Abstract

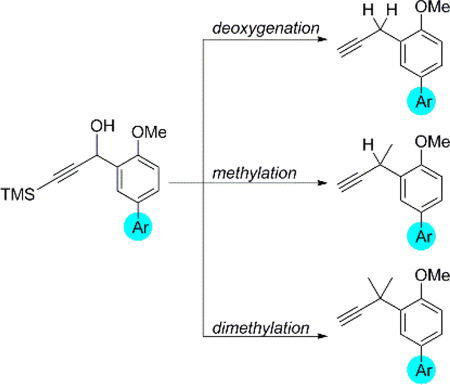

To develop next generation antifolates for the treatment of trimethoprim-resistant bacteria, synthetic methods were needed to prepare a diverse array of 3-aryl-propynes with various substitutions at the propargyl position. A direct route was sought whereby nucleophilic addition of acetylene to aryl carboxaldehydes would be followed by reduction or substitution of the resulting propargyl alcohol. The direct reduction, methylation, and dimethylation of these readily available alcohols provide efficient access to this uncommon functional array. In addition, an unusual silane exchange reaction was observed in the reduction of the propargylic alcohols.

Graphical Abstract

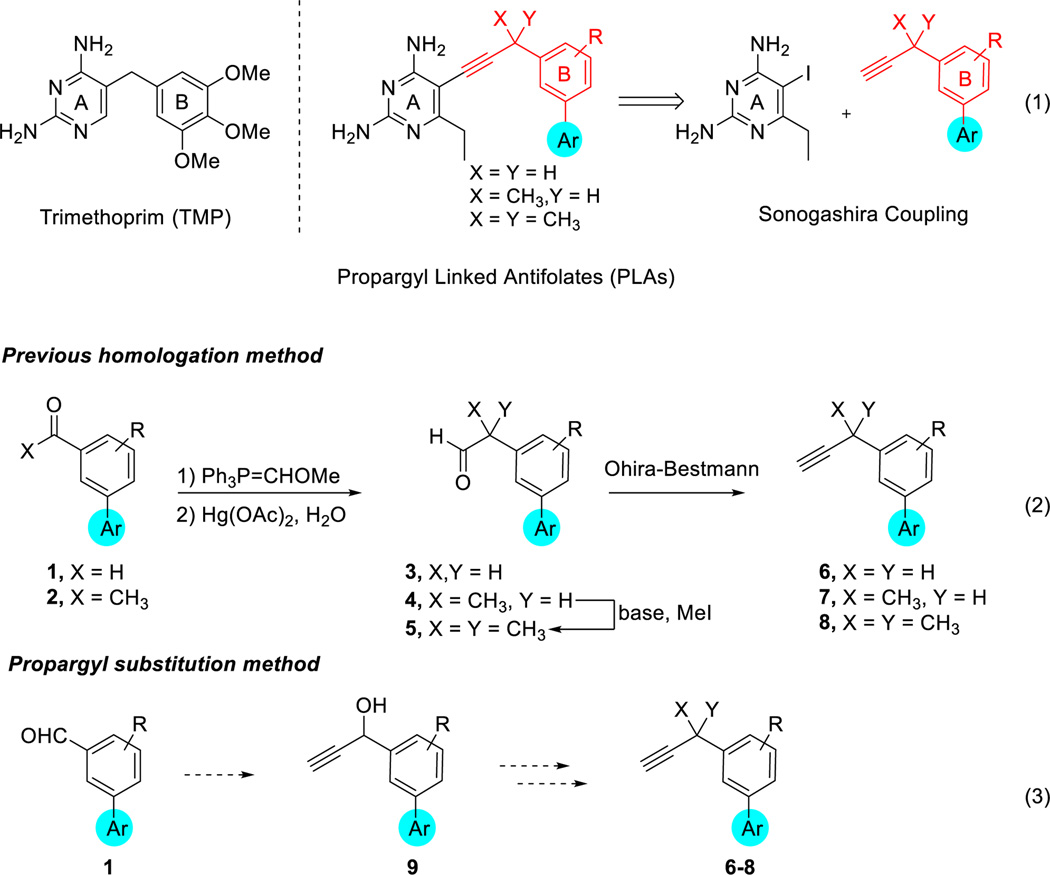

The incorporation of alkyne functionality in screening libraries,1 biological probes,2 and therapeutic agents3 is becoming increasing prevalent, owing both to the relative ease of their incorporation into complex molecules through cross-coupling chemistry,4 participation in biocompatible azide “click” cycloadditions,5 and distinct topological features. Over the past several years, we have been pursuing the development of next-generation trimethoprim (TMP) (Scheme 1, eq 1) analogs to target a variety of organisms6 that are either naturally insensitive or have evolved resistance to the clinically used agent. These antimicrobial agents exert their effects by inhibiting dihydrofolate reductase (DHFR), depleting the organism of thymidine and other metabolites essential for replication. Our efforts employing a structure-based approach has led to a series of propargyl-linked antifolates (PLAs) (Scheme 1, eq 1) characterized by the insertion of a propargylic linker6a between the diaminopyrimidine A ring and a hydrophobic B-ring in place of the simple methylene spacer found in TMP. The acetylenic linker offers unique advantages as it projects the B-ring deeper into a large hydrophobic cavity in the enzyme while the small, linear projection of the alkyne allows it to pass through a narrow channel in the reductase.

Scheme 1.

Antibacterial antifolates and synthetic route to Propargyl linked antifolates

