Abstract

Objective:

This study analyzed Ohio workers’ compensation data to identify potential prevention strategies for common oil and gas extraction industry claims.

Methods:

Claim rates for 2001–2018 were calculated per full-time equivalent employee. Descriptive analyses on free-text descriptions of lost-time (LT) claims (>7 days away from work) identified common characteristics among claims and injured workers.

Results:

Among 3134 claims, 860 (27%) were LT. The industry group, drilling contractors, experienced the highest LT claims rate, whereas the cost from servicing contractors was the highest. Contact with objects and equipment caused the highest LT claims rate. The most frequent LT occupation was roustabout, and the most frequent LT work activity was material handling. Transportation incidents caused most fatalities and hospitalizations. Over half of LT claims were from short-tenured workers.

Conclusions:

Both proven and innovative approaches are needed to reduce severe workers’ compensation claims in this industry.

Keywords: workers’ compensation, oil and gas extraction, intervention, drilling, contact with objects and equipment

Many occupational injuries and fatalities are experienced every year in the oil and gas extraction (OGE) industry.1 Workers in this industry regularly face hazardous exposures and conditions such as flammable and toxic gases and vapors, long driving distances, and working at heights, around heavy equipment, below suspended loads, and with explosive materials.1 In addition, well sites are temporary worksites, creating the potential for changing work conditions and hazards, possibly resulting in severe and fatal consequences. From 2001 to 2018, the OGE industry averaged over 434,000 workers, with a peak of over 621,000 employed in 2014.2 Over half of these workers were employed by servicing contractors who perform specialized tasks to service existing wells (coded as 213112 in the North American Industrial Classification System [NAICS]), 36% by operators who lease and manage well sites (NAICS 211), and the remaining 11% by drilling contractors (NAICS 213111).3

The US Bureau of Labor Statistics (BLS) reported that, in 2011, the recordable injury and illness rates of days-away-from-work cases, the most severe nonfatal cases, for drilling contractors and for servicing contractors were significantly higher than the rate for operators.4 The median days away from work for injuries among servicing contractors was 24 days, three times as high as the median for all private industry. This difference was attributed to the large number of bone fractures experienced in this industry.4 For comparison, the median days away from work in 2011 for the mining industry was 28 and that for construction was 14 days.5

Catastrophes, such as the Pryor Trust gas well blowout in 2018, capture the public’s attention; however, fatalities occur in oil and gas extraction each year, with a fatality rate approximately seven times higher than for US workers in general.6 Mason et al6 found that drilling contractors experienced the highest fatality rate in comparison to other OGE subsectors. An analysis of motor vehicle fatalities by Retzer et al7 found that servicing contractors had the highest rates of crash death in comparison to other OGE subsectors. Speeding and lack of seat belt use were leading contributing factors for those events.7 Transportation incidents and contact with objects and equipment were responsible for over half the fatalities in this industry from 2003–2017.6,8,9 Other hazards of the OGE industry include fires and explosions, falls, confined spaces, high pressure pipes and equipment, electrical hazards, chemical exposures, long work hours, long commutes to remote locations, and fatigue.1,10

Ohio produces 90,000 barrels per day of crude oil and over 2 trillion cubic feet per year of natural gas, accounting for 0.5% of US oil production and 6% of US natural gas production.11 Over 6000 workers were employed in the oil and gas extraction industry in Ohio in 2018. Most oil and gas extraction in the state of Ohio takes place in southeast Ohio, where part of the Appalachian Basin is found. The purpose of this report is to utilize the Ohio Bureau of Workers’ Compensation (OHBWC) claims data from private employers in the OGE industry from 2001 to 2018 to identify the most frequent occupational injuries and illnesses so that prevention efforts can be prioritized and targeted. To our knowledge, this report is the first of its kind analyzing workers’ compensation (WC) claims of Ohio oil and gas workers to identify common causes of claims, with a focus on more severe claims.

METHODS

Data Source

Through a longstanding partnership and data sharing agreement, OHBWC shares administrative WC claims and policy data with the National Institute for Occupational Safety and Health (NIOSH) Center for Workers’ Compensation Studies. OHBWC insures all public and private employers in the state of Ohio except for sole proprietorships and partnerships, who can also opt to purchase WC coverage from OHBWC, and larger employers (typically with 500 or more employees), who may self-insure, if financially able. Of all Ohio employers, 99% are insured by OHBWC, accounting for two thirds of all Ohio workers. OHBWC collects information on incidents resulting in occupational injuries and illnesses, as well as demographic information for injured workers (such as age, gender, and tenure in the current job). Race and ethnicity data are unavailable in WC systems.

Along with demographic and contact information and specifics of the injured worker’s employment, claimants are asked to provide a free-text accident description, specifically, “Describe the sequence of events that directly caused the injury or death.”12 These free-text descriptions were used to code the cause of each claim (event or exposure) and were searched for common circumstances of claims (see the subheadings, “Data Coding and Processing” and “Free-Text Descriptions of Incidents” below).

Claims are defined as medical only (MO) or lost-time (LT) by OHBWC based on the number of days away from work. The MO claims are less severe injuries or illnesses, requiring only medical treatment expenses and/or seven or fewer days away from work. The LT claims are more severe, requiring eight or more days away from work. This study focused primarily on incidents leading to LT claims. Hospitalization and cost are also used as indicators of claim severity.

For most claims, days away from work are calculated as the number of days between the last day worked and the actual return to work, summed if there was more than one instance of days away from work. For fatalities, the number of days away from work are the days between the last day worked and the date of death. For claims where the employee has not yet returned to work, a running count of days away from work is maintained.

To calculate rates of injury and illness, the annual number of full-time equivalent (FTE) employees insured by OHBWC was estimated in this industry using the detailed methods described in previous studies.13,14 OHBWC claims data were linked via their employer’s federal tax identification number with quarterly figures from Ohio’s unemployment insurance database from the Ohio Department of Job and Family Services. This database includes the employer’s NAICS code and number of employees. Hours worked per employee from the BLS National Labor Productivity and Costs survey data were used to adjust unemployment insurance data and estimate FTE.15 Claim rates were calculated by dividing annual numbers of claims by the number of FTEs for that year, aggregated by NAICS codes for OGE.

Costs

Because not all claims to OHBWC have been fully paid out, the cost as of the second quarter of 2021 was used for comparison of the cost of claims. These “as-of” costs include the medical cost, indemnity cost (partial wage replacement, including any death benefit), and a reserve to cover future payouts. Claim costs are net after deductibles, but very few of the claims are subject to a deductible.

Zero-cost claims were excluded when calculating the median cost of claims. For example, some zero-cost claims exist because OHBWC has programs that allow some employers to pay medical costs up to $15,000 and some indemnity directly. OHBWC provided estimated employer costs for indemnity, but some claims still may have zero cost to OHBWC if employers participated in these programs. Some zero-cost claims may also occur if no medical treatment beyond first aid or indemnity is involved.13,16 Costs for individual claims may have been paid out over several years, and no inflation adjustments were applied. Due to the highly skewed distribution of WC claim costs, data for the 100 highest-cost claims were examined more closely to determine the causes of those impactful claims.

Study Population

Accepted claims from OHBWC-insured, private-sector OGE operators, drilling contractors, and servicing contractors (NAICS codes 211, 213111, and 213112) were examined. Only those injuries and illnesses that occurred from 2001 to 2018 for which reliable employee counts were available were included. Public employees have been excluded from this study, but it is unlikely that many OGE industry employees work in the public sector. For employers who have multiple locations, different locations may correspond to different industries; the NAICS code corresponding to the majority of employees was assigned to the entire policy for purposes of calculation. The method used has been described more fully in a prior study.13

Claims accepted by OHBWC must be verified to be work-related and must be filed completely. From 2001 to 2018, claimants had 2 years from the date of injury to file a claim.12 Claims filed between 2011 and 2018 were accepted by OHBWC at a rate of 88% to 90%.17

Data Coding and Processing

The event or exposure is defined as the “manner in which the injury or illness was produced or inflicted by the source of injury or illness”18 and can be considered the cause of the injury or illness. Bertke et al19 developed a machine learning algorithm to assign an event or exposure category to each OHBWC claim according to the BLS Occupational Injury and Illness Classification System (OIICS version 2.01)18 based on the free-text description of the claim. The algorithm was recently improved for better coding accuracy,20 and the improved algorithm was applied to classify the claims in this study. For even better precision, manual coding was performed for a subset of LT claims.19 This study examined claims only at the broadest level of classification (1-digit OIICS Divisions).

Free-Text Descriptions of Incidents

As in previous studies,14,21 the short free-text descriptions of claims incidents were analyzed to identify common circumstances leading to occupational injury or illness. A variety of keywords relating to injuries and illnesses in this industry were used to search the free-text descriptions for each incident. OGE-specific expert knowledge of tools, equipment, and activities specific to this industry, as well as conditions common to injury incidents across a range of industries, were used to develop the lists of words. These keywords included parts of the body, words pertaining to the event or exposure, oil and gas industry tools and equipment, activities, and the environment. Words and groups of words used in searching the free-text descriptions are listed in Supplemental Digital Content Tables S1 (http://links.lww.com/JOM/B584) and S2 (http://links.lww.com/JOM/B585).

Descriptions of work activities developed for use in the NIOSH Fatalities in Oil and Gas Extraction database9 were used along with the free-text description of the claim to classify the activity occurring during each incident resulting in an LT WC claim into 1 of 39 categories, such as material handling, pressure pumping, or drilling, pulling, or running tubulars. Two NIOSH researchers familiar with the OGE industry agreed on the classification of the incident for it to be assigned. Those descriptions that did not correspond to a recognizable work activity (37%) were classified as “unspecified.” The definitions associated with each category of activity are given in Supplemental Digital Content Table S3 (http://links.lww.com/JOM/B586).

Worker occupation was a free-text field in the database, and many different variations of occupations were listed. Where the description allowed, occupations were categorized in 1 of 14 Standard Occupational Classification categories, including heavy and tractor-trailer truck drivers; construction laborers; roustabouts, oil, and gas; and so on.22 Two NIOSH researchers with expertise related to OGE-specific occupations agreed on the assignment of each occupation to a category using the reported job titles and tasks listed in the O*NET database.23 In 11% of claims, the occupation did not fit into 1 of the 14 Standard Occupational Classification categories and was classified in a category of “all other.”

