Abstract

Recent advances in nanotechnology have generated wide interest in applying nanomaterials for neural prostheses. An ideal neural interface should create seamless integration into the nervous system and performs reliably for long periods of time. As a result, many nanoscale materials not originally developed for neural interfaces become attractive candidates to detect neural signals and stimulate neurons. In this comprehensive review, an overview of state-of-the-art microelectrode technologies provided first, with focus on the material properties of these microdevices. The advancements in electro active nanomaterials are then reviewed, including conducting polymers, carbon nanotubes, graphene, silicon nanowires, and hybrid organic-inorganic nanomaterials, for neural recording, stimulation, and growth. Finally, technical and scientific challenges are discussed regarding biocompatibility, mechanical mismatch, and electrical properties faced by these nanomaterials for the development of long-lasting functional neural interfaces.

1. Introduction

Recent advances have generated wide interest in the creation of interfaces between neurons and external devices to restore or supplement the function of the nervous system lost during injury or disease. The objective of neural interface technology is to create a link between the outside world and the nervous system by stimulating or recording from neural tissue in order to assist people with neurological disabilities[1–4] These devices can improve our understanding of the organization and operation of the nervous system and may lead to improving the current state-of-art neural technologies for tackling of some mankind’s most debilitating disorders, including deafness, paralysis, blindness, epilepsy, and Parkinson’s disease. Since the 1960s, brain-machine interfaces have been used to record neural activity or stimulate neural tissue in humans and animals.[5,6] Today, implantation of macro and microdevices into the brain is increasingly used for treatment of neurological disorders.[7–9] Electrical stimulation of the brain can alter the brain function by injecting electrical signals into neurons. A deep brain stimulator implant is a remarkable treatment that manipulates basal ganglia to relieve the rigidity of Parkinson’s disease;[10] however, this device does not establish a communication link with the patient. Advances have been made in the development of intracortical recording systems to detect neural signals and translate them into command signals that can control external devices.[4,9,11,12] Such systems are potentially valuable for restoring lost neuronal function associated with neurological diseases and injuries.[11,13] Neural interfaces communicate with the nervous system via implantable electrodes that transduce electric signals to and from bioelectric signals (Figure 1).[14,15] The primary requirements of these electrodes include communication with as many individual neurons as possible with a high degree of signal-to-noise ratio (SNR) for specific time periods that may extend from hours to years.[13,16,17] This translates toward new electrode materials for development of high-density neural probes that are biologically transparent and biocompatible,[18,19] support seamless integration with neurons,[16,20] and remain functional for long period of time.[21,22] As a result, many materials that were not originally developed for neural interfaces have been recently applied for neural recording and stimulation.

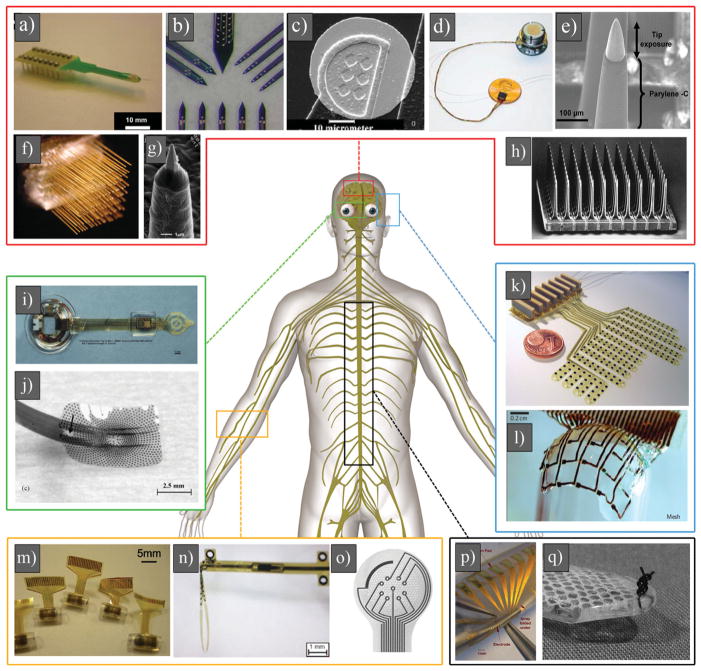

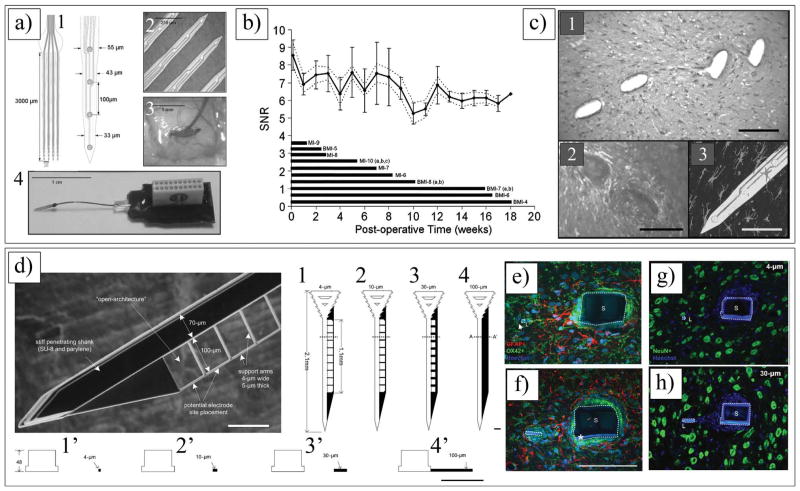

Figure 1.

a) Eight-channel silicon substrate acute Michigan electrode. Reproduced with permission.[174] Copyright 2008, Elsevier. b) High-magnification photograph illustrating four different types of sites layouts for Michigan electrode (NeuroNexus Technologies). Reproduced with permission.[3] Copyright 2008, Society for Neuroscience. c) SEM image of a single gold site of Michigan electrode. Reproduced with permission.[170] Copyright 2003, Elsevier. d) BrainGate microelectrode array (i.e. Utah array) connected by a 13 cm ribbon cable to percutaneous Ti pedestal secured to skull. Reproduced with permission.[84] Copyright 2006, Nature Publishing Group. e) High-magnification image of an electrode of Utah array. Reproduced with permission.[427] Copyright, 2010, Elsevier. f) Multiple boards stacked up to form arrays with up to 128 microwires. Reproduced with permission.[414] Copyright 2003, National Academy of Sciences. g) SEM image of a microwire, showing Au tip coated with parylene. Reproduced with permission.[428] Copyright 2012, IOP Publishing. h) SEM image of 100 microelectrodes of Utah electrode array. Reproduced with permission.[84] Copyright 2006, Nature Publishing Group. i) An epiretinal vision prosthesis, final implant with parylene C and silicone rubber encapsulation. Reproduced with permission.[429] Copyright 2009, IOP Publishing.) Heat molded and annealed retinal electrode array with retained spherical curvature (arrow denotes retinal tack hole). Reproduced with permission.[430] Copyright 2008, Elsevier. k) Fully assembled electrode array. The diameter of the coin is 16 mm. Reproduced with permission.[110] Copyright 2009, IOP Publishing. l) Optical image of silk-supported polyimide electrode arrays of a 25 μm mesh wrapped onto a glass hemisphere. Reproduced with permission.[431] Copyright 2010, Nature Publishing Group. m) Schematic cross-section of the channel pattern showing the structure neutral plane (strain & 0%) at the electrode layer. Reproduced with permission.[432] Copyright, 2010 Springer. n) Transversal intrafascicular multichannel electrode. Reproduced with permission.[433] Copyright 2011, Wiley. o) Enlarged view of the sieve portion of the regenerative electrodes, with nine ring electrodes around via holes and a larger counter electrode. Reproduced with permission.[434] Copyright 2004, Elsevier. p) Fabricated PDMS-substrate MEA wrapped around a wire of similar diameter (2 mm) to that of the neonatal intact or hemisected juvenile in vitro rat spinal cord. Reproduced with permission.[435] Copyright 2008, Springer. q) Distal aspect of paddle-style epidural electrode prepared with a 3–0 suture passed and knotted through the tip. The knot serves as a fixation point for wire snare. Reproduced with permission.[436] Copyright 2011, Congress of Neurological Surgeons; published by Wolters Kluwer Health.

Existing neural electrodes use conventional electronic materials that are often not intrinsically compatible with biological systems and do not conduct integration with neural tissue.[14,15,22] Although biocompatible metallic materials do exist, the hard, electronic, dry, and static nature of metals and metal oxides are quite foreign to biological tissue, which is soft, ionic, wet, and dynamic.[18,23] The performance of electrode-tissue interface ultimately rests on the quality of the martial substrate, which enables a long-lasting functional neural device. The challenge for materials science is to apply nanotechnology strategies and develop innovative biocompatible nanomaterials that mimic neural tissue characteristics, cause minimal inflammation and neuronal cell loss, and are functional for a long period of time.[24,25] The complex nanoscale structural features of neural tissue require a neural interface with nanoscale components. Many elements of neurons, glial cells, and extracellular matrix (ECM) have nanoscale dimensions; thus, the unique intrinsic properties of nanomaterials offer a great promise to seamlessly integrate with neural tissue and simulate features and functions of cells and ECM.[26] Electrically active nanomaterials (EANs)[27] such as carbon nanotubes,[28,29] silicon nanowires,[30] gallium phosphide nanowires,[31] and conducting polymer nanotubes[32] have been already interfaced with central and peripheral nervous systems. These conductive nanomaterials are able to provide a more-effective surface area than regular metals for signal transduction at the electrode-tissue interface, thus enhancing the electrical characteristics of neural recordings and stimulations, such as SNR and safe charge injection density.[24,33] Incorporation of drugs and bioactive molecules into EANs can improve the biocompatibility of neural electrodes, reduce reactive tissue response, and promote neural process outgrowth.[18,34–37] Recently EANs have been hybridized with hydrogels and were used as soft and conductive coatings for neural electrodes to decrease the mechanical mismatch between stiff electrodes and soft tissue.[38,39] While there are a number of excellent review articles focused on technologies and materials applied to neural interfaces,[14,24,40,41] this report will attempt to review the application of biomaterials, in particular, conducting polymers, carbon nanotubes, graphene, silicon nanowires, and hybrid organic-inorganic nanomaterials for neural interfaces.

2. Reactive Tissue Responses to Neural Implants

It has been shown that the distance between the electrode and the neurons significantly influences the strength and quality of the recording signals.[16,18] The extracellular spike amplitude decreases rapidly as a function of distance from the neuron. Based on theoretical models and direct measurements, the maximum distance required for maintaining a stable recording between an electrode and a neuron cell body is between 50 and 100 μm.[16,42–45] In addition to the strength of the spike amplitude sent from nearby neurons, the degree of foreign body response occurring at the interface between the electrode and the surrounding neural tissue plays an important role in determining the success of neuroprosthetic devices.[19,34,46,47] An ideal recording electrode should be very small to minimize brain injury and have a large number of recording sites to monitor many neurons.[16,48,49] In order to design neural electrodes with minimized tissue response and stable recording capability, it is necessary to understand the biological mechanisms involved in the response of the brain to implanted electrodes.

