Abstract

Culturable microorganisms from various samples taken at an active factory performing wool and goat hair cleaning were isolated and analyzed. Bacillus anthracis was found in air filter dust, wastewater, and goat hairs, where it accounted for approximately 1% of the total counts of viable bacteria. Consistent with the countries of origin of the processed material (South Caucasian and Middle Eastern), all B. anthracis isolates belonged to the same phylogenetic cluster, as determined by variable-number tandem repeat (VNTR) typing at eight loci. Within this cluster, five closely related VNTR subtypes could be identified, of which two were previously unreported. Additional diversity was observed when more sensitive genetic markers were assayed, demonstrating the multifocal nature of goat hair contamination. Goat hair originating from areas where anthrax is endemic remains a material with high biological risk for modern woolworkers.

Bacillus anthracis is a gram-positive endospore-forming bacterium that is capable of infecting both livestock and humans (20). Virulent strains of B. anthracis cause disease by secreting the lethal factor and edema factor toxins, together with a pore-forming unit known as the protective antigen (13, 21). Humans are infected primarily through contact with products derived from contaminated animals when contaminated material is ingested or inhaled or comes into contact with an open wound (1). Industrial anthrax, also known as woolsorter's disease, was a serious threat in the 19th and early 20th centuries, when the wool industry was flourishing (2). In Great Britain, substantial numbers of industrial anthrax cases were reported for many years in western Yorkshire, where most of the woolworking factories were clustered (18). The victims were not only woolworkers but also included people and cattle that had been infected through the environmental release of contaminated waste (4). The concern was such that the British government eventually voted in 1919 on the so-called Anthrax Prevention Act, stating that any goods potentially contaminated with anthrax must be disinfected upon entering United Kingdom territory (6). In the United States, apart from the 2001 attacks (17), the most recent anthrax epidemic was reported in 1957 in connection with a goat hair-processing mill in Manchester, NH (3). Today, the industrial processing of wool and goat hair has almost disappeared from Western industrialized countries. A very few factories exist, often in regions with historical textile industries. In the European Community, where the import of undisinfected wool is authorized, an industrial plant performing middle-scale cleaning and disinfection of wool and goat hair has been operating since 1890. In the present study, we investigated the microbiological flora associated with hairs, dust, wastewater, and sewage sludge at this plant, with a particular focus on B. anthracis. Since goat hair and sheep wool are processed in separate sections of the plant, the relative contamination of each material was analyzed separately. Living anthrax spores could be isolated only from goat hair, untreated wastewater, and air dust collected from industrial filters. Forty-one B. anthracis isolates selected at random were analyzed by two different typing techniques (8, 22). The results show that beyond apparent relatedness, molecular diversity can be observed, demonstrating the multiple origins of goat hair contamination.

MATERIALS AND METHODS

Sampling.

Samples were taken from materials representing different points in the manufacturing process, namely, (i) gross hairs, (ii) air dust, (iii) wastewater, and (iv) sewage sludge. Samples of approximately 100 g of hairs were collected from the packed bales and shaken overnight in 100 ml of phosphate-buffered saline supplemented with 0.01% Triton X-100 (Sigma-Aldrich, St. Louis, MO). The supernatant was concentrated into a final volume of 5 ml by centrifugation. For the analysis of industrial dust, 100-mg samples of material recovered from ventilation filters were suspended in 10 ml of phosphate-buffered saline. Wastewater and wet sewage sludge samples (1 g each) were analyzed as described above.

Culture media and strain isolation.

Bacteria were routinely grown on sheep blood agar (Bio-Rad, La Jolla, CA) at 37°C. For enrichment with Bacillus strains, serial dilutions (500 μl each) of sampled material were plated onto polymyxin-lysozyme-EDTA-thallous acetate (PLET) medium (10). Environmental fungi were routinely grown for 5 days at 25°C on Bengal rose supplemented with chloramphenicol (100 μg ml−1). Thermoactinomycetes were isolated by incubating tryptic soy agar plates for 2 days at 52°C. Bacillus cereus ATCC 11778 and the vaccine strain B. anthracis Sterne were used for culture and PCR controls.

Air sampling and analysis.

Airborne particles were collected at the goat hair-loading place in the plant and counted. A control count of particles from another floor of the plant, where no industrial activity occurred, was performed simultaneously. APC Plus and RCS Plus devices (Biotest Hycon, Dreieich, Germany) were used for particle counting and direct inoculation of the particles onto specific solid media. An Airport MD8 device was used to collect air particles contained in 500-liter samples on circular gelatin filters that were subsequently deposited onto selective agar plates (Sartorius, Palaiseau, France).

Bacterial counting, identification, and typing.

Bacteria were identified by partial 16S rRNA gene sequencing as described previously (7). PCR primers and probes are listed in Table 1. The presence of typical anthrax virulence genes was investigated by two-color TaqMan real-time PCR performed with autoclaved, gross bacterial suspensions obtained by suspending PLET-grown colonies in 100 μl of 0.9% NaCl (wt/vol). A first PCR primer set (CAPC-F and CAPC-R) amplified a 96-bp fragment of capC, and a second pair (PAGA-F and PAGA-R) amplified a 97-bp portion of pagA. TaqMan probes (CAPC-1 and PAGA-1) labeled with a fluorophore at the 5′ ends and the black hole quencher 1 at the 3′ ends were used for real-time detection. These probes contained four internal locked nucleic acids each and hybridized to a target sequence in the amplified portions of capC and pagA. The capC and pagA primers and probes were designed with the software AlleleID (Premier Biosoft, Palo Alto, CA). Real-time PCR amplifications were conducted with a 25-μl volume containing premixed PCR reagents (ABgene, Epsom, United Kingdom) and each PCR primer at a 0.4 μM concentration. Double-dye probes were used at a 0.2 μM concentration. The following conditions were used for real-time PCR amplification on an IQ5 instrument (Bio-Rad, La Jolla, CA): 15 min at 95°C (1 cycle), followed by 20 s at 95°C, 30 s at 56°C, and 30 s at 72°C (45 cycles).

