e.g., in E. coli that are grown offline (with the protein remaining in the bacterial cytosol) and compartmentalized into droplets, followed by cell lysis. If single bacteria are coencapsulated with a lysis agent and substrate, it is especially important that a high-copy-number plasmid is used to allow for efficient DNA recovery. High-copy-number plasmids are readily available and typically harbor inserts of 3–5 kb in length. This is optimal when screening for improved variants in a directed evolution project,2,117,125,128 but also functional metagenomic campaigns for the discovery of new enzymes from environmental DNA in plasmids have been successful.118,196 When larger inserts are screened, i.e., fosmids or cosmids (with 30–40 kb environmental DNA per vector), no high-copy-number constructs are available. The very low copy number of fosmids or cosmids requires amplification for successful recovery.131 To this end, single cells can be compartmentalized and then grown in droplets.144 Adding a level of control, an E. coli system has been introduced that allows for the titratable induction of lysis of a defined fraction of the bacterial population.239 Alternatively, after bacterial growth, complete lysis can be achieved by picoinjection of lysis agents.144 Avoiding the need for lysis, enzymes can also be expressed in the bacterial periplasm80,240 into which many substrates can diffuse, be displayed on the bacterial120,241 or yeast surface,122 or be secreted.113,114,242 In these four approaches, living cells are recovered after sorting, offering the possibility to enhance recovery by growth amplification.

Microfluidic assays with whole cells have also been successfully applied to the discovery of active catalysts.243 The screening of intact cells can be especially useful in metabolic engineering when entire pathways or different genomic locations are involved in the target phenotype, e.g., improved protein secretion.112,113,115,116 or the production of secondary metabolites combined with a sensor strain for detection.225

6.2. In Vitro Evolution

In vitro expression systems are an attractive alternative to cell-based screening systems. They either use the unpurified protein synthesis machinery of cells244 or a defined mix of purified components.245 Cell-free directed evolution campaigns have four key advantages: (i) they are unconstrained by transformation efficiency; (ii) they are unaffected by potential toxic side effects of the expressed protein to the survival of the host organism; (iii) they can be carried out under conditions that avoid biological (arising from the proteome of the host organism) and chemical background reactions (e.g., by changing to a nonphysiological pH); and (iv) they enable quick workflows not depending on cell-based library cloning. Indeed in vitro expression systems were already used in the first functional screening studies in polydisperse droplets targeting DNA modifying enzymes.29,90 In addition, there is the conceptual beauty of the droplet as an in vitro compartment that resembles artificially created protocells, as a vessel accommodating just one biochemical process that is to be evolved without interference from other processes.

On the other hand, practical challenges complicate in vitro evolution. Since monoclonality requires just one variant per droplet, DNA recovery can be difficult. Early studies reported successful enrichment of active library members from only one DNA molecule per droplet,26,29,89 or bead,30,106 but DNA recovery may be suboptimal. Emulsion PCR231 or rolling circle amplification (RCA)150 in droplets prior to expression is an option for amplification. Regarding workflow design, thermal cycling and the reagents required for RCA are incompatible with the available in vitro expression systems which must be built into later steps. For example, IVTT components were added via picoinjection130 or electrocoalescence of two droplets150 only after the DNA amplification step. This was achieved by Holstein et al.121 in a multistep workflow for the directed evolution of proteases that thus far is the only demonstration of screening of in vitro expressed enzymes in microfluidic droplets.

Experimental in vitro alternatives exist: the coding DNA, expressed protein,106 and products can, after initial droplet compartmentalization, be captured on a single bead28,32,75,204 to preserve the genotype–phenotype linkage. After de-emulsification and washing steps, the addition of chemicals in a solution and sorting by FACS can proceed without microfluidics, and the union of genotype and phenotype on a bead allows recovery and decoding of hits without compartmentalization.