2.1. Acute Response

Acute inflammation in the central nervous system (CNS) is initiated by the mechanical trauma of electrode insertion.[18,50] It occurs mainly due to a difference between the mechanical properties of the implanted electrode (e.g., elastic modulus of ca. 150 GPa for silicon) and the neighboring tissues (elastic modulus of ca. 100 kPa for brain tissue). As the electrode is inserted (Figure 2a), neurons will be either ripped or sliced,[48] and the tissue may swell and push the neighboring neurons away from the electrode surface.[51–53] Moreover, the formation of necrotic tissue following the insertion and fluid movement across the blood vessels will cause edema, exerting hydrostatic pressure around the implanted electrodes.[51,54] Acute inflammation can be characterized by the presence of erythrocytes, activated platelets, clotting, and factors released from disrupted blood vessels.[18,51,55] Activated microglia will then approach the site of the injury from a blood vessel as early as one day post-implantation (Figure 2a and 2b), These inflammatory cells release numerous neurotoxic factors, including cytokines, chemokines, neurotransmitters, and reactive oxygen species. After about 6–8 days of implantation, microglia have degraded most cellular debris and damaged matrix by phagocytosis.[51,56] The physiological changes occurring near an implanted electrode during acute response can appear as a spike in the impedance values during in vivo impedance spectroscopy measurements.[51,52,57] Initially, few neurons can be found within 100 μm of the electrode, but the neuron density is almost normal outside this zone. Since the acute response normally causes neuronal death, it takes roughly 4 to 6 months for healthy-appearing neurons to grow closer to the electrode. Among the viable neurons that have survived the acute reaction, remaining electrically active in proximity of the chronically implanted electrode is an important factor determining the strength of the neuronal signals to be recorded by implants.[18,48,58–60]

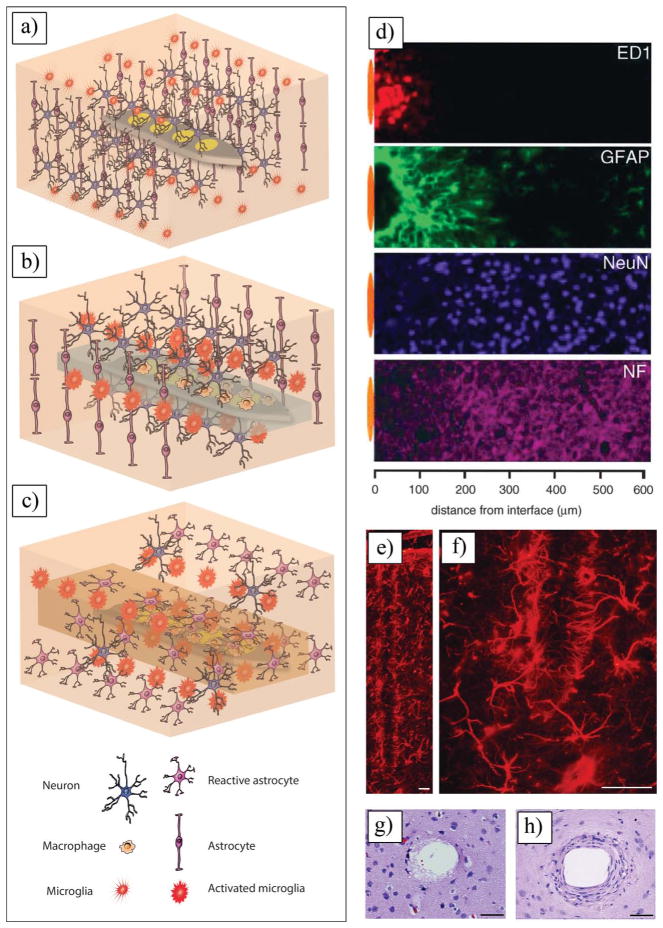

Figure 2.

a) Schematic of insertion of a neural electrode inside the brain. b) Schematic of acute response to an implanted electrode. c) Schematic of chronic response to an implanted electrode. d) Immunoreactivity images using cell-type-specific markers at microelectrode brain tissue interface. Representative image collected from adjacent section of an animal with 4-week microelectrode implant illustrates general appearance of foreign body response. Position of microelectrode illustrated by orange oval (drawn to scale) left to each image. d) Reproduced with permission.[53] Copyright 2005, Elsevier. e,f) Reactive astrocytes labeled with GFAP staining encapsulate neural probes in a dense cellular sheath, Calibration bar = 50 μm. g) Acute injury caused by inserting a microelectrode into brain cortex, showing activation and migration of astrocytes and microglial cells to injury site, Calibration bar = 50 μm. h) Chronic response forming dense sheath of fibroblasts, macrophages, and astrocytes around implant, Calibration bar = 50 μm. e–h) Reproduced with permission.[97] Copyright 2010, C. Marin, E. Fernandez; published by Frontiers.

2.2. Chronic Response

Once acute inflammation declines, chronic response will initiate (Figure 2c). Chronic inflammation is characterized by the presence of both reactive astrocytes and activated microglia (Figure 2c and 2d) that form a glial scar (Figure 2e–h).[19,53] After the initial wound healing is complete, activated microglia remain at the surface of the implanted microelectrode. Microglia colonies can be mediated by the adsorption of serum factors such as monocyte/macrophage chemotactic proteins on the surface of an implanted electrode.[61,62] During the colonization of microglia, it will lead further events such as releasing lytic enzymes and reactive oxygen agents to degrade and finally remove the foreign material.[63] Furthermore, microglia regulate the production of a thin layer of ECM proteins, basal lamina that can aid in organizing the glial scar.[51] Microglia attempt to phagocytose the foreign objects and complete the elimination process.[64–66] On the contrary, if the individual macrophages fail to degrade the foreign object, they will fuse into multinucleated foreign-body giant cells and continue the secretion of degradative agents.[19,34,67] Glial scars (i.e., gliosis) are the most common observation of the CNS response to chronically implanted neural electrodes.[34,68–70] Gliosis will lead to astrocyte proliferation, a protection against further injury or infection, which creates glial scars. Studies have shown that glial scars isolate neural electrodes from the surrounding tissue in a process similar to the fibrotic encapsulation process. in which non-degradable implants are encapsulated in soft tissues.[51,71–74] The glial scar insulates the electrode from nearby neurons and increases the impedance of the tissue-electrode interface. Gliosis pushes away the surrounding tissues, and this extends the distance between the electrode and its nearest target neurons, thus dramatically degrading the amplitude of the recording signals from neurons.[34,48,75–80]

3. Classification of Neural Signals and Sensors for Neural Interface Systems

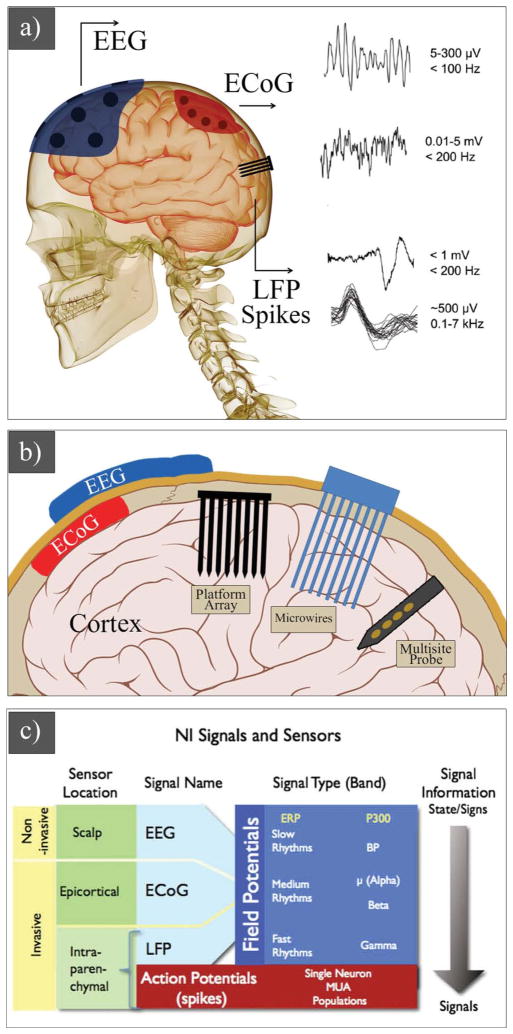

Field potentials and action potentials (spikes) are two classes of recording signals for neural prosthetic devices (Figure 3). Field potentials, including electroencephalogram (EEG) signals, electrocortiogram (ECoG) signals, and local field potentials have been largely used in humans,[7,81,82] while action potentials-based electrodes have been adopted to animal models,[11,83] and more recently in humans.[13,84] EEG signals are slow rhythms (5–300 μV, <100 Hz) and can be recorded non-invasively from single or multiple sites on the scalp. ECoG signals are medium rhythms (0.01–5 mV, <200 Hz) and can be monitored using epicortical electrodes by placing them on the surface of the brain (invasive method). Penetrating electrodes are used to record local field potentials (<1 mV, <200 Hz) and action potentials (ca. 500 μV, 0.1–7 kHz) (Figure 3a–c).

Figure 3.

Schematic of a) neural signals (EEGs, ECoGs, LFPs, and spikes) and their properties. b) EEG electrode on the skull, ECoG electrode on the surface of brain, and penetrating electrodes: three main types of intraparenchymal (intracortical) sensors now in use are illustrated: platform array, an array of electrodes emanating from a substrate that rests on the cortical surface; multisite probe, with contacts along a flattened shank; and microwire assemblies, consisting of fine wires. c) Signals and sensors for neural interface systems. c) Reproduced with permission.[88] Copyright 2008, Elsevier.

EEG recordings could be used in human with severe paralysis for applications ranging from letter-by-letter spelling[9,81] to 2D cursor control.[82] EEG signals have several drawbacks as field potential signal sources for neural interfaces, including limited bandwidth (loss of higher frequency due to scalp filtering), variability in sensor contact over time, multiple wirings and tethering to instrumentation, significant noise, and environmental artifacts. In comparison with EEG signals, ECoG can provide a lower noise signal and higher bandwidth and power, because filtering by the scalp is reduced.[85] Wireless ECoG electrodes can eliminate some of the drawbacks associated with EEG electrodes, but US Food and Drug Administration (FDA)-approved ECoG electrodes for longterm neural interfaces are currently unavailable. ECoG electrodes are used for short-term subdural placement in patients with epilepsy. These electrodes are ca. 4 mm in size, arranged in a silastic sheet that covers a large area of cortical surface in order to map surgical resections. It is widely accepted that spikes hold the richest neural movement information and the amount of data available from action potential is impressive. For example, neurons in the motor cortex carry hand velocity, position, and forces.[86] The number of neurons in the motor cortex required for reliable reconstruction of hand movement in a 2D or 3D space is around 50 cells.[12,20] Penetrating microwires and micromachined electrodes are used to record spikes and local field potentials in animals and humans. Although spikes can be separated to the level of single unit activity using signal-sorting algorithms, gathering information from a population of a few dozen neurons (multiunit activity recording) has shown to be of great interest for neural interface technologies.[87] There is an ongoing debate in the field of neural interface technology regarding the concerns of whether the invasiveness of neural electrodes that are used to obtain action potentials or field potentials from ECoGs or local field potentials can provide sufficiently stable and reliable signals to justify the risk of implantation and the longterm presence of an object inside the brain.[1,88] Safety and long-term, reliable signal recording are the major concerns in the neural interface community. Deep brain stimulators are FDA-approved neurological devices implanted centimeters deep in the brain to help more than 30 000 people with Parkinson’s disease.