Several categories of occupation were combined in this analysis due to having similar occupational hazards as determined by an expert in OGE health and safety. For example, the two categories of rotary drill operators, oil and gas, and Derrick operators, oil and gas, were combined. First-line supervisors of construction trades and extraction workers were combined with general and operations managers as supervisory/management occupations. Three construction and maintenance occupations were also combined: maintenance and repair workers, general; mobile heavy equipment mechanics, except engines; and plumbers, pipefitters, and steamfitters. Occupation titles included in each category for LT claims are listed in Supplemental Digital Content Table S4 (http://links.lww.com/JOM/B587), and titles for MO claims are listed in Supplemental Digital Content Table S5 (http://links.lww.com/JOM/B588).

RESULTS

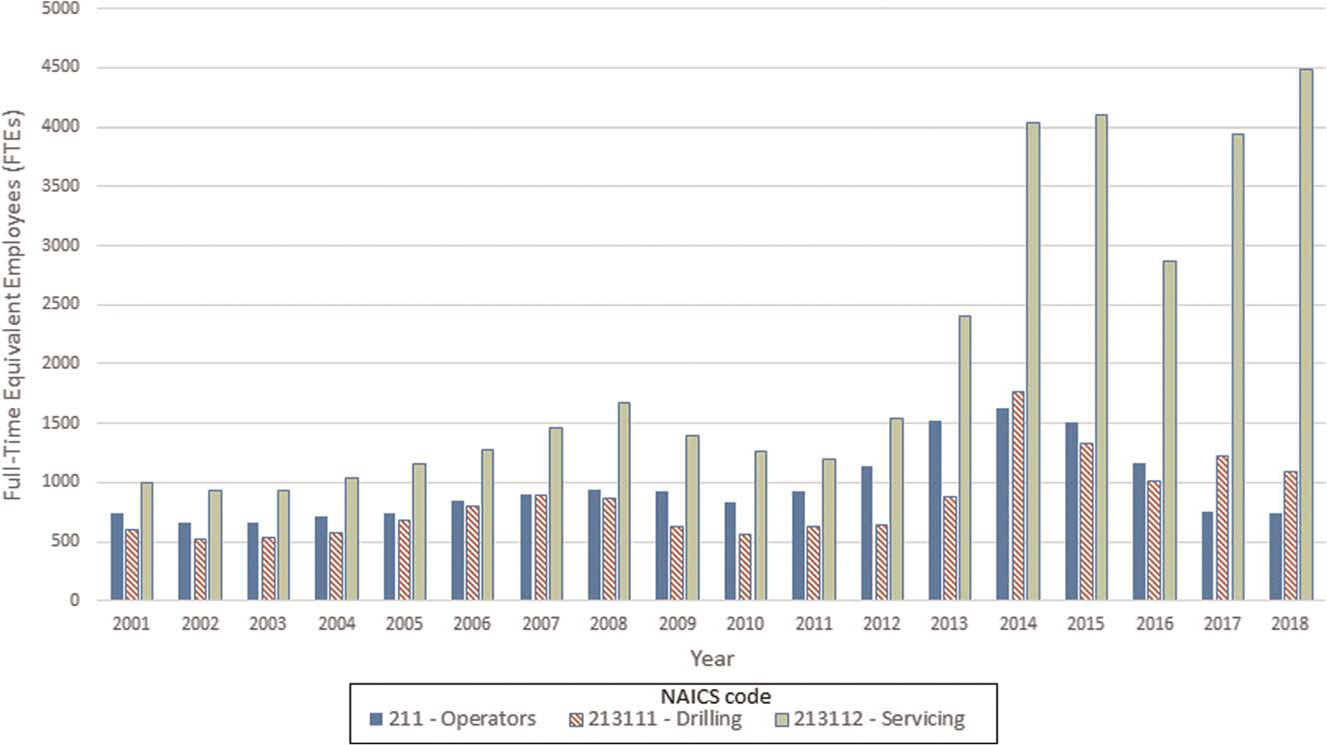

The number of OGE workers insured by OHBWC increased by 170% from 2001 (n = 2336) to 2018 (n = 6316) (Fig. 1). Most of the increase was in servicing contractors. A total of 3134 WC claims were accepted by OHBWC from the OGE industry from 2001 to 2018; 2274 (73%) were MO and 860 (27%) were LT (Table 1). As a result of their injuries, 15 workers were killed and 181 workers were hospitalized, including two workers who were each hospitalized twice during the period studied.

FIGURE 1.

Full-time equivalent (FTE) employees in the oil and gas extraction industry in the state of Ohio insured by the Ohio Bureau of Workers’ Compensation by year and detailed industry (NAICS code 211, oil and gas extraction; 213111, drilling oil and gas wells; 213112, support activities for oil and gas operations), as estimated by Ohio unemployment insurance data.

TABLE 1.

Medical-Only (MO) and Lost-Time (LT) Workers' Compensation Claims From the Oil and Gas Extraction Industry to the Ohio Bureau of Workers' Compensation for 2001 to 2018 by Selected Characteristics

| MO Claims (Percent of MO Claims, Not Including Unknowns)a | LT Claims (Percent of LT Claims, Not Including Unknowns)a | |

|---|---|---|

|

| ||

| Claims | ||

| All claims | 2274 (73%) | 860 (27%) |

| Hospitalization claims | 15 (1%) | 168 (20%) |

| Fatalities | - | 15 (2%) |

| Worker age (years) | ||

| <25 | 440 (19%) | 143 (17%) |

| 25–34 | 684 (30%) | 220 (26%) |

| 35–44 | 551 (24%) | 228 (27%) |

| 45–54 | 397 (17%) | 190 (22%) |

| 55–64 | 168 (7%) | 68 (8%) |

| 65+ | 32 (1%) | 11 (1%) |

| Unknown | 2 | - |

| Worker sex | ||

| Male | 2216 (98%) | 832 (98%) |

| Female | 36 (2%) | 17 (2%) |

| Unknown | 22 | 11 |

| Job tenure (days) | ||

| ≤90 | 235 (21%) | 172 (28%) |

| 91–365 | 333 (30%) | 186 (30%) |

| 366–730 | 161 (15%) | 82 (13%) |

| 731–1095 | 85 (8%) | 45 (7%) |

| 1096–1460 | 54 (5%) | 24 (4%) |

| 1461–1825 | 37 (3%) | 11 (2%) |

| ≥1826 | 196 (18%) | 99 (16%) |

| Unknown | 1173 | 241 |

| Occupation | ||

| Roustabout, oil and gas | 342 (15%) | 188 (22%) |

| Heavy and tractor-trailer truck drivers | 248 (11%) | 124 (14%) |

| Rotary drill operators, oil and gas, and derrick operators, oil and gas | 198 (9%) | 118 (14%) |

| Construction laborers | 334 (15%) | 103 (12%) |

| Extraction workers, all other | 309 (14%) | 101 (12%) |

| Wellhead pumpers | 159 (7%) | 53 (6%) |

| Construction and maintenance occupationsb | 197 (9%) | 49 (6%) |

| Service unit operators, oil and gas | 47 (2%) | 38 (4%) |

| Supervisory/management occupationsc | 177 (8%) | 38 (4%) |

| Operating engineers and other construction equipment operators | 14 (1%) | 14 (2%) |

| All other | 249 (11%) | 34 (4%) |

| Company size (est. FTEsd) | ||

| >0 to 10 | 446 (20%) | 180 (21%) |

| >10 to <50 | 957 (42%) | 378 (44%) |

| ≥50 to <100 | 282 (12%) | 131 (15%) |

| ≥100 to <250 | 420 (19%) | 132 (15%) |

| ≥250 to <1000 | 138 (6%) | 31 (4%) |

| ≥1000 | 23 (1%) | 8 (1%) |

| Unknown | 8 | - |

Percentages may not add up to 100% due to rounding. Unknowns were not included in percentages so that relative proportions of identified claims could be compared more readily.

The construction and maintenance occupations are maintenance and repair workers, general; mobile heavy equipment mechanics, except engines; and plumbers, pipefitters, and steamfitters.

The supervisory/management occupations are first-line supervisors of construction trades and extraction workers and general and operations managers.

Full-time equivalent employees.

The LT claims rate decreased over the period of this study from 201 LT claims per 10,000 FTEs in 2001 to 73 in 2018. The 3134 WC claims accepted in this industry occurred among 2522 individual workers. Overall, 17% of the injured workers filed multiple claims in this industry between 2001 and 2018; the maximum number of claims accepted from a single worker during this period was seven. The most frequent age group for injured workers in MO claims was 25 to 34 years old, whereas the most frequent age group for injured workers in LT claims was 35 to 44 years old (Table 1). Only 53 of the workers filing claims were female (2%).

Job Tenure

Job tenure in the current job, defined as the length of time with the current employer, was unavailable for 1414 of the 3134 WC claims in the database (45%). For claims in which job tenure in the current job was listed, claims were tabulated for durations of 90 days or less, 91–365 days, 366–730 days, 731–1095 days, 1096–1460 days, 1461–1825 days, and 1826 days or more (Table 1). The largest number of both MO and LT claims (30%) was found for job tenure of 91–265 days, followed by 90 days or less of job tenure, with 21% and 28%, respectively (Table 1).

Occupation

The occupation category, roustabout, oil, and gas, was most frequently listed by injured workers filing both LT (n = 188) and MO (n = 342) claims (Table 1). Roustabouts had a particularly large share of the LT claims (22%) compared with other occupations, which were all less than 15%. The next most frequent occupation for those filing LT claims was heavy and tractor-trailer truck drivers (14%). The combination of rotary drill operators, oil and gas, and Derrick operators, oil and gas, was the third most frequent occupation category for LT WC claims (14%).

Company Size

The largest number of OGE workers insured by OHBWC worked for companies that employed more than 10 but less than 50 FTEs (38%) during the period studied. The largest percentage of LT claims (44%) also came from companies of this size (Table 1). There were no companies larger than 250 FTEs in size insured by OHBWC before 2013 and no companies larger than 1000 FTEs in size until 2018.

