Abstract

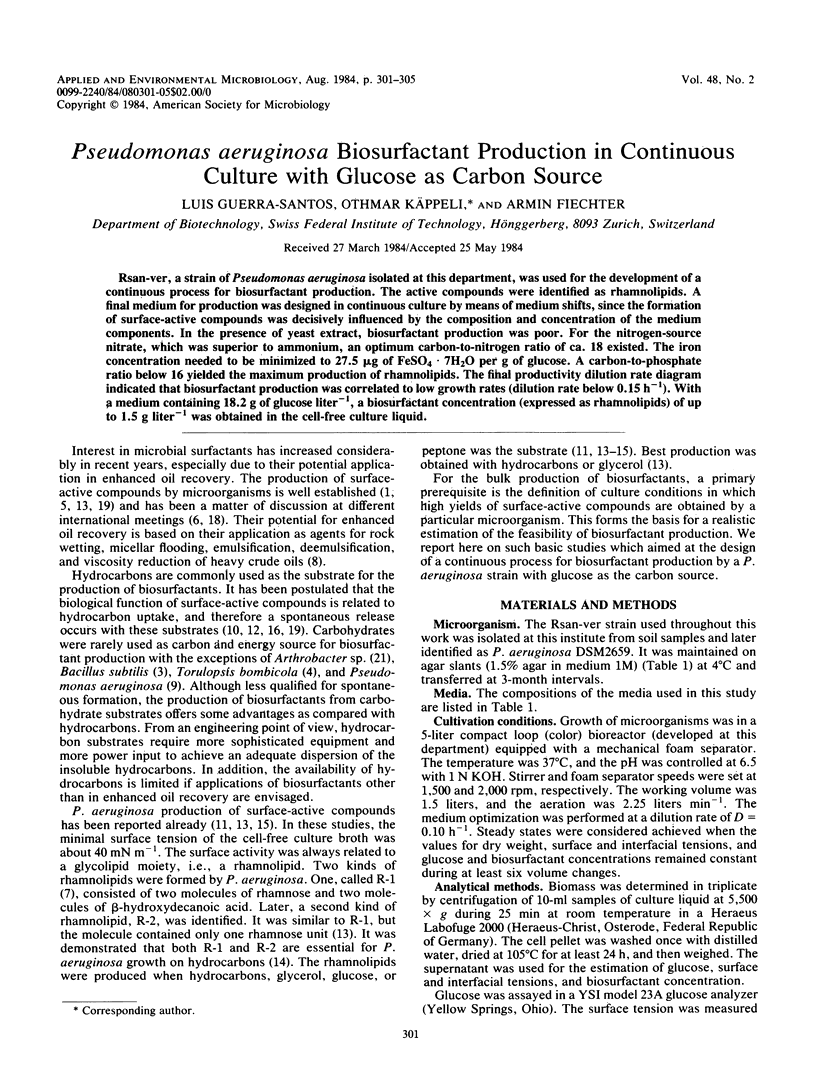

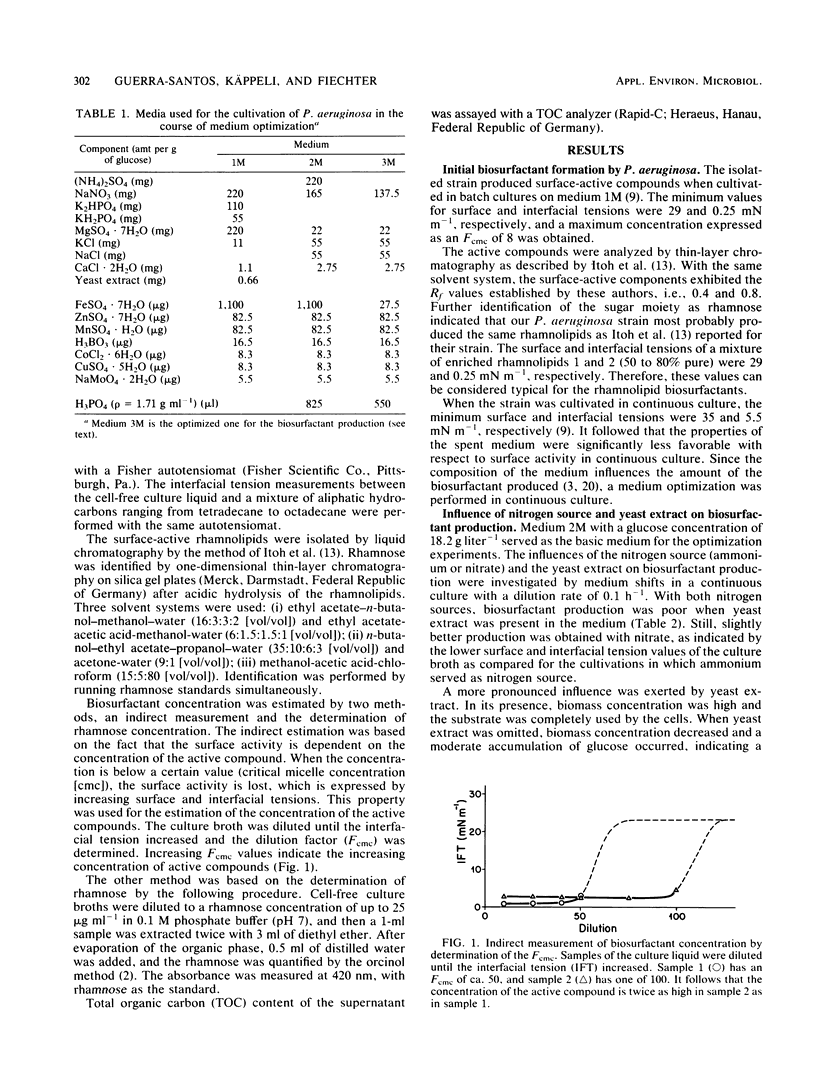

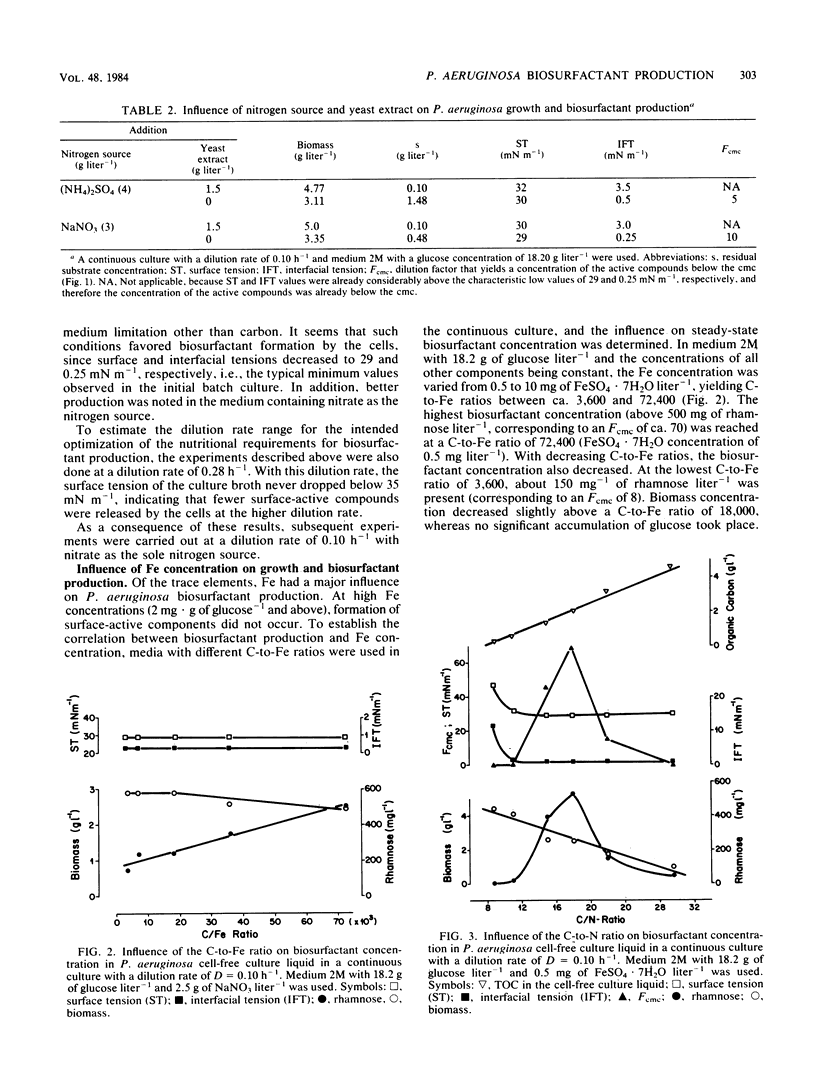

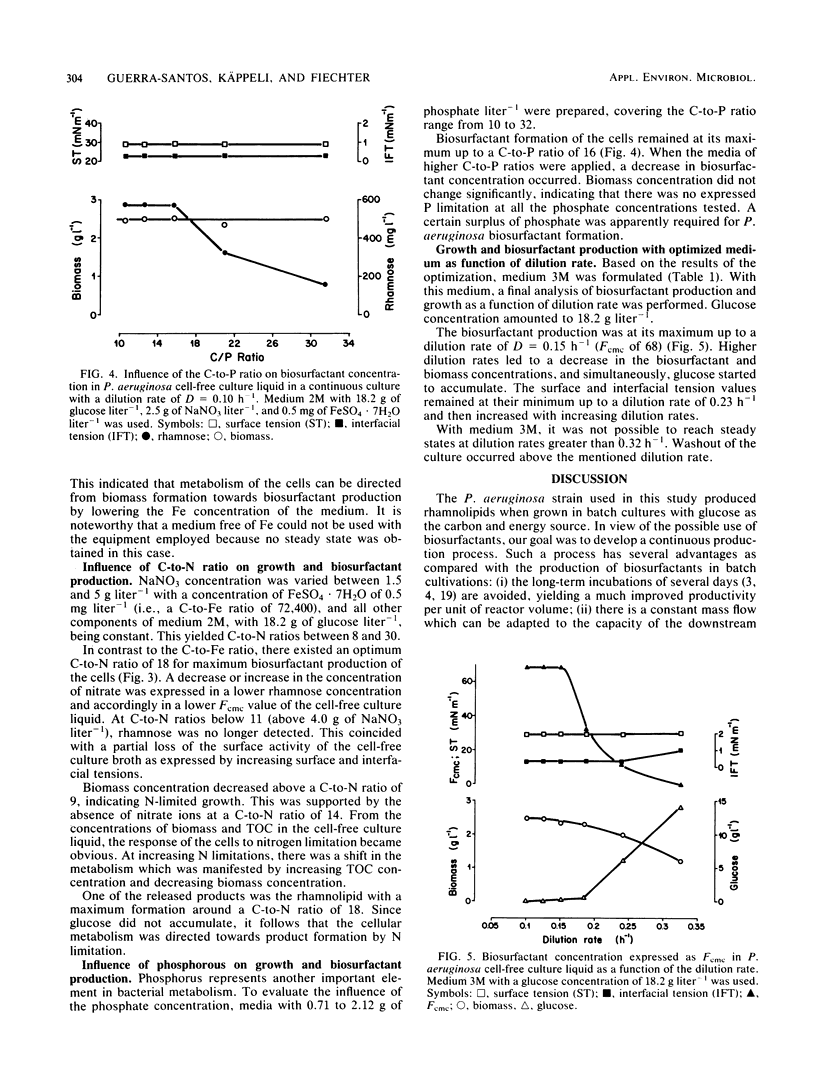

Rsan-ver, a strain of Pseudomonas aeruginosa isolated at this department, was used for the development of a continuous process for biosurfactant production. The active compounds were identified as rhamnolipids. A final medium for production was designed in continuous culture by means of medium shifts, since the formation of surface-active compounds was decisively influenced by the composition and concentration of the medium components. In the presence of yeast extract, biosurfactant production was poor. For the nitrogen-source nitrate, which was superior to ammonium, an optimum carbon-to-nitrogen ratio of ca. 18 existed. The iron concentration needed to be minimized to 27.5 micrograms of FeSO4 X 7H2O per g of glucose. A carbon-to-phosphate ratio below 16 yielded the maximum production of rhamnolipids. The final productivity dilution rate diagram indicated that biosurfactant