Abstract

Francisella tularensis live vaccine strain (F. tularensis LVS), a promising vaccine candidate for protection against F. tularensis exposure, is a particularly thermolabile vaccine and difficult to stabilize sufficiently for storage under refrigerated conditions. Our preliminary data show that F. tularensis LVS can be stabilized in the dried state using foam drying, a modified freeze drying method, with sugar-based formulations. The process was conducted under mild drying conditions, which resulted in a good titer retention following processing. The inclusion of osmolytes in the growth media resulted in an acceleration of growth kinetics, although no change in osmotolerance was observed. The optimized F. tularensis formulation, which contained trehalose, gelatin, and Pluronic F68 demonstrated stability for approximately 1.5 weeks at 37°C (i.e., time required for the vaccine to decrease in potency by 1 log10 colony forming unit) and for 12 weeks at 25°C. At refrigerator storage condition (4°C), stabilized F. tularensis LVS vaccine exhibited no activity loss for at least 12 weeks. This stabilization method utilizes conventional freeze dryers and pharmaceutically approved stabilizers, and thus can be readily implemented at many manufacturing sites for large-scale production of stabilized vaccines. The improved heat stability of the F. tularensis LVS could mitigate risks of vaccine potency loss during long-term storage, shipping, and distribution.

Keywords: Francisella tularensis, foam drying, freeze drying, spray drying, vaccine, stability, formulation, solid state

INTRODUCTION

Francisella tularensis (F. tularensis), a Gram-negative intracellular bacterium found most prevalently in the Northern hemisphere, is the causative agent of tularemia, a zoonotic disease that is highly virulent in ticks, rabbits, rodents, and humans.1 The facultative nature of F. tularensis suggests that it can persist in protozoa, specific foods, and even as a free-living bacterium.2 Over 250 species have been identified as being infected by this bacterium, an indication of its pervasiveness through various ecosystems.3 Potential pathways of infectious transfer to humans include: direct contact with infected animal products (i.e., blood and feces), insect bites (i.e., tick, fly, and mosquito), and aerosolization of infected material.4 Recently, increased emphasis has been placed on the possibility of this bacterium being utilized as a potential bioweapon, as F. tularensis is highly virulent, requires a low infectious dose, and can be readily aerosolized. Inhalation of the subspecies tularensis has a 50% infectious dose of less than ten colony forming units (CFU) and case fatalities between 30% and 60%.1,5

Therapeutic approaches to treat F. tularensis infections have been met with varying degrees of success. Streptomycin has been the standard of care for tularemia; however, its adverse ototoxic effects have stymied the use of this antibiotic, except in severe cases.6,7 Doxycycline and ciprofloxacin have been shown to be efficacious when following a stringent antibiotic regimen. However, the possibility of a relapse should be anticipated once the antibiotic regimen is halted, mainly caused by the survival of tularemia in intracellular sites that are impervious to high pH antibiotics.8 Thus, there is a need for effective vaccines against F. tularensis. Additionally, a readily available, stockpiled vaccine would facilitate mass vaccination campaigns under threat conditions.

A live attenuated vaccine, F. tularensis live vaccine strain (LVS), has been used to immunize laboratory workers at risk from tularemia infection. F. tularensis LVS is the only effective vaccine against tularemia developed to date.1 This attenuated vaccine can induce long-term protective humoral and cell-mediated immunity, as evidenced by positive IgA, IgG, and IgM response after immunization.1,9,10 Although robust immunogenic response can be difficult to obtain with subunit or inactivated bacteria,11 live attenuated F. tularensis vaccine candidates have demonstrated potent, long-lasting cytotoxic T-cell response against highly virulent strains of F. tularensis.11,12 Recent clinical studies on a new lot of LVS confirmed its immunogenicity.13 Even so, for long-term storage, this liquid vaccine must be stored frozen at −80°C or below.14

In order to stabilize F. tularensis LVS effectively, it would likely require processing into a solid dosage presentation. Solid formulations have a marked decrease in molecular motion and hydrolytic cleavage, thus resulting in a biopharmaceutical product with superior stability and shelf life. Freeze drying and spray drying are two common methods that have been used to dehydrate solutions containing biologically active reagents. Few studies have been performed that have documented the effects of spray drying on bacterial vaccines.15–17 Spray drying subjects the liquid solution to large shear and air–water interfacial stresses, which are undesirable conditions that could induce deformation and alter the immunogenicity of the vaccine. Lyophilization as a means to stabilize a vaccine is much more common.18 In fact, this drying method has proven to be a useful tool for long-term storage of bacterial vaccines, including Lactobacillus salivarius and Salmonella typhimurium,19,20 among others.21–23 Even more recently, the long-term stability of F. tularensis LVS was tested after being freeze-dried in an infant formula24; the vaccine titer decreased by more than 3 log10 following 12 weeks of storage at ambient condition, which is an indication that F. tularensis may be more difficult to stabilize than originally presumed.

Although spray drying can expose the vaccine to high temperatures and freeze drying to low temperatures, foam drying offers the opportunity to dehydrate sensitive materials at moderate temperatures. We have previously shown that foam drying is a practical procedure for the stabilization of Salmonella vaccine, Ty21a.25 Given the need for a more stable F. tularensis vaccine that could be used in the event of bioterrorism, we optimized the foam drying procedure to produce a high-temperature-resistant vaccine that minimized bacterial loss during processing and subsequent storage. This study presents unique formulations that are used to stabilize F. tularensis LVS, followed by a 12-week stability study conducted at various temperatures.

MATERIALS AND METHODS

Materials

Francisella tularensis LVS was kindly provided by Dr. Karen Elkins at the Center for Biologics Evaluation & Research/Food and Drug Administration (CBER/FDA) and stored at −70°C with 15% glycerol. Mueller Hinton Broth (MHB) was obtained from Becton Dickinson Microbiology Systems (Sparks, Maryland) and IsoVitaleX was obtained from Becton Dickinson (Cockeysville, Maryland). Chemicals were all used as supplied. Sucrose and trehalose were purchased from Pfanstiehl Laboratories (Waukegan, Illinois). L-Arginine, glycerol, methionine, sodium L-glutamate, dimethyl sulfoxide (DMSO), hydranal solution, Pluronic F68, glucose, and ferric pyrophosphate were purchased from Sigma–Aldrich (St. Louis, Missouri). Potassium phosphate dibasic was purchased from EMD (Gibbstown, New Jersey). Special LE200 SOL-KKA gelatin was purchased from Gelita (Sioux City, Iowa). Fetal Bovine Serum (FBS) was obtained from Thermo Fisher Scientific (Waltham, Massachusetts).

Growth and Drying of F. tularensis LVS

A frozen stock of F. tularensis LVS was thawed at 37°C and then added to fortified MHB (fMHB), which consists of MHB, 10% glucose, 2.5% ferric pyrophosphate, and IsoVitaleX. The suspension was then shaken at 225 rpm and incubated overnight at 37°C. F. tularensis was harvested when the optical density (OD600 nm) reached 0.9 and then centrifuged at 4000 × g for 10 min. The pellet was resuspended using the appropriate concentrated stock solution of the formulations and the titer was adjusted to approximately 8.5 log10 CFU/mL. All stock solutions were sterile filtered prior to adjusting the bacterial titer. The solution pH varied from 5.5 to 8.5, whereas the solids content varied from 10% to 40% (w/v).

