Abstract

Low-cost thermoelectric materials with simultaneous high performance and superior plasticity at room temperature are urgently demanded due to the lack of ever-lasting power supply for flexible electronics. However, the inherent brittleness in conventional thermoelectric semiconductors and the inferior thermoelectric performance in plastic organics/inorganics severely limit such applications. Here, we report low-cost inorganic polycrystalline Mg3Sb0.5Bi1.498Te0.002, which demonstrates a remarkable combination of large strain (~ 43%) and high figure of merit zT (~ 0.72) at room temperature, surpassing both brittle Bi2(Te,Se)3 (strain ≤ 5%) and plastic Ag2(Te,Se,S) and organics (zT ≤ 0.4). By revealing the inherent high plasticity in Mg3Sb2 and Mg3Bi2, capable of sustaining over 30% compressive strain in polycrystalline form, and the remarkable deformability of single-crystalline Mg3Bi2 under bending, cutting, and twisting, we optimize the Bi contents in Mg3Sb2-xBix (x = 0 to 1) to simultaneously boost its room-temperature thermoelectric performance and plasticity. The exceptional plasticity of Mg3Sb2-xBix is further revealed to be brought by the presence of a dense dislocation network and the persistent Mg-Sb/Bi bonds during slipping. Leveraging its high plasticity and strength, polycrystalline Mg3Sb2-xBix can be easily processed into micro-scale dimensions. As a result, we successfully fabricate both in-plane and out-of-plane flexible Mg3Sb2-xBix thermoelectric modules, demonstrating promising power density. The inherent remarkable plasticity and high thermoelectric performance of Mg3Sb2-xBix hold the potential for significant advancements in flexible electronics and also inspire further exploration of plastic inorganic semiconductors.

Subject terms: Thermoelectrics, Electronic devices, Mechanical properties

Authors realize simultaneous high thermoelectric performance and high plasticity in Mg-based semiconductors at room temperature, demonstrating their great potential for use in flexible thermoelectrics.

Introduction

Thermoelectric (TE) materials have gained significant attention for their ability to convert heat into electricity in a solid-state form1. With the rapid advancement of flexible electronics2, there is a growing demand for TE materials exhibiting both high performance and plasticity at room temperature for reliable and sustainable power generation3,4. Despite the discovery and development of numerous high-performance TE materials in inorganic semiconductors over the past century, they are inherently brittle5. Unlike metallic bonds in metals or polymer chains in organics, the directional covalent bonds in inorganic semiconductors impede atomic layer slipping, leading to sudden and unpredictable breakdown under external forces6. For instance, commercially available Bi2Te3-based compounds typically withstand less than 5% compressive strain before fracturing abruptly7,8. The undesirable brittleness imposes severe limitations on the available processing methods, yield rates, and overall service lifespan of the TE semiconductors, thereby hindering their broader application in various fields, including but not limited to flexible electronics.

In recent years, several inorganic semiconductors with remarkable plasticity have been uncovered, primarily within the chalcogenide systems9–15. Notably, ZnS demonstrates a remarkable 45% compressive strain in darkness9, while Ag2S and its alloys can endure over 10% tensile strain10,16–20. Additionally, van der Waals crystals like InSe11 and SnSe221 can exhibit obvious flexibility, easily being bent and curved. Compared to organic semiconductors, plastic inorganic semiconductors typically possess superior carrier mobility22,23, making them promising candidates in flexible touch panels24, memristors25,26, and TE generators3,27. However, among these plastic inorganic semiconductors, only Ag2(Te, Se, S) and SnSe2 have been reported to exhibit moderate TE performance at room temperature, with a figure of merit (zT = S2σT/κ, where S, σ, κ and T represent Seebeck coefficient, electrical conductivity, thermal conductivity, and absolute temperature, respectively) of ~0.43,8,21, which are notably higher than that of plastic organic TE materials, but fall significantly short of that in conventional TE compounds. Currently, the absence of materials exhibiting simultaneous high room temperature TE performance and plasticity imposes a significant barrier to the advancement of flexible TE technology.

Low-cost n-type Mg3Sb2-xBix has attracted significant interest since its discovery due to its impressive high TE performance28–31. Peak zT values of 1.5–1.8 at mid-temperatures (~773 K) have been achieved in Mg3Sb2-xBix with x = 0.5–1.0. Apart from its exceptional TE performance, abundant raw materials, high fracture toughness, and good machinability make n-type Mg3Sb2-xBix highly competitive for future practical applications, particularly at room temperature32,33. Optimizing the Bi content plays a significant role in enhancing the room-temperature performance of Mg3Sb2−xBix. The synergic effects of reduced bandgap, increased band curvature, strengthened phonon scattering, and enhanced grain size by Bi alloying make Mg3Sb2-xBix (x = 1.4–1.75) exhibit zT values above 0.6 at room temperature34,35, which approach to that of the state-of-the-art n-type Bi2(Te, Se)3 and are much superior to the plastic Ag2(Te, Se, S) and organic TE materials31,36–39.

The remarkably high zT values of Mg3Sb2-xBix have also sparked significant development in its TE modules over the past decades40–42. However, these advancements have predominantly focused on rigid TE modules, neglecting the potential application of Mg3Sb2-xBix in flexible electronics. Given its notable TE performance and potential plasticity at room temperature36, there exists a compelling opportunity to explore the suitability of Mg3Sb2-xBix for power generation in flexible electronics. Achieving simultaneous high TE performance and plasticity in Mg3Sb2-xBix remains a challenge.

In this work, we first focus on binary Mg3Sb2 and Mg3Bi2, uncovering an exceptionally high compressive strain of >30% in polycrystalline samples. Remarkably, single-crystalline Mg3Bi2 also exhibits excellent deformability when subjected to bending, cutting, and twisting. By optimizing the Bi contents to modulate both TE performance and plasticity, a large compressive strain of 43% and a high zT of 0.72 at room temperature are achieved simultaneously in polycrystalline Mg3Sb0.5Bi1.498Te0.002. The observed dense dislocation network is attributed to facilitating atomic layer slipping in Mg3Sb2-xBix, while the persistent Mg-Sb/Bi bonds during slipping are crucial for maintaining structural integrity. Additionally, we demonstrate the good machinability of Mg3Sb2-xBix, which can be processed to unbroken small granules and thin TE legs via dicing and cutting. By assembling thin TE legs on flexible substrates, we have successfully fabricated both in-plane and out-of-plane flexible modules based on polycrystalline Mg3Sb0.5Bi1.498Te0.002, showcasing their potential in flexible electronics. The simultaneous high plasticity and high TE performance of Mg3Sb2-xBix, as well as the demonstration of flexible Mg3Sb2-xBix TE modules, pave the way for its utilization in flexible electronics and will spur the development of high-performance plastic TE semiconductors.