TABLE 1.

Sequences of PCR primers and probes

| Gene or locus | Primer or probe | Coordinatesa | Nucleotide sequencec (5′-3′) | Reference |

|---|---|---|---|---|

| capC | CAPC-F | 55852-55874 | ATTCATGATTTTATATGGCCGTA | This work |

| CAPC-R | 55778-55801 | TGGCATAACAGGATAACAATAATC | This work | |

| CAPC-1b | 55842-55822 | HEX-CGGCAACGCTAATTACAGGTA-BHQ1 | This work | |

| pagA | PAGA-F | 277-300 | TCTGAGTTAGAAAATATTCCATCG | This work |

| PAGA-R | 351-374 | GCAAATGTATATTCATCACTCTTC | This work | |

| PAGA-1b | 319-343 | FAM-TGATAAATCCTGACCAAATAGCAGA-BHQ1 | This work | |

| CL7 | CL7F-Cy5 | 1891607-1891626 | Cy5-TCCCCCAATACACTCCCATA | 22 |

| CL7R | 1892335-1891354 | AAATTGGTTCTGCAGCTGGT | 22 | |

| CL10 | CL10F | 4571209-4571229 | TTCGAAAACGGTAGAACAACA | 22 |

| CL10R2-Cy5 | 4570959-4570981 | Cy5-TCGTTTTCATACGTTTCATTACC | This work | |

| CL12 | CL12F-Cy5 | 1448194-1448213 | Cy5-TCTCACTGTGCCTCGCTAAA | 22 |

| CL12R | 1448040-1448059 | AAGCCAGGTGCAAAAACAGT | 22 | |

| CL33 | CL33F | 60120-60139 | TGGGGTATATTCCCATCGAA | 22 |

| CL33R-Cy5 | 60413-60432 | Cy5-TGTACCGCAGATACCAACCA | 22 |

Coordinates are given according to the numbering of GenBank entries AF188935 (capC), AF306782 (pagA), AE017225 (CL7, CL10, and CL12), and AE17335 (CL33).

Probe used for real-time PCR detection. Underlined positions in the nucleotide sequence identify locked nucleic acids.

HEX, 6-carboxy-2′,4,4′,5′,7,7′-hexachlorofluorescein; BHQ1, black hole quencher 1; FAM, 6-carboxyfluorescein.

Variable-number tandem repeat (VNTR) typing was performed exactly as described previously (8), and the products were analyzed by capillary electrophoresis on an ABI 3130XL genetic analyzer (Applied Biosystems, Foster City, CA).

Single-nucleotide repeat (SNR) typing was conducted at four loci (CL7, CL10, CL12, and CL33) described by Stratilo et al. (22) by using four pairs of PCR primers. One primer in each pair was labeled with Cy5 at the 5′ end. The nucleotide sequences of the SNR primers were as described by Stratilo et al. (22), except for one used for the amplification of locus CL10 (Table 1). For size analysis, 2 μl of a 50-fold dilution of the amplified PCR product was added to 38 μl of deionized formamide and 0.5 μl of DNA size standard 400 (Beckman Coulter, Fullerton, CA). Fragment analysis was conducted by capillary electrophoresis on a CEQ8000 instrument according to the instructions of the manufacturer (Beckman Coulter, Fullerton, CA).

Identification of fungi.

Fungi were identified according to macroscopic characteristics (colony aspects on specific agar media) and microscopic characteristics (mainly spore and conidiophore morphologies) (25).

RESULTS

The factory under investigation operates according to a rather simple continuous process. Briefly, bales of packed wool or goat hair are transferred from a storing area to a processing area. Bales are opened, and their contents are loaded manually onto a treadmill connected to a large mechanical shaker that removes a substantial part of the mineral and organic material attached to the fibers. The fibers are then transferred mechanically to five successive washing tanks fed with freshwater by a counterflow. Soaps, formaldehyde, and other cleaning substances are added during the washing process according to proprietary procedures, and the temperature is raised up to 50 to 55°C. The resulting fibers, cleaned and disinfected, are eventually dried by being heated at 80°C. Wastewater is purified at an on-site treatment plant operating on the activated-sludge principle in open air. The treated water is released into the municipal wastewater treatment piping, and the residual sewage sludge is recycled in different agricultural processes depending on its sanitary quality.

In order to investigate the microbiological flora encountered in the factory, four different matrices were sampled and analyzed, namely, (i) hairs, (ii) air dust, (iii) wastewater, and (iv) sewage sludge. Since sheep wool and goat hair were processed at separate places in the plant, we concentrated on the goat hair section on the assumption that it had a greater chance of being contaminated by anthrax spores. Air dust samples were taken from collectors placed at the outlet of an industrial ventilation system running continuously during the processing whose inlets were connected to the treadmill-loading area and to the dry mechanical shaker. Wastewater was collected from the first washing tank, and sewage sludge was taken from the last decanter in the treatment plant.