Foam Drying

Solutions were foam dried using a Virtis Advantage XL-70 freeze dryer (Gardiner, New York). Vials (10 mL) with a fill volume of 1 mL were used. The samples were placed on the freeze dryer shelf at 15°C and allowed to equilibrate for 10 min. Foaming was initiated by gradually reducing the chamber pressure below the vapor pressure of the solution to 100 mTorr at 15°C. For a more detailed description of the foam drying process, refer to Ohtake et al.25 The pressure was maintained at this level for 42 h and then the temperature was slowly increased to 20°C, which was maintained for at least 20 h. Vials were sealed under argon gas at the end of the drying cycle prior to being removed from the chamber. A typical foam dried sample is shown in Figure 1.

Figure 1.

Typical appearance of a foam dried sample. The structure, which occupies a larger volume than a lyophilized cake, is translucent and brittle.

Characterization

Residual Water Content Analysis

Residual water content of all foam dried F. tularensis samples was measured using Aquacounter AQ-300 Karl Fischer titrator (Hiranuma Sangyo, Ibaraki, Japan). Foam dried samples were dissolved in approximately 2 mL of hydranal solution, and 1 mL of the dissolved solution was injected for analysis. Hydranal solution was injected prior to sample analysis to determine the amount of water in the solvent. The average value and standard deviation from three replicate samples are reported.

Differential Scanning Calorimetry

The glass transition temperature (Tg) of several formulations was analyzed using a Mettler Toledo DSC 821e (Columbus, Ohio). The Tg was recorded as the midpoint temperature of the discontinuity in the curve of heat flow versus temperature. All measurements were made at 10°C/min, using sealed aluminum pans and an empty pan was used as a reference. The average value and standard deviation of three replicate samples are reported.

Viability Assay for F. tularensis LVS

Francisella tularensis LVS was cultured on solid media consisting of MHB, 10% glucose, 2.5% ferric pyrophosphate, IsoViatelX, and FBS to determine the viability following processing and storage. The cultured plates were incubated for 2 days at 37°C (with 5% CO2) and the number of colonies was counted. Typically, two vials of foam dried F. tularensis were reconstituted using nanopure water to assess the titer at each time point. Each vial was assessed on two plates, and for each plate, several dilution ranges were examined. Thus, each data point represents the average of two samples, for which, several dilutions have been examined to ensure accuracy of the plating protocol. The assay-associated error is typically ±0.2 log10 CFU.

Storage Stability of Foam Dried F. tularensis LVS

All foam dried F. tularensis LVS was stored at 37°C for up to 6 weeks and the viability of the bacteria was measured by the culturing assay as described above. Additionally, some formulations were stored at 4°C and 25°C for up to 12 weeks.

Intracellular Replication Assay

The intracellular replication of F. tularensis LVS was evaluated in the murine macrophage cell line, J774 (American Type Culture Collection, Manassas, Virginia). Briefly, wells containing 3 × 105 J774 cells were infected with LVS samples at a multiplicity of infection of 100 for 2 h. Following this period, cells were washed three times with PBS and incubated in Dulbecco’s Modified Eagle Medium (DMEM) containing 50 μg/mL of gentamicin (Gibco Invitrogen, Carlsbad, California) for 1 h to kill extracellular bacteria. After gentamicin treatment, cells were washed and maintained in DMEM medium with 2 μg/mL gentamicin at 37°C in humidified air containing 5% CO2 throughout the assay. Intracellular bacterial replication was evaluated at 0, 24, 48, and 72 h after gentamicin treatment. At each time point, cells were washed with PBS and lysed with a 0.02% sodium dodecyl sulfate-phosphate buffered saline (SDS-PBS) solution, and the number of bacteria present in the infected cells was determined by plating serial 10-fold dilutions on Mueller Hinton Agar (MHA-B) (Becton Dickinson Microbiology Systems) containing 10% defibrinated sheep blood, 1% IsoVitaleX (Becton Dickinson), 0.1% glucose, and 0.025% ferric pyrophosphate (Sigma Chemical Co., St. Louis, Missouri). Doublings were calculated as follows: log10 CFU (time 2)–log10 CFU (time 1) × 3.32.

Evaluation of LVS Activity in Mice

The virulence of the LVS samples was evaluated in mice. Groups of four BALB/c mice, each 6–8 weeks old (Charles River, New York), were housed in microisolator cages in a barrier environment at the School of Medicine Animal Facility, University of Maryland. All experiments were performed according to the protocols approved by the UMB Institutional Animal Care and Use Committee. Animals were inoculated with 1 mL of inocula by the intraperitoneal (i.p.) route. The inocula consisted of: (1) a control sample of LVS, which was grown in MHB broth and frozen at −80°C; (2) samples of formulated and vialed LVS that were re-suspended in a solution containing 1% gelatin in PBS; or (3) a control solution of 1% gelatin in PBS. The groups of mice were inoculated with escalating doses of approximately 80–95, 800–950, or 8000–9500 CFU. The actual number of bacteria in each sample was confirmed by plate counts of the inocula on MHA-B. Mice were monitored daily for signs of disease for 28 days. Clinical signs include hunched posture, ruffled or ungroomed fur, lethargy, and closed eyes. Moribundity is defined as a clinical score of “3,” which includes exhibition of any three of these signs. Mice that reach a clinical score of 3 are euthanized as predicated by the IACUC approved protocol.

RESULTS

Effect of Media Composition on the Growth Kinetics of F. tularensis

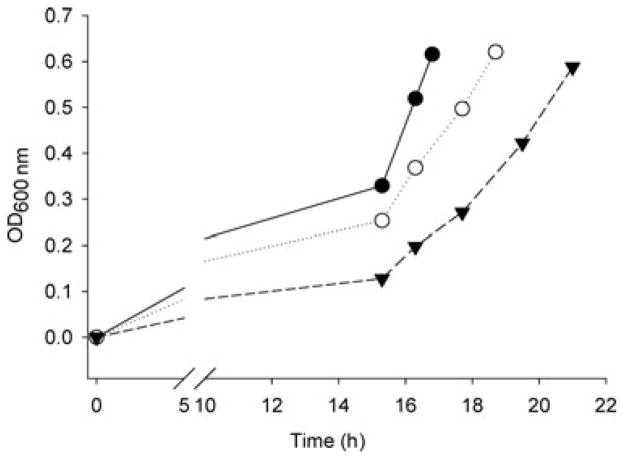

Prior to commencing formulation and processing screen, optimization of growth condition and harvest time of F. tularensis LVS was conducted. Fermentation and media conditions, as well as the growth stage have all been demonstrated to impact the stability of bacteria.26–28 Figure 2 shows the growth curve for F. tularensis grown in fMHB at 37°C at 225 rpm shaker speed. Under such condition, the vaccine required approximately 12 h of incubation for detectable growth. The growth kinetics of F. tularensis can be accelerated considerably with the addition of osmolytes. The growth curve of F. tularensis grown in fMHB containing either 29 mM trehalose (equivalent to 1%, w/v) or 250 mM NaCl is shown in Figure 2. In the presence of trehalose, 0.6 OD600 nm can be reached after approximately 18 h, whereas in the presence of NaCl, the same titer was obtained after 16 h. In comparison, more than 20 h was required to reach the same OD600 nm value in the absence of osmolytes.

Figure 2.

Growth curve for Francisella tularensis grown in fMHB (◀), fMHB+1% (w/v) trehalose (○), and fMHB+250 mM NaCl (●). During incubation at 37°C, F. tularensis was shaken at 225 rpm.