Results

High TE performance and remarkable plasticity in Mg3Sb2-xBix

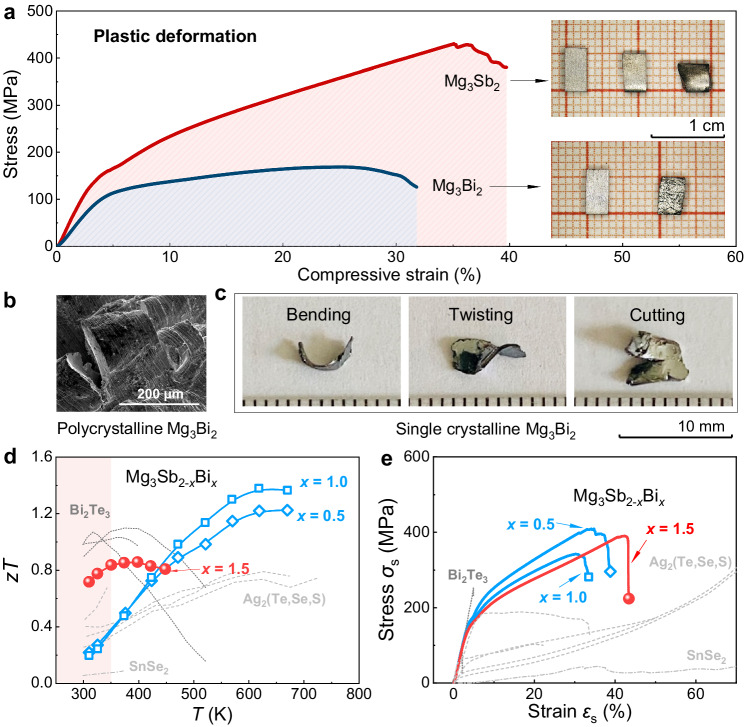

Mg3Sb2−x Bix represents a solid solution combining Mg3Sb2 and Mg3Bi2. As depicted in Fig. 1a, both polycrystalline Mg3Sb2 and Mg3Bi2 exhibit remarkable plastic deformation, achieving over 30% strain under uniaxial compression. The optical images inset in Fig. 1a visually demonstrate their high plasticity, where polycrystalline Mg3Sb2 can be compressed from 6 mm to 3.6 mm. It should be mentioned that unlike Mg3Sb2, which breaks suddenly with a noticeable drop in the stress, Mg3Bi2 can be compressed after the first noticeable drop in the stress. The full compressive data for Mg3Bi2 is shown in Supplementary Fig. 1, which indicates that Mg3Bi2 can be compressed to about 1.6 mm (suggesting a compressive strain of about 80%) after experiencing two noticeable drops in the stress. However, upon examining the optical image of Mg3Bi2 after compression, it can be seen that Mg3Bi2 bulk shatters into some small pieces. Thus, it is not convincing to take this high compressive strain of 80% as the true compressive performance of Mg3Bi2. In addition, polycrystalline Mg3Sb2 and Mg3Bi2 also exhibit decent tensile strains of about 7.4% and 12.7%, respectively (Supplementary Fig. 2), surpassing numerous inorganic semiconductors and ceramics and even better than plastic Ag2S (4.2% elongation)10. The fracture surface morphology of polycrystalline Mg3Sb2 and Mg3Bi2 after compression is displayed in Supplementary Fig. 3 and Fig. 1b, where the fracture surface of polycrystalline Mg3Bi2 exhibits a notable wavy-like characteristic, indicative of its better plasticity and deformability than polycrystalline Mg3Sb2. Moreover, it is found that single-crystalline Mg3Bi2 in Fig. 1c also demonstrates remarkable deformability, which can be manually bent, twisted and cut, showcasing its potential for flexible electronics, while single-crystalline Mg3Sb2 cannot be bent and twisted like single-crystalline Mg3Bi2.

Fig. 1. The plasticity of Mg3Sb2-xBix.

a Compressive stress and strain curves of polycrystalline Mg3Sb2 and Mg3Bi2 with optical images inset showing Mg3Sb2 and Mg3Bi2 after 33.3% and 16.7% compression, respectively; b fracture surface morphology of compressed polycrystalline Mg3Bi2; c optical images of single-crystalline Mg3Bi2 by bending, twisting and cutting; d temperature dependence of zT and e compressive strain–stress curves of polycrystalline Te-doped Mg3Sb2-xBix, Bi2Te3-based compounds, Ag2(Te,Se,S) and SnSe23,7,8,18–21,27,37,58.

While both Mg3Sb2 and Mg3Bi2 exhibit favorable plasticity, their TE performances, particularly at room temperature, are rather inferior. Bi alloying is rather crucial in optimizing the room temperature zT of Mg3Sb230,34. As shown in Supplementary Fig. 4, Bi alloying has significant impacts on electrical transport properties of Mg3Sb2-xBix. The downward shift of the peak S in Mg3Sb2-xBix with higher Bi contents suggests that the bandgap is reduced, in consistency with previous reports30–32,34. Additionally, when Bi content (x) increases to 1.5, there is an obvious rise in room temperature σ, which suggests that the grain boundary scattering is weakened due to the larger grain sizes30,34 (fracture morphology of Mg3Sb0.5Bi1.5 in Supplementary Fig. 3). Moreover, Bi alloying leads to lower κ due to the enhanced point defect scattering of phonons. As a result, for polycrystalline Mg3Sb2-xBix, substantial improvement in room-temperature zT is obtained after increasing the amounts of Bi (x = 1.5). A peak zT of 0.72 has been attained at room temperature, while zT values of 0.72–0.86 can be obtained within the near room temperature range (300–478 K) in Mg3Sb0.5Bi1.498Te0.002, rivaling the commercial high-cost polycrystalline Bi2(Te,Se)3. Besides the high TE performance achieved in Mg3Sb2-xBix, as shown in Fig. 1e, all polycrystalline Mg3Sb2-xBix samples demonstrate considerable plastic deformation, with compressive strains exceeding 30%, displaying cracks upon finally fracturing. It can also be noticed that the fracture morphology of polycrystalline Bi-rich Mg3Sb2-xBix (x = 1.5) closely resembles that of Mg3Bi2 (Supplementary Fig. 3). Notably, polycrystalline Mg3Sb0.5Bi1.498Te0.002 achieves an impressive strain of 43%, overriding the Sb-rich Mg3Sb2-xBix (x = 0.5 and 1). The higher strain of Mg3Sb0.5Bi1.498Te0.002 can be attributed to the better plasticity of Mg3Bi2 compared to Mg3Sb2 as revealed above, which is consistent with the result recently reported43. As a result of the optimized Bi contents, a combination of high plasticity and high TE performance at room temperature has been achieved in low-cost Bi-rich Mg3Sb0.5Bi1.498Te0.002, which significantly surpasses both commercial Bi2(Te,Se)3 (strain ≤ 5%), plastic Ag2(Te,Se,S) and organic TE materials (zT ≤ 0.4).

