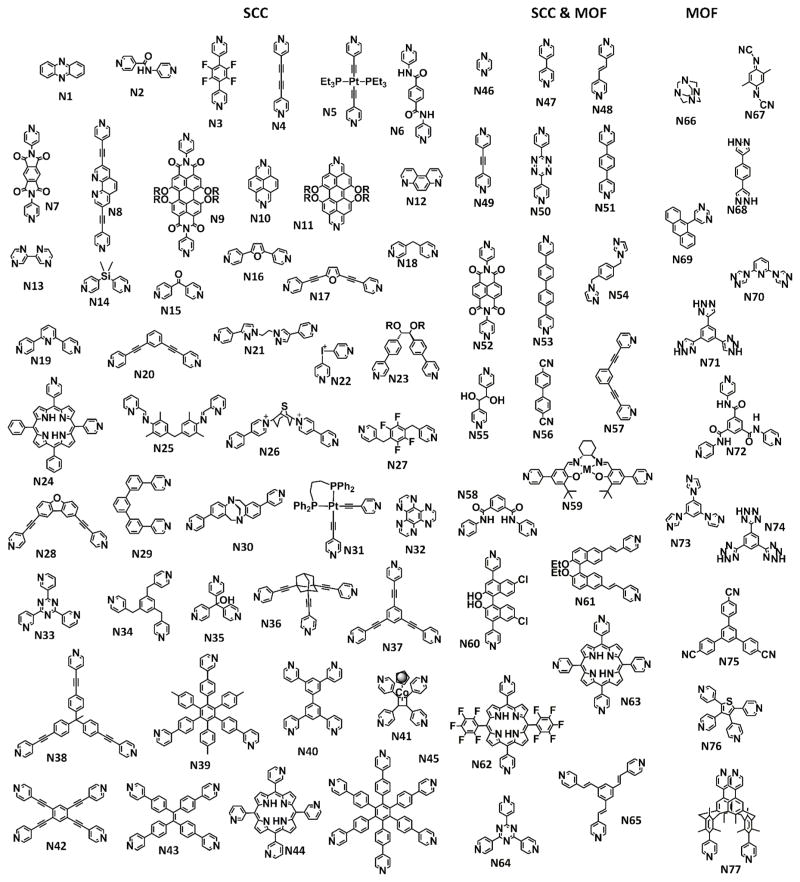

1. Introduction

In 1893, Alfred Werner described the structure of octahedral transition metal complexes and provided the basis for assigning coordination number and oxidation state to what were then known as double salts.1 This term arose from the observation that transition metal ions appeared to form bonds not only to anion ligands with which to neutralize their charge, but also to additional species which seemed unnecessary since neutrality was already achieved. This work was the origin of modern coordination chemistry and greatly expanded the field of inorganic chemistry. By understanding the preferred coordination geometry about a metal ion, rational synthetic methodologies to install specific ligands was now possible. The past 119 years have witnessed a tremendous growth in coordination chemistry, leading to advances in our understanding of the synthesis, structure and reactivity of novel complexes and materials from simple metal-ligand complexes to organometallic catalysts and extended inorganic polymers. In recent decades, two new branches of coordination chemistry have emerged—metal-organic frameworks (MOFs) and supramolecular coordination complexes (SCCs). The former is comprised of infinite networks of metal centers or inorganic clusters bridged by simple organic linkers through metal-ligand coordination bonds. The latter encompasses discrete systems in which carefully-selected metal centers undergo self-assembly with ligands containing multiple binding sites oriented with specific angularity to generate a finite supramolecular complex. On the most basic level, both SCCs and MOFs share the design of metal nodes linked by organic ligands and such constructs can be broadly defined as metal-organic materials (MOMs).

1.1 Supramolecular Coordination-Driven Self-Assembly

Supramolecular polygons and polyhedra based on metal-ligand coordination emerged in part as a result of studies in the 1960s by Pedersen and coworkers which demonstrated that complementary small molecules could exhibit intermolecular recognition via noncovalent interactions.2 Early molecular-recognition systems were simple: crown ethers could by synthesized and selectively accommodate simple guest ions. New host/guest systems quickly followed, leading to more complex ensembles such as cryptand and spherand hosts with small molecule guests, pioneered by Lehn3 and Cram.4 The non-covalent interactions governing host/guest formation were then applied to construct large entities from molecular components. These constructs, held together by intramolecular hydrogen bonding, π-π interactions, van der Waals forces and other weak interactions were dubbed “supermolecules.” Supramolecular chemistry is a broad field, owing to the vast number of diverse structures which can be formed by using a variety of noncovalent intermolecular interactions. Notable examples include biologically relevant enzyme mimics,5 molecular devices including light harvesters,6 sensors,7 wires8 and rectifiers,9 liquid crystals,10 molecular flasks11 and more.12 One subset of this chemistry is the self-assembly of coordination compounds.

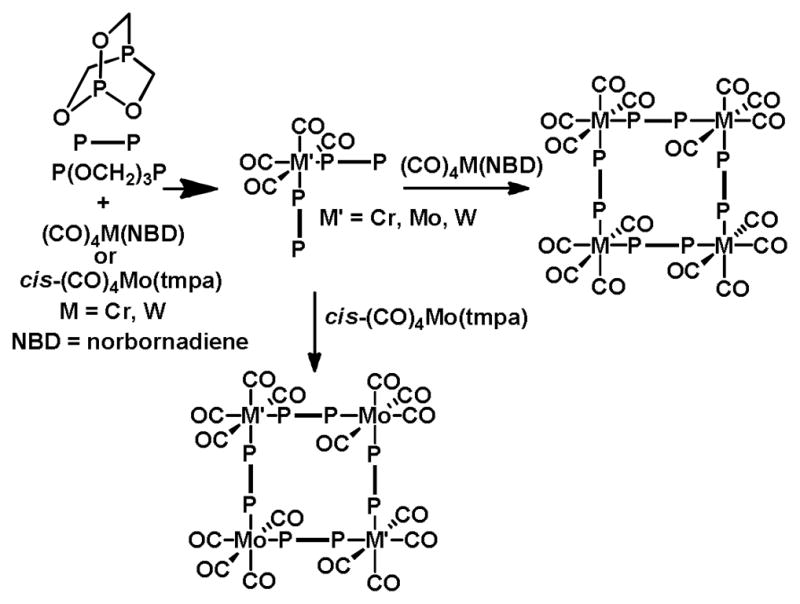

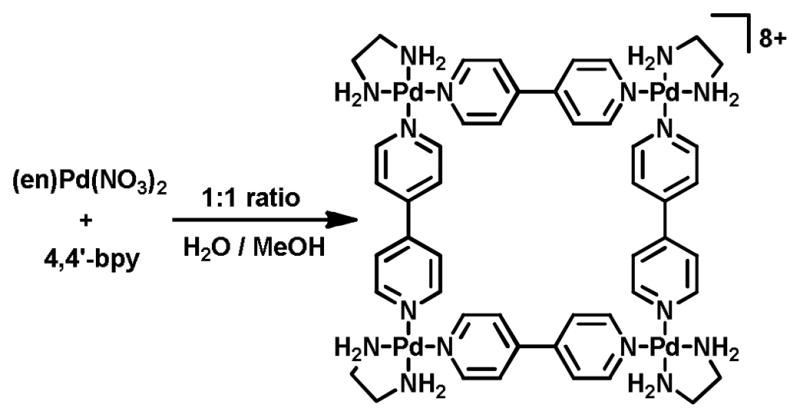

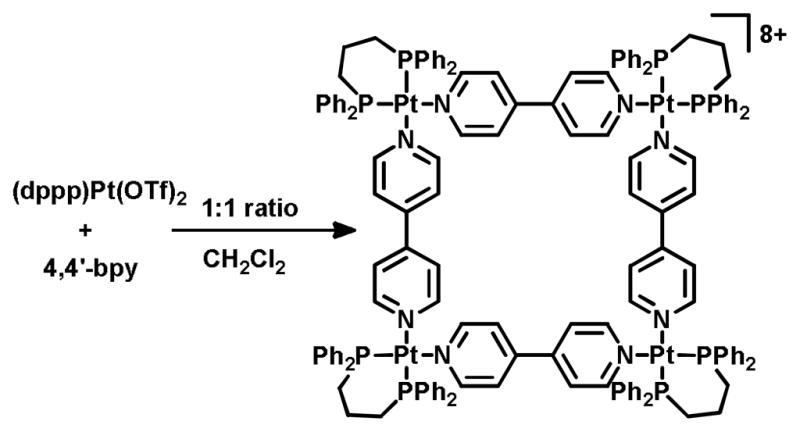

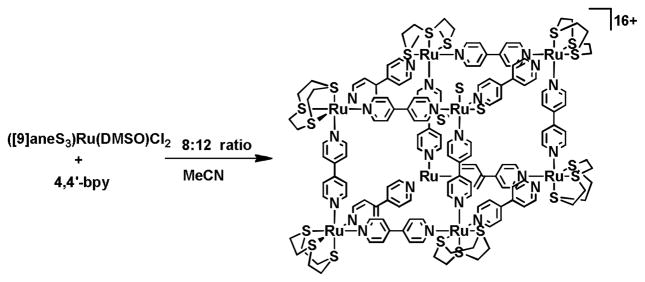

Supramolecular coordination complexes are discrete constructs, typically obtained by mixing soluble metal and ligand precursors which spontaneously form metal-ligand bonds to generate a single thermodynamically-favored product. Since coordination bonds are the impetus for formation, this process is often referred to as coordination-driven self-assembly. A pioneering example of macrocycles formed from coordination bonds was given by Verkade and coworkers in 1983.13 By mixing a diphosphine bridging ligand, P(OCH2)3P,14 with either Cr, Mo or W carbonyl precursors, 20-membered tetranuclear rings were obtained (Figure 1). Exploiting the directionality of transition metal coordination spheres and rigid organic ligands was largely overlooked until the early 1990s when Fujita15 and Stang16 provided examples of rationally-designed supramolecular squares with Pd and Pt. Over the next two decades, various methodologies for the rational design of polygons, polyhedra and prisms were developed, led by the groups of Stang,17 Raymond,11c,d,18 Fujita,11a,19 Mirkin20 and Cotton.21 From squares came the rationale to generate triangles,22 rectangles23 and higher polygons,24 as well as extensions to 3D systems including tetrahedra,25 cubes,26 octahedra,27 cuboctahedra,28 dodecahedra29 and others.30 As a subset of supramolecular chemistry, SCCs have been employed in a range of applications including those listed above.

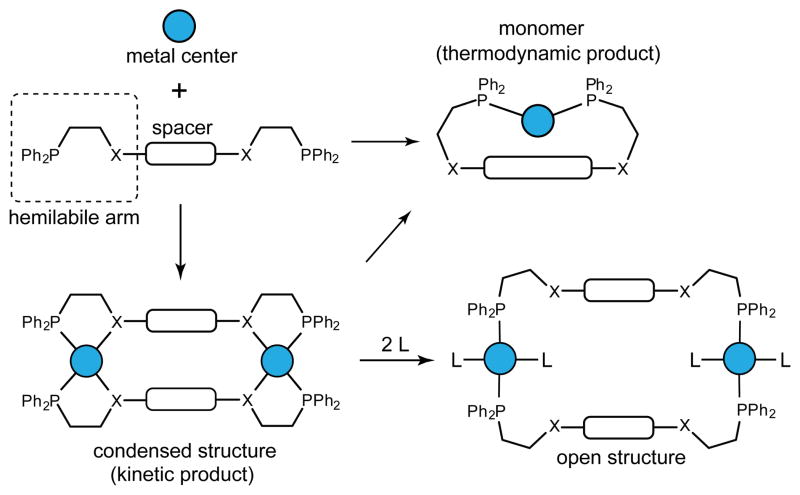

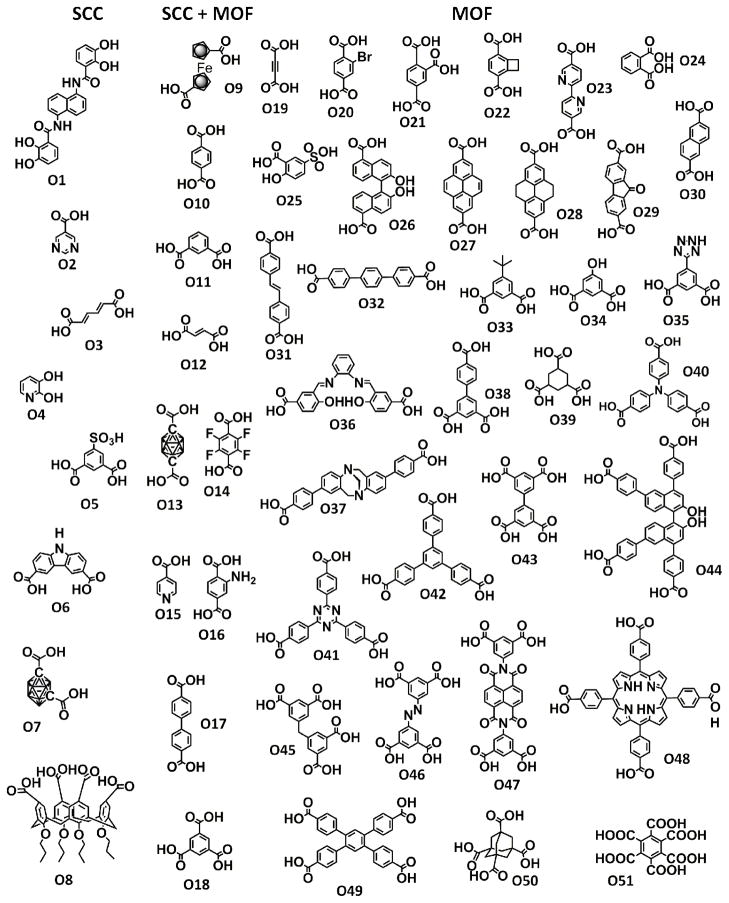

Figure 1.