3.1. Past and Current Neural Interface Technologies

In 1870, Fritz and co-workers demonstrated the controllability over animal muscle movements by applying electrical stimulation to the brain motor cortex regions.[60,89] In 1963, Gray Walter, a pioneer in the use of electroencephalography, demonstrated the use of recorded brain signals from human motor cortex to operate a slide projector. This was the first attempt to show the feasibility of cortical neural prosthetics.[90] Since then, extensive scientific research has been done to design and develop neural devices that can be implanted into the nervous system for both recording and stimulation.[15,33,48,91–93] In 1996, cortical microwire electrodes were implanted in the right and left hemispheres of a monkey’s brain, generating population vectors for prosthetic arm control.[49] Much later, Nicolelis et al. reported successful neural recording from implanted microwires (totaling 96–704 per subject) in a monkey’s brain, up to 18 months after implantation.[22] Donoghue and co-workers implanted an array of 96 microfabricated silicon electrodes in the primary motor cortex, for the control of prosthetic devices in a human with tetraplegia.[13,84] They remarkably recorded neuronal activity of neurons 3 years after spinal cord injury. Their results suggested that recording neural signals could be used for the development of new technologies to restore independence for humans with paralysis.[13] More recently, flexible surface microelectrodes have been designed for acute and chronic neural recoding.[94,95] Flexible electrodes that are made of polyimide (PI) and parylene C have elastic modulus (ca. 3.2 GPa) significantly lower than that of silicon; therefore, these electrodes may generate less tissue damage and be functional longer than silicon-based electrodes. Rogers and co-workers developed ultrathin (2.5 μm) polyimide-based neural electrode arrays to record signals form the visual cortex in cats.[94] The ultrathin PI electrode array outperformed thick PI electrodes (75 μm) with nearly all channels in good conformal contact and a still higher SNR.

4. Materials for Neural Electrodes

Neural electrodes have evolved in their unique material, chemistry, shape, size, and texture, to modify the electrical properties, mechanical properties, and biocompatibility of the electrode-tissue interface, and thus to improve the electrode longevity and performance.[96,97] Several materials have been explored for the electrode substrate, including silicon, ceramic, glass, sapphire, and polymers.[98–101] For targeting specific regions of the brain, microwires and glass micropipette electrodes have been used. Later, they advanced into silicon shafts and even more complex micromachined silicon and polyimide flexible recording systems capable of monitoring neuron networks with improved temporal and spatial resolution.[19,57,70] Table 1 summarizes the materials that have been utilized for neural interface technologies.

Table 1.

Comparison of microelectrode technologies.

| Type | Properties

|

|||||

|---|---|---|---|---|---|---|

| Substrate Materials | Electrode Site Materials | Recording duration | Dimension | Ref | ||

| Wires | Single microwire | Glass or polyimide insulated microwires | Pt/Ir Pt/Ir | 62%/1 week 25%/151 weeks |

Single wire | 447,448 |

| Microwire array | S-isonel (or Teflon)-coated tungsten (or stainless steel) | Tungsten, Ir, Pt/Ir alloy | up to 18 months | 3D array with diameters ranging from 20 to 50 μm | 1,449,450 | |

| Single NW FET | Quartz/Silicon | Si3N4, Germanium | Seconds In vitro | 3D array with diameters ranging from 30 to 200 nm | 367 | |

| Vertical NW array | Silicon-on-insulator | Metal-coated | N/A | 3D array 150 nm | 442 | |

| Silicon MEMS arrays | Michigan electrode | Silicon w/Silicon dioxide/nitride | Ir Pt | 92%/12 weeks 92%/18 weeks |

Planar, 2D and 3D array Site area: ca. 1250 μm2 | 17,21,378,419,451–457 |

| Utah array | Silicon coating materials: Parylene-C | Au and Pt | 45%/12 weeks 18%/52 weeks |

3D array, Site area: ca. 760 μm2 | 15,458 | |

| Other Si micro-electrode array | Silicon on insulator (SOI) wafer | Cr, Pt | N/A | N/A | 459–461 | |

| Polymer MEMS arrays | Polyimide | Pt | N/A | Site area: ca. 900 μm2 | 101,462 | |

| Flexible array | Polyimide–platinum–polyimid | N./A | 8 weeks | Planar array | 463 | |

| Flexible array | Silk-supported PI array | Cr/Au | 4 weeks | Planar array | 431 | |

| Flexible array | Silk array | Cr/Au | 4 weeks | Planar array | 431 | |

4.1. Microwires

Microwire electrodes (Figure 1f) are mainly made of conducting metal wires, such as platinum, gold, iridium, stainless steel, and tungsten. Neural recording occurs through the non-insulating tip of the wire and the rest of the wire is coated with a non-cytotoxic insulator material (Figure 1g). Microwires can be easily made into an array of 4 to over 100 electrodes with spacing of 100–300 μm supported by polyethylene glycol and methacrylate.[15,22,48,102] Numerous attempts have been made to obtain chronic single-neural recording from behaving animals using arrays of microwires.[15,69,103,104] Nicolas et al. recorded 247 individual cortical neurons from 384 out of 704 chronically implanted microwires in monkey’s brain up to 18 months after implantation.[22] However, microwire electrodes suffer from: i) a risk of surgical complications due to the transcutaneous wire connection; ii) forces and movements associated with the tethered electrodes, stimulating tissue responses; and iii) bending of the microwires during implantation due to the curvilinear surface of the brain tissue.[68,105]

4.2. Micromachined Electrodes

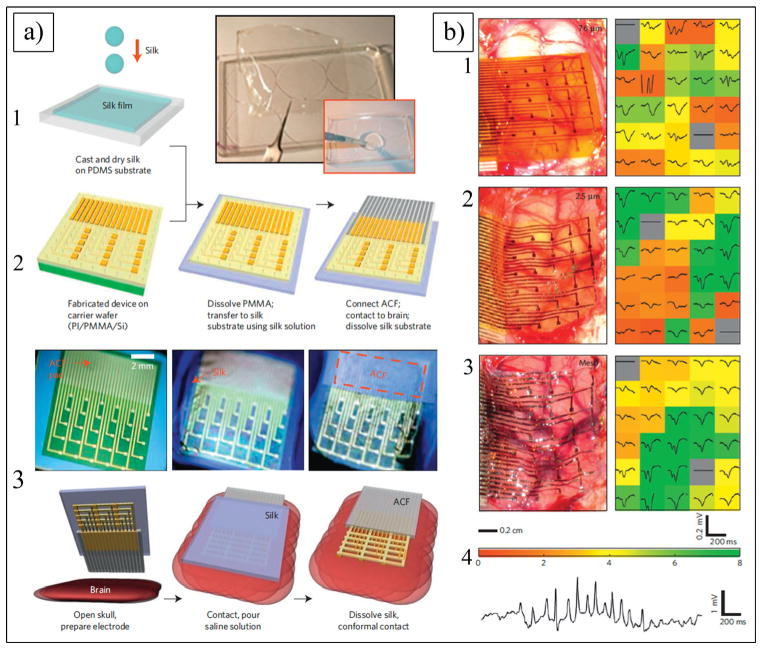

The next generation of neural electrodes is micro-electromechanical system (MEMS) electrodes (Figure 1a–e and 1h), which can be fabricated into complicated structures using microfabrication techniques.[17,67,106] MEMS-based single-shank silicon electrodes (e.g., Michigan electrodes (Figure 1a–c) can overcome the technical barriers associated with microwire electrodes because, with the same amount of tissue displacement, the number of recording sites can be substantially increased, and they are significantly smaller in size.[3,107] Furthermore, multiple sites can be formed over the shank of the electrode, thus enabling simultaneous recording of the neuronal activity in the various layers of the cortex. Multi-shank electrodes are able to record from as many as neurons. Two major types of silicon microelectrode array are the Utah array (Figure 1d,e,h) and the Michigan electrode (Figure 1a–c). The Utah array has been used for over 20 years; its basic structure is that of a needle-like electrode, which is made of a single shank of silicon. It is made of 25 to 100 shanks per electrode (each shank being 1.5 mm in length and 1–100 μm in diameter).[108] Unlike the Utah array, the Michigan probe is a single-shank electrode having several recording sites placed on the surface of the shank. In order to overcome the challenges associated with the mechanical mismatch between the hard, planar silicon electrodes and the soft curvature tissues of the brain, Kim et al. fabricated electrodes with a soft and curvilinear surface made with a bioresorbable film of silk covering an array of ultrathin (<10 μm) polyimide (PI) electrodes (Figure 1l, Figure 4a).[109] Reducing the thickness of the electrode substrate decreases the bending rigidity of the electrode, thereby improving the conformal contact. Unfortunately, thick clinical electrode arrays (700 μm[110]) and even the thinnest devices designed for research (>10 μm[111]) have thicknesses that are larger than desired to ensure conformal contact. Kim et al. implanted three different arrays of surface electrodes (30 electrodes per array) in cats for neural recording from the visual cortex (Figure 4b) (i.e., (1) PI thick electrodes (75 μm); (2) PI thin electrodes (2.5 μm) supported by a silk layer; and (3) silk mesh electrodes (2.5 μm). The authors successfully demonstrated that the 2.5 μm mesh electrode showed the best performance, with nearly all the channels in good contact, and a still higher SNR of 5.7. The lower standard deviation of the 2.5 μm array illustrated that most of the electrodes recorded good neural activity. Placing such devices on soft brain tissue and then allowing the silk to dissolve and resorb generates a spontaneous, conformal wrapping process driven by capillary forces at the biotic-abiotic interface. Remarkably, the authors did not observe any evidence of immune response after 4 weeks of implantation.[109]

Figure 4.

a) Schematics and images showing fabricating steps for conformal silk-supported PI electrode arrays. a1) Casting and drying of silk fibroin solution on temporary PDMS substrate. a2) Fabricating steps for electrode arrays. a3) Schematics of clinical use of a representative device in ultrathin mesh geometry with dissolvable silk support. b) Photos and data from animal validation experiments. b1–b3) Images of electrode array on a feline brain (left) and average evoked response from each electrode (right) with color showing ratio of root mean square (rms) amplitude of each average electrode response in 200 ms window (plotted) immediately preceding the stimulus presentation for a 76 μm (b1), 2.5 μm (b2) and 2.5 μm mesh (b3) electrode array. Color bar at bottom of (b3) provides scale used in right frames of b1–b3 to indicate rms amplitude ratios. b4) Representative voltage data from a single electrode in 2.5 μm mesh electrode array showing a sleep spindle. a,b) Reproduced with permission.[431] Copyright 2010, Nature Publishing Group.

