Abstract

One of the most important issues facing cartilage tissue engineering is the inability to move technologies into the clinic. Despite the multitude of review articles on the paradigm of biomaterials, signals, and cells, it is reported that 90% of new drugs that advance past animal studies fail clinical trials (1). The intent of this review is to provide readers with an understanding of the scientific details of tissue engineered cartilage products that have demonstrated a certain level of efficacy in humans, so that newer technologies may be developed upon this foundation. Compared to existing treatments, such as microfracture or autologous chondrocyte implantation, a tissue engineered product can potentially provide more consistent clinical results in forming hyaline repair tissue and in filling the entirety of the defect. The various tissue engineering strategies (e.g., cell expansion, scaffold material, media formulations, biomimetic stimuli, etc.) used in forming these products, as collected from published literature, company websites, and relevant patents, are critically discussed. The authors note that many details about these products remain proprietary, not all information is made public, and that advancements to the products are continuously made. Nevertheless, by fully understanding the design and production processes of these emerging technologies, one can gain tremendous insight into how to best use them and also how to design the next generation of tissue engineered cartilage products.

1. Introduction

An adequate therapy for the long-term repair of cartilage lesions has yet to be developed. Being largely avascular and with low cellularity, articular cartilage has a limited ability to heal itself. Despite possessing remarkable mechanical properties, the tissue can develop defects following long-term wear or acute trauma. Defects in the highly organized matrix can progressively deteriorate through mechanisms of stress concentration and cell signaling cascades. Ultimately, the tissue loses mechanical integrity, breaks, thins, loses lubrication, and no longer functions in cushioning bone-to-bone contact – imparting great physical pain to the patient.

Focal lesions are the ideal indication for the repair of articular cartilage. The prevalence of focal lesions is difficult to estimate. In 2005, an estimated 27 million people in the U.S. had osteoarthritis (2). In one study, 60% of all arthroscopies revealed the presence of articular lesions (36% being Outerbridge Grade III and IV lesions) and, of these, 67% were characterized as focal lesions (3). From a surgical perspective, an estimated 250,000 articular cartilage repair procedures (involving chondroplasty, microfracture, mosaicplasty, and autologous chondrocyte implantation (ACI)) are performed annually in the U.S. (4). These cartilage repair therapies, however, do not consistently produce hyaline repair tissue, fill the entirety of the defect, and integrate repair tissue with adjacent native tissue.

To overcome these limitations, a number of cell-based, tissue engineered cartilage products have recently entered clinical trials in the U.S. and abroad. In this review, tissue engineered cartilage is defined as a construct formed by following the paradigm of integrating chondrocytes, signals, and scaffolds. The scaffolds can be exogenously provided or endogenously produced by the cells; the latter are usually referred to as scaffold-free or scaffold-less approaches if no exogenous scaffold is provided. Acellular scaffolds, considered an augmented form of microfracture, are not included in this definition. Tissue grafts including osteochondral autografts and allografts, as well as their particulated forms such as DeNovo® NT from Zimmer, are also not considered tissue engineered cartilage. Finally, using this definition, injection of passaged chondrocytes into a cartilage defect is also not considered tissue engineering. Through systematic design, tissue engineered cartilage can be manipulated in vitro to enhance its biochemical and biomechanical properties. Complete fill and good integration can be achieved by manipulating construct shape, the use of adhesives and other fixation methods, and other strategies. Tissue engineering offers a promising solution for the long-term treatment of cartilage lesions.

The first section of this review aims to provide a description of current repair therapies and the tissue engineered cartilage products – BioCart™II, Bioseed®-C, CaReS®, Cartipatch®, Chondrosphere®, Hyalograft® C, INSTRUCT, NeoCart®, NOVOCART® 3D, MACI, and RevaFlex™. Table 1 lists the construct specifications and Table 2 lists the products’ clinical indications, current status, and clinical trials. The second section aims to discuss the tissue engineering strategies used in product fabrication, identify current challenges, and suggest future directions. The authors note that the information in this review was gathered from published literature, company websites, and relevant patents. Owing to this and the fact that there may be a plethora of proprietary details not publicly available, the current status of the products may not be adequately reflected. In reviewing the details on the science behind each product, one quickly realizes that improvements can be made on five areas. These include 1) defining and optimizing the chondrocyte cell source, 2) understanding tissue-scaffold interaction and scaffold degradation, 3) identifying and applying novel stimuli, 4) understanding construct maturation, biomechanics, and functionality, and 5) improving implantation, fixation, and rehabilitation methods. The current challenges and future directions in these five areas, along with challenges in commercialization, are discussed in Perspectives. Thus, by understanding the general details of how these clinically used tissue engineered products are fabricated, one can gain insight as to how to best use them and how to design the next generation of tissue engineered cartilage.

Table 1.

List of cell-based, tissue engineered cartilage products, their approximate production specifications, and their implantation method

| Product | No. of Surgeries |

Chondrocytes | Scaffold | Seeding Density (areal) |

Construct Size |

3D Culture Duration |

Implantati on Technique |

Fixation Technique |

|---|---|---|---|---|---|---|---|---|

| Biocart™II | 2 | Autologous (unspecified passage) |

Freeze-dried fibrin/ hyaluronan |

500,000 cells/cm2 |

NA | 3-4 days | Cut to size using template |

Fibrin glue |

| Bioseed®-C | 2 | Autologous (unspecified passage) |

Polyglactin/ polydiaxanon, fibrin carrier |

3-5 million/cm2 |

3×2×0.2, 3×2×0.11, 3×3×0.11, 5×2×0.11 cm |

NA | Cut to size | Transosseous sutures, sewn, or fibrin glue |

| Cartipatch® | 2 | Autologous, up to P3 |

Agarose- alginate hydrogel |

10 million cells/mL |

1.0, 1.4, or 1.8 cm in diameter, 4 mm thick |

NA | Use of drills to create matching defects and constructs |

Press fit, fibrin glue optional |

| Chondrosphere® | 2 | Autologous (unspecified passage) |

Scaffold-free | 200,000 cells/sphe- roid, 10-70 spheroids/ cm2 |

500-800 μm in diameter |

2 weeks | Injected to defect bed |

Spheroids naturally adhere |

| Hyalograft® C | 2 | Autologous, up to P3 |

Non-woven mesh of hyaluronic acid-based microfibers |

1 million cells/cm2 |

2×2 cm (×2) | 2 weeks | Use of punches to create matching defects and constructs |

Press fit, fibrin glue optional |

| MACI | 2 | Autologous, P1-P3 |

Collagen I/III scaffold from porcine peritoneum |

0.5-1 million cells/cm2 |

4×5 cm (×2) | 3-4 days | Cut to size using template |

Fibrin glue |

| NeoCart® | 2 | Autologous (unspecified passage) |

Honeycomb bovine type I collagen scaffold, cell carrier |

NA | NA | 3-5 weeks | Cut to size | Collagen/PEG glue |

| NOVOCART® 3D | 2 | Autologous, P1 |

Bilayer type I collagen sponge containing chondroitin sulfate |

0.5-3 million cells/cm2 |

NA | 2 days | Use of punches to create matching defects and constructs |

Sutures or pins |

| RevaFlex™ | 1 | Allogeneic, juvenile (unknown passage) |

Scaffold-free | NA | 2.2-2.5 cm diameter |

> 40 days | Cut to size using template |

Fibrin glue |

| CaReS® | 2 | Autologous, primary |

Type I collagen hydrogel |

NA (possibly 20,000 cells/mL) (2500- 3,333 cells/cm2 |

3.4 cm diameter, 6- 8 mm thick |

10-13 days | Cut to size | Fibrin glue |

| INSTRUCT | 1 | Autologous, primary chondrocytes + bone marrow cells |

PEOT/PBT 3D printed scaffold |

NA (possibly 240,000 cells/cm2) |

0.4 cm diameter, 4 mm thick |

Immediate | NA | NA |

Table 2.

Clinical status of the reviewed cartilage products

| Product | Completed Clinical Studies | Ongoing Clinical Studies/Current Status | Clinical Indication |

|---|---|---|---|

| Biocart™II | - Prospective, preliminary study (n=8) (26) - Phase II study (n=40) (NCT00729716) (29) |

- Future trials not available | 1.5-7.5 cm2, up to 6 mm deep, symptomatic single contained lesion of femoral condyle/trochlea, can treat OCD |

| Bioseed-C | - Over 3,000 patients treated since 2002 - Randomized study comparing to ACI (n=21) (37) - Prospective study (n=79) (30, 36) |

- Available in some European countries - Future trials not available |

Grade III to IV focal chondral and osteochondral lesion |

| Cartipatch® | - Prospective, multi-center study (n=17) (39) - Phase III study (n=58) (NCT00560664) (41, 270) |

- Phase III study terminated (NCT00945399); future trials not available |

2.5-7.5 cm2, up to 10 mm deep, Grade III or IV isolated femoral osteochondral lesion, can treat OCD |

| Chondrosphere® | - Over 7,200 patients treated since 2004 - Prospective, multi-center study (n=42) (47) - Prospective, investigator-initiated trial (n=37) (49) |

- Phase II study to finish Nov. 2017 with 5- year outcome measures (NCT01225575) - Phase III study to finish Dec. 2020 with 5-year outcome measures (NCT01222559) |