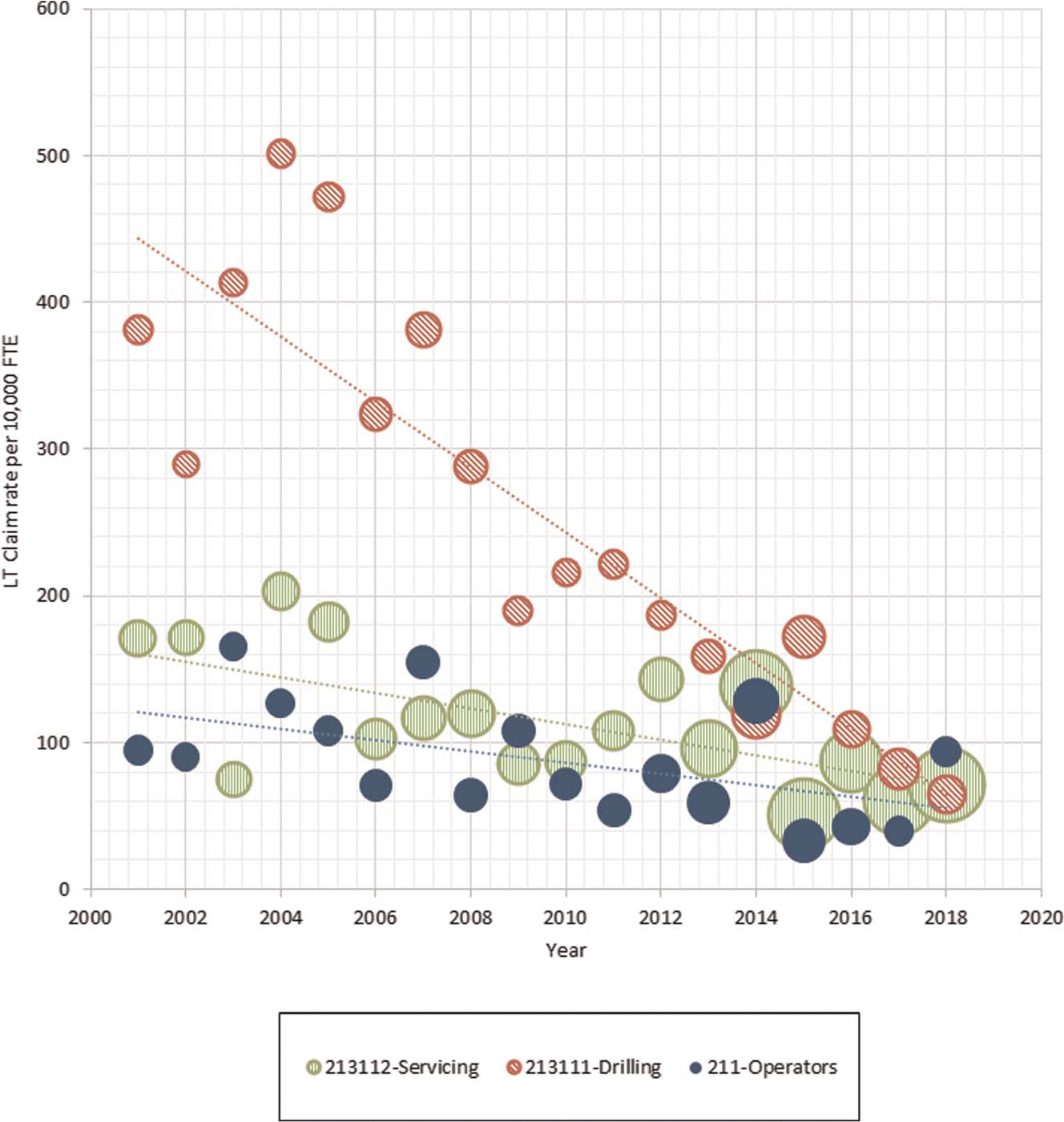

Detailed Industry

Rates of LT claims for all three of the detailed industry codes in OGE decreased from 2001 to 2018, with the LT claims rate for drilling contractors decreasing the most (Fig. 2). Nine of the fatally injured workers were drilling contractors, six were servicing contractors, and none were operators (data not shown). Servicing contractors experienced the highest number of LT claims (n = 371), but drilling contractors experienced the highest LT claim rate (Table 2). LT claim rates for drilling contractors were highest for transportation incidents, falls, slips, trips, contact with objects and equipment, and overexertion and bodily reaction. The claim rate for fires and explosions was highest for servicing contractors, whereas the claim rate for exposure to harmful substances or environments was highest for operators (Table 2). In the category of contact with objects and equipment, the LT claim rate for drilling contractors was approximately three times as high as that for servicing contractors, the next highest detailed industry. The rates of overexertion and bodily reaction and falls, slips, and trips were over twice as high for drilling contractors as for servicing contractors (Table 2).

FIGURE 2.

Bubble plot of lost-time (LT) claim rates per 10,000 full-time equivalent (FTE) employees by year and detailed industry for claims to the Ohio Bureau of Workers’ Compensation from the oil and gas extraction industry from 2001 to 2018. Size of the bubble corresponds to the number of workers insured in each detailed industry.

TABLE 2.

Lost-Time (LT) Claims Numbers and Rates per 10,000 Full-Time Equivalent (FTE) Employees by Detailed Industry and Event or Exposure (Coded According to the Bureau of Labor Statistics Occupational Injury and Illness Classification System [OIICS Version 2.01]) for Claims From the Oil and Gas Extraction Industry to the Ohio Bureau of Workers’ Compensation for 2001 to 2018

| LT Claims by Detailed Industry (Percent of LT Claims in that Industry) |

LT Claim Rate per 10,000 FTE by Detailed Industry |

|||||||

|---|---|---|---|---|---|---|---|---|

| Event or Exposurea | Operatorsb | Drilling Contractorc | Servicing Contractorsd | Overalle | Operatorsb | Drilling Contractorsc | Servicing Contractorsd | Overalle |

|

| ||||||||

| Contact with objects and equipment | 38 (26%) | 142 (42%) | 116 (31%) | 296 (34%) | 21.9 | 93.3 | 31.6 | 42.7 |

| Falls, slips, trips | 44 (30%) | 93 (27%) | 99 (27%) | 236 (27%) | 25.3 | 61.1 | 27.0 | 34.1 |

| Overexertion and bodily reaction | 34 (23%) | 68 (20%) | 78 (21%) | 180 (21%) | 19.6 | 44.7 | 21.3 | 26.0 |

| Transportation incidents | 17 (12%) | 25 (7%) | 49 (13%) | 91 (11%) | 9.8 | 16.4 | 13.4 | 13.1 |

| Fires and explosions | 4 (3%) | 6 (2%) | 17 (5%) | 27 (3%) | 2.3 | 3.9 | 4.6 | 3.9 |

| Exposure to harmful substances or environments | 8 (5%) | 5 (1%) | 9 (2%) | 22 (3%) | 4.6 | 3.3 | 2.5 | 3.2 |

| Sum of all events and exposures | 147 | 342 | 371 | 860 | 84.6 | 224.6 | 101.2 | 124.1 |

The event or exposure, violence and other injuries by persons or animals, was not included due to small numbers of claims.

NAICS code 211.

NAICS code 213111.

NAICS code 213112.

NAICS codes 211, 213111, and 213112.

Event or Exposure

The event or exposure associated with the highest rate of LT claims in the OGE industry was contact with objects and equipment (Table 2), followed by falls, slips, and trips and overexertion and bodily reaction. In the free-text description of LT claims, the words most frequently associated with contact with objects and equipment referred to the hand area: “hand,” “finger,” “thumb,” or “pinky” (n = 125); this was followed by words associated with tubulars: “pipe” or “piping” (n = 96) (Table 3). Many of the claims with the words “pipe” or “piping” mentioned pipe falling or being dropped; an employee being hit by pipe; a pipe trailer, tub, or rack; or loading and unloading of pipe. In reading the free-text description of the 125LT “contact with objects and equipment” claims mentioning the hand area, the words “pinch,” “caught,” “crush,” or “smash” were mentioned in 68 of the claims, with the words “hit” or “struck” appearing only 18 times, and the words “cut” or “lacerated” appearing 14 times. Fingers and hands were smashed or caught by pipe, tongs, pulleys, hammers, wrenches, belts, trailers, bars, cylinders, sheets, or metal beams.

TABLE 3.

Number of Lost-Time Claims Including One of the Listed Words by Event or Exposure

| Event or Exposurea |

|||||||

|---|---|---|---|---|---|---|---|

| Word or Words | Transportation Incidents (n = 91) | Fires and Explosions (n = 27) | Falls, Slips, Trips (n = 236) | Exposure to Harmful Substances or Environments (n = 22) | Contact With Objects and Equipment (n = 296) | Overexertion and Bodily Reaction (n = 180) | All Events and Exposures (n = 860)b |

|

| |||||||

| Leg area: including foot, knee, ankle, leg, toe, or hip | 9 | 3 | 99 | 1 | 74 | 49 | 236 |

| Fell or fall | 4 | 2 | 150 | 1 | 45 | 0 | 202 |

| Vehicle-related words: including truck, trailer, tailgate, pickup, semi, or vehicle | 50 | 2 | 60 | 0 | 28 | 29 | 169 |

| Pipe or piping | 0 | 1 | 30 | 1 | 96 | 32 | 161 |

| Hand area: including hand, finger, thumb, or pinky | 4 | 1 | 18 | 0 | 125 | 6 | 154 |

| Slip, slipped, or slipping (omit slips) | 0 | 0 | 95 | 0 | 24 | 0 | 119 |

| Arm area: including shoulder, elbow, wrist, or arm | 7 | 2 | 32 | 2 | 29 | 41 | 115 |

| Backc | 4 | 0 | 29 | 0 | 10 | 45 | 89 |

The event or exposure, violence and other injuries by persons or animals, was not included due to small numbers of claims.

May not equal the sum of the other columns as some claims had events or exposures not listed here.

Includes 110 phrases referring to the human back. See Table S5.

