Abstract

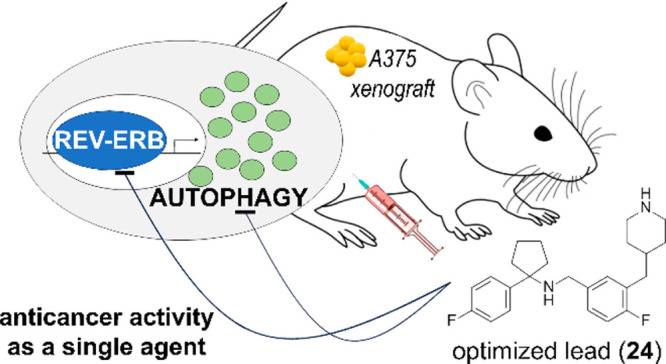

The autophagy process appears as a promising target for anticancer interventions. Chloroquine (CQ) and its derivative hydroxychloroquine (HCQ) are the only FDA-approved autophagy flux inhibitors. Although diverse anticancer clinical trials are providing encouraging results, several limitations associated with the need of high dosage and long-term administration of these autophagy inhibitors are also emerging. We showed that the inhibition of REV-ERB, a nuclear receptor regulating circadian rhythm and metabolism, enhances CQ-mediated cancer cell death and identified a class of dual inhibitors of autophagy and REV-ERB displaying an in vitro anticancer activity against diverse tumor cells greatly higher than CQ. Herein, we describe our lead optimization strategy that led to the identification of compound 24 as a dual autophagy and REV-ERB inhibitor, showing improved potency in blocking autophagy, enhanced toxicity against cancer cells, optimal drug-like properties, and efficacy in a mouse xenograft model of melanoma as a single anticancer agent.

Introduction

Macro-autophagy, generally simply called autophagy, is a multistep process driving the degradation of damaged and excess proteins and organelles to generate macromolecular building blocks and fuel metabolic pathways.1,2 The autophagy pathway involves diverse protein complexes coordinating the formation of double-membrane vesicles, named autophagosomes, which encapsulate intracellular substrates, referred to as cargo. Upon the fusion of autophagosomes with lysosomes, the cargo is degraded in the resulting autophagolysosomes.3

Autophagy has critical roles in many biological processes, such as protein homeostasis, stress response, metabolism, and cell death. Accordingly, altered autophagic degradation has been linked to diverse pathologies.2 In cancer, autophagy presents a double-edged sword effect on tumor development and progression. Although functional autophagic degradation has a protective role against the development of multiple tumor types, after a tumor is fully established, autophagy takes on a pro-survival role for cancer cells.4,5 Multiple cancers hijack autophagy to reprogram their proteome and cope with cancer metabolic needs and the activity of many chemotherapeutic agents.6 Accordingly, the autophagy–lysosome system appears as a promising target for anticancer interventions.

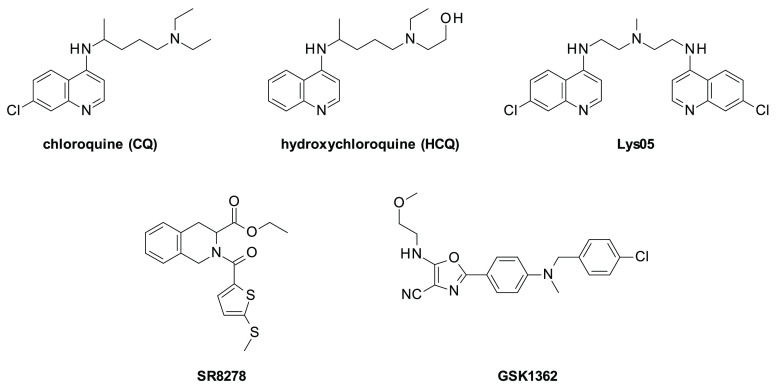

Chloroquine (CQ) and its derivative hydroxychloroquine (HCQ) are the only FDA-approved autophagy flux inhibitors (Figure 1).7

Figure 1.

Structures of known autophagy inhibitors (chloroquine (CQ), hydroxychloroquine (HCQ), and Lys05, top) and known antagonist ligands of REV-ERB (SR8278 and GSK1362, bottom).

Both CQ and HCQ target autophagy at the late stage by preventing the final maturation of autophagolysosomes, thus interrupting the autophagic flux and preventing autophagy-mediated degradation.8

Because of their long history of use in humans for the treatment of malaria, these agents have been repurposed in numerous clinical trials for the treatment of diverse cancers.

However, both CQ and HCQ presented several limitations in the treatment of tumors, especially for their use as single anticancer agents. High concentrations of these compounds are usually required for inhibiting the growth of cancer cells already in vitro and in animals,8 which implies the use of high dosages and long-term administration that could lead to severe toxicity. Indeed, adverse effects such as cardiac disorders and retinopathy have been associated with CQ and HCQ long-term use in humans.9−12 Moreover, a recent study indicated that CQ and HCQ can block the activity of the human ether-a-go-go-related gene (hERG) potassium channel at concentrations in the single-digit μM value,13 and regular 6-month cardiac monitoring tests are advised for patients taking a high dosage of either drugs.14 Accordingly, in recent years, different drug discovery projects have been focused on the identification of more potent autophagy inhibitory compounds for reducing the doses to be used in patients.15−17

An additional strategy to overcome the limitations deriving from the need of high doses of CQ and HCQ for inhibiting tumor growth is represented by a multitarget approach targeting both autophagy and pathways associated with autophagy-dependent cancer cell death. We previously reported that REV-ERB, a nuclear receptor regulating circadian rhythm and metabolism,18−20 plays a role in sustaining cancer cell survival when the autophagy flux is compromised.21 Indeed, pharmacological inhibition of REV-ERB significantly enhanced the cytotoxic activity of CQ against breast cancer cells, and cells from different cancer types knocked-down for REV-ERB were more sensitive to CQ-induced cell death.21,22 In addition, the knockdown of the essential autophagy gene ATG5 in breast cancer cells enhanced the toxicity of the REV-ERB antagonist, SR8278 (Figure 1), further indicating that REV-ERB inhibition induces cell death when autophagy is inhibited.21

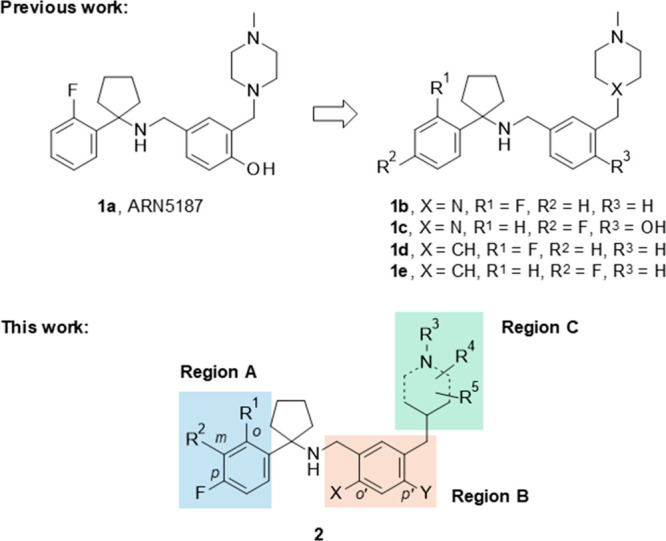

An in house drug discovery screening campaign led to the identification of the hit compound 4-[[[1-(2-fluorophenyl)cyclopentyl]amino]methyl]-2-[(4-methylpiperazin-1-yl)methyl]phenol (1a, ARN5187, Figure 2) that inhibits both REV-ERB and autophagy.

Figure 2.

(A) Structures of known dual autophagy and REV-ERB antagonists 1a–e (top) and our planned chemical exploration around the scaffold of this class of molecules 2 (bottom).

Specifically, 1a disrupts lysosomal function and blocks the autophagy process at the late stage.21 In addition, 1a directly binds REV-ERB ligand binding domain (LBD) in fluorine magnetic resonance (NMR)-based assays and relieves REV-ERB-mediated transcriptional repression enhancing the expression of REV-ERB target genes in breast cancer cells.21 Notably, the single inhibition of autophagy by CQ does not affect REV-ERB-mediated transcription, indicating that the effect of 1a on REV-ERB transcriptional repression does not depend on its autophagy inhibitory activity.22

Preliminary structure–activity relationship (SAR) studies resulted in the identification of the lead compound, 1e, showing a greater REV-ERB inhibitory activity than 1a and a potency in inhibiting autophagy comparable to CQ.22 Of note, the in vitro anticancer activity of 1e against several tumor cell lines was up to 50 times higher than CQ. In addition, 1e did not affect the viability of mammary epithelial cells from healthy donors, supporting the development of this class of dual autophagy and REV-ERB inhibitors as novel anticancer agents with a good therapeutic index.22

However, additional investigation on the drug-like properties of 1e suggested further chemical optimization to be performed for advancing this class of molecules in the drug discovery pipeline.

Herein, we describe our lead optimization strategy that resulted in the identification of compound 24, which shows improved biological activity, optimal drug-like properties, and efficacy in a mouse xenograft model of melanoma as a single anticancer agent.

Chemistry

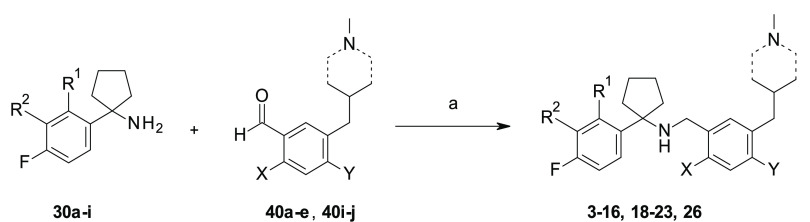

The preparation of all target compounds 3–26 has been accomplished through a convergent approach, involving the synthesis of amines 30a–i (Schemes 1–3) and aldehydes 40a–n (Schemes 4–7), followed by their condensation via reductive amination under standard reaction conditions,22 as depicted in Schemes 5 and 8. An additional step of N-Boc removal was performed for the preparation of compounds 17 and 24 and 25, as illustrated in Scheme 5.

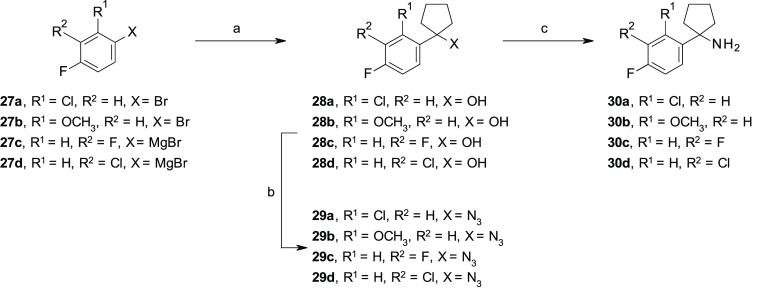

Scheme 1. Synthesis of 30a–d.

Reagents and conditions: for 28a,b: (a) n-BuLi, anhydrous THF, −78 °C, 1 h, then, cyclopentanone, −78 °C to rt, 3 h, for 28c,d, cyclopentanone, anhydrous THF, 0 °C to rt, 3 h; (b) NaN3, TFA, anhydrous CH2Cl2, −5 °C to rt, (4–11% over two steps); (c) LiAlH4, anhydrous THF, 0 °C to rt.

Scheme 3. Synthesis of 30h–i.

Reagents and conditions: (a) Br(CH2)4Br, LiHMDS, anhydrous THF, 0 °C to rt, on (69–77%); (b) H2SO4, THF/H2O, 120 °C (42% for 34b); (c) for 30h: (i) ClCO2CH2CH3, NaN3, Et3N, acetone, (ii) anhydrous toluene, reflux, 1 h, (iii) 8 N HCl, 70 °C, 3 h; for 30i, (i) SOCl2, anhydrous toluene, rt, 2 h, (ii) NaN3, anhydrous toluene, rt, (iii) BnOH, reflux, (iv) Et3SiH, 10% Pd/C, MeOH, 90 °C, MW, 30 min.

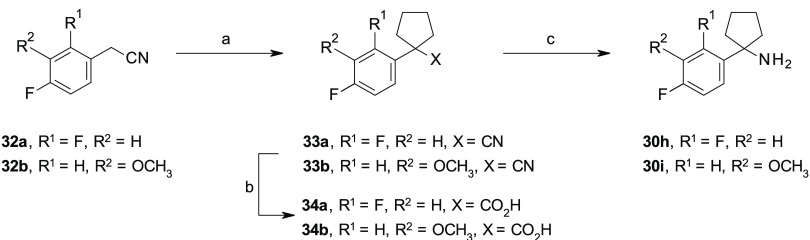

Scheme 4. Synthesis of 40a–e.

Reagents and conditions: (a) P(OEt)3 or PPh3, anhydrous toluene, reflux, on (39–99%); (b) LiHMDS or t-BuOK, 1-Boc-4-piperidone, anhydrous THF, 0 °C to rt, (20–58%); (c) Et3SiH, 10% Pd/C, MeOH, rt, 7 h; (d) for 39a,b,d,e, LiAlH4, anhydrous THF, 0 °C to rt; for 39c, (i) 4 M HCl in dioxane, CH2Cl2, 0 °C to rt, (quant), (ii) Et3N, formaldehyde 37 wt % in H2O, NaBH(OAc)3, 0 °C to rt, (iii) DIBALH, anhydrous THF, 0 °C to rt; (e) MnO2, anhydrous Et2O, rt, 8 h.

