Abstract

Many human tissues exhibit a highly oriented architecture that confers them with distinct mechanical properties, enabling adaptation to diverse and challenging environments. Hydrogels, with their water-rich "soft and wet" structure, have emerged as promising biomimetic materials in tissue engineering for repairing and replacing damaged tissues and organs. Highly oriented hydrogels can especially emulate the structural orientation found in human tissue, exhibiting unique physiological functions and properties absent in traditional homogeneous isotropic hydrogels. The design and preparation of highly oriented hydrogels involve strategies like including hydrogels with highly oriented nanofillers, polymer-chain networks, void channels, and microfabricated structures. Understanding the specific mechanism of action of how these highly oriented hydrogels affect cell behavior and their biological applications for repairing highly oriented tissues such as the cornea, skin, skeletal muscle, tendon, ligament, cartilage, bone, blood vessels, heart, etc., requires further exploration and generalization. Therefore, this review aims to fill that gap by focusing on the design strategy of highly oriented hydrogels and their application in the field of tissue engineering. Furthermore, we provide a detailed discussion on the application of highly oriented hydrogels in various tissues and organs and the mechanisms through which highly oriented structures influence cell behavior.

1. Introduction

Tissue engineering (TE), which was first defined in 1993, is an interdisciplinary field that combines the principles of life science and engineering in vitro with the ultimate goal of developing biological substitutes or entire tissues and organs for use in basic research on physiological processes and translational therapies aimed at repairing, preserving or enhancing tissue function 1. To achieve this, bionic scaffolds have been designed using various strategies to provide cells with biochemical and/or biophysical cues replicating the in vivo cellular survival environment, aiming to regulate cellular behavior toward proliferation and differentiation for tissue repair and regeneration. As such, emulating the structural and physicochemical properties of natural tissues or organs is paramount in TE.

Hydrogel, a cross-linked polymer network containing water, has emerged as a promising candidate for biomedical TE applications owing to its biocompatibility, ease of functionalization, and ability to mimic the chemical and biophysical properties of various structures in vivo 2-4. However, traditional hydrogels' poor mechanical properties and brittleness, which impede their wider use (Table 1), have led researchers to explore and develop numerous approaches to address these limitations over the past decades. For instance, double-network 5, nanocomposite 6, dynamically cross-linked 7, and polyampholyte 8 hydrogels have shown great potential in improving the mechanical properties of hydrogels. However, as TE research advances, it has become clear that these efforts are insufficient to replicate natural tissues; replicating the structure of natural tissues and organs is also crucial in pursuing bionics.

Table 1.

Mechanical properties and applicable clinical applications of traditional hydrogels and highly oriented hydrogels.

| Highly Oriented Hydrogel | Traditional Hydrogels | |

|---|---|---|

| Properties | • A special type of hydrogel, based on the distribution of internal components • With highly oriented structure (Most important properties) • Anisotropic mechanical properties • For special application purposes |

• Mechanical property (Comparatively soft materials) • Water-absorbing quality (Wet materials) • Biocompatibility • Biodegradability • Swellability • Stimulti sensitivity (“Smart” materials) • Based on different purposes and applications, special properties will be highlighted |

| Clinical applications | • Main applications for tissue repair and regeneration of oriented tissues, such as cartilage, bone, skeletal muscle, tendons, myocardium, nerves, blood vessels, and cornea, et al. | • Main applications for tissue repair and regeneration of soft tissues, such as muscle, skin, nerves, blood vessels, et al. • With special mechanical properties enhanced, also used in tissue repair and regeneration of hard tissues, such as bone, cartilage, tendon, et al. |

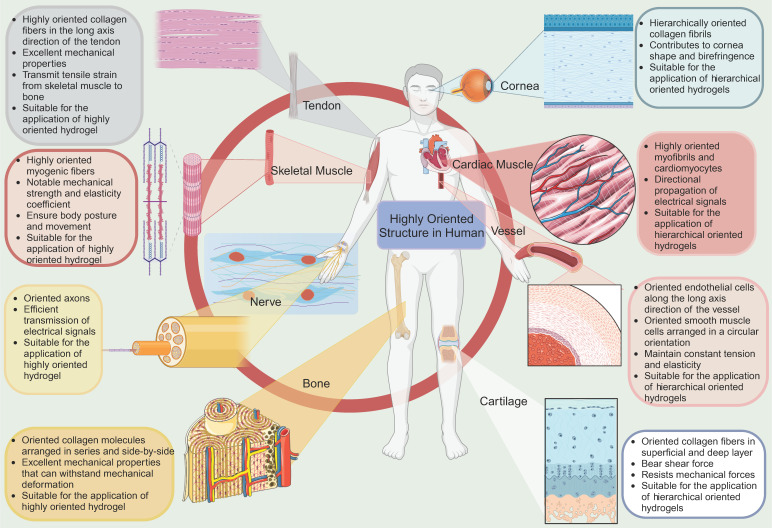

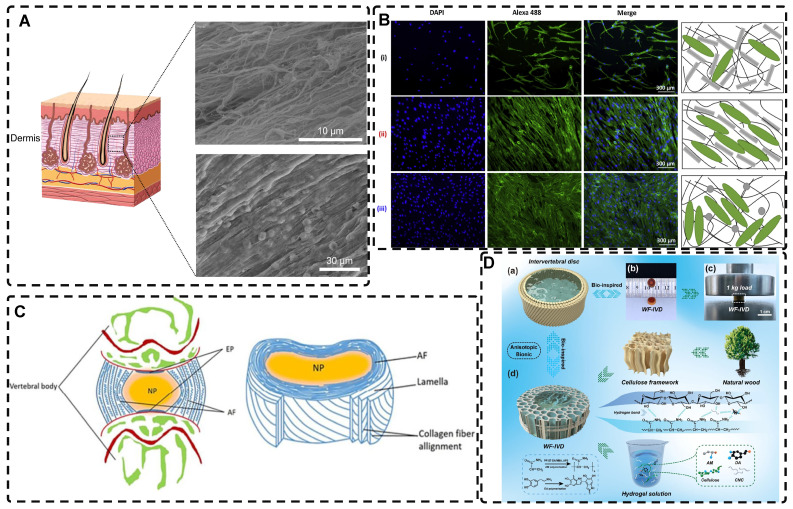

Natural biological tissues such as cartilage 9, bone 10, skeletal muscle 11, tendons 12, myocardium 13, nerves 14, blood vessels 15, 16, and cornea 17 exhibit highly oriented structures that bestow them with distinctive mechanical properties, which are fundamental to their biological function (Figure 1). For example, the layered, highly oriented cartilage structure confers different tasks to each layer, allowing them to work in synergy to dissipate compressive loads and absorb impact 9. Similarly, the highly oriented arrangement of collagen fibers in skeletal muscle imparts superior mechanical properties 11. The importance of highly oriented microenvironments in the body for regulating cell behavior and tissue development demonstrates the need to construct highly oriented 3D hydrogels in vitro to replicate natural tissues' unique mechanical properties and functions. This approach enhances hydrogels' mimicry of natural tissues and broadens their applications 18.

Figure 1.

Highly oriented tissues and organs in the human body (Figure was created with Biorender.com).

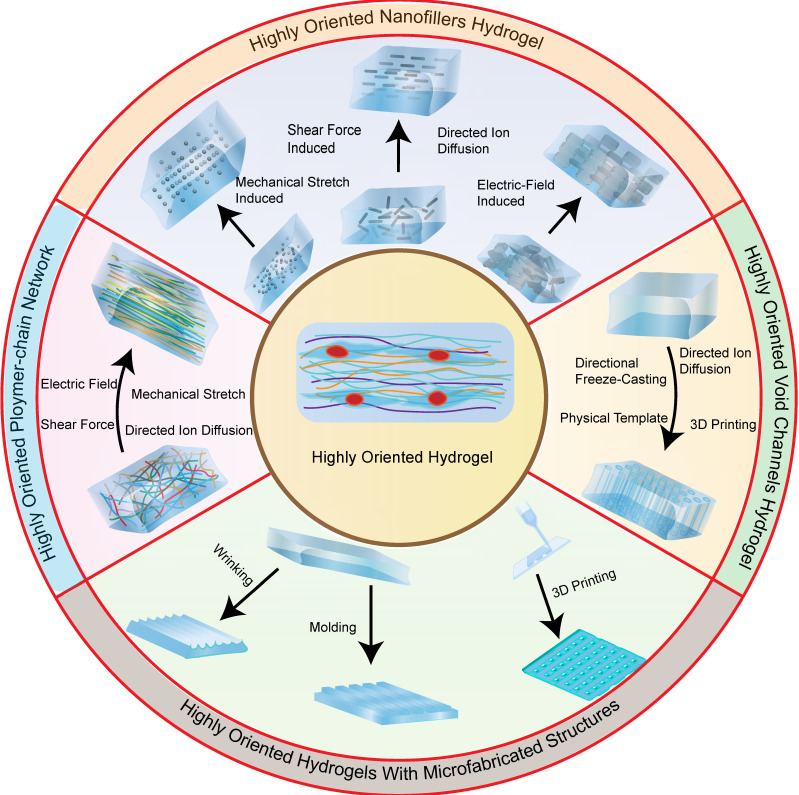

Recent studies have reported on a variety of highly oriented hydrogels, which can be broadly summarized as (i) highly oriented nanofillers hydrogels obtained using strategies such as magnetic/electric fields 19, 20 and mechanical forces 21, (ii) hydrogels with a highly oriented polymer-chain network obtained by strategies such as mechanical forces 22 and ion diffusion 23, (iii) hydrogels with highly oriented void channels prepared by strategies such as directed freezing/ice templates 24, and (iv) highly oriented hydrogels with microfabricated structures using strategies such as 3D printing 25, and (v) other highly oriented hydrogels prepared by special methods (Figure 2). This paper aims to review each of these strategies, discussing their unique strengths and limitations and the progress of research.

Figure 2.

Classification of highly oriented hydrogels, which can be broadly summarized as highly oriented nanofillers hydrogels obtained using strategies such as magnetic/electric fields and mechanical force, highly oriented polymer-chain network hydrogels obtained by strategies such as mechanical force and ion diffusion, highly oriented void channels hydrogels prepared by strategies such as directed freezing/ice template, and highly oriented hydrogels with microfabricated structures using strategies such as 3D printing.

In addition, although hydrogels have been widely used in TE and regenerative medicine, the specific mechanism of action of how hydrogels affect cell behavior is still not fully understood. Similarly, the mechanism of how highly oriented hydrogels affect specific cell behaviors and promote tissue repair and regeneration is unknown, with only limited literature suggesting that they can regulate specific cellular behaviors by influencing cell physiological processes such as cell adhesion, proliferation, migration, and differentiation 26, 27. Although their cytological mechanisms are not well understood, studies have confirmed that highly oriented hydrogels are effective for structural and functional tissue repair and regeneration, especially for highly oriented tissues such as nerve 28, skeletal muscle 29, tendon 30, ligament 31, cartilage 32, bone 33, blood vessels 34, heart 35, etc., by mimicking their structure. However, the extensive literature on the biological applications of highly oriented hydrogels remains to be summarized and reviewed.

Several exceptional previously published reviews exist on anisotropic hydrogels, ranging from comprehensive reviews covering their diverse applications across various fields to reports focusing on their use in a specific TE domain 36-41. Additionally, some reviews delve into specific preparation strategies for anisotropic hydrogels in TE applications 42, 43. Nancy Khuu et al. 44 reviewed the synthesis, characterization, and physical properties of anisotropic hydrogels for use in TE; however, they did not provide an overview of recent advances in TE applications. This review aims to fill that gap by focusing on the design strategy of highly oriented hydrogels and their application in TE (Table 2). In particular, we provide a detailed discussion of the applications of highly oriented hydrogels in different tissues and organs and the mechanisms by which highly oriented structures may influence cell behavior. This comprehensive review provides valuable insights into the progress and challenges in preparing highly oriented hydrogels and their potential applications in TE. By understanding the strengths and weaknesses of each strategy, researchers can more effectively develop novel approaches to prepare highly oriented hydrogels with improved properties and functionalities, leading to better outcomes for TE applications.

Table 2.

