Abstract

Low-cost diagnostics for drinking water contamination have the potential to save millions of lives. We report a method that uses inkjet printing to copattern an enzyme–nanoparticle sensor and substrate on a paper-based test strip for rapid detection of bacteria. A colorimetric response is generated on the paper substrate that allows visual detection of contamination without the need for expensive instrumentation. These strips demonstrate a viable nanomanufacturing strategy for low-cost bacterial detection.

Keywords: inkjet printing, gold nanoparticles, bacteria, enzymes, sensing

Introduction

Detection of bacteria in drinking water is critical for global public safety and health. According to the World Health Organization, ∼1.7 million people are killed every year by bacteria-related diseases such as infectious diarrhea and cholera.1 Several methodologies have been developed for bacterial detection based on techniques such as culturing,2 chemiluminescence,3 bioluminescence,4 and mass spectrometry.5 Each of these systems has its advantages; however, the utility of these methods is generally limited by the high cost of analysis, the need for trained personnel, and the overall stability of the sensor. Furthermore, all of these strategies are laboratory-based, limiting their utility for bacterial analysis at the water source.

Nanotechnology has significantly enhanced sensing strategies for detecting bacteria through the use of nanoparticles, using unique physicochemical properties that are absent from their macroscale counterparts.6 For example, Weissleder et al. reported the use of magneto-DNA probes specific to bacteria strains capable of rapid and specific profiling directly in clinical samples.7 Functionalized gold nanoparticles (AuNPs) have also been shown to aid detection in systems for sensing proteins,8 cells,9 and viruses.10 In our research, we have developed an array-based sensing system based on noncovalent conjugates of AuNPs and a fluorescent polymer that allows the detection and classification of a wide range of bacteria within minutes in a laboratory setting.11

Developing nanoparticle-based sensors that are portable and highly sensitive yet inexpensive is extremely challenging. While sensors exist with low limits of detection that do not require instruments for readouts,12 most do not have the robustness to be used for on-site detection, nor can they be manufactured economically. Point-of-use utility is critical as most off-site testing takes 24 h or longer for proper analysis. As water conditions can change rapidly due to fecal contaminants,13 the results obtained with these methods do not provide up-to-date water safety information. Rapid testing for bacteria, ideally performed at the water source on a low-cost strip platform, would be ideal given the inherent advantages of these platforms such as efficiency and portability.14

Signal amplification is generally required to maintain high sensitivity in rapid-detection visual sensors.15 In laboratories, enzymatic amplification has been widely employed in enzyme-linked immunosorbent assays.16 This strategy has great potential for visual instrument-free detection due to the wide range of fluorescent and colorimetric enzyme substrates available. However, effective implementation of enzymatic amplification to low-cost platforms is challenging. Lateral flow approaches have shown success in performing enzyme immunoassays in a test-strip format,17 where enzymes preconjugated or labeled with antibodies are separated from enzyme substrates in different zones of the strip during fabrication.18 Recently, our group developed an enzyme–AuNP conjugate system for the colorimetric detection of bacteria.19 However, this system still requires the use of solution-based methods for both fabrication and analysis that are difficult to use outside of the laboratory.

Inkjet printing is an attractive noncontact material deposition method as it is low-cost, simple, fast, reproducible, and generates a low amount of waste during printing.20 These attributes have made this strategy highly promising for patterning both synthetic and biological systems.21−24 Previous reports have investigated the use of inkjet-printed enzymes to create horseradish peroxidase25 and glucose26 electrochemical biosensors as well as for fabricating colorimetric sensors for the detection of neurotoxins27 and pesticides using a lateral flow format.28