The bridge that connects implanted electrodes to the external connector cable is the source of electrode micromotion. This micromotion is closely related to the foreign body response around the implant.[18] Kipke and co-workers made a hybrid system that used silicon-substrate microelectrodes with a printed circuit board on flexible PI ribbon cables (Figure 5a).[17] The 16-channel microelectrodes consisted of four penetrating shanks with four recording sites on each shank. The electrode assembly included an integrated silicon ribbon cable and a percutaneous connector. These neural electrodes were found to consistently and reliably provide high-quality neural recordings over extended periods of time up to 127 days (Figure 5b). Fourteen electrodes were implanted in the cortices of 10 rats and 93% of them remained functional throughout the assessment period. More than 90% of the electrode sites consistently recorded neural activity with high SNR. Histological analysis of the tissue surrounding the electrodes indicated the development of a stable interface sufficient for sustained electrical contact (Figure 5c). The results of this study demonstrate that these hybrid silicon/flexible PI ribbon cable probes are suitable for long-term recording in the cerebral cortex.[17] The shape and size of the neural electrodes may have a significant effect on the quality of signal recording and electrode-tissue interactions. Szarowski et al. showed the effect of electrode shape, size, and tip geometry on the level of cellular encapsulation to silicon neural electrodes.[19] The authors compared different sizes of three cross-sectional shapes of the shafts (i.e., trapezoid, square, and elliptical). For each of these electrodes, they also used two tip geometries (i.e., sharp and rounded) with different insertion techniques. These studies demonstrated no significant reduction in the response of the brain to the implanted electrodes.[19] While Rousche et al. and Schimidt et al. suggested that specific material surface characteristics such as the texture of an implant can reduce the chronic response,[15,112] Szarowski et al. claimed that the effect of the electrode shape, size, texture, and tip geometry is insignificant to the immune response. Recently, Kipke and co-workers designed subcellular-sized parylene branches connected to parylene-based neural electrodes and implanted them in rat cerebral cortex for 4 weeks (Figure 5d).[113] The parylene-based neural electrodes were fabricated with a thick shank (48 μm) and an integrated, thin lateral platform (5 μm, either solid or one of three lattice sizes). The authors hypothesized that a subcellular-sized lateral edge would have less tissue encapsulation relative to the larger electrode shank. Immunostaining revealed that there was significant differential tissue response within 25 μm of the lateral edge, compared with the shank (Figure 5e–h). The density of astrocytes and microglia in this region of the lateral edge was less than one-third of that of the corresponding region of the shank (129% and 425% increase, respectively). Moreover, neuronal density around the platform’s lateral edge was about one-third higher than at the shank. Microglia reactivity and extracellular protein deposition was reduced at the lateral edge. The authors concluded that the ideal electrode location for their designs was on the outermost position at the edge 50 μm thick, extending far from the probe shank.[113]

Figure 5.

a) Michigan 16-channel probe. a1) Schematic of four shanks. a2) Four shank, 16-channel probe with 20 μm diameter-recording sites. a3) Implanted probe in auditory cortex. Thin layer of ALGEL covers implanted probe and surface of the brain. a4) Assembled probe. b) Average percent of active electrodes on implanted arrays. Time bars at bottom of figure represent each animal’s contribution to mean results. c) c1) 20 μm H&E stained section from a four-shank device implanted in animal for 127 days. c2) 50 μm immunostained section (GFAP and laminin) showing a close-up of two shanks from four-shank device implanted in animal for 36 days. c3) 150 μm section taken parallel to a probe with a single shank remaining intact within the section for 38 days. Calibration bar = 100 μm. a–c) Reproduced with permission.[17] Copyright 2004, Institute of Electrical and Electronics Engineers. d) SEM image of a parylene-based open-architecture probe used for in vivo testing. d1–d4) CAD drawings of each probe design indicating overall length and width of three lattice platforms (4, 10, 30 μm), and d4) one nonlattice platform (100 μm wide). d12–d42) Crosssectional view of line A–A2 shown in (d1–d4). All the probes have identical shank and outer dimensions. Calibration bar = 100 μm. e,f) Expression of astrocytes (dyed with red GFAP stain), microglia (dyed with green OX-42 protein stain), and cell nuclei (dyed with blue Hoechst 33342 stain) of parylene electrode implanted in the rat brain. Calibration bar = 100 μm. g,h) IHC images showing NeuN + reactivity (green) and Hoechst counterstain (blue) for each probe type. Shank marked with S and much smaller lateral edge marked with L. Calibration bar = 100 μm. d–h) Reproduced with permission.[113] Copyright 2007, Elsevier.

5. Electroactive Nanomaterials for Electrode-Tissue Interfaces

An immense amount of effort has been made in the development of neural interfaces that relieve local inflammation, a major contributor in the failure of neural probes. Previous studies suggested that the chemical, physical, and mechanical properties of implanted electrodes are important factors for suppressing chronic tissue encapsulation.[18,22,101] Electrode size, tip shape, cross-sectional area, and surface roughness have been modified to elicit the minimum tissue responses.[19,22,68,101] These studies suggested that the physical characteristics of neural electrodes may affect the initial wound healing response; however, glial-scar formation is not affected. To improve electrode-tissue interactions and minimize the chronic response, multiple material-based strategies have been implemented to control the molecular and cellular aspects of the immune response and to prevent electrode failure.[18,60,97] One strategy to modulate the inflammatory response and achieve better integration of the neural electrodes with brain tissue is the chemical modification of the neural probe surface with antiinflammatory compounds, adhesion proteins, and bioactive molecules.[41,71,93,113–118] The surface modification of neural electrodes includes biological modification, such as coating with hyaluronic acid, peptides, and growth factors,[93,119–121] and non-biological modification, such as hydrogels,[122–124] conducting polymers,[52,96,125,126] and carbon nanotubes.[127–130] The design and development of new materials that generate seamless neural interfaces with a high degree of sensitivity is a great challenge in applying neural electrodes for recording neural activity both in vitro and in vivo. Maintaining a high degree of electrode sensitivity is essential, especially when measuring single unit action potentials with signals on the order of microvolts. Long-term stability is another challenge that has motivated the design of novel materials. Electroactive nanomaterials such as silicon nanowires,[30,131] carbon nanotubes[28,127] and conducting polymer nanostructures[32,132] may be able to achieve stable and sensitive chronic neural interfaces by significantly increasing the SNR. Neural probes with dimensions that are several orders of magnitude smaller than the dimension of the cell may appear invisible to the immune cells. These devices may penetrate into the neurons and therefore are able to accurately measure intracellular action potentials. It has been suggested that these nanomaterials may integrate into the cell membrane and create electrical shortcuts, improving the responsiveness of the neurons by forming tight contacts with the cell membranes that might favor electrical shortcuts between the proximal and distal compartments of the neuron.[29]

5.1. Conducting Polymers

While metallic and inorganic semiconductor materials are routinely made for neural interfaces, the preparation of polymeric materials has been relatively unexploited. Polymers provide a variety of advantages over other materials because they have a wide range of chemical structures and tunable surface functionalities. Among synthetic polymers, electroactive conducting polymers (CPs) have received considerable attention since the initial discovery of polyacetylene in the late 1970s.[133] In 2000, the Nobel Prize in chemistry was awarded jointly to three scientists for the discovery and development of CPs.[134–136] CPs have alternate single and double bond conjugation (Figure 6a), which provides the electronic conductivity after doping with suitable dopants.[137] Their response to electrochemical oxidation and reduction can produce a remarkable change in wettability,[138] color,[139] volume,[140,141] and conductivity.[136] CPs can be synthesized by chemical and electrochemical methods. Chemical polymerization is desirable for mass production, but the processing time is significantly longer than electrochemical polymerization and entails the use of non-biocompatible oxidants such as ferric chloride. In addition, the resulting film suffers from poor electrical properties and may require a post doping process to enhance the electrical conductivity.[134–136] In contrast, electrochemical polymerization is useful particularly when well-defined thin films are deposited on a surface of metallic substrate and no further improvement process is required (Figure 6b). The main advantage of electrochemical deposition is that a CP film can be formed in a simple one-step process with a high degree of control over the film thickness, surface properties, and electrical conductivity.[135,136]

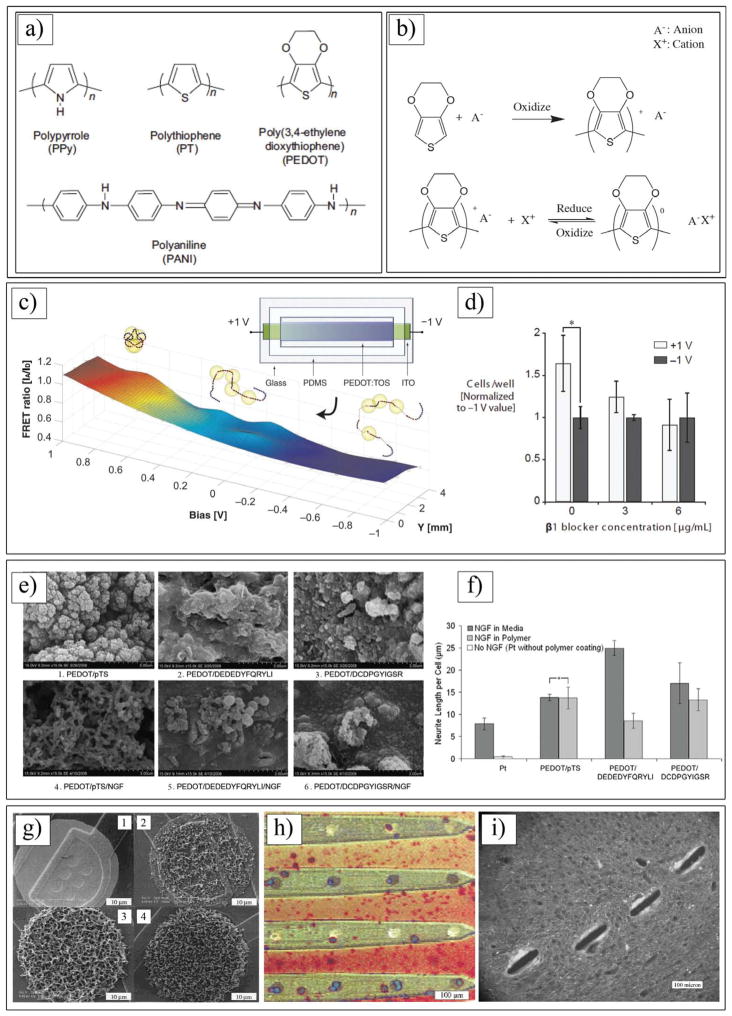

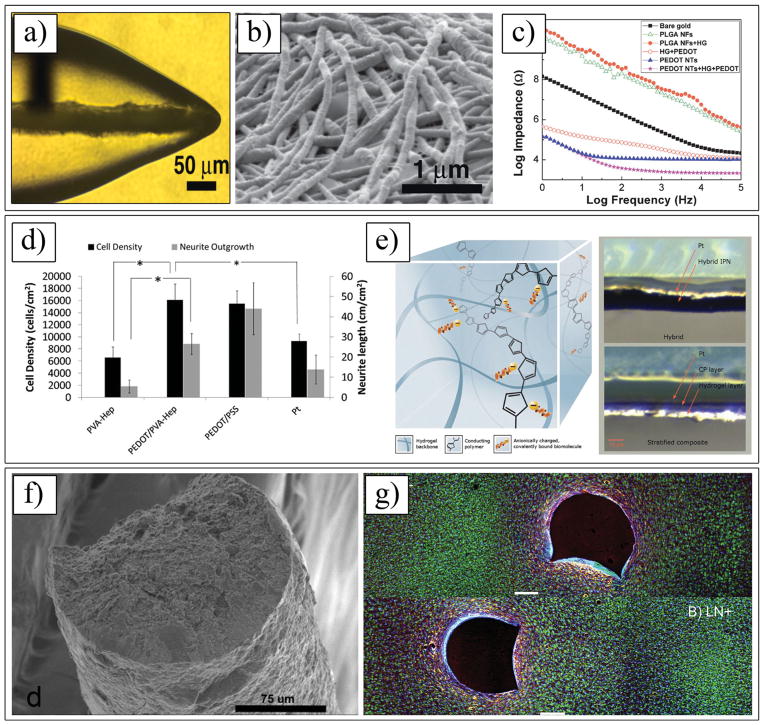

Figure 6.