Effect of F. tularensis Growth Media and Maturity on Process Recovery

The presence of osmolytes during bacterial fermentation may also influence their desiccation tolerance. F. tularensis, grown in various media (Table 1), were formulated with either formulation 1 (Fr 1) or formulation 2 (Fr 2) and then foam dried. The foam drying process recovery, shown in Table 1, is influenced by the presence of osmolytes. In the presence of either NaCl or trehalose, the process recovery decreased, and this loss was not dependent on the concentration of osmolytes present in the growth media (29 mM and 250 mM for trehalose and NaCl, respectively). The degree of increased process-associated loss, however, was dependent on the formulation used for foam drying (i.e., Fr 1 or Fr 2).

Table 1.

Effect of Growth Media on the Foam Drying Process Recovery of F. tularensis. Formulation 1 (Fr 1) contained 30% (w/v) trehalose and 0.2 wt % Pluronic F68 at pH 6.5, and formulation 2 (Fr 2) further contained 1% (w/v) cysteine and 10 mM potassium phosphate buffer (n = 2 replicates per data point or # of experiment).

| Formulation | Growth Media | Foam Drying Process Loss (log10 CFU ± s.d.) |

|---|---|---|

| Fr 1 | fMHB | 2.8 ± 0.6 |

| fMHB + 250 mM NaCl | 2.9 ± 0.0 | |

| fMHB + 29 mM trehalose | 3.0 ± 0.2 | |

| Fr 2 | fMHB | 2.3 ± 0.1 |

| fMHB + 250 mM NaCl | 2.8 ± 0.2 | |

| fMHB + 29 mM trehalose | 3.0 ± 0.2 |

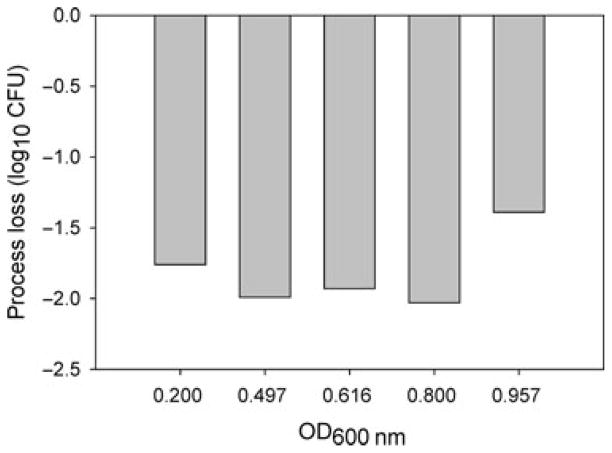

There are reports citing the dependence of desiccation tolerance on the maturation level of bacteria (i.e., bacteria harvested during stationary phase are more resistant to osmotic stress).25,26 To examine the impact of growth phase on resistance to activity loss from desiccation, F. tularensis LVS was grown in fMHB and harvested at various time points during its growth phases. Samples collected at various OD were formulated (see Fig. 3 for formulation composition) and half was subjected to foam drying, followed by enumeration of bacterial colony to compare the titer to that of the predried material (i.e., the other half). The process-associated loss was typically greater than 2 log10, however, F. tularensis harvested later during its growth (i.e., 0.957 OD600 nm, corresponding to late stationary phase) resulted in higher recovery of titer (Fig. 3).

Figure 3.

Process-associated titer loss for foam dried Francisella tularensis harvested at various time points during its growth. F. tularensis was grown in fMHB while being shaken at 225 rpm at an incubation temperature of 37°C. The formulation contained 40% (w/v) sucrose, 4.17% (w/v) gelatin, 0.19% (w/v) methionine, 0.2 wt % Pluronic F68, and 1.75 wt % glycerol in 10 mM potassium phosphate buffer at pH 6.5.

Effect of Solution pH on Process Recovery and Storage Stability of Foam Dried F. tularensis

The effect of solution pH, ranging from 5.5 to 8.5, on the process recovery and storage stability of foam-dried F. tularensis was examined (Table 2). Foam drying process loss ranged from 2.2 to 2.8 log10, with the lowest process loss (2.2 log10) observed at pH 7.5. In terms of storage stability, the vaccine dried at pH 7.5 lost the most titer following 1 week of storage at 37°C. However, when both process loss and storage stability are factored together, the formulation at pH 8.5 exhibited the lowest loss. Nevertheless, given the large standard deviation in the slope of titer loss, statistical significance has not been established.

Table 2.

Effect of Solution pH on the Process-Associated Loss and Storage Stability of F. tularensis Following Foam Drying. Formulation contained 30% (w/v) trehalose and 0.2 wt % Pluronic F68 in 10 mM potassium phosphate at the indicated pH (n = 2 replicates per data point or # of experiment).

| pH | Foam Drying Process Loss (log10 CFU ± s.d.) | Titer Loss After 1 Week at 37°C (log10 CFU ± s.d.) | Total Titer Loss from Drying and After 1 Week of Storage at 37°C (log10 CFU ± s.d.) |

|---|---|---|---|

| 5.5 | 2.8 ± 0.3 | 3.1 ± 0.5 | 5.9 ± 0.7 |

| 7.5 | 2.2 ± 0.1 | 4.0 ± 0.1 | 6.2 ± 0.2 |

| 8.5 | 2.5 ± 0.2 | 2.8 ± 0.8 | 5.3 ± 1.0 |

Effect of Surfactant on Process Recovery of Foam Dried F. tularensis

Surfactants are useful in enhancing the foaming capacity of formulations as well as in improving the storage stability of labile biologicals. These effects occur by modulating the surface tension of the solution and by accumulating at various interfaces, at which biological molecules are prone to denature or deactivate. At too high a concentration, however, the surfactant may destabilize the bacterial membrane of F. tularensis, leading to decreased activity of the bacteria. The level of surfactant in the foam drying formulation was varied from 0 to 1 wt % in order to determine the optimum level. At the lowest concentration examined, the foam drying process loss was 2.1 log10 and increased to 2.6 log10 at higher concentrations (Table 3), all of which are higher than the process-associated loss observed in the absence of surfactants (1.0 log10). These results indicate that for the formulation examined (i.e., trehalose in phosphate buffer), Pluronic F68 addition did not improve stability. In cases where several other components are present, as will be described in the section Effect of Gelatin on Process Recovery and Storage Stability of Foam-Dried F. tularensis, its inclusion may be beneficial.

Table 3.

Effect of Surfactant (Pluronic F68) Concentration on the Foam Drying Process Loss of F. tularensis. With increasing surfactant concentration, process loss from foam drying increased (n = 2 replicates per data point or # of experiment).

| Surfactant Concentration (wt %) | Process Loss (log10 CFU ± s.d.) |

|---|---|

| 0 | 1.0 ± 0.1 |

| 0.02 | 2.1 ± 0.3 |

| 0.2 | 2.2 ± 0.2 |

| 1 | 2.6 ± 0.2 |

Effect of Amino Acids on Process Recovery and Storage Stability of Foam Dried F. tularensis

Several amino acids were incorporated into the formulation that comprised 30% (w/v) trehalose and 25 mM potassium phosphate at pH 8.0. Methionine was incorporated at either 0.5% or 2% (w/v), whereas arginine was incorporated at 0.5%, 2%, and 4% (w/v). The inclusion of either amino acid significantly reduced the foam drying process loss (e.g., from 1.0 to less than 0.6 log10). For example, process loss was decreased from 1.0 log10 (without arginine) to 0.3 log10 (with 0.5% arginine) (Table 4). The protection against process loss was higher at low arginine concentrations. Methionine was marginally less protective than arginine in process loss but improved the storage stability significantly better than arginine. For example, methionine addition at 0.5% improved the storage stability by reducing the titer loss from 3.1 to 2.3 log10 (Table 4). It should be noted that the moisture contents of the formulations tested were relatively high (>3.8%), which could have curtailed the positive impact of these amino acid-based stabilizers on storage stability.

