Abstract

Two solvent-tolerant Pseudomonas putida S12 strains, originally designed for phenol and p-coumarate production, were engineered for efficient production of p-hydroxystyrene from glucose. This was established by introduction of the genes pal and pdc encoding l-phenylalanine/l-tyrosine ammonia lyase and p-coumaric acid decarboxylase, respectively. These enzymes allow the conversion of the central metabolite l-tyrosine into p-hydroxystyrene, via p-coumarate. Degradation of the p-coumarate intermediate was prevented by inactivating the fcs gene encoding feruloyl-coenzyme A synthetase. The best-performing strain was selected and cultivated in the fed-batch mode, resulting in the formation of 4.5 mM p-hydroxystyrene at a yield of 6.7% (C-mol of p-hydroxystyrene per C-mol of glucose) and a maximum volumetric productivity of 0.4 mM h−1. At this concentration, growth and production were completely halted due to the toxicity of p-hydroxystyrene. Product toxicity was overcome by the application of a second phase of 1-decanol to extract p-hydroxystyrene during fed-batch cultivation. This resulted in a twofold increase of the maximum volumetric productivity (0.75 mM h−1) and a final total p-hydroxystyrene concentration of 21 mM, which is a fourfold improvement compared to the single-phase fed-batch cultivation. The final concentration of p-hydroxystyrene in the water phase was 1.2 mM, while a concentration of 147 mM (17.6 g liter−1) was obtained in the 1-decanol phase. Thus, a P. putida S12 strain producing the low-value compound phenol was successfully altered for the production of the toxic value-added compound p-hydroxystyrene.

The demand for so called “green” production of chemicals is rapidly increasing due to the declining availability of fossil fuels and the urgency to reduce CO2 emissions (10, 30). However, this bioproduction may be hindered by the toxicity of the product of interest, such as substituted aromatics, to the production host (1, 2, 12, 29). One way to cope with this product toxicity is to deploy solvent-tolerant microorganisms as biocatalysts (5, 28). Of special interest among these solvent-tolerant hosts are Pseudomonas putida strains that have been engineered to produce a variety of compounds such as p-hydroxybenzoate (25, 33), p-coumarate (19), and (S)-styrene oxide (22). In our laboratory, we study and employ the solvent-tolerant P. putida S12. This strain is well suited for the production of substituted aromatic chemicals (18, 19, 33, 38) thanks to its extreme solvent tolerance (5, 35) and metabolic versatility toward aromatics (14, 16, 34).

An example of an industrially relevant but extremely toxic aromatic is p-hydroxystyrene (4-vinyl phenol) (23). This compound is widely used as a monomer for the production of various polymers that are applied in resins, inks, elastomers, and coatings. Ben-Bassat et al. (2, 3, 23) reported p-hydroxystyrene production from glucose in Escherichia coli. In this strain, phenylalanine/tyrosine ammonia lyase (PAL/TAL; encoded by pal) from Rhodotorula glutinis and p-coumaric acid decarboxylase (PDC; encoded by pdc) from Lactobacillus plantarum were introduced for the conversion of l-tyrosine into p-hydroxystyrene via p-coumarate. The maximum concentration of p-hydroxystyrene was limited to 3.3 mM due to the toxicity of the product to the E. coli host (3, 23). To alleviate product toxicity, a two-phase fermentation with 2-undecanone as the extractant was performed. This approach resulted in a modest 14.2 mM p-hydroxystyrene in the organic phase and 0.5 mM p-hydroxystyrene in the water phase (2). Toxicity-related adverse effects on p-hydroxystyrene production may also be avoided by dividing the whole process into three stages: production of l-tyrosine from glucose by E. coli, conversion of l-tyrosine into p-coumarate by immobilized PAL-overexpressing E. coli cells, and chemical decarboxylation of p-coumarate into p-hydroxystyrene (29).

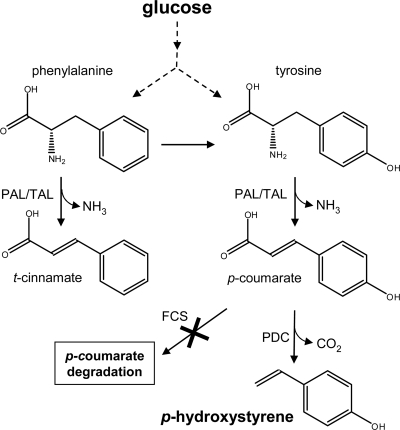

In this report, we address and strongly enhance the bio-based production of p-hydroxystyrene from glucose by employing the solvent-tolerant P. putida S12 as a host. Previously, two strains, P. putida S12 C3 (19) and P. putida S12 TPL3 (38), have been constructed for the production of the l-tyrosine-derived aromatics p-coumarate and phenol, respectively. These strains were highly optimized for aromatics production, resulting in a heavily increased metabolic flux toward l-tyrosine. Therefore, they are suitable platform strains for the production of other l-tyrosine-derived aromatics (33). The bifunctional enzyme PAL/TAL (EC 4.3.1.25) from Rhodosporidium toruloides and the enzyme PDC (EC 4.1.1.-) from L. plantarum were introduced into these strains to allow the conversion of l-tyrosine into p-hydroxystyrene (Fig. 1). These minor modifications resulted in an efficient biocatalyst for the production of the value-added compound p-hydroxystyrene from glucose.