The rate of LT falls, slips, and trips was the second-highest event or exposure overall in this dataset (Table 2). After the words “fell” or “fall” (n = 150), one of the words referring to the leg area, including “foot,” “knee,” “ankle,” “leg,” “toe,” and “hip,” was most frequently mentioned (n = 99), followed by “slip,” “slipped,” or “slipping” (n = 95) in 1 of the 236 LT falls, slips, and trips claims (Table 3). Many of these slips involved mud, oil, or wet or frozen conditions. Of the 70 mentions of adverse environmental conditions (eg, ice, mud, rain, etc) in LT claims, 42 of them were in the free-text descriptions of LT falls, slips, and trips. Of the 46 mentions of the word “walk” in LT claims, 30 of them were in falls, slips, and trips. Seven of the LT falls, slips, and trips while walking on site specifically mentioned stepping in a hole. Twenty-one of the free-text descriptions of LT falls, slips, and trips mentioned the word “trip.” Workers tripped over many objects, including valves, clods of mud, vegetation, pipe, hose, stairs, containment, and cables.

In LT overexertion and bodily reaction claims, the leg area was most frequently mentioned, followed by the back (Table 3). Common circumstances of the “overexertion” claims included walking on site, lifting something, entering or exiting a truck or heavy equipment, or pulling something. Contributing factors included uneven ground and slippery conditions.

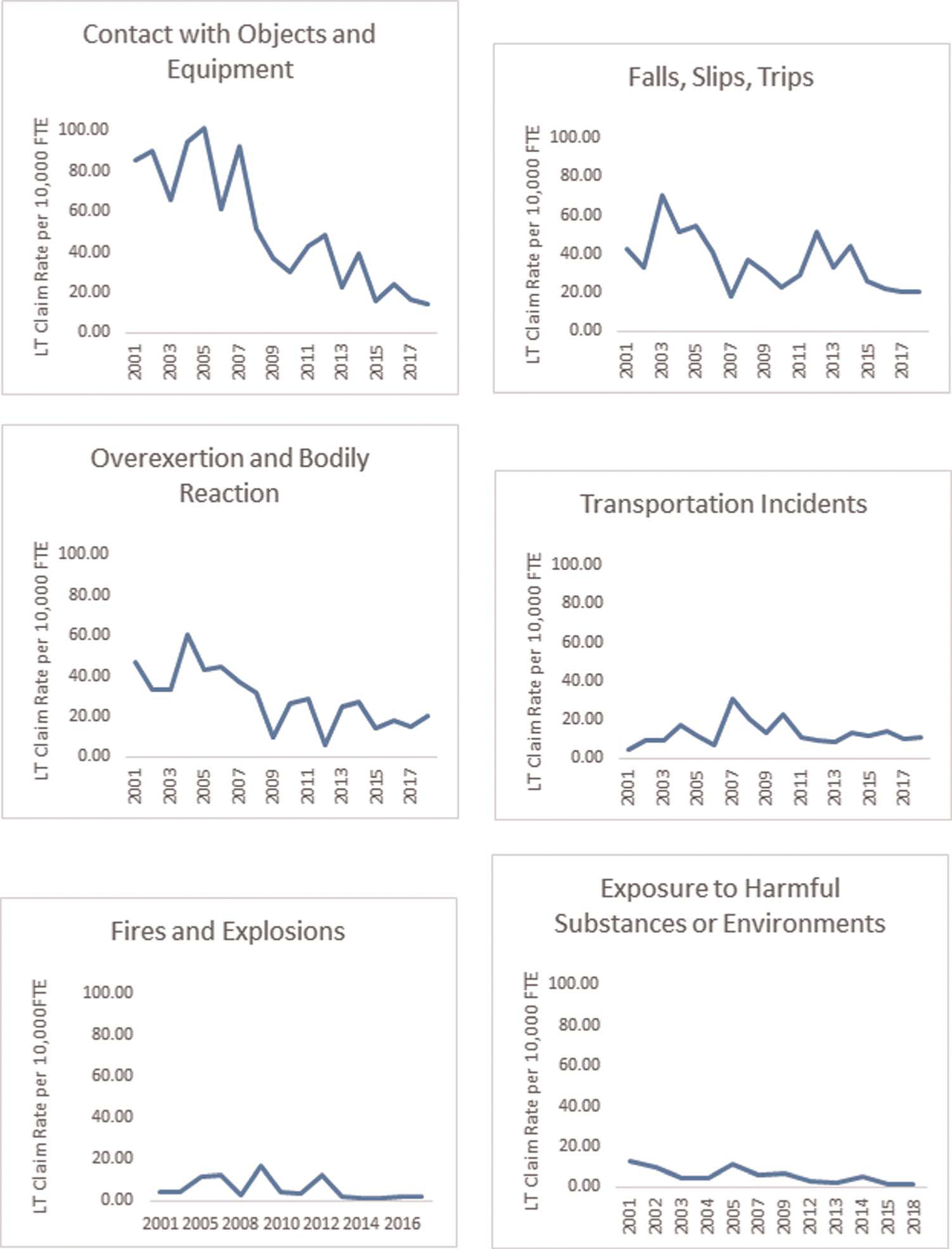

The LT rate of claims for contact with objects and equipment fell from 85.6 to 14.3 per 10,000 FTEs from 2001 to 2018 (Fig. 3). The LT rates of falls, slips, and trips and of overexertion and bodily reaction fell more slowly over that period, with the rate of falls, slips, and trips decreasing from 42.8 to 20.6 and the rate of overexertion and bodily reaction decreasing from 47.1 to 20.6. In 2018, the LT claims rates for those two events or exposures exceeded the rate for contact with objects and equipment, and the rate of claims for falls, slips, and trips was the highest in the OGE industry for 6 of the 7 years from 2012 through 2018 (Fig. 3).

FIGURE 3.

LT claim rates to the Ohio Bureau of Workers’ Compensation from the oil and gas extraction industry by event or exposure and year.

Although the rate of LT claims for transportation incidents was fourth highest, the rate has not improved over the 18-year period, increasing from 4.3 to 12.7 from 2001 to 2018 (Fig. 3). The most frequent mentions of one of the vehicle-related words occurred not in the free-text description of LT transportation incidents (n = 50) but in the free-text descriptions of LT falls, slips, and trips (n = 60) (Table 3). According to the free-text description of the falls involving trucks or trailers, many occurred simply when exiting the truck cab; others involved falling from a semitrailer, pump truck, or tank truck; and several specifically mentioned pipe trailers. Eight of the 15 fatalities were caused by transportation incidents; three were due to falls, slips, and trips; and two were attributed to contact with objects and equipment (data not shown).

Work Activities

Many of the free-text descriptions of LT WC claims contained insufficient information to determine the work activity at the time of the incident and were classified as unspecified (n = 321). Of those descriptions with sufficient information, the most frequent activities were material handling (n = 105); travel (n = 91); drilling, pulling, or running tubulars (n = 89); transport (and transfer) (n = 48); and repair or maintenance (n = 47) (Table 4). Twenty-five other activities were identified fewer than 20 times each in LT claims.

TABLE 4.

Work Activities for Lost-Time (LT) Claims

| Work Activity (Percent of Claims for each Work Activity)a |

|||||||

|---|---|---|---|---|---|---|---|

| Material Handling (n = 105) | Travel (n = 91) | Drilling, Pulling, or Running Tubulars (n = 89) | Transport (and Transfer) (n = 48) | Repair or Maintenance (n = 47) | Unspecified (n = 321) | Sum of all Work Activities (n = 860)a | |

|

| |||||||

| Claims | |||||||

| Hospitalizations | 12 (11%) | 25 (27%) | 15 (17%) | 7 (15%) | 7 (15%) | 54 (17%) | 183 |

| Fatalities | - | 7 (8%) | - | - | - | 5 (2%) | 15 |

| Event or exposure | |||||||

| Transportation incidents | 2 (2%) | 71 (78%) | 0 (0%) | 7 (15%) | 1 (2%) | 6 (2%) | 91 |

| Fires and explosions | 0 (0%) | 1 (1%) | 0 (0%) | 0 (0%) | 2 (4%) | 12 (4%) | 27 |

| Falls, slips, trips | 25 (24%) | 15 (16%) | 10 (11%) | 25 (52%) | 11 (23%) | 114 (36%) | 236 |

| Exposure to harmful | 0 (0%) | 0 (0%) | 0 (0%) | 0 (0%) | 0 (0%) | 12 (4%) | 22 |

| substances or environments | |||||||

| Contact with objects and equipment | 38 (36%) | 0 (0%) | 60 (67%) | 8 (17%) | 22 (47%) | 114 (36%) | 296 |

| Overexertion and bodily reaction | 40 (38%) | 4 (4%) | 18 (20%) | 8 (17%) | 10 (21%) | 59 (18%) | 180 |

| Keywords | |||||||

| Pipe or piping | 38 (36%) | 0 (0%) | 47 (53%) | 5 (10%) | 4 (9%) | 46 (14%) | 161 |

| Load or unload | 30 (29%) | 0 (0%) | 1 (1%) | 13 (27%) | 0 (0%) | 0 (0%) | 47 |

| Leg area: including foot, knee, ankle, leg, toe, or hip | 30 (29%) | 14 (15%) | 22 (25%) | 20 (42%) | 8 (17%) | 108 (34%) | 236 |

| Vehicle-related words: including truck, trailer, tailgate, pickup, semi, or vehicle | 27 (26%) | 56 (62%) | 4 (4%) | 36 (75%) | 8 (17%) | 27 (8%) | 169 |

| Lift | 25 (24%) | 1 (1%) | 3 (3%) | 2 (4%) | 3 (4%) | 8 (2%) | 53 |

| Hand area: including hand, finger, thumb, or pinky | 17 (16%) | 5 (5%) | 27 (30%) | 6 (13%) | 16 (34%) | 61 (19%) | 154 |

| Slip, slipped, or slipping | 14 (13%) | 6 (7%) | 11 (12%) | 6 (13%) | 11 (23%) | 52 (16%) | 119 |

| Drive, driver, or driving | 1 (1%) | 26 (29%) | 1 (1%) | 5 (10%) | 0 (0%) | 2 (1%) | 41 |

Only the most frequent of the 39 categories of work activity are shown. Those work activities identified fewer than 20 times and not listed in this table were break or rest, cementing, chemical handling, coiled tubing activities, drilling during workover activities, drilling fluid mixing and pumping, equipment assembly or dismantle, fishing, hot oiling, hotwork and welding, housekeeping and cleaning, lease operation, office and administrative activities, perforating, plug drill out, pressure pumping, pressure testing, production rig activities, rigging up or down, setting packers or plugs, snubbing, spotting, swabbing, tank opening, gauging, or sampling, tank refurbishment and custom fabrication, training, well cleanout, well control equipment activities, wellhead or pumping unit activities, well kill, wellsite construction or upkeep, well testing or logging, wireline and slickline activities. See Table S3 in the supplemental material for definitions of work activities.