An early example of coordination-driven self-assembly. Square metallacycles may be formed upon combination of a metal precursor with a linear ligand with two bridgehead phosphorus atoms. An intermediate monomer species is isolable, permitting the construction of both homo and hetero-tetranuclear squares.13

1.2 Coordination Polymers and Metal-Organic Frameworks

Like SCCs, metal-organic frameworks owe their development to coordination chemistry. In a broad sense, MOFs have a rich history beginning with the development of coordination polymers.31 Coordination polymers are a subset of inorganic polymers which contain metal-ligand bonds as the primary design feature. The term coordination polymer has been traced back to a 1964 review by J. C. Bailar which was concerned with polymeric structures comprised of metals and ligands. The motivation behind early interest in inorganic and coordination polymers was application-driven from the very beginning. Inorganic materials were recognized to potentially withstand thermal and oxidative stress better than their organic counterparts.31 The induction time between the first coordination polymers and modern MOF chemistry is much greater. The synthetic pigment commonly known as Prussian Blue has been in use since the early 1700s. Its structure was determined by X-ray diffraction in 1977 to reveal a mixed-valent Fe(II)/Fe(III) network with Fe(II)-carbon distances of 1.92 Å and Fe(III)-nitrogen distances of 2.03 Å (Figure 2).32

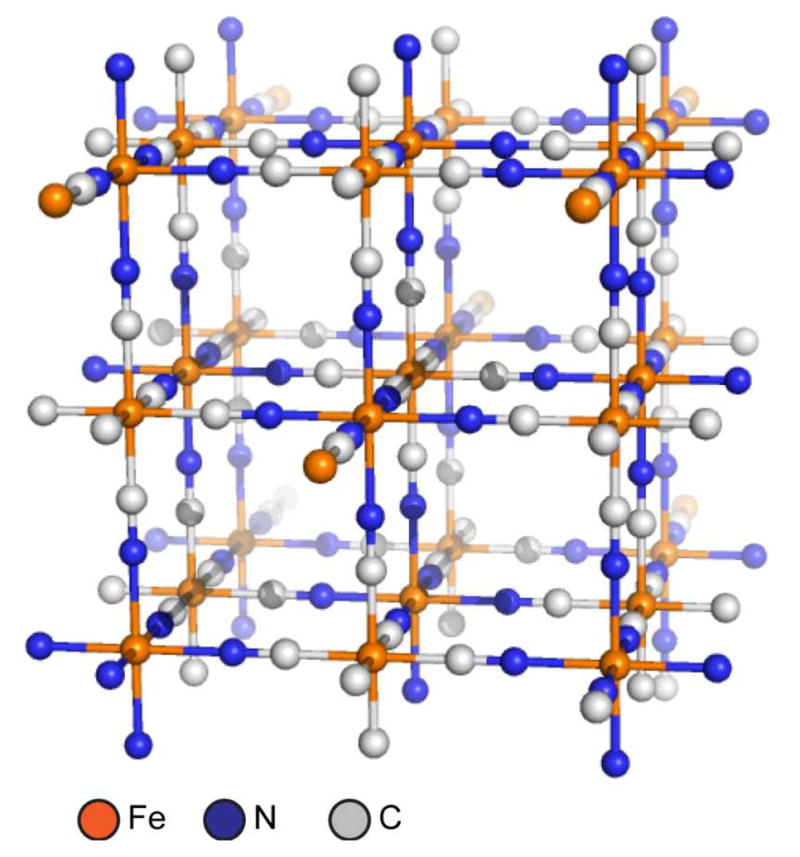

Figure 2.

Idealized structure of Prussian Blue, the first synthetic coordination polymer. Alternating octahedral sites of Fe(II) and Fe(III) ions are bridged by cyanide ligands to generate a cubic 3D array.32

In 1897, Hoffman and coworkers discovered that the addition of benzene into a solution of Ni(CN)2 in ammonia furnished a coordination network but early work on these polymers was hindered by a lack of structural characterization techniques. In fact, the structure of the Hoffman complex was not fully understood until X-ray studies by Powell and coworkers over half a century after the initial synthesis was reported.34 The material, Ni(CN)2(NH3)·C6H6 shared similar structural elements with Prussian Blue; the extended structure consisted of metal nodes bridged by cyanide ligands. However, the Ni(CN)2 network did not extend into three dimensions. Instead, parallel 2D sheets with ammine-capped nickel sites were layered to give benzene-containing channels between independent arrays. These exemplary coordination polymers provided the motivation to explore alternative bridging ligands, guests, and capping moieties. As characterization techniques became more refined, efforts to define, classify, and synthesize such materials accelerated throughout the 1960s, cementing coordination polymers as a distinct area of research.35 Early MOMs consisted of Hoffman type topologies in which the metal centers, capping ligands and guests were systematically swapped with similar species, for example by replacing the original benzene guests with biphenyl (Figure 3).33 From the late 1960s into the 1980s, a variety of such species were reported. The final exodus from these early materials occurred when the cyanide ligand was replaced with alternative organic ligands which rapidly led to the discovery of a myriad of new MOMs.

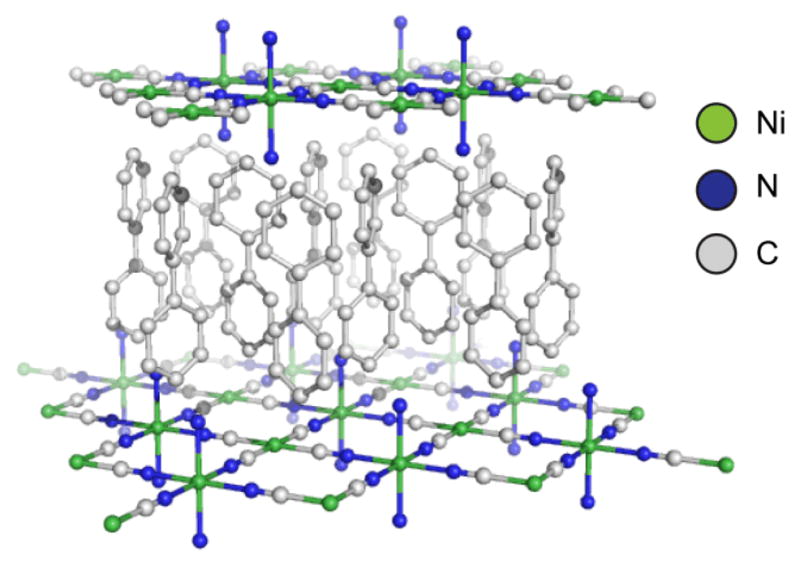

Figure 3.

The structure of a Hoffman-type complex, Ni(CN)2(NH3)(C12H10)2. Hydrogen atoms omitted for clarity.33

A hallmark discovery was made by Robson and coworkers in 1989, in which Cu(I) centers were linked with 4,4′,4″,4‴-tetracyanotetraphenylmethane (tctpm; Figure 4).36 This tetratopic organic donor adopted a tetrahedral geometry due to the central carbon atom. The four nitrogen atoms each coordinate to a unique Cu(I) center, which are themselves coordinated to three other tctpm ligands. The extended network adopts a diamond-like topology comprised of repeating adamantanoid subunits. This was a key material in that it set the foundation for the use of tunable organic ligands in coordination polymers; such materials were not limited to cyanide bridges.

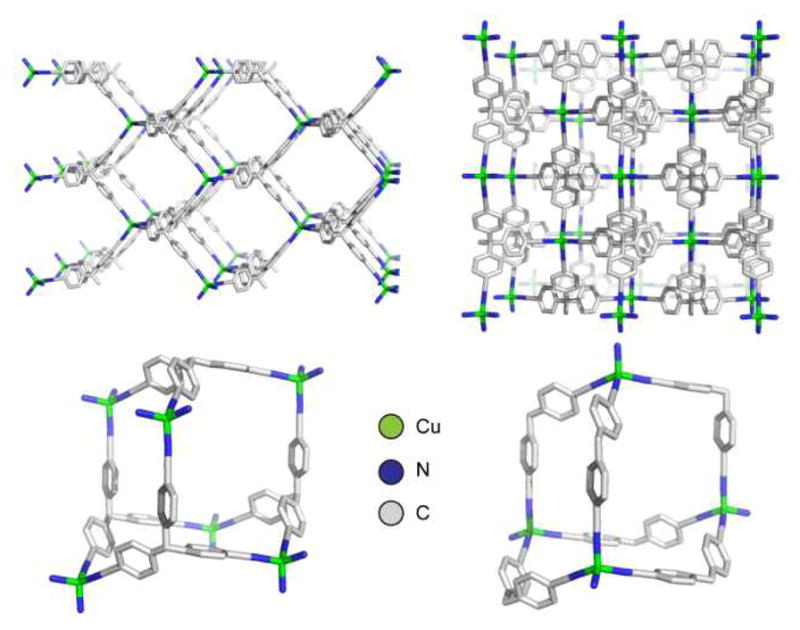

Figure 4.

The slow evaporation of a solution of a tetranitrile ligand with a Cu(I) precursor deposits a coordination polymer containing tetrahedral metal nodes with tetrahedral tetratopic spacers. Two views are shown (top) with hydrogen atoms omitted for clarity revealing a diamond-like network comprised of repeating adamantanoid units (bottom).36

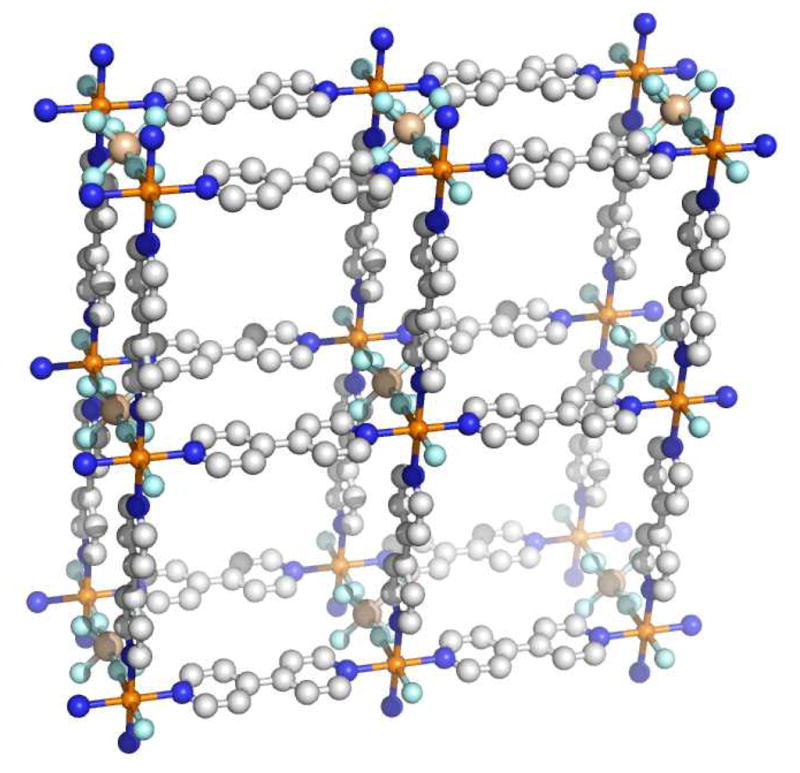

Soon thereafter, ligand diversity continued to increase, from cyanide, to organic nitriles, to pyridyl-based donors. Of the pyridyl ligands, 4,4′-bipyridine (4,4′-bpy) is the most iconic. The early adoption of 4,4′-bpy as a building block for both MOFs and SCCs can be attributed to its suitability as a ligand for a variety of metals, its structural rigidity as a linear, ditopic donor, and its ready availability from a number of commercial sources. Four years after demonstrating its use in forming a supramolecular square, Fujita and coworkers utilized 4,4′-bpy in the assembly of square grids.37 Treatment of Cd(NO3)2 with 4,4′-bipy in a 1:2 ratio in aqueous ethanol led to the deposition of colorless crystals characterized as [Cd(4,4′-bpy)2(NO3)2] (Figure 5). Motivated by materials utilizing the ditopic 4,4′-bpy, the field then moved towards polytopic donors with varying geometries. In the mid 1990s, the exploration of carboxylate-based materials garnered significant interest, building upon the milestone discovery of permanently microporous pyridyl-based MOMs by Kitagawa and coworkers38 with an example of carboxylate-based porosity by Yaghi and coworkers.39 These coordination polymers distinguished themselves by possessing reversible gas adsorption and adopted the name metal-organic frameworks. The term metal-organic framework is technically suitable for any extended array comprised of metal nodes (either mono- or polynuclear), however it’s not uncommon for the term MOF to be reserved for materials which are characterized as micro-crystalline, well-defined materials containing polynuclear clusters and often showing permanent porosity. The clusters themselves are stabilized by bridging ligands and the networks of clusters are supported by the strong covalent bonds found within the organic components of the MOFs40

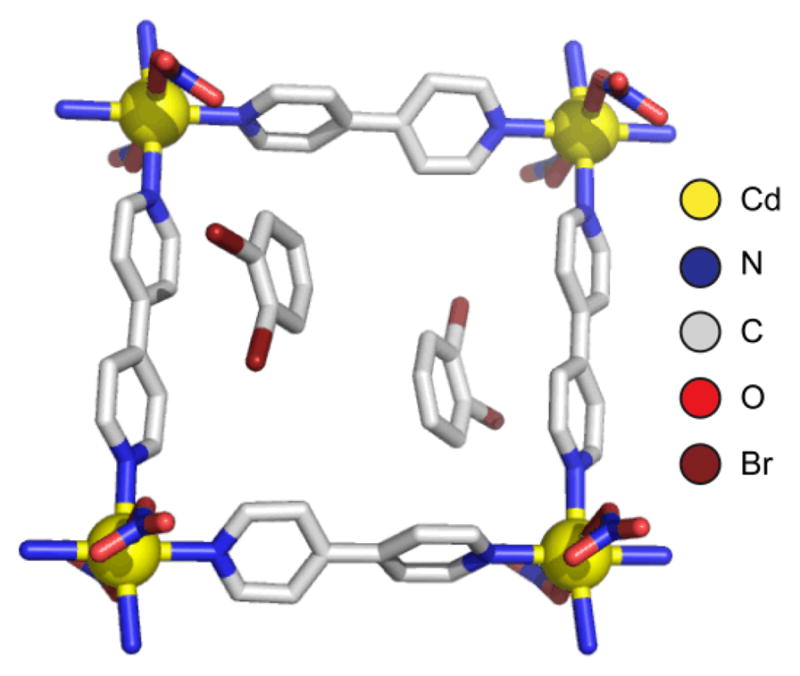

Figure 5.

The structure of [Cd(4,4′-bpy)2(NO3)2], a square lattice with channels capable of accommodating guests such as o-dibromobenzene. Hydrogen atoms omitted for clarity. 37

Modern MOF synthesis is driven in part by a goal to generate extremely porous materials often accompanied by very large internal surface areas. This is accomplished by a careful selection of molecular precursors and reaction conditions which dictate the thermodynamically-favored architecture. In addition to ongoing synthetically-focused research, a major hallmark of MOF chemistry results from the properties afforded by the aforementioned surface area and porosities. MOFs are increasingly applied towards applications which require efficient uptake of substrates, such as energy storage41, chemical purification,42 sensing,43 and more.44

1.3 Scope of this Review

The coordination bond between a metal center and organic ligands is the fundamental theme underpinning the synthesis of both MOFs and SCCs. Because of this common element, there are many similarities including the specific building blocks used, the structural topologies and the possible applications. However, the two fields have also diverged due to the differences—sometimes subtle, other times straightforward—associated with targeting infinite arrays versus discrete molecular systems. While some groups have provided elegant examples that bridge the gap between MOFs and SCCS, sometimes even using the same molecular building blocks, a wider appreciation of the relationship between the two fields would be beneficial to the chemical community at large. This comprehensive review provides a discussion of the commonality and differences of SCCs and MOFs, in order to present a linkage between these two important fields and share concepts and applications which may be useful to both. To achieve this, we compare four different aspects of a collection of reported SCCs and MOFs: design methodologies, synthetic conditions, post-assembly modifications and applications. It is important to note that both SCCs and MOFs have grown to contain a gigantic body of work. Independent reviews detailing SCCs or MOFs are themselves typically limited to one area, be it a particular class of building blocks, design methodology or application. As such, this review does not attempt to exhaustively present all known MOFs and SCCs, which would require several hundred pages and many thousands of references, resulting in little practical value. Instead, representative examples are given in each section which best highlight the relationship of the two fields, from pioneering work to contemporary discoveries. The reader will also be directed to a number of relevant manuscripts and reviews which will guide further investigations into a particular aspect of SCC or MOF chemistry which may be of interest.

2. Design Methodologies

2.1 Classifying Networks

Every MOF and SCC necessarily contains at least two components, a ligand and a metal center. While the complexity of these units can vary widely from one assembly to the next, they can often be simplified conceptually. Important fundamental characteristics of a given material include the number of binding sites available on the metal or metal clusters, the relative orientation of these binding sites, the number of Lewis-basic sites on a ligand, the modes of coordination of these sites, and the relative angularity of these sites. Modern researchers often think of MOFs and SCCs in terms of their constituent building blocks. This methodology has origins as early as the mid-1950s, during which time A. F. Wells developed a description of the structure of inorganic polymers by reducing the components to nodes and spacers.45

By viewing an extended network as an array of nodes connected by linear spacers it became possible to assign a given structure to a specific network, or net. Since this method requires that all spacers are linear in nature, all divergent sites become nodes, including sites on organic ligands which break linearity. For example, in Robson’s coordination polymer introduced, the central carbon of the tctpm ligand would be described as a 4-conneted node with the 4-cyanophenyl fragments acting as linear spacers to a second type of node, the Cu centers (Figure 6).