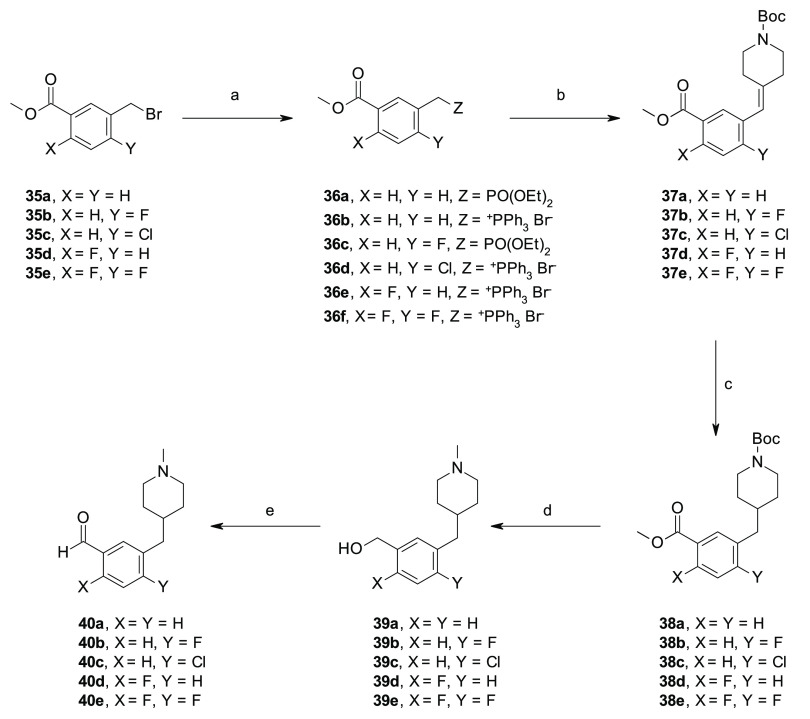

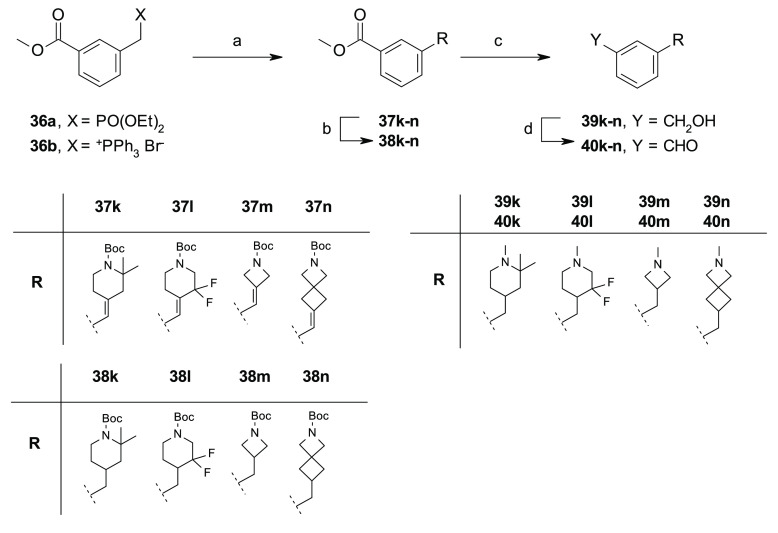

Scheme 7. Synthesis of 40k–n.

Reagents and conditions: (a) LiHMDS or t-BuOK, cyclic amino ketone, anhydrous THF, 0 °C to rt or 80 °C, (83–34%); (b) Et3SiH, 10% Pd/C, MeOH, rt, 7 h; (c) LiAlH4, anhydrous THF, 0 °C to rt; (d) MnO2, anhydrous Et2O, rt, 8 h.

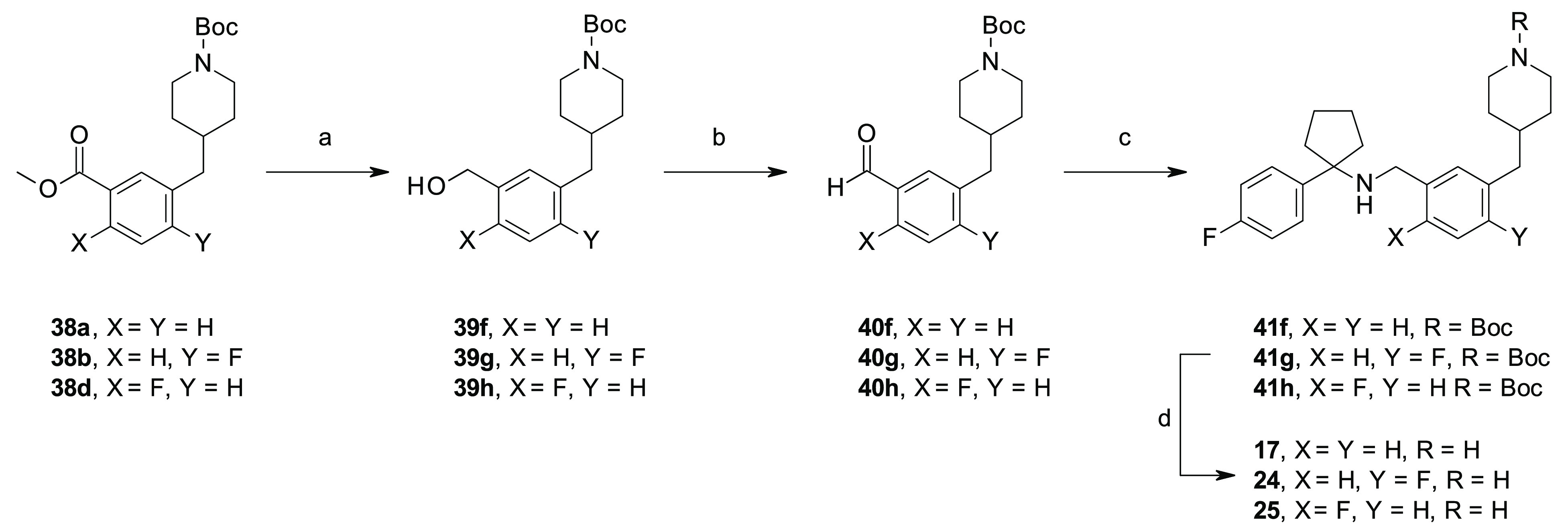

Scheme 5. Synthesis of 41f–h and 17, 24, and 25.

Reagents and conditions: (a) DIBALH, anhydrous THF, 0 °C to rt, (60–89%); (b) MnO2, anhydrous Et2O, rt, 8 h (74% for 40g); (c) 30e, NaBH(OAc)3, anhydrous CH2Cl2 0 °C to rt, rt (13–84%); (d) 4 M HCl in 1,4-dioxane, CH2Cl2, 0 °C to rt, (quant).

Scheme 8. Synthesis of 3–16, 18–23, and 26.

Reagents and conditions: (a) NaBH(OAc)3, anhydrous CH2Cl2, rt, on (11–60% over four steps).

Our versatile synthetic strategy allowed for rapid exploration of the targeted chemical modifications in the regions A, B, and C of scaffold 2 (Figure 2).

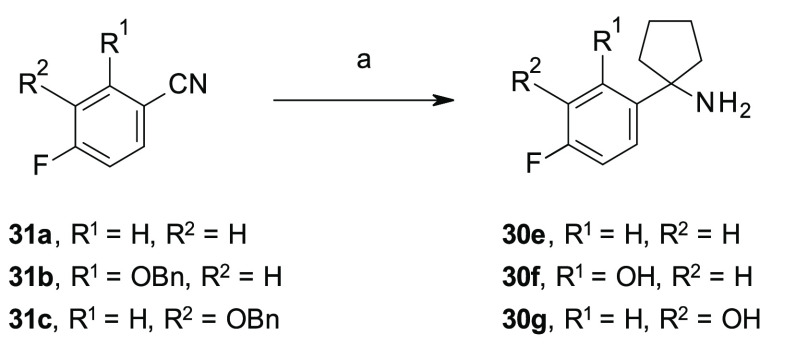

To overcome the issues associated with the limited commercial availability of some building blocks or the low yields of some synthetic routes, different procedures for the preparation of the key amines 30a–i were exploited, as illustrated in Schemes 1–3, which allowed the insertion of different substituents at the ortho- and meta-positions of the para-fluoro phenyl ring of our lead compound 1e (Figure 2). In the specific, the amines 30a–d were prepared through a previously reported three-step synthetic procedure,23,24 consisting of a nucleophilic addition of the appropriate in situ generated organolithium or commercially available Grignard reagents to cyclopentanone, followed by the treatment of the corresponding phenyl cyclopentyl alcohols 28a–d with sodium azide (NaN3) under acidic conditions to afford the azides 29a–d. Subsequent reduction of the azides 29a–d in the presence of lithium aluminum hydride (LiAlH4) gave the targeted amines 30a–d (Scheme 1). For the synthesis of the amines 30e–g, we exploited an alternative procedure, as previously reported by Tomashenko and co-workers,25 consisting of a one-step conversion of the nitriles 31a–c into the targeted amines 30e–g by reaction with 1,4-bis(bromomagnesio)butane, in situ generated from 1,4-dibromobutane and metallic magnesium (Mg) in anhydrous diethyl ether (Et2O), followed by the addition of titanium tetraisopropoxide Ti(iPrO)4 (Scheme 2). An alternative three-step procedure was exploited for the synthesis of amines 30h,i, starting from the phenylacetonitriles 32a,b, which were reacted with 1,4-dibromobutane in the presence of lithium bis(trimethylsilyl)amide (LiHMDS), followed by acid hydrolysis of the nitriles 33a,b to the corresponding carboxylic acids 34a,b under standard conditions (Scheme 3).26 Then, 34a was reacted with ethylchloroformate (ClCO2CH2CH3) in the presence of NaN3, followed by acidic hydrolysis, under thermal conditions, of the in situ generated isocyanate intermediate by Curtius rearrangement to afford the targeted amine 30h.27 Alternatively, 34b was reacted with thionylchloride (SOCl2) in the presence of NaN3, followed by Curtius rearrangement in the presence of BnOH which afforded the amine 30i, upon N-Cbz removal using triethylsilane (Et3SiH) and Pd/C under microwave (MW) conditions (Scheme 3).

Scheme 2. Synthesis of 30e–g.

Reagents and conditions: (a) Mg, Br(CH2)4Br, anhydrous Et2O, 40 °C; then, Ti(iPrO)4, anhydrous Et2O, rt, 24 h (20–26%).

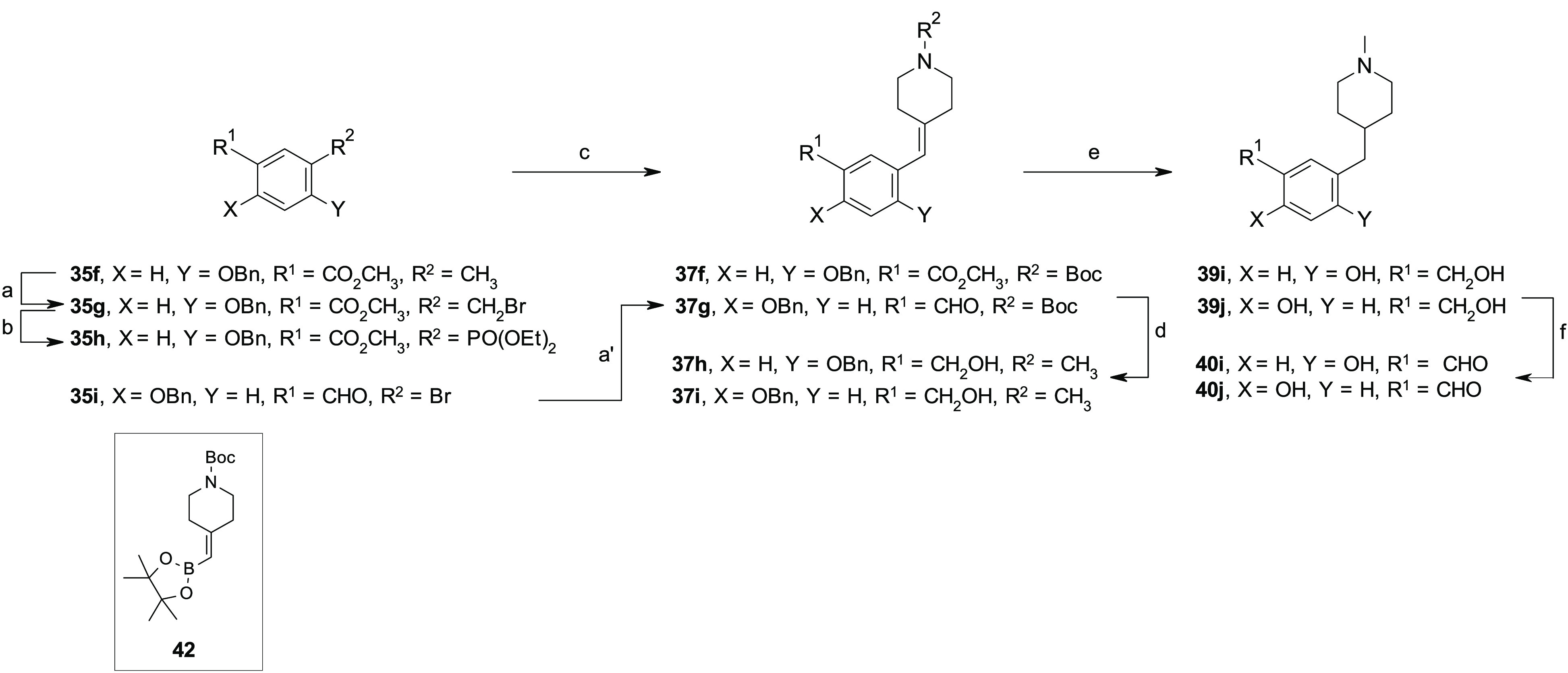

The aldehydes 40a–e were prepared following a slightly modified five-step synthetic procedure, as previously reported for the preparation of compound 1e,22 which involved an olefination reaction between the activated intermediates 36a–f, obtained from the corresponding commercially available benzyl bromides 35a–e under standard conditions, and the appropriate cyclic amino ketones under Horner–Wadsworth–Emmons or Wittig reaction conditions to obtain the olefins 37a–e, which, upon hydrogenation reaction with Et3SiH and Pd/C and a reduction–oxidation procedure by the use of LiAlH4 and MnO2, were converted to the corresponding aldehydes 40a–e (Scheme 4). Alternatively, a chemo-selective reduction of the methylester functionality of intermediates 38a,b and 38d was used for the preparation of benzyl alcohols 39f–h, which, upon oxidation with MnO2, afforded the aldehydes 40f–h (Scheme 5). Same procedure was adopted for the preparation of compounds 40i,j and 40k–n (Schemes 6,7). Notably, for the synthesis of the aldehyde 40j, an alternative synthetic approach was exploited which involved a Pd cross-coupling reaction by the use of the commercially available phenylbromide 35i and tert-butyl 4-[(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)methylidene]piperidine-1-carboxylate 42 that afforded the key olefin 37g in good yield (Scheme 6).

Scheme 6. Synthesis of 40i,j.

Reagents and conditions: for 37f: (a) NBS, AIBN, anhydrous CH3CN, 80 °C, 24 h; (b) P(OEt)3, anhydrous toluene, 120 °C, 20 h (20% over two steps); (c) t-BuOK, 1-Boc-4-piperidone, anhydrous THF, 0 °C to rt, (67%), for 37g: (a′) 42, Xphos, Pd2dba3, K3PO4, 1,4-dioxane/H2O, 100 °C, on (75%); (d) LiAlH4, anhydrous THF, 0 °C to rt, on; (e) Et3SiH, 10% Pd/C, MeOH, rt, 7 h; (f) MnO2, anhydrous CH2Cl2 or anhydrous CH2Cl2/iPrOH, rt, 8 h.

