Abstract

Avian campylobacteriosis is a vandal infection that poses human health hazards. Campylobacter is usually colonized in the avian gut revealing mild signs in the infected birds, but retail chicken carcasses have high contamination levels of Campylobacter spp. Consequently, the contaminated avian products constitute the main source of human infection with campylobacteriosis and result in severe clinical symptoms such as diarrhea, abdominal pain, spasm, and deaths in sensitive cases. Thus, the current review aims to shed light on the prevalence of Campylobacter in broiler chickens, Campylobacter colonization, bird immunity against Campylobacter, sources of poultry infection, antibiotic resistance, poultry meat contamination, human health hazard, and the use of standard antimicrobial technology during the chicken processing of possible control strategies to overcome such problems.

Key words: broiler processing, Campylobacter, control strategies, foodborne infection, natural compounds

INTRODUCTION

Campylobacter is a gram-negative, facultative intracellular bacteria which belongs to epsilon proteobacteria which is a class of proteobacteria (Mota-Gutierrez et al., 2022). At the same time, it has been described as an animal pathogen since the early 1900s due to its particular growing conditions (Skirrow, 2006). Its importance as a causative agent of bacterial gut illness was not established until the 1970s with a selective medium that could isolate and sustain the growth of Campylobacter in the laboratory (Allos, 2001).

Campylobacter was previously taxonomically grouped as Vibrio spp., and its infections in humans and animals were described as “related Vibrio infections” (Johnson et al., 2017; Wales et al., 2019). In 1963, the genus Campylobacter had been proposed by Sebald and Veron (1963). Subsequently, Vibrio-like organisms, including Campylobacter coli and Campylobacter jejuni, were regrouped as Campylobacter spp., in 1973 (Véron and Chatelain, 1973).

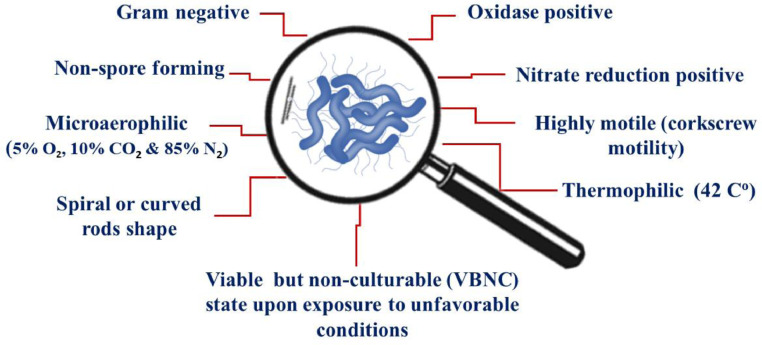

Campylobacter is a strain of bacteria that thrives only under very specific conditions, and it requires extraordinary conditions to grow (Hazeleger et al., 1998). Campylobacter is a thermophilic bacterium, growing optimally at temperature of 42°C, while minimal growth appears at 31°C to 32°C (Hazeleger et al., 1998). Furthermore, it is a microaerobic bacteria that requires approximately 5% O2, 10% CO2, and 85% N2 to grow (Bolton et al., 1997). Another distinctive characteristic that separates Campylobacter from other enteric bacteria is its inability to metabolize glucose (Hofreuter, 2014).

In addition, Campylobacter utilizes tricarboxylic acid cycle intermediates and amino acids as carbon resources (Guccione et al., 2008; Hofreuter, 2014). Despite the metabolic limitations, Campylobacter can colonize wild and domestic animal hosts (Sheppard and Maiden, 2015). The avian species is the preferred host species of Campylobacter, as its optimal growth is supported by the avian species' natural intestinal temperature (Wagenaar et al., 2015). Campylobacter is also sensitive to several environmental stressors, including exposure to atmospheric oxygen levels (Smith et al., 2016; Hsieh et al., 2018), dehydration (Line, 2006), as well as heat (Klančnik et al., 2014) and cold shocks (Josefsen et al., 2015).

However, using different survival mechanisms, Campylobacter can survive extended periods in unfavorable environmental conditions (Hughes et al., 2009). Campylobacter has been noticed to be a viable but nonculturable (VBNC) conditions upon subject to unfavorable circumstances (Hazeleger et al.,1994). Morphological changes characterize the VBNC state, reduced metabolic rates, increased chemical and physical stressors tolerance, and decreased culture ability in growth media (Lv et al., 2020).

It is also debatable whether VBNC Campylobacter cells can be resuscitated to colonize the host and initiate infection in the host (Ballou et al., 2016). Additionally, it was noticed that Campylobacter could perform biofilm when subjected to an aerobic environment (Bezek et al., 2016). Ica et al. (2012) revealed that Campylobacter cells might enter a VBNC state once the biofilm is formed to protect the cells from dangerous conditions. However, Teh et al. (2014) argued that there is not enough evidence to conclude that biofilm formation in Campylobacter is a part of the survival mechanism; instead, the observed formation of biofilm may be a result of simple attachment to abiotic surfaces or food matrices (Teh et al., 2014). Nonetheless, the capability of Campylobacter to live outside the host and adapt to different environmental circumstances demonstrates how Campylobacter can survive via the food production chain (Firlieyanti et al., 2016; EFSA and ECDPC, 2019; Elgamoudi et al., 2020; Habib et al., 2023).

The morphological, biochemical, and physiological characteristics of Campylobacter spp. are presented in Figure 1. Recently molecular tools were known as the best methods used for microbial identification (Hong et al., 2023). The world is directed to the use of natural materials which have been proved to have antimicrobial effects against different species of Campylobacter (Balta et al., 2021). The antimicrobial activity of some natural compounds against different species of Campylobacter biofilm, their minimal inhibitory concentration (MIC), and their mode of action are summarized in Table 1.

Figure 1.

The morphological, biochemical, and physiological characteristics of Campylobacter species.

Table 1.

The antimicrobial activity of some natural compounds against different species of Campylobacter biofilm, their minimal inhibitory concentration (MIC), and their mode of action.

| Natural compounds | MIC | Campylobacter strain | Mechanism | References |

|---|---|---|---|---|

| Essential oils and polyphenolic extracts | ||||

| Cinnamaldehyde | 1.76 µg mL−1 | Campylobacter coli | A substance deposited on the bilayer surface that causes membrane instability | Wagle et al., 2019 |

| Eugenol | 2.69 µg mL−1 | Campylobacter jejuni NCTC 81–176 | Degradation of the extracellular matrix | Klančnik et al., 2021 |

| Carvacrol | 31.25 µg mL−1 | Campylobacter jejuni NCTC 11168 | Disintegration of hydrophobicity by binding membrane hydrophobic groups | Šimunović et al., 2020 |

| (−)-α-Pinene | 125 µg mL−1 | Campylobacter jejuni RC039 | A substance deposited on the bilayer surface that causes membrane instability | Salehi et al., 2019 |

| Resveratrol | 200 µg mL−1 | Campylobacter jejuni S-8 | Inhibition of AI-2 molecule activity | Roila et al., 2019 |

| Diallyl sulfide | 40 µg mL−1 | Campylobacter jejuni F38011 | Disintegration of hydrophobicity by binding membrane hydrophobic groups | Duarte et al., 2015 |

| Clove oil | 400 µg mL−1 | Campylobacter jejuni 180ip | A substance deposited on the bilayer surface that causes membrane instability | Wagle et al., 2021 |

| Lavender essential oil | 1000 µg mL−1 | Campylobacter jejuni 238ip | Inhibition of AI-2 molecule activity | Gahamanyi et al., 2020 |

| Juniper essential oil | 1000 µg mL−1 | Campylobacter coli | A substance deposited on the bilayer surface that causes membrane instability | Gahamanyi et al., 2020 |

| Grapefruit seed extract | 60 µg mL−1 | Campylobacter jejuni NCTC 81–176 | A substance deposited on the bilayer surface that causes membrane instability | Silveira et al., 2019 |

| Citrus lemon peel extract | 225 µg mL−1 | Campylobacter jejuni NCTC 11168 | Degradation of the extracellular matrix | Castillo et al., 2014 |

| Green tea extract | 50 µg mL−1 | Campylobacter jejuni RC039 | Disintegration of hydrophobicity by binding membrane hydrophobic groups | Wagle et al., 2021 |

| Antimicrobial peptides and amino acids | ||||

| Puroindoline A (PinA) | 512 µg mL−1 |

Campylobacter jejuni 81–176 Campylobacter jejuni RC039 Campylobacter jejuni S-8 |

Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | McDougald et al., 2012 |

| White kidney bean protein hydrolysate | 90 µg mL−1 | Campylobacter jejuni NCTC 11168 | Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Saad et al., 2021 |

| Red kidney bean protein hydrolysate | 75 µg mL−1 | Campylobacter jejuni NCTC 11168 | Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Saad et al., 2021 |

| Black kidney bean protein hydrolysate | 45 µg mL−1 | Campylobacter jejuni NCTC 11168 | Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Saad et al., 2021 |

| D-Tryptophan | 1000 µg mL−1 |

Campylobacter jejuni 180ip Campylobacter jejuni 238ip |

Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Elgamoudi et al., 2020; Saad et al., 2021 |

| D-Serine | 1000 µg mL−1 |

Campylobacter jejuni RC039 Campylobacter jejuni S-8 |

Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Elgamoudi et al., 2020; Saad et al., 2021 |

| D-Alanine | 1000 µg mL−1 |

Campylobacter jejuni RC039 Campylobacter jejuni S-8 |

Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Elgamoudi et al., 2020; Saad et al., 2021 |

| D-Methionine | 1000 µg mL−1 |

Campylobacter jejuni NCTC 11168 Campylobacter jejuni 180ip Campylobacter jejuni 238ip |