In developing this class of inhibitors, the importance of propargyl substitution has shown itself to be critical with unsubstituted, mono-methylated, and dimethylated derivatives showing strong effects on organism-specific potency,6c,7–9 selectivity over the human enzyme,10 metabolic stability,11a and its influence over the co-factor binding.11b To probe the hydrophobic pocket of the enzyme requires various propargyl substituents to determine structure-activity relationship.

We had previously developed12 a route (Scheme 1, eq 2) to the acetylenic component of PLAs based on step-wise Wittig homologation of biaryl aldehydes 1 or methyl ketones 2 to produce the unsubstituted and monomethylated intermediates 3 and 4 respectively; the dimethyl congener 5 is prepared by a subsequent enolate alkylation. Condensation of the homologated aldehydes with the Ohira-Bestmann13 reagent delivers the terminal alkyne building blocks 6–8, that undergoes Sonogashira coupling with the diaminopyrimidine A ring. The limitations of the above route include (1) repetitive homologation required from ketone and aldehyde starting material to generate CH3 and H substitution respectively, at the propargyl position, (2) use of toxic mercury acetate salts for hydrolysis, (3) use of expensive Ohira-Bestmann reagent and (4) formation of isomeric allene byproducts during Ohira-Bestmann homologation, leading to lower yields of terminal alkyne. We have been interested in developing an alternative route to this terminal acetylene building blocks that would allow access to the different propargyl-substitution variants from a common starting material. We envisioned that the new route (Scheme 1, eq 3) would begin with nucleophilic acetylide addition to biaryl aldehydes 1, obtained by Suzuki coupling, to produce propargylic alcohols 9. Divergence from 9 via substitution of the propargyl alcohol would generate the unbranched, mono-methyl, and dimethyl derivatives 6–8. The direct substitution of these types of systems has been poorly studied and are often complicated by the formation of allene products. Moreover, the frequent presence of basic heterocycles in the inhibitors could also limit the ability to effect such direct substitution reactions. Herein, we describe an efficient series of propargylic substitution reactions compatible with the functionality in these inhibitors that can be used to generate a homologous series of propargylic variants from a common starting material.