Results and Discussion

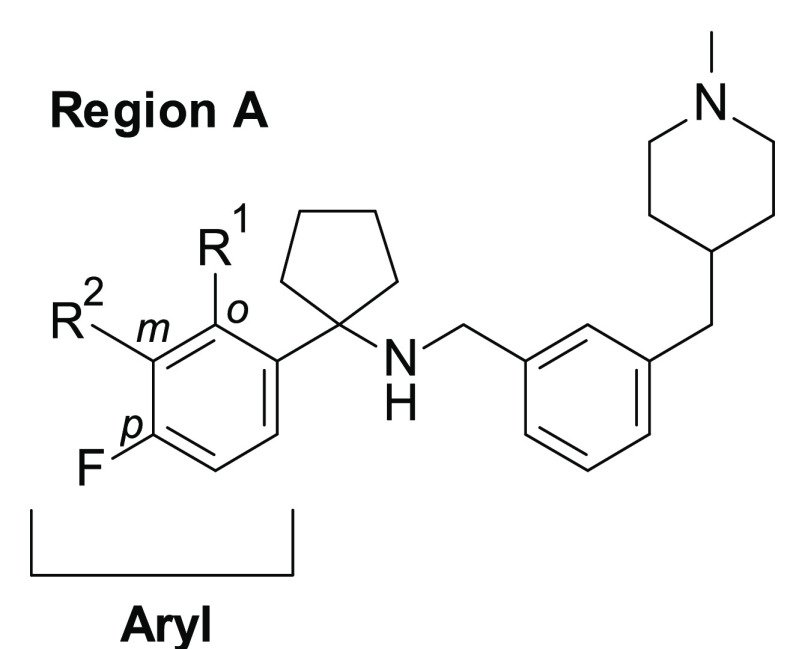

Our previous studies reported the identification of 1a as the first dual autophagy and REV-ERB inhibitor.21 Preliminary SAR studies around the 1a scaffold led to the discovery of new analogues 1b–e (Figure 2) with a good cytotoxicity profile against breast cancer BT-474 and selectivity against noncancerous human mammary epithelial cells (HMECs). In addition, 1e efficiently killed different cancer cells with diverse origins.22 Despite the enhanced potency and improved drug-likeness of 1e compared to the initial hit 1a (e.g., IC50 = 2.10 μM and IC50 = 30.14 μM, respectively, after 72 h treatment;22m-liver microsomal stability, t1/2 95 and 12 min, respectively), its moderate metabolic stability limits its use in in vivo studies. To address this issue, we performed a focused lead optimization strategy by exploring additional structural modifications on the three main regions of the scaffold of our class of molecules (regions A, B, and C of 2, Figure 2). The new synthesized compounds were first tested for their anticancer activity against BT-474 cells and toxicity against HMECs after 48 h treatment.

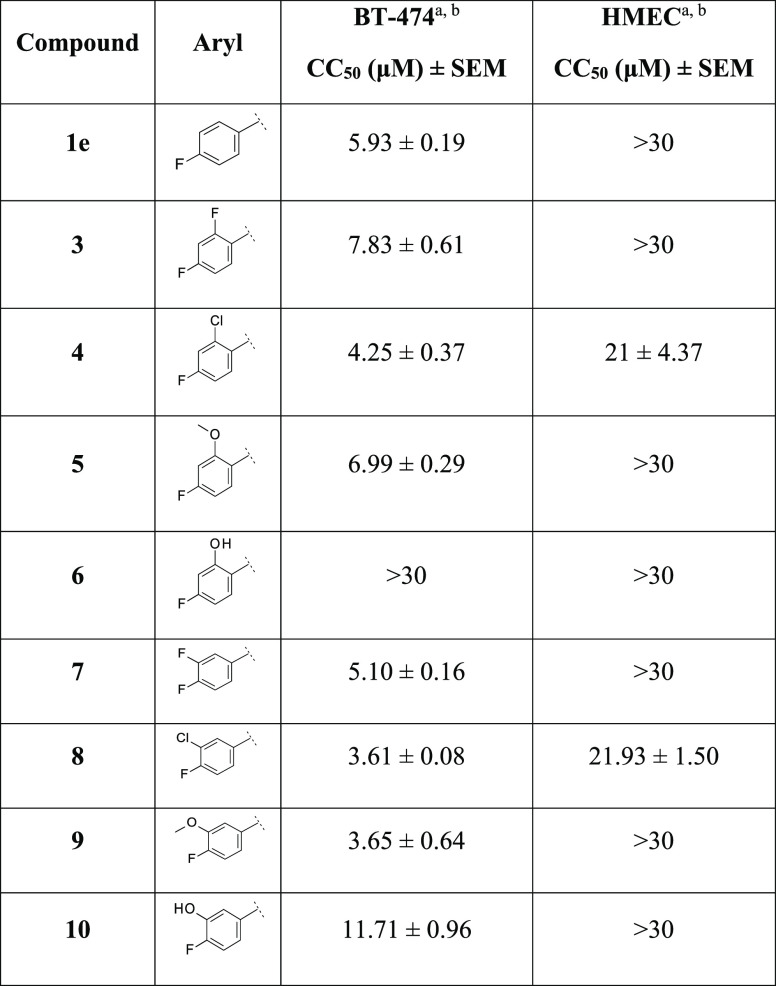

We started investigating modifications at the para-fluoro phenyl group of 1e with the aim of blocking or modifying potential metabolic “soft spots” present on the aromatic ring (region A) (Table 1).

Table 1. Cancer Cell Cytotoxicity of Compounds 1e–10 against Human Breast Cancer BT-474 and Noncancer HMEC Cells.

Concentration–response plots of indicated compounds cytotoxicity against human breast cancer BT-474 cells and nontumorigenic human mammary epithelial cells (HMECs) were used to calculate the concentration producing 50% cytotoxicity (CC50), as described in the Experimental Section. Shown as mean CC50 ± SEM (n ≥ 3).

For compounds showing a reduction in cell viability less than 50% of the vehicle treatment at the maximum concentration tested (30 μM), the CC50 value is indicated as >30 μM.

We were pleased to observe that, except for the phenolic derivative 6, the insertion of different substituents at the ortho-position of the para-fluoro phenyl ring (both electron-withdrawing and electron-donating groups, such as F, Cl, and CH3O) was tolerated (Table 1). Compounds 3–5 showed almost equipotent cytotoxicity activity on the BT-474 cells compared to the reference compound 1e. A similar trend was observed with compounds 7–10, bearing the same substituents at the meta-position of the para-fluoro phenyl ring, showing a slightly improved activity against BT-474 cells. Notably, the two chloro, fluoro regioisomers 4 and 8 also showed a double-digit μM toxic effect in HMECs.

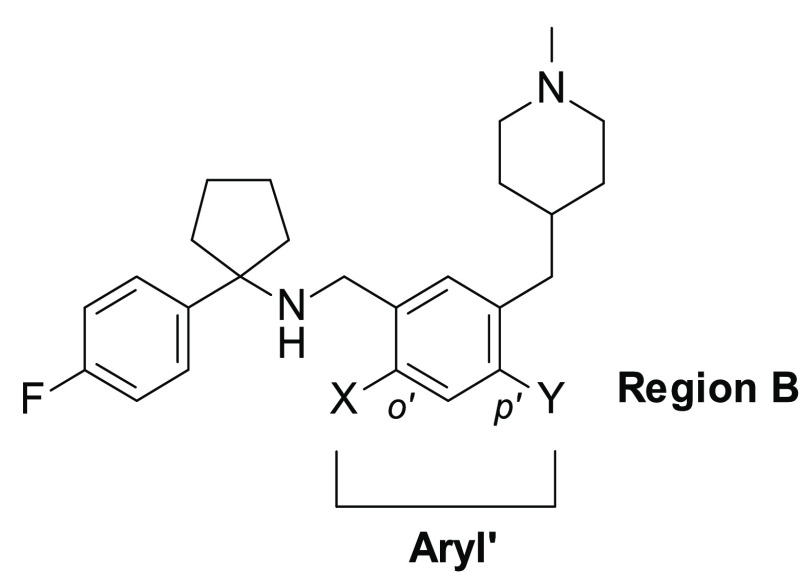

We then continued the SAR exploration by modifying the scaffold with the insertion of different substituents on the phenyl ring at region B (Table 2).

Table 2. Cancer Cell Cytotoxicity of Compounds 11–16 against Human Breast Cancer BT-474 and Noncancer HMEC Cells.

Concentration–response plots of indicated compounds cytotoxicity against human breast cancer BT-474 cells and nontumorigenic human mammary epithelial cells (HMECs) were used to calculate the concentration producing 50% cytotoxicity (CC50), as described in the Experimental Section. Shown as mean CC50 ± SEM (n ≥ 3).

For compounds showing a reduction in cell viability less than 50% of the vehicle treatment at the maximum concentration tested (30 μM), the CC50 value is indicated as >30 μM.

In the specific, we first prepared analogues 11–13, bearing a F, OH, and Cl atom, respectively at the para-position with respect to the benzylic amine of 1e. These compounds were equipotent to 1e, except for the chloro analogue 13, which resulted to be more potent against BT-474 cells with undesired toxicity against HMECs (CC50 = 2.34 μM and CC50 = 15.38 μM, respectively). We applied the same strategy with the preparation of analogues 14 and 15, by blocking the ortho-position with respect to the benzylic amine on the phenyl ring of 1e at region B. Both compounds showed a similar profile, as reference 1e, and selectivity against BT-474 cells (Table 2). Interestingly, the di-F derivative 16, although showing improved cytotoxicity in cancer cells (CC50 = 3.11 μM), elicited an undesired effect in HMECs (CC50 = 20.39 μM).

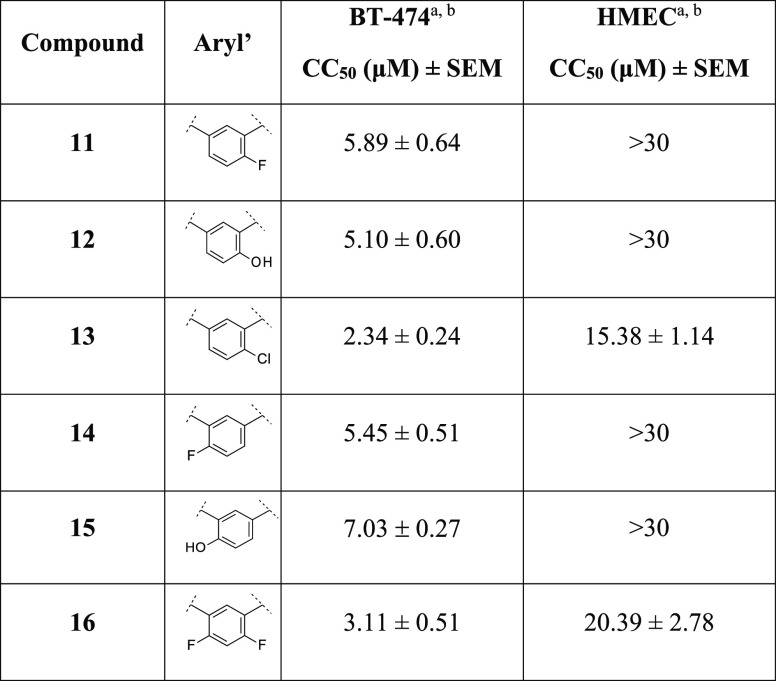

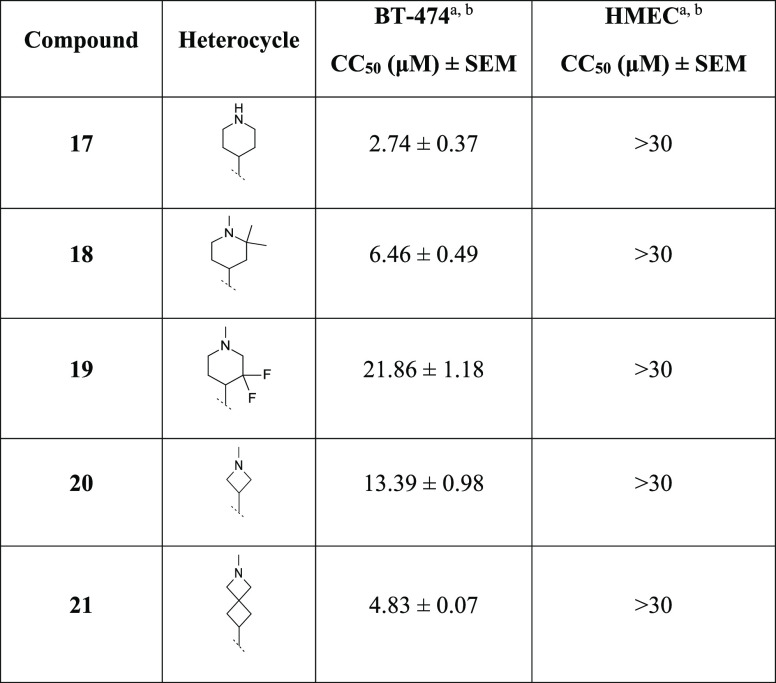

We then moved our attention to the right-hand side (region C) of the scaffold by evaluating the effect of different substituents on the piperidine ring or alternative heterocycles (e.g., azetidine, spiro-bicycle) (Table 3), with the aim of improving the physicochemical and metabolic properties of our series.

Table 3. Cancer Cell Cytotoxicity of Compounds 17–21 against Human Breast Cancer BT-474 and Noncancer HMEC Cells.

Concentration– response plots of indicated compounds cytotoxicity against human breast cancer BT-474 cells and nontumorigenic human mammary epithelial cells (HMECs) were used to calculate the concentration producing 50% cytotoxicity (CC50), as described in the Experimental Section. Shown as mean CC50 ± SEM (n ≥ 3).

For compounds showing a reduction in cell viability less than 50% of the vehicle treatment at the maximum concentration tested (30 μM), the CC50 value is indicated as >30 μM.

A loss in potency was observed with the difluorinated analogue 19 and the azetidine 20 (CC50 = 21.86 and 13.39 μM, respectively), while the des-methylated piperidine 17 and the gem-dimethyl 18 resulted more and almost equipotent potent, respectively, compared to 1e (CC50 = 2.74 and 6.46 μM, respectively). The chemical exploration continued with the preparation of the spiro-bicycle 21 which resulted in a valid bioisosteric replacement of the piperidine ring, being slightly more potent (CC50 = 4.83 μM) than 1e, without showing toxicity against HMECs (Table 3).

With these results in hand, a comparative analysis of some selected analogues in terms of aqueous kinetic solubility (PBS, pH 7.4) and in vitro metabolism (t1/2, liver microsomes, in the presence of NADPH or UDPGA cofactors) was performed and reported in Tables 4 and 5.