Reacting with specific membrane components, such as anionic phospholipids and lipopolysaccharides, which break down the membrane and kills bacteria. The reaction may depend on the hydrophobicity of peptides by binding hydrophobic membrane groups. Additionally, peptides are deposited on the bilayer surface due to ionic/electrostatic interactions, resulting in membrane instability and disintegration. When peptides contain both hydrophobic and hydrophilic residues, a property known as amphipathicity, both of the preceding mechanisms may be at work. In addition, peptide length is crucial; short peptides have an excellent amphipathic structure and potent antimicrobial activity. | Elgamoudi et al., 2020; Saad et al., 2021 |

| Probiotics derivatives | ||||

| Bacteriocin Reuterin |

32 µg mL−1 580 µg mL−1 |

Campylobacter jejuni Campylobacter coli |

DNA synthesis interfering with the membrane integrity of bacterial cells | Asare et al., 2020 |

|

Campylobacter jejuni Campylobacter jejuni |

DNA synthesis interfering with the membrane integrity of bacterial cells | Asare et al., 2020 | ||

| Glycolipid biosurfactant | ||||

|

Sophorolipid |

32 µg mL−1 |

Campylobacter jejuni subsp. jejuni 33560 |

Lysis of the cell membrane | Silveira et al., 2019 |

EPIDEMIOLOGY OF CAMPYLOBACTER IN BROILER PRODUCTION

Avian Campylobacteriosis

Campylobacter can multiply in the gut epithelium of almost warm-blooded host species (Biswas et al., 2019; Barker et al., 2020). Poultry is the predominant host for Campylobacter spp., possibly due to their elevated body temperature (Kers et al., 2018; Tram et al., 2020; Beterams et al., 2023). Even while all commercial bird species may host Campylobacter spp., the risk is greater in chicken due to the massive volumes consumed (Ijaz et al., 2018; Dubovitskaya et al., 2023). Campylobacter is a commensal in broiler chickens that forms a benign condition with multiplication up to 1010 colony-forming units (CFU) g droppings−1 (Dhillon et al., 2006; Battersby et al., 2016). Campylobacter was collected from practically every area of the broiler's gut; however, it is instantly present in the caeca and cloaca, which do not attach to the villus epithelium but rather to the mucus coating the intestinal villi (Achen et al., 1998).

In contrast to the illness in humans, Campylobacter do not cause any lesion in chickens and cohabits with the lower gut in a commensal state (Ingresa-Capaccioni et al., 2016; Myintzaw et al., 2023). Histopathological investigations showed no pathological lesions or marked alteration in crypt features (Shaughnessy et al., 2011; Golz et al., 2020). Furthermore, multiplication persists, implying that immunity is inefficient in eradicating infection, at least in these conditions. At the same time, older birds, such as layers, may have had less colonization over time (Johannessen et al., 2020). In summary, this situation has enormous advantages for Campylobacter and no adverse consequences for the host (Beterams et al., 2023).

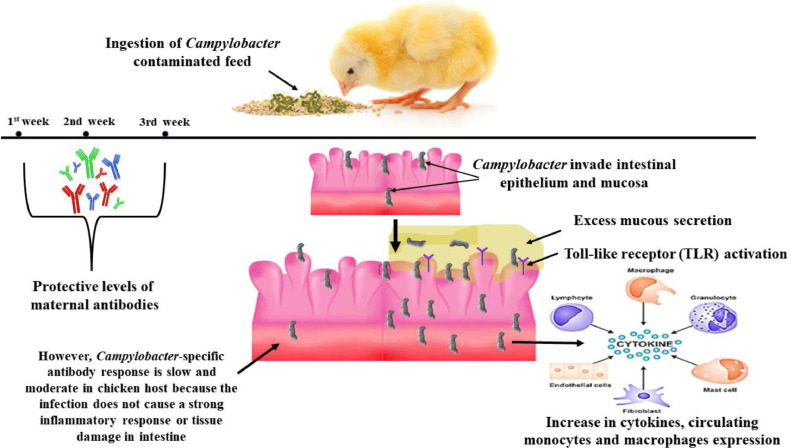

Campylobacter Colonization and Immunity

Ingestion of 35 CFU of Campylobacter was sufficient to induce multiplication in chicken tissues (Umar et al., 2016; Urdaneta et al., 2023). After ingestion, Campylobacter were directed to cecal and cloacal crypts, revealing an established Campylobacter multiplication for 24 h postintroduction (Coward et al., 2008). Campylobacter is rarely noticed in chicken below 2 to 3 wk old (van Gerwe et al., 2009). This young age-linked resistance (commonly called lag phase) expanded against various Campylobacter spp., which is not fully known (Sahin et al., 2002). Campylobacter specified maternal antibodies are predominant in chicken and might be included in this resistance (Šimunović et al., 2020). The high concentration of antibodies detected within the first 2 wk declines to negligible levels within 3 to 4 wk (Sahin et al., 2002; Šimunović et al., 2020).

In addition, the phase of intestinal growth was hypothesized to be included in this age-related resistance, as bird gut tissues undergo physiological modifications within the brooding time (van Der Wielen et al., 2000; Natsos et al., 2019). Alterations in the gut microbiota and competitive cecal microbiome (Mead, 2002) are also related to the lag stage and raising techniques, such as ration and medication changes that occur during the rearing period (Mead, 2002).

Chickens are easily colonized with Campylobacter due to their rapid reproduction (Bailey et al., 2019). Most (>95%) of the chickens of that flock are multiplied for days (Stern et al., 2001) and stay so until slaughter (Coward et al., 2008; Bailey et al., 2019). However, after 8 wk, colonization could lower the bacterial count and number of colonized chickens, accompanied by adaptive immunity and modification in the nutritious tract microbiome (Sahin et al., 2003a; Vandeplas et al., 2010).

However, no lesion was noticed with chicken colonization, and gut immunity to the disease was detected with elevated cytokine expression (Borrmann et al., 2007; Larson et al., 2008; Li et al., 2008) and toll-like receptor (TLR) activation (de Zoete et al., 2010). Campylobacter can stimulate both systemic and mucosal immunity in birds, as various research reported the presence of immune-accompanied gene and protein expression post-Campylobacter multiplication of birds (de Zoete et al., 2007).

However, it is still unknown how Campylobacter reacts with the bird's immune organs to excite immunity (Lin, 2009). Analysis of collected chicken samples showed increased cytokine expression (Smith et al., 2008) and circulating monocytes/macrophages (Meade et al., 2009; Pumtang-On et al., 2021). Various avian cells provoke or upregulate cytokines throughout in vitro challenges (Li et al., 2008). However, the chicken host's Campylobacter-specific antibody response was slow and moderate since the infection did not cause obvious intestinal inflammation or cell death (Lin, 2009; Gorain et al., 2020). In some investigations, Campylobacter was also recovered from the thymus, bursa of Fabricius, reproductive tract, spleen, hepatic tissue, and blood in chicken, supposing that Campylobacter may attack gut tissue and induce systemic reaction (Meade et al., 2009; Nothaft et al., 2021).

Recent research established that C. jejuni could attach to and enter the villi of birds in vitro and in vivo. However, the C. jejuni strains that attack chicken epithelium tissues could not colonize intracellularly but rapidly escape from the cells (Byrne et al., 2007). Thus, Van Deun et al. (2008) supposed a new multiplication procedure of C. jejuni by evading short-term clearance via fast epithelial invasion and then evasion, with rapid multiplication in the mucus. Other studies have demonstrated that chicken immunity may be ineffectively stimulated upon Campylobacter multiplication, and expression of different antimicrobial peptide genes may be lowered (Hermans et al., 2012; Gorain et al., 2020). All these remarks may suggest that C. jejuni is correctly acclimatized to the avian host, and bacteria can be considered a commensal gut microbiota. This fact may contribute to the continuous multiplication of Campylobacter in the bird's alimentary tract (Gorain et al., 2020). Campylobacter colonization and bird immune response against the infection with campylobacteriosis are expressed in Figure 2.

Figure 2.

Campylobacter colonization and bird immune response against the infection with campylobacteriosis. At the first 3 wk of age, the bird has a protective level of maternal antibodies against Campylobacter. After this age, the bird ingests contaminated food with Campylobacter. The bacteria then invade intestinal epithelium and mucosa stimulating excess mucous secretion and activation of toll-like receptors. The bird immunity stimulates cytokines, circulating monocytes, and macrophage expression.

Broiler Production and Campylobacter Jejuni

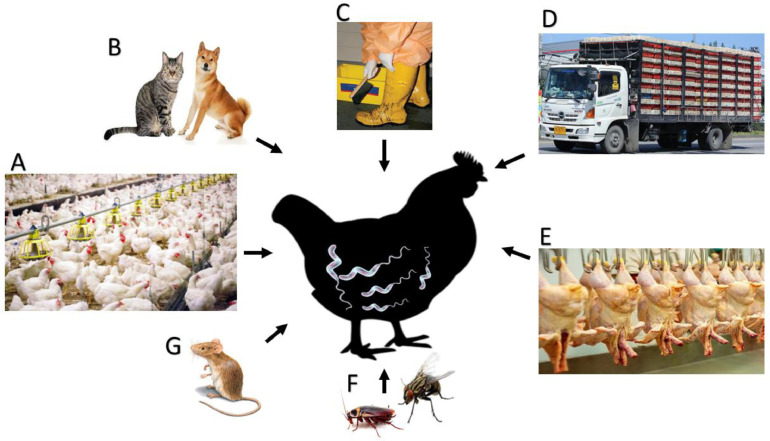

The different mechanisms of Campylobacter transmission in chickens are summarized in Figure 3.

Figure 3.