Travel was the most common work activity identified among hospitalizations (n = 25) and the 15 fatal claims (n = 7). Five of the fatal claims were unspecified, and the remaining work activities occurred only once among fatalities (Table 4).

Of LT claims that had work activities associated with them, transportation incidents occurred most often during travel activities (n = 71). During drilling, pulling, or running tubulars, contact with objects or equipment occurred most frequently (n = 60), followed by overexertion and bodily reaction (n = 18).

For the work activity, material handling, the most frequent event or exposure was overexertion and bodily reaction (n = 40), closely followed by contact with objects and equipment (n = 38). Falls, slips, and trips occurred most often during material handling and transport (and transfer) (both n = 25). There were over three times as many LT claims for falls, slips, and trips (n = 25) during the work activity of transport (and transfer) as there were claims for transportation incidents (n = 7). During repair or maintenance activities, contact with objects and equipment was the most frequent event or exposure (n = 22) (Table 4).

Vehicle-related words were most frequently found in the free-text description of claims from the travel activity (n = 56), followed by drive, driver, or driving (n = 26). Vehicle-related words also occurred most frequently for the transport (and transfer) activity (n = 36), followed by words pertaining to the leg area (n = 20). The words pipe or piping occurred most frequently in claims for the work activity of drilling, pulling, or running tubulars (n = 47), followed by words pertaining to the hand area (n = 27). Pipe or piping also occurred most frequently in material handling claims (n = 38), followed by the words load or unload and words pertaining to the leg area (both n = 30). Words pertaining to the hand area occurred most frequently in claims for the work activity, repair, or maintenance (n = 16), followed by one of the words slip, slipped, or slipping (n = 11) (Table 4).

Days Away From Work

Days away from work were reported for 3070 of the 3134 claims in the database (98%) and for 845 of the 860 LT claims (98%). The median days away from work for LT claims was 67 (Table 5), ranging from 48 days for operators to 81 days for servicing contractors.

TABLE 5.

Median Days Away From Work and Nonzero Cost of Claims to the Ohio Bureau of Workers’ Compensation From the Oil and Gas Extraction Industry for 2001 to 2018 by Type of Claim, Medical-Only (MO) or Lost-Time (LT), and Detailed Industry, Using Costs as of the Second Quarter of 2021 Plus Estimated Employer Costs for Salary Continuation

| MO Claims (n = 2274) |

LT Claims (n = 860) |

All (MO + LT) Claims (n = 3134) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Operatorsa (n = 517) | Drilling Contractorsb (n = 740) | Servicing Contractorsc (n = 1017) | Overalld (n = 2274) | Operatorsa (n = 147) | Drilling Contractorsb (n = 342) | Servicing Contractorsc (n = 371) | Overalld (n = 860) | Operatorsa (n = 664) | Drilling Contractorsb (n = 1082) | Servicing Contractorsc (n = 1388) | Overalld (n = 3134) | |

|

| ||||||||||||

| Medical cost | $532 (n = 467) | $543 (n = 702) | $489 (n = 951) | $518 (n = 2120) | $6582 (n = 147) | $5500 (n = 340) | $6870 (n = 369) | $6481 (n = 856) | $769 (n = 614) | $890 (n = 1042) | $732 (n = 1320) | $778 (n = 2976) |

| Indemnity cost | - | - | - | - | $9236 (n = 135) | $6653 (n = 332) | $9415 (n = 350) | $8116 (n = 817) | $7816 (n = 145) | $5860 (n = 365) | $8204 (n = 376) | $6736 (n = 886) |

| Total cost | $536 (n = 467) | $552 (n = 702) | $499 (n = 953) | $525 (n = 2122) | $14,343 (n = 147) | $13,653 (n = 342) | $17,646 (n = 371) | $15,096 (n = 860) | $824 (n = 614) | $1054 (n = 1044) | $838 (n = 1324) | $903 (n = 2982) |

| Days away from work | 0 | 0 | 0 | 0 | 48 | 64 | 81 | 67 | 0 | 1 | 0 | 0 |

NAICS code 211.

NAICS code 213111.

NAICS code 213112.

NAICS codes 211, 213111, and 213112.

Please note: Indemnity costs for MO claims were not listed due to small numbers of claims having indemnity costs.

Cost of Claims

The total cost of claims from the OGE industry from 2001 to 2018 as of the second quarter of 2021 was over $65 million, including over $29 million in indemnity paid by OHBWC and $1.6 million in employer-paid indemnity. LT claims accounted for 95% of this cost, or approximately $62 million; MO claims cost $3 million. There were 152 claims that had zero cost to OHBWC.

The median total cost of all (MO and LT) nonzero-cost claims in this dataset was $903, and it ranged from $824 for operators to $1054 for drilling contractors (Table 5). The median total cost of LT claims was much higher, $15,096, ranging from $13,653 for drilling contractors to $17,646 for servicing contractors (Table 5).

The 100 most expensive claims ranged from $130,000 to over $2,000,000 and comprised 69% of the cost of all claims. Of the 100 most expensive claims to OHBWC, 44 were from servicing contractors and 39 were from drilling contractors, while 17 were from operators. The median days away from work for the 100 most expensive claims was 771. The event or exposure most frequently found in these claims was contact with objects and equipment (n = 32), followed by falls, slips, and trips (n = 23), transportation incidents (n = 20), and overexertion and bodily reaction (n = 17). The 100 most expensive claims included 57 hospitalizations and 11 fatalities.

The most frequently mentioned words in the free-text description of the 100 most expensive claims were one of the vehicle-related words (n = 23); eight of these mentions were in transportation incidents, whereas seven mentions were in falls, slips, and trips and six mentions were in contact with objects and equipment. The words “pipe” or “piping” were found in the free-text description of 19 of the 100 most expensive claims. Fifteen of the 19 “pipe” claims were for contact with objects and equipment.

Every occupation category showed up at least once among the 100 most expensive claims. The combination of rotary drill operators, oil and gas, and Derrick operators, oil and gas, occurred most frequently (n = 24). The occupation category for 20 of the 100 most expensive claims was heavy and tractor-trailer truck drivers, followed by 16 claims in the category of extraction workers, all other. Over a third of the 100 most expensive claims had an unspecified work activity (n = 36). The most frequently identified work activity was travel (n = 18), followed by material handling (n = 12).

Although the overall rate of LT claims for drilling contractors was more than double the rate of LT claims for servicing contractors (Table 2), the median nonzero total cost of LT claims from servicing contractors was over 30% higher than the cost for drilling contractors (Table 5), and servicing contractors filed 44 of the 100 most expensive claims from the OGE industry in this dataset. This may be because LT claims in this detailed industry have the highest median days away from work (Table 5).

DISCUSSION

The findings of this study generally agree with other studies in this industry.6,9,24–26 Although the small number of fatalities in this study did not permit calculation of rates, transportation incidents were responsible for the largest number of fatalities, as found by Mason et al6 in their study of OGE industry data from the BLS Census of Fatal Occupational Injuries for 2003–2013 and by Wingate et al9 in their study of 470 OGE fatalities for 2014–2019 identified from multiple sources, including Occupational Safety and Health Administration (OSHA) reports, newsletters, and industry Web sites, among others.

Although the number of insured workers in the OGE industry in Ohio is increasing every year, the rate of nonfatal LT WC claims is decreasing, as has been found in many industries, and as also found by Wurzelbacher et al26 in their study of over 771,000 OHBWC claims from all industry sectors for 2007–2017. During the period 2007–2017, LT claims made up 27.5% of the WC claims for the OGE industry in Ohio, compared with 22.4% for construction, 21.3% for mining, and 18.2% for all private industry.26 Although only 27% of WC claims in the OGE industry in Ohio for 2001 to 2018 in this study were LT, LT claims accounted for 96% of the total cost of claims, and reducing these claims further will pay an enormous dividend in worker safety, quality of life, morale, and reduced employer expense.

Drilling contractors continue to experience particularly high rates of injury. Contact with objects and equipment was the most frequent event or exposure for LT claims for drilling contractors. Further, drilling, pulling, or running tubulars was the work activity most often identified for LT contact with objects and equipment claims, and the occupation category of roustabouts, oil and gas was most frequently associated with these claims.

As described in the O*NET database,23 the tasks of roustabouts, oil and gas include connecting and disconnecting pipes, casing, tubing, and pump rods, using hand and power wrenches and tongs, moving pipes to and from trucks, and dismantling and repairing oil field machinery. Much of the work is manual labor, posing the risk of overexertion and bodily reaction, and performed at elevation, posing the risk of falls, slips, and trips and injuries due to being struck by dropped objects. New-technology drilling rigs incorporating engineering controls, such as automated pipe handling, have contributed to a significant reduction in incidence of severe injuries for workers primarily working on the rig floor, such as roustabouts, as found in a study by Blackley et al25 of 671 injuries on new- and old-technology drilling rigs during 2003–2012.

The Incident Statistics Program (ISP), in which the International Association of Drilling Contractors collects voluntary safety and accident information from drilling contractors, also showed steadily decreasing nonfatal injury rates in this industry from 2001 to 2018, as well as for earlier and later years.24 As in this study, the ISP reported that the most frequent event or exposure causing severe injury was contact with objects and equipment, followed by falls, slips, and trips, and overexertion and bodily reaction. The ISP also reported a higher number of injuries among floormen, motormen, and roustabouts than other occupations such as drivers, heavy equipment operators, supervisors, and maintenance personnel,24 as found here. Some of the decrease in injury rates in the OGE industry may be due to the increased automation of pipe handling in this industry, as pipe is involved in many severe and costly WC claims. The ISP reported that pipe and tubulars were the equipment most associated with LT and recordable injuries for drilling contractors, and fingers and thumbs were the body part most often injured,24 which agrees with the findings of this study.