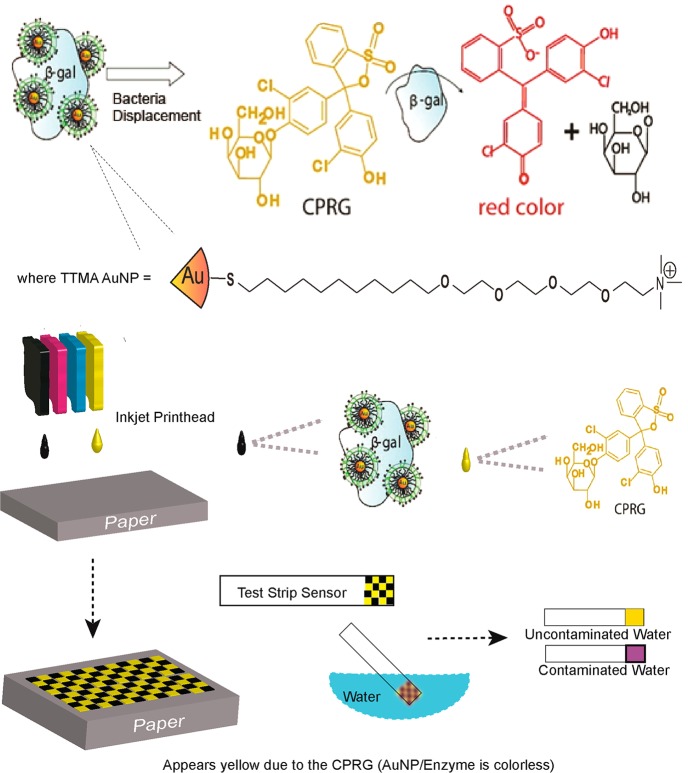

Rapid response time and simplicity of use are important for point-of-use systems. To achieve rapid response times and simple “dip and use” utility, the enzyme and a colorimetric substrate were spatially printed from different cartridges to prevent mixing before immersion. The close proximity of enzyme and substrate provides a rapid sensing platform. To create the colorimetric response needed for visual detection of bacteria, we adapted a sensing construct that uses β-galactosidase (β-gal) and surface-functionalized AuNPs (Scheme 1).19 In brief, cationic AuNPs were electrostatically bound to the anionic β-gal, causing reversible inhibition of the enzyme. When incubated with a colorimetric substrate (chlorophenol red-β-d-galactopyranoside (CPRG)), the color of the sensor remains pale yellow. When negatively charged bacteria are present, a competitive equilibrium is formed between the bacteria and the enzyme for the nanoparticles. This displacement restores enzymatic activity to the β-gal, which then cleaves the colorimetric substrate to produce a deep purple color.

Scheme 1. Chemical Basis and Inkjet Printing Scheme for the Test Strips Used in These Studies.

Experimental Section

Materials and Instruments

The β-galactosidase was purchased from Sigma-Aldrich and used without purification. The CPRG substrate was purchased from Roche Analytical and used as purchased. Sodium chloride (NaCl), lead, cadmium, copper, zinc, sodium sulfate, and sodium dodecyl sulfate were purchased from Fisher Scientific. Gold nanoparticles with the attached ligand were synthesized in a two-step method. This entailed the preparation of pentanethiol-stabilized nanoparticles with a core size of approximately 2.5 nm using the Brust method followed by a ligand-exchange reaction.29,30 The tetraethylene glycol trimethyl ammonium (TTMA) ligand was synthesized according to previous methods.8 Before printing, the nanoparticles, CPRG, and enzymes were filtered through a 0.2 μm polypropylene membrane (Puradisc 25AS, Whatman) and syringed into a virgin aftermarket Epson inkjet cartridge for printing (MIS Associates, Auburn Hills, MI USA). Inkjet printing was done using an Epson Artisan 50 inkjet printer. Procedures for printing, fabrication, image processing, and stability can be found in the Supporting Information.

Test Strip Procedure

Paper test strips were immersed into the analyte solution for 30 s and removed for drying. In the case of the drinking water studies, Poland Springs bottled water was used and adjusted as needed. After 5 min, the strips were evaluated both visually and by use of a scanner. Six cyan–magenta–yellow–black (CMYK) values for each test strip were obtained from the scanned images through the use of Adobe Photoshop and averaged to generate the colorimetric response. The K value was shown to be negligible in all readings and therefore is not reported. The cyan–magenta–yellow (CMY) values are reported in the Supporting Information.

