Abstract

A series of novel (E)-N-aryl-2-arylethenesulfonamides (6) were synthesized and evaluated for their anticancer activity. Some of the compounds in this series showed potent cytotoxicity against a wide spectrum of cancer cell-lines (IC50 values ranging from 5 to 10 nM) including all drug resistant cell-lines. Nude mice xenograft assays with compound (E)-N-(3-Amino-4-methoxyphenyl)-2-(2′,4′,6′-trimethoxyphenyl)ethenesulfonamide (6t) showed dramatic reduction in tumor size indicating their in vivo potential as anticancer agents. A preliminary drug development study with compound 6t is predicted to have increased blood-brain barrier permeability relative to many clinically used anti-mitotic agents. Mechanistic studies indicate that 6t and some other analogs disrupted microtubule formation, formation of mitotic spindles and arrest of cells in mitotic phase. Compound 6t inhibited purified tubulin polymerization in vitro and in vivo and circumvented drug resistance mediated by P-glycoprotein. Compound 6t specifically competed with colchicine binding to tubulin and with similar avidity as podophylltoxin indicating its binding site on tubulin.

INTRODUCTION

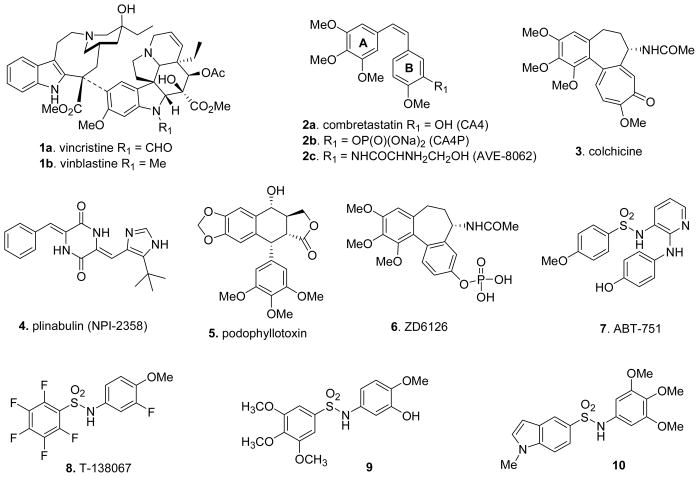

Microtubules, formed by α- and β-tubulin heterodimers, are essential constituents of the cytoskeleton in eukaryotic cells and are involved in a number of important structural and regulatory functions, including the maintenance of cell shape, intracellular transport machinery, as well as cell growth and mitosis.1 Their highly ordered structures, rigidity, and their ability to grow and shrink via polymerization/depolymerization mechanisms are critical to their function in several cellular processes. Perhaps the most important role of microtubules is during mitosis, where they serve to organize and segregate chromosomes. Tubulin is the major structural component of the microtubules and a well verified target for a variety of highly successful anticancer drugs.2 Thus, vinca alkaloids 1 (vincristine and vinblastine)3 have been successfully used for the therapy of hematological disorders for the past three decades and the seminal discovery of paclitaxel (Taxol) by Wani and Wall4 in 1971 had a profound impact on the treatment of breast and ovarian cancers. The success of these agents has also led to the identification of several new tubulin interactive agents that have found application in cancer chemotherapy.5 Based on the mechanism of action of alternation of microtubule dynamics, drugs can be classified into two categories. Amongst the compounds (Chart 1) that inhibit tubulin polymerization and destabilize microtubules are the combretastatins (2), colchicine (3), Plinabulin (NPI-2358) (4), podophyllotoxin (5), curcumin and the vinca (1) alkaloids, and those that promote the polymerization of tubulins and stabilize the microtubules in their polymerized state include discodermolide, eleutherobins, the epothilones, laulimalide, the sarcodictyins, and the taxanes.6 Both microtubule stabilizers and destabilizers alter the tubulin-microtubule equilibrium causing mitotic arrest at G2/M phase7 and ultimately apoptotic cell death. Because of the clinical success of microtubule-affecting compounds such as paclitaxel, the vinca alkaloids, and epothilone derivatives in the treatment of a wide variety of cancers, it has been argued that microtubules represent the single most important protein target for anticancer therapy.8

Chart 1.

Structures of microtubule depolymerizing agents

These antimitotic drugs, however, are not without limitations. Many, including paclitaxel and the vinca alkaloids, are large (MW>700Da) natural products that display ADME-Tox shortcomings (including poor water solubility, bioavailability, and significant dose-limiting toxicity). In addition, a common problem observed with this class of compounds is that these large natural products are substrates for efflux pumps of the ABC transporter family, such as P-glycoprotein (P-gp) and multidrug resistance (MDR) proteins that can alter their pharmacokinetic characteristics.9 Furthermore, drugs such as taxanes are typically poor chemotherapeutics for the treatment of many brain cancers, as high levels of P-gp in the blood-brain barrier (BBB) and the chemical properties of the molecules themselves prevent significant accumulation of drug in the brain. Because of these factors, there has been an intense search for more effective antimitotics.10

A variety of synthetic small molecules have also been reported11 as inhibitors of polymerization, which compete with the colchicine-binding site of tubulin.12 While no colchicine-site binders are currently approved for cancer chemotherapy, compounds like combretastatin A-4P (CA4P) (2b),13 AVE-8062 (2c),14 ZD6126 (6),15 ABT-751(7),16 T-138067 (8),17 N-(3-Hydroxy-4-methoxyphenyl)-3,4,5-trimethoxybenzenesulfonamide (9) 18 and 1-Methyl-1H-indole-5-sulfonic acid (3,4,5-trimethoxyphenyl)amide (10) 19 are now under clinical investigation as potential new chemotherapeutic agents (Chart 1).20 However, a report of the activity and SAR information for these compounds, especially in vivo efficacy, is limited.

Hence herein we report the synthesis, in vitro evaluations, cell cycle progression and structure activity relationship (SAR) of (E)-N-aryl-2-arylethenesulfonamides, which cause cell death through destabilization of microtubules. In this study, we also report the caspase activation and tubulin depolymerization study along with blood-brain barrier (BBB) permeability of the active compound (E)-N-(3-Amino-4-methoxyphenyl)-2-(2′,4′,6′-trimethoxyphenyl)ethenesulfonamide (6t).

CHEMISTRY

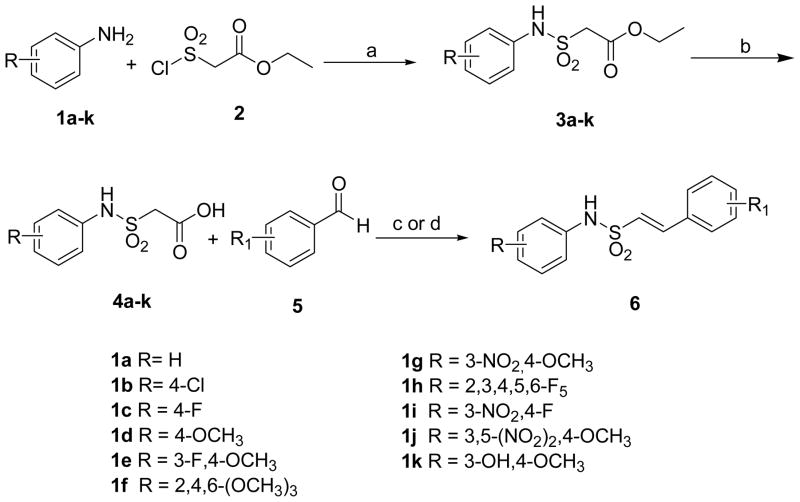

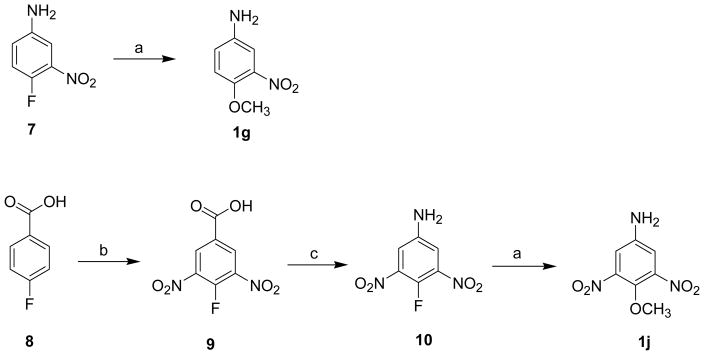

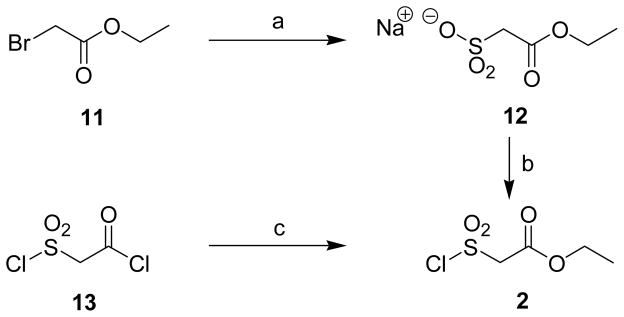

The syntheses of (E)-N-aryl-2-arylethenesulfonamides (6) were achieved by multiple synthetic routes as illustrated in Schemes 1, 5 & 6. The initial method involved for the synthesis of 6 by the condensation of chlorosulfonylacetic acid ethyl ester (2) with various anilines 1 in the presence of triethylamine in DCM to obtain the arylsulfamoylacetic acid ethyl esters (3) in high yields. Hydrolysis of 3 with 10% NaOH in water afforded the corresponding arylsulfamoylacetic acids (4) in good yields. Knovenagel condensation of 4 with various aromatic aldehydes 5 either in benzylamine/acetic acid21 or piperidine/benzoic acid22 in toluene afforded 6 in good yields (Scheme 1). All 3-nitro and 3,5-dinitro substituted arylethenesulfonamides were reduced to their corresponding amino analogs either with sodium hydrosulfite in acetone/water or with iron powder in methanol/acetic acid as shown in the Scheme 2.23 The substituted anilines 1g and 1j which are not available commercially were synthesized as shown in the Scheme 3. 1g was prepared by the treatment of 4-fluoro-3-nitro-aniline (7) with 6% methanolic KOH in absolute methanol at room temperature to afford the required 1g in moderate yields. The dinitro aniline 1j was synthesized starting from 4-fluorobenzoic acid (8) by nitration with fuming nitric acid and 30% sulfuric acid to get 3,5-dinitro-4-fluorobenzoic acid (9) which on treatment with 20% oleum and ethylene dichloride in presence of sodium azide afforded 3,5-dinitro-4-fluoro aniline (10). Treatment of 10 with 6% methanolic KOH in absolute methanol gave the required 3,5-dinitro-4-methoxy aniline (1j) in moderate yields (Scheme 3).24 Commercially not available chlorosulfonylacetic acid ethyl ester (2) was in turn made as shown in Scheme 4. Treatment of ethyl bromoacetate (11) with sodium sulfite gave sodium ethoxycarbonylmethanesulfonate (12) which on reaction with PCl5 at 100 °C resulted in 2 in moderate yields.25 The 2 was also prepared directly by the esterification of chlorosulfonyl acetyl chloride (13) with absolute ethanol in diethyl ether in 55% yield.26

Scheme 1.

Synthesis of (E)-N-Aryl-2-arylethenesulfonamides (6) from N-Arylsulfonylacetic Acidsa

a Reagents and conditions: (a) Et3N, DCM, room temp, 3 h, 80%; (b) 10% NaOH, H2O, room temp, 3 h, 84%; (c) C6H5CH2NH2, AcOH, reflux, 8 h, 50%; (d) piperidine, benzoic acid, toluene, reflux, 4 h, 60%.

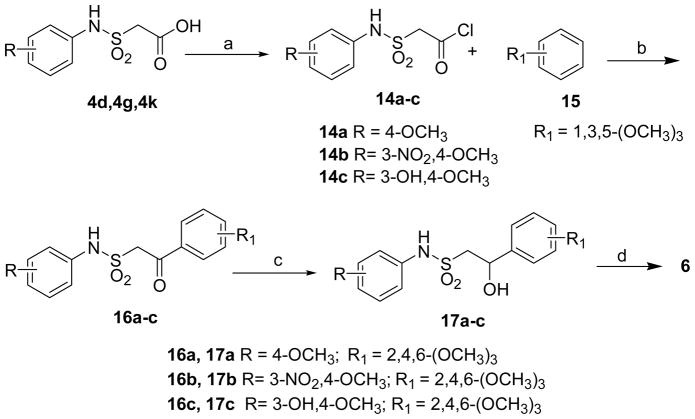

Scheme 5.

Synthesis of (E)-N-Aryl-2-arylethenesulfonamides (6) from Phenacyl N-Arylsulfonesa

a Reagents and conditions: (a) SOCl2, DCM, room temp, 6 h, 81% or (COCl)2, DMF, anhydrous CH2Cl2, room temp, 12 h, 67%; (b) AlCl3, DCM, room temp, 4 h, 80%; (c) NaBH4, THF, room temp, 3 h, 88%; (d) p-TSA, toluene, reflux, 3 h, 78%.

Scheme 6.

Synthesis of (E)-N-Aryl-2-arylethenesulfonamides (6) from (E)-Styryl sulfonyl chloridea

a Reagents and conditions: (a) SO2Cl2, DMF, 0 °C to room temp, 3 h, 90%; (b) Et3N, DCM, room temp, 5 h, 85%; (c) pyridine, room temp, 6 h, 80%.

Scheme 2.

