Abstract

Ginger rhizomes sliced to various lengths of 5, 10, 15, 20, 30, 40, 50 mm and whole rhizomes were dried from an initial moisture content of 81.3 % to final moisture content of less than 10 % by various drying methods like sun drying, solar tunnel drying and cabinet tray drying at temperatures of 50, 55, 60 and 65 °C. Slicing of ginger rhizomes significantly reduced the drying time of ginger in all the drying methods. It was observed that drying of whole ginger rhizomes under sun took the maximum time (9 days) followed by solar tunnel drying (8 days). Significant reduction in essential oil and oleoresin content of dry ginger was found as the slice length decreased. The important constituents of ginger essential oil like zingiberene, limonene, linalool, geraniol and nerolidol as determined using a gas chromatography was also found to decrease during slicing and as the drying temperature increased. The pungency constituents in the oleoresin of ginger like total gingerols and total shogoals as determined using a reverse phase high performance liquid chromatography also showed a decreasing trend on slicing and with the increase in drying temperature. It was observed from the drying studies that whole ginger rhizomes dried under sun drying or in a solar tunnel drier retained the maximum essential oil (13.9 mg/g) and oleoresin content (45.2 mg/g) of dry ginger. In mechanical drying, the drying temperature of 60 °C was considered optimum however there was about 12.2 % loss in essential oil at this temperature.

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-012-0823-8) contains supplementary material, which is available to authorized users.

Keywords: Ginger, Drying methods, Quality

Introduction

Ginger, the rhizome of Zingiber officinale Roscoe is one of the most widely used spices of the family Zingiberaceae. India is the largest ginger producing country in the world with an annual production of 7,95,028 tonnes from an area of 1,38,479 ha during 2008–09 (Spices Board 2011).

Ginger grown in different parts of the country varies considerably in its intrinsic properties and its suitability for processing. The important quality parameters of ginger are its fibre content, volatile oil content and non volatile ether extract. The size of ginger rhizome is particularly important when it is processed to dried ginger. Some areas grow ginger yielding very large rhizomes, which are marketed as fresh ginger, but unsuitable for converting to the dried spice due to their high moisture content. This causes difficulties in drying and frequently a heavy wrinkled product is obtained and the volatile oil content is often low and below standard requirements.

Ginger when used as vegetable is harvested from sixth month onwards while for preparing dry ginger, the produce is harvested after eight months of planting when the leaves of the plant turn yellow and starts drying. The harvested clumps of ginger are cleaned manually to remove the dried roots and soil clods. The clumps are then broken to sufficiently large size rhizomes suitable for preparing dry ginger. After cleaning, the rhizomes are subjected to peeling. Peeling, in case of ginger is definitely an important unit operation where the fully matured rhizomes are scraped with bamboo splits having pointed ends to remove the outer skin before drying to accelerate the drying process. Deep scraping with knifes need to be avoided to prevent the damage of oil bearing cells which are present just below the outer skin. Excessive peeling will result in the reduction of essential oil content of the dried produce. The peeled rhizomes are washed before drying. The dry ginger so obtained is valued for its aroma, flavour and pungency (Balakrishnan 2005).

Traditionally, ginger is sun dried in a single layer in open yard to get a brown, irregular wrinkled surface dry ginger which when broken shows a dark brown colour. Dried ginger is available in different forms like the whole dried ginger, splits or slices. The quality of dried ginger obtained from different driers was necessary to be evaluated before selecting a suitable method for commercial drying of ginger. Hence the present study was undertaken to study the effect of slicing and drying methods on the quality of dry ginger.