1-4 cm2, up to 6 mm deep, Grade III or IV isolated single chondral lesion on femoral condyle |

| Hyalograft® C | - Over 5,000 patients treated since 1999 (53) |

- Withdrawn from market; future trials not available |

1.0-5.0 cm2, Grade III or IV chondral lesion of the femoral condyle/trochlea |

| MACI | - Study comparing to microfracture (n=60) (72) - Study comparing to C-ACI (n=91) (73) - Phase III study (n=144) (NCT00719576) (69) |

- Approved in the EU but production stopped |

≥3.0 cm2, Grade III or IV focal chondral lesion of femoral condyle/trochlea |

| NeoCart® | - Phase I study (n=8) (82) - Phase II study comparing to microfracture (n=30) (NCT00548119) (80) |

- Phase III study (n=245) to finish July 2017 with 1-year outcome measures (NCT01066702) |

symptomatic articular cartilage lesion of femur/trochlea |

| NOVOCART® 3D | - Over 6,000 patients treated since 2003 - Prospective study (n=23) (91) - Other prospective studies (n=30-41) (86, 93, 94) - Study on treatment of OCD (95) |

- Phase III study (n=233) to finish July 2018 with 2-year outcome measures (NCT01957722) - Non-interventional study (n=80) to finish Sept. 2019 with 3-year outcome measures (NCT02348697) - Phase III study (n=261) to finish June 2019 with 5-year outcome measures (NCT01656902) |

2-6 cm2, isolated articular cartilage lesions of femoral condyle |

| RevaFlex™ | - Phase I/II study (n=12) (102) | - Phase III study (n=225) to finish July 2019 with 5-year outcome measures (NCT01400607) |

<5 cm2 lesion of the distal femur |

| CaReS® | - Prospective, multi-center study (n=116) (109) - Retrospective study comparing to microfracture (n=20) (116) |

- available in select European countries, Turkey, Iran, and China - Future trials not available |

3.5-14 cm2, Grades III or IV lesion, can treat OCD |

| INSTRUCT | - Phase II study (n=40) finished June 2014 with 2-year outcome measures (127) (NCT01041885) |

- Future trials not available | symptomatic articular cartilage defects in knee |

2. Current cartilage repair therapies

Chondroplasty (76.6%) and microfracture (22.0%) account for the majority of the procedures performed on articular cartilage in the knee (4, 5). However, these cartilage repair options may have several shortcomings (6-11). Chondroplasty, used only when wear is minor, has acceptable short-term but potentially poor long-term results (6, 7). In microfracture, the defect is cleaned and the bone punctured to induce bleeding, resulting in a fibrocartilaginous repair tissue formed by multipotent marrow cells. Despite favorable short-term outcomes, studies have indicated deteriorating repair tissue quality after 1.5-5 years (8-11). Failure has been attributed to the inferior biochemical and biomechanical properties of the fibrocartilaginous fill (12) and alterations of the subchondral bone (13). On the other hand, mosaicplasty with osteochondral auto/allografts has been reported to offer better clinical results than microfracture (14, 15). However, issues with failure at the osseous region, lateral integration, and deterioration of graft edges have contributed to graft failure in 15-55% of patients after 10 years (16-18). Furthermore, mosaicplasty with autografts is limited to treating lesions less than 4 cm2 to minimize donor site morbidity. Although fresh allografts can be used to treat large defects, they are also limited in supply.

Autologous chondrocyte implantation (ACI) has been emerging as a superior, long-term treatment option (16, 19). When compared to multipotent marrow cells, passaged articular chondrocytes possess greater innate potential to form hyaline-like cartilage (20). When compared to mature osteochondral grafts, the immature neocartilage fill formed by ACI may have a better ability to integrate and conform to the defect. Despite these advantages, a 10-year follow-up study showed graft failure in up to 25% of ACI-treated patients (21). Although use of a collagen membrane instead of a periosteal flap drastically reduced complications such as hypertrophy, only 75% of patients reported good to excellent Cincinnati scores with this newer technique at a 2-year follow-up (22) (see Table 3 for common knee evaluation outcome measures). In addition, ACI commonly resulted in a fibrocartilaginous or fibrous fill, with only 15-30% of patients developing hyaline-like repair tissue in some studies (23, 24). These inconsistencies may arise from cell passaging, patient age, and surgical discrepancies. However, the procedure is also inherently inconsistent owing to a lack of control; for example, how many cells are retained, where they adhere, and how they form neocartilage is uncontrolled. Off-label use of first injecting the cell suspension to a collagen sponge represents a desire by physicians to place the cells more consistently into the defect (25). Currently, a number of cartilage products with pre-seeded cells have been developed to address the limitations of current practices. Although these products are often described as second- or third-generation ACI, they actually represent the first generation of tissue engineered cartilage products.

Table 3.

Common outcome measures in clinical studies involving cartilage repair

| Outcome Measure | Purpose |

|---|---|

| International Knee Documentation Committee (IKDC) Subjective Knee Evaluation Form |

To measure knee symptoms, sports and daily activities, and function |

| Knee Injury and Osteoarthritis Outcome Score (KOOS) and KOOS Physical Function Short Form (KOOS-PS) |

To measure patients’ opinions about their knee and associated problems |

| Cincinnati knee rating system (and modified versions) | To measure patient’s symptoms and perception of knee function with a focus on physical abilities |

| Western Ontario and McMaster Universities Osteoarthritis Index (WOMAC) |

To measure pain, stiffness, and physical function; widely used to evaluate knee or hip osteoarthritis |

| Lysholm Knee Scoring Scale | To measure patient’s evaluation of knee function; originally designed to assess ligament injuries |

| Tegner Activity Scale | To measure activity level; developed to complement the Lysholm scale. |

| Visual Analog Scale (VAS) for Pain Short Form 36 (SF-36) |

To measure patient pain on an analog scale from 1-100 To measure patient-reported general health |

| International Cartilage Repair System (ICRS) Cartilage Injury Evaluation |

Includes questions from SF-36, IKDC, Lysholm, and Tegner evaluation forms |

| Bern and O’Driscoll Scores | To histologically evaluate the quality of cartilage repair tissue relative to native articular cartilage |

| Magnetic Resonance Observation of Cartilage Repair Tissue (MOCART) |

To use different MRI variables to describe the constitution of the cartilage repair tissue and the surrounding structures |

3. Tissue engineered articular cartilage products

3.1. BioCart™II (Histogenics, Waltham, MA)

Biocart™II was first developed by Prochon Biotech, Ltd. until the company’s acquisition by Histogenics in 2011. The product is a fibrinogen/hyaluronic acid scaffold seeded with expanded autologous chondrocytes. Cells were expanded in the presence of autologous serum and 10 ng/mL fibroblast growth factor 2 variant (FGF2v) (26). FGF2v has been shown to increase cell proliferation rates and maintain the chondrocytic phenotype during expansion (27). The scaffold was described to be composed of homologous human fibrinogen (Omrix Biopharamceuticals, New York, NY) copolymerized with recombinant hyaluronan (Ferring Pharmaceuticals, Switzerland) with the use of thrombin and freeze-dried to yield a sponge-like, 3D structure (26). A company patent indicated that hyaluronic acid not only provides bioactivity to the matrix but also imparts viscoelastic properties to the scaffold (28). Cells were injected into the scaffold with a syringe at 500,000 cells/cm2 (26). The construct was cultured for 3-4 days prior to the implantation date. BioCart™II was ready for implantation 3 to 4 weeks after the first surgery (26).

During the operation, as described (26), the lesion was debrided and a template of the defect created with aluminum foil. Whether bleeding was avoided was not made clear. The BioCart™II construct was then cut to size using the template, press fit into the defect, and fixed with fibrin glue applied to the border of the defect. BioCart™II was described to contain some self-adhesive properties due to its high fibrinogen content. Rehabilitation involved continuous passive motion (CPM) for 4 weeks up to 30° range of motion. Touch-weight bearing was prescribed from day 2 to week 6 followed by increases in weight until free walking without assists at 12 weeks.

A Phase I trial (n=8) demonstrated the feasibility of BioCart™II for treating femoral lesions and osteochondritis dissecans (26). Defects were 1 to 8 cm2 (mean=3 cm2) and no deeper than 5 mm (mean=4.4 mm). IKDC scores improved at 6 and 12 months, while Lysholm scores improved at 6 months (see Table 3 for scoring methods). MRI at 12 months showed 75-100% fill in all patients, an intact surface (i.e., no damage and fissures) in 75% (6/8) of patients, and one case of construct delamination at the bone-cartilage interface. Integration was described as stable via MRI analysis. Another clinical study (n=31, defect size=3.3±1.9 cm, all femoral condylar defects) showed that BioCart™II treatment increased IKDC and MOCART scores at 12 months (29). Full results of the Phase II trial have not yet been published and plans for continuation toward Phase III trials have not been made available.