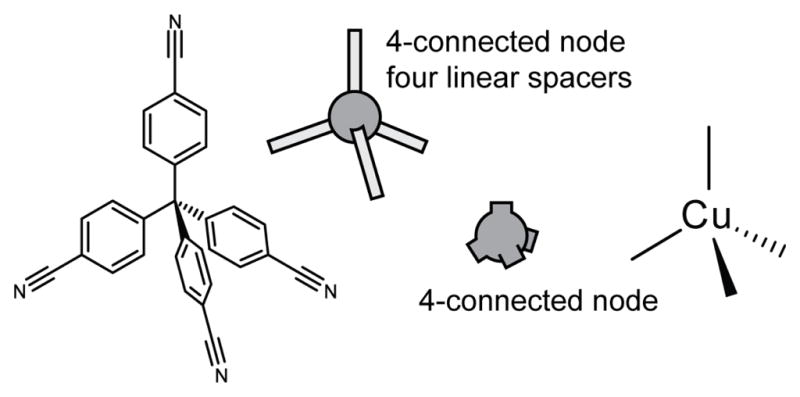

Figure 6.

The Cu coordination network of Robson and coworkers36 can be broken down to nodes and spacers. The tetrahedral organic ligand is deconstructed to a four-connected node and linear spacers while the Cu centers represent a second four-connected node.

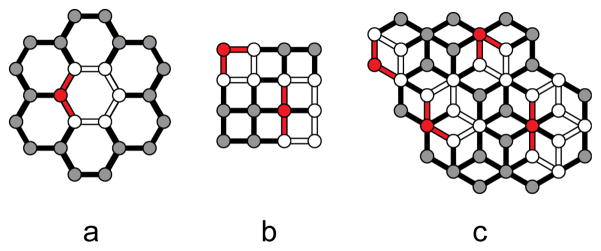

Since Well’s introductory papers in the 50s, the net approach has been widely applied and reviewed.46 There are a few common ways to name nets which are based on a few parameters: the connectivity of the nodes, the number of nodes in the smallest loop containing a spacer-node-spacer unit, and the size of these loops (sometimes referred to as shortest circuits). When a net possesses both one type of node and identically sized loops, it is dubbed a Platonic uniform net. Wells introduced the (n,p) nomenclature to describe nets of this type, wherein n is the number of nodes in the smallest loop and p is the connectivity of the nodes. For example, Figure 7(a) shows a honeycomb lattice which is comprised of three-connected nodes with six nodes comprising the smallest loop containing a unique spacer-node-spacer motif. Since all nodes are the same and all shortest circuits are identical, this is a Platonic uniform net designated (6,3). Nets (b) and (c) are not Platonic uniform. This is readily apparent in net (c) since it contains both six-connected and three-connected nodes. Net (b) contains only one type of four-connected node, but there are two unique loops. If the spacer-node-spacer unit contains cis-spacers, the loop contains four nodes. However, taking a trans-spacer orientation results in a six-node shortest loop. These unique loops appear as outlines in Figure 7, with the cis or trans spacer motifs highlighted in red. Since this is not technically a Platonic uniform net due to the two different loops, the common designation as a (4,4) net is not correct and a more detailed naming scheme is needed.

Figure 7.

Inorganic polymers may be classified as nets consisting of nodes and linear spacers. For these three examples of 2-periodic nets, the shortest circuits containing unique spacer-node-spacer motifs are outlined, with the motifs highlighted in red.

A second naming system uses Schläfli symbols and can also be used for non-Platonic uniform nets. This system also indicates the number of nodes in a shortest loop and then indicates the number of times this loop occurs as a superscripted number. For example, in Figure 7(b), the cis-oriented spacer-node-spacer motif repeats four times at each node, giving rise to four independent four-node loops. The trans motif occurs twice for each node, one set oriented vertically and the other horizontally. This results in the Schläfli symbol 44.62. When the topology increases in complexity with multiple types of nodes, for example in Figure 7(c), the Schläfli symbol still indicates all unique shortest circuits with the unique nodes separated by parenthesis, such as (43)2(46.66.83). Though it can be applied to any net, the Schläfli notation is still limited in that two different geometric nets can still have the same symbol. In addition, it can be very difficult to convert from a complicated Schläfli symbol to a corresponding topology. Because of the disconnect between the symbols and a spacial description, many nets are simply named in analogy to well-known topologies.

Schläfli symbols also appropriately describe discrete polyhedra and thus have relevance to SCCs in addition to extended networks. In fact, the symbols originate in the realm of geometry rather than chemistry and took their name from Ludwig Schläfli, a mathematician who studied multidimensional geometry.47 When describing polygons, the notation indicates regular shapes as {n} where n is the number of edges. Regular polyhedra are represented by {p,q} where p is the number of sides of the polygons acting as faces and q is the number of faces meeting at each vertex. For example, {4} represents a square, whereas {4,3} represents a cube, which consists of vertices at which three squares meet. While used even less in the description of SCCs than for MOFs, Schläfli symbols are nonetheless intriguing in their ability to mathematically describe both infinite tessellations (i.e. extended networks) as well as discrete polytopes. It has long been known from a geometric standpoint that increasing the dimensionality of a vertex figure requires a change to the angle defect. That is, if the angles of a vertex do not sum to 360° or 180°, the figure folds around itself to close around itself. This is exactly what occurs when moving from an infinite square lattice (2D) to a cube (3D). Chemists forming MOFs and SCCs exploit this by designing ligands and metal nodes with specific angularity, oftentimes without realizing the relevance to multidimensional geometry. It remains to be seen whether the mathematical tools utilized in exploring polytopes, such as Schläfli symbols, will be useful in the design of new MOMs.

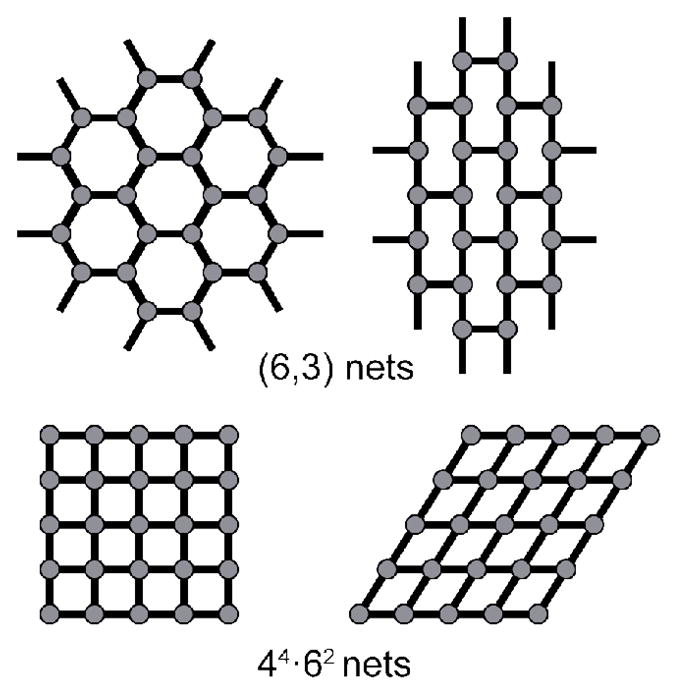

It is important to note that the classification of a network concerns only topology. The methods described above are naming tools to sort existing frameworks into common groups. As a topological description, two very different geometric arrays will sometimes share a net type and a single array can be described multiple ways, depending on how one defines the nodes and spacers (Figure 8).35 A honeycomb lattice contains the same shortest circuits as an array containing offset rectangular loops. It may be useful to recall that topology is the study of properties that are preserved upon deformation of a system. Deformation of a net does not affect the connectivity of the nodes, nor the number of components in the shortest circuits. For example, compressing the nodes in a hexagonal grid so that offset rectangular loops are formed does not result in any topological change and such nets thus share the same name (see the (6,3) nets in Figure 8). Likewise, shearing a square lattice into one containing repeating rhomboids does not change the topological description despite the obvious geometric differences in these nets (Figure 8). This is, of course, problematic when used as a synthetic tool. Since the properties and potential applications of a material are intimately linked to its size and shape, especially for supramolecular applications which so often rely on host/guest phenomena, topology is too general to guide complex designs. While the connectivity of a node is undoubtedly important, rational design strategies emerge only when considering other fundamental parameters of a MOM. From a synthetic standpoint it is advantageous to consider organic ligands as complete building blocks which need not be linear or ditopic. Metal clusters can be represented as single nodes with specific connectivities, rather than considering each metal ion as an independent node. The size of the ligands and clusters cannot be ignored, nor can the angularity and coordination geometries of these species.

Figure 8.

Net descriptions are based on topology and can result in distinct arrays sharing a common name.

2.2 Directional Bonding and Reticular MOFs

While the net approach was used to classify inorganic structures, it was not until the 1990s that its node-and-spacer foundations would be used to develop synthetic methodologies to construct discrete and infinite self-assemblies. The realization that the concept of nodes and spacers could be exploited not for the description of structures, but for the rational design of new constructs, would later grow into a suite of methodologies and a myriad of novel SCCs and MOFs.

The early 1990s reports of molecular squares by Stang and Fujita using Pt and Pd, respectively, using 4,4′-bipyridine as linear donors to link four metal centers were the start of a design methodology based on distilling a target construct to rigid molecular precursors encoded with the proper directionality.15–16 Using Well’s description, these squares are classified as 0-periodic nets, as phosphine or amine “caps” enforce discrete, closed constructs. Over the next decades, Stang used these early squares as motivation for what would become known as the “directional bonding” approach to self-assembly.17a

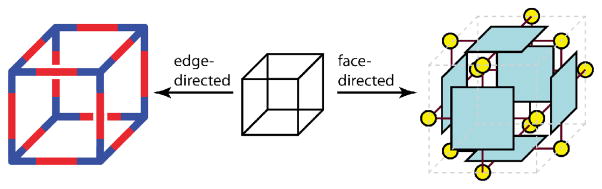

Beginning with 2D architectures, this emerging methodology was used to construct macrocycles in the shape of selected polygons by rationally designing organic ligands and metal-containing precursors to occupy the edges and vertices of the target shape. As such, this design approach is sometimes referred to as “edge-directed self-assembly,” in contrast to “face-directed self-assembly” which uses molecular precursors as panels to occupy the faces of a given 3D shape. Regular convex polygons were logical early targets for edge-directed self-assembly since satisfying the geometric requirements was possible by employing traditional organic and organometallic syntheses. To refresh, a regular convex polygon requires identical internal angles of less than 180° and sides of uniform length. By breaking such a polygon along its edges, each component consists of a fragment with no higher than a two-fold symmetry axis (see Figure 9).12,17a The internal angles found in these shapes are serendipitously found in simple molecules and were employed by Stang and others to generate a suite of polygons. Fused aromatics and benzene ring substitutions are especially useful, as are ethynyl groups to provide additional spacing and a site for organometallic carbon-metal bond formation.

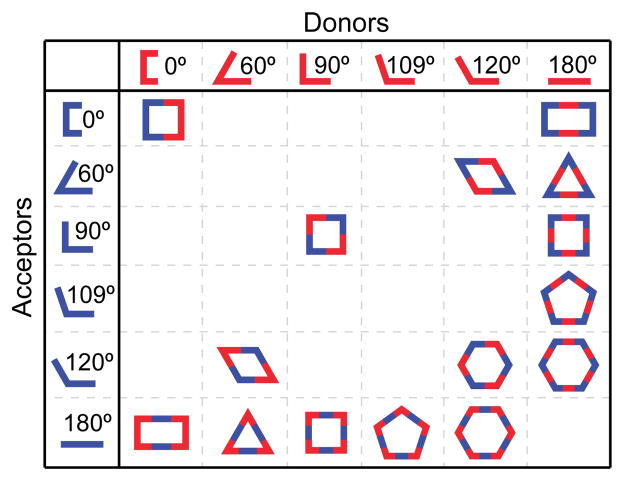

Figure 9.

Ditopic building blocks generate a suite of 2D convex polygons via self-assembly.

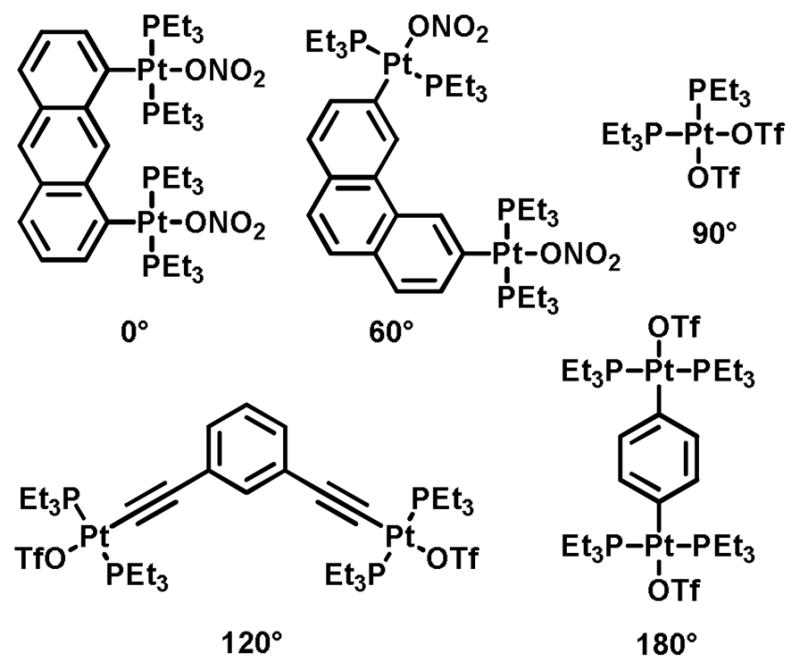

Examples from the molecular library of directional bonding components populated by Stang and others are shown in Figure 10. An angle of 0°, found in the so-called molecular clips, can be encoded by functionalization of the 1 and 8 position of anthracene.48 A 60° precursor is similarly exemplified by a dinuclear organoplatinum complex in which the anthracene is replaced by a 3,6-substituted phenanthrene.49 The iconic 90° acceptor used by the Stang group is a cis-capped mononuclear Pt complex found in a number of SCCs similar to the use of diamine-capped Pd precursors popularized by Fujita.12 Angles of 120° are readily encoded by meta substitution of a benzene ring.24b Lastly, para substitution of a benzene ring provides a scaffold for dinuclear 180° acceptor.50 The current molecular library of rigid building blocks far exceeds the Pt-based examples shown here. Many of these angles are readily encoded using other functionalities, such as the 120° orientation enforced by sp2 carbonyl carbon atoms. Two-component SCCs are often referred to as an [m + n] self-assembly, wherein m and n denote the total number of acceptor and donor units in a single discrete ensemble.

Figure 10.

Metal-based molecular precursors possessing rigid directionality for coordination-driven self-assembly.