Materials and methods

Studies on slicing and drying of ginger (variety Varada) obtained from Indian Institute of Spices Research, Kozhikode, were conducted at Tamil Nadu Agricultural University, Coimbatore during February 2008 to determine the effect of slicing and drying methods on the quality of dry ginger. Fully matured ginger harvested after eighth month of planting was used for the drying studies. Ginger was thoroughly washed to remove the dirt and hand peeled for the total removal of the peel. The fingers of ginger rhizomes were separated and the fingers were cut into slices of 5, 10, 15, 20, 30, 40 and 50 mm long. The slices of various lengths and whole rhizomes were immediately weighed (1,000 g each) and dried. Drying was performed by three methods viz. open sun drying (minimum ambient drying temperature of 29 °C at 9.00 h and relative humidity of 66 % to a maximum temperature of 38 °C and relative humidity of 21 % at 13.00 h), solar tunnel drier of size 2 × 3 m with the hoop structure covered with UV-stabilized transparent polyethylene sheet to form the drying chamber to a height 2 m and mechanical drying in cabinet tray drier (M/s. Kilburn oven, 024E) from 9.00 to 17.00 h at temperatures of 50, 55, 60 and 65 °C.

The dried ginger were analyzed for its essential oil content by hydro distillation in a modified Clevenger apparatus (AOAC 1975) and for its oleoresin content by cold extraction process using the solvent acetone (ASTA 1968). The moisture content was estimated by toluene distillation method as per the procedure enumerated in ASTA (1968). GLC profile of the ginger essential oil was carried out on a Perkin Elmer Auto System Gas chromatograph (Connecticut, USA) equipped with PE Nelson 1022 GC plus integrator. Peaks were integrated using the Total chrom software (1204-WS0084). Column used was OV-17 (50 % phenyl 50 % methyl silicone, 30 m × 0.25 mm, 0.15 μm)) at an oven temperature of 70 °C to 210 °C @ 5 °C/min using nitrogen gas @ 30 ml/min as carrier gas. The temperature of flame ionization detector (FID) was 300 °C and injection port temperature was 200 °C. The compounds identified were zingiberene, limonene, linalool, geraniol and nerolidol using authentic standards obtained from Sigma Chemical Co., USA.

The important pungency constituents of dry ginger powder like the total gingerols and total shogoals were estimated by the method described by International Organization for Standardization (ISO IS:13685 1997) using reverse phase high performance liquid chromatography (SPD-10A Shimadzu, Kyoto, Japan, UV–VIS detector having LC-6A and with Shimadzu pump). The column used was steel column—5 μm Waters Symmetry TM C (4.6 × 250 mm), Mobile phase: Acetonitrile: water (65:35) with 1 % acetic acid in water (degassed), the injection volume was 20 μl, the flow rate was 1 ml/min and the UV absorbance was read at 280 nm.

The quantification was done by external standardization with nonanoic acid vanillyl amide (NVA) obtained from Sigma Chemical Co., USA, which has a retention time comparable to that of gingerol-[6] and has a similar UV absorption spectrum. Two standard solutions of NVA (0.2 mg/ml and 0.4 mg/ml) were injected into the instrument and the retention time of NVA was around 6 min.

Statistical analysis

A two factor completely randomized block design was followed to determine the effects of slicing and drying methods on biochemical constituents of dry ginger. All the experiments were replicated thrice. The quality parameters of ginger obtained by drying ginger slices of varying lengths in different driers were analyzed by AGRES (Version 7.01, Pascal Intl software solutions) statistical software.