3.2. Bioseed®-C (BioTissue Technologies GmbH, Freiburg, Germany)

Bioseed®-C consists of a polyglactin 910/poly-p-dioxanone fleece scaffold seeded with a solution of fibrin and expanded autologous chondrocytes (30). During the first surgery, 250 mg healthy cartilage is collected along with 100 mL blood (31). Cells are expanded in presence of autologous serum for 3 weeks (31) to an unknown passage number. In a preclinical horse study, cells were expanded to P3 or P4 in RPMI, 1% horse serum, 5% FBS, and penicillin/streptomycin (32). The product comes in a variety of rectangular sizes (3×2×0.2, 3×2×0.11, 3×3×0.11, 5×2×0.11 cm) and is seeded with 28.8 × 106 cells per unit, which correlates to a seeding density of 2.9-4.8 × 106/cm2 (33). Fibrin glue is used as a cell carrier. The polymeric fleece has an interconnected porosity of about 90%. In the preclinical horse study, constructs were cultured for 3 weeks prior to implantation in Ham’s F-12 medium, 5% horse serum, penicillin/streptomycin, and 50 μg/mL ascorbic acid (32). Whether this stage is used in the actual product is unclear. On the company website, scaffold degradation is stated to occur within 6 months (34). The implant is ready 4.5 weeks after the first surgery (33).

For implantation, the defect zone is debrided down to the subchondral bone and the construct cut to size (31). For deep defects, two constructs may be layered. The construct is either fixed into place using a transosseous suture (Erggelet) technique, a regular suture, or fibrin glue. The procedure can be done arthroscopically or arthrotomically depending on the defect size and location (35). Rehabilitation involved CPM and loading of 15% bodyweight until for 6 weeks (30). After week 13, patients progressively increased loads until full weightbearing; mild exercise was allowed after 6 months.

Bioseed®-C has been used to treat more than 3000 patients since 2002 (33). A Phase II clinical study (n=79) with 2- and 4-year outcome measures showed significant beneficial effects with Bioseed®-C treatment (30, 36). At 2 years, significant increase in KOOS scores over baseline was observed (36). Histology of second-look biopsies were said to show good integration and formation of cartilaginous repair tissue. At 4 years, patients (n=50) showed significant improvements in ICRS, IKDC, KOOS, Lysholm, and Noyes scores compared to baseline values (30). MRI showed complete filling in 72.7%, moderate filling in 25%, and less than 50% filling in 0.3% of patients. In another clinical study (n=21), Bioseed®-C was compared to ACI (periosteal flap method) in a randomized trial (37). No significant differences were found in IKDC, SF-36, Tegner, and MRI scores at 12 and 24 months. However, the ACI method scored better in knee functionality (Lysholm and Gillquist) tests. Complication rates with Bioseed®-C treatment was similar to that of ACI (38). Bioseed®-C is currently available in Europe.

3.3. Cartipatch® (Tissue Bank of France, Lyon, France)

Cartipatch® is an agarose-alginate hydrogel seeded with expanded autologous chondrocytes. As described (39), chondrocytes were expanded to a maximum of passage 3 (P3) in medium consisting of DMEM/Ham’s F-12 (1:1), 10% autologous serum, ascorbic acid (50 mg/L), and gentamicin/Fungizone. Use of antibiotics and Fungizone was discontinued after P1. Cells were then suspended in medical grade, ultrapurified agarose-alginate (GelForCel; Tissue Bank of France, Paris, France) at a minimum concentration of 10 million cells/mL and cast into plugs 10, 14, or 18 mm in diameter. The cell embedding technique is presumably similar to that commonly used with low-melt agarose.

For implantation, the defect was drilled to a depth up to 4 mm using specially-designed drill bits to match the construct size (39). The size and number of constructs used (up to three) were preplanned to provide the best coverage of the defect. Implanted Cartipatch® constructs were generally level with the surrounding tissue. Fibrin glue was used in one case to improve construct stability.

A prospective, multi-center study (n=17) showed positives results with Cartipatch® treatment (39). Because the operation involved removal of subchondral bone, Cartipatch® was largely used to treat osteochondritis dissecans (76% of patients). The defects ranged from 1.0 to 5.1 cm2 (mean=3 cm2). At 2 years, patient IKDC scores significantly improved over baseline. Second-look arthroscopy revealed the repair cartilage as “normal and nearly normal” in 85% (11/13) of patients, level with surrounding tissue in 77% (10/13) of patients, and smooth in 38% (5/13) of patients. Histological analysis of biopsies showed hyaline cartilage in 62% (8/13) of patients, while others developed fibrocartilage. A Phase III trial (n=58) comparing Cartipatch® to mosaicplasty was completed on August 2013 with 2-year outcome measures (IKDC, MRI, arthroscopy with biopsy) (40). Published histological results at 2 years showed that mosaicplasty resulted in superior repair tissue quality (41), prompting the authors to note that 2 years was insufficient for the construct to fully develop into cartilage tissue. A Phase III trial comparing Cartipatch® to microfracture was scheduled for completion for September 2014 but had been terminated (42).

3.4. Chondrosphere®/ACT3D/Athrocell 3D (co.don AG, Teltow, Germany)

Chondrospheres® (also known as ACT3D-CS or ARTHROCELL 3D®) are small spheroids of neocartilage composed of expanded autologous chondrocytes and their associated matrix. Autologous chondrocytes are expanded in the presence of human serum and in the absence of antibiotics, fungicide, or exogenous growth factors (43). A company patent indicates the potential use of DMEM/Ham’s F-12 (1:1) and 10% autologous serum for expansion (44). Passage number is kept to a minimum (45). For spheroid formation, one study described seeding 200,000 cells per well of hydrogel-coated, 96-well plates (46). These wells were possibly concavely tapered (44). After 2 weeks of culture, the spheroids grew to 600-800 μm in diameter and were then used for implantation (47). During 3D culture, the chondrocytes began a process of redifferentiation and secreted an abundance of cartilage-specific matrix. Penicillin and streptomycin was stated not to be used because it slowed cell expansion, delayed spheroid formation, and decreased the expression of chondrogenic markers (48). Spheroids could be fused at 1 week to form larger neotissue depending on the patient’s needs (45, 46), although this strategy does not seem to be used in recent clinical studies. The spheroid outer layer was stated to contain a zone of proliferating and migratory cells that facilitate integration with other spheroids and adjacent native tissue (47, 48). The Chondrosphere® product is available 5-10 weeks after the first surgery (49).

During the operation, Chondrospheres® were suspended in a saline solution and evenly placed with a syringe into the debrided defect. Generally, subchondral bleeding is avoided or the bleeding is stopped before implantation (49). Information on a planned Phase III clinical trial recommends a dose of 10-70 spheroids/cm2 in the defect (50). One study involving 37 patients reported the use of 14-170 spheroids/cm2 (average = 60 spheroids/cm2) in defects ranging from 1-12 cm2 (average = 4.4 cm2) (49). No glue or overlying material was used, as the spheroids naturally adhered to the defect bed within 20 minutes. Rehabilitation involved knee immobilization for 48 h followed by 6 weeks of CPM and partial weightbearing exercises (49).

Since 2004, Chondrosphere® has been used to treat defects of the knee, ankle, shoulder, and hip (47) and, as of 2015, has treated over 7,200 patients in Germany (43). However, few clinical studies have been published. One publication briefly described a prospective, multi-center study (total n=42) in treating patellofemoral lesions 1.5-10 cm2 in size (47). At a 2-year follow-up, Chondrosphere® treatment was reported to improve range of motion, pain levels, and Lysholm scores, while IKDC and WOMAC scores remained unchanged. Second-look arthroscopy of nine patients performed at 3 months was reported to reveal filled defects, excellent integration, and a smooth repair tissue surface (47). In an investigator-initiated trial (n=37), Chondrosphere® treatment was shown to significantly improve patient evaluation scores (IKDC, VAS for pain, Lysholm, Tegner, and SF-36) over baseline values at 1-year follow-up (49). Fast filling of the defect was reported, as indicated by MOCART, although baseline values were not reported. A Phase III trial (n=102) comparing Chondrosphere® to microfracture is estimated to finish September 2017 with 2-year outcome measures (KOOS) and December 2020 with 5-year outcome measures (KOOS, MOCART, arthroscopy with biopsy, Bern, ICRS/IKDC, Lysholm) (50).

3.5. Hyalograft® C (Anika Therapeutics, Bedford, MA)

Hyalograft® C is hyaluronic acid-based scaffold seeded with expanded autologous chondrocytes. The product was developed as early as 1998 by Fidia Advanced Biopolymers (Abano Terme, Italy), which was then acquired by Anika Therapeutics in 2009. As described (51-53), primary chondrocytes were expanded up to P3 in medium consisting of Ham’s F-12, 10% fetal calf serum (FCS), 1% penicillin/streptomycin, 1% L-glutamine, 1 ng/mL TGF-α1 or TGF-β1, 1 ng/mL insulin, 1 ng/mL EGF, and 10 ng/mL bFGF (51, 52). After chondrocyte expansion, 8 million cells in 0.4 mL medium (now containing 50 mg/mL ascorbic acid) were seeded to two 2×2 cm Hyaff®11 scaffolds. The next day, medium was added to submerge the construct. The medium was changed twice a week for 2 weeks before implantation. The Hyaff®11 scaffold has been described as a non-woven, 3D mesh of 20 μm diameter fibers with 10-400 μm pore size and 80% porosity (54). The fibers were composed of hyaluronic acid with 90-100% of its carboxyl groups substituted with benzyl esters (55). Upon esterification, these hydrophobic polymeric chains can undergo aggregation, allowing the material to be processed into various forms including extrusion into microfibers. The Hyalograft® C product has been reported to be available for implantation 6 weeks after the first surgery (56).