Results and Discussion

Enzymes can easily be damaged during the inkjet printing process.31 To minimize the impact of the printing process piezoelectric printing was used, avoiding the harsh ∼300 °C used in thermal inkjet printing.20 In Figure 1a, we show a piece of paper printed solely with a 2.5 mM CPRG solution in Milli-Q water that shows the pale yellow color of the material. We then printed a solution of 500 nM β-gal in Milli-Q water directly onto the same paper. In Figure 1b, we show that the enzyme does in fact survive the printing process as the paper changes color from yellow to purple as patterned. This result indicates that the enzyme survives the inkjet printing process and therefore can be incorporated as a component of the sensor.

Figure 1.

(a) Before and (b) after printing β-gal onto a piece of paper that was preprinted with CPRG by inkjet printing.

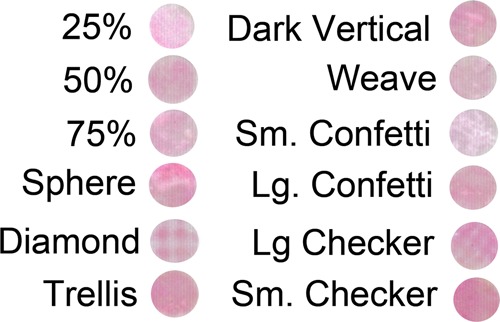

Precise patterning of the material is needed to produce a large uniform color change as well as ensure that the materials do not mix before immersion in the water. By creating different patterns such as spheres, checkerboards, and waves (Supporting Information, Figure S1) but keeping both the CPRG and β-gal solution concentrations constant, we created 12 different test strips to optimize our design. To quantify the strip response, each sensor was digitally scanned using a Canon LiDE 210 desktop scanner to produce average CMY component values. As seen in Figure 2, multiple patterns showed a deep purple color when immersed; however, the small checker response showed the most consistent and highest response across the test-strip surface. This visual interpretation is confirmed by graphing the color change measurements of a cross section of each of the 12 strips both before and after immersion into water (Supporting Information, Figures S2 and S3). Therefore, we chose the small checker pattern for test-strip construction (Supporting Information, Figure S4). To better quantify the mobility of the sensor components, we printed a simple line of both CPRG and enzyme and immersed the strip into a solution of the opposite material. As shown in Supporting Information, Figure S5, the CPRG substrate moves approximately 1 mm along the strip in both directions, but the printed enzyme does not move. This differential mobility indicates that the sensor operates by the substrate moving over the enzyme. Given that the sensor works through the use of a water-soluble substrate, we tested to ensure that the substrate does not leach out into the analyte solution. Even after leaving the sensor in an analyte solution for 5 min, very little substrate was seen photometrically in solution (Supporting Information, Table S1).

Figure 2.

Colorimetric response of the patterned test strip after immersion in water.

The quantities of β-gal, AuNP, and CPRG were optimized to produce vivid sensor responses when incubated with bacteria. As the colorimetric response is based on how much of the substrate is processed by the enzyme, we first determined the response generated by varying quantities of β-gal and substrate. The solutions were inkjet printed in an alternating ∼2 mm square checkerboard pattern to provide close proximity without intermixing. In Figure 3, we show images of the various concentrations of substrate and enzyme printed onto W. B. Mason Flagship paper and immersed in Milli-Q water for 30 s. As the concentration of CPRG increases, the color change from yellow to purple is significantly enhanced. However, this effect lessens at higher concentrations of CPRG, possibly due to enzyme aggregation. This visual interpretation can also be seen graphically by plotting the magenta response as shown in Supporting Information, Figure S6. Given these results, we chose 500 nM β-gal and 2.5 mM CPRG as our testing amount as it provided the greatest color change within a reasonable 5 min time period.

Figure 3.

