Abstract

As energy demands increase, new, more direct, energy collection and utilization processes must be explored. We present a system that intrinsically combines the absorption of sunlight with the production of useful work in the form of locomotion of objects on liquids. Focused sunlight is locally absorbed by a nanostructured composite, creating a thermal surface tension gradient and, subsequently, motion. Controlled linear motion and rotational motion are demonstrated. The system is scale independent, with remotely powered and controlled motion shown for objects in the milligram to tens of grams range.

Sunlight provides a vast resource that has spurred the development of various methods to convert photons into work: photovoltaics for conversion to electricity, solar thermal for water heating, fast growing plants to produce bio-fuels, and solar water splitting to produce hydrogen and oxygen.1 Though useful, these disparate methods are often based on complicated, capital intensive, multistage processes:2 light is collected and converted to a high energy intermediate (e.g. electrical potential, thermal loading, or chemical fuel), which is then used to run a process, such as an engine, that performs work. This multistage approach is ubiquitous and allows for a myriad of applications, but requires production, transportation, and possible storage of intermediates. Considerable effort has been devoted to improving energy collection, storage, and utilization;2,3 however, strategic simplification through the removal of the intermediates remains under-investigated and could provide reductions in capital costs. Here we report that a simple and robust solid/liquid interfacial system can convert light directly into useful work through thermal surface tension effects. This is demonstrated by the propulsion of objects on the surface of water. The simplicity of the system allows for controlled linear motion and rotational motion.

Few strategies exist for the direct conversion of light into work. Concepts such as the solar sail4 for interstellar travel and optical trapping of small particles5 rely on weak momentum transfer from photons. Harnessing the energy of photons is a far more powerful process. A few opto-thermal methods have been developed;6 for example, the Crookes Radiometer produces rotational motion in part via light-based heating of gases, but requires stringent conditions (i.e. low pressure) to function. When applied to liquids, local heating can produce thermally induced surface tension gradients. Such gradients have been shown to induce thermocapillary convective flows in oils7 and as first realized by Brochard-Wyart et. al.,8 can move silicone oil droplets on hydrophobic surfaces under precisely defined conditions or water droplets in oil filled channels.9 Nature has shown that surface tension gradients, created from chemical gradients, can move insects on the surface of water.10 Similarly, camphor chips,11 soap boats,12 and decomposing hydrogen peroxide13 have been used to produce surface tension gradients and motion in the laboratory, but all inherently rely on the supply of exhaustible chemical intermediates to function. Our goal is to couple optical heating with the capability of surface tension gradients to move objects on the surface of liquids. With this approach, a direct means of converting light into useful work is realized, and a simple strategy for remotely powering and controlling small objects is demonstrated.

We show that with a highly absorptive material capable of locally converting light energy into heat, concentrated light can be used to selectively generate thermal surface tension gradients and move objects on the surface of a liquid, such as water (Fig. 1 a-b and in greater detail in Supplemental Fig. S1). This approach combines energy collection and utilization into one material. Furthermore, the interfacial system allows control to be readily enacted in two ways: (i) selectively focusing light on different regions of the absorber to affect the direction of the exerted forces (Fig. 1a-b); and (ii) through device design providing specific orientations of the light absorbing material within the device. This versatility gives access to work in the form of controlled linear motion and rotational motion.

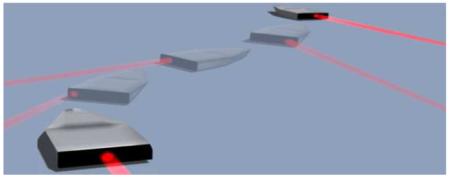

Figure 1.

Light-based control of VANT-PDMS objects on water. When illuminated, as in (a), the retarding surface tension force diminishes and the object is pulled forward. Alternatively, when the back-left side is heated (b), an asymmetry of forces is created, resulting in forward and right turning propulsion. Such selective irradiation can be used to produce and remotely control motion. Optical images (c-d) of a VANT-PDMS composite in a water filled trough show the linear propulsion described in (a). The VANT-PDMS object is briefly irradiated at time zero with focused near-IR light (450 mW) just right of center on the back, absorbing face of the object. The laser source is roughly 13 cm away, with the beam nearly grazing the surface of the water, and the focus set to coincide with the absorbing face of the object.