Several in vitro studies have characterized various aspects of chondrocyte-seeded Hyaff®11 scaffolds. Two days after cell seeding, 92-96% of initial chondrocytes were reported to have adhered to the scaffold (57). At day 33 post-seeding, cells were evenly distributed over the scaffold surface but appear to only penetrate ~200 μm inwards (57). As early as day 7 of culture, chondrocytes in the scaffold were able to redifferentiate in the 3D environment, as shown by increasing collagen type II expression. Chondrocytes continuously exhibited proliferation within the scaffold up to day 21 (58). Such proliferation may be beneficial in contributing to initial cell infiltration and neocartilage growth but raises concerns for potential overgrowth (53). Collagen I expression was present in cell-seeded Hyaff®11 constructs up to 21 days of culture (58). More recent in vitro studies have shown that use of a perfusion bioreactor can improve cell penetration into Hyaff®11 scaffolds (59, 60). The bioreactor also substantially increased construct size and matrix content (59).

The operation, as previously described (61), involves the use of diameter-adjustable drills to debride the lesion to a predetermined diameter and thickness of 2 mm, as to avoid subchondral bleeding. The same instrument is used to punch out one or multiple circular Hyalograft® C constructs from two 2×2 cm stock constructs to fill the defect. The constructs are press fit into the defect without additional fixation. Rehabilitation involved immobilization for 24 h and CPM from 0-30° until full range after 4 weeks (62). Crutch-assisted, non weight-bearing ambulation was ordered for 6 weeks; touch-down weight-bearing to full weight-bearing was prescribed from weeks 7 to 12. Moderate exercise started at 3-6 months.

Clinical efficacy of Hyalograft®C has been comprehensively reviewed in a European Medicines Agency report (53). From 1999 to 2011, Hyalograft®C have been used in 5348 patients and a total of 28 studies (n=793) have reported clinical results. Hyalograft®C treatment was shown to generally improve patient evaluation scores over baseline and, in some cases, was superior over microfracture treatment. Biopsies taken at various time points showed hyaline tissue in 53%, fibrocartilage in 22%, and mixed cartilage in 25% of patients (n=68). MOCART scoring at 24 months reported complete defect repair and complete integration in 68% and 86% of patients (n=118), respectively. Overall failure rate was found to be 9.3% in 551 patients. Scaffold degradation was said to occur within 10 months in the vast majority of patients. Despite supportive evidence of clinical efficacy, several objections were raised, including quality control and lack of randomization typical of Phase III studies. Commercialization was stopped in 2013.

3.6. Matrix-induced Autologous Chondrocyte Implantation (MACI; Vericel, Cambridge, MA)

MACI was first developed and marketed in 1999 by Verigen AG (Leverkusen, Germany) until its acquisition by Genzyme in 2005, by Sanofi 2011, and then by Vericel Corporation (Cambridge, MA) in 2014. In a European Medicines Agency (EMA) report, which approved the marketing of MACI in the European Union, the product is described as a 14.5 cm2 type I/III collagen membrane (ACI-Maix™; Matricel, Herzogenrath, Germany) seeded with expanded autologous chondrocytes (63). Chondrocytes were described to be passaged to either P2 or P3 in medium consisting of DMEM, 9% FBS, and 45 μg/mL gentamycin. Cells are then seeded to a 4×5 cm ACI-Maix™ scaffold (5.5 cm2 is used for product testing) at a density of 0.5-1 million cells/cm2. Constructs have been reportedly cultured for an additional 3 (64) or 4 (65) days before implantation. The ACI-Maix™ scaffold is derived from decellularized porcine peritoneal tissue and largely consists of collagen and elastin (63). The resulting scaffold has a bilayer structure with a porous side to allow cell infiltration and a non-porous side for cell retention, as shown by scanning electron microscopy (65, 66). The porous side is placed facing the defect bed. Detailed characterization of the scaffold structure could not be found. The approximate dried scaffold thickness has been reported to be 400 μm (65). Histology of the pre-implanted MACI product shows a fairly inhomogeneous infiltration of cells into the scaffold ranging from 10 to 200 μm deep (65, 67, 68). Upon receiving the implant, cells were shown to already exhibit characteristics of redifferentiation, such as rounded cell morphologies and increased collagen II, aggrecan, and S-100 expression (65). The MACI product is available 4-8 weeks after the first surgery.

During the operation, the lesion was debrided without breaching the subchondral bone (69). A foil piece was used to template the defect and the MACI product is cut to size according to the template (70). A thin layer of fibrin glue was used at the base and edges of the defect for fixation (69), although previous studies have used suture fixation (70). Because the scaffold is thinner than the defect thickness, it resides depressed relative to adjacent cartilage. Rehabilitation was based on a 4-phase program (71) and consisted of 1) restricted CPM and weightbearing (0-6 weeks), 2) gradual progress toward full range of motion and full weightbearing exercises (7-12 weeks), 3) light exercises (3-6 months), and 4) normal activity (6-12 months) (69).

Several studies have shown clinical efficacy of MACI. In a randomized, open-labeled, multi-center Phase III trial (n=144) (69), where only lesions > 3 cm2 were treated, MACI scored high in KOOS pain and function than microfracture at a 2-year follow up. In the MACI group, no cases were identified as treatment failures. Another study (n=60) showed that several outcome measures (Lysholm, Tegner, and patient and surgeon ICRS scores) improved significantly with MACI than with microfracture at 2 years (72). In a study comparing MACI to C-ACI (i.e., ACI with a collagen sponge, n=91), both groups showed improved clinical results but were not different from one another at 1-year follow-up (73). Interestingly, 4 of 11 (36%) MACI biopsies showed fibrocartilage, as also supported by other studies (74, 75), indicating a potential need for improvement. In a 5-year follow-up study (n=21) with only MACI-treated patients, 19 patients exhibited improved clinical scores and two exhibited graft failure; 76% of grafts had normal filling, as assessed by MRI. Other long-term clinical studies found similar results (76-78). Although MACI has gained EU market approval, its facilities closed in Europe and the technology was sold to Vericel. Market approval in the U.S. remains to be determined.

3.7. NeoCart® (Histogenics, Waltham, MA)

NeoCart® is comprised of a honeycomb bovine type I collagen scaffold seeded with expanded autologous chondrocytes. The company website describes 2-3 weeks are needed for cell isolation, expansion, and seeding of the 3D scaffold; 1 week culture is needed in a biomimetic bioreactor; and 2-4 weeks are needed for static culture before implantation (79). The bioreactor involves hydrostatic pressure, perfusion, and hypoxia as biomimetic stimuli (80). Data presented in a company patent showed that cyclic hydrostatic pressure (0.5 MPa, 0.5 Hz) applied during the first 6 days of culture increased S-GAG production (81). Culture in hypoxia (2% O2) also improved GAG production, while perfusion (5 μL/min) was said to increase cell proliferation (81). To create the construct, the patent mentions first suspending the cells in a thermoreversible collagen gel at a concentration of 5-10×106 cells/mL before seeding it to a freeze-dried, type I collagen sponge (81). The construct was reported to be available, on average, 67 days after the first surgery (82).

During the operation, the defect is debrided and bleeding avoided (82). The construct is cut to size and fixed into the defect with a collagen/PEG-based adhesive (CT-3 glue; Histogenics) applied to the underlying and adjacent tissue. The CT-3 glue, stated to be 10× stronger than fibrin glue (83), was found to be the preferred strategy of fixation after two failed surgeries that involved the use of suture fixation (82). Rehabilitation followed the standard protocol for microfracture: toe-touch weightbearing for 6 weeks, a CPM regimen, and restriction of sports activities for 6 months (82).

A Phase I and Phase II study have shown beneficial results of NeoCart®. In the Phase I trial (n=8), NeoCart® implantation significantly improved pain scores and range of motion over baseline values at 24 months (82). Five patients showed improvement in all categories; six patients showed good fill (>66%); and four patients demonstrated an organized collagen matrix characteristic of native cartilage, as indicated by MRI. In the Phase II trial, NeoCart® (n=21) significantly improved KOOS, IKDC, and VAS scores over microfracture (n=9) at 24 months (80). Advantages of NeoCart® were recorded as early as six months. In addition, a greater percentage of patients treated with NeoCart® (76%) were considered “therapeutic responders” than those treated with microfracture (22%) at 12 months. A randomized Phase III trial (n=245) comparing NeoCart® to microfracture is estimated to finish July 2017 with 1-year outcome measures (KOOS, IKDC, and MRI) (84).

3.8. NOVOCART® 3D (TETEC, Melsungen, Germany)

NOVOCART® 3D consists of a biphasic type I collagen scaffold seeded with autologous chondrocytes. Isolated chondrocytes are expanded in monolayer in the presence of homologous serum until P1 (67). No antibiotics of antimycotics are used (85). One layer of the bilayer scaffold is a dense, cell-impermeable membrane derived from bovine pericardium (86). This membrane is lyophilized with a collagen sponge layer, allowing the two layers to be firmly connected. A company patent describes the collagen sponge layer as consisting of type I collagen and chondroitin sulfate with pores 130 to 200 μm in diameter arranged in columns (87). In one study, the scaffold is seeded with 1.45 million cells/cm2 and cultured for 2 days (67). The patent indicates the possible use of a solution of collagen VI as a cell-carrier prior to seeding (87). Histology of the pre-implanted construct shows dense, homogeneous cell distribution in the porous layer and devoid of cells in the dense layer (67). The product can be manufactured and delivered in 3 weeks (85).