Optimization matrix for the β-galactosidase and CPRG substrate components after 30 s of immersion in Milli-Q water and 5 min of development time.

Given that the sensor depends on enzymes that can be altered by pH, we tested our NP-free strips to ensure durability against real world samples. To investigate, we dipped the strips into a range of Milli-Q water buffered to a range of pH values to see at what level will the enzyme degrade, producing no colorimetric response. In Supporting Information, Figure S7, the strips showed that the enzymes on the strip operate best between pH 5 and 7. To investigate further the range between pH 6.5 and 8.5 whose range is acceptable for drinking water, we used pH-adjusted bottled water to more closely probe the response of the strip (Supporting Information, Figure S8). These strips only showed an altered response when the pH was above 8. This result indicates that while most water will be suitable for our sensor system, water with a particularly high pH value will need pretreatment for analysis.

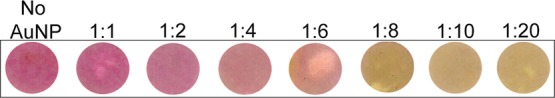

The proper ratio of AuNP to β-gal was determined next. The β-gal enzyme must be properly inhibited before testing for bacteria, as uninhibited β-gal will process the substrate as if bacteria are present, providing a false positive. Premixed β-gal/AuNP solutions were inkjet-printed alongside the 2.5 mM CPRG substrate. The strips were then tested in Milli-Q water to see if any change in color was apparent. As shown in Figure 4, ratios below 1:8 enzyme to particle showed incomplete inhibition of the enzyme generating a purple color. While the 1:8 enzyme to particle test strip had only a slight color change when immersed into water, the 1:10 ratio showed no visible change at all and therefore was selected for further use in this study. This result is quantitatively shown by graphing the magenta response against AuNP equivalents, showing a plateau of response around 10 equiv of AuNPs (Supporting Information, Figure S9).

Figure 4.

Ratios of β-Gal/AuNP to test the inhibition concentration for the test strips after 30 s of immersion in Milli-Q water and 5 min of development time.

We immersed the printed strips into various concentrations of both Gram-negative (Escherichia coli XL1) and Gram-positive (Bacillus subtilis) bacteria to test the sensitivity of the printed strips. As seen in Figure 5a, visible changes in color were observed for E. coli XL1 to 102 bacteria mL–1 (cfu) 5 min after dipping. Similar behavior was seen in test strips immersed in the B. subtilis bacteria (Figure 5b). As seen in Figure 5c, plotting the magenta component value against bacteria concentrations clearly indicates that the strip used in the water contaminated with 103 cfu does show a color change similar to that seen at higher concentrations. These results indicate that these strips can detect bulk concentrations of bacteria whose output can be determined visually. By adding a portable low-cost scanner, we have also shown that we can lower the limit of bacterial detection by analyzing the sensor response.

Figure 5.

Test-strip sensitivity in cfu against (a) E. coli XL1 and (b) B. subtilius. The average magenta component values of the strips are plotted in (c). Error bars represent six measurements of each test strip.

As bacteria can inherently generate β-gal,32 a control experiment was done to investigate whether the native enzyme will impact test strip response. To test this impact, we incubated a test strip containing CPRG but no printed β-gal into both a clean Milli-Q water solution and a concentrated (108 bacteria/mL) E. coli XL1 solution and scanned each for visual determination. As seen in Supporting Information, Figure S10, the strip showed no colorimetric response after 30 s of immersion in the bacteria indicating that the native bacteria does not produce enough β-gal to interfere with sensor operation. However, it is important to note that other strains of bacteria do produce β-gal, so further sensor testing to determine total as well as fecal coliforms against a wider range of bacteria will be needed to address regulatory requirements.