Conversion of 3-Nitro and 3,5-Dinitro N-Aryl-2-arylethenesulfonamides to corresponding Amines (6) a

aReagents and conditions: (a) Sodium hydrosulfite, acetone / water (2:1), 50 °C, 30 min, 40%; (b) Iron powder, MeOH / AcOH (2:1), 80 °C, 2 h, 55%.

Scheme 3.

Synthesis of 4-Methoxy-3-nitro Aniline (1g) and 4-Methoxy-3,5-dinitrophenyl Amine (1j) a

aReagents and conditions: (a) absolute methanol, 6% methanolic KOH, room temp, 30 min, 50%; (b) fuming H2SO4 (30%), HNO3 (90%), 95 °C, 3 h, 70%; (c) fuming H2SO4 (20%), ClCH2CH2Cl, NaN3, reflux, 1 h, 70%.

Scheme 4.

Synthesis of Chlorosulfonylacetic acid ethyl ester (2)a

a Reagents and conditions: (a) Na2SO3, H2O, EtOH, 50 °C, 30 min, 70 %; (b) PCl5, 100 °C, 45 min, 85%; (c) EtOH, diethyl ether, 0 °C, 3 h, 55%.

Alternatively, the sulfonamides 6 were also prepared by acylation of the acids 4d, 4g or 4k by thionyl chloride in DCM to get the corresponding acid chlorides 14a-c which on Friedel-Crafts acylation with 1,3,5-trimethoxy benzene (15) afforded 2-aryl-2-oxoethanesulfonic acid aryl amides (16a-c). Sequential reduction of 16 with sodium borohydride and subsequent dehydration with p-toluenesulfonic acid (p-TSA) afforded the desired product 6 in moderate yields (Scheme 5).27 To explore for the simple reaction conditions, less number of steps to obtain the targeted compounds and better overall yields, sulfonamides 6 were also prepared by the condensation of anilines (1a-c) with 2-arylethenesulfonyl chlorides (19a-c) in the presence of triethylamine in DCM in good yields. The sulfonyl chlorides 19 were in turn made by the addition of sulfuryl chloride to styrenes (18a-c)27c in DMF at 0 °C to room temperature to get the desired product in quantitative yields (Scheme 6). The method described in Scheme 6 is superior to the other two methods as it involves less steps, cheaper chemicals and relatively higher yields.

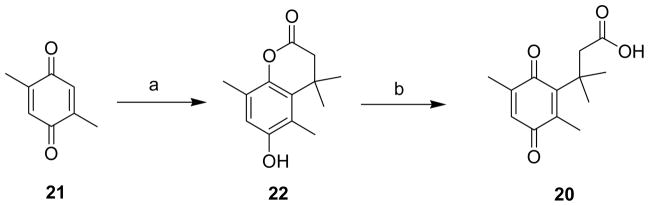

To enhance the bioavailability of the active sulfonamide (E)-2-(2,4,6-trimethoxyphenyl)-2-(3-hydroxy-4-methoxyphenyl)ethanesulfonamide (6p), we explored to make its ester analog 6q. Condensation of 3-(2,5-dimethyl-3,6-dioxocyclohexa-1,4-dienyl)-3-methylbutanoic acid (20) with 6p in the presence of EDAC and DMAP in dichloromethane resulted in ester (E)-2-methoxy-5-(2-(2,4,6-trimethoxyphenyl)vinylsulfonamido)phenyl 2-(2,5-dimethyl-3,6-dioxo-cyclohexa-1,4-dienyl)-2-methylpropanoate (6q) in moderate yields (Scheme 7). The benzoquinone ester 20 in turn was synthesized from 2,5-Dimethyl[1,4]benzoquinone (21) in presence of 3,3-dimethylacrylic acid, aqueous sodiumhydrosulfite and methane sulfonic acid in diethyl ether at 85 °C to yield 6-Hydroxy-4,4,5,8-tetramethylchroman-2-one (22) in 59% yield. N-Bromosuccinimide ring opening reaction of 22 afforded the target compound 20 in moderate yields (Scheme 8).28

Scheme 7.

Synthesis of (E)-2-Methoxy-5-(2-(2,4,6-trimethoxyphenyl)vinylsulfonamido)phenyl 2-(2,5-dimethyl-3,6-dioxocyclohexa-1,4-dienyl)-2-methylpropanoate (6q)

Scheme 8.

Synthesis of 3-(2,5-dimethyl-3,6-dioxocyclohexa-1,4-dienyl)-3-methylbutanoic acid (20)a

a Reagents and conditions: (a) diethyl ether, aq. Na2S2O4, (CH3)2C=CHCOOH, CH3SO3H, 85 °C, 3 h, 81%; (b) CH3CN, acetone, water, NBS, room temp, 30 min, 60%.

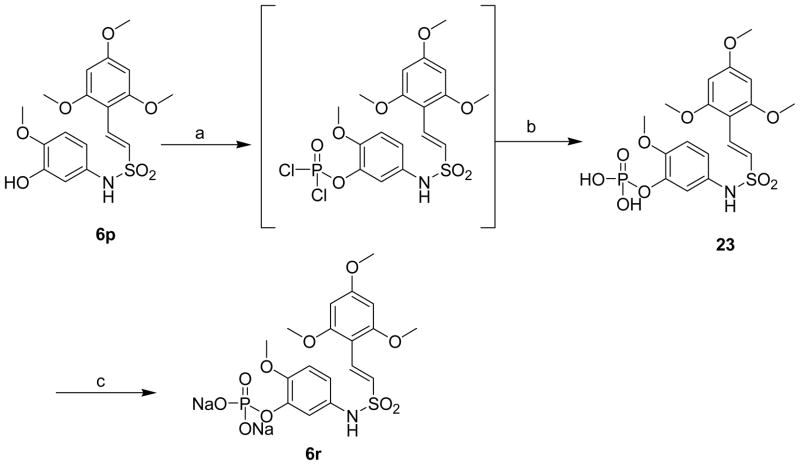

To further enhance the bioavailability and water solubility of the active sulfonamide (E)-2-(2,4,6-trimethoxyphenyl)-2-(3-hydroxy-4-methoxyphenyl)ethenesulfonamide 6p, its disodium phosphate prodrug was synthesized in two steps as shown in the Scheme 9. Phosphorylation of the phenolic group in 6p employing phosphorous oxychloride under basic conditions gave 3-O-phosphate 23. Treatment of the phosphate 23 with 25% aq. sodium hydroxide in ethylene glycol dimethyl ether yielded disodium O-phosphate 6r (Scheme 9).29

Scheme 9.

Synthesis of Sodium (E)-2-Methoxy-5-(2-(2′,4′,6′-trimethoxyphenyl)vinylsulfon-amido) phenyl phosphate (6r)a

aReagents and conditions: (a) phosphorus oxychloride, THF, triethylamine, 0 °C-room temp, 3 h; (b) water, room temperature,18 h, 69%; (c) 25% aq.NaOH, CH3OCH2CH2OCH3, 0 °C-room temp, 3 h, 85%.

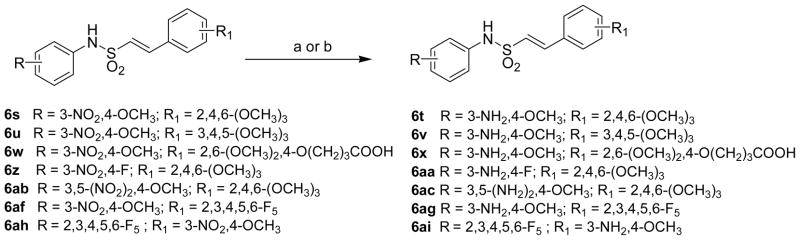

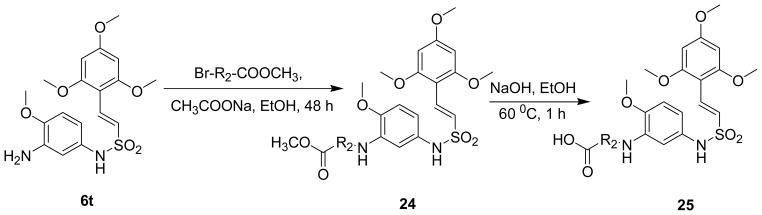

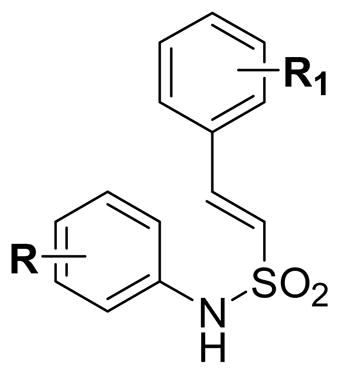

To further enhance the bioavailability and water solubility of the active sulfonamide 6t, several 3- amino substituted esters and acids were made by the reaction of α-bromo esters in the presence of mild base sodium acetate in ethanol to give amine esters (24) which on subsequent hydrolysis with sodium hydroxide in ethanol afforded the corresponding acids 25 (Scheme 10).30

Scheme 10.

Synthesis of amine esters and acids of (E)-N-(3-Amino-4-methoxyphenyl)-2-(2′,4′,6′-trimethoxyphenyl)ethenesulfonamide (6t)

Structure-Activity Relationships (SAR)

The newly synthesized compounds were tested for their in vitro cytotoxicity activity against two different human cell lines derived from human prostate (DU145) and leukemic (K562) cancers. The study results are presented in Table 1. These studies reveal that the cytotoxicity of the N-aryl-2-arylethenesulfonamide (6) is totally dependent on the nature and position of the substituents present on the two aromatic rings. For the purpose of structure-activity relationship, we have selected few compounds from a library of more than 500 arylethenesulfonamides synthesized in our laboratory. The cytotoxicity data (Table 1) clearly shows that the molecules are less active when the aromatic rings are without any substitution or mono substituted with halogens or with a combination of a methoxy and a halogen atom (6a-6d). The improvement in the cytotoxicity profile was observed when each aromatic ring has a methoxy group on it (6e, 6f). Based on this observation, additional methoxy groups were added on the styryl aromatic ring keeping a methoxy group constantly at the 4th position of the aryl sulfamyl ring to evaluate the influence of these groups on the cytotoxicity of the molecules (6g-6i). From the cytotoxicity data (Table 1) it is clear that 2,4 and 2,6-dimethoxy substitutions (6g, 6h) moderately enhanced the potency of the molecules while 2,4,6-trimethoxy substitution (6i) enhanced the cytotoxicity potency to several folds higher in the molecule. Altering the positions of the methoxy groups from 2,4,6 to 3,4,5 (6j) resulted in the loss of the cytotoxicity indicating that the optimum activity could be achieved only when the substitution pattern is 2,4,6 on the styryl aromatic ring. Also to evaluate the importance of the location of 2,4,6-trimethoxy groups on styryl aromatic ring, we switched these methoxy groups on to sulfamyl aromatic ring and tested the resulting molecule (6k) for the cytotoxicity. The loss of cytotoxicity activity in 6k clearly shows that the trimethoxy groups not only should be on the styryl aromatic ring but also at 2,4,6- positions. Further to make 6i more water soluble we replaced the methoxy group with a hydroxyl group at the 4th position of the 2,4,6-trimethoxy styryl ring and the resulted molecule (6l) lost the activity indicating that hydrophobic group at that position is required for the activity of the molecule. When fluorine atoms are introduced in place of 2,4,6-trimethoxy groups on 6i, the resulting molecules (6m, 6n) lost their cytotoxic potential on cancer cells showing that the methoxy groups at those positions are critical for the activity of the molecule. After fixing the styryl aromatic ring with 2,4,6-trimethoxy groups to attain the best activity, we then focused our attention on to aryl sulfamyl ring of the molecule. Addition of a fluorine atom at the third position of the sulfamyl ring in 6i retained the activity of the molecule (6o) indicating that the meta position in the ring is vulnerable and can be used for introducing groups that enhance water solubility and bioavailability without affecting the potency of the molecule. Replacing the fluorine in 6o with a hydroxyl group resulted in a potent molecule (6p) that has 5–7 folds higher cytotoxicity than 6o. Conversion of 6p into dimethyl quinone prodrug (6q) enhanced the cytotoxicity of the molecule compared to 6p probably due to better cell permeability compared to 6p. But the solubility of 6q in aqueous buffers has not much improved compared to 6p. Also introduction of the hydroxyl group on the sulfamyl ring created the possibility of producing a highly water-soluble disodium phosphate salt (6r) having more or less same potency as that of 6p. Further attempts to enhance the cytotoxicity with an electron withdrawing nitro group at 3rd position of the sulfamyl ring resulted in a molecule (6s) that is several folds less active than 6p, 6q and 6r. Surprisingly reduction of the nitro group (6s) to an electron releasing amino group resulted in the formation of the most active molecule (6t) of this series. Any other alterations and modifications on 6t resulted in molecules (6u-6z and 6aa-6aj) with reduced or total loss of cytotoxicity indicating that the best activity in N-aryl-2-arylethenesulfonamide series could be obtained only when a molecule bears 3-amino, 4-methoxy on the arylsulfamyl ring and 2,4,6-trimethoxy groups on the styryl ring.

Table 1.