Results and discussion

Effect of slicing on dying characteristics of ginger

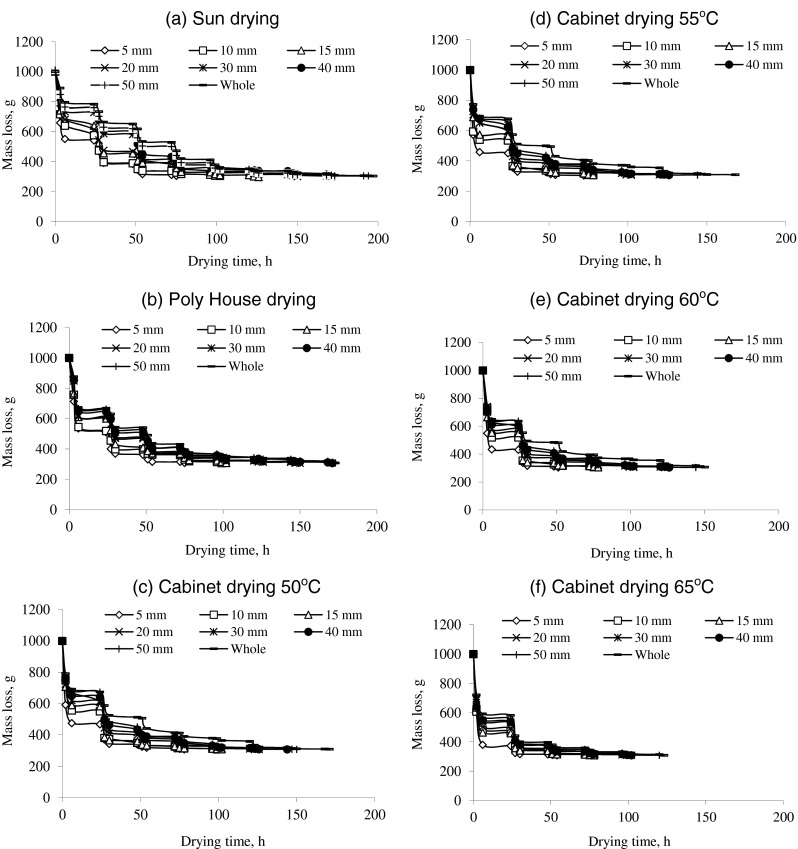

Ginger rhizomes of various slice lengths were dried from an initial moisture content of 81.3 % to final moisture content of less than 10 % by various drying methods. Slicing of ginger rhizomes significantly reduced the drying time of ginger in all the drying methods. It was observed that drying of whole ginger rhizomes under sun took the maximum time (9 days) followed by solar tunnel drying (8 days) (Fig. 1a and b). In mechanical drier, the time taken for drying at temperatures of 50, 55, 60 and 65 °C was 8, 8, 7 and 6 days, respectively. In a mechanical drier, as the temperature increased from 50 to 65 °C, the drying time decreased from 8 to 6 days, respectively (Fig. 1c–f).

Fig. 1.

Drying characteristics of ginger slices by various drying methods

Effect of slice length and drying methods on essential oil content

The essential oil content of sliced ginger, dried under various drying methods was found to increase, as the slice length increased and the maximum retention was obtained in the whole dry rhizomes (Table 1). Among the drying methods, sun dried and solar tunnel dried rhizomes could retain the maximum essential oil content than tray dried samples. It was found to vary from a minimum of 7.0 mg/g for drying 5 mm long ginger slice in a solar tunnel drier to 13.9 mg/g for drying whole ginger rhizomes under open sun and in a solar tunnel drier. In mechanical drying, the whole rhizomes lost about 12.2 % of essential oil at drying temperatures from 50 to 65 °C. The analysis of variance indicated that slice thickness and drying methods had significant effect on essential oil content of dried ginger.

Table 1.

Variation in essential oil content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Essential oil content (mg/g of dry ginger) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 10.4 | 7.0 | 9.6 | 8.7 | 10.4 | 8.7 |

| 10 | 10.4 | 7.0 | 10.4 | 8.7 | 10.4 | 8.7 |

| 15 | 10.4 | 8.7 | 10.4 | 8.7 | 10.4 | 10.4 |

| 20 | 12.2 | 10.4 | 10.4 | 8.7 | 10.4 | 10.4 |

| 30 | 12.2 | 10.4 | 10.4 | 8.7 | 10.4 | 10.4 |

| 40 | 12.2 | 10.4 | 10.4 | 10.4 | 10.4 | 10.4 |

| 50 | 12.2 | 13.9 | 10.4 | 10.4 | 10.4 | 12.2 |

| Whole (control) | 13.9 | 13.9 | 12.2 | 12.4 | 12.2 | 12.2 |

| SED | CD at 5 % | |||||

| Slice length | 0.14 | 0.28 | ||||

| Drying methods | 0.12 | 0.24 | ||||

| Slice length × Drying method | 0.34 | 0.69 | ||||

N = 3

Drying of ginger usually leads to loss of volatile oil by evaporation and this loss could be as high as 20 % during sun drying (Mathew et al. 1973). The extent of cleaning ginger rhizomes prior to drying had a considerable influence on the volatile oil and the fibre content of the end product. The removal of skin not only reduces the fibre content but also enhances the volatile oil loss through rupture of oil bearing cells, which are present near the skin. Purseglove et al. (1981) reported that the essential oil content of major types of dry ginger from India was usually in the range 1–3 %.