Table 4. Aqueous Kinetic Solubility and in Vitro Metabolism of Compounds 1e–10.

| compd | solubility (μM)a(PBS, pH 7.4) | m-LMbt1/2 (min) [% at 60, 120 min] | h-LMct1/2 (min) [% at 60, 120 min] | m,h-LMdt1/2 (min) [% at 120 min] |

|---|---|---|---|---|

| 1ee | 235 | 95 [66%, 39%] | >120 [79%, 50%] | >120 [>95%] |

| 3 | 209 | <30 [19%, 5%] | ||

| 4 | 220 | 11 ± 1 | ||

| 5 | 247 | 98 [64%, 42%] | 92 [70%, 50%] | >120 [>95%] |

| 6 | 27 | 42 [34%, 13%] | >120 [>95%] | |

| 7 | 245 | 70 [56%, 31%] | >120 [75%, 53%] | >120 [>95%] |

| 8 | 249 | >60 [53%] | ||

| 9 | 219 | 91 [62%, 40%] | >120 [80%, 55%] | >120 [>95%] |

| 10 | >250 | >120 [80%, 63%] | >120 [84%, 71%] | >120 [>95%] |

Aqueous kinetic solubility in phosphate buffered saline (PBS). Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Mouse liver microsomes in the presence of NADPH cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Human liver microsomes in the presence of NADPH cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Mouse and human liver microsomes in the presence of UDPGA cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Rat liver microsomes in the presence of NADPH cofactor: t1/2 44 ± 4, dog liver microsomes in the presence of NADPH cofactor: t1/2 56 ± 1. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Table 5. Aqueous Kinetic Solubility and in Vitro Metabolism of Compounds 11–21.

| compd | solubility (μM)a (PBS, pH 7.4) | m-LMbt1/2 (min) [% at 60, 120 min] | h-LMct1/2 (min) [% at 60, 120 min] | m,h--LMdt1/2 (min) [% at 120 min] |

|---|---|---|---|---|

| 11 | >250 | 91 [60%, 39%] | >120 [84%, 71%] | >120 [95%] |

| 12 | >250 | 87 [61%, 43%] | >120 [83%, 63%] | >120 [95%] |

| 13 | 216 | 56 [51%, 29%] | ||

| 14 | 246 | 107 [68%, 46%] | >120 [75%, 53%] | >120 [95%] |

| 15 | 246 | 82 [79%, 61%] | >120 [74%, 54%] | >120 [95%] |

| 16 | 228 | 80 [58%, 34%] | >120 [76%, 52%] | >120 [95%] |

| 17 | 248 | >120 [85%, 71%] | >120 [80%, 62%] | >120 [95%] |

| 18 | 239 | >60 [58%] | ||

| 19 | 41 | <5 | ||

| 20 | >250 | >60 [63%] | ||

| 21e | 232 | 115 [70%, 49%] | >120 [82%, 66%] | >120 [95%] |

Aqueous kinetic solubility in phosphate buffered saline (PBS). Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Mouse liver microsomes in the presence of NADPH cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Hhuman liver microsomes in the presence of NADPH cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Mouse and human liver microsomes in the presence of UDPGA cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Rat liver microsomes in the presence of NADPH cofactor: t1/2 > 60 min, 64% compound remaining, dog liver microsomes in the presence of NADPH cofactor: t1/2 53 ± 4. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

We focused the in vitro ADME compound profiling on phase I oxidative and phase II conjugative metabolic processes in liver microsomes, considering that our class of molecules does not contain groups that may be susceptible to plasma enzyme hydrolysis and/or chemical instability at certain pH values. In general, we observed that our compounds showed high aqueous kinetic solubility, except for compound 6 (Table 4). Notably, the insertion of different substituents both in ortho- and meta- positions of the para-fluoro phenyl ring (region A) modulated the metabolic stability of our compounds both in mouse and human liver microsomes, in the presence of the NADPH cofactor. In general, meta,para- disubstituted phenyl cyclopentyl analogues showed a better liver microsomal stability profile compared to the corresponding ortho,para- disubstituted phenyl cyclopentyl analogues. As a representative example, compound 7 showed improved metabolic stability compared to 3. A similar trend was observed for analogues 8 and 10 in comparison to 4 and 6. On the contrary, compound 5 showed a similar metabolic profile compared to the corresponding meta,para- disubstituted phenyl cyclopentyl analogue 9 and our reference 1e (Table 4). Selected compounds were also evaluated in mouse and human liver microsomal stability assay in the presence of the UDPGA cofactor, showing t1/2 > 120 min with compound remaining >95% in both species, as reported in Table 4.

We then continued with the structure–property relationship (SPR) evaluation of some compounds from the chemical exploration of regions B and C, as reported in Table 5. In general, all the targeted compounds showed high solubility in aqueous media, except for the difluoro piperidine 19, which also suffered from a high metabolic instability in mouse liver microsomes in the presence of NADPH cofactor (Table 5). Analogues bearing F or OH groups on the central phenyl ring at region B showed a better overall metabolic profile compared to 1e, both in mouse and human microsomes, as for example, the fluorinated analogues 11 and 14. On the other hand, the insertion of a Cl atom, as for 13, did not give any beneficial effect in terms of metabolic stability, showing a half-life (t1/2) of 56 min in mouse liver microsomes (Table 5). Some important differences were observed with the chemical exploration of region C (Table 5). Notably, while we were pleased to observe that the des-methylated piperidine 17 and the spiro-bicycle 21 showed improved metabolic stability compared to 1e both in mouse and human microsomes, the gem-dimethyl piperidine 18 and the azetidine 20 were less stable with an t1/2 of almost 1 h in mouse microsomes in the presence of NADPH cofactor.

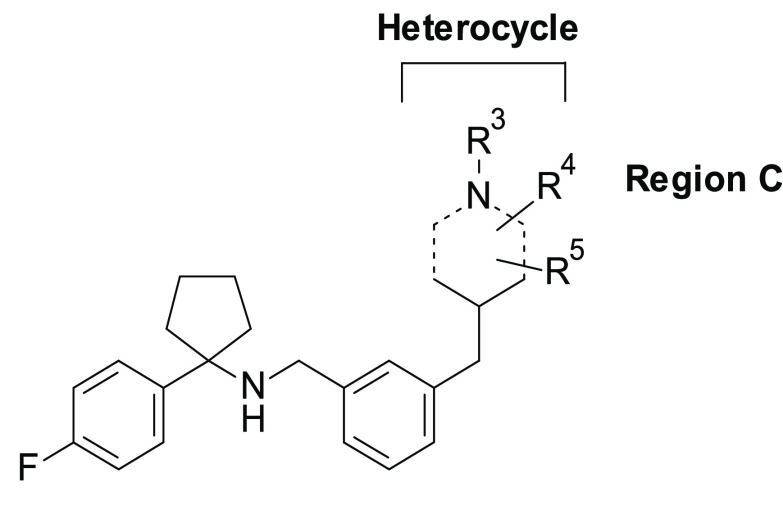

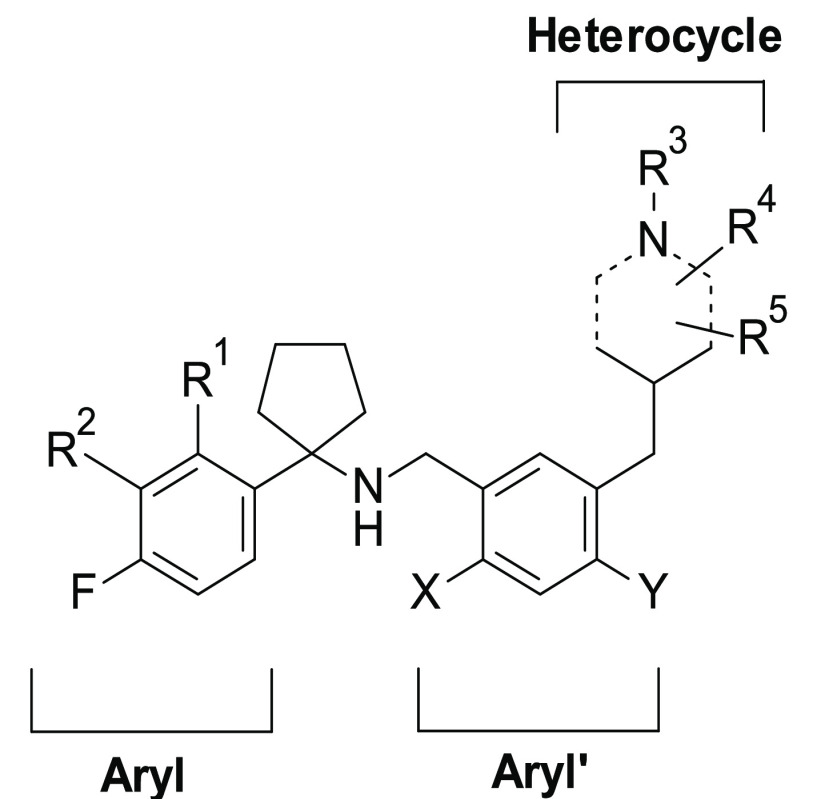

With these results in hand, we were finally interested in studying the effect of the combinations of some representative moieties identified during our SAR/SPR explorations of the three main regions A, B, and C. With this aim, we prepared and evaluated analogues 22–26 as reported in Table 6.

Table 6. Cancer Cell Cytotoxicity of Compounds 22–26 against Human Breast Cancer BT-474 and Noncancer HMEC Cells.

Concentration–response plots of indicated compounds cytotoxicity against human breast cancer BT-474 cells and nontumorigenic human mammary epithelial cells (HMECs) were used to calculate the concentration producing 50% cytotoxicity (CC50), as described in the Experimental Section. Shown as mean CC50 ± SEM (n ≥ 3).

For compounds showing a reduction in cell viability less than 50% of the vehicle treatment at the maximum concentration tested (30 μM), the CC50 value is indicated as >30 μM.

We were pleased to observe that, except for analogue 22, all the targeted compounds were more potent than the reference 1e against the BT-474 cells, with compounds 25 and 26 showing an undesired toxicity in HMECs. The new synthesized analogues were evaluated in kinetic solubility and liver microsomal stability assays (Table 7). All the targeted compounds 22–26 showed high solubility in aqueous media. Moreover, analogues 24 and 25 resulted in an improved microsomal stability profile with t1/2 > 2 h, both in mouse and human microsomes in the presence of NADPH and UDPGA cofactors. On the other hand, the spiro-cycle 26 showed an overall metabolic profile similar to the corresponding piperidine 7, with a slightly improved stability in human microsomes in the presence of NADPH cofactor (Table 7).

Table 7. Aqueous Kinetic Solubility and in Vitro Metabolism of Some Selected Compounds.

| compd | solubility (μM)a (PBS, pH 7.4) | m-LMbt1/2 (min) [% at 60, 120 min] | h-LMct1/2 (min) [% at 60, 120 min] | m,h-LMdt1/2 (min) [% at 120 min] |

|---|---|---|---|---|

| 22 | >250 | 69 [55%, 31%] | >120 [75%, 58%] | >120 [95%] |

| 23 | 231 | 58 [48%, 21%] | >120 [77%, 56%] | |

| 24e | >250 | >120 [84%, 72%] | >120 [81%, 68%] | >120 [95%] |

| 25e | 245 | >120 [82%, 74%] | >120 [75%, 54%] | >120 [95%] |

| 26 | 226 | 75 [56%, 32%] | >120 [84%, 65%] |

Aqueous kinetic solubility in phosphate buffered saline (PBS). Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Mouse liver microsomes in the presence of NADPH cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Human liver microsomes in the presence of NADPH cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Mouse and human liver microsomes in the presence of UDPGA cofactor. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Rat liver microsomes in the presence of NADPH cofactor: t1/2 > 60 min, 98% and 75% compound remaining for 24 and 25, respectively, dog liver microsomes in the presence of NADPH cofactor: t1/2 > 60 min, 89% and 83% compound remaining for 24 and 25, respectively. Values are reported as the mean of at least two independent experiments, performed in two technical replicates.

Because of the overall property profiles, compounds 21, 24, and 25 were profiled in metabolic stability assays using rat and dog liver microsomes in the presence of NADPH cofactor (Tables 5 and 7). The experiments revealed that compound 24 was more stable than compounds 21 and 25, with t1/2 > 60 min in both species with higher percentage of compound remaining after 1 h incubation (t1/2 > 60 min, 98% and 89% compound remaining in rat and dog microsomes, respectively). More pronounced differences were observed by comparing 24 to 1e in rat and dog liver microsomal stability properties (Tables 4 and 7).

Because of the overall property profile, compound 24 was selected for additional studies.

We previously showed that the cytotoxicity of our class of compounds is mediated by the induction of apoptosis, as indicated by caspase activation and enhanced cleaved PARP levels in BT-474 cells treated with 1a.21 Indicating that 24 preserved this mechanism of action of cell death, BT-474 treated with different concentrations of 24 showed a dose-dependent induction of both caspase-activity and cleaved PARP protein levels (Supporting Information, Figure S1).

We then aimed to compare 24 biological activity with the lead compound 1e. First, we evaluated the potency of 24 and 1e in reducing the viability of different human cancer cells with diverse origins. Specifically, we tested the in vitro anticancer activity of compounds against an additional breast cancer cell line (MDA-MD-231), and cells deriving from melanoma (A375), uveal melanoma (OMM-1 and UPMM-2), pancreatic (CAPAN-2), hepatocellular carcinoma (HEPG2), and colorectal (HT-29 and HCT116) tumors (Table 8).

Table 8. In Vtro Anticancer Activity of Compounds 1e and 24 against Cancer Cell Lines with Diverse Origins.

| cell line | origin | 1ea,b CC50 (μM) ± SEM | 24a,b CC50 (μM) ± SEM | P valuec |

|---|---|---|---|---|

| BT-474 | breast ductal carcinoma | 5.93 ± 0.19 | 2.31 ± 0.11 | <0.001 |

| MDA-MB-231 | breast adenocarcinoma | 7.42 ± 0.15 | 2.97 ± 0.07 | <0.001 |

| A375 | melanoma | 5.67 ± 0.11 | 2.56 ± 0.08 | <0.001 |

| OMM-1 | uveal melanoma | 2.28 ± 0.11 | 1.14 ± 0.24 | <0.05 |

| UPMM-2 | uveal melanoma | 1.91 ± 0.12 | 1.09 ± 0.16 | <0.05 |

| CAPAN-2 | pancreatic adenocarcinoma | >30 | 6.86 ± 0.65 | not applicable |

| HEPG2 | liver hepatocellular carcinoma | 2.80 ± 0.27 | 1.49 ± 0.16 | <0.01 |

| HT-29 | colorectal adenocarcinoma | 18.88 ± 0.36 | 4.74 ± 0.77 | <0.01 |

| HCT116 | colorectal carcinoma | 13.51 ± 1.09 | 4.56 ± 1.06 | <0.01 |

Concentration– response plots of 1e and 24 cytotoxicity against the indicated cancer cell lines were used to calculate the concentration producing 50% cytotoxicity (CC50), as described in the Experimental Section. Shown as mean CC50 ± SEM (n ≥ 6).