Microbiological analysis.

A representative dust sample taken during the processing of goat hair was investigated for its microbiological content. Total viable bacteria were isolated on either rich medium (blood agar) or selective medium for Bacillus (PLET) (10), and partial 16S rRNA gene sequencing was conducted for 41 colonies picked at random. Table 2 shows that Bacillus was by far the dominating genus. Macrococcus caseolyticus was isolated occasionally on blood agar, whereas Enterococcus, Vagococcus, and Wautersiella species were enriched together with Bacillus on the selective PLET medium. Hairs, dust, and wastewater taken from the first washing tank turned out to display similar bacterial contents. The fungal content of the same dust sample was analyzed in detail. As shown in Table 3, Penicillium and Aspergillus were the dominating genera, accounting for 30 and 20% of the total fungal load, respectively. Cladosporium, Alternaria, Ulocladium, Scopulariopsis, and Fusarium species were found in limited quantities, while thermoactinomycetes (Thermoactinomyces candidus) represented up to 7% of the total culturable fungi. The occasional occurrence of opportunistic pathogens or mycotoxin-producing molds (11), such as Aspergillus fumigatus, Cladosporium cladosporioides, and Alternaria and Ulocladium species, was noticed.

TABLE 2.

Identification of bacteria collected during goat hair processing

| Strain no. | Strain designation | Closest relativea | GenBank accession no. | Isolation mediumb |

|---|---|---|---|---|

| 1 | VAR-F4 BP#1 | Bacillus sp. | AY504442.1 | BA |

| 2 | VAR-F4 BP#2 | Bacillus sp. | AY504442.1 | BA |

| 3 | VAR-F4 BP#4 | Bacillus sp. | AY504442.1 | BA |

| 4 | VAR-F4 BP#5 | Bacillus sp. | AY504442.1 | BA |

| 5 | VAR-F4 BP#6 | Bacillus pumilus | DQ207559.1 | BA |

| 6 | VAR-F4 BP#7 | Bacillus sp. | AY504442.1 | BA |

| 7 | VAR-F4 BP#8 | Bacillus sp. | AY504442.1 | BA |

| 8 | VAR-F6 BP#1 | Macrococcus caseolyticus | Y15711 | BA |

| 9 | VAR-F6 BP#2 | Bacillus cereus | AY795568.1 | BA |

| 10 | VAR-F6 BP#3 | Bacillus sp. | AY504442.1 | BA |

| 11 | VAR-F6 BP#4 | Bacillus sp. | AY504442.1 | BA |

| 12 | VAR-F6 BP#5 | Acinetobacter sp. | AY673994 | BA |

| 13 | VAR-F6 BP#6 | Bacillus cereus | AY795568.1 | BA |

| 14 | VAR-F6 BP#7 | Bacillus cereus | AY795568.1 | BA |

| 15 | VAR-F6 BP#8 | Bacillus cereus | AY795568.1 | BA |

| 16 | VAR-F6 BP#9 | Macrococcus caseolyticus | Y15711 | BA |

| 17 | VAR-F6 BP#10 | Bacillus sp. | AY504442.1 | BA |

| 18 | VAR-F6 BP#12 | Bacillus pumilus | DQ207559.1 | BA |

| 19 | VAR-F6 BP#14 | Macrococcus caseolyticus | Y15711 | BA |

| 20 | VAR-F6 BP#15 | Bacillus cereus | AY795568.1 | BA |

| 21 | VAR-T 41 | Bacillus cereus | AY795568.1 | PLET |

| 22 | VAR-T 42 | Enterococcus faecium | AJ968582.1 | PLET |

| 23 | VAR-T 43 | Bacillus cereus | AY826631.1 | PLET |

| 24 | VAR-T 45 | Enterococcus sp. | DQ847430.1 | PLET |

| 25 | VAR-T 49 | Enterococcus faecium | AB246407.1 | PLET |

| 26 | VAR-T 51 | Uncultured Vagococcus sp. | DQ355181.2 | PLET |

| 27 | VAR-T 52 | Vagococcus fluvialis | AB272361.1 | PLET |

| 28 | VAR-T 53 | Vagococcus sp. | AB064501.1 | PLET |

| 29 | VAR-T 54 | Enterococcus sp. | DQ376915.1 | PLET |

| 30 | VAR-T 55 | Vibrio (Enterococcus) fluvialis | DQ683079.1 | PLET |

| 31 | VAR-T 56 | Enterococcus casseliflavus | DQ343843.1 | PLET |

| 32 | VAR-T 57 | Enterococcus casseliflavus | DQ343843.1 | PLET |

| 33 | VAR-T 58 | Bacillus pumilus | DQ207559.1 | PLET |

| 34 | VAR-T 61 | Bacillus cereus | AY826631.1 | PLET |

| 35 | VAR-T 62 | Bacillus pumilus | DQ207559.1 | PLET |

| 36 | VAR-T 63 | Brevundimonas sp. | DQ108394.1 | PLET |

| 37 | VAR-T 64 | Bacillus sp. | AY504442.1 | PLET |

| 38 | VAR-T 64 | Bacillus cereus | AY826631.1 | PLET |

| 39 | VAR-T 65 | Bacillus cereus | AY826631.1 | PLET |

| 40 | VAR-T 66 | Wautersiella falsenii | AM238680.1 | PLET |

| 41 | VAR-T 69 | Bacillus sp. | DQ490404.1 | PLET |

| 42 | VAR-T 70 | Wautersiella falsenii | AM238680.1 | PLET |

As assessed by partial 16S rRNA gene sequencing and nucleotide sequence comparison using BLASTN.