Carbon black and multiwall carbon nanotubes (MWNT), and vertically aligned carbon nanotube forests (VANTs) as shown in Fig. 3. can be used to produce responses.14 We focused on VANTs as a highly absorptive surface material to maximize heating close to the interface with the liquid. Low density VANTs, with very high surface roughness, have recently been reported to be the blackest known material, absorbing greater than 99.9% of incident visible light.15 Thermal relaxation of excited electrons converts absorbed light into heat, thus making VANTs ideal light-activated thermal switches, which can heat the surrounding liquid and maximize surface tension gradients.16

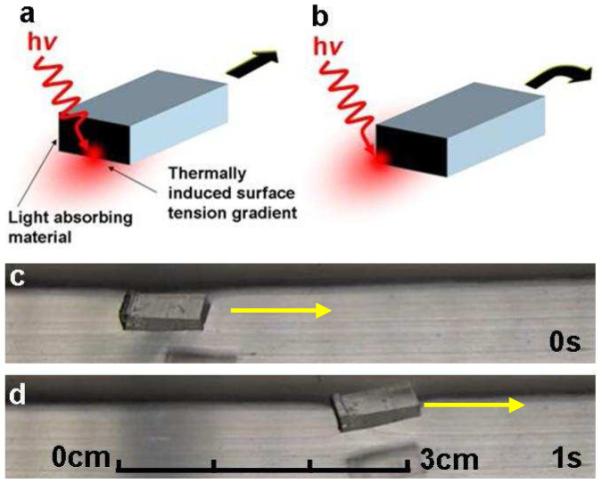

Figure 3.

Nanotube-PDMS composites. a) VANT-PDMS with blow up scanning electron micrographs (b) and inset, after exposure to water and isopropyl alcohol. Scale bar in inset is 10um. Optical images of 0.1 wt % MWNT-PDMS, c, 5 wt. % MWNT-PDMS composites, d. The VANT-PDMS composite contains roughly 0.1 wt. % NTs localized at the back face. Motion curves, e, for VANT-PDMS, 5 wt. % MWNT-PDMS, 0.1 wt. % MWNT-PDMS and pristine PDMS under constant, collimated laser illumination beginning at t∼0 s.

To increase their structural integrity, VANTs were embedded in a supporting polymer, Fig 3a. Polydimethylsiloxane (PDMS) was employed for four reasons: (i) it is optically transparent, focusing absorption on the thin nanotube surface layer; (ii) it has a density similar to that of water; (iii) it strongly adheres to the VANTs; and (iv) it provides elasticity while maintaining the nanoscale roughness and macroscopic structure of the forests. The VANT-PDMS composites (Fig. 3a,b) are stable to water and solvents, are superhydrophobic17 with contact angles of >155° (Supplemental Fig. S2) and can be created with various shapes and orientations.

When subjected to focused sunlight or a near-infrared laser18 (450 mW, 785 nm Diode Laser), the VANT-PDMS composites heat dramatically. Under static conditions, water droplets can be boiled and carbonaceous material on the VANTs can be burnt in air. When placed in a liquid, this dramatic heating of the VANTs leads to significant temperature gradients as the substrate transfers energy to the surrounding liquid.

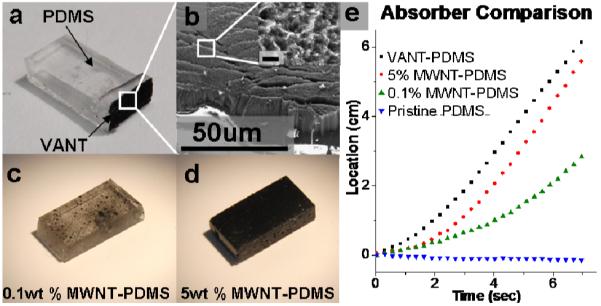

To test the ability of light to directly produce work, VANT-PDMS composites were floated on liquids and sunlight or laser light was focused on the light absorbing material. Light induced heating directly resulted in linear propulsion (Fig. 1c-d and Supplemental Movie S1) without boiling.19 To determine the mechanism by which the objects move we performed a number of control experiments. First, no response was observed when irradiating transparent PDMS objects lacking absorbing materials, Fig. 3e. Second, substantial heating of substrates was observed when irradiated.20 Third, motion was quenched upon addition of surfactant, sodium dodecyl sulfate (Fig. 2a), which cuts surface tension effects.21 Finally, because the absorbing material is only on one face of the VANT-PDMS composites (i.e. the back of the boat), absorption and heating can occur from the front, with irradiation through the transparent PDMS material. In this configuration we still obtained forward propulsion, indicating that radiation pressure from the incident light is not a dominant force. With these facts in mind, it appears clear that optically induced thermal surface tension gradients are the cause of the laser induced motion.