For compounds showing a reduction in cell viability equal or greater than 50% at the maximum concentration tested (30 μM), the CC50 value is indicated as >30 μM.

P values were calculated with a two-tailed unpaired t test comparison between CC50 of compound 1e and 24.

The result of this analysis indicated that 24 has significantly improved in vitro anticancer activity compared to 1e against all the cancer cells tested. Of note, compound 24 showed a comparable cytotoxicity against the ERBB2-positive BT-474 and the triple-negative MDA-MB-231 breast cancer cells, which is in line with our previous analysis indicating that the anticancer activity of this class of compounds is independent of ERBB2 expression.21 Remarkably, uveal melanoma cells showed a high sensitivity to compound toxicity. This result is particularly interesting considering that the cells adopted in our analysis present a loss of chromosome 3. Uveal melanoma is the most common primary intraocular malignant tumor in adults and has a predilection for hematogenous dissemination to the liver. Total or partial deletions of chromosome 3 in uveal melanoma are associated with a high incidence of mortality mainly due to liver metastasis, for which there is no effective treatment.28,29

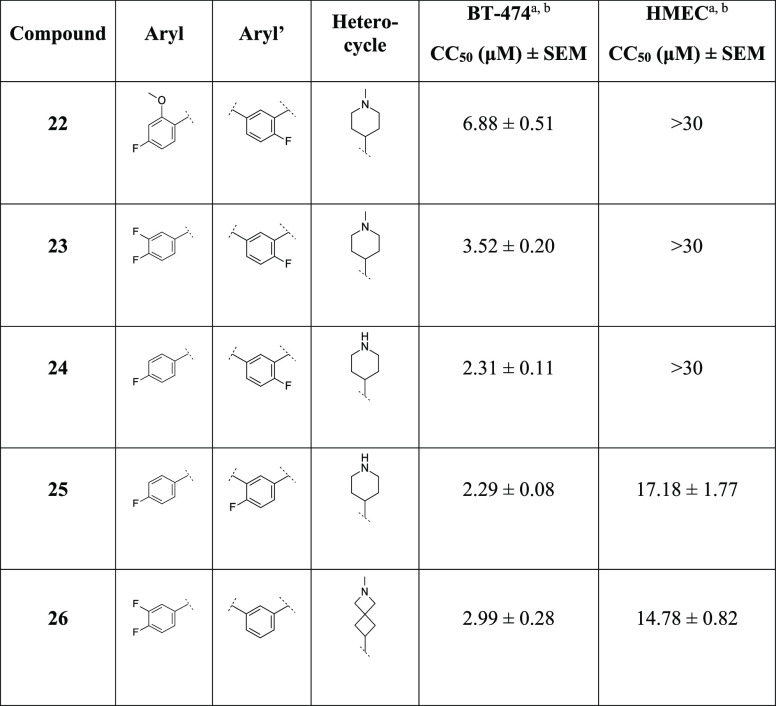

We then compared the ability of 1e and 24 to inhibit REV-ERB and autophagy. For evaluating the effect of the compounds on REV-ERB transcriptional repression activity, we adopted a luciferase cell-based assay consisting of a reporter vector expressing a Cypridina luciferase gene under the control of a minimal SV40 promoter containing a REV-ERB responsive element (RevRE) (Figure 3A).21 In addition, a reporter bearing a mutated RevRE that is not able to bind REV-ERB protein was used for assessing the specificity of the luminescence response (Figure 3B).

Figure 3.

Comparison of the REV-ERB inhibitory activity of compounds 1e and 24. (A) Cotransfection assay in 1e- and 24-treated HEK-293 cells with REV-ERBβ and a luciferase REV-ERB-responsive reporter driven by two repetitions of a REV-ERB element (RevRE) consensus. A schematic representation of the reporters is shown at the top. Data are expressed as fold increase of luciferase activity versus vehicle (DMSO). Shown as mean ± SEM, n = 6. EC50 values for 1e and 24 antagonism versus REV-ERBβ were 3.61 ± 0.82 μM and 3.78 ± 0.94 μM, respectively. (B) Cotransfection assay in 1e- and 24-treated HEK-293 cells with REV-ERBβ and a REV-ERB-unresponsive reporter bearing a mutated RevRE that is not recognized by REV-ERB DNA binding domain. Shown as mean ± SEM, n = 6.

Indicating that 24 preserved the REV-ERB inhibitory activity, this compound activated the RevRE reporter in a concentration-dependent manner with an average EC50 value comparable to the one of compound 1e (3.61 ± 0.82 μM and 3.78 ± 0.94 μM, respectively) (Figure 3A), while it had no effects on the expression of the mutated RevRE (Figure 3B). To further validate the REV-ERB inhibitory activity of 24, we tested its effect on the expression of a REV-ERB target gene, BMAL1, in BT-474 knocked down for REV-ERBβ, which we previously demonstrated to be the predominantly functional REV-ERB variant expressed in this cell line.21 In line with our luciferase reporter assay, REV-ERBβ silencing abolished the 24-mediated induction of BMAL1 expression (Supporting Information, Figure S2).

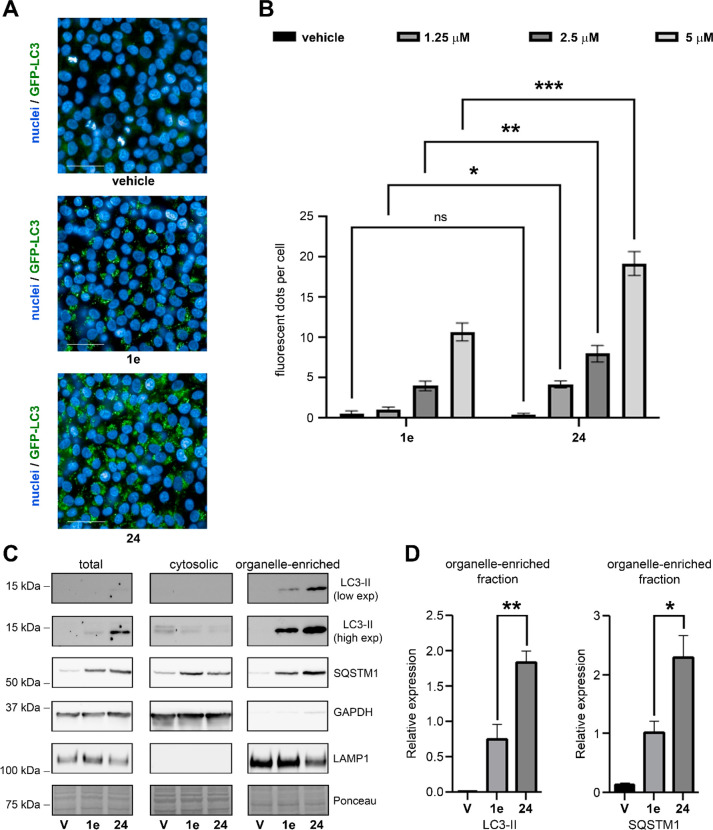

We then compared the effect of the two compounds on the inhibition of autophagy. To this aim, we generated a fluorescent reporter cell-based assay in which melanoma A375 cells stably express a chimeric autophagy marker LC3B fused with an enhanced green fluorescence protein (GFP-LC3). During autophagosome maturation, a lipid conjugated version of LC3 protein (LC3-II) is recruited on the membrane of autophagosomes.3 Accordingly, GFP-LC3-containing autophagosomes will appear as fluorescent perinuclear dots, differing from a diffuse fluorescence signal deriving from the unconjugated GFP-LC3 protein (Figure 4A).30

Figure 4.

Comparison of the autophagy inhibitory activity of compounds 1e and 24. (A) Representative fluorescent images of melanoma A375 cells stably expressing a chimeric autophagy marker LC3B fused with a green fluorescence protein (GFP-LC3) treated with 5 μM of 1e, 24, or vehicle (DMSO) for 24 h. Nuclei were stained with Hoechst 33342 (blue) after fixation with 4% paraformaldehyde (PFA). White scale bar = 20 μm. (B) Melanoma A375 cells expressing GFP-LC3 reporter were treated with the indicated concentrations of 1e or 24 for 24 h. After fixation with 4% PFA and nuclear staining, fluorescent signals were acquired with a fluorescent microscope and images were used for quantifying GFP-LC3-positive fluorescent dots per cell as described in the Experimental Section. Shown as average number of fluorescent dots per cell ± SEM, n = 10. *P < 0.05, **P < 0.01, and ***P < 0.001, 24 vs 1e (two-way ANOVA with Bonferroni’s multiple comparison test). (C) Immunoblot analysis of total, cytosolic and organelle-enriched fractions from cells treated 24 h with vehicle (DMSO), 2.5 μM of 1e or 2.5 μM of 24. Lysosomal LAMP1 was used to confirm the enrichment in autophagolysosomes in organelle-enriched fractions, while cytoplasmic GAPDH protein was adopted to evaluate potential cytosolic contaminations. Immunoblot with antibodies against the autophagic receptors, SQSTM1 (also known as p62), and the autophagy marker LC3 were used to evaluate the effects of the treatments on autophagy. (D) Quantification of immunoblot analysis from organelle-enriched fractions of cells treated as in C. Relative LC3-I and LC3-II expression were calculated normalizing the optical density of LC3-II signals with the optical density of the Ponceau staining. Shown as mean ± SEM, n = 3. *P < 0.05 and **P < 0.01, 24 vs 1e (one-way ANOVA with Tukey’s multiple comparison test).

We thus treated GFP-LC3 A375 cells with different concentrations of 1e and 24 and evaluated the average number of fluorescent perinuclear dots per cell (Figure 4B). Consistent with the ability of both compounds to inhibit autophagy at the late stage, cells treated with 1e or 24 showed a dose-dependent accumulation of GFP-LC3-positive autophagosomes. However, compound 24 generated a significantly higher increase in fluorescent dots compared with 1e at all the doses tested (Figure 4B), indicating an improved autophagy inhibitory activity of this analogue.

To confirm this result with an independent approach, we prepared total protein extracts, cytosolic and organelle-enriched fractions from A375 cells treated with an equal dose of 1e or 24 (2.5 μM). Consistent with our fluorescence microscopy analysis, immunoblot with a specific LC3B antibody showed higher increasing in LC3-II protein levels in total and autophagosome-containing organelle-enriched fractions from cells treated with 24 compared to 1e-treated cells (Figure 4C,D). Furthermore, the treatment with 24 resulted in increased protein levels of the autophagic receptor SQSTM1 (also known as p62) in organelle-enriched fraction compared to 1e. SQSTM1 protein is incorporated into the completed autophagosome and is degraded in autolysosomes, thus serving as an index of autophagic degradation.30 Accordingly, the higher accumulation of SQSTM1 in organelle-enriched fraction from cells treated with 24 compared to 1e-treated cells indicates that this analogue is more potent in inhibiting the autophagic flux than the lead.

Collectively, our analyses indicate that compound 24 retains the REV-ERB inhibitory activity of 1e and improves the ability of blocking autophagy.

We then evaluated the plasma concentration–time profile of 24 following a single intraperitoneal (ip) dose of 10 mg/kg in female CD1 mice. This compound presented a biphasic elimination profile with a long half-life (9.67 h) and a large volume of distribution (106.07 L/kg) estimated through a noncompartmental analysis (NCA) of the plasma concentrations. Of note, a similar profile has also been reported for CQ, and it could represent the general pharmacokinetic (PK) behavior of lysosomotropic agents.31 The Cmax of 24 was 280.23 μg/L and resulted about 3-fold higher than the Cmax of 1e assessed in similar conditions.

Based on the observed biphasic elimination profiles, we used the Akaike Information Criterion (AIC) for comparing how one- and two-compartment models with a different weight fit to the plasma concentrations of 24 and 1e. A two-compartment model provided the best fit to the data, and it indicated that 24 has a half-life of distribution (t1/2α) 3.6-fold higher than 1e (12.78 and 46.40 min, respectively), which is consistent with the improved stability of 24 compared to 1e showed in mouse liver microsomal studies.

We then evaluated the tolerability of 24 in mice. Except for certain models of pancreatic cancer,32 the use of CQ as a single anticancer agent does not impair tumor growth in many animal models. In addition, doses of CQ lower than 50 mg/kg (ip daily) are completely ineffective in xenograft models.33 This dose of CQ corresponds to 138 μmol/kg. Of note, a similar dose of Lys05 (Figure 1), a CQ derivative compound showing a higher autophagy inhibitory activity than CQ, has been reported to not be tolerated by animals, producing arched backs and lethargy after 2 days of an ip treatment.34

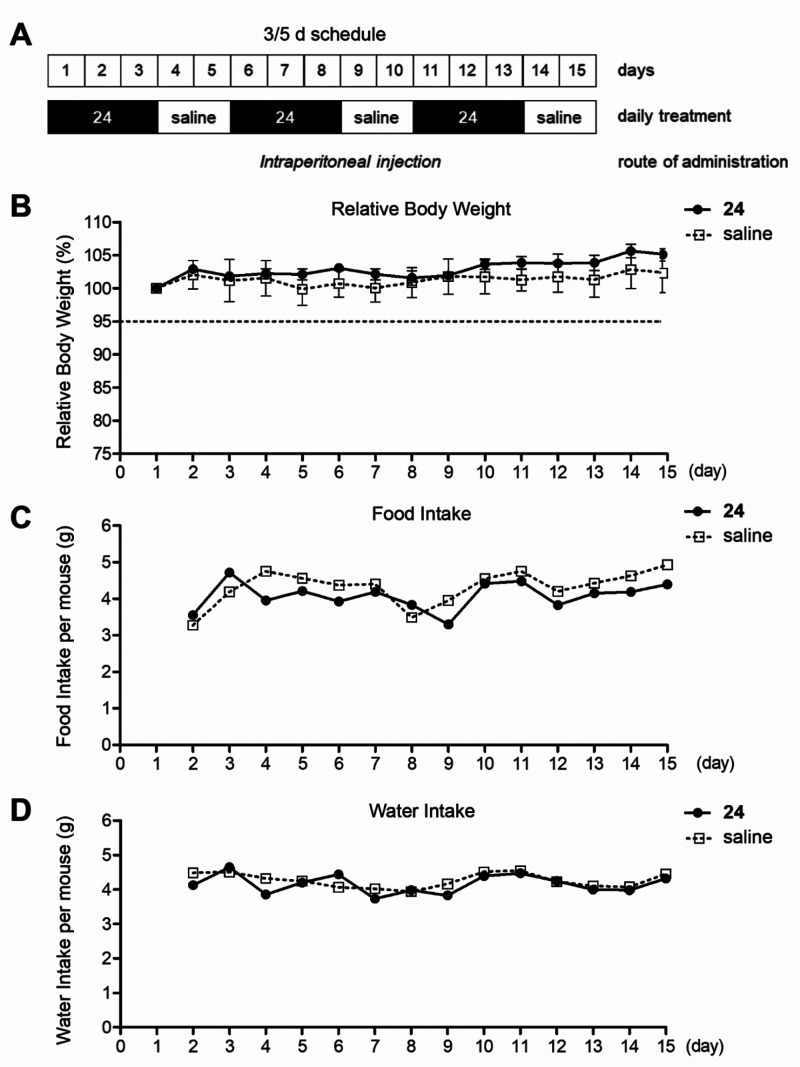

Therefore, we first tested the tolerability of 24 in CD1 female mice treated with daily ip injections at the dose of 138 μmol/kg of compound, corresponding to 62 mg/kg. In contrast to the reported observation on Lys05, we did not observe clear signs of arched backs and lethargy in mice treated with this dose of 24. However, after 2 days of treatment, animal body weight was significantly reduced (data not shown). We thus evaluated the tolerability in mice treated with 138 μmol/kg (62 mg/kg) every other day or with 69 μmol/kg (31 mg/kg) daily over an 8-day period. Both treatments displayed only a minor reduction in body weight after 8 days (≤5%; Supporting Information, Figure S3). To identify a treatment schedule producing negligible effects on the weight of mice for avoiding potential confounding factors in our in vivo efficacy study, we thus evaluated the tolerability of 24 in mice treated with 69 μmol/kg (31 mg/kg) of compound dosed for 3 days of daily treatment with 2 days off treatment (3/5 d schedule) (Figure 5A). This schedule was well tolerated by animals over a 15-day period and treated mice did not show significant differences in body weight, water, and food intake compared to saline-treated animals (Figure 5B–D). Therefore, this treatment schedule was adopted for the in vivo efficacy study of 24.