In vitro Cytotoxicity of (E)-N-Aryl-2-arylethenesulfonamides (6)

| ||||

|---|---|---|---|---|

| Compd | R | R1 | IC50(μM)a | |

| DU145 | K562 | |||

| 6a | H | H | 10 | 10 |

| 6b | 4-Cl | H | 20 | 20 |

| 6c | 4-F | 4-Br | 10 | 10 |

| 6d | 4-F | 4-OCH3 | 10 | 10 |

| 6e | 4-OCH3 | 2-OCH3 | 5 | 5 |

| 6f | 4-OCH3 | 4-OCH3 | 5 | 5 |

| 6g | 4-OCH3 | 2,4-(OCH3)2 | 15 | 15 |

| 6h | 4-OCH3 | 2,6-(OCH3)2 | 0.375 | 5 |

| 6i | 4-OCH3 | 2,4,6-(OCH3)3 | 0.2 | 0.075 |

| 6j | 4-OCH3 | 3,4,5-(OCH3)3 | 35 | 35 |

| 6k | 2,4,6-(OCH3)3 | 4-OCH3 | 7.5 | 2.5 |

| 6l | 4-OCH3 | 2,6-(OCH3)2,4-OH | 10 | 10 |

| 6m | 4-OCH3 | 2,4,6-F3 | 75 | 15 |

| 6n | 4-OCH3 | 2,3,4,5,6-F5 | 10 | 5.0 |

| 6o | 3-F,4-OCH3 | 2,4,6-(OCH3)3 | 0.2 | 0.075 |

| 6p | 3-OH,4-OCH3 | 2,4,6-(OCH3)3 | 0.03 | 0.015 |

| 6q | 3-OCOCH2C(CH3)2-C6H(CH3)2O2, 4-OCH3 | 2,4,6-(OCH3)3 | 0.009 | 0.008 |

| 6r | 3-OPO(ONa)2,4-OCH3 | 2,4,6-(OCH3)3 | 0.04 | 0.0075 |

| 6s | 3-NO2,4-OCH3 | 2,4,6-(OCH3)3 | 2.5 | 1.0 |

| 6t | 3-NH2,4-OCH3 | 2,4,6-(OCH3)3 | 0.005 | 0.003 |

| 6u | 3-NO2,4-OCH3 | 3,4,5-(OCH3)3 | 75 | 75 |

| 6v | 3-NH2,4-OCH3 | 3,4,5-(OCH3)3 | 35 | 15 |

| 6w | 3-NO2,4-OCH3 | 2,6-(OCH3)2,4-O(CH2)3COOH | 100 | 100 |

| 6x | 3-NH2,4-OCH3 | 2,6-(OCH3)2,4-O(CH2)3COOH | 10 | 10 |

| 6y | 3-OH,4-OCH3 | 2,6-(OCH3)2,4-O(CH2)3COOH | 10 | 10 |

| 6z | 3-NO2,4-F | 2,4,6-(OCH3)3 | 100 | 75 |

| 6aa | 3-NH2,4-F | 2,4,6-(OCH3)3 | 10 | 5 |

| 6ab | 3,5-(NO2)2,4-OCH3 | 2,4,6-(OCH3)3 | 10 | 10 |

| 6ac | 3,5-(NH2)2,4-OCH3 | 2,4,6-(OCH3)3 | 2.5 | 7.5 |

| 6ad | 3-F,4-OCH3 | 4-OCH3 | 5 | 1 |

| 6ae | 3-F,4-OCH3 | 2,3,4,5,6-F5 | 10 | 10 |

| 6af | 3-NO2,4-OCH3 | 2,3,4,5,6-F5 | 100 | 100 |

| 6ag | 3-NH2,4-OCH3 | 2,3,4,5,6-F5 | 75 | 75 |

| 6ah | 2,3,4,5,6-F5 | 3-NO2,4-OCH3 | 100 | 75 |

| 6ai | 2,3,4,5,6-F5 | 3-NH2,4-OCH3 | 35 | 35 |

| 6aj | 2,3,4,5,6-F5 | 2,3,4,5,6-F5 | 35 | 35 |

IC50 values are the compound concentrations (μM) required to inhibit cell proliferation by 50% of tumor cells following 96 h treatment with the tested compound; values represent the mean SD from the dose response curves of two independent experiments and are within 5–10%.

After identifying the most potent molecule (6t) in the series, we made several modifications on the amino group of 6t to make it more water-soluble and bioavailable. Alkylation of the meta-amino group in 6t with methyl bromoacetate and 2-alkyl, aryl substituted bromoacetates produced 3-glycine esters (24a-g) which on hydrolysis resulted in acids (25a-g). All the glycine analogs (25a-g) showed enhanced water solubility (10–20 mg/mL) and excellent cytotoxicity (Table 2) compared to the glycine esters (24a-g).

Table 2.

In vitro cytotoxicity of Amine esters (24) and Acids (25)

| |||

|---|---|---|---|

| Compd | R2 | IC50 (μM)a | |

| DU145 | K562 | ||

| 24a | CH2 | 0.35 | 0.35 |

| 24b | CH(CH3) | 0.1 | 0.30 |

| 24c | C(CH3)2 | 0.2 | 0.30 |

| 24d | CH(C6H5) | 2.5 | 2.5 |

| 24e | CH(C6H44-F) | 2.5 | 2.5 |

| 24f | CH(C6H44-Cl) | 5.0 | 2.5 |

| 24g | CH(C6H44-Br) | 7.5 | 1.0 |

| 25a | CH2 | 0.4 | 0.02 |

| 25b | CH(CH3) | 0.04 | 0.008 |

| 25c | C(CH3)2 | 0.07 | 0.005 |

| 25d | CH(C6H5) | 0.075 | 0.30 |

| 25e | CH(C6H44-F) | 0.075 | 0.02 |

| 25f | CH(C6H44-Cl) | 0.075 | 0.015 |

| 25g | CH(C6H44-Br) | 0.25 | 0.075 |

IC50 values are the compound concentrations (μM) required to inhibit cell proliferation by 50% of tumor cells following 96 h treatment with the tested compound; values represent the mean SD from the dose response curves of two independent experiments and are within 5–10%.

BIOLOGICAL RESULTS AND DISCUSSION

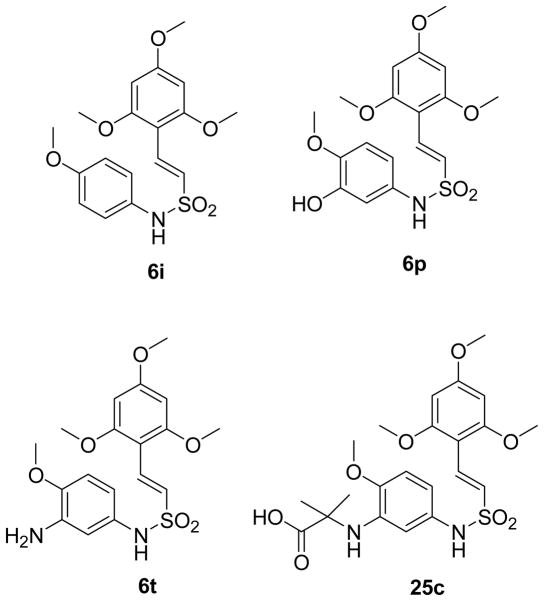

In vitro Anti-tumor Effects of 6i, 6p, 6t, and 25c Compounds

Screening of the novel arylethenesulfonamide compound library of molecules for anti-tumor activity using cell biological assays yielded several candidate molecules that induced dose-dependent growth inhibition and death of tumor cells (Tables 1 & 2). To identify the arylethenesulfonamides with the broadest range of activity in a wider selection of cancer cell types we chose four of the most potent compounds from the series shown in Chart 2 and found high potency with similar GI50 values (selected data shown in Table 3). The appreciable cell killing across multiple tumor types suggests that these compounds are inhibiting an intrinsically important process of tumor cell division. 6t was found to be the most active of the four compounds exhibiting IC50 values of between 0.003 – 0.01 μM (Table 3), and on that basis, we further investigated the mechanism of action of this compound.

Chart 2.

Chemical structures of lead compounds

Table 3.

In vitro cytotoxicity profiles of most active molecules 6i, 6p, 6t and 25c in various tumor cell lines.

| Cell Line | Tumor Type | IC50 (>M)a

|

|||

|---|---|---|---|---|---|

| 6i | 6p | 6t | 25c | ||

| DU145 | Prostate | 0.075 | 0.050 | 0.008 | 0.15 |

| K562 | Leukemia | 0.075 | 0.015 | 0.003 | 0.01 |

| LNCAP | Prostate | 0.100 | 0.050 | 0.008 | 0.10 |

| PC3 | Prostate | 0.100 | 0.025 | 0.008 | N/D |

| SK-MEL-28 | Melanoma | 0.050 | 0.025 | 0.008 | N/D |

| MCF-7 | Breast | 0.050 | 0.025 | 0.004 | 0.08 |

| SK BR-3 | Breast | 0.050 | 0.025 | 0.004 | N/D |

| BT474 | Breast | 0.250 | 0.025 | 0.010 | 0.15 |

| BT20 | Breast | 0.250 | 0.250 | 0.008 | 0.10 |

| T47D | Breast | 0.100 | 0.025 | 0.008 | N/D |

| A431 | Epidermoid | 0.030 | 0.600 | 0.005 | 0.15 |

| HCT116 | Colo-Rectal | 0.100 | 0.010 | 0.004 | N/D |

| HCT15 | Colo-Rectal | 0.100 | 0.025 | 0.008 | 0.20 |

| SKOV3 | Ovarian | 0.100 | 0.025 | 0.008 | N/D |

| OVCAR3 | Ovarian | 0.100 | 0.100 | 0.004 | N/D |

| H187 | NSCLC | 0.100 | 0.010 | 0.004 | N/D |

| N417 | SCLC | 0.050 | 0.010 | 0.004 | 0.03 |

| RF-48 | Gastric | 0.025 | 0.010 | 0.004 | N/D |

| RF-1 | Gastric | 0.050 | 0.010 | 0.004 | N/D |

| MIAPaCa2 | Pancreatic | 0.100 | 0.010 | 0.004 | 0.08 |

| H80 | Glioma | 0.100 | 0.025 | 0.004 | N/D |

| MES-SA | Uterine | 0.050 | 0.025 | 0.004 | N/D |

| NAMALWA | Lymphocytic | 0.100 | 0.025 | 0.008 | N/D |

| DAUDI | Lymphocytic | 0.100 | 0.025 | 0.008 | 0.03 |

| MOLT-4 | Lymphocytic | 0.100 | 0.025 | 0.008 | 0.03 |

| U87 | Gliomab | 0.229 | 0.026 | 0.009 | 0.09 |

GI50 (growth inhibitory concentration-50%). Cells were treated with 6i, 6p, 6t and 25c in a 96 h dose response assay. The GI50 concentration (μM) was determined from duplicate cell counts using a Hemocytometer following trypsinization and trypan blue staining.

Values are IC50 as measured by SRB assay. ND = not determined

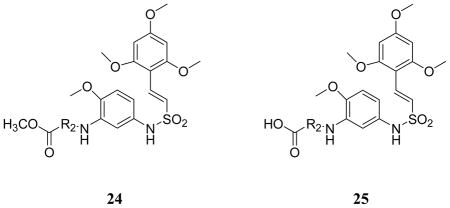

Effects of 6t on Cell Cycle Progression of Tumor Cells

The effect of 6t on cell cycle progression in DU145 human prostate cancer cells using fluorescence-activated cell sorting (FACS) analysis indicated that the addition of 6t to tumor cells resulted in gradual accumulation of cells in the G2/M phase of the cell cycle in a concentration-dependent manner. Figure 1 shows that tumor cells accumulated in the G2/M phase of the cell cycle at 0.005 μM concentration of 6t, and a majority of cells showed G2/M arrest at a 0.02 μM concentration, whereas a normal cell cycle distribution was seen in the vehicle treated cells. In addition, treatment of the tumor cells with 6t resulted in an accumulation of cells containing subG1 content of DNA which is an indication of mitotic arrest.31

Figure 1.

Cell cycle arrest and apoptosis of DU145 cells treated with 6t. DU145 cells were treated with various concentrations of 6t for 24 h and subjected to flow cytometry following propidium iodide staining. DU145 cells were arrested in the G2/M phase of the cell cycle.

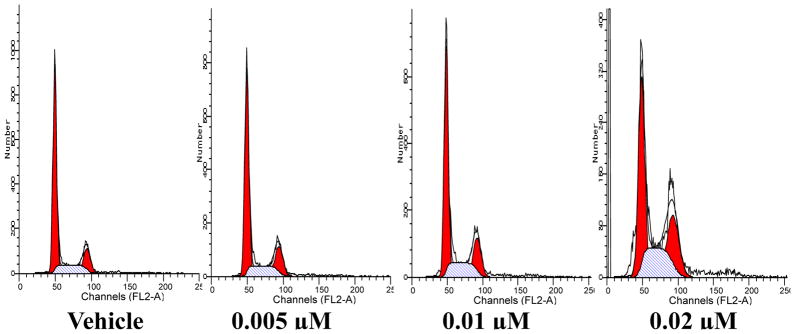

Compound 6t Treatment Induces Abnormal Mitotic Spindle Development

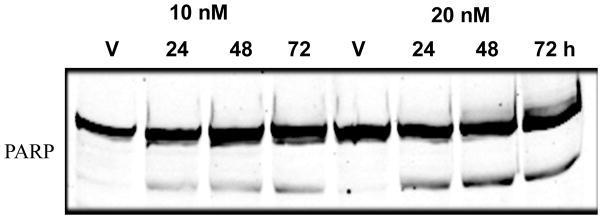

We tested if 6t was able to depolymerize cellular microtubules in the same way as other depolymerizing agents. Exposure of DU145 cells to different concentrations of 6t for 24 h led to a complete depolymerization of the microtubule cytoskeleton. Confocal laser microscopy showed that while DMSO-treated cells (vehicle) went through various phases of mitosis without any abnormality, 6t treated cells exhibited profound abnormalities in spindle-formation, resulting in the appearance of abnormal spindles, misalignment of chromosomes and complete loss of co-ordination in mitotic spindle assembly (Figure 2). Some cells were micro-nucleated, and others were arrested in pro-metaphase with a ball or rosette of condensed DNA without a mitotic spindle (type IV spindle).32 The mitotic arrest caused by 6t was accompanied by net microtubule depolymerization. These data suggested that 6t acts as a mitotic inhibitor by blocking cell cycle progression at a time between pro-metaphase and metaphase by its ability to disrupt spindle assembly that led to the caspase activation and apoptosis as evidenced by PARP [Poly(ADP-ribose) polymerase-1] cleavage 33 (Figure 3). Treatment of 6t selectively induced PARP cleavage in the tumor cell line while there was no PARP cleavage in the treated normal cell line (data not shown). These results correlate quite well with those obtained in tubulin assembly experiments.