FIG. 1.

Schematic overview of the biochemical pathway for p-hydroxystyrene production. TAL, tyrosine ammonia lyase; FCS, feruloyl-coenzyme A synthetase. The cross indicates the disruption of fcs, disabling p-coumarate degradation.

MATERIALS AND METHODS

Bacterial strains, plasmids, and culture conditions.

The strains and plasmids used in this study are listed in Table 1. The media used were Luria broth (LB) (26) and a phosphate-buffered mineral salts medium, as described previously (9). In the mineral salts medium 20 mM glucose (MMG medium) was used as the sole carbon source. For cultivation of l-phenylalanine auxotrophic strains, 10 mg liter−1 l-phenylalanine was added to the medium. The expression of the introduced copy of aroF-1 in derivatives of P. putida S12 strain 427 as well as the expression of pal pdc in the pJNTpalpdc vector were induced by addition of 0.1 mM sodium salicylate. Antibiotics were added to the medium as required at the following concentrations: ampicillin, 100 mg liter−1 gentamicin, 10 mg liter−1 (MMG) or 25 mg liter−1 (LB); kanamycin, 50 mg liter−1; and tetracycline, 10 mg liter−1 (E. coli) or 60 mg liter−1 (P. putida S12). Shake flask cultivations of P. putida S12 were performed in 100-ml Erlenmeyer flasks containing 20 ml of medium in a horizontally shaking incubator at 30°C. Cultures were inoculated with cells from an overnight preculture to a starting optical density at 600 nm (OD600) of approximately 0.2.

TABLE 1.

Strains and plasmids used in this study

| Strain or plasmid | Characteristic(s)a | Source or reference |

|---|---|---|

| Strains | ||

| P. putida S12 | Wild type; ATCC 700801 | 9 |

| P. putida S12 427b | Derived from P. putida S12 strain optimized for phenol production | 37 |

| P. putida S12 427Δfcs | fcs knockout strain of P. putida S12 427 | This study |

| P. putida S12 427Δfcs pJNTpalpdc | fcs knockout strain of P. putida S12 427 containing plasmid pJNTpalpdc | This study |

| P. putida S12 427Δfcs pJT′Tpalpdc | fcs knockout strain of P. putida S12 427 containing plasmid pJT′Tpalpdc | This study |

| P. putida S12 C3 | Derived from P. putida S12 strain optimized for p-coumarate production containing a disrupted fcs gene | 19 |

| P. putida S12 C3Δsmo | smo knockout strain of P. putida S12 C3 | This study |

| P. putida S12 C3Δsmo pJNTpalpdc | smo knockout strain of P. putida S12 C3 containing plasmid pJNTpalpdc | This study |

| P. putida S12 C3Δsmo pJT′Tpalpdc | smo knockout strain of P. putida S12 C3 containing plasmid pJT′Tpalpdc | This study |

| E. coli DH5α | λ− φ80dlacZΔM15 Δ(lacZYA-argF)U169 recA1 endA1 hsdR17(rK− mK−) supE44 thi-1 gyrA relA1 | 26 |

| L. plantarum | Source of pdc; DSMZ20174 | 31 |

| Plasmids | ||

| pTacpal | Apr Gmr; expression vector containing the pal gene under the control of the tac promoter and tac RBS | 19 |

| pJT′Tpal | Apr Gmr; expression vector derived from pTacpal containing the pal gene under the control of the tac promoter and tac RBS | Unpublished data |

| pJNTpal | Apr Gmr; pJNT containing the pal gene under the control of the salicylate-inducable NagR/pNagAa promoter and tac RBS | Unpublished data |

| pJNTpalpdc | Apr Gmr; pJNT containing the pal and pdc genes under the control of the salicylate-inducable NagR/pNagAa promoter and tac RBS | This study |

| pJT′Tpalpdc | Apr Gmr; expression vector derived from pJT'Tpal containing the pal and pdc genes under the control of the tac promoter and tac RBS | This study |

| pJQ200SK | Suicide vector; P15A ori sacB RP4 Gmr pBluescriptSK MCS | 24 |

| pJQfcs::tet | pJQ200SK containing the tetA interrupted fcs gene | 19 |

| pJQsmo::km | pJQ200SK containing the km interrupted smo gene | This study |

Apr, Gmr, Kmr, and Tcr indicate ampicillin, gentamicin, kanamycin, and tetracycline resistance respectively. MCS, multiple cloning site.

Previously known as P. putida S12 TPL3c.