BA, blood agar.

TABLE 3.

Identification of fungi collected during goat hair processing

| Species | Occurrence | Isolation conditionsb |

|---|---|---|

| Aspergillus spp. | 18.6%a | BR + Cm, 25°C, 5 days |

| Aspergillus versicolor | Abundant | BR + Cm, 25°C, 5 days |

| Aspergillus niger | Occasional | BR + Cm, 25°C, 5 days |

| Aspergillus ochraceus | Rare | BR + Cm, 25°C, 5 days |

| Aspergillus fumigatus | Occasional | BR + Cm, 25°C, 5 days |

| Aspergillus glaucus | Rare | BR + Cm, 25°C, 5 days |

| Aspergillus carneus | Rare | BR + Cm, 25°C, 5 days |

| Aspergillus penicilloides | Rare | BR + Cm, 25°C, 5 days |

| Cladosporium cladosporioides | Occasional | BR + Cm, 25°C, 5 days |

| Cladosporium sphaerospermum | Rare | BR + Cm, 25°C, 5 days |

| Cladosporium herbarum | Rare | BR + Cm, 25°C, 5 days |

| Alternaria alternata | Occasional | BR + Cm, 25°C, 5 days |

| Alternaria chlamydospora | Rare | BR + Cm, 25°C, 5 days |

| Ulocladium botrytis | Occasional | BR + Cm, 25°C, 5 days |

| Ulocladium atrum | Rare | BR + Cm, 25°C, 5 days |

| Scopulariopsis candidus | Rare | BR + Cm, 25°C, 5 days |

| Fusarium dimerum | Rare | BR + Cm, 25°C, 5 days |

| Penicillium spp. | 31.4%a | BR + Cm, 25°C, 5 days |

| Thermoactinomyces candidus | 4.1%a | TSA, 52°C, 2 days |

The percentage is relative to the total fungal load and is a mean value from three independent measurements.

BR, Bengal rose; Cm, chloramphenicol; TSA, tryptic soy agar.

B. anthracis identification tests were performed systematically on any CFU growing on PLET medium. The isolation of B. anthracis from hairs was difficult due to the large amount of fibers required (a minimum of 100 g), which rendered the handling of the fibers in common laboratory vessels arduous. Dust and wastewater samples were much more convenient to handle and were used to isolate a representative pool of B. anthracis strains. Heating the samples for 10 min at 85°C did not affect the number of B. anthracis CFU significantly, suggesting that mainly the sporulated form accounted for goat hair contamination. All B. anthracis strains were nonhemolytic on sheep blood agar and contained both pXO1 and pXO2 plasmids as assessed by real-time PCR. Repeated attempts to isolate B. anthracis from sewage sludge were unsuccessful. As shown in Table 4, B. anthracis could be retrieved from samples derived from the processing of goat hair but not of sheep wool. Besides differences in the bacterial loads due to the way the animals are farmed, the origins of the tested material (European sheep wool versus Eastern goat hair) are the most probable explanation for the observed B. anthracis counts.

TABLE 4.

Typical levels of B. anthracis bacteria in various wool-processing samples

| Sample type | Total no. of CFU g−1 | No. of CFU on PLET g−1 | B. anthracis CFU g−1 | Animal sourcec | Origin(s)d |

|---|---|---|---|---|---|

| Dust | 2.2 × 106 | 1.2 × 105 | 0b | Sheep | SK, FR |

| Wastewatera | 2.9 × 104 | 1.5 × 103 | 0b | Sheep | SK, FR |

| Fibers | 680 | 55 | 1 | Goat | RU |

| Fibers | 330 | 25 | 1 | Goat | AF |

| Fibers | 110 | 10 | 0b | Goat | IR |

| Dust | 7.2 × 105 | 3 × 104 | 900 | Goat | RU, KA |

| Wastewatera | 0.9 × 105 | 7.1 × 103 | 120 | Goat | AF |

| Wastewater sludge (wet) | NTe | 190 | 0b |

Untreated wastewater taken from the first hair-washing tank.

Below the detection limit for the amount of the sample tested.

Samples were derived from the processing of sheep wool or goat hair.

SK, Slovakia; FR, France; RU, Russia; AF, Afghanistan; IR, Iran; KA, Kazakhstan.

NT, not tested.

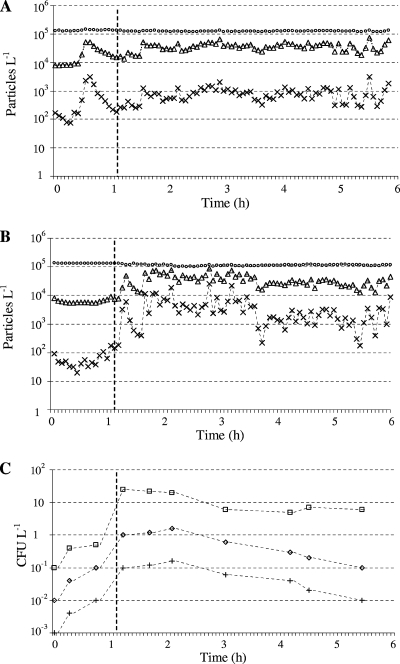

Air-suspended-particle counts.