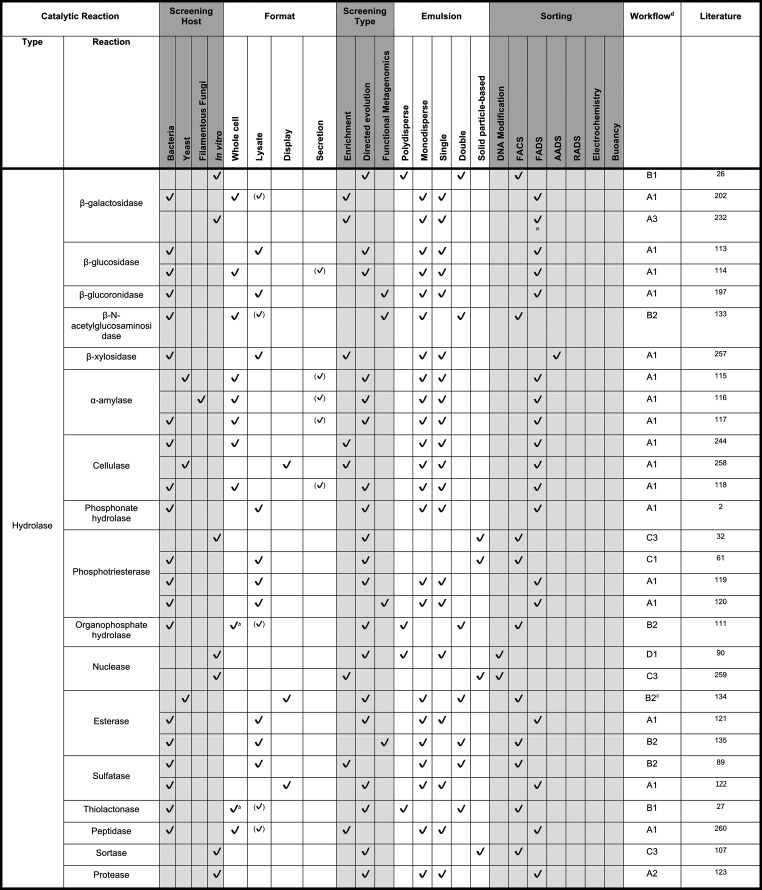

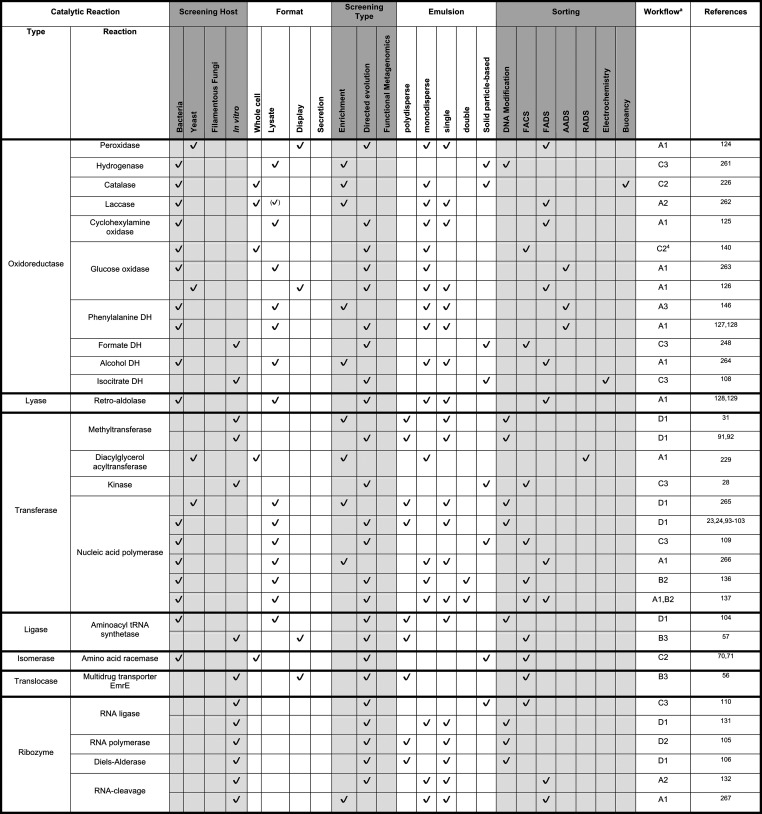

7. Reaction Types Amenable to Microfluidic Enzyme Screening

The starting point of any directed evolution campaign is the availability of a robust assay that allows for accurate quantification of the reaction progress in each droplet. Tables 4 and 5 give an overview of the reactions currently amenable to droplet screening, covering all seven enzyme commission number (EC) classes (oxidoreductases, transferases, hydrolases, lyases, isomerases, ligases, and translocases). The criterion for inclusion in these tables is at least a successful enrichment in monoclonal format (one gene per droplet). Evidence of successful directed evolution experiments is indicated as the proof that single library members in a library of great diversity can be identified and recovered.

Table 4. Enzyme Assays Demonstrated in Microfluidic Droplets Categorized by Reaction Type, Part 1e.

Fluorescence-activated electrocoalescence rather than FADS (i.e., a sorted droplet is merged into an aqueous stream for more efficient DNA recovery).

Substrate added to oil phase and diffused into droplets and cross cell membranes or spontaneous lysis.

In a variation to most other procedures, the second emulsification step is performed before incubation.

Assigned worflows are discussed in section 8, Figure 9. Check marks in brackets indicate formats inferred from publication.

Only assays in a monoclonal format that achieved at least enrichment are included.

Table 5. Enzyme Assays Demonstrated in Microfluidic Droplets Categorized by Reaction Type - Part 2c.