Fed-batch experiments were performed in 3-liter fermentors (New Brunswick Scientific) using a BioFlo3000 controller. The initial stirring speed was set to 150 rpm, and air was supplied at 1 liter min−1 using Brooks mass-flow controllers (5850 E series and 5850 TR series) and a Brooks 0154 control unit. Dissolved oxygen tension was continuously monitored with an InPro model 6810 probe and maintained at 15% air saturation by automatic adjustment of the stirring speed and mixing with pure oxygen. The pH was maintained at 7.0 by automatic addition of 4 N NaOH, and the temperature was kept at 30°C. Initial batch fermentation was started with washed cells from an overnight culture in 150 ml of MMG medium with gentamicin and salicylate. The batch phase for both the single- and two-phase fermentations was started with 1.5 liters of medium of the following composition: glucose, 13.5 g; (NH4)2SO4, 1.5 g; K2HPO4, 5.82 g; NaH2PO4 · H2O, 2.44 g; gentamicin, 15 mg; sodium salicylate, 0.15 mmol; and 15 ml of a trace element solution (9). After depletion of the initial ammonium, the feed was started. The feed for the single-phase fermentation contained the following (liter−1): glucose, 158 g; (NH4)2SO4, 16.5 g; K2HPO4, 3.88 g; NaH2PO4 · H2O, 1.63 g; gentamicin, 10 mg; sodium salicylate, 1 mmol; MgCl2, 1.5 g; and 0.1 liter of a trace element solution. The feed for the two-phase fermentation contained the following (liter−1): glucose, 316 g; (NH4)2SO4, 33 g; gentamicin, 10 mg; sodium salicylate, 1 mmol; MgCl2, 3 g; and 0.2 liters of a trace element solution. Samples were drawn during the culture to determine the OD600 and concentrations of ammonium, glucose, p-coumarate, p-hydroxystyrene, and t-cinnamate.

Analytical methods.

Cell densities were determined at 600 nm with an Ultrospec 10-cell density meter (Amersham Biosciences). An OD600 of 1 corresponds to 0.49 g liter−1 of cell dry weight (CDW). Glucose and organic acids were analyzed by ion chromatography (Dionex ICS3000 system) as described by Meijnen et al. (15). The p-coumarate, p-hydroxystyrene, and t-cinnamate concentrations were analyzed by high-performance liquid chromatography (Agilent 1100 system) using a Zorbax SB-C18 column (length, 5 cm; inside diameter, 4.6 mm; particle size, 3.5 μm) and a diode array detector. For analysis of aromatic compounds in aqueous solutions, 25% of acetonitrile in KH2PO4 buffer (50 mM, pH 2, 1% acetonitrile) was used as eluant at a flow of 1.5 ml min−1 for 4.5 min. For analysis of p-hydroxystyrene in 1-decanol, the eluant was 50% acetonitrile in MilliQ at a flow of 1.5 ml min−1 for 2.5 min. The samples of p-hydroxystyrene in the 1-decanol phase were diluted 100-fold in acetonitrile before analysis. The total p-hydroxystyrene concentration in the two-phase fed-batch cultures was calculated as follows (36): ctot = (caq × Vaq + cdec × Vdec) × Vtot−1, where ctot, caq, and cdec are, respectively, the total p-hydroxystyrene concentration and the concentrations in the aqueous and the 1-decanol phases. Vtot, Vaq, and Vdec are, respectively, the total liquid volume and the volumes of the aqueous and the 1-decanol phases.

DNA techniques.

Plasmids were introduced into P. putida S12 by electroporation using a Gene Pulser electroporation device (Bio-Rad). The targeted gene disruption of the fcs gene in P. putida S12 strain 427 was performed as described by Nijkamp et al. (19). The gene replacement vector for the smo gene, pJQsmo::km, was created from pJQ200SK (24) with primers 1 to 4 listed in Table 2, and gene replacement was performed as described previously (33). The kanamycin resistance gene was amplified from plasmid pTnMod-KmO (6) using primers 5 and 6 (Table 2). pJQsmo::km was introduced in P. putida S12 C3 by triparental mating using E. coli HB101 RK2013 (8) as the mobilizing strain and established procedures (7). Cells were plated on Pseudomonas isolation agar (Difco) containing tetracycline and kanamycin. Colonies that were kanamycin resistant and gentamicin sensitive were selected. Replacement of the native smo gene by a smo gene disrupted by the kanamycin resistance marker was confirmed by screening the colonies on LB-agar plates containing 1 mM indole in the presence of air saturated with styrene for styrene monooxygenase (SMO) induction. Native SMO converts indole into indigo, resulting in blue colonies; colonies with inactivated SMO remain white (20).

TABLE 2.

Oligonucleotide primers used in this study

| Primer no. | Sequence (5′→3′)a | Description |

|---|---|---|

| 1 | GCGGCGGCCGCATGAAAAAGCGTATCGGTATTGTTG | Start of smo; forward primer |

| 2 | GCGTCTAGATCAATCAGCTCGCCATGCCCTG | Position 569-590 bp in smo; reverse primer |

| 3 | GCGTCTAGAGAAGTTCTCGCCCACACCAAG | Position 661-681 bp in smo, forward primer |

| 4 | GCGGGATCCTCAGGCCGCGATAGTCGGTGC | End of smo; reverse primer |

| 5 | GCGTCTAGAATGAGCCATATTCAACGGGAAACG | Start of Km resistance marker from pTnMod-KmO (6); forward primer |

| 6 | GCGTCTAGATTAGAAAAACTCATCGAGCATCAAATG | End of Km resistance marker from pTnMod-KmO (6); reverse primer |

| 7 | GCGGCGGCCGCGACATAAGGAAGGTAATTCTAATGAC | Start of pdc from L. plantarum; forward primer |

| 8 | GCGGCTAGCTTACTTATTTAAACGATGGTAGTTTTG | End of pdc from L. plantarum; reverse primer |

Restriction sites are underlined.