The construct, implanted via miniarthrotomy, was attached to the healthy cartilage using absorbable Vicryl sutures or pins when there was no healthy cartilage adjacent to the implant (88, 89). Rehabilitation followed a standard program (90) involving CPM, toe-touch weightbearing for 4 weeks, and full weightbearing by 8 weeks (91).

Over 6,000 patients in Europe have undergone successful treatment with NOVOCART® 3D since 2003 (92). A prospective clinical study (n=23) showed that NOVOCART® 3D treatment led to increased IKDC, Tegner, Noyes, and MOCART scores over baseline at 2-year follow-up (91). Defect filling was described as complete or “slightly incomplete” in most cases. Other clinical studies have also shown increased IKDC, VAS, and MOCART scores over baseline at 1- or 2-year follow-up (86, 93, 94). NOVOCART® 3D coupled with a cancellous bone autograft has been used to treat osteochondritis dissecans; after 2- to 5-year follow-up, patients (n=26) exhibited improved Lysholm, Cincinnati, and MOCART scores (95). However, some of these studies have reported graft hypertrophy in 20-27% of patients at 2-years (91, 93, 94), indicating a need for long-term evaluation. A Phase III trial (n=233) comparing NOVOCART® 3D to microfracture is estimated to finish in July 2018 with 2-year outcome measures (KOOS pain and function); the estimated study completion date is 2021 (96). A non-interventional study (n=80) to evaluate the safety and efficacy of NOVOCART® is estimated to finish in September 2019 with 3-year outcome measures (IKDC, number of adverse events) (97). Finally, another Phase III trial (n=261) comparing NOVOCART® 3D plus and microfracture is estimated to finish in June 2019 with 5-year outcome measures (IKDC, KOOS, MOCART, SF-36 scores, and others) (92).

3.9. RevaFlex™/DeNovo® ET (Isto Technologies, St. Louis, MO)

DeNovo® ET has been renamed RevaFlex™ since Isto Technologies obtained full control of its development in 2013. RevaFlex™ is a scaffold-free neocartilage disc composed of allogeneic juvenile chondrocytes and their associated matrix. Juvenile chondrocytes have been shown to have better proliferation and matrix secretion capabilities than adult chondrocytes (98, 99). Although current production methods are unknown, published studies describe a method that involves expansion of chondrocytes and growth of a 3D neocartilage construct in a single step (98, 100). Primary chondrocytes were seeded onto an unknown surface at 500,000-1,000,000 cells/cm2 and cultured for 44-63 days to form a 3D neocartilage construct (98). Whether cell expansion occurs after the initial seeding is unknown. As a culture medium, HL-1 or a proprietary, chemically-defined medium, displaying growth characteristics similar to HL-1, was used. The medium was supplemented with 50 μg/mL ascorbate after 3 days. An earlier study described use of 10% serum that was gradually reduced to 0% (10% at day 3 to 5% at day 7 and to less than 2% at day 10) (100). Initial serum concentrations were said to be necessary for sufficient cell adhesion, while the transition to serum-free medium significantly increased sGAG and collagen type II production. Construct growth and dimensions were also described in this study. At day 90 of culture, construct thickness ranged from 0.75 to 1.5 mm. At an unspecified time during the process, the neocartilage discs were transferred to larger diameter culture plates as lateral growth continuously occurred – 150 day constructs were 50% wider than 90 day constructs. In another study, the mechanical integrity was qualitatively described as robust enough to be picked up by forceps at day 20, to hold sutures at day 30, and be implanted at day 40 (101). Because the cell source is allogeneic, only one surgery is required and the construct could theoretically be available at any time.

During the operation, the defect site is first debrided and bleeding avoided or hemostasis achieved with fibrin glue (102). A foil piece is used to create a template of the defect. The RevaFlex™ construct, 2.2-2.5 cm in diameter, is cut to size using the template as a guide and fixed into the defect with a thin layer of fibrin glue. It is recommended that the construct sit 0.5 mm below the surface relative to the surrounding native tissue. A recommended post-operative regimen consists of 4-6 weeks of protected or non-weight bearing with continuous passive motion and rehabilitative exercises.

Several animal studies have supported the ability of this construct to treat cartilage lesions. In an ovine model study, allogeneic neocartilage constructs (2.5 cm in diameter, 0.2-0.3 mm thick, cultured for 107-130 days) were cut to 0.5 cm diameter discs and implanted into partial thickness defects (0.55 cm diameter and 400-500 μm deep) in the femoral condyle using resorbable sutures as fixation (103). At 8 and 12 weeks, 70-80% of the animals (n=13) exhibited graft survival. Cases of failure were attributed to problems in post-operative leg immobilization. Of the survived constructs, histological analysis showed 70-100% cell viability in the neocartilage, partial filling, fair integration, and a layer of fibrous tissue covering the neocartilage construct. In a longer-term caprine model study, human neocartilage constructs were implanted into 6 mm condylar and 4 mm trochlear, full-thickness defects in each animal (n=8, two defects per animal) using fibrin glue (Tisseel; Baxter, Deerfield, IL) fixation (104). After 6 weeks immobilization followed by 18 weeks uninhibited movement, only 50% of the constructs survived, which was attributed to the difficulty of maintaining leg immobilization. In that study, the grafts were xenogeneic. Xenogeneic cartilage constructs have been previously shown to elicit a significant immune reaction (105), although such was not described here. The majority of the eight surviving grafts were described as completely filling the defect, having a smooth surface, and exhibiting partial integration.

In a Phase I/II study, 12 patients with 1-5 cm2 femoral or trochlear lesions were treated with RevaFlex™ (102). At 1 year, a second-look arthroscopy revealed the repair as normal or nearly normal in 67% (6/9) and “level” with surrounding tissue in 78% (7/9) of patients. The remaining 22% (2/9) had repair cartilage 75% of the lesion depth. Patient-reported evaluations and histology of biopsies were conducted but not reported. In all studies, immunological and histological analysis showed no adverse immune response, supporting in vitro findings that allogeneic chondrocytes may be immune-privileged (106). A Phase III trial (n=225) comparing RevaFlex™ to microfracture is estimated to finish July 2019 with 5-year outcome measures (KOOS, IKDC, various questionnaires) (107).

3.10. CaReS® (Arthro Kinetics Biotechnology, Krems, Austria)

The Cartilage Regeneration System (CaReS®) implant consists of a type I collagen hydrogel embedded with primary autologous chondrocytes. To form the constructs, isolated primary chondrocytes were suspended in 2× buffer solution, mixed with a rat tail-derived type I collagen solution (6 mg/mL) in 0.1% acetic acid at a 1:1 volume ratio, and gelled at 37°C (108, 109). At physiological pH and temperature, acid-extracted collagen solutions are able to form a hydrogel (110). The cell density used in CaReS® was unspecified and may be patient-dependent. Preclinical studies have indicated the use of 20,000 cells/mL (108, 111). A cell-free version of this collagen gel is sold as CaReS®-1S. Constructs formed are 3.4 cm in diameter and 6-8 mm thick (109), although the company website indicates any size can be made. Constructs are approximately twice the thickness of human cartilage, as about 50% of its water content can be lost during the implantation procedure (109). Other publications by the same authors have used a compressed collagen gel for increased mechanical stability (112, 113); whether this is used in the product is unknown. After gelation, constructs are cultured in vitro for 10-13 days in the presence of autologous serum and are then ready for implantation (109).

Although CaReS® has a relatively low cell density compared to other products, the high cellularity needed for sufficient neotissue formation can be achieved through in vivo cell proliferation and migration. Primary chondrocytes were shown to expand a factor of 33 in CaReS® gels after 6 weeks of in vitro culture (111). Although in this study evidence of chondrocyte dedifferentiation was observed, the chondrocytes maintained their differentiated state when implanted in vivo. On the other hand, P2 chondrocytes did not exhibit such chondrogenic phenotype in vivo, justifying the use of primary cells in the CaReS® product. Some evidence of cell migration from the host tissue into the collagen gel has also been shown in several in vivo animal models (108, 114, 115). However, the origin of these cells and whether they contribute to the formation of hyaline repair tissue remain unclear.

During the operation, the cartilage defect is first debrided to the subchondral bone (109). The CaReS® constructs were prepared using a punch 1 mm wider than the defect and molded into the defect with blunt forceps. Fixation was achieved by application of fibrin glue to the defect base. Rehabilitation involves immobilization for 48 hours, continuous passive motion for 6 weeks, and partial weight bearing up to 12 weeks.

A prospective, multi-center study (n=116) of patients treated with CaReS® from 2003-2008 supports its safety and clinical efficacy (109). Mean follow-up time was 30 months and mean defect size was 5.4 cm2. IKDC, global pain, SF-36, and IKDC functional knee score significantly increased from baseline with treatment. Total adverse events were low and fell below those seen in ACI. Unfortunately, second-look arthroscopy, MRI analysis, or biopsies were not reported, giving little information on repair tissue fill and quality. However, histological analysis of these constructs at 1 year in a minipig model indicates that they promote hyaline cartilage formation (108). When compared to microfracture, a small retrospective study (n=20) indicated no differences between the two treatment options (116). CaReS® has been used in select European countries and is also approved in Iran, Turkey, and China.

