Abstract

Piezoelectric materials lie at the heart of electromechanical devices. Applications include actuators, ultrasonic imaging, high intensity focused ultrasound, underwater ultrasound, nondestructive evaluation transducer, pressure sensors, and accelerometers, to name a few. In this work, the advantages and disadvantages of relaxor-PbTiO3-based single crystals are discussed, based on the requirements (figure of merit) of various applications, with emphasis on recent developments of the shear properties of single crystals as a function of temperature and applied fields.

I. Introduction

Relaxor-PbTiO3 (PT) single crystals, including Pb(Mg1/3Nb2/3)O3-PT (PMNT) and Pb(Zn1/3Nb2/3)O3-PT (PZNT), have been extensively studied, because of their high piezoelectric coefficients, >1500 pC/N, high electromechanical coupling factors, > 0.9, and high usable strain levels, far outperforming the state-of-art of polycrystalline Pb(Zr, Ti)O3 (PZT) ceramics, as shown in Table I [1]–[7]. These crystals have been commercialized and employed in medical ultrasonic imaging transducer applications [1], [9], [10]. In addition, the cryogenic properties of relaxor-PT single crystals were reported to be superior to their polycrystalline counterparts, with piezoelectric coefficients being on the order of ~70% of their room temperature values at −150°C, whereas polycrystalline ceramics possess much lower values, being only 30% of the original data [11], [12], which have been demonstrated for actuator or ultrasonic motor applications at cryogenic temperature [13]–[15]. Another advantage of relaxor-PT single crystals is their strong anisotropic characteristics. Because of the symmetry of crystals, many modes can be obtained by “domain engineering” [16], [17], giving rise to optimized piezoelectric properties with different vibration modes. Table II gives the summary of various vibration modes in single crystals with rhombohedral phase [1], [18], when the crystals were poled along [001] direction, 4mm symmetry was formed with 4R engineered domain configuration, in which the highest longitudinal piezoelectric coefficient d33 was observed to be on the order of ~2000 pC/N, whereas mm2 macroscopic symmetry was induced when the crystals were poled along [011] direction, with 2R engineered domain configuration, in which the highest lateral piezoelectric coefficient d32 was obtained and found to be on the order of −1780 pC/N. In contrast, single-domain state 1R, with macroscopic symmetry 3m, was achieved when rhombohedral crystals were poled along their spontaneous polarization direction [111], leading to ultrahigh shear piezoelectric coefficient d15, on the order of ~3700 pC/N. Of particular significance is that electromechanical coupling factors for both extensional (longitudinal and lateral) and transverse vibration modes were found to be on the order of ~0.9, promising for broad bandwidth transducer applications. However, these crystals were found to possess low coercive fields (EC ~2 to 3 kV/cm), low mechanical quality factors (Q ~75), and Curie temperatures TC ~130°C to 170°C, restricting their acceptance in numerous applications. Furthermore, they are limited by their low ferroelectric rhombohedral-to-tetragonal phase-transition temperature TRT, on the order of 60°C to 100°C, because of the strongly curved morphotropic phase boundary (MPB), as shown in Table I [1]. Thus, extensive effort has been put into the development of new ferroelectric crystal systems with expanded temperature and field usage ranges [1], [2]. To separate the crystal systems, the previously mentioned PMNT and PZNT binary single crystals were categorized as first-generation relaxor-PT crystals, whereas crystals with higher TC/TRT and EC values are categorized as second-generation relaxor-PT crystals, which may include, but are not limited to ternary systems with a PMN end member, such as Pb(In0.5Nb0.5)O3-PMN-PT (PIN-PMN-PT) [19]–[26] and PMN-PT-PbZrO3 (PMN-PZT) [27]–[29] ternary crystals, with EC and TRT values being on the order of ~5 kV/cm and 90°C to 150°C, greatly expanding their potentials for transducer applications [1]. In addition, for high-power applications, low dielectric loss and mechanical loss are desirable for reducing heat generation. Based on these requirements, third-generation crystals have been explored by adding a small amount of acceptor dopants to tailor the crystal’s electromechanical parameters to specific device needs, such as manganese-modified PMNT-based crystals, with greatly improved mechanical quality factors [1], [30]–[33]. The property comparison for the three generations of relaxor-PT single crystals is also shown in Table I.

TABLE I.

Property Comparison of Single Crystals and Polycrystalline Ceramics.

| TC (°C) | TRT (°C) | K | loss | d33 (pC/N) | k33 | s33E (pm2/N) | EC (kV/cm) | Qm | |

|---|---|---|---|---|---|---|---|---|---|

| Generation I | 135 | 95 | 5400 | 0.004 | 1540 | 0.91 | 60.0 | 2.3 | 120 |

| Generation II | 191 | 125 | 4400 | 0.004 | 1510 | 0.92 | 69.0 | 5.0 | 180 |

| Generation III | 193 | 128 | 3810 | 0.002 | 1340 | 0.92 | 62.4 | 5.0 | 700 |

| PZT5H | 193 | / | 3400 | 0.02 | 600 | 0.75 | 20.7 | 7.0 | 70 |

| PZT5A | 365 | / | 1700 | 0.02 | 370 | 0.71 | 18.8 | 18 | 70 |

| PZT4 | 328 | / | 1300 | 0.004 | 290 | 0.70 | 14.9 | 14 | 500 |

| PZT8 | 300 | / | 1000 | 0.004 | 230 | 0.64 | 14.6 | 18 | 1000 |

Ceramics data are from [8].

TABLE II.

Piezoelectric Property Comparison for Relaxor-PT Crystals With Various Vibration Modes.