Assigned worflows are discussed in section 8, Figure 9. Check marks in brackets indicate formats inferred from publication.

Type refers to enzyme classes, with ribozymes as a seperate category. EC classes are surrounded by bold frames. The remaining EC class “hydrolase” is covered in Table 4.

Only published assays in a monoclonal format that achieved at least enrichment are included.

As in directed evolution, in general, many screening campaigns have targeted hydrolase reactions, for which fluorogenic or chromogenic substrates are readily available for the most straightforward way of following reaction progress by optical interrogation of droplets. Typically the natural leaving group is replaced by a fluorophore or chromophore, and the reaction product lights up: the hydrolyses of peptides, sugars, and carboxy-, phospho-, phosphono-, and sulfoesters have been assayed in this way. Such substrates have large optically active hydrophobic leaving groups, so the molecular recognition properties of such model substrates may be altered, and their typically higher reactivity (with leaving groups with lowered pKa values compared to native substrates) makes observation of promiscuous reactions more likely. Alternatively, assays of proteolytic121 or glycolytic113 activity based on the autoquenching of BODIPY-labeled substrates that generate fluorescence after cleavage have also been successful. While chemically unactivated bonds are cleaved, the assay is not sequence-specific, reporting on activity rather than specificity.

For many relevant substrates, the cleavage of one particular bond does not directly result in the generation (or unquenching) of an optically active molecule. Coupled reaction systems that convert an optically inactive product into a downstream optical signal can potentially expand the scope of the assayable reactions. For example, free thiol groups produced by thiolactonase activity can be detected by fluorogenic compounds that react with the product thiol to form a fluorophore. Thioester hydrolysis can thus be followed by fluorescence without a custom-made substrate and without a potentially non-natural bulky leaving group.27 In more complex cascades, optically inactive reactants were coupled to downstream fluorescence123 or absorbance125,126,144,256 readouts via secondary reactions, covering redox reactions. Once reliably established, coupled reactions simplify the requirement for custom-made or expensive substrates that may only be available for standard reactions. Cascade reactions can be highly specific for the initial substrate (e.g., a natural sugar256 identified by a specific hydrolase, albeit without an optical signal), while the downstream reactions that process the initial product to create an optical signal are generic.256 In this way, the same assay mode can be used for a range of evolution campaigns. As long as high-quality enzymes with sufficient specificity for the first reaction are available, direct selection pressure can be applied e.g. to a range of natural substrates, with the same detection setup.

In vitro systems provide an avenue to set up product detection manifolds that would be hard to use in cell-based systems. A potentially generalizable platform has been developed for NAD(H)-utilizing enzymes, taking advantage of protein (and, in the future, nucleic acid) sensors for product detection. Here, highly functionalized microbeads were decorated with multiple copies of identical enzyme variant-encoding DNA on each bead,246 together with a bead-immobilized analogue of the cosubstrate NAD+. These beads were then compartmentalized in polydisperse water-in-oil emulsion droplets, where they were exposed to a cell-free expression mixture and enzyme substrate so that reaction progress (in this case by the model enzyme format dehydrogenase) led to a concomitant turnover of NAD+ to NADH. The addition of a fluorescent-protein-based sensor of NAD(H) then serves to report the redox state of the bead-immobilized cofactor, and flow cytometric sorting of beads identifies those with maximal reaction progress by sensing the ratio of NAD+:NADH on each bead.247 Reminiscent of earlier work,30 the beads constitute a genotype–phenotype linkage248 that is initially isolated by a droplet compartment and sorted after its removal on the basis of the distinguishing capacity of an added sensor. The more sensor molecules that become available,249−254 the more versatile this approach will be for future assay design.

8. Fully Integrated Workflows in Directed Evolution Campaigns: From Model Enrichments to Examples for Successfully Integrated Systems Validated by Library Screening

The availability of devices, analytical interfaces, a range of assays (with an understanding of their dynamic range and sensitivity), and proof-of-principle experiments is an important preliminary of setting up screening experiments (Figure 9). Enrichment experiments can help to assess whether a workflow is fit to operate and quantification of the observed enrichment is a helpful benchmark for iterative improvements. In enrichment experiments, a defined mix of positive and negative clones is sorted, and the amount of positive variants after sorting is assessed experimentally. There are two ways to calculate enrichments, different in how they define the fraction of positive clones before and after sorting.

Baret et al. define enrichment η as follows:201

with N+1 representing positive clones after sorting (true positive), N– negative clones after sorting (false positive), N+0 positive clones before sorting, and N– negative clones before sorting. In contrast, Zinchenko et al. define enrichment η′ as the ratio of percentages of positive clones after and before sorting:87

This can lead to large differences in reported enrichment factors (η and η′) as illustrated by the following example. If a 1:100 dilution is used in an enrichment experiment and after screening 95 positive and 5 negative clones are found, the enrichment calculated according to Zinchenko et al. would be η′ = 95 and an enrichment of η = 1881 would be calculated according to Baret et al. These different ways of calculation need to be taken into consideration when evaluating reported enrichment factors.