It should be mentioned that Te doping has fewer effects on the plasticity of Mg3Sb2-xBix. As shown in Supplementary Fig. 5, besides the high plasticity of Mg3Sb2-xBix with Te doping (Fig. 1e), p-type polycrystalline Mg3Sb2-xBix without doping also exhibits high plasticity (30% compressive strain) across various Sb/Bi ratios. This suggests that plasticity is an inherent characteristic of the Mg3Sb2-xBix system, and also implies that plasticity is less dependent on electrical transport properties. Therefore, by fine-tuning the carrier concentration and mobility, it is feasible to achieve simultaneous high TE performance and high plasticity in Mg3Sb2-xBix, i.e., the combination of large strain (~43%) and high zT (~0.72) achieved in this work via sintering, which is much better than the result reported recently via cold compression43.

Plastic deformation mechanism

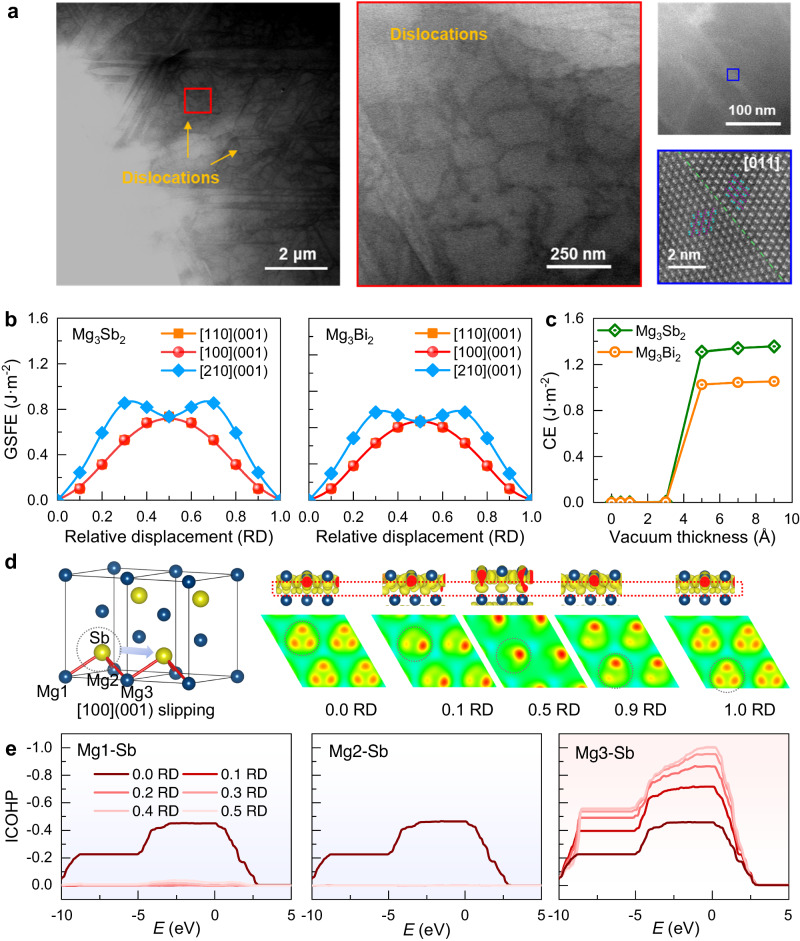

Generally, in metals and alloys, dislocations are pivotal in facilitating atomic layer slipping, thus enabling plastic deformation. To reveal the origin of high plasticity in Mg3Sb2-xBix semiconductors, a microstructure study using the scanning transmission electron microscope (STEM) was conducted. Single-crystalline Mg3Sb2 was selected due to its high resistance against moisture in the air, favorable for efficient microstructure analysis44. As shown in Fig. 2a, a notable presence of dislocations can be identified, which will contribute to the high plasticity of Mg3Sb2. During the plastic deformation of Mg3Sb2, the slipping can readily occur owing to the dislocation generation and movement. In addition, an orientation difference can be observed in Mg3Sb2 single crystal, which should also contribute to the plasticity by providing an alternative energy-consuming mechanism, akin to twinning- and amorphization-facilitated plastic deformation in high-entropy alloys45.

Fig. 2. The plastic deformation mechanism of Mg3Sb2-xBix.

a STEM images of single-crystalline Mg3Sb2 revealing dislocations and different crystal orientations; b the GSFE of Mg3Sb2 and Mg3Bi2; c the CE of Mg3Sb2 and Mg3Bi2; d the CDDs between Mg and Sb atoms in the slipped layer; e the ICOHPs for Mg1-Sb, Mg2-Sb and Mg3-Sb bonds with different relative displacements RDs.

Why do the slipping and dislocations easily occur in Mg3Sb2 semiconductors? Recent studies on Ag2S and other plastic inorganic semiconductors propose small slipping energy or generalized stacking fault energy (GSFE) and large cleavage energy (CE) as criteria for high plasticity10. In this study, the GSFE and CE of Mg3Sb2 and Mg3Bi2 have been calculated, as shown in Fig. 2b, c, respectively. Taking Mg3Sb2 as an example, both [100](001) and [110](001) directions are identified as probable slipping directions due to their small GSFE values. Considering the crystal symmetry in Mg3Sb2 (trigonal crystal structure with P−3m1 space group), there are 8 equivalent slip systems. Moreover, the maximum CE (of ~1.4 J m−2) is twice the maximum value of GSFE along these directions (of ~ 0.7 J·m−2), indicating ease of slipping but difficulty of cleaving. The abundance of available slip systems, coupled with small GSFE and large CE, contributes to the high plasticity of Mg3Sb2. Similar findings can be confirmed in Mg3Bi2, which also exhibits small GSFE and high CE.

Intrinsically, from a chemical bonding perspective, unlike the delocalized metallic bonds in metals, covalent and ionic bonds typically hinder plastic deformation due to localized electrons. However, in the case of inorganic semiconductors like Mg3Sb2 and Mg3Bi2, which both possess covalent bonds according to the charge density difference (CDD) in Supplementary Fig. 6, it is intriguing that they exhibit such high plasticity. Focusing on the [100](001) slipping direction of Mg3Sb2, we calculated the variation of chemical bonding during slipping. As shown in Fig. 2d, CDDs at five different relative displacements (RDs) during slipping were examined, with their corresponding projections on the (001) plane highlighted in the red dashed box. The whole CDDs with RD increasing from 0 to 1 can be found in Supplementary Figs. 7, 8.