| Vibration mode | εii/ε0 | dij (pC/N) | kij | sjjE (pm2/N) |

|---|---|---|---|---|

| Longitudinal ij = 33 [001] | 6000 | 2000 | 0.90 | 93.0 |

| Lateral ij = 32 [011] | 4500 | −1780 | 0.90 | 100 |

| Shear ij = 15 [111] | 8130 | 3700 | 0.93 | 220 |

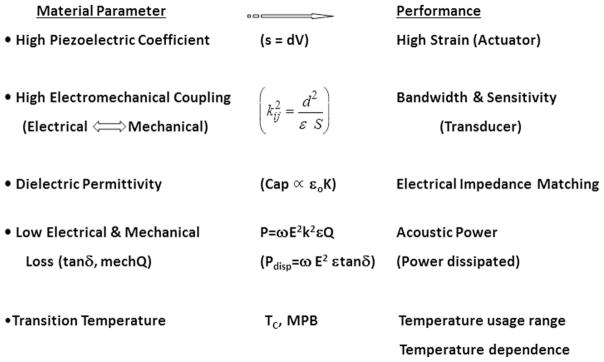

From a viewpoint of material, different figures of merit (FOMs) have been considered for various applications. For example, actuator applications require large piezoelectric strain coefficient with large nonhysteretic strain level to achieve large displacements under an external drive field, whereas transducer applications need an FOM of electromechanical coupling factor and dielectric permittivity to achieve broad bandwidth and high sensitivity. Low dielectric loss is important for devices operating at off-resonance frequency, accounting for low heat generation [34], whereas mechanical loss is critical for devices operating at resonance frequency because the acoustic power output is closely associated with the mechanical quality factor [35]. In addition, high coercive field is necessary for applications under high drive condition, which will improve the field stability and simplify the device design (for example, dc bias may be required to stabilize the poling status of PMNT crystals for transducer applications, because of their low coercive fields) [1], [9], [33], [36]–[38]. For all applications, ferroelectric materials with high Curie temperatures are desirable for the following reasons: first, ferroelectric crystals with higher Curie temperatures are found to possess expanded temperature usage range with less-temperature-dependent properties; second, ferroelectric crystals with higher Curie temperatures have larger coercive field [2]. Fig. 1 gives a schematic diagram showing the material properties related to electromechanical device performance.

Fig. 1.

Relationship between material property and device performance.

Until now, piezoelectric investigations for relaxor-PT-based crystals have been mainly focused on their extensional behavior, whereas limited attention was paid to the transverse (shear) piezoelectric property for electromechanical applications. In this work, the advantages and disadvantages of the three generations of ferroelectric relaxor-PT crystals are discussed with respect to various electromechanical applications. Recent developments of shear properties, including thickness shear and face shear vibration modes, were investigated based on different crystal compositions/phases and poling directions.

II. Experimental

Relaxor-PT single crystals, including PMNT, PIN-PMN-PT and Mn:PIN-PMN-PT crystals were grown using the modified Bridgman method. The as-grown crystal boules are typically 3 inches in diameter and 5 inches in length [1]. The crystals were oriented along various crystallographic directions, [001], [011], and [111], and made into different samples with geometries following the IEEE standard on piezoelectricity [39]. The samples were vacuum sputtered with gold thin films as electrodes on the side faces and poled at electric fields of 10 to 20 kV/cm, depending on their respective coercive fields. For samples poled along their spontaneous polarization, the poling condition was selected to be 5 kV/cm electric field and above their Curie temperature, and then field cooled down to room temperature, to avoid the cracks induced in single-domain state [40]. For thickness-shear samples, the electrodes on the side faces were removed after poling, and subsequently re-electroded on the large faces vertical to the original electrode planes. The capacitance, resonance, and anti-resonance frequencies for different vibration modes are measured using a multi-frequency LCR meter (HP4284A, Agilent Technologies Inc., Santa Clara, CA) and HP4194A impedance-phase gain analyzer, respectively, from which, the dielectric permittivity, elastic constant, electromechanical coupling factor, piezoelectric coefficient, and mechanical quality factor can be calculated.

III. Applications (Advantages and Disadvantages of Relaxor-PT Crystals)

As shown in Table I, PMNT first-generation single crystals were found to possess high dielectric and electromechanical properties, exhibit great benefit over poly-crystalline ceramics; however, their low TC, TRT, and EC are the main concerns for practical applications, thus, second- and third-generation relaxor-PT single crystals with comparable piezoelectric properties have been developed, with enhanced TRT, EC, and Qm, which greatly expand the temperature and field usage ranges, potential for various electromechanical applications.

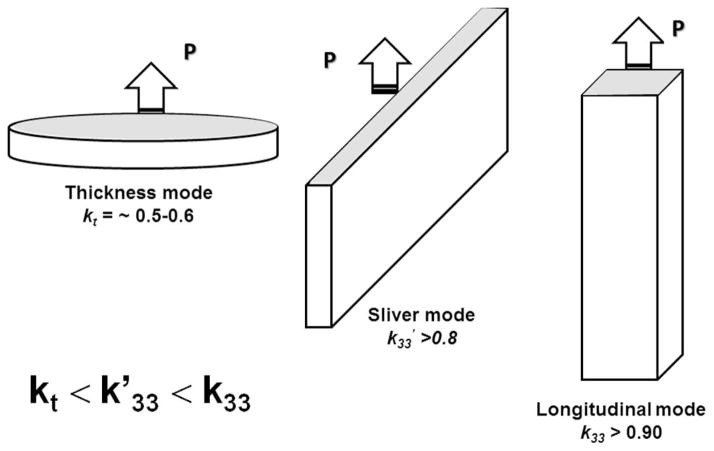

For medical ultrasound imaging applications, including single-element and phased-array structures, 1–3 and 2–2 crystal/epoxy composites have been extensively studied, because of the high electromechanical coupling factors, with values of longitudinal k33 > 0.90 and sliver k33′ > 0.80, respectively, both much higher than that of thickness kt ~ 0.60, as shown in Fig. 2. Furthermore, the composites are found to possess the advantage of lower acoustic impedance, being about 12 to 20 MRayls, much smaller than single crystals (~30 MRayls), which will benefit the matching of the transducers to the human body (~3 to 5 MRayls) [41]. However, recent experimental data for PMNT crystal/epoxy 1–3 composites (piezoelectric composite- micromachined ultrasound transducer PC-MUT) operating at high frequencies > 20 MHz exhibited a large decrease in electromechanical coupling, with values being less than 0.80 [42], [43], showing a strong scaling effect and leading to the question of the origin of property degradation at high frequencies [44], [45]. Besides medical imaging transducers, other applications, including underwater acoustic transducers, nondestructive evaluation (NDE) transducers, piezoelectric actuators, and sensors are also benefit from the high extensional piezoelectric properties of relaxor-PT crystals [1]. Recently, single crystals with shear vibration mode drew attention for low-frequency acoustic transducer applications, because of the ultrahigh elastic compliance and piezoelectric coefficients (listed in Table II).

Fig. 2.

The comparison of the electromechanical coupling for thickness, sliver, and longitudinal single-crystal samples.