The pdc gene was amplified from genomic L. plantarum DNA by PCR using primers 7 and 8 (Table 2), which were designed based on the publicly available pdc sequence (GenBank accession no. U63827) (4). Restriction sites NotI and NheI were added for cloning purposes. The pdc gene was cloned into pJT′Tpal or pJNTpal, resulting in pJT′Tpalpdc and pJNTpalpdc, respectively.

RESULTS

Degradation of p-hydroxystyrene by P. putida S12.

P. putida S12 is able to utilize styrene as a sole carbon source (9). The first step in styrene degradation is the oxidation to styrene oxide by SMO. The encoding smo gene is induced by styrene (21, 27). The ability to degrade p-hydroxystyrene in the presence or absence of styrene was assessed in P. putida S12 and in the smo-negative mutant P. putida S12 C3Δsmo. Wild-type P. putida S12 degraded p-hydroxystyrene only in the presence of styrene. P. putida S12 C3Δsmo did not degrade p-hydroxystyrene, in either the presence or absence of styrene. These results suggest that p-hydroxystyrene is oxidized by SMO and that p-hydroxystyrene is not an inducer for smo. Therefore, deletion of the smo gene is not required for stable p-hydroxystyrene production in P. putida S12. This was confirmed by the observation that p-hydroxystyrene was never degraded in the production experiments with strain 427-derived constructs, which have an intact smo gene (data not shown).

Construction of p-hydroxystyrene producing P. putida S12 strains.

Two different strains with an enhanced flux toward l-tyrosine, P. putida S12 C3 and P. putida S12 427, were modified to produce p-hydroxystyrene via l-tyrosine. Since p-coumarate is the direct precursor for p-hydroxystyrene, the degradation of p-coumarate via the p-coumarate catabolic pathway should be blocked for optimal p-hydroxystyrene production. To this end, the first gene of the p-coumarate degradation pathway, fcs (encoding feruloyl-coenzyme A synthetase), was inactivated by homologous recombination in P. putida S12 427 (Table 1), similar to the inactivation of fcs in P. putida S12 C3 (19). The pal and pdc genes were introduced in strains P. putida S12 C3Δsmo and P. putida S12 427Δfcs by transformation of one of the pal-pdc expression plasmids pJNTpalpdc or pJT′Tpalpdc, enabling the conversion of l-tyrosine into p-hydroxystyrene (Fig. 1). Production of p-hydroxystyrene by the resulting four different P. putida S12 constructs was assessed during growth on MMG medium in shake flask cultures (Table 3).

TABLE 3.

Characteristics of p-hydroxystyrene production by different P. putida S12 strains

| P. putida strain | Cultivation method | Max pHS concn (mM)a | Yp/s (C-mol %)b | rp,max (mM h−1)c |

|---|---|---|---|---|

| S12 C3Δsmo pJT'Tpalpdc | Shake flask | 0.35 | 2.3 | 0.01 |

| S12 C3Δsmo pJNTpalpdc | Shake flask | 0.72 | 4.8 | 0.03 |

| S12 427Δfcs pJT'Tpalpdc | Shake flask | 0.88 | 5.9 | 0.1 |

| S12 427Δfcs pJNTpalpdc | Shake flask | 1.1 | 7.4 | 0.1 |

| S12 427Δfcs pJNTpalpdc | Single-phase fed batch | 4.5 | 6.7 | 0.4 |

| S12 427Δfcs pJNTpalpdc | Biphasic fed batch | 21d | 4.1 | 0.75 |

Max, maximum; pHS, p-hydroxystyrene.

Product to substrate yield in C-mol of p-hydroxystyrene per C-mol of glucose.

Maximum volumetric production rate.

For the calculation, see Materials and Methods.

Both P. putida S12 427-derived strains show a higher product-to-substrate yield (Yp/s, where p is the amount of product and s is the amount of substrate) and maximum volumetric production rate (rp,max) than the strains derived from P. putida S12 C3. The pJNTpalpdc vector enabled better p-hydroxystyrene production than the pJT′Tpalpdc vector in both hosts (Table 3). Therefore, P. putida S12 427Δfcs pJNTpalpdc was selected for further study.

Production of p-hydroxystyrene in a fed-batch fermentation.

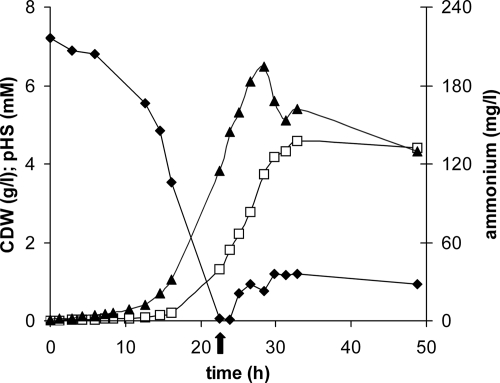

In order to increase productivity under controlled conditions, the production of p-hydroxystyrene by strain S12 427Δfcs pJNTpalpdc was studied in fed-batch cultures (Fig. 2). p-Hydroxystyrene accumulated to a maximum concentration of 4.5 mM with a Yp/s of 6.7 C-mol%, a biomass (x) to substrate yield (Yx/s) of 50 C-mol%, and a product to biomass yield (Yp/x) of 13 C-mol% (Table 3). Only trace amounts of p-coumarate were observed, and the by-product t-cinnamate accumulated to a final concentration of 0.36 mM. The ammonium concentration increased slightly after the feed was started, likely due to a decreased growth rate caused by increasing p-hydroxystyrene toxicity. The feed rate was adapted to keep the nitrogen concentration below 30 mg liter−1. At all time points, glucose or its corresponding acid metabolites gluconate and 2-ketogluconate were present in the broth at a minimum total concentration of 40 mM. Thus, carbon was always present in large excess to nitrogen.

