Abstract

Chemical reactions that are named in honor of their true or at least perceived discoverers are known as “name reactions”. This review is a collection of biological representatives of named chemical reactions. Emphasis is placed on reaction types and catalytic mechanisms that showcase both the chemical diversity in natural product biosynthesis as well as the parallels with synthetic organic chemistry. An attempt has been made to describe the enzymatic mechanisms of catalysis within the context of their synthetic counterparts whenever possible and to discuss the mechanistic hypotheses for those reactions that are presently active areas of investigation. This review has been categorized by reaction type, e.g., condensation, nucleophilic addition, reduction and oxidation, substitution, carboxylation, radical-mediated, and rearrangements, which are subdivided by named reactions.

Keywords: name reaction, enzyme, mechanism, biosynthesis, catalysis

1. Introduction

The field of organic chemistry is extraordinarily rich due to the seemingly limitless number of structurally diverse compounds that can be constructed with carbon. A significant catalog of chemical reactions has been compiled in the last several decades. Many of these reactions have been developed by generation after generation of scientists, each working, often in obscurity, to make their own small addition to this vast collection of chemical knowledge. For those lucky enough to discover a new process involving a particularly useful and exciting transformation or one that simply came to represent an established paradigm, the honor of having the reaction named after them stamps their mark on the history of scientific discovery. Approximately 500 named reactions exist in the Merck index, from the Pelouze synthesis,[1] first described in 1834 to the Shi epoxidation[2] described in 1996. While the majority of these named reactions do not have a direct biological counterpart, the ongoing study of primary and secondary metabolic pathways has shown that a good number of them do.

In contrast to the tools available to the synthetic organic chemist, for whom there is considerable leeway with regard to efficiency as well as a full panoply of available solvents, temperatures and reagents, biochemical reactions are generally constrained by limited resources and restricted to the relatively narrow range of conditions that living systems can tolerate. Thus, it is not surprising that a large number of biological reactions are characterized by fairly standard Lewis acid-base chemistry. However, while a researcher will use thought and reason in the lab to discover new and possibly beneficial reactions, nature has used mutation and selection in approximately 1030 cells[3] over billions of years to expand life’s chemical processes to the current level of diversity. The Bergman cyclization in the activation of enediyne antibiotics[4] or the Baeyer-Villiger oxidation in the degradation of xenobiotic toxins[5] are just two examples of how biology uses novel chemical processes to expand its capabilities. Thus, named organic reactions are indeed well represented in biology.

As we delve deeper into the inner workings of the cell we find that just as often as chemistry can explain biology, biology can inspire chemistry. This symbiotic relationship drives both fields to new heights of understanding. In this review we highlight the parallels in the “lab” chemistry to the chemistry of the cell by describing a number of examples of named reactions that have also been identified in biology. We included the enzymatic reaction mechanism whenever it is known, but have also included examples where the reaction mechanism for the biological process has strong support, even the specific role of the enzyme remains obscure. This review is categorized according to the type of reaction being discussed: condensation, nucleophilic addition, reduction and oxidation, substitution, carboxylation, radical-mediated, and rearrangements. These sections are then subdivide into the named reactions with the examples of their biological parallels.

2. Condensation Reactions

2.1. Aldol Condensation/Aldol Reaction

The aldol condensation reaction is the nucleophilic attack by the α-carbon of an aldehydic or ketonic enolate upon the carbonyl carbon of another aldehyde or ketone to form a β-hydroxy product (Figure 1). This is followed by dehydration of the nascent aldol product to give a conjugated enone product. The aldol condensation, first reported by Charles Adolph Wurtz in 1872,[6] derives its name from a particular case in which an enolate reacts with an aldehyde carbonyl to afford an alcohol. While Aldol condensation is not a real “name reaction” by strict definition, we decide to include it here since a number of name reactions are variations of the aldol condensation, such as Claisen condensation, which is an aldol condensation between two esters to generate a β-keto ester,[7] and Dieckmann condensation which is an intramolecular version of Claisen condensation.[8] It should be noted that many biological reactions involve nucleophilic addition of an enolate to an aldehyde to yield a β-hydroxyl aldol product without subsequent dehydration. In this review, we opt to group reactions leading to the formation of aldol products under the class of aldol condensation and aldol reaction. The aldol reaction and the related Claisen reaction are the methods-of-choice for enzymes catalyzing C-C bond formation (biosynthetic mode) and C-C bond cleavage (degradative mode) reactions. In fact, aldol reaction is the underlining theme of a great number of enzymes catalyzing diverse reactions.

Figure 1.

Aldol condensation and related reactions.

2.1.1. Aldolases

Many enzymes are capable of catalyzing aldol reactions. A group of them known as aldolases are especially synthetically useful. These enzymes can be divided into two classes, type I and type II aldolases, and have distinct evolutionary origins (Figure 2).[9] The reaction mechanism of type I aldolases includes the formation of a Schiff base (2) between the donor substrate (1) and a conserved lysine residue in the active site, which after α-deprotonation adds stereospecifically to the carbonyl group of an acceptor (3). Instead of relying on employing an iminium ion to facilitate enolate formation, type II aldolases utilize a bound Zn2+ ion to stabilize the enolate intermediate generated after deprotonation (5). Type I aldolases are found primarily in animals and higher plants and the type II enzymes are found in microorganisms.

Figure 2.

Reaction mechanisms of type I and II aldolases. (a) Fructose 1,6-diphosphate aldolase (type I) and (b) fuculose 1-phosphate aldolase (type II).

The canonical aldolase enzyme, fructose 1,6-diphosphate (FDP) aldolase, catalyzes the fourth step in the glycolytic pathway – the reversible cleavage of FDP (4) to glyceraldehyde-3-phosphate (G3P, 3) and dihydroxyacetone phosphate (DHAP, 1). FDP aldolase can accept a wide range of aldehyde acceptor substrates with DHAP as the donor to generate (3S,4R) vicinal diols as the products.[9] Besides DHAP, pyruvate, phosphoenol pyruvate, or acetaldehyde can also be used by various aldolases as the donor substrate to generate the reactive enolate intermediate. Because the enzymatic aldol C-C bond formation and cleavage reactions are versatile and highly stereospecific, they are useful for synthetic applications. For a comprehensive review on aldolases see Brovetto et. al.[10]

2.1.2. Porphobilinogen synthase-catalyzed aldol condensation reaction

While it is not always apparent, many enzyme-catalyzed reactions consisting of multi-step transformations involve aldol addition as a key reaction. For example, the first common step in the biosynthesis of tetrapyrroles in heme and vitamin B12 catalyzed by porphobilinogen synthase is the condensation of two molecules of 5-aminolevulinic acid (8) to give porphobilinogen (12, Figure 3).[11] The reaction is initiated by Schiff base (9) formation between the first 5-aminolevulinic acid (at P-side) with a lysine residue in the active site. The second 5-aminolevulinic acid (at A-side) is bound to a Zn2+ ion, which facilitates the formation of the second Schiff base between the amino group from the substrate at P-side with the 4-keto group of the substrate at A side.[12] α-Deprotonation to give the enamine 10 followed by an intramolecular aldol addition leads to a 5-membered ring intermediate (11, Figure 3, route A). It is also possible that ring formation is a direct aldol addition of the C-3 enolate of the substrate at A-side to the 4-iminium group of the substrate at the P-side (Figure 3, route B). Subsequent elimination and tautomerization gives porphobilinogen (12) as the final product. It is important to note that the conversion of 10 to 11 is reminiscent to that of Stork Enamine Alkylation reaction, which was developed by Gilbert Stork in 1960s and is a widely used C-C bond coupling reaction.[13]

Figure 3.

