Abstract

The concept of a novel sanitization device specifically designed for helmets used in bike share services is presented in this scientific work. The system uses ozone, a powerful oxidizing agent, to completely remove dust and bacteria from the helmet surface. Throughout the development process, special attention has been paid to the dual initial goals of efficacy in removing dirt and batteries, as well as ease of use related to the device's safety. In fact, today's sharing services are rarely capable of providing adequate disinfection of the tools, which is especially troubling given the most recent years of pandemic caused by Covid-19. The invention of the ozone-based sanitization device addresses the growing concern about hygiene and safety in bike share services. Furthermore, due to its portability and ease of use, the device is a cost-effective and viable solution for use in a variety of settings. A significant contribution to the advancement of sanitization technology and public health is expected with this work.

Keywords: Sanitation system, Sharing services, Safety, Hygiene, Innovation, Eco-sustainability design

1. Introduction

In recent years, the onset of Covid-19 has arguably been the primary catalyst for a series of new measures concerning the sanitization of shared transportation and public health [1]. The virus is primarily transmitted through respiratory droplets and contact with contaminated surfaces, necessitating the upkeep of clean and sanitary public spaces [2,3]. Recent events have highlighted the importance of sanitation in public places. Notably, the COVID-19 outbreak has affected millions of people worldwide and impacted significantly on the global economy. Furthermore, the pandemic has raised awareness of the importance of sanitation [4] and hygiene, particularly in public places [5]. Studies have demonstrated that the virus can persist on surfaces for several hours to days, thereby mandating the frequent disinfection of high-contact surfaces like door handles, elevator buttons, and public restrooms [6]. Moreover, insufficient sanitation facilities in public spaces can propagate other infectious diseases like cholera and typhoid.

Chemical disinfectants, UV-C light [7], steam cleaning [8,9], dry fogging [10], and ozone [11,12] are all used in industrial settings to sanitize and disinfect environments. Chemical disinfectants, such as chlorine, hydrogen peroxide, and quaternary ammonium compounds, are widely available and can effectively eliminate viruses and bacteria. However, they may leave toxic residues on surfaces and be harmful to humans and the environment. UV-C light kills bacteria and viruses by disrupting their DNA with UV radiation. Although it is efficient and environmentally friendly, its effectiveness is limited, and equipment costs can be prohibitively expensive [13]. High-temperature steam is used in steam cleaning to kill pathogens on surfaces and equipment. It is chemical-free and leaves no harmful residues, but it may not be appropriate for all surfaces. Dry fogging creates a fine mist of disinfectant that can reach hard-to-reach areas. It is efficient and effective, but it requires specialized equipment and can be expensive [14]. Finally, ozone is a powerful disinfectant capable of killing bacteria, viruses, and other pathogens by destroying their cell walls and metabolic processes [15,16]. It is environmentally friendly, versatile, and effective, but it must be used with proper training and equipment to be used safely and effectively [17].

Ozone is a powerful disinfectant that uses its oxidation properties to destroy pathogens' cell walls and disrupt their metabolic processes [18]. It is currently used for sanitization and hygiene purposes in a variety of industrial sectors, including food and beverage processing, pharmaceuticals, healthcare facilities, water treatment, and air purification [[19], [20], [21], [22], [23]]. There are several benefits and drawbacks to using ozone for sanitizing and hygienizing [24]. On the plus side, ozone is a highly effective disinfectant capable of eliminating a wide range of pathogens such as bacteria, viruses, and other microorganisms such as Salmonella, Listeria, E.coli, and Legionella [[25], [26], [27], [28]]. In addition, unlike traditional disinfectants such as chlorine and bromine, ozone is an environmentally friendly technology that leaves no residues or harmful byproducts. Furthermore, ozone sanitization is faster than traditional methods, and ozone systems can be cost-effective in the long run. On the negative side, ozone is a powerful oxidizing agent that, if inhaled, might cause respiratory problems, chest pain, and eye and nose irritation. Since ozone has no residual effect, it does not prevent the growth of microorganisms after sanitization. Moreover, since ozone has limited penetration power, it is ineffective in disinfecting surfaces with cracks or crevices. Finally, the equipment required for ozone generation can be costly, which may discourage its use. In fact, ozone (O3) is a gas with high reactivity and instability, making it unsuitable for long-term storage in its pure form because of its proclivity to decompose into molecular oxygen (O2). Nonetheless, dissolving ozone in a liquid medium produces an ozone solution that can be stored, subject to environmental factors such as temperature, pH, and the presence of other substances that could affect its stability. Ozone solutions are typically kept in opaque, sealed containers in a dark, cool environment to mitigate the impact of decomposition and degradation. However, it is crucial to emphasize that the storage and handling of ozone should be conducted with caution due to its reactive nature and potential hazards.