Figure 5.

Tolerability of 24 in female CD1 mice. (A) Female CD1 mice were treated with 69 μmol/kg (31 mg/kg) of 24 dosed for 3 days of daily treatment with 2 days off treatment (3/5 d schedule). (B) Animal body weight, (C) food intake and (D) water intake were monitored daily over a 15-day period. The weight of mice the day before starting the treatment was set as 100% and used for calculating the relative body weight (%) and is shown as mean ± SEM, n = 3.

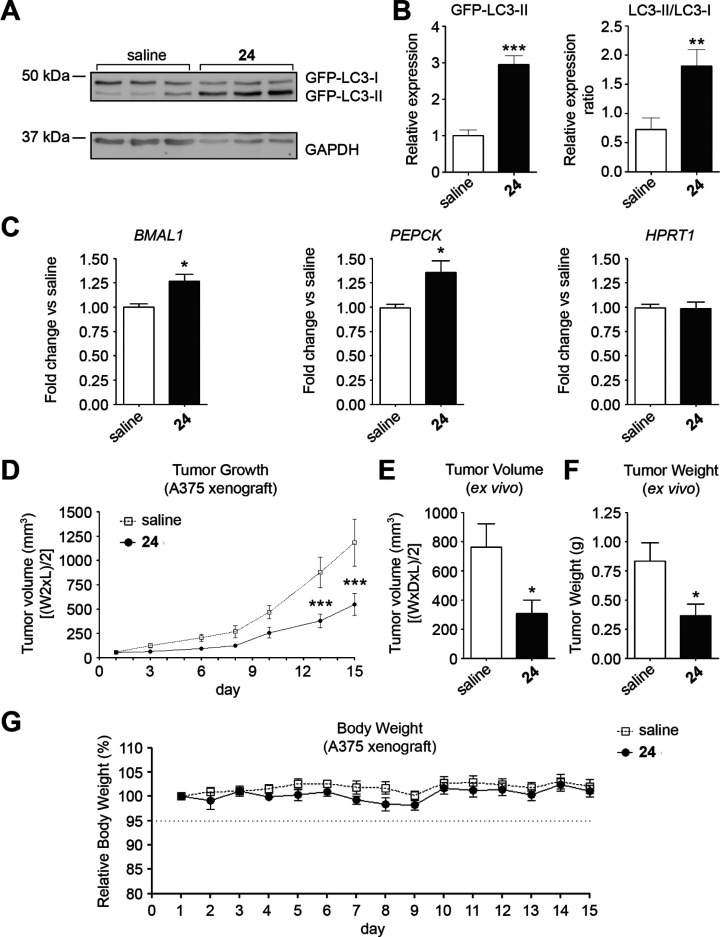

To this aim, we decided to take advantage of our GFP-A375 reporter cells. In fact, the expression of the exogenous LC3 chimeric protein permits the specific evaluation of tumor autophagy by immunoblotting from tumor protein extracts. We thus tested whether an acute treatment of 24 could affect autophagy and circadian gene expression in A375 flank xenografts. Accordingly, female NMRI-Foxn1nu mice were subcutaneously injected in the flank with reporter A375 cells and xenografts matched for tumor size received an ip injection of 24 (30 mg/kg) or saline for 2 days. After 48 h of treatment, mice were euthanized, and tumors were processed for immunoblot and qRT-PCR analyses.

Indicating that 24 affected tumor autophagy in vivo, 24-treated tumors showed increased GFP-LC3-II levels and LC3-II/LC3-I ratio compared with saline treated tumors (Figure 6A,B). In addition, RNA samples from tumors treated with 24 showed a significantly higher expression of the REV-ERB target genes, BMAL1 and PEPCK, compared with control tumors (Figure 6C).

Figure 6.

In vivo anticancer activity of 24 in the A375 xenograft tumor model. (A) Female NMRI-Foxn1nu mice were subcutaneously injected in the flank with reporter A375 cells and xenografts matched for tumor size received an ip injection of 24 (30 mg/kg) or saline for 2 days. After 48 h from the first injection, mice were euthanized, and tumors were collected and processed for immunoblot with an anti-LC3B antibody to evaluate the levels of GFP-LC3-I and GFP-LC3-II proteins. GAPDH was used as a loading control. (B) Quantification of immunoblot analysis from tumors collected as in A. GFP-LC3-I and GFP-LC3-II expression were normalized by GAPDH levels and are shown as mean ± SEM, n = 3, **P < 0.01 and ***P < 0.001, 24 versus saline (unpaired two-tail t test). (C) Expression of REV-ERB-regulated BMAL1 and PEPCK genes in tumors collected as in A. The HPRT1 gene was used as representative of a REV-ERB independent gene. Shown as relative expression normalized by GAPDH. The value in the vehicle sample was set to 1. Reported as mean ± SEM, n = 3, *P < 0.05; **P < 0.01 24 versus saline, unpaired two-tail t test. (D) Female NMRI-Foxn1nu mice bearing tumors matching for tumor volume were treated with 24 (30 mg/kg, ip) or saline dosed for 3 days of daily treatment with 2 days off treatment (3/5 d schedule). Tumor growth was monitored by digital caliper until several tumors in the saline-group reached a volume close to the defined human end point (day 15). Shown as mean tumor volume mean ± SEM, n = 8. ***P < 0.001, 24 versus saline, two-way ANOVA with Bonferroni posttest analysis. (E) On day 15, tumors were excised and tumor volumes were calculated according to the formula [(W × D × L)/2]. Shown as mean tumor volume mean ± SEM, n = 8. *P < 0.05, two-tailed Mann–Whitney t test. (F) The weight of excised tumors is shown as mean ± SEM, n = 8. *P < 0.05, two-tailed Mann–Whitney t test. (G) Animal body weight was monitored daily. The weight of mice the day before starting the treatment was set as 100% and used for calculating the relative body weight (%). Shown as mean ± SEM, n = 8.

We next evaluated the effects of 24 on tumor growth in A375 xenografts. Female NMRI-Foxn1nu mice bearing tumors were divided in two groups matching for tumor volume and treated with 24 (30 mg/kg, ip) or saline according to the 3/5d treatment schedule. Tumor growth was monitored by digital caliper until several tumors in the saline-group reached a volume close to the defined human end point (day 15, Figure 6D). Animals were sacrificed and tumors were excised and weighed. In addition, length, height, and depth of excised tumors were measured to obtain a more precise assessment of tumor volumes (Figure 6E).

Tumor growth curves indicated that the treatment with compound 24 produced a significant reduction of tumor growth compared to saline (Figure 6D; tumor growth inhibition = 55%).

On day 15, 24-treated excised tumors showed a significant 60% reduction in the average tumor volume compared with saline (307.7 vs 761.9 mm3; P = 0.0127 two-tailed Mann–Whitney t test, Figure 6E). In addition, 24-treated tumors showed a 56% significant reduction in the average tumor weight compared with controls (0.365 vs 0.836 g; P = 0.0127 two-tailed Mann–Whitney t test, Figure 6F). Consistent with our tolerability analysis in female CD1 mice, 24 treatment was tolerated by NMRI-Foxn1nu mice bearing A375 xenografts having negligible effects on body weight (Figure 6G).

Conclusions

Growing evidence on the role of autophagy in affecting cancer progression and response to chemotherapy has been making the pharmacological inhibition of this process a promising strategy for the development of novel anticancer therapies. We previously showed that when the autophagy flux is blocked in combination with the inhibition of the circadian nuclear receptor, REV-ERB, the autophagy-mediated cell death of cancer cells is augmented. We also identified the first class of dual REV-ERB and autophagy inhibitors showing a greater in vitro anticancer activity than the single autophagy inhibitor, CQ, against different cancer cells with diverse origins. In this study, we described the lead optimization strategy around the early lead 1e that resulted in the identification of analogues with improved biological and drug-like profiles, such as compounds 21, 24, and 25 (please compare Table 1 with Tables 3 and 6, and Table 4 with Tables 5 and 7).

The most promising candidate, 24, shows optimal physicochemical and metabolic stability properties in liver microsomes from different species (Table 7).

Compound 24 presents an improved ability to block the autophagic flux (Figure 4) and it has a greater in vitro anticancer activity than 1e against different cancer cells with diverse origins (Table 8).

Our data indicate that compound 24 inhibits REV-ERB transcriptional activity in the low μM range; this potency, on the one hand is comparable to that of 1e (Figure 3), and on the other hand is similar to those of the single REV-ERB inhibitors SR8278 and GSK1362 (Figure 1).35,36 For example, in luciferase transcriptional reporter assays GSK1362’s EC50 is 2.5 μM36 compared to 24’s EC50 of 3.6 μM (Figure 3). However, both SR8278 and GSK1362 were reported to have unfavorable PK profiles that limit their usage in vivo.20 In marked contrast, 24 shows desirable PK profile in mice following ip administration and it can block tumor autophagy and REV-ERB transcriptional activity in mice bearing melanoma A375 tumors (Figure 6).

Moreover, 24 shows a significant anticancer activity as a single agent in melanoma xenograft mouse model at a dose that was completely tolerated by both CD1 mice and NMRI-Foxn1nu mice bearing A375 xenografts (Figures 5 and 6). Nonetheless, future studies will focus on investigating additional treatment regimens for improving the in vivo anticancer activity of our compound. In this respect, it is worthy notice that because 24 targets a nuclear receptor with a different circadian expression pattern in cancerous and noncancerous cells,37 this compound represents an optimal candidate for evaluating the efficacy of a chronotherapeutic approach to maximize the efficacy and minimize possible adverse effects.38,39

In addition, because both the circadian cycle and autophagy have been related to cancer drug resistance,30,40−4224 constitutes a valuable experimental candidate in dedicated preclinical studies for identifying improved drug combination therapies.

Experimental Section

Chemistry

Synthetic Materials and Methods

Solvents and reagents were obtained from commercial suppliers and were used without further purification. Automated column chromatography purifications were done using a Teledyne ISCO apparatus (CombiFlash Rf 200) with prepacked SiO2 columns of different sizes (from 4 g to 80 g). Mixtures of increasing polarity of Cy and EtOAc or CH2Cl2 and MeOH were used as eluents. TLC analyses were performed using a precoated TLC sheets ALUGRAM Xtra SIL G/UV254 from Macherrey-Nagel. The visualization was done by UV light (254 nm) or staining with KMnO4 or H3[Mo12PO40]·12H2O. NMR experiments of all the intermediates and final compounds were run on a Bruker Avance III 400 system (400.13 MHz for 1H NMR and 100.62 MHz for 13C NMR) equipped with a BBI probe and Z-gradients. Spectra were acquired at 300 K using deuterated dimethyl sulfoxide (DMSO-d6) or deuterated chloroform (CDCl3) as solvent. Chemical shifts for 1H and 13C NMR spectra were recorded in parts per million using the residual nondeuterated solvent as the internal standard (for DMSO-d6: 2.50 ppm, 1H NMR, 39.52 ppm; 13C NMR, for CDCl3, 7.26 ppml 1H and 77.16 ppm, 13C NMR). Data are reported as follows: chemical shift (ppm), multiplicity (indicated as bs, broad singlet; s, singlet; d, doublet; t, triplet; q, quartet; p, quintet, m, multiplet, and combinations thereof), coupling constants (J) in hertz (Hz), and integrated intensity. Quantitative 1H NMR analyses of the freshly prepared 10 mM DMSO-d6 stock solutions (used for biological screenings) of the final compounds were performed using the PULCON method (Pulse Length Based Concentration determination, Bruker software, topspin 3.0. Refs: (a) ref (46) and (b) ref (47). UPLC/MS analyses of all the intermediates and final compounds were performed on Waters Acquity UPLC/MS system consisting of a single quadrupole detector (SQD) mass spectrometer (MS) equipped with an electrospray ionization (ESI) interface and a photodiode array detector (PDA). The PDA range was 210–400 nm. Analyses were performed on an Acquity UPLC BEH C18 column (50 mm × 2.1 mm ID, particle size 1.7 μm) with a VanGuard BEH C18 precolumn (5 mm × 2.1 mm ID, particle size 1.7 μm). The mobile phase was 10 mM NH4OAc in H2O at pH 5 adjusted with AcOH (A) and 10 mM NH4OAc in MeCN/H2O (95:5) at pH 5 (B). ESI in both positive and negative modes was used in the mass scan range of 100–650 Da. Analyses were performed with methods A, B, C, or D. Method A: gradient 0–100% B over 3.0 min. Flow rate 0.5 mL min–1. Temperature 40 °C. Method B: gradient 5–100% B over 3.0 min. Flow rate 0.5 mL min–1. Temperature 40 °C. Method C: gradient 50–100% B over 3.0 min. Flow rate 0.5 mL min–1. Temperature 40 °C. Method D: gradient 80–100% B over 3.0 min. Flow rate 0.5 mL min–1. Temperature 40 °C. UPLC/MS analyses of the final compounds were performed using freshly prepared 10 mM DMSO-d6 stock solutions (used for biological screenings), diluted 20-fold or 100-fold in MeCN/H2O (1:1) and directly analyzed. The analysis was performed on an Acquity UPLC BEH C18 column (100 mm × 2.1 mm ID, particle size: 1.7 μm) with a VanGuard BEH C18 precolumn (5 mm × 2.1 mm ID, particle size: 1.7 μm) at 40 °C using 10 mM NH4OAc in H2O at pH 5 adjusted with AcOH (A) and 10 mM NH4OAc in MeCN-H2O (95:5) at pH 5 (B) as mobile phase at 0.5 mL/min. Method E: gradient 10–90% B over 6.0 min. Flow rate 0.5 mL min–1. Temperature 40 °C. The detection wavelength (λ) was set at 215 nm for relative purity determination. Rt (min) of the final compounds under method E UPLC/MS analytical conditions are reported in Supporting Information, Table S2. Accurate mass measurements were performed on a SCIEX TripleTOF high-resolution LC-MS using a Waters UPLC Acquity chromatographic system (Waters, Milford, MA, USA) coupled to a TripleTOF 5600+ mass apectrometer (Sciex, Warrington, UK) equipped with a NanoSpray III Ion source. The analyses were run on an Acquity UPLC BEH C18 column (50 mm × 2.1 mm ID, particle size 1.7 μm), using H2O + 0.1% HCOOH (A) and CH3CN + 0.1% HCOOH as mobile phase. All final compounds displayed ≥95% purity as determined by NMR and UPLC/MS analysis.