Initially (0.0 RD), three bonds exist between Sb and Mg atoms. As RD increased slightly to 0.1, one Mg-Sb bond disappeared quickly, while the other two Mg-Sb bonds can still be observed. Further increasing RD to 0.5 results in only one remaining Mg-Sb bond, with the other two broken. Surprisingly, with a continued increase of RD, new Mg-Sb bonds are sequentially formed until returning to the initial state with three intact bonds. Consequently, despite the breakage of some Mg-Sb bonds during slipping, at least one bond remains within the slipped layers, crucial for maintaining the structural integrity of Mg3Sb2 without fracturing during deformation.

To gain a deeper understanding of these persistent bonds between Mg and Sb atoms, we calculated the integrated crystal orbital Hamilton population (ICOHP) for Mg1-Sb, Mg2-Sb, and Mg3-Sb bonds. Illustrated in Fig. 2e, as the RD increased, both Mg1-Sb and Mg2-Sb bonds swiftly break, aligning with CDD results in Fig. 2d. However, Mg3-Sb bonds, instead of breakage, undergo continuous strengthening, ensuring the retention of bonding states in the slipped layer. In conventional covalent compounds, directional chemical bonding between slipping layers typically leads to bond breakdown and crack formation during slipping, but the circumstance is quite different for Mg3Sb2. Although Mg1-Sb and Mg2-Sb bonds are broken during deformation, Mg3-Sb bonds persist and even strengthen, which maintains the structural integrity. Similar trends are observed in Mg3Bi2, where Mg1-Bi and Mg2-Bi bonds break while Mg3-Bi bonds persist and strengthen during slipping (Supplementary Figs. 9–11). Consequently, from a chemical bonding perspective, the high plasticity of Mg3Sb2 and Mg3Bi2 can be attributed to the persistent Mg3-Sb/Bi bonds in the slipped layer, which prevents structural collapse and may also facilitate the dislocation generation and movement, just as the high density of dislocations observed in STEM (Fig. 2a).

High toughness and good machinability in Mg3Sb2−xBix

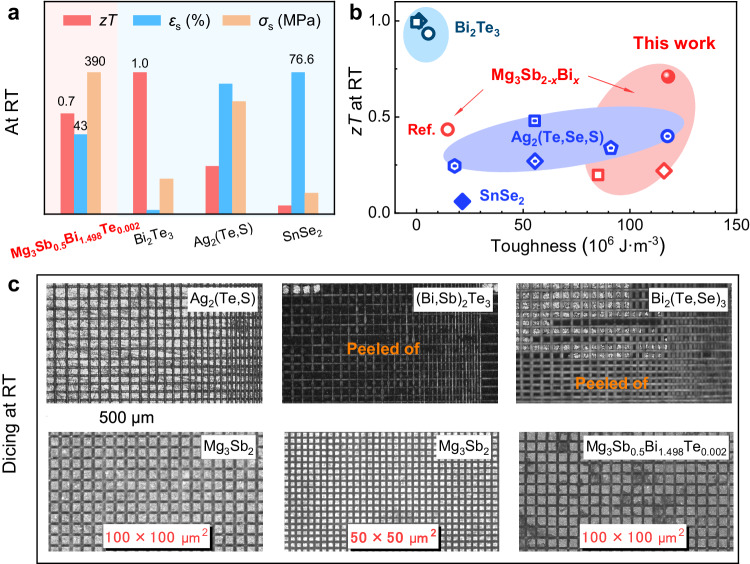

Synthesized TE materials are typically cut or diced into TE legs, and materials with high toughness can withstand substantial energy, allowing them to be cut or diced into small dimensions with a high yield rate. Toughness can be assessed by the area under the strain-stress curve. Therefore, alongside high plasticity, high strength is also crucial for materials exhibiting high toughness. Figure 3a summarizes both TE and mechanical performances of Mg3Sb0.5Bi1.498Te0.002, Bi2Te38, Ag2(Te,S)20 and SnSe221. Among them, polycrystalline Mg3Sb0.5Bi1.498Te0.002 exhibits high zT, high plasticity (high strain εs), and high compressive strength σs simultaneously at room temperature. This compelling combination of TE and mechanical performance makes polycrystalline Mg3Sb0.5Bi1.498Te0.002 particularly suitable for room temperature applications, especially considering its low cost. Due to the high strength and plasticity, all polycrystalline Mg3Sb2-xBix possesses intrinsic high toughness. As shown in Fig. 3b, polycrystalline Mg3Sb0.5Bi1.498Te0.002 displays simultaneously high TE performance and high toughness at room temperature, making it competitive among the current plastic TE materials.

Fig. 3. The mechanical performance, TE performance and machinability of polycrystalline Mg3Sb2-xBix.

a The summarized zT, εs and σs of Mg3Sb0.5Bi1.498Te0.002, Bi2Te3-based compounds8, Ag2(Te,S)20 and SnSe221 at room temperature; b the room temperature zT vs. toughness in Mg3Sb2-xBix, Bi2Te3-based compounds, Ag2(Te,Se,S) and SnSe23,7,8,18–21,27,37,58; c the optical images of diced Ag2(Te,S), (Bi,Sb)2Te3, Bi2(Te,Se)3, Mg3Sb2 and Mg3Sb0.5Bi1.498Te0.002.

Due to the high toughness resulting from both high plasticity and strength, polycrystalline Mg3Sb2-xBix can be diced into small sizes without damage. In contrast, commercial polycrystalline (Bi,Sb)2Te3 and Bi2(Te, Se)3 fail to be diced much smaller with numerous granules peeled off, as demonstrated in Fig. 3c (detailed dicing images with gradual cut distances from 200 μm to 10 μm can be found in Supplementary Fig. 12). For Mg3Sb2, intact granules with dimensions of about 100 × 100 μm2 and 50 × 50 μm2 can be readily obtained with a high yield rate. Mg3Sb0.5Bi1.498Te0.002 with superior TE performance can also be effectively diced with the dimension of 100 × 100 μm2. However, diced (Bi,Sb)2Te3 and Bi2(Te,Se)3 with dimensions of ~ 150 × 150 μm2 show obvious damaged edges, as shown in Supplementary Fig. 13. Recently, micro-TE devices made of micrometer TE legs have gained much attention, especially for potential applications in 5G communications. The high yield rate of smaller dimension TE legs in Mg3Sb2-xBix will also benefit its development in micro-TE modules.

