Abstract

Rasamanikya is a famous drug, frequently used by Ayurvedic physicians for Vata-Kaphaja diseases like Shwasa, Kasa and Kushtha (Skin disorders). Various methods of preparation have been found described in Rasa classics. Generally it is prepared by Shuddha Haratala which is kept between two thin transparent Abharaka Patra (mica sheets) in small scale and in sharava for large scale, heated up to desired level. There are so many methods and different liquid media have been found described for Shodhana of Haratala. Therefore the methods of preparation of Rasamanikya and Shodhana process of Haratala have been validated through various experiments. Tankana-treated Haratala (T. Treated) is found best for Shodhana process and final product too i.e. Rasamanikya in terms of pharmaceutical standards i.e. Ruby in colour, along with reproducibility of fixed quality.

Keywords: Shodhana, Validation, T-Treated Haratala

Introduction

Rasamanikya has been first described in Rasendra Chintamani by Dhundhukanath3 in 13th century A.D. as “Rasam Manikya Prabham” which directly indicates the standard of finished product i.e. Ruby colour. The same product has been described by Krishnaram Bhatt in Siddha Bheshaja Manimala5 as Kumuda Rasa. The product of Kupipakva method of preparation i.e. Tala Manikya also was one of the synonym called Rasamanikya. This product is one of the familiar medicaments used throughout India by Ayurvedic physicians for various disorders including Jwara5 (Fevers), Kasa (Cough), Shwasa (Dyspnoea), Arshas (Piles), Bhagandara (Fissures), Nadi Vrana (Chronic wounds) and Kushtha4 (skin ailments), with different Anupanas2 in various dosage forms. Haratala, one of the Arsenical raw materials emphasized since Samhita period8,9 turns into ambrosia after Shodhana processes and manufacturing techniques. This requires proper care, critical understanding and computed technology to get the desired character of Rasamanikya.

Standardization of Rasaushadhies can be defined with the number of processes, involved in the production of a drug. The standard protocols mentioned in the classics7, which may be applied to the present manufacturing scientific pharmaceutical ambience, such as quality of raw materials1 to be taken for the process. The process standardization protocols are like temperature, time space, instrument and heating devices etc. along with purification protocols like number of Bhavana4, Swedana6 etc. and the finished drug protocol2 viz colour, fineness, safety profile, bioavailability and therapeutic efficacy etc. Validation13,14 of the method of preparation is to be done by manufacturing the same product by similar method and instrumentation, for any number of times, with standard raw material getting output of same product with specification of parameters. The analysis of the raw material (Ashuddha Haratala), intermediate (Shodhita Haratala) and finished product (Rasamanikya) in terms of percentage of Arsenic and Sulphur etc.as compared with standard parameters, was carried out in same respect.

Aims and Objective

To develop standard product (Rasamanikya) as per classical parameters.

Material & Methods

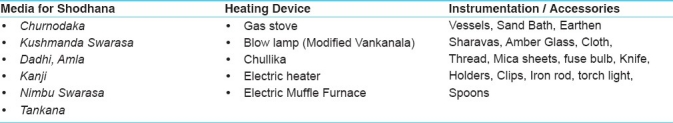

The Media for Shodhana like Kushmanda, Dadhy amla, Kanji etc. various heating devices like gas burner, electric muffle furnace etc. and instruments along with other accessories used as per (Table 1)

Table 1.

Material, Media and Accessories required for Shodhana & preparation of Rasamanikya

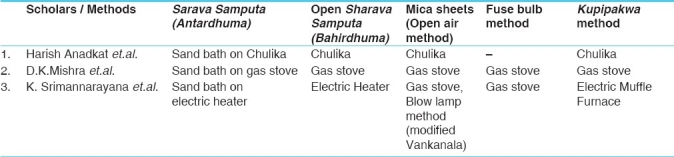

Table 2.

Different Method of Preparation of Rasamanikya

Methods for Shodhana: Shodhana of Haratala was done by adapting following procedures as unit process.