Claims Caused by Contact With Objects and Equipment

Wurzelbacher et al26 also reported that the highest rates of LT WC claims in the oil and gas sector in Ohio were for contact with objects and equipment. This rate (0.356 per 100 FTEs) was second only to the rate in the mining sector (0.432 per 100 FTEs) for the highest rate among private industry sectors and was 2.5 times as high as the rate for all private industry (0.142 per 100 FTEs) for 2007 to 2017. It was over 1.5 times the rate for the construction sector (0.225 per 100 FTEs).26 Contact with objects and equipment was the event or exposure most frequently found in the 100 most expensive claims in this study, demonstrating its possible severe consequences.

Words referring to the hand area were frequently found in the free-text description of LT contact with objects and equipment claims. Pipe handling, especially that associated with drilling rigs, poses a serious risk of injury. Drill pipe used in oil and gas operations can weigh more than 2000 lb each. Crushing injuries to hands were frequently described in this dataset. Hand and finger injuries can be severe and life-altering. Over 1 million injuries to hands and fingers occur each year in the United States,27 and they account for nearly 15% of days away from work occupational injuries (one or more days away from work) tabulated by the BLS across all US industries.28 In the state of Ohio from 2012 to 2018, between 70 and 280 injuries to the hand and fingers resulting in days away from work were recorded each year.29 Common factors in such injuries include inappropriate tool design, use of malfunctioning tools or equipment, insufficient training, inexperience, handling heavy objects, rushing, fatigue, and distraction.27,28 In a study of 2101 nonfatal OSHA severe injury reports from the OGE industry from January 2015 to July 2022, Parasram et al30 found that 771 of the reports involved the hands.

Claims filed during repair or maintenance activities were most often caused by contact with objects and equipment, which is consistent with an analysis by Pollard et al27 of 21,799 reports of maintenance- and repair-related incidents to the US Mine Safety and Health Administration between 2002 and 2011. Contributing factors cited in this mining industry study included the diverse nature of the work, the many different locations where it takes place, the presence of pinch points, posture issues, and the application of physical force.27 Many of these issues are present in the OGE industry and might be mitigated by redesigning equipment, tools, and work practices, and employing guarding.27

Claims Caused by Fall, Slip, and Trip

As found in this study, a NIOSH survey of mobile equipment operators in the mining industry in three different states found that entering and exiting vehicles could lead to falls.31 Many of the LT fall, slip, and trip claims in this study were filed for transport (and transfer) work activities. Vehicle egress has been found to be more risky than ingress due to lack of visibility when moving backwards.31 Inadequate traction on stairs and other walking surfaces, slippery contaminants, and lack of maintenance were also cited as factors.31 Falls from work vehicles and trailers were also noted in an earlier WC study as a frequent cause of severe occupational injury.14

Many LT falls, slips, and trips occurred when simply walking on site. Factors identified in falls, slips, and trips in the study by Pollard et al27 included environmental factors, obstructed walkways, an obstructed view, or poor design. As in the mining industry, workers in the OGE industry spend a lot of time walking outdoors day and night in all weather, putting them at risk for falls, slips, and trips.27 Truck traffic, rain, snow, and ice can lead to the presence of ruts, holes, and slippery conditions. Hoses, containment, clods of mud, and other obstructions pose a tripping hazard. Maintaining safe, well-lit well pads, parking areas, and walking paths is a challenge that can bear fruit in improved safety and reduced cost.

Claims Caused by Material Handling

Material handling was the work activity most frequently associated with LT WC claims in this dataset. This is consistent with other studies.32,33 In a study of 6 years of WC claims, Dempsey and Hashemi found that over 36% were for injuries due to manual materials handling.32 Similarly, data compiled from the BLS Survey of Occupational Injuries and Illnesses by the Center for Construction Research and Training showed that lifting, lowering, pushing, pulling, holding, carrying, and catching materials caused 67% of work-related musculoskeletal disorders in construction.33

Claims Caused by Transportation Incidents

Serious incidents during transportation are known to happen frequently in the OGE industry,4,6,7,9,34 and transportation incidents were identified as the leading cause of fatalities in this study. This agrees with the findings of Mason et al,6 Retzer et al,7 Wingate et al,9 and Mode and Conway,34 who reported that transportation incidents are the leading cause of occupational fatalities in the OGE industry, and with a 2014 BLS report, which states that nearly half of all workplace fatalities in oil and gas extraction in 2011 were due to transportation incidents.4

The rate of transportation incidents in the OGE industry in the state of Ohio has not improved in 18 years. A study by Yeoman et al35 identified OGE workers as significantly less likely to always wear seat belts than other manual labor workers. Wingate et al9 found that approximately half of transportation fatalities in the OGE industry identified through a pilot study of the Texas Department of Transportation Crash Records Information System were not wearing seat belts. An in-depth study of motor vehicle crash data collected from members of the International Association of Oil & Gas Producers for the year 2015 revealed that most of those fatally injured were not wearing seat belts.36 New and innovative solutions may be needed to address the ongoing issue of transportation incidents.

Cost of Claims

The cost of WC claims in the OGE industry is high. For comparison, the median cost for nonzero-cost claims from the OGE industry in the state of Ohio to OHBWC for 2001 to 2018 was $903, 56% higher than the cost from all private industry ($577). The median cost of MO claims was $525, 16% higher than the MO cost for all private industry ($452). The median cost of LT claims was $15,096. Forty-two percent higher than the LT cost for all private industry ($10,666). This could indicate that WC claims in the OGE industry are more severe than the average claim from all private industry.

Risks for Short Job Tenure Workers

Previous research has found that workers with short job tenure had higher rates of occupational injury in comparison to longer-tenured workers.14,37–41 In this study, we found that, in claims where tenure was recorded, 58% of LT claims were for workers with a year or less of job tenure, and four of the seven fatally injured workers with known job tenure had less than 90 days of job tenure (57%). Workers are four times more likely to suffer an LT injury during their first 30 days on the job than workers who have been at the job for more than a year.37 New workers are often performing unfamiliar tasks, may not have received adequate training, may underestimate risks, or may not be aware of their safety rights and might feel uncomfortable speaking up about hazards on site. These factors place new workers at an increased risk for workplace incidents.

In a systematic review of studies of the correlation between job tenure and acute occupational injury, Breslin et al38 suggested that reducing job turnover could improve occupational safety by decreasing the number of new workers hired. However, the boom-and-bust nature of the OGE industry makes it difficult to recruit and keep workers.42 Factors contributing to difficulties in retention include the tight job market and the lack of skills among new recruits. Some companies are developing new training and retention interventions, but research into their effectiveness is needed.42 To reduce job turnover, Breslin et al38 recommend reducing the hazardous exposures experienced by new workers, increasing hazard awareness through training, and empowering new workers to reduce their risks.

Safety Interventions

There are many hazards endemic to oil and gas extraction. The Hierarchy of Controls recommends controls for hazards in order from most to least preferred as follows: elimination, substitution, engineering controls, administrative controls, and finally personal protective equipment (PPE).43 Although elimination and substitution can be incorporated in the design phase, engineering controls are the most-preferred controls that can be readily utilized in an existing process.

Engineering controls, such as increased automation, that separate workers from drill pipe are the most effective methods of preventing contact injuries while handling pipe.25 When controls are not available or in place, workers can benefit from using the proper PPE. Across-sectional survey of 472 OGE workers in three states by Wingate et al44 found that most workers surveyed reported employer glove requirements, but smaller percentages of workers used them when needed or required. Inadequate communication of glove requirements and poor fit and function of gloves may be factors in the noncompliance.44

Requiring the use of gloves, with their inherent limitations, is not sufficient to reduce hand and finger injuries. Instead, recommendations of a NIOSH study of injuries in the mining industry during maintenance or repair include engineering controls and administrative controls such as examining the work environment, properly blocking equipment during maintenance, modularizing equipment into smaller sections that are lighter in weight, guarding pinch points, and increasing the use of mechanical assist devices to avoid hand and finger injuries.27 Appropriate PPE policies should also be in place and enforced.

Useful recommendations for interventions to reduce falls from work vehicles and trailers can be found in a comprehensive report on falls from work vehicles from the United Kingdom Health and Safety Executive,45 in a study by Nasarwanji et al46 of 1457 injuries when entering or exiting front-end loaders, and a study by Pollard et al47 of slip potential on different styles of grated walkways, with and without contaminants. These recommendations include engineering controls such as improving fall protection; reducing the incline on sloped walkways; improving slip resistance of walking surfaces, ladders, and stairs; and improving lighting. Recommended administrative controls include reducing activities, such as tarping of loads, that might require climbing on a semitrailer; providing vehicle washing facilities where contaminants could be removed; routinely inspecting ingress and egress systems for maintenance issues; and ensuring that yards are smooth and free from ruts and obstacles.45

Providing engineering controls such as lifting assist devices could help to reduce the incidence of overexertion and bodily reaction injuries. In a study of 174 workers at 33 different employers in industries involving heavy material handling who completed surveys, use of material handling interventions such as motorized lifts and hoists was associated with a lower incidence of pain in the lower back and upper extremities among workers who frequently handled objects weighing more than 50 lb.48 Kaur et al49 examined 10,347 WC claims for work-related musculoskeletal disorders in the construction industry and concluded that interventions including engineering controls such as the use of ergonomic tools and equipment and administrative controls such as task modification and additional training should be considered.