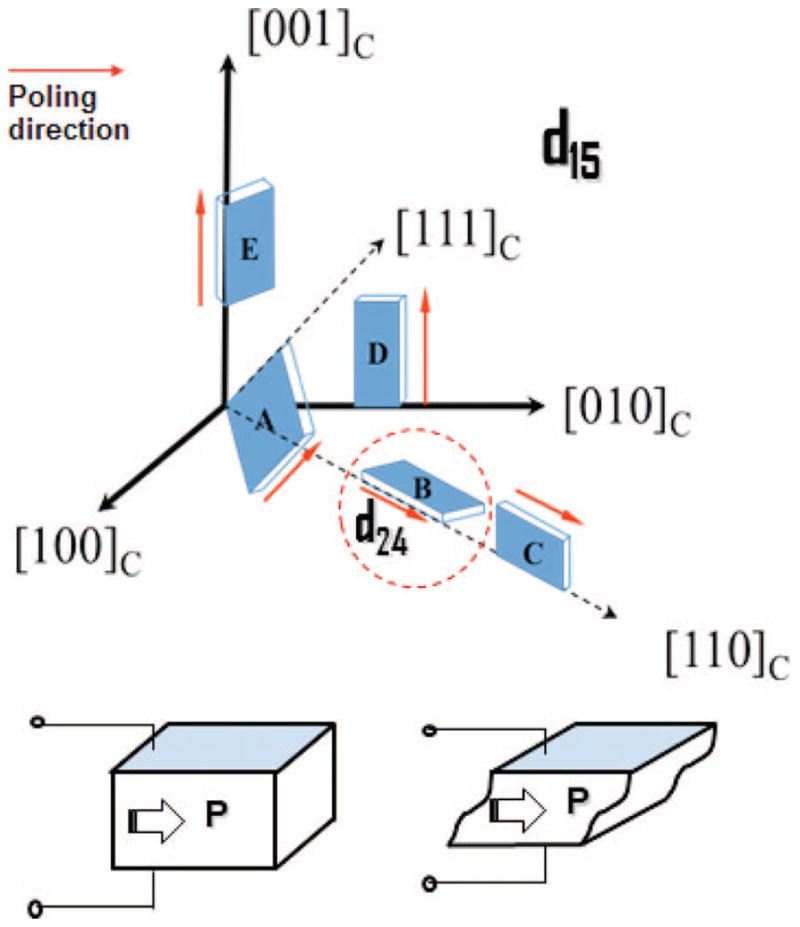

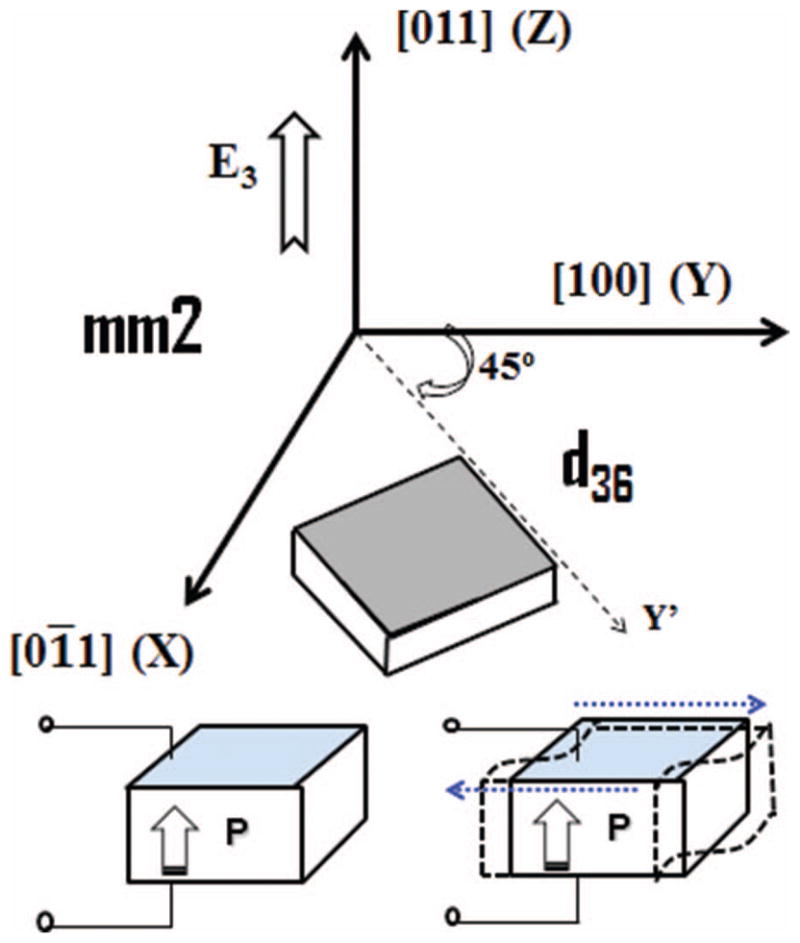

Schematic figures of the various thickness shear mode crystal samples are shown in Fig. 3 [31], [46], including the standard crystal cut A: [111]/(1–10) (the first [hkl] is the poling direction and the second (hkl) is the electroding surface), which is rhombohedral phase and shows single domain state 1R; other crystal cuts, B: [110]/(−110) and C: [110]/(001) are rhombohedral and/or orthorhombic crystal samples with domain structures 2R or 1O after the poling process; D: [001]/(110) and E: [001]/(100) are tetragonal crystal samples with a 1T domain state. The bottom figure shows the piezoelectric deformation of the thickness shear vibration. Of particular significance for [011]-poled rhombohedral crystals is the large face shear vibration that can be achieved in Zt ± 45°-cut samples, which incorporates two extensional lateral modes, as shown in Fig. 4 [46]–[50], with the piezoelectric deformation of the face shear vibration given in bottom figure. The benefit of this mode is that the resonance is associated with the length of the sample and not the thickness, thus further reducing the device dimensions for a given frequency when compared with thickness shear.

Fig. 3.

(top) Schematic figure of the various thickness-shear mode samples of relaxor-PT crystals (adapted from [33]) and (bottom) the related thickness-shear piezoelectric deformation. The arrows represent the poling direction.

Fig. 4.

(top) Schematic of Zt ± 45°-cut sample and (bottom) related face-shear piezoelectric deformation. The arrow represents the poling direction (adapted from [46]).

Table III summarizes the thickness shear properties for various crystals with different domain configurations and compared with commercial PZT polycrystalline ceramics. It is evident that high shear piezoelectric coefficients and elastic compliances can be easily achieved in crystals with single-domain states, such as 1R and 1O, which will benefit the broad bandwidth transducer applications (high electromechanical coupling) at low operational frequency range (large elastic compliance). In addition, the high shear elastic compliance (low frequency constant) of single crystals results in small parts for the same frequency compared with polycrystalline ceramics, allowing miniaturization of the transducers or sensors. However, there are problems for the usage of shear vibration modes, including the temperature instability of dielectric and piezoelectric properties; low allowable drive field stability because the working direction is vertical to the poling direction in the thickness-shear mode; low mechanical quality factor, which is very important for high-power application and cross-talk effects, etc. [1]. Furthermore, large shear properties have been observed in crystals with a single-domain state, however; as a single-domain material, it is subject to cracking from the large electric-field-induced strain/stress during the poling process [1], [40], which can be avoided in multi-domain states. As listed in Table III, large shear d15 and elastic values, being on the order of ~3350 pC/N and 208 pm2/N, respectively, were obtained in engineered domain configuration 2R, with the advantage of no cracking during the poling process.