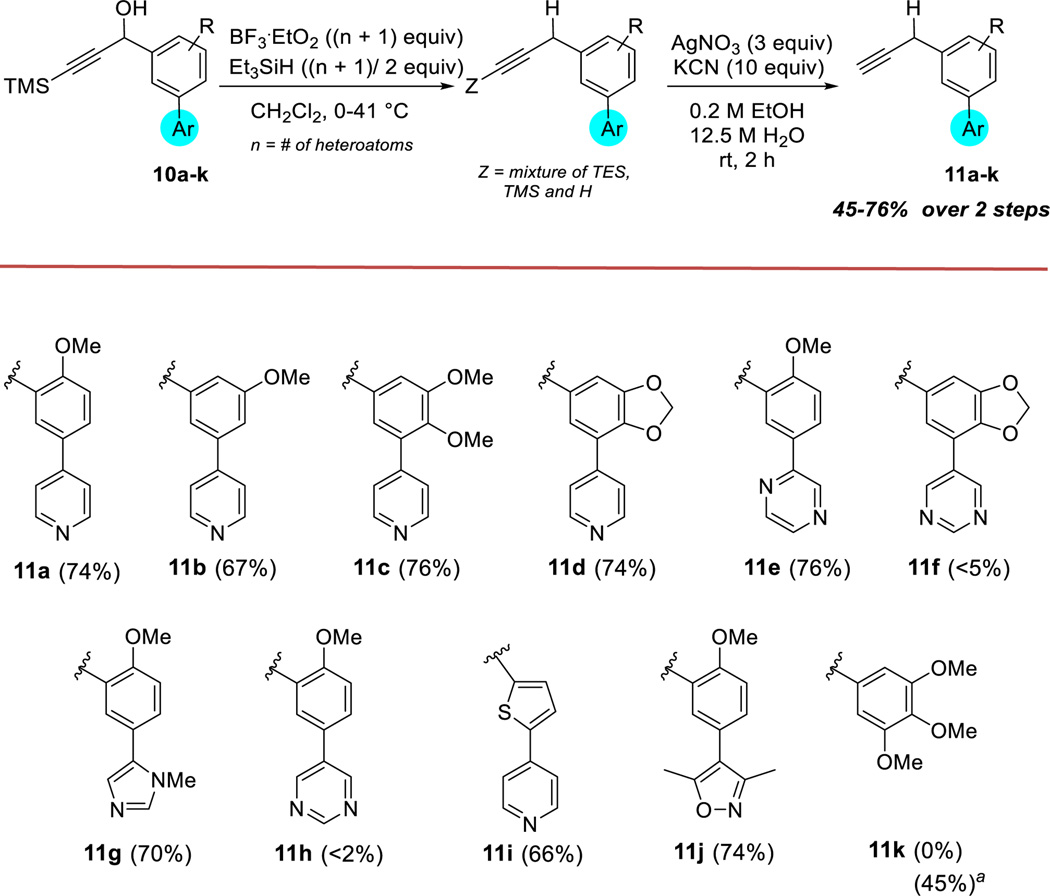

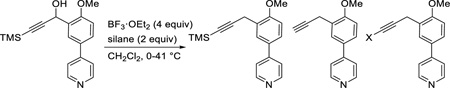

Several commercially or readily available mbromobenzaldehydes were directly converted to a variety of heterobiaryl aldehydes 9a–j by Suzuki cross-coupling with a suitable boronic acid. The aryl propargyl alcohols 10a–k were prepared by nucleophilic addition of trimethylsilylacetylene to the aryl aldehyde. Initial studies focused on the direct reductive deoxygenation of the highly activated carbinol to produce the unsubstituted building blocks. Although there are examples of this type of process on secondary alcohols14 and internal alkynes,15 there are far fewer studies involving such highly activated systems with the alcohol flanked by both an acetylenic and aryl substituent. Nitrogenous heteroaromatics and silyl protected terminal alkynes are also uncommon functionality in the reported examples. After screening a variety of conditions, it was observed that treatment of the alcohols with an excess of boron trifluoride etherate and triethylsilane led to the reduced methylene derivatives, as an unexpected mixture of TMS-, TES- and desilylated terminal acetylenes (Table 1). Other Lewis acids including aluminum chloride, indium chloride, and zinc bromide also facilitated deoxygenation leading to a mixture of silyl- and terminal alkyne products. The reaction was compatible with several different nitrogenous heterocycles (Scheme 2), with the exception of pyrimidine (11f, 11h), where there was competitive reduction of the heterocycle itself. Surprisingly, a simple aromatic alkynol 10k underwent extensive decomposition with no deoxygenated product formation. This result suggested that the basic heteroaromatic ring found in most of the substrates (10a–j) may be playing an active role in facilitating the reduction reaction. Support for this participation was observed as the addition of exogenous pyridine to substrate 10k resulted in a 45% yield of the deoxygenated product 11k.

Table 1.