In order to get a picture of the microbiological load in the factory air, air particles were collected during the processing of a representative goat hair batch and counted. Figure 1 shows that the number of 5-μm particles in the treadmill-loading area increased by about 2 orders of magnitude upon the start of processing and reached a maximum of 25,000 per liter of air after 2 h of processing. The increase in 1-μm particles was less substantial (from 6,000 to 45,000 particles liter−1 on average), while the number of 0.3-μm particles remained stable, in the range of 100,000 particles liter−1. A slight increase in 1- and 5-μm particles was observed in a control area located on another floor of the factory, suggesting that the process induced a global increase in particle counts inside the whole factory. Total particles from 500-liter air samples were suspended in physiological water, and serial dilutions were plated onto either rich or selective medium. Total counts of viable organisms did not exceed 25 CFU liter−1, meaning that just 1 of 3,000 particles of 1 μm or more was culturable. As observed during dust and wastewater analysis, B. anthracis bacteria represented about 1% of the total counts of viable organisms and were never detected at a concentration higher than 1 CFU in 5 liters of air.

FIG. 1.

Analysis of airborne particles generated during goat hair processing. Data collection was initiated 70 min before the start of processing (at the time point identified by vertical dashed lines). All counts are plotted on a logarithmic scale. The following symbols were used: × for 5-μm, ▵ for 1-μm, and ○ for 0.3-μm particles. (A) Particle counts as a function of time as determined in a control area of the factory located on floor 0. (B) Particle counts in the goat hair-loading area located on floor 1. (C) CFU issuing from total particles at least 0.5 μm in size filtered from 500-liter air samples and inoculated onto either sheep blood agar (□) or PLET medium (⋄). B. anthracis counts (+) were derived from the molecular characterization of the colonies growing on PLET.

VNTR and SNR typing.

VNTR analysis of 41 B. anthracis isolates was conducted according to the method of Keim et al. (8), which involves eight genetic markers. Table 5 shows that all 41 isolates belonged to VNTR cluster A4. Five closely related genotypes differing at only two VNTR loci were identified, of which two (those of strains 40 and 41) were so far unreported. Genotype 71 was by far the most abundant and accounted for 88% of the total isolates. Indigenous Belgian strains causing natural anthrax in cows some 30 years ago were included in the study to further ascertain the exogenous nature of the B. anthracis spores contaminating the factory. As expected, these strains displayed VNTR genotypes unrelated to those of goat hair isolates, ruling out any possible contamination from the outdoor environment. More sensitive markers of the SNR type were assessed for all strains as well. From the 29 SNR markers for B. anthracis described previously (22), 4 were chosen for their presumptive variability among strains of the A4 VNTR cluster. Of these four markers, three exhibited substantial variability and demonstrated further diversity among the goat hair isolates, as evidenced by the eight different SNR subtypes (numbered 71-A through 71-H in Table 5) observed for strains matching VNTR genotype 71.

TABLE 5.

Summary of VNTR and SNR typing of B. anthracis isolates

| Isolate no. | Isolate designation | Sample type, country(ies),a and animal specimen of origin | Yr of isolation | Amplicon lengthb (bp) for VNTR typing at locus:

|

VNTR cluster | Amplicon lengthb (bp) (no. of repeats) for SNR typing at locus:

|

SNR genotype | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| vrrA | vrrB1 | vrrB2 | vrrC1 | vrrC2 | CG3 | pXO1 | pXO2 | CL7 | CL10c | CL12 | CL33 | ||||||

| 1 | VAR 06/F6 CAP#6 | Air dust; RU, AF, IR; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 294 (16) | 71-A |

| 2 | VAR 06/F7 CAP#3 | Air dust; RU, AF, IR; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 294 (16) | 71-A |

| 3 | VAR 06/7570.4 CAP | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 294 (16) | 71-A |

| 4 | VAR 06/7570.4 d1#2 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 294 (16) | 71-A |

| 5 | VAR 06/7570.4 d2#1 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 294 (16) | 71-A |

| 6 | VAR 06/AF 1#4 | Goat hair bale; AF | 2007 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 294 (16) | 71-A |

| 7 | VAR 06/7570.4 d2#5 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 8 | VAR 07/RUS 13 | Goat hair bale; RU | 2007 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 9 | VAR 06/1106.3#1 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 10 | VAR 06/2093.3#1 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 11 | VAR 06/2093.3#2 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 12 | VAR 06/2093.3#4 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 13 | VAR 06/2093.3#5 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 14 | VAR 06/6324.1#1 | Wastewater; AF | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 15 | VAR 06/6324.2#1 | Wastewater; AF | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 16 | VAR 06/6324.2#2 | Wastewater; AF | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 17 | VAR 06/6324.2#3 | Wastewater; AF | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 18 | VAR 06/6324.2#4 | Wastewater; AF | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 298 (20) | 71-B |

| 19 | VAR 06/7570.4 d1#3 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 20 | VAR 06/7570.4 d2#2 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 21 | VAR 06/7570.4 d2#3 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 22 | VAR 06/5348.2#1 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 23 | VAR 06/5348.2#2 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 24 | VAR 06/5348.2#3 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 25 | VAR 06/5348.2#5 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 26 | VAR 06/5348.2#6 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 172 (12) | 295 (17) | 71-C |

| 27 | VAR 06/5348.3#1 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 171 (11) | 298 (20) | 71-D |