TABLE III.

Shear Mode Property Comparison for Single Crystals and Polycrystalline Ceramics.

| d15 (pC/N) | d24 (pC/N) | s55E (pm2/N) | Q | |

|---|---|---|---|---|

| Rhom 1R | 3700 | 3700 | 220 | ~30 |

| Rhom 2R | 3350 | 160 | 208 | ~40 |

| Orthor 1O | 4550 | 4100 | 316 | ~30 |

| Tetra 1T | 2350 | 2350 | 55 | ~30 |

| PZT4 | 500 | 500 | 39 | ~70 |

| PZT8 | 330 | 330 | 32 | ~160 |

| PZT5A | 580 | 580 | 48 | ~15 |

| PZT5H | 740 | 740 | 44 | ~15 |

In the following, the details addressing these issues are discussed, to optimize material properties for transducer applications.

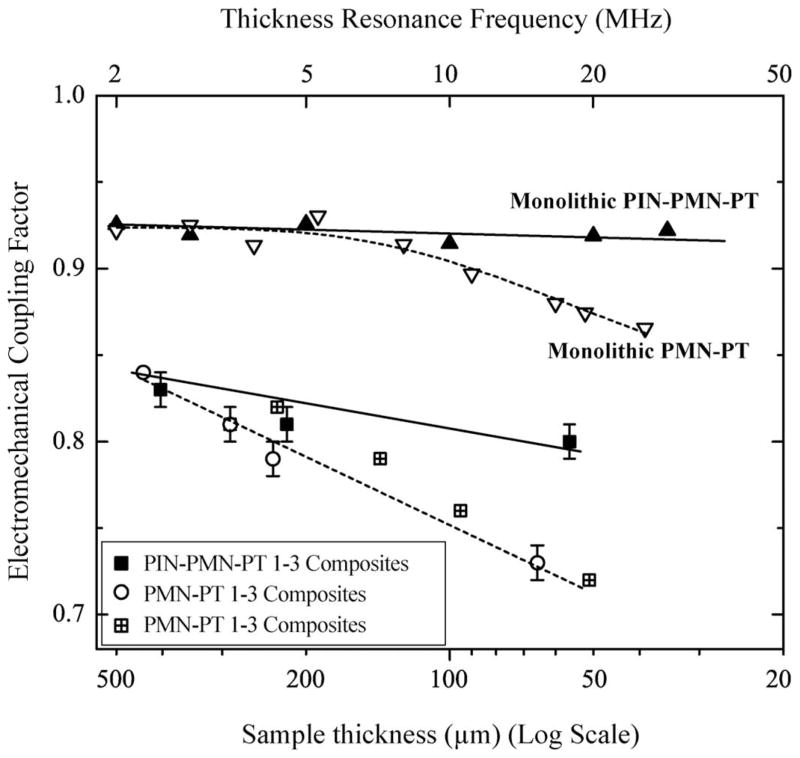

A. Scaling Effect

Fig. 5 shows the electromechanical properties of relax-or-PT crystal/epoxy 1–3 composites as a function of sample thickness. For comparison, the longitudinal coupling factors (k33) of the monolithic PMNT and PIN-PMN-PT samples were calculated by the equation and plotted as a function of sample thickness. In addition, the reported coupling factors for PMNT/epoxy 1–3 composites were included in Fig. 5 [42], [43]. Note that the corresponding resonance frequencies on the top x-axis of Fig. 5 were calculated from the frequency constants by assuming ~1000 Hz·m for both monolithic and 1–3 composites samples. From Fig. 5, the monolithic PMNT crystals were found to exhibit a decreasing trend in coupling (k33) with decreasing sample thickness, because of the degradation of the free dielectric permittivity [44], [45]. The 20 MHz PIN-PMN-PT/epoxy 1–3 composites were found to maintain higher electromechanical coupling factors, being on the order of 0.80, when compared with 20-MHz PMNT composites, with coupling being only 0.74. The observed scaling effect is reported to be associated with the ferroelectric domain size; the large domains will be clamped by the surface boundary when the physical size of the samples becomes of the same order as the domain size. This can be confirmed by the domain observations, in which the domain size of PMNT crystals was found to be on the order of 10 to 20 μm, whereas it is only about 1 μm for PIN-PMN-PT crystals, showing a large advantage of the ternary system [44], [45]. To confirm the role of domain size on the dielectric and piezoelectric properties in ultrathin samples, a field-cool poling approach was applied to PMNT crystals, for which significantly smaller domain sizes, being on the order of ~5 μm, were achieved; consequently, the dielectric permittivity and piezoelectric coefficient were greatly improved, from 3000, 1300 pm/V to 5600, 2200 pm/V, respectively [51].

Fig. 5.

Electromechanical coupling factor for monolithic and crystal/epoxy 1–3 composites as a function of sample thickness and corresponding ultrasound frequency (after [44] copyright © 2010, the American Institute of Physics).