Figure 2.

Location plots for a VANT-PDMS composite under constant, collimated laser illumination. (a) The quenching effect of the addition of the surfactant, SDS, on the motion of the composite. Illumination began at t∼1.3 s. (b) Motion curve depicting the distance travelled by VANT-PDMS composites in water, IPA or DMF filled troughs under nIR laser illumination, beginning at t∼0 s.

Surface tension based force responses are directly related to the temperature differential and the contact length of the heated interface. For our test system we chose to focus on the millimeter scale, where powering and controlling motion are normally difficult due to viscous effects13,22 and machining limitations. For VANT-PDMS composites of millimeter dimensions under focused laser illumination, we obtained speeds up to 8 cm/s and forces of 29 μN.23 These results are at par with reports from chemically fueled surface tension based propulsion systems.24 This force suggests a local increase in temperature of as much as 50 °C.19 In principle, the power density of the motors can be raised by increasing the length of the heated area, perhaps through the use of a multi-fin system.

Motion was not limited to the surface of water but was also demonstrated on liquids as varied as glycerol, alcohols, DMF, fluorinated solvents, salt water, and even at the boundary between immiscible liquids.25 The light-induced propulsion of the composites was quantified for water, isopropyl alcohol (IPA), and dimethyl formamide (DMF). To compare solvent effects a nIR laser was used under collimated conditions to produce consistent irradiation. Characteristic motion curves are presented in Fig. 2b. On water the VANT-PDMS composite produced an average force of 1.19±0.36 μ N (error is reported as the 95% confidence interval over four samples). The composite was significantly less responsive when floating in IPA and DMF, with forces produced on the order of 0.23±0.12 μN and 0.13±0.03 μN respectively. The obtained solvent dependence on the generated force appears complicated and may be attributed to differences in the heat capacities, buoyancy, viscosity and the temperature dependence of the surface tension. These effects are currently under investigation.

To investigate the effect of light absorption on the system, we compared VANT-PDMS composites with dispersed composites of MWNT and PDMS (MWNT-PDMS) as shown in Fig. 3a-d. Larger composites (∼250mg) were tested so as to normalize the effective absorbing area.26 Typical motion curves are shown in Fig. 3e. Incorporation of 1-5 wt. % MWNT, Fig. 3d, produces an opaque black composite that performs similarly to the VANT-PDMS composite, with forces of 1.9±0.3 μN, 2.2±0.3 μN, 2.9±0.9 μN for the 1 wt. %, 5 wt. % and VANT composites respectively. Less absorbing 0.1 wt. % MWNT-PDMS composites were gray, Fig. 3c, and produced ∼60% less force, 1.0±0.1 μN, compared to VANT-PDMS.

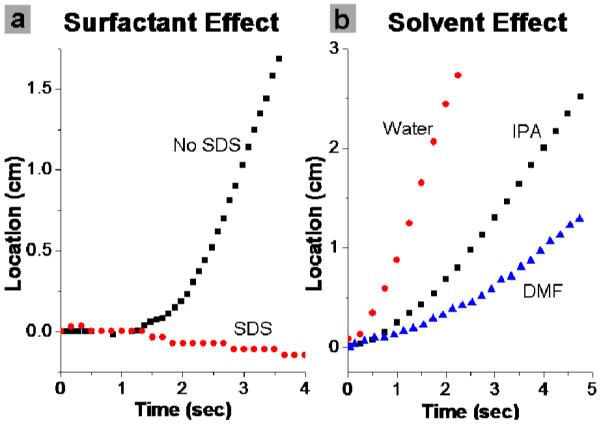

The simplicity of this system allows it to be easily applied to multiple forms of work: spatially controlled illumination gives controlled “linear” motion, while specific device design can produce rotational motion. Controlled linear motion was obtained by focusing light on different parts of the object, dictating the loci of the relevant temperature gradient and, thus, the direction of the exerted surface tension force and the motion (Fig. 4, Laser light: Supplemental Movie S2, and Sunlight: Supplemental Movie S3). This remotely controlled and powered sub-centimeter object, which is not limited by external fields,13,22 is a clear example of the utility of the technique. Our approach provides a simple, scale-independent and robust way to produce directionally controlled linear motion. Objects ranging in size from the millimeter (milligrams) to tens of centimeters (tens of grams) were controllably moved with laser or concentrated sunlight. This scale independence and versatility of light sources presents an advantage over other optical techniques such as optical trapping.