Proposed reaction mechanism for porphobilinogen synthase.

2.1.3. Enzyme-catalyzed retro-aldol reactions

Since aldol addition reaction is reversible, a number of enzymes catalyze the retro-aldol reaction as their primary biological functions. For example, dihydroneopterin aldolase catalyzes the cleavage of 7,8-dihydroneopterin (15) to 6-hydroxymethyl-7,8-dihydropterin (18) and glycolaldehyde (17) during folic acid biosynthesis (Figure 4).[14] The pyridoxal-5′-phosphate (PLP, 21)-dependent serine hydroxymethylase catalyzes the reversible conversion of L-serine (22) to glycine (27) and a one-carbon fragment at the oxidation level of formaldehyde (24), which is then transferred to tetrahydrofolate (THF, 20) to form N5-N10-methylene-THF (28), an important methyl source in biological systems (Figure 5).[15] The transformation from 23 to 25 is a retro-aldol reaction and the stabilized glycine-coenzyme imine intermediate (26) is eventually hydrolyzed to glycine (27).

Figure 4.

The folic acid biosynthetic pathway in bacteria.

Figure 5.

Proposed mechanism of serine hydroxymethylase.

The first committed step in the non-mevalonate pathway to produce isoprenes is the conversion of 1-deoxy-D-xylulose 5-phosphate (DXP, 29), to methyl-D-erythritol 4-phosphate (MEP, 30) catalyzed by the NADPH-dependent DXP reductoisomerase (DXR, also known as MEP synthase, see Figure 6).[16] Studies of the secondary kinetic isotope effects measured in the equilibrium perturbation experiments with [3-2H]- and [4-2H]-DXP provided direct evidence supporting a retro-aldol/aldol mechanism for the DXR-catalyzed rearrangement of DXP (29) to MEP (30).[17, 18]

Figure 6.

Proposed mechanism of 1-deoxy-D-xylulose-5-phosphate reducto-isomerase.

In a recent study of the biosynthesis of baumycin A1 (31), the flavin adenine dinucleotide (FAD)-dependent nitrososynthase (DnmZ) was shown to catalyze the oxidation of TDP-L-epi-vancosamine (32) to a vicinal-hydroxyl-nitrososugar (33) which then underwent C3−C4 bond cleavage to give an acyclic aldehyde-oxime product (34, Figure 7).[19] The overall rearrangement is a retro oxime-aldol transformation and bears a resemblance to that by Type I aldolases. The polarized nitroso functional group in this case is the surrogate for the iminium group of an aldolase. This aldehyde-oxime product (34) will eventually be reduced and incorporated (in the form of 35) into baumycin A1 (31).

Figure 7.

Proposed mechanism of DnmZ.

2.2. Claisen Condensation

The Claisen condensation is named after Rainer Ludwig Claisen, who first reported this reaction in 1887.[7] Similar to the aldol condensation, the Claisen condensation is a common mode of C-C bond formation in nature. It differs from aldol reaction in which the acceptor is an ester or thioester instead of an aldehyde or ketone, and the product is a β-keto ester or thioester (Figure 1). The Claisen condensation fulfills a prominent role in biological chemistry as the means by which C-C bonds are formed during the biosynthesis of fatty acids and polyketides, which will be highlighted in the following section. Many enzyme-catalyzed C-C bond cleavage reactions are effectively the reverse Claisen reactions. Some well-known examples include citrate lyase[20] and thiolase.[21] The reaction catalyzed by PLP-dependent kynureninase also involves a retro-Claisen step to cleave L-kynurenine (36) to anthranilic acid (37) and L-alanine (38, Figure 8).[22] Interestingly, enzymes catalyzing Claisen condensation generally produce a new C-C bond with inversion of stereochemistry relative to the α-proton that is abstracted; this is in contrast to the retention of configuration observed for the enzyme-catalyzed aldol reactions.

Figure 8.

Kynureninase catalyzes a retro-Claisen reaction.

2.2.1. Claisen condensations in fatty acid biosynthesis

Fatty acid biosynthetic systems can be divided into two groups. The type II system found in plants and bacteria is composed of seven discrete enzymes,[23] whereas the type I system found in animals is a single, high molecular weight protein dimer containing all of the functionalities of the type II system in each polypeptide chain.[24] The designations of the enzymes described below is based on the type II system of Escherichia coli but is generalizable to the type I system as well. The proposed reaction mechanisms are based largely on X-ray crystal structures of the enzymes.[25]

Fatty acid carbon chains are elongated two carbons at a time in a reaction catalyzed by β-ketoacyl-acyl carrier protein (ACP) synthases (Figure 9a). The two-carbon unit is provided by malonyl-ACP (40), which is derived from coupling of malonyl-CoA (39) to ACP via a phosphopantetheinyl linkage by malonyl-CoA-ACP transacylase, known as FabD (where “Fab” stands for fatty acid biosynthesis). Fatty acid biosynthesis is initiated by β-ketoacyl-ACP synthase III (FabH), which uploads an acetate from acetyl-CoA (41) to a conserved cysteine residue in its active site to form an enzyme-linked thioester (acetyl-FabH). The second half of the FabH reaction is a decarboxylating Claisen condensation. As shown in Figure 9b, malonyl-ACP (40) undergoes decarboxylation and the resulting enolate attacks the thioester carbonyl carbon of acetyl-FabH to give acetoacetyl-ACP (42). The β-carbonyl group of acetoacetyl-ACP is reduced to a hydroxyl group and the reduced product (43) undergoes dehydration resulting in a C-C double bond, which is subsequently saturated. These steps are catalyzed by FabG, FabA or Z, and FabI, respectively, and occur after each round of condensation.

Figure 9.

(a) Type II fatty acid biosynthesis. (b) Mechanisms of Fab-H catalyzed and (c) FabB or FabF-catalyzed decarboxylating Claisen condensations.

After the first condensation reaction mediated by FabH, carbon chain elongation is carried out by further decarboxylating Claisen condensations catalyzed by β-ketoacyl-ACP synthases I and II (FabB and FabF, respectively). Both enzymes operate via the same mechanism as FabH (Figure 9c). The acyl chain is transferred from ACP to a conserved active site cysteine residue on β-ketoacyl-ACP synthase and the resulting enzyme-thioester carbonyl carbon is attacked by acetyl-ACP enolate (derived from decarboxylation of malonyl-ACP). The difference between FabB and FabF is that FabB is specifically involved in the elongation of unsaturated fatty acids and FabF controls the temperature-dependent regulation of fatty acid composition. The final fatty acid product is hydrolytically cleaved from ACP by the thioesterase (TEs).[26]

There is also a family of enzymes known as thiolases that catalyze non-decarboxylating Claisen condensations. They fall into two classes: biosynthetic and degradative thiolases. Biosynthetic thiolase catalyzes the condensation of acetyl-CoA with an acetate, which is derived from a second molecule of acetyl-CoA, to give acetoacetyl-CoA.[27] Degradative thiolase, known as FadA in E. coli, catalyzes the reverse reaction – the thiolytic cleavage of an acetate from β-ketoacyl-CoA, which is part of fatty acid breakdown commonly referred as β-oxidation.[28] The activities of both degradative and biosynthetic thiolases are reversible and their general reaction mechanism is depicted in Figure 10.