The mechanisms of Campylobacter transmission in chickens. (A) Contaminated feed, water, and utensils at the farm level. (B) Carnivorous, especially dogs and cats. (C) Human movement between different farms with contaminated utensils. (D) During birds’ transportation from previously contaminated cages or contaminated environments. (E) At slaughterhouses level during bird evisceration and processing with previously contaminated machines. (F) Insects and (G) rodents (insects and rodents can transmit infection during all stages of bird rearing, transportation, slaughtering, processing, and handling).

Infection With Campylobacter During the Rearing Period (at the Farm Level)

Independent farmers grow broiler chickens until the birds reach the market weight, which takes about 6 to 7 wk. During the grow-out and processing stages, Campylobacter can enter the production chain and contaminate either flock on the farm or carcasses at the processing area. C. jejuni is commensal in broilers due to the absence of inflammatory reactions induced by C. jejuni colonization and the failure of chickens to clear C. jejuni out from the intestines (National Chicken Council, 2019). Because of this, there are no clinical indications linked with the multiplication of C. jejuni in broilers (Salem et al., 2019; Abd El-Hack et al., 2021a).

In broilers, C. jejuni multiplication takes place in the lower gastrointestinal tissue. It is thought to persist in the intestine by undergoing fast replication in the mucus after invasion and evasion from the cecal crypt, thereby avoiding expulsion from the intestine (Van Deun et al., 2008; Wysok et al., 2020). Broilers can harbor high concentrations up to 109 CFU of C. jejuni g cecal matter−1 (Beery et al.,1988). Once C. jejuni enters a farm, the whole flock is expected to become colonized by C. jejuni in a few days (Newell and Fearnley, 2003; Gorain et al., 2020). However, several studies pointed out that not all chickens become colonized with Campylobacter within a positive flock, and colonization levels may vary broadly within flocks (Hansson et al., 2004, 2007, 2010). The multiplication of C. jejuni in broilers is not observed until 2 to 3 wk of broiler age (Shange et al., 2019). Because the timing of colonization coincides with maternal immunity, maternal antibodies may protect broilers from C. jejuni multiplication at a young age (Sahin et al., 2001; Singh et al., 2019).

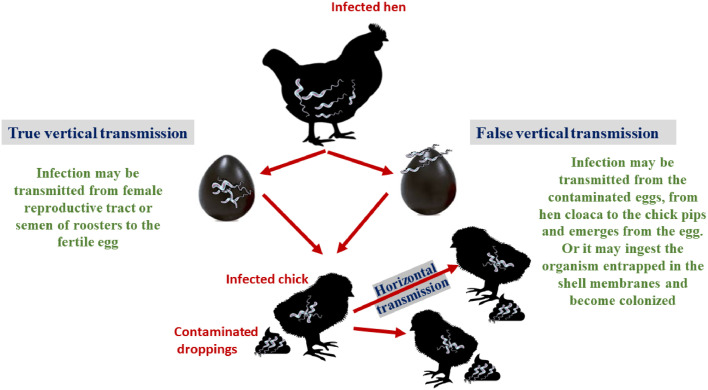

Furthermore, as broilers age, there is a decrease in Campylobacter shedding (Dipineto et al., 2011). Dipineto et al. (2011) revealed that Campylobacter multiplication lowered over time in laying hens, resulting in some birds being free of Campylobacter (Dipineto et al., 2011; Taha-Abdelaziz et al., 2018). This finding provides support for the hypothesis that age-related improvements in immunity and gut bacterial stability contribute to the more obvious Campylobacter colonization in older birds (Taha-Abdelaziz et al., 2018). Figure 4 provides a concise summary of the various modes of transmission of the Campylobacter infection.

Figure 4.

Transmission of Campylobacter disease hypothesis. True vertical transmission via female reproductive tract or contaminated roosters’ semen. False vertical transmission via contaminated eggs and the bacteria penetrates the eggshell. Horizontal transmission from infected bird to susceptible bird.

The potential of the vertical route of transmission of Campylobacter in broilers was studied extensively (Callicott et al., 2006; Vandeputte et al., 2019). Shanker et al. (1986) discovered that unless C. jejuni was directly injected into albumin, natural colonization did not occur, even when C. jejuni-challenged eggshells were used. In addition, a number of investigations have failed to differentiate the identical genotypes of C. jejuni in parent farms and their chicken offspring (Petersen et al., 2001; Vandeputte et al., 2020). The presence of anti-Campylobacter antibodies in the mother reduces both the vertical transmission and proliferation of the bacteria in newly hatched chickens (Sahin et al., 2001).

Campylobacter is most commonly spread from one flock of broilers to another through horizontal transmission (Gregory et al., 1997). There has been a significant amount of epidemiological research done to shed light on the identification of origins of Campylobacter in bird farms, and various possible sources have been found. These sources reported are insects (Dale et al., 2015), rodents (Hiett et al., 2002a,b,c; Gorain et al., 2020), wild birds (Hald et al., 2016), other livestock and avian farms (Zweifel et al., 2008), the environment around and within the poultry farm (e.g., soil, puddle, and drinking water) (Messens et al., 2009), and residual Campylobacter population from previous flocks (Hald et al., 2016; Taha-Abdelaziz et al., 2018).

Despite numerous attempts, researchers have been unable to differentiate Campylobacter from other possible sources until after the flock had been infested (Vandeputte et al., 2019). This failure could be because 1) many research had inadequate study design and sampling schemes, 2) previous studies failed to identify unknown sources of Campylobacter around and within the poultry farm, 3) Current laboratory techniques are incapable of reviving and cultivating Campylobacter in the VBNC state, or 4) the current genotyping techniques are not sensitive enough to differentiate Campylobacter strains due to high frequency of DNA recombination observed in Campylobacter genome (Agunos et al., 2014; Vandeputte et al., 2019).

Depending on the investigations that were conducted to determine the origins of the outbreak, multiple on-farm danger agents together with Campylobacter colonization in broiler farms have been found (Natsos et al., 2019). The majority of these risk factors are associated with poor biosecurity and hygiene standards in the chicken house (Chowdhury et al., 2012; Natsos et al., 2019). The failure to sanitize drinking water, the absence of anteroom and boot dips, and the absence of adequate pest treatments all contribute to the easy access that natural Campylobacter reservoirs have to the farm (Bailey et al., 2019).

Some other on-farm risk factors include the time of year (summer vs. other season) (Ellis-Iversen et al., 2012; Bailey et al., 2019), the practice of reusing litter (Sandberg et al., 2015), the length of the downtime period (the time between flocks when the broiler houses are cleaned and disinfected) (Sommer et al., 2016), the routine of thinning practice (Näther et al., 2009; Pumtang-On et al., 2021; Taha-Abdelaziz et al., 2023), general conditions of broiler farms (Chowdhury et al., 2012), and broilers age (Chowdhury et al., 2012).

Campylobacter Incidence in Broiler Chickens

The incidence in commercial broiler farms differs mostly according to the age of the animals (Koutsoumanis et al., 2020; Elhelw et al., 2022). Under the commercial system, Campylobacter is hardly detected in broilers 1 to 3 wk of age, but newly born chicken can be in vitro challenged with C. jejuni (Sahin et al., 2001). Campylobacter infection is commonly noticed post the third week of age for most commercial farms. While some chicken become infected, C. jejuni spreads throughout the rest of the farm and stays there until slaughter, polluting the meat in the processing facilities (Shreeve et al., 2000; Nothaft et al., 2021).

C. jejuni is most commonly seen in commercial birds, and as many as 100% of broilers at slaughter may be infected (Deng et al., 2020). Results from a European union survey in member states to evaluate the incidence of Campylobacter in broilers revealed a mean prevalence of 71.2% (95% confidence intervals: 68.5; 73.7), with results varying from 2% (Estonia) to 100% (Luxembourg). The median member states prevalence of Campylobacter-colonized broiler batches was 57.1% (EFSA and ECDC, 2021a,b).

In addition, results from the European summary report on trends and sources of zoonoses, zoonotic agents, and foodborne outbreaks in 2014 reported an overall prevalence of Campylobacter in fresh broiler flesh collected at slaughter, processing, and retail of 38.4% of the 6,703 examined units (EFSA and ECDC, 2015). Different recording member states had very different rates of Campylobacter-positive chicken meat samples. Campylobacter was found in 35.5% of single samples at retail, and 6 of the 11 member states that took samples at retail found that less than 50% of them were positive. At the slaughterhouse level, Campylobacter was found in 44.4% of the single samples that were checked (EFSA and ECDC, 2015).

Birds' Campylobacter shedding rates fluctuate throughout the year, with summer seeing the highest rates (Wedderkopp et al., 2000). However, C. jejuni is prevalent in broilers, and some flocks remain Campylobacter-negative during their raising period (Stern et al., 2001; Gorain et al., 2020). Campylobacter is prevalent in organic and free-range chicken flocks (Heuer et al., 2001; Clavijo and Florez, 2018), suggesting that all manufacture techniques are susceptible to Campylobacter infection.

Broiler Farms: Potential Sources of Contamination and Risk Factors

Campylobacter potential origins and transmission routes in bird farms have been widely investigated. However, no apparent factor(s) has been discovered to explain the organism's prevalence in commercial avian farms (Higham et al., 2018; Chintoan-Uta et al., 2020). According to numerous studies, the most likely cause of C. jejuni infection in chickens is horizontal dissemination from the surrounding environment (O'Mahony et al., 2011). Possible sources include old litter (Thakur et al., 2013), untreated drinking water (Zimmer et al., 2003), other farm animals or domestic pets (Ellis-Iversen et al., 2009, 2012), insects (Hazeleger et al., 2008), rodents (McDowell et al., 2008), instruments, and transport vehicles and farm laborers (Ridley et al., 2008; Sibanda et al., 2018).