Prototype flexible TE modules based on Mg3Sb2-xBix

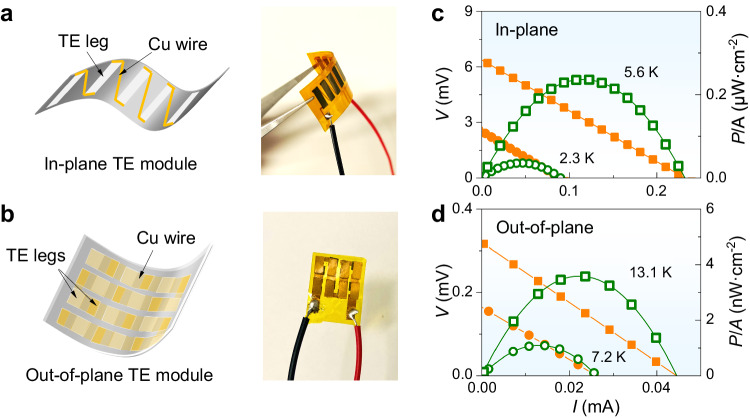

Due to the high toughness demonstrated above, bulk Mg3Sb2-xBix can be processed into TE legs with varied and small dimensions (Supplementary Fig. 14) and exhibit possible flexibility if the thickness is thin enough46. Considering its high TE performance and high plasticity, thin Mg3Sb2-xBix TE legs are very suitable to be fabricated as flexible TE modules. Here, we fabricate and demonstrate prototype flexible in-plane (Fig. 4a) and out-of-plane (Fig. 4b) TE modules based on high-performance Mg3Sb0.5Bi1.498Te0.002. These prototype TE modules are all assembled using flexible polyimide (PI) film bases, Cu conducting wires and Mg3Sb0.5Bi1.498Te0.002 TE legs.

Fig. 4. The in-plane and out-of-plane TE modules of Mg3Sb2-xBix.

The fabricated (a) in-plane and (b) out-of-plane TE module based on Mg3Sb0.5Bi1.498Te0.002 with its schematics on the left; the output voltage V and power density P/A of (c) in-plane and (d) out-of-plane TE modules. The temperature value is the temperature difference of the module ΔTmodule.

The in-plane TE module consists of nine n-type Mg3Sb0.5Bi1.498Te0.002 legs, exhibiting a maximum output voltage V of ~6.2 mV and a maximum power density P/A of ~0.24 μW·cm−2 when the measured temperature difference of the module ΔTmodule is ~5.6 K (Fig. 4c), where the P is the output power, A is the area of the TE module. Considering the length of the TE legs L, the obtained normalized power density P×L/A of this in-plane TE module reaches 14.4 μW·m−1, significantly surpassing that of PEDOT and Poly[Ax(M-ett)]-based organic flexible TE modules27. However, compared to the state-of-art in-plane flexible TE modules based on Ag2S0.5Se0.527, the performance of this Mg3Sb0.5Bi1.498Te0.002 flexible TE module is relatively inferior, primarily due to the substantial internal resistance, about 27 Ω in Mg3Sb2-xBix against 9 Ω in Ag2S0.5Se0.527. The high internal resistance in Mg3Sb0.5Bi1.498Te0.002 flexible TE module arises from the significant contact resistance between Mg3Sb0.5Bi1.498Te0.002 and electrodes. As shown in Supplementary Fig. 15, the contact resistance between Mg3Sb0.5Bi1.498Te0.002 and Cu electrode is very high, of about 3500 μΩ·cm2. Given the excellent room-temperature zT of plastic Mg3Sb0.5Bi1.498Te0.002, the reduction of the interfacial resistance of the flexible TE module holds the promise of substantially enhanced performance and fosters future applications in flexible electronics.

In the case of the out-of-plane TE module, it consists of 8 Mg3Sb0.5Bi1.498Te0.002/Cu pairs. A maximum V of 0.3 mV and P/A of 3.9 nW·cm−2 are achieved with ΔTmodule of 13.1 K (Fig. 4d). However, it is notable that the performance of the out-of-plane TE module is significantly inferior to that of the in-plane module. This is primarily attributed to the small effective temperature difference ΔTleg established along the thickness direction of TE legs. The ΔTleg can be calculated by using the output voltage of the modules and the Seebeck coefficient of the TE material3. Specifically, the calculated ΔTleg is 3.1 K for the in-plane TE module (with a measured ΔTmodule of 5.6 K), whereas it is only 0.17 K for the out-of-plane TE module (with a measured ΔTmodule of 13.1 K). Considering this ΔTleg for the calculation of the normalized power density P/(A × ΔT2) proposed by ref. 3, it reaches 0.13 μW·cm−2·K−2, which surpasses nearly all organic-based flexible TE modules but falls short of Ag2S-based flexible TE modules3, primarily due to the much higher internal resistance ~ 7 Ω. It is worth mentioning that regardless of whether it is an in-plane or out-of-plane TE module made of Mg3Sb0.5Bi1.498Te0.002, the interface between materials and electrodes remains the principal obstacle limiting the module’s high performance, despite the materials exhibiting high TE performance. Additionally, in previous Ag-based flexible TE modules, high-performance p-type AgCuSe-based materials were used3. This also suggests possible ways to future improve the output performance of Mg3Sb2-xBix flexible modules if high-performance p-type Mg-based TE materials are developed. Optimization of the interface, such as using appropriate interface materials47,48, and advancement of high-performance p-type plastic TE materials hold promise for achieving significantly better performance of the flexible TE module based on Mg3Sb2-xBix.

Discussion

In this study, the inherent high plasticity of Mg3Sb2 and Mg3Bi2 has been revealed. Despite intrinsic covalent/ionic bonding, polycrystalline Mg3Sb2 and Mg3Bi2 hold over 30% compressive strain. By optimizing the Bi contents, compressive strain ~43% and zT ~ 0.72 can be achieved simultaneously in Bi-rich polycrystalline Mg3Sb0.5Bi1.498Te0.002 at room temperature, surpassing the room temperature performance of known plastic TE semiconductors. The persistent Mg-Sb/Bi bonds within the slipped layer, along with the abundance of dislocations, are revealed as important contributors to the high plasticity of Mg3Sb2-xBix, ensuring structural integrity maintenance and facilitating atomic layer slipping during deformation, respectively.

Furthermore, the high toughness resulting from the high plasticity and strength enables polycrystalline Mg3Sb2-xBix to be easily diced into granules below 100 × 100 μm2 without edge damage and cut into TE legs of various dimensions. Both in-plane and out-of-plane flexible TE modules based on polycrystalline Mg3Sb0.5Bi1.498Te0.002 have been assembled and demonstrated, exhibiting much higher performance compared to organic-based flexible TE modules with promising opportunities for further enhancement by reducing the interface resistance. The revealed intrinsically high plasticity, high TE performance as well as good machinability in polycrystalline Mg3Sb2-xBix will advance their potential applications in flexible electronics.