Comparison of different highly oriented hydrogels and their applications in tissue engineering.

| Highly Oriented hydrogel | Strategy | Advantages | Challenges | Applications in tissue engineering |

|---|---|---|---|---|

| Highly oriented nanofillers hydrogels | • Magnetic-Field-Induced | • Remote control • Nanofillers of different dimensions (0D, 1D, 2D) |

• Non-magnetic fillers require high-intensity magnetic fields • Safety of different magnetic fillers in tissue engineering |

Tendon 19, 29, 31, Skin 81, Bone 110, Cartilage 309, Nerve 51, 368, 373 |

| • Electric-Field-Induced | • Fast and easy preparation • Nanofillers of different dimensions (0D, 1D, 2D) |

• Noncontact strategy • Electrochemical stability of the material |

Cardiac Muscle 129, 130, Nerve 375 | |

| • Mechanical force-Induced | • Fast and simple preparation • Easy processing • Excellent mechanical properties |

• Unevenly distributed shear forces • Precise control |

Cardiac Muscle 152, 153, Cartilage 152, Tendon 154, 177, Skeletal Muscle 170, Nerve 380, Vessel 409 |

|

| • Directed freezing | • Easy processing • Large-scale fabrication |

• Time/energy-consuming during freezing • Low temperature environment below zero • Precise control |

Nerve 374 | |

| • Self-assembly | • No external force required | • Large-scale fabrication • Easy processing • Precise control |

Skeletal Muscle 170, Nerve 390 | |

| Hydrogels with highly oriented polymer-chain network | • Mechanical Stretch Induced | • Fast and simple preparation • Easy processing • Excellent mechanical properties • Good reproducibility |

• Precise control • Huge mechanical force |

Tendon 177, 180, 184, Bone 181, 321, 322, Cardiac Muscle 35 |

| • Directed Ion Diffusion | • Easy processing | • Non-homogeneous | Vessel 186 | |

| • Shear Force Induced | • Easy processing | • Unevenly distributed shear forces • Precise control |

Bone 188, 189, 192, Skeletal Muscle 190, Tendon 190, Nerve 14, 28, 383, Cardiac Muscle 192 | |

| • Electric-Field-Induced | • Fast and easy preparation | • Noncontact strategy • Electrochemical stability of the material |

Vessel 194, Bone 195, Nerve 196 | |

| Hydrogels with highly oriented void channels | • Directional Freeze-Casting | • Easy processing • Controllable pore size • Controllable pore arrangement • Large-scale fabrication |

• Time/energy-consuming during freezing • Low temperature environment • Uncontrollable pore shape |

Bone 307, 318, Cartilage 32, 307, 308, Nerve 202 |

| • physical template/molding | • Easy processing • Personalized assembly |

• Low mechanical strength | Nerve 211-215 | |

| • Directed Ion Diffusion | • Easy processing | • Low mechanical strength | Vessel 186 | |

| • 3D Printing | • Precise control • Complex architectures • Rapid prototyping • Scalability • Versatile |

• Limited to printable hydrogels • Expensive • Resolution |

Nerve 14, 219, Cornea 393 | |

| Highly oriented hydrogels with microfabricated structures | • 3D Printing | • Precise control • Complex architectures • Rapid prototyping • Scalability • Versatile • Personalization |

• Limited to printable hydrogels • Expensive • Resolution |

Skin 25, Skeletal Muscle 192, 346, Cardiac Muscle 192, 355, 357, Tendon 227, 332, Nerve 364, 369, 381, Disc 226, Bone 319, 320, Cornea 394, 395, Vessel 34, 408 |

| • Molding | • Easy processing • Personalized assembly |

• Template's design and prepared | Cardiac Muscle 228, 356, Nerve 231, Skeletal Muscle 231 | |

| • Wrinkling | • Fast and easy preparation • Easy processing |

• Precise control | Bone 240 | |

| Special highly oriented hydrogels | • Biotemplating | • Excellent mechanical properties | • In vivo degradation | Disc 418, Cartilage Muscle 312, Bone 33 |

| • Filamented Light biofabrication | • Ultrahigh aspect ratios • Complex architectures • Rapid production |

• Expensive | Tendon, Skeletal Muscle 30 | |

| • Embed highly oriented structure in hydrogel | • Personalized assembly | • Complicated | Cartilage 245, 310, 311, Cardiac Muscle 246 |

2. Design and Preparation of Highly Oriented Hydrogels

Scientists have designed and reported several types of highly oriented structural hydrogels. These include nanofiller hydrogels obtained through magnetic/electrical fields, mechanical forces, self-assembly, and other methods; polymer-chain network hydrogels can be prepared through mechanical forces, ion diffusion, and other methods; void channel hydrogels can be obtained through sacrificial template methods such as directed freezing; hydrogels with microfabricated structures can be created through techniques such as 3D printing; and lastly, other specialized techniques can be used to prepare highly oriented hydrogels.

2.1. Highly Oriented Nanofillers Hydrogels

A common method for preparing highly oriented hydrogels is to disperse highly oriented nanofiller materials within them. Various methods, including magnetic/electrical fields, mechanical forces, directed freezing, and self-assembly, can control the distribution and orientation of the filler material. This section presents the principles and recent advances of these different methods and discusses their respective advantages and disadvantages.

2.1.1. Magnetic-Field-Induced Highly Oriented Nanofillers Hydrogels

Magnetic highly oriented hydrogels are prepared by controlling the distribution of magnetic field-responsive materials in the hydrogel using a magnetic field to obtain an oriented structure. Magnetism-responsive electrons in the filler material allow for the formation of a highly oriented morphology in the external magnetic field, which is then fixed in the 3D hydrogel during the gelation process, resulting in a highly oriented structure that is maintained after the withdrawal of the external magnetic field 38. This composite hydrogel is highly oriented and magnetic, while also exhibiting excellent biocompatibility, which is particularly important in TE. Its preparation, involving magnetically responsive materials, both magnetic and non-magnetic, and an external magnetic field, offers a non-invasive and therefore advantageous alternative to other methods of creating highly oriented hydrogels.

2.1.1.1. Magnetically Responsive Materials

Magnetically responsive materials can be categorized into two types: magnetic and non-magnetic materials. Among magnetic materials, magnetic nanoparticles (MNPs) are extensively employed for TE repair due to their remarkable magnetic responsiveness 42, 45-52. The MNPs used for biomedical applications include iron oxide-based MNPs such as hematite (α-Fe2O3), magnetite (γ-Fe2O3), and magnetite (Fe3O4), transition metal ferrites such as CoFe2O4, MnFe2O4, and transition metal alloys like FePT, which are incorporated into hydrogels 53-57. Iron oxide-based MNPs have been approved by the FDA for clinical use due to their good biocompatibility, high magnetization ability, low toxicity, easy preparation, and low cost. Consequently, they have gained significant attention in biomedical applications such as TE and drug delivery, and are more commonly used than other types of MNPs 42, 58-66.

The arrangement of MNPs into highly oriented hydrogels depends on various properties such as the size, shape, and saturation magnetic strength of MNPs, as well as the strength and shape of the magnetic field 67. These factors have a significant impact on the physicochemical properties and magnetic responsiveness of the final hydrogels, which in turn are influenced by the method of MNP synthesis 47, 59, 68. Currently, the three main synthesis methods for MNPs are physical, chemical, or biological 69. Chemical synthesis methods such as sol-gel, solvothermal synthesis, co-precipitation, and thermal decomposition account for the majority of all MNPs produced as they deliver better particle quality and higher homogeneity. Compared to chemical synthesis methods, physical synthesis methods including thermal evaporation, pulsed laser deposition and grinding produce less than 10% of all MNPs. Biological synthesis methods as the third synthesis method for MNPs include using microorganisms, enzymes, fungi, plants and plant extracts. Similarly, biological synthesis methods are also used for the preparation of only a small amount of MNPs 42, 58, 70. Among the chemical methods, the thermal decomposition method has better application potential than the simple, fast, cheap, and high-yield co-precipitation method, as it allows for better control over the shape and size of MNPs 42.

The size of MNPs is one of the most influential factors that affect their properties. When the particle diameter is less than a well-defined size (Dcr), the particles become single domain and have uniform magnetization, regardless of the presence of an external magnetic field 42, 71. Further reduction in diameter to less than a certain critical size (Dsp) results in particles entering the superparamagnetic regime, where the magnetic moment becomes thermally unstable and changes spontaneously and rapidly in the absence of an external magnetic field 72, 73. Superparamagnetic particles have zero magnetization in the absence of an external magnetic field and exhibit magnetic responsiveness only in the presence of such a field, making them highly remote-controllable in practical applications 74. Additionally, they have little tendency to form aggregates, which, along with their low toxicity, make highly oriented hydrogels of superparamagnetic state MNPs promising for TE applications 42, 70, 75.

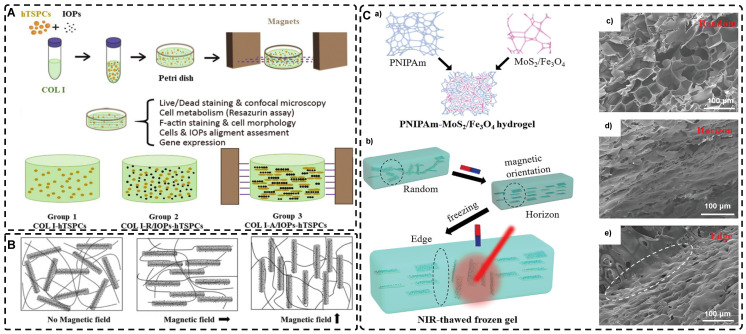

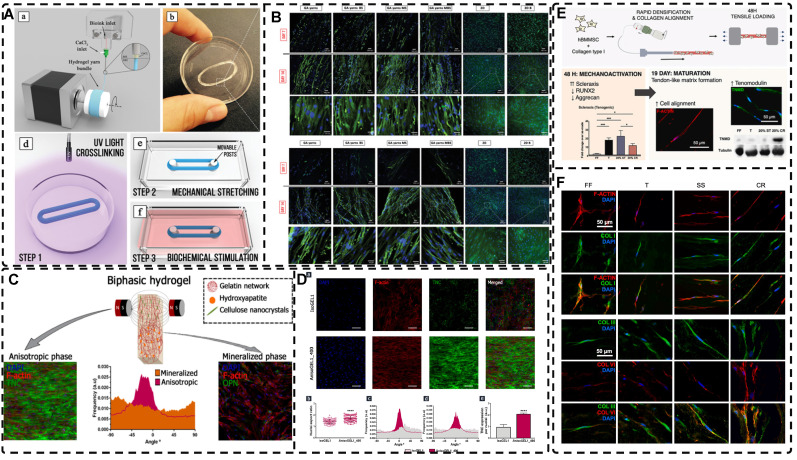

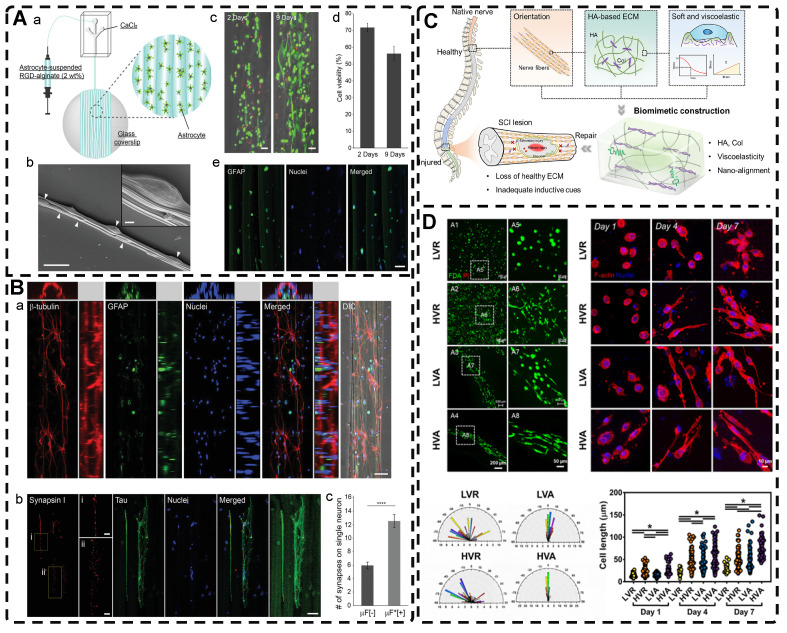

Magnetic nanomaterials of various dimensions (0D, 1D, 2D) can be magnetically assembled and oriented in a pre-hydrogel solution under the influence of an external magnetic field. The 0D MNPs typically form a chain-like oriented structure when exposed to a magnetic field19, 76-80. Recently, Xu et al. 19 successfully produced highly oriented nanocomposite hydrogels that consist of type I collagen and oriented MNPs (Figure 3A). Compared to pristine type I collagen and isotropic hydrogels, human Tendon Stem/Progenitor Cells (hTSPCs) had a higher value-added rate in highly oriented hydrogels, resulting in significant upregulation of tendon-related genes and good potential for clinical translation. Zhang et al. 80 also reported the self-assembly of SiO2-coated Fe3O4 nanoparticles into highly oriented unconfined filled arrays in a pre-hydrogel solution. The MNPs conferred magnetic and photothermal properties to the highly oriented hydrogels, resulting in self-healing properties, and their results showed that the viability of cells is not affected by the temperature changes induced by light and alternating magnetic fields.