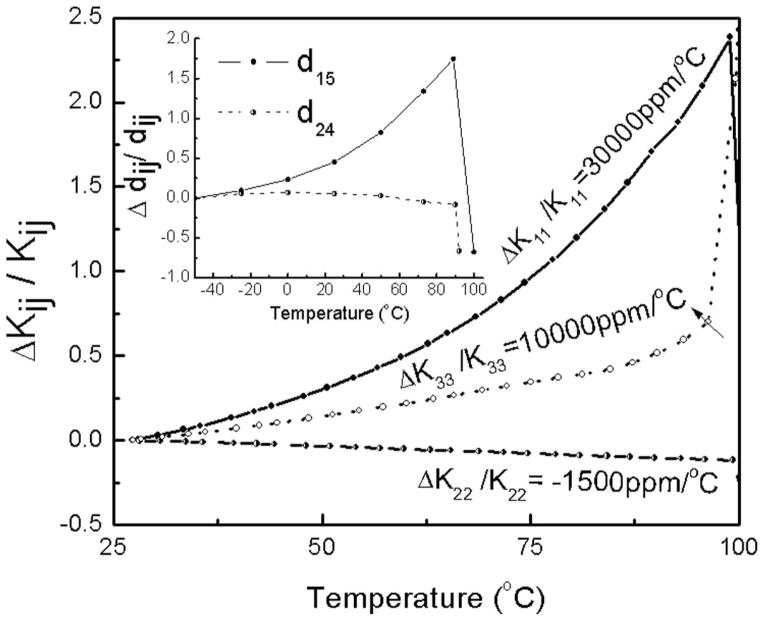

B. Temperature Stability

The thermal stability of dielectric and piezoelectric properties is very important for most electromechanical applications. In general, the dielectric and piezoelectric response of relaxor-PT ferroelectric crystals exhibit relatively large temperature variation, because of the multiple ferroelectric–ferroelectric phase transitions lying in or near the temperature range of −50°C to 100°C [1], [2]. Based on thermodynamic analysis of perovskite single crystals, the temperature dependence of the transverse dielectric permittivity is strongly related to the ferroelectric phase transitions. Fig. 6 shows the temperature dependent dielectric permittivity variation of 1O single-domain-state crystals, where the variation of dielectric K11 was found to be on the order of 30 000 ppm/°C, because of the curved orthorhombic to tetragonal phase boundary, whereas variation of dielectric K22 was found to be on the order of 1500 ppm/°C, much flatter than that of K11 [26]. This phenomena can be explained by the fact that the orthorhombic to rhombohedral phase boundary is vertical and not related to the temperature variation [1], [40], [52]. Correspondingly, the shear piezoelectric coefficient d24 was found to maintain a similar value until the TOT transition temperature, being less than 6%, much less than the variation of d15 in the same temperature range, which was found to be on the order of ~180%. As expected, the longitudinal coefficient d33 along [111] direction for crystals with 3O engineered domains, which is closely associated with d24 in the 1O single-domain state, was found to show temperature-independent behavior, yet with a high value of ~900 pC/N; thus, it is promising for applications in which high temperature stability is demanded [1].

Fig. 6.

Dielectric permittivity variation as a function of temperature for [011]-poled single-domain crystals; the small inset shows the shear piezoelectric variation as a function of temperature (after [26] copyright © 2011, the American Institute of Physics).

C. Drive Field Stability

Ferroelectrics exhibit nonlinear properties under high drive field, because of the interfaces’ (domain wall and/or phase boundary) motion [1], [53], [54]. The piezoelectric and dielectric responses of relaxor-PT single crystals generally increase with increasing drive field up to a threshold value, above which, the samples will be depolarized and loss their piezoactivity. The threshold value is closely related to the respective coercive field of ferroelectrics, which is on the order of 2 to 10 kV/cm for relaxor-PT crystals, depending on the phase and composition. In the case of thickness-shear vibrations, the allowable drive field is much lower than coercive field, because the working direction of thickness shear is perpendicular to the poling direction [33]. As listed in Table IV, the field stability ratios (allowable drive field level divided by coercive field) of pure relaxor-PT single crystals were found to be on the order of ~40%, less than half of the coercive field, regardless of crystal systems and different thickness-shear vibrations. However, for the acceptor (Mn) modified relaxor-PT single crystals, internal bias was found to be on the order of 0.6 to 1.2 kV/cm, leading to the enhanced allowable drive field, with field stability ratio increasing to >65%, much higher than that of pure counterparts [33]. Furthermore, it should be noted that drive field stability of relaxor-PT crystals can also be enhanced by applying the uniaxial stress to crystals [55]. Of particular significance is that the field stability ratio of the face-shear vibration mode, being on the order of 100%, greatly expands the usage range for high-power applications, which is due to the fact that the working direction is along the poling direction in face shear vibration [48].

TABLE IV.

Drive Field Stability of Shear Vibration for Relaxor-PT Single Crystals, (PIN: PIN-PMN-PT; PIN-Mn: Mn:PIN-PMN-PT).

| Material | Vibration | EC (kV/cm) | Allowable drive field (kV/cm) | Field stability ratio (%) |

|---|---|---|---|---|

| PMNT | d15 (2R) | 2.5 | 1.0 | 40 |

| PIN | d15 (2R) | 5 | 2.0 | 40 |

| PIN | d24 (1O) | 5 | 2.0 | 40 |

| PIN-Mn | d15 (2R) | 7.3 | 5.0 | 68 |

| PIN-Mn | d24 (1O) | 4.5 | 3.0 | 65 |

| PIN | d36 (2R) | 5 | 5.0 | 100 |

D. Mechanical Quality Factor

High-power applications, such as high-intensity focused ultrasound (HIFU), NDE, and underwater acoustic transducers, not only require high allowable drive field, also need high mechanical quality factor Qm, which will efficiently increase the vibration velocity and decrease the heat generation under high drive condition at resonance frequency. In ferroelectrics, the Qm was mainly affected by the existence of domain wall motion and polarization rotation, where the polarization rotation angle was found to play an important role in the determination of Qm value in relaxor-PT crystals, because of the inherent anisotropic characteristics [1]. From Table III, the Qm values for thickness-shear vibration modes were found to be very low, being on the order of ~30 for relaxor-PT single-crystal systems. For comparison, the mechanical Qm was reported to be on the order of >1000 for longitudinal vibration mode in single-domain crystals. This is because the polarization rotation angle for thickness shear vibration in single-domain state is 90°, whereas the angle is 0° for longitudinal vibration [1]. To improve the mechanical Qm, acceptor dopant was employed to modify relaxor-PT crystals, analogous to “hard” PZT ceramics; however, although large improvement was found for the longitudinal vibration (Qm increases to >800), limited success was achieved for thickness-shear vibration. Of particular importance is that the new face shear vibration, as shown in Fig. 4, taking advantage of the working direction being the same to the poling direction and the small polarization rotation angle (~35.3°), exhibited higher mechanical Qm, being on the order of >100, further increased to >200 for Mn-modified crystals, significantly higher than those values of thickness-shear vibrations, as given in Table V [46], [48].

TABLE V.

Piezoelectric Face Shear Properties for Single Crystals With Rhombohedral Phase (PIN-Mn: Mn:PIN-PMN-PT).

| d36 (pC/N) | k36 | s66E (pm2/N) | Q36 | |

|---|---|---|---|---|

| PMNT (low PT) | 1730 | 0.78 | 129 | 200 |

| PMNT (high PT) | 2800 | 0.83 | 225 | 150 |

| PIN-Mn (low PT) | 1810 | 0.80 | 166 | 500 |

| PIN-Mn (high PT) | 2270 | 0.82 | 230 | 300 |

Data are from [46]. Mechanical Qs were measured using 4 × 4 × 1 mm devices.

E. Cross-Talk

For an ideal sensor application, the sensors only give an output when they are loaded (such as force, pressure, or acceleration) along their sensitivity axis, and the load normal to that axis should not produce any output. However, real sensors may give an output also to a force normal to their sensitive axis, which will have significant influence on the accuracy of the measurement results; this is called cross-talk [56]. For example, thickness-shear piezoelectric d16, being on the order of −1700 pC/N, was observed in crystals with 1R single-domain state, strongly cross-talks with piezoelectric d15. Thus, it is desirable to reduce or eliminate the cross-talk effect in practical applications. It was reported that d16 can be eliminated by rotating the sample around the x-axis with an angle of α = arctan (−d16/d15) [49], [57]. Other approaches to obtain thickness shear samples without cross-talk include the utilization of domain configurations other than 1R single-domain state, such as 1T and 1O/2R, with macroscopic symmetries of 4mm and mm2, respectively, where the d16 value is zero. It should be noted that for face-shear vibration, cross-talk from extensional vibrations d31 or d32 can be eliminated by rotating the sample along Z-axis with angle of α = arctan(d31/−d32) or α = arctan (−d32/d31), without sacrificing the large d36 [58].