Drinking water can also be contaminated with other materials that could affect the sensitivity of the paper-based sensor. As drinking water can contain levels of sodium chloride as high as 5 mM, which can interfere with the electrostatic behavior of our sensor system, we first tested our sensor system against varying levels of salt. In Figure 6a, we show that at concentrations above 150 mM the sensor generates a strong visual false positive for high concentrations of bacteria. By scanning these test strips, we were able to graphically show in Figure 6b that the salt affects the response at concentrations >25 mM, a level 5 times higher than the highest acceptable salt standard for drinking water as well as higher than 10 mM that can be detected by human taste.33 Therefore, these strips will not be affected by the ionic strength of normal drinking water.

Figure 6.

(a) Visual and (b) graphical response of our test strips to various concentrations of sodium chloride in water. Error bars represent six measurements of each test strip.

We also investigated the effect of six different chemicals found in heavily contaminated water that have been shown to inhibit the β-gal enzyme (Supporting Information, Table S8). In these cases, high concentrations of contaminants will not allow the strip to change color, showing a clean water result when the sample is anything but safe. To test the impact of contaminants on the strip, water containing high concentrations of bacteria was spiked with water containing cadmium, lead, copper, zinc, sulfate, and sodium dodecyl sulfate and allowed to mix. After 5 min, the strips were immersed to note the visible change between water contaminated with simply bacteria and samples contaminated with metal and bacteria. As seen in Supporting Information, Table S8, only cadmium and copper showed any degradation due to the added metal. Furthemore, the amounts of these contaminants needed to cause changes to the strip far exceed the highest acceptable values for drinking water.34

Conclusion

In summary, we have created a printable paper-based sensor for the rapid determination of concentration/presence of bacteria in water. By using inkjet printing, we can create inexpensive water monitors that can be read and interpreted by untrained people simply by visual inspection. Further real-world testing of these strips, especially using contaminated water sources will, however, be required for implementation of this strategy. Furthermore, this system shows the potential for creating other enzyme/substrate systems by coprinting the components using inkjet printing, with potential impacts in environmental, laboratory, and biomedical science as a whole.

Acknowledgments

The research was supported by the NSF IGERT (DGE-0504485) to B.C., the Center for Hierarchical Manufacturing (CMMI-1025020), the U.S. National Institutes of Health (CA155866), and the National Academies Pakistan-U.S. Science and Technology Cooperation Program.

Supporting Information Available

Details of experimental procedures for test-strip printing, the CMYK analysis of the test strips, and the results of the heavy metals testing. This material is available free of charge via the Internet at http://pubs.acs.org.

The authors declare no competing financial interest.

Funding Statement

National Institutes of Health, United States

Supplementary Material

References

- Kindhauser M. K.Global defence against the infectious disease threat. Communicable Diseases 2002 ;World Health Organization: Geneva, 2003. [Google Scholar]

- Kim J. H.; Grant S. B. Public Mis-Notification of Coastal Water Quality: A Probabilistic Evaluation of Posting Errors at Huntington Beach, California. Environ. Sci. Technol. 2004, 38, 2497–2504. [DOI] [PubMed] [Google Scholar]

- Oleniaz W. S.; Pisano M. A.; Rosenfeld M. H.; Elgart R. L. Chemiluminescent Method for Detecting Microorganisms in Water. Environ. Sci. Technol. 1968, 2, 1030–1033. [Google Scholar]

- Frischer M. E.; Danforth J. M.; Foy T. F.; Juraske R. Bioluminescent Bacteria as Indicators of Chemical Contamination of Coastal Waters. J. Environ. Qual. 2005, 34, 1328–1336. [DOI] [PubMed] [Google Scholar]

- Pineda F. J.; Lin J. S.; Fenselau C.; Demirev P. A. Testing the Significance of Microorganism Identification by Mass Spectrometry and Proteome Database Search. Anal. Chem. 2000, 72, 3739–3744. [DOI] [PubMed] [Google Scholar]