a) Chemical structures of various conducting polymers. b) Electrochemical polymerization of PEDOT and redox behavior of PEDOT doped with motile anion A. c) FRET (Förster Resonance Energy Transfer) ratios on gradient devices as a function of applied bias and position. d) Relative number of adhered 3T3-L1 mouse fibroblasts on fully oxidized (+1 V) and reduced (–1 V) pixels, for varying doses of a β1 function-blocking antibody. c,d) Reproduced with permission.[190] Copyright 2012, Wiley-VCH. e) SEM images at 15,000×magnification of NGF entrapped in PEDOT films compared with control films produced without NGF modification of the electrolyte. f) Neurite outgrowth of PC12 cells on laminin peptide-doped PEDOT with NGF incorporation at 96 h post-plating. Neurite outgrowth is represented as neurite length per adhered cell, calculated by normalizing total neurite length to cell density. Standard error of mean is given (n = 3). *No significant difference. e,f) Reproduced with permission.[36] Copyright 2010, Elsevier. g) SEM images of Ppy/SLPF-coated electrode sites. From g1) to g4), deposition time increased, corresponding to a total charge passed of (g1) 0 μC, (g2) 1 μC, (g3) 4 μC and (g4) 10 μC. Area of uncoated electrode site is 1250 μm2. Reproduced with permission.[168] Copyright 2001, Wiley. h) Ppy/SLPF coated 4-shank 16-channel neural probe cultured with rat glial cells. Dark black spots are coated electrode sites and bright ones are uncoated. i) Neurofilament immunostained tissue sections of guinea pig brain where 4-shank Ppy/DCDPGYIGSR coated probes were implanted and pulled out after 3 weeks. h,i) Reproduced with permission.[35] Copyright 2003, Elsevier.

CPs have numerous advantages for biomedical applications, including the ability to: i) entrap and release drugs and biomolecules;[36,125,142] ii) be functionalized with bioactive molecules and proteins;[35,143–145] iii) transfer the electrical charge from ions in living tissue to electrons in an electrode;[146–148] and iv) alter the electrical, chemical, and physical properties of the surface to mediate the cellular response.[149] Among these polymers, poly(pyrrole) (Ppy), poly(aniline) (PANI), poly(thiophene) (PT), and poly(3,4-ethylenedioxythiophene) (PEDOT) (Figure 6a), and some of their derivatives have received more attention for biomedical applications,[146,149–151] especially neural interfaces[25,32,35,37,38,52,57,132,140,146,147,152–178] since these CPs exhibit good biocompatibility,[149,177,179] excellent electrical conductivity, and ease of synthesis.[134,136] Ppy is the most commonly utilized CP for neural applications because of the superior water solubility of the pyrrole monomer. Due to its good biocompatibility, Ppy has been electrodeposited with different dopants on neural electrodes.[25,35,57,145,157,160,179–183] The application of PEDOT in this field has, however, remained relatively unexplored. In comparison with the widely used Ppy, PEDOT exhibits a very high conductivity (ca. 1200 S/cm),[139,174] outstanding chemical stability in the oxidized state,[139,184] and excellent biocompatibility.[126,172,185–187]

5.1.1. Biocompatibility and Tissue Interaction

The biocompatibility of CPs is highly sensitive to the ionic species that can be integrated into the polymer structures during the polymerization process. CPs can be used as a substrate for the attachment, proliferation, and differentiation of neural cells.[57,160,164,188] These capabilities are directly dependent upon the molecular composition of the dopants and overall electrical charge of the electrodeposited CPs on the surface of the electrode. Lundin et al. cultured neural stem cells on Ppy films containing different dopants and demonstrated a distanced coloration between the dopants and cell viability. The authors showed that cell viability was high on Ppy doped with dodecylbenzenesulfonate (DBS) compared with that on Ppy films containing chloride, perchlorate, and tosylate.[164] In general, neural stem cell proliferation and differentiation on Ppy/DBS were comparable to cells on standard tissue culture polystyrene. Reduction of Ppy films decreased neural stem cell viability, with widespread cell death upon polymer reduction with a bias voltage of −0.9 V for 120 s.[164] These results suggested that different conformations of an adsorbed protein layer of fibronectin (Fn) on the surface of Ppy films doped with different dopants and reduced by a bias voltage might contribute to different cellular responses.[164,189] Protein conformation plays a significant role in cell signalling and biological functions. Malliaras and co-workers showed a precise electrical control of protein conformation on the surface of PEDOT doped with p-toluenesulfonate (TOS). The authors assessed the Fn conformation using Forster resonance energy transfer (FRET) imaging (Figure 6c). They created gradients in the Fn conformation consisting of a 2 cm long, 0.7 cm wide PEDOT:TOS film on top of an indium tin oxide (ITO) electrode. A gradient in the surface potential was established by applying ±1.0 V across the electrode while the electrode was incubated for 1 h in cell culture medium containing Fn (Figure 6c and 6d).[190]

More recent research has focused on enhancing the biocompatibility and tissue interactions of CPs through the use of biomolecules and therapeutic agents. Drugs and biomolecules can be incorporated as charged dopants[142,155,168] or non-doping inclusions[144,191,192] during polymerization. Biological dopants include laminin peptide sequences,[155] hyaluronic acid,[176] or silk-like polymer having fibronectin fragments (SLPF).[168] Neurotrophic factors, whole laminin, and human serum albumin have been entrapped during polymerization, post-fabrication adsorption, and pre-attachment to the monomer.[144,155,193,194] The trapped biomolecules either can be immobilized in the polymer structure or can be released from the polymer.[195] These biological components can potentially enhance the biocompatibility and the integration of tissue with the surface of a neural electrode. Incorporation of brain-derived nerve growth factor (BDNF) and nerve growth factor (NGF) into the Ppy film significantly enhanced neurite extension of spiral ganglion explants and PC12 cells.[145,193,196] These biomolecules have a significant impact on the physical, chemical, and optical polymer properties of CPs.[36] Pool-Warren and co-workers showed that the dopant size appears to play a significant role in the polymer mechanical performance, with larger dopants producing softer and less-adherent films.[155] In addition, the inclusion of additional large non-doping molecules, such as the NGF molecule, increases this effect. The authors incorporated NGF within PEDOT films doped with DEDEDYFQRYLI and DCDPGYIGSR laminin peptides and, additionally, a conventional dopant, paratoluene sulfonate (pTS) (Figure 6e). The peptide dopants produced a softer polymer interface than the PEDOT doped with pTS. The authors found that entrapment of NGF into PEDOT doped with peptide resulted in polymers with diminished electrical and mechanical stability. Entrapped NGF was determined to be biologically active, with PEDOT/ pTS/NGF producing neurite outgrowth (Figure 6f). While these results indicated the possibility of inclusions of multiple biomolecules in the CP films, the synergy, the molecular interactions between these bioactive molecules, monomer and dopants, and the anionic charges of the dopants must be considered for the development of functional CPs.[155] In another study, Martin and co-workers entrapped two ECM proteins (i.e., SLPF and CDPGYIGSR peptide) within Ppy doped with lithium perchlorate on the surface of neural electrodes.[168] The morphologies of the resulting films were rough and fuzzy, providing a high surface area for interaction with neural cells (Figure 6g). This high interfacial area also helped to significantly decease the impedance of the electrode site and to improve the quality of neural recording from the cerebellum of a guinea pig. The in vitro cell-culture results showed that glial cells appeared to attach better to Ppy/SLPF-coated electrodes than to bare gold electrodes (Figure 6h and 6i). Neuroblastoma cells grew preferentially on and around the Ppy/CDPGYIGSR coated electrode sites. The in vivo experiments confirmed that high-quality neural signals could be recorded from single neurons using Ppy/SLPF-coated electrode sites.[168]

5.1.2. Controlled Release of Drugs and Biomolecules

CPs can undergo a reversible redox reaction, which involves the charging and discharging of the polymer, and is accompanied by the movement of ions and solvent into or out of the polymer. This mass transfer is the primary mechanism for the volume change of a CP. When ions and solvent enter the polymer, it expands, and when they exit it contracts (Figure 7a).[195,197–200] The volume change mechanism in CPs is complex because the electrical, mechanical, and chemical properties of the materials are closely related.[201] Actuation strains are large, from a few percent to over 30%[202] and can be operated in bending geometries or expansions/contractions. CP actuators are unique in that they not only can be switched between fully expanded and contracted situations, but also can be held at an intermediate state.[195,202,203] This feature enables the actuator to carefully move and be held precisely in a desired position. Utilizing this feature, efforts have been made to develop CP-based biomedical actuators,[202] in particular for artificial muscles,[204,205] microsurgical instruments,[206] implants,[207] bioMEMS,[208] and drug delivery systems.[166,209]

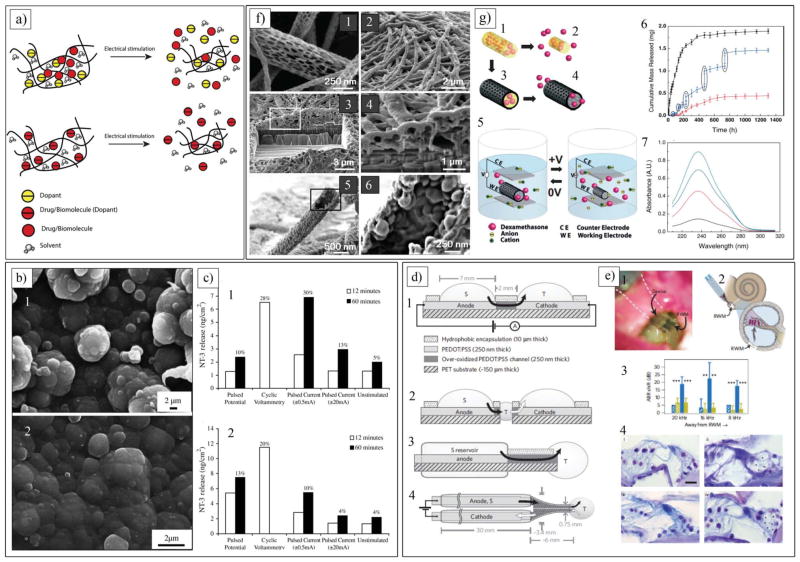

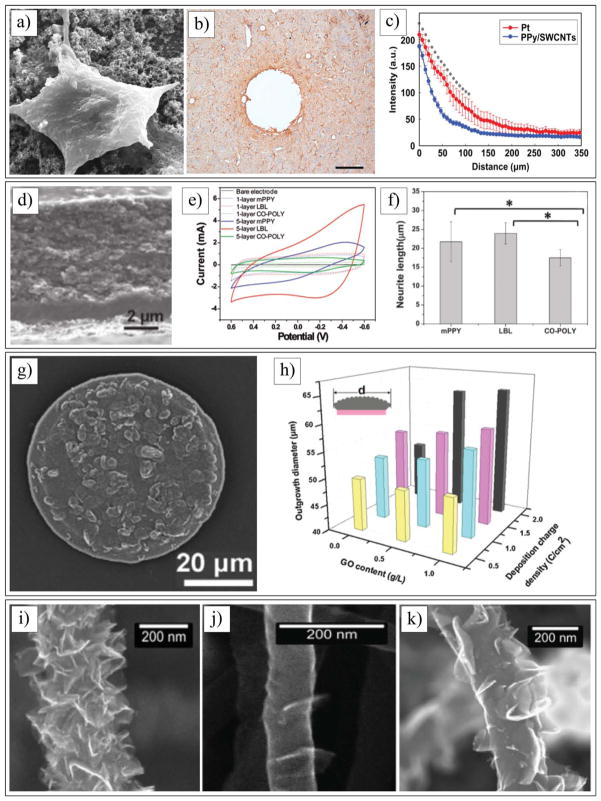

Figure 7.