Figure 2.

DU145 cells were plated onto glass coverslips and exposed to either 25 nM 6t or DMSO and then fixed, stained with FITC conjugated (green) anti-tubulin antibodies and propidium iodide (red) and analyzed by confocal microscope (Olympus). 6t inhibits the normal formation of mitotic microtubules.

Figure 3.

DU145 cells were treated with the indicated concentrations of 6t and harvested at the indicated times. Protein lysates were subjected to western blotting against PARP antibodies. Full length PARP gets cleaved in the 6t treated cells indicating the cells are undergoing apoptosis.

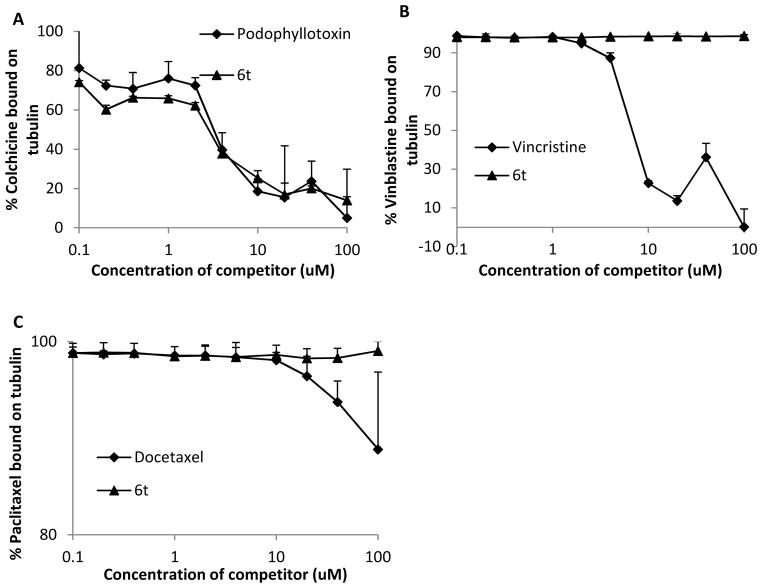

Compound 6t Destabilizes Tubulin Polymerization by Binding to the Colchicine Binding Site on Tubulin

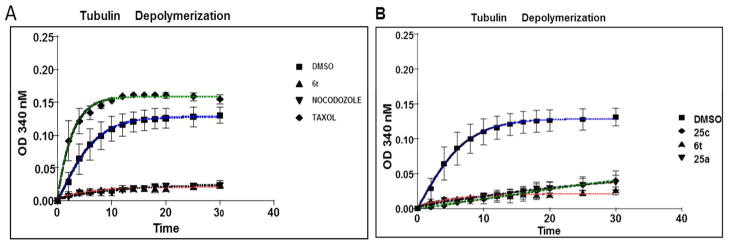

Since chromosomal architecture showed abnormalities in spindle formation, we examined whether 6t effected polymerization of tubulin in vitro. For these assays, the spontaneous polymerization of purified bovine brain tubulin was measured to determine if the antimitotic properties of 6t were due to either stabilization or destabilization of microtubule polymerization. The extent of tubulin polymerization was determined spectrophotometrically by the increasing absorbance at 340 nM. DMSO vehicle is known to slightly stabilize microtubules and produces an intermediate polymerization phenotype.34 As expected, the microtubule stabilizer paclitaxel induced a strong increase in turbidity, whereas nocodazole destabilized growing microtubules such that depolymerization at the (-)-end is faster than polymerization at the (+)-end, giving rise to a net “depolymerization” phenotype and no rise in turbidity (Figure 4A). Attempted polymerization of tubulin in the presence of 6t produced a depolymerization phenotype, suggesting that 6t and related arylethenesulfonamides, 25a and 25c, caused cytotoxicity through destabilization of microtubule polymerization (see Figure 4B). The ability of 6t compounds to compete for known binding sites on tubulin was determined using a mass spectrophotometric (MS) competitive binding assay.35 Three tubulin ligands, corresponding to the 3 binding sites on tubulin, colchicine, vinblastine, and paclitaxel were used for these competitive binding studies. 6t (IC50 = 3.68 μM) specifically competed with colchicine binding to tubulin and with similar avidity as podophylltoxin, (IC50 = 3.71 μM), but it did not compete with either vinblastine or paclitaxel binding to tubulin (Figure 5). Known tubulin binding ligands, podophylltoxin, vincristine and docetaxel effectively competed for the colchicine-, vinblastine- and paclitaxel-tubulin binding sites, respectively, indicating the validity of the MS binding assay.

Figure 4.

6t inhibit in vitro tubulin polymerization. A. Purified tubulin was incubated in the presence of 10 μM concentration of taxol, nocodazole, 6t and DMSO at 37 °C. The extent of tubulin polymerization was determined by the increasing absorbance at 340 nM over 40 min. 6t and nocodazole (a known tubulin depolymerizer) were able to completely inhibit tubulin polymerization compared to Taxol (tubulin polymerizer) and DMSO suggesting that 6t interfere with normal tubulin polymerization kinetics. Data shown are representative of three independent experiments. B. Purified tubulin was incubated in the presence of 10 μM concentration of 6t, 25a, 25c and DMSO at 37 °C. The extent of tubulin polymerization was determined by the increasing absorbance at 340 nM over 40 min. All three compounds were able to completely inhibit tubulin polymerization suggesting that these compounds interfere with normal tubulin polymerization kinetics. Data shown are representative of three independent experiments.

Figure 5.

Tubulin competitive binding studies. 6t competes with colchicine (A), but not with vinblastine (B) and paclitaxel (C) to bind to tubulin. In panel A and B, tubulin was incubated with colchicine or vinblastine (1.2 μM) in the absence of GTP with increasing concentrations of the test compounds. In panel C, performed microtubules were incubated with paclitaxel (1.2 μM) and 1 mM GTP, and increasing concentration of the test compounds. Podophyllotoxin, vincristine and docetaxel were used as positive controls for competitive binding with colchicine, vinblastine and paclitaxel, respectively.

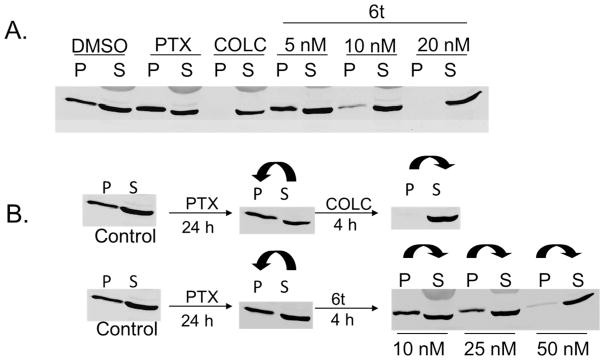

In Vivo Tubulin Polymerization of 6t

To determine whether this compound also inhibits tubulin polymerization in vivo, we treated human prostate cancer cells (DU145) with increasing concentrations of 6t for 24 h and determined the extent of polymerized tubulin present in cell lysates. This assay, based on differential precipitation of depolymerized (soluble) and polymerized (precipitated) tubulin, detects the abundance of polymerized tubulin (spindle formation) present in normal mitotic cells. Paclitaxel and colchicine were used as controls since paclitaxel promotes tubulin polymerization while colchicine induces de-polymerization of tubulin. Figure 6A shows that 6t caused a concentration-dependent depolymerization of tubulin in treated cells, similar to colchicine. Furthermore, 6t caused tubulin depolymerization even in cells pre-treated with paclitaxel for 24 h that had high levels of polymerized tubulin; colchicine had a similar effect (Figure 6B). These studies clearly indicate that 6t acts as a tubulin-depolymerizing agent and this property explains its ability to induce mitotic arrest of human tumor cells which results in their apoptotic death.

Figure 6.

6t inhibits in vivo tubulin polymerization. A. DU145 cells were treated with vehicle (DMSO), paclitaxel (PTX), colchicine (COLC) or the indicated concentrations of 6t for 24 h and lysed in a hypotonic buffer. The pellet and supernatants were resolved by SDS-PAGE. The polymerized tubulin in the pellet (P) and the soluble tubulin in supernatant (S) were analyzed for presence of tubulin by western blotting. Like colchicine, a known tubulin depolymerizer, 6t treatment completely inhibits the polymerization of tubulin. B. DU145 cells were first treated with paclitaxel for 24 h and subsequently treated for 4 h with colchicine or 6t. As expected, paclitaxel treatment induced a shift from soluble to polymerized tubulin (see arrow) while both colchicine and 6t were both effective at depolymerizing paclitaxel induced polymerized tubulin (see arrows).

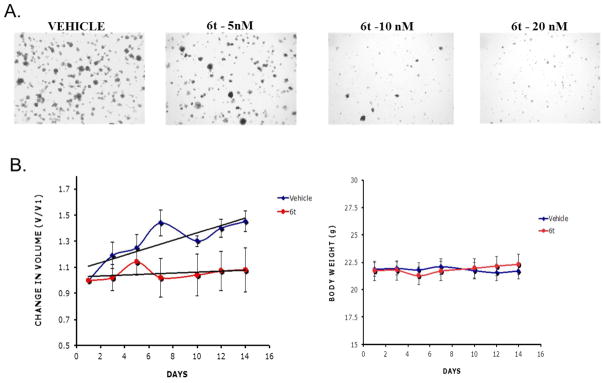

In vivo Anti-tumor Effects of 6t

6t was next tested for its anti-tumor activity in soft agar and nude mouse assays. For soft agar assays, we used a well-known pancreatic cancer cell line, MIA-Pa-Ca2. Treatment of these cells line with 6t resulted in inhibition of anchorage-independent growth of tumor cells in a dose dependent manner (Figure 7A). In these assays, paclitaxel was used as a positive control, which showed similar potency (data not shown). To examine the anticancer efficacy, we used ER-negative human breast tumor cells (BT-20) grown as xenografts in nude mice. Female athymic (NCr-nu/nu) mice were injected subcutaneously with 0.5–1×107 tumor cells in 0.2 mL of PBS and the tumors allowed to grow for 7–10 days to a size of 100–150 mm prior to treatment. The mice were then paired such that the pairs harbored equal sized tumors which were used to test the therapeutic effects of 6t. Of the pairs, one mouse received the vehicle alone while the second mouse received the compound by intraperitoneal (IP) injection. The tumor size was measured on alternate days for a total of 14 days. Figure 7B shows that 6t readily inhibited tumor growth in this xenograft model system. Of the 8 mice included in each group, 100% of the control mice (placebo administered) showed a doubling of the total tumor volume. On the other hand, most of the mice administered with 6t showed growth arrest or a gradual reduction in their tumor volume, suggesting that this compound could be valuable anti-cancer therapeutic. Measurement of the body weights during the experimental period showed no reduction in body weight indicated the safety profile of the drug.

Figure 7.

6t Inhibition of tumor growth. A. MIA-PaCa-2 cells were plated in soft agar containing increasing concentrations of 6t in triplicates. After three weeks of growth, the plates were stained for 48-h using 0.05% nitroblue tetrazolium solution. Representative plates were photographed using an Olympus stereoscope mounted with a Sony digital camera system (DKC 5000, Sony Inc). 6t inhibits the semi-solid growth of pancreatic cells indicating activity. B. Human estrogen receptor negative breast cancer cells (BT20) were implanted into the hind quarter of female nude mice. When the tumors became palpable, they were treated with either 20 mg/kg 6t or an equal volume of vehicle every other day for a total of 6 injections. The tumor volumes and body weights were determined and plotted (Blue diamonds: Vehicle; Red circles: 6t) as the average per group along with SEM values (Vehicle: N=7, 6t: N=8). Trend lines were added using linear regression model (Microsoft Excel).

Compounds 6t and 25c are Highly Active Against Drug Resistant Tumor Cell Lines

One major limitation of anticancer drug therapy is intrinsic and acquired multidrug resistance. Tumor expression of the ATP-dependent drug efflux pump, P-glycoprotein (Pgp), is associated with anticancer treatment failure.36 Many microtubulin poisons such as paclitaxel, vincristine, and vinblastine are substrates for the multidrug resistant family members. Drugs that are not substrates for the drug efflux pumps can overcome these mechanisms of resistance and be more efficacious. The ability of the arylethenesulfonamides, specifically 6t and 25c, to overcome drug-induced mechanisms of resistance was tested in pairs of isogenic cell line pairs (see Table 4). In all three pairs of sensitive and drug-resistant cancer cells, 6t and 25c exhibit greatly improved activity with resistance factors < 2. The uterine sarcoma cell line MES-SA and its multidrug resistant subline MES-SA/DX537 has been shown to express high levels of P-glycoprotein and is resistant to a number of drugs including doxorubicin, paclitaxel, vincristine, vinblastine, etoposide, mitoxantrone, dactinomycin, and daunorubucin; in our studies paclitaxel was 190-fold resistant based on GI50 values, whereas both 6t and 25c were nearly equally active. Similar phenomenon was seen in the parental leukemic cell line CEM and its MDR subline CEM/C238 that was selected for resistance to camptothecin and has cross-resistance to etoposide, dactinimycin, bleomycin, mitoxantrone, doxorubicin, and daunorubicin. Finally 6t was equally active in the ovarian carcinoma cell line 2008 and its paclitaxel-resistant clone 2008/17/4, which supports our contention that 6t, based on its activity in multiple drug-resistance cell lines, may be more effective in tumors that exhibit the MDR phenotype.