Figure 10.

Thiolase-catalyzed biosynthetic and degradative reactions.

2.2.2. Claisen condensations in polyketide biosynthesis

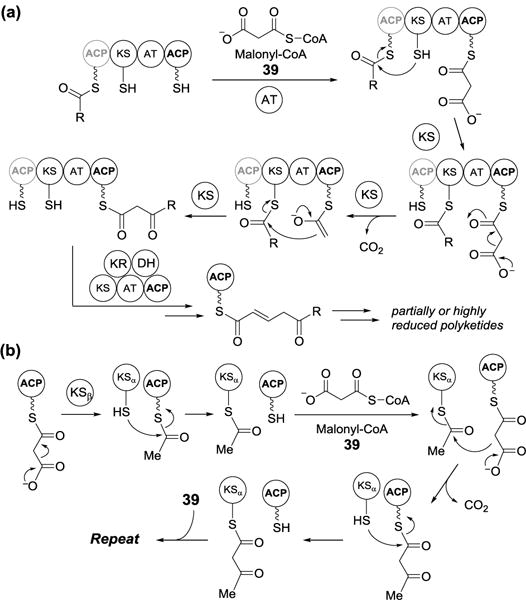

Similarly, β-ketoacyl synthase mechanisms are operative in the biosynthesis of polyketides, which are one of the most important classes of natural products. The formation of polyketides is catalyzed by polyketide synthases (PKSs), which are divided into type I and II PKS (Figure 11). These designations mirror those described for fatty acid biosynthesis in that a type I PKS is a single, large enzyme containing multiple functional domains, including ketosynthase (KS), acyl transferase (AT), ACP domains and possibly ketoreductase (KR), dehydratase (DH), enoyl reductase (ER), methyltransferase (MT), TE domains. In contrast, a type II PKS is a catalytic protein complex consisting of two ketosynthase units (KSα and KSβ) and an ACP. Biosynthesis of the polyketide chain is constructed via a series of decarboxylative Claisen condensations catalyzed by ketosynthases (KSs) in a manner analogous to fatty acid biosynthesis (Figure 11a).[29] PKSs can be further classified as iterative or non-iterative systems based on whether the KS domain is reused in the chain elongation or not.

Figure 11.

(a) Type 1 and (b) type II polyketide synthase-catalyzed reactions.

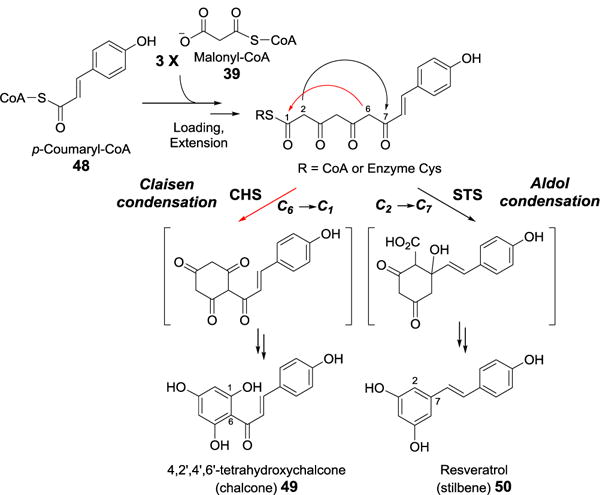

Interestingly, a third class of PKSs (type III) are singular bifunctional enzymes that catalyze both Claisen condensation and cyclization reactions.[30] The prototypical type III PKSs is chalcone synthase (CHS), which catalyzes the condensation of p-coumaric acid (from p-coumaryl-CoA, 48) to 3 molecules of acetate (from malonyl-CoA, 39). The linear ketide intermediate then undergoes cyclization and aromatization to yield chalcone (49), a starting material for a number of plant metabolites (Figure 12).[31] The cyclization portion of the CHS reaction is a Claisen-like C6→C1 condensation. This is a contrast to the C2→C7 aldol-like cyclization catalyzed by the type III PKS stilbene synthase (STS). The difference in the cyclization mechanism between these two enzymes is the result of subtle, electrostatic variation between their active sites (Figure 12).[32] Since PKSs have been extensively reviewed,[33–36] the details of their catalyses will not be discussed here.

Figure 12.

Reaction mechanisms of chalcone and stilbene synthase.

2.3. Dieckmann Condensation

The Dieckmann condensation is an intramolecular cyclization of a diester to form a β-ketoester product under basic conditions (Figure 1). It is named after the German chemist, Walter Dieckmann, who first reported this reaction in 1894.[8] This reaction has been widely used to prepare five- and six-membered cyclic β-ketoester structures. A few biological precedents of Dieckmann-like condensations have recently been identified, such as formation of tetramic acid catalyzed by several hybrid PKS-non-ribosomal peptide synthases (PKS-NRPS), the MenB-catalyzed naphthoquinone formation in the biosynthesis of vitamin K, and the BadI-mediated production of pimelyl-CoA in the catabolism of benzoate. Although the molecules involved in these examples are not exactly diesters, the intramolecular condensations between two carbonyl-containing functional groups catalyzed by these enzymes show strong resemblance to Dieckmann condensation.

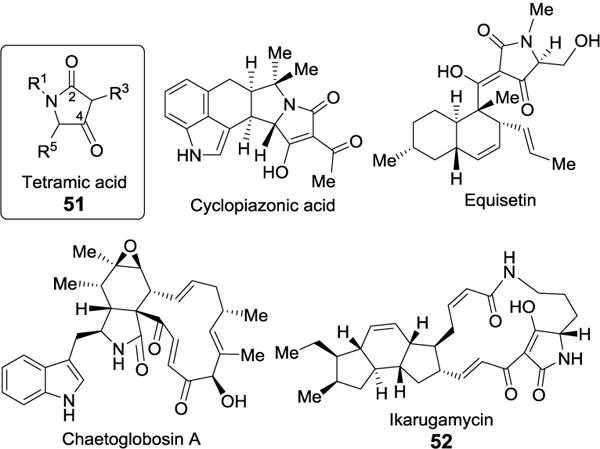

2.3.1. Formation of tetramic acid catalyzed by hybrid polyketide-non-ribosomal peptide synthase

A number of hybrid polyketide-non-ribosomal peptides, or their precursors, contain pyrrolidine-2,4-dione ring systems, also known as tetramic acids (51, Figure 13). These compounds are produced by an array of terrestrial and marine organisms such as fungi, cyanobacteria, and actinobacteria and display various bioactivities.[37] Examples include equisetin,[38] cyclopiazonic acid,[39] chaetoglobosin A,[40] heat-stable antifungal factor (HSAF),[41] and ikarugamycin (52).[42]

Figure 13.

Tetramic acid-containing natural products.

