Abstract

The rapid development of delivery systems for cosmetics has revealed two critical challenges in the field: enhancing the solubility of active ingredients and ensuring the stability of natural materials used in cosmetics. Nanoemulsion technology has emerged as an indispensable solution for addressing these challenges, not only enhancing the stability of cosmetics but also improving the solubility of pharmaceuticals and active ingredients with poor solubility. Nanoemulsion formulations have reinforced stability and amended the bioavailability of hydrophobic drugs. Moreover, nanoemulsion exhibit excellent skin penetration and long-lasting effects, making them particularly appealing to consumers, especially in the cosmetic industry. This article aims to provide an overview of herbal nanoemulsion formulations as cosmetic products, covering formulation, production, and characterization. Herbal nanoemulsions is an effective, stable, and promising option for cosmetic delivery. The nanoemulsions were characterized by their key properties, such as particle size, polydisperse index (PDI), zeta potential, viscosity, stability and others. Techniques like zeta potential measurement, transmission electron microscopy (TEM) and scanning electronmicroscopy (SEM) were used to analyze the surface morphology, whereas stability tests were employed to evaluate nanoemulsion performance. This review also delves into the high-energy and the low-energy methods of manufacturing nanoemulsions. Additionally, we also explore the selection of appropriate surfactants, co-surfactants, and ingredients for creating herbal nanoemulsions with desirable attributes and qualities. Overall, this review consolidates the current knowledge on herbal nanoemulsion formulations for cosmetic preparations, designs, shedding light on their effectiveness, characteristics, and stability. These formulations hold promise in overcoming challenges related to meeting the increasing demand for effective herbal nanoemulsion and high-quality cosmetic products.

Keywords: Cosmetic, Formulation, Nanoemulsion, Natural product

1. Introduction

The Food and Drug Administration (FDA) defines cosmetics as substances intended to be applied to the human body or any part thereof for purposes such as cleansing, beautifying, promoting attractiveness, or altering appearance [1,2]. In a broader sense, cosmetics refer to products designed to improve skin appearance, enhance beauty, and facilitate thorough cleansing [3,4]. These definitions encompass a wide range of products falling under the cosmetics category, each serving specific functions related to personal care and aesthetics. Cosmetics consist of a range of commercial products, such as skin moisturizers, anti-aging products, facial makeup, shampoos, toothpaste, deodorants, hair dyes, and various other items utilized to smarten up one's appearance. This classification reflects the diverse nature of cosmetics, including items that cater to different aspects of personal grooming and aesthetic preferences [5,6]. In the cosmetic industry, cosmeceuticals are recognized as cosmetic products infused with biologically active ingredients that offer therapeutic benefits for enhancing the personal appearance [7,8]. These formulations cover a diverse range, spanning from skincare to body care to hair care, allowing for their application in various treatments [9,10]. Cosmeceuticals play a crucial role in addressing specific concerns such as skin aging, skin dryness, dark spots, pigmentation, hair damage, and many more [11,12]. This distinct category represents the fusion of cosmetic and pharmaceutical attributes, catering to individuals seeking beauty and personal care products with enhanced therapeutic properties [13–15].

The utilization of cosmetic products containing chemically active ingredients brings forth a spectrum of challenges and considerations. One primary concern lies in the potential skin sensitivity and allergic reactions, as certain individuals may experience adverse responses, including redness and irritation. Moreover, the disruption of the skin barrier function by certain chemical components raises concerns about susceptibility to environmental factors [16,17]. Prolonged and frequent use of cosmetics with specific chemical ingredients may cause unknown long-term effects due to the accumulation of potentially harmful substances in the body [18,19]. The environmental impact of these products during disposal, also contributes to water and land pollution, posing threats to our ecosystems. Additionally, certain chemical ingredients, such as parabens and phthalates, are endocrine disruptors, raising concerns about hormonal imbalances [20–22]. Ethical considerations, regulatory compliance, personalized reactions, and the lack of long-term safety data further compound the complex landscape of cosmetic use with chemical active ingredients. As public awareness grows, there is an increasing call for transparency, safety, and ethical practices in the cosmetic industry to address these multifaceted challenges and promote informed consumer decision-making [23,24].

The utilization of herbal remedies and medicinal plants to deal with diverse ailments traces back to ancient civilizations [25]. In modern times, spurred by the perceived health benefits of these natural remedies, this traditional practice has experienced a resurgence of interest among researchers and innovators globally [26]. The growing popularity of herbal medicines as alternative therapies in the western world emphasizes the necessity for further investigation, especially when combined with pharmaceutical nanotechnology, to ensure the safety and efficacy of these remedies [27,28]. In contemporary times, nano-drug delivery systems (NDDS) have emerged as a highly effective approach for delivering bioactive components or drugs within the human body [29,30]. These systems possess the ability to direct the drug or active molecule to specific tissue sites or cell types, ensuring the desired concentration is maintained throughout the effective treatment period within the therapeutic index [31,32]. The use of nanoparticles or nanodroplets enhances the drug's solubility and bioavailability. In this context, nanoencapsulation-based nanoemulsions, a process that utilizes nanocarriers to encapsulate active components within the lipidic or polymeric core of excipients, play a pioneering role in encapsulating herbal bioactives, resulting in improved solubility and bioavailability. The effectiveness of phytopharmaceuticals therefore depends on the development of efficient drug delivery systems [33–35].

A nanoemulsion is a type of emulsion, which is a mixture of two immiscible liquids (such as oil and water) stabilized by an emulsifying agent. It exists as a homogeneous, thermodynamically stable, and isotropic system composed of aqueous components, surfactants/co-surfactants (Smix), and an oil phase. Nanoemulsions are commonly used in various fields of industry such as pharmaceuticals, food, cosmetics, and agriculture [36,37]. In pharmaceuticals, for instance, nanoemulsions can be employed to improve the solubility and delivery of poorly soluble drugs. In the food industry, they are utilized to create products with a smoother texture and better flavor. The cosmetic industry uses them for skincare products to enhance the absorption of active ingredients [35,38].

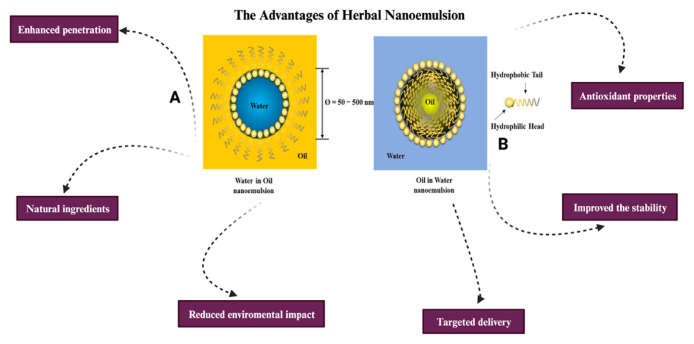

A herbal nanoemulsion refers to a specialized form of nanoemulsion that incorporates herbal extracts or bioactives as its active components. This type of nanoemulsion is designed to address the challenges associated with the solubility, permeability, and bioavailability of herbal compounds [39,40]. By reducing the droplet size to the nanometer range, herbal nanoemulsions aim to enhance the stability and delivery of these bioactive components, thereby optimizing their therapeutic effects. All these advantages render the nanoemulsion technique promising for developing to be an effective and efficient delivery system for herbal medicines [38,41].

The use of natural herbal components, such as extracts derived from mangosteen rind, rhizome plants, essential oils, aloe vera, and phylanthus niruri, has experienced a notable increase in the field of cosmetic formulations [42,43]. This surge is motivated by the desire to create effective and high-quality products that prioritize both safety and nutritional benefits. The integration of herbal ingredients into cosmetic formulations reflects a growing trend, propelled by a discerning customer base that acknowledges the diverse benefits of natural components, particularly in the realm of skincare and cosmetics [44–46].

The nanoemulsion delivery system in cosmetics is a heterogeneous one, characterized by the presence of one or two immiscible liquids, where liquid molecules disperse as tiny droplets, typically measuring less than 500 nm in diameter. Nanoemulsions, unlike conventional formulations, along with other nanocarrier options, offer solutions to challenges such as creaming, flocculation, coalescence, sedimentation, and the troublesome phenomenon known as Ostwald ripening [47–49]. Ostwald ripening occurs when small, highly soluble droplets undergo diffusion, resulting in the formation of larger droplets a problem commonly encountered in formulations with large droplet particle size distributions [50,51].

Nanoemulsions in cosmetic science offer heightened aesthetic appeal, formulation customization of formulations, and reduced irritation as well, which make them popular in the cosmetic formulations and therapeutic products [52,53]. These characteristics contribute to the development of innovative and effective cosmetic products that align with consumer preferences and expectations [54,55]. The rapid expansion of the cosmetics industry in recent years highlights the practicality and effectiveness of integrating natural ingredients into cosmetic formulations [56–58]. Thus, given the significant demand for skincare and cosmetic products, this review focuses on the existing insights into the design, preparation, formulation, and characterization of potent herbal nanoemulsions in cosmetic applications. Additionally, particular attention will be paid to developments in nanoemulsion use in cosmetics over the past decade, particularly emphasizing products that utilize nanoemulsion technology in their formulations and incorporate active ingredients derived from herbal or natural sources. Nanoemulsion is an advanced technology that enhances the delivery and absorption of active ingredients into the skin, thereby increasing the efficacy of cosmetic products. Cosmetics that feature herbal or natural active ingredients are often perceived as gentler and more skin-friendly, potentially offering additional benefits depending on the specific herbs used. The combination of nanoemulsion technology with natural ingredients is generally expected to yield optimal results with minimal adverse effects.