Table 4.

Evaluation of 6t and 25c against a panel of Multidrug- resistance Human Tumor Cell lines

| compd | cell Line | tumor type | GI50 (nM)a | resistance factor |

|---|---|---|---|---|

| Paclitaxel | MES-SA | sarcoma | 4 | 190 |

| MES-SA / DX5 | resistant sarcoma | 750 | ||

| 6t | MES-SA | sarcoma | 6 | 1.6 |

| MES-SA / DX5 | resistant sarcoma | 10 | ||

|

| ||||

| 25c | MES-SA | sarcoma | 70 | 1.3 |

| MES-SA / DX5 | resistant sarcoma | 90 | ||

|

| ||||

| Camptothecin | CEM | leukemic | 2 | 500 |

| CEM / C2 | resistant leukemic | 1000 | ||

| 6t | CEM | leukemic | 8 | 1 |

| CEM / C2 | resistant leukemic | 8 | ||

|

| ||||

| Paclitaxel | 2008 | ovarian | 3 | 600 |

| 2008 / 17/ 4 | resistant ovarian | 2000 | ||

| 6t | 2008 | ovarian | 6 | 1 |

| 2008 / 17/ 4 | resistant ovarian | 6 | ||

Cytotoxicity results are expressed as GI50 values, the compound concentrations producing 50% cell growth inhibition, and represent the mean ± SD of two independent experiments and are within 5–10%.

Pharmacological and Toxicological data of 6t

A study was conducted to assess the solubility, cytotoxicity, permeability, metabolic stability and protein binding of compound 6t (Table 5). 6t had moderate solubility in aqueous buffer with a limit of complete solubility (as measured by a statistical increase of light scattering over blank) of 62.5 μM measured by nephelometry. 6t was non-toxic to the human adenocarcinoma cell line, Caco-2 with an LD50 of >1000 μM (one hour incubation) in comparison to the negative control compounds, tamoxifen and 2-thiouracil that yielded LD50 values of 343 and >1000 μM, respectively. 6t Was also non-toxic to HepG2 cells, a human hepatocyte cell line, with an LD50 > 1000 μM following a 4 h exposure. Membrane permeability of 6t was determined using MDCK-MDR1 cells, a model for blood-brain barrier (BBB) permeability, as previously reported.39,40 Briefly, confluent MDCK-MDR1 monolayers expressing Pgp were obtained 3–4 days post-seeding and their integrity assessed by measurement of the transepithelial electrical resistance (TEER, Ω · cm2) with a Volt-Ohm Meter (Millicell-ERS, Millipore Corpration, Billerica, MA). After subtraction of the background TEER (i.e. the resistance exhibited by the filter alone) only MDCK-MDR1 cell monolayers that exhibited a TEER > 1000 Ω · cm2 throughout [measured before and after the study] the experiments were used. Drug transport across the cell monolayers was measured in both apical to basolateral (A-B) and basolateral to apical (B-A) directions based on 6t concentrations measured by LC/MS/MS. The starting concentration of 6t was 10 μM and the duration of the studies were 90 min. Apparent permeability values and the efflux ratio (ER) (see Table 5) indicated that 6t underwent passive transcellular diffusion with no appreciable active efflux that is normally indicated by ER values > 30. Metabolic stability of 6t in human, rat and dog S9 liver fractions showed that 6t was most extensively metabolized by human liver S9 followed by rat and dog with 20%, 33% and 57% of parent remaining following 1 h incubations, respectively. Binding of 6t to rat, dog and human plasma was measured by equilibrium dialysis at concentrations of 10 and 50 μM at 37 °C. 6t is extensively bound (>98%) to rat, dog and human plasma proteins.

Table 5.

Pharmacological and Toxicological data of 6t.

| Assay | Parameter | 6t |

|---|---|---|

| Solubility a | Maximum soluble concentration in PBS | 62.5 μM |

| Cytotoxicity b | LD50 to Caco-2 cells | >1000 μM |

| LD50 to HepG2 cells | >1000 μM | |

| Permeability c | A-B Papp x E06 | 9.1 cm/s |

| B-A Papp x E06 | 72 cm/s | |

| ER | 7.9 | |

| S9 Metabolic Stability (1h) c,d | Rat - % remaining | 33% |

| Dog -% remaining | 57% | |

| Human -% remaining | 20% | |

| Plasma Protein Binding (>M) c | Rat -% Bound | 99.73% |

| Dog - % Bound | 98.48% | |

| Human - % bound | 99.67% |

Determined by nephelometry

determined by fluorescence of Alamar Blue dye

quantification of samples was by LC-MS/MS.

S9 liver fractions microsomes (1 mg/mL) incubated for 0, 30 and 60 min with 10 μM concentration of 6t.

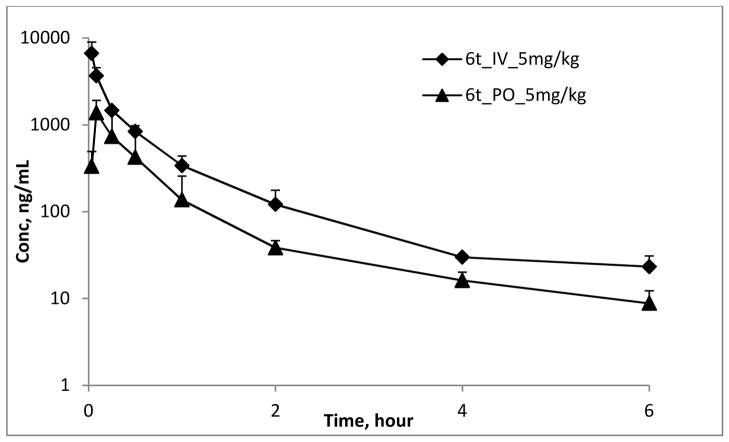

In vivo PK profile of 6t

Male ICR mice (N=3 per group) 6–8 weeks of age were used to examine the pharmacokinetics (PK) of 6t. The compound was formulated in NMP:PEG300: water at a volume ratio of 1:4:5 for both administrations at 5 mg/kg by intravenous bolus (IV, 20 μL total volume) and oral gavage (PO, 200 μL total volume). One day prior to drug administrations, a vascular cannula (vinyl tubing of I.D 0.28 mm × O.D 0.61 mm, Scientific Commodities Inc., Lake Havasu City, AZ) was surgically implanted in the right common carotid artery to allow for serial collection of blood (20 μL of blood per time point). For both 6t administrations, blood samples were collected at 2, 5, 15, 30, 60, 120, 240 and 360 min after administration. Plasma sample were prepared by centrifuging the blood samples at 8,000g for 5 min. All plasma samples were stored immediately at −80 °C until analyzed by LC/MS/MS. A protein precipitation method was used for sample preparation. An 80 μL aliquot of acetonitrile containing the internal standard was added to 20 μL of plasma and then thoroughly vortexed for 15 s. After centrifugation, the supernatant was analyzed by LC/MS/MS. The pharmacokinetic parameters were determined using noncompartmental analysis (WinNonlin 6.0, Pharsight Corporation, Mountain View, CA). Evan at this relatively low dose effective concentrations (> than GI50 concentrations) were achieved following single doses.

CONCLUSION

In summary, we have described the synthesis of a new series of tubulin polymerization inhibitors, which induce G2/M-phase cell cycle arrest leading to apoptotic cell death in a wide variety of human tumor cell lines at nanomolar concentrations by disrupting tubulin assembly. Our studies show that the cytotoxic activities of these compounds are completely dependent on the nature and position of the substituents on the two aromatic rings along with a substituted or unsubstituted sulfonamide group. SAR studies revealed that a molecule with an aryl sulfonamide moiety either with 3-hydroxy, 4-methoxy groups or 3-amino, 4-methoxy groups and a styryl ring with methoxy groups at 2, 4 and 6-positions, 6p and 6t, respectively, showed optimum biological activity. The dimethyl quinone ester (6q) and water soluble disodium phosphate (6r) of 6p showed very good activity in both the cell lines tested. The water soluble glycine analog (25c) of 6t showed superior activity among all the 3-amino substituted amino acids tested.

Preliminary mode of action studies demonstrated that the lead compound 6t arrests tumor cell cycle at G2/M-phase and induces apoptotic cell death by microtubule depolymerization and caspase activation. In vivo anti-tumor effect of 6t in soft agar and nude mouse assays showed that this compound demonstrated considerable regression in tumor growth in a xenograft model. The fact that 6t does not appear to be a substrate of P-glycoprotein and other MDR-mediated efflux pumps based on cytotoxicity and cell permeability assays suggests 6t may penetrate the BBB sufficiently to be active in brain tumors, tumors not amenable to therapy by other natural product anti-mitotics. In conclusion, the lead compound 6t possessed oral bioavailability, pharmacological and toxicological characteristics that warrant further development as an exciting new class of anticancer agents.

EXPERIMENTAL SECTION

Chemistry

General Experimental Procedures

Melting points were determined on Electrothermal MEL-Temp 3.0 apparatus and were uncorrected. The proton nuclear resonance (1H NMR) spectra were performed on a Bruker AVANCE 300, 600 (1H, 300, 600 MHz; 13C, 75 MHz), Varian INOVA (400 MHz), and GE (500 MHz). Chemical shifts δ are given in ppm, and the following abbreviations are used: singlet (s), doublet (d), triplet (t), multiplet (m) and broad singlet (br s). Coupling constants (J) were measured in hertz (Hz). All LC/MS data were gathered on an Agilent 1200 LC with Agilent 6410 triple quadrupole mass spectrometer detectors. The compound solution was infused into the electrospray ionization source operating positive and negative modes in methanol/water/trifluoroacetic acid (50:50:0.1% v/v) at 0.4 mL/min. The sample cone (declustering) voltage was set at 100 V. The instrument was externally calibrated for the mass range m/z 100 to m/z 1000. The reactions were followed by TLC (Silica gel,) using chloroform: methanol (9.5:0.5 v/v). The purity of the newly synthesized compounds was determined by LC/MS analysis and was confirmed to be higher than 95% for all compounds. All reagents and solvents were purchased from commercial suppliers and used without further purification unless otherwise stated. Solvents were dried using standard procedures and reactions requiring anhydrous conditions were performed under N2 atmosphere. Reactions were monitored by Thin Layer Chromatography (TLC) on pre-coated silica gel F254 plates (Sigma-Aldrich) with a UV indicator. Yields were of purified product and were not optimized.

General Procedure for the Preparation of 3-Nitro-4-methoxyaniline (1g) (Scheme 3)

To a mixture of 4-fluoro-3-nitroaniline 7 (15.61 g, 100 mmol) in absolute methanol (364 mL) was added 6% methanolic potassium hydroxide (182 mL) at room temperature and stirred for 30 min. After completion of the reaction, the reaction mixture was acidified with concentrated hydrochloric acid and evaporated the methanol under vacuum to dryness. The crude residue on crystallization with aqueous methanol resulted pure 1g. Yield: 50%; pale yellow solid, mp 51–53 °C. 1H NMR (CDCl3, 300 MHz): δ 3.83 (s, 3H, OCH3), 6.28 (br s, 1H, NH2), 7.24 (d, J = 9.0 Hz, 1H, Ar-H), 7.32 (dd, J = 2.7, 9.0 Hz, 1H, Ar-H), 7.55 (d, J = 2.7 Hz, 1H, Ar-H). HRMS found [M+H]+ (m/z): 169.0568. Calcd for C7H8N2O3 m/z: 168.0535.

General Procedure for the Preparation of 4-Methoxy-3,5-dinitroaniline (1j) (Scheme 3)

Step 1: Synthesis of 4-Fluoro-3,5-dinitrobenzoic acid (9).24

4-Fluorobenzoic acid 8 (14.0 g, 10 mmol) was added in small portions to a mixture of 30 % oleum (121 g, 121 mmol) and 90% nitric acid (83.4 g, 132 mmol), under stirring at below 25 °C. The resulting clear yellow solution was heated initially to 85 °C and once the initial exothermic subsided, the reaction mixture was heated to 95 °C and maintained at same temperature for 3 h. After completion of the reaction, the mixture was cooled to room temperature and poured onto ice. The solid formed filtered, and washed with cold water, gave pure 9. Yield: 70%; mp 238–240 °C. 1H NMR (DMSO-d6, 300 MHz): δ 8.06 (s, 2H, Ar-H). HRMS found [M-H]− (m/z): 228.9968. Calcd for C7H3FN2O6 m/z: 229.9975.

Step 2: Synthesis of 4-Fluoro-3,5-Dinitroaniline (10)

To a solution of 4-fluoro-3,5-dinitrobenzoic acid, 9 (11.4 g, 49.5 mmol) in 20 % oleum (30 mL) was added ethylene dichloride (40 mL) and continued stirring at below 25 °C. To this sodium azide (3.7 g, 56.9 mmol) was added in small portions and the reaction mixture then heated to reflux and refluxed for 1 h. Once the reaction was completed, cool the reaction mixture to room temperature and separate the ethylene dichloride layer. The acidic solution was poured over ice, the solid formed filtered and washed with water, gave crude 10. Recrystallization from ethylene dichloride gave pure 10. Yield: 70.3%; yellow-orange crystals, mp 149–150 °C. 1H NMR (CDCl3, 500 MHz): δ 6.17 (s, 2H, NH2), 7.52 (d, J = 5.5 Hz, 2H, Ar-H). HRMS found [M+H]+ (m/z): 202.0156. Calcd for C6H4FN3O4 m/z: 201.0186.