IV. Summary

The advantages and disadvantages of relaxor-PT single crystals for transducer applications were discussed in this paper. The second-generation ternary PIN-PMN-PT single crystals were found to possess a higher usage temperature range and coercive field; of particular important is the small domain size, being on the order of ~1 μm, exhibiting less scaling effect and promising for ultrahigh frequency transducer applications. The enhanced coercive field and the existence of internal bias for third-generation Mn:PIN-PMN-PT crystals improved the field stability ratio greatly when compared with their pure counterparts, allowing high drive condition. Specifically, face-shear vibration was found to possess large drive field stability and high mechanical Qm, in addition to the high piezoelectric coefficient and elastic compliance. Furthermore, the controlling dimension of face shear is the length direction, instead of the thickness, making face-shear vibration a promising candidate for compact, low-frequency and high-power transducer applications.

Acknowledgments

This work was supported by the Office of Naval Research (ONR) and the National Institutes of Health (NIH) under grant number 2P41EB002182-15A1.O.

Biographies

Shujun Zhang received his Ph.D. degree from The State Key Laboratory of Crystal Materials, Shandong University, China, in 2000. He is a Senior Research Associate at the Material Research Institute and an Associate Professor in the Materials Science and Engineering Department of The Pennsylvania State University. He is an associate editor for the IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control (UFFC) and the Journal of the American Ceramic Society. He was a recipient of the Ferroelectrics Young Investigator Award of the IEEE UFFC Society in 2011. He holds two patents and has coauthored more than 220 papers in the area of functional single crystals and ceramics. He is now focusing on the structure– property–performance relationship of high-temperature, high-power, and high-performance piezoelectric crystals and ceramics for sensor and transducer applications.

Fei Li was born in Shannxi, China, in 1983. He received his B.Eng. and Ph.D degrees in electronics science and electronic materials from Xi’an Jiaotong University, Xi’an, China, in 2006 and 2012, respectively. From September 2009 to September 2010, he worked in the Material Research Institute of The Pennsylvania State University as visiting scholar. He is now a faculty member at Xi’an Jiaotong University and is working in the field of piezoelectric and ferroelectric single crystals and ceramics.

Jun Luo is a Research Scientist at TRS Technologies Inc. He received his Ph.D. degree in materials science from the Shanghai Institute of Ceramics, Chinese Academy of Sciences (CAS), in 2000. From 2001 to 2002, he worked at Lightwaves 2020 Inc. as an R&D Engineer and developed new magneto-optical materials by liquid phase epitaxy (LPE) technique for Faraday rotator applications. From 2002 to 2004, he worked at the University of Central Florida as a Research Associate. During this period, he studied Czochralski growth of langasite and its isomorphs for high-precision bulk and surface acoustic waves (BAW & SAW) devices. His current research interest includes developing and processing advance relaxor ferroelectric-based single crystal materials for new piezoelectric sensors, actuators, and transducers applications.

Raffi Sahul is the Director of Business and Product Development at TRS Technologies Inc. He received his master’s degree in mechanical engineering from Clemson University in 2001. He has headed numerous research programs as Principal Investigator, coauthored several papers, and holds a few patents. Between 2001 and 2006, he worked as Team Leader and Principal Investigator at MM Inc., where he developed processing techniques, devices, and applications for several smart materials and nanomaterials. Currently, he heads the research and development at TRS, with focus on relaxor single-crystal materials and piezoceramics and their applications in actuators, sensors, and acoustic transducers.

Thomas R. Shrout is Professor of Materials and Senior Scientist at The Pennsylvania State University. He received B.S. and Ph.D. degrees in ceramic science from The Pennsylvania State University in 1976 and 1981, respectively. Prior to joining the faculty at Penn State, Dr. Shrout was with Sprague Electric Co. and AVX Co. He was a recipient of the Ikeda Memorial Award in Ferroelectrics in 2005, the IEEE Ferroelectrics Recognition Award in 2006, the Electroceramics Bridge Building Award in 2009, and distinguished lecturer (IEEE-UFFC) in 2007–2008. He is a fellow of the American Ceramic Society and IEEE-UFFC. He was senior VP of Ferroelectrics, IEEE-UFFC from 2006 to 2009. He holds 19 patents and has coauthored more than 300 papers in the area of electronic single crystals and ceramics with an emphasis on processing property relationships.

Contributor Information

Shujun Zhang, Materials Research Institute, The Pennsylvania State University, University Park, PA.

Fei Li, EMRL, Key Lab of the Ministry of Education and International Center for Dielectric Research, Xi’an Jiaotong University, Xi’an, China.

Jun Luo, TRS Technologies Inc., State College, PA.

Raffi Sahul, TRS Technologies Inc., State College, PA.

Thomas R. Shrout, Materials Research Institute, The Pennsylvania State University, University Park, PA.

References

- 1.Zhang S, Li F. High performance ferroelectric relaxor-PT single crystals: Status and perspective. J Appl Phys. 2012;111(3):art. no. 031301. [Google Scholar]

- 2.Zhang SJ, Shrout TR. Relaxor-PT single crystals: Observations and developments. IEEE Trans Ultrason Ferroelectr Freq Control. 2010;57(10):2138–2146. doi: 10.1109/TUFFC.2010.1670. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Park SE, Shrout TR. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals. J Appl Phys. 1997;82(4):1804–1811. [Google Scholar]

- 4.Luo HS, Xu GS, Xu HQ, Wang PC, Yin ZW. Compositional homogeneity and electrical properties of lead magnesium niobate titanate single crystals grown by a modified Bridgman technique. Jpn J Appl Phys. 2000;39(9B):5581–5585. [Google Scholar]

- 5.Ye ZG. High performance piezoelectric single crystals for complex perovskite solid solution. Mater Res Soc Bull. 2009;34(4):277–283. [Google Scholar]

- 6.Luo NN, Li YY, Xia ZG, Li Q. Progress in lead based ferroelectric and antiferroelectric single crystals: Composition modification, crystal growth and properties. CrystEngComm. 2012;14:4547–4556. [Google Scholar]

- 7.Davis M. Picturing the elephant: Giant piezoelectric acitivity and the monoclinic phases of relaxor ferroelectric single crystals. J Electroceram. 2007;19(1):25–47. [Google Scholar]

- 8.Berlincourt D. Piezoelectric crystals and ceramics. In: Mattiat OE, editor. Ultrasonic Transducer Materials: Piezoelectric Crystals and Ceramics. London, UK: Plenum; 1971. pp. 63–124. [Google Scholar]