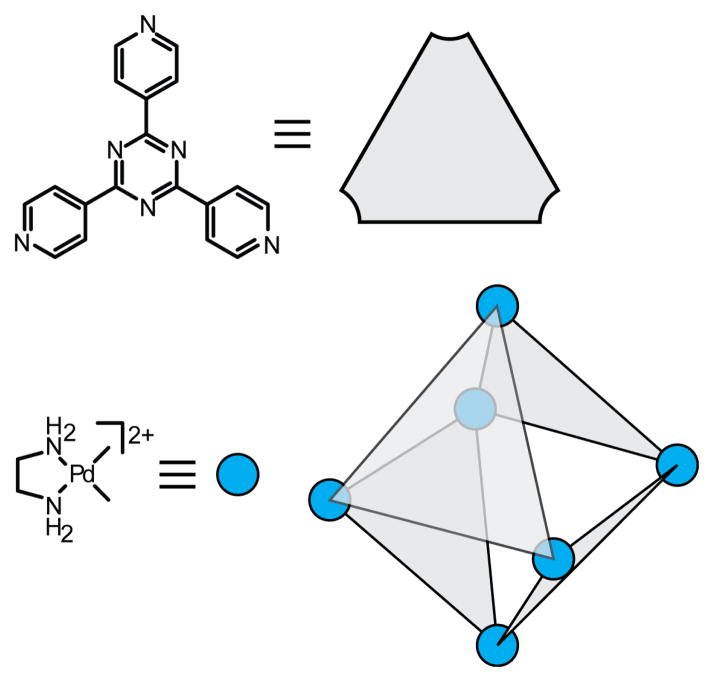

When a molecular component possesses a symmetry axis that is higher than two-fold, more complex geometries can be achieved. There are a few ways to encode this higher symmetry. The method most similar to that used to form the 2D polygons above is to simply increase the number of binding sites on a donor, the number of labile coordination sites on a metal, or the number of metals in an organometallic acceptor. When tritopic building blocks are combined with simpler ditopic precursors, the species formed are 3D metallacages (Figure 11).12,17a There are a few notable points illustrated by this expansion from 2D to 3D systems. The first is that the ditopic subunits may be chemically identical in both cases. The same molecules developed to make 2D assemblies are readily adapted to 3D ensembles when paired with a different donor or acceptor. A second point to note is that the specific identity of the acceptor and donor is not important. If the precursor is designed such that metal ligand bond formation can occur, the identity of the organic fragment and metal-containing fragment can be exchanged, provided that the necessary angles are preserved. That is, for a given [n + m] two-component assembly, suitable precursors can often be synthesized such that an [m + n] assembly will generate a geometrically similar ensemble. A hexagon can thus be assembled from the [6 + 6] combination of a linear, ditopic organic donor and a dinuclear metal acceptor with 120° between metal sites or from the combination of a linear metal acceptor with a ditopic, 120° ligand. This versatility allows for a variety of unique chemical compositions for a single structure type. However, synthetic feasibility often guides the identity of one component over another. For example, 90° angles are readily available from square planar metal coordination geometries but are substantially rarer for organic-only molecules.

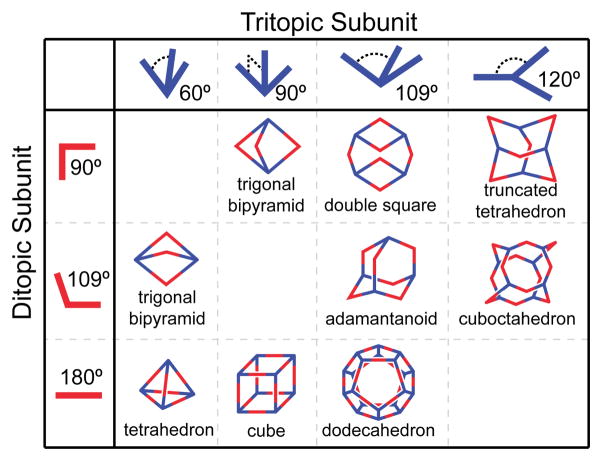

Figure 11.

The combination of ditopic and tritopic building blocks results in 3D polygons.

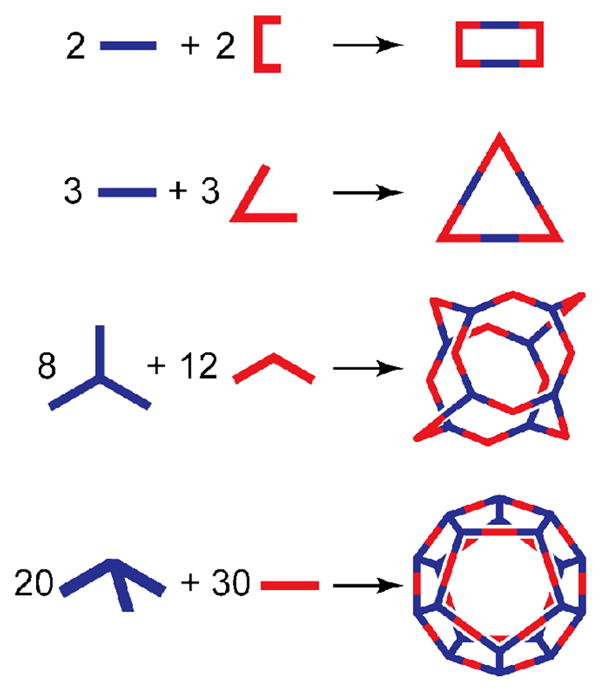

The versatility of directional-bonding becomes apparent when considering that the same strategy used by Stang and coworkers to construct [2 + 2] rectangles48 and [3 + 3] triangles49 comprised of four and six total building blocks has been used to design [8 + 12] cuboctahedra of twenty individual units28a and [20 + 30] self-assembled dodecahedra consisting of fifty total precursors.29b Once properly encoded ligands and metal acceptors are in hand, there is fundamentally little difference between these self-assembly reactions (Figure 12). In theory, the two components are simply mixed under suitable reaction conditions and the thermodynamics of the system delivers the desired closed structure.

Figure 12.

The versatility of the directional bonding approach to SCC formation allows the same methodology used to make simple rectangles and triangles to be applied to far more complex structures, such as a cuboctahedron or dodecahedron.

A noteworthy consideration for edge-directed self-assembly which has implications for SCC versus MOF chemistry is the relationship of the angularity of the two components. In order to generate a closed structure, either one or both components must have a bite angle of less than 180 degrees. One way to visualize this is to consider 3D Cartesian coordinate axes (Figure 13). Each Lewis-basic site of a polytopic ligand or coordination site of a metal can be used to orient a coordination vector. That is, the vector collinear with a metal-ligand bond involving that site. If the bisector of these vectors is placed at the origin, it is easy to predict which combinations of ligands will give closed structures by considering which octants the coordination vectors occupy. If their highest symmetry axes are placed along the positive x-axis, one or both of the building blocks must have coordination vectors which extend only into the four octants with positive x-values (octants i, ii, iii, and iv in Figure 13). If the bite angle is exactly 180 degrees such that the building block is planar, the only way for a convergent structure to be realized is for the other component to have an angle of less than 180°. This may appear to be a needless analysis for the simple polygons shown in Figure 9, but it illustrates why capping ligands are oftentimes used for metal centers which can extend coordination vectors into a variety of directions. Ditopic building blocks contain either two Lewis basic sites or two subsitutionally labile ligands on a metal. Such molecules never have a symmetry axis greater than two-fold, and thus either are planar, or have bite angles of less than 180 degrees. Most transition metal coordination spheres have more than two ligands, introducing higher order symmetry axes. This can be problematic when trying to generate closed structures, since extension into all eight octants is not conducive to closed structures. The archetypal Pt(II) and Pd(II) ions used in coordination-driven self-assembly of SCCs adopt square planar geometries. By capping specific sites, a level of control is afforded since the number of coordination vectors is reduced and the relative angularity of these vectors is controlled. An octahedral geometry which extends vectors in all three dimensions is harder to force into convergent structures. As such, octahedral building blocks are more commonly found in MOFs. That said, it is possible to confine the coordination vectors of an octahedron to the positive x octants. A fac-capped octahedral metal center has three coordination vectors oriented with 90 degree angularity, meaning closed structures are possible. Indeed, hexanuclear cubes have been synthesized by using a three-site capping ligand.

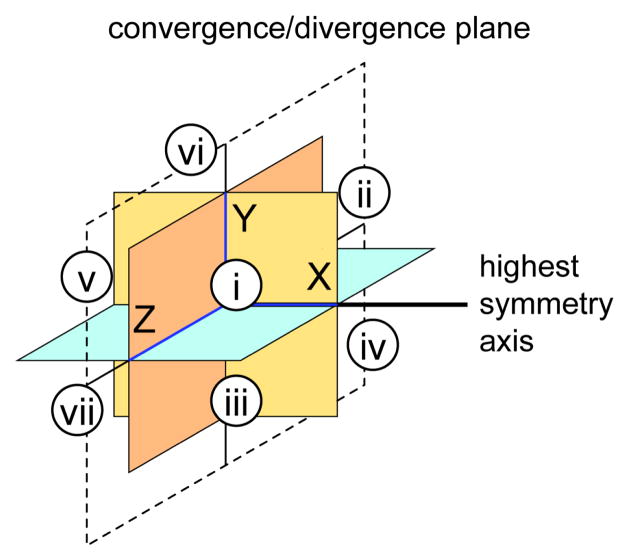

Figure 13.

A Cartesian axis defines octants (eighth octant is hidden) which can be useful for determining if a convergent (discrete SCC) or divergent (MOF) construct will be obtained for a two-component self-assembly of well-defined building blocks.

Using uncapped transition metals or metal clusters is more difficult from a design perspective, leading to an increasing in complexity when using planar coordination environments (trigonal and square), to tetrahedral and octahedral geometries which are inherently divergent due to the orientation of their coordination vectors. Since the planar geometries do not extend beyond the positive x octants, it is possible to form closed structures when a suitably angled ditopic building block is also used. This is the theory behind the formation of [8 + 12] cuboctahedra, first reported by Stang and coworkers.28a A planar, trinuclear organoplatinum precursor will assemble with a ditopic ligand to give a closed structure if the bite angle of the ligand is 108°. In practice, it is easier to synthesize a ligand based around a tetrahedral carbon center, and structural distortion easier accommodates the ~109.5° disposition of the coordination vectors. Interestingly, a tritopic planar tripyridyl donor will assemble with a dinuclear organoplatinum acceptor with a bite angle of 120 degrees. It was theorized that the large size of the assembly allowed for the necessary structural distortions to still furnish a closed cuboctahedron despite the non-ideal angle of the acceptor unit.

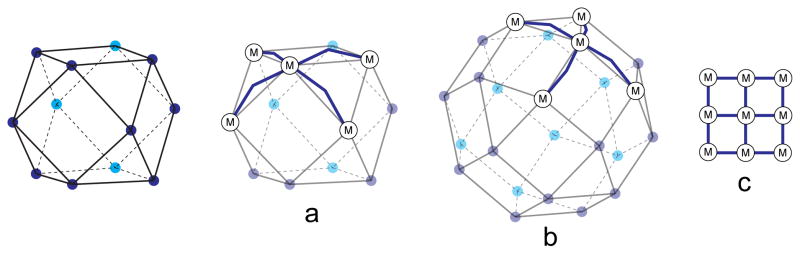

Elegant examples of uncapped square planar metal centers used for coordination-driven self-assembly of SCCs can be found in recent reports by Fujita and coworkers on the construction of a suite of “molecular spheres” based on homoleptic Pd-pyridine self-assembly. These impressive examples of edge-directed assembly draw upon the observation that MnL2n constructs are well suited for the construction of entropically favored regular and semi-regular polyhedra for finite values of n. Such species are designed so that the four-coordinate metal centers occupy the vertices of the structure with ditopic ligands occupying the edges (Figure 14). Four-coordinate metal centers with ditopic bridging ligands are special in that closed structures consisting of these two components will always utilize twice as many ligands as metal nodes. The smallest example occurs when n = 6, the easily recognized octahedron consisting of six vertices and twelve edges.26c The next value for which the number of edges is twice the number of vertices occurs when n = 12.51 This describes a cuboctahedron. The next largest assembly of this type is a M24L48 rhombicuboctahedron. Fujita and coworkers described this 72 component self-assembly by carefully tuning the angularity between the binding sites of a dipyridyl donor.52 Subsequent studies concerning these MnL2n complexes highlights the importance of the careful angular control required of directional bonding.53 When a furan-based dipyridyl donor was employed, a M12L24 cuboctahedral sphere was obtained. This ligand possess a bite angle (defined as the angle between the two coordination vectors of the pyridine groups) of 127°. When this angle was expanded to 149° by replacing the furan with a thiophene, the system shifted to favor M24L48 spheres. A systematic tuning of angles between 127° and 149° revealed that no intermediate structure was possible. Expansion of the ligand only eight degrees to a pyrrole-based 135° ligand resulted in exclusively M24L48 spheres.53

Figure 14.

Molecular spheres of general formula MnL2n may be formed for specific values of n by using homoleptic square planar metal nodes joined by ditopic ligands. The specific polyhedron formed is sensitive to the angularity encoded in the ligand: a cuboctahedron (a) has four-connected nodes, but the dihedral angle is ~125 degrees. Square planar metal nodes thus require angled ligands to close the structure. This angle is reduced for a rhombicuboctahedron (b). If this angle is flattened to 180 degrees, a closed structure is not possible and a square lattice is produced (c).

In the case of uncapped square planar geometries and ditopic ligands, as the ligand bite angle approaches 180 degrees, the ideal MnL2n closed structure becomes larger and larger (reducing the curvature of the sphere) until ultimately resulting in no curvature. An MnL2n material with zero curvature is readily recognizable as a 2D square lattice. Fujita and coworkers first reported such a material by replacing the Pd centers with Cd(II) ions and utilizing 4,4′-bpy as a linear, ditopic donor, as mentioned in Section 1.2. When the uncapped, square planar Cd(II) ions assembled with the dipyridyl donor in a 1:2 ratio, a repeating network of [Cd(4,4′-bpy)2]2+ was generated.37 Other examples of square MnL2n lattices are known with 4,4′-bpy,54 as well as larger diptopic pyridyl-based ligands.55

Other researchers have found creative ways to utilize uncapped metal centers to generate closed, discrete SCCs despite the divergent nature of naked metal ions. In all cases, the methodology is highly dependent on carefully understanding the directionality and angularity of the subunits.

The directional bonding approach developed to construct SCCs translates well into synthetic approaches for MOF formation, though there has been a divergence in terminology. One of the major design strategies which has fueled MOF synthesis since its development in the mid 1990s has been termed reticular synthesis by Yaghi and coworkers.56 Generally speaking, this term refers to the formation of periodic networks. The fundamentals are more or less identical to the directional bonding paradigm developed by Stang and coworkers, but with its own unique nomenclature and nuances.

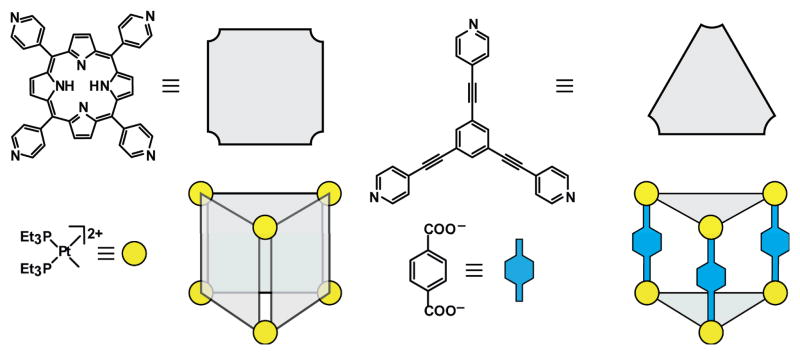

Ligands are categorized by their number and orientation of Lewis-basic sites and are combined with metal centers or clusters with well-defined geometries. These ligands and metal nodes can be combined to give predictable arrays via coordination-driven self-assembly. The term Secondary Building Unit (SBU) was borrowed from zeolite chemistry to refer to metal nodes and clusters used in an array and are analogous to the metal acceptors used in SCC formation. While oftentimes chemically distinct from the metallic building blocks used for SCCs, the various SBUs used in MOF formation are themselves an extension of the molecular library of the directional bonding approach. These SBUs are rigid, well-defined molecular entities which maintain their directionality through the self-assembly process.