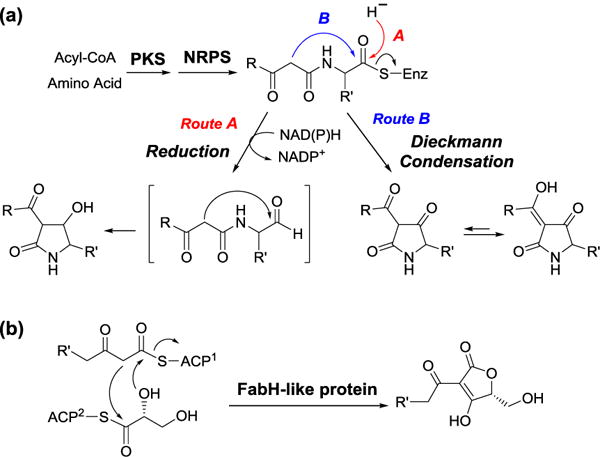

The genes responsible for the biosynthesis of these tetramic acid-containing compounds have been identified. In all cases, a hybrid PKS-NRPS is believed to be responsible for the production of the tetramic acid moiety. Based on bioinformatic analysis, the C-terminal domain of this PKS-NRPS appears to encode a putative NAD(P)H-dependent thioester reduction (R) domain. The R domain has been proposed to catalyze the reductive hydrolysis of the thioester linkage joining the precursor to PKS-NRPS to yield an aldehyde intermediate, which then undergoes aldol-type cyclization to generate tetramic acid (Figure 14a, route A). However, studies the biosynthesis of equisetin,[43] cyclopiazonic acid[44] and HSAF[45] revealed that the suspected R domain actually catalyzes a NAD(P)H independent cyclization to form tetramic acid and its concomitant release from the PKS-NRPS. The fact that the reaction is NAD(P)H independent supports the turnover via a Dieckmann mechanism (Figure 14a, route B). Similar Dieckmann cyclases have later been discovered in other tetramate and pyridine-based natural products biosynthesis.[46] Likewise, the biosynthesis of tetronic acid moiety, an oxygen analog of tetramic acid, has been proposed to proceed via an analogous pathway as that of tetramic acid. However, Sun et al. has recently reconstituted the biosynthetic pathway of RK-682 in vitro and demonstrated that the formation of tetronate does not involve Dieckmann reaction (Figure 14b).[47]

Figure 14.

Proposed biosynthesis of (a) tetramic and (b) tetronic acid.

2.3.2. Reaction catalyzed by 1,4-dihydroxynaphthoyl-CoA synthase (MenB)

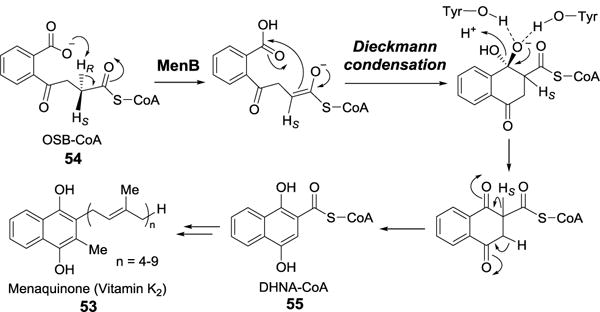

Vitamin K2 (menaquinone, 53) is a redox cofactor in the electron transport chain of most Gram-positive and a few Gram-negative bacteria (Figure 15).[48, 49] It is a polyisoprenylated naphthoquinone. Menaquinone is derived from chorismate in nine biosynthetic steps.[50–52] During the sixth step, the aromatic naphthoquinone ring in 1,4-dihydroxynaphthoyl-CoA (DHNA-CoA, 55) is formed from o-succinylbenzoyl-CoA (OSB-CoA, 54) via a Dieckmann cyclization catalyzed by DHNA-CoA synthase (MenB). A mechanism for the MenB reaction has been proposed based on the X-ray crystal structure of the E. coli enzyme in complex with the substrate analog, o-succinylbenzoylamino-CoA (Figure 15).[53]

Figure 15.

MenB-catalyzed Dieckmann condensation.

2.3.3. Reaction catalyzed by (S)-2-ketocyclohexanecarboxyl-CoA hydrolase (BadI)

Benzoate (56) is a common intermediate in the anaerobic breakdown of aromatic compounds including aromatic hydrocarbons, phenols, halogenated aromatics, and phenylpropanoids by bacteria.[54–56] Benzoate is further catabolized to pimelyl-CoA (59), which is ultimately degraded to acetyl-CoA (41, Figure 16).[57–59] The key step leading to the formation of pimelyl-CoA in the catabolic process is the ring opening of (1S)-2-ketocyclohexanecarboxyl-CoA ((S)-KC-CoA, 58) catalyzed by BadI. Despite good sequence homology to MenB, BadI actually catalyzes a reverse-Dieckmann reaction. A study using recombinant BadI from Rhodopseudomonas palustris demonstrated that BadI utilizes (S)-KC-CoA (58) as the substrate and incorporates a solvent-derived proton into the 2-pro-S position of pimelyl-CoA (59), consistent with the proposed mechanism (Figure 16).[60]

Figure 16.

BadI-catalyzed reverse Dieckmann condensation involved in the anaerobic degradation of aromatic compounds.

2.4. Pictet-Spengler Condensation

The Pictet-Spengler reaction was first discovered in 1911 by Amé Pictet and Theodore Spengler who observed formation of 1,2,3,4-tetrahydroisoquinoline (THIQ, 61) when heating β-phenylethylamine (60) and formaldehyde (24) together with hydrochloric acid (Figure 17a).[61] Seventeen years later, Tatsui reacted tryptamine (62) with acetaldehyde (63) in the presence of sulfuric acid and noted the production of 1-methyl-1,2,3,4-tetrahydro-β-carboline (THBC, 64, Figure 17b).[62] THIQ and THBC comprise the core structures of numerous naturally occurring isoquinoline and indole alkaloids. Many of them are medicinally valuable, such as morphine, the muscle relaxants papaverine and turbocurarine, the antimicrobials berberine and sanguinarine, the anti-cancer drugs vincristine and vinblastine, the antihypertensive drug ajmalicine, and the toxin strychnine.[63]

Figure 17.

Pictet-Spengler reactions for the synthesis of (a) THIQ and (b) THBC.

It is interesting that Pictet-Spengler reaction is in fact the method-of-choice for the biosynthesis of benzylisoquinoline and monoterpenoid indole alkaloids in nature. Representative enzymes capable of catalyzing Pictet-Spengler reactions include strictosidine synthase (STR) and norcoclaurine synthase (NCS), which have been biochemically characterized. The catalyses of these enzymes are discussed below. Pictet-Spenglerases have also been recognized in the biosynthesis of β-carboline (72) and saframycin A (81).

2.4.1. Strictosidine synthase

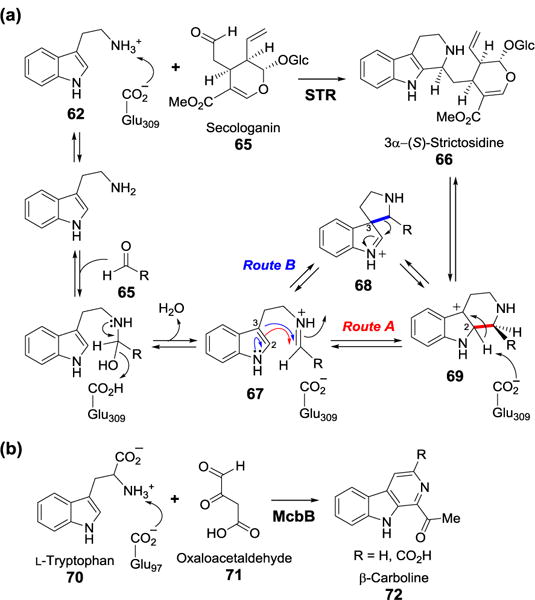

STR catalyzes the condensation between tryptamine (62) and the monoterpenoid aldehyde secologanin (65) to produce 3α-(S)-strictosidine (66). The STR activity was first detected over 35 years ago when radiolabeled precursors were added to the cell-free extracts of Catharanus roseus leading to radiolabel incorporation into the indole alkaloid, ajmalicine.[64] Soon thereafter, STR was partially purified from C. roseus,[65] and the Rauvolfia serpentina enzyme, designated STR1, was isolated and purified to homogeneity nine years later.[66] The gene encoding STR1 was identified allowing recombinant expression of the enzyme in E. coli[67] and in insect cells.[68] X-ray crystal structures containing bound tryptamine or secologanin,[69] and bound strictosidine[70] were also obtained. An active site glutamate residue is within H-bonding distance to the amine group of tryptamine.[69] These results implied that Glu309 may deprotonate the amine allowing the nucleophilic attack on the secologanin aldehyde carbonyl to form a Schiff base (67).