Bhavana (Wet-Trituration):It is a process in which the drug material is taken in a Khalva Yantra and the liquid material is added to it slowly up to Rasapankawat stage (semi solid) and then it is triturated till dryness. The process is repeated for 1 or 3 or 7 or more times as per reference.2,4

Kshipta (submerging in media): Kshipta is a process in which the drug material is kept in the media for one day (24 hours) or more as per reference, which is to be changed every day by adding the fresh media and this repeated for 3 or 5or 7 days2,4.

Swedana (Heating under liquid bath) - Swedana is a process in which the substance is placed in a cloth which should be four-folded and made into Pottali. Then it is hanged with a glass rod in a pot in such a manner that it should not touch any side and remain suspended in centre. It is known as Dola Yantra which is filled with liquid media and subjected to mild heat up to prescribed duration.

Following liquid media were taken for Shodhana-

Churnodaka11 (limewater12), Kushmanda Swarasa (juice of Benincasa Hispida), Shalmali Kwatha (Decoction of Salmalia malabarica), Tilakshara Jala (Alkaline water of Sesamum indicum) and Kanji + Churnodaka (T. method) (Sour gruel and limewater)1.

Total six methods were adopted for the preparation of Rasamanikya including Sarava Samputa (Antardhuma), Open Sharava Samputa, (Bahirdhuma), Mica sheets (Open air method), Fuse bulb method along with modified heating device pattern i.e. blow lamp method (Modified Vankanala2) and Kupipakwa11 method, also used to befit present scientific and technological advancement with the control on temperature pattern and duration of heat as mentioned above.

Results

Lime water (After purification of Hartala)

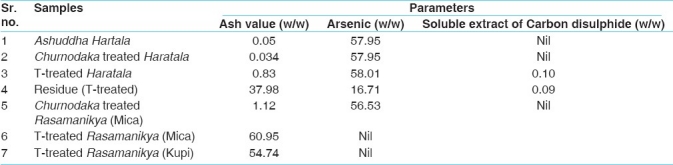

Physical appearance was Pale yellow solution with suspended particles, smell of Hydrogen Sulphide H2S having Ash value 0.58 % w/w, test for Arsenic (Reinsch Test) positive and in Qualitative analysis of ash following Cations were present viz., Fe, Ca, Mg, Na and CO3, SO4, Cl, S , AsO4 Anions were present. Analysis of Ash value, Arsenic content and free sulphur of samples of Ashuddha Haratala, Churnodaka treated Haratala, T-treated Haratala, Residue (T-treated), Churnodaka treated Rasamanikya (Mica), T-treated Rasamanikya (Mica) and T-treated Rasamanikya (Kupi) were carried out. Results are shown in Table 3.

Table 3.

Results of quantitative chemical analysis

Methods of preparation of Rasamanikya

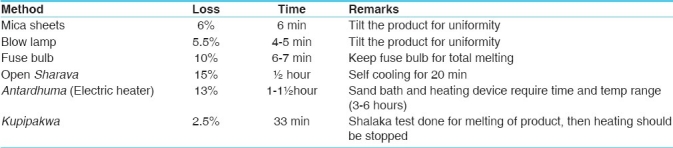

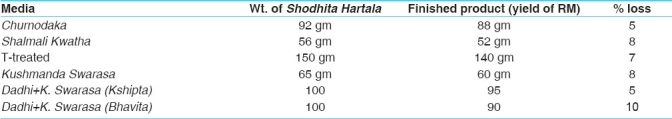

In preparation of Rasamanikya by Mica sheets, Blow lamp and Fuse bulb loss was 5%-10% on an average where as in Kupipakwa method loss was minimum i.e. 2.5%. Time consumed and remarks are shown in Table 5. General observation of yield of Rasamanikya with various media are shown in Table 6

Table 5.

Results of Rasamanikya prepared by different methods with respect to time duration & loss

Table 6.

Results of Rasamanikya prepared with various media

Table 7.