Due to extreme sensitivity to oxygen and moisture, Campylobacter cannot thrive in the natural environment (Singh et al., 2019). Campylobacter is seldom found in fresh litter or feed testing before birds become ill (Thakur et al., 2013). Campylobacter is a bacterium that may be spread from contaminated used litter to agricultural settings (Montrose et al., 1985). Due to frequent cleaning, disinfection, and the replacement of litter between flocks, litter is seldom a cause of contamination in EU broiler production (Evans, 1992). Furthermore, in the USA, national epidemiologic studies found no significant variations in the prevalence and onset of Campylobacter among flocks on different grow-out farms employing different litter utilization practices (Stern et al., 2001). Cattle, swine, and other poultry have all been found to serve as important reservoirs for Campylobacter (Lyngstad et al., 2008; Vandeputte et al., 2019).

Molecular epidemiological research on farm animals has shown that strains spreading to bird flocks are sometimes discovered alongside other livestock, such as cows and swine (Korsak et al., 2015; Di Giannatale et al., 2019; Ito and Kishimoto, 2023). In longitudinal investigations, the route of transfer from the animals to the broilers may be seen before avian flock multiplication (Katsma et al., 2007). Removing other livestock from a chicken farm will only lower infection by 41 to 44% (Katsma et al., 2007). However, this appears to be a rather infrequent event (Johnsen et al., 2006; Vandeputte et al., 2020), and most of the strains discovered near cattle are not detected later in broilers. In addition, domestic animals such as dogs and cats were seen to harbor on a regular basis (Vandeputte et al., 2020). They shed C. coli and C. jejuni and have been identified as a risk agent of Campylobacter disease in broiler farms (Torralbo et al., 2014; Hwang and Singer, 2020).

Insects, like beetles, flies, may act as mechanical vectors for Campylobacter transmission from livestock to chickens (Hald et al., 2008). Shane et al. (1985) was the first to demonstrate Campylobacter transmission by flies across chicken flocks in a controlled laboratory setting. Hald et al. (2004) showed that C. jejuni was mainly transported by house flies from animals to the broiler farms via ventilation inlets. Furthermore, flies may have a linking effect in Campylobacter epidemiology, since several studies have proven the influence of hygiene barriers and fly screens in reducing the prevalence of Campylobacter spp., between farms of broiler chickens (Bahrndorff et al., 2013; Gölz et al., 2018). However, the role of flies as a key cause of Campylobacter infection in broilers was controversial (Gölz et al., 2018).

Although some Campylobacter serotypes and genotypes were found from insects and broilers on farms, the path of spread was unclear (Bailey et al., 2019). Prior to the positive confirmation of Campylobacter in the broilers, it was unusual for insects to test positive in a chicken farm, suggesting that insects are not the predominant source of Campylobacter in a broiler farm (Nesbit et al., 2001). The larvae of darkling beetles have also been linked to the transmission of C. jejuni between breeding populations (Refrégier-Petton et al., 2001).

There is also evidence that rats and mice can spread Campylobacter (Arsenault et al., 2007; McDowell et al., 2008; Newell et al., 2011). In addition, there have been reports of rodents in certain contemporary poultry farms (Evans and Sayers, 2000). This threat may be minimal because Campylobacter carriage is seldom identified in trapped rats (Vandeputte et al., 2020). The risk of Campylobacter being introduced to poultry farms through the hands of a farm worker is high (Ridley et al., 2008; Hakeem et al., 2021). Humans providing poultry through a nonsterile environment increase the risk of Campylobacter multiplication, as shown by Johnsen et al. (2006).

Campylobacter may spread easily from the outside environment into the avian farm, and human traffic is a major vector for this pathogen (Cardinale et al., 2004; Hofshagen and Kruse, 2005). Another study by Hansson et al. (2010) confirmed the importance of agricultural workers following thorough hygiene protocols and using appropriate hygiene. There is a clear correlation between the number of agricultural employees and the number of tourists and the prevalence of Campylobacter infections (Huneau-Salaun et al., 2007).

Campylobacter was isolated from the hands, boots, and clothing of agricultural workers, catchers, and managers, as well as truck drivers (Ramabu et al., 2004). Human visitors to the avian home may bring Campylobacter in from the outside ecosystem, since molecular epidemiology shows that these strains are commonly followed by flock expansion (Ridley et al., 2008, 2011). Workers in the agricultural sector may not be the only ones concerned about the spread of Campylobacter in the birdhouse. The most recent European baseline assessment of Campylobacter in bird farms confirms the widespread belief that thinning or partial depopulation is a significant risk factor for infectious disease (EFSA, 2010; Kittler et al., 2021a). Many catching crews work for poultry companies. Like workers, they move from one farm to another with their trucks, tools, boots, and clothes, often without caring about their own hygiene (Harris et al., 2021; Malavi et al., 2021).

Both the sources of drinking water and the treatment procedure can have an effect on the proliferation of Campylobacter (Zimmer et al., 2003). Ogden et al. (2007) used multilocus sequence typing (MLST) to discover C. jejuni sequence types in water tanks and broiler houses, providing more evidence that water is likely a source of infection in broilers. In addition to finding C. coli in groundwater, Pérez-Boto et al. (2010) concluded that drinking water was a potential source of C. coli on bird farms. Even though Campylobacter has been found in water systems, whether or not this indicates recent fecal contamination from cattle or wild birds is still up for debate (Zimmer et al., 2003).

Drinking water in avian dwellings is often positive after chickens have been grown, raising questions about the potential significance of this source in introducing Campylobacter into avian environments (Nothaft et al., 2021). Consequently, the contaminated water does not support the growth of Campylobacter; rather, it only serves as a passive channel for the bacteria to spread (Sahin et al., 2002). Water treatments with disinfectants may prevent Campylobacter from accessing a farm rather than spreading within a livestock (Ellis-Iversen et al., 2009).

Campylobacter may also be introduced to poultry farms by a vertical pathway, from the hen to the egg to the fowl (Takeshita et al., 2021). The possibility that Campylobacter may be transmitted from birds' eggs to the next generation was, nevertheless, examined. Researchers have noted the potential for Campylobacter to be transmitted from birds to humans through contaminated egg products (Takeshita et al., 2021). Campylobacter was successfully found in 10% of 275 semen samples from commercial broiler breeder roosters, with quantities as high as 1,000 CFU mL−1, as reported by Cox et al. (2002b). Furthermore, Campylobacter has been detected in the oviducts and other reproductive organs of breeder chickens (Hiett et al., 2002a; Cox et al., 2005; Natsos et al., 2019). Campylobacter may survive in the moist membranes of eggshells. The chicken may eat the bacterium as soon as it pips and emerges from the egg, becoming infected and spreading it to other chickens in the flock through its cecal droppings (Tang et al., 2020). It is hypothesized that Campylobacter can be transmitted from one generation of broilers to the next via the egg, which becomes contaminated with droppings as it travels through the cloaca (Allen and Griffiths, 2001; Cox et al., 2012; Marotta et al., 2015; Tang et al., 2020).

Cox et al. (2002a) detected ribotypes and flaA short-variable-region alleles in a commercial broiler breeder flock and its progeny broiler flock, providing molecular evidence of the occurrence of vertical transmission. Further evidence that Campylobacter might be present in chicken before to transit to the farm comes from the finding of amplifiable Campylobacter DNA in samples taken from hatchery fluff, a gut of developing embryos, and newly hatched chicken (Thibodeau et al., 2015).

On the other hand, Dion et al. (2020) concluded that while vertical transmission between breeders and broilers is necessary, it is infrequent and poses little threat to commercial farms. Newell and Fearnley (2003) observed that the vertical spread of C. jejuni is unusual because of a constant lag stage in recognizing C. jejuni multiplication in birds. However, Campylobacter may be present in the hatching chicken in very low numbers, and factors such as maternal antibodies keep the population from expanding too rapidly (Sahin et al., 2003a). This is supported by the fact that, when using standard culture methods, many laboratories have been unable to identify Campylobacter in day-old chicks (Herman et al., 2003; Mazengia et al., 2015).

The ability to reliably isolate Campylobacter from a variety of biological and dietary samples is presently unavailable because to the lack of a suitable culture technique. Most culture methods were developed to isolate Campylobacter from highly contaminated feces (Taha-Abdelaziz et al., 2018). However, these techniques may not identify Campylobacter in foods or biological materials if the quantity of cells is minimal, the cells are sublethally injured or stressed, or if they are living but cannot be cultured (Taha-Abdelaziz et al., 2018).

It has been hypothesized by Agunos et al. (2014) that a major roadblock in studying Campylobacter in broilers is the difficulty to cultivate the bacteria from younger birds (>2 wk old). There is still a significant prejudice against the assumption that viable eggs might generate Campylobacter infection in breeder and broiler farms due to the inability to grow Campylobacter. The evidence that there are other modes of egg transmission than the traditional transovarial route has been largely ignored by previous investigations (Cox et al., 2012; Gorain et al., 2020).

Campylobacter Contamination of Broiler Flocks During Transport and Slaughter

Transport from farm to processing plant, live haul, bleeding, scalding, plucking (defeathering), evisceration, and chilling are the traditional primary processing stages for broiler chickens (Barbut, 2016). There is a high probability of intra- and intercongregational Campylobacter infection during the transportation of a flock from the farm to the processing plant (Slader et al., 2002; Hansson et al., 2005). According to epidemiological study, insufficient cleaning and disinfection of transportation modules and trucks can lead to Campylobacter-negative birds becoming contaminated with persistent Campylobacter observed on this equipment during transit, since the surface of broilers has the potential to get contaminated with Campylobacter (Shang et al., 2018; Karki et al., 2019; Rasschaert et al., 2020).