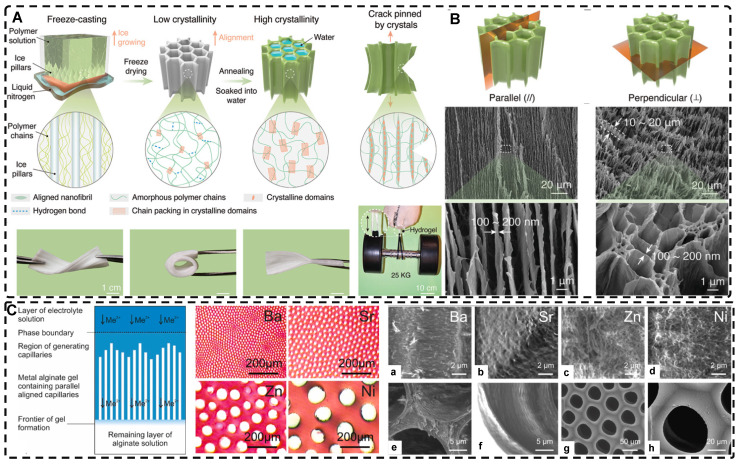

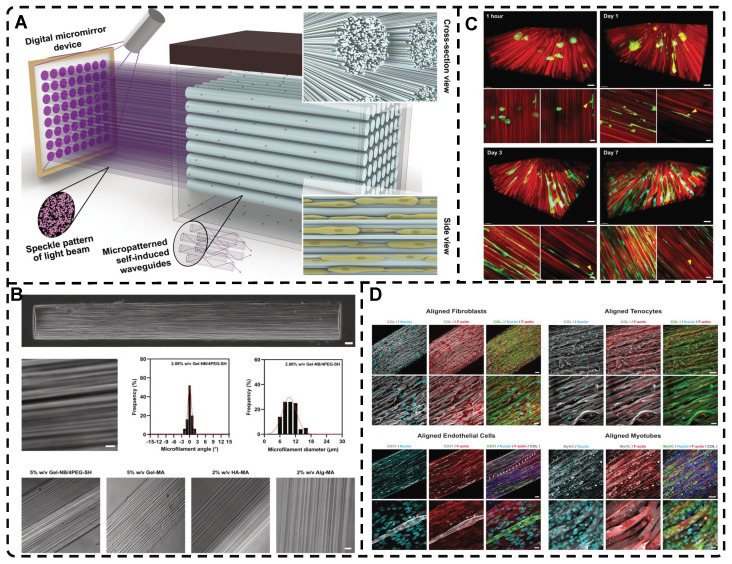

Figure 3.

Fabrication of highly oriented hydrogels based on 0D nanoparticles (A), 1D nanotubes (B) and 2D nanosheets (C) in an external magnetic field. A). Schematic illustration of the formation of anisotropic hTSPC-nanocomposite hydrogel induced by the addition of paramagnetic iron oxide nanoparticles (IOPs) under exposure to magnetic field and cartoon of the three study groups. Adapted with permission from 19, copyright 2021, Royal Society of Chemistry. B) Schematic representation of 1D nanorods in hydrogel oriented under an external magnetic field. Adapted with permission from 81, copyright 2020, Elsevier. C) Schematic representation of a) the fabrication of PNIPAm-MoS2/Fe3O4 hydrogel and b) programming the orientation of MoS2/Fe3O4 under the magnetic field followed by NIR light-treatment of frozen hydrogels. Representative SEM images of PNIPAm-MoS2/Fe3O4 hydrogels under different conditions. Adapted with permission from 93, copyrights 2022, Wiley-VCH.

Magnetic 1D nanorods or nanowires and 2D nanosheets may facilitate better orientation compared to magnetic spherical particles 81, 82. Several studies have reported the preparation of highly oriented hydrogels based on 1D nanomaterials utilizing magnetic fields 71, 81, 83-88. Rincón-Iglesias et al. 83 synthesized highly monodisperse ferrimagnetic Fe3O4 nanorods with adjustable size by solvothermal synthesis and varied the amount of hexadecylamine capping ligands. Subsequently, the nanorods were coated with gold shells and doped into agarose hydrogels, to obtain hydrogels with anisotropic magnetic and optical properties. These hydrogels have applications in fields such as regenerative medicine, cancer ablation, local therapy, and sensors due to their magneto-thermal and photothermal properties. Shi et al. 81 dispersed silica nanorods coated with Fe3O4 in a sol-gel state type I collagen and aligned the nanorods along the magnetic field with a weak magnetic field (<100 mT) generated by two plate-like magnets (Figure 3B). Next, the sol-gel state was transformed into the gel state at 37°C to prepare a highly oriented hydrogel that facilitates the directional growth of normal human dermal fibroblasts.

Similarly, recent studies have shown that 2D magnetic nanosheets can create highly oriented structures when subjected to an external magnetic field 89-94. Dai et al. 91 accomplished the formation of two-dimensional magnetic nanosheet structures (MDS) by interleaving γ-Fe2O3 nanoparticles between two silicate layers. They then rotated the magnetic field (± 260 mT) to obtain a range of highly oriented poly(N-isopropylacrylamide) (PNIPAm) nanocomposite hydrogels. These MDS structures exhibit controlled anisotropy in optical and mechanical properties due to their sandwich structure, high aspect ratio, high charge density, and responsiveness to light and magnetic fields. Additionally, they exhibit anisotropic responses to temperature or light irradiation. Chen et al. 93 developed a novel programmable hydrogel that is magneto-thermally responsive and highly oriented (Figure 3C). They anchored thermally sensitive PNIPAm and Fe3O4 magnetic nanoparticles onto the surface of MoS2 nanosheets and then embedded them in 3D-printed hydrogel cubes. They controlled the orientation of the 2D nanosheets by applying a magnetic field. In a separate study, Yan et al. 92 prepared a highly oriented hydrogel using catechol-mediated precipitation of Fe3O4 nanoparticles encapsulated on the surface of dialdehyde cellulose-polydopamine (DAC-PDA) nanomaterials, cross-linked with PAM chains under a magnetic field. The hydrogel possessed high electrical conductivity, strong adhesion, and biocompatibility, making it a promising candidate for various advanced applications, especially for flexible wearable sensors. The above examples demonstrate the wide range of current applications of magnetic materials in the preparation of highly oriented hydrogels and their potential for future use in TE.

Non-magnetic materials exhibit an extremely weak response to external magnetic stimuli and can be categorized as either antimagnetic or paramagnetic 42, 95. Several non-magnetic materials, including peptides 96, 97, protein fibers such as fibrin and collagen 98-101, cellulose nanocrystals 31, 102, 103, carbon nanotubes 88, 104, graphene 105, 106, and rare earth elements 107, have been explored for the preparation of highly oriented structural hydrogels. For instance, Radvar et al. 96 designed peptides that contained phenylalanine residues at the C-terminus and fabricated hydrogels with highly oriented nanofiber alignment through the self-assembly of peptides with hyaluronic acid. By exploiting the antimagnetic properties of phenylalanine residues under magnetic fields (12T, 6T, 1T), they achieved highly oriented hydrogels. Echave et al. 31 incorporated cellulose nanocrystals (CNC) into a gelatin network and utilized the antimagnetic properties of CNC to create highly oriented hydrogels that mimicked the alignment of tendon tissues under a magnetic field. The preparation of highly oriented hydrogels using antimagnetic materials is promising but challenging; most non-magnetic materials require high-intensity external magnetic fields, which can be unsafe for clinical TE, limiting their practical use.

2.1.1.2. External Magnetic Field

For TE, magnetic fields can be categorized as static or alternating, depending on whether they are constant or continuously varying in amplitude and direction. Typically, static magnetic fields, generated with two parallel permanent magnets for a more uniform effect than single magnets, are used to generate the orientation of magnetic hydrogels. The size, composition, and purity of the magnets can be varied to control the magnitude of the static field 108. To date, several studies have employed static magnetic fields to orient MNPs in hydrogels along the magnetic field lines 76-80. Alternating magnetic fields can also be used to prepare highly oriented hydrogels 77, 109. Hu et al. 77 demonstrated this using a high-frequency (400 kHz) alternating magnetic field to orient MNPs into chains in a hydrogel matrix, enhancing its magneto-thermal properties. This technique allows control over thermogenesis by adjusting the angle between the hydrogel's structure and the magnetic field, making it suitable for controlled drug release.

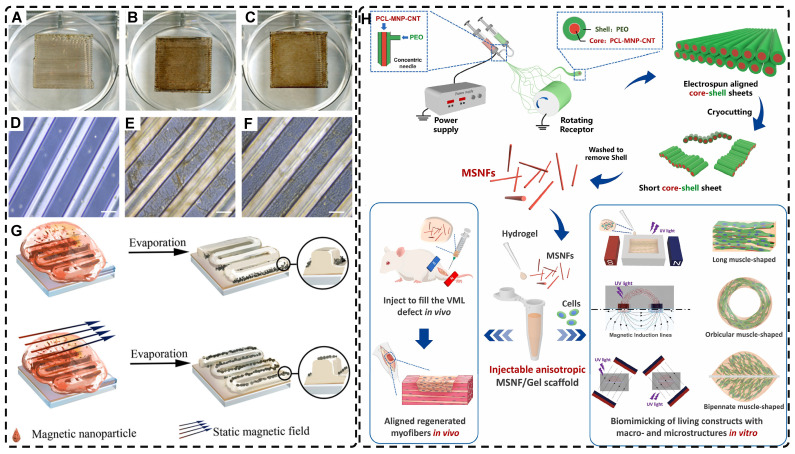

In addition, a magnetic field can guide the orientation arrangement of MNPs directly to assist in 3D printing or electrostatic spinning techniques. Hu et al. 110 also created hydrogels with oriented structures at both hundred microns and ~10 microns by combining 3D printing with MNPs induced by magnetic fields. These MNPs were sized similarly to adipose tissue-derived stem cells (ADSCs), allowing ADSCs to better sense the orientation structure and promote their differentiation towards osteogenesis (Figure 4A-G). Johnson et al. 51 used oleic acid-coated superparamagnetic iron oxide nanoparticles doped into poly-l-lactic acid (PLLA) to prepare small conduits of aligned magnetic fibers through electrospinning. These small conduits were combined with collagen and fibrinogen hydrogel solutions, and then prepared under magnetic fields to form a highly oriented hydrogel that directed the growth of primary dorsal root ganglion. Wang et al. 29 prepared monodisperse magnetic controlled short nanofibers (MSNFs) using an advanced coaxial electrospinning-cyrocutting method and further designed an injectable oriented MSNF/Gel nanofiber hydrogel scaffold (Figure 4H) that guided the 3D alignment and mimicry of cells with macroscopic and microscopic biological structures in vitro, demonstrating great potential in promoting skeletal muscle regeneration in vivo.

Figure 4.

A-F) Macroscopic and microscopic images of MNP-, MNP+MNA-, and MNP+MNA+. G) Schematic diagram of hydrogels with oriented structures by combining 3D printing with MNPs induced by magnetic fields. Adapted with permission from 110, copyright 2021, Nature Publishing Group. H) Schematic illustration of injectable oriented MSNF/Gel nanofiber hydrogel scaffold for biomimicking of living constructs with macro- and micro-structures in vitro and aligned regenerated myofibers in vivo. Adapted with permission from 29, copyright 2022, Elsevier.

In fact, designing oriented hydrogels by orienting magnetic materials in hydrogel matrices with low-intensity magnetic fields has been a preferred method 42, 111. This approach enhances biocompatibility, orientation, and magnetic responsiveness while also providing unique advantages in remote control, bionanotechnology, and mechanical properties. Randomly oriented MNPs can transit from superparamagnetic to weakly ferromagnetic; the alignment of MNPs changes their magnetic properties, explained by dipolar moments, creating local magnetic order that persists even without an external magnetic field 112. This enables MNPs to generate a micro-magnetic driving forces between the hydrogel scaffold and the cells, activating cell surface-sensitive receptors, ion channels and triggering mechanotransduction pathways for remote cell stimulation for remote cell stimulation to influence cell growth 59, 112-114. Several studies have shown that the bionic oriented structure of magnetic highly oriented hydrogels enhances cellular localization, proliferation, and differentiation, making them an excellent candidate for TE e.g., tendon regeneration, skin regeneration, and nerve regeneration 19, 29, 76, 81, 84, 85, 115, 116.