In the following sections, the device design is analyzed in relation to aspects of aesthetics and functionality. The main components of the product are assembled to minimize the internal dimensions while leaving the necessary space for the helmet. CFD analyses are performed to predict the effectiveness of the sanitization system considering the air-ozone mixing and the specific weights of the two phases. A set of final pictures of the product is proposed to the reader.

2. Material and methods

2.1. Case study

Several factors influenced the decision to use ozone as the helmet's sanitizing agent. As first, a portable system integrated with the vehicle that can continuously sanitize the helmet for the user's comfort was needed. Then, a non-toxic sanitizing agent was required. Ozone meets these two criteria. This gas must be produced on-site using specialized ozone generators that use electrical discharges to convert atmospheric oxygen into ozone and it is not possible to store it in tanks. This brings to the production of small generators built with long lifespan corona effect cells that can exceed ten years while maintaining high productivity. Unlike other sanitizing technologies, such as UV rays, ozone can uniformly sanitize porous surfaces or areas covered in dust or dirt, including hard-to-reach areas. Ozone has been recognized in Italy by the Ministry of Health as a natural aid for the sanitization of contaminated environments, adding to its social legitimacy with the protocol of July 31, 1996 24482 [29].

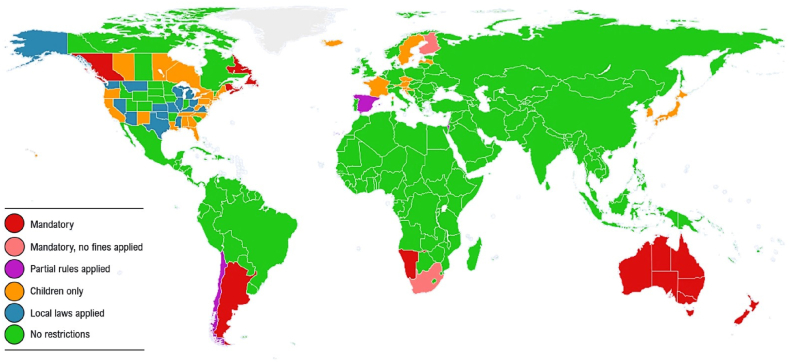

Conducting thorough research to identify an optimal sanitization method for bike share service devices is a practical consideration and serves an important social function. Providing users with sanitized helmets instills confidence enhancing the overall comfort of the service. The use of helmets is nowadays mandatory in many countries worldwide, including the United States, Spain, France, Australia. This means that it is imperative to ensure that helmets are properly sanitized to prevent the spread of infectious diseases, as part of a social responsibility that benefits the broader community. In Fig. 1 a comprehensive map with reference to the global state legislation on helmet use is proposed [30].

Fig. 1.

Global map with reference to the actual state legislation on helmet use.

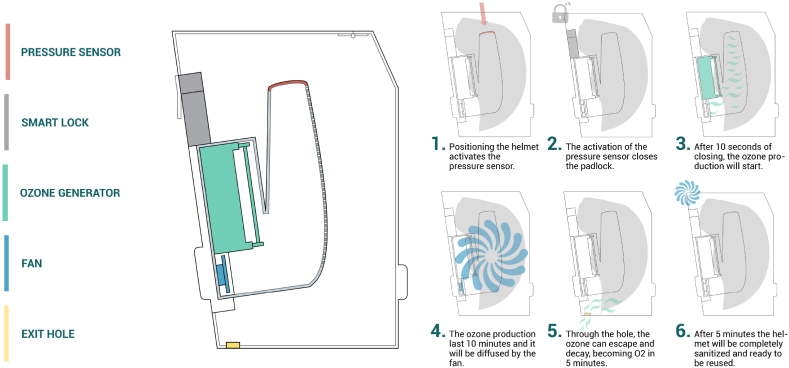

The sanitizing mechanism is an automated system designed for fast and efficient sanitization in small spaces. Upon placing the helmet back inside the box, the sensor system connected to an internal circuit is activated to detect the weight of the helmet. Then, the sanitization process starts. This is the main idea of the project. Alternatively, the presence of the helmet could be linked to the user's payment, where the helmet must be returned for the payment to cease. Once the weight of the helmet is detected, the box locking system is activated, and ozone production commences for a duration of 10 min. To ensure proper distribution of ozone, a special fan is activated to push the gas through the exit holes of the helmet holder and into the compartment. After the 10-min production of ozone, the sanitization process stops, and the ozone gas is allowed to decay back into oxygen (O2) through two small holes beneath the helmet holder compartment. The ozone decay process takes an additional 5 min to complete, making the total sanitization process last for 15 min, after which the helmet will be fully sanitized, and the vehicle will be available for the next user. Two schemes of the ozone disinfection and internal water washing cycles designed for the service are summarized in Fig. 2, Fig. 3.