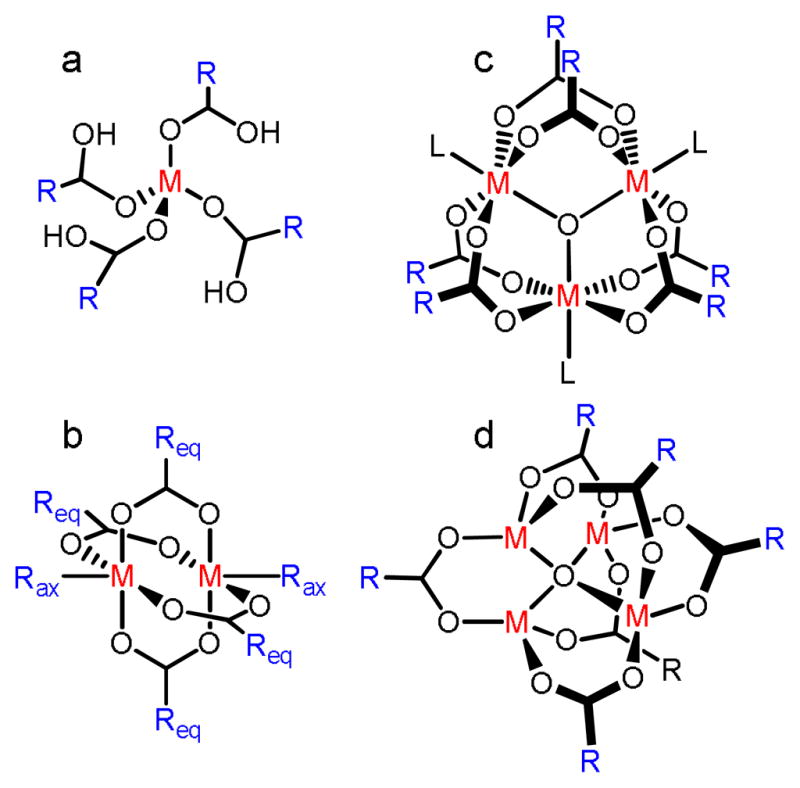

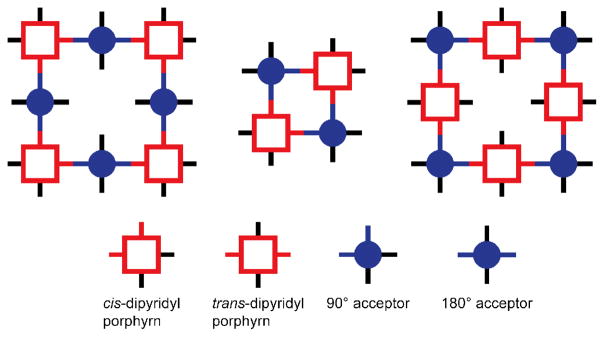

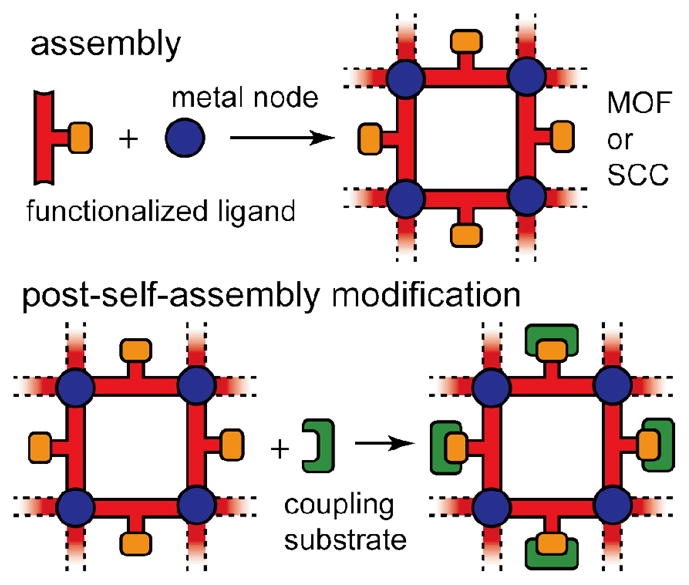

For a given ligand, it is easy to conceptually transition between SCCs and MOFs simply by replacing a “capped” metal-center iconic of SCC formation with its uncapped analogue. For example, a 90° cis-capped square planar metal center which is the basis for molecular squares will become a four-coordinate square node, resulting in a square grid. In practice, however, reticular MOF synthesis typically employs metal clusters rather than single metal ions (see Figure 15).57 As discussed above, naked metal ions are challenging to use in SCC synthesis since they have inherently divergent coordination vectors and for a given geometry, the orientation may differ from one site to the next. Certain SCCs circumvent this through the use of capping ligands which, in addition to preventing infinite array formation, add directionality. A cis-capped metal precursor will have two and only two sites for incoming ligands and these sites are oriented with a 90° angle. While a divergent coordination sphere is well suited for MOF formation, the lack of orientation associated with single metal-centers can lead to low-quality MOFs and higher instances of defect sites. In addition, the chelating ligands which are used in many clusters afford structural stability which is advantageous from an application standpoint in which permanent pores are sought. When multiple metal ions are arranged as a cluster, usually using carboxylate linkers, rigid well-defined metal SBUs can be accessed which avoid the geometric ambiguity of naked metal ions.

Figure 15.

Some common SBUs used in reticular MOF synthesis: a) a mononuclear tetrahedral center with four monodentate acetate ligands; b) a dinuclear paddlewheel center with four bridging acetates and two axial ligands; c) a trinuclear basic chromium acetate structure with six bridging acetates and three terminal ligands; d) a tetranuclear basic zinc acetate structure with six bridging acetate ligands

While SBUs based on metal-nodes can be described by the directional-bonding method of noting the number and orientation of their attachment sites, these building blocks are often formed in situ during MOF synthesis since the individual clusters are oftentimes not isolable. As such, the molecular library of isolable building blocks for MOF synthesis is populated predominantly by organic linkers and has substantial overlap with the building blocks of SCCs. The use of metal-based SBUs focuses more on elucidating the synthetic conditions and precursors needed to generate the metal clusters during the self-assembly process. Conditions are chosen such that the organic linkers act solely as ligands and maintain their structural integrity during the synthesis. It is important to note that the geometry of an SBU is determined by the carboxylate carbons of the organic ligands. Many inorganic and organometallic precursors for SCC formation possess substitutionally labile ligands which are displaced by organic donors. In MOF chemistry, the bridging ligands are an important structural part of the cluster. Using carboxylate clusters as an example, the carboxylate carbons are the points from which the MOF will extend.

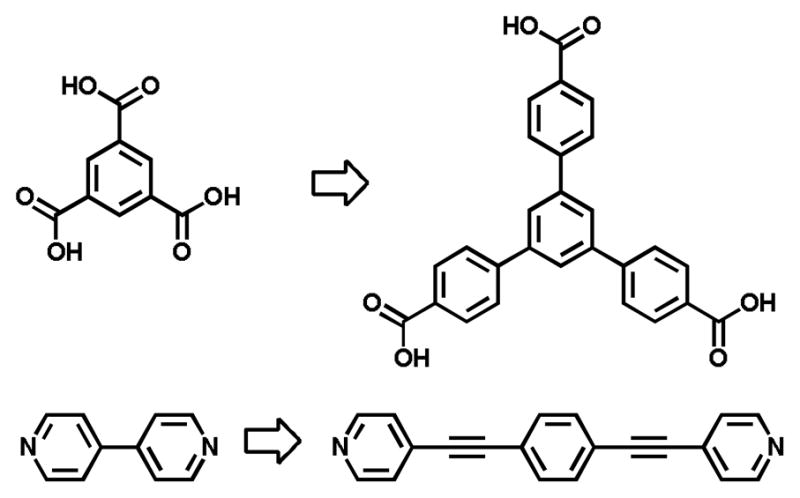

A common design feature of both reticular MOF synthesis and directional-bonding formation of SCCs is “expansion.” That is, for a given structure, increasing the distance between nodes can often be achieved simply by employing extended spacers.58 Most commonly this is done by adding phenyl or ethynyl groups, which rigidly and linearly increase the distance between Lewis basic sites of a polytopic ligand while maintaining the angularity between sites (Figure 17). A series of reticular MOFs which have the same topology is most easily formed simply by expanding a ligand for use with a particular SBU. Yaghi and coworkers grouped together sets of isoreticular MOFs (IRMOF), which share a net type, typically assigning each as IRMOF-n where n is simply a unique integer designator for members of the series.

Figure 17.

By adding rigid phenyl or ethynyl spacers, the pore size of MOFs and inner cavities of SCCs can be expanded without significant effects on the synthetic conditions used for self-assembly

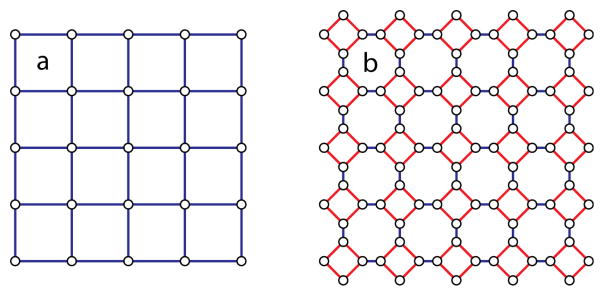

A further ramification of the use of clusters rather than single metal sites for MOF synthesis is the concept of decoration, which refers to the replacement of a vertex in a periodic net with a group of vertices.58 This is shown in Figure 18 wherein a square lattice comprised of four-connected nodes and linear spacers is expanded by replacing the nodes with square clusters. The Schläfli symbols of Figure 18(a) and Figure 18(b) are 44.62 and 4.82, respectively. While these are obviously very different nets in terms of topology, the reticular MOF approach takes advantage of the synthetic similarities between the two systems. If conditions to make a suitable square SBU in situ are known, the square precursors simply replace whatever mononuclear node was used previously. In this way, decoration allows for the rapid formation of many topologically different frameworks without having to completely reinvent synthetic routes. Whereas expansion is typically a ligand-centered modification, preserving the metallic SBU used across an isoreticular series, decoration allows one to use the same ligand while altering the SBU.

Figure 18.

Decoration of a net replaces a vertex with a group of vertices. The four-connected nodes of (a) are replaced by square clusters of four nodes in (b).

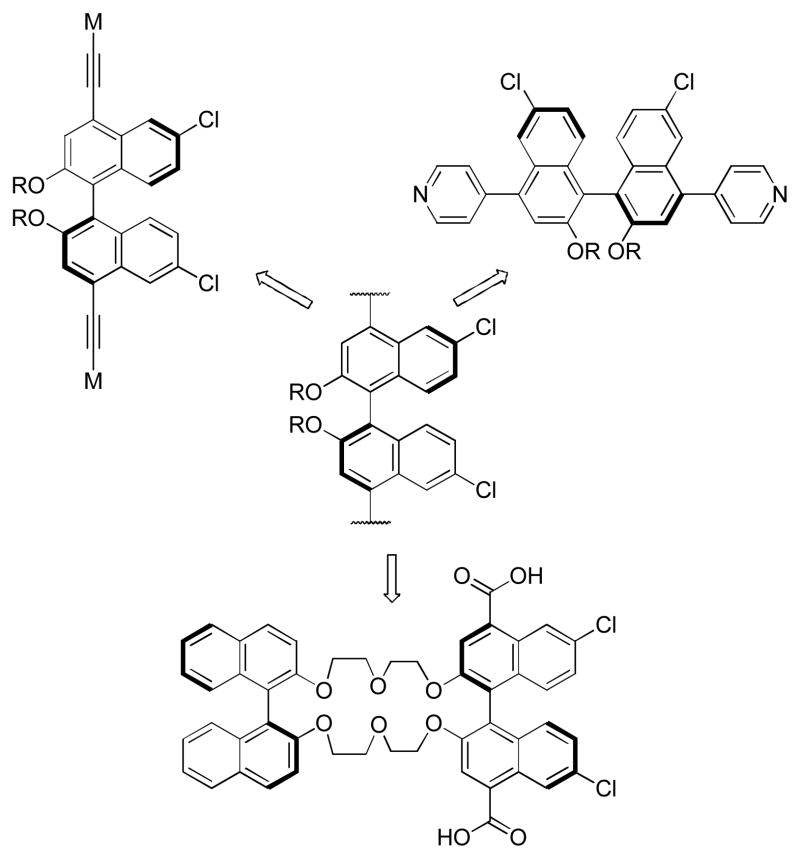

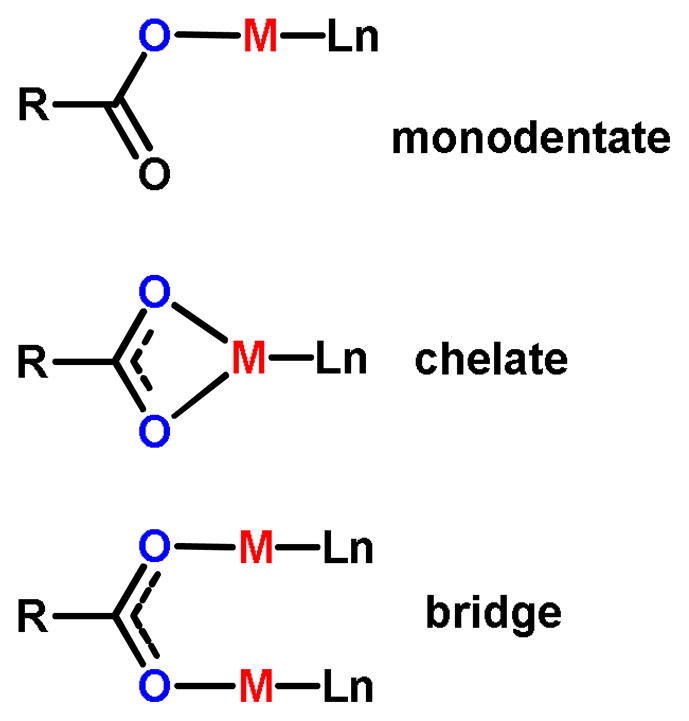

The decoration of a net need not be limited to replacing mononuclear sites with metal clusters. Metal clusters can themselves be replaced by larger and larger constructs, which has led to the use of SCCs as building blocks for MOFs, described as supramolecular building blocks (SBBs) by Zaworotko and coworkers in a critical review.59 This recent strategy for MOF formation typically uses metal-organic polyhedra (MOPs) which are well-suited to act as building blocks since they are modular, highly symmetric and compatible with the synthetic conditions used in MOF formation. MOPs are a subset of SCCs constructed using metal-nodes more commonly employed for MOF synthesis. A recent paper on SBBs coauthored by Zaworotko observes the overlap in building blocks between MOF and SCC chemistry.60 Yaghi and coworkers developed a series of MOPs after extensive experience with MOF chemistry, so it follows that studies of such materials often employ the jargon of MOF chemistry. The synthetic approach to these materials follows the same systematic analysis of angularity and number of binding sites enumerated by Stang’s directional bonding strategy. As such, a molecular library of SBUs and linkers has been developed to generate a number of polyhedra.61