FIG. 2.

Production of p-hydroxystyrene by P. putida S12 427Δfcs pJNTpalpdc in fed-batch cultivation. Concentration p-hydroxystyrene (pHS; □), CDW (▴), and ammonium (⧫). The arrow indicates the time that the feed was started. The data presented are from a single representative experiment.

When a concentration of 4.5 mM p-hydroxystyrene was reached, growth and p-hydroxystyrene production were completely halted, and lysis occurred (Fig. 2). Twofold dilution of the culture broth with phosphate buffer resulted in a resumption of growth and production until the p-hydroxystyrene concentration reached 4.5 mM again (data not shown). These observations suggest that 4.5 mM is a critical concentration that prevents both cellular growth and p-hydroxystyrene production.

p-Hydroxystyrene production in a nitrogen-limited two-phase water-decanol fed-batch fermentation.

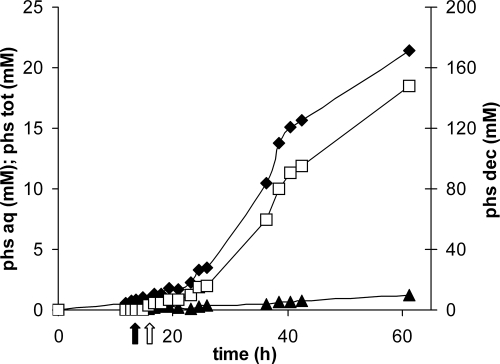

In order to maintain product concentrations below inhibitory levels, biphasic fed-batch cultures were performed with P. putida S12 427Δfcs pJNTpalpdc using 1-decanol as the second phase. The conditions were comparable to the single-aqueous phase fermentation except for the addition of 500 ml of 1-decanol after 15 h of cultivation (Fig. 3). Also, the feed was concentrated twofold in order to compensate for the volume that the 1-decanol phase occupies in the bioreactor.

FIG. 3.

Production of p-hydroxystyrene by P. putida S12 427Δfcs pJNTpalpdc during a two-phase water-1-decanol nitrogen-limited fed-batch fermentation. The total concentration of p-hydroxystyrene (phs tot [⧫]; left y axis) calculated as described in the Material and Methods section, concentration of p-hydroxystyrene in the 1-decanol phase (phs dec [□]; right y axis), and the concentration of p-hydroxystyrene in the aqueous phase (phs aq [▴]; left y axis) are shown. The filled arrow indicated the time that the feed was started, and the open arrow indicates the time that 1-decanol was added. The data presented are from a single representative experiment.

The second phase of 1-decanol maintained the maximum p-hydroxystyrene concentration in the water phase (1.2 mM) well below the inhibitory value of 4.5 mM during the fermentation (Fig. 3). The final concentration of p-hydroxystyrene in the 1-decanol phase reached 147 mM, and the total p-hydroxystyrene concentration was 21 mM at the time when the fermentation was halted (Table 3). Although the p-hydroxystyrene concentration was still increasing at the end of the cultivation, the cultivation was stopped due to limitations of the reactor volume (Fig. 3).

The partition coefficient of p-hydroxystyrene in this medium/solvent system (Ps/w) was approximately 120, based on the final concentrations p-hydroxystyrene in the aqueous and 1-decanol phases. In the water phase, only trace amounts of p-coumarate were detected, and t-cinnamate accumulated to a final concentration of 0.55 mM. p-Coumarate, t-cinnamate, and salicylate were not extracted by 1-decanol. The growth-limiting compound during fed-batch fermentation (ammonium) was measured to monitor cell growth since the cell growth rate (μ) is related to the ammonium consumption rate. Accumulation of ammonium indicates that the ammonium consumption rate has fallen below the feeding rate, likely due to a decrease in μ caused by p-hydroxystyrene toxicity. No ammonium was detected during the feed phase, indicating that p-hydroxystyrene did not reach inhibitory concentrations. Glucose, gluconate, and/or 2-ketogluconate was always present throughout the fermentation at a minimum total concentration of 30 mM. The CDW was 2.7 g liter−1 when 1-decanol was added. The presence of 1-decanol made further OD600 measurements impracticable due to emulsion formation. Therefore, the biomass formation was estimated based on the ammonium consumption, resulting in an estimated final biomass concentration of 30 g liter−1. Based on this estimation, the Yp/x is 13 C-mol%. The Yx/s and Yp/s were 33 C-mol% and 4.1 C-mol%, respectively, assuming that glucose was the sole carbon source. However, in a separate experiment P. putida S12 was shown to utilize 1-decanol as a sole carbon source (not shown). Therefore, coutilization of 1-decanol in the biphasic culture cannot be excluded and would serve to reduce the above calculated yield estimates.