However, the bar for a successful library experiment is higher still. Several additional challenges have to be met: (i) Long-term operability: Devices have to run for hours (instead of the few seconds of a movie that characterizes a device or module functionality) to screen an entire library. (ii) Single-gene recovery: In contrast to an enrichment experiment, where multiple copies of the positive model hit are supplied, libraries may contain just a few clones that satisfy the selection criterion. These have to be recovered efficiently to make the screen successful and represent the selection output faithfully. (iii) Compatibility: Modules developed in isolation have to be assembled to implement multistep workflows. For workflow design, the intrinsic throughput per time of individual module operations determines whether to develop continuous or discontinuous workflows (with the latter allowing more flexibility in the combination of modules). Practicalities (e.g., back-pressure and convenient operational control) will also be important considerations when modules are combined.

This is why the implementation of fully integrated workflows that have yielded genuine hits in library screening experiments is the decisive step en route to making universal use of droplets to find functional proteins. Figure 9 represents the patterns of workflows that have passed this test, and Figures 10–14 detail successful examples.

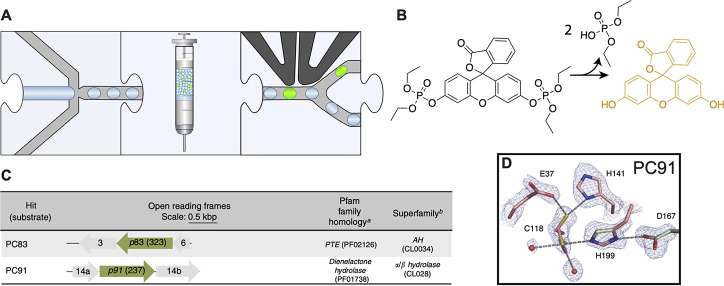

Figure 10.

Functional metagenomic discovery of phosphotriesterases.118 (A) Workflow. Monodisperse droplets are generated with a metagenomic library expressed in an E. coli host and a fluorogenic substrate. The droplets are stored off-chip and then reinjected into a FADS device that sorts fluorescent droplets. (B) Fluorogenic assay. A fluorescein-phosphoester derivative is hydrolyzed to yield fluorescein that can be detected in FADS. (C) Hits from metagenomic screening. While PC83 was predicted to be a potential phosphotriesterase by Pfam domain recognition, the hit PC91 has open reading frames with Pfam family and superfamily assignments that had not been previously associated with triesterase activity. (D) Active site of the novel phosphotriesterase PC91 that uses a catalytic triad in its catalytic mechanism.

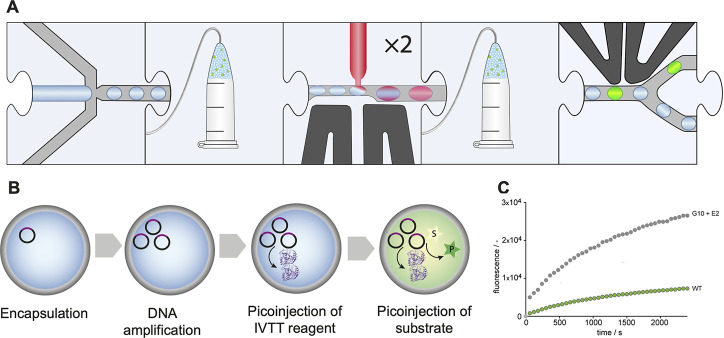

Figure 14.

Droplet manipulation by picoinjection enables sequential addition of reagents.121 (A) Monodisperse droplets are produced and stored off-chip, followed by two picoinjection steps with incubation off-chip, and FADS. (B) The workflow enables stepwise DNA amplification by RCA, protein expression by IVTT, and conversion of substrate to generate a fluorescent readout using reagents that otherwise would be incompatible with each other. (C) The improved variant G10+E2 shows a 5.5-fold improved activity.

The first workflow (Figure 9A) summarizes a screen in monodisperse microfluidic droplets using assays with an optical readout, e.g., fluorescence or absorbance. A monodisperse emulsion is generated by compartmentalizing library members together with substrates. The emulsion is either incubated or directly screened using droplet sorting activated by a readout (e.g., FADS201). In addition, on-chip manipulation steps, including, e.g., picoinjection121,130 or droplet fusion,231 can be carried out prior to sorting.