The biosafety and fate of biomimetic hydrogels in living organisms are critical for TE. Iron oxide-based MNPs, commonly used in MRI, drug delivery, thermal therapy etc., are recognized for their biosafety and eventual metabolism by the host immune system following in vivo administration 117-121. However, MNPs' effects and pharmacokinetics vary based on size, shape, chemical composition, and surface coating. Magnetic hydrogels interact differently with cells or tissues depending on their intended use, and comprehensive data are necessary to ensure their controlled, stable, safe, and effective use in clinical TE 122, 123. Future TE studies should consider as many of these factors as possible to demonstrate the potential and promising future of highly oriented hydrogels induced by magnetic fields in conjunction with other ordered manufacturing methods.

2.1.2. Electric-Field-Induced Highly Oriented Nanofiller Hydrogels

Applying an external electric field induces the distributed polarization of free electrons on particles, generating an electric dipole moment. This phenomenon enables the electric field to manipulate the alignment and assembly of materials in solution that have permanent or induced dipole moments, in addition to the magnetic field. The migration of dispersed particles in a fluid under a uniform electric field is referred to as electrophoresis (EP), while the migration of particles in a non-uniform electric field is referred to as dielectrophoresis (DEP) 124-126. Using different pre-gel media and electro-responsive building blocks of varying sizes, oriented structures with diverse orientations can be obtained by driving them with EP or DEP under different external electric fields. These oriented structures are then immobilized in the hydrogel matrix via a sol-to-gel state transition.

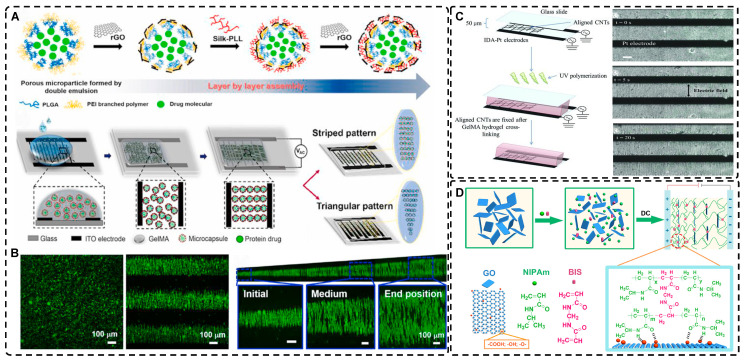

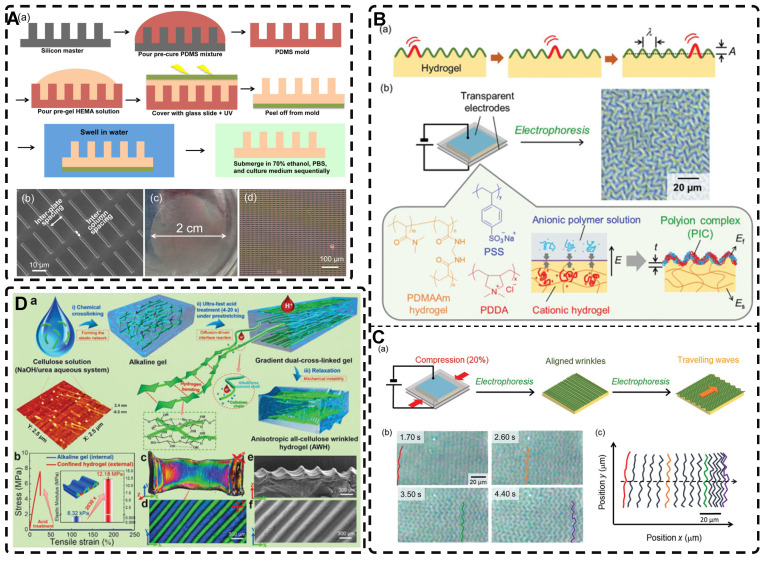

Electric fields, like magnetic fields, can induce materials of different morphologies to assemble into oriented structures in hydrogels. Morales et al. 127 and Zhang et al. 20 aligned 0D polystyrene particles into chains of different orientations using DEP forces under an alternating current (AC) electric field, creating endoskeleton-like particle chains, resulting in composite hydrogels with unique mechanical, optical, and anisotropic properties compared to isotropic hydrogels. Potential applications of these hydrogels include the development of soft robots and smart materials. Recently, Chiang et al. 128 designed graphene oxide/filament-poly-L-lysine layer-assembled PLGA 0D porous microcapsules (PM) loaded with NT-3 (Figure 5A), arranged in linear or triangular highly oriented structures within photocrosslinked gelatin methacrylic acid (GelMA) hydrogels by DEP. These triangular hydrogels can form a gradient distribution of NT-3 that could significantly guide the migration of NSCs and enhance spinal cord injury repair. Such spatially highly oriented 4D hydrogels have great potential to replace 3D hydrogels in bionic TE for better mimicking the pericellular microenvironment.

Figure 5.

A) a) Synthesis of 0D microcapsule assembly. b) The fabrication process of orienting 0D microcapsule alignment by DEP manipulation. B) Random distribution of 0D microcapsule and subsequent orientation alignment within the hydrogel after DEP. Adapted with permission from 128, copyright 2021, Elsevier. C) Schematic representation of the fabrication process for CNT alignment within the GelMA hydrogel and phase contrast images of the CNT alignment over time. CNTs were aligned after 20 seconds. Adapted with permission from 129, copyright 2013, Wiley-VCH. D) Scheme of preparation of 2D PNIPAm/GO oriented hydrogel. Adapted with permission from 131, copyright 2018, American Chemical Society.

Carbon nanotubes, commonly used as 1D filler materials in hydrogel substrates, can be assembled into oriented composite hydrogels under the influence of an external electric field 129, 130. Ahadian et al. 129 utilized DEP to align carbon nanotubes (CNTs) within GelMA hydrogels under a 2 MHz AC electric field at 20 V, resulting in oriented hydrogels that achieved superior maturation of muscle myofibers compared to hydrogels with randomly distributed CNTs (Figure 5B). Moreover, their oriented GelMA-CNT hydrogels, prepared under a 1 MHz AC electric field at 20 V, promoted the differentiation of mouse embryoid bodies (EBs) to cardiomyocytes more efficiently than isotropic hydrogels 130. Notably, cells on the oriented hydrogels exhibited enhanced migration and differentiation after applying electrical stimulation in the direction of orientation, which is attributed to the excellent electrical conductivity.

Electric fields have also been used to orient 2D graphene nanosheets as hydrogel filler materials 131, 132. Yang et al. 131 achieved an anodically oriented arrangement of negatively charged 2D graphene oxide (GO) through EP under a DC electric field, which resulted in a bionic gradient-oriented structure after cross-linking gelation in poly(N-isopropylacrylamide) hydrogels (Figure 5C). Its near-infrared light response and programmable motion make it a promising candidate for artificial muscles and soft brakes. MXenes are a new class of 2D materials that consist of transition metal carbides, nitrides or carbonitrides with the general formula of M n+1Xn (n = 1-3), where M represents an early transition metal (such as Sc, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo) and X is either carbon or nitrogen 133-135. Using the electric field-assisted forced-assembly technique, Dutta et al. 136 were able to obtain hydrogels with aligned Ti3C2Tx Mxene nanosheets. The gelation process depended on the type of metal electrode and redox potential, and adjusting the electric field distribution allowed for various sheet-like alignments, useful for capacitors and hot water evaporators. MXene's oriented structure also promoted cell adhesion, proliferation, and guided growth, highlighting its potential in biomedicine TE 137. Zhu et al. 138 induced highly charged nanosheets (Hectorite [Na0.5]inter[Li0.5Mg2.5]oct[Si4]teterO10F2) to form complex oriented structures in a pre-hydrogel matrix using patterned electrodes etched on glass substrates. Subsequently, these structures were immobilized by UV photopolymerization to form highly oriented bionic hydrogels that can deform in a directed way under external stimuli, which is compelling for applications in artificial muscles and soft brakes. Furthermore, the controllable patterned distribution of electric fields could be applied to orienting other charged particles through electrophoresis.

Several studies have shown that external electric fields can be utilized for straightforward, cost-effective, and flexible assembly of materials into bionic hydrogels with oriented structures, with great potential in TE. They are favored by researchers to regulate the growth, orientation, migration, and differentiation of various cell phenotypes in vitro and in vivo, given the involvement of endogenous electric fields in the growth and repair of cells, tissues, and organs 139. Future research can explore the potential of electric field induction to create oriented structural hydrogels and direct the alignment of cell growth within these hydrogels for TE.

However, it should not be ignored that electric fields are more reliant on the electrochemical stability of the hydrogel substrate material when filling the oriented hydrogel with nanomaterials or its own polymer network, compared with magnetic fields. Moreover, direct contact with the precursor solution during gel synthesis may result in unforeseen electrochemical reactions and/or electrophoresis. Consequently, optimization of voltage and current based on the electrochemical stability of various materials is necessary. These limitations greatly restrict the use of electric field-induced oriented hydrogels.

2.1.3. Mechanical Force-Induced Highly Oriented Nanofiller Hydrogels

Mechanical force-induced alignment involves arranging disordered polymer chains or filler materials in hydrogels in response to external stress, like stretching or shearing. The mechanical force or strain can be applied during or after partial or complete gelation, resulting in the alignment of the nanofiller material and/or hydrogel polymer network in the direction of the applied strain. Compared to other methods, this technique is simple, fast, and straightforward, making it widely used in the preparation of highly oriented nanocomposite hydrogels.