A schematic representation of the proposed mechanism for the STR1 reaction is depicted in Figure 18. After formation of the Schiff base, an electrophilic attack of C-2 of the tryptamine indole ring to the iminium carbon of the Schiff base may occur to yield the intermediate 69 (Figure 18a, route A). It is also plausible that the electrophilic attack takes place at C-3 position, resulting in a spiro-intermediate (68), which then undergoes a 1,2-alkyl shift to give 69 (Figure 18a, route B). However, ab-initio calculations suggest that the proposed 1,2-alkyl shift is energetically unfavorable, implying that 68 is unlikely a productive intermediate.[71] Further experiments revealed a kinetic isotope effect of ~2.7 when [2-2H]-tryptamine was used as the reactant in the STR1 reaction. The results indicate that re-aromatization, rather than ring closure, is the rate limiting step for both (although only the enzymatic reaction is stereospecific) and that all steps prior to re-aromatization are reversible. It was also proposed that Glu309 protonates the Schiff base to give the iminium intermediate and that, after cyclization, it deprotonates the resulting carbocation intermediate (69) resulting in re-aromatization.

Figure 18.

(a) Proposed mechanism of the STR-catalyzed reaction. (b) The microbial McbB-catalyzed Pictet-Spengler reaction.

In addition to STR1, a new class of Pictet-Spenglerase was recently found in the microbial biosynthesis of indole alkaloids (Figure 18b).[72] McbB from Marinactinospora thermotolerans catalyzes the condensation between L-tryptophan (70) and oxaloacetaldehyde (71) to produce β-carboline (72). Although McbB displays a different protein fold from that of strictosidine synthase, site-directed mutagenesis studies of McbB identified Glu97 as the catalytic residue.[73] This structural evidence supports that both McbB and strictosidine synthase likely catalyze the condensation reactions via a similar mechanism.

2.4.2. Norcoclaurine synthase

NCS represents another well-documented Pictet-Spenglerase catalyzing the stereospecific condensation of dopamine (73) and 4-hydroxyphenylacetaldehyde (4-HPAA, 74) to yield (S)-norcoclaurine (76). NCS was originally named as “norlaudanosoline synthase” based on the early studies in which the partially purified enzyme from various plant extracts was capable of converting dopamine (73) and 3,4-dihydroxyphenylacetaldehyde (75) to norlaudanosoline (77, Figure 19).[74] Further studies on the biosynthesis of reticuline, a precursor to a number of benzylisoquinoline alkaloids, demonstrated that norcoclaurine (76), rather than norlaudanosoline (77), is the central precursor for this class of compounds. The identification of the gene encoding NCS in Thalictrum flavum led to its recombinant expression in E. coli facilitating further structural and mechanistic studies.[75, 76] Interestingly, no significant amino acid sequence homology is detected between STR and NCS, indicating that the two enzymes are not evolutionarily related.

Figure 19.

Proposed mechanism of the NCS-catalyzed reaction.

The X-ray crystal structure of NCS containing bound dopamine and 4-hydroxybenzaldehyde, a non-reactive 4-HPAA homolog, was solved in 2009.[77] The crystal structure, along with prior mechanistic studies,[76] allowed a mechanism to be proposed (Figure 19). As with STR1, the NCS reaction could also proceed through a spirocyclic intermediate (78, Figure 19, route A) or not (route B). Lys122 is thought to stabilize the negative charge on the 4-hydroxyphenylacetaldehyde carbonyl oxygen during the formation of the Schiff base with dopamine. Mutation of Lys122 to Ala led to enzyme inactivation. Glu110 is proposed to abstract a proton after cyclization resulting in re-aromatization. Earlier mechanistic experiments with [2,5,6-2H]dopamine revealed an isotope effect of 1.7 ± 0.1 on kcat/KM, which implicated that re-aromatization is at least partially rate limiting and is the first irreversible step in the reaction.[76] This result is similar to that observed for the STR1 reaction. Both 4-deoxydopamine and 4-methoxydopamine serve as substrates for the NCS reaction but neither 3-deoxydopamine nor 3-methoxydopamine are accepted. These results strongly disfavor the spiro-species (78) as a productive intermediate.

2.4.3. Deacetylipecoside synthase

An enzyme from Alangium lamarckii that catalyzes a Pictet-Spengler condensation between dopamine (73) and secologanin (65) to give deacetylipecoside (79, Figure 20) has been purified and partially characterized.[78] The enzyme is designated deacetylipecoside synthase. Deacetylipecoside and its C1-epimer, deacetylisoipecoside (80), are the biosynthetic precursors for ipecac alkaloids. The gene encoding diacetylipecoside synthase has not been identified.

Figure 20.

Biosynthetic pathway of the alkaloids in Alangium lamarckii.

2.4.4. Saframycin biosynthesis: Pictet-Spenglerase activity in a non-ribosomal peptide synthase

Recently, an interesting example of a biological Pictet-Spengler condensation was uncovered in the biosynthesis of the non-ribosomal peptide antitumor antibiotic saframycin A (81, Figure 21).[79, 80] Saframycin isolated from Streptomyces lavendulae belongs to a group of THIQ antibiotics. The primary saframycin biosynthetic machinery consists of the NRPS modules: SfmA, B, and C (Figure 21). Notably, the R-domain of SfmC catalyzes the NADPH-dependent reductive release of NRPS-bound thioester intermediates to yield their corresponding aldehydes (e.g., 82 and 84). The C-domain of SfmC is responsible for two consecutive Pictet-Spengler condensations: the first between modified, NRPS-bound tyrosine (83) and a fatty-acyl-dipeptidyl aldehyde (82) produced by SfmA and B, and the second between the resulting bicyclic aldehyde (84) and a second modified, NRPS-bound tyrosine. The C13-fatty acyl chain is required for substrate recognition by the Pictet-Spenglerase and it is removed at a later stage of the pathway. The mechanism by which the C-domain catalyzes the Pictet-Spenglerase condensation reactions remains unclear so additional research is required for a complete understanding of this fascinating system.

Figure 21.

Proposed biosynthetic pathway of saframycin A.