To compile this information, we accessed the latest and pertinent references from reputable databases, including Science Direct, Google Scholar, MEDLINE (PubMed), Scopus, and SciFinder. We anticipate that this review will prove beneficial for researchers and serve as a valuable contribution to the field.

2. Cosmetic science and skin barrier

2.1. Cosmetic science

Cosmetic science is a multifaceted discipline that applies scientific principles to the intricate process of developing, formulating, and producing cosmetic and personal care products. Drawing from fields such as chemistry, biochemistry, biology, dermatology, and materials science, cosmetic scientists engage in a comprehensive exploration of raw materials, including active ingredients, preservatives, emollients, and surfactants [52]. The primary goal is to understand how these components interact to create stable and effective formulations that enhance the appearance and well-being of the skin, hair, and overall personal aesthetics [59,60].

A crucial aspect of cosmetic science involves the selection of ingredients based on their chemical properties, safety profiles, and intended effects. Cosmetic scientists conduct rigorous testing, including laboratory experiments and clinical studies, to evaluate product efficacy, safety, and stability over time. Ensuring regulatory compliance and ethical consideration is integral to the process, as is the constant pursuit of innovation to incorporate new technologies, ingredients, and trends into cosmetic formulations [61,62]. Collaborating with experts in dermatology, toxicology, and marketing, cosmetic scientists contribute to the continuous evolution of skincare, haircare, makeup, and fragrance products that align with both safety standards and consumer expectations [63,64].

2.2. Structure and function of skin

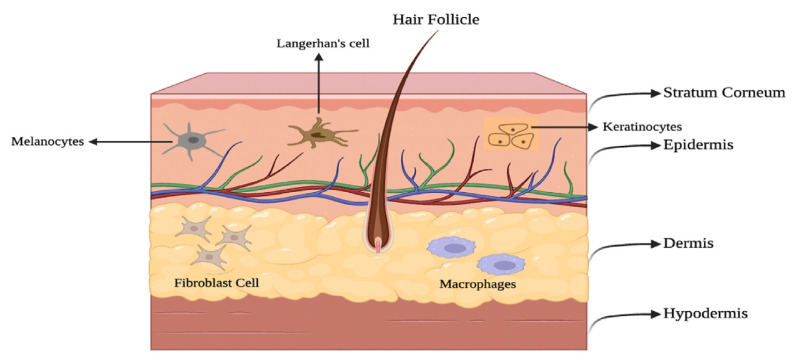

The skin, the body's largest organ, acts as a protective barrier between internal organs and the environment, shielding against potential damage. Consisting of three layers - epidermis, dermis, and hypodermis - each has unique cell compositions. The epidermis, the top layer, is mostly keratinocytes (95%), with the rest being melanocytes, Langerhans cells, and Merkel cells. These cells play crucial roles in skin structure and function, collectively contributing to its protective capabilities (Fig. 1) [65,66].

Fig. 1.

Schematic representation of human skin structure.

The epidermis can also be divided into four main layers: stratum basale, stratum spinosum, stratum granulosum, and stratum corneum (SC) from inner to upward layers respectively (Figs. 1 and 2). The stratum basale is a single layer of actively dividing keratinocytes, melanocytes, and Merkel cells. The stratum spinosum is a significant layer contributing to the skin structure and renewal [66]. Composed predominantly of keratinocytes, its distinct feature is the presence of desmosomes which provide strength and resilience to the skin, resisting mechanical stress. Actively dividing keratinocytes populate the stratum spinosum, as cells move upward from the stratum basale, ensuring a continual renewal process. The cells in this layer are metabolically engaged in RNA (ribonucleic acid) and protein synthesis, preparing for their transition into the next layer, the stratum granulosum. In essence, the stratum spinosum stands as a vital intermediary in the epidermal layers, balancing cell division, structural integrity, and the dynamic process of skin regeneration [67,68].

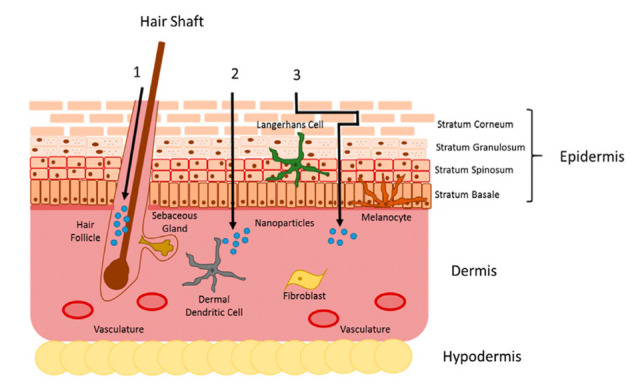

Fig. 2.

Illustration depicting skin penetration pathways of nanoparticles. Nanoparticles applied topically can penetrate the skin in one of three different routes: (1) the appendageal route, involving entry into hair follicles, sweat glands, or skin furrows for potential dermal penetration or enhanced drug release; (2) the intracellular route, which involves a direct passage through the cell membrane across multiple epidermal layers; or (3) the intercellular route, where nanoparticles traverse a more intricate route between epidermal cells. The selection of pathways is influenced by nanoparticle characteristics such as size, charge, morphology, and material. Figure and illustration credit [79].

The stratum granulosum is a pivotal layer that marks a transition in the process of keratinocyte differentiation. Comprising flattened and mature keratinocytes, the stratum granulosum is characterized by the presence of granules within the cells. These granules, known as keratohyalin granules, contain proteins that participate in the development of the skin's protective barrier. During this stage, the keratinocytes synthesize keratin filaments and the degrade of their cell nuclei [69]. This process is essential for forming a resilient, impermeable skin barrier against environmental stressors. As keratinocytes progress through the stratum granulosum, they further dehydrate, enhancing the compact structure. Ultimately, the stratum granulosum is vital for keratinocyte maturation, establishing skin barrier function and integrity [68,70–73].

The stratum corneum, situated at the outermost layer of the epidermis, is crucial for skin barrier function. Composed of flattened, keratin-filled cells called corneocytes, the stratum corneum acts as a protective shield, preventing the entry of pathogens and minimizing water loss from the body. These corneocytes are surrounded by a lipid-rich matrix, creating a water-resistant barrier that contributes to the impermeability of the skin [71]. The stratum corneum plays a pivotal role in maintaining skin hydration, preventing microbial invasion, and safeguarding the body against environmental stressors, thus ensuring the overall health and integrity of the skin [74,75]. The dermis, beneath the epidermis, comprises two layers enhancing its integrity and function. The upper layer, the papillary dermis, features finger-like projections called papillae extending into the epidermis, creating a unique interface. It contains blood vessels, nerve endings, and sensory receptors, crucial for regulating temperature, sensation, and skin nourishment [15,74].

2.3. Mechanism of nanocarrier skin transport

The skin also plays a role in regulating the transport of substances between the internal and external environments. This dynamic process involves various mechanisms that collectively contribute to the function and selective permeability of the skin barrier [76]. The skin allows certain molecules to pass through different routes. Lipophilic substances can penetrate the skin through the lipid-rich intercellular spaces, while hydrophilic molecules utilize aqueous channels formed by sweat ducts and hair follicles. Additionally, passive diffusion, facilitated by concentration gradients, plays a role in the transport of substances across the skin. The skin's pH, hydration level, and the presence of natural moisturizing factors influence these transport mechanisms. Understanding the intricate interplay of these factors is crucial in fields such as dermatology and drug delivery, as it impacts the absorption of topically applied substances and the overall health of the skin [73,77,78].

Nanoparticles penetrate the skin through one of three routes: Apendageal penetration, Intracellular penetration and Intercelluler penetration, by passing through corneocytes, by navigating around corneocytes, or by penetrating through dermal structures like hair follicles (Fig. 2). Appendageal penetration involves nanoparticles entering the skin via hair follicles and sweat glands, which act as natural openings that bypass the outermost layer of the skin, known as the stratum corneum. This route allows the nanoparticles to reach deeper skin layers more effectively. Intracellular penetration, on the other hand, involves nanoparticles entering skin cells through processes such as endocytosis, where the cell membrane engulfs the particles. Once inside the cells, the nanoparticles can be transported within vesicles or released into the cytoplasm, allowing them to interact with intracellular components. Lastly, intercellular penetration involves nanoparticles traveling between skin cells, navigating through the intercellular spaces in the stratum corneum and other skin layers. This movement is influenced by the extracellular matrix and tight junctions between cells, and factors such as particle size, charge, and hydrophobicity play a role in the effectiveness of this pathway. Each of these routes offers unique advantages for delivering drugs, cosmetics, or other therapeutic agents, depending on the properties of the nanoparticles and the intended application [73,77,78].

The process of nanoparticle skin penetration entails complex interactions and intricate mechanisms that depend on various factors, including nanoparticle characteristics and skin properties. Moreover, nanoparticles may exhibit skin penetration through multiple pathways, each influenced by distinct physical and chemical attributes [73,79].

♦ Apendageal penetration: Nanoparticles can also penetrate through skin appendages such as hair follicles, sweat glands, or skin furrows. This pathway provides an alternative route for nanoparticles to reach deeper layers of the skin, potentially facilitating enhanced drug delivery or retention.

♦ Intracellular penetration: Nanoparticles can directly penetrate through the outermost layer of the skin, known as the stratum corneum, by passing through corneocytes, which are the dead skin cells. This intracellular route involves the nanoparticles traversing multiple layers of the epidermis, eventually reaching the viable layers beneath.