Table 4.

Effect of Amino Acid Addition on the Process-Associated Loss, Storage Stability, and Residual Water Content of F. tularensis Following Foam Drying. The formulation further comprised 30% (w/v) trehalose and 25 mM potassium phosphate at pH 8.0 (n = 2 replicates per data point or # of experiment, except for residual water content analysis, for which n = 3)

| Amino Acid | Process Loss (log10 CFU ± s.d.) | Stability Loss, 1 Week at 37°C (log10 CFU ± s.d.) | Residual Water (%) |

|---|---|---|---|

| None | 1.0 ± 0.2 | 3.1 ± 0.1 | 5.2 ± 0.1 |

| Methionine, 0.5% (w/v) | 0.6 ± 0.2 | 2.3 ± 0.3 | 4.2 ± 0.2 |

| 2% (w/v) | 0.5 ± 0.2 | 3.5 ± 0.2 | 5.5 ± 0.4 |

| Arginine, 0.5% (w/v) | 0.3 ± 0.2 | 4.9 ± 0.1 | 3.8 ± 0.4 |

| 2% (w/v) | 0.4 ± 0.2 | ND | 4.5 ± 0.8 |

| 4% (w/v) | 0.6 ± 0.2 | 3.8 ± 0.9 | 4.1 ± 0.3 |

Effect of DMSO on Process Recovery and Storage Stability of Foam Dried F. tularensis

Dimethyl sulfoxide, a plasticizer, was screened to determine its efficacy in improving the stability of F. tularensis. The addition of 0.5 wt % DMSO to the base formulation, composed of 30% (w/v) trehalose and 25 mM potassium phosphate at pH 8.0, had no significant effect on process loss, although the storage stability was improved in a dose-dependent manner (>0.3 log10, Table 5). It should be noted that the addition of DMSO decreased the residual water content from 5.2% to less than 4.8% (Table 5). However, it is unclear whether such modest reduction in water content had a significant impact on the observed improvement in stability.

Table 5.

Effect of DMSO Addition on the Process-Associated Loss, Storage Stability, and Residual Water Content of F. tularensis Following Foam Drying. The formulation further contained 30% (w/v) trehalose and 25 mm potassium phosphate at pH 8.0 (n = 2 replicates per data point or # of experiment, except for residual water content analysis, for which n = 3).

| DMSO | Process Loss (log10 CFU ± s.d.) | Stability Loss, 1 Week at 37°C (log10 CFU ± s.d.) | Residual Water (%) |

|---|---|---|---|

| None | 1.0 ± 0.1 | 3.0 ± 0.1 | 5.2 ± 0.1 |

| 0.5 (wt %) | 0.9 ± 0.1 | 2.7 ± 0.5 | 4.9 ± 0.3 |

| 2.4 (wt %) | 0.9 ± 0.2 | 2.4 ± 0.6 | 4.7 ± 0.3 |

Effect of Gelatin on Process Recovery and Storage Stability of Foam Dried F. tularensis

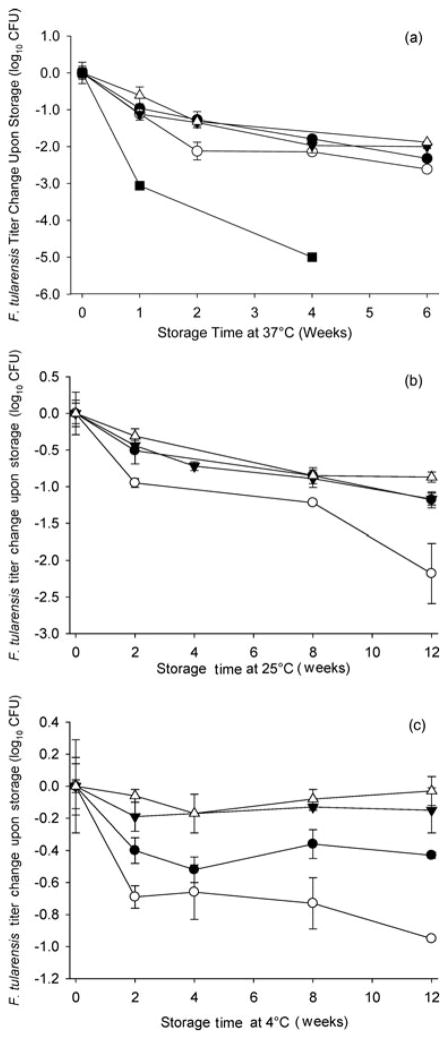

Polymers, such as gelatin, were incorporated into the solution to evaluate their effectiveness in stabilizing F. tularensis (Table 6). Inclusion of 5% (w/v) gelatin to the base formulation, comprised 30% (w/v) trehalose and 25 mM potassium phosphate at pH 8.0, significantly improved the stability of foam dried F. tularensis stored at 37°C (Fig. 4a); the rate constant of degradation has been reduced from −3.5 log10/week0.5 to −0.9 log10/week0.5 (Table 7). Furthermore, the inclusion of gelatin decreased the residual water content from 5.2% to 2.5% and increased the Tg from 57.6°C to 99°C.

Table 6.

Effect of Gelatin Addition, With and Without methionine, DMSO, and Pluronic F68, on the Process-Associated Loss, Residual Water Content, and Glass Transition Temperature (Tg) of F. tularensis Following Foam Drying (n = 2 Replicates per Data Point or # of Experiment, Except for Residual Water Content and Tg Analysis, for Which n = 3)

| Excipients | Fr 3 | Fr 4 | Fr 5 | Fr 6 | Fr 7 |

|---|---|---|---|---|---|

| Trehalose ( %,w/v) | 30 | 30 | 30 | 30 | 30 |

| Gelatin (%,w/v) | 5 | 5 | 5 | 5 | |

| Methionine (%,w/v) | 2 | ||||

| DMSO (wt %) | 0.5 | ||||

| Pluronic F68 (wt %) | 0.02 | ||||

| Potassium phosphate (mM) | 25 | 25 | 25 | 25 | 25 |

| pH | 8 | 8 | 8 | 8 | 8 |

| Process loss (log10 CFU) | 1.0 ± 0.2 | 1.0 ± 0.7 | 0.7 ± 0.5 | 0.7 ± 0.3 | 1.0 ± 0.2 |

| Residual Water (%) | 5.2 ± 0.1 | 2.5 ± 0.1 | 1.2 ± 0.1 | 1.2 ± 0.3 | 2.6 ± 0.3 |

| Tg (°C) | 57.6 ± 1.3 | 99.4 ± 2.2 | 103.5 ± 1.6 | 103.3 ± 2.8 | 90.9 ± 1.4 |

Figure 4.

Storage stability of foam dried Francisella tularensis stabilized in formulation Fr 3 (■), Fr 4 (●), Fr 5 (○), Fr 6 (◀), and Fr 7 (△). The formulation components are given in Table 6. The storage temperatures are 37°C (a), 25 °C (b), and 4°C (c).

Table 7.

Calculated Rate Constant of Degradation for the Five Formulations, Fr 3–Fr 7, at Three Storage Temperatures

| Rate Constant of Degradation (log/week0.5 ± s.d.)

| |||

|---|---|---|---|

| Formulation | T = 37°C | T = 25°C | T = 4°C |

| Fr 3 | −3.45 ± 0.02 | ND | ND |

| Fr 4 | −0.93 ± 0.03 | −0.33 ± 0.09 | −0.11 ± 0.10 |

| Fr 5 | −1.07 ± 0.08 | −0.56 ± 0.05 | −0.25 ± 0.04 |

| Fr 6 | −0.87 ± 0.08 | −0.33 ± 0.02 | −0.04 ± 0.02 |

| Fr 7 | −0.91 ± 0.07 | −0.27 ± 0.01 | −0.01 ± 0.02 |

ND, Not determined.