Effect of slice length and drying methods on oleoresin content

Drying studies indicated that as the slice length increased the oleoresin content increased and the maximum retention was obtained for the whole dry rhizomes and for longer slice lengths when dried under sun or in a solar tunnel drier (Table 2). The oleoresin content of dry ginger varied from a minimum of 30.3 mg/g for drying 5 mm long ginger slice in a tray drier at 65 °C to a maximum of 45.2 mg/g for drying whole ginger under open sun drying. In case of mechanical drying, minimum loss in oleoresin content was found when whole ginger was dried at 60 °C (5.3 %). The analysis of variance showed that both slice thickness and drying methods had significant effect on the oleoresin content of dry ginger. The heat treatment of the spice and its oleoresin can lead to the degradation of both volatile oil and the pungent principles. The yield of oleoresin from the commercial dried ginger was reported in the range of 3.5–10 % (Purseglove et al. 1981).

Table 2.

Variation in oleoresin content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Oleoresin content (mg/g of dry ginger) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 31.8 | 32.2 | 30.9 | 33.8 | 28.7 | 30.3 |

| 10 | 31.9 | 32.4 | 31.2 | 34.9 | 32.9 | 31.5 |

| 15 | 32.2 | 33.6 | 31.7 | 37.8 | 32.9 | 33.5 |

| 20 | 32.8 | 33.9 | 32.8 | 38.1 | 33.9 | 35.2 |

| 30 | 38.8 | 36.9 | 33.2 | 39.2 | 34.8 | 38.2 |

| 40 | 42.6 | 38.9 | 33.4 | 39.4 | 38.5 | 38.6 |

| 50 | 44.5 | 43.5 | 34.8 | 39.8 | 41.6 | 39.1 |

| Whole (control) | 45.2 | 43.8 | 36.2 | 40.2 | 42.8 | 41.2 |

| SED | CD at 5 % | |||||

| Slice length | 0.49 | 0.96 | ||||

| Drying methods | 0.42 | 0.83 | ||||

| Slice length × Drying method | 1.19 | 2.31 | ||||

N = 3

Volatile oil constituents of essential oil

Effect of slice length and drying methods on the zingiberene content

Zingeberene is an important volatile oil constituent of ginger and it was found to increase as the slice length increased. Maximum retention of zingiberene after drying was obtained for whole dry rhizomes and for rhizomes of longer slice lengths dried under sun and solar tunnel drier. It was found to vary from a minimum of 4.0 mg/g for drying 5 mm long ginger slice in a solar tunnel drier to a maximum of 8.6 mg/g for drying whole ginger under solar tunnel drier and was at par with the sun dried samples (Table 3). Analysis of variance showed that both slice length and drying methods had significant effect on zingiberene content of dry ginger. Narayanan and Mathew (1985) reported that among the 15 varieties of ginger investigated, the major constituent of volatile oil was α-zingiberene (16.6–28.7 %). The formation of sesquiterpene hydrocarbons in ginger oils was studied by Rani (1999) and reported that the oil contained α-zingiberene (22 %) and β-zingiberene (22 %) as the important constituents.

Table 3.