♦ Intercelluler penetration: Another pathway involves nanoparticles moving between the skin cells (keratinocytes) rather than penetrating through them. This intercellular route is characterized by a more tortuous path through the spaces between the skin cells. The nanoparticles navigate through these intercellular spaces to reach deeper layers of the skin.

Sungput and colleagues [80] in their study on mangosteen extracts loaded with coconut oil nanoemulsion, demonstrated that the size of particles is influenced by the inclusion of surfactant, cosurfactant, and the oil phase. Larger particle sizes result in faster skin penetration of the nanoemulsion. Furthermore, the study elucidated that nanoemulsion gel preparation exhibits superior penetration compared to emulsion gel preparation containing mangosteen extracts, with penetration rates of approximately 94.19% and 88.20%, respectively, for effectively delivering the active substances. Moreover, the oil phase and enhancer play a significant role in enhancing drug penetration into the lipophilic layer of the skin.

The success of nanoparticle skin penetration depends on several key factors such as nanoparticle size, charge, surface properties, morphology, and material composition. It is equally important to consider the potential safety implications associated with skin penetration. Current research endeavors aim to further elucidate these mechanisms and refine the design of nanoparticles to enhance the efficacy and safety across a spectrum of skin-related applications [81,82].

In the context of nanoemulsions and skin penetration, small and large particle sizes exhibit distinct characteristics and mechanisms that influence their penetration efficacy. Smaller particles benefit from a higher surface area to volume ratio, which enhances their interaction with the skin and facilitates diffusion through the skin's intercellular spaces. This increased surface contact allows them to navigate the tight junctions between skin cells more readily. However, smaller particles are more prone to aggregation, which can hinder their penetration efficiency. In contrast, larger particles can penetrate the skin more effectively through appendageal routes such as hair follicles and sweat glands, which can accommodate larger particles more readily and provide a pathway for deeper and faster penetration. Additionally, larger particles can create a higher osmotic gradient or pressure differential, driving them more forcefully into the skin layers and accelerating the penetration process. Larger particles may also disrupt the skin's lipid barriers more effectively, facilitating faster penetration. Despite the advantages of smaller particles in terms of surface area and diffusion, larger particles can sometimes achieve faster skin penetration due to their ability to utilize appendageal routes and create a higher driving force. Therefore, while both small and large particles have unique advantages, their effectiveness in penetrating the skin depends on their specific properties and the intended application of the nanoemulsion [15,74].

3. Design, formulation and techniques for making nanoemulsion

3.1. Nanoemulsion preparation

The production of nanoemulsions involves employing techniques that break down large droplets into significantly smaller ones, resulting in heightened stability and improved physical properties [80,83,84]. The nano-sized droplets within the emulsion create a larger surface area, providing advantages in diverse applications such as drug delivery, formulating food and beverages, creating cosmetics, and meeting the needs of industries seeking enhanced dispersion and absorption properties [85–87].

Nanoemulsions typically consist of several key components, all of which are pivotal in the formulation and stability of the emulsion. The main components of a nanoemulsion include [87,88]:

♦ Oil Phase: Nanoemulsions involve the dispersion of oil droplets in water or vice versa. The oil phase can be various oils, such as vegetable oils, mineral oils, or other lipids depending on the application.

♦ Water Phase: The continuous aqueous phase surrounds the dispersed oil droplets. It provides a medium for dispersion and is often responsible for carrying water-soluble components.

♦ Surfactants: They are molecules with hydrophilic (water-attracting) and hydrophobic (oil-attracting) regions. Surfactants reduce the interfacial tension between the oil and water phases, stabilizing the emulsion. They function in preventing the coalescence of droplets.

♦ Co-surfactants: In some formulations, co-surfactants are used along with the surfactants to enhance the stability and reduce the concentration of the primary surfactant.

♦ Co-solvents: These are optional components that can improve the solubility of certain ingredients and contribute to the overall stability of the nanoemulsion.

♦ Bioactive Compounds: In many cases, nanoemulsions are designed to carry specific active ingredients, such as drugs, herbs, nutrients, flavors, or fragrances. The small droplet size increases the surface area and enhances the bioavailability of these active compounds.

♦ Polymeric Stabilizers: Polymers can be added to further stabilize the nanoemulsion by providing a protective coating around the droplets.

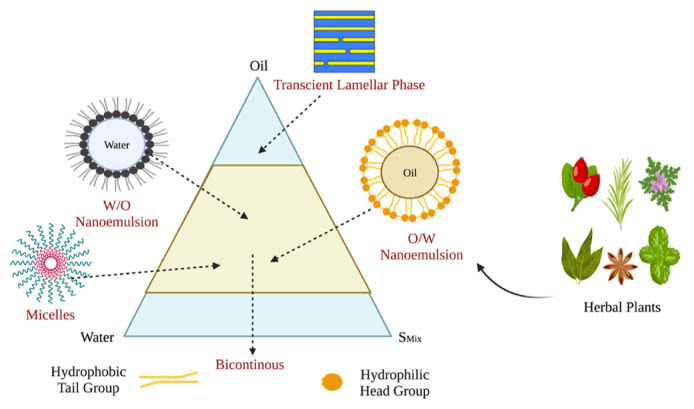

Screening excipients is important in the process of formulating nanoemulsions. The primary excipients involved in nanoemulsion formulation include oil, surfactant mixture (Smix), and water. Assessing drug solubility aids in the optimal selection of oils and surfactants for the development of nanoemulsion formulations. The use of a pseudoternary phase diagram is predominant in determining the proper ratio of water to oil to Smix in nanoemulsions. The actual ratio within the ternary system significantly influences the maximum drug solubility, encapsulation efficiency, and drug loading in the formulation [89,90]. Fig. 3 illustrates the distinct properties of the three components: oil, water, and Smix and their respective formulations.

Fig. 3.

An illustrative diagram depicting the interactions between oil, water, and Smix (surfactant mixture), highlighting the emulsification process and various formulations.

Understanding and optimizing the ratios and interplay between these elements are vital for creating a stable and efficient nanoemulsion customized for specific purposes, such as pharmaceuticals, food, cosmetics, or other industries [91,92].

3.2. Oil phase

The oil phase in a nanoemulsion refers to the component that comprises the dispersed oil droplets within the emulsion. This phase typically consists of various oils or lipids, depending on the desired properties and intended applications of the nanoemulsion. The choice of oil phase is the key point as it affects the emulsion's stability, texture, and compatibility with specific active ingredients [92–94]. Common types of oils used in the oil phase of nanoemulsions include vegetable oils such as soybean oil, sunflower oil, olive oil, or other plant-based oils. Mineral oils, derived from petroleum, can be used in certain applications. Lipids, including triglycerides or fatty acids, can be chosen based on their compatibility with the target formulation [95,96].

The selection of the oil phase depends on factors such as the intended use of the nanoemulsion, the desired characteristics of the final product, and the solubility of the active ingredients. Along with the water phase and emulsifying agents (surfactants and co-surfactants), the oil phase forms the fundamental structure of the nanoemulsion [57]. The goal is to create a stable dispersion of tiny oil droplets within the continuous water phase, and the choice of the oil phase significantly influences the overall performance and functionality of the nanoemulsion [97,98].

The nanoemulsion formulation conducted by Wuttikul and Sinakham [58] employed coconut oil as the oil phase, capitalizing on its inherent antioxidant properties. Additionally, the nanoemulsion preparation in this investigation featured Curcuma xanthorizza as a natural component, which also served as an active agent in cosmetic drug delivery [58].

Another study by Uchida and colleagues [99] focused on the development of nanoemulsions using Terminalia catappa Linn, employing crodamol as the oil phase, with concentrations of up to 3% of the oil carrier. Crodamol, an oil recently used for nanoemulsion formulations, has gained significant traction in cosmetics due to its versatile applications as an emollient, humectant, and more. This is attributed to crodamol's composition with medium-chain triglycerides, offering favorable properties such as colorlessness, odorlessness, stability, and antioxidant activity, rendering it suitable for both cosmetics and nanoemulsion preparations [100–102].

Another role for oil in nanoemulsions is to dissolve the lipophilic active substances. The choice of oil impacts the HLB due to variations in penetration abilities compared to the surfactant layer. Short to medium-chain oils exhibit superior penetration into the tail group area compared to long-chain alkanes, thereby reducing the HLB. Saturated fatty acids, such as lauric, myristic, and capric acids, along with unsaturated fatty acids like oleic and linoleic acids, have been demonstrated to enhance penetration [103]. In formulating, selecting lipophilic pharmaceuticals or those with high solubility in the oil phase is essential for size reduction in the formulation [104].

3.3. Surfactant

A surfactant, short for surface-active agent, is a chemical compound that reduces the surface tension between two immiscible substances, typically between a liquid and a solid or between two liquids. Surfactants have molecules with both hydrophilic (water-attracting) and hydrophobic (water-repelling) portions. This dual nature allows them to interact with and stabilize emulsions, which are colloidal dispersions of two immiscible liquids, such as oil and water [105,106].

Surfactants are widely used in various industries, including pharmaceuticals, cosmetics, food, and agriculture, due to their ability to improve the dispersal, solubility, and stability of substances that do not naturally mix. They are essential components in the formulation of products like emulsions, soaps, detergents, and foams [105,107].