Thinning is a prevalent practice in European countries when a subset of a flock is slaughtered early or late to satisfy varied market weight standards. Without adequate biosecurity measures being taken during the capture and transportation of broiler chickens, there is a considerable increase in the danger of introducing Campylobacter to the remaining broilers (Newell et al., 2011). Campylobacter concentrations on carcasses are known to fluctuate widely throughout the various stages of processing. While it may be challenging to eliminate all Campylobacter from carcasses during processing, it is possible to significantly reduce the amount of Campylobacter present (Newell et al., 2011). However, there is also a chance that harmful carcasses will be cross-contaminated. Scalding, plucking, and eviscerating are practices that are known to increase the spread of foodborne pathogens (Berrang et al., 2011; Nothaft et al., 2021). Scalding entails immersing carcasses in hot water to open feather follicles and allow feathers to be easily removed during the harvesting process. The defeathering phase occurs prior to the evisceration stage and entails the removal of feathers and the top layer of the integument (USDA-FSIS, 2008).

Feathers with a high concentration of feces can contaminate slaughterhouse scalding tanks and spread disease to meat (Singh et al., 2019). When picking fingertips rub against carcasses, feces can be released, resulting in cross-contamination between carcasses (Berrang et al., 2001; Vandeputte et al., 2019). Evisceration is a technique that eliminates internal viscera and any processing errors from carcasses before chilling. Because high levels of Campylobacter are commonly found in broiler chicken intestines, rupturing the intestine can release Campylobacter, contaminating carcasses (Izat et al., 1988). Carcasses are tested for contamination and reprocessed if any is found. It has been shown, however, that reprocessing does not always reduce bacterial levels in carcasses (Fletcher et al., 1997). It is critical to avoid both indirect contact between contaminated and uncontaminated carcasses and the release of Campylobacter from contaminated carcasses. Reducing Campylobacter levels on carcasses and minimizing cross-contamination throughout each processing step requires the use of appropriate antimicrobial and sanitary techniques. Frequently rinsing the processing equipment is recommended by USDA-FSIS (2015) to prevent the accumulation of contaminants and bacteria.

Chloride and peroxides are two examples of antimicrobial agents that could be added to chilling tanks and washing water to prevent the growth of bacteria (USDA-FSIS, 2015; Bailey et al., 2019). It is also recommended to use countercurrent water flow so that carcasses are gradually exposed to cleaner water (Buhr et al., 2014). Another recommended technique is maintaining a healthy pH in water tanks to prevent the establishment of Campylobacter and other foodborne bacteria (USDA-FSIS, 2015). Lastly, it has been established that less contamination of one carcass by another can be achieved through better machine and equipment maintenance (USDA-FSIS, 2015).

Potential Risks During and Just Prior to Transport and Slaughter

When they are approximately 6 wk old, broilers are placed in crates, transported, and then processed at the butchery. Movement, crowding, temperature changes, and lack of water and food all contribute to the high levels of stress that animals experience during travel (Mainali et al., 2009; Dogan et al., 2019). Stress during transport from the farm to the processing facility disrupts gastrointestinal function, lowers an animal's resistance, and promotes the spread of gastrointestinal bacteria (Klančnik et al., 2013). Transportation stress has been linked to a 1,000-fold increase in bacterial populations on carcasses (Altekruse et al., 1999). Pollution levels could rise and Campylobacter could be introduced to wild farms if crates are not properly cleaned (Stern et al., 2001; Ridley et al., 2011). Even after cleaning and disinfecting, the contents of transport boxes are still microbiologically contaminated, even though the boxes have a clean outward appearance (Gorain et al., 2020). Some studies found that, even after cleaning and disinfecting, 60 and 71% of the transport crates examined were positive for Campylobacter (Rasschaert et al., 2007, 2020).

Furthermore, 80% of chicken farmers do not sterilize containers, and only 18.3% clean trucks and trailers properly, according to a survey conducted by Auburn University, USA among more than 10,000 poultry enterprises of varying sizes (O'Mahony et al., 2011; Nothaft et al., 2021). Frequent detection of organic residue on truck crates after washing indicates that the sanitizing process is ineffective and the germs are able to survive (O'Mahony et al., 2011). Consequently, the transmission in these contaminated crates may cause external contamination in Campylobacter-negative birds (Hansson et al., 2005; Rasschaert et al., 2020). Genotypes recovered from sanitized containers were also discovered on the carcasses of slaughtered chickens after shipment and slaughter (Vandeputte et al., 2019). According to Schroeder et al. (2014), the concentration of these pathogens on the surface of birds correlates with the concentrations found on thoroughly processed carcasses. Therefore, it is crucial to reduce the farm prevalence of these pathogens and transport stress throughout the process in order to lower the risk of contaminated meat products entering the food chain (Vandeputte et al., 2019).

Risk Factors During Slaughter, Dressing, and Processing

Using data from 2008, the European Food Safety Authorities were able to estimate the prevalence of Campylobacter and Salmonella-contaminated broiler carcasses across the community and in each EU member state, and they released those findings in 2010 (EFSA and ECDC, 2021b). The investigation centered on birds entering the food chain at the level of broiler batches in slaughterhouses (Thames and Sukumaran, 2020; Lindqvist et al., 2022). Campylobacter contamination of broiler carcasses was studied on a national scale by analyzing the contamination rate, sample size, and concentration of slaughterhouses. Carcass samples from 9,324 broiler batches were analyzed for Campylobacter in the European Union (Bertram et al., 2019). An increase in Campylobacter in the intestine's points to the possibility of contamination of bird carcasses during slaughter, most likely due to the spillage of droppings during defeathering and evisceration and the spread of disease in the slaughterhouse environment (Hakeem et al., 2020).

However, the European Union has yet to adopt the use of Hazard Analysis and Critical Control Points Programs (HACCP) to reduce Campylobacter contamination of meat carcasses (EFSA and ECDC, 2015; Giangaspero, 2018). Campylobacter is transported to the corpses during the slaughtering process, and the load may decrease during scalding, cooling, and freezing while increasing during defeathering and disemboweling (Gonzalez-Fandos et al., 2020). There have been multiple studies looking at how scalding affects Campylobacter contamination of carcasses. However, there have been reports of contrasting findings (Gonzalez-Fandos et al., 2020).

However, scalding has been identified by some research as a possible source of Campylobacter cross-contamination. The pathogen was found in scald tank water before the first birds arrived, indicating that contamination persists even after cleanliness measures have been taken (Schroeder et al., 2014; Perez-Arnedo and Gonzalez-Fandos, 2019). Scald tank water had an average of 2.90 CFU mL−1 of C. jejuni (Osiriphun et al., 2012). Thus, even after the tank was thoroughly cleaned, some Campylobacter remained. Previous research has documented the bacterium's ability to survive in this setting (Rahimi et al., 2010). The attachment of the Campylobacter to the broiler skin may be aided by the feather follicles in the integument, which are thought to shield the Campylobacter and prevent the loss of stratum corneum at high scalding temperatures (Chantarapanont et al., 2004; Vandeputte et al., 2020).

Campylobacter spp. are particularly well-adapted to life on the skin of broilers, where they can thrive in organic biofilms. Furthermore, the temperature in subcutis is frequently 3°C to 4°C lower than the scalding temperature (Yang et al., 2001). Similarly, Ellerbroek et al. (2010) found that scalding had no effect on the eradication of Campylobacter, even though the postscalding isolation rate was 91.1%. However, it has been reported that the total number of bacteria on skin carcasses decreases after scalding (Guerin et al., 2010; Lawes et al., 2012). Berrang et al. (2007) found a mean reduction of 0.43 log CFU after chilling, while Guerin et al. (2010) found the largest reduction of 2.9 CFU postscalding and 1.7 CFU after chilling. Campylobacter contamination has also been prevalent during the defeathering process (Duffy et al., 2014; Vandeputte et al., 2020).

Previous research has indicated that the disembowelment process may greatly enhance the cross-contamination of Campylobacter due to the shattering of internal organs and stomach contents (Seliwiorstow et al., 2015; Da Rosa et al., 2021). Droppings are expelled from the cloaca by the selector's fingers pressing on the abdomen during defeathering, resulting in high broiler carcass and slaughter equipment contamination (Mendes et al., 2020). Furthermore, the surface of the finger becomes rough with use, allowing bacteria to colonize the crevices on the surface of the rubber finger and multiply overnight if not adequately disinfected. This results in cross-contamination between flocks as bacteria on the rubber fingers are transferred to the corpses during the subsequent defeathering (Golden and Mishra, 2020). There has been no recent agreement on the trend in Campylobacter counts following evisceration, and Rosenquist et al. (2006) observed an increase in Campylobacter populations following evisceration. However, other authors reported a decrease (Reich et al., 2008; Taha-Abdelaziz et al., 2018) or no difference in Campylobacter numbers postevisceration (Berrang and Dickens, 2000; Zhang et al., 2020).

Processing facilities have various options for chilling corpses to lower their temperature (Berrang et al., 2008; Zeiger et al., 2017). Meat that has been immersed in cold water has a significantly lower Campylobacter counts than air-chilled meat (Berrang et al., 2008; Lee et al., 2017). Sanitizers like chlorine are used in some immersion chill tanks to help reduce contaminants like blood and tissue fragments (Guerin et al., 2010; Urdaneta et al., 2023). Chlorine use in the chill tank has been shown to significantly reduce the amount of Campylobacter but not completely remove bacteria (Berrang et al., 2007). Samples of water from the chill tank were found to contain Campylobacter, which suggests that this is the most likely source of cross-contamination (Lindblad et al., 2006; Vandeputte et al., 2019).