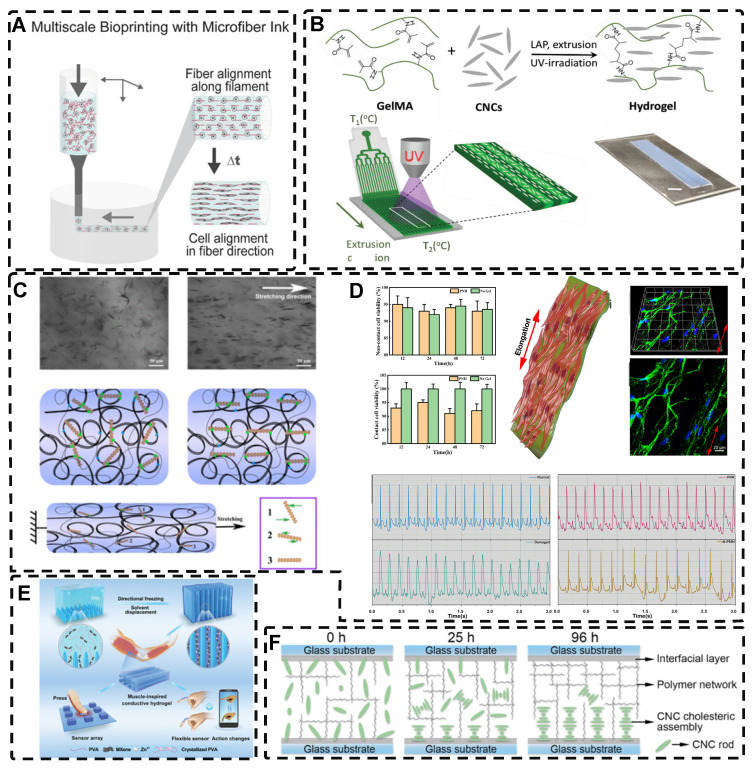

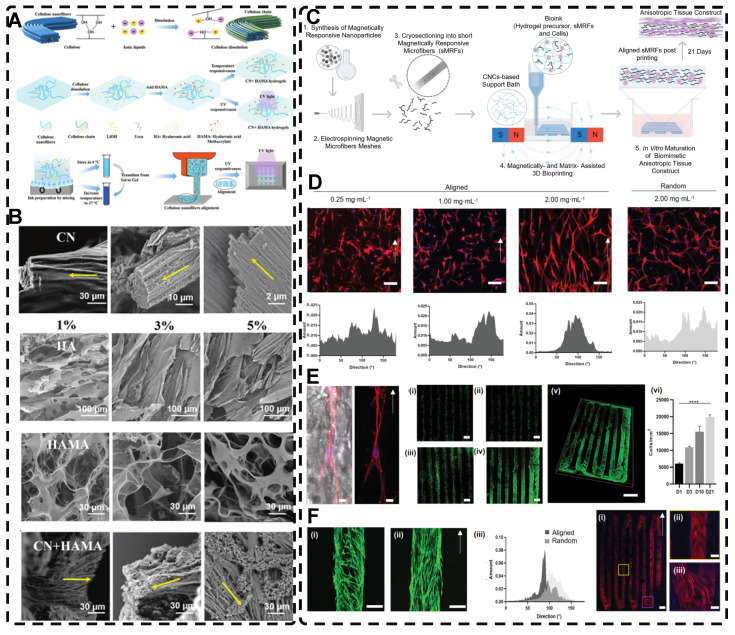

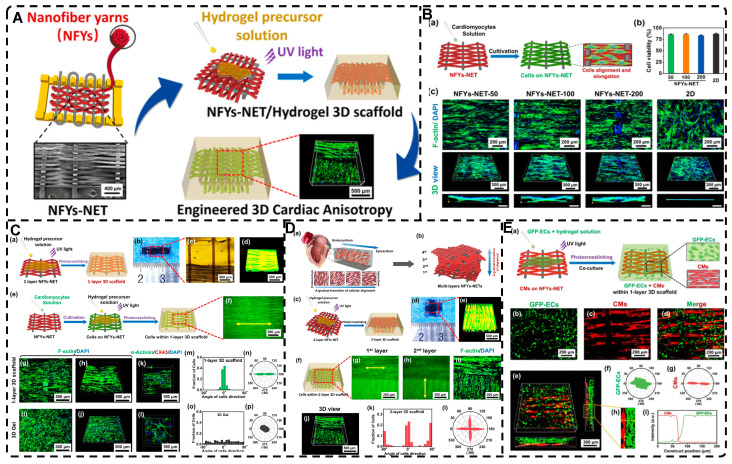

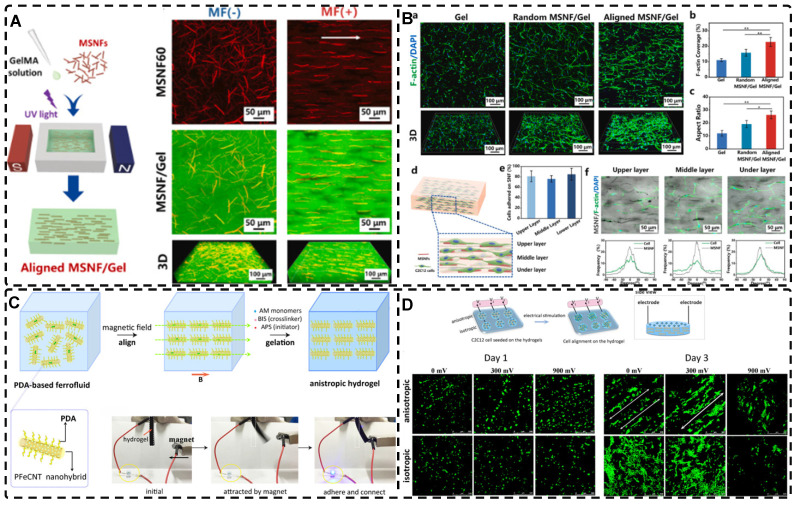

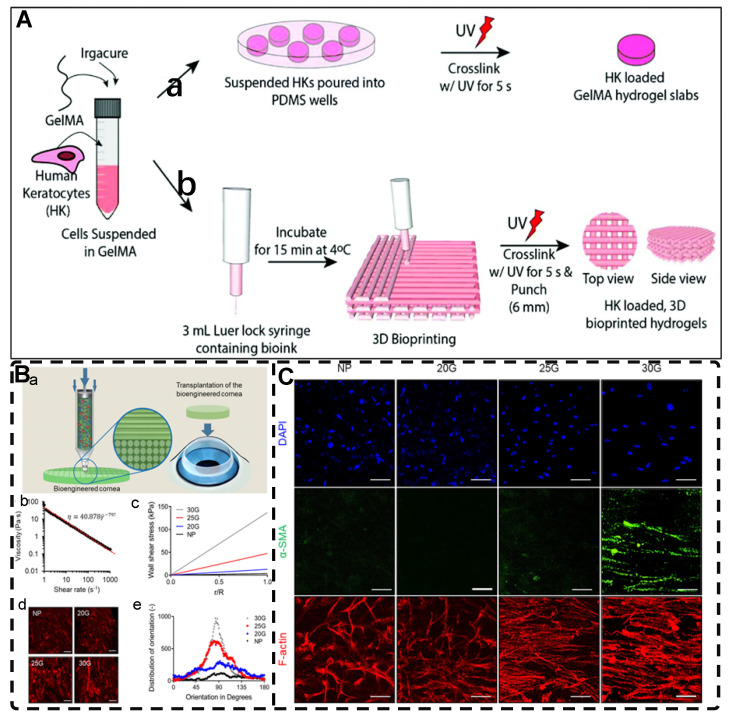

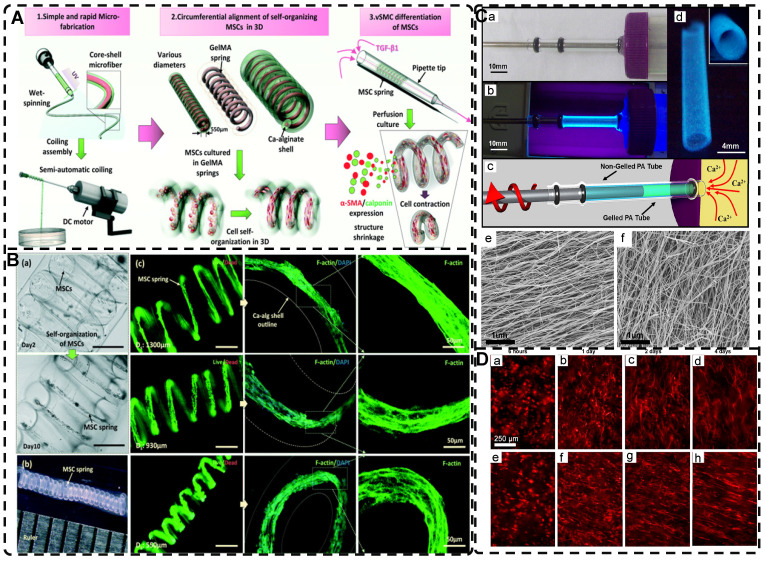

Among the mechanical induction methods, the preferred method for preparing highly oriented nanofiller hydrogels is using shear forces 21, 140-151, which induce larger and more well-ordered alignments compared to magnetic and electric fields, and cover larger areas. However, as with magnetic and electric fields, the metastable state of the induced highly oriented alignment structure may be changed or destroyed when the external field is removed or altered. To prevent loss of the oriented structure, the hydrogel can act as an external matrix to fix the highly oriented structure during the transition from the sol to the gel state. In recent years, 3D printing has led to tremendous growth in the application of bionic hydrogel scaffolds in TE. Shear force-induced directional alignment of polymer chains and/or filler materials within hydrogels is widely used during the printing process when the bioink passes through the nozzle and generates shear forces. Zhao et al. 21 utilized shear force to align and distribute CNTs within hydroxyethyl methacrylate (HEMA) gels, resulting in composite hydrogels with varying CNTs orientations that exhibited distinct mechanical properties. Kumacheva et al. 141-143 published a series of studies on the preparation of highly oriented hydrogels by shear induction (Figure 6B). They recently used a 3D printed microfluidic print head to extrude a hydrogel consisting of CNCs and GelMA through 16 microchannels with varying shear forces 143. Due to the different shear forces, the CNCs were oriented differently and subsequently photo-crosslinked to lock the oriented CNCs within the hydrogel matrix. This uniaxially oriented hydrogel could be applied in TE and regenerative medicine of e.g., artificial muscles.

Figure 6.

A) Schematic of prepared highly oriented, fiber-aligned hydrogels using shear forces during extrusion printing. Adapted with permission from 152, copyright 2021, IOP Publishing. B) (a,b)Schematic of shear-mediated extrusion of highly oriented hydrogel from the mixture of CNCs, GelMA, and LAP using a microfluidic printhead, and (c) photograph of the hydrogel sheet. Adapted with permission from 143, copyright 2021, Wiley-VCH. C) Confocal microscopy images of random aligned hydrogels and highly oriented hydrogels, and schematic of preparation of highly oriented PPy nanocomposite hydrogels after repeated stretching. D) They have good biocompatibility, induce targeted growth of cardiomyocytes and promote restoration of electrical conductivity. Adapted with permission from 153, copyright 2021, American Chemical Society. E) Schematic representation of the synthesis procedures of oriented void channels hydrogels with an ordered internal orientation structure and further applications in wearable flexible sensors and 3D sensor arrays. Adapted with permission from 162, copyright 2021, Wiley-VCH. F) Schematic of self-assembled oriented structures of CNC arrangement in the polymer network after UV curing with different standing times Adapted with permission from 168, copyright 2021, Elsevier.

In addition to orienting filler material, 3D printing can also align cells within hydrogels using shear force has become a popular topic in hydrogel development. When hydrogels contain both filler and cells, this aligned structure allows cells to grow along it, more effectively replicating the anisotropic nature of human tissues. Prendergast et al. 152 created fiber-aligned hydrogels by mixing hydrogel fiber suspensions, derived from mechanically fragmented electrospun scaffolds of norbornene-modified hyaluronic acid (NorHA), with GelMA. They used shear forces during extrusion printing to achieve high orientation (Figure 6A). After optimizing the suspension properties and printing flow rate, meniscal fibroblasts, mesenchymal stromal cells, or cardiac fibroblasts immobilized in composite-oriented hydrogels were induced to align by the highly oriented fibers, in contrast to random cell growth in non-oriented hydrogels. This provided the possibility to construct meniscus, cartilage, heart, and other tissues in vitro for TE repair and the development of physiological tissue models.

Stretch induction, the other common method for orienting hydrogel polymer chains, can also induce the alignment of filler materials within the hydrogel. Wang et al. 153 elastically stretched a composite hydrogel of sodium alginate, acrylamide, and polypyrrole (PPy), and found that PPy nanotubes tended to align parallel to the stretching direction and slide relative to the hydrogel network, resulting in the successful preparation of highly oriented PPy nanocomposite hydrogels after repeated stretching (Figure 6C). The highly oriented hydrogel induced by stretching can promote the formation of an elongated cellular morphology in cardiomyocytes, and its highly biocompatible, electrically conductive, and stretchable properties make it a promising candidate for cardiac TE (Figure 6D). Hu et al. 154 developed stretchable supramolecular hydrogels through host-guest interactions between β-cyclodextrin-modified tunicate cellulose nanocrystals (TCNCs) and damantane-containing polymers. Pre-stretching of the hydrogels caused the polymer chains and TCNCs in the network to move and align in the direction of the stretching force, and the highly oriented TCNC structures were then locked in the hydrogel network through the ionic coordination between Fe3+ and -COO on acrylic acid, by immersion in a FeCl3 solution. Additionally, the group utilized TCNC fillers to pre-stretch the oriented structure within a semi-rigid sodium alginate network and subsequently locked it via Ca2+/-COO ion coordination. These hydrogels exhibited superior mechanical properties compared to isotropic hydrogels due to their highly oriented filler structures, making them promising candidates for TE applications such as ligaments and tendons.

The preparation of highly oriented nanofiller hydrogels by mechanical induction is a simpler and more feasible method compared to other techniques. Mechanical tensile induction is more commonly used to achieve the highly oriented orientation of hydrogel polymer chains. While the development of 3D printing has led to an increased application of shear force induction in preparing highly oriented hydrogels, producing thicker highly oriented filled structure hydrogels is challenging due to the uneven distribution of shear force 37. In addition, the orientation of the filler material by shear force is influenced by various factors, such as the rheological properties of the ink, the properties of the filler material, and the specifications of the nozzle. If the ink viscosity is low, the orientation structure may be lost before the hydrogel gels, whereas high viscosity can result in higher flow resistance leading to clogging of the extruder and inconsistent ink deposition 123. Moreover, when hydrogels are used with cells, the impact of shear force on the cells should be considered, as excessive shear force can reduce the activity and function of the cells and even cause apoptosis 155. Therefore, in the field of TE, optimizing the relationship between shear force, nanomaterial orientation, hydrogel rheology, and viability of the loaded cells is a major challenge that needs to be addressed in producing highly oriented biomimetic hydrogels.