a) Schematic of incorporation and controlled release of drugs and biomolecules as dopants or non-doping inclusion in CPs. b) SEM images of Ppy/pTS/NT-3 films (b1) before and (b2) after 60 min electrical stimulation in 0.9% NaCl solution. c) Mass of NT-3 released from a (c1) thin (3.6 μm) and (c2) thick (26 μm) Ppy/pTS/NT-3 polymer films in 1mL of 0.9% NaCl by various electrochemical release methods. b,c) Reproduced with permission.[213] Copyright 2006, Elsevier. d) Planar and encapsulated geometries of delivery device. d1) Side view of planar device used in initial Glu, Asp and GABA transport studies. Black arrow indicates flow of charged neurotransmitters from source electrolyte, S, through anode, then through over-oxidized channel and finally out into target electrolyte, T, through cathode. d2) Side view showing developmental progression from planar device (d1), d3) Side-view scheme of encapsulated device. d4) Top view of encapsulated device with electrolyte reservoir tubes 2 mm in outer diameter. e) In vivo application of ion pump. e1) Photograph of device mounted on RWM, with two ion channels visible as dark blue strips on transparent substrate. e2) Experimental scheme. e3) Mean ABR shift (re:pre-treatment thresholds) as a function of recording frequency after 15 min (hatched bars) and 60 min (filled bars) of Glu (blue) and HC (yellow) delivery. Frequencies are illustrated in relation to their increasing distance from RWM. Error bars indicate standard deviation. e4) Histological sections of cochlea with inner hair cells on right and outer hair cells on left showing (i) effect of HC delivery (as control) and (ii) effect of Glu delivery (excitotoxic-induced damage to auditory dendrites indicated with asterisks) in lower basal region (turn 1), and similar (iii) HC and (iv) Glu effect in upper basal region (turn 2). Calibration bar = 20 μm. d,e) Reproduced with permission.[166] Copyright 2009, Nature Publishing Group. f) SEM images of PLGA nanofibers and PEDOT nanotubes. f1) Diameters of the PLGA fibers range 40–500 nm. f2) Electropolymerized PEDOT nanotubes on electrode site of an acute neural probe tip after removing the PLGA core fibers. f3) A section of f2) cut with a FIB showing silicon substrate layer and PEDOT nanofiber coating. f4) Higher-magnification image of f3) showing PEDOT nanotubes crossing each other. f5) PEDOT nanotube. f6) Higher-magnification image of PEDOT nanotube. g) Schematics of controlled release of dexamethasone: g1) dexamethasone-loaded electrospun PLGA, g2) hydrolytic degradation of PLGA fibers leading to release of drug, and g3) electrochemical deposition of PEDOT around dexamethasone loaded electrospun PLGA fiber slows down release of dexamethasone. g4) PEDOT nanotubes in a neutral electrical condition. g5) External electrical stimulation controls the release of dexamethasone from the PEDOT nanotubes due to contraction or expansion of the PEDOT. g6) Cumulative mass release of dexamethasone from: PLGA nanofibers (black squares), PEDOT-coated PLGA nanofibers (red circles) without electrical stimulation, and PEDOT-coated PLGA nanofibers with electrical stimulation of 1 V applied at five specific times indicated by circled data points (blue triangles). g7) UV absorption of dexamethasone-loaded PEDOT nanotubes. f,g) Reproduced with permission.[173] Copyright 2006, Wiley-VCH.

CPs can be utilized for the precise delivery of ions to cells in a controlled fashion. Cells are regulated by ion fluxes for intercellular communication, and the biological signals are often represented as gradients in their environments. Berggren and co-workers took advantage of the combined electronic and ionic conduction properties of PEDOT doped with poly(styrene sulphonate) (PEDOT:PSS) to develop an electrophoretic ion pump that translates electronic signals into ion fluxes that communicate with cells.[147] This ion pump device is able to control the ion homeostasis of individual neuronal cells. The PEDOT:PSS ion pump device can be used as an actuator, and pumps cations from a reservoir electrolyte to a target electrolyte with spatial and temporal resolutions that match a range of signalling events at the individual-cell level. The authors showed that ions were delivered in high quantities at an associated on/off ratio exceeding 300. This induces physiological signalling events that can be recorded at the single-cell level. Furthermore, by fabricating a 50 μm-wide microchannel, a size that corresponds to many eukaryotic cell types, stimulation of individual cells was achieved.[147]

Drugs and bioactive molecules can be incorporated into CPs during electrochemical polymerization as charge dopants or entrapped inclusions (Figure 7a), or stored as reservoirs in the micro- and nanocavities of the CP (Figure 7f and 7g).[144,173,202,210–212] In this context, Ppy containing pTS and neurotrophin-3 (NT-3) (Ppy/pTS/NT-3) was developed by Thompson et al. for controlled release of NT-3.[213] During electrochemical polymerization, the positively charged NT-3 was entrapped within the Ppy doped with pTS (Figure 7b). Electrochemical stimulation of the Ppy by a pulsed voltage (±0.6 V), pulsed current (±20 mA), or cyclic voltammetry (from −0.8 V to +1.0 V at a scan rate of 50 mV/s) promoted the release of NT-3 at a greater rate than natural diffusion of NT-3 from Ppy film without electrical stimulation (Figure 7c). NT-3 was released from the Ppy film because of a volume change of the polymer during the mass transfer process (Figure 7a). NT-3 was released from Ppy as an initial burst in the first 24 h, followed by prolonged release over the subsequent 6 days. The authors demonstrated that the amount of NT-3 incorporated into the polymer could be controlled either by varying the polymerization time or by developing multiple polymer film layers. Later, Richardson et al. applied a Ppy/pTS/NT-3 coating to 1.7 mm2 cochlear electrodes and implanted them in guinea pigs. The Ppy/pTS/NT-3-coated electrode stored 2 ng of NT-3 and released 0.1 ng/day with electrical stimulation (i.e., 1 mA cm−2 biphasic current pulses).[125] Guinea pigs implanted with electrically stimulated Ppy/pTS/NT3-coated electrodes had lower electrically evoked auditory brainstem response thresholds and greater spiral ganglion neurons densities in implanted cochleae compared with non-implanted cochleae and compared with animals implanted with Ppy/pTS-coated electrodes. This work demonstrated the use of the cochlear implant to deliver neurotrophins to neurons in a safe and controlled manner, in addition to electrical stimulation for enhanced preservation of spiral ganglion neurons after hearing loss.[125] Another study utilized electrophoretic transport for the delivery of neurotransmitters from a device with distinct structural components (Figure 7d and 7e).[166] Using PEDOT doped with PSS (PEDOT:PSS), Daniel et al developed an organic electronic device capable of precisely delivering neurotransmitters, such as glutamate, aspartic acid, and γ-amino butyric acid, that could mimic nerve synapses. This device was composed of: i) an electrolyte source; ii) an electrolyte target; iii) an anode; and iv) a cathode (Figure 7d). These components were fabricated into a variety of shapes and sizes and packed using encapsulating biomaterials. The devices were able to produce zero-order release kinetics of neurotransmitters. They demonstrated that the rate of release depended upon the magnitude of the applied voltage along with the mass and net charge of the molecule. They verified the release of the neurotransmitter in vitro by intracellular calcium recordings (Figure 7e). Using the peripheral auditory system and measuring the auditory brain response in cochlea, the in vivo controlled delivery of glutamate was validated. The authors showed that the device could selectively stimulate nerve cells out of a diverse population of cells (Figure 7e).

While the previously mentioned methods are able to release drugs and biomolecules incorporated into the CP structure, development of techniques that enable precise loading and delivery of a desired amount of drug is essential for the longterm performance of neural devices. Martin and co-workers developed a templating approach for loading a large volume of therapeutic agents into the cavities of CP nanotubes and precisely deliver it over 60 days.[173] Dexamethaosne, an anti-inflammatory drug, was loaded into biodegradable poly(lactide-co-glycolide) (PLGA) nanofibers that were electrospun on the surface of neural electrodes (Figure 7g). The amount of incorporated dexamethasone within the PLGA nanofibers on each electrode was approximately 2 mg. PEDOT was electropolymerized around the drug-loaded nanofibers. Dexamethaosne was controllably released by electrical actuation of nanotubes at +1.0 V (Figure 7f). As shown in Figure 7f, a release burst of 75% was detected after 7 days for PLGA nanofibers (black squares), which can be explained by fast hydrolytic degradation and backbone cleavage of the PLGA nanofibers. Addition of the PEDOT coating around the PLGA nanofibers dramatically slowed the release rate (blue triangles). Under this condition, less than 25% dexamethasone was released after 54 days. This extremely slow release was attributed to the hindered diffusion of dexamethasone through the walls of the PEDOT nanotubes, requiring the dexamethasone to migrate to the tube ends in order to escape. In other words, in the absence of any actuation, more than 75% of dexamethasone remained trapped inside the PEDOT nanotubes. To release the entrapped dexamethasone in a controlled fashion, the PEDOT nanotubes were actuated by applying a bias voltage of +1 V for 5 times at different time points. Figure 7f illustrates the effect of this actuation on the release profile of dexamethasone (the vertical jumps in the data correspond to the applied electrical stimulations, red curve). Expansion and contraction of the PEDOT nanotubes after electrochemical stimulation produced a mechanical force creating pressure within the nanotubes. The hydrodynamic force inside the PEDOT nanotubes resulted in expulsion of degraded PLGA and dexamethasone. They suggested that dexamethasone released either from cracks on the surface of nanotubes or through the nanotube ends. A control experiment was also carried out to show that dexamethasone did not exhibit significant diffusion though the PEDOT nanotube walls. In this experiment, dexamethasone was incorporated inside the PEDOT layers; no dexamethasone elution into the media was detected. An externally applied voltage bias provides a means of controlling the release of the drug, as has been seen for other CPs. These results show that expansion and contraction of the CP cavities can provide an additional means for controlling the kinetics of drug release.