- Yeh Y.-C.; Creran B.; Rotello V. M. Gold Nanoparticles: Preparation, Properties, and Applications in Bionanotechnology. Nanoscale 2012, 4, 1871–1880. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chung H. J.; Castro C. M.; Im H.; Lee H.; Weissleder R. A Magneto-DNA Nanoparticle System for Rapid Detection and Phenotyping of Bacteria. Nat. Nanotechnol. 2013, 8, 369–375. [DOI] [PMC free article] [PubMed] [Google Scholar]

- You C. C.; Miranda O. R.; Gider B.; Ghosh P. S.; Kim I. B.; Erdogan B.; Krovi S. A.; Bunz U. H. F.; Rotello V. M. Detection and Identification of Proteins Using Nanoparticle–Fluorescent Polymer “Chemical Nose” Sensors. Nat. Nanotechnol. 2007, 2, 318–323. [DOI] [PubMed] [Google Scholar]

- Bajaj A.; Miranda O. R.; Kim I. B.; Phillips R. L.; Jerry D. J.; Bunz U. H. F.; Rotello V. M. Detection and Differentiation of Normal, Cancerous, and Metastatic Cells Using Nanoparticle-Polymer Sensor Arrays. Proc. Natl. Acad. Sci. U. S. A. 2009, 106, 10912–10916. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shawky S. M.; Bald D.; Azzazy H. M. E. Direct Detection of Unamplified Hepatitis C Virus RNA Using Unmodified Gold Nanoparticles. Clin. Biochem. 2010, 43, 1163–1168. [DOI] [PubMed] [Google Scholar]

- Phillips R. L.; Miranda O. R.; You C. C.; Rotello V. M.; Bunz U. H. F. Rapid and Efficient Identification of Bacteria Using Gold-Nanoparticle–Poly(para-phenyleneethynylene) Constructs. Angew. Chem. 2008, 120, 2628–2632. [DOI] [PubMed] [Google Scholar]

- Zhao W.; Brook M. A.; Li Y. F. Design of Gold Nanoparticle-based Colorimetric Biosensing Assays. ChemBioChem 2008, 9, 2363–2371. [DOI] [PubMed] [Google Scholar]

- Halkos G. E.; Tzeremes N. G. Advances in the Bacteriology of the Coliform Group: Their Suitability as Markers of Microbial Water Safety. Annu. Rev. Microbiol. 2001, 55, 201–234. [DOI] [PubMed] [Google Scholar]

- Yetisen A. K.; Akram M. S.; Lowe C. R. Paper-based Microfluidic Point-of-Care Diagnostic Devices. Lab Chip 2013, 13, 2210–2251. [DOI] [PubMed] [Google Scholar]

- Cao X. D.; Ye Y. K.; Liu S. Q. Gold Nanoparticle-based Signal Amplification for Biosensing. Anal. Biochem. 2011, 417, 1–16. [DOI] [PubMed] [Google Scholar]

- Baldrich E.; Vigues N.; Mas J.; Munoz F. X. Sensing Bacteria but Treating Them Well: Determination of Optimal Incubation and Storage Conditions. Anal. Biochem. 2008, 383, 68–75. [DOI] [PubMed] [Google Scholar]

- Then W. L.; Garnier G. Paper Diagnostics in Biomedicine. Rev. Anal. Chem. 2013, 32, 269–294. [Google Scholar]

- Parolo C.; de la Escosura-Muniz C. A.; Merkoci A. Enhanced Lateral Flow Immunoassay Using Gold Nanoparticles Loaded with Enzymes. Biosens. Bioelectron. 2012, 40, 412–416. [DOI] [PubMed] [Google Scholar]

- Miranda O. R.; Li X.; Garcia-Gonzalez L.; Zhu Z.-J.; Yan B.; Bunz U. H. F.; Rotello V. M. Colorimetric Bacteria Sensing Using a Supramolecular Enzyme–Nanoparticle Biosensor. J. Am. Chem. Soc. 2011, 133, 9650–9653. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Komuro N.; Takaki S.; Suzuki K.; Citterio D. Inkjet Printed (Bio)chemical Sensing Devices. Anal. Bioanal. Chem. 2013, 405, 5785–5805. [DOI] [PubMed] [Google Scholar]