2.1.4. Other Strategies for Preparing Highly Oriented Nanofillers Hydrogels

In addition to using magnetic fields, electric fields, and mechanical forces, methods like directed freezing and self-assembly are also utilized to prepare highly oriented nanofiller hydrogels.

Directed freezing is a common method used to prepare directed macroporous hydrogels, as will be further discussed in Section 2.3. During the formation of ice crystals caused by a temperature gradient, the hydrogel network and/or filler material can be separated and confined to the interstitial region between the ice crystals, which allows the filler material to be oriented in the hydrogel while preparing the macroporous structure 156-161. Drawing inspiration from muscles, Feng et al. 162 developed oriented void channels hydrogels with an ordered internal orientation structure, by repeatedly freezing MXene nanosheets processed with Ti3AlC2, mixed with polyvinyl alcohol (PVA), and ZnSO4 in Polytetrafluoroethylene (PTFE) molds. The MXene nanosheets were connected to the PVA main chain through hydrogen bonding, and the addition of Zn2+ ions disrupted the electrostatic repulsion between the MXene sheets, generating high binding energy with the -OH groups on the MXene surface, forming an ion-chelated cross-linked network that was crucial in improving the mechanical properties of the hydrogels. During the freezing process, ice crystals created occupancy, while PVA chain segments and MXene nanosheets were squeezed at the water-ice interface to form a highly ordered arrangement in the hydrogel. This reduced the distance between nanosheets, thus enhancing the electrical conductivity of the hydrogel. Moreover, the formation of small microcrystals after repeated freeze-thawing of PVA strengthened the network structure of the hydrogel, resulting in excellent shape recovery properties. These outstanding properties make this muscle-inspired, highly oriented macroporous hydrogel a promising material for sensor applications (Figure 6E).

Self-assembly is a widespread phenomenon that plays a crucial role in biological growth and development. Examples include the hybridization of the DNA double helix, protein folding, and the self-assembly of troprocollagen into highly ordered and tightly arranged collagen fibers in tissues like tendons 163, 164. Drawing inspiration from these natural processes, self-assembly has become prominent in TE. This method, where the basic structural units within a hydrogel spontaneously assemble into an ordered structure through non-covalent bonds, such as hydrogen bonds, van der Waals forces, and hydrophobic forces 165, 166, has been researched for the construction of tissues and organs. The lack of need for external forces enhances cell-material interactions in TE, expanding the potential applications of self-assembly methods 167. Liu et al. 168 embedded self-assembled oriented structures of CNCs into polyethylene glycol derivatives/polyacrylamide hydrogel precursors. The arrangement of CNCs in suspension or pre-polymerization solution was influenced by time and self-assembly angle (Figure 6F); over time, the CNC rods sank due to gravity, and as the self-assembly angle increased from 0° to 90°, the arrangement of CNC rods transitioned from a chiral nematic structure to a symmetrical nematic structure. These hydrogels thus exhibited great potential as mechanical stress and temperature multi-stimulation sensors. Furthermore, the high transparency of hydrogels in visible light makes them suitable for anti-counterfeiting applications.

Self-assembly is a highly organized process at the molecular level, but achieving highly oriented spatial structures in hydrogels solely by using self-assembling filler material can be challenging. External forces are often needed to control the mesoscopic order of self-assembly and create highly ordered hydrogel-filled structures 169. For instance, Akhil Patel et al. 170 self-assembled graphene-doped chitosan (CHT) with gellan gum (GG) in a microfluidic chamber and aligned them with the aid of long needles (shear force) to form self-assembled hydrogels with a unidirectional fiber structure. These hydrogels were then manually collected to form films with graphene sheets evenly dispersed within them. The inclusion of graphene enhanced the mechanical strength and electrical conductivity of the hydrogels, promoted cell adhesion, and induced the initial orientation of myogenic cells, leading to the formation of multinucleated myotubes. As a result, these hydrogels may have potential applications in skeletal muscle TE.

In addition to shear, magnetism-induced and directional ultrasound can also be applied in conjunction with self-assembly 171-175. Despite the significant progress made in self-assembly strategies in recent decades, the preparation of highly oriented hydrogels through self-assembly still poses challenges, such as the development of simple and feasible strategies, and the need for more precise control of self-assembled modules.

In general, although most of the nanofillers materials themselves have excellent biocompatibility and thus influence the hydrogel performance, such as MNPs, CNTs, MXene and other materials, they can enhance the biocompatibility, mechanical properties and other characteristics of the composite hydrogel in different degrees and fulfill the function of the material itself. More importantly, when endowed with a highly oriented structure, the hydrogel nanofiller material more closely resembles the bionic structure of highly oriented tissues, thereby regulating tissue repair and regeneration. Although the study of how highly oriented hydrogels affect the mechanism of cell behavior is not clear so far, highly oriented nanofillers hydrogels occupy an important position in the field of TE.

2.2. Highly Oriented Polymer-Chain Network Hydrogels

In addition to manipulating the orientation of nanofiller materials, utilizing polymer-chain networks is another strategy for preparing highly oriented hydrogels. Highly oriented polymer-chain network hydrogel is a type of hydrogels which the polymer-chain networks of hydrogel monomers are oriented. And thevmost important preparation methods for highly oriented polymer-chains hydrogel is mechanical stretching.

2.2.1. Mechanical Stretch-Induced Highly Oriented Polymer-Chain Network Hydrogels

As previously discussed in the section on mechanical force-induced orientation of filled materials, mechanical stretching is also a widely used method for inducing the orientation of hydrogel polymer chains. This method can easily orient a network of randomly oriented hydrogel polymer chains along the stretching direction. However, due to the elastic nature of hydrogel polymer networks, it is difficult to maintain the structure as they tend to revert to their original, less ordered isotropic state once external forces are removed. For example, dual network hydrogels made of calcium alginate (ALg) and polyacrylamide (PAM), crosslinked ionically and covalently, are highly stretchable 2 . When stretched, the ionically cross-linked ALg chains in the stretched state become unlinked, break and align in the direction of the stretching force. However, the stable deformability of PAM chains makes the double network hydrogels reversible. To maintain the structure and maximize orientation retention after stretching, a strategy has been developed. Kim et al. 176 achieved an irreversible fixation state of the highly oriented structure by crosslinking alginate chains after directional stretching. This secondary ionic crosslinking largely retained the orientation after the stretching force was removed and increased the elastic modulus of the hydrogel. Additionally, by embedding mesoporous silica microrods as inorganic fillers in the double network hydrogels 177 they improved the mechanical properties of the hydrogels, creating structures that resemble ligaments or tendons.

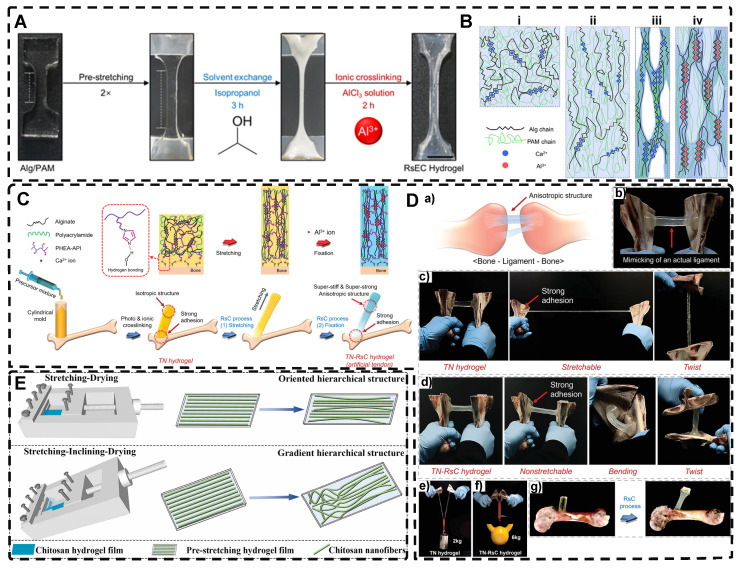

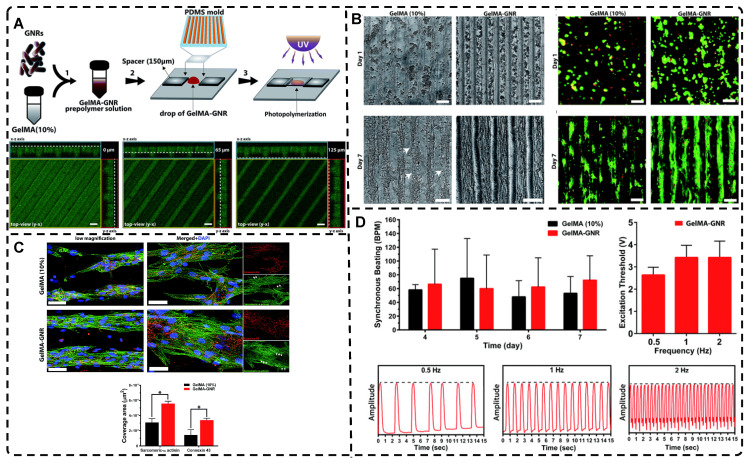

Chen et al. 178 also prepared highly oriented ALg/PAM hydrogels using stretching and subsequent ionic cross-linking strategies. Their hydrogel, which was significantly oriented in both microstructure and ion transport, provides a promising direction for the development of next-generation wearable electronics. In another study, Park et al. 179 replaced Ca2+ with Al3+ as the cross-linking agent (Figure 7A-B). By adjusting the degree of directional stretching, the mechanical properties of the hydrogel could be controlled within a certain range. The layered combination of oriented hydrogel cables prepared by applying a braiding textile process exhibited a significant load-bearing capacity and tensile behavior similar to that of tendons. Additionally, Choi et al. 180 developed highly oriented triple network hydrogels by combining poly (2-hydroxyethyl aspartamide) modified with aminopropyl imidazole (PHEA-API), which provided strong bone adhesion through multiple hydrogen bonds, and an energy-dissipative Alg/PAM double-network (Figure 7C-D). The triple network hydrogels had high tensile modulus and strength, mimicking natural ligaments, and exhibited high adhesion properties at the interface with bone. This work set the foundation for future hydrogels with high mechanical properties and adhesion to bone.

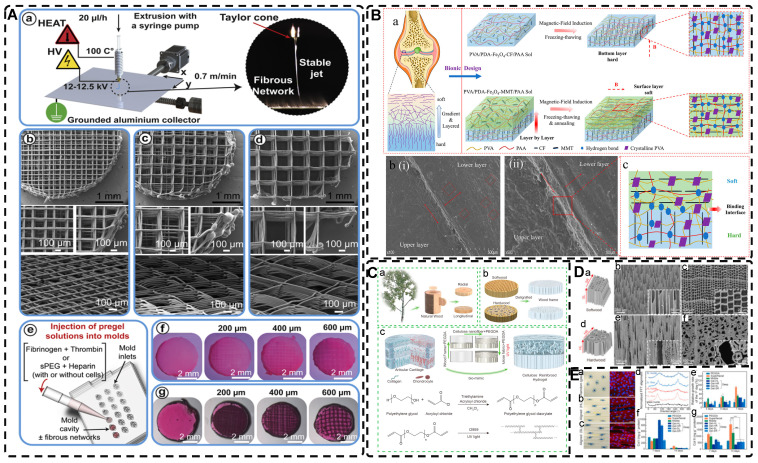

Figure 7.

A) Photographs of the highly oriented Alg/PAM hydrogels during the RsEC process; remodeling (pre-stretching) and subsequent solvent exchange followed by ionic crosslinking (RsEC). B) Illustrations of the changes in the molecular structure during the RsEC process: (i) as-prepared Ca2+-crosslinked Alg/PAM hydrogel, (ii) pre-stretched hydrogel, (iii) solvent-exchanged hydrogel, and (iv) Al3+ crosslinked hydrogel. Adapted with permission from 179, copyright 2022, American Chemical Society. C) Design of the strong, stiff adhesive highly oriented TN hydrogel. The final TN-RsC highly oriented hydrogel subjected to the RsC process was cross-linked by Al3+ ions and exhibited strong mechanical and adhesion properties. D) a) Schematic of the real ligament and anisotropic structure of the ligament, and b) photographs of TN-RsC hydrogel mimic the real ligament. Adapted with permission from 180, copyright 2022, Wiley-VCH. E) Graphical illustrations for the production of oriented and gradient chitosan hydrogel films with hierarchical structure via the self-made mold. Adapted with permission from 181, copyright 2022, Elsevier.