General Procedure for Organometallic Nucleophilic Addition Reaction (Procedure A)

Method A: To a solution of the appropriate aryl bromide (1.0 equiv) in anhydrous THF (0.5 M) at −78 °C under N2 atmosphere, a solution of n-BuLi (2.5 M in hexane, 1.0 equiv) was added dropwise. The reaction mixture was stirred for 1 h at the same temperature, and then the cyclopentanone (1.3 equiv) was added. The reaction mixture was quenched with saturated aqueous NH4Cl and extracted with CH2Cl2. The organic layers were combined, washed with brine, dried over Na2SO4, filtered, and the solvent was evaporated under reduced pressure. The crude was used in the next step without further purification. Method B: To a solution of cyclopentanone (1.0 equiv) in anhydrous THF (5.0 M), the appropriate Grignard reagent (1.2 equiv) was added dropwise at 0 °C under N2 atmosphere. The reaction mixture was quenched with saturated aqueous NH4Cl and extracted with CH2Cl2. The organic layers were combined, washed with brine, dried over Na2SO4, filtered. and the solvent was evaporated under reduced pressure. The crude was used in the next step without further purification.

General Procedure for Nucleophilic Substitution Reaction (SN1) (Procedure B)

To a solution of the appropriate alcohol (1.0 equiv) in anhydrous CH2Cl2 (0.4 M), NaN3 (2.2 equiv) was added under N2 atmosphere. The reaction was stirred at −5 °C, and then a solution of TFA (8.2 equiv) in anhydrous CH2Cl2 was slowly added dropwise. The resulting suspension was stirred at 0 °C for 1 h. To the cold solution, distilled H2O was added dropwise, followed by the addition of 1:1 mixture of distilled H2O and 28% aqueous NH4OH solution dropwise. After 30 min, the reaction mixture was extracted with CH2Cl2, and the organic layers were combined, dried over Na2SO4, filtered, and concentrated under reduced pressure. The crude was purified by column chromatography, eluting with Cy.

General Procedure for Azide Reduction Reaction (Procedure C)

To a solution of the appropriate azide (1.0 equiv) in anhydrous THF (0.25 M), LiAlH4 (2.0 M in THF, 1.0 equiv) was added dropwise at 0 °C under N2 atmosphere. The reaction mixture was stirred at rt until the disappearance of the starting material, as indicated by UPLC/MS analysis. The reaction was quenched with a solution of NaOH (1N) and stirred for 30 min. The mixture was extracted with CH2Cl2, the organic layers were combined, dried over Na2SO4, filtered, and the solvent was removed under reduced pressure. The crude was used in the next step without further purification.

General Procedure for the Synthesis of 1-Substituted-Phenyl Cyclopentylamines (Procedure D)

1,4-Dibromobutane (2.0 equiv) dissolved in anhydrous Et2O (0.4 M) was added dropwise to Mg turnings (4.4 equiv) covered with 1 mL of the dibromide solution at 40 °C. After the formation of the Grignard reagent, a solution of the appropriate aryl nitrile in anhydrous Et2O (1.0 M) was added at rt. After stirring for an additional 30 min, a solution of Ti(OiPr)4 in anhydrous Et2O or THF (2.0 M) was added dropwise. The reaction was stirred at rt for 24 h, and then 10% aqueous solution of NaOH was added. The mixture was filtered and the filtrate was extracted with CH2Cl2. The organic layers were combined, dried over Na2SO4, filtered, and the solvent was removed under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc as indicated in each case.

General Procedure for Cyclization Reaction (Procedure E)

To a solution of 1,4-dibromobutane (1.5 equiv) and the appropriate benzyl nitrile in anhydrous THF (0.15 M), LiHMDS (1.0 M in THF, 1.2 equiv) was added dropwise at 0 °C. The reaction was stirred at rt for 2 h. Then, LiHMDS (1.0 M in THF, 1.2 equiv) was added dropwise at 0 °C. The reaction mixture was warmed up to rt and stirred on. The reaction was quenched with brine and extracted with EtOAc. The combined organic layers were dried over Na2SO4, filtered, and the solvent was concentrated under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc as indicated in each case.

General Procedure for Hydrolysis Reaction (Procedure F)

To the appropriate nitrile (1.0 equiv) H2O and H2SO4 (ratio 1:1, 0.7 M) was added. The reaction was stirred at 120 °C on in a sealed tube. The mixture was poured onto ice-H2O and then extracted with EtOAc. The combined organic layers were dried over Na2SO4, filtered, and the solvent was concentrated under reduced pressure. The crude was used in the next step without further purification.

General Procedure for the Synthesis of Phosphonium Salts (Procedure G)

To a solution of the appropriate alkyl bromide (1.0 equiv) in anhydrous toluene (0.2 M) was added PPh3 (1.0 equiv) under N2 atmosphere. The reaction was stirred at reflux. The reaction was cooled to rt, and the solid was filtered off and washed with cold toluene. The solid was used in the next step without further purification.

General Procedure for the Synthesis of Phosphonates (Michaelis–Arbuzov Reaction) (Procedure H)

To a solution of the appropriate alkyl bromide (1.0 equiv) in anhydrous toluene (0.8 M) was added P(OEt)3 (3.0 equiv). The reaction was stirred at reflux in a sealed tube. The reaction was cooled to rt, and the solvent was evaporated under reduced pressure. The crude was purified by column chromatography eluting with Cy/EtOAc or used as crude, in the next step without further purification, as indicated in each case.

General Procedure for Wittig Reaction (Procedure I)

To a suspension of the appropriate phosphonium salt (1.0 equiv) in anhydrous THF (0.3 M), LiHMDS (1.0 M in THF, 1.5 equiv) was added dropwise at 0 °C under N2 atmosphere. After 15 min, a solution of the appropriate ketone (1.5 equiv) in anhydrous THF (1.0 M) was added dropwise. The reaction was stirred at rt or at 80 °C, as indicated in each case. The reaction mixture was quenched with H2O and extracted with EtOAc. The organic layers were combined, washed with brine, dried over Na2SO4, filtered, and concentrated under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc as indicated in each case.

General Procedure for Horner–Wadsworth–Emmons Reaction (Procedure J)

Method A: To a solution of the appropriate phosphonate (1.0 equiv) in anhydrous THF (0.3 M), LiHMDS (1.0 M in THF, 1.2 equiv) was added dropwise at −40 °C under N2 atmosphere. After 15 min, a solution of the appropriate ketone in anhydrous THF (1.0 M) was added dropwise. The reaction was stirred at rt. The reaction mixture were quenched with H2O and extracted with EtOAc. The organic layers were combined, washed with brine, dried over Na2SO4, filtered, and concentrated under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc as indicated in each case. Method B: To a solution of the appropriate phosphonate (1.0 equiv) in anhydrous THF (0.3 M), KOtBu (1 or 3 equiv, as indicated in each case) was added dropwise at 0 °C under N2 atmosphere. After 15 min, a solution of the appropriate ketone in anhydrous THF (1.0 M) was added dropwise. The reaction was stirred at rt. The reaction mixture were quenched with H2O and extracted with EtOAc. The organic layers were combined, washed with brine, dried over Na2SO4, filtered, and concentrated under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc as indicated in each case.

General Procedure for Pd Catalyzed Hydrogenation Reaction (Procedure K)

Method A: To a solution of the appropriate alkene (1.0 equiv) in MeOH (0.4 M) were added 10% Pd/C (0.15 equiv) and cyclohexene (25 equiv). The reaction mixture was stirred at reflux until the disappearance of the starting material, as indicated by UPLC/MS analysis. The suspension was filtered through a pad of Celite, and the filtrate was quickly evaporated under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc, or used in the next step without further purification, as indicated in each case. Method B: To a solution of the appropriate alkene (1.0 equiv) in MeOH (0.15 M) were added Et3SiH (10 equiv) and 10% Pd/C (0.02 equiv). The reaction mixture was stirred at rt until the disappearance of the starting material, as indicated by UPLC/MS analysis. The suspension was filtered through a pad of Celite, and the filtrate was quickly evaporated under reduced pressure. The crude was used in the next step without further purification.

General Procedure for Carbonyl Compounds Reduction Reaction (Procedure L)

Method A: To a solution of appropriate carbonyl compound (1.0 equiv) in anhydrous THF (0.2 M) LiAlH4 (2 M in THF, 2 equiv) was added dropwise at 0 °C under N2 atmosphere. The reaction mixture was stirred at rt until the disappearance of the starting material, as indicated by UPLC/MS analysis. The reaction mixture was quenched with a solution of NaOH (1N), and it was stirred for 15 min. Then, the mixture was extracted with CH2Cl2. The organic layers were combined, dried over Na2SO4, filtered, and concentrated under reduced pressure. The crude was used in the next step without further purification. Method B: To a solution of the appropriate carbonyl compound (1.0 equiv) in anhydrous THF (0.2 M), DIBALH (1 M in hexane, 1.5 equiv) was added dropwise at 0 °C under N2 atmosphere. The reaction mixture was stirred at rt until the disappearance of the starting material, as indicated by UPLC/MS analysis. The reaction mixture was quenched with H2O and the extracted with CH2Cl2. The organic layers were combined, dried over Na2SO4, filtered, and concentrated under reduced pressure. The crude was purified by column chromatography, eluting with Cy/EtOAc, or used in the next step without further purification, as indicated in each case.

General Procedure for Oxidation Reaction (Procedure M)

To a solution of the appropriate alcohol (1.0 equiv) in Et2O or CH2Cl2 or CH2Cl2/iPrOH (0.1 M) was added activated MnO2 (10.0 equiv). The reaction mixture was stirred at rt until the disappearance of the starting material, as indicated by UPLC/MS analysis. The suspension was filtered through a pad of Celite, and the filtrate was quickly evaporated under reduced pressure. The crude was used in the next step without further purification.

General Procedure for Reductive Amination Reaction (Procedure N)

To a solution of the appropriate aldehyde (1.0 equiv) in anhydrous CH2Cl2 (0.1 M), a solution of the appropriate primary amine (1.0 equiv) in anhydrous CH2Cl2 (0.1 M) was added. The reaction was stirred at rt on. Then, NaBH(OAc)3 (2.0 equiv) was added, and the reaction was stirred at rt. The reaction mixture was quenched with 10% aqueous solution of K2CO3 and extracted with CH2Cl2. The organic layers were combined, dried over Na2SO4, filtered, and the solvent was removed under reduced pressure. The crude was purified by column chromatography, eluting with CH2Cl2/MeOH as indicated in each case. The free base was dissolved in CH2Cl2 (0.1 M) and HCl (4 M in 1,4-dioxane, 19.0 equiv) was added. Evaporation of the solvent afforded the desired compound. Synthesis of 1-(2-chloro-4-fluoro-phenyl)cyclopentanol (28a). Compound 28a was prepared according to general procedure A (method A) using compound 27a (0.58 mL, 4.77 mmol), n-BuLi (2.07 mL, 4.77 mmol), and cyclopentenone (0.52 mL, 6.21 mmol) in anhydrous THF (9.54 mL). The crude was used in the next step without further purification. UPLC/MS (method B) Rt 2.29 min. MS (ES): C11H12ClFO, no ionization. 1H NMR (400 MHz, CDCl3) δ 7.62–7.54 (m, 1H), 7.16–7.09 (m, 1H), 7.00–6.91 (m, 1H), 2.25–2.03 (m, 2H), 2.00–1.73 (m, 6H).

Synthesis of 1-(4-Fluoro-2-methoxy-phenyl)cyclopentanol (28b)

Compound 28b was prepared according to general procedure A (method A) using compound 27b (0.62 mL, 4.88 mmol), n-BuLi (2.93 mL, 7.32 mmol), and cyclopentenone (0.66 mL, 7.80 mmol) in anhydrous THF (9.76 mL). The crude was used in the next step without further purification. UPLC/MS (method B) Rt 2.21 min. MS (ES): C12H15FO2 requires, 210 m/z; found, 193 m/z [M – H2O]+. 1H NMR (400 MHz, CDCl3) δ 7.20 (dd, J = 6.9, 9.2 Hz, 1H), 6.63–6.57 (m, 1H), 6.37–6.34 (m, 1H), 3.85 (s, 3H), 1.85–1.67 (m, 2H), 1.67–1.50 (m, 6H).

Synthesis of 1-(3,4-Difluorophenyl)cyclopentanol (28c)

Compound 28c was prepared according to general procedure A (method B) using compound 27c (28.54 mL, 14.27 mmol) and cyclopentenone (0.63 mL, 11.89 mmol) in anhydrous THF (2.00 mL). The crude was used in the next step without further purification. UPLC/MS (method B) Rt 2.32 min. MS (ES): C11H12F2O no ionization. 1H NMR (400 MHz, CDCl3) δ 7.35–7.27 (m, 1H), 7.21–7.15 (m, 1H), 7.14–7.05 (m, 1H), 2.06–1.90 (m, 2H), 1.89–1.75 (m, 6H).