Variation in zingiberene content in the essential oil of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Zingiberene content (mg/g of ginger essential oil) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 5.9 | 4.0 | 5.8 | 4.6 | 5.9 | 4.8 |

| 10 | 6.0 | 4.0 | 6.2 | 4.5 | 5.9 | 4.9 |

| 15 | 6.5 | 4.8 | 6.2 | 5.1 | 5.8 | 6.0 |

| 20 | 6.7 | 5.8 | 6.2 | 5.1 | 5.9 | 6.1 |

| 30 | 6.7 | 6.1 | 6.2 | 5.6 | 6.0 | 6.1 |

| 40 | 7.3 | 6.3 | 6.0 | 5.9 | 6.1 | 6.1 |

| 50 | 7.4 | 8.6 | 6.3 | 6.3 | 6.2 | 7.2 |

| Whole (control) | 8.5 | 8.6 | 7.4 | 6.2 | 7.3 | 7.3 |

| SED | CD at 5 % | |||||

| Slice length | 0.10 | 0.20 | ||||

| Drying methods | 0.09 | 0.17 | ||||

| Slice length × Drying method | 0.24 | 0.48 | ||||

N = 3

Effect of slice length and drying methods on limonene content

Limonene, a constituent in ginger which gives a lemony flavour, was found to decrease significantly during slicing and maximum retention was found in whole dried samples dried in solar tunnel dried samples followed by sun dried rhizomes. The loss during mechanical drying at all the four temperatures was also significant when compared to sun and solar tunnel drying. The limonene content varied from a minimum of 0.3 mg/g for drying 5 mm long ginger slice at 55 °C in a tray drier to a maximum of 1.0 mg/g for drying whole ginger rhizomes under solar tunnel drying (Table 4). Thus both slicing and drying methods had significant effect on the on limonene content of dry ginger. Limonene content of 0.3–1.7 % was reported by Narayanan and Mathew (1985) in the essential oils of 15 cultivars of ginger investigated by them.

Table 4.

Variation in limonene content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Limonene content (mg/g of ginger essential oil) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 0.6 | 0.4 | 0.4 | 0.3 | 0.5 | 0.5 |

| 10 | 0.6 | 0.4 | 0.4 | 0.3 | 0.5 | 0.5 |

| 15 | 0.6 | 0.6 | 0.4 | 0.3 | 0.6 | 0.6 |

| 20 | 0.7 | 0.7 | 0.6 | 0.3 | 0.6 | 0.6 |

| 30 | 0.7 | 0.7 | 0.5 | 0.3 | 0.5 | 0.6 |

| 40 | 0.7 | 0.7 | 0.6 | 0.3 | 0.6 | 0.6 |

| 50 | 0.7 | 0.9 | 0.6 | 0.4 | 0.7 | 0.7 |

| Whole (control) | 0.9 | 1.0 | 0.7 | 0.5 | 0.7 | 0.7 |

| SED | CD at 5 % | |||||

| Slice length | 0.01 | 0.02 | ||||

| Drying methods | 0.01 | 0.01 | ||||

| Slice length × Drying method | 0.01 | 0.04 | ||||

N = 3

Effect of slice length and drying methods on linalool content

Linalool content of sliced ginger dried by various drying method was found to increase significantly with increase in the slice length and maximum retention was obtained during sun drying and by solar tunnel drying when dried whole or for a maximum length of 50 mm. In case of smaller slice lengths, the values were lower than the control sample value (whole rhizome) for all the treatments of slicing and drying methods. Its value varied from a minimum of 0.2 mg/g for drying 5 mm long ginger slice dried in a tray drier for all the temperature treatments to a maximum of 0.5 mg/g for drying whole or 50 mm long ginger slice under open sun drying or in a solar tunnel drier (Table 5).

Table 5.