Pollution of Campylobacter can occur in uncontaminated carcasses brought to the chill tank, although extensively contaminated carcasses will have less bacteria when they are removed from the tank. However, the elimination of Campylobacter from the surface of the carcass through immersion freezing does not prevent cross-contamination (Bashor et al., 2004; Bailey et al., 2019). Chilling air has been shown to have either no microbiological effects (Vandeputte et al., 2019) or just minor effects (Bailey et al., 2019) on Campylobacter levels.

One final important consideration for this pathogen is the possibility of cross-contamination during manufacture. Close contact between carcasses and equipment results in the accumulation of tissue fragments harboring Campylobacter, which in turn contaminate succeeding carcasses (Oh et al., 2018; Nothaft et al., 2021). Furthermore, there is a risk of cross-contamination between bird carcasses when their outer surfaces come into contact with one another, with personnel hands, and with trimming mesh gloves and knives (Furukawa et al., 2017; Zhong et al., 2020). Slaughterhouse workers become vectors for the development of these diseases as soon as they come into contact with livestock (Myintzaw et al., 2020). Ellerbroek et al. (2010) discovered that processing instruments and laborers are a source of cross-contamination, and that Campylobacter can be found on staff's hands, slaughtering implements, and transport crates. Many researchers have also observed cross-contamination between batches from different flocks, as well as contamination of noninfected batches from previously slaughtered batches (Ellerbroek et al., 2010). Specifically, the first carcasses of subsequent negative batches are contaminated by Campylobacter-positive batches, as reported by Hue et al. (2010). Aerosols and droplets created by excessive washing during the hanging, defeathering, and evisceration stages of slaughter may also contribute to the spread of disease (Peyrat et al., 2008).

Campylobacter Jejuni as a Human Foodborne Disease

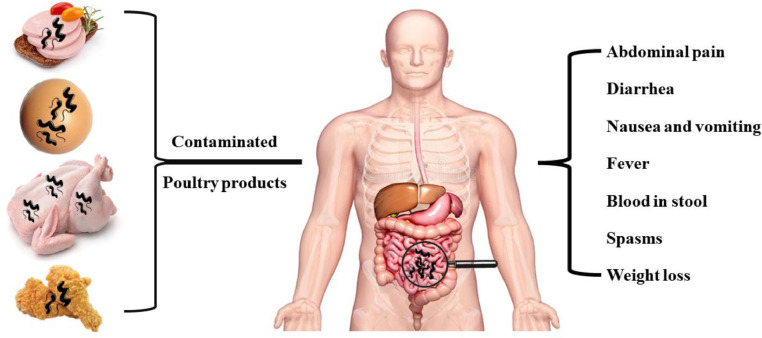

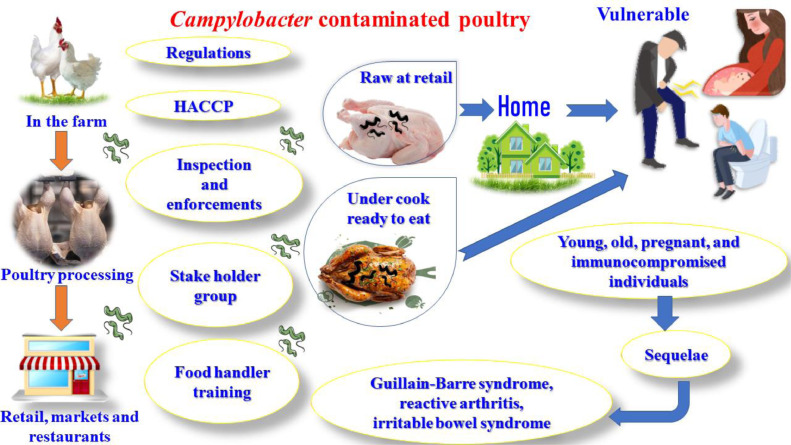

In affluent countries, Campylobacter is a common cause of acute gastroenteritis (Lynch et al., 2022). Figure 5, Figure 6 provide a summary of the avian reservoirs of human Campylobacter infections and the associated human symptoms. Campylobacteriosis is mostly caused by C. jejuni and is frequently encountered in solitary instances. However, campylobacteriosis outbreaks have previously been observed (Lahti et al., 2017; Šimunovi´c et al., 2022). Most people infected with campylobacteriosis either show no symptoms or experience only moderate ones, including diarrhea (which may or may not be bloody), nausea, fever, and abdominal pain (Allos, 2001). These moderate clinical manifestations can last for up to a week without demanding special antibiotic treatments or alternatives such as probiotics (ISO, 2017a; Neijat et al., 2019).

Figure 5.

Avian sources of Campylobacter infection in humans. This can be through contaminated eggs, chicken meat, and chicken meat products. The related symptoms in humans including abdominal pain, diarrhea, nausea, vomiting, fever, blood in stool, spams, and weight loss.

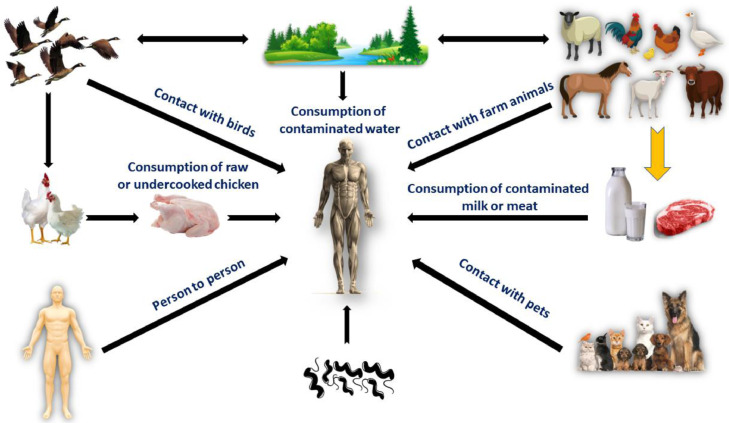

Figure 6.

Campylobacter infection sources in humans. Consumption of contaminated water; contact with infected farm animals, pets, or wild birds; consumption of contaminated milk, eggs, meat; consumption of undercooked or raw chicken or chicken products; and contact of diseased human with susceptible person.

Pancreatitis, peritoneal inflammation, bacteremia, reactive arthritis, and Guillain-Barré syndrome are only some of the more serious complications that could arise, with potentially devastating results (Ahmed et al., 2018). The precise mechanism by which an infection with Campylobacter brings about these long-term effects is unclear. The estimated incidence of campylobacteriosis in the USA is 14 cases per 100,000 people (CDC, 2019). In 2015, 13 deaths were attributed to Campylobacter infections, with 6,289 confirmed cases recorded by the Food Net surveillance system in the USA (CDC, 2017). The true incidence of campylobacteriosis is estimated to be 9 million cases annually in Europe due to the disease's asymptomatic character (Facciolà et al., 2017; ISO, 2017b).

Campylobacteriosis cases are most common in July and August, which coincides with the peak season for isolating Campylobacter from chickens and other fowl in industrialized countries (Sibanda et al., 2018). In contrast, campylobacteriosis is common and mild in third-world nations, where the vast majority of infections are asymptomatic (Platts-Mills and Kosek, 2014). Campylobacteriosis is estimated to be more prevalent in developing countries (Kaakoush et al., 2015). In a self-inflicted experiment, Robinson (1981) demonstrated that as little as 500 C. jejuni cells were sufficient to cause diarrhea and stomach pain, suggesting that the infective dose of C. jejuni is low. Similarly, investigations in healthy adults demonstrated that exposure to 800 to 105 CFU of C. jejuni could result in clinical symptoms (Tribble et al., 2010).

In addition, several experimental tests demonstrated that greater doses resulted in a higher frequency of attacks (Tribble et al., 2010; Weerasooriya et al., 2022). C. jejuni has an estimated incubation time of 2 to 4 d, while infections caused by more potent strains tend to have shorter incubation periods (Tribble et al., 2010). Campylobacteriosis is usually self-limiting, therefore patients recover without special therapy in most cases (Silva et al., 2011). Electrolyte and fluid replacement is suggested for mild cases (Vandeputte et al., 2019). Antibiotics may be advised for severe instances, particularly in vulnerable groups such as the young, the old, and those with impaired immune systems (Pacanowski et al., 2008; Pumtang-On et al., 2021; Abd El-Hack et al., 2022a; Taha-Abdelaziz et al., 2023).

Macrolides are a commonly used antibiotic for treating campylobacteriosis, especially in children when fluoroquinolones cannot be used (Pacanowski et al., 2008; Gorain et al., 2020). Many investigators of disease etiology have concluded that the most significant risk factor for campylobacteriosis is the ingestion or handling of raw or undercooked avian products (Rodrigues et al., 2001; Domingues et al., 2012). Avian spp. is the most important source of Campylobacter in humans due to the high levels of colonization they can maintain and the rising global consumption of avian items (Ramakrishnan et al., 2019; Kittler et al., 2021b).

Campylobacteriosis is caused by several factors, including consuming raw dairy products (Domingues et al., 2012), coming into contact with animals or pets, swimming in polluted water (Ravel et al., 2016; Campagnolo et al., 2018), and consuming untreated water (Domingues et al., 2012; Ravel et al., 2016). Travel to third-world countries may be responsible for a significant number of cases of USA campylobacteriosis, according to research by Ricotta et al. (2014). In the yr 2005 to 2011, international travel was linked to approximately 18% of campylobacteriosis cases in the USA. Antibiotic-resistant Campylobacter was more likely to be the source of these infections than common Campylobacter (Ricotta et al., 2014).

Reducing Campylobacter contamination in avian goods is seen as an effective technique for reducing the public health burden of campylobacteriosis in people, as chicken is the primary source of sporadic campylobacteriosis (Hankel et al., 2022). The success of countries like Iceland and New Zealand in drastically reducing campylobacteriosis rates shows that this disease is complex and requires a wide range of approaches (Sears et al., 2011; Tustin et al., 2011). There was a nationwide outbreak of campylobacteriosis in Iceland in 1998, just 1 yr after the disease was made reportable (Tustin et al., 2011; Hankel et al., 2022).