An example of finding a “needle in a haystack” against overwhelming odds is the screen of a metagenomic library of more than a million members from various natural environments for a phosphotriesterase reaction, a hydrolytic reaction related to a non-natural substrate. Here monodisperse droplet generation was followed by incubation and FADS to screen for hydrolase activity (Figure 10A).118 A substrate generating fluorescence upon cleavage has been used (Figure 10B), and 8 phosphotriesterases (with a kcat/KM = 9 × 105 s–1 M–1 for the best one, PC83) have been identified. In addition to homologues of previously identified metal-dependent triesterases, the hit PC91 turned out to be a member of the α/β-hydrolase superfamily, with an esterase-like catalytic triad and without an active site metal (Figure 10C and D). PC91 is the first metal-free bacterial triesterase to be described and—when represented in a sequence similarity network—breaks new ground in unannotated regions of sequence space, showing that microdroplet-based ultrahigh-throughput screening of metagenomic libraries provides functional information that cannot be predicted. Finding such hits by sequence-based methods would not have been possible, as this type of enzyme had only been associated with carboxyester hydrolysis. Promiscuous activities such as this one are hard to predict, and hits are rare for non-natural substrates. This is to say that a screen of tens of thousands of clones in a robot would—statistically (based on the finding of 8 hits among 106 library members)—only have been successful every 10th time: droplet technology was necessary to find any hits. The same assay has been used to further evolve PC91, yielding variants with a 400-fold increase in activity after only two rounds of directed evolution.117 Here, the initially discontinuous workflow was made continuous by the introduction of delay lines to account for the increased proficiency of the catalysts emerging from selection rounds, requiring incubation times of tens of minutes (rather than initially days).

In a further example of harvesting enzymes from the same metagenomic library using the workflow depicted in Figure 9A, a screen for β-glucuronidases identified a candidate for this particular activity in an unexpected sequence context, i.e., with neglectable homology to previously characterized enzymes with this function.196 While having little sequence homology to known β-glucuronidases, it was located in a glycosyl hydrolase family (as classified by CAZy) that had no recorded evidence of β-glucuronidase activity at the outset of this study but several other recorded activities.

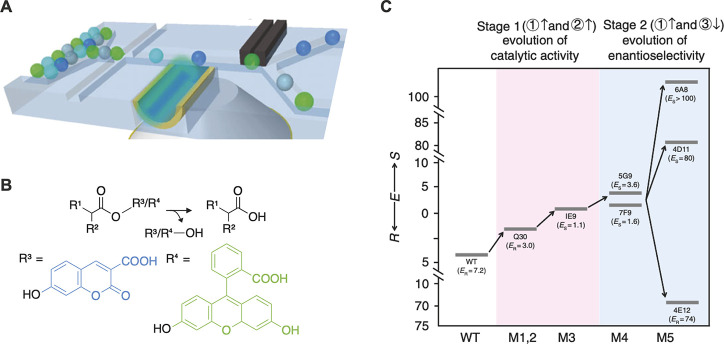

Another workflow implementation in Figure 9A (monodisperse droplet generation, incubation off-chip, and FADS) was the work of Ma et al.,119 who engineered an enantioselective profen esterase. An innovative dual laser FADS device was used (Figure 11A) to monitor the turnover of two different fluorogenic substrates to screen for selective variants (Figure 11B). Multiple rounds of directed evolution gave a variant with 700-fold improved enantioselectivity.

Figure 11.

Directed evolution of an enantioselective esterase using a dual-channel device.119 (A) A FADS device allowing excitation with two lasers was designed to simultaneously report on the conversion of two different fluorophores (indicated by green and blue droplets), in a workflow similar to that in ref (128). (B) The profen ester substrate of the enzyme can be modified with either a coumarin or a fluorescein leaving group. Modification of different profen enantiomers with distinct fluorophores allows screening for enantioselective esterases using the dual-channel FADS device. (C) A profen esterase was evolved over multiple rounds of directed evolution. Cumulative improvements in enantioselectivity E are displayed for the wild type and variants arising from several rounds of directed evolution. First, a library was screened for general improvement of catalytic activity, without regard to enantioselectivity. This screen yielded Q30 (with a 2-fold improvement) and, after a further round of error-prone PCR, 1E9 (4-fold improvement) as the top performers. In stage two, the dual-channel device was used to gate for enantioselective variants, and variants 6A8 and 4E11, with 700-fold and 560-fold improved enantioselectivity, were identified.

Similarly, Obexer et al. used the workflow in Figure 9A to improve a previously optimized artificial aldolase 30-fold.128 Monodisperse droplets were incubated on a chip to enable short incubation times (Figure 12A). A methodol derivative that forms a fluorescent product upon reaction was used as the substrate (Figure 12B). The delay line was varied in length to reduce the incubation time from 1 h to 5 min. This controlled approach in delay line design allowed for the selection of increasingly more proficient catalysts during the campaign. After five rounds of directed evolution, the aldolase was improved 30-fold, salvaging a previously stalled directed evolution campaign (Figure 12C and D). Intriguingly, the evolution campaign yielded a completely remodelled active site with a new catalytic tetrad erasing the original catalytic apparatus (Figure 12E).