DISCUSSION

In the present study, strains P. putida S12 427 (37) and P. putida S12 C3 (19) have been adapted to produce the l-tyrosine-derived aromatic product p-hydroxystyrene. By using these strains as platform hosts, two key issues for the efficient production of toxic aromatics from glucose were addressed. First, these platform strains possess an optimized flux to the central metabolite l-tyrosine, which is a prerequisite for efficient product formation. Second, toxicity of p-hydroxystyrene severely limits its production as demonstrated previously (2). This can be averted by using a solvent-tolerant strain such as P. putida S12, in combination with in situ product removal using a second phase of extractant.

The biocatalysts derived from strain P. putida S12 C3 are l-phenylalanine auxotrophic, resulting in a negligible production of the by-product t-cinnamate (19), which is advantageous for downstream processing. However, the auxotrophy strongly affected the growth rate of this strain and therefore also the p-hydroxystyrene production rate since growth and production are directly linked. The biocatalysts derived from strain P. putida S12 427 show some t-cinnamate formation but have a higher growth rate, Yp/s and rp,max than strain C3 derivatives (Table 3). The latter three factors were regarded as more important for efficient production, and thus P. putida S12427Δfcs pJNTpalpdc was selected for further study.

Despite the high solvent tolerance of P. putida S12, p-hydroxystyrene production exerted negative effects on the host cell system. The Yp/s for p-hydroxystyrene was approximately 1.5-fold lower than for the less toxic product p-coumarate (19; also unpublished data). No accumulation of p-coumarate was observed in shake flask cultures, indicating that the conversion of p-coumarate into p-hydroxystyrene by PDC was not the bottleneck as it was for the E. coli production system (23).

In the fed-batch culture of P. putida S12 427Δfcs pJNTpalpdc, growth and production were completely inhibited at the critical concentration of 4.5 mM of p-hydroxystyrene. Ben-Bassat et al. encountered similar problems with their E. coli system but at lower p-hydroxystyrene concentrations. To alleviate product toxicity, they added a second phase of 2-undecanone (Ps/w of 20) (2, 23), resulting in the production of 14.2 mM p-hydroxystyrene in the organic solvent phase. Due to its inherent solvent tolerance, P. putida S12 can tolerate both a higher p-hydroxystyrene concentration and a second phase of the more efficient extractant 1-decanol (Ps/w of 120). This led to the production of 147 mM p-hydroxystyrene in the 1-decanol phase, which is a significant 10-fold improvement compared to the E. coli system.

Although product toxicity could be substantially alleviated by addition of a second phase of 1-decanol, allowing considerably increased productivity and product titers, a clear negative effect of the extractant phase itself was observed on Yp/s. The negative impact of solvents on Yx/s has been extensively studied and can be attributed to both a direct uncoupling effect of the solvent on the proton motive force and the energy demand by RND (resistance-nodulation-cell division)-type solvent extrusion pumps (13, 17). Since biomass and product formation are closely linked, a decreased Yx/s will translate directly into a lower Yp/s, which was underlined by the constant Yp/x of 13 C-mol% in both the aqueous and the biphasic water-solvent fed-batch cultivations. The decreased Yx/s caused by the extractant toxicity may be averted by the physical separation of the aqueous and organic phases by using advanced in situ product removal techniques such as solvent-impregnated resins (32) or membrane extraction (11). This, together with a stable genomic integration of the heterologous pal-pdc construct, would also lead to a more stable process.

The study presented here clearly demonstrates the usefulness of solvent-tolerant biocatalysts for the production of toxic aromatics in combination with integrated product extraction. By further process optimization of the solvent-to-water ratio, the reactor volume, and the solvent selection, the product titers could be significantly increased. Thus, this work may greatly assist the economically viable production of the value-added chemical p-hydroxystyrene from cheap renewable resources, which will be of great environmental as well as economic benefit.

Acknowledgments

This project was financially supported by The Netherlands Ministry of Economic Affairs and the B-Basic partner organizations (www.b-basic.nl) through B-Basic, a public-private NWO-ACTS (Advanced Chemical Technologies for Sustainability) program.

We thank Corjan van den Berg for helpful discussions concerning the product extraction for the two-phase fermentation and Jan Wery for his contribution to the initial phase of this work.

Footnotes

Published ahead of print on 5 December 2008.

REFERENCES

- 1.Barker, J. L., and J. W. Frost. 2001. Microbial synthesis of p-hydroxybenzoic acid from glucose. Biotechnol. Bioeng. 76:376-390. [DOI] [PubMed] [Google Scholar]

- 2.Ben-Bassat, A., and D. J. Lowe. October 2004. A method for producing para-hydroxystyrene and other multifunctional aromatic compounds using two-phase extractive fermentation. International patent WO/2004/092392.

- 3.Ben-Bassat, A., W. W. Qi, F. S. Sariaslani, X. S. Tang, and T. Vannelli. June 2007. Microbial conversion of glucose to para-hydroxystyrene. International patent WO/2003/099233.