Thus, the preservation of the highly oriented structure after directional stretching can be achieved by controlling the supramolecular interactions between polymer chains. Mredha et al. 22 stretched rigid/semi-rigid alginate/cellulose chains to obtain a highly oriented single polymer network hydrogel. Subsequently, the supramolecular interactions between the highly oriented polymer chains, such as hydrogen bonds/ionic bonds, were strengthened by a specific drying method, thereby strengthening and maintaining the structure and preventing it from being destroyed upon rehydration. Li et al. 181 achieved highly oriented chitosan hydrogels using the same method, and the good biocompatibility of the hydrogel and the highly oriented structure induced the proliferation and orientation of osteoblasts and fibroblasts (Figure 7E). For flexible polymer chains, Chen et al. 182 prepared highly oriented PVA hydrogels using stretch-freezing cycles. Stretching oriented the PVA chains and brought the isotropic and loose PVA chains relatively close together, while freezing further brought the chains into close contact. The PVA chains in close contact easily adopted suitable conformations for hydrogen bond formation, and therefore more hydrogen bonds were formed between the oriented PVA chains, and even the cooperativity of hydrogen bonding became possible when consecutive hydrogen bonds were formed. As a result, the hydrogels maintained high orientation even after thawing, significantly enhancing their mechanical properties. Wang et al. 183 prepared PVA/NaCl highly oriented hydrogels using a hot stretch freezing method. These hydrogels exhibited various anisotropic ion transport behaviors, providing a new strategy for developing human sensors. Sun et al. 184 utilized the abundant hydrogen bonding between stiff aramid nanofibers (ANFs) and flexible PVA to achieve permanent alignment of the fiber network, resulting in hydrogels with robust mechanical properties, which was confirmed by SEM analysis. The excellent mechanics and functionality of these hydrogels, which mimic tendons, suggested their potential for use in advanced TE. Although the mechanical stretching method is simple and effective, its requirement for a large stretching force for the precursor hydrogel polymer network imposes some limitations.

2.2.2. Other Strategies for Preparing Highly Oriented Polymer-Chain Network Hydrogels

The polymer network of hydrogels can also be directed by ion diffusion, shear induction, and electric field induction.

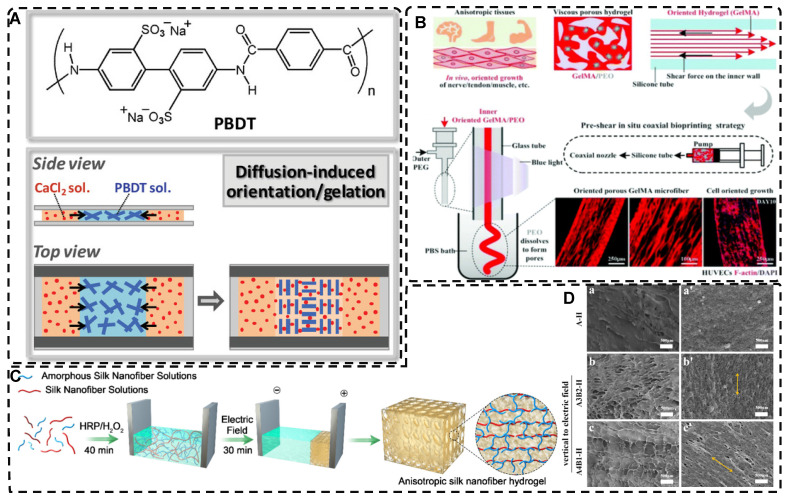

In directional ion diffusion, a cationic aqueous solution is brought into contact with an anionic polymer aqueous solution to drive directional cation diffusion. As diffusion proceeds, the anionic polymer chains are cross-linked, forming a hydrogel with a network of directional polymer chains 23, 185-187. Yang et al. 23 physically formed poly(2,2'-disulfonyl-4,4'-benzidine terephthalamide) (PBDT) gels with a highly ordered structure by uniaxially controlling the diffusion of Ca2+ as a cross-linking agent in the solution of PBDT in the reaction mold. The highly oriented PBDT gels were then immersed in an acrylamide (AAM) solution containing the chemical cross-linker to chemically form the PAAm gel as a second network, resulting in highly oriented double network hydrogels with excellent mechanical properties. Qiao et al. 185 designed masks with holes to guide the diffusion of multivalent metal ions into the bottom solution of anionic PBDT, allowing for the preparation of hydrogels with complex ordered structures (Figure 8A). By programming the diffusion field and adjusting the pattern and position of the mask containing holes, such highly oriented hydrogels with high mechano-optical sensitivity have potential for use in e.g., optical devices and sensors, and provide new ideas for preparing hydrogels without bionic complex tissues. In addition to polysaccharides and alginates, which have been used as anionic polymers in aqueous solutions, Ca2+, Zn2+, and Cu2+ have been used as the corresponding cations. Mredha et al. 186 formed an anisotropically oriented structured hydrogel on the surface of a core hydrogel by the controlled diffusion of cations in a pre-designed core hydrogel through a biopolymer storage solution, resulting in an oriented tubular alginate hydrogel with mechanical properties comparable to those of natural blood vessels. By controlling the concentration, diffusion time, and flow direction of ions and the size and shape of the core hydrogel, complex ordered tubular hydrogels with different 3D structures can be prepared, and even live cells can be carried. While this synthesis process is relatively simple, the relationship between the diffusion direction and polymer chain orientation has not been elucidated, and the resulting hydrogels had a non-homogeneous crosslink density gradient along the diffusion direction.

Figure 8.

A) Chemical structure of the rigid polyanion, PBDT, and schematic for the formation of anisotropic hydrogel by unidirectional diffusion of Ca2+ ions into PBDT solution from two opposite lateral sides. The diffusion induced the alignment of PBDT perpendicular to the diffusion direction near the entrance yet parallel to the diffusion direction at the middle region where the two fluxes met. Adapted with permission from 185, copyright 2019, WILEY‐VCH. B) Schematic illustration and effect of pre-shear bioprinting of highly oriented hydrogel microfiber-enabled oriented growth of cells. Adapted with permission from 191, copyright 2021, Royal Society of Chemistry. C) Process to Form Tough Silk Nanofiber Hydrogels with highly oriented Architectures. D) Characterization of SF hydrogels with highly oriented structures. Adapted with permission from 195, copyright 2020, American Chemical Society.

Shear forces can also be applied to orient a polymer chain network of a hydrogel. Nazhat et al. 188, 189 developed the gel aspiration-ejection (GAE) method, which uses shear stress to prepare injectable dense collagen (I-DC) hydrogels with highly oriented collagen fibers. The shear stress reshaped the geometry of the gel and aligned the collagen nanofibers along the long-axis direction. In addition to its ability to guide the orientation and alignment of inoculated cells, this highly oriented hydrogel mediated osteoblast differentiation of murine mesenchymal stem cells (MSCs) and supported and accelerated neuronal transdifferentiation. Additionally, a high strain mechanical stimulation of this highly aligned dense collagen fibril hydrogel induced tenogenic commitment of MSCs 190. Shao et al. 191 produced a highly oriented, porous, cell-laden GelMA hydrogel by mixing PEO, different types of cells, and GelMA (Figure 8B). The oriented hydrogel chains were sheared through a coaxial nozzle, followed by photo-crosslinking, fixation, and washing off polyethylene glycol PEG in PBS. The cells encapsulated in this hydrogel showed highly oriented growth behavior similar to that in vivo, offering more biomimetic options for TE. Chen et al. 14 developed an alginate-assisted microfluidic system that can be fine-tuned with a combination of methacrylate hyaluronan (HA-MA) and fibrin (Fb) as well as microfluidic shear and stretch parameters to optimize the homogeneous orientation of bionic nerve fibers. The highly oriented hydrogel was guided by nano-topography in a focal adhesion kinase-associated manner, promoting aligned neurite growth, directional extension of axons, and myelin maturation of Schwann cells. This bionic neural composite hydrogel has significant potential in neural regeneration as well as other bionic TE applications. Kim et al. 192 utilized the shear stress of 3D printing nozzles to prepare highly oriented collagen hydrogels that contained various types of cells. The physical and biochemical cues provided by the collagen induced attachment, growth, and alignment of cardiomyocytes (H9C2), preosteoblasts (MC3T3-E1), and human adipose stem cells (hASCs) in a synergistic manner. Additionally, the shear force-induced cell alignment was achieved without losing cell viability.

Electric fields can also orient hydrogel polymer chains in addition to inducing the orientation of the filler material within the hydrogel, as described in the previous section 193. Tong et al. 194 developed highly oriented chitosan hydrogels with complex layering by exposing chitosan solutions to electrical signals of varying intensities; chitosan chains assembled and aligned at the cathode and reacted with OH- ions to create an ordered structure. By regulating the electrical signal, a direct equilibrium between OH- diffusion rate and chitosan electrophoretic rate was established, allowing for precise and continuous control of the internal structure of the hydrogel. This novel approach for multilayered, orderly assembly of polysaccharides facilitates the replication of complex structures. It serves as a valuable tool in TE for creating for example bionic, multi-layered blood vessel structures. Ding et al. 195 used horseradish peroxidase (HRP) cross-linked with amorphous silk nanofibers (ASNFs) in an electric field to form the native hydrogel, and at the same time, β-sheet-rich silk nanofibers (BSNFs) were aligned and oriented as reinforcing chains during cross-linking, resulting in a structured composite with enhanced mechanical properties (Figure 8C-D). The highly oriented structure can provide various physical cues for cells, such as better stiffness and alignment aggregation, promoting stem cell proliferation and osteodifferentiation induction in vitro, with potential applications in bone TE. Moreover, Abu-Rub et al. 196 used an electric field to prepare highly oriented collagen fiber hydrogels, which supported directional orientation, growth, and guidance of nerve protrusions, overcoming the inhibitory aspect of myelin-associated glycoprotein on nerve protrusion growth. This work provides a reference for preparing nerve-guided catheters for spinal cord injury.

Compared to hydrogels filled with highly oriented materials, orienting the polymer chains is relatively straightforward, requires less equipment, and is more reproducible. Moreover, the oriented polymer chains within the hydrogel provide a continuous physical topographic cue to the cells, facilitating cell adhesion, migration, and growth, which is crucial for TE regeneration. Nonetheless, several preparation strategies have limitations. Mechanical stretching necessitates a specific polymer chain tolerance, ion orientation yields non-homogeneous hydrogels, and electric field induction may produce unexpected electrochemical reactions or electrophoresis of the polymer solution. Additionally, accurately replicating complex and intricate tissue structures while maintaining highly oriented structures and mechanical properties similar to human tissues remains challenging. However, as further investigations proceed, hydrogels with highly oriented polymer chains have a bright future in TE.

2.3. Highly Oriented Void Channel Hydrogels

The primary role of hydrogels in most applications is to regulate transport through pores, which is done by varying size and pore distribution; the porous structure of hydrogels plays a crucial role in regulating the transport of nutrients, gases, and waste and providing physical space for cell diffusion and communication, facilitating the formation of the final tissues. Conventional hydrogels are limited to a pore size of 100 nm, which hinders the potential for TE applications requiring micrometer-scale cell permeation. While some template-sacrificing methods, such as salt/porogen templating and gas foaming, can create hydrogels with micron-scale pores, they lack control over the interconnectivity and directionality of the pore network. Creating highly oriented continuous void channel hydrogels, makes it possible to better mimic natural biological tissues and more efficiently direct solute diffusion or transport.