Product distribution using alternative silanes

| |

|---|---|

| silane | alkyne distributiona |

| triethylsilane | 1 : 0.4 : 0.3b |

| triisopropylsilane | 1 : 0.4 : 0.8 |

| triphenylsilane | 1 : 0.5 : 0.4 |

| 1,1,3,3-tetramethyldisiloxane (1 equiv) |

1 : 0.1 : 0 |

| polymethylhydrosiloxane | 1 : 0 : 0 |

Ratios obtained by NMR.

Ratios of TMS alkyne: free alkyne: silyl exchanged alkyne

Scheme 2.

Deoxygenation of propargyl alcohols

In order to process the mixture of deoxygenated products, the crude reaction mixture was subjected to a mild deprotection involving either a silver/cyanide mediated16a hydrolysis or a less toxic equimolar mixture16b of n-Bu4NF and CH3COOH was utilized to convert all species to the desired terminal alkyne. In addition to the potential participatory role of the heterocyclic moiety, the exchange of the silyl groups during the reduction stood out as an unusual observation. There is no precedent, to our knowledge, for the silyl exchange reaction that occurs in the reduction process. We investigated whether alteration of the silyl hydride reagent would impact the silyl exchange process using a representative substrate 10a (Table 1).

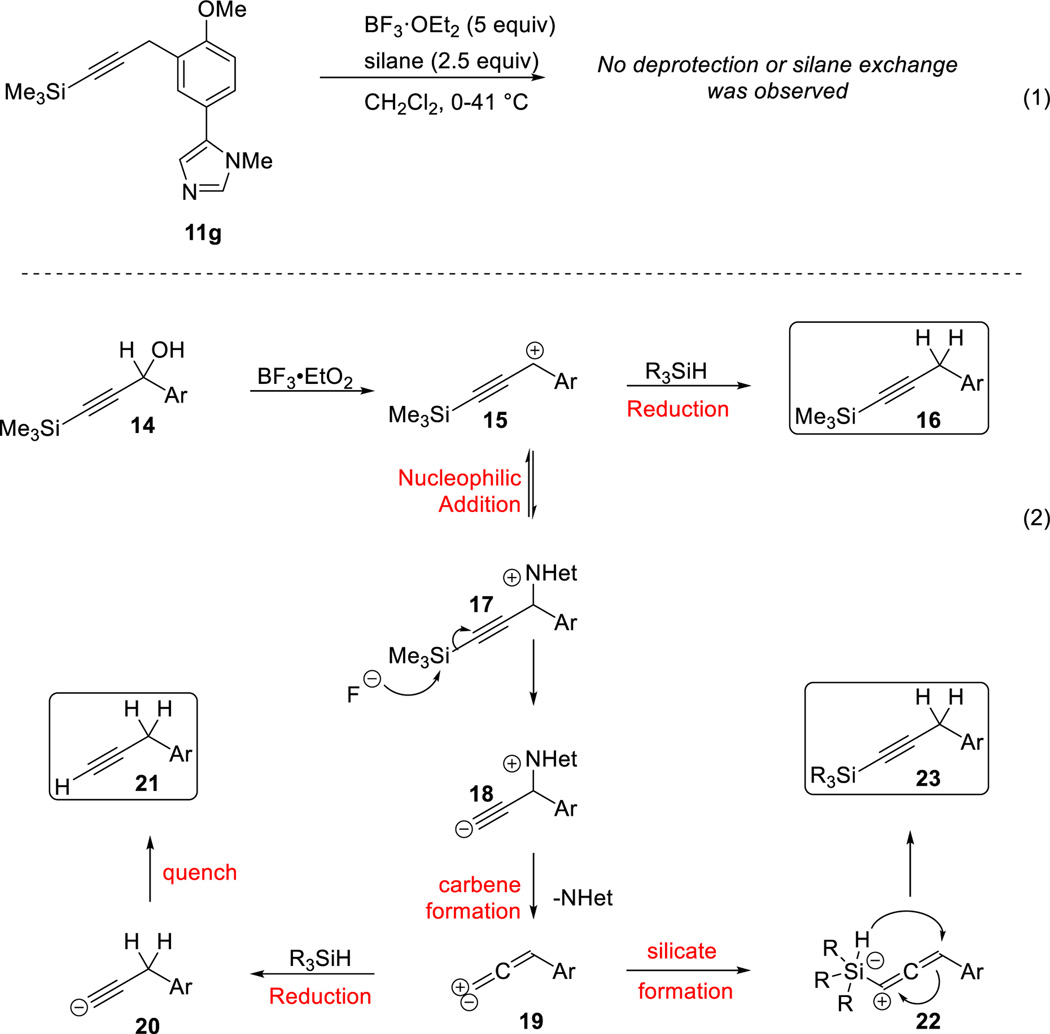

Using five different silanes, it was possible to show that the environment of the reducing agent impacted the distribution between the three products. Increasing steric bulk on the silane from triethyl to triisopropyl to triphenylsilyl, had little impact on the overall product distribution. However, we were pleased to see that the use of hydrosiloxanes gave almost exclusively the TMS-protected