To examine the potential additive effect of other stabilizers with the gelatin-containing formulation, methionine, DMSO, and Pluronic F68 were incorporated individually (Table 6) and then foam dried. All of the formulations retained less than 3% residual water content and demonstrated Tg greater than 90°C. Although the methionine-containing formulation demonstrated a slightly higher degradation rate constant at 37°C (−1.1 log10/week0.5), the other three formulations demonstrated similar values (−0.9 log10/week0.5, Table 7). It is interesting to note that the enhanced titer loss previously reported with Pluronic usage was not observed in the presence of gelatin; whereas 0.02 wt % Pluronic F68 addition enhanced the process-associated loss from 1.0 to 2.1 log10 (Table 3), no change was observed in the presence of gelatin (Fr 4 and Fr 7, Table 6). The relative effectiveness of the gelatin-containing formulations became clearer upon comparing their storage stability at lower temperatures. At 25°C, it is evident that the formulation containing methionine demonstrated the poorest storage stability (−0.56 compared with ≤ −0.33 log10/week0.5 for the others), and the difference became more evident at 4°C. The storage stability of trehalose formulation lacking gelatin (Fr 3) was not evaluated at the lower temperatures as it demonstrated significantly high loss in titer when stored at 37°C.

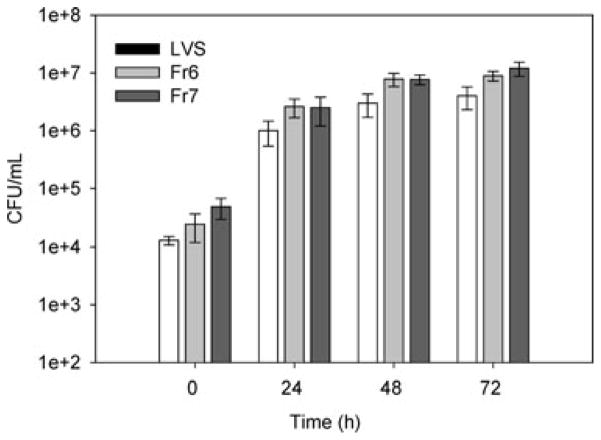

Formulated LV Maintains Biological Activity

The potential effects of the formulation process on the biological activity of LVS were evaluated in the macrophage intracellular replication assay and in the mouse virulence model. The ability of F. tularensis to survive and replicate within macrophages is a hallmark of its pathogenic process. In a typical assay, F. tularensis LVS were efficiently taken up by macrophages following a 2 h incubation period and proceeded to replicate to high levels over the following 72 h. During the first 24 h, LVS underwent approximately six doublings. At subsequent 48 and 72 h time points, the number of bacteria increased slightly as F. tularensis began to damage the macrophages. Two formulations of LVS (Fr 6 and Fr 7) were tested for their ability to survive and replicate within macrophages. As shown in Figure 5, both foam-dried materials behaved comparably to the control LVS. All samples were taken up by macrophages to equally high number and proceeded to replicate with 5.7–6.7 doublings within the first 24 h. Intracellular bacterial numbers were slightly increased at the 48 and 72 h time points for all samples.

Figure 5.

Comparison of intracellular replication of Francisella tularensis live vaccine strain (LVS) evaluated at various incubation times after gentamicin treatment. The examined samples included fresh LVS as well as foam dried LVS (Fr 6 and Fr 7).

The foam drying process did not affect the virulence of LVS in the mouse model. Although LVS is safe for use in humans, it is highly virulent in mice where the Lethal Dose, 50% (LD50) following an i.p. inoculation is approximately 15 CFU. Three different doses of each strain were tested for virulence in the mouse model. As shown in Table 8, all LVS inocula, including control and foam dried samples, were highly virulent. An inoculum containing 80–95 CFU resulted in moribundity in 50%–100% of mice, and doses containing 10× or 100× higher numbers of bacteria caused all mice to reach a moribund state within 4 days.

Table 8.

Virulence of Live Vaccine Strain LVS Samples Administered Intraperitoneally in Mice. Samples included freshly prepared LVS, foam-dried LVS (Fr6 and Fr7), and control (1% gelatin in PBS), administered at several dose levels. Mice were monitored daily for signs of disease for 28 days.

| Strain | Dose (CFU) | # Moribunda/Total | Time to Moribundity (days) |

|---|---|---|---|

| LVS | 95 | 4/4 | 4, 4, 5, 5 |

| 950 | 4/4 | 4, 4, 4, 4 | |

| 9500 | 4/4 | 4, 4, 4, 4 | |

| Fr 6 | 90 | 3/4 | 4, 4, 5 |

| 900 | 4/4 | 4, 4, 4, 4 | |

| 9000 | 4/4 | 4, 4, 4, 4 | |

| Fr 7 | 80 | 2/4 | 4, 4 |

| 800 | 4/4 | 4, 4, 4, 4 | |

| 8000 | 4/4 | 4, 4, 4, 4 | |

| PBS | – | 0/3 | – |

Moribundity was determined by the exhibition of any three of the following clinical signs: lack of grooming (ruffled fur), hunched gait, lethargy, and closed eyes.

DISCUSSION

Foam drying is a desiccation process whereby the solution is converted in a single step to a dried foam structure (Fig. 1). Compared with the other conventional drying processes, that is, spray drying and freeze drying, foam drying may have an advantage in processing labile biologicals because desiccation is conducted at near ambient conditions (i.e., 15°C–25°C), and therefore spare the organism’s exposure to extreme temperature regimes and process stresses, such as those involved with freeze drying and spray drying (e.g., ice crystals, shear, etc.).29,30

The foaming process was originally described by Annear31 in the 1960s as a method for preservation of bacteria. Briefly, the suspension of bacteria was contained in a glass ampoule and dried over phosphorous pentoxide, while controlling the sample temperature using a water bath to avoid freezing. The key aspect of the foam drying process is the boiling, or foaming, of the solution under low vapor pressure condition followed by rapid evaporation. Unlike the original foam drying method described by Annear,31 the current method employs improved temperature and pressure control with the use of a conventional lyophilizer. The foam drying method used for the current study has been described in more detail elsewhere.25 In addition to the processing variables, the formulation composition has a significant effect on the foaming efficiency as well as on the resulting storage stability of the labile biologicals. The formulation may consist of sugars, polyols, polymers, and surfactants. These excipients are included alone or in combination to vary the solids content, viscosity, and surface tension (to affect the foaming process) as well as strength of water binding (to modulate the residual water content). Foam drying does introduce its own unique set of stresses not encountered in other processes, namely the surface tension stress associated with cavitation. However, the detrimental impact conferred on labile biologicals appears to be reduced30; for parainfluenza virus stored at 25°C for 20 weeks, foam drying outperformed spray drying and freeze drying by demonstrating 0.73 log/week0.5 loss in titer, whereas the other two processes demonstrated greater than 1 log/week0.5 decrease in titer.30 This has been attributed to the lower specific surface area of the foam dried samples and the avoidance of ice formation achieved by drying at intermediate temperatures.19,25,30 It should be noted that similar process comparison was not conducted for the current work and foam drying was chosen due to its superiority over the other processing methods based on prior publications.