Within 4 yr, the campylobacteriosis rate increased from 12.2 to 116 per 100,000 people, and the increase was blamed on the accessibility of fresh poultry products (Stern et al., 2003). Control measures in the food production chain include a number of activities implemented at different stages (Sakaridis et al., 2018; Béjaoui et al., 2022). To reduce the amount of viable Campylobacter on items sold to the public, pre- and postharvest surveillance and monitoring systems were put in place, and goods from farms that tested positive for Campylobacter were mandated to be frozen before being sold (García-Sánchez et al., 2017, 2018; Gorain et al., 2020). Producer education initiatives improved the biosecurity measures taken on farms and the general cleanliness of farms and processing plants (Tustin et al., 2011; Eriksson et al., 2023).

Campylobacter awareness and safe food handling and preparation practices have been the subject of consumer education efforts (Stern et al., 2003; Tustin et al., 2011). Campylobacteriosis cases dropped by 72% in Iceland after these measures were taken (Wagenaar et al., 2013). New Zealand had a 54% decrease in the average prevalence of campylobacteriosis after implementing similar measures that targeted both pre- and postharvest sectors as well as retail and consumers (Sears et al., 2011). Even though the decline in these two countries is remarkable, it is unclear whether or not similar results can be achieved elsewhere (Wagenaar et al., 2013; Myintzaw et al., 2020).

Campylobacter infections are more likely to occur when raw poultry is handled improperly in a home kitchen (Kingsbury et al., 2023). According to Bull et al. (2006), C. jejuni may be present in 98% of commercially available chicken flesh in the USA and Europe. Table 2 presents information about the prevalence of Campylobacter spp. in raw chicken in various countries.

Table 2.

Campylobacter species prevalence in retail raw poultry meat in various countries.

Antimicrobial Resistance in Campylobacter Spp

Antibiotics are a type of antibacterial that either prevent the proliferation of bacteria or slow its progression (Lynch et al., 2020; Abd El-Hack et al., 2022b). Since the discovery of penicillin by Alexander Fleming in 1928 (Tan and Tatsumura, 2015; Kovács et al., 2019), antibiotics have greatly improved the prevention and treatment of infectious diseases in both human and veterinary medicine due to their ability to kill off harmful bacteria (Qin et al., 2023). Antibiotics were first used in animal production in the 1940s when they were introduced as growth boosters (Casagrande Proietti et al., 2018; Dai et al., 2020).

In response to the widespread use of antibiotics in hospitals and farms, Campylobacter has evolved multiple methods of resistance. Since then, the abuse of antibiotics in agriculture has led to an increase of antimicrobial-resistant foodborne bacteria, such as Campylobacter, which poses a severe threat to the efficacy of antibiotic therapies and raises serious public health issues (Van Boeckel et al., 2015; Khan et al., 2018; García-Sánchez et al., 2019). Antibiotics that are medically important to people were banned as growth promoters in food animal production in the USA in 2017. This was done in response to growing public health concerns about the spread of antibiotic-resistant foodborne bacteria to humans along the food chain (WHO, 2015, 2020; USDA, 2017).

In both underdeveloped and developed nations, Campylobacter isolates resistant to many antibiotics have been found (Bolinger and Kathariou, 2017; Myintzaw et al., 2023). Naturally occurring Campylobacter strains have developed resistance to many medications, including vancomycin, trimethoprim, rifampin, and bacitracin (Myintzaw et al., 2023). However, the precise resistance mechanisms remain unclear (Sproston et al., 2018; Santos-Ferreira et al., 2022). In addition, Campylobacter is resistant to fluoroquinolone, macrolides, and tetracycline (Tang et al., 2017; Vizzini et al., 2021). Less than 10% of Campylobacter isolates in the USA and other industrialized nations are resistant to macrolides (Engberg et al., 2001; Cha et al., 2016). However, this trend was more pronounced in developing countries (Okeke et al., 2005; Buiatte et al., 2023). Most macrolide-resistant C. coli strains have been found in pigs because tylosin is commonly used as a growth stimulant in the pig industry (Natsos et al., 2019). Campylobacter isolated from other animals, appears to have poor macrolide resistance (Tedersoo et al., 2022).

Expected low levels of macrolide resistance in Campylobacter suggest that longer courses of treatment are necessary (Caldwell et al., 2008; García-Sánchez et al., 2020). Another factor is that the resistance phenotype is less permanent because to the large fitness cost associated with macrolide resistance, so Campylobacter might quickly lose the phenotypic in the absence of selection pressure (Luangtongkum et al., 2009; Vandeputte et al., 2020). Unlike with macrolides, there has been a consistent worldwide increase in fluoroquinolone resistance among Campylobacter isolates (Sproston et al., 2018). In the 1980s, fluoroquinolone was initially introduced to the chicken industry as a means of preventing and treating respiratory illnesses (Kovács et al., 2016).

Resistance to fluoroquinolones in Campylobacter can be challenging to treat because of the antibiotic's broad range activity and widespread usage in the treatment of infectious diseases, including campylobacteriosis (Andersson and MacGowan, 2003). Since then, however, there has been an alarming increase in cases of human and avian fluoroquinolone-resistant Campylobacter (Engberg et al., 2001). Nachamkin et al. (2002) conducted a study and found that the percentage of C. jejuni isolates showing resistance to fluoroquinolones has increased dramatically from 5% in 1992 to 40.5% in 2002. Between 2008 and 2014, studies in China found that among Campylobacter isolates from chicken, nearly 100% were resistant to fluoroquinolones (Wang et al., 2016).

Multiple studies have linked campylobacteriosis to fluoroquinolones-resistant Campylobacter found in contaminated poultry products as the likely source of the bacteria (Nothaft et al., 2021). Patients identified with fluoroquinolone-resistant campylobacteriosis were less likely to have taken fluoroquinolones prior to diagnosis than those diagnosed with fluoroquinolone-susceptible campylobacteriosis, according to Kassenborg et al. (2004). In addition, those who developed fluoroquinolone-resistant campylobacteriosis were ten times more likely to eat poultry items in the week prior to getting sick than the healthy controls were. Nothaft et al. (2021) hypothesized that the infection originated from ingesting fluoroquinolone-resistant Campylobacter from contaminated bird items.

Results from in vitro and in vivo studies by Luo et al. (2003) and Han et al. (2012) suggested that resistance to fluoroquinolones improves the fitness of Campylobacter. In 2005, the USA Food and Drug Administration (FDA) banned the use of fluoroquinolones in the USA chicken sector due to this problem (Han et al., 2012). However, in spite of these efforts, no less fluoroquinolone-resistant Campylobacter has been found in either poultry or humans in the USA. In the absence of such selective forces, it was hypothesized that fluoroquinolone-resistant Campylobacter would persist in broilers (Han et al., 2012).

Several in vivo and in vitro experiments demonstrated that less than 24 h is required to detect fluoroquinolones-resistant C. jejuni following drug uptake, demonstrating the rapidity with which Campylobacter acquires resistance to these antibiotics (Gencay et al., 2018). Point mutation accumulation in the gyrA and parC genes is a necessary and sufficient condition for the development of fluoroquinolones resistance in other enteric bacteria, such as Salmonella and E. coli (Morgan-Linnell et al., 2009).

Campylobacter, on the other hand, only needs a single point mutation in gyrA to become resistant to fluoroquinolones. The most commonly documented point mutation in Campylobacter is a change from threonine to isoleucine at position 86 in the gyrA (Yan et al., 2006). This gyrA mutation alters DNA architecture during transcription, replication, and recombination by decreasing negative supercoiling (Han et al., 2012).

DNA supercoiling variations affect a wide range of promoter functions and transcriptome expressions, both in vitro and in vivo (Nothaft et al., 2021). Variable gene expressions were also observed in C. jejuni, according to another in vitro investigation that evaluated the transcriptome expressions of fluoroquinolone-resistant and -susceptible Campylobacter (Han, 2009). Results showed that negative supercoiling and regulatory mechanisms in C. jejuni were attenuated in the absence of fluoroquinolones, suggesting that resistance to these antibiotics improves iron uptake (Han, 2009). Although fluoroquinolone-resistant Campylobacter has emerged and persisted in USA broiler production, our understanding of the ecological drivers of fluoroquinolones resistance dynamics within the Campylobacter population and the hazard agents associated with this phenomenon is limited (Han, 2009).

Using commercial antimicrobials to reduce Campylobacter contamination in poultry processing

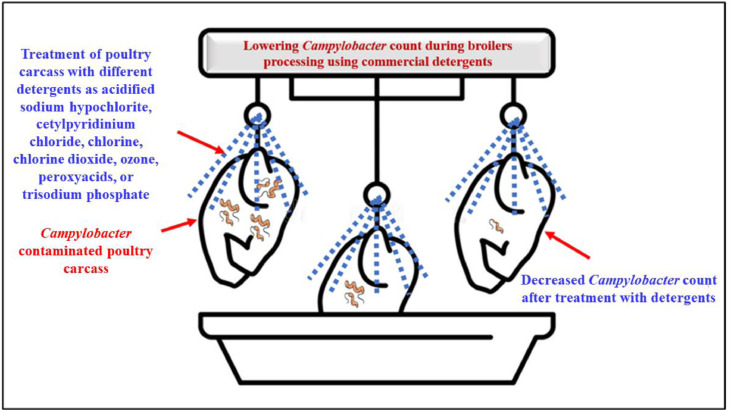

Reductions in Campylobacter spp. have been attributed to the use of commercially available antimicrobial technologies throughout the processing of broiler chickens (McKenna et al., 2020; Gichure et al., 2022). Kemp et al. (2001) reduced microbial levels on contaminated chicken carcasses utilizing an online acidified sodium chlorite spray system and an inside-outside broiler chickens carcass washer. Several agents, such as acidified sodium hypochlorite, cetylpyridinium chloride, ozone, chlorine dioxide, chlorine, peroxy acids, or trisodium phosphate, have been used to decrease the number of Campylobacter spp., in carcasses (Oyarzabal, 2005). Figure 7 shows the results of utilizing commercial antimicrobials to reduce Campylobacter contamination in broilers throughout processing.