- 9.Chen J, Panda R. Review: Commercialization of piezoelectric single crystals for medical imaging applications. IEEE Ultrasonic Symp. 2005:235–240. [Google Scholar]

- 10.Zhou QF, Xu X, Gottlieb EJ, Sun L, Canata JM, Ameri H, Humayun M, Han PD, Shung KK. PMN-PT single crystal, high frequency ultrasonic needle transducers for pulsed-wave Doppler application. IEEE Trans Ultrason Ferroelectr Freq Control. 2007;54(3):668–675. doi: 10.1109/tuffc.2007.290. [DOI] [PubMed] [Google Scholar]

- 11.Li F, Zhang SJ, Xu Z, Wei XY, Luo J, Shrout TR. Piezoelectric activity of relaxor-PT based single crystals and poly-crystalline ceramics at cryogenic temperatures: Intrinsic and extrinsic contributions. Appl Phys Lett. 2010;96(19):art. no. 192903. doi: 10.1063/1.3430059. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Martin F, Brake MT, Lebrun L, Zhang SJ, Shrout TR. Dielectric and piezoelectric activities in (1−x)PMN-xPT single crystals from 5K to 300K. J Appl Phys. 2012;111(10):art. no. 104108. [Google Scholar]

- 13.Dong SX, Yan L, Viehland D, Jiang XN, Hackenberger WS. A piezoelectric single crystal traveling wave step motor for low temperature application. Appl Phys Lett. 2008;92(15):art. no. 153504. [Google Scholar]

- 14.Dong SX, Yan L, Wang NG, Viehland D, Jiang XN, Rehrig P, Hackenberger WS. A small linear piezoelectric ultrasonic cryomotor. Appl Phys Lett. 2005;86(5):art. no. 053501. [Google Scholar]

- 15.Jiang XN, Rehrig PW, Hackenberger WS, Smith E, Dong SX, Viehland D, Moore J, Patrick B. Advanced piezoelectric single crystal based actuators. Proc SPIE. 2005;5761:253–262. [Google Scholar]

- 16.Davis M. PhD dissertation. Ceramic Laboratory, Swiss Federal Institute of Technology (EPFL); Lausanne, Switzerland: 2006. Phase transitions, anisotropy and domain engineering: The piezoelectric properties of relaxor-ferroelectric single crystals. [Google Scholar]

- 17.Davis M, Damjanovic D, Hayem D, Setter N. Domain engineering of the transverse piezoelectric coefficient in perovskite ferroelectrics. J Appl Phys. 2005;98(1):art. no. 014102. [Google Scholar]

- 18.Cao WW. Full-set material properties and domain engineering principles of ferroelectric single crystals. In: Ye ZG, editor. Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials—Synthesis, Characterization and Applications. Cambridge, England: Woodhead Publishing Ltd; 2008. pp. 235–265. [Google Scholar]

- 19.Zhang SJ, Luo J, Hackenberger W, Shrout TR. Characterization of PIN-PMN-PT ferroelectric crystal with enhanced phase transition temperatures. J Appl Phys. 2008;104(6):art. no. 064106. doi: 10.1063/1.2978333. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Zhang SJ, Luo J, Hackenberger W, Sherlock NP, Meyer RJ, Jr, Shrout TR. Electromechanical characterization of PIN-PMN-PT crystals as a function of crystallographic orientation and temperature. J Appl Phys. 2009;105(10):art. no. 104506. doi: 10.1063/1.3131622. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Tian J, Han PD, Huang XL, Pan HX. Improved stability for piezoelectric crystals grown in the lead indium niobate-lead magnesium niobate-lead titanate system. Appl Phys Lett. 2007;91(22):art. no. 222903. [Google Scholar]

- 22.Xu GS, Chen K, Yang DF, Li JB. Growth and electrical properties of large size PIN-PMN-PT crystals prepared by the vertical Bridgman technique. Appl Phys Lett. 2007;90(3):art. no. 032901. [Google Scholar]

- 23.Hosono Y, Yamashita Y, Sakamoto H, Ichinose N. Large piezoelectric constant of high Curie temperature Pb(In1/2Nb1/2) O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 ternary single crystal near morphotropic phase boundary. Jpn J Appl Phys. 2002;41(11A):L1240–L1242. [Google Scholar]

- 24.Gao J, Xu Z, Zhang C, Li Z, Wu X, Wang L, Liu Y, Liu G, He H. Pyroelectric properties of rhombohedral and tetragonal PIN-PMN-PT crystals. J Appl Phys. 2011;110(10):art. no. 106101. [Google Scholar]

- 25.Finkel P, Robinson H, Stace J, Amin A. Study of phase transition in ternary lead indium niobate-lead mangesium niobate-lead titanate relaxor ferroelectric morphotropic single crystals. Appl Phys Lett. 2010;97(12):art. no. 122903. [Google Scholar]

- 26.Zhang SJ, Liu G, Jiang WH, Luo J, Cao WW, Shrout TR. Characterization of single domain PIN-PMN-PT crystals with monoclinic phase. J Appl Phys. 2011;110(6):art. no. 064108. doi: 10.1063/1.4772617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Zhang SJ, Lee SM, Kim DH, Lee HY, Shrout TR. Characterization of high TC PMN-PZ-PT single crystals fabricated by solid state crystal growth. Appl Phys Lett. 2007;90(23):art. no. 232911. [Google Scholar]

- 28.Zhang SJ, Lee SM, Kim DH, Lee HY, Shrout TR. Temperature dependence of the dielectric, piezoelectric and elastic constants for PMN-PZ-PT piezocrystals. J Appl Phys. 2007;102(11):art. no. 114103. [Google Scholar]

- 29.Li Q, Zhang Y, Xia Z, Chu X. MPB design and crystal growth of PMN-PT-PZ relaxor ferroelectrics. J Cryst Growth. 2011;318(1):851–855. doi: 10.1016/j.jcrysgro.2010.11.043. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Zhang SJ, Lee SM, Kim DH, Lee HY, Shrout TR. Characterization of Mn modified PMN-PZ-PT single crystals for high power broad bandwidth transducers. Appl Phys Lett. 2008;93(12):art. no. 122908. doi: 10.1063/1.2992081. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Luo L, Zhou D, Tang Y, Jia Y, Xu H, Luo HS. Effects of Mn doping on dielectric and piezoelectric properties of 0.71PMN-0.29PT single crystals. Appl Phys Lett. 2007;90(10):art. no. 102907. [Google Scholar]

- 32.Luo J, Hackenberger W, Zhang S, Shrout T. A high Qm relaxor ferroelectric single crystal: Growth and characterization. IEEE Ultrasonic Symp. 2010:68–71. [Google Scholar]