2.5. Unnatural Condensation Reactions Catalyzed by Enzymes with Broad Substrate Specificity

2.5.1. Knoevenagel condensation

The Knoevenagel condensation is an aldol reaction involving the attack of a carbanion species to the carbonyl carbon of a ketone or an aldehyde followed by dehydration to give a conjugated enone product (Figure 22a). This reaction is named after Emil Knoevenagel who first reported this reaction in 1898.[81] Two enzymes, porcine pancreatic lipase[82] and Bacillus licheniformis alkaline protease,[83] have been shown to catalyze Knoevenagel condensation. The reaction catalyzed by porcine lipase was demonstrated with a series of benzaldehyde derivatives (85) and methylcyanoacetate (86) in ethanol (Figure 22b). During these reactions, the methyl ester was transesterified with solvent ethanol to yield ethyl esters (87). The alkaline protease-catalyzed Knoevenagel condensation was conducted with a series of salicylaldehyde (88) and β-keto-ethyl esters (89). The reactions were followed by transesterification to yield 2H-1-benzopyran-2-one derivatives (90), which are the core structures in a number of biologically active compounds with anticoagulant and antitumor activity (Figure 22b).

Figure 22.

(a) Knoevenagel reaction and (b) enzymatic Knoevenagel reactions.

2.5.2. Friedländer quinoline synthesis

The Friedländer quinoline synthesis involves condensation between 2-aminobenzaldehydes and the α-anion of a ketone under acid or Lewis acid catalyzed conditions to form a quinoline product (91, Figure 23). This reaction is named after Paul Friedländer who first reported this useful quinoline synthesis in 1880s,[84] when the scientific interests and commercial activities focused on the utilization of quinolines as dyes or medicines. Two mechanisms are conceivable. The distinction lies at whether the C-C bond (92) or the C-N bond (93) is formed first (route A versus route B). However, in both cases the key step is an aldol condensation reaction. Interestingly, lipase from porcine pancreatic was found to be able to catalyze the Friedländer quinoline synthesis when using 2-amino-3,5-dibromo-benzaldehyde and cyclopentanone as substrates.[85] This discovery may provide a useful tool to generate quinoline derivatives under mild conditions.

Figure 23.

Friedländer quinoline synthesis.

3. Nucleophilic Addition to C-C and C-Hetero Multiple Bonds

3.1. Michael Addition

The Michael addition which was originally reported by Arthur Michael in 1887 is the addition of an enolate of a ketone or aldehyde to an α,β-unsaturated carbonyl compound at the β carbon.[86] The definition of Michael has now been generalized to include addition of any nucleophile to a conjugated π-system. Thus, 1,4-addition of a heteroatom nucleophile to form a carbon-heteroatom bond is also considered to be a Michael addition reaction. Because numerous enzyme-catalyzed reactions in which Michael addition is a key step, it is considered to be one of the most prevalent C-C bond formation reactions, along with the aldol reaction, in biological system. For example, biosynthesis of lanthionine (Lan, 96) and methyllanthionine (MeLan, 97), which are the unifying structural motifs present in lantibiotics, includes a nucleophilic conjugate addition step (Figure 24a).[87] The thioether linkage in lantibiotics is generated by intramolecular Michael addition of a cysteine thiolate to a dehydroalanine (Dha, 94) or dehydrobutyrine (Dhb, 95) residue catalyzed by lantibiotic cyclase (LanC). The proposed mechanism illustrated in Figure 24a is based on the biochemical characterization and the X-ray crystal structure of NisC, the cyclase involved in nisin biosynthesis.[88] Although dehydro amino acids are less electrophilic than common Michael acceptors due to the build-in enamine substituent, nucleophilic addition to dehydro amino acids proceeds relatively fast. The cis-trans isomerization between maleylacetoacetate (98) and fumarylacetoacetate (99) catalyzed by maleylacetoacetate isomerase also involves a Michael addition of glutathione (GSH) to generate an enolate adduct (100), which after bond rotation and elimination of glutathione completes the isomerization (Figure 24b).[89] A few other examples where participation of coenzyme is needed are discussed below.

Figure 24.

Proposed mechanism for (a) LanC-catalyzed Michael addition and (b) the reaction catalyzed by maleylacetoacetate isomerase.

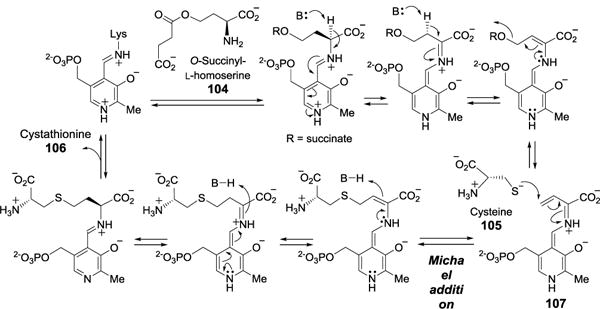

3.1.1. Tryptophan synthase and cystathionine γ-synthase

Both tryptophan synthase[90] and cystathionine γ-synthase[91] are PLP-dependent enzymes catalyzing the coupling of serine (22) and indole (101) to form tryptophan (70) and the replacement of the succinate group of O-succinyl-L-homoserine (104) with cysteine (105) to form cystathionine (106), respectively. Tryptophan synthase exists as an α2β2 tetramer. The β-subunits, where PLP resides, catalyze the conversion of serine (22) to an aminoacrylate-PLP intermediate (102) in an β-elimination reaction (Figure 25). Subsequently, indole (101), channeled from the α subunit, acts as nucleophile and attacks the highly conjugated intermediate (102) in a Michael addition manner to give 103, which after deprotonation and regeneration of the PLP coenzyme yields the final product tryptophan. In this case, a PLP-mediated 1,8-conjugate addition instead of classical 1,4-Michael addition is involved. The γ-replacement reaction catalyzed by cystathionine γ-synthase[91] follows a similar mechanism involving the formation of an extended conjugated intermediate (107), which serves as Michael acceptor for cysteine (105, Figure 26).

Figure 25.

Proposed mechanism for tryptophan synthase.

Figure 26.

Proposed mechanism for cystathionine γ-synthase.

3.1.2. Nitroalkane oxidase and alkyldihydroxyacetone phosphate synthase

The nitroalkane oxidase is a flavoprotein catalyzing the oxidation of nitroalkanes (109) to the corresponding aldehydes or ketones with concomitant elimination of a nitrite anion and the consumption of O2 to give H2O2 (Figure 27).[92, 93] The reaction is initiated by deprotonation of the Cα-H of the nitroalkane substrate, and the resulting carbanion (110) adds to the N5 of FAD (108) in a Michael addition to form a covalent adduct (111). Subsequent elimination of the nitrite anion leads to an N5-iminium dihydroflavin intermediate (112), which yields the aldehyde product (114) after hydrolysis. Re-oxidation of the reduced coenzyme (113) by O2 produces H2O2 as a byproduct.

Figure 27.

Proposed mechanism for nitroalkane oxidase.

The replacement of a long chain fatty acid in diacylglycerol phospholipids (115) by a long chain fatty alcohol to generate the monoacyl, monoalkyl ether phosphate lipids (119) catalyzed by alkyldihydroxyacetone phosphate synthase (ADPS) also involves the intermediacy of an N5-substrate adduct with the bound flavin coenzyme (Figure 28).[94] The catalytic cycle is believed to proceed with C1 deprotonation of the substrate followed by addition of the resulting carbanion (116) to N5 of FAD to give 117. Cleavage of the ester linkage to expel the acyl product leads to a N5-flavin iminium intermediate (118), which is then reacted with the fatty alcohol substrate. Re-oxidation of the flavin coenzyme along with C–N bond cleavage affords the alkyldihydroxyacetone phosphate product (119). In the mechanisms for both nitroalkane oxidase and ADPS, formation of the N5-adduct (112 and 117) results from addition of a carbon nucleophile to the conjugated diimine moiety in the oxidized flavin cofactor, which serves as the Michael acceptor.