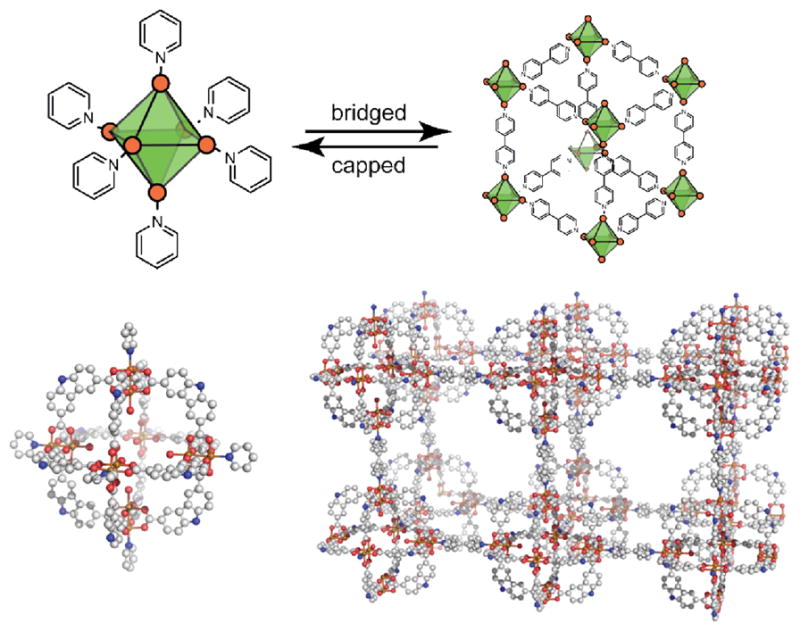

In some cases, discrete polyhedra can be isolated or incorporated into frameworks depending on synthetic conditions. For example, Eddaoudi and coworkers showed that the combination of Ni2+ ions and 4,5-imidazoledicarboxylic acid generates a M8L12 cube in an edge-directed assembly when a base such as dipiperdine is present to partially deprotonate the carboxylic acid.62a This base then occupies a structural role in the solid state, bridging the cubes through hydrogen bonding interactions. Xu and coworkers later carried out the self-assembly of the same ligand with Ni2+ in the presence of NaOH which led not to discrete cubes, but rather a framework of deprotonated cubes linked by sodium ions (Figure 19).62b

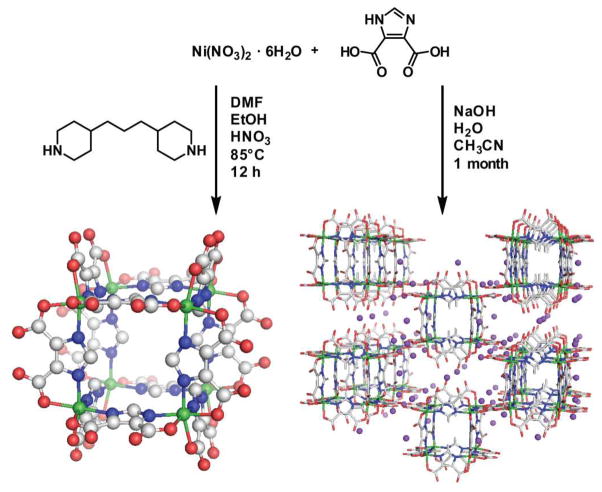

Figure 19.

Treatment of nickel nitrate with 4,5-Imidazoledicarboxylic acid generates cubic clusters. Depending on the reaction conditions, a discrete cube (left) or an extended cubic network bridged by sodium atoms (right) can be isolated.62

In other cases, discrete polyhedra are formed with terminal capping ligands. By replacing specific ligands with bridging analogues, extended networks comprised of the MOPs are generated. For instance, Fe-based polyhedra can be formed by capping three sites of Fe3O(CO2)6 clusters with sulfate groups to form triangular building blocks.63 The angularity of the remaining sites is suitable for the formation of closed structures, either truncated tetrahedra or truncated heterocubanes, when combined with linear ditopic or trigonal tritopic carboxylate ligands, respectively. The formation of these MOPs requires the presence of pyridine, which is incorporated into the Fe3O(RCO2)3(SO4)3(py)3 clusters (R = linking polyphenyl moiety). By replacing pyridine with cis-1,2-bis-4-pyridylethane in the assembly process, the resulting MOPs were linked into an extended framework dubbed MOF-500.64

While the MOF-500 formation was best achieved as a one-pot synthesis due to the insolubility of the MOP precursor, examples of stepwise interconversion between MOPs and MOFs are known. Zhou and coworkers described the synthesis of solvated [Cu2(CDC)2(DMA)(EtOH)]6 (CDC = 9H-carbazole-3,6-dicarboxylate; DMA = N,N-dimethylacetamide) which adopts a supramolecular octahedral geometry.65 This polyhedron possessed somewhat rare solubility in organic solvents which made it well suited as a precursor for further chemistry. When solutions of the octahedral-like MOP were treated with 4,4′-bipy, a twofold-interpenetrated framework was formed. In addition to being an interesting example of MOP to MOF conversion, the framework could be deconstructed back to discrete polyhedra when dissolved in DEF/py solvent mixtures (Figure 20).

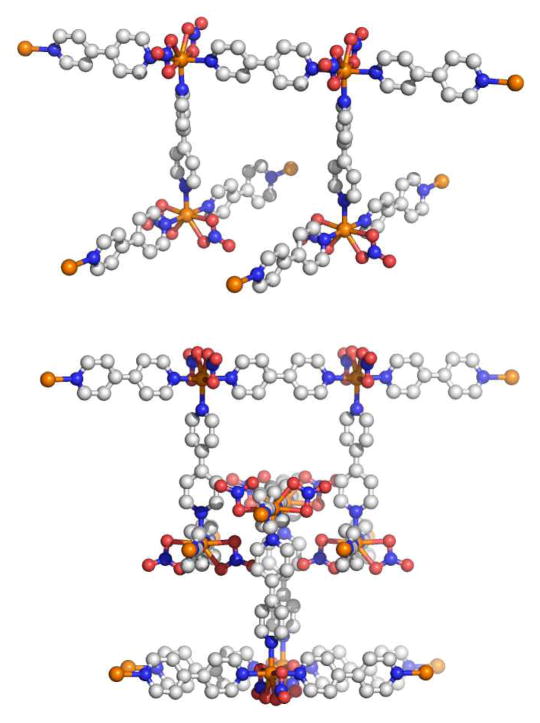

Figure 20.

Discrete octahedra containing capping ligands are closely related to cubic networks of bridged octahedral sites. In some cases, such SCCs can be used as precursors to generate MOFs when suitable conditions may be found to replace capping ligands with bridging ligands. Solvated paddlewheel complexes of the type [Cu2(CDC)2(DMA)(EtOH)]6 may be converted to a pyridine-capped analog (left) or a 4,4′-bipy bridged network (right, only one of the two interpenetrating networks shown).65

A versatile MOP SBB was reported by Zaworotko and coworkers based on anionic “nanoballs” of the formula [Cu2(BDC)2L2]12 (L = pyridine, substituted pyridine, MeOH).66 These rhombihexahedra have multiple sites of possible modification, either at the axial ligation sites of Cu, or on the BDC organic linkers. When sulfonated BDC was employed to the 24- charged [Cu2(5-SO3-bdc)2(4-methoxypyridine)0.50(MeOH)x(H2O)1.50-x]12 MOP, the sulfonate groups were nicely disposed to bind additional metal ions. Upon treatment with a Cu(II) source, a framework was generated comprised of nanoballs bridged by cross-linking [Cu(methoxypyridine)4]2+ ions. If methoxy-substituted BDC is used in lieu of the sulfonated form, a neutral rhombihexahedron is formed. The Lewis-basic methoxy sites form double cross links between nanoballs, resulting in 1D chains.67

These examples nicely illustrated the close relationship between SCCs and MOFs in that for certain groups of SCCs which utilized capped nodes, freeing these capped sites will generate extended frameworks. That is, if synthetic conditions can be found which generated closed, capped MOPs, an analogous synthesis of MOFs can sometimes involve simply replacing the capping reagent with a suitable bridging ligand.

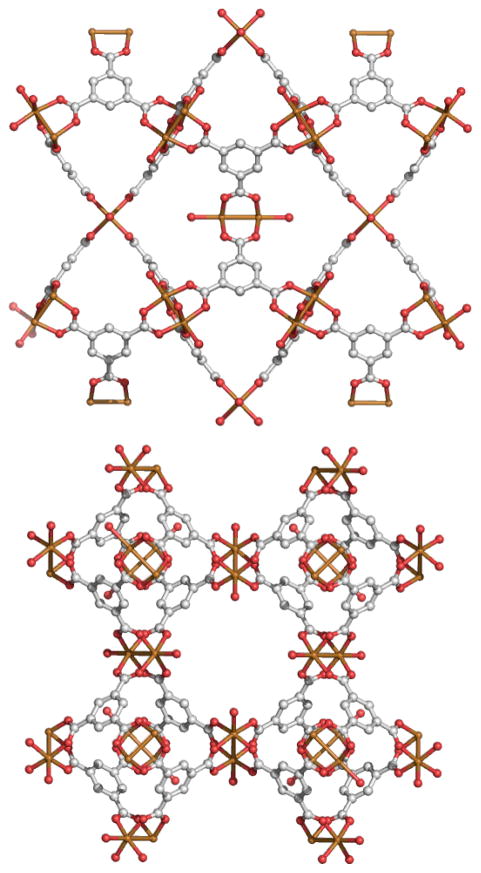

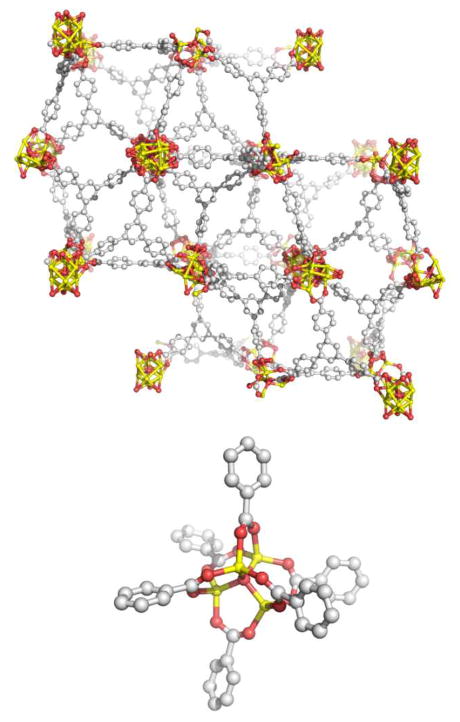

A second class of MOFs is comprised of MOP building blocks which share polyhedral faces, rather than having discrete linkers joining the polyhedra together. In 1999, Williams and coworkers reported the combination of copper nitrate with H3BTC in an aqueous ethanol solution.68 In order to avoid lower dimensionality frameworks previously observed when mild conditions were used,69 the mixture was heated to 180°C for 12 hours in a high-pressure vessel. This produced crystals of face-sharing rhombihexahedra dubbed HKUST-1 (Figure 21). Zawortko and coworkers observed that this type of fused structure does not utilize the MOP as a node and is therefore distinct from the concept of MOPs as SBBs. These fused faces and resulting extended frameworks are difficult to approach from a rational design standpoint and rationally-designed constructs of this type are relatively rare.

Figure 21.

Mixtures which gave low-dimensionality frameworks under mild reaction conditions generated fused Cu-based rhombihexahedra (HKUST-1) with solvothermal techniques. Atom (color): copper (copper), carbon (grey), oxygen (red). Hydrogen atoms omitted for clarity.68

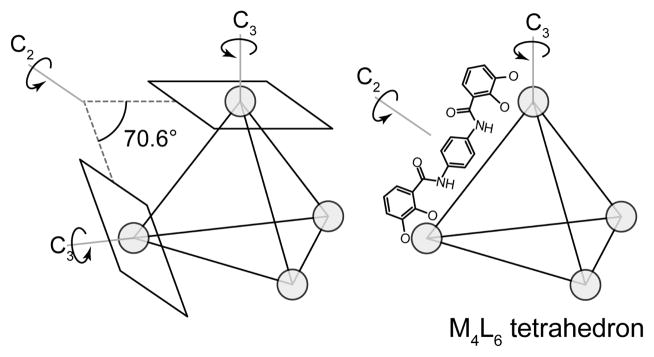

2.3 Symmetry-Interaction Self-Assembly

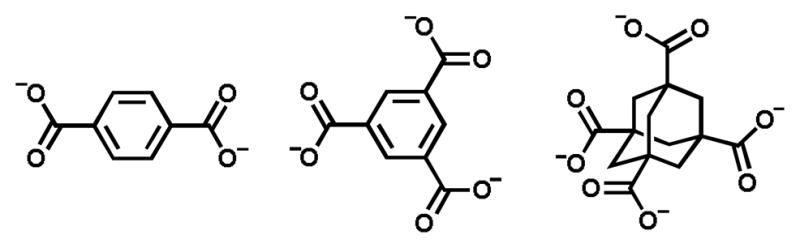

The symmetry interaction approach to forming SCCs oftentimes employs uncapped, tetrahedral metal centers as nodes. As such, very careful ligand design is necessary to ensure that single, discrete thermodynamic products can be favored over unwanted side-products. Due to the divergent nature of a tetrahedral coordination environment, combining tetrahedral centers with non-chelating ligands will not produce discrete, closed structures. Simple examples are diamond-like networks consisting of tetrahedral nodes and linear spacers which give repeating adamantanoid units. To favor discrete systems without using capping ligands, the spacers themselves must enforce structural convergence, achieved by carefully designing polytopic chelating ligands which occupy all available coordination sites of the metal nodes while still maintaining strict directionality.

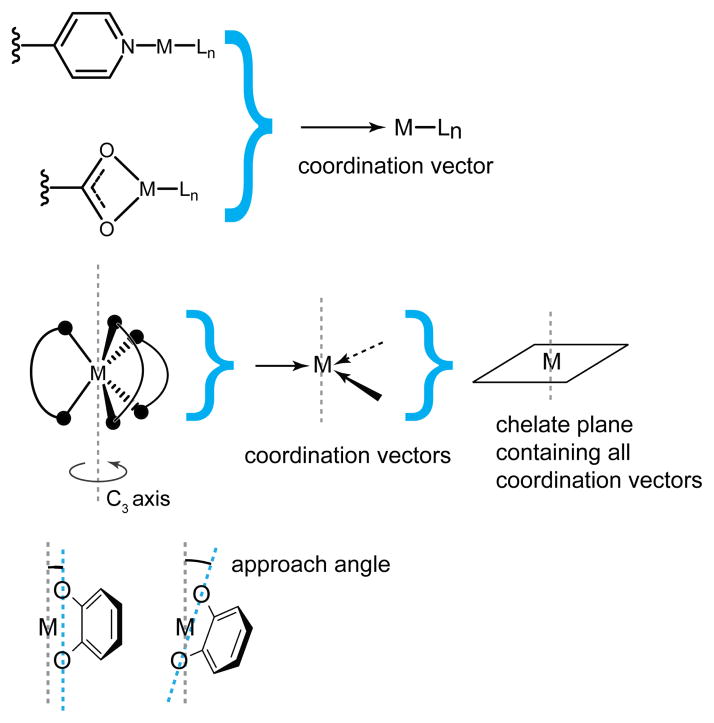

This methodology introduces and expands upon concepts from edge-directed self-assembly. The coordination vectors that were critical to defining the angularity and directionality of molecular building blocks remain an important parameter when designing ligands for symmetry-interaction self-assembly (see Figure 22). As was discussed previously, for monodentate ligands the coordination vector is simply the vector collinear with the M-L bond. For chelating ligands, it bisects the chelating atoms and is oriented towards the metal. When multiple chelating ligands are bound to a single metal center, the coordinate vectors define the chelate plane, which is the plane containing all of these vectors. A final parameter required for rational design using the symmetry interaction approach is the approach angle. This angle is found between the principle rotation axis of the metal center and the line defined by the two coordinating atoms of the chelating ligand.