3.11. INSTRUCT (CellCoTec, Bilthoven, Netherlands)

INSTRUCT is a poly(ethylene oxide-terephtalate)/poly(butylene terephtalate) (PEOT/PBT) scaffold seeded with primary autologous chondrocytes and bone marrow cells. Although details of the scaffold are unknown, one study described the use of a Bioplotter device (Envisiontec, Germany) to create a porous lattice structure with approximately 170 μm diameter fibers, 200 μm pore size, and 56% porosity (117). The softer PEOT functions to support the chondrogenic phenotype, while the PBT increases material stiffness (118). The scaffolds were said to be “mechanically functional” (119), with one study showing a “compressive dynamic stiffness” of 10 MPa (117). Scaffold degradation occurs via hydrolysis of ester groups and oxidation and scaffolds are said to be resorbed within 12 months (119). Cell seeding is conducted at point-of-care. The patient’s cartilage biopsy and bone marrow aspirate are inserted into a semi-automated machine, termed the INSTRUCT cell processor, that isolates the chondrocytes, mixes them with marrow cells, adds fibronectin, and seeds the cell mixture to the scaffolds (120). Fibronectin was said to facilitate cell aggregation and enhance matrix formation (117). The cell seeding density is unknown and may be patient-dependent. A density of 60 million cells/mL (i.e., 3 million cells seeded per 0.4 cm diameter, 4 mm thick scaffolds) has been used in in vitro (117, 118). The cell processor is able to produce a usable implant within 1 hour (120). Details on the surgical procedure could not be found.

Different scaffold compositions and structures have been explored to determine the parameters that best support neocartilage formation. PEOT/PBT 2D films with a higher PEOT mass ratio were found to support a rounded chondrocyte morphology, no proliferation, and higher collagen II:collagen I gene expression; films with a higher PBT mass ratio supported a flat cell morphology, cell adhesion, and proliferation (121, 122). Similarly, chondrocytes cultured in 3D scaffolds with the composition 1000PEG-70:30 (PEG molecular weight = 1000 g/mol; 70% PEOT and 30% PBT by mass) secreted more sulfated glycosaminoglycans (GAGs) than those in 300PEG-55:45 scaffolds after 4 weeks of in vitro culture (117). Different scaffold structures have also been compared. A 3D printed scaffold with a lattice structure supported more neocartilage growth than in a salt-leached, porous scaffold, most likely due to the former’s pores being larger and more accessible (123). When comparing two 3D printed scaffolds of different porosities, the scaffolds with lower porosity (56%) supported more GAG production than scaffolds with higher porosity (74%) (these less porous scaffolds were said to exhibit mechanical properties matching those of native tissue) (117).

Neocartilage formation within these scaffolds has been assessed. SEM images of 1 day-old constructs show chondrocytes largely aggregated within the pores with few cells adhered to the scaffold (117). After 4 weeks of in vitro culture, neocartilage completely filled the pore space. After 4 weeks subcutaneous implantation in nude mice, the neotissue formed was described to be largely hyaline. However, after 3 months in vivo in a rabbit osteochondral defect, the scaffold (0.4 cm diameter, 4 mm thick) formed repair tissue described as fibrous tissue, incompletely differentiated mesenchyme, and cartilage (123). Bleeding in the osteochondral model may have led to fibrous tissue formation. Acellular salt-leached, porous scaffolds in the same osteochondral model was shown to support a top layer of hyaline neocartilage formation, indicating the scaffold’s potential chondroinductive properties (124).

Scaffold degradation occurs through hydrolysis and oxidation. In vitro hydrolysis experiments show more rapid degradation of scaffolds with a higher PEOT content (125). When implanted subcutaneously in mini-pigs for 52 weeks, 300PEG-55:45 scaffolds remained largely intact, while 2000PEG-80:20 scaffolds largely fragmented to < 1 μm particles (122). Molecular weight of polymer chains decreased 34% and 90%, respectively. In the latter, macrophages dominated the cellular response, but cell viability in the region was reportedly high. After 3 months in a rabbit osteochondral or mouse subcutaneous model, 300PEG-55:45 and 1000PEG-70:30 scaffolds seemed to exhibit minimal degradation (117, 123). Ideally, long-term analysis of PEOT/PBT degradation, specifically in an ectopic defect, would better demonstrate its degradation profile and biocompatibility. The company website states scaffolds resorb within 12 months (119).

A Phase II trial (n=40), single group assignment, open-label) was completed June 2014 with 2-year outcome measures (KOOS, IKDC, VAS, histopathology, and MRI) (126). In the study, patients showed improvement in VAS, IKDC, and all KOOS scores over baseline at 1-year follow-up (127). Biopsies taken at the 1 year showed 72% (21/29) of patients with hyaline cartilage and 97% (28/29) with either fibrocartilage or hyaline cartilage. Full publication of the results or additional clinical trials could not be found.

4. Tissue engineering strategies used in current clinical products

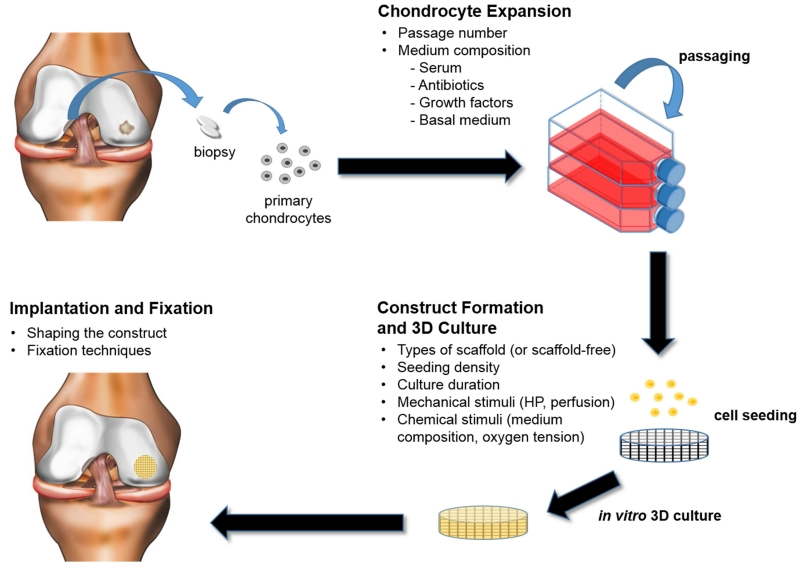

This section of the review compares the different tissue engineering strategies used during each stage of the tissue engineering paradigm. The paradigm consists of 1) identifying a cell source (i.e., primary or passaged articular chondrocytes), 2) forming the construct either using scaffold or scaffold-free approaches, and 3) culturing the construct in vitro, where biomimetic stimuli can be further applied, before implantation (Figure 1). Construct maturation, implantation, fixation, and rehabilitation are also included in this section. For each topic, advantages and disadvantages of different strategies are discussed, current challenges identified, and future directions suggested.

Figure 1.

The classical tissue engineering paradigm used for the fabrication of the reviewed cartilage products. Various factors can be manipulated in each stage, as listed.

Any comparisons made should not be construed to advocate one product over another. Because there is probably proprietary information unknown to us, the comparisons below may not reflect fully the final products. The ultimate aim of this section is to provide insights to clinically translatable strategies for tissue engineering articular cartilage.

4.1. Chondrocyte expansion

Most products involve a chondrocyte expansion stage, except for CaReS® and INSTRUCT which use primary chondrocytes. To obtain sufficient cell numbers for therapy, 200-300 mg autologous biopsies from less loaded regions of the knee are first digested to yield primary chondrocytes. As human articular cartilage contains 1000-8000 cells/mg tissue (128, 129), a biopsy can yield 0.2-2.4 million cells. Seeding with 0.5-5 million cells/cm2 in lesions 1-12 cm2 in size would require 0.5-60 million cells. Assuming that the cell expansion factor after each passage is four, although this is highly dependent on the initial seeding density, then primary chondrocytes need to be passaged one to four times to reach sufficient numbers.

A caveat of chondrocyte expansion is the rapid loss of the chondrogenic phenotype. To mitigate chondrocyte dedifferentiation, one can minimize the passage number (or cell expansion factor) or optimize the expansion medium components to best maintain the chondrogenic phenotype (e.g., serum, antibiotics, and growth factors). Table 4 lists the expansion medium composition used in the reviewed products. How these factors affect the chondrocyte phenotype and ultimately neocartilage formation is described next.

Table 4.