Different media used, Shodhita Haratala and yield of Rasamanikya

Discussion

Grahya Lakshanas of Patra Haratala as per the classics has been taken as Qualitative Protocols viz. authentication of raw material - Patra Haratala, Chemical configuration - As2S3, Colour -(Swranabhavm) Golden Yellow, Texture - (Bhupatrakam) with layer, Weight -(Guru) heavy.

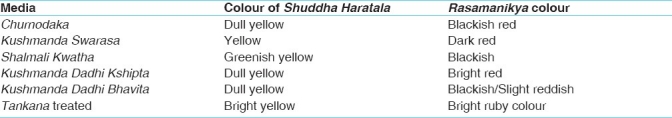

Based on characteristics of purified Haratala, the limewater treated Haratala and other methods of purification as said to be well and good. The marker of purification is said to be quality of finished product i.e. Rasamanikya. Various colour obtained after Shodhana and preparation of Rasamanikya varied with different media.

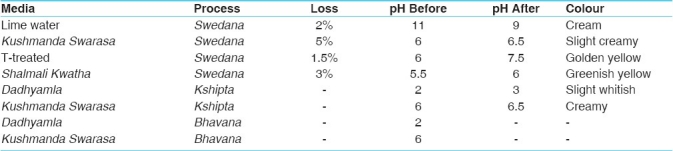

Results of Shodhana by Swedana, Kshipta and Bhavana processes of various media were shown in Table 4. Shodhana by limewater and Kushmanda Swarasa showed a loss of 2% and 5% respectively and cream colour and slight cream colour of Shodhita Haratala. Where as a loss of 1.5% of media by T-treated and golden yellow colour of Shodhita Haratala was observed.

Table 4.

Results of Shodhana with various Procedures and Media

Standard protocol of Shodhana - Swedana

Media: Churnodaka, Kushmanda Swarasa, Shalmali Kwatha, Kanji+Churnodaka (Tankana treated)

The stainless steel vessel was taken for study, which was having diameter of 15 cm diameter, height of vessel from out side 10cm,. The size of vessel, from in side (occupied) 5cm height of the media, 4 cm vacant, 12 cm diameter. It was heated on LPG stove, for 3 hours. The temperature of the liquid has been maintained 90°C - 95°C.

Details of T method

Ashuddha Haratala (500 g.) was made into yavakuta (coarse powder) passed through 40no. mesh Added 10% of Tankana i.e. 50 g. by weight to it. And first wash was given with lemon juice (200 ml.) followed by second wash which was given with Kanji (200 ml.). The washed Haratala (498 g.) was transferred into a cloth and prepared in the form of pottali. This pottali was hanged in Dola Yantra filled with the mixture of Kanji and Churnodaka (Equal quantity i.e.1:1). Then it was heated for three hours by maintaining the temperature range of liquid at 90°C to 95°C on mild heat. After completion of heating process and Ten minutes of cooling, the Haratala was taken out from Pottali and washed with hot water to remove the residue of liquid. The obtained material was dried at room temperature weighed and stored in suitable container.

The Shodhita Haratala was spread between two mica sheets and closed with clips. It was then heated on LPG stove till it converts into Rasamanikya.

In Kupipakwa method, Shodhita Haratala was filled in a Kupi which was coated by three layers of mud smeared cloth and subjected to heat. During the preparation the temperature formelting was observed 359°C and boiling at 415°C while the temperature at which product was prepared at 450°C. The colour of finished product was Ruby i.e. Rasamanikya. Total time consumed by E.M.F. was 33 minutes and after self cooling the Rasamanikya was collected from the bottle.