Variation in linalool content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Linalool content (mg/g of ginger essential oil) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 0.3 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 10 | 0.3 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 |

| 15 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| 20 | 0.4 | 0.3 | 0.3 | 0.2 | 0.3 | 0.3 |

| 30 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| 40 | 0.4 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 |

| 50 | 0.5 | 0.5 | 0.3 | 0.3 | 0.4 | 0.4 |

| Whole (control) | 0.5 | 0.5 | 0.4 | 0.4 | 0.4 | 0.4 |

| SED | CD at 5 % | |||||

| Slice length | 0.004 | 0.009 | ||||

| Drying methods | 0.004 | 0.008 | ||||

| Slice length × Drying method | 0.01 | 0.021 | ||||

N = 3

Effect of slice length and drying methods on geraniol content

Geraniol content decreased significantly as the drying temperature increased in tray drier and also as the slice length decreased (Table 6). The maximum retention of gingerol content was observed for the sun dried samples followed by solar tunnel dried samples. Geraniol content of dry ginger varied from a minimum of 0.1 mg/g for drying 5 mm long ginger slice in a tray drier for all the temperatures to a maximum of 0.8 mg/g for drying whole ginger under open sun drying. The analysis of variance showed that the independent variables like slice length and drying methods had significant effect on geraniol content of dry ginger. The geraniol content in the essential oil of ginger was reported to vary between 5.8 and 11.5 % for the 15 cultivars investigated by Narayanan and Mathew (1985).

Table 6.

Variation in geraniol content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Geraniol content (mg/g of ginger essential oil) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 0.5 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 |

| 10 | 0.5 | 0.2 | 0.1 | 0.1 | 0.2 | 0.1 |

| 15 | 0.5 | 0.2 | 0.1 | 0.2 | 0.2 | 0.2 |

| 20 | 0.5 | 0.3 | 0.1 | 0.2 | 0.2 | 0.2 |

| 30 | 0.5 | 0.4 | 0.1 | 0.3 | 0.2 | 0.2 |

| 40 | 0.6 | 0.3 | 0.2 | 0.3 | 0.2 | 0.2 |

| 50 | 0.6 | 0.4 | 0.2 | 0.3 | 0.2 | 0.2 |

| Whole (control) | 0.8 | 0.4 | 0.2 | 0.3 | 0.3 | 0.2 |

| SED | CD at 5 % | |||||

| Slice length | 0.004 | 0.008 | ||||

| Drying methods | 0.003 | 0.007 | ||||

| Slice length × Drying method | 0.01 | 0.02 | ||||

N = 3

Effect of slice length and drying methods on nerolidol content

A significant decrease in nerolidol content was observed as the rhizomes were sliced. Nerolidol content was found to vary from a minimum of 0.3 mg/g of dry ginger when 5 mm long ginger slices were dried at temperatures of 50 and 55 °C to 0.5 mg/g when dried under sun, solar tunnel drier and in a mechanical drier at 60 and 65 °C (Table 7). The gas chromatographic analysis of essential oils obtained by hydrodistillation of seven popular varieties of ginger, showed the nerolidol content in Indian ginger as 4.7 % (Gopalam and Ratnambal 1989).

Table 7.

Variation in nerolidol content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Nerolidol content (mg/g of ginger essential oil) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 0.4 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 |

| 10 | 0.4 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 |

| 15 | 0.4 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 |

| 20 | 0.4 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 |

| 30 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| 40 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.5 |

| 50 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 |

| Whole (control) | 0.5 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 |

| SED | CD at 5 % | |||||

| Slice length | 0.006 | 0.01 | ||||

| Drying methods | 0.005 | 0.01 | ||||

| Slice length × Drying method | 0.015 | 0.03 | ||||

N = 3

Pungency constituents

Effect of slice length and drying methods on total gingerol content

Gingerol, the major pungent component of ginger oleoresin, was found to reduce significantly on slicing when compared to the whole dry ginger. It varied from a minimum of 17 mg/g of dry ginger for drying 5 mm long ginger slice in a tray drier at 60 and 65 °C to a maximum of 28.2 mg/g, for drying whole ginger rhizome in a solar tunnel drier (Table 8). However, the maximum retention obtained was at par with the values obtained for whole ginger rhizomes dried under sun. Analysis of variance showed that the slice length and drying methods had significant effect on the total gingerol content of dry ginger. Connell and Sutherland (1969) reported that the major pungent component of ginger oleoresin was [6]-gingerol along with the other well known [8]-gingerol, and [10]-gingerols. The gingerol content in nine popular ginger cultivars of India, Brazil and Jamaica was determined by Gopalam and Ratnambal (1989) and reported the minimum amount of gingerol for the cultivars Wynad local, Narasapattanam and Maran to be 17.7–19.3 %.