- 4.Cavin, J. F., L. Barthelmebs, and C. Divies. 1997. Molecular characterization of an inducible p-coumaric acid decarboxylase from Lactobacillus plantarum: gene cloning, transcriptional analysis, overexpression in Escherichia coli, purification, and characterization. Appl. Environ. Microbiol. 63:1939-1944. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.de Bont, J. A. M. 1998. Solvent-tolerant bacteria in biocatalysis. Tibtech 16:493-499. [Google Scholar]

- 6.Dennis, J. J., and G. J. Zylstra. 1998. Plasposons: modular self-cloning minitransposon derivatives for rapid genetic analysis of gram-negative bacterial genomes. Appl. Environ. Microbiol. 64:2710-2715. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Ditta, G., S. Stanfield, D. Corbin, and D. R. Helinski. 1980. Broad host range DNA cloning system for gram-negative bacteria: construction of a gene bank of Rhizobium meliloti. Proc. Natl. Acad. Sci. USA 77:7347-7351. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Figurski, D. H., and D. R. Helinski. 1979. Replication of an origin-containing derivative of plasmid RK2 dependent on a plasmid function provided in trans. Proc. Natl. Acad. Sci. USA 76:1648-1652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Hartmans, S., J. P. Smits, M. J. van der Werf, F. Volkering, and J. A. M. de Bont. 1989. Metabolism of styrene oxide and 2-phenylethanol in the styrene-degrading Xanthobacter strain 124X. Appl. Environ. Microbiol. 55:2850-2855. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Hatti-Kaul, R., U. Tornvall, L. Gustafsson, and P. Borjesson. 2007. Industrial biotechnology for the production of bio-based chemicals-a cradle-to-grave perspective. Trends Biotechnol. 25:119-124. [DOI] [PubMed] [Google Scholar]

- 11.Husken, L. E., M. Oomes, K. Schroen, J. Tramper, J. A. M. de Bont, and R. Beeftink. 2002. Membrane-facilitated bioproduction of 3-methylcatechol in an octanol/water two-phase system. J. Biotechnol. 96:281-289. [DOI] [PubMed] [Google Scholar]

- 12.Isken, S., and J. A. M. de Bont. 1998. Bacteria tolerant to organic solvents. Extremophiles 2:229-238. [DOI] [PubMed] [Google Scholar]

- 13.Isken, S., A. Derks, P. F. Wolffs, and J. A. M. de Bont. 1999. Effect of organic solvents on the yield of solvent-tolerant Pseudomonas putida S12. Appl. Environ. Microbiol. 65:2631-2635. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Jimenez, J. I., B. Minambres, J. L. Garcia, and E. Diaz. 2002. Genomic analysis of the aromatic catabolic pathways from Pseudomonas putida KT2440. Environ. Microbiol. 4:824-841. [DOI] [PubMed] [Google Scholar]

- 15.Meijnen, J. P., J. H. de Winde, and H. J. Ruijssenaars. 2008. Engineering Pseudomonas putida S12 for efficient utilization of d-xylose and l-arabinose. Appl. Environ. Microbiol. 74:5031-5037. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Nelson, K. E., C. Weinel, I. T. Paulsen, R. J. Dodson, H. Hilbert, V. A. Martins dos Santos, D. E. Fouts, S. R. Gill, M. Pop, M. Holmes, L. Brinkac, M. Beanan, R. T. DeBoy, S. Daugherty, J. Kolonay, R. Madupu, W. Nelson, O. White, J. Peterson, H. Khouri, I. Hance, P. Chris Lee, E. Holtzapple, D. Scanlan, K. Tran, A. Moazzez, T. Utterback, M. Rizzo, K. Lee, D. Kosack, D. Moestl, H. Wedler, J. Lauber, D. Stjepandic, J. Hoheisel, M. Straetz, S. Heim, C. Kiewitz, J. A. Eisen, K. N. Timmis, A. Dusterhoft, B. Tummler, and C. M. Fraser. 2002. Complete genome sequence and comparative analysis of the metabolically versatile Pseudomonas putida KT2440. Environ. Microbiol. 4:799-808. [DOI] [PubMed] [Google Scholar]

- 17.Neumann, G., S. Cornelissen, F. van Breukelen, S. Hunger, H. Lippold, N. Loffhagen, L. Y. Wick, and H. J. Heipieper. 2006. Energetics and surface properties of Pseudomonas putida DOT-T1E in a two-phase fermentation system with 1-decanol as second phase. Appl. Environ. Microbiol. 72:4232-4238. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Nijkamp, K., N. van Luijk, J. A. M. de Bont, and J. Wery. 2005. The solvent-tolerant Pseudomonas putida S12 as host for the production of cinnamic acid from glucose. Appl. Microbiol. Biotechnol. 69:170-177. [DOI] [PubMed] [Google Scholar]

- 19.Nijkamp, K., R. G. M. Westerhof, H. Ballerstedt, J. A. M. de Bont, and J. Wery. 2007. Optimization of the solvent-tolerant Pseudomonas putida S12 as host for the production of p-coumarate from glucose. Appl. Microbiol. Biotechnol. 74:617-624. [DOI] [PubMed] [Google Scholar]