Figure 22.

The symmetry interaction approach defines a coordination vector collinear to the metal-ligand bond of a monodentate ligand and bisecting the metal-ligand bonds of a chelate ligand. A collection of coplanar coordination vectors defines the chelate plane of a metal node. The angle between the highest order symmetry axis and the line defined by the chelate atoms is known as the approach angle.

As pioneers of this strategy, Raymond and coworkers have demonstrated the formation of triple helicates,70 triple mesocates,71 M4L6 clusters,72 M4L4 clusters73 and two-metal clusters.74 In each of these designs, a careful assessment of the required symmetries of metals and ligands guides the selection of building blocks. Rigid, polychelating ligands with predictable configurations of coordinate vectors are at the heart of this design strategy. While the metal centers are, of course, important, many structures feature homoleptic octahedral or tetrahedral geometries. Since many different metals can adopt these geometries, a particular structure can oftentimes be accessed using a suite of different metals.

To this point, the methodologies discussed have focused on edge-directed self-assembly. However, for 3D polyhedra and prisms, it is possible to design ligands to occupy the faces of a given shape, oriented by metal nodes at the vertices. Thus, a distinction may be made between edge-directed and face-directed self-assembly. Some species, such as supramolecular cubes, have been constructed using both approaches. An edge-directed cube assembles from eight tritopic building blocks with 90° angles between sites and twelve linear ditopic units. Alternatively, a face-directed cube may be constructed from six tetratopic panels held together by twelve 90° ditopic units, as shown in Figure 24.

Figure 24.

A supramolecular cube can be constructed from a linear ditopic and 90° tritopic building blocks using a edge-directed method (left) or from six tetratopic panels joined by twelve 90° ditopic building blocks using a face or panel-based approach (right).

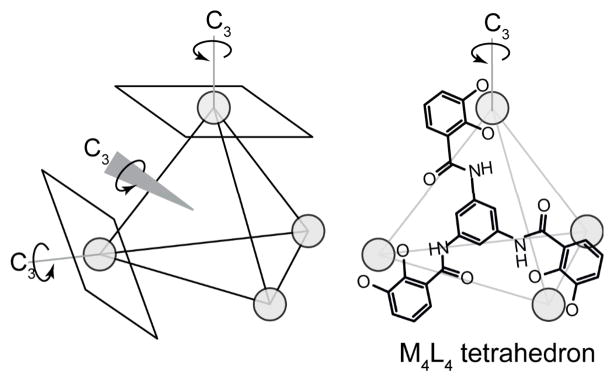

Symmetry-interaction self-assembly is well-suited for face-directed assembly with uncapped metal centers. A face-directed assembly requires that the ligands match the symmetry elements found affecting the faces of a desired geometry. The faces of a tetrahedron have 3-fold symmetry, which can be built into a tritopic ligand (Figure 25). This route yields M4L4 tetrahedra. The orientation of the coordination vectors must be maintained since the metal nodes are identical between M4L4 and M4L6 tetrahedra. The same octahedral tris-chelate metal centers are used in both designs, which is one advantage of this approach over traditional directional bonding. Since almost all structural information is encoded in the ligand, a single metal center may be used for a variety of structures and swapping out the metal for a different element does not require new syntheses. In contrast, the conditions used to cap a square planar or octahedral metal center may not work for a different metal ion.

Figure 25.

A M4L4 face-directed tetrahedron can be constructed from four ligands reflecting the facial symmetry of the four triangular panels with the proper orientation between coordination vectors.

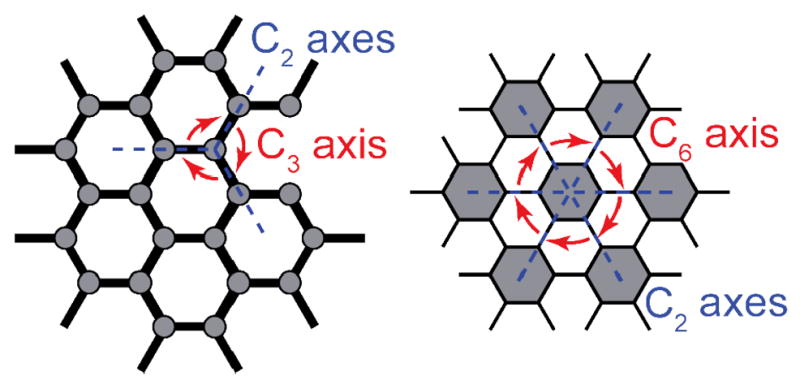

The geometry of a carboxylate cluster SBU for MOF synthesis is not determined by the coordination environment of the metal, but rather by the carboxylate carbons which are the points where the node is extended. This geometric analysis is also applicable to the SCC structures formed by the symmetry-interaction approach. Returning to the Cartesian octant analysis of two-component assembly, it is readily apparent that a tetrahedral metal ion extends coordination sites on both sides of the convergence/divergence plane described in Figure 13. However, the points of extension of a symmetry-interaction self-assembly are not the metal ions, but rather the metal-ligand fragments. That is, the determination of the space group and the highest rotation axis must be determined for the resulting coordination sphere. This makes it somewhat harder to apply the symmetry interaction approach to extended networks. This is related to the relatively small number of MOF structure types compared to the theoretical possibilities. Certain SBUs orient a specific number of points of extension into space and these common fragments (see Figure 15) end up being shared among most MOFs. The clusters that have delivered stable, robust frameworks are naturally favored by chemists such that they dominate the known materials. That said, an analysis of the symmetry of a given framework will provide guidelines for the symmetry elements required of the bridging ligands. For instance, one type of honeycomb lattice has nodes with D3h symmetry so the construction of such a MOF requires SBUs with the associated symmetry elements. The C2 axes dictate that linear ditopic links must join these D3h SBUs. Alternatively, a hexatopic fragment with D6h symmetry will also fulfill the symmetry of a similar looking lattice. In this case, the D6h SBUs would again require linear ditopic spacers to maintain the mirror plane and C2 axes, while it fulfilled the requirements for C6 axes at the center of each node (Figure 26). Similar analyses can of course be made on 3D lattices; all symmetry elements of a given lattice must logically manifest themselves in the building blocks used. While the use of the symmetry interaction method has not yet been exploited by MOF chemists, it is nonetheless a potential tool, and in some cases is used without realization. A diamondoid network necessarily contains adamantane-like units. The network of Robson and coworkers36 which has been previously discussed in terms of tetrahedral metal centers and tetratopic, tetrahedral-based ligands is easily broken down to its symmetry elements. Each adamantanoid has Td symmetry and thus building blocks used to construct diamondoid must reflect this. That is, they must have C3, C2, S4 and σd elements in accordance with the Td space group. A quick analysis of the Cu and organic fragments used in the aforementioned example confirms this to be the case.

Figure 26.

The symmetry interaction approach can be applied to extended networks. In this case, the symmetry elements of the entire lattice must appear as local symmetry elements of the building blocks.

2.4 Face-Directed Self-Assembly: Molecular Paneling

Briefly introduced in Section 2.3, face-directed assembly is a subset of directional bonding that deconstructs 3D architectures to their faces rather than edges. This technique has been used to construct a wide range of structures, from relatively small prisms and truncated tetrahedra to the significantly larger cuboctahedra.

It is not always necessary to occupy all the faces of a given polyhedron with panels. For example, rather than constructing all eight faces of an octahedron, trigonal panels can be joined by 90° metal centers to cover alternating faces, as shown in Figure 27. Since the alternating faces destroy the C4 rotational axis of symmetry, the resulting structure is a truncated tetrahedron with Td symmetry. The organic ligands that comprise the faces of these cages oftentimes do not occupy the full space implied by their representation as panels. While this gives rise to opening in the cages, such constructs are often well-suited for host/guest chemistry, even in the case of a truncated tetrahedron with alternating trigonal faces.

Figure 27.

Polytopic organic linkers can be represented as panels for the construction of 3D SCCs, such as truncated tetrahedra

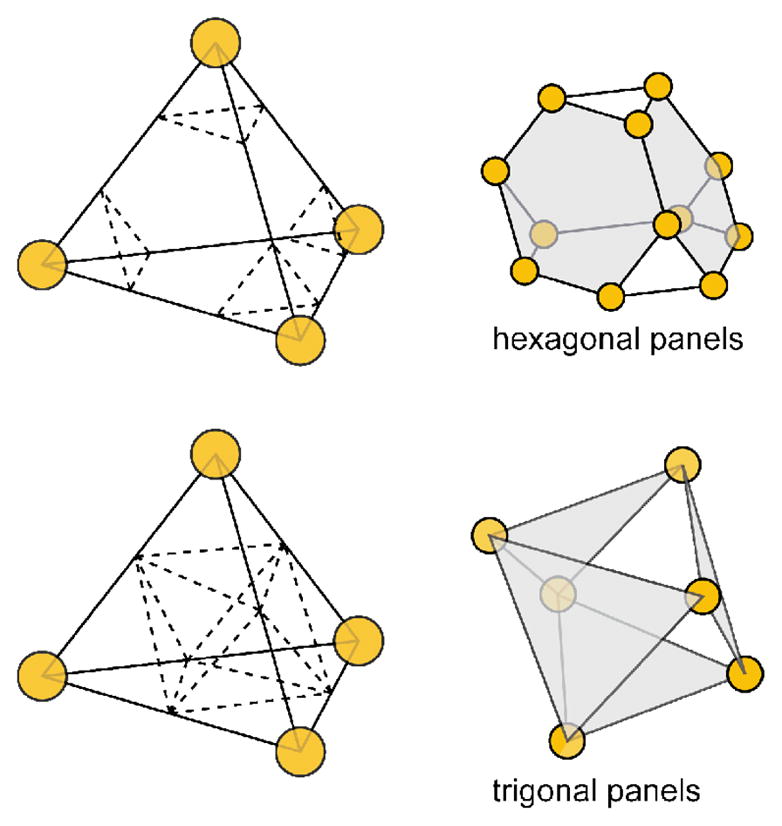

Truncated polyhedra are excellent examples of applying the reticular MOF concept of decoration to SCCs. A special case of decoration is the replacement of an n-connected node with a group of n nodes, a process which is known as augmentation. A tetrahedron contains four vertices which are most simply represented as three-connected nodes. If each of these three vertices are replaced by three new nodes, an augmented structure results. In the case of a tetrahedron, augmentation delivers a truncated tetrahedron, converting the structure from a Platonic solid to an Archimedean solid (see Figure 28). A truncated tetrahedron is an eight-sided solid with four hexagonal faces and four triangular faces. From a synthetic standpoint, only the hexagonal faces share edges, making them the logical choice for panels to be joined by two-connected nodes. If the depth of the truncation is large enough such that the new vertices overlap, the resulting solid is octahedral with eight trigonal faces. However, if the faces corresponding to the previously hexagonal sites are occupied with the remaining trigonal faces still open the symmetry of the solid remains Td. This augmentation may also be applied to octahedra to generate truncated octahedra. Unlike the tetrahedral case, however, when the depth of the augmentation is such that the new nodes overlap, an entirely new solid results, known as a cuboctahedron.

Figure 28.

Depending on the depth of the cuts, truncated tetrahedra contain hexagonal (top) or trigonal (bottom) faces. Note that if all faces of the bottom truncated tetrahedron are occupied, the structure is an octahedron.

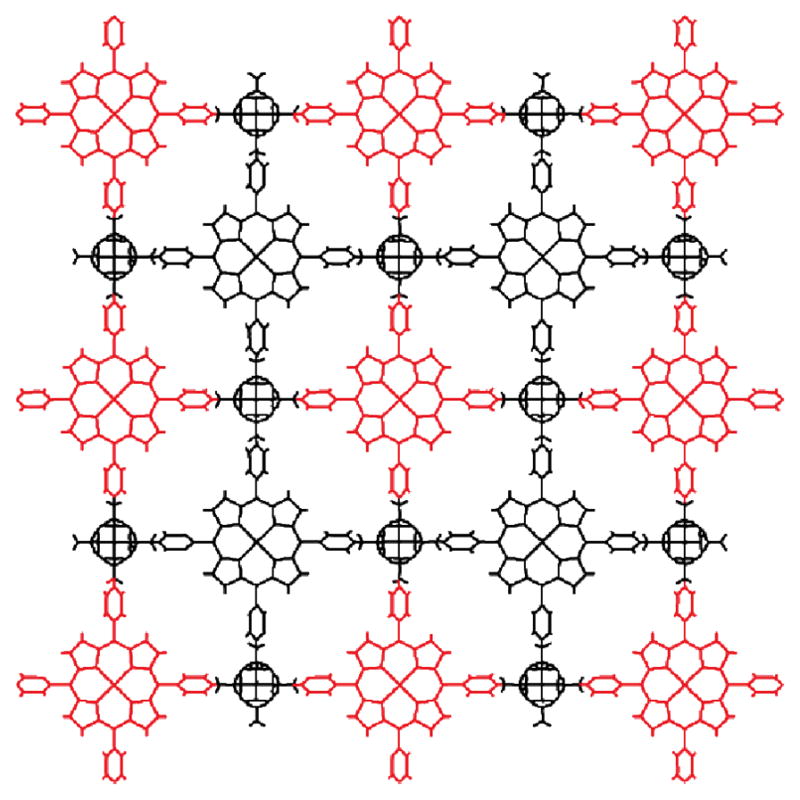

Aside from the Platonic and Archimedean solids, a number of prisms have also been formed which contain panels or faces in their design. As shown in Figure 29, a trigonal prism can be constructed either by combining three square panels with six ditopic donors or by using two triangular panels with ditopic nodes spanned by linear ligands acting as pillars. The former design requires a two-component self-assembly and delivers an open-faced prism. The latter requires a third building block for a multi-component self-assembly. It is important to note that the steric bulk surrounding the metal nodes can play a role in determining overall structure. If large phosphines are used, rather than assembling a trigonal prism, the angles between panels can be expanded to give other prismatic shapes. For instance, open hexagonal barrels are formed when tetrapyridyl porphyrin is combined with Pt(dppf)(OTf)2 (dppf=1,1′-bis(diphenylphosphino)ferrocene).75 Multicomponent self-assembly is a relatively new technique for the formation of SCCs and as demonstrated by Fujita76 and Mukherjee,77 such structures can require a fourth species to act as a template for prism formation.78 Despite the need for a template in some syntheses, template-free prism formation can occur, as demonstrated by Stang79 and Mukherjee.77,80 Multicomponent self-assembly is especially appealing since structures of higher complexity, if controllable, are promising for a variety of applications. This topic is the focus of a recent tutorial review by Ward and Raithby in which supramolecular assemblies are used to illustrate current design methods for multicomponent structures, potential applications are highlighted, and future directions are proposed.81

Figure 29.

The panel approach to forming SCCs provides a logical route to two types of trigonal prisms. One using a two-component assembly with a square or rectangular panel, the other a three component using a triangular panel and linear pillars.