Synthesis of 1-(3-Chloro-4-fluoro-phenyl)cyclopentanol (28d)

Compound 28d was prepared according to general procedure A (method B) using 27d (28.54 mL, 14.27 mmol) and cyclopentenone (0.63 mL, 11.89 mmol) in anhydrous THF (2.00 mL). The crude was used in the next step without further purification. UPLC/MS (method B) Rt 2.16 min. MS (ES): C11H12ClFO no ionization. 1H NMR (400 MHz, CDCl3) δ 7.42–7.35 (m, 1H), 7.25–7.19 (m, 1H), 7.11–7.04 (m, 1H), 2.03–1.91 (m, 2H), 1.90–1.78 (m, 4H).

Synthesis of 1-(1-Azidocyclopentyl)-2-chloro-4-fluoro-benzene (29a)

Compound 29a was prepared according to general procedure B using alcohol 28a (0.79 g, 3.68 mmol), NaN3 (0.53 g, 8.10 mmol) and TFA (2.31 mL, 30.20 mmol) in anhydrous CH2Cl2 (9.20 mL). The crude was purified by column chromatography (SiO2), eluting with Cy to afford 29a as yellow oil (0.054 g, 5% over 2 steps). UPLC/MS (method C) Rt 1.58 min. MS (ES): C11H11ClFN3 requires, 239 m/z; found, 211 m/z [M – N2]+. 1H NMR (400 MHz, CDCl3) δ 7.43 (dd, J = 6.0, 8.8 Hz, 1H), 7.20 (dd, J = 2.7, 8.4 Hz, 1H), 6.96 (ddd, J = 2.7, 7.5, 8.9 Hz, 1H), 2.52–2.39 (m, 2H), 2.15–2.03 (m, 2H), 1.96–1.76 (m, 4H).

Synthesis of 1-(1-Azidocyclopentyl)-4-fluoro-2-methoxy-benzene (29b)

Compound 29b was prepared according to general procedure B using alcohol 28b (0.92 g, 4.37 mmol), NaN3 (0.62 g, 9.62 mmol) and TFA (2.74 mL, 35.84 mmol) in anhydrous CH2Cl2 (10.90 mL). The crude was purified by column chromatography (SiO2), eluting with Cy to afford 29b as a brown oil (0.123 g, 4% over 2 steps). UPLC/MS (method B) Rt 1.90 min. MS (ES): C12H14FN3O no ionization. 1H NMR (400 MHz, CDCl3) δ 7.27 (dd, J = 6.8, 8.6 Hz, 1H), 6.68–6.58 (m, 2H), 3.85 (s, 3H), 2.41–2.33 (m, 2H), 2.03–1.75 (m, 6H).

Synthesis of 4-(1-Azidocyclopentyl)-1,2-difluoro-benzene (29c)

Compound 29c was prepared according to general procedure B using alcohol 28c (1.14 g, 5.76 mmol), NaN3 (0.82 g, 12.67 mmol), and TFA (3.62 mL, 47.23 mmol) in anhydrous CH2Cl2 (14.40 mL). The crude was purified by column chromatography (SiO2), eluting with Cy to afford 29c as yellow oil (0.172 g, 7% over 2 steps). UPLC/MS (method C) Rt 2.11 min. MS (ES): C11H11F2N3 no ionization. 1H NMR (400 MHz, CDCl3) δ 6.94–6.86 (m, 1H), 6.85–6.78 (m, 2H), 1.91–1.78 (m, 2H), 1.66–1.46 (m, 6H).

Synthesis of 4-(1-Azidocyclopentyl)-2-chloro-1-fluoro-benzene (29d)

Compound 29d was prepared according to general procedure B using alcohol 28d (1.23 g, 5.73 mmol), NaN3 (0.82 g, 12.61 mmol), and TFA (3.60 mL, 46.99 mmol) in anhydrous CH2Cl2 (14.30 mL). The crude was purified by column chromatography (SiO2), eluting with Cy to afford 29d as a colorless oil (0.220 g, 11% over 2 steps). UPLC/MS (method B) Rt 1.87 min. MS (ES): C11H11ClFN3 no ionization. 1H NMR (400 MHz, CDCl3) δ 7.46 (dd, J = 2.4, 6.9 Hz, 1H), 7.29 (ddd, J = 2.4, 4.5, 8.6 Hz, 1H), 7.14 (t, J = 8.7 Hz, 1H), 2.25–2.12 (m, 2H), 1.99–1.82 (m, 6H).

Synthesis of 1-(2-Chloro-4-fluoro-phenyl)cyclopentanamine (30a)

Compound 30a was prepared according to the general procedure C using azide 29a (0.054 g, 0.24 mmol), LiAlH4 (0.12 mL, 0.24 mmol), in anhydrous THF (1.00 mL). The crude was used in the next step without further purification. UPLC/MS (method B): Rt 1.58 min. MS (ES): C11H13ClFN requires, 213 m/z; found, 214 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.43 (dd, J = 6.2, 8.9 Hz, 1H), 7.12 (dd, J = 2.7, 8.4 Hz, 1H), 6.91 (ddd, J = 2.7, 7.7, 8.8 Hz, 1H), 2.19–1.86 (m, 6H), 1.81–1.69 (m, 2H).

Synthesis of 1-(4-Fluoro-2-methoxy-phenyl)cyclopentanamine (30b)

Compound 30b was prepared according to the general procedure C using azide 29b (0.123 g, 0.52 mmol), LiAlH4 (0.31 mL, 0.63 mmol), in anhydrous THF (2.00 mL). The crude was used in the next step without further purification. UPLC/MS (method B): Rt 1.54 min. MS (ES): C12H16FNO requires, 209 m/z; found, 210 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.23 (dd, J = 6.8, 8.5 Hz, 1H), 6.65–6.55 (m, 2H), 3.84 (s, 3H), 2.09–1.82 (m, 6H), 1.76–1.65 (m, 2H).

Synthesis of 1-(3,4-Difluorophenyl)cyclopentanamine (30c)

Compound 30c was prepared according to the general procedure C using azide 29c (0.172 g, 0.77 mmol), LiAlH4 (0.72 mL, 1.54 mmol), in anhydrous THF (3.08 mL). The crude was used in the next step without further purification. UPLC/MS (method B): Rt 1.27 min. MS (ES): C11H13F2N requires, 197 m/z; found, 198 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.34–7.29 (m, 1H), 7.21–7.14 (m, 1H), 7.12 (dd, J = 8.2, 10.1 Hz, 1H), 2.09–1.62 (m, 8H).

Synthesis of 1-(3-Chloro-4-fluoro-phenyl)cyclopentanamine (30d)

Compound 30d was prepared according to the general procedure C using azide 29d (0.22 g, 0.92 mmol), LiAlH4 (0.46 mL, 0.92 mmol), in anhydrous THF (3.70 mL). The crude was used in the next step without further purification. UPLC/MS (method B): Rt 1.44 min. MS (ES): C11H13ClFN requires, 213 m/z; found, 214 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.52 (dd, J = 2.4, 7.2 Hz, 1H), 7.33 (ddd, J = 2.4, 4.6, 8.7 Hz, 1H), 7.07 (t, J = 8.7 Hz, 1H), 2.01–1.82 (m, 8H).

Synthesis of 1-(4-Fluorophenyl)cyclopentanamine (30e)

Compound 30e was prepared according to procedure D using 1,4-dibromobutane (1.08 g, 5.00 mmol), Mg turnings (0.27 g, 11.0 mmol) in anhydrous Et2O (12.50 mL), nitrile 31a (0.30 g, 2.50 mmol) in anhydrous Et2O (2.50 mL), Ti(OiPr)4 (0.75 mL, 2.05 mmol) in anhydrous Et2O (1.50 mL). The crude was purified by column chromatography (SiO2), eluting with CH2Cl2/MeOH from 100 to 95:5 to afford 30e as a yellowish oil (0.101 g, 22%). UPLC/MS (method B): Rt 1.30 min. MS (ES): C11H14FN requires, 179 m/z; found, 197 m/z [M+NH4]+. 1H NMR (400 MHz, CDCl3) δ 7.46–7.39 (m, 2H), 7.03–6.95 (m, 2H), 2.00–1.74 (m, 8H).

Synthesis of 2-(1-Aminocyclopentyl)-5-fluoro-phenol (30f)

Compound 30f was prepared according to the general procedure D using 1,4-dibromobutane (1.08 g, 5.00 mmol), Mg turnings (0.27 g, 11.00 mmol), in anhydrous Et2O (12.50 mL), nitrile 31b (0.57 g, 2.50 mmol) in anhydrous Et2O (2.50 mL), Ti(OiPr)4 (0.75 mL, 2.50 mmol) in anhydrous Et2O (1.25 mL). The crude was purified by column chromatography (SiO2), eluting with Cy/EtOAc from 100 to 50:50 to afford 30f as a brownish solid (0.99 g, 20%). UPLC/MS (method B): Rt 1.33 min. MS (ES): C11H14FNO requires, 195 m/z; found, 196 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.06–6.98 (m, 1H), 6.56–6.51 (m, 1H), 6.49–6.40 (m, 1H), 5.27 (br s, 1H), 2.12–2.05 (m, 2H), 1.90–1.76 (m, 6H).

Synthesis of 5-(1-Aminocyclopentyl)-2-fluoro-phenol (30g)

Compound 30g was prepared according to procedure D using 1,4-dibromobutane (1.33 g, 6.16 mmol), Mg turnings (0.33 g, 13.50 mmol) in anhydrous Et2O (15.40 mL), nitrile 31c (0.70 g, 3.08 mmol) in anhydrous Et2O (3.00 mL), Ti(OiPr)4 (2.31 mL, 3.08 mmol) in anhydrous Et2O (1.50 mL). The crude was purified by column chromatography (SiO2), eluting with CH2Cl2/MeOH from 95:5 to 80:20 to afford 30g as a white solid (0.154 g, 26%). UPLC/MS (method A): Rt 1.18 min. MS (ES): C11H14FNO requires, 195 m/z; found, 196 m/z [M + H]+. 1H NMR (400 MHz, DMSO-d6) δ 7.06 (dd, J = 2.3, 8.9 Hz, 1H), 6.99 (dd, J = 8.5, 11.2 Hz, 1H), 6.85 (ddd, J = 2.4, 4.3, 8.5 Hz, 1H), 1.90–1.60 (m, 8H).

Synthesis of 1-(2,4-Difluorophenyl)cyclopentanamine (30h)

To a solution of compound 34a (0.112 g, 0.50 mmol, 1.0 equiv) in acetone (0.50 mL), Et3N (0.08 mL, 0.55 mmol, 1.1 equiv) was added. The reaction was stirred at −5 °C and ethyl chloroformate (0.05 mL, 0.54 mmol, 1.1 equiv) was added slowly. The reaction was stirred for 15 min at the same temperature. A solution of NaN3 (0.065 g, 1.00 mmol, 2.0 equiv) in H2O (0.2 mL) was added. The reaction was stirred for additional 30 min at the same temperature. Then, the reaction mixture was poured into ice–H2O and extracted with toluene. The organic layers were combined, dried over Na2SO4, and transferred to two neck round-bottom flask. The reaction mixture was heated cautiously under reflux for 1 h. Then, the solvent was removed under reduced pressure and 8 N HCl (0.75 mL) was added at 0 °C. The reaction was gradually heated up to 70 °C. The reaction was cooled at rt and poured into ice–H2O. A solution of NaOH (1N) was added up to pH 9. The mixture was extracted with CH2Cl2, dried over Na2SO4, filtered, and concentrated under reduced pressure. Then, the crude was solubilized with CH2Cl2, washed with a solution of HCl (0.1 N), and extracted with CH2Cl2. The aqueous phase was treated with a solution of NaOH (0.1 N) up to pH 9 and extracted with CH2Cl2. The organic layers were combined, dried over Na2SO4, filtered, and concentrated under reduced pressure. The product was used in the next step without further purification. UPLC/MS (method A): Rt 1.22 min. MS (ES): C11H13F2N requires, 197 m/z; found, 198 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.39–7.28 (m, 1H), 6.83–6.72 (m, 2H), 2.05–1.86 (m, 4H), 1.81–1.64 (m, 4H).

Synthesis of 1-(4-Fluoro-3-methoxy-phenyl)cyclopentanamine (30i)

To a solution of compound 34b (0.216 g, 0.91 mmol, 1.0 equiv) in anhydrous toluene (5.00 mL), SOCl2 (0.33 mL, 4.53 mmol, 5.0 equiv) was added. The reaction was stirred at room temperature until the consumption of the starting material. The solvent was removed under reduced pressure. The oil residue was solubilized in anhydrous toluene (5.00 mL) and NaN3 (0.118 g, 1.81 mmol, 2.0 equiv) was added. The reaction was stirred. The reaction mixture was cooled down and concentrated under reduced pressure. The crude was purified by column chromatography (SiO2), eluting with Cy/EtOAc from 100 to 100 to afford the desired intermediate benzyl N-[1-(4-fluoro-3-methoxy-phenyl)cyclopentyl]carbamate (0.048 g, 15%). UPLC/MS (method A): Rt 1.18 min. MS (ES): C20H22FNO3 requires, 343 m/z; found, 344 m/z [M + H]+. The protecting group was removed using Et3SiH (0.19 mL, 0.73 mmol, 10 equiv), 10% Pd/C (0.001 g, 0.02 equiv), and MeOH (1.00 mL). The reaction was stirred at 90 °C under microwave irradiation for 30 min. The crude was used for the next step without further purification. UPLC/MS (method B): Rt 1.38 min. MS (ES): C12H16FNO requires, 209 m/z; found, 210 m/z [M + H]+. 1H NMR (400 MHz, CDCl3) δ 7.11 (dd, J = 8.3, 2.2 Hz, 1H), 7.02–6.92 (m, 2H), 3.90 (s, 3H), 2.04–1.76 (m, 8H).

Synthesis of 1-(2,4-Difluorophenyl)cyclopentanecarbonitrile (33a)

Compound 33a was prepared according to the general procedure E using benzyl nitrile 32a (0.50 g, 3.26 mmol), 1,4-dibromobutane (1.57 g, 4.90 mmol), and LiHMDS (3.91 mL, 3.91 mmol) in anhydrous THF (22.00 mL). The crude was purified by column chromatography (SiO2), eluting with Cy/EtOAc from 100 to 90:10 to afford 33a as a colorless oil (0.46 g, 69%). UPLC/MS (method A): Rt 1.03 min. MS (ES): C12H11F2N no ionization. 1H NMR (400 MHz, CDCl3) δ 7.44–7.36 (m, 1H), 6.92–6.84 (m, 2H), 2.61–2.46 (m, 2H), 2.17–1.84 (m, 6H).

Synthesis of 1-(4-Fluoro-3-methoxy-phenyl)cyclopentanecarbonitrile (33b)