2.3.1. Directional Freeze-Casting for Preparing Highly Oriented Void Channel Hydrogels

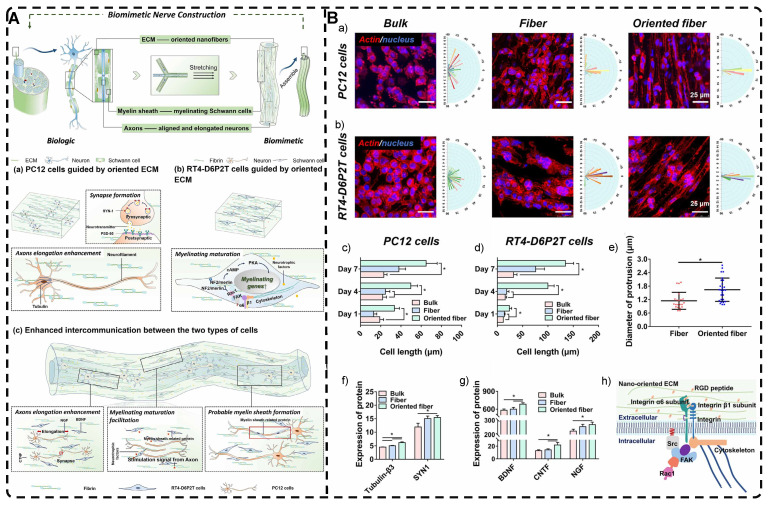

Directional freezing, also known as ice templating, freeze casting, or ice separation-induced self-assembly, involves freezing a pre-reaction solution in a cold bath along a unidirectional temperature gradient to form ordered ice crystals that grow in the freezing direction. As one of the sacrificial template methods, the solute material repels from the ice and separates into the interstitial region defined by the curing solvent during ice crystal formation, while the ice crystals sublimate and then form highly oriented 3D pore channels along the freezing direction without disturbing the interstitial region. The orientation, number, morphology, and size of the porous or channel structure can be controlled by several factors, including solvent content, freezing temperature, freezing rate, and ice template support. Nucleation theory is the fundamental principle used to control pore size and the number of pores; lower freezing temperatures and faster freezing rates result in an increase in hydrogel nucleation sites and the formation of a large number of smaller ice crystals, while at higher freezing temperatures, the distribution of nucleation sites becomes looser, and the ice crystals increase in size. Lowering the polymer/solute concentration can also produce larger pore sizes. This method is environmentally beneficial compared to other methods for preparing highly oriented hydrogels, and since most hydrogels are made from aqueous precursor solutions, it is relatively easy to control highly oriented ice crystallization. Therefore, this simple, effective, and controllable method is commonly used to prepare hydrogels with highly oriented pore channels by templates and has been widely used recently to design highly oriented void channel hydrogels with various functions.

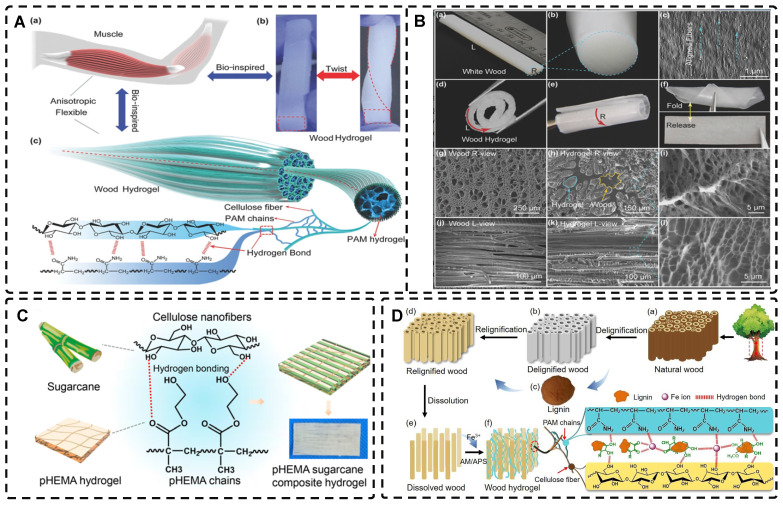

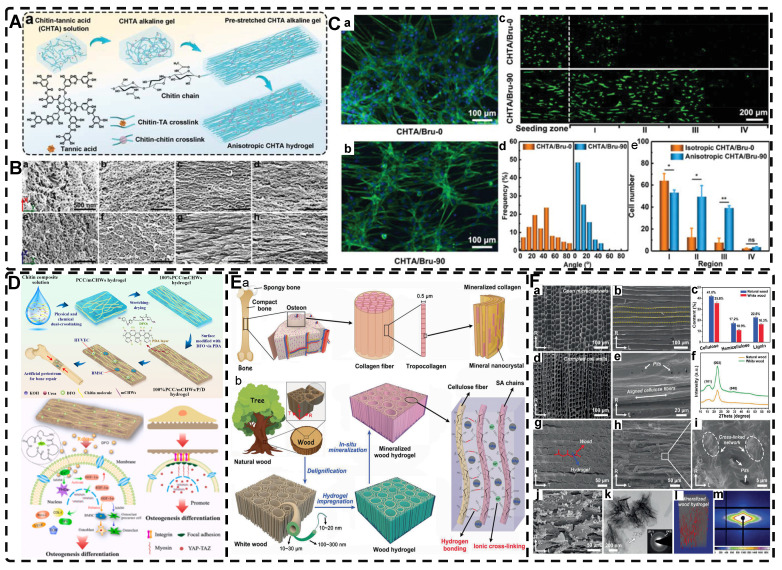

Since the initial report by Wu et al. 24 on preparing aligned porous hydrogels through unidirectional freezing, an increasing number of researchers have been using this method to develop highly oriented void channel hydrogels 162, 197-205. Liang et al. 198 used an ice-template freeze casting process to create highly oriented aligned micro/nanostructures in PVA hydrogels, followed by crystal growth initiated by thermal annealing (Figure 9A-B). The resulting hydrogels exhibited excellent mechanical properties, high fatigue threshold, anti-crack sensitivity, and anisotropy, with a 100-fold increase in fatigue threshold compared to normal PVA hydrogels after swelling to equilibrium in deionized water. These properties make it a promising material for use in low-cost, high-performance, and durable soft applications such as robotics and artificial muscles. Additionally, this strategy is applicable to various hydrogel materials, including polysaccharides, proteins, synthetic polymers, and corresponding polymer composites. Hua et al. 199 synergistically created highly oriented void channel hydrogels at different length scales across multiple levels, from millimeter to molecular, by using directional freeze-casting, resulting in the Hofmeister effect and subsequent salting-out treatment. The researchers used PVA as the model material, and the solution was directly soaked in a kosmotropic salt solution after directional freezing. Directional freezing caused the PVA hydrogel to form highly directional honeycomb microchannels with arranged pore walls, and the polymer was concentrated and accumulated in the gap area between the channels, which was then ready for the subsequent strong aggregation and crystallization of polymer chains through salting-out. The preconcentrated PVA chains strongly self-coalesced and phase-separated from the original homogeneous phase under the influence of kosmotropic ions, which in turn formed a mesh-like nanofiber network on the surface of the micron-sized aligned pore walls. The hydrogels developed by this method exhibited high strength, toughness, tensile properties, and fatigue resistance. Since the Hofmeister effect is present in various polymer and solvent systems, this method may offer some assistance for other originally weak hydrogel applications in TE.

Figure 9.

A) Schematic illustration for the highly oriented void channels hydrogels fabrication by using an ice-template freeze casting process. B) SEM images of the highly oriented void channels hydrogels. Adapted with permission from 198, copyright 2021, Wiley‐VCH. C) Schematic drawing of the void channels formed by unidirectional diffusion of divalent metal cations (Me2+) into a solution of sodium alginate, and cross-sections of the void channels in hydrogels formed by different cations. (a-h). Scanning electron microscopy images for highly oriented void channels hydrogels. Adapted with permission from 218, copyright 2022, Elsevier.

The subzero temperature environment during the fabrication of directed freeze casting may impair cell viability and limit the application of hydrogels intended to encapsulate functional cells in TE 206, 207, as the formation of ice crystals in the extracellular matrix results in an osmotic gradient in the cell membrane, leading to cellular dehydration and damage 208. Although cryoprotectants such as dimethyl sulfoxide and glycerol can be used, their concentration at low temperatures may cause osmotic shock or toxic damage to cells and lead to adverse effects in humans, such as clonic seizures and cardiac arrest 208, 209. Therefore, the development and exploration of advanced cell cryopreservation agents, such as vitrification agents, ice recrystallization inhibitors, macromolecular cryoprotectants, ice nucleating agents, and regulation of biochemical pathways, will contribute to expanding the applications of targeted cryogels in TE.

2.3.2. Other Strategies for Preparing Highly Oriented Void Channels Hydrogels

Similar to the directional freeze-casting method, He et al. 210 developed highly oriented pore hydrogels using a crystal template technique called "hot ice",the principle of which is that needle-like and micrometer-sized aligned NaAc·3H2O crystals can form from saturated NaAc solutions at room temperature. A saturated NaAc and agarose mixture solution was prepared at a high temperature of 90°C, which was then cooled to room temperature to create an agarose gel in the supersaturated solution. Next, NaAc·3H2O crystals were placed on the surface of the supersaturated mixture solution to induce the formation of oriented crystals in the hydrogel in the vertical direction. Finally, the crystals were removed by multiple washes with water to obtain oriented pore hydrogels. The highly oriented pore hydrogels prepared using this technique exhibited great potential in TE due to the resulting high survival rate of cultured NIH3T3 cells and linear alignment.

The physical template method is a common technique for preparing highly oriented void channel hydrogels. This process involves polymerizing the hydrogel precursor solution in a mold which then determines the orientation and shape of the void channels in the hydrogel. For instance, Chen et al. 211 were inspired by the preparation of oriented pore PLGA scaffolds and used a mold comprising seven uniformly distributed stainless steel rods and glass tubes to fabricate oligo(polyethylene glycol) fumarate (OPF) and positively charged OPF (OPF+) hydrogel scaffolds with oriented void channels. These hydrogels were designed to closely match the mechanical properties of rat spinal cord tissue, and animal studies showed that OPF+ hydrogel promoted a unique pattern of axonal regeneration with a large number of regenerated axons concentrated in the channel. Subsequent studies have explored the potential value of such hydrogels loaded with cells or growth factors for neurological and spinal cord injuries 212-214. To further improve tissue integration and uniaxial tissue growth, Dumont et al. 215 utilized a two-step cross-linking process to modularly assemble hydrogel tubes prepared via templates. The multiple void channels of the hydrogel tubes promoted tissue integration while the directional void channels supported uniaxial tissue growth, which is crucial for highly structured tissue regeneration. Hydrogel tubes can be easily customized by cutting and packaging to the desired size and shape with directed regenerative void channels. This strategy has the potential for personalized repair of spinal cord, peripheral nerve, muscle, and vascular tissue defects.

Directed ion diffusion can also be used to prepare highly oriented pore channels in hydrogels. Weidner et al. 216, 217 achieved this by using electrolyte solutions containing Ba2+, Sr2+, Zn2+, and Ni2+ cations to prepare highly oriented capillary pore hydrogels with capillary sizes ranging from 12-100 μm. The oriented capillary pore channels were formed through a self-organizing process driven by the unidirectional diffusion of divalent cations into sodium alginate sols, opposite diffusion gradients, and the dissipation of the driving force of convective processes during friction of alginate chains. This led to the continuous precipitation of metal alginate, resulting in highly oriented capillary gels with honeycomb-like structures. The mechanical properties and chemical stability of this hydrogel were recently studied by Müller et al. 218, who found that the mechanical properties and degradation stability can be varied by the degree of chemical cross-linking and the formation of interpenetrating networks (Figure 9C). The higher the concentration of cross-linking agent, the higher the mechanical strength. Additionally, the mechanical strength of the hydrogel generally decreased with an increase in capillary pore diameter, and the concentration of the cross-linking agent positively correlated with the resistance of the hydrogel to degradation.

3D printing enables the fabrication of hydrogel structures with highly oriented pore channels of various dimensions and directions. Li et al. 219 utilized digital light processing-based 3D printing to produce HA gelatin-based hydrogels with controlled and oriented microchannels, and they investigated the impacts of different microchannel sizes on NSC neural stem cell viability and proliferation. The outcomes demonstrated that directional microchannels could direct the migration of NSC spheroids, and the aligned microchannels could constrain the neuronal growth of NSCs within the channels, promoting alignment and preventing disorganization. Furthermore, 3D printing could accurately match the size of the hydrogel to the size of the lesion area, offering promising potential for personalizing TE treatments, with the highly oriented channel structure facilitating directed cell growth.

Hydrogels with highly oriented void channels facilitate the transport, diffusion, and growth of macromolecules like growth factors or cells due to the presence of micrometer or larger pore channels compared to void-free channel hydrogels. However, their inherently poorer mechanical properties compared to homogeneous void-free hydrogels can limit their use in load-bearing tissues 199. Template-sacrifice methods such as directional freeze-casting methods are simple, easy, economical, and environmentally friendly but do not provide precise geometric control of the material's dimensional characteristics compared to techniques like 3D printing. Additionally, accurately simulating natural tissue organs remains a challenge. In the future, hydrogels with highly oriented pore channels should aim to improve their mechanical strength and achieve more precise bionic direction.