Figure 12.

Directed evolution of an aldolase.128 (A) Workflow. Monodisperse droplets are generated, including the library expressed in E. coli and the substrate. The droplets are incubated on-chip to enable short incubation times. Fluorescent droplets are sorted. (B) Assay. The aldolase cleaves the substrate, releasing a ketone and a fluorophore. (C) 11 mutations (yellow spheres) were introduced to generate the starting point that was subsequently optimized by low-throughput directed evolution (green spheres) over 13 rounds of evolution followed by five rounds of directed evolution in droplets (cyan spheres). (D) Michaelis–Menten plot comparing the starting point of the ultrahigh-throughput campaign (RA95.5-8, green) with the variant with the highest activity (RA95.5-8F, blue) after directed evolution. (E( Catalytic tetrad emerging after directed evolution. We thank Prof. Donald Hilvert for providing the material for the subfigures C, D and E.

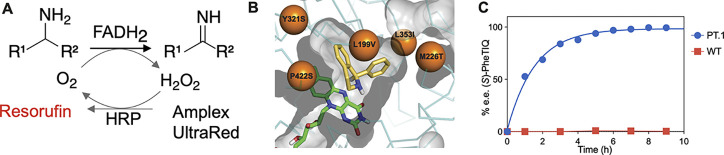

To engineer an amine oxidase, Debon et al.123 implemented a different assay within the familiar setup of Obexer et al. (Figure 12A).128 Coupled assays are far more versatile than direct assays, as they can be used for a broader range of target reactions. Additionally, they do not rely on mock substrates with bulky fluorogenic groups, allowing screening for authentic substrates used in the targeted application. In their assay, Debon et al. read out the production of H2O2 by the amine oxidase indirectly via oxidation of Amplex UltraRed to the fluorescent dye resorufin (Figure 13A). The identification of a mutant with a 960-fold improvement in kcat/KM with a completely remodelled active site (Figure 13A and B) in only one round of screening demonstrates the potential of ultrahigh-throughput screening to improve biocatalysts in time scales compatible with the fast pace of product development in industry.

Figure 13.

Directed evolution of an amine oxidase.123 (A) Coupled assay used to screen for amine oxidase activity. The amine substrate is oxidized, yielding H2O2 as byproduct, which oxidizes Amplex UltraRed to Resorufin. (B) After one round of directed evolution, the active site of the enzyme is remodeled by introduction of five mutations. (C) The variant yielded from directed evolution (PT.1, blue) has a 960-fold improved kcat/KM. We thank Prof. Donald Hilvert for providing the material for the subfigures B and C.

The previously mentioned formats rely on expression in cells and, therefore, cannot be used to engineer cytotoxic proteins. To engineer a cytotoxic protease, Holstein et al. developed a microfluidic workflow enabling in vitro expression of the enzyme (Figure 14A).121 Reaction conditions are complex (>70 components) and cannot be performed in one pot. To ensure compatibility of the reagents, DNA amplification by rolling circle amplification (RCA) is followed by two picoinjection steps used to sequentially inject IVTT reagent and substrate (Figure 14B). Directed evolution (based on focused libraries followed by their reshuffling) using this workflow yielded Savinase variants with up to 5.5-fold improved activity (Figure 14C). This evolution experiment would not have been possible in E. coli. (Indeed, the resulting variants had to be expressed in B. subtilis to obtain sufficient quantities to be characterized.)

The more accessible, “democratic” format of double-emulsion droplets (water-in-oil-in-water) is shown in the workflow in Figure 9B, where flow cytometric sorting in a FACS replaces on-chip FADS. Both initially poly-77 and monodisperse87 droplet formats have been used for screening of libraries from environmental131,133 or randomized26,27,109,132,134 origins. Similarly, liposomes can be used for encapsulation, followed by screening using FACS. This has been successfully applied for the directed evolution of β-glucoronidase,110 aminoacyl-tRNA synthetase,55 and the multidrug transporter EmrE.54

Another innovative workflow in microfluidics-based ultrahigh-throughput screening for enzyme activity employs immobilization on solid particles (beads)28,30,59,68,69,105−108,138,225,247,258,260 and is shown in Figure 9C. A variety of different systems have been used in a fashion compatible to enzyme engineering. (i) Agarose beads coated by a polyelectrolyte complex around the core (gel-shell beads) retain small molecules that can be used as a readout in FACS and the enzyme-encoding gene. This system has previously been used in the directed evolution of phosphotriesterase.59 (ii) Another technique to couple genotype and phenotype is based on monodisperse nL-sized hydrogels that can be formed by laminar jet breakup.66 Hydrogels couple genotype and phenotype, for example, by retaining a fluorescent bacterial host,68,69 enabling sorting by FACS or by gas formation inducing a density shift.225 (iii) Reaction partners can also be displayed on DNA-carrying microbeads enabling the coupling of genotype and phenotype (microbead display). For enzyme engineering, microbead display has been pioneered in the directed evolution of phosphotriesterase30 and has been used in modified formats for screening for kinase,28 dehydrogenase,106 nucleic acid polymerases,107 RNA ligase,108 hydrogenase,260 and sortase105 activity.