Methods

Materials synthesis

Mg3Sb2-xBix and Mg3Sb2-xBix-yTey (x = 0.5, 1.0, 1.5; y = 0.002, 0.01, 0.02) were synthesized by mechanical alloying with 10% excessive Mg contents. Mg powders (99.8%), Sb powers (99.9%), Bi powders (99.9%) and/or Te powders (99.999%) were used and weighed in the glove box, and then mechanically alloyed for 2 h (SPEX-8000D, PYNN). The obtained powder products were solidated by vacuum spark plasma sintering (LABOX-650F, Sinter Land Inc.) under 973 K and 60 MPa for 2 min. The relative density of all sintered samples reaches above 97%. The single-crystalline Mg3Sb2 and Mg3Bi2 were grown by self-flux method with excess Sb/Bi44,49. The Ag2(Te,S) used for dicing tests were obtained by melting method. High-purity Ag shots (99.999%), Te shots (99.999%), and S flakes (99.999%) were used and weighted accordingly, which were then loaded and sealed in the quartz tube for the melting at 1273 K19, and the commercial Bi2(Te,Se)3 and (Bi,Sb)2Te3 were produced by hot extrusion.

Characterization and measurements

The compressed fracture surface morphology was investigated by the SEM (Hitachi, S-3400N). The microstructures of Mg3Sb2 single crystal were studied by high-resolution STEM (Cs corrected JEOL ARM 200F microscope). The TE performance zT of Mg3Sb2-xBix-yTey was calculated by the formula: zT = S2σT/κ, in which the S and the σ were measured by Linseis LSR-3 system with measurement uncertainties of S and σ about ±5% and ±3%, respectively, and the κ was calculated by the formula: κ = DρCp, where the thermal diffusivity D was measured by Netzsch LFA457 with about ±3% uncertainty, the sample density ρ was estimated by the Archimedes method, and heat capacity Cp was calculated according to a previous study50. The calculated uncertainty of zT is within ±10%. Compressive tests of cuboids (3 × 3 × 6 mm3) and tensile tests of plates (3 × 0.7 × 27 mm3) were performed by a universal testing machine (Siomm, JVJ-20S, China) under a loading rate of 1 mm·min−1. The experiments of dicing were carried out by using a commercialized dicing machine (Qisheng-D0620, China) with a spindle speed of about 30,000 rpm and a dicing speed of 0.3 mm/s. The dicing did not cut the ingot thoroughly, which allowed the cut blocks to remain attached to the original ingot. Two types of cutting programs have been used. The first is a regular cut, where the ingot is cut into blocks of 150 × 150 μm2, 100 × 100 μm2 or 50 × 50 μm2. The second is a gradual cut, where the cut distance decreases in every two cut steps: 200 μm, 150 μm, 100 μm, 50 μm, 20 μm, and finally 10 μm.

Module fabrication and test

High-performance Mg3Sb0.5Bi1.498Te0.002 TE legs with dimensions of 1.8 × 0.12 × 6 mm3 and 1.8 × 1.8 × 0.12 mm3 were used for fabricating in-plane and out-of-plane TE modules, respectively. The thickness of Mg3Sb0.5Bi1.498Te0.002 TE legs is first reduced by cutting to 0.5 mm and then by manually polishing to 0.12 mm. PI films and Cu sheets were used as support bases and conducting wires. High conductive Ag pastes were used to connect TE legs and Cu wires. Contact resistance between Mg3Sb0.5Bi1.498Te0.002 and Cu joint was measured by using a home-build instrument51. A home-build instrument with a source meter (K2400, Keithley) was used to measure the output voltage and source current of the TE modules. The temperature gradient is applied along the length direction in the in-plane module and thickness direction in the out-of-plane module by one-side heating and the other-side cooling. Two K-type thermocouples were used to record the temperatures of the hot and cold sides of the module, respectively. ΔTmodule was obtained by the differences of the temperatures measured by the two thermocouples, while ΔTleg was calculated by using the output voltage of the modules and the Seebeck coefficient of the TE material3.

First-principles calculations

First-principles calculations were performed by the software Vienna ab initio Simulation Package (VASP) with the projector augmented-wave method based on density functional theory52,53. Generalized gradient approximation - Perdew-Burke-Ernzerhof type (GGA-PBE) and modified Becke-Johnson were used as the exchange-correlation functionals54,55. Plane-wave energy cutoff, Hellmann-Feynman force on each atom energy and convergence criterion were set as 500 eV, 0.001 eV·Å−1 and 10−8 eV, respectively. Geometry relaxation and self-consistent static calculations adopted the Gamma-centered k-point sampling with k = 30/L and 60/L, respectively, where the L is the corresponding lattice parameter. The GSFE and CE were calculated based on the 2 × 2 × 4 supercell. To analyze the GSFE, 2 × 2 × 2 half of the supercell is artificially shifted along a specific crystallographic direction at 10-step RDs. For CE analysis, a vacuum layer with varied thickness is inserted into the half of the supercell to simulate the artificial separation of the crystal into two parts. VASPKIT56 and Lobster57 have been used to post-process the calculated data, including CDD and ICOHP.

Supplementary information

Acknowledgements

This work was supported by the National Key Research and Development Program of China (No. 2023YFB3809400, T.Z.), the National Natural Science Foundation of China (No. U23A20553, T.Z.; No. 92163203, T.Z.; No. 52101275, C.F.), the Fundamental Research Funds for the Zhejiang Provincial Universities (No. 226-2023-00001, C.F.).

Author contributions

A.L., C.F. and T.Z. designed the project. A.L. and Y.W. prepared the samples and carried out the transport measurements, mechanical tests and first-principles calculations. Y.W., Y.L. and X.Y. provided the samples of Ag2(Te,S), Bi2(Te,Se)3 and (Bi,Sb)2Te3. P.N. and B.G. carried out the scanning transmission electron microscopy study. A.L. fabricated the flexible thermoelectric modules and measured the performance with input from K.L. A.L. analyzed the data and wrote the original manuscript with input from Y.W. and C.F. C.F. and T.Z. supervised the whole project. All the authors reviewed and edited the manuscript.

Peer review

Peer review information

Nature Communications thanks Chengyi Hou, Longlu Wang and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information file).

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

These authors contributed equally: Airan Li, Yuechu Wang.

Contributor Information

Chenguang Fu, Email: chenguang_fu@zju.edu.cn.

Tiejun Zhu, Email: zhutj@zju.edu.cn.

Supplementary information

The online version contains supplementary material available at 10.1038/s41467-024-49440-5.