In a survey of 363 OGE workers in three states who drove a vehicle as part of their work duties, Wingate et al50 identified several risky driving behaviors and recommended cell phone bans, speed management, journey management, and in-vehicle monitoring systems (IVMS) as potential safety interventions. The OGE industry is increasingly adopting IVMS, engineering controls that could be effective in reducing transportation incidents. These systems monitor basic driving behavior, such as speeding and harsh braking events. A review of OGE industry papers published on IVMS showed 49%–93% reductions in crash rates after implementing IVMS in conjunction with a motor vehicle safety program.51 For IVMS to be most effective, it should be coupled with feedback cues and coaching.52

Hagan-Haynes et al10 studied surveys of 500 OGE workers from three states and recommended that companies should limit long work hours, reduce long daily commutes, and promote quality sleep to improve driving outcomes. The researchers recommended further study of the effectiveness of fatigue management, journey management, and maximum work hours policies.10A recommended-practices document published by the International Association of Oil & Gas Producers promotes 12 elements of safety practices, including vehicle-related, driver-related, and journey-related elements, for improved safety.51 The NIOSH Center for Motor Vehicle Safety also offers many resources to help enhance driving safety.53

Newly hired workers can benefit from administrative controls including training that complies with the OSHA training requirements for general industry, general safety training, as well as job-specific training in a language they can understand.54 Several companies in the OGE industry have successfully implemented “green hat” programs. These programs require new hires to wear green hard hats during their comprehensive training and mentoring period; once competencies have been demonstrated, the new hire is considered to have graduated from the program and “earned” the white hard hat worn among the rest of the crew.55,56 Companies that implemented these programs saw improvements in safety measures and safety culture and a reduction in workplace safetyincidents.55,56 Additionally, fostering an environment where workers are encouraged to speak up about hazards or unsafe practices without fear of reprisal is essential to safeguarding workers in this hazardous industry. There may not be a second chance.

Strengths and Limitations

A strength of this study is that it examines nonfatal as well as fatal injuries. Nonfatal injuries have not been as thoroughly studied as fatal injuries in this industry, although they outnumber fatal injuries in this database by over 200 to 1. In addition, the data on the costs of claims in this database can be used by health and safety professionals to help make the business case for implementing safety and health interventions in the workplace, for example, using the OSHA Safety Pays tool or the methods of the NIOSH Safety Pays in Mining tool.57,58

One limitation of this study is that claims were only studied in the state of Ohio, where a relatively small fraction of oil and gas extraction takes place, 0.5% of US oil production and 6% of US natural gas production.11 However, the findings of this study largely agree with other studies of health and safety in the OGE industry.6,7,9,10,24,34,35,41,44,50

There are several reasons why results reported here may underestimate the true figures. Most, but not all, companies in Ohio are insured by the OHBWC, so injuries and illnesses from self-insured companies or uninsured sole proprietorships or partnerships are not captured here. Although WC data may capture more or different occupational injuries and illnesses than BLS data based on OSHA-reportable cases, rates reported here may still be undercounts.59,60 Occupation and work activity data reported here were based on free text, and some of the descriptions could not be reliably matched to a worker’s occupation or work activity, so those results may be less representative.

An improved auto-coding method based on the free-text description of the claim was used to classify the event or exposure for each claim in this database, but some classifications may still be inaccurate. Manual coding was only performed on a subset of LT claims. Because the focus of this article is on high-frequency claims at the lowest level of detail (1-digit OIICS code), the accuracy of classification is likely better than that projected for more detailed levels. We would not expect misclassification of event or exposure to vary by detailed industry.

Job tenure data were missing for 45% of the claims studied. To draw conclusions about the relationship between job tenure and WC claims, it is necessary to assume that data on job tenure is missing proportionally across the full range of job tenure. This article focuses on LT claims, in which only 28% were missing data on job tenure, so this is less of a concern. Although most claims did report the number of days away from work, this number may be less reliable for workers who resign or retire rather than returning to work. We reported only median days away from work, which should be a more reliable number.

Results reported here cover a period in which major changes occurred in the OGE industry, including changing work processes, a boom, a bust, and a recession. The effects of these changes on our findings cannot be determined. Rates of transportation incidents were reported based on the number of FTEs, but they may be more appropriately reported on the basis of miles driven.61 Data on miles driven were unavailable for this study. Pay rates indifferent detailed industries and occupations may be different and played an unknown role in the indemnity costs of claims.

CONCLUSIONS

Rates of claims and the cost of claims in the OGE industry remain far higher than the average for all private industry. Although LT claims are a small fraction of all claims, they make up the majority of the costs of claims and should be prioritized for prevention.

Rig floor workers such as roustabouts and workers involved in transportation had the highest numbers of LT claims. Drilling contractors had the highest overall rate of LT claims, and contact injuries exhibited the highest claims rate for the overall OGE industry during the period of study. Engineering controls found in new-technology drilling rigs have contributed to a reduction in the incidence of severe injuries for workers by removing the workers from exposures associated with working on the rig floor.

Additionally, many of the workers with LT WC claims had short job tenure. Investing in new worker training, mentorship such as “green hat” programs, and fostering an environment where workers are encouraged to speak up about hazards or unsafe practices will not only help keep new workers safe but also help with worker retention.

Though the rate of transportation incidents was not as high as some other causes of WC claims, transportation incidents were associated with a high proportion of fatal injuries and costly injuries. Although IVMS has been successfully implemented in many OGE companies, new and innovative solutions are still needed to address the ongoing issue of transportation incidents.

Although these findings only focused on WC claims from the state of Ohio, the findings of this study largely agree with other studies of health and safety in the OGE industry. Continued analysis of WC claims from other oil and gas producing states is needed to truly understand the full economic burden of injuries and fatalities in this industry. NIOSH invites members of the OGE industry to partner with us in research to help improve health and safety in this industry.

Supplementary Material

LEARNING OUTCOMES.

Identify the most common causes of workers’ compensation claims in the oil and gas extraction industry in Ohio.

Summarize the differences among workers’ compensation claims experienced by the three industry groups: drilling contractors, servicing contractors, and operators.

Discuss interventions that could reduce the occurrence of some of the most severe workers’ compensation claims in the oil and gas extraction industry.

ACKNOWLEDGMENTS

The authors wish to thank Chih-Yu Tseng for her assistance with data programming, and Shelby Zuchowski for her assistance with manual quality control coding.

The authors report that there was no funding source for the work that resulted in the article or the preparation of the article.

The authors declare no outside sources of support.

Footnotes

The authors report no conflicts of interest.

EQUATER Network Reporting Requirements: Not applicable, this was neither a randomized trial nor an observational study.

Ethical considerations: This activity was reviewed by Centers for Disease Control and Prevention, deemed not research involving human subjects, and was conducted consistent with applicable federal law and Centers for Disease Control and Prevention policy (see, eg, 45 C.F.R. part 46; 21 C.F.R. part 56; 42 U.S.C.§241(d), 5 U.S.C. §552a, 44 U.S.C. §3501 et seq.).

Disclaimer: The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the Ohio Bureau of Workers’ Compensation (OHBWC), National Institute for Occupational Safety and Health (NIOSH), or the Centers for Disease Control and Prevention (CDC). Mention of any company or product does not constitute endorsement by OHBWC, NIOSH, or CDC. In addition, citations to Web sites external to NIOSH or OHBWC do not constitute OHBWC, NIOSH, or CDC endorsement of the sponsoring organizations or their programs or products. Furthermore, OHBWC, NIOSH, and CDC are not responsible for the content of these Web sites. All Web addresses referenced in this document were accessible as of the publication date.

Supplemental digital contents are available for this article. Direct URL citation appears in the printed text and is provided in the HTML and PDF versions of this article on the journal’s Web site (www.joem.org).

Contributor Information

Barbara M. Alexander, Division of Field Studies and Engineering, National Institute for Occupational Safety and Health, Cincinnati, Ohio.

Alejandra Ramirez-Cardenas, Western States Division, National Institute for Occupational Safety and Health, Lakewood, Colorado.

Steven J. Wurzelbacher, Division of Field Studies and Engineering, National Institute for Occupational Safety and Health, Cincinnati, Ohio.

Alysha R. Meyers, Division of Field Studies and Engineering, National Institute for Occupational Safety and Health, Cincinnati, Ohio.

Steven J. Naber, Ohio Bureau of Workers’ Compensation, Columbus, Ohio.

Data availability statement:

The workers’ compensation claims data are not available to the public.

REFERENCES

- 1.OSHA. Oil and Gas Extraction. Safety and Health Topics. Available at: https://www.osha.gov/oil-and-gas-extraction/hazards. Accessed July 5, 2022.

- 2.BLS, et al. Quarterly Census of Employment and Wages. Available at: https://www.bls.gov/cew/data.htm. Accessed February 21, 2024.

- 3.BLS. Employment and Wages Data Viewer. Quarterly Census of Employment and Wages. 2022. Available at: https://data.bls.gov/cew/apps/table_maker/v4/table_maker.htm#type=11&year=2020&qtr=A&own=5&area=US000&supp=1. Accessed October 4, 2022. [Google Scholar]

- 4.BLS. Oil and Gas Industry Factsheet, Fatal and Nonfatal Occupational Injuries and Illnesses in the Oil and Gas Industry. Washington, DC; 2014. Available at: https://www.bls.gov/iif/factsheets/archive/injuries-illnesses-fatalities-oil-and-gas-2014.htm. Accessed July 6, 2023. [Google Scholar]

- 5.BLS. Occupational Injuries and Illnesses by Selected Characteristics for State and Local Government News Release. Economic News Release 2012. Available at: https://www.bls.gov/news.release/archives/osh2_11082012.htm. Accessed February 20, 2024.

- 6.Mason KL, Retzer KD, Hill R, Lincoln JM. Occupational fatalities during the oil and gas boom—United States, 2003–2013. MMWR Morb Mortal Wkly Rep 2015;64:551–554. [PMC free article] [PubMed] [Google Scholar]

- 7.Retzer KD, Hill RD, Pratt SG. Motor vehicle fatalities among oil and gas extraction workers. Accid Anal Prev 2013;51:168–174. [DOI] [PubMed] [Google Scholar]

- 8.BLS. Fact Sheet | Mining, Quarrying, and Oil and Gas Extraction | May 2019. Washington, DC. 2019. Available at: https://www.bls.gov/iif/factsheets/mining-fact-sheet-2017.htm. Accessed July 7, 2023. [Google Scholar]

- 9.Wingate KC, Ramirez-Cardenas A, Hill R, Ridl S, Hagan-Haynes K. Fatalities in Oil and Gas Extraction Database, an Industry-Specific Worker Fatality Surveillance System—United States, 2014–2019. MMWR Surveill Summ 2023;72:1–15. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Hagan-Haynes K, Ramirez-Cardenas A, Wingate KC, et al. On the road again: a cross-sectional survey examining work schedules, commuting time, and driving-related outcomes among U.S. oil and gas extraction workers. Am J Ind Med 2022;65:749–761. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.USEIA. Ohio State Energy Profile. 2022. Available at: https://www.eia.gov/state/print.php?sid=OH. Accessed September 11, 2023.