Both the growth condition and the harvesting time have been reported to have an effect on the physical properties of microorganisms.26 In particular, the addition of osmolytes to the growth media has been reported to affect the growth rate and the osmotolerance of various bacteria and fungi.26–28 In fact, the growth kinetics of F. tularensis LVS was accelerated upon the addition of osmolytess (Fig. 2), and the degree of acceleration appeared to be correlated to the amount of osmolyte present in the growth media. However, F. tularensis grown in high-osmolality growth media did not develop desiccation tolerance (Table 1), contrary to reports for Ty21a.25 The formulation used to subsequently stabilize the bacteria, however, appears to mask the effect to differing degrees.

Next, the optimum harvesting time for F. tularensis was examined to improve the process recovery following foam drying. This study was based on previous reports, which demonstrated the dependence of desiccation tolerance of bacteria on their maturation level.25,26 Although the process loss was rather high, irrespective of the harvesting time, F. tularensis harvested later during its growth cycle (i.e., 0.957 OD600 nm) resulted in higher recovery (Fig. 3). This may be related to the strength or “durability” of the bacterial membrane or simply to the amount of internal osmolytes (i.e., proteins, carbohydrates, etc.) that may have accumulated during growth.

The effect of pH on the stability of various bacteria has been studied extensively, however most reports are either in solution or complex growth media.32–37 For example, the effect of pH on the storage stability of Ty21a was compared in solution to that in the dried state, but there appeared to be no direct correlation.25,33 Our examination of pH effects also suggested no clear pH optimum. However, based on process loss from foam drying, F. tularensis LVS prepared in neutral-to-alkaline condition demonstrated the lowest process-associated loss.

Several amino acids have been successfully employed to stabilize a wide variety of complex biomolecules.38–42 In the current study, methionine and arginine were examined. Arginine addition was effective in reducing the process-associated loss, in particular at 0.5% concentration, although the storage stability was worsened in comparison to the trehalose-only formulation (Table 4). In comparison to the base formulation, only the 0.5% methionine addition appeared to increase the stability of F. tularensis. Interestingly, similar improvement in stability using the same concentration of methionine was reported for foam dried Ty21a,25, with the antioxidant property of the amino acid being cited as one possible mechanism of stabilization. In all cases examined, except for 2% methionine, the addition of amino acid improved the drying efficiency, as evidenced by the decreased water content in comparison to that of the base trehalose formulation.

Surfactants are typically incorporated into the formulation to reduce the accumulation of labile biologicals, such as proteins and viruses, at various interfaces (i.e., air–liquid, liquid–enclosure, etc.). This has been demonstrated to reduce the degree of denaturation and subsequent aggregation for a number of systems,30,43–45 thereby leading to enhanced stability. In the present study, surfactant was also incorporated to enhance the foaming capacity due to the lowered surface tension. Visually, it was noted that the surfactant-containing formulations foamed quicker and more effectively than those lacking surfactant. The inclusion of surfactant may be beneficial only for certain formulations, as evidenced by the negative impact of Pluronic F68 addition on the storage stability of the trehalose formulation lacking gelatin (Table 3), whereas a stabilizing effect was observed in the presence of gelatin (Table 7).

Plasticizers are well known for their propensity to enhance the mobility of solids, which may correlate with the lowered Tg, and thus are typically avoided in formulation design.46,47 Mobility examined on a large scale (i.e., translational motion) suggests that plasticizers are detrimental to the storage stability of labile biologicals that are effectively encased in a glassy matrix. However, on the local scale (i.e., vibrational and rotational motion), plasticizers have been demonstrated to dampen the high frequency motions, leading to enhanced storage stability.48,49 Thus, the effects of plasticizers are profound in the local environment of the labile biologicals, and not in the bulk, which is the property readily evaluated using techniques such as differential scanning calorimetry. Accurate evaluation of the role of plasticizers requires the use of instruments such as neutron scattering and dielectric spectroscopy.49,50 In the present study, DMSO inclusion resulted in improved storage stability and reduced residual water content (Table 5).

As mentioned above, the viscosity of the formulation is an important parameter that can influence the foaming process and can be modulated by varying the solids content of the formulation. Another viable approach is to include large molecular weight proteins or polymers, which on its own may have other stabilizing effects such as high Tg and hydrogen bonding capability (upon drying). Gelatin was evaluated in the current study and was observed to have positive effects in enhancing the storage stability of foam dried F. tularensis (Fig. 4). Inclusion of 5% gelatin to the trehalose formulation improved the storage stability, reducing the rate constant of degradation from −3.5 log10/week0.5 to −0.9 log10/week0.5 at 37°C (Table 7). Furthermore, the inclusion of gelatin resulted in the reduction of residual water content and Tg increase (Table 6). Next, several other components (examined previously) were incorporated into the gelatin–trehalose formulation to determine their compatibility. Methionine-containing formulation demonstrated the highest rate constant of degradation (−1.1 log10/week0.5), whereas the other formulations demonstrated similar values (−0.9 log10/week0.5). The observed differences became clearer upon comparing their rate constants at lower temperatures (Table 7). At 4°C, the stability of foam-dried F. tularensis follows the order:

All of the formulations also contain trehalose. It should be noted that the storage stability of formulations lacking gelatin was inferior to any of those listed above. It is also interesting to note that the difference in the effectiveness of the formulations became clearer at the lower storage temperatures, whereas such differences are typically observed at high temperatures. Stability data presented in Figure 4c (and water content data in Table 6) also shows that the residual water content is likely not the driving force for the difference in the observed stability because Fr 7 and Fr 4 both retained higher water content (~2.5% H2O) compared with Fr 6 (~1.2% H2O), yet the storage stability for those two formulations were greater and worse, respectively, than that for Fr 6. Thus, the formulation composition appears to play a greater role in the stability of the foam dried vaccine than the residual water content. And finally, in the presence of gelatin, the incorporation of Pluronic F68 had no destabilizing effect, as was observed in its absence (Tables 6 and 3, respectively). Surfactants have both positive and negative effects on the stability of bacterial membrane (depending on the concentration used), and the observed effect is the sum of all factors involved, that is, membrane disruption, surface adsorption, surface tension reduction, and so on. The trehalose–gelatin-based formulation may be broadly applicable to stabilizing other bacterial vaccine strains, as evidenced by the optimal formulation for Ty21a, which also contained trehalose and gelatin.25

Finally, the two foam dried materials (Fr 6 and Fr7) were shown to survive and replicate within macrophages (Fig. 5) and demonstrated virulence comparable to the unprocessed LVS (Table 8).

CONCLUSION

A foam drying processing method coupled with growth conditions and formulation components were developed that stabilized F. tularensis LVS. Improved desiccation tolerance was observed for F. tularensis harvested in the late stationary growth phase. Various pharmaceutically acceptable stabilizers were examined, including sugars, plasticizers, polymers, amino acids, and surfactants. The optimized formulation for foam dried F. tularensis consisted of trehalose and gelatin with Pluronic F68. The storage stability of trehalose–gelatin–Pluronic F68 formulation was 1.5 weeks at 37°C (i.e., time required for the vaccine to decrease in potency by 1 log10 CFU) and the formulation demonstrated less than 1 log10 decrease in titer following 12 weeks of storage at 25°C. Under refrigerated condition (4°C), no loss in activity was observed for at least 12 weeks. In comparison, lyophilized F. tularensis LVS demonstrated 3 log10 or more decrease in titer following 12 weeks of storage under ambient condition.24 The improved stability of the F. tularensis LVS could mitigate risks of vaccine potency loss during long-term storage, shipping, and delivery to geographical areas with warmer climates. Furthermore, in preparation for biological threat, the improved storage stability of the current vaccine would allow for stockpiling and immediate use, if needed.