derivatives. It is interesting to note that desilylation likely proceeded prior to product formation as exposure of a TMS-protected product 11g to the reaction conditions did not lead to silyl exchange or deprotection (Scheme 3, eq 1). A plausible mechanistic pathway that accounts for both the silane exchange as well as a stabilization role for the N-heteroaromatic (N-Het) substituent was conceived (Scheme 3, eq 2). Rapid ionization of the activated alcohol 14 leads to the stabilized cation 15 that can conceivably suffer three different fates, direct reduction leading to the TMS-derivative 16, reversible capture by the nucleophilic N-heteroaromatic to give iminium ion 17, or in the absence of this stabilization, decomposition of the cation as seen with substrate 10k. Fluoride ion liberated in the ionization step could effect a subsequent desilylation reaction leading to zwitterionic species 18 which upon loss of N-heteroaromatic would generate an allenyl carbene such as 19. Rapid reduction of the carbene with a silyl hydride would produce the acetylide 20 that upon work-up would deliver the unprotected alkyne 21. Alternatively, formation of a silicate-like complex 22 followed by a hydride migration could lead to the product containing the terminal silyl group 23 derived from the reducing agent. The formation of neutral allenyl silane byproduct from complex 22 was not observed. The steric environment and reactivity of the silane would be a factor in the relative preponderance of the deprotected/exchanged materials as rapid reduction of the initial carbocation would limit these other products.

Scheme 3.