| 28 | VAR 06/5348.3#3 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 171 (11) | 298 (20) | 71-D |

| 29 | VAR 06/5348.3#4 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 171 (11) | 298 (20) | 71-D |

| 30 | VAR 06/5348.3#5 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 171 (11) | 298 (20) | 71-D |

| 31 | VAR 06/5348.3#6 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 171 (11) | 298 (20) | 71-D |

| 32 | VAR 06/5348.3#2 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 266 (14) | 171 (11) | 297 (19) | 71-E |

| 33 | VAR 06/F6 BP#8 | Air dust; RU, AF, IR; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 299 (21) | 71-F |

| 34 | VAR 06/2093.3#3 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 171 (11) | 299 (21) | 71-F |

| 35 | VAR 06/7570.4 d1#1 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 264 (12) | 172 (12) | 298 (20) | 71-G |

| 36 | VAR 06/1106.3#4 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 295 (17) | 71-H |

| 37 | VAR 06/7570.4 d2#4 | Air filter; RU, KA; goat hairs | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 129 | 139 | A4 | 294 (11) | 268 (16) | 172 (12) | 293 (15) | 72 |

| 38 | VAR 06/5348.1#1 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 135 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 295 (17) | 73 |

| 39 | VAR 06/5348.2#4 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 162 | 538 | 604 | 158 | 135 | 139 | A4 | 294 (11) | 265 (13) | 172 (12) | 296 (18) | 73 |

| 40 | VAR 06/1106.3#2 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 153 | 538 | 604 | 158 | 126 | 139 | A4 | 294 (11) | 268 (16) | 172 (12) | 297 (19) | X |

| 41 | VAR 06/1106.3#3 | Wastewater; AF; goat hair mix | 2006 | 313 | 229 | 153 | 538 | 604 | 158 | 132 | 139 | A4 | 294 (11) | 268 (16) | 172 (12) | 297 (19) | Y |

| 42 | VAR85/1665 | Cow blood; BE | 1978 | 313 | 229 | 162 | 583 | 532 | 158 | 123 | 141 | A3.b | 293 (10) | 268 (16) | 173 (13) | 302 (24) | 57 |

| 43 | VAR83/1653 | Cow specimen; BE | 1983 | 313 | 229 | 162 | 583 | 532 | 158 | 129 | 136 | A3.b | 293 (10) | 268 (16) | 173 (13) | 298 (20) | 61 |

| 44 | VAR1982/78 | Cow specimen; BE | 1978 | 301 | 256 | 171 | 583 | 532 | 158 | 123 | 137 | B1 | 297 (14) | 268 (16) | 178 (18) | 285 (7) | 83 |

| 45 | VAR88/28-8/1 | Cow spleen; BE | 1988 | 301 | 256 | 171 | 583 | 532 | 158 | 123 | 137 | B1 | 297 (14) | 268 (16) | 178 (18) | 285 (7) | 83 |

| 46 | Sterne | Reference strain | Reference strain | 313 | 229 | 162 | 583 | 532 | 158 | 129 | A3.b | 293 (10) | 271 (19)(19)(10) | 173 (13) | |||

AF, Afghanistan; BE, Belgium; IR, Iran; KA, Kazakhstan; RU, Russia.

Values are given as in the analysis conducted by Keim et al. (8) but do not match the exact amplicon lengths reported previously in all cases (9, 15).

The amplicon length for this locus is known to vary independently of the SNR length.

DISCUSSION

Industrial anthrax was a threat for woolworkers in Western countries until the second half of the 20th century. Scientific investigations conducted during the 1957 U.S. epidemic in Manchester, NH, led to the conclusion that the processing of goat hairs, especially carding and combing, posed a very high risk and prompted the authorities to close down the incriminated mill (3, 5). The finding of B. anthracis in a Belgian factory raised an opportunity to reinvestigate the issues some 50 years later with modern methods for microorganism characterization and airborne-particle analysis. The present article reports the microbiological results of this investigation. Epidemiological assessment and occupational medicine aspects will be reported elsewhere.

Our study confirmed the presence of anthrax spores in goat hair originating from South Caucasian and Middle Eastern countries, where anthrax is endemic. The contamination of goat hair by anthrax spores is thus an ongoing problem and should in no way be underestimated as far as biosafety and health protection are concerned. The counting and analysis of airborne spores revealed concentration peaks in the range of 1 B. anthracis spore in 5 liters of air, which is close to the rates observed in the Manchester mill in 1957 (5). The area in the Belgian factory highly loaded with dust was, however, just transiently so; it is much smaller than the 1800 m2 of the Manchester mill's card-comb area (3), and it is equipped with air extractors. Moreover, the woolworkers now wear protective equipment. The factory employs fewer personnel than the Manchester mill, about 70 people compared to the 600 Manchester employees. These noticeable differences, together with the overall moderate incidence of industrial anthrax (1.5 cases per 100 employees for the 1957 epidemic), probably account for the lack of a single industrial anthrax case report from the Belgian factory over its 120 years of activity.