Cell expansion medium composition (blank entries indicate the information was not available to the authors). The last column represents additional supplements that were added to the existing expansion medium to formulate the medium used for 3D culture. Cell passage numbers are indicated in Table 1.

| Product | Base Medium | Serum | Antibiotics | Growth Factors | Ascorbate | Other Additives |

3D Culture |

|---|---|---|---|---|---|---|---|

| Biocart™II | Autologous serum | FGF-2 variant (10 ng/mL) |

|||||

| Bioseed-C | Autologous serum | ||||||

| Cartipatch® | DMEM/Ham’s F-12 (1:1) |

10% autologous serum |

Gentamycin fungizone (discontinued after P1 |

50 μg/mL | |||

| Chondrosphere® | DMEM/Ham’s F-12 (1:1) |

Autologous serum | None | None | |||

| Hyalograft® C | Ham’s F-12 | 10% FCS | Penicillin streptomycin |

TGF-B1 (1ng/mL), FGF-2 (5ng/mL), EGF (1ng/mL) |

1 ng/mL insulin 1% L-glutamine |

+ 50 mg/mL ascorbic acid |

|

| MACI | DMEM | 9% FBS | Gentamycin | ||||

| NeoCart® | |||||||

| NOVOCART® 3D | Allogeneic serum | None | |||||

| RevaFlex™ | HL-1 or similar | 10% serum to serum-free |

Yes | 50 μg/mL |

4.1.1. Chondrocyte passage number (or cell expansion factor)

Of the reviewed products, few details on the passage number and no information on the cell expansion factor can be found. Passage number refers to the number of times chondrocytes are serially passaged in monolayer. The cell expansion factor is calculated by dividing the final cell yield by the initial number of primary chondrocytes seeded for expansion. An important note is that cell expansion factor does not correlate with passage number. Cartipatch®, Hyalograft® C, and MACI indicate use up to P3 cells, while NOVOCART® 3D indicates use of only P1 cells. Unfortunately, the other products lack this description. Nevertheless, given the calculations above, use of P2 and P3 chondrocytes can be generally inferred for most products, with infrequent use of P1 and P4 chondrocytes. Whether passage number in these ranges can affect the quality of neocartilage formation is discussed below.

The hallmarks of chondrocyte dedifferentiation include a progression from rounded to fibroblastic cell morphologies, an increase in cell size, and decreased secretion of cartilage-specific matrix (130, 131). Microarray analysis comparing P0 and P2 chondrocytes shows changes in 137 genes (132). Changes generally follow a downregulation of chondrogenic genes including SZP, BMP-2, TGF-β1, FGFR3, COMP, aggrecan, collagen II, collagen XI, collagen IX, and SOX 9 and an upregulation of fibroblastic or mesenchymal genes including collagen I, collagen X, and collagen III, tenascin, and versican (133-142). These changes occur rapidly within the first passage (133, 135, 137, 138), with one study showing changes within 4 days (135). Gene expression changes from P0 to P1 also appear the largest among these studies. From P1 to P4, the incremental changes between each passage are less pronounced, but a decreasing trend in chondrogenic gene expression exists. When comparing P1 and P4 chondrocytes, large differences can be found. However, when comparing P2 and P3 chondrocytes, significant differences are less commonly found. Nevertheless, these results indicate that cells of each passage possess a different gene expression profile. Whether these differences are carried over to protein synthesis and, thus, affect neocartilage formation is discussed below.

Chondrocyte redifferentiation can be induced by prolonged 3D culture (e.g., pellet culture, alginate encapsulation, suspension culture, culture within a scaffold, etc.), where chondrocytes largely cease proliferating (143), change gene expression that is generally conducive to redifferentiation, and secrete cartilage-specific matrix. Upon 3D culture, chondrocytes of different passage numbers in the low range (approximately P1 to P4) have been shown to upregulate chondrogenic genes to similar levels (137, 144-147). Therefore, among the reviewed products, the use of different passage numbers seems to be of little consequence in affecting neocartilage formation. On the other hand, high-passage chondrocytes (> P4) have been shown to lose their ability to partially or completely redifferentiate (133, 144, 146, 148, 149). However, defining this critical passage number is difficult because of several confounding factors. For one, P4 cells from one study most likely have undergone a significantly different cell expansion number than P4 cells from another study, making the passage number inadequate in expressing how many times the cells have divided. Furthermore, differences in the cell source, such as age (98, 128) and the use of exogenous stimuli (145, 150), during expansion can affect chondrocyte dedifferentiation and redifferentiation. Therefore, comparisons among studies are difficult and one cannot assume use of P1 or P4 chondrocytes will lead to the same clinical outcome. Therefore, it should be critical to report both the passage number, as well as the cell expansion factor. Finally, ideally, authors of clinical studies should acquire the cell expansion factor of each graft from the manufacturer to determine potential correlations with clinical outcome, such as is sometimes done with lesion size and patient age.

4.1.2. Expansion medium compositions

The expansion medium compositions used in the reviewed products remain largely proprietary, though some information can be gleaned from early studies. Known differences among the media used include the use of serum, antibiotics, growth factors, basal medium, and other supplements.

4.1.2.1. Serum

Without additional growth factors, serum is necessary to induce chondrocyte proliferation in monolayers (151, 152). MACI and Hyalograft® C use fetal bovine serum (FBS) and NOVOCART® 3D uses allogeneic serum, while the majority use autologous serum – all typically at 10% (v/v). Only RevaFlex™ uses a largely serum-free medium. Despite the majority of products using serum for cell expansion, there is a large body of literature supporting the use of serum-free media. One disadvantage of serum is that its composition is source-dependent and its use may confound product quality. FBS batch-to-batch composition is potentially more consistent than the serum composition among individual patients. On the other hand, the use of autologous serum can eliminate risk of disease transmission. Secondly, serum may adversely affect the cell’s chondrogenic potential. As articular cartilage is non-vascularized, a serum-free environment may more closely mimic in vivo conditions. Early studies have shown serum to prevent chondrogenesis in limb buds during development (153, 154). Currently, use of serum-free medium is standard for culturing chondrocytes in 3D (e.g., pellets, hydrogels, suspension culture, etc.), as supported by studies showing more hyaline-like matrix production in serum-free 3D cultures (155-157).

Many studies have demonstrated the feasibility of expanding chondrocytes in serum-free medium. Such a medium is supplemented with growth factors (e.g., FGF2, PDGF-BB, TGF-β1, IGF-1, BMP-2, EGF etc.) and other additives (e.g., ITS+ and Ham’s F-12 medium) to promote cell growth and proliferation (158-160). Matrix-coated culture flasks have also been used to promote cell adhesion and provide chondroinductive cues (161, 162).

Whether use of a serum-free expansion medium is clinically beneficial remains unclear. Chondrocyte expansion in serum-free medium promotes chondrogenic gene expression, such as SOX-9, as assessed in the cells immediately after monolayer culture (155, 160, 163). When chondrocytes were expanded with or without serum and then cultured in 3D (e.g., pellets, hydrogels, suspension cultures, etc.) in serum-free medium, the latter group expressed enhanced chondrogenic markers (160, 162, 164) and formed neocartilage with higher compressive properties (165). However, other studies have shown no difference in the type II collagen (165) and GAG (160) content of the neocartilage formed by chondrocytes expanded with or without serum. The most compelling evidence that serum may be an insignificant factor comes from a clinical study which reported that presence or absence of serum during chondrocyte expansion did not affect the clinical outcome in patients treated with a MACI-like graft (166). Therefore, although several studies have indicated a beneficial effect of using a serum-free medium for expansion, further studies may need to justify this switch.

4.1.2.2. Antibiotics and antimycotics

Chondrosphere® and NOVOCART® 3D do not use any antibiotics or antimycotics during production, while most other products have indicated use of these agents. A Cartipatch® study mentioned discontinuing such agents after P1 (39). In a study related to Chondrosphere®, antibiotics were mentioned to inhibit neocartilage matrix synthesis (48). However, no other supporting studies could be found. It is known that antibiotics and antimycotics can induce global changes in the proteome (167). In addition, antibiotics have been shown to inhibit proliferation of musculoskeletal cells in vitro (168). Furthermore, antibiotics are known to reduce the proliferation and differentiation capacity of embryonic stem cells (169). Some researchers have argued that the use of antimicrobials can potentially hide latent infections (170). However, mycoplasma tests are routinely conducted for each cartilage product. Finally, not using antibiotics can simplify safety concerns for allergic patients. Whether these benefits outweigh the risk of contamination remains open to debate.

4.1.2.3. Growth factors during 2D expansion

During expansion, exogenous supplementation of growth factors aims to either increase cell proliferation, especially in serum-free medium, or enhance the chondrogenic phenotype. The former is beneficial in minimizing construct production times, while the latter may allow the formation of more functional neocartilage. Various growth factors and their effects on chondrocytes have been thoroughly reviewed elsewhere (171, 172). Here, select agents are briefly described. Of the reviewed products, FGF-2 variant (10 ng/mL) has been used in BioCart™II, while FGF-2 (10 ng/mL), EGF (1 ng/mL), and TGF-β1 (1 ng/mL) have been used in Hyalograft® C. FGF-2 has been generally used to promote cell proliferation and stem cell renewal (173). For chondrocyte expansion, FGF-2 has not only been shown to enhance proliferation but also maintain the chondrogenic phenotype (150, 174, 175). Specifically, FGF-2-expanded chondrocytes were more differentiated immediately after monolayer expansion and formed neocartilage with higher matrix content. EGF has also been shown to enhance chondrocyte proliferation in monolayer (152, 176). Although EGF is generally known to suppress chondrogenic differentiation and matrix secretion, it may also have anabolic effects (177). TGF-β1 can also act as a mitogen for chondrocytes (151, 152, 176, 178). TGF-β1 plays an important role in cartilage development, is extensively used in the chondrodifferentiation of stem cells (179, 180), and promotes matrix synthesis in 3D-cultured chondrocytes (148, 181). Use of TGF-β1 may not always be beneficial, as addition of anti-TGFβ antibody during chondrocyte expansion led to enhanced chondrogenesis in subsequent pellet cultures (182). Other pro-mitogenic or pro-chondrogenic growth factors (e.g., IGF-1, PDGF-BB, TGF-β2, TGF-β3, BMP-2, BMP-7, BMP-14, etc.) may also have beneficial effects during monolayer expansion. Synergism between two or more growth factors may be key in finding the optimal expansion medium. For example, a cocktail of TGF-β1, FGF-2, and PDGF-BB (TFP) has been shown to promote chondrocyte proliferation and the chondrogenic phenotype (128, 165, 183, 184). TFP-expanded chondrocytes formed neocartilage with higher GAG and collagen content, as well as compressive and tensile properties than those formed by FGF-2-expanded cells (165). Finding optimal growth factor cocktails for chondrocyte expansion remains a relevant and ongoing field of research. However, the expanded use of growth factors in tissue engineering of clinically relevant products will necessitate overcoming additional regulatory hurdles.