Plausible mechanistic routes to deoxygenated products

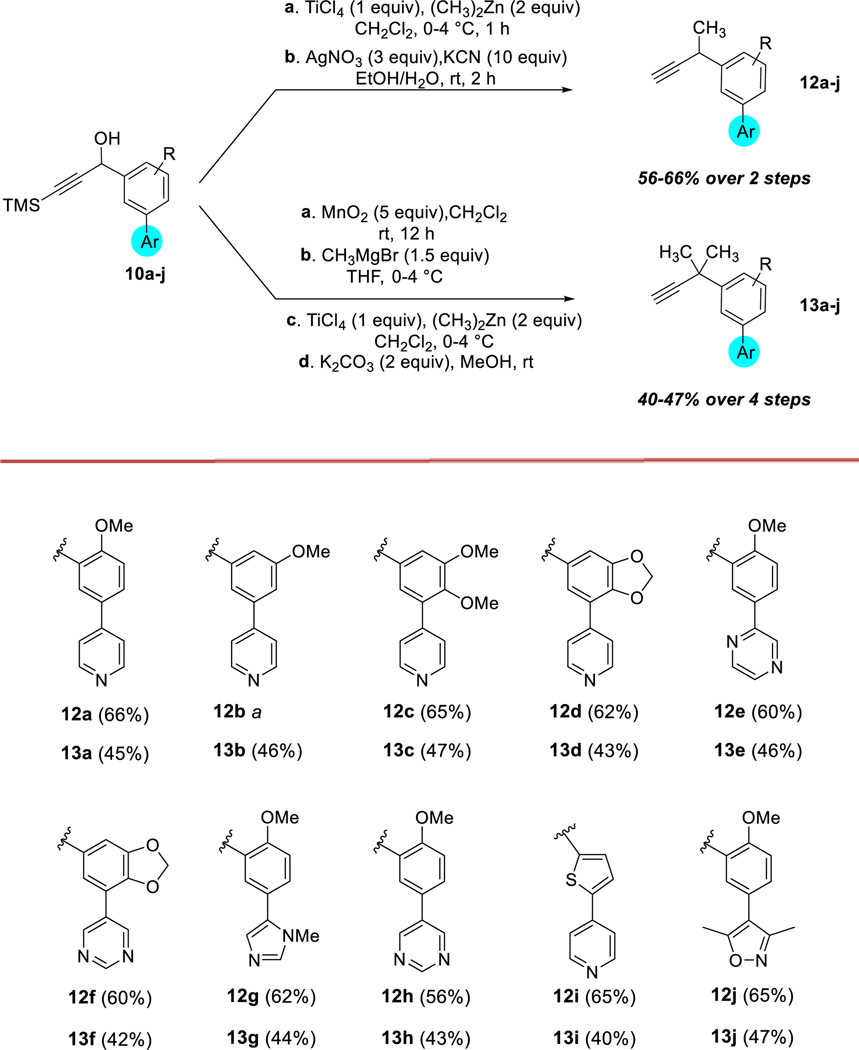

With the success of the direct reduction of the intermediate alcohols, our attention turned to alkylation reactions of the putative carbocation intermediate 15 (Scheme 3, eq 2). Here-in, we show that treatment of the secondary alcohols with dimethylzinc17 in the presence of titanium tetrachloride led to direct formation of the methyl branched systems in good overall yields (Scheme 4). Addition to the pendant heterocycles or formation of allenic products were observed only in trace amounts. But with substrate 12b lacking an electron donating group at the ortho and para position of the aromatic ring, allenyl by-product formation appeared to be competitive. This compliments other methods for installing propargyl methyl groups such as cuprate displacement18a and Negishi coupling.18b Likewise, it was relatively straightforward to prepare the gemdimethyl congener from the propargylic alcohols by initial oxidation to the ynone and subsequent introduction of methyl groups and final desilylation. Again, addition to the alkyne carbons or allene formation was not observed under these reaction conditions.

Scheme 4.

Alkylation

In summary, these methods allow for the ready access to a series of 3-aryl propynes with both unsubstituted and branched propargylic carbons. Additional stabilization of the putative aryl substituted propargyl cation by suitably placed donor groups on the aromatic ring improves the overall efficiency of the reaction. These direct substitution reactions were sufficiently mild to allow the incorporation of the wide range of nitrogenous heterocycles in the substrate. In addition, there is evidence that the basic heterocycle plays a role in the facility of the reduction process, an effect that can be mimicked by the addition of exogenous pyridine to the reaction. These direct methods provide for the preparation of the series of differentially substituted 3-aryl propynes from propargyl alcohols by direct reduction or substitution of the readily ionized hydroxyl group.

Supplementary Material

Acknowledgments

We gratefully acknowledge the support of NIH AI104841 and NIH AI11957 to A.C.A and D.L.W.

Footnotes

ASSOCIATED CONTENT

Supporting Information

Experimental procedures and full characterization data for all new compounds. This material is available free of charge via the Internet at http://pubs.acs.org.

REFERENCES

- 1.(a) Srinivasan R, Tan LP, Wu H, Yang P, Kalesh KA, Yao SQ. Org. Biomol. Chem. 2009;7:1821. doi: 10.1039/b902338k. [DOI] [PubMed] [Google Scholar]; (b) Liu J, Numa MMD, Liu H, Huang S-J, Sears P, Shikhman AR, Wong C-H. J. Org. Chem. 2004;69:6273. doi: 10.1021/jo049355h. [DOI] [PubMed] [Google Scholar]; (c) IsidroL A, Murillo T, Bello P, Cilibrizzi A, Hodgkinson JT, Galloway WRJD, Bender A, Welch M, Spring DR. Proc. Natl. Acad. Sci. USA. 2011;108:6793. doi: 10.1073/pnas.1015267108. [DOI] [PMC free article] [PubMed] [Google Scholar]; (d) Tan DS, Foley MA, Stockwell BR, Shair MD, Schreiber SL. J. Am. Chem. Soc. 1999;121:9073. [Google Scholar]