Fig. 2.

Ozone sanitization cycle designed for the project.

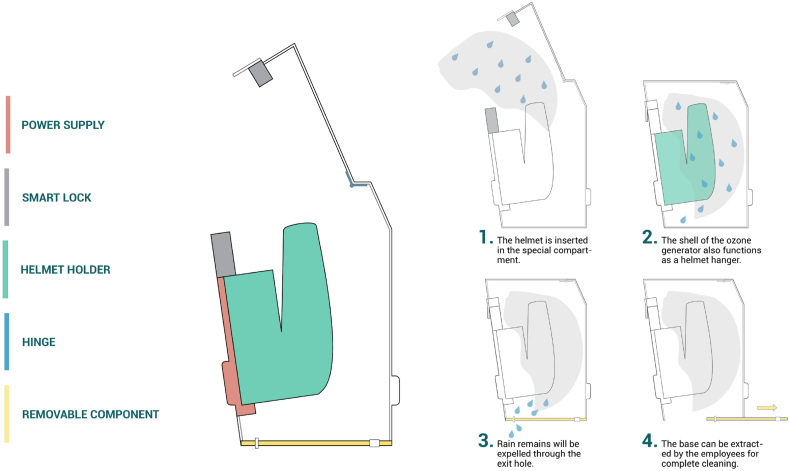

Fig. 3.

Water storage outlet system and internal cleaning designed for the project.

2.2. Ozone generation

Ozone is generated by subjecting molecular oxygen (O2) to a high-energy electrical discharge or corona discharge [31]. Corona discharge causes the O2 molecules to split into individual oxygen atoms, which then react with other O2 molecules to form ozone (O3). This process is summarized in the following equations with the chemical reaction:

| (1) |

The overall reaction can be represented as follows: 3O2 → 2O3

The evaluation of the current intensity in the corona is accomplished through the integration of current density over the surface of the conductor. The calculation of power dissipation entails the multiplication of current with the voltage that exists between the electrodes. To describe mathematically this effect, Peek's empirical law (1929) can be utilized as proposed in the following equation [32,33].

| (2) |

is the “corona inception voltage" (CIV) of a visible corona between the electrodes, expressed in kilovolts; is a factor related to physical condition. In the case of perfect brightness = 1, for oxidized and dirty wires it is 0.98–0.93. For wires, on the other hand, it is 0.87–0.83; is the radius of the wires, is the distance between the wires, δ is the air density factor, calculated by equation (3).

| (3) |

Here, is the pressure in centimeters of mercury and is the temperature expressed in degrees Celsius. Under standard conditions (25 °C and 76 cmHg) it is equal to 1. The last term in Peek's formula not yet described is gv; it expresses the potential gradient and is given by equation (4).

| (4) |

Where is the dielectric strength, which is about 30 kV/cm for air.

Various electrical devices can be utilized to generate corona effect, including corona discharge tubes, dielectric barrier discharge (DBD) devices, and pulsed corona discharge (PCD) systems. The selection of a specific device depends on the desired ozone production rate and concentration for a particular application. Among these devices, corona discharge tubes are the most used for ozone generation. These tubes contain a gas mixture of oxygen and a small quantity of an inert gas, such as helium or argon, in a cylindrical glass tube with two electrodes. Upon application of a high voltage, an electrical discharge is produced, generating a corona of electrons that collides with the oxygen molecules, creating ozone. Alternatively, DBD devices employ a thin insulating layer between electrodes to create a uniform electrical field and facilitate ozone production, while PCD systems employ short, high-voltage electrical pulses to generate corona discharge and produce ozone. The efficiency of ozone generation depends on various factors such as the input voltage, frequency, and waveform, gas mixture composition, electrode geometry, and the temperature and pressure of the reaction chamber. Factors such as electrode fouling, gas impurities, and byproduct accumulation can reduce the efficiency of ozone generation, making periodic maintenance and cleaning of ozone generators necessary to ensure optimal performance.