Table 8.

Variation in total gingerol content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Gingerol content (mg/g of dry ginger) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 18.2 | 19.0 | 17.1 | 17.1 | 17.0 | 17.0 |

| 10 | 19.5 | 19.5 | 17.2 | 17.1 | 19.2 | 18.0 |

| 15 | 20.5 | 21.1 | 17.6 | 20.3 | 20.1 | 18.0 |

| 20 | 23.6 | 22.8 | 18.4 | 21.2 | 22.0 | 19.0 |

| 30 | 24.3 | 23.2 | 19.4 | 22.4 | 23.8 | 21.9 |

| 40 | 25.4 | 24.6 | 21.1 | 23.5 | 24.2 | 24.0 |

| 50 | 27.5 | 26.0 | 23.0 | 26.0 | 26.1 | 25.5 |

| Whole (control) | 28.0 | 28.2 | 26.5 | 26.2 | 26.8 | 26.2 |

| SED | CD at 5 % | |||||

| Slice length | 0.29 | 0.59 | ||||

| Drying methods | 0.25 | 0.51 | ||||

| Slice length × Drying method | 0.72 | 1.44 | ||||

N = 3

Effect of slice length and drying methods on total shogaol content

Shogoal, the less pungent constituent of ginger oleoresin decreased as the slice length decreased. It was found to vary from a minimum of 1.8 mg/g dry ginger for drying 5 mm long ginger slice at 60 and 65 °C in a tray drier to a maximum of 3.5 mg/g for drying whole ginger rhizomes under open sun drying and in a solar tunnel drier (Table 9). Significant variation in shogoal content was observed with respect to slice length and drying methods. Purseglove et al. (1981) reported that when gingerols are prone to dehydration, transformation of gingerols to corresponding, less pungent shogaols are formed. This reaction was markedly influenced by temperature.

Table 9.

Variation in total shogaol content of dry ginger for various slice lengths and drying methods

| Slice length, (mm) | Shogaol content (mg/g of dry ginger) | |||||

|---|---|---|---|---|---|---|

| Drying methods, | ||||||

| Open sun drying | Solar tunnel drier | Tray drier 50 °C | Tray drier 55 °C | Tray drier 60 °C | Tray drier 65 °C | |