Step 3: Synthesis of 4-Methoxy-3,5-Dinitroaniline (1j)

The title compound was obtained from 4-fluoro-3,5-dinitroaniline 10 following the procedure as described in compound 1g. Yield: 50.3%; mp 200–205 °C. 1H NMR (DMSO-d6, 500 MHz): δ 3.77 (s, 3H, OCH3), 6.09 (s, 2H, NH2), 7.34 (s, 2H, Ar-H). HRMS found [M+H]+ (m/z): 214.0409. Calcd for C7H7N3O5 m/z: 213.0386.

General Procedure for the Preparation of Ethyl 2-(Chlorosulfonyl)acetate (2) (Scheme 4)

Method A

Step 1: Synthesis of Sodium 2-Ethoxy-2-oxoethanesulfonate(12).25

To a solution of sodium sulfite (12.6 g, 100 mmol) in water (400 mL) at 18–20 °C was added a mixture of ethyl bromoacetate 11 (16.7 g, 100 mmol) in ethanol (200 mL) drop wise under stirring. After the addition was complete, the reaction mixture was heated to 50 °C and maintained for 30 min. Once the reaction completed, concentrated the reaction mass to dryness with the help of ethanol/benzene mixture (2 X 200 mL, 1:1 v/v) and make sure the water was removed completely. The resulted crude solid was extracted with boiling 2:1 acetic acid/ ethyl acetate (900 mL) and the hot solution was filtered through celite. The filtrate left overnight at room temperature, the solid separated was filtered, washed with cold ethyl acetate, dried under vacuum resulted pure 12 was used without characterization. Yield: 70% as white solid.

Step 2: Synthesis of Ethyl 2-(Chlorosulfonyl)acetate (2)

The mixture of sodium 2-ethoxy-2-oxoethanesulfonate, 12 (17.6 g, 100 mmol) and phosphorus (V) chloride (23.0 g, 110 mmol) was stirred until the reaction mass no longer exothermic. Then the reaction mixture was warmed on a steam bath for 45 min and distills off excess phosphorus (V) chloride under vacuum. To the residue, benzene was added (100 mL), stirred for 10 min and filtered through celite, washed with benzene and removal of solvent under vacuum gave pure 2, as clear oil. Yield: 85%. 1H NMR (CDCl3, 300 MHz): δ 1.29 (t, J = 6.9 Hz, 3H, CH3), 3.94 (s, 2H, CH2), 4.12 (q, J = 7.2 Hz, 2H, OCH2). HRMS found [M+H]+ (m/z): 186.9734. Calcd for C4H7ClO4S m/z: 185.9754.

Method B: Preparation of Ethyl 2-(Chlorosulfonyl)acetate (2).26

To a cooled solution of chlorosulfonylacetyl chloride, 13 (22.2 g, 125 mmol) in anhydrous diethyl ether (115 mL) was added absolute ethanol (5.78 g, 125 mmol) and maintained for 3 h at 0 °C. Removal of diethyl ether under vacuum resulted crude 2. Distillation of the crude resulted pure 2 as an oil. Yield: 55%; bp 123–126 °C (15 mm Hg). The analytical data are in accord with above method A product.

General Procedure for the Preparation of Ethyl Phenylsulfamoyl acetate (3). (Scheme 1)

To a solution of aniline, 1 (10.0 g, 107 mmol) in dichloromethane (150 mL) at 10 °C, was added triethylamine (16.3 g, 161 mmol) dropwise and stirred for 15 min at same temperature. To this ethyl 2-(chlorosulfonyl)acetate, 2 (22.0 g, 118 mmol) dissolved in dichloromethane (25 mL) was added slowly at same temperature. Once the addition is over, the reaction mixture was allowed to warm to room temperature and stirred for 3 h. After completion of reaction, water was added, stirred for 15 min and separated the organic layer, dried over anhydrous sodium sulfate and evaporated under reduced pressure resulted crude 3, as an oil. The crude on silica gel column purification (1:1, ethyl acetate: hexane) resulted pure 3. The following ethyl phenylsulfamoyl acetates 3 were prepared using the above procedure.

Ethyl 2-(N-Phenylsulfamoyl)acetate (3a)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to aniline, 1a yielded the corresponding ethyl 2-(N-phenylsulfamoyl)acetate. Yield: 80%, as oil. 1H NMR (CDCl3, 300 MHz): δ 1.31 (t, J = 6.9 Hz, 3H, CH3), 3.96 (s, 2H, CH2), 4.31 (q, J = 7.2 Hz, 2H, OCH2), 6.85 (br s, 1H, NH), 7.38–7.46 (m, 5H, Ar-H). HRMS found [M+H]+ (m/z): 244.0589. Calcd for C10H13NO4S m/z: 243.0565.

Ethyl 2-(N-(4-Chlorophenyl)sulfamoyl)acetate (3b)

Addition of ethyl 2-(chlorosulfonyl)-acetate, 2 to 4-chloroaniline, 1b yielded the corresponding ethyl 2-(N-(4-chlorophenyl)sulfamoyl)acetate. Yield: 81%; light yellow solid, mp 78–79 °C. 1H NMR (CDCl3, 300 MHz): δ 1.34 (t, J = 6.9 Hz, 3H, CH3), 3.94 (s, 2H, CH2), 4.29 (q, J = 7.2 Hz, 2H, OCH2), 7.05 (br s, 1H, NH), 7.27–7.38 (m, 4H, Ar-H). HRMS found [M+H]+ (m/z): 278.0201. Calcd for C10H12ClNO4S m/z: 277.0176.

Ethyl 2-(N-(4-Fluorophenyl)sulfamoyl)acetate (3c)

Addition of ethyl 2-(chlorosulfonyl)-acetate, 2 to 4-fluoroaniline, 1c yielded the corresponding ethyl 2-(N-(4-fluorophenyl)-sulfamoyl)acetate. Yield: 79%; light brown solid, mp 65–66 °C. 1H NMR (CDCl3, 300 MHz): δ 1.33 (t, J = 7.2 Hz, 3H, CH3), 3.93 (s, 2H, CH2), 4.29 (q, J = 7.2 Hz, 2H, OCH2), 7.03–7.13 (m, 2H, Ar-H), 7.18 (br s, 1H, NH), 7.32–7.40 (m, 2H, Ar-H). HRMS found [M+H]+ (m/z): 262.0500. Calcd for C10H12FNO4S m/z: 261.0471.

Ethyl 2-(N-(4-Methoxyphenyl)sulfamoyl)acetate (3d)

Addition of ethyl 2-(chlorosulfonyl)-acetate, 2 to 4-methoxyaniline, 1d yielded the corresponding ethyl 2-(N-(4-methoxyphenyl)-sulfamoyl)acetate. Yield: 79%; pale yellow sold, mp 74–76 °C. 1H NMR (CDCl3, 300 MHz): δ 1.34 (t, J = 6.9 Hz, 3H, CH3), 3.83 (s, 2H, CH2), 3.86 (s, 3H, OCH3), 4.30 (q, J = 7.2 Hz, 2H, OCH2), 6.82 (br s, 1H, NH), 6.88 (d, J = 9.0 Hz, 2H, Ar-H), 7.14 (d, J = 9.0 Hz, 2H, Ar-H). HRMS found [M+H]+ (m/z): 274.0694. Calcd for C11H15NO5S m/z: 273.0671.

Ethyl 2-(N-(3-Fluoro-4-methoxyphenyl)sulfamoyl)acetate (3e)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 3-fluoro-4-methoxyaniline, 1e yielded the corresponding ethyl 2-(N-(3-fluoro-4-methoxyphenyl)sulfamoyl)acetate. Yield: 79%; light yellow solid, mp 81–83 °C. 1H NMR (CDCl3, 300 MHz): δ 1.33 (t, J = 7.2 Hz, 3H, CH3), 3.82 (s, 2H, CH2), 3.87 (s, 3H, OCH3), 4.28 (q, J = 7.2 Hz, 2H, OCH2), 6.84 (br s, 1H, NH), 6.92 (d, J = 9.0 Hz, 1H, Ar-H), 7.08 (dd, J = 2.4, 8.4 Hz, 1H, Ar-H), 7.19 (d, J = 2.4 Hz, 1H, Ar-H). HRMS found [M+H]+ (m/z): 292.0600. Calcd for C11H14FNO5S m/z: 291.0577.

Ethyl 2-(N-(2,4,6-Trimethoxyphenyl)sulfamoyl)acetate (3f)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 2,4,6-trimethoxyaniline, 1f yielded the corresponding ethyl 2-(N-(2,4,6-trimethoxyphenyl)sulfamoyl)acetate. Yield: 78%; light yellow solid, mp 76–78 °C. 1H NMR (CDCl3, 300 MHz): δ 1.33 (t, J = 7.2 Hz, 3H, CH3), 3.81 (s, 9H, 3 X OCH3), 3.90 (s, 2H, CH2), 4.29 (q, J = 7.2 Hz, 2H, OCH2), 6.04 (s, 2H, Ar-H), 6.79 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 334.0906. Calcd for C13H19NO7S m/z: 333.0882.

Ethyl 2-(N-(4-Methoxy-3-nitrophenyl)sulfamoyl)acetate (3g)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 3-nitro-4-methoxyaniline, 1g yielded the corresponding ethyl 2-(N-(4-methoxy-3-nitrophenyl)sulfamoyl)acetate. Yield: 80%; white crystalline solid, mp 100–102 °C. 1H NMR (CDCl3, 300 MHz): δ 1.36 (t, J = 7.2 Hz, 3H, CH3), 3.94 (s, 2H, CH2), 3.99 (s, 3H, OCH3), 4.32 (q, J = 7.2 Hz, 2H, OCH2), 7.07 (br s, 1H, NH), 7.13 (d, J = 9.0 Hz, 1H, Ar-H), 7.62 (dd, J = 2.7, 9.0 Hz, 1H, Ar-H), 7.86 (d, J = 2.7 Hz, 1H, Ar-H). HRMS found [M+H]+ (m/z): 319.0535. Calcd for C11H14N2O7S m/z: 318.0522.

Ethyl 2-(N-(Perfluorophenyl)sulfamoyl)acetate (3h)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 2,3,4,5,6-pentafluoroaniline, 1h yielded the corresponding ethyl 2-(N-(perfluorophenyl)sulfamoyl)acetate. Yield: 78%; brown liquid. 1H NMR (CDCl3, 300 MHz): δ 1.35 (t, J = 7.2 Hz, 3H, CH3), 3.94 (s, 2H, CH2), 4.32 (q, J = 7.2 Hz, 2H, OCH2), 7.07 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 334.0118. Calcd for C10H8F5NO4S m/z: 333.0094.

Ethyl 2-(N-(4-Fluoro-3-nitrophenyl)sulfamoyl)acetate (3i)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 4-fluoro-3-nitroaniline, 1i yielded the corresponding ethyl 2-(N-(4-fluoro-3-nitrophenyl)sulfamoyl)acetate. Yield: 78%; light yellow solid, mp 98–100 °C. 1H NMR (CDCl3, 300 MHz): δ 1.35 (t, J = 7.2 Hz, 3H, CH3), 3.92 (s, 2H, CH2), 4.30 (q, J = 7.2 Hz, 2H, OCH2), 7.05 (br s, 1H, NH), 7.32 (d, J = 9.0 Hz, 1H, Ar-H), 7.69 (dd, J = 2.7, 9.0 Hz, 1H, Ar-H), 7.80 (d, J = 2.7 Hz, 1H, Ar-H). HRMS found [M+H]+ (m/z): 307.0345. Calcd for C10H11FN2O6S m/z: 306.0322.

Ethyl 2-(N-(4-Methoxy-3,5-dinitrophenyl)sulfamoyl)acetate (3j)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 4-methoxy-3,5-dinitroaniline, 1j yielded the corresponding ethyl 2-(N-(4-methoxy-3,5-dinitrophenyl)sulfamoyl)acetate. Yield: 79%; light yellow solid, mp 126–128 °C. 1H NMR (DMSO-d6, 300 MHz): δ 1.31 (t, J = 7.2 Hz, 3H, CH3), 3.92 (s, 3H, OCH3), 4.13 (q, J = 7.2 Hz, 2H, OCH2), 4.43 (s, 2H, CH2), 8.04 (s, 2H, Ar-H), 10.90 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 364.0400. Calcd for C11H13N3O9S m/z: 363.0372.

Ethyl 2-(N-(3-Hydroxy-4-methoxyphenyl)sulfamoyl)acetate (3k)

Addition of ethyl 2-(chlorosulfonyl)acetate, 2 to 3-hydroxy-4-methoxyaniline, 1k yielded the corresponding ethyl 2-(N-(3-hydroxy-4-methoxyphenyl)sulfamoyl)acetate. Yield: 79%; light brown solid, mp 116–118 °C. 1H NMR (CDCl3, 300 MHz): δ 1.35 (t, J = 7.2 Hz, 3H, CH3), 3.91 (s, 3H, OCH3), 3.93 (s, 2H, CH2), 4.31 (q, J = 7.2 Hz, 2H, OCH2), 5.63 (br s, 1H, OH), 6.76 (br s, 1H, NH), 6.83 (d, J = 8.4 Hz, 1H, Ar-H), 6.88 (dd, J = 2.4, 8.4 Hz, 1H, Ar-H), 6.96 (d, J = 2.4 Hz, 1H, Ar-H). HRMS found [M+H]+ (m/z): 290.0644. Calcd for C11H15NO6S m/z: 289.0620.