The mica sheet method was found cheaper and easier for less quantity i.e. only 10 gm at a time but it is not useful for pharmaceutical companies and due to same reason the fuse bulb method was also not found suitable in present context. Antaradhuma (sand bath) method produced good quantum of Rasamanikya but it is time consuming and not economical. It was also not found suitable for reproducibility of the good quality product. The Open Sharava method produces a lot of Arsenic vapours due to which causes exposure to the person and polluted the environment too. Thus, it is not a suitable method considering the hygienic point of view, and due to same problem the blow lamp method is also not found suitable

The Kupipakwa method was found best because, it produces good quality of Rasamanikya also supported by previous studies by Harish et al. and D.K. Mishra et al. though they have prepared it by valuka yantra and with churanodaka Shodhita Haratala. Here the Haratala was Shodhita by Tankana treated method and Rasamanikya was prepared in electric muffle furnace which is found easier and economical too.

Conclusion

Tankana treated method for the Shodhana of Haratala is found better because the Rasamanikya prepared by it is having good quality, so it is validated qualitatively and quantitatively,The Rasamanikya prepared by Kupipakwa method stands economical, less time consuming and gives best results in terms of reproducibility.

References

- 1.Shri Vagbhattacharya, Rasa Samuchchaya Ratna, Kulkarni D.A. Hindi commentary. 70-72. Vol. 3. New Delhi: Meharchand Laxmandas Publication; 1998. p. 64. [Google Scholar]

- 2.Sharma Sadananda, Tarangini Rasa. 11th Edition. 2. Vol. 49. New Delhi: Motilal Banarsidas; 2000. p. 21. 11/83-93, p. 257-258. [Google Scholar]

- 3.Dhundhukanath, Chintamani Rasendra, Mishra S. N. Hindi commentary. 128-133. Vol. 9. Varanasi: Chaukhamba Orientallia; 2000. p. 376. [Google Scholar]

- 4.Bhatta K.G, Sangraha Rasendra Sara, Tripathi I. D. Hindi commentary. 2nd Edition. 191-196. Vol. 1. Varanasi: Chaukhamba Orientallia; 1998. pp. 48–49. [Google Scholar]

- 5.Bhatt Krishnaram, Manimala Siddha Bheshaja. Kaladhar Bhatt Hindi commentary Published by Chaukhamba Krishnadas Academy. 3rd Edition. 66-67. Vol. 4. Varanasi: pp. 159–160. [Google Scholar]

- 6.Parvatiputra Nityanath, Rasa Ratnakar. Vadikhanda Ridhhikhanda, commentary by Swaminath Mishra, Published by Chaukhamba Publishers. 2nd Edition. 84-86. Vol. 3. Varanasi: p. 35. [Google Scholar]

- 7.Hari Prapanna Ji, Rasa Yoga Sagar. 1st Edition. II. Varanasi: Krishnadas Academy; 1998. pp. 563–565. 2531-2538. [Google Scholar]

- 8.Acharya Y. T., editor. Ayurved Dipika & Jalpa Kalpataru commentary. 2nd Edition. V. Chaukhambha Publishers: Varanasi; 2002. Agnivesha's Charaka Samhita; pp. 3197–3199. [Google Scholar]

- 9.Acharya Y.T, et al., editors. Sushruta, Sushruta Samhita, Kalpa Sthan, Nibandha Sangraha Dalhana commentary. 9th Edition. 5. Vol. 2. Chaukhambha Surabharati Prakashan: Varanasi; 2003. p. 564. [Google Scholar]

- 10.Patel, Bhatt Rasamanikyam - P.G. Thesis, GAU. 1966-1967 [Google Scholar]

- 11.Anadkat Harish A, et al. Pharmaceutico - clinical study of Rasamanikyam resulting its efficacy on Kshudra Kushta. 1988 [Google Scholar]

- 12.Mishra D.K, et al. Rasamanikya Evam Yashadamrut MalAhara Ka Nirmanatmaka Tatha Vicharchika Vyadhi Par Prabhavotpadaka Adhyayana. 1999 [Google Scholar]

- 13.Shrimannarayan K. “A compilation work on Drug Research Standardisation of Rasaushadhi”, GAU. 2004 [Google Scholar]

- 14.W.H.O.'s General guidelines for methodologies on research of traditional medicine, Geneva. 2000 [Google Scholar]