- 33.Zhang S, Li F, Luo J, Xia R, Hackenberger W, Shrout T. Field stability of piezoelectric shear properties in PIN-PMN-PT crystals under large drive field. IEEE Trans Ultrason Ferroelectr Freq Control. 2011;58(2):274–280. doi: 10.1109/TUFFC.2011.1804. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Sherlock NP, Garten LM, Zhang SJ, Shrout TR, Meyer RJ., Jr Nonlinear dielectric response in piezoelectric materials for sonar transducer applications. J Appl Phys. 2012;112(12):art. no. 124108. [Google Scholar]

- 35.Sherlock NP, Zhang SJ, Luo J, Meyer RJ, Jr, Shrout TR. Large signal, dynamic properties of low loss modified PMNT single crystals. J Appl Phys. 2010;107(7):art. no. 074108. [Google Scholar]

- 36.Amin A, McLaughlin E, Robinson H, Ewart L. Mechanical and thermal transitions in morphotropic PZN-PT and PMN-PT single crystals and their implication for sound projectors. IEEE Trans Ultrason Ferroelectr Freq Control. 2007;54(6):1090–1095. doi: 10.1109/tuffc.2007.362. [DOI] [PubMed] [Google Scholar]

- 37.McLaughlin EA, Liu TQ, Lynch CS. Relaxor ferroelectric PMN-32%PT crystals under stress and electric field loading: I-32 mode measurements. Acta Mater. 2004;52(13):3849–3857. [Google Scholar]

- 38.Zhou QF, Zhu B, Wu D, Hu C, Cannata J, Tian J, Han P, Shung K. PIN-PMN-PT single crystal high frequency ultrasound transducers for medical applications. IEEE Ultrasonic Symp. 2008:1433–1436. doi: 10.1109/TUFFC.2009.1367. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.IEEE Standard on Piezoelectricity. ANSI/IEEE Standard. 1987;176 [Google Scholar]

- 40.Li F, Zhang SJ, Xu Z, Wei XY, Shrout TR. Critical property in relaxor-PT single crystals—Shear piezoelectric response. Adv Funct Mater. 2011;21(11):2118–2128. doi: 10.1002/adfm.201002711. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Hackenberger W, Luo J, Jiang XN, Snook KA, Rehrig PW, Zhang SJ, Shrout TR. Recent developments and applications of piezoelectric crystals. In: Ye ZG, editor. Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials—Synthesis, Characterization and Applications. Cambridge, England: Wood-head Publishing Ltd; 2008. pp. 73–100. [Google Scholar]

- 42.Jiang X, Snook K, Hackenberger W, Geng X. Single crystal piezoelectric composites for advanced NDT ultrasound. Proc SPIE. 2007;6531:art. no. 65310F. [Google Scholar]

- 43.Jiang X, Snook K, Walker T, Portune A, Haber R, Geng X, Welter J, Hackenberger W. Single crystal piezoelectric composite transducers for ultrasound NDE. Proc SPIE. 2008;6934:art. no. 69340D. [Google Scholar]

- 44.Lee HJ, Zhang SJ, Shrout TR. Scaling effects of relaxor-PT crystals and composites for ultrasonic transducers. J Appl Phys. 2010;107(12):art. no. 124107. doi: 10.1063/1.3437068. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Lee HJ, Zhang SJ, Luo J, Li F, Shrout TR. Thickness dependent properties of relaxor-PT piezoelectrics for ultrasonic transducers. Adv Funct Mater. 2010;20(18):3154–3162. doi: 10.1002/adfm.201000390. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Zhang SJ, Li F, Shrout TR, Luo J. Relaxor-PT single crystals for various applications. Proc Int Symp Applications of Ferroelectrics. 2012 http://dx.doi.org/10.1109/ISAF.2012.6297735.

- 47.Zhang SJ, Li F, Jiang WH, Luo J, Meyer RJ, Jr, Cao WW, Shrout TR. Face shear piezoelectric properties of relaxor-PbTiO3 single crystals. Appl Phys Lett. 2011;98(18):art. no. 182903. doi: 10.1063/1.3584851. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Zhang S, Jiang W, Meyer RJ, Jr, Li F, Luo J, Cao W. Measurements of face shear properties in relaxor-PT single crystals. J Appl Phys. 2011;110(6):art. no. 064106. doi: 10.1063/1.3584851. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Han P, Yan W, Tian J, Huang X, Pan H. Cut directions for the optimization of piezoelectric coefficients of lead magnesium niobate-lead titanate ferroelectric crystals. Appl Phys Lett. 2005;86(5):art. no. 052902. [Google Scholar]

- 50.Tol DJV, Meyer RJ., Jr Acoustic transducer. 7 615 912. US Patent. 2009 Nov 10;

- 51.Lin DB, Lee HJ, Zhang SJ, Li F, Li ZR, Xu Z, Shrout TR. Influence of domain size on the scaling effects in PMN-PT ferroelectric crystals. Scr Mater. 2011;64(12):1149–1151. doi: 10.1016/j.scriptamat.2011.03.018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Li F, Zhang S, Xu Z, Wei X, Luo J, Shrout T. Temperature independent shear piezoelectric response in relaxor-PT based crystals. Appl Phys Lett. 2010;97(25):art. no. 252903. doi: 10.1063/1.3529952. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Li F, Zhang SJ, Xu Z, Wei XY, Luo J, Shrout TR. Composition and phase dependence of the intrinsic/extrinsic piezoelectric activity in domain engineered (1−x)PMN-xPT crystals. J Appl Phys. 2010;108(3):art. no. 034106. doi: 10.1063/1.3466978. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Damjanovic D. Hysteresis in piezoelectric and ferroelectric materials. In: Mayergoyz I, Bertotti G, editors. The Science of Hysteresis. Vol. 3. New York, NY: Elsevier; 2005. pp. 337–465. [Google Scholar]

- 55.Li F, Zhang SJ, Xu Z, Lin D, Gao J, Li Z, Wang L. An efficient way to enhance output strain for shear mode PIN-PMN-PT crystals: Applying uniaxial stress perpendicular to polar direction. Appl Phys Lett. 2012;100(19):art. no. 192901. [Google Scholar]

- 56.Gautschi G. Piezoelectric Sensorics. New York, NY: Springer; 2002. pp. 106–109. [Google Scholar]

- 57.Deng KK. Underwater acoustic vector sensor using transverse response free, shear mode PMN-PT crystal. US7066026. US Patent. 2006 Jun 27;

- 58.Goljahi S, Gallagher J, Zhang S, Luo J, Sahul R, Hackenberger W, Lynch CS. A relaxor ferroelectric single crystal cut resulting in large d312 and zero d311 for a shear mode accelerometer and related applications. Smart Mater Struct. 2012;21(5):art. no. 055005. [Google Scholar]