General Procedure for the Preparation of Phenylsulfamoyl acetic acid (4). (Scheme 1)

A cooled solution of sodium hydroxide (4.88 g, 122 mmol) in water (122 mL) was added to ethyl 2-(N-phenylsulfamoyl)acetate, 3a (4.15 g, 18.1 mmol) slowly and continued stirring for 3 h at room temperature. After completion of the reaction, the reaction mixture was cooled to 0 °C; concentrated hydrochloric acid was added slowly at 0 °C until the pH of the reaction mixture is in between 3.0–4.0 and stir for 30 min. The solid formed was filtered, washed with cold water and dried under vacuum. The dried product was used without further purification. The following phenylsulfamoyl acetic acids 4 were prepared using the above procedure.

2-(N-Phenylsulfamoyl)acetic acid (4a)

Hydrolysis followed by neutralization of ethyl 2-(N-phenylsulfamoyl) acetate 3a resulted the corresponding 2-(N-phenylsulfamoyl)acetic acid. Yield: 81%: light yellow solid, mp 110–111 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.98 (s, 2H, CH2), 7.38–7.46 (m, 5H, Ar-H), 9.85 (br s, 1H, NH), 12.70 (br s, 1H, COOH). HRMS found [M-H]−(m/z): 214.0276. Calcd for C8H9NO4S m/z: 215.0252.

2-(N-(4-Chlorophenyl)sulfamoyl)acetic acid (4b)

Hydrolysis followed by neutralization of ethyl 2-(N-(4-chlorophenyl)sulfamoyl)acetate, 3b resulted the corresponding 2-(N-(4-chlorophenyl)sulfamoyl)acetic acid. Yield: 84%; white solid, mp 126–128 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.84 (s, 2H, CH2), 7.23 (d, J = 9.0 Hz, 2H, Ar-H), 7.37 (d, J = 9.0 Hz, 2H, Ar-H), 10.32 (br s, 1H, NH). HRMS found [M-H]− (m/z): 247.9833. Calcd for C8H8ClNO4S m/z: 248.9863.

2-(N-(4-Fluorophenyl)sulfamoyl)acetic acid (4c)

Hydrolysis followed by neutralization of ethyl 2-(N-(4-fluorophenyl)sulfamoyl)acetate, 3c resulted the corresponding 2-(N-(4-fluorophenyl)sulfamoyl)acetic acid. Yield; 81%; light brown solid, mp 114–116 °C. 1H NMR (DMSO-d6, 300 MHz): δ 4.06 (s, 2H, CH2), 7.17–7.28 (m, 4H, Ar-H), 10.04 (br s, 1H, NH), 12.70 (br s, 1H, COOH). HRMS found [M-H]− (m/z): 234.0182. Calcd for C8H8FNO4S m/z: 233.0158.

2-(N-(4-Methoxyphenyl)sulfamoyl)acetic acid (4d)

Hydrolysis followed by neutralization of ethyl 2-(N-(4-methoxyphenyl)sulfamoyl)acetate, 3d resulted the corresponding 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid. Yield: 82%; white solid, mp 166–168 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.70 (s, 2H, CH2), 3.73 (s, 3H, OCH3), 6.90 (d, J = 9.0 Hz, 2H, Ar-H), 7.17 (d, J = 9.0 Hz, 2H, Ar-H), 9.76 (br s, 1H, NH). HRMS found [M-H]− (m/z): 246.0381. Calcd for C9H11NO5S m/z: 245.0358.

2-(N-(3-Fluoro-4-methoxyphenyl)sulfamoyl)acetic acid (4e)

Hydrolysis followed by neutralization of ethyl 2-(N-(3-fluoro-4-methoxyphenyl)sulfamoyl)acetate, 3e resulted the corresponding 2-(N-(3-fluoro-4-methoxyphenyl)sulfamoyl)acetic acid. Yield: 82%; light brown sold, mp 176–178 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.77 (s, 2H, CH2), 3.81 (s, 3H, OCH3), 6.98–7.02 (m, 1H, Ar-H), 7.05–7.13 (m, 1H, Ar-H), 7.18 (d, J = 9.0 Hz, 1H, Ar-H), 9.72 (br s, 1H, NH). HRMS found [M-H]− (m/z): 262.0285. Calcd for C9H10FNO5S m/z: 263.0264.

2-(N-(2,4,6-Trimethoxyphenyl)sulfamoyl)acetic acid (4f)

Hydrolysis followed by neutralization of ethyl 2-(N-(2,4,6-trimethoxyphenyl)sulfamoyl)acetate, 3f resulted the corresponding 2-(N-(2,4,6-trimethoxyphenyl)sulfamoyl)acetic acid. Yield: 80%; white solid, mp 150–152 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.81 (s, 9H, 3 X OCH3), 3.90 (s, 2H, CH2), 6.04 (s, 2H, Ar-H), 9.89 (br s, 1H, NH). HRMS found [M-H]− (m/z): 304.0545. Calcd for C11H15NO7S m/z: 305.0569.

2-(N-(4-methoxy-3-nitrophenyl)sulfamoyl)acetic acid (4g)

Hydrolysis followed by neutralization of ethyl 2-(N-(4-methoxy-3-nitrophenyl)sulfamoyl)acetate, 3g resulted the corresponding 2-(N-(4-methoxy-3-nitrophenyl)sulfamoyl)acetic acid. Yield: 84%; light yellow solid, mp 154–156 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.91 (s, 3H, OCH3), 4.14 (s, 2H, CH2), 7.39 (d, J = 9.0 Hz, 1H, Ar-H), 7.50 (dd, J = 2.7, 9.0 Hz, 1H, Ar-H), 7.73 (d, J = 2.7 Hz, 1H, Ar-H), 10.22 (br s, 1H, NH), 12.71 (br s, 1H, COOH). HRMS found [M-H]− (m/z): 289.0232. Calcd for C9H10N2O7S m/z: 290.0209.

2-(N-(Perfluorophenyl)sulfamoyl)acetic acid (4h)

Hydrolysis followed by neutralization of ethyl 2-(N-(perfluorophenyl)sulfamoyl)acetate, 3h resulted the corresponding 2-(N-(perfluorophenyl)sulfamoyl)acetic acid. Yield: 79%; white crystalline solid, mp 142–144 °C. 1H NMR (DMSO-d6, 300 MHz): δ 4.35 (s, 2H, CH2), 10.07 (br s, 1H, NH), 12.71 (br s, 1H, COOH). HRMS found [M-H]− (m/z): 303.9802. Calcd for C8H4F5NO4S m/z: 304.9781.

2-(N-(4-Fluoro-3-nitrophenyl)sulfamoyl)acetic acid (4i)

Hydrolysis followed by neutralization of ethyl 2-(N-(4-fluoro-3-nitrophenyl)sulfamoyl)acetate, 3i resulted the corresponding 2-(N-(4-fluoro-3-nitrophenyl)sulfamoyl)acetic acid. Yield: 78%; light yellow solid, mp 132–134 °C. 1H NMR (DMSO-d6, 500 MHz): δ 4.35 (s, 2H, CH2), 7.47 (dd, J = 2.7, 9.0 Hz, 1H, Ar-H), 7.75 (d, J = 9.0 Hz, 1H, Ar-H), 7.85 (d, J = 2.7 Hz, 1H, Ar-H), 10.78 (br s, 1H, NH), 13.26 (br s, 1H, COOH). HRMS found [M-H]− (m/z): 277.0026. Calcd for C8H7FN2O6S m/z: 278.0009.

2-(N-(4-Methoxy-3,5-dinitrophenyl)sulfamoyl)acetic acid (4j)

Hydrolysis followed by neutralization of ethyl 2-(N-(4-methoxy-3,5-dinitrophenyl)sulfamoyl)acetate, 3j resulted the corresponding 2-(N-(4-methoxy-3,5-dinitrophenyl)sulfamoyl)acetic acid. Yield: 79%; brown solid, mp 150–152 °C. 1H NMR (DMSO-d6, 300 MHz): δ 3.92 (s, 3H, OCH3), 4.43 (s, 2H, CH2), 8.04 (s, 2H, Ar-H), 10.90 (br s, 1H, NH), 12.98 (br s, 1H, COOH). HRMS found [M-H]− (m/z): 334.0081. Calcd for C9H9N3O9S m/z: 335.0059.

2-(N-(3-Hydroxy-4-methoxyphenyl)sulfamoyl)acetic acid (4k)

Hydrolysis followed by neutralization of ethyl 2-(N-(3-hydroxy-4-methoxyphenyl)sulfamoyl)acetate, 3k resulted the corresponding 2-(N-(3-hydroxy-4-methoxyphenyl)sulfamoyl)acetic acid. Yield: 78%; off-white solid, mp 150–152 °C. 1H NMR (DMSO-d6, 500 MHz): δ 3.78 (s, 2H, CH2), 3.94 (s, 3H, OCH3), 6.61 (dd, J = 2.4, 8.4 Hz, 1H, Ar-H), 6.76 (d, J = 2.7 Hz, 1H, Ar-H), 6.82 (d, J = 8.7 Hz, 1H, Ar-H), 9.28 (br s, 1H, NH), 9.52 (br s, 1H, COOH). HRMS found [M-H]− (m/z): 260.0326. Calcd for C9H11NO6S m/z: 261.0307.

General Procedure for the Preparation of (E)-N-Aryl-2-arylethenesulfonamide (6)

Method A (Scheme 1)

A mixture of 2-(N-phenylsulfamoyl)acetic acid 4 (10 mmol), araldehyde 5 (10 mmol), glacial acetic acid (15 mL) was stirred at room temperature for 10 min. A catalytic amount of benzylamine (200 μL) was added and refluxed for about 8 h. After completion of the reaction, the contents were cooled to room temperature and dilute with ethyl acetate. The precipitated solid was filtered and washed with ethyl acetate, the resulted crude 6 on silica gel column purification recrystallized resulted pure 6. If solid was not formed, the diluted reaction mixture with ethyl acetate was washed successively with saturated sodium bicarbonate, dilute hydrochloric acid, and water. The organic layer was dried over anhydrous sodium sulfate, filtered, and concentrated under vacuum to obtain the desired crude product 6. The crude product on silica gel column purification yielded an analytically pure 6. The following (E)-N-aryl-2-arylethenesulfonamide 6 were prepared using the above procedure.

(E)-N,2-Diphenylethenesulfonamide (6a)

The title compound was obtained from 2-(N-phenylsulfamoyl) acetic acid 4a and benzaldehyde following the procedure as described in method A. Yield, 50%; off white solid, mp 112–114 °C. 1H NMR (CDCl3, 300 MHz): δ 6.58 (br s, 1H, NH), 6.81 (d, J = 15.3 Hz, 1H, =CH), 7.14–7.24 (m, 3H, Ar-H), 7.30–7.37 (m, 2H, Ar-H), 7.38–7.46 (m, 5H, Ar-H), 7.53 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 260.0689. Calcd for C14H13NO2S m/z: 259.0667.

(E)-N-(4-Chlorophenyl)-2-phenylethenesulfonamide (6b)

The title compound was obtained from 2-(N-(4-chlorophenylsulfamoyl)acetic acid 4b and benzaldehyde following the procedure as described in method A. Yield, 49%; white crystalline solid, mp 108–110 °C. 1H NMR (CDCl3, 300 MHz): δ 6.57 (br s, 1H, NH), 6.79 (d, J = 15.3 Hz, 1H, =CH), 7.17 (dd, J = 6.9, 2.4 Hz, 2H, Ar-H), 7.30 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.37–7.48 (m, 5H, Ar-H), 7.52 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 294.0301. Calcd for C14H12ClNO2S m/z: 293.0277.

(E)-2-(4′-Bromophenyl)-N-(4-fluorophenyl)ethenesulfonamide (6c)

The title compound was obtained from 2-(N-(4-fluorophenylsulfamoyl)acetic acid 4c and 4-bromobenzaldehyde following the procedure as described in method A. Yield, 48%; white crystalline solid, mp 138–140 °C. 1H NMR (CDCl3, 300 MHz): δ 6.46 (br s, 1H, NH), 6.71 (d, J = 15.3 Hz, 1H, =CH), 7.05–7.13 (m, 4H, Ar-H), 7.43–7.46 (m, 4H, Ar-H), 7.49 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 355.9702. Calcd for C14H11BrFNO2S m/z: 354.9678.

(E)-N-(4-Fluorophenyl)-2-(4′-methoxyphenyl)ethenesulfonamide (6d)

The title compound was obtained from 2-(N-(4-fluorophenylsulfamoyl)acetic acid 4c and 4-methoxybenzaldehyde following the procedure as described in method A. Yield, 49%; off white crystalline solid, mp 98–100 °C. 1H NMR (CDCl3, 300 MHz): δ 3.85 (s, 3H, OCH3), 6.43 (br s, 1H, NH), 6.71 (d, J = 15.3 Hz, 1H, =CH), 6.88–6.92 (m, 2H, Ar-H), 6.98–7.06 (m, 2H, Ar-H), 7.17–7.24 (m, 2H, Ar-H), 7.36–7.40 (m, 2H, Ar-H), 7.41 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 308.0703. Calcd for C15H14FNO3S m/z: 307.0678.