The genetic typing of 41 B. anthracis isolates selected at random showed that they all belonged to the same phylogenetic cluster, A4, defined by Keim et al. (8) and matched one major and four minor genotypes within this cluster. This genotyping method uses an eight-locus VNTR typing scheme which has been shown previously to display valuable and consistent subspecies typing capacities worldwide, in spite of the highly monomorphic character of the B. anthracis genome. However, the discriminative power of these markers becomes limited when faced with strains of close geographical origins, as exemplified in the present study and elsewhere (16). In such contexts, diversity can be demonstrated only if a larger number of VNTR markers (12, 15) are analyzed or if more sensitive markers (9, 14, 19, 22-24) are assessed. In the present study, we chose to analyze four markers of the SNR type, of which three exhibited substantial diversity when the goat hair isolates were assayed and allowed no fewer than 12 subtypes to be defined (22). It is hence very unlikely that hair bale contamination issued from just one carrier animal or from one herd of carrier goats; rather, it likely originated from many carriers which had been exposed to multiple endemic foci. The tentative assignment of particular B. anthracis genotypes to countries of origin was complicated by the fact that hairs of different origins and colors are mixed together at the start of processing to meet customers' quality requirements. At best, B. anthracis strains isolated directly from packed hairs may be considered to be representative of a country. This association could be illustrated for just two strains isolated from Russian and Afghan batches but could not be assessed consistently due to the difficulty and poor yield of B. anthracis isolation from this material.

Four Belgian indigenous strains of B. anthracis were included in the genotyping study to ascertain the external origins of the strains isolated in the factory. As expected, these indigenous strains displayed genotypes unrelated to the goat hair strains, with two of them matching VNTR cluster A3.b and the remaining two matching cluster B1. Thus, the indigenous strains were clearly unrelated to the strains retrieved from imported goat hair, all of which matched cluster A4. From a general point of view, it is surprising to observe more intrinsic diversity at the VNTR level among strains originating from the small territory of Belgium than among strains issuing from large countries in the Middle East. Whether the latter are representative of the global B. anthracis diversity in the Middle East or reflect goat carriage only or whether the differences in diversity result from the higher-level resistance of sporulated B. anthracis strains belonging to cluster A4 is a question raised by this study that would deserve further investigation in the future.

The occurrence of opportunistic pathogens or mycotoxin-producing fungi, such as Aspergillus fumigatus, Cladosporium cladosporioides, and Alternaria and Ulocladium species in the form of airborne spores, in the manufacture should also be considered a risk for the woolworkers' health since these organisms are known to induce or exacerbate allergic reactions and may cause respiratory diseases (11).

Attempts to isolate B. anthracis from materials derived from sheep wool processing in the investigated factory were unsuccessful, probably due to the origin of the sheep wool in countries where anthrax is not considered to be endemic. An analysis of sludge material sampled at the on-site treatment plant revealed no anthrax contamination within the detection limits of the methodology used. Chemicals such as formaldehyde added during hair processing, as well as heating and the inhibitory effect of and competition from the activated-sludge organisms, are likely to account for B. anthracis clearance from the treated wastewater. The present study thus also validated the efficiency of the disinfection process and of the activated-sludge treatment applied to the factory's wastewater for the removal of anthrax spores. Waste controls should be conducted regularly, however, to ensure the safe and permanent removal of such high-threat contaminants.

Acknowledgments

We thank the manager and employees of the wool-processing plant for their courtesy and collaboration and M. Govaerts (Veterinary and Agrochemical Research Centre) and B. China and G. Hanquet (Scientific Institute of Public Health), as well as Y. Pirenne (chief medical inspector) and M. Poncin and J. M. Henkinbrant (occupational medicine), for helpful discussions. Special thanks to E. Kissling (Scientific Institute of Public Health) for critical reading of the manuscript and to J. Tesch (Robert Koch-Institut) for expert technical assistance.

Footnotes

Published ahead of print on 16 May 2008.

REFERENCES

- 1.Brachman, P. S. 1984. Anthrax, p. 826-830. In K. S. Warren and A. F. Mahmoud (ed.), Tropical and geographic medicine. McGraw-Hill, New York, NY.

- 2.Brachman, P. S., A. F. Kaufman, and F. G. Dalldorf. 1966. Industrial inhalation anthrax. Bacteriol. Rev. 30:646-659. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Brachman, P. S., S. A. Plotkin, F. H. Bumford, and M. M. Atchisson. 1960. An epidemic of inhalation anthrax: the first in the twentieth century. II. Epidemiology. Am. J. Hyg. 72:6-23. [DOI] [PubMed] [Google Scholar]

- 4.Carter, T. 2004. The dissemination of anthrax from imported wool: Kidderminster 1900-14. Occup. Environ. Med. 61:103-107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Dahlgren, C. M., L. M. Buchanan, H. M. Decker, S. W. Freed, C. R. Phillips, and P. S. Brachman. 1960. Bacillus anthracis aerosols in goat hair processing mills. Am. J. Hyg. 72:24-31. [DOI] [PubMed] [Google Scholar]

- 6.His Majesty's Privy Council. 1919. Anthrax Prevention Act 1919 (c. 23). Law J. Rep. 88:62-63. [Google Scholar]

- 7.Johnson, J. 1994. Similarity analysis of rRNAs, p. 683-700. In P. Gerhardt, R. Murray, A. Wood, and N. Krieg (ed.), Methods for general and molecular bacteriology. American Society for Microbiology, Washington, DC.