Some examples of commercialized ozone generators are the Enerzen Commercial Ozone Generator, OdorStop OS2500UV Professional Ozone Generator, Airthereal MA10K-PRODIGI Digital Ozone Generator, Green Air Deluxe 3 Plate HEPA and Carbon Filter Alpine Air Purifier Ozone Generator. They typically range in price from $100 to $400. The employed generator has a capacity to produce 10 g/h of ozone, operating at a supply voltage of 12 V. Utilizing high voltage, it transforms dry air into O3. This system effectively eradicates odors, revitalizes stagnant air, ensuring safety, quiet operation, and high efficiency with low energy consumption. Its compact dimensions measure 146 mm × 55 mm x 45 mm. Input voltage is 12V, while the output voltage reaches 3800 V. Operating at a frequency of 18–20 kHz, it consumes 95 W of power.

2.3. CFD simulation of the ozone generation process

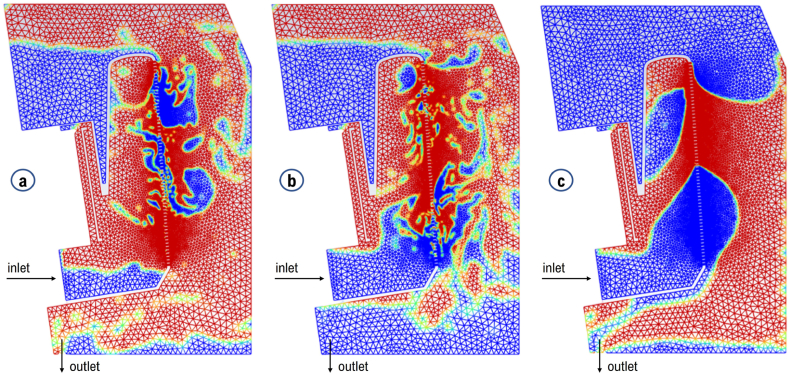

A finite element CFD simulator (Ansys Fluent) was used to evaluate the fluid dynamic behavior of the ozone molecules generated inside the device. A simplified 2-D model of the mid-section of the helmet holder was drawn from the product concept sketches. Initial conditions of the fluid-dynamic transient inherent in ozone generation and its movement due to the pressure gradient generated by the fan placed at the bottom are placed on some edge areas. Considering the mesh of the model, greater infiltrations were made in the narrower air-ozone mixture passage zones. In fact, the presence of greater pressure and velocity gradients inside should be analyzed in depth to properly approximate the considered fluids motion. While the average mesh element size was set at 4.75 mm, linear elements of average size of 1.25–1.75 mm were used in these areas. The "sizing" and "inflation" commands (useful in areas of ozone leakage from the diffuser) in Ansys Workbench's Mechanical module are suitable for local mesh modifications.

The transient CFD model with two Eulerian phases was set considering densities of 1.225 and 1.7 kg/m3 for air and ozone, respectively. These data depend directly on the molecular weights of both substances, which are 28.96 and 48 g/mol (ozone in its allotropic form is in fact composed of three oxygen atoms whose molecular weight is 16 g/mol).

Gravity acceleration (g) was considered to examine the effect of the two phases' density involved. The best-known analytic model in literature describing a fluid's behavior is offered by the Navier-Stokes equations (5), (6)) in this paper) [34].

| (5) |

| (6) |

Within the equations the main reference parameters of the fluid appear, i.e., the density , viscosity , velocity and pressure to which it is subjected. Their analytical resolution is impractical at present; computational fluid dynamics methods provide approximate solutions with low error rates and experimentally confirmable results [35,36]. To ensure proper distribution of oxygen across all surfaces, it is necessary to numerically simulate the behavior of the various phases included in the model. A simplified 2-D simulation is proposed as a preliminary analysis to determine the speed at which the fan should rotate to ensure proper oxygen distribution. A series of tests revealed that at high speeds, the air transports the ozone without mixing with it uniformly, resulting in an excess of surface area. However, at such slow speeds, the ozone takes too long to reach all internal surfaces. It is worth noting that it is a heavier molecule than air. A velocity range of 1–2.5 mm/s of air inlet is considered as optimal. As can be seen in Fig. 4, the only exit route from phase O3 is located on the floor of the helmet holder, through an atmospheric pressure hole. Ensuring an optimal airflow derived from fan rotation is critical to the efficient distribution of ozone within the compartment. Excessively slow airflow extends the ozone filling time, while excessively fast airflow results in areas left untreated due to heightened internal turbulence. Fluid dynamics simulations set at different ozone inlet rates were carried out to understand which was the best setting for the generator, as shown in the various examples in Fig. 4.

Fig. 4.

Air (blue) and ozone (red) fractions' contours at different air inlet speed; a) 0 mm/s b) 1 mm/s c) 10 mm/s.