Figure 7.

Using commercial antimicrobials such acidified sodium chloride, chlorine, chlorine dioxide, ozone, peroxy-acids, or trisodium phosphate to reduce Campylobacter contamination during broiler production.

Campylobacter load in raw chicken carcasses was observed to be reduced by Arritt et al. (2002). Commercial use of an effective antibacterial chemical spray consisting of 10% trisodium phosphate, 0.1% acidified sodium hypochlorite, 0.1 and 0.5% cetylpyridinium chloride, or 1% tween 80 could reduce the amount of rinse water necessary for cleaning carcasses (Arritt et al., 2002). Adding chlorine to cold water during chicken processing has been investigated and shown to be effective by Yang et al. (2001). They demonstrated that it did not drastically lower the number of S. typhimurium and Campylobacter on the chicken integument (Yang et al., 2001).

Chilling water with chlorine dioxide has been shown to reduce microbiological contamination in commercial broiler processing plants by Doyle and Waldroup (1996). The number of Campylobacter was reduced by 1.5 logs in 1 d and 1.2 logs in 6 d storage on trisodium phosphate-treated carcasses, according to Slavik et al. (1994). Iwata et al. (2023) reported that tryptanthrin reduced the number of C. jejuni bacteria in the intestines of chickens.

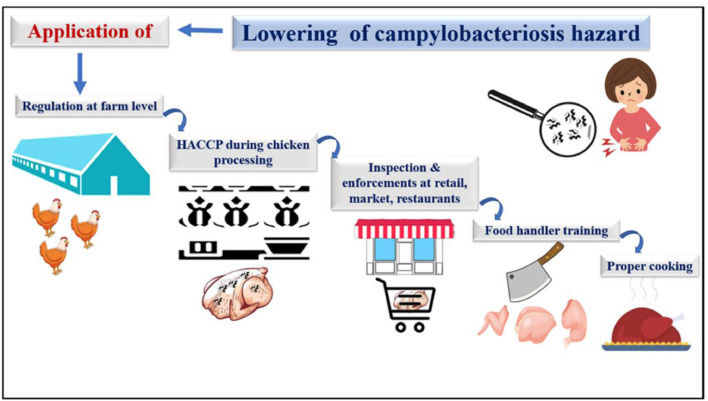

Control of Campylobacter Infection in Poultry

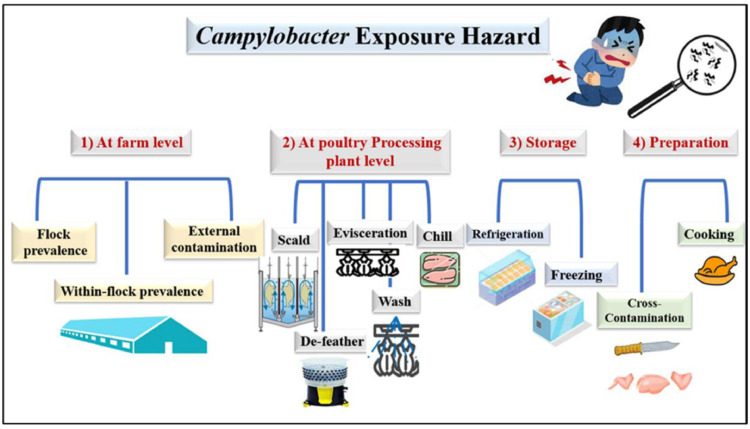

Figure 8 shows that the risk of Campylobacter in broiler chickens exists from the time they are raised on farms through the time they are processed in poultry plants, stored, and finally cooked. Figure 9 provides a concise overview of the methods used to prevent the spread of Campylobacter illness in broiler chickens.

Figure 8.

Campylobacter exposure risk at various stages of broiler chicken rearing, such as the farm (flock prevalence, within flock prevalence, external contamination), the processing plant (scald, evisceration, chill), storage (refrigeration, freezing), and preparation (cross contamination, cooking).

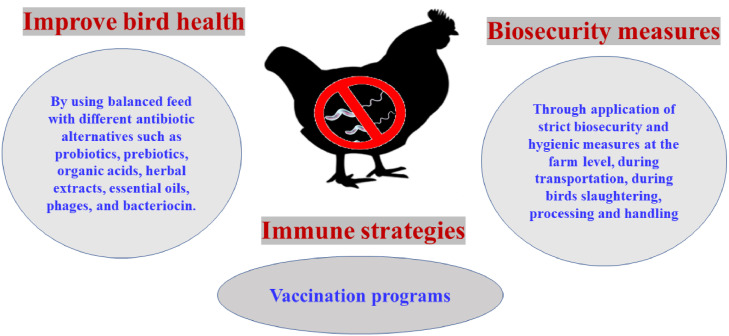

Figure 9.

Control of Campylobacter infection in broiler chickens includes increasing immunity in birds through vaccination, improving bird health through balanced feed with additives (antimicrobial or natural antibiotic alternatives), and implementing biosecurity measures at various levels of rearing, transportation, processing, and handling.

The most effective on-farm intervention to prevent the introduction of Campylobacter into broilers is an increase in biosecurity and general hygiene standards (D'angelantonio et al., 2021; Dogan et al., 2022). To prevent the spread of Campylobacter in broilers, even the most stringent on-farm biosecurity measures have proven ineffective (Sibanda et al., 2018; Poudel et al., 2022).

However, these precautions only appear to work in the Scandinavian countries, where the prevalence of Campylobacter in broilers is already low, and severe weather patterns may prevent the survival of certain insect and rodent populations that may be harboring Campylobacter (Lianou et al., 2017; Zhang et al., 2018). Feed and water acidification are two more examples of on-farm interventions that have proven ineffective (Hermans et al., 2011; El Haddad et al., 2019). To a lesser extent, it appears that acidifying litter treatments, which are meant to make the litter environment less hospitable to Campylobacter and other foodborne pathogens such as Salmonella, have only a modest effect on Campylobacter levels in broilers (Chinivasagam et al., 2020; Hwang and Singer, 2020). Probiotics have been shown to drastically lower Campylobacter count, according to studies by Arsi et al. (2015) and Taha-Abdelaziz et al. (2019). Bacillus subtilis PS-216 showed substantial anti-Campylobacter activities, as determined by Šimunovi´c et al. (2022), although the medium growth temperature and presence of oxygen are both crucial for B. subtilis.

The effectiveness of several dietary supplements against Campylobacter in broilers was also assessed by Guyard-Nicodème et al. (2016) throughout the whole of the rearing process. Khan et al. (2020) showed that prebiotics significantly decreased Campylobacter colonization in the guts of layering organisms and Erega et al. (2021) demonstrated that probiotics could be used to control Campylobacter infection. A similar antibacterial effect was obtained for carrots essential oil against Campylobacter infection by Luc et al. (2020). Glycyrrhiza glabra (Liquorice) extract was shown to decrease C. jejuni colonization in the intestines of broiler chickens in a separate investigation conducted by Ibrahim et al. (2020). According to Peh et al. (2020), organic acids have strong antibacterial action and may be able to lower the number of Campylobacter spp. When tested against C. jejuni in sterile distilled water, sodium caprate, thymol, carvacrol, and potassium sorbate were all found to diminish C. jejuni count when used at various concentrations and exposure times by Greene et al. (2022). Bacteriophages have been studied for their potential to reduce the prevalence of Campylobacter in broiler chickens by Richards et al. (2019), Chinivasagam et al. (2020), Ushanov et al. (2020), and Nafarrate et al. (2021).

There are currently no on-farm therapies proven to be effective and cost-efficient in reducing Campylobacter occurrence and levels in broilers (Thomas et al., 2020; Beterams et al., 2023). Bacteriocins, immunization, and probiotics were three more innovative methods used to reduce Campylobacter colonization on farms and in slaughterhouses (Nishiyama et al., 2014; Meunier et al., 2017; Helmy et al., 2022). The most encouraging outcomes have been shown with the immunization of broiler chicks against Campylobacter (Helmy et al., 2022). Using a Campylobacter vaccine created from multiplication proteins exposed on the surface of C. jejuni, Neal-McKinney et al. (2014) demonstrated a 2 log reduction in the degree of C. jejuni colonization in 20 d old chickens following intramuscular injection (Neal-McKinney et al., 2014). Two recent studies have employed an effective vaccine against Campylobacter infection in broilers (Meunier et al., 2017; Nothaft et al., 2017).

To transport Campylobacter immunogenic surface proteins, Wyszyńska et al. (2004) used attenuated Salmonella as a vector. Broiler chicks as young as 4 wk old were vaccinated orally, and the results demonstrated a significant decrease in the prevalence and levels of C. jejuni multiplication compared to control groups (Wyszyńska et al., 2004; Poudel et al., 2023). However, these novel interventions are still in the early stages of development, so more study is needed to optimize the best delivery system and test efficacy in real-world settings (Djennad et al., 2017; Mota-Gutierrez et al., 2022). Producers will have to rely on biosecurity improvements to poultry farms until these interventions are ready for widespread application (Mota-Gutierrez et al., 2022).