Surfactants play a crucial role in reducing the interfacial tension between typically immiscible phases, facilitating their emulsification. These amphiphilic molecules contain both hydrophilic and lipophilic groups within a single molecule. Changes or adjustment to the interfacial layer can significantly affect factors influencing the emulsion system. As described by Lima and colleagues [108].

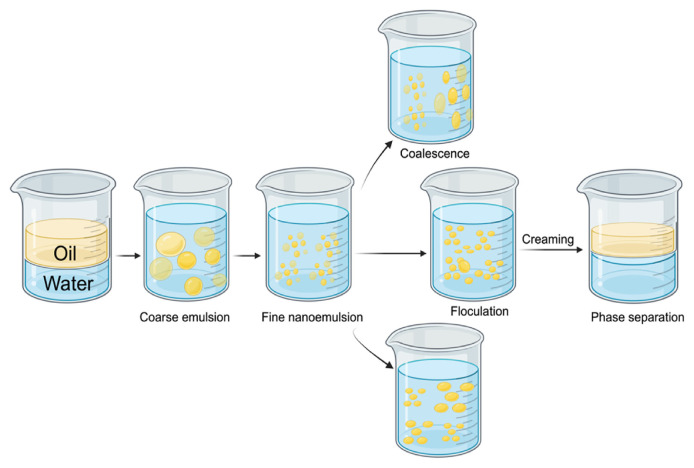

Emulsion breakdown primarily occurs via three mechanisms: creaming, flocculation, and coalescence. Creaming is a phase separation phenomenon resulting from the upward or downward movement of particles due to gravitational attraction in phases with varying density values. Flocculation is characterized by the agglomeration of droplets, and due to the lack of concentrated films between surfaces, it leads to quicker creaming formation. Coalescence, on the other hand, entails the merging of droplets into larger ones, accompanied by concentrated film formation between surfaces (see Fig. 3) [109,110].

Several surfactants, including Tween 80, Span 80, Span 85, Transcutol, and various natural surfactants, have been utilized in several studies discussed herein, typically at concentrations ranging from 4% to 15% in each formulation. Emulsion stability is influenced by various factors, including emulsion composition and processing techniques. Internal factors affecting emulsion stability include the type and concentration of emulsifying agents, the nature and concentration of components in the dispersed and continuous phases, the viscosity of the continuous phase, the ratio of dispersed phase to continuous phase, and particle size. External factors that impact emulsion stability include agitation, evaporation, and temperature variations [111,112].

In the development of nanoemulsions for herbal cosmetics, newer surfactants such as Transcutol® and Labrasol® have emerged as significant advancements beyond traditional agents like Tween and Span. Transcutol® (diethylene glycol monoethyl ether) is utilized for its exceptional skin penetration enhancement and solvent properties, which facilitate the effective delivery of active ingredients into the dermal layers. Labrasol® (caprylocaproic triglyceride) serves as both an emulsifier and solubilizer, stabilizing nanoemulsions and improving the dispersion of hydrophobic compounds, thereby enhancing their bioavailability. Additionally, caprylic/capric triglycerides, derived from coconut oil and glycerin, are employed for their emulsifying and moisturizing properties, contributing to a smooth texture and better delivery of actives. Polysorbate 80 and lecithin are also used for their stabilizing effects; polysorbate 80 improves dispersion and reduces surface tension, while lecithin, a natural emulsifier, enhances skin compatibility and formulation stability [97,98]. Polyglyceryl-10 oleate and sodium lauroyl glutamate are innovative possibilities for surfactants that are both natural and gentle. These choices are in line with the current movement towards using cosmetic chemicals that are more friendly to the skin and the environment. Together, these contemporary surfactants enhance the effectiveness and user satisfaction of herbal cosmetic products by improving performance in nanoemulsions [105,107].

3.4. Co-surfactant/co-solvent

In cosmetic nanoemulsions, various surfactants are utilized to stabilize the formulation and enhance its cosmetic properties. Commonly employed surfactants include Tween 20 (Polysorbate 20) and Tween 80 (Polysorbate 80), which are nonionic surfactants known for their emulsifying and solubilizing properties. Additionally, Span 20 (Sorbitan Monolaurate) and Span 80 (Sorbitan Monooleate) are often used as lipophilic surfactants to stabilize oil-in-water nanoemulsions. Cremophor EL (Polyoxyl 35 Castor Oil) is another nonionic surfactant frequently employed in cosmetic formulations due to its compatibility with a wide range of substances. Sodium lauryl sulfate (SLS) and cetyltrimethylammonium bromide (CTAB) are examples of anionic and cationic surfactants, respectively, which may be used in specific formulations to achieve desired properties. Additionally, Poloxamer 188, a nonionic surfactant with both hydrophilic and lipophilic properties, is often utilized for its emulsifying and stabilizing effects in cosmetic nanoemulsions. These surfactants play essential roles in stabilizing the emulsion, enhancing the solubility of active ingredients, and improving the overall cosmetic performance of the product [113,114].

Guzman and colleagues [48] investigated the production of nanoemulsions from Passiflora edulis var. edulis using Span 85 and Tween 80 as surfactants and cosurfactants. In addition to one surfactant, multiple studies [45,115,116] have demonstrated that the use of co-surfactants is necessary for the creation of nanoparticles. This is because a mixture of surfactants provides better stability during storage compared to nanoemulsions that use only a single surfactant.

In a study conducted by Harimurti and colleagues [117] (Table 2), the utilization of two surfactants such as Tween 80 and Span 20 in the formulation of nanoemulsions involving Curcuma xanthoriza and Hylocereus polyrhizus yielded improved properties and stability [117]. This was evidenced by favorable characteristics, starting with particle size and the polydisperse index value, which met the criteria for nanoemulsion preparations. Moreover, the combination of low HLB values for surfactants and cosurfactants with high HLB values for surfactants and co-surfactants may enhance the stability of nanoemulsion preparations [118]. HLB serves as an empirical measure for assessing the interaction between hydrophilic and hydrophobic groups in surfactants or co-surfactants. This technique is also used to gauge surfactant emulsification of the oil and water phases, with HLB values ranging from 1 to 40. Lower values indicate oil solubility, while higher values signify water solubility. According to Almeida and colleagues [118], HLB value differentials can be employed to calculate surfactant combinations and percentages [118,119].

Table 2.

Formulation and methodology of cosmetic nanoemulsions from natural/herbal sources: Insights from previous studies.

| Herbal plant | Properties | Formulation | Methods | Ref | |

|---|---|---|---|---|---|

|

| |||||

| Oil-phase | Surfactant & Co-surfactant | ||||

| Rhodiola rosea | Antioxidant | NMa | Tween 80 | Low-energy method | [46] |

| Lonicera japonica | Stiring (Spontaneous emulsification) | ||||

| Curcuma aromatica | Antioxidant | Coconut oil | Tween 80, Span 80 | Low-energy method | [58] |

| Anti-aging | Stirring (spontaneous emulsification) | ||||

| Garcinia mangostana L. | Antioxidant | Virgin coconut oil | Span 20 | High-energy method | [80] |

| Tween 80 | High speed homogenization | ||||

| Propylene glycol | |||||

| Terminalia catappa Linn | Antioxidant | Crodamol | Tween 80 | Low-energy method | [99] |

| Anti-aging | Stirring (spontaneous emulsification) | ||||

| Dipteryx alata vog | Anti-aging | Palmitic acid | Tween 80 | High-energy method | [103] |

| Linoleic acid | High speed homogenization | ||||

| Passiflora edulis var. edulis | Antioxidant | NMa | Tween 80, Span 85 | High-energy method | [116] |

| Anti-aging | Ultrasonication | ||||

| Curcuma xanthoriza | Antioxidant | Corn oil | Tween 80 | High-energy method | [117] |

| Hylocereus polyrhizus | Anti-wrinkle | High speed homogenization | |||

| Rhodiola rosea | Whitening | Soybean oil, | Transcutol, Labrasol, | Low-energy method | [128] |

| Anti-aging | Labrafac oil | Tween 80, Span 80 | Stiring (Spontaneous emulsification) | ||

| Sunflower oil | Sunscreen | Sunflower oil | Tween 80 | Low-energy method | [137] |

| Span 80 | Sorbitol | Stiring (Spontaneous emulsification) | |||

| Psoralea corylifolia | Anti-aging | NMa | Coco bectaine, | Low-energy method | [140] |

| Surfactin | Stirring (spontaneous emulsification) | ||||

| Curcumin | Antioxidant | Virgin coconut oil | Tween 80, Span | High-energy method | [141] |

| Anti-aging | High speed homogenization | ||||

| Agave sisalana | Moisturizer | Ethylhexyl palmitate | Crodamol | High-energy method | [142] |

| Anti-aging | Tween 80 | Ultrasonic probe sonication | |||

| Span 80 | |||||

| Mauritia flexuosa | Sunscreen | Buriti oil | Tween 80, Span 80 | High-energy method | [145] |

| Antioxidant | High pressure homogenization | ||||

| Curcumin | Antioxidant | Echium oil | Tween 80 | High-energy method | [146] |

| High pressure homogenization | |||||

| Brown mustard seed | Moisturizer | Rice bran oil | Sorbitan oleate, | Low-energy method | [167] |

| Anti-aging | Polyethylene glycol | Stirring (spontaneous emulsification) | |||

| Pea protein | Antioxidant | NMa | Tween 80 | Low-energy method | [197] |

| Stirring (spontaneous emulsification) | |||||

| Cordyceps militaris | Antioxidant | Sea buckthorn oil (fruit oil) | Tween 80 | High-energy method | [198] |

| Chitosan | High pressure homogenization | ||||

| Opuntia ficus-indica | Moisturizer | Capric/Caprilic | Tween 80 | High-energy method | [199] |

| Triglycerides, Ethylhexyl Palmitate | Sorbitan oleate | (Ultra turrax mod) | |||

| Vellozia squamata | Antioxidant | Babacu oil | Span 60 | Low-energy method | [182] |

| PEG-40 | Stirring (spontaneous emulsification) | ||||

| Hydrogenated castor oil | |||||

| Phyllanthus niruri | Antioxidant | Citrullus lannatus seed oil | Tween 80 | Low-energy method | [200] |

| Stirring (spontaneous emulsification) | |||||

| Punica grantum var. Rabab | Antioxidant | Flaxseed oil | Tween 80 | High-energy method | [188] |

| High-pressure homogenization and Ultrasonication | |||||

NM: Not mentioned.