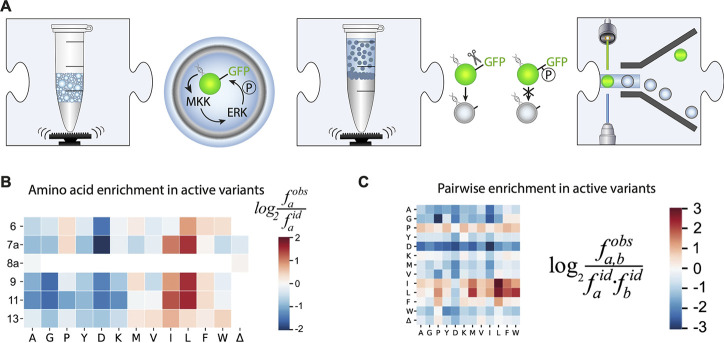

Bead-display-based screening has also been adapted by Scheele et al. to disentangle the encoding of substrate specificity in kinases.28 The encoding DNA of a kinase (MKK1) library is generated on a bead,246 encapsulated into a polydisperse emulsion, and expressed using IVTT (Figure 15A). Functional kinases then activate purified ERK2 by phosphorylation. The bead also harbors GFP that is immobilized with a linker peptide containing a serine residue that ERK2 phosphorylates. The emulsion is broken, and the beads are treated with chymotrypsin which only cleaves the non-phosphorylated linker. The beads are then sorted by FACS and NGS is used to correlate cascade activity and the encoded kinase gene. Thereby the fitness of 5 × 105 independent variants was determined, and large hydrophobic residues were identified as a core feature of the MKK1 docking domain (Figure 15B). Additionally, substitutions to large hydrophobic residues exhibit pervasive positive epistasis, widening the available D-domain active sequence space and generating evolutionary contingency.

Figure 15.

Paramagnetic bead-based kinase screening platform.28 (A) Screening workflow. Beads carrying an SpliMLiB MKK library are encapsulated into a polydisperse emulsion. The beads also carry GFP that is coupled to the bead via a peptide sequence that serves as a recognition motif to chymotrypsin and can be phosphorylated by ERK. In vitro transcription and translation are used to express MKK from the library, which then activates ERK by phosphorylation. After de-emulsification, beads are treated with chymotrypsin. Beads carrying GFP with a phosphorylated linker (encoding active MKK1) are resistant to proteolysis and so remain GFP-labeled and can be sorted with ultrahigh-throughput with FACS. (B) Enrichment in the active variants. Enrichment of the observed frequency (fobs) vs expected frequency (fid) is calculated for each amino acid at each position as a proxy for fitness. Large hydrophobic amino acids (especially leucine and isoleucine) are enriched at nearly all tested positions. (C) Pairwise enrichment. Enrichment of the observed frequency (fobs) for each double mutation over the expected frequency calculated from single-point mutation data. Mutation to leucine and isoleucine serves as the anchor allowing mutation to nonpreferred amino acids by exhibiting positive epistasis.

The seminal demonstrations of in vitro compartmentalized screening were evolution campaigns for DNA modifying enzymes. The corresponding schematic workflow is shown in Figure 9D and relies on self-modification of the in vitro compartmentalized gene. For example, methyltransferases were evolved that rendered their encoding genetic element resistant to restriction digest.29,89 Beyond that, ribozymes catalyzing RNA ligation129 and nucleases88 have been engineered. In vitro compartmentalization (IVC) has also been modified to engineer Diels–Alderase ribozymes by a physical linkage between the gene and the substrate.104 Perhaps the most robust example of this workflow is compartmentalized self-replication (CSR), which has been used extensively for engineering nucleic acid polymerases.23,24,91−101 CSR can also be coupled to other enzymatic activities in an approach called compartmentalized partnered replication, which has been used to engineer yeast tryptophanyl synthetase.102