- 8.Keim, P., L. Price, A. Klevytska, K. Smith, J. Schupp, R. Okinaka, P. Jackson, and M. Hugh-Jones. 2000. Multiple-locus variable-number tandem repeat analysis reveals genetic relationships within Bacillus anthracis. J. Bacteriol. 182:2928-2936. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Klee, S. R., H. Nattermann, S. Becker, M. Urban-Schriefer, T. Franz, D. Jacob, and B. Appel. 2006. Evaluation of different methods to discriminate Bacillus anthracis from other bacteria of the Bacillus cereus group. J. Appl. Microbiol. 100:673-681. [DOI] [PubMed] [Google Scholar]

- 10.Knisely, R. F. 1966. Selective medium for Bacillus anthracis. J. Bacteriol. 92:784-786. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Kuhn, D. M., and M. A. Ghannoum. 2003. Indoor mold, toxigenic fungi, and Stachybotrys chartarum: infectious disease perspective. Clin. Microbiol. Rev. 16:144-172. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Le Fleche, P., Y. Hauck, L. Onteniente, A. Prieur, F. Denoeud, V. Ramisse, P. Sylvestre, G. Benson, F. Ramisse, and G. Vergnaud. 2001. A tandem repeats database for bacterial genomes: application to the genotyping of Yersinia pestis and Bacillus anthracis. BMC Microbiol. 1:2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Leppla, S. H. 1982. Anthrax toxin edema factor: a bacterial adenylate cyclase that increases cyclic AMP concentrations of eukaryotic cells. Proc. Natl. Acad. Sci. USA 79:3162-3166. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Levy, H., M. Fisher, N. Ariel, Z. Altboum, and D. Kobiler. 2005. Identification of strain specific markers in Bacillus anthracis by random amplification of polymorphic DNA. FEMS Microbiol. Lett. 244:199-205. [DOI] [PubMed] [Google Scholar]

- 15.Lista, F., G. Faggioni, S. Valjevac, A. Ciammaruconi, J. Vaissaire, C. le Doujet, O. Gorge, R. De Santis, A. Carattoli, A. Ciervo, A. Fasanella, F. Orsini, R. D'Amelio, C. Pourcel, A. Cassone, and G. Vergnaud. 2006. Genotyping of Bacillus anthracis strains based on automated capillary 25-loci multiple locus variable-number tandem repeats analysis. BMC Microbiol. 6:33. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Maho, A., A. Rossano, H. Hachler, A. Holzer, E. Schelling, J. Zinsstag, M. H. Hassane, B. S. Toguebaye, A. J. Akakpo, M. Van Ert, P. Keim, L. Kenefic, J. Frey, and V. Perreten. 2006. Antibiotic susceptibility and molecular diversity of Bacillus anthracis strains in Chad: detection of a new phylogenetic subgroup. J. Clin. Microbiol. 44:3422-3425. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.McCarthy, M. 2001. Anthrax attack in the USA. Lancet Infect. Dis. 1:288-289. [DOI] [PubMed] [Google Scholar]

- 18.Metcalfe, N. 2004. The history of woolsorters' disease: a Yorkshire beginning with an international future? Occup. Med. (London) 54:489-493. [DOI] [PubMed] [Google Scholar]

- 19.Pearson, T., J. D. Busch, J. Ravel, T. D. Read, S. D. Rhoton, J. M. U'Ren, T. S. Simonson, S. M. Kachur, R. R. Leadem, M. L. Cardon, M. N. Van Ert, L. Y. Huynh, C. M. Fraser, and P. Keim. 2004. Phylogenetic discovery bias in Bacillus anthracis using single-nucleotide polymorphisms from whole-genome sequencing. Proc. Natl. Acad. Sci. USA 101:13536-13541. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Poretz, D. M. 1979. Bacillus anthracis (anthrax), p. 1634-1637. In G. L. Mandell, R. G. Douglas, Jr., and J. E. Bennet (ed.), Principles and practice of infectious diseases. John Wiley and Sons, Inc., New York, NY.

- 21.Stanley, J. L., K. Sargeant, and H. Smith. 1960. Purification of factors I and II of the anthrax toxin produced in vivo. J. Gen. Microbiol. 22:206-218. [DOI] [PubMed] [Google Scholar]

- 22.Stratilo, C. W., C. T. Lewis, L. Bryden, M. R. Mulvey, and D. Bader. 2006. Single-nucleotide repeat analysis for subtyping Bacillus anthracis isolates. J. Clin. Microbiol. 44:777-782. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Van Ert, M. N., W. R. Easterday, L. Y. Huynh, R. T. Okinaka, M. E. Hugh-Jones, J. Ravel, S. R. Zanecki, T. Pearson, T. S. Simonson, J. M. U'Ren, S. M. Kachur, R. R. Leadem-Dougherty, S. D. Rhoton, G. Zinser, J. Farlow, P. R. Coker, K. L. Smith, B. Wang, L. J. Kenefic, C. M. Fraser-Liggett, D. M. Wagner, and P. Keim. 2007. Global genetic population structure of Bacillus anthracis. PLoS ONE 2:e461. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Van Ert, M. N., W. R. Easterday, T. S. Simonson, J. M. U'Ren, T. Pearson, L. J. Kenefic, J. D. Busch, L. Y. Huynh, M. Dukerich, C. B. Trim, J. Beaudry, A. Welty-Bernard, T. Read, C. M. Fraser, J. Ravel, and P. Keim. 2007. Strain-specific single-nucleotide polymorphism assays for the Bacillus anthracis Ames strain. J. Clin. Microbiol. 45:47-53. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Von Arx, J. A. 1981. The genera of fungi sporulating in pure culture, 3rd ed. Lubrecht & Cramer Ltd., Vaduz, Germany.