2.5 Weak-Link Approach

The design principles discussed thus far focused on obtaining singular, thermodynamic products by the careful selection of building blocks. The weak-link approach, as developed by Mirkin and coworkers, utilizes hemilabile ligands such that the initial SCCs formed can undergo post-self-assembly modifications to access new structures.20b The majority of SCCs made using this approach are 2D macrocycles containing asymmetric chelating ligands in which one donor atom of the chelate forms a stronger M-L bond than the other. The moniker stems from the displacement of this weaker donor, rendering the bis-chelator into a bis-monodentate bridging ligand upon addition of a suitable exogenous ligand. As the chelating coordination mode is broken, the macrocycle expands and the metal centers incorporate new ancillary ligands en route to the formation of a new thermodynamic product.

Upon expansion, the resulting macrocycle is typically conformationally flexible, owing to the once-chelating ligand sites which are necessarily non-rigid. The conversion from a condensed to expanded structure has been shown to trigger catalytic activity and useful applications in sensing.

It is important to note that the initial condensed structure is not always the thermodynamically favored product in the primary self-assembly reaction. By carefully selecting reaction conditions the kinetic condensed structure can be isolated preferentially. Treatment of this SCC with an additional ligand alters the system such that the expanded structure is now the favored product (Figure 30). The demonstration of post-self-assembly modifications of the ligand sphere of a metal node has since been applied to SCCs formed using directional bonding in the conversion of 2D and 3D constructs to entirely new topologies. At elevated temperatures, the condensed structure can be driven to the thermodynamic monomer species, however in practice this requires temperatures of over 100°C and the stability of the kinetic product is thus high enough to circumvent the unwanted thermodynamic sink.82

Figure 30.

The weak-link approach generates condensed structures as kinetic products. These [2 + 2] macrocycles can convert to [1 + 1] monomeric species under thermodynamic control, or be expanded to open structures upon treatment with strong ligands.

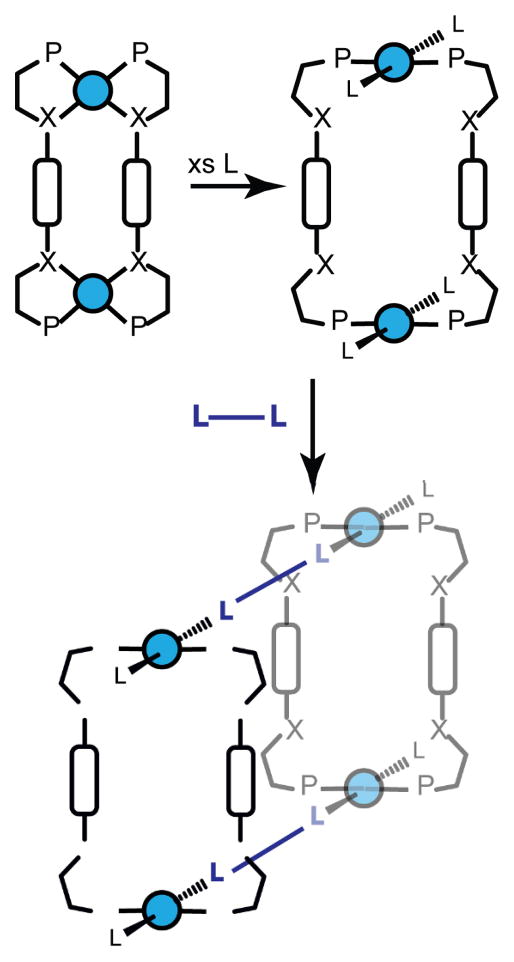

Since the ligands which initial the expansion from the condensed structure to the open structure can be multitopic, it is possible to use condensed structures as precursors to larger constructs and potentially networks (Figure 31). For example, Mirkin and coworkers describe the formation of a molecular cylinder by linking two open structures using either 4,4′-biphenyldicarbonitrile or 4,4′-biphenyldiisocyanide.83 The tetranuclear cylinders were examined by single crystal X-ray diffraction to confirm the tetranuclear structure comprised of two linked macrocycles capped by either CO or acetonitrile. Since each end of the cylinder could conceivably be uncapped and treated with further equivalents of bridging ligands, the weak-link approach could be used to generate extended MOF tubes.

Figure 31.

The weak-link approach can be used to extend 2D structures into 3D cylinders consisting of two macrocycles linked by ditopic ligands. In theory, the remaining monodentate ligands could be replaced by additional bridging ligands to give extended frameworks.

2.6 Dimetallic Building Block Self-Assembly

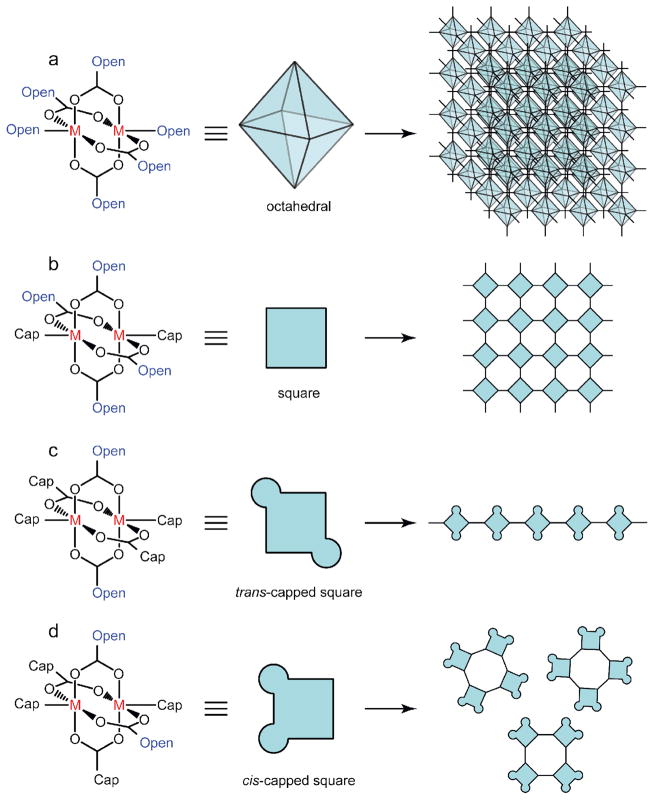

The dimetallic building block approach wonderfully illustrates the intimate relationship between MOFs and SCCs in that the paddlewheel metal units used to form SCCs are widely employed in MOF syntheses as well. Paddlewheel complexes are characterized as two metal centers bridged by four ligands. Depending on the metal centers used, direct metal-metal bonding can occur. The bridging ligands occupy equatorial coordination sites. If present, ligands that cap the remaining coordination sites which fall along the metal-metal axis are assigned as axial ligands.

The dinuclear paddlewheel building block is versatile in that individual units can be fused either by linkages between equatorial sites, linkages between axial sites, or both. As demonstrated most prolifically by Cotton and coworkers,21 a variety of different linking ligands can be used in controllable stoichiometries to furnish rhomboidal “loops,” triangles, squares and polygons. In most cases, a dinuclear precursor is utilized in which two or more equatorial sites are occupied by easily displaced acetonitrile ligands. The remaining equatorial sites are capped with bridging ligands, commonly N,N’-di(p-anisyl)formamidinate, which stabilize the dinuclear building blocks and prevent oligimerization.

Since there is synthetic control over which ligands occupy which site, there are a variety of different outcomes when using a dimetallic SBU. As shown in Figure 32, paddlewheel complexes can theoretically lead to 3D cubic grids, 2D square lattices, linear wires and supramolecular squares. When all sites are used, the building block can be represented by an octahedron. A square SBU results either from capping both axial sites, or capping two equatorial sites trans to one-another (the axial sites then complete two vertices of the square). A trans-capped square requires all sites to be capped save for two trans equatorial sites or by capping all equatorial sites and instead using the axial positions. Alternatively, all equatorial sites can be capped and the dinuclear sites linked through the axial positions instead. Lastly, a cis-capped square can be made either by capping all but two cis-oriented equatorial sites or by capping all but one equatorial and one axial site. In practice, such species usually use two cis equatorial sites.

Figure 32.

Paddlewheel dimetallic building blocks can be used to make 3D MOFs (a), 2D MOFs (b), 1D wires (c) or supramolecular squares (d) depending on how the six sites of the equatorial and axial ligands are used: either as bridges to neighboring dinuclear sites or as caps to prevent propagation along that vector. Note that capped squares can be achieved by alternate capping methods, as discussed in the text.

Dinuclear building blocks were described previously in the system described by Zhou and coworkers which can convert between discrete octahedra and a bridged cubic network. This conversion was possible due to the versatility of the dinuclear building block. By extending all four equatorial sites using a ligand with a 90 degree turn, the discrete octahedron was formed. In this case, one axial site from each of the six dinuclear centers was oriented inward, with the remaining axial sites capped by pyridine. By extending not only from the equatorial sites, but also from the axial positions, the octahedra were linked into a MOF.65

The first chelate-carboxylate SCC, dubbed MOP-1 contains dinuclear paddlewheel building blocks, specifically copper ions bridged by meta-BDC.66c While similar in composition to MOFs (hence the MOP moniker), MOP-1 is readily soluble in refluxing DMF which allowed traditional recystallization methods and afforded single crystals suitable for X-ray diffraction studies. Since the vast majority of SCCs to this point utilized pyridyl-based ligands, the discovery that chelating carboxylate ligands could be used to form discrete structures set the state for a myriad of SCCs sharing carboxylate-based chelating ligands and SBUs more traditionally found in MOF synthesis.

2.7 Alternative MOMs

Strictly speaking, the various design methodologies described above for forming both SCCs and MOFs are all based on directional bonding first proposed and described by Stang and coworkers.84 The only way to rationally design a material comprised of nodes and spacers to possess a given topology is to enforce specific interactions between building blocks. However, the different approaches have led to different methodologies which oftentimes employ unique nomenclatures, ideally to distinguish between strategies but sometimes to distinguish between researchers. While this review focuses primarily on MOFs and SCCs, there are other coordination polymers that merit note:

Metal-Organic Zeolites (MOZs) are a subset of coordination polymers which are MOF-like in that they are microporous extended networks comprised of metal and organic building blocks. In fact, MOZs are perhaps best described as a subset of MOFs in which the building blocks are chosen to closely mimic the directionality and topology of existing zeolite materials. For example, the tetrahedral Si, Al, etc. sites of known zeolites can be replaced by common transition metals such as Zn, Co or Cu. Zeolites often contain Si-O-Si motifs which have an angle of 145 degrees. This angularity is also present in bridged M-Im-M imidazolate moieties. As such, a number of zoelitic imidazolate frameworks (ZIFs) have been developed with over eleven unique topologies. A pioneering example of such a material was reported in 2002 by You and coworkers with the synthesis of [Co5(im)10·2 MB] (im = imidazolate, MB = 3-methyl-1-butanol).85 Originally these MOFs were known as metal-azolate frameworks (MAFs) before the term ZIF was popularized in a paper by Yaghi and coworkers in 2006 in which twelve unique frameworks were synthesized and characterized.86 Nonetheless, the term MAF persists, especially in a recent review by Chen and coworkers which offers an excellent analysis of these frameworks.87 Recent work by Feng, Bu and coworkers has explored the use of trifunctional ligands such as BTC in the formation of zeolite-type MOFs.88 By breaking the paradigm of tetrahedral nodes and ditopic ligands, the library of potential ligands is greatly expanded which may prove promising in the discovery of new zeolite mimics.

A second class of MOF-like materials has been dubbed infinite coordination polymers (ICPs) by Mirkin and coworkers. ICPs are distinguished by an emphasis not only on the building blocks used, but also additional factors such as size dispersity and intramolecular interactions. ICPs encompass a range of materials, spanning between crystalline (MOF-like) and amorphous structure types. Since a goal of ICP chemistry is to arrest network formation to give controllable particle size, synthetic methods often rely on triggering precipitation of the material from a mixture of its building blocks. These building blocks have some overlap with traditional MOF and SCC chemistry, with Lewis binding sites oftentimes consisting of carboxylates, amines or N-heterocyclic donors. Unlike SCC and MOF chemistry which can employ diffraction techniques for characterization, ICPs rely heavily on microscopy due to their oftentimes amorphous nature. Unlike traditional nanoparticles which are constructed from simple elemental precursors, ICPs enjoy the tunability and modularity associated with MOF chemistry due to the similarity in building blocks. An informative tutorial review of ICPs has been written by Mirkin and coworkers and is an excellent resource on this emerging field.89

It is important to note that the use of metal nodes is attractive from a synthetic standpoint due to the ease of self-assembly afforded by metal-ligand coordination. These metal sites also can impart interesting functional characteristics if redox, photophysical or catalytically active metals are used. Of course, the very moniker metal-organic materials requires their presence in order to be an accurate description. That said, from a structural standpoint, if proper angles can be encoded into purely organic-based building blocks, metal sites are not required for the formation of extended frameworks. Such is the case in the covalent organic frameworks recently reviewed by Jiang and coworkers,90 which offers an interesting look at a related class of materials to which traditional MOF and SCC chemists may be underexposed.

3. Synthetic Conditions and Characterization

The conditions used for SCC and MOF synthesis are necessarily dictated by the chemical properties of the building blocks and final materials. Forming large, high-quality crystalline porous MOFs which are stable to solvent loss require robust metal-ligand bonds. Because labile bonds are detrimental to crystal integrity, MOFs are often inert at ambient conditions. Conversely, SCCs are often soluble constructs which are isolated like more traditional coordination compounds, either as powders or small crystals. If single crystals are desired, either for characterization or a specific application, these crystals need not be formed upon the initial synthesis. The solubility of SCCs allows standard methods of crystallization to be applied and if suitable quality is not obtained, the material can be recycled and used again. Thus, the major distinction is that MOF synthesis contains strong metal-ligand bonds throughout the entire material in the solid state, while SCCs are subject to the same relatively weak intramolecular interactions which are found in small molecule chemistry.

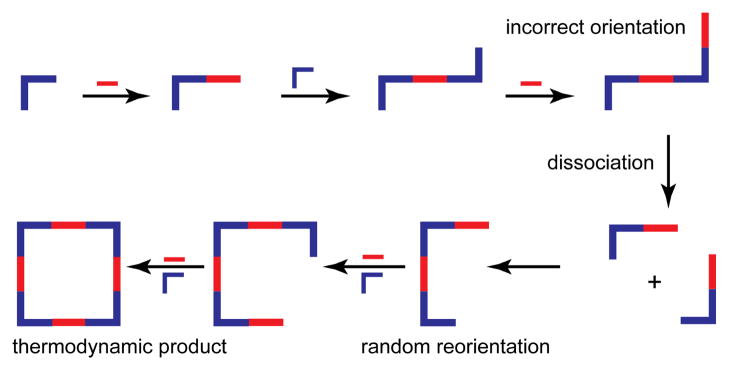

The synthesis of SCCs and MOFs typically target thermodynamic products. One major advantage of coordination-driven self-assembly is that metal-ligand bonds are oftentimes substitutionally labile. If a rigid ligand coordinates in an improper orientation such that a closed structure will not form, the ligand can dissociate. In a sense, SCCs and MOFs are self-healing during their assembly, automatically rectifying structural defects en route to a thermodynamic minimum (see Figure 33). Thus, a major characteristic of coordination-driven self-assembly, both for SCCs and MOFs, is kinetic reversibility. If kinetic products are inert or sluggish to self-correct the reaction time may become unfeasible and the product mixture may be plagued by impurities. One particular issue can be insoluble kinetic products. If an incomplete or incorrectly oriented fragment precipitates out of solution there is no way for ligand dissociations and substitutions to occur to remedy the defects. As such, synthetic conditions must be determined such that all kinetic intermediates are free to transform further.

Figure 33.

The self-assembly of a square may proceed through incorrectly oriented intermediate species. As these fragments associate and dissociate in solution, they will eventually funnel to the thermodynamically favored square, automatically healing any defects.