Information:

HLBr: the ratio of the combined value of 2 surfactants

HLBA: the ratio HLB of lipophilic surfactant

HLBB: the ratio HLB of hydrophilic surfactant

A%: percentage of lipophilic surfactant

B%: percentage of hydrophilic surfactant

Co-surfactants, also known as co-emulsifiers, cosolubilizers, or co-solvents, typically have a similar molecular structure to surfactants. The addition of a co-surfactant can improve the formulation by providing additional stability, reducing the required concentration of the primary surfactant, or modifying the characteristics of the emulsion, such as its droplet size or viscosity [120]. In summary, co-surfactants work in conjunction with primary surfactants to fine-tune the emulsification process, thereby improving the overall stability and performance of emulsions across various applications [121,122].

3.5. Herbal active ingredients

Herbal active ingredients refer to bioactive compounds derived from plants that have therapeutic or beneficial properties. These active ingredients are often extracted from different parts of medicinal plants, including leaves, roots, stems, flowers, and seeds. Herbs have been used for centuries in traditional medicine for their natural healing properties [41,85].

Examples of herbal active ingredients include:

Alkaloids: Potent compounds found in plants like opium poppy (morphine), cinchona (quinine), and caffeine-containing plants (coffee, tea).

Flavonoids: Antioxidant compounds present in fruits, vegetables, and herbs such as quercetin in onions, catechins in green tea, and rutin in buckwheat.

Terpenes: A diverse group of compounds found in plant-based essential oils, like menthol in mint, limonene in citrus fruits, and cannabinoids in cannabis.

Glycosides: Plant compounds with sugar molecules attached, such as cardiac glycosides in foxglove (used for heart conditions) or saponins in various plants.

Polyphenols: Broadly occurring compounds with antioxidant properties, including resveratrol in grapes, curcumin in turmeric, and epigallocatechin gallate (EGCG) in green tea.

Essential Oils: Volatile aromatic compounds found in plants, like eucalyptus, lavender, or peppermint, which are often used in aromatherapy or as topical agents.

These herbal active ingredients have various pharmacological effects including anti-inflammatory, antioxidant, antimicrobial, analgesic, and other therapeutic properties [123]. The active compounds are also frequently used as herbal medicine and natural remedies to improve the health and well-being of individuals. Nevertheless, it's essential to acknowledge that the effectiveness and safety of herbal products may vary, highlighting the importance of validating the therapeutic claims with extensive scientific research [85,124].

A herbal nanoemulsion, derived from plants, incorporates active compounds such as bioactive compounds, essential oils, or other therapeutic substances extracted from medicinal plants. In essence, herbal nanoemulsions offer a technologically advanced approach to delivering herbal active ingredients in a more efficient and bioavailable manner, promising potential advantages across diverse health and wellness applications [124–126].

Herbal nanoemulsions offer several unique advantages over conventional nanoemulsions in cosmetic sciences, primarily due to the incorporation of natural, plant-derived active ingredients. One of the main benefits is enhanced safety, as herbal nanoemulsions generally pose a reduced risk of adverse reactions due to the use of natural ingredients, which are less likely to cause skin irritation or sensitization compared to synthetic chemicals found in conventional nanoemulsions. Additionally, herbal nanoemulsions demonstrate improved efficacy, with the natural active compounds exhibiting better skin compatibility and enhanced penetration, ensuring higher bioavailability and effectiveness in delivering therapeutic benefits [100–102].

Moreover, herbal nanoemulsions are rich in natural antioxidants, providing superior protection against oxidative stress and environmental damage. They also possess natural anti-inflammatory properties, which help to reduce inflammation and provide soothing and calming effects on the skin. This anti-inflammatory benefit is often absent in conventional nanoemulsions that rely on synthetic ingredients. Furthermore, certain herbal extracts have inherent antimicrobial properties, making herbal nanoemulsions effective against various skin pathogens without the need for additional antimicrobial agents [121,122].

Consumer preference is another significant advantage of herbal nanoemulsions, as there is a growing trend towards natural and organic products. This preference makes herbal nanoemulsions more appealing in the cosmetic market. By highlighting these benefits—enhanced safety, improved efficacy, antioxidant properties, anti-inflammatory effects, antimicrobial activity, and consumer preference—the superiority of herbal nanoemulsions in cosmetic applications can be clearly demonstrated, showcasing their potential to deliver safer, more effective, and multifunctional skincare solutions [41,85].

4. Preparation method of herbal nanoemulsion

The preparation of herbal nanoemulsions involves several critical steps aimed at achieving a stable and effective formulation. Below is a general outline of the preparation method [126,127]:

-

Selection of Ingredients:

- Choose a suitable oil phase containing herbal extracts or essential oils.

- Select an aqueous phase, usually composed of water or an herbal aqueous extract.

- Pick appropriate surfactants and co-surfactants based on compatibility and stability considerations.

-

Determination of Ratios:

- Evaluate the optimal proportions among the oil phase, aqueous phase, surfactants, and cosurfactants. This assessment often involves utilizing a pseudoternary phase diagram to identify the appropriate ratios conducive to stable nanoemulsion formulation.

-

Preparation of Oil Phase:

- Combine the herbal extracts or essential oils with the chosen oil phase, possibly requiring heating and stirring to achieve homogeneity.

-

Preparation of Aqueous Phase:

- Combine the components of the aqueous phase, including water or herbal extracts.

-

Emulsification:

- Merge the oil phase and aqueous phase.

- Employ a low-energy method for spontaneous emulsification or a high-energy method such as high-pressure homogenization, ultrasonication, or microfluidization to break down droplets into nanoscale sizes, a crucial step for nanoemulsion formation.

-

Addition of Surfactants and Co-surfactants:

- Introduce the surfactants and co-surfactants to stabilize the nanoemulsion. This step helps prevent droplet coalescence and ensures long-term stability.

-

Post-processing:

- Allow the nanoemulsion to cool if heating was involved during the preparation.

- Check for any signs of phase separation or instability.

-

Characterization:

- Evaluate the characteristics of the nanoemulsion, including droplet size, polydispersity, zeta potential, pH and stability storage time.

-

Storage:

- Store the herbal nanoemulsion in appropriate conditions to maintain its stability until use.

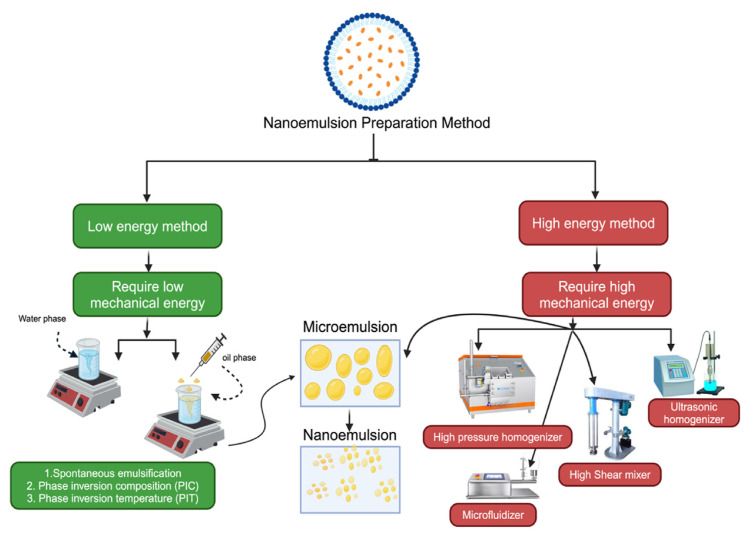

It's important to note that the specific details of the preparation method may vary depending on selected ingredients, intended application, and available equipment. Furthermore, adherence to Good Manufacturing Practices (GMP) and proper documentation are crucial for consistent and reproducible preparation of herbal nanoemulsions. Additionally, the creation of herbal nanoemulsions typically employs two primary methods: low-energy and high-energy methods, each offering distinct advantages and serving different purposes (Fig. 4). Below is an overview of several frequently utilized methods for preparing nanoemulsions, as outlined by Wuttikul and colleagues [58,128,129].

Fig. 4.

Study of nanoemulsion preparation method.

4.1. Low energy method preparation

In the context of formulations, a “low energy method” typically refers to processes or techniques that do not involve high levels of mechanical energy or intense processing conditions. This approach is often preferred for formulating pharmaceuticals, cosmetics, or emulsions, where the goal is to achieve a stable product without subjecting it to excessive energy that could compromise its stability or integrity [130,131].