3. Results

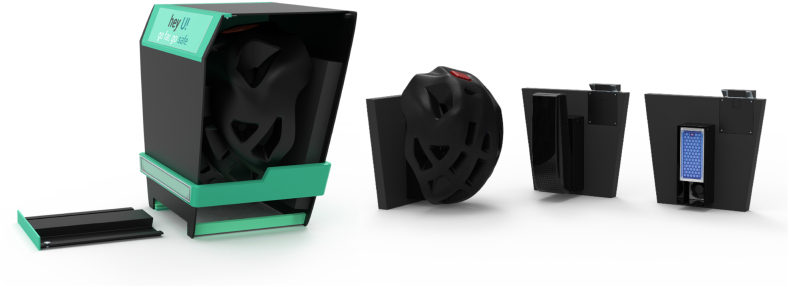

In the subsequent section, the geometries and functionalities of the ultimate design are expounded. The internal volume of the helmet holder is determined based on the comprehensive dimensions of a cyclist's standardized homologated helmet. The interior is also tailored to accommodate both the ozone generator and the fan, which facilitate the movement of the former within the enclosure. To enhance comprehension regarding the implementation of the helmet holder on the service's vehicles, please refer to Fig. 5.

Fig. 5.

Internal components of the helmet holder. Overall view and details of the ozone generator and fan.

At the uppermost extremity of the holder, a compact and uncomplicated pressure sensor is installed. This sensor is comprised of a printed circuit on a highly pliable plastic film with two metallic contacts at the terminus. This system enables continual monitoring of the presence or absence of the helmet within the compartment. The ozone generator with corona effect is undoubtedly the most consequential and innovative aspect of this project. A small ozone generator with ceramic plates is installed within the helmet holder's specially perforated casing. The generator derives power directly from the vehicle's battery, capable of producing up to 10 g/h of ozone, more than adequate for sterilizing a small product like a helmet. This already marketed generator is widely utilized for sterilizing objects and environments, using a 12V power supply, ideal for connection to a simple lithium battery. The corona effect occurs within the ceramic plates, and a small fan allows the circulation of the ozone throughout the compartment, ensuring comprehensive sterilization of even the most intricately shaped portions of the helmet. In Fig. 6 a view of the ozone generator and its location in the helmet holder is proposed. Most of the sanitizer components are made from PVC. They have shapes that are easy to make and are commercially available. Some small internal support parts were made with the help of an FDM 3D printer [37].

Fig. 6.

Internal component of the helmet holder. Focus on the ozone generator and fan.

An example of installation on a scooter or bicycle is shown in Fig. 7, to clarify to readers how the product should be used. The device is employed before and after the vehicle is used for short trips by customers. The use of new manufacturing technologies in additive manufacturing also enables rapid prototyping, even for different dimensions and geometry models, to anticipate the quality of the final product before its definitive production. A product like the one here discussed can be easily prototyped using 3D printers [[38], [39], [40]] and low-cost materials with adequate resistance to external loads, such as PLA or PETG. A subsequent phase of surface smoothing and painting can maximize the product's yield [41,42]. The potentially large number of users involved daily requires an effective and rapid device that can eliminate almost all germs, bacteria, and dust on helmets, which was the aim of the project.

Fig. 7.

Sanitizer mounted on some vehicles (scooter and bicycle).

3.1. Limitations of the project

In our quest to develop an ozone-based sanitization system for integration with bicycles and scooters within the operational framework of a bike-sharing service, it is essential to recognize and elucidate certain inherent constraints pertinent to our endeavor. Firstly, it is crucial to emphasize that the effectiveness of ozone-based sanitization relies on various variables, including ozone concentration, ambient environmental conditions, and the duration of exposure. Our empirical investigation was based on specified parameters and carefully controlled laboratory conditions, potentially rendering our findings less directly applicable to the intricate complexities of diverse real-world scenarios.

Secondly, our analysis, based on a two-dimensional Computational Fluid Dynamics (CFD) assessment of the internal environment within the sanitization chamber, while providing valuable insights into ozone distribution dynamics, represents an oversimplification compared to the three-dimensional and dynamically fluctuating nature inherent in vehicle compartments. This simplification raises concerns about the absolute accuracy of our findings in relation to the nuanced intricacies of genuine operational conditions. Furthermore, it is essential to underscore that the 'corona effect,' although pivotal to our ozone generation mechanism, represents just one aspect of a multifaceted phenomenon. Thus, it warrants further investigation and refinement to achieve a comprehensive understanding of ozone control and dissemination within our apparatus. In conclusion, the present study highlights that deploying ozone as a sanitization agent involves multifaceted considerations. Safety and regulatory compliance concerning ozone exposure in practical implementation require meticulous attention. Moreover, we must not overlook the critical aspect of cost-effectiveness, which encompasses procurement, installation, and ongoing maintenance of the ozone-based sanitization system. These limitations epitomize significant challenges that necessitate collaborative efforts in future research and development, with the aim of enhancing the practical applicability and efficacy of our ozone-based sanitization device within the dynamic milieu of bike-sharing services.