5.1.3. Neural Recording and Stimulation

The ability to record action potentials from individual neurons or stimulate neurons is dependent upon a trade-off between the size and the electrical properties of the electrode site, often referred to as the trade-off between selectivity and sensitivity.[52,214,215] Ideally, the site of a microelectrode should have a small geometric area to communicate with individual neurons (selectivity). A low-impedance recording and high injection charge density site is necessary during recording and stimulation (sensitivity).[214–217] Unfortunately, decreasing the geometric area of a recording site causes an increase in the impedance and a decrease in the capacity of the injection charge density of neural microelectrodes.[218,219] Current neural microelectrode technologies suffer from a poor electrical performance because of their small-feature geometry.[57,174] Moreover, the encapsulation process of the chronic response progressively increases the impedance of the electrode-tissue interface.[18,19,34,220] While a number of studies have explored methods such as deposition metals,[169] metal oxides,[221] and applying bias voltage pulses[222] to improve the electrical properties of neural microelectrodes, these methods have some drawbacks, including unstable impedance and poor adherence to the electrode site. Recently, CPs have been employed to improve the electrical properties of neural microelectrodes.[25] CPs can significantly decrease electrode impedance and increase charge injection density as compared with metal sites of similar geometric area.[57,170] The improvement of the electrical performance can be explained by increasing the effective surface area for ionic-to-electronic charge transfer at the interface between the brain tissue and the recording site.[168,223] In addition, a CP is able to act as a mediator between the brain and the electrode to buffer the mechanical mismatch and reduce the foreign body response of the brain to the electrode, thus allowing recording of the brain electrical activity for a longer period of time.[32,52]

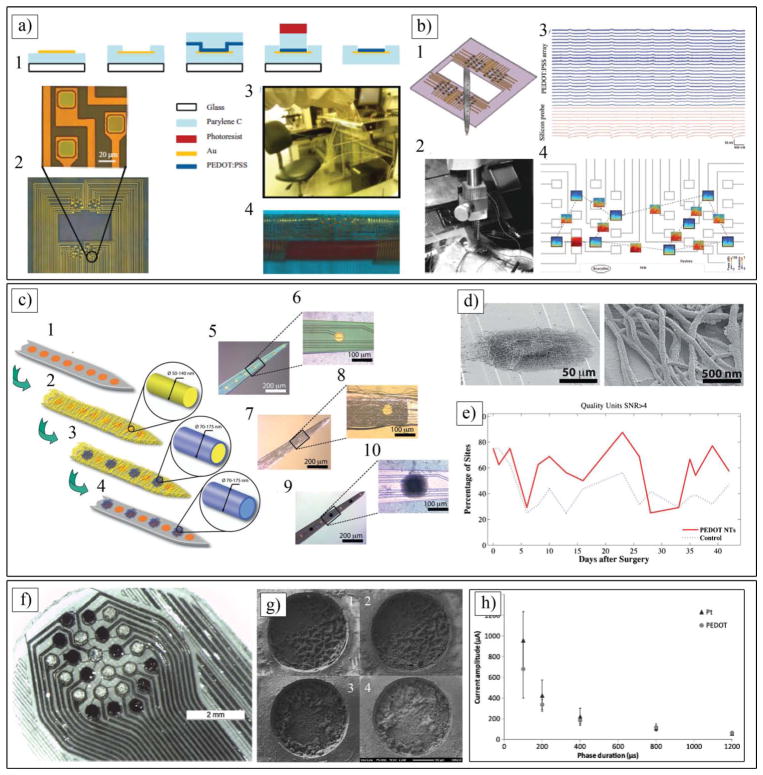

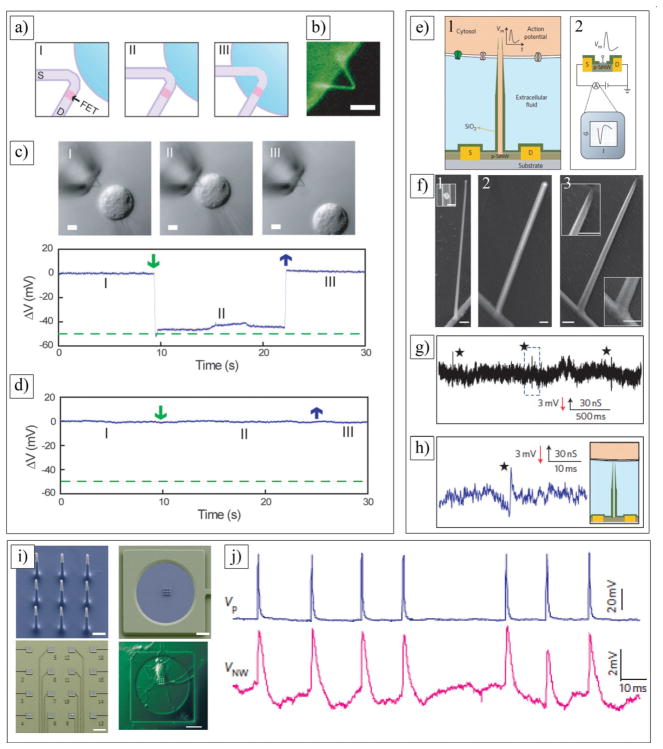

Given the high demand for the development of flexible electrodes for in vivo applications, Malliaras and co-workers reported a novel method to fabricate highly conformable CP electrodes (Figure 8a).[95] They developed a general procedure for integrating CPs with a flexible substrate. The process involved the direct patterning of a commercially available PEDOT:PSS layer on gold (Au) sites of 4 μm thickness of parylene C substrates (Figure 8a). Given the combination of the biocompatibility of PEDOT:PSS and parylene C,[224] the good chemical stability,[225] the excellent electrical conductivity of PEDOT:PSS, and the flexibility of parylene C, this highly conformable electrode has a great potential for chronic application of neural electrodes. Each PEDOT:PSS array consisted of two subsets of 16 electrodes each, placed on a hexagonal lattice, with individual electrodes having an area of 20 μm × 20 μm and a center-to-center distance of 60 μm. The array had a hole in the middle to allow simultaneous insertion of a silicone electrode (Figure 8b). The silicon electrode had a single shank with 16 electrodes (177 μm2 area each) arranged in a linear configuration with 100 μm spacing. In order to validate the PEDOT:PSS array and demonstrate that it can record neural signals, the electrodes were placed on the surface of rat brains and, at the same time, the silicone probe was also inserted into the brain. As ECoG signals were recorded by surface array, the silicon electrode also recorded the strong activity at the deepest layer for 20 min. The authors showed that, even if all the sites do record synchronously the sharp-wave events, each ECoG signal is specific to the particular location of the electrode, meaning that the spatial resolution of the array is of the order of the interelectrode spacing (Figure 8b). Furthermore, the PEDOT:PSS electrode proved to outperform Au electrodes of similar geometry. This conformable electrode array with high mechanical flexibility and low invasiveness compared with traditional electrode arrays has the potential to be applied in other areas of neuroscience.[95]

Figure 8.

a) a1) Schematic representation of the fabrication process indicating the cross-section of an electrode (not to scale). a2) Microscopy images of the array and a detailed view of three electrodes. a3) The electrode array is shown to support the weight of a quartz wafer a4) to conform to a cylinder with a radius of 2.2 mm. b) b1) Schematic of the experiment used for the validation of the PEDOT:PSS array with a silicon probe viewed from inside the brain. b2) photograph showing the implantation. b3) Recordings from 25 electrodes in the PEDOT:PSS array, and from 10 electrodes in the silicon probe, ordered from superficial to deeper in the cortex. b4) Time-frequency (TF) analysis of the signals recorded by a few electrodes (black frames, X-axis: time, 10 min; y-axis: frequency, 0.1–50 Hz; color coding: power, dB) and their cross-spectrum coherences (open boxes, same axes as TF plots, color coding: coherence). a,b) Reproduced with permission.[95] Copyright 2011, Wiley-VCH. c) Schematic illustration of PEDOT nanotube fabrication on neural microelectrodes: c1, c2) Electrospinning of biodegradable PLLA template fibers. c3) Electrochemical deposition of PEDOT. c4) dissolving the electrospun core fibers to create conducting polymer nanotubes. c5-c10) Optical microscopy images of the entire microelectrode (c5) and single electrode site (c6) before surface modification. (c7) and single electrode site (c8) after electrospinning of PLLA nanofibers. (c9) and single electrode site (c10) after electrochemical deposition of PEDOT and removing the PLLA core fibers. d) PEDOT nanotubes on the surface of a single microelectrode site. Right image is a higher magnification of left image. e) Percentage of sites recording low-and high-quality units. PEDOT nanotube sites demonstrated a significant improvement in percentage of sites recording high-quality units on a day-to-day basis. f) 24-electrode array in hexagonal (hex) configuration used for in vivo studies with 12 bare Pt (light electrode sites) and 12 PEDOT/pTS-coated electrodes (dark electrodes). g) SEM images of g1) active PEDOT (prior to stimulation), g2) active PEDOT (after stimulation), g3) passive PEDOT (prior to stimulation) and g4) passive PEDOT (after stimulation). c–g) Reproduced with permission.[32] Copyright 2009, Wiley-VCH. h) Strength vs duration curve, demonstrating the relationship between average current required to reach threshold and duration of phases for biphasic current driven stimulation of tissue using suprachoroidal electrodes (n = 5). h,j) Reproduced with permission.[156] Copyright 2013, IOP Publishing.

Abidian et al. developed a templating technique to fabricate CP nanotubes on the surface of microfabricated neural electrodes.[57,173,174] The fabrication process includes: i) electrospinning of biodegradable poly(L-lactide) (PLLA) nanofibers on the shank of neural microelectrodes; ii) electrochemical deposition of PEDOT on the individual electrode sites (1250 μm2) and around the PLLA nanofibers; and iii) removal of the PLLA templates (Figure 8c). The wall thickness of the PEDOT nanotubes varied from 20 to 35 nm, and the inner nanotube diameter ranged from 50 to 140 nm. By controlling the polymerization time, the authors could reproducibly prepare tubular structures with thin walls or thick walls. The overall thickness of the PEDOT nanotube scaffolds was between 2.4 and 3.1 μm, depending on the thickness of the electrospun fiber mesh on the neural microelectrodes (Figure 8d). Impedance spectroscopy results revealed that that the impedance of both bare gold and PEDOT nanotube-coated electrode sites decreased with increasing frequency, while the impedance of coated electrodes was significantly lower than that of uncoated gold electrodes over the whole range of frequencies. The magnitude of the impedance was decreased from 800 ± 20 kΩ for uncoated sites to 4 ± 2 kΩ (about two orders of magnitude) for PEDOT nanotubes (at 1 kHz). These extremely low values of electrode impedance have been shown to significantly enhance the performance of these probes in vivo. The cyclic voltammetry measurements showed that the charge injection density increased from 0.001 ± 10−4 μC for bare gold electrodes to 4.9 ± 0.6 μC for PEDOT nanotubes.[174] To validate the signal recordings of the PEDOT nanotubes, 6 chronic neural microelectrodes were implanted in the barrel cortex of rats. The impedances of the implanted microelectrodes were monitored after the surgery for 7 weeks.[32] Although the impedance of both uncoated and PEDOT nanotube sites increased, the PEDOT nanotube sites always had lower impedance than the control sites, which should help in the quality of the recording signal. The electrodes modified with PEDOT nanotubes registered high quality unit activity (SNR > 4) on 35% more sites than the controls (uncoated), primarily as a result of a reduced noise floor (Figure 8e). The increase in the average number of quality units is likely a result of a decrease in the noise. As expected, the average noise floor for the PEDOT nanotube sites across days was 6.1 ± 0.8 mV, significantly lower than the control site noise floor of 6.4 ± 0.9 mV. Moreover, local field potential (LFP) recordings demonstrated that the sites modified with PEDOT nanotubes have significantly less low frequency artifacts in LFP recordings. Other groups showed that the implantation of CPs for several weeks has led to only minimal inflammation, again pointing to low toxicities and good tissue compatibility of CPs. The results of this study indicate that PEDOT nanotubes provide an incremental benefit for obtaining high quality neural recordings.