A formulation utilizing the low-energy method focuses on minimizing the use of high-energy procedures (Fig. 4). This approach emphasizes gentle and controlled techniques to ensure the stability and quality of the end product. It begins with the careful selection of suitable components, taking into account their physicochemical characteristics. Moderate temperatures are employed to facilitate liquid phase mixing, eliminating the necessity for high-speed mixers or homogenizers.

The gradual addition of solid components is achieved through gentle agitation, minimizing degradation or undesired alterations in formulation qualities. If needed, minor adjustments in temperature and viscosity are made using low-energy techniques such as gentle heating or cooling. Emulsification methods, such as the surfactant utilization, enable the creation of stable emulsions without the need for high-intensity homogenization [132].

To achieve a more refined texture, filtration or straining techniques can be employed, while stringent quality control measures ensure stability, uniformity, and desired attributes. The packaging process is meticulously carried out to preserve product quality, and efforts are made to ensure that energy-efficient techniques can be effectively scaled up for expanded production.

This strategy is particularly beneficial in industries where minimize stress on the formulation to maintain the desired qualities of the final product [133,134]. For instance, in emulsion production, a low-energy approach could entail employing mild agitation, mixing, or homogenization techniques to attain the desired emulsion without subjecting the ingredients to excessive heat or strain. This is especially important when handling delicate substances or when preservation of formulation integrity is crucial [135,136].

The formulation of a low-energy method can vary depending on product characteristics and constituents involved, often requiring a delicate balance of components and a gradual approach to prevent undesired alterations during production [114]. For instance, Arianto and colleagues investigated a low-energy method employing spontaneous emulsification (3000–4000 rpm for 30 min) in their study of sunflower oil emulsification [137], They successfully produced three distinct nanoemulsions of sunflower oil with particle sizes less than 500 nm, resulting in a transparent solution. This study demonstrated the efficacy of the low-energy technique in reducing particle size and fulfilling the requirements for nanoemulsion preparation [106,138].

Similarly, Uchida and co-workers [99] conducted research on T. catappa Linn nanoemulsion utilizing the low-energy method of spontaneous emulsification. This method produced nanoemulsions with particle sizes less than 70 nm, along with clear and stable nanoemulsions. Another advantage of this method is its simplicity, quickness, and lack of requirement for special or expensive equipment. Spontaneous emulsification is a modification of the solvent evaporation method, where a water-soluble solvent (methanol or acetone) is added to a water-insoluble organic solvent (dichloromethane or chloroform). Interfacial turbulence formed between the two phases facilitates the formation of smaller particles through spontaneous emulsification of the water-soluble solvent. Additionally, diffusion of water-soluble solvents contributes to particle size reduction [98,139].

In essence, the low-energy approach involves employing mild processing techniques that minimize mechanical strain and energy consumption, resulting in the production of stable and superior products.

In a study by Lewinska et al. [140] investigating the formulation of nanoemulsion Psoralea corylifolia for anti-ageing cosmetic applications, the formulation employed spontaneous emulsification with stirring at 1000 rpm for 25 min. The modification and expansion of the liquid and air phases were achieved through dripping at a temperature of 25 °C [140,141]. The spontaneous emulsification method uses the chemical energy released during the dilution process to create a continuous phase at a constant temperature with no phase transitions during emulsification (Table 1). During dilution, water-soluble components (solvent, surfactant, or cosurfactant) diffuse from the organic phase into the aqueous phase, creating an oil-in-water nanoemulsion, as a result significantly increasing interfacial area and establishing a metastable emulsion state. Achieving nanoscale droplets through spontaneous diffusion emulsification requires careful consideration of the solvent or oil ratio. Turbulence facilitates solvent diffusion, promoting the formation of nanoscale droplets [98,138].

Table 1.

| Provision | Low energy methods | High energy methods |

|---|---|---|

| Equipment/instrument | Generally not required |

|

| Energy input Pressure | 103–105 W/kg Not applied | >108 W/kg for diameter below than 200 nm

|

| Droplet size distribution | Up to 50 nm |

|

| Total production cost | Low production cost |

|

4.2. High energy method preparation

Numerous scientific studies have demonstrated the formation of micellar nanoparticles within nanoemulsion systems, particularly within the cosmetic field. Characterization methods and pre-clinical investigations have been employed to validate the effectiveness of micellar nanoparticles as a delivery system for cosmeceuticals [114,132].

One notable study by Gomes et al. [142] focused on formulating a skin moisturizer based on nanoemulsion, utilizing ultrasonication techniques to incorporate micelles of Agave sisalana droplets as the active ingredient. The nanoemulsion system was initially developed by combining A. sisalana with various non-ionic surfactant types. The researchers successfully achieved a stable nanoemulsion formulation by using surfactants such as crodamol, Tween 80 and Span 80. This formulation contributed to the creation of smaller micellar particles, ranging between 83 and 155 nm in size. This innovative approach highlights the potential of micellar nanoparticles within nanoemulsions for enhancing the delivery and efficacy of active ingredients in cosmeceutical applications [143,144].

In another study by Paulo et al. [103], almond nanoemulsion formulations were examined using high-energy methods. Utilizing a high-pressure homogenizer (Omni Macro ES Digital Programmable Homogenizer, Kennesaw, USA) operating at 7500 rpm for 3 min resulted in the smallest particle size of 219 nm. This formulation exhibited favorable nanoemulsion characteristics and passed the stability testing. High-energy methodology is commonly employed for the preparation of nanoemulsions, utilizing high-temperature pressure devices to induce elevated temperatures and velocities for nanoemulsion formulation (Table 1) [139,145].

Furthermore, Inal et al. [146] used a high-energy method with the Ultra-Turrax T18 (IKA, Germany) instrument operating at a speed of 12500 rpm for 10 min at room temperature in the production of curcumin nanoemulsion and echium seed oil. The use of Ultra-Turrax in this formulation process is highly advantageous and proficient in generating nanoemulsions with sizes below 200 nm, aligning with the specific attributes of nanoemulsions. The efficacy of high-energy techniques in the manufacturing process, coupled with the optimal combination of surfactants, water phase, and oil phase, are key factors in achieving desirable features and stability in this nanoemulsion [146,147].

A study conducted by Gauthier and colleagues [148] demonstrated that the high-energy production process can be delineated into numerous alternatives, encompassing ultrasonication, high-pressure homogenizer, microfluidization, and rotorstator methods. The selection of nanoemulsion creation method hinges on factors such as the dosage formulation objective, material selection, instrument availability, and the economic considerations. This choice is pivotal for subsequent generation and characterization of nanoemulsion preparations that meet specified requirements [43,148,149].

5. Characterization of nanoemulsion

Previous studies have illustrated that cosmetic nanoemulsion formulations derived from herbal sources exhibit notable attributes. These formulations undergo nanoemulsion production and testing, as detailed in Tables 2 and 3.

Table 3.

Evaluation of the characteristics and functions of herbal nanoemulsions.

| Herbal plant | Characteristics Evaluation | Experimental Results | Functional Testing | Ref |

|---|---|---|---|---|

| Curcuma aromatica | Organoleptic PZ PDI Viscosity pH |

|

Antioxidant activity assessment, lipid peroxidation inhibition assay, protein denaturation inhibition test, heating-cooling cycle evaluation | [58] |

| Terminalia catappa Linn | Organoleptic PZ PDI ZP pH |

|

Carotenoid assay, <-amylase inhibition assay, antioxidant activity assay | [99] |

| Dipteryx alata vog | PZ PDI Stability |

|

None | [103] |

| Mauritia flexuosa | PZ PDI pH SM |

|

In vitro phototoxicity test, SPF test, radiation exposure assessment | [145] |

| Curcumin | Organoleptic PZ PDI ZP pH |

|

Solubility assessment, antioxidant capacity evaluation, in vitro simulated digestion analysis, fatty acid composition determination | [146] |

| Passiflora edulis var. edulis | PZ PDI Viscosity SM |

|

determination of >-anisidine value in nanoemulsion, conductivity test, skin viscoelasticity and firmness evaluation, transpidermal water loss measurement | [116] |

| Curcuma xanthoriza Hylocereus polyrhizus | PZ PDI ZP Stability Surface morphology |

|

Antoxodant activity, Fourier-Transform Infrared Spectroscopy (FTIR) examination | [117] |

| Rhodiola rosea | Organoleptic PZ PDI ZP pH Stability Surface morphology |

|

Skin irritation assessment, antioxidant activity evaluation, viscosity analysis, FTIR spectroscopy examination, centrifugation test, encapsulation efficiency determination | [128] |

| Curcumin | Organoleptic PZ PDI ZP Surface morphology |

|

Antioxidant activity assessment, skin penetration test, uorescent imaging analysis, scratch assay for wound healing assessment, cell cultivation and proliferation assay | [141] |

| Agave sisalana | PZ PDI ZP pH Stability Surface morphology |

|

Allergy testing, centrifugation analysis, skin hydration test | [142] |

| Rice bran oil | Organoleptic PZ Stability Surface morphology |

|

In vitro simulated lipid digestion and bioavailability assessment, measurement of free fatty acid release, ex vivo bioactivity analysis, assessment of prophylactic mitigation against mitogen (LPS) induced oxidative stress, uptake studies | [167] |

| Cordyceps militaris | PZ PDI ZP pH Stability Surface morphology |

|

FTIR, antioxidant activity, in vitro cytotoxicity, antibacterial activity, | [198] |

| Opuntia ficus-indica | PZ PDI pH Stability Surface morphology |

|

Electrical conductivity, evaluation of in vivo moisturizing properties, transepidermal water loss | [199] |

| Vellozia squamata | PZ PDI pH Stability |

|

Antioxidant activity, rheology test, total phenolic content | [182] |

| Phyllanthus niruri | PZ PDI ZP Stability Surface morphology |

|

Antioxidant activity, penetration test by cumulative percentage of release, refractive index and viscosity, release kinetic study | [200] |

| Punica grantum var. Rabab | PZ PDI ZP Stability |

|

Antioxidant activity, creaming stability, Ostwald ripening test, chemical stability | [188] |

| Garcinia mangostana L. | PZ PDI ZP pH Stability Surface morphology |

|

Antioxidant activity, clarity, glitter, viscosity | [201] |

PZ = Particle size.