4. Conclusions

The design and implementation of an ozone sanitization system for shared service helmet devices has been presented. The effectiveness of the system was assessed and validated using computational fluid dynamics simulations, which revealed information about ozone distribution and sanitization. The proposed system design considers the unique needs and constraints of shared helmet devices, such as the need for a quick and thorough sanitization process, as well as the challenges posed by the geometry of the helmets. The system's small size, ease of use, and low cost make it a viable option for shared helmet service providers looking to ensure the safety and well-being of their customers. This research helps to develop safe and sustainable shared mobility services, which improves public health and urban livability.

Data availability statement

The data presented in this study might be available depending on the type of demand and use and are linked to authorities’ authorization. A request must be sent to the corresponding author with the permission of all authors.

CRediT authorship contribution statement

Leonardo Frizziero: Methodology, Funding acquisition, Formal analysis, Conceptualization. Giampiero Donnici: Validation, Resources, Project administration, Formal analysis. Giorgia Venditti: Writing – original draft, Software, Resources. Marco Freddi: Writing – review & editing, Writing – original draft, Supervision, Software, Investigation.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Hiscott J., Alexandridi M., Muscolini M., Tassone E., Palermo E., Soultsioti M., Zevini A. The global impact of the coronavirus pandemic. Cytokine Growth Factor Rev. 2020;53:1–9. doi: 10.1016/J.CYTOGFR.2020.05.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Bontempi E. First data analysis about possible COVID-19 virus airborne diffusion due to air particulate matter (PM): the case of Lombardy (Italy) Environ. Res. 2020;186 doi: 10.1016/J.ENVRES.2020.109639. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Atiaga O., Guerrero F., Páez F., Castro R., Collahuazo E., Nunes L.M., Grijalva M., Grijalva I., Otero X.L. Assessment of variations in air quality in cities of Ecuador in relation to the lockdown due to the COVID-19 pandemic. Heliyon. 2023;9 doi: 10.1016/j.heliyon.2023.e17033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Khan M.H., Yadav H. Sanitization during and after COVID-19 pandemic: a short review. Transactions of the Indian National Academy of Engineering. 2020;5:617. doi: 10.1007/S41403-020-00177-9. [DOI] [Google Scholar]

- 5.Lee D., Moy N., Tritter J., Paolucci F. The COVID-19 pandemic: global health policy and technology responses in the making. Health Policy Technol. 2020;9:397–398. doi: 10.1016/J.HLPT.2020.10.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Afsah-Hejri L., Hajeb P., Ehsani R.J. Application of ozone for degradation of mycotoxins in food: a review. Compr. Rev. Food Sci. Food Saf. 2020;19:1777–1808. doi: 10.1111/1541-4337.12594. [DOI] [PubMed] [Google Scholar]

- 7.Lombini M., Cortecchia F., Fiorini G., Pareschi G., Malaguti G., Zanutta A., Bianco A., Fiorini M., Diolaiti E., Lessio L., De Rosa A. Design of optical cavity for air sanification through ultraviolet germicidal irradiation. Opt Express. 2021;29(12):18688–18704. doi: 10.1364/OE.422437. 29. 18688–18704. [DOI] [PubMed] [Google Scholar]

- 8.Lorenzi S. Use of a steam generator for disinfection of hospital ward room surfaces. Br. Microbiol. Res. J. 2012;2:228–232. doi: 10.9734/BMRJ/2012/1959. [DOI] [Google Scholar]

- 9.Umemura T., Mutoh Y., Sukawa M., Hioki T., Sakanashi D., Kato H., Hagihara M., Yamada T., Ikeda Y., Mikamo H., Ichihara T. Diminishment of carbapenemase-producing enterobacterales from sink outlets using a steam cleaner. Hygie. 2023;3:13–17. doi: 10.3390/HYGIENE3010003. 3 (2023) 13–17. [DOI] [Google Scholar]

- 10.Krishnan J., Fey G., Stansfield C., Landry L., Nguy H., Klassen S., Robertson C. Evaluation of a dry fogging system for laboratory decontamination. Applied Biosafety. 2012;17:132–141. doi: 10.1177/153567601201700305. [DOI] [Google Scholar]