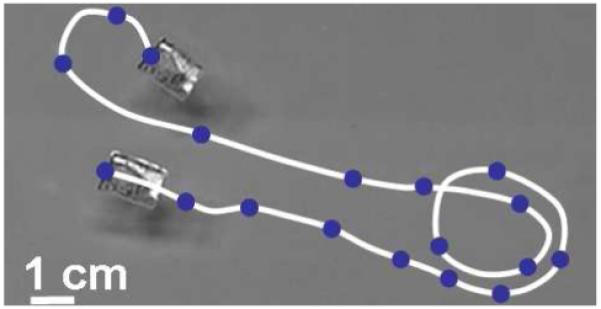

Figure 4.

Light controlled linear motion of a VANT-PDMS composite floating on water. The top of the object has been colored black to aide the eye. The white line shows the path of the composite, with the dots representing two second time points. The composite is directed to the right, turned around in a circle and sent back to the left. The final location of the boat has been superimposed upon the original image. Videos depicting sunlight controlled motion can also be found in the supplemental material.

Rotational motion can be achieved by introducing directionality into the device design. For instance, by placing light absorbing VANTs on the clockwise face of each fin of a rotor (Fig. 5), localized heating produces surface tension forces that cause the object to rotate in the counterclockwise direction. Alternatively, flipping the object over affords clockwise rotation. As shown in Fig. 5, when placed under focused sunlight or irradiated with a near-IR laser these rotors spin at rates up to 70 rpm (Supplemental Movie S4). Built-in directionality is particularly useful for sunlight powered motion, as it is relatively difficult to focus the sun on small moving objects. In this case, Fresnel lenses can be used to focus sunlight on floating rotors, resulting in continuous rotation. Rotors can also be mounted on an axle or stiff metal wire, which may increase the utility of the rotors with potential application for simple solar powered pumps.

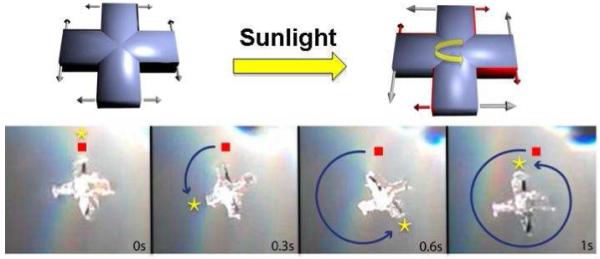

Figure 5.

VANT-PDMS rotor timeline. Schematic (top) showing forces (gray arrows and with heating, red arrows) on PDMS rotor with absorbing material embedded on the clockwise face of each fin while dark and illuminated. Timeline (bottom) of a VANT-PDMS rotor floating on deionized water with embedded VANTs on clockwise face of each fin and irradiated with focused sunlight. The square remains stationary as the star follows one fin.

In summary, we have presented a simple, versatile, method for the direct conversion of light energy into useful linear and rotational work expressed through the motion of objects on a liquid. Additionally, this demonstrates a solution to the challenging problem of remotely controlling the motion of small objects on water.23 It is important to note that in addition to harnessing sunlight to do work; this effect is size-independent and can be extended into the micro and macro regimes.

Supplementary Material

Acknowledgments

The authors acknowledge financial support from the Director, Office of Science, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, of the U.S. Department of Energy under Contract No. DE-AC02-05CH11231. The project described (SJP) was also supported by award number F32GM078780 from the National Institute of General Medical Sciences. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institute of General Medical Sciences or the National Institutes of Health. We thank Mark Llorente for the production of VANTs, Brian Kessler for helpful discussions and the Miller Institute (Professorship for AZ).

REFERENCES

- (1).(Photovoltaic) Hagfeldt A, Gratzel M. Acct. Chem. Res. 2000;5:269–277. doi: 10.1021/ar980112j. (Solar Thermal) Cuomo JJ, Ziegler JF, Woodall JM. Appl. Phys. Lett. 1975;26:557–559. (Bio-fuel) St. Clair S, Hillier J, Smith P. Biomass & Bioenergy. 2008;32:442–452. (Water splitting) Khan S, Al-Shahry M, Ingler WB. Science. 2002;297:2243–2245. doi: 10.1126/science.1075035.