In another study, Pool-Warren and co-workers demonstrated the capability of CPs for electrical stimulation of neural tissue.[156] In this study, PEDOT/pTS was coated on Pt sites of microfabricated PDMS electrode array (Figure 8f and 8g). The physical and electrical stability of PEDOT/pTS following ethylene oxide sterilization and electrical stimulation using a biphasic voltage waveform was evaluated in the feline model. The charge injection limit of PEDOT was found to be on average 30 times larger than that of Pt when tested in physiological saline, and 20 times larger than that of Pt when tested in protein supplemented media. PEDOT doped with PSS is stable for up to 10 days,[154] but PEDOT doped with pTS demonstrated superior stability. In vivo acute stimulation with a biphasic voltage waveform confirms PEDOT-coated electrodes elicit neural responses at an average of 67.0 μC cm−2 of injected charge, which was not significantly different to that of the Pt controls (average of 74.5 μC cm−2) (Figure 8h). This could be explained by suprachoroidal placement; thus, no reduction in charge threshold was observed when CP was coated on Pt sites. This study demonstrates the potential application of CPs in neural stimulation implants, as CP coating provides a lower voltage drop, resulting in improvements of power consumption and the potential to miniaturize systems without compromising the injection limit or safety.

5.2. Carbon Nanotubes

Carbon nanotubes (CNTs) are made of rolled-up graphite sheet(s) composed of either single or multi-walled nanotubes (SWCNTs and MWCNTs).[226] SWCNTs consist of a single graphite sheet seamlessly wrapped into a cylindrical tube (Figure 9a–d). MCWNTs comprise an array of such nanotubes that are concentrically nested like rings of a tree trunk.[227–229] SWCNTs may have either metallic or semiconducting properties, depending on the sheet direction rolled to form a nanotube cylinder, while the electronic properties of perfect MWNTs are rather similar to those of perfect SWNTs, because the coupling between the cylinders is weak in MWNTs. They possess remarkable properties, including a high electrochemically accessible surface area (700–1000 m2 g−1),[28] high mechanical strength (elastic modulus ca. 0.64 TPa for an individual nanotube[230]), excellent thermal conductivity (individual MWNT > 3000 W m−1 K−1)[231] and high electronic current (up to 109 A cm−2).[232] Because of these properties, CNTs are attractive for the fabrication of devices that use electrochemical double-layer charge injection, such as supercapacitors and actuators.[233] CNTs have been used in the field of biotechnology, such as for DNA and protein biosensors,[234,235] in ion channel blockers,[236] and as bioseparators and biocatalysts.[237] Regarding the biomedical applications of CNTs, these materials are becoming relevant in neuroscience research,[26] and neural tissue engineering[238] CNTs have been developed as 3D scaffolds for the regeneration of CNS (e.g., brain and spinal cord)[239–241] and the recording of neural activity.[28,29,127] While a major technical barrier of CNTs for biomedical applications is insolubility in solvents, their functionalization with some reagents and biomolecules enhance the solubility.[242] In addition, recent improvements of CNT synthesis and purification methods have opened pathways for CNTs as components of biosensors and implant coatings.[243–245] Additionally the functionalization of the CNT surface with different polymers or bioactive molecules can improve their biocompatibility and bioactivity.[227,246–248] They can be used to modulate neuronal behavior either at the structural (i.e., synaptogenesis and neurite elongation) or functional (i.e., synaptic efficacy) level.[241,249] CNTs notably increase the effective surface area of the electrode-tissue interface and charge transfer capacity, and decrease the interfacial impedance of a recording site.[28,29,250] This section highlights experiments addressing the biocompatibility of CNTs, cell-CNTs interactions, and the effect of CNTs on the functional performance of neural interfaces.

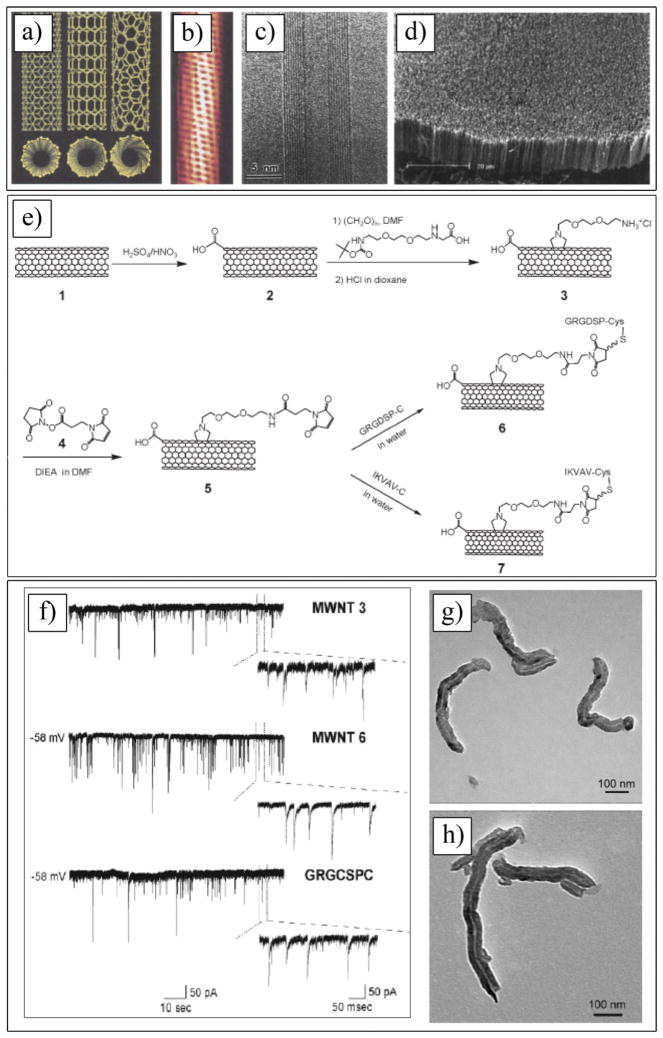

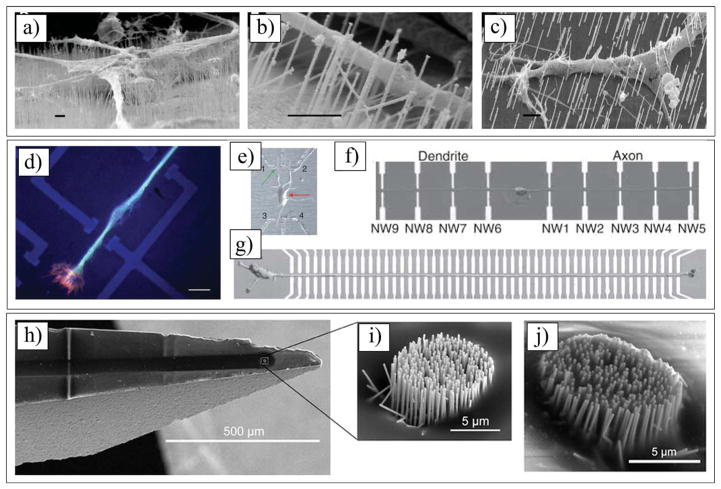

Figure 9.

a) Schematic illustrations of the structures of armchair, zigzag, and chiral SWCNTs. Projections normal to the tube axis and perspective views along the tube axis are on the top and bottom, respectively. b) Tunneling electron microscope image showing the helical structure of a 1.3-nm-diameter chiral SWCNT. c) TEM image of a MWCNT containing a concentrically nested array of nine SWCNTs. d) SEM image of an array of MWCNTs grown as a nanotube forest. a–d) Reproduced with permission.[227] Copyright 2002, American Association for the Advancement of Science. e) Synthesis of MWNT–peptide conjugates. f) MWCNTs 3, 6, and peptide GRGDSPC (Pep 1) alone do not affect neuronal survival and activity. Tracings represent spontaneous synaptic activity recorded from neurons (8 days in vitro) after MWCNTs 3, 6, and GRGDSPC incubation at 24 h washout. Below each recording, on the right, the magnifications show the presence of heterogeneous events (inward currents), representing the activation of mixed synapses impinging on the recorded neurons. g,h) TEM images of MWCNTs 2, and 7. e–h) Reproduced with permission.[437] Copyright 2009, Wiley-VCH.

5.2.1. Biocompatibility and Cell Interaction

CNTs have been interfaced with neural tissue with an appropriate host response.[251,252] While the biocompatibility of CNTs has been reported by several groups, the utilization of CNTs for biomedical applications, especially in human healthcare needs to be more investigated due to the potential cytotoxicity of CNTs. Although numerous studies have been performed to investigate the toxicity of CNTs, only a few clear conclusions have been reported, and there are mixed results about the toxicity of CNTs.[127,240,253–256] Toxicity has not been observed for CNTs as coating and hybrid materials, which do not produce freely floating nanotubes. However, the possible toxicity of CNTs must be considered due to potential decomposition of the CNT composites used to manufacture neural electrodes. This is because various factors are involved in determining the toxicity of CNTs, such as composition, surface functionalization, and size. Thus, a clear understanding of the biocompatibility of CNTs is required in order to use these nanomaterials for neural applications. CNTs have been studied as substrate materials for neuronal cell adhesion, proliferation, and differentiation,[240,241,249,257,258] and these studies have supported CNTs for neural applications.

Aggregation of CNTs has been known to have a strong impact on toxicity. Some studies have shown that aggregated bundles of CNTs are more toxic than well-dispersed CNTs.[259–261] Raja et al. showed that the removal of large SWCNT aggregates (>0.22 mm) from cell culture test medium using a filter could produce a slightly lower toxic response compared with an unfiltered medium.[261] The degree of dispersion is a factor that can moderate CNT toxicity.[262] Riviere and co-workers revealed that even micrometer-sized well-dispersed CNTs were less toxic than aggregated one.[260] It has been hypothesized that aggregated CNTs may bind to cells through their extracellular proteins and alter the cell membrane’s ability to pass nutrients and waste.[261,263] Another study examined the biocompatibility of different degrees of agglomeration of CNTs on neurons and glial cells using non-covalently wrapped SWCNTs.[264] It is hypothesized that the degree of toxicity partially depends on the agglomeration state of the CNTs; larger SWCNT aggregates resulted in a reduced cell number over time. Thus, if SWCNTs can enter the nervous system at sufficiently high concentrations, activation and proliferation of glial cells might occur. Charge also appears to play a role in the toxicity of CNTs. More neurite branching and growth cones were observed when dorsal root ganglion (DRG) cells were exposed to positively charged CNTs.[240] The CNT dimension can be another factor determining the toxicity of CNTs. From studies performed in the lung, the toxicity level of CNTs follows a trend based on their size.[265] It was shown that CNTs with the smallest surface area appeared to be the most toxic in which SWCNTs induced stronger toxicity than MWCNTs.[262] The exact mechanism behind this effect is unclear, but it may be explained by a theory that the dimension of the CNTs is similar to the dimension of a virus; thus, CNTs may resemble viruses and induce an immune response.[266]