(E)-2-(2′-Methoxyphenyl)-N-(4-methoxyphenyl)ethenesulfonamide (6e)

Method B (Scheme 1)

A mixture of 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid, 4d (5 mmol), 2-methoxy-benzaldehyde (5.5 mmol), benzoic acid (0.30 mmol), and piperidine (0.30 mmol) in toluene (50 mL) was refluxed for 4 h with continuous removal of water using a Dean-Stark water separator. After the reaction completion, the solvent was evaporated. To the residue added methanol and stirred for 10 min. The solid formed was filtered and washed with cold methanol and dried under vacuum yielded product 6e. If no formation of solid observed, concentrated and water was added to the residue and extracted with ethyl acetate. The organic phase was washed with saturated sodium bicarbonate solution, dilute hydrochloric acid, and water and dried over anhydrous sodium sulfate. The organic phase was filtered, and evaporation of the solvent under vacuum yielded a crude product 6. The pure compound 6 was obtained following purification by silica gel flash column chromatography. Yield, 65%; white solid, mp 112–114 °C. 1H NMR (DMSO-d6, 600 MHz): δ 3.61 (s, 3H, OCH3), 3.76 (s, 3H, OCH3), 6.79 (d, J = 7.9 Hz, 2H, Ar-H), 6.89 (t, J = 6.8 Hz, 1H, Ar-H), 7.03 (m, 4H, Ar-H), 7.34 (t, J = 6.8 Hz, 1H, Ar-H), 7.41 (d, J = 15.4 Hz, 1H, =CH), 7.55 (d, J = 6.9 Hz, 1H, Ar-H), 9.53 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 320.0849. Calcd for C16H17NO4S m/z: 319.0878.

(E)-N,2-Bis(4-methoxyphenyl)ethenesulfonamide (6f)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid (4d) and 4-methoxybenzaldehyde following the procedure as described in 6e method B. Yield, 60%; semi solid. 1H NMR (DMSO-d6, 600 MHz): δ 3.61 (s, 3H, OCH3), 3.70 (s, 3H, OCH3), 6.78 (d, J = 9.0 Hz, 2H, Ar-H), 6.87 (d, J = 8.9 Hz, 2H, Ar-H), 6.92 (d, J = 15.4 Hz, 1H, =CH), 7.03 (d, J = 8.9 Hz, 2H, Ar-H), 7.18 (d, J = 15.4 Hz, 1H, CH=), 7.54 (d, J = 8.7 Hz, 2H, Ar-H), 9.50 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 320.0846. Calcd for C16H17NO4S m/z: 319.0878.

(E)-2-(2′,4′-Dimethoxyphenyl)-N-(4-methoxyphenyl)ethenesulfonamide (6g)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid (4d) and 2,4-dimethoxybenzaldehyde following the procedure as described in 6e method B. Yield, 60%; white solid, mp 162–164 °C. 1H NMR (DMSO-d6, 600 MHz): δ 3.61 (s, 3H, OCH3), 3.72 (s, 3H, OCH3), 3.76 (s, 3H, OCH3), 6.48 (dd, J = 8.5, 1.5 Hz, 1H, Ar-H), 6.53 (d, J = 1.5 Hz, 1H, Ar-H), 6.78 (d, J = 8.8 Hz, 2H, Ar-H), 6.86 (d, J = 15.5 Hz, 1H, =CH), 7.02 (d, J = 8.8 Hz, 2H, Ar-H), 7.33 (d, J = 15.5 Hz, 1H, CH=), 7.48 (d, J = 8.5 Hz, 1H, Ar-H), 9.42 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 350.1007. Calcd for C17H19NO5S m/z: 349.0984.

(E)-2-(2′,6′-Dimethoxyphenyl)-N-(4-methoxyphenyl)ethenesulfonamide (6h)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid (4d) and 2,6-dimethoxybenzaldehyde following the procedure as described in 6e method B. Yield, 65%; white solid, mp 160–162 °C. 1H NMR (DMSO-d6, 600 MHz): δ 3.61 (s, 3H, OCH3), 3.75 (s, 6H, 2 X OCH3), 6.63 (d, J = 8.4 Hz, 2H, Ar-H), 6.79 (d, J = 8.7 Hz, 2H, Ar-H), 7.02 (d, J = 8.8 Hz, 2H, Ar-H), 7.05 (d, J = 15.9 Hz, 1H, =CH), 7.29 (t, J = 8.3 Hz, 1H, Ar-H), 7.51 (d, J = 15.6 Hz, 1H, CH=), 9.41 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 350.0959. Calcd for C17H19NO5S m/z: 349.0984.

(E)-N-(4-Methoxyphenyl)-2-(2′,4′,6′-trimethoxyphenyl)ethenesulfonamide (6i)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid 4d and 2,4,6-trimethoxybenzaldehyde following the procedure as described in method A. Yield, 49%; light yellow solid, mp 176–178 °C. 1H NMR (CDCl3, 300 MHz): δ 3.79 (s, 3H, OCH3), 3.84 (s, 6H, 2 X OCH3), 3.85 (s, 3H, OCH3), 6.09 (s, 2H, Ar-H), 6.12 (br s, 1H, NH), 6.85 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.11 (d, J = 15.6 Hz, 1H, =CH), 7.18 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.81 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 380.1113. Calcd for C18H21NO6S m/z: 379.1090.

(E)-N-(4-Methoxyphenyl)-2-(3′,4′,5′-trimethoxyphenyl)ethenesulfonamide (6j)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid 4d and 3,4,5-trimethoxybenzaldehyde following the procedure as described in 6e method B. Yield, 60%; pale yellow solid, mp 66–68 °C. 1H NMR (DMSO-d6, 600 MHz): δ 3.61 (s, 3H, OCH3), 3.65 (s, 3H, OCH3), 3.71 (s, 6H, 2 X OCH3), 6.84 (d, J = 8.9 Hz, 2H, Ar-H), 6.95 (s, 2H, Ar-H), 7.07 (d, J = 8.9 Hz, 2H, Ar-H), 7.15 (d, J = 15.3 Hz, 1H, =CH), 7.19 (d, J = 15.3 Hz, 1H, CH=), 9.58 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 380.1068. Calcd for C18H21NO6S m/z: 379.1090.

(E)-2-(4′-Methoxyphenyl)-N-(2,4,6-trimethoxyphenyl)ethenesulfonamide (6k)

The title compound was obtained from 2-(N-(2,4,6-trimethoxyphenyl)sulfamoyl)acetic acid 4f and 4-methoxybenzaldehyde following the procedure as described in method A. Yield, 49%; off white solid, mp 156–158 °C. 1H NMR (CDCl3, 300 MHz): δ 3.81 (s, 9H, 3 X OCH3), 3.86 (s, 3H, OCH3), 5.84 (br s, 1H, NH), 6.13 (s, 2H, Ar-H), 6.83 (d, J = 15.3 Hz, 1H, =CH), 6.92 (dd, J = 2.1, 6.6 Hz, 2H, Ar-H), 7.32 (d, J = 15.6 Hz, 1H, CH=), 7.42 (dd, J = 2.1, 6.6 Hz, 2H, Ar-H). HRMS found [M+H]+ (m/z): 380.1071. Calcd for C18H21NO6S m/z: 379.1090.

(E)-2-(4′-Hydroxy-2′,6′-dimethoxyphenyl)-N-(4-methoxyphenyl)ethenesulfonamide (6l)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid 4d and 2,6-dimethoxy-4-hydroxybenzaldehyde following the procedure as described in 6e method B. Yield, 60%; white solid, mp 146–148 °C. 1H NMR (CDCl3, 300 MHz): δ 3.82 (s, 3H, OCH3), 3.86 (s, 6H, 2 X OCH3), 6.05 (s, 2H, Ar-H), 6.50 (br s, 1H, NH), 6.86 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.13 (d, J = 15.6 Hz, 1H, =CH), 7.20 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.82 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M-H]− (m/z): 364.0957. Calcd for C17H19NO6S m/z: 365.0933.

(E)-N-(4-Methoxyphenyl)-2-(2′,4′,6′-trifluorophenyl)ethenesulfonamide (6m)

The title compound was obtained from 2-(N-(4-methoxyphenyl)sulfamoyl)acetic acid 4d and 2,4,6-trifluorobenzaldehyde following the procedure as described in 6e method B. Yield, 60%; pale yellow solid, mp 120–122 °C. 1H NMR (DMSO-d6, 600 MHz): δ 3.62 (s, 3H, OCH3), 6.81 (d, J = 8.9 Hz, 2H, Ar-H), 6.94 (d, J = 15.8 Hz, 1H, =CH), 7.05 (d, J = 8.9 Hz, 2H, Ar-H), 7.06 (d, J = 15.8 Hz, 1H, CH=), 7.28 (t, J = 9.1 Hz, 2H, Ar-H), 9.68 (br s, 1H, NH). HRMS found [M+H]+ (m/z): 344.0511. Calcd for C15H12F3NO3S m/z: 343.0490.

(E)-N-(4-Methoxyphenyl)-2-(perfluorophenyl)ethenesulfonamide (6n)

The title compound was obtained from 2-(N-(4-methoxyphenylsulfamoyl)acetic acid 4d and 2,3,4,5,6-pentafluorobenzaldehyde following the procedure as described in method A. Yield, 48%; light yellow solid, mp 131–133 °C. 1H NMR (CDCl3, 300 MHz): δ 3.85 (s, 3H, OCH3), 6.43 (b r s, 1H, NH), 6.85 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.12 (d, J = 15.3 Hz, 1H, =CH), 7.18 (dd, J = 6.6, 2.1 Hz, 2H, Ar-H), 7.81 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 380.0326. Calcd for C15H10F5NO3S m/z: 379.0302.

(E)-N-(3-Fluoro-4-methoxyphenyl)-2-(2′,4′,6′-trimethoxyphenyl)ethenesulfonamide (6o)

The title compound was obtained from 2-(N-(3-fluoro-4-methoxyphenyl)sulfamoyl)acetic acid 4e and 2,4,6-trimethoxybenzaldehyde following the procedure as described in method A. Yield, 49%; light yellow solid, mp 152–154 °C. 1H NMR (CDCl3, 300 MHz): δ 3.85 (s, 6H, 2 X OCH3), 3.86 (s, 3H, OCH3), 3.87 (s, 3H, OCH3), 6.10 (s, 2H, Ar-H), 6.24 (br s, 1H, NH), 6.86 – 6.95 (m, 2H, Ar-H), 7.07 (dd, J = 12.0, 2.1 Hz, 1H, Ar-H), 7.09 (d, J = 15.6 Hz, 1H, =CH), 7.85 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 398.1014. Calcd for C18H20FNO6S m/z: 397.0995.

(E)-N-(3-Hydroxy-4-methoxyphenyl)-2-(2′,4′,6′-trimethoxyphenyl)ethenesulfonamide (6p)

The title compound was obtained from 2-(N-(3-Hydroxy-4-methoxyphenyl)sulfamoyl)acetic acid 4k and 2,4,6-trimethoxybenzaldehyde following the procedure as described in 6e method B. Yield, 64%; light green solid, mp 148–150 °C. 1H NMR (CDCl3, 300 MHz): δ 3.84 (s, 6H, 2 X OCH3), 3.85 (s, 3H, OCH3), 3.87 (s, 3H, OCH3), 5.63 (br s, 1H, OH), 6.09 (s, 2H, Ar-H), 6.11 (br s, 1H, NH), 6.73 – 6.83 (m, 3H, Ar-H), 7.12 (d, J = 15.6 Hz, 1H, =CH), 7.86 (d, J = 15.6 Hz, 1H, CH=). HRMS found [M+H]+ (m/z): 396.1062. Calcd for C18H21NO7S m/z: 395.1039.

(E)-2-Methoxy-5-(2-(2,4,6-trimethoxyphenyl)vinylsulfonamido)phenyl 2-(2,5-dimethyl-3,6-dioxocyclohexa-1,4-dienyl)-2-methylpropanoate (6q). (Scheme 7)

Step 1: Preparation of 3-(2,5-dimethyl-3,6-dioxocyclohexa-1,4-dienyl)-3-methylbutanoic acid (20). (Scheme 8).29

Stage 1: Preparation of 6-Hydroxy-4,4,5,8-tetramethylchroman-2-one (22)

To a solution of 2,5-Dimethylbenzoquinone 21 (10 g, 73.5 mmol) in diethyl ether (300 mL) was added an aqueous solution of sodium hydrosulfite (178.0 g, 870 mmol in 150 mL water). The mixture was shaken until the ether layer became colorless. The ether layer was separated and the aqueous layer was extracted with diethyl ether (3 X 200 mL). The combined ether layer were washed with brine (2 X 150 mL) and dried over anhydrous sodium sulfate. Evaporation of solvent under vacuum resulted dihydroquinone as a white solid. The above dihydroquinone (10.03 g, 72.6 mmol) was mixed with 3,3-dimethylacrylic acid (8.0 g, 80 mmol) and methanesulfonic acid (111 mL) and stirred at room temperature for 10 min and heated to 85 °C for 3 h. After completion of reaction, cooled to room temperature and poured onto ice and extracted with ethyl acetate (4 X 100 mL). The combined organic layers were washed with saturated sodium bicarbonate solution (2 X 100 mL), water (3 X 100 mL) and dried over anhydrous sodium sulfate. Evaporation of solvent under vacuum resulted crude 22, which on recrystallization with ethyl acetate and hexane (1:1) resulted pure 22. Yield, 81%; light brown solid, mp 194–196 °C. 1H NMR (CDCl3, 400 MHz): δ 1.64 (s, 6H, 2 X CH3), 2.39 (s, 3H, CH3), 2.51 (s, 3H, CH3), 2.74 (s, 2H, CH2), 5.10 (bs, 1H, OH), 6.75 (s, 1H, Ar-H). HRMS found [M+H]+ (m/z): 221.1112. Calcd for C13H16O3 m/z: 220.1099.

Stage 2: Preparation of 3-(2,5-dimethyl-3,6-dioxocyclohexa-1,4-dienyl)-3-methylbutanoic acid (20)