- de Gans B. J.; Duineveld P. C.; Schubert U. S. Inkjet Printing of Polymers: State of the Art and Future Developments. Adv. Mater. 2004, 16, 203–213. [Google Scholar]

- Tekin E.; Smith P. J.; Schubert U. S. Inkjet Printing as a Deposition and Patterning Tool for Polymers and Inorganic Particles. Soft Matter 2008, 4, 703–713. [DOI] [PubMed] [Google Scholar]

- Derby B. Bioprinting: Inkjet Printing Proteins and Hybrid Cell-containing Materials and Structures. J. Mater. Chem. 2008, 18, 5717–5721. [Google Scholar]

- Creran B.; Yan B.; Moyano D. F.; Gilbert M. M.; Vachet R. W.; Rotello V. M. Laser Desorption Ionization Mass Spectrometric Imaging of Mass Barcoded Gold Nanoparticles for Security Applications. Chem. Commun. 2012, 48, 4543–4545. [DOI] [PubMed] [Google Scholar]

- Setti L.; Fraleoni-Morgera A.; Mencarelli I.; Filippini A.; Ballarin B.; Di Biase M. An HRP-based Amperometric Biosensor Fabricated by Thermal Inkjet Printing. Sens. Actuators, B 2007, 126, 252–257. [Google Scholar]

- Setti L.; Fraleoni-Morgera A.; Ballarin B.; Filippini A.; Frascaro D.; Piana C. An Amperometric Glucose Biosensor Prototype Fabricated by Thermal Inkjet Printing. Biosens. Bioelectron. 2005, 20, 2019–2026. [DOI] [PubMed] [Google Scholar]

- Hossain S. M. Z.; Luckham R. E.; Smith A. M.; Lebert J. M.; Davies L. M.; Pelton R. H.; Filipe C. D. M.; Brennan J. D. Development of a Bioactive Paper Sensor for Detection of Neurotoxins Using Piezoelectric Inkjet Printing of Sol–Gel-Derived Bioinks. Anal. Chem. 2009, 81, 5474–5483. [DOI] [PubMed] [Google Scholar]

- Hossain S. M. Z.; Luckham R. E.; McFadden M. J.; Brennan J. D. Reagentless Bidirectional Lateral Flow Bioactive Paper Sensors for Detection of Pesticides in Beverage and Food Samples. Anal. Chem. 2009, 81, 9055–9064. [DOI] [PubMed] [Google Scholar]

- Brust M.; Walker M.; Bethell D.; Schiffrin D. J.; Whyman R. Synthesis of Thiol-Derivatised Gold Nanoparticles in a Two-phase Liquid–Liquid System. J. Chem. Soc., Chem. Commun. 1994, 801–802. [Google Scholar]

- Hostetler M. J.; Templeton A. C.; Murray R. W. Dynamics of Place-Exchange Reactions on Monolayer-Protected Gold Cluster Molecules. Langmuir 1999, 15, 3782–3789. [Google Scholar]

- Nishioka G. M.; Markey A. A.; Holloway C. K. Protein Damage in Drop-on-Demand Printheads. J. Am. Chem. Soc. 2004, 126, 16320–16321. [DOI] [PubMed] [Google Scholar]

- Griffith K. L.; Wolf R. E. Measuring b-Galactosidase Activity in Bacteria: Cell Growth, Permeabilization, and Enzyme Assays in 96-Well Arrays. Biochem. Biophys. Res. Commun. 2002, 290, 397–402. [DOI] [PubMed] [Google Scholar]

- Rabin M.; Poli de Figueiredo C. E.; Wagner M. B.; Antonello I. C. Salt Taste Sensitivity Threshold and Exercise-induced Hypertension. Appetite 2009, 52, 609–613. [DOI] [PubMed] [Google Scholar]

- Drinking Water Contaiminants. http://water.epa.gov/drink/contaminants/ (accessed 6/24/14).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.