Figure 28.

Proposed mechanism for alkyldihydroxyacetone phosphate synthase.

3.1.3. Branching module in rhizoxin biosynthesis

Polyketide biosynthesis was briefly discussed in the previous section. While chain growth proceeds linearly, branched polyketides also exist and are usually resulted from the incorporation of α-branched building blocks during chain extension or post-chain-extension modification of the linear backbone at the α-position. Another branching mechanism involves a β-aldol reaction catalyzed by hydroxymethylglutaryl-CoA synthase (HCS) cassette.[95] Recently, a novel β-branching PKS module catalyzing Michael-addition was identified in the biosynthetic pathway of rhizoxin (120), a phytotoxin produced by Burkholderia rhizoxinica (Figure 29).[96, 97] Using synthetic thioester (121) as surrogate substrate, Bretschneider et al. demonstrated the activity of the β-branching module, which is consisted of a KS domain, an ACP domain and a branching (B) domain.[97] The chain branching mechanism was proposed to involve a Michael addition of the extender unit to the α,β-unsaturated thioester bound to the KS domain. The nucleophilic hydroxyl group can either attack the KS-bound or the ACP-bound thioester to form δ-lactone (Figure 29). In order to distinguish these two mechanisms, 13C-labeled malonyl-CoA was used as the extender unit to trace the lactonization reaction. Characterization of the ACP-bound product by nuclear magnetic resonance (NMR) experiments showed that the labeled atoms were incorporated in the polyketide chain (122) instead of the lactone ring (123) and therefore supported route A.

Figure 29.

Michael addition and lactonization catalyzed by a branching module.

3.2. Morita-Baylis-Hillman Reaction

The Morita–Baylis–Hillman (MBH) reaction is a synthetically useful transformation named after Ken-ichi Morita, Anthony Baylis and Melville Hillman. It is a carbon-carbon bond forming reaction between the α-position of an activated alkene and an aldehyde (or an imine).[98, 99] The reaction requires a nucleophilic catalyst, such as tertiary amine or phosphine, and produces a densely functionalized product (Figure 30a).

Figure 30.

(a) Morita-Baylis-Hillman reaction. (b) Rauhut-Currier reaction.

The transformation catalyzed by thymidylate synthase is the biological precedent of the MBH reaction. Thymidylate synthase facilitates the methylation of 2′-deoxyuridine 5′-monophosphate (dUMP, 124) to thymidine 5′-monophosphate (TMP, 128) using N5,N10-methylene-THF (28) as the methyl donor (Figure 31). The mechanism of thymidylate synthase-catalyzed reaction has been extensively studied.[100] This one-carbon transfer reaction is initiated by the addition of an active site cysteine to dUMP (124) to generate an enolate intermediate (125), which is used to attack N5,N10-methylene-THF (28) to form a new C-C bond (126). Subsequent C-5 deprotonation triggers β-elimination of THF to form an enone intermediate (127), which after reduction by THF (20) yields the TMP product (128). The activation of deoxyuridylate by cysteine as a nucleophilic catalyst, and the addition of the resulting enolate to the iminium group of N5,N10-methylene-THF are all characteristics for a MBH reaction.

Figure 31.

Proposed reaction mechanism for thymidylate synthase.

3.3. Rauhut-Currier Reaction

Rauhut-Currier reaction is a nucleophilic conjugated coupling of one active alkene/latent enolate to a second Michael acceptor, not an aldehyde or an imine, to form a new C–C bond between the α-position of the activated alkene and the β-position of the second alkene under the influence of a nucleophilic catalyst (Figure 30b). While it is also known as a vinylogous MBH reaction, the Rauhut-Currier reaction reported by Rauhut and Currier in 1963 is actually predated the MBH reaction.[101]

SpnL, in the biosynthetic pathway of spinosyns, has been proposed to catalyze a Rauhut-Currier-type C-C bond formation reaction. The spinosyns are a complex of polyketide insecticides produced by Saccharopolyspora spinosa. The aglycone core of spinosyns has a tetracyclic architecture in which a 12-membered lactone ring is fused with a perhydro-as-indacene moiety (129, Figure 32).[102] The biosynthetic route for the formation of the macrolactone can be largely inferred by analysis of genes encoding the polyketide biosynthetic modules.[103] All of the post-PKS tailoring steps including cyclization of the macrolactone to form the tetracyclic core have been elucidated (Figure 32).[104, 105] SpnF catalyzes a [4+2] cycloaddition reaction resulting in the formation of a cyclohexene ring (130 → 131). This may represent an example of a biological Diels-Alder reaction, a possibility that will be discussed in detail later. The SpnF reaction is followed by a second cross-bridging reaction catalyzed by SpnL (132 → 135), which has been proposed to proceed via a Rauhut-Currier mechanism. Accordingly, coupling between C-3 and C-14 likely results from the nucleophilic addition of an enolate to a Michael acceptor (133 → 134) facilitated by a nucleophilic residue in the active site (Figure 32). In the case of SpnL, the nucleophilic catalyst has yet to be identified.

Figure 32.

The biosynthetic pathway of spinosyn A.

Iridoid alkaloids are bicyclic monoterpenes found in plants[106] and insects[107] to defend themselves against predators. Rauhut-Currier reaction has been proposed for the cyclization of 8-oxogeranial (136) to iridodial (137), a key intermediate for the biosynthesis of iridoids, in Chrysomelina species (Figure 33a).[108] However, the biosynthesis of iridoids in beetles may be quite different from what happens in plants. In fact, mechanistic studies of plant iridoid synthase from Catharanthus roseus (CrISY) suggested that the cyclization is a Michael reaction and occurs after the reduction of 136 by NADPH (Figure 33b).[109, 110] Moreover, the hypothetic Rauhut-Currier mechanism is unlikely for CrISY due to the absence of suitably placed nucleophilic residues (cysteine or histidine) in the active site.[111]

Figure 33.

Proposed mechanisms of the conversion of 8-oxogeranial to iridodial. (a) Rauhut-Currier reaction covalently assisted by a nucleophilic residue occurs first followed by reduction. (b) Reduction occurs priot to Michael reaction.

3.4. Mannich Reaction

The Mannich reaction, named after Carl Mannich, is a three-component condensation between an amine and an aldehyde to give an electrophilic iminium ion, which then joins with the α-carbon of an enolate to give a β-amino-carbonyl compound (Figure 34).[112] Mannich reaction has been established to be an important transformation in the biosynthesis of plant alkaloids. This subject has been the focus of several reviews.[113–116] Here, tropane alkaloid is selected as an example to illustrate the involvement of Mannich reaction in alkaloid biosynthesis. Tropane alkaloids, such as hyoscyamine (142), scopolamine (143) and cocaine, have been popular targets for organic synthesis and used in the development of clinically useful pharmaceutics.[117] The synthesis of tropinone (140) from succindialdehyde, methylamine and acetonedicarboxylate was first reported by Robert Robinson in 1917.[118] Robinson later proposed that the biosynthesis of the bicyclic ring of tropane may follow a similar route involving an amino acid and an acetone equivalent.[119] This hypothesis is supported by many lines of evidence collected over 60 years of research. Our current understanding of the tropane alkaloids biosynthesis is summarized in Figure 34.[114, 117] The coupling between the enolate of an acetone equivalent and the pyrrolinium cation (139) proceeds through a Mannich-like mechanism. Formation of the tropane skeleton in the subsequent step is likely accomplished by an aldol reaction which may be considered as an intramolecular Mannich reaction (139 → 140).