- 11.Dubuis M.E., Dumont-Leblond N., Laliberté C., Veillette M., Turgeon N., Jean J., Duchaine C. Ozone efficacy for the control of airborne viruses: bacteriophage and norovirus models. PLoS One. 2020;15 doi: 10.1371/JOURNAL.PONE.0231164. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Grignani E., Mansi A., Cabella R., Castellano P., Tirabasso A., Sisto R., Spagnoli M., Fabrizi G., Frigerio F., Tranfo G. Safe and effective use of ozone as air and surface disinfectant in the conjuncture of covid-19. Gases. 2021;1:19–32. doi: 10.3390/GASES1010002. 1 (2020) 19–32. [DOI] [Google Scholar]

- 13.Kim D.K., Kang D.H. UVC LED irradiation effectively inactivates aerosolized viruses, bacteria, and fungi in a chamber-type air disinfection system. Appl. Environ. Microbiol. 2018;84 doi: 10.1128/AEM.00944-18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Schinköthe J., Scheinemann H.A., Diederich S., Freese H., Eschbaumer M., Teifke J.P., Reiche S. Airborne disinfection by dry fogging efficiently inactivates severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), mycobacteria, and bacterial spores and shows limitations of commercial spore carriers. Appl. Environ. Microbiol. 2021;87 doi: 10.1128/AEM.02019-20/SUPPL_FILE/AEM.02019-20-S0001.PDF. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Yano H., Nakano R., Suzuki Y., Nakano A., Kasahara K., Hosoi H. Inactivation of severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) by gaseous ozone treatment. J. Hosp. Infect. 2020;106:837–838. doi: 10.1016/j.jhin.2020.10.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Bayarri B., Cruz-Alcalde A., López-Vinent N., Micó M.M., Sans C. Can ozone inactivate SARS-CoV-2? A review of mechanisms and performance on viruses. J. Hazard Mater. 2021;415 doi: 10.1016/j.jhazmat.2021.125658. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Luo S., Wong C.P. Effect of UV/ozone treatment on surface tension and adhesion in electronic packaging. IEEE Trans. Compon. Packag. Technol. 2001;24:43. [Google Scholar]

- 18.Kaushik N., Mitra S., Baek E.J., Nguyen L.N., Bhartiya P., Kim J.H., Choi E.H., Kaushik N.K. The inactivation and destruction of viruses by reactive oxygen species generated through physical and cold atmospheric plasma techniques: current status and perspectives. J. Adv. Res. 2023;43:59–71. doi: 10.1016/J.JARE.2022.03.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Derco J., Dudáš J., Valičková M., Šimovičová K., Kecskés J. Removal of micropollutants by ozone based processes. Chem. Eng. Process: Process Intensif. 2015;94:78–84. doi: 10.1016/J.CEP.2015.03.014. [DOI] [Google Scholar]

- 20.Aguayo E., Escalona V.H., Artés F. Effect of cyclic exposure to ozone gas on physicochemical, sensorial and microbial quality of whole and sliced tomatoes. Postharvest Biol. Technol. 2006;39:169–177. doi: 10.1016/J.POSTHARVBIO.2005.11.005. [DOI] [Google Scholar]

- 21.Akbas M.Y., Ozdemir M. Effect of gaseous ozone on microbial inactivation and sensory of flaked red peppers. Int. J. Food Sci. Technol. 2008;43:1657–1662. doi: 10.1111/J.1365-2621.2008.01722.X. [DOI] [Google Scholar]

- 22.De Santis D., Garzoli S., Vettraino A.M. Effect of gaseous ozone treatment on the aroma and clove rot by Fusarium proliferatum during garlic postharvest storage. Heliyon. 2021;7 doi: 10.1016/j.heliyon.2021.e06634. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.El Darra N., Xie F., Kamble P., Khan Z., Watson I. Decontamination of Escherichia coli on dried onion flakes and black pepper using Infra-red, ultraviolet and ozone hurdle technologies. Heliyon. 2021;7 doi: 10.1016/j.heliyon.2021.e07259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Ishiwata S., Hibino T., Sakashita T., Nishioka M., Inoue T., Kotake T. Applicability of on-site disinfection of personal protective equipment by ozone gas. Heliyon. 2023;9 doi: 10.1016/J.HELIYON.2023.E13360. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Yasuda K., Okazaki Y., Abe Y., Tsuga K. Effective UV/Ozone irradiation method for decontamination of hydroxyapatite surfaces. Heliyon. 2017;3 doi: 10.1016/j.heliyon.2017.e00372. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Pandiselvam R., Subhashini S., Banuu Priya E.P., Kothakota A., Ramesh S.V., Shahir S. Ozone based food preservation: a promising green technology for enhanced food safety. Ozone Sci. Eng. 2019;41:17–34. doi: 10.1080/01919512.2018.1490636. [DOI] [Google Scholar]