- 12.OHBWC. Filing a claim. 2021. Available at: https://info.bwc.ohio.gov/wps/portal/gov/bwc/for-workers/claims/filing-a-claim. Accessed September 27, 2021.

- 13.Wurzelbacher SJ, Al-Tarawneh IS, Meyers AR, et al. Development of methods for using workers’ compensation data for surveillance and prevention of occupational injuries among state-insured private employers in Ohio. Am J Ind Med 2016;59:1087–1104. [DOI] [PubMed] [Google Scholar]

- 14.Alexander BM, Wurzelbacher SJ, Zeiler RJ, Naber SJ. Lessons learned from Ohio workers’ compensation claims to mitigate hazards in the landscaping services industry. Am J Ind Med 2021;64:699–713. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.BLS. Labor Productivity and Costs. 2020. Available at: https://www.bls.gov/lpc/#tables. Accessed August 20, 2020.

- 16.Wurzelbacher SJ, Meyers AR, Bertke SJ, et al. Comparison of Cost Valuation Methods for Workers’ Compensation Data. Cincinnati, OH: Paper presented at: Use of Workers’ Compensation Data for Occupational Safety and Health: Proceedings from June 2012 Workshop; 2013; 2012. Available at: https://www.cdc.gov/niosh/docs/2013-147/pdfs/2013-147.pdf?id=10.26616/NIOSHPUB2013147. Accessed July 26, 2021. [Google Scholar]

- 17.OHBWC. Annual Reports,2013–2018. Columbus, OH; 2020. Available at: https://www.ic.ohio.gov/news/reportsnewsletters.html. Accessed September 25, 2020. [Google Scholar]

- 18.BLS. Occupational Injury and Illness Classification Manual. Washington, DC; 2012. Available at: https://www.bls.gov/iif/oiics_manual_2010.pdf. Accessed July 1, 2020. [Google Scholar]

- 19.Bertke SJ, Meyers AR, Wurzelbacher SJ, Measure A, Lampl MP, Robins D. Comparison of methods for auto-coding causation of injury narratives. Accid Anal Prev 2016;88:117–123. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Meyers AR, Bertke SJ, Wurzelbacher SJ. Narrative Auto-Coding Improvements Using Deep Neural Network Methods. Cincinnati, OH: National Institute for Occupational Safety Health Center for Workers’ Compensation Studies Meeting; 2022. [Google Scholar]

- 21.Alexander BM, Wurzelbacher SJ, Zeiler RJ, Naber SJ, Kaur H, Grosch JW. The role of worker age in Ohio workers’ compensation claims in the landscaping services industry. J Occup Environ Med 2022;64:766–776. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.BLS. Standard Occupational Classification. 2023. Available at: https://www.bls.gov/SOC/. Accessed April 18, 2023.

- 23.O*NET. O*NET Resource Center. 2023. Available at: https://www.onetcenter.org/overview.html. Accessed April 19, 2023.

- 24.IADC. IADC ISP Program 2018 Summary of Occupational Incidents (US Land Totals). Houston, TX; 2019. Available at: https://www.iadc.org/wp-content/uploads/2019/06/2018-Annual-Report-for-Industry-Totals.pdf. Accessed August 10, 2022. [Google Scholar]

- 25.Blackley DJ, Retzer KD, Hubler WG, Hill RD, Laney AS. Injury rates on new and old technology oil and gas rigs operated by the largest United States onshore drilling contractor. Am J Ind Med 2014;57:1188–1192. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Wurzelbacher SJ, Meyers AR, Lampl MP, et al. Workers’ compensation claim counts and rates by injury event/exposure among state-insured private employers in Ohio, 2007–2017. J Safety Res 2021;79:148–167. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Pollard J, Heberger J, Dempsey PG. Maintenance and repair injuries in US mining. J Qual Maint Eng 2014;20:20–31. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Heberger JR, Nasarwanji MF, Pollard JP, Kocher LM. The necessity for improved hand and finger protection in mining. Min Metall Explor 2022;39:507–520. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.BLS. Occupational Injuries and Illnesses and Fatal Injuries Profiles. Available at: https://data.bls.gov/gqt/InitialPage. Accessed February 22, 2024.

- 30.Parasram V, Socias-Morales C, Reichard A. Severe work-related injuries in the oil and gas extraction industry—32 Federal Occupational Safety and Health Administration Jurisdictions, United States, January 2015–July 2022. MMWR Morb Mortal Wkly Rep 2024;73:104–109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Pollard J, Kosmoski C, Porter WL, Kocher L, Whitson A, Nasarwanji M. Operators’ views of mobile equipment ingress and egress safety. Int J Ind Ergon 2019;72:35–44. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Dempsey PG, Hashemi L. Analysis of workers’ compensation claims associated with manual materials handling. Ergonomics 1999;42:183–195. [DOI] [PubMed] [Google Scholar]

- 33.CPWR. The Construction Chart Book, 6th ed. Silver Spring, MD: CPWR – The Center for Construction Research and Training; 2018. [Google Scholar]

- 34.Mode NA, Conway GA. Fatalities among oil and gas extraction workers—United States, 2003–2006. MMWR Morb Mortal Wkly Rep 2008;57:429–431. [PubMed] [Google Scholar]

- 35.Yeoman K, Sussell A, Retzer K, Poplin G. Health risk factors among miners, oil and gas extraction workers, other manual labor workers, and nonmanual labor workers, BRFSS 2013–2017, 32 states. Workplace Health Saf 2020;68:391–401. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Walker K, Hawkes C, Poore W, Carvalho M. Industry safety data, what is it telling us? Paper presented at: SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility 2018. Available at: 10.2118/190545-MS. Accessed October 18, 2022. [DOI] [Google Scholar]

- 37.Breslin FC, Smith P. Trial by fire: a multivariate examination of the relation between job tenure and work injuries. Occup Environ Med 2006;63:27–32. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Breslin FC, Dollack J, Mahood Q, Maas ET, Laberge M, Smith PM. Are new workers at elevated risk for work injury? A systematic review. Occup Environ Med 2019;76:694–701. [DOI] [PubMed] [Google Scholar]

- 39.Morassaei S, Breslin FC, Shen M, Smith PM. Examining job tenure and lost-time claim rates in Ontario, Canada, over a 10-year period, 1999–2008. Occup Environ Med 2013;70:171–178. [DOI] [PubMed] [Google Scholar]

- 40.Bradley C, Brennan J, Wagner B. Workplace injury rates and firm-level turnover in Montana’s oil and gas industry. Am J Ind Med 2019;62:535–541. [DOI] [PubMed] [Google Scholar]

- 41.Retzer KD, Hill RD, Conway GA. Mortality Statistics for the US Upstream Industry: An Analysis of Circumstances, Trends, and Recommendations Society of Petroleum Engineers (SPE) Americas E&P Health, Safety, Security and Environmental Conference. Houston, TX; 2011:21–23. [Google Scholar]

- 42.Scott KA, Bushnell T. Oil and Gas Workers Count. In: U.S. Department of Health and Human Services CfDCaP, National Institute for Occupational Safety and Health. NIOSH Science Blog: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 2023. [Google Scholar]

- 43.NIOSH. Hierarchy of Controls. Workplace Safety & Health Topics 2023. Available at: https://www.cdc.gov/niosh/topics/hierarchy/default.html. Accessed February 2, 2024.

- 44.Wingate KC, Scott KA, Pratt S, et al. Self-reported exposure to hazards and mitigation strategies among oil and gas extraction workers in three U.S. states. J Occup Environ Hyg 2022;19:676–689. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Scott A, Miller M, Hallas K. The Underlying Causes of Falls From Vehicles Associated With Slip and Trip Hazards on Steps and Floors. 2006. Available at: https://www.hse.gov.uk/research/rrpdf/rr437.pdf. Accessed January 13, 2022.

- 46.Nasarwanji MF, Pollard J, Porter W. An analysis of injuries to front-end loader operators during ingress and egress. Int J Ind Ergon 2018;65:84–92. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Pollard JP, Heberger JR, Dempsey PG. Slip potential for commonly used inclined grated metal walkways. IIE Trans Occup 2015;3:115–126. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Wurzelbacher SJ, Lampl MP, Bertke SJ, Tseng C-Y. The effectiveness of ergonomic interventions in material handling operations. Appl Ergon 2020;87:103139. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Kaur H, Wurzelbacher SJ, Bushnell PT, et al. Workers’ compensation claim rates and costs for musculoskeletal disorders related to overexertion among construction workers - Ohio, 2007–2017. MMWR Morb Mortal Wkly Rep 2021;70:577–582. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Wingate KC, Pratt S, Ramirez-Cardenas A, Hagan-Haynes K. Risky driving behaviors and employer motor vehicle safety policies among U.S. oil and gas extraction workers. J Safety Res 2023;86:12–20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.IOGP. Land Transportation Safety Recommended Practice, Version 4.0. London, UK: International Association of Oil & Gas Producers; 2020:365. Available at: https://www.iogp.org/bookstore/product/land-transportation-safety-recommended-practice/. Accessed August 11, 2023. [Google Scholar]

- 52.Bell JL, Taylor MA, Chen G-X, Kirk RD, Leatherman ER. Evaluation of an in-vehicle monitoring system (IVMS) to reduce risky driving behaviors in commercial drivers: comparison of in-cab warning lights and supervisory coaching with videos of driving behavior. J Safety Res 2017;60:125–136. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.NIOSH. Motor vehicle safety at work. 2021. Available at: https://www.cdc.gov/niosh/motorvehicle/default.html. Accessed September 8, 2022.