- 20.O'Connor, K. E., A. D. Dobson, and S. Hartmans. 1997. Indigo formation by microorganisms expressing styrene monooxygenase activity. Appl. Environ. Microbiol. 63:4287-4291. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Panke, S., B. Witholt, A. Schmid, and M. G. Wubbolts. 1998. Towards a biocatalyst for (S)-styrene oxide production: characterization of the styrene degradation pathway of Pseudomonas sp. strain VLB120. Appl. Environ. Microbiol. 64:2032-2043. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Park, J. B., B. Buhler, S. Panke, B. Witholt, and A. Schmid. 2007. Carbon metabolism and product inhibition determine the epoxidation efficiency of solvent tolerant Pseudomonas sp. strain VLB120ΔC. Biotechnol. Bioeng. 98:1219-1229. [DOI] [PubMed] [Google Scholar]

- 23.Qi, W. W., T. Vannelli, S. Breinig, A. Ben-Bassat, A. A. Gatenby, S. L. Haynie, and F. S. Sariaslani. 2007. Functional expression of prokaryotic and eukaryotic genes in Escherichia coli for conversion of glucose to p-hydroxystyrene. Metab. Eng. 9:268-276. [DOI] [PubMed] [Google Scholar]

- 24.Quandt, J., and M. F. Hynes. 1993. Versatile suicide vectors which allow direct selection for gene replacement in gram-negative bacteria. Gene 127:15-21. [DOI] [PubMed] [Google Scholar]

- 25.Ramos-Gonzalez, M. I., A. Ben-Bassat, M. J. Campos, and J. L. Ramos. 2003. Genetic engineering of a highly solvent-tolerant Pseudomonas putida strain for biotransformation of toluene to p-hydroxybenzoate. Appl. Environ. Microbiol. 69:5120-5127. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Sambrook, J., E. F. Fritsch, and T. Maniatis. 1982. Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY.

- 27.Santos, P. M., J. M. Blatny, I. Di Bartolo, S. Valla, and E. Zennaro. 2000. Physiological analysis of the expression of the styrene degradation gene cluster in Pseudomonas fluorescens ST. Appl. Environ. Microbiol. 66:1305-1310. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Sardessai, Y. N., and S. Bhosle. 2004. Industrial potential of organic solvent tolerant bacteria. Biotechnol. Prog. 20:655-660. [DOI] [PubMed] [Google Scholar]

- 29.Sariaslani, F. S. 2007. Development of a combined biological and chemical process for production of industrial aromatics from renewable resources. Annu. Rev. Microbiol. 61:51-69. [DOI] [PubMed] [Google Scholar]

- 30.Schmid, A., J. S. Dordick, B. Hauer, A. Kiener, M. Wubbolts, and B. Witholt. 2001. Industrial biocatalysis today and tomorrow. Nature 409:258-268. [DOI] [PubMed] [Google Scholar]

- 31.Sharpe, M. E. 1955. A serological classification of lactobacilli. J. Gen. Microbiol. 12:107-122. [DOI] [PubMed] [Google Scholar]

- 32.van den Berg, C., N. Wierckx, J. Vente, P. Bussmann, J. A. M. de Bont, and L. van der Wielen. 2008. Solvent-impregnated resins as an in situ product recovery tool for phenol recovery from Pseudomonas putida S12TPL fermentations. Biotechnol. Bioeng. 100:466-472. [DOI] [PubMed] [Google Scholar]

- 33.Verhoef, S., H. J. Ruijssenaars, J. A. M. de Bont, and J. Wery. 2007. Bioproduction of p-hydroxybenzoate from renewable feedstock by solvent-tolerant Pseudomonas putida S12. J. Biotechnol. 132:49-56. [DOI] [PubMed] [Google Scholar]

- 34.Wackett, L. P. 2003. Pseudomonas putida—a versatile biocatalyst. Nat. Biotechnol. 21:136-138. [DOI] [PubMed] [Google Scholar]

- 35.Wery, J., and J. A. M. de Bont. 2004. Solvent tolerance of pseudomonads: a new degree of freedom in biocatalysis, p. 609-634. In J. L. Ramos (ed.), Pseudomonas, vol. 3. Kluwer Academic Publishers, Dordrecht, The Netherlands. [Google Scholar]

- 36.Wery, J., D. I. Mendes da Silva, and J. A. M. de Bont. 2000. A genetically modified solvent-tolerant bacterium for optimized production of a toxic fine chemical. Appl. Microbiol. Biotechnol. 54:180-185. [DOI] [PubMed] [Google Scholar]

- 37.Wierckx, N. J. P., H. Ballerstedt, J. A. M. de Bont, J. H. de Winde, H. J. Ruijssenaars, and J. Wery. 2008. Transcriptome analysis of a phenol-producing Pseudomonas putida S12 construct: genetic and physiological basis for improved production. J. Bacteriol. 190:2822-2830. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Wierckx, N. J. P., H. Ballerstedt, J. A. M. de Bont, and J. Wery. 2005. Engineering of solvent-tolerant Pseudomonas putida S12 for bioproduction of phenol from glucose. Appl. Environ. Microbiol. 71:8221-8227. [DOI] [PMC free article] [PubMed] [Google Scholar]