- (2).Basic Research Needs for Solar Energy Utilization, Report of the BES Workshop on Solar Energy Utilization; April 18-21, 2005. [Google Scholar]

- (3).Gratzel M. Phil. Trans. R. Soc. A. 2007;365:993–1005. doi: 10.1098/rsta.2006.1963. [DOI] [PubMed] [Google Scholar]; Burke A. J. Power Sources. 2000;91:37–50. [Google Scholar]

- (4).Forward RL. J. Spacecraft. 1990;27:411–416. [Google Scholar]

- (5).Ashkin A. Proc. Natl. Acad. Sci. 1997;94:4853–4860. doi: 10.1073/pnas.94.10.4853. [DOI] [PMC free article] [PubMed] [Google Scholar]

- (6).(a) Denninghoff DJ, Starman LA, Kladitis PE, Perry C. IEEE Circuits and Systems 48th Midwest Symposium. 2005;1:367–370. [Google Scholar]; (b) Crookes W. Phil. Trans. Roy. Soc. Of London. 1874;164:501–527. [Google Scholar]

- (7).Rybalko S, Magome N, Yoshikawa K. Phys. Rev. E. 2004;70:046301. doi: 10.1103/PhysRevE.70.046301. [DOI] [PubMed] [Google Scholar]

- (8).(a) Brzoska JB, Brochard-Wyart F, Rondelez F. Langmuir. 1993;9:2220–2224. [Google Scholar]; Brochard F. Langmuir. 1989;5:432–438. [Google Scholar]; (b) Farahi RH, Passian A, Zahrai S, Lereu AL, Ferrell TL, Thundat T. Ultramicroscopy. 2006;106:815–821. doi: 10.1016/j.ultramic.2005.12.018. [DOI] [PubMed] [Google Scholar]

- (9).Baroud CN, de Saint Vincent MR, Delville JP. Lab Chip. 2007;7:1029–1033. doi: 10.1039/b702472j. [DOI] [PubMed] [Google Scholar]

- (10).Schildknecht H. Angew. Chem. Int. Ed. Engl. 1976;15:214–222. [Google Scholar]

- (11).Nakata S, Kirisaka J, Arima Y, Ishii T. J. Phys. Chem. B. 2006;110:21131–21134. doi: 10.1021/jp063827+. [DOI] [PubMed] [Google Scholar]

- (12).Bush JWM, Hu DL. Annu. Rev. Fluid Mech. 2006;38:339–369. [Google Scholar]

- (13).(a) Kline TR, Paxton WF, Mallouk TE, Sen A, Catalytic Angew. Chem. Int. Ed. 2005;44:744–746. doi: 10.1002/anie.200461890. [DOI] [PubMed] [Google Scholar]; (b) Ismagilov RF, Schwartz A, Bowden N, Whitesides GM. Angew, Chem. Int. Ed. 2002;41:652–654. [Google Scholar]

- (14).5% MWNT produce a similar response to VANT absorber.

- (15).Yang ZP, Ci L, Bur JA, Lin SY, Ajayan PM. Nano Lett. 2008;8:446–451. doi: 10.1021/nl072369t. [DOI] [PubMed] [Google Scholar]

- (16).Other advantages of the VANT are discussed in the supp. material.

- (17).Pastine SJ, Okawa D, Kessler B, Rolandi M, Llorente M, Zettl A, Fréchet JMJ. J. Am. Chem. Soc. 2008;130:4238–4239. doi: 10.1021/ja8003446. [DOI] [PubMed] [Google Scholar]

- (18).In principle, any laser absorbed by the composite should be effective.

- (19).Discussed in the supplemental material.

- (20).Stable temperatures of 150 °C were observed under collimated laser illumination and measured with a thermocouple embedded in the PDMS.

- (21).Gugliotti M, Baptista MS, Politi MJ. Langmuir. 2002;18:9792–9798. [Google Scholar]

- (22).(a) Shapere A, Wilczek F. Phys. Rev. Lett. 1987;58:2051–2054. doi: 10.1103/PhysRevLett.58.2051. [DOI] [PubMed] [Google Scholar]; (b) Chang ST, Paunov VN, Petsev DN, Velev OD. Nat. Mater. 2007;6:235–240. doi: 10.1038/nmat1843. [DOI] [PubMed] [Google Scholar]

- (23).Forces were derived from location vs. time, as discussed in the supp.

- (24).Luo C, Luo H, Li X, Liu J. Micromech. Microeng. 2008;18:1–6. [Google Scholar]

- (25).Discussion of the necessity for controllably moving small objects on a variety of non-caustic liquids: Wang J. ACS Nano. 2009;3:4–9. doi: 10.1021/nn800829k.

- (26).Composites larger than the spot size of the laser were used to allow absorption to be focused solely on the back face. This resulted in larger forces being produced compared to the previous examples, where the spot size was larger than the back face of the composites.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.