- 27.Xue W., Macleod J., Blaxland J. The use of ozone technology to control microorganism growth, enhance food safety and extend shelf life: a promising food decontamination technology. Foods. 2023;12:814. doi: 10.3390/FOODS12040814. 12 (2023) 814. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Simpson A.M.A., Mitch W.A. Chlorine and ozone disinfection and disinfection byproducts in postharvest food processing facilities: a review. Crit. Rev. Environ. Sci. Technol. 2022;52:1825–1867. doi: 10.1080/10643389.2020.1862562. [DOI] [Google Scholar]

- 29.Superiore I., Sanità D. 2020. Focus on the Professional Use of Ozone Also in Reference to COVID-19 Working Group ISS-INAIL. [Google Scholar]

- 30.Bicycle helmet laws by country - Wikipedia, (n.d.). https://en.wikipedia.org/wiki/Bicycle_helmet_laws_by_country (accessed January 27, 2024).

- 31.Qu J., Zeng M., Zhang D., Yang D., Wu X., Ren Q., Zhang J. A review on recent advances and challenges of ionic wind produced by corona discharges with practical applications. J. Phys. D Appl. Phys. 2021;55 doi: 10.1088/1361-6463/AC3E2C. [DOI] [Google Scholar]

- 32.Hartmann G. Theoretical evaluation of peek's law. IEEE Trans Ind Appl IA- 1984;20:1647–1651. doi: 10.1109/TIA.1984.4504655. [DOI] [Google Scholar]

- 33.Monrolin N., Praud O., Plouraboue F. Open Archive TOULOUSE Archive Ouverte (OATAO) Revisiting the positive DC corona discharge theory: beyond Peek's and Townsend's law. Phys. Plasmas. 2018;25 doi: 10.1063/1.5031780. [DOI] [Google Scholar]

- 34.Mohammadian A., Gildeh H.K., Nistor I. CFD modeling of effluent discharges: a review of past numerical studies. Water. 2020;12:856. doi: 10.3390/W12030856. 12 (2020) 856. [DOI] [Google Scholar]

- 35.Opoku F., Uddin M.N., Atkinson M. A review of computational methods for studying oscillating water columns – the Navier-Stokes based equation approach. Renew. Sustain. Energy Rev. 2023;174 doi: 10.1016/J.RSER.2022.113124. [DOI] [Google Scholar]

- 36.Van Hoecke L., Boeye D., Gonzalez-Quiroga A., Patience G.S., Perreault P. Experimental methods in chemical engineering: computational fluid dynamics/finite volume method—CFD/FVM. Can. J. Chem. Eng. 2023;101:545–561. doi: 10.1002/CJCE.24571. [DOI] [Google Scholar]

- 37.Ferretti P., Santi G.M., Leon-Cardenas C., Fusari E., Cristofori M., Liverani A. Production readiness assessment of low cost, multi-material, polymeric 3D printed moulds. Heliyon. 2022;8 doi: 10.1016/J.HELIYON.2022.E11136. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Bacciaglia A., Falcetelli F., Troiani E., Di Sante R., Liverani A., Ceruti A. Geometry reconstruction for additive manufacturing: from G-CODE to 3D CAD model. Mater. Today Proc. 2023;75:16–22. doi: 10.1016/J.MATPR.2022.09.496. [DOI] [Google Scholar]

- 39.Liverani A., Bacciaglia A., Nisini E., Ceruti A. Conformal 3D material extrusion additive manufacturing for large moulds. Appl. Sci. 2023;13 doi: 10.3390/APP13031892. [DOI] [Google Scholar]

- 40.Ferretti P., Pagliari C., Montalti A., Liverani A. Design and development of a peristaltic pump for constant flow applications. Front. Mech. Eng. 2023;9 doi: 10.3389/FMECH.2023.1207464. [DOI] [Google Scholar]

- 41.Bacciaglia A., Ceruti A., Liverani A. Surface smoothing for topological optimized 3D models. Struct. Multidiscip. Optim. 2021;64:3453–3472. doi: 10.1007/S00158-021-03027-6. [DOI] [Google Scholar]

- 42.Liverani A., Bacciaglia A., Nisini E., Ceruti A. Conformal 3D material extrusion additive manufacturing for large moulds. Appl. Sci. 2023;13:1892. doi: 10.3390/APP13031892. 13 (2023) 1892. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data presented in this study might be available depending on the type of demand and use and are linked to authorities’ authorization. A request must be sent to the corresponding author with the permission of all authors.