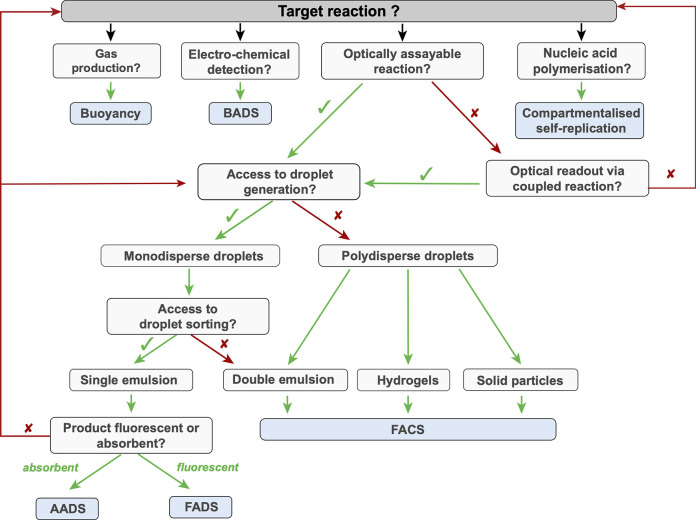

To facilitate custom workflow design for future droplet-based enzyme assays, we summarized relevant considerations in a decision tree (Figure 16) that guides the experimentalist from target reaction to assay type, droplet format, and sorting.

Figure 16.

Decision tree for planning of microfluidic droplet assays according to a target reaction. This chart illustrates the choices that can be made when designing screening assays for microfluidic droplets and highlights the paths to sorting in different droplet formats, optical interrogation or reaction progress, and corresponding analytical interfaces. A successful demonstrated monoclonal enrichment experiment is the requirement for inclusion in this decision tree.

9. Troubleshooting

The successful examples of droplet-compartmentalized library screening experiments for directed evolution and functional metagenomics discussed in the previous section suggest that several complete workflows are in principle ready to be used by a wider audience. To make this happen, it will be important to understand the day-to-day troubleshooting that made the implementation of these examples successful. Interdisciplinary challenges can arise at several unfamiliar fronts, including emulsion and colloid science and their compatibility with biological processes (and cross-compatibility of biochemical reagents). Likewise, complex biological processes must be compatible with each other. Here, we discuss practical protocols to address implementation problems and facilitate or rescue experimental campaigns (Table 6).

Table 6. Troubleshooting Tips and Tricks for Microfluidic Experimentsa.

| Observation causing problems for high-throughput microfluidic screening experiments | Tips and Tricks |

|---|---|

| Running a microfluidic device | |

| Droplets split after the formation junction or a jetting regime is reached | → Reduce flow rate |

| Satellites or small droplets formed | → Reduce surfactant concentration |

| Droplets merge after generation | → Reduce flow rates |

| → Increase the surfactant concentration | |

| Tubing does not stay in the device | → Ensure tubing size is correct |

| → Check for blockage in the channels | |

| → Check flowrates for pressure (e.g., μL/min vs μL/h) | |

| Aqueous stream pulses away from channel edge | → Ensure hydrophobic or hydrophilic coating is uniform |

| Aqueous stream pulsing irregularly | → Check for air bubbles along the tubing and in the device |

| → Check for blockage | |

| → Ensure the flow rates are not too low for the pump | |

| → Ensure tubing is not too long (pressure increases with length of tubing) | |

| Fibers arriving with the oil | → Add filters to the device design (has become standard to help reduce blocking of the inlet) |

| → Filter all solutions before droplet generation | |

| → Flush tubing to prevent microfibers/particles | |

| Dust in a channel | → Attempt to run the phase of that channel at higher rate and wait for dust to slowly move |

| → Press up and down on top of the PDMS to try to dislodge smaller particles | |

| → Remove the tubing of the closest inlet/outlet to suck the dust/cells out. Follow this by backflushing from another inlet/outlet in the opposite direction, so that the dust moves out of the device | |

| → Change device. It is often best to just start with a clean chip, as flushing and pressures can delaminate the chip | |

| Droplets are not being made, and one of the phases cannot be seen | → Check all connections for evidence of leaking |

| → Check for delamination | |

| → Check for air bubbles along the tubing and in the device | |

| Collection of droplets | |

| Droplet generation is unstable upon addition of outlet tubing | → Inserting tubing increases the pressure in the device geometry |

| → Wait a few seconds for the flow to stabilize | |

| → Reduce length of the outlet tubing (back-pressure increases as tubing length increases) | |

| Incubation | |

| Droplets merge after incubation | → If droplets are incubated in a collection tube or syringe, the emulsion at the top can get dehydrated and start breaking, causing merging |

| o Add mineral oil layer on top of the emulsion (if using fluorous oil) or make droplets in mineral oil | |

| o Incubate within a humidity chamber | |

| → Increase surfactant concentration | |

| → If droplets are incubated in a closed chamber: | |

| o Check for air bubbles | |

| o Use anti-static gloves | |

| Substrate or product leakage | → Check background reaction leaking of substrate or product: |

| o Test with equal volumes of your chosen buffer and max concentration of Substrate or Product to generate droplets | |

| o Incubate and image or analyze in flow cytometry | |