Acknowledgments

This work was supported by NIH grant number NI-AID U54 AI057168 (to E.M.B.).

References

- 1.Ellis J, Oyston PC, Green M, Titball RW. Tularemia. Clin Microbiol Rev. 2002;15(4):631–646. doi: 10.1128/CMR.15.4.631-646.2002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Titball RW, Johansson A, Forsman M. Will the enigma of Francisella tularensis virulence soon be solved? Trends Microbiol. 2003;11(3):118–123. doi: 10.1016/s0966-842x(03)00020-9. [DOI] [PubMed] [Google Scholar]

- 3.Hopla CE. The ecology of tularemia. Adv Vet Sci Comp Med. 1974;18(0):25–53. [PubMed] [Google Scholar]

- 4.McLendon MK, Apicella MA, Allen LA. Francisella tularensis: Taxonomy, genetics, and immunopathogenesis of a potential agent of biowarfare. Annu Rev Microbiol. 2006;60:167–185. doi: 10.1146/annurev.micro.60.080805.142126. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Eigelsbach HT, Downs CM. Prophylactic effectiveness of live and killed tularemia vaccines. I. Production of vaccine and evaluation in the white mouse and guinea pig. J Immunol. 1961;87:415–425. [PubMed] [Google Scholar]

- 6.Ikaheimo I, Syrjala H, Karhukorpi J, Schildt R, Koskela M. In vitro antibiotic susceptibility of Francisella tularensis isolated from humans and animals. J Antimicrob Chemother. 2000;46(2):287–290. doi: 10.1093/jac/46.2.287. [DOI] [PubMed] [Google Scholar]

- 7.Oyston PC, Sjostedt A, Titball RW. Tularaemia: Bioterrorism defence renews interest in Francisella tularensis. Nat Rev Microbiol. 2004;2(12):967–978. doi: 10.1038/nrmicro1045. [DOI] [PubMed] [Google Scholar]

- 8.Russell P, Eley SM, Fulop MJ, Bell DL, Titball RW. The efficacy of ciprofloxacin and doxycycline against experimental tularaemia. J Antimicrob Chemother. 1998;41(4):461–465. doi: 10.1093/jac/41.4.461. [DOI] [PubMed] [Google Scholar]

- 9.Waag DM, Galloway A, Sandstrom G, Bolt CR, England MJ, Nelson GO, Williams JC. Cell-mediated and humoral immune responses induced by scarification vaccination of human volunteers with a new lot of the live vaccine strain of Francisella tularensis. J Clin Microbiol. 1992;30(9):2256–2264. doi: 10.1128/jcm.30.9.2256-2264.1992. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Waag DM, McKee KT, Jr, Sandstrom G, Pratt LL, Bolt CR, England MJ, Nelson GO, Williams JC. Cell-mediated and humoral immune responses after vaccination of human volunteers with the live vaccine strain of Francisella tularensis. Clin Diagn Lab Immunol. 1995;2(2):143–148. doi: 10.1128/cdli.2.2.143-148.1995. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Fulop M, Mastroeni P, Green M, Titball RW. Role of antibody to lipopolysaccharide in protection against low-and high-virulence strains of Francisella tularensis. Vaccine. 2001;19(31):4465–4472. doi: 10.1016/s0264-410x(01)00189-x. [DOI] [PubMed] [Google Scholar]

- 12.Tarnvik A. Nature of protective immunity to Francisella tularensis. Rev Infect Dis. 1989;11(3):440–451. [PubMed] [Google Scholar]

- 13.El Sahly HM, Atmar RL, Patel SM, Wells JM, Cate T, Ho M, Guo K, Pasetti MF, Lewis DE, Sztein MB, Keitel WA. Safety, reactogenicity and immunogenicity of Francisella tularensis live vaccine strain in humans. Vaccine. 2009;27(36):4905–4911. doi: 10.1016/j.vaccine.2009.06.036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Amorij JP, Huckriede A, Wilschut J, Frijlink HW, Hinrichs WL. Development of stable influenza vaccine powder formulations: Challenges and possibilities. Pharm Res. 2008;25(6):1256–1273. doi: 10.1007/s11095-008-9559-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Garcia-Contreras L, Wong YL, Muttil P, Padilla D, Sadoff J, Derousse J, Germishuizen WA, Goonesekera S, Elbert K, Bloom BR, Miller R, Fourie PB, Hickey A, Edwards D. Immunization by a bacterial aerosol. Proc Natl Acad Sci USA. 2008;105(12):4656–4660. doi: 10.1073/pnas.0800043105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Smith DJ, Bot S, Dellamary L, Bot A. Evaluation of novel aerosol formulations designed for mucosal vaccination against influenza virus. Vaccine. 2003;21(21–22):2805–2812. doi: 10.1016/s0264-410x(03)00224-x. [DOI] [PubMed] [Google Scholar]

- 17.Wong YL, Sampson S, Germishuizen WA, Goonesekera S, Caponetti G, Sadoff J, Bloom BR, Edwards D. Drying a tuberculosis vaccine without freezing. Proc Natl Acad Sci USA. 2007;104(8):2591–2595. doi: 10.1073/pnas.0611430104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Brandau DT, Jones LS, Wiethoff CM, Rexroad J, Middaugh CR. Thermal stability of vaccines. J Pharm Sci. 2003;92(2):218–231. doi: 10.1002/jps.10296. [DOI] [PubMed] [Google Scholar]

- 19.Simon EM, Stahl KL, Wilson JB. Preservation by freeze-drying and the stability of virulence of Salmonella typhimurium. Appl Microbiol. 1963;11:371–376. doi: 10.1128/am.11.4.371-376.1963. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Zayed G, Roos YH. Influence of trehalose and moisture content on survival of Lactobacillus salivarius subjected to freeze-drying and storage. Process Biochem. 2004;9:1081–1086. [Google Scholar]

- 21.Amorij JP, Meulenaar J, Hinrichs WL, Stegmann T, Huckriede A, Coenen F, Frijlink HW. Rational design of an influenza subunit vaccine powder with sugar glass technology: Preventing conformational changes of haemagglutinin during freezing and freeze-drying. Vaccine. 2007;25(35):6447–6457. doi: 10.1016/j.vaccine.2007.06.054. [DOI] [PubMed] [Google Scholar]

- 22.deJonge J, Amorij JP, Hinrichs WL, Wilschut J, Huckriede A, Frijlink HW. Inulin sugar glasses preserve the structural integrity and biological activity of influenza virosomes during freeze-drying and storage. Eur J Pharm Sci. 2007;32(1):33–44. doi: 10.1016/j.ejps.2007.05.112. [DOI] [PubMed] [Google Scholar]

- 23.Huang J, Garmise RJ, Crowder TM, Mar K, Hwang CR, Hickey AJ, Mikszta JA, Sullivan VJ. A novel dry powder influenza vaccine and intranasal delivery technology: Induction of systemic and mucosal immune responses in rats. Vaccine. 2004;23(6):794–801. doi: 10.1016/j.vaccine.2004.06.049. [DOI] [PubMed] [Google Scholar]

- 24.Day JB, Nguyen H, Sharma SK, Al-Khaldi SF, Hao YY. Effect of dehydrated storage on the survival of Francisella tularensis in infant formula. Food Microbiol. 2009;26(8):932–935. doi: 10.1016/j.fm.2009.06.005. [DOI] [PubMed] [Google Scholar]