- 2.(a) Kambe T, Correia BE, Niphakis MJ, Cravatt BF. J. Am. Chem. Soc. 2014;136:10777. doi: 10.1021/ja505517t. [DOI] [PMC free article] [PubMed] [Google Scholar]; (b) Grammel M, Hang HC. Nat. Chem. Biol. 2013;9:475. doi: 10.1038/nchembio.1296. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.(a) Yamaguchi M, Park HJ, Ishizuka S, Omata K, Hirama M. J. Med. Chem. 1995;38:5015. doi: 10.1021/jm00026a008. [DOI] [PubMed] [Google Scholar]; (b) Chandregowda V, Rao GV, Reddy GC. Org. Process Res. Dev. 2007;11:813. [Google Scholar]

- 4.(a) Chinchilla R, Najera C. Chem. Soc. Rev. 2011;40:5084. doi: 10.1039/c1cs15071e. [DOI] [PubMed] [Google Scholar]; (b) Schilz M, Plenio H. J. Org. Chem. 2013;77:2798. doi: 10.1021/jo202644g. [DOI] [PubMed] [Google Scholar]; (c) Chinchilla R, Najera C. Chem. Rev. 2007;107:874. doi: 10.1021/cr050992x. [DOI] [PubMed] [Google Scholar]; (d) Siemsen P, Livingston RC, Diederich F. Angew. Chem. Int. Ed. 2000;39:2632. [PubMed] [Google Scholar]

- 5.Thirumurugan P, Matosiuk D, Jozwiak K. Chem. Rev. 2013;113:4905. doi: 10.1021/cr200409f. [DOI] [PubMed] [Google Scholar]

- 6.(a) Pelphrey PM, Popov V, Joska TM, Beierlein JM, Bolstad E, Fillingham Y, Wright DL, Anderson AC. J. Med. Chem. 2007;50:940. doi: 10.1021/jm061027h. [DOI] [PubMed] [Google Scholar]; (b) Viswanathan K, Frey K, Scocchera E, Martin B, Swain P, III, Alverson J, Priestley ND, Anderson AC, Wright DL. PLoS ONE. 2012;7:e29434. doi: 10.1371/journal.pone.0029434. [DOI] [PMC free article] [PubMed] [Google Scholar]; (c) Beierlein JM, Frey KM, Bolstad DB, Pelphrey PM, Joska TM, Smith AE, Priestley ND, Wright DL, Anderson AC. J. Med. Chem. 2008;51:7532. doi: 10.1021/jm800776a. [DOI] [PMC free article] [PubMed] [Google Scholar]; (d) G-Dayanandan N, Paulsen JL, Viswanathan K, Keshipeddy S, Lombardo MN, Zhou W, Lamb KM, Sochia AE, Alverson JB, Priestley ND, Wright DL, Anderson AC. J. Med. Chem. 2014;57:2643. doi: 10.1021/jm401916j. [DOI] [PMC free article] [PubMed] [Google Scholar]; (e) Lamb KM, Lombardo MN, Alverson JB, Priestley ND, Wright DL, Anderson AC. Antimicrob. Agents. Chemother. 2014;58:7484. doi: 10.1128/AAC.03555-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Paulsen JL, Viswanathan K, Wright DL, Anderson AC. Bioorg. Med. Chem. Lett. 2013;23:1279. doi: 10.1016/j.bmcl.2013.01.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Scocchera E, Reeve SM, Keshipeddy S, Lombardo MN, Hajian B, Sochia AE, Alverson JB, Priestley ND, Anderson AC, Wright DL. ACS Med. Chem. Lett. 2016;7:692. doi: 10.1021/acsmedchemlett.6b00120. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Hajian B, Scocchera E, Keshipeddy S, G-Dayanandan N, Shoen C, Krucinska J, Reeve S, Cynamon M, Anderson AC, Wright DL. PLoS ONE. 2016;11:e0161740. doi: 10.1371/journal.pone.0161740. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Lamb KM, G-Dayanandan N, Wright DL, Anderson AC. Biochemistry. 2013;52:7318. doi: 10.1021/bi400852h. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.(a) Zhou W, Viswanathan K, Hill D, Anderson AC, Wright DL. Drug. Metab. Dispos. 2012;40:2002. doi: 10.1124/dmd.112.046870. [DOI] [PMC free article] [PubMed] [Google Scholar]; (b) Keshipeddy S, Reeve S, Anderson AC, Wright DL. J. Am. Chem. Soc. 2015;137:8983. doi: 10.1021/jacs.5b01442. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Bolstad DB, Bolstad ESD, Frey KM, Wright DL, Anderson AC. J. Med. Chem. 2008;51:6839. doi: 10.1021/jm8009124. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Ohira S. Syn. Comm. 1989;19:561. [Google Scholar]