4.1.2.4. Basal medium and other additives

Of the reviewed products, the basal media that have been used include Dulbecco’s Modified Eagle Medium (DMEM), Ham’s F-12, HL-1, and DMEM/Ham’s F-12 (1:1) mixtures. DMEM is a standard cell culture medium containing amino acids, salts, vitamins, and glucose. Compared to DMEM, Ham’s F-12 contains additional supplements including B vitamins, linoleic and lipoic acid, copper, zinc, hypoxanthine, putrescine, and thymidine. HL-1 medium is composed of a modified DMEM/Ham’s F-12 base with additional supplements including insulin, transferrin, selenium, testosterone, ethanolamine, various fatty acids, and proprietary stabilizing proteins. These nutrient components play important cellular roles and some are known to specifically affect chondrocyte biology and neocartilage matrix formation, such as copper (185) and putrescine (186, 187). Insulin-transferrin-selenium (ITS) is often added to reduced-serum or serum-free medium to support cell culture. ITS has been shown to mitigate dedifferentiation and lead to the formation of neocartilage with greater matrix content (188, 189). One study showed that insulin, rather than transferrin or selenium, exerted a significant effect on chondrocyte matrix metabolism (190). Glucose concentration has been shown to significantly affect the chondrogenic potential of expanded chondrocytes, with lower glucose being more beneficial (191). Unfortunately, glucose or pyruvate concentrations in the expansion medium are rarely specified in literature. No study could be found that directly compared the effects of different basal media on chondrocyte expansion and neocartilage formation; such a study would be informative.

4.2. Construct formation and 3D culture

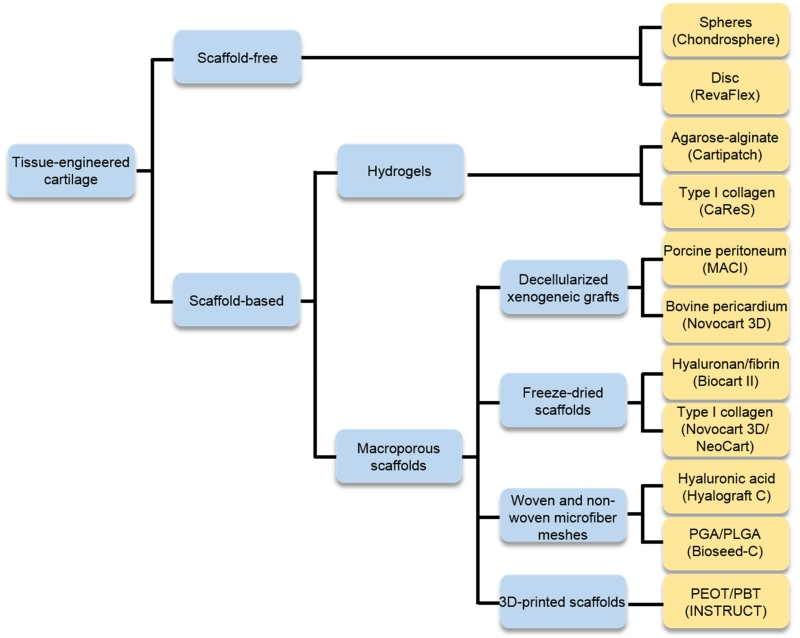

Integration of passaged articular chondrocytes into a 3D construct can be achieved through a scaffold-based or scaffold-free approach (Figure 2). Advantages and disadvantages of each will be outlined. For products using a scaffold-based approach, the different types of scaffolds used and their properties will be described. Because neocartilage properties are largely influenced by the cells, the cell seeding density and cell distribution in these products will also be briefly discussed. Finally, the tissue engineering strategies used during 3D culture will be described.

Figure 2.

The reviewed products use either scaffold-free or scaffold-based approaches. For the scaffold-based products, the various types of scaffolds are listed. NeoCart® and Bioseed®-C may use a collagen and fibrin gel, respectively, as a cell carrier.

4.2.1. Scaffold-free constructs

Chondrosphere® and RevaFlex™ are both scaffold-free constructs. The versatility and advantages of a scaffold-free approach have been recently reviewed (192, 193). In general, scaffold-free, engineered cartilage constructs can be fabricated by culturing chondrocytes at high density in wells or molds. Over hours, the cells adhere to one another and, over weeks, secrete an abundance of cartilage-specific matrix, subsequently forming solid neotissues. Initial chondrocyte self-aggregation is mediated by cell-matrix (e.g., α10β1-collagen II (194)) and cell-cell (e.g., cadherins (195)) interactions. Once aggregated, the cells can continue to secrete cartilage-specific matrix over many weeks. Scaffold-free neocartilage formed by primary bovine articular chondrocytes steadily increased in GAG and collagen content over 8 weeks (195). By week 1, these constructs can be gently handled (195) and by week 4, under a specific regimen of chemical stimulation, they can reach biomechanical properties on par with native juvenile cartilage (196).

There are several advantages of a scaffold-free over a scaffold-based approach. For one, matrix formation is not hindered by potentially harmful surface chemistries and degradation products of a scaffold; instead, it may more closely follow mechanisms similar to cartilage development (i.e., via mesenchymal condensation). Secondly, the construct is completely biological, thus potentially having fewer biocompatibility issues. Finally, the high cellularity may help integration.

In the case of Chondrosphere®, the authors noted spheres were designed to be less than 800 μm to avoid the 800-1000 μm diffusion limit seen in tumor spheroid cultures (48). However, this limit is probably also dependent on cell type, cell density, and tissue permeability, as 1.5-2 mm thick neocartilage discs can be achieved without necrotic centers (100, 197).

In the case of Chondrosphere®, the scaffold-free spheroids can adhere to, conform to, and fill the defect over time. The high cellularity and immature matrix of the 2-week-old neocartilage may contribute to these properties. For example, complete filling and integration within the defect has been reported, although the spheroids cover only a fraction of the defect area (47). In an in vitro explant model, histological observations show spheroid adherence to human cartilage explants within 45 minutes (48). After 3 weeks, spheroids flattened on the explant, presumably due to cell migration and matrix secretion. When spheroids were used to fill a defect in a human cartilage explant and then subcutaneously implanted in SCID mice (46), the spheroids were observed to continuously secrete matrix from 4-24 weeks, adapt to the shape of the defect, and integrate with adjacent native tissue. In a pig model study, Chondrospheres® were described to regenerate tibiofemoral, full-thickness defect sites with no visible gaps, suggesting good integration (47). Finally, a second-look arthroscopy performed on nine patients 3 months after Chondrosphere® implantation showed good filling of the defect with smooth, hyaline-like tissue and no visible gaps at the defect boundary (47). These studies not only provide preliminary evidence that Chondrospheres® are able to fill and integrate with the defect site over time, but also that scaffold-free neocartilage can be a responsive tissue that can grow in size, conform to the defect site, and integrate with adjacent native cartilage.

Although also a scaffold-free construct, RevaFlex™ differs significantly from Chondrosphere®. RevaFlex™ or similar constructs were grown for months in vitro and appeared relatively stiff (100). Unlike Chondrosphere®, these constructs did not naturally adhere to the defect and required fixation with sutures or glue. Initial fixation seemed a significant issue, as in vivo animal model studies required extensive leg immobilization and graft failure (20-50%) was attributed to incomplete immobilization (103, 104). On the other hand, advantages of implanting a more mature neocartilage construct are that construct growth can be consistently controlled and manipulated to enhance certain properties. In addition, more mature neocartilage grafts have higher initial mechanical properties, allowing for potentially faster rehabilitation. Histologically, these constructs (100) resemble native tissue more closely than many other products, affirming their potential as promising tissue engineered cartilage grafts.

4.2.2. Scaffold-based constructs

In a scaffold-based approach, expanded chondrocytes are seeded into or onto a porous scaffold, cultured in vitro (0-35 days), and then implanted. Depending on the scaffold material, the seeded chondrocytes can either adhere to the scaffold, aggregate within the pores, or exhibit both behaviors. These chondrocytes then form neocartilage in the pores and spaces left over by the degrading or remodeled scaffold. Scaffolds used in cartilage tissue engineering can fall in two general categories: hydrogels (microporous scaffolds) or macroporous scaffolds (Figure 2). They can be composed of biopolymers, synthetic polymers, or a mix.

4.2.2.1. Decellularized xenogeneic grafts