| 5 | 2.1 | 2.1 | 1.9 | 1.9 | 1.8 | 1.8 |

| 10 | 2.1 | 2.1 | 2.0 | 2.0 | 1.8 | 1.8 |

| 15 | 2.1 | 3.2 | 2.0 | 2.0 | 1.9 | 1.9 |

| 20 | 3.3 | 3.3 | 3.2 | 3.1 | 2.6 | 2.2 |

| 30 | 3.3 | 3.5 | 3.2 | 3.1 | 2.8 | 2.6 |

| 40 | 3.3 | 3.5 | 3.4 | 3.3 | 3.0 | 2.9 |

| 50 | 3.5 | 3.5 | 3.4 | 3.3 | 3.2 | 3.0 |

| Whole (control) | 3.5 | 3.5 | 3.4 | 3.3 | 3.2 | 3.1 |

| Slice length | 0.04 | 0.08 | ||||

| Drying methods | 0.03 | 0.06 | ||||

| Slice length × Drying method | 0.09 | 0.18 | ||||

N = 3

Optimization of drying process

Drying characteristics curves indicated that slicing significantly reduced the drying time. Whole ginger rhizomes when dried under sun took the maximum drying time. The quality of dry ginger for commercial purposes is generally evaluated based on two important parameters, the essential oil and the oleoresin content. Ginger when dried under sun drying and solar tunnel drier had the maximum retention of essential oil (13.9 mg/g of dry ginger). Slicing significantly reduced the essential oil content of ginger and reduction was significant even when ginger was sliced to a length of 50 mm. Below 20 mm length of slice, the loss in essential oil content was very high. The maximum retention of oleoresin content (45.2 mg/g of dry ginger) was observed again for whole ginger samples dried under open sun drying and in solar tunnel drier (Table 2). It is found that the oleoresin content of 50 mm long ginger samples was at par with the oleoresin content of whole dry rhizomes. However, the reduction in oleoresin content of ginger for slice lengths less than 50 mm was significant. In case of mechanical drying at 60 °C could retain to a greater extent the quality and the drying time was 7 days. Hence, it can be concluded from drying studies that whole ginger dried under sun drying or in solar tunnel drier or in case of mechanical drier, drying temperature of 60 °C could be adopted to produce quality dried ginger.

Conclusion

Drying studies of ginger rhizomes sliced to various lengths of 5, 10, 15, 20, 30, 40 and 50 mm and dried by various drying methods like sun drying, solar tunnel drying and cabinet drying at temperatures of 50, 55, 60 and 65 °C indicated that slicing (5mm) significantly reduced the drying time (4 days) compared to drying whole rhizomes (9 days) under sun. In case of mechanical drying, with the increase in temperature from 50 to 65 °C, reduction in drying time from 8 to 6 days for drying whole rhizomes was observed. Gas chromatographic analysis of volatile constituents of ginger essential oil like zingiberene, limonene, linalool, geraniol and nerolidol showed significant reduction in its content as the slice length decreased when compared to whole rhizome. Non volatile constituents of dry ginger like total gingerols and total shogoals decreased as the sliced length reduced. Sun drying and solar tunnel drying retained the maximum essential oil content (13.9 mg/g of dry ginger) and oleoresin content (45.2 mg/g of dry ginger). In case of mechanical drying, the optimum drying temperature was considered as 60 °C and whole rhizomes lost about 12.2 % of essential oil and 5.3 % oleoresin when dried at this temperature.

Electronic supplementary material

(PDF 2194 kb)

References

- AOAC . Official methods of analysis. 10. Washington D.C: Association of Official Analytical Chemists; 1975. [Google Scholar]

- ASTA . Official analytical methods. 2. New Jersey: American Spice Trade Association; 1968. [Google Scholar]

- Balakrishnan KV. Postharvest and industrial processing of ginger. In: Ravindran PN, Nirmal Babu K, editors. Ginger-The genus Zingiber. Massachusetts: CRC Press; 2005. pp. 391–434. [Google Scholar]

- Connell DW, Sutherland MD. Re-examination of gingerol, shogaol and zingerone, the pungent principles of ginger. Aust J Chem. 1969;22:1033–1043. doi: 10.1071/CH9691033. [DOI] [Google Scholar]

- Gopalam A, Ratnambal MJ. Essential oils of ginger. Indian Perfum. 1989;33(1):63–69. [Google Scholar]

- ISO IS:13685 . Ginger and its oleoresins—determination of the main pungent components (Gingerols and shogoals)—method using high performance liquid chromatography. Geneva: International Organization for Standardization; 1997. [Google Scholar]

- Mathew AG, Krishnamurthy N, Nambudri ES, Lewis YS. Oil of ginger. Flavour Ind. 1973;3:78–81. [Google Scholar]

- Narayanan CS, Mathew AG. Chemical investigation on spice oils. Indian Perfum. 1985;29(1–2):15–22. [Google Scholar]

- Purseglove JW, Brown EG, Green CL, Robbins SRJ. Ginger. Spices. New York: Longman; 1981. pp. 447–531. [Google Scholar]

- Rani K. Cyclization of farnesyl pyrophosphatateinto sesquiterpenoids in ginger rhizomes (Zingiber officinale) Fitoterapia. 1999;70(6):568–574. doi: 10.1016/S0367-326X(99)00090-8. [DOI] [Google Scholar]

- Spices Board (2011) Spices Board of India. http://indianspices.com. Accessed 1 Aug 2011

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

(PDF 2194 kb)