- 14.(a) Hartwig W. Tetrahedron. 1983;39:2609. [Google Scholar]; (b) Yasuda M, Onishi Y, Ueba M, Miyai T, Baba A. J. Org. Chem. 2001;66:7741. doi: 10.1021/jo0158534. [DOI] [PubMed] [Google Scholar]; (c) Gevorgyan V, Rubin M, Benson S, Liu J, Yamamoto Y. J. Org. Chem. 2000;65:6179. doi: 10.1021/jo000726d. [DOI] [PubMed] [Google Scholar]

- 15.(a) Saito T, Furukawa N, Otani T. Org. Biomol. Chem. 2010;8:1126. doi: 10.1039/b924301a. [DOI] [PubMed] [Google Scholar]; (b) Trost BM, Michael TR. J. Am. Chem. Soc. 2005;127:4763. doi: 10.1021/ja043097o. [DOI] [PubMed] [Google Scholar]; (c) Nicholas KM. Acc. Chem. Res. 1987;20:208. [Google Scholar]; (d) McComsey DF, Reitz AB, Maryanoff CA, Maryanoff BE. Synth. Commun. 1986;16:1535. [Google Scholar]; (e) Teobald BJ. Tetrahedron. 2002;58:4133. [Google Scholar]; (f) Egi M, Kawai T, Umemura M, Akai S. J. Org. Chem. 2012;77:7092. doi: 10.1021/jo300889p. [DOI] [PubMed] [Google Scholar]; (g) Kumar GG, Laali KK. Org. Biomol. Chem. 2012;10:7347. doi: 10.1039/c2ob26046h. [DOI] [PubMed] [Google Scholar]; (h) Meyer VJ, Niggemann M. Chem. Eur. J. 2012;18:4687. doi: 10.1002/chem.201103691. [DOI] [PubMed] [Google Scholar]; (i) Sakai N, Hirasawa M, Konakahara T. Tetraheron Lett. 2005;46:6407. [Google Scholar]; (j) Georgy M, Boucard V, Debleds O, Zotto CD, Campagne J-M. Tetrahedron. 2009;65:1758. [Google Scholar]; (k) Nishibayashi Y, Shinoda A, Miyake Y, Matsuzawa H, Sato M. Angew. Chem. Int. Ed. 2006;45:4835. doi: 10.1002/anie.200601181. [DOI] [PubMed] [Google Scholar]; (l) Masuyama Y, Takahara JP, Hashimoto K, Kurusu Y. J. Chem. Soc. Chem. Commun. 1993:1219. [Google Scholar]

- 16.(a) Chung ME, Hagenah J. J. Org. Chem. 1987;52:1889. [Google Scholar]; (b) Imperio D, Pirali T, Galli U, Pagliai F. Bioorg. Med. Chem. 2007;15:6748. doi: 10.1016/j.bmc.2007.08.020. [DOI] [PubMed] [Google Scholar]

- 17.(a) Reetz M, Westermann J, Steinbach R. J. Chem. Soc. Chem. Commun. 1981:237. [Google Scholar]; (b) Reetz M, Westermann J. J. Org. Chem. 1983;48:254. [Google Scholar]; (c) Reetz M, Westermann J, Steinbach R. Angew. Chem. Int. Ed. 1980;19:901. [Google Scholar]

- 18.(a) Macdonald T, Reagan D, Brinkmeyer R. J. Org. Chem. 1980;45:4740. [Google Scholar]; (b) Smith S, Fu G. J. Am. Chem. Soc. 2008;130:12645. doi: 10.1021/ja805165y. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.