References

- 1.He J, Tritt TM. Advances in thermoelectric materials research: Looking back and moving forward. Science. 2017;357:eaak9997. doi: 10.1126/science.aak9997. [DOI] [PubMed] [Google Scholar]

- 2.Sanderson K. Electronic skin: from flexibility to a sense of touch. Nature. 2021;591:685–687. doi: 10.1038/d41586-021-00739-z. [DOI] [PubMed] [Google Scholar]

- 3.Yang Q, et al. Flexible thermoelectrics based on ductile semiconductors. Science. 2022;377:854–858. doi: 10.1126/science.abq0682. [DOI] [PubMed] [Google Scholar]

- 4.Nan K, et al. Compliant and stretchable thermoelectric coils for energy harvesting in miniature flexible devices. Sci. Adv. 2018;4:eaau5849. doi: 10.1126/sciadv.aau5849. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Hou C, Zhu M. Semiconductors flex thermoelectric power. Science. 2022;377:815–816. doi: 10.1126/science.add7029. [DOI] [PubMed] [Google Scholar]

- 6.Schoeck, G. Advances in Applied Mechanics, Vol. 4 (eds H. L. Dryden & Th von Kármán) 229–279 (Elsevier, 1956).

- 7.Zhu Y-K, et al. Mediating point defects endows n-type Bi2Te3 with high thermoelectric performance and superior mechanical robustness for power generation application. Small. 2022;18:2201352. doi: 10.1002/smll.202201352. [DOI] [PubMed] [Google Scholar]

- 8.Qiu J, et al. 3D printing of highly textured bulk thermoelectric materials: mechanically robust BiSbTe alloys with superior performance. Energy Environ. Sci. 2019;12:3106–3117. doi: 10.1039/C9EE02044F. [DOI] [Google Scholar]

- 9.Oshima Y, Nakamura A, Matsunaga K. Extraordinary plasticity of an inorganic semiconductor in darkness. Science. 2018;360:772–774. doi: 10.1126/science.aar6035. [DOI] [PubMed] [Google Scholar]

- 10.Shi X, et al. Room-temperature ductile inorganic semiconductor. Nat. Mater. 2018;17:421–426. doi: 10.1038/s41563-018-0047-z. [DOI] [PubMed] [Google Scholar]

- 11.Wei T-R, et al. Exceptional plasticity in the bulk single-crystalline van der Waals semiconductor InSe. Science. 2020;369:542–545. doi: 10.1126/science.aba9778. [DOI] [PubMed] [Google Scholar]

- 12.Zhang J, et al. Plastic deformation in silicon nitride ceramics via bond switching at coherent interfaces. Science. 2022;378:371–376. doi: 10.1126/science.abq7490. [DOI] [PubMed] [Google Scholar]

- 13.Gao Z, et al. High-throughput screening of 2D van der Waals crystals with plastic deformability. Nat. Commun. 2022;13:7491. doi: 10.1038/s41467-022-35229-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Wu Y, et al. Twisted-layer boron nitride ceramic with high deformability and strength. Nature. 2024;626:779–784. doi: 10.1038/s41586-024-07036-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Li X, et al. Multislip-enabled morphing of all-inorganic perovskites. Nat. Mater. 2023;22:1175–1181. doi: 10.1038/s41563-023-01631-z. [DOI] [PubMed] [Google Scholar]

- 16.Yang S, et al. Ductile Ag20S7Te3 with excellent shape-conformability and high thermoelectric performance. Adv. Mater. 2021;33:2007681. doi: 10.1002/adma.202007681. [DOI] [PubMed] [Google Scholar]

- 17.Gao Z, et al. p-Type plastic inorganic thermoelectric materials. Adv. Energy Mater. 2021;11:2100883. doi: 10.1002/aenm.202100883. [DOI] [Google Scholar]

- 18.He S, et al. Semiconductor glass with superior flexibility and high room temperature thermoelectric performance. Sci. Adv. 2020;6:eaaz8423. doi: 10.1126/sciadv.aaz8423. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Wang Y, Li A, Hu H, Fu C, Zhu T. Reversible room temperature brittle-plastic transition in Ag2Te0.6S0.4 inorganic thermoelectric semiconductor. Adv. Funct. Mater. 2023;33:2300189. doi: 10.1002/adfm.202300189. [DOI] [Google Scholar]

- 20.Hu H, Wang Y, Fu C, Zhao X, Zhu T. Achieving metal-like malleability and ductility in Ag2Te1-xSx inorganic thermoelectric semiconductors with high mobility. Innovation. 2022;3:100341. doi: 10.1016/j.xinn.2022.100341. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Deng T, et al. Plastic/ductile bulk 2D van der Waals single-crystalline SnSe2 for flexible thermoelectrics. Adv. Sci. 2022;9:2203436. doi: 10.1002/advs.202203436. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Wang Y, et al. Flexible thermoelectric materials and generators: challenges and innovations. Adv. Mater. 2019;31:1807916. doi: 10.1002/adma.201807916. [DOI] [PubMed] [Google Scholar]

- 23.Wei T-R, Qiu P, Zhao K, Shi X, Chen L. Ag2Q-based (Q = S, Se, Te) silver chalcogenide thermoelectric materials. Adv. Mater. 2023;35:2110236. doi: 10.1002/adma.202110236. [DOI] [PubMed] [Google Scholar]

- 24.Zhao X-F, et al. A fully flexible intelligent thermal touch panel based on intrinsically plastic Ag2S semiconductor. Adv. Mater. 2022;34:2107479. doi: 10.1002/adma.202107479. [DOI] [PubMed] [Google Scholar]

- 25.Zhu Y, Liang J-s, Shi X, Zhang Z. Full-inorganic flexible Ag2S memristor with interface resistance–switching for energy-efficient computing. ACS Appl. Mater. Interfaces. 2022;14:43482–43489. doi: 10.1021/acsami.2c11183. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Jo S, et al. Solution-processed stretchable Ag2S semiconductor thin films for wearable self-powered nonvolatile memory. Adv. Mater. 2021;33:2100066. doi: 10.1002/adma.202100066. [DOI] [PubMed] [Google Scholar]

- 27.Liang J, et al. Flexible thermoelectrics: from silver chalcogenides to full-inorganic devices. Energy Environ. Sci. 2019;12:2983–2990. doi: 10.1039/C9EE01777A. [DOI] [Google Scholar]

- 28.Tamaki H, Sato HK, Kanno T. Isotropic conduction network and defect chemistry in Mg3+δSb2-based layered zintl compounds with high thermoelectric performance. Adv. Mater. 2016;28:10182–10187. doi: 10.1002/adma.201603955. [DOI] [PubMed] [Google Scholar]

- 29.Zhang J, et al. Discovery of high-performance low-cost n-type Mg3Sb2-based thermoelectric materials with multi-valley conduction bands. Nat. Commun. 2017;8:13901. doi: 10.1038/ncomms13901. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Imasato K, Kang SD, Snyder GJ. Exceptional thermoelectric performance in Mg3Sb0.6Bi1.4 for low-grade waste heat recovery. Energy Environ. Sci. 2019;12:965–971. doi: 10.1039/C8EE03374A. [DOI] [Google Scholar]