PDI = Polydispersity index.

ZP = Zeta potential.

pH = Acidity.

SM = Surface morphology.

TEM = Transmission electron microscopy.

FTIR = Fourier-transform infrared spectroscopy.

Nanoemulsions, characterized in Table 3, typically exhibit stability and transparent appearance, with small droplet sizes typically less than 500 nm. Furthermore, they demonstrate enhanced stability, often with particle sizes falling within the range of 10–250 nm [150]. Nanoemulsions are formulated by combining oil and water phases using surfactants and cosurfactants, effectively reducing the interfacial surface tension [116,140,142,145].

6. Characteristics of nanoemulsion

Various methods were employed in the preparation of nanoemulsions using different herbal plants and ingredients (Table 2). Each method is associated with characteristic assessments to evaluate the quality and stability of the resulting nanoemulsions. Nanoemulsions were prepared using two primary methods: high energy and low energy methods [151].

To verify the fundamental characteristics of herbal nanoemulsions including particle size, PDI, organoleptic properties, visual inspection, viscosity, acidity, zeta potential, surface morphology and stability [152,153]. Several tests such as stirring (spontaneous emulsification), phase inversion composition (PIC), phase inversion temperature for low energy methods, high-pressure homogenization, ultrasonication and high-speed homogenization for high energy method were conducted (Fig. 4). The methods and corresponding results are integrated into Table 3.

The results varied among the different herbal plants and methods used, with some formulations exhibiting stability during storage, while others experienced separation or changes in characteristic properties. These findings provide valuable insights into the formulation and characterization of nanoemulsions, which have applications in the pharmaceutical and food industries for encapsulating bioactive compounds. In conclusion, Table 3 provides a comprehensive overview of the preparation methods, experimental models and characteristic testing results of nanoemulsions involving various herbal plants and ingredients. The selection of the preparation method and the distinct characteristics of each nanoemulsion differed, influencing their stability and quality over the course of storage [154,155].

6.1. Visual inspection and organoleptic test

Visual inspection and organoleptic tests are crucial techniques for evaluating the quality and sensory characteristics of nanoemulsions, especially in industries such as cosmetics, medicines, and food, where nanoscale formulations are widely used. Nanoemulsions, consisting of droplets finely scattered in the nanoscale range, undergo thorough visual examination to assess hue, clarity, and overall uniformity [156,157]. Anomalies such as phase separation, sedimentation, or visual irregularities are carefully observed as they can provide valuable information about formulation difficulties or instability. Visual examination ensures that the nanoemulsion satisfies aesthetic criteria andcomplies with rigorous quality requirements, delivering a visually appealing product [82,118].

In a study conducted by Paulo and colleagues [103] on Dypteryx alata vog. nanoemulsion for macroscopic stability, the creaming effect, a frequently observed destabilizing mechanism in O/W nanoemulsions, was examined visually at various salt concentrations and pH levels over a 28-day period, with evaluations conducted weekly. A creaming index approaching 0% indicates that the emulsified system maintains stability during the 28-day storage period, a distinctive characteristic of nanoemulsions being their small particle size, evident by their clear and stable visual appearance [158,159].

Organoleptic tests play a vital role in assessing the sensory characteristics of nanoemulsions, engaging human senses such as taste, smell, and touch. In skincare or cosmetics applications, parameters like texture, smoothness, and absence of grittiness are evaluated; whereas for pharmaceutical or food products, taste, odor, and mouthfeel are crucial factors. Deviations from expected sensory attributes may indicate formulation issues or the presence of undesirable elements. Organoleptic testing ensures that the nanoemulsion delivers a satisfactory sensory experience, aligning with consumer expectations [77,134,160].

The subjective nature of human sensory perception underscores the importance of these assessments in quality assurance. Visual inspection and organoleptic tests collectively contribute to ensuring that nanoemulsions not only meet technical benchmarks, such as droplet size and stability, but also deliver a satisfying sensory experience to consumers. These rigorous evaluations play a crucial role in maintaining the overall quality and market acceptance of nanoemulsions in industries characterized by constant innovation and dynamic consumer preferences [62,107]. Both visual inspection and organoleptic tests rely on subjective human perceptions, making them valuable tools for quality assurance. The combined use of these methods ensures that products not only meet technical specifications but also align with consumer expectations by delivering a satisfactory sensory experience [82,161].

6.2. Particle size and PDI (polydispersity index)

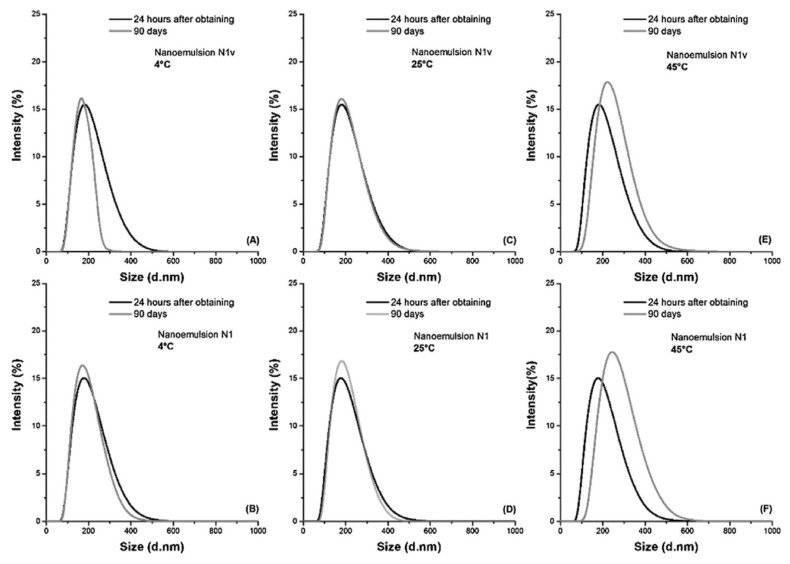

Barreto and colleagues [142] discussed the evaluation of droplet size distribution by intensity, revealing the presence of a monomodal peak with high intensity (Fig. 5). Moreover, the formulations exhibited lower PDI values, indicating the stability of the systems and the effectiveness of the ultrasound method in achieving stable nanoemulsions. Over a 90-day storage period at 4 °C, 25 °C, and 45 °C, no significant alteration in zeta potential values was observed, indicating the stability of the nanoemulsions. The lower values of zeta potential may be attributed to the steric stabilization mechanism.

Fig. 5.

Dynamic light scattering analysis revealing the distribution of droplet sizes (intensity plotted against droplet diameter) in Agave sisalana nanoemulsion [142].

Nanoparticle characterization involves determining the particle size, particle size distribution, and PDI values. Particle size analysis using laser diffraction operates on the principle that particles passing through diffracted light exhibit varying angles of diffraction corresponding to their size. As the diffraction angle increases, the particle size decreases. A narrow beam of monochromatic light, emitted from a He–Ne laser (λ = 633 nm), is transmitted through the suspension, and the diffracted light is concentrated on the detector. This procedure is grounded in the principles of scattered light energy [92,111].

In a study conducted by Saari and colleagues [141], specifically focusing on curcumin nanoemulsion formulation, the particle size was measured at 19.92 nm, with a corresponding PDI value of 0.17. This measurement is of paramount importance, ensuring that the size of the formulated preparation falls within the nanoscale range [141]. Another investigation, carried out by Inal and colleagues [146], involved curcumin nanoemulsions. Particle size analysis comparing curcumin-containing and curcumin-free nanoemulsions showed variations between the two, yet both remained within the particle size distribution range typical of curcumin nanoemulsions, namely <50 nm [48,146].

The PDI serves as a vital metric for assessing the size dispersion of oil droplets within nanoemulsions. Monodisperses is indicated when the PDI falls within the range of 0.1–0.7, denoting a narrow particle size distribution. The PDI value functions as a parameter for evaluating the uniformity or homogeneity of nanoparticles. Smaller PDI values correspond to greater particle homogeneity [142,162]. A PDI value approaching 0 signifies a high degree of particle size homogeneity, with values below 0.3 indicating monodispersity. PDI values ranging from 0.3 to 0.7 reflect polydispersity

In a study conducted by Barreto and colleagues [142], eight nanoemulsion formulations were developed, resulting in particle size distribution test measurements ranging from 83.57 nm to 155.80 nm, with PDI values ranging from 0.09 to 0.23. These findings confirm that the nanoemulsion formulations adhere to the specified criteria and align with typical nanoemulsion characteristics. It's important to highlight that this examination not only verifies particle sizes are within the nano range but also evaluates the appropriate distribution of particle sizes. This assessment is critical to prevent issues such as aggregation, sedimentation, and other factors that may jeopardize the stability of the formulations [98,142,163].

6.3. Zeta potential

Zeta potential values are indicative of the surface charge of nanoparticles in liquid formulations and are vital for evaluating their stability. This measurement relies on assessing the surface tension of nanoparticles in liquid preparations, offering valuable insights into the stability of the liquid formulation [164,165].