- 25.Ohtake S, Martin R, Saxena A, Pham B, Chiueh G, Osorio M, Kopecko D, Xu D, Lechuga-Ballesteros D, Truong VL. Room temperature stabilization of oral, live attenuated Salmonella enterica serovar Typhi-vectored vaccines. Vaccine. 2011;29(15):2761–2771. doi: 10.1016/j.vaccine.2011.01.093. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Prasad J, McJarrow P, Gopal P. Heat and osmotic stress responses of probiotic Lactobacillus rhamnosus HN001 (DR20) in relation to viability after drying. Appl Environ Microbiol. 2003;69(2):917–925. doi: 10.1128/AEM.69.2.917-925.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Mahdy HM, el-Sheikh HH, Ahmed MS, Refaat BM. Physiological and biochemical changes induced by osmolality in halotolerant Aspergilli. Acta Microbiol Pol. 1996;45(1):55–65. [PubMed] [Google Scholar]

- 28.Fonseca F, Beal C, Corrieu G. Operating conditions that affect the resistance of lactic acid bacteria to freezing and frozen storage. Cryobiology. 2001;43(3):189–198. doi: 10.1006/cryo.2001.2343. [DOI] [PubMed] [Google Scholar]

- 29.Abdul-Fattah AM, Truong-Le V, Yee L, Nguyen L, Kalonia DS, Cicerone MT, Pikal MJ. Drying-induced variations in physicochemical properties of amorphous pharmaceuticals and their impact on stability (I): Stability of a monoclonal antibody. J Pharm Sci. 2007;96(8):1983–2008. doi: 10.1002/jps.20859. [DOI] [PubMed] [Google Scholar]

- 30.Abdul-Fattah AM, Truong-Le V, Yee L, Pan E, Ao Y, Kalonia DS, Pikal MJ. Drying-induced variations in physicochemical properties of amorphous pharmaceuticals and their impact on stability II: Stability of a vaccine. Pharm Res. 2007;24(4):715–727. doi: 10.1007/s11095-006-9191-2. [DOI] [PubMed] [Google Scholar]

- 31.Annear DI. Recoveries of bacteria after drying in vacuo at a bath temperature of 100°C. Nature. 1966;211(5050):761. doi: 10.1038/211761a0. [DOI] [PubMed] [Google Scholar]

- 32.Shepard MC, Lunceford CD. Effect of Ph on human mycoplasma strains. J Bacteriol. 1965;89:265–270. doi: 10.1128/jb.89.2.265-270.1965. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Zeng Y, Fan H, Chiueh G, Pham B, Martin R, Lechuga-Ballesteros D, Truong VL, Joshi SB, Middaugh CR. Towards development of stable formulations of a live attenuated bacterial vaccine: A preformulation study facilitated by a biophysical approach. Hum Vaccin. 2009;5(5):322–331. doi: 10.4161/hv.5.5.7559. [DOI] [PubMed] [Google Scholar]

- 34.Amaral JA, Ren T, Knowles R. Atmospheric methane consumption by forest soils and extracted bacteria at different pH values. Appl Environ Microbiol. 1998;64(7):2397–2402. doi: 10.1128/aem.64.7.2397-2402.1998. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Chander M, Setlow B, Setlow P. The enzymatic activity of phosphoglycerate mutase from gram-positive endospore-forming bacteria requires Mn2+ and is pH sensitive. Can J Microbiol. 1998;44(8):759–767. doi: 10.1139/cjm-44-8-759. [DOI] [PubMed] [Google Scholar]

- 36.Deveci H, Akcil A, Alp I. Bioleaching of complex zinc sulphides using mesophilic and thermophilic bacteria: Comparative importance of pH and iron. Hydrometallurgy. 2004;73(3–4):293–303. [Google Scholar]

- 37.Mayo AW, Noike T. Effects of temperature and pH on the growth of heterotrophic bacteria in waste stabilization ponds. Water Res. 1996;30(2):447–455. [Google Scholar]

- 38.Ohtake S, Martin RA, Yee L, Chen D, Kristensen DD, Lechuga-Ballesteros D, Truong-Le V. Heat-stable measles vaccine produced by spray drying. Vaccine. 2010;28(5):1275–1284. doi: 10.1016/j.vaccine.2009.11.024. [DOI] [PubMed] [Google Scholar]

- 39.Mattern M, Winter G, Kohnert U, Lee G. Formulation of proteins in vacuum-dried glasses. II. Process and storage stability in sugar-free amino acid systems. Pharm Dev Technol. 1999;4(2):199–208. doi: 10.1081/pdt-100101354. [DOI] [PubMed] [Google Scholar]

- 40.Izutsu K, Kadoya S, Yomota C, Kawanishi T, Yonemochi E, Terada K. Freeze-drying of proteins in glass solids formed by basic amino acids and dicarboxylic acids. Chem Pharm Bull. 2009;57(1):43–48. doi: 10.1248/cpb.57.43. [DOI] [PubMed] [Google Scholar]

- 41.Izutsu K, Fujimaki Y, Kuwabara A, Aoyagi N. Effect of counterions on the physical properties of l-arginine in frozen solutions and freeze-dried solids. Int J Pharm. 2005;301(1–2):161–169. doi: 10.1016/j.ijpharm.2005.05.019. [DOI] [PubMed] [Google Scholar]

- 42.Pikal MJ, Dellerman KM, Roy ML, Riggin RM. The effects of formulation variables on the stability of freeze-dried human growth hormone. Pharm Res. 1991;8(4):427–436. doi: 10.1023/a:1015834724528. [DOI] [PubMed] [Google Scholar]

- 43.Chang BS, Kendrick BS, Carpenter JF. Surface-induced denaturation of proteins during freezing and its inhibition by surfactants. J Pharm Sci. 1996;85(12):1325–1330. doi: 10.1021/js960080y. [DOI] [PubMed] [Google Scholar]

- 44.Katakam M, Bell LN, Banga AK. Effect of surfactants on the physical stability of recombinant human growth hormone. J Pharm Sci. 1995;84(6):713–716. doi: 10.1002/jps.2600840609. [DOI] [PubMed] [Google Scholar]

- 45.Kim MH, Lee SB, Ryu DDY, Reese ET. Surface deactivation of cellulase and its prevention. Enzyme Microb Technol. 1982;4(2):99–103. [Google Scholar]

- 46.Dimarzio EA, Gibbs JH. Molecular interpretation of glass temperature depression by plasticizers. J Polym Sci. 1963;1(4):1417–1428. [Google Scholar]

- 47.Roos Y, Karel M. Plasticizing effect of water on thermal behavior and crystallization of amorphous food models. J Food Sci. 1991;56(1):38–43. [Google Scholar]

- 48.Curtis JE, Dirama TE, Carri GA, Tobias DJ. Inertial suppression of protein dynamics in a binary glycerol-trehalose glass. J Phys Chem B. 2006;110(46):22953–22956. doi: 10.1021/jp0615499. [DOI] [PubMed] [Google Scholar]

- 49.Cicerone MT, Soles CL. Fast dynamics and stabilization of proteins: Binary glasses of trehalose and glycerol. Biophys J. 2004;86(6):3836–3845. doi: 10.1529/biophysj.103.035519. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Psurek T, Soles CL, Page KA, Cicerone MT, Douglas JF. Quantifying changes in the high-frequency dynamics of mixtures by dielectri spectroscopy. J Phys Chem B. 2008;112(50):15980–15990. doi: 10.1021/jp8034314. [DOI] [PubMed] [Google Scholar]