production was correlated to low growth rates (dilution rate below 0.15 h-1). With a medium containing 18.2 g of glucose liter-1, a biosurfactant concentration (expressed as rhamnolipids) of up to 1.5 g liter-1 was obtained in the cell-free culture liquid.

Full text

PDF

Selected References

These references are in PubMed. This may not be the complete list of references from this article.

- Arima K., Kakinuma A., Tamura G. Surfactin, a crystalline peptidelipid surfactant produced by Bacillus subtilis: isolation, characterization and its inhibition of fibrin clot formation. Biochem Biophys Res Commun. 1968 May 10;31(3):488–494. doi: 10.1016/0006-291x(68)90503-2. [DOI] [PubMed] [Google Scholar]

- Cooper D. G., Macdonald C. R., Duff S. J., Kosaric N. Enhanced Production of Surfactin from Bacillus subtilis by Continuous Product Removal and Metal Cation Additions. Appl Environ Microbiol. 1981 Sep;42(3):408–412. doi: 10.1128/aem.42.3.408-412.1981. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cooper D. G., Paddock D. A. Production of a Biosurfactant from Torulopsis bombicola. Appl Environ Microbiol. 1984 Jan;47(1):173–176. doi: 10.1128/aem.47.1.173-176.1984. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Edwards J. R., Hayashi J. A. Structure of a rhamnolipid from Pseudomonas aeruginosa. Arch Biochem Biophys. 1965 Aug;111(2):415–421. doi: 10.1016/0003-9861(65)90204-3. [DOI] [PubMed] [Google Scholar]

- Ito S., Honda H., Tomita F., Suzuki T. Rhamnolipids produced by Pseudomonas aeruginosa grown on n-paraffin (mixture of C 12 , C 13 and C 14 fractions). J Antibiot (Tokyo) 1971 Dec;24(12):855–859. doi: 10.7164/antibiotics.24.855. [DOI] [PubMed] [Google Scholar]

- Mian F. A., Jarman T. R., Righelato R. C. Biosynthesis of exopolysaccharide by Pseudomonas aeruginosa. J Bacteriol. 1978 May;134(2):418–422. doi: 10.1128/jb.134.2.418-422.1978. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Williams A. G., Wimpenny J. W. Exopolysaccharide production by Pseudomonas NCIB11264 grown in continuous culture. J Gen Microbiol. 1978 Jan;104(1):47–57. doi: 10.1099/00221287-104-1-47. [DOI] [PubMed] [Google Scholar]