In a study conducted by Tran and colleagues [98] investigating nanoemulsions and the impact of zeta potential values on stability, it was observed that all nanoemulsion preparations exhibited negative (−) zeta potential values. Notably, the most stable nanoparticles displayed zeta potential values ranging from 25 mV to −25 mV. The assessment of zeta potential for a sample was performed using the Zetasizer-Nano Malvern Instrument, which monitored the direction and velocity of droplet movement in response to an applied electrical field after a diluted sample was introduced into the instrument chamber [58,98,166].

6.4. Surface morphology

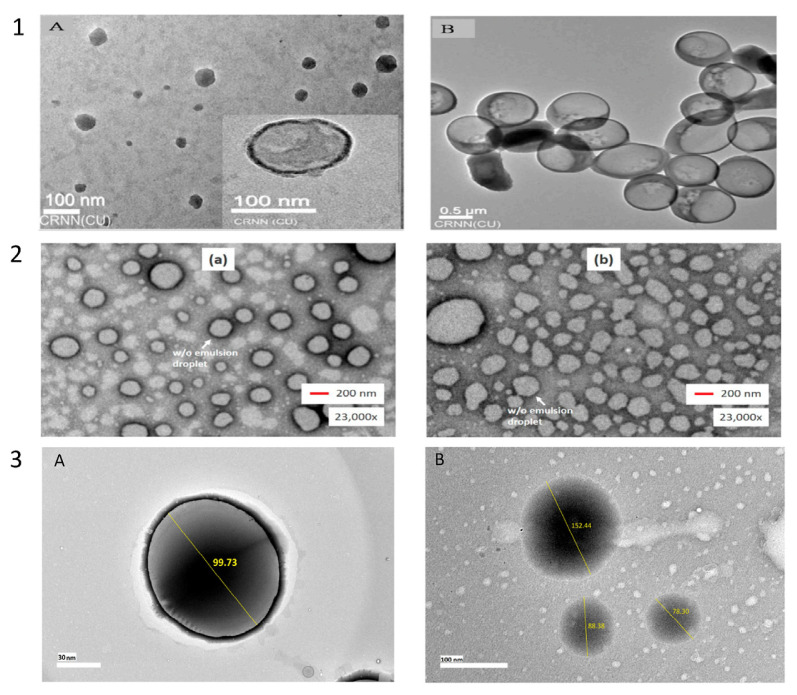

Harimurti and colleagues [117] conducted an investigation employing Transmission Electron Microscopy (TEM) for morphology testing, revealing that nanoscale dimensions could be determined by observing the shape and morphology of particles at a magnification of 200 nm. The TEM results allowed for a more detailed examination of the shape and size of the nanoemulsion preparations. The impact of oil addition to the nanoemulsion preparation was evident as a distinct dark outline around the globules. Additionally, TEM data provided valuable insights into particle size distribution [55,117,140].

Das and colleagues [167] (Fig. 6. (1A & 1B)) observed spherical droplets of the selected rice bran oil nanoemulsion, evenly distributed across the entire field, as revealed by TEM pictures. The average droplet diameter obtained from TEM analysis can be compared to the hydrodynamic droplet diameters obtained from dynamic light scattering (DLS) analysis. Typically, the hydrodynamic diameters of nanoemulsions are slightly larger than the sizes of dry droplets. Additionally, TEM allowed for the observation of aggregation of larger droplets in the conventional emulsion. In another study by Harimurti and colleagues [117] (Fig. 6. (2A & 2B)), TEM analysis complemented particle size and distribution assessments performed using the Zetasizer, providing a comprehensive characterization of the nanoparticles [105, 138]. Fig. 6 (3A & 3B) displays TEM images of the optimized nanoemulsion incorporating KMO. The TEM findings revealed that the optimized nanoemulsion containing KMO exhibited a polydisperse system, with droplet sizes ranging from 70 to 160 nm. The droplets appeared spherical, with no observable aggregation within the system [168].

Fig. 6.

(1A & 1B) Morphological examination of Rice bran oil-in-water nanoemulsions NE2 (MPI: Tween 20 – 1:1) and the corresponding conventional emulsion. Nanoemulsion analysis conducted using A-TEM, while traditional emulsion analysis performed using B-TEM [167]. (2A & 2B) TEM images depicting Nanoemulsions Containing Temulawak (Curcuma xanthorriza Roxb) and Red Dragon Fruit (Hylocereus polyrhizus) [117]. (3A & 3B) TEM images of kojic monooleate (KMO) nanoemulsion [168].

6.5. Stability study

The stability assessment performed by Paulo et al. [103] underscores the significance of evaluating nanoemulsion formulations, particularly due to the presence of oil content, which can render nanoemulsions vulnerable to instability. Many prior studies have used stability testing protocols to evaluate various particle properties, including size, PDI, zeta potential, pH, and viscosity, under different conditions and storage periods. This comprehensive assessment ensures that nanoemulsions demonstrate extended durability and consistent stability over time. Paulo et al. note that stability testing is essential for assessing the efficacy of cosmetics throughout their shelf-life.

The study noted an increase in particle size from 230 nm initially to 253 nm after 28 days, along with a rise in PDI value from 0.29 to 0.34 on the first day, although statistically insignificant. The observed change indicates potential particle aggregation and repulsion, impacting both particle size and PDI values [55,57,150].

Nanoemulsions, despite their promising properties and applications, can have issues related to instability. Various factors, including formulation components and external conditions, influence nanoemulsion stability. External conditions refer to environmental factors outside of the nanoemulsion formulation that can affect its stability. These conditions may include temperature fluctuations, exposure to light or oxygen, pH changes, mechanical agitation, and interactions with other substances present in the surrounding environment [169]. Temperature variations can lead to phase separation or changes in viscosity, while exposure to light or oxygen can cause degradation of sensitive ingredients or oxidation of lipid components [170,171]. pH changes can impact the stability of the emulsion by affecting the charge of the droplets and the interactions between surfactant molecules. Mechanical agitation, such as mixing or shaking, can disrupt the emulsion structure and lead to coalescence or droplet size changes. Interactions with other substances, such as salts or additives, can also influence the stability of the nanoemulsion. Overall, external conditions play a critical role in determining the stability and performance of nanoemulsions in various applications [157,172]. One common issue that compromises the stability of nanoemulsion is coalescence, where smaller droplets combine into larger ones [173]. Additional stability concerns include flocculation, the aggregation of droplets into loose clusters, and creaming or sedimentation, where droplets migrate to the top or bottom of the formulation. Ostwald ripening, a process where larger droplets grow at the expense of smaller ones, can also reduce stability. Chemical instability, such as oxidation or hydrolysis, temperature fluctuations, and pH variations, exacerbate instability risks (Fig. 7) [82,103,110].

Fig. 7.

Process of nanoemulsion preparation and various forms of stability changes [195].

To address and mitigate instability issues, formulation adjustments, incorporation of stabilizing agents, and optimization of manufacturing procedures are common practices. Stabilizers, including surfactants and co-surfactants, play a crucial role in preserving nanoemulsion stability by preventing droplet coalescence and forming a protective barrier [174]. Furthermore, the stability of nanoemulsions over time depends on factors such as storage conditions, packaging, and the careful selection of ingredients in the formulation [175].

In the formulation of nanoemulsions, stabilizers such as surfactants and co-surfactants are pivotal in maintaining droplet stability and preventing coalescence. Surfactants like Polysorbate 80, an example of a nonionic surfactant, function by reducing interfacial tension between the oil and water phases, thereby facilitating the formation and stabilization of smaller droplets. This is achieved through the formation of a protective monolayer around the droplets, which prevents coalescence via steric hindrance and reduced surface tension. Anionic surfactants, such as Sodium Lauryl Sulfate (SLS), impart a negative charge to the droplet surfaces, creating electrostatic repulsion that inhibits droplet aggregation [168]. Conversely, cationic surfactants like Cetyltrimethylammonium Bromide (CTAB) provide a positive charge, similarly contributing to stability through electrostatic repulsion. Co-surfactants, including amphoteric surfactants like Cocamidopropyl Betaine and nonionic cosurfactants like Polyglyceryl-10 Oleate, enhance the emulsification process by further reducing interfacial tension and providing additional stabilization [157,172]. The combined effect of these surfactants and co-surfactants ensures the formation of a stable nanoemulsion through mechanisms of reduced interfacial tension, protective barrier formation, electrostatic repulsion, and steric stabilization. This multifaceted approach is crucial for maintaining the uniformity, efficacy, and shelf-life of nanoemulsion formulations in various applications [82,103,110].

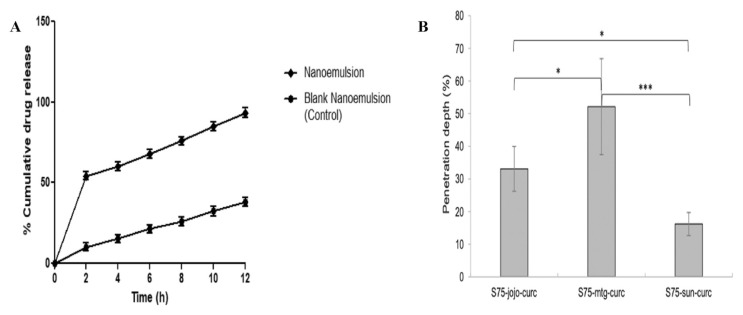

6.6. In vitro release study