- 31.Shu R, et al. Mg3+δSbxBi2−x family: a promising substitute for the state-of-the-art n-type thermoelectric materials near room temperature. Adv. Funct. Mater. 2019;29:1807235. doi: 10.1002/adfm.201807235. [DOI] [Google Scholar]

- 32.Mao J, et al. High thermoelectric cooling performance of n-type Mg3Bi2-based materials. Science. 2019;365:495–498. doi: 10.1126/science.aax7792. [DOI] [PubMed] [Google Scholar]

- 33.Zhang F, et al. High-performance N-type Mg3Sb2 towards thermoelectric application near room temperature. Adv. Funct. Mater. 2020;30:1906143. doi: 10.1002/adfm.201906143. [DOI] [Google Scholar]

- 34.Li A, Fu C, Zhao X, Zhu T. High-performance Mg3Sb2-xBix thermoelectrics: progress and perspective. Research. 2020;2020:1934848. doi: 10.34133/2020/1934848. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Wang L, et al. Realizing high thermoelectric performance in N-Type Mg3(Sb, Bi)2-based materials via synergetic Mo addition and Sb–Bi Ratio Refining. Adv. Energy Mater. 2023;13:2301667. doi: 10.1002/aenm.202301667. [DOI] [Google Scholar]

- 36.Li J, et al. Point defect engineering and machinability in n-type Mg3Sb2-based materials. Mater. Today Phys. 2020;15:100269. doi: 10.1016/j.mtphys.2020.100269. [DOI] [Google Scholar]

- 37.Lei J, et al. Efficient lanthanide Gd doping promoting the thermoelectric performance of Mg3Sb2-based materials. J. Mater. Chem. A. 2021;9:25944–25953. doi: 10.1039/D1TA07988C. [DOI] [Google Scholar]

- 38.Jiang F, et al. Extraordinary thermoelectric performance, thermal stability and mechanical properties of n-type Mg3Sb1.5Bi0.5 through multi-dopants at interstitial site. Mater. Today Phys. 2022;27:100835. doi: 10.1016/j.mtphys.2022.100835. [DOI] [Google Scholar]

- 39.Wan C, et al. Flexible n-type thermoelectric materials by organic intercalation of layered transition metal dichalcogenide TiS2. Nat. Mater. 2015;14:622–627. doi: 10.1038/nmat4251. [DOI] [PubMed] [Google Scholar]

- 40.Liu Z, et al. Demonstration of ultrahigh thermoelectric efficiency of ∼7.3% in Mg3Sb2/MgAgSb module for low-temperature energy harvesting. Joule. 2021;5:1196–1208. doi: 10.1016/j.joule.2021.03.017. [DOI] [Google Scholar]

- 41.Liu Z, et al. Maximizing the performance of n-type Mg3Bi2-based materials for room-temperature power generation and thermoelectric cooling. Nat. Commun. 2022;13:1120. doi: 10.1038/s41467-022-28798-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Ying P, et al. Towards tellurium-free thermoelectric modules for power generation from low-grade heat. Nat. Commun. 2021;12:1121. doi: 10.1038/s41467-021-21391-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Zhang, Z. et al. Plastic Mg3(Sb,Bi)2-based thermoelectric compounds with enhanced texture via cold-deformation. J. Mater. Chem. A12, 8893–8899 (2024).

- 44.Li A, et al. Chemical stability and degradation mechanism of Mg3Sb2-xBix thermoelectrics towards room-temperature applications. Acta Mater. 2022;239:118301. doi: 10.1016/j.actamat.2022.118301. [DOI] [Google Scholar]

- 45.Zhao S, et al. Amorphization in extreme deformation of the CrMnFeCoNi high-entropy alloy. Sci. Adv. 2021;7:eabb3108. doi: 10.1126/sciadv.abb3108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Peng J, Snyder GJ. A figure of merit for flexibility. Science. 2019;366:690–691. doi: 10.1126/science.aaz5704. [DOI] [PubMed] [Google Scholar]

- 47.Yin L, et al. Low-temperature sintering of Ag nanoparticles for high-performance thermoelectric module design. Nat. Energy. 2023;8:665–674. doi: 10.1038/s41560-023-01245-4. [DOI] [Google Scholar]

- 48.Xie L, et al. Screening strategy for developing thermoelectric interface materials. Science. 2023;382:921–928. doi: 10.1126/science.adg8392. [DOI] [PubMed] [Google Scholar]

- 49.Nan P, et al. Visualizing the Mg atoms in Mg3Sb2 thermoelectrics using advanced iDPC-STEM technique. Mater. Today Phys. 2021;21:100524. doi: 10.1016/j.mtphys.2021.100524. [DOI] [Google Scholar]

- 50.Agne MT, et al. Heat capacity of Mg3Sb2, Mg3Bi2, and their alloys at high temperature. Mater. Today Phys. 2018;6:83–88. doi: 10.1016/j.mtphys.2018.10.001. [DOI] [Google Scholar]

- 51.Xiong B, et al. Low interfacial resistivity in CoSi2/ZrCoSb thermoelectric junctions. Mater. Today Energy. 2022;25:100960. doi: 10.1016/j.mtener.2022.100960. [DOI] [Google Scholar]

- 52.Kresse G, Furthmüller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 1996;54:11169–11186. doi: 10.1103/PhysRevB.54.11169. [DOI] [PubMed] [Google Scholar]

- 53.Kresse G, Joubert D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B. 1999;59:1758–1775. doi: 10.1103/PhysRevB.59.1758. [DOI] [Google Scholar]

- 54.Perdew JP, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996;77:3865–3868. doi: 10.1103/PhysRevLett.77.3865. [DOI] [PubMed] [Google Scholar]

- 55.Tran F, Blaha P. Accurate band gaps of semiconductors and insulators with a semilocal exchange-correlation potential. Phys. Rev. Lett. 2009;102:226401. doi: 10.1103/PhysRevLett.102.226401. [DOI] [PubMed] [Google Scholar]

- 56.Wang V, Xu N, Liu J-C, Tang G, Geng W-T. VASPKIT: A user-friendly interface facilitating high-throughput computing and analysis using VASP code. Comput. Phys. Commun. 2021;267:108033. doi: 10.1016/j.cpc.2021.108033. [DOI] [Google Scholar]

- 57.Dronskowski R, Bloechl PE. Crystal orbital Hamilton populations (COHP): energy-resolved visualization of chemical bonding in solids based on density-functional calculations. J. Phys. Chem. 1993;97:8617–8624. doi: 10.1021/j100135a014. [DOI] [Google Scholar]

- 58.Zheng Y, et al. High-temperature mechanical and thermoelectric properties of p-Type Bi0.5Sb1.5Te3 commercial zone melting ingots. J. Electron. Mater. 2014;43:2017–2022. doi: 10.1007/s11664-013-2938-8. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data generated or analyzed during this study are included in this published article (and its supplementary information file).