Figure 34.

(a) Mannich reaction. (b) The proposed biosynthetic pathway of hyoscyamine and scopolamine.

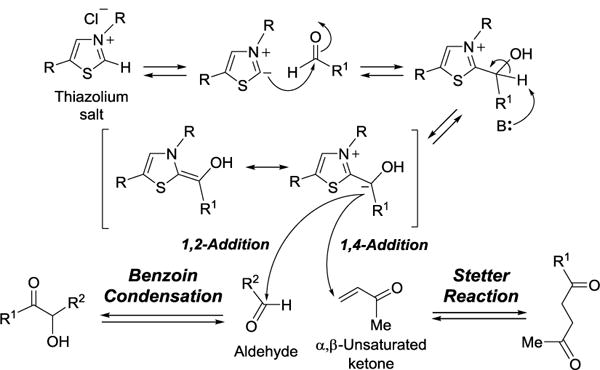

3.5. Stetter Reaction and Benzoin Condensation

The Stetter reaction is a coupling reaction between an aldehyde and an α,β-unsaturated ketone to yield a 1,4-dicarbonyl product.[120, 121] The reaction is catalyzed by cyanide ion or a safer surrogate, the thiazolium salt, which is analogous to the biological cofactor thiamine diphosphate (TPP, 144). This reaction was first reported by Hermann Stetter in 1973.[120] Under the reaction conditions, the aldehyde undergoes polarity inversion (umpolung)[122] to become a nucleophile instead of an electrophile. The mechanism of Stetter reaction is related to that of benzoin condensation. However, the latter reaction occurs in 1,2-addition manner, whereas the Stetter reaction proceeds with 1,4-conjugate addition (Figure 35). The reactions catalyzed by MenD and PigD are the biological equivalents of Stetter reactions.

Figure 35.

Stetter reaction and benzoin condensation.

MenD is a TPP-dependent enzyme responsible for the second step of menaquinone (53) biosynthesis. Its catalysis consists of two reactions, the decarboxylation of α-ketoglutarate (α-KG, 145) to generate a succinic semialdehyde-TPP anion (146), and the addition of this anion to isochorismate (147) to yield (1R,2S,5S,6S)-2-succinyl-5-enolpyruvyl-6-hydroxy-3-cyclohexene-1-carboxylate (SEPHCHC, 148) as the product (Figure 36).[51] The TPP stabilized ketol fragment (146) is an α-imine anion equivalent and serves as the nucleophile to attack the β carbon of the conjugated olefin in 146 in a Michael addition to form a new C-C bond. In this reaction, the thiazolium cofactor has to be deprotonated first to be catalytic. The absence of an appropriate general acid/base residue in the active site led to the proposal that the cofactor N4′ may serve this role in the mechanism of MenD (Figure 36).[123]

Figure 36.

Proposed mechanism of MenD-catalyzed reaction.

PigD from Serratia marcescens, has been postulated to catalyze the decarboxylating condensation of (2E)-octenal (149) with pyruvate during the biosynthesis of the antibiotic prodigiosin. Its catalytic function is assigned based on gene knockout experiments and sequence annotation as a TPP-dependent protein (Figure 37).[124] However, the recombinant PigD enzyme was shown to catalyze the 1,2-addition of acetaldehyde (the decarboxylated product of pyruvate, 63) instead of the predicted 1,4-addition with 2-octenal (149). The 1,4-selectivity was only observed when the (2E)-octenoyl-N-acetyl cysteamine thioester ((2E)-octenoyl-SNAC, 150) was used as substrate.[125] These observations suggested that either an acyl thioester or CoA derivative is the substrate for PigD in prodigiosin biosynthesis.

Figure 37.

PigD-catalyzed Stetter reactions.

The reaction catalyzed by transketolase is another example in which coenzyme TPP (144) is required to stabilize an anion intermediate used in the aldol reaction.[126] The overall transformation is the reversible transfer of a two-carbon fragment from D-xylulose 5-phosphate (151) to D-ribose 5-phosphate (154) to give D-sedoheptulose 7-phosphate (155) and glyceraldehyde 3-phosphate (3) as products (Figure 38). This is an important reaction in the pentose phosphate pathway for glucose metabolism. Since the nucleophilic attack occurs in a 1,2-addition manner, this reaction is a biological example of benzoin condensation. Although benzoin condensation is not a so-called “name reaction”, it is perhaps the oldest reaction which has given a name based on the product from condensation of two molecules of benzaldehyde.[127]

Figure 38.

Reaction mechanism of transketolase.

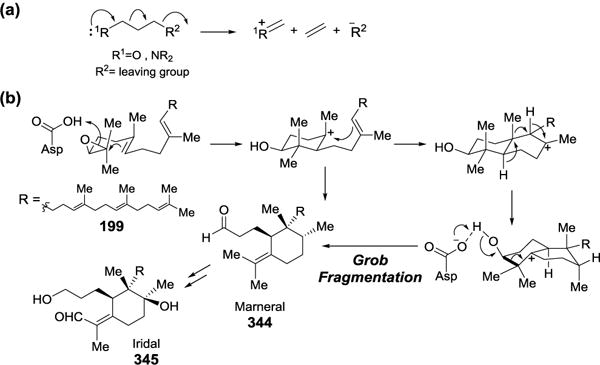

3.6. Retro-Prins Reaction

In 1919, Hendrik Jacobus Prins reported the acid-catalyzed coupling of aldehydes to olefinic compounds to make 1,3-diols.[128] Depending on the reaction conditions, different products can also be produced (Figure 39). The reverse process called retro-Prins reaction is a thermal elimination reaction and has proved synthetically useful.[129] The cyclization and fragmentation of farnesyl diphosphate (FPP, 156) to geosmin catalyzed by geosmin synthase from Streptomyces coelicolor (ScGS) has been proposed to involve retro-Prins reaction. Geosmin is a volatile metabolite responsible for the characteristic smell of moist soil. Geosmin synthase has been shown to be a bifunctional enzyme.[130] The N-terminal domain catalyzes the conversion of FPP to germacradienol (156 → 157), while the C-terminal domain catalyzes the subsequent cyclization of 157 to form geosmin (158) and acetone via a retro-Prins reaction. The two domains function independently and there is no obvious channel between the two active sites.[131] It thus remains unclear that germacradienol intermediate (157) generated in the N-terminal domain is processed by the C-terminal domain of the same or a different protein molecule.

Figure 39.

(a) Prins reaction. (b) Proposed reaction mechanism catalyzed by geosmin synthase.

3.7. Unnatural Addition Reactions Catalyzed by Enzymes with Broad Substrate Specificity

It is well known that some enzymes can catalyze conversions of small molecules distinct from their natural substrates to give new products in stereospecific manner. Enzymes that accept alternative substrates are said to be “promiscuous” with regard to substrate specificity. The activity of an enzyme can also be altered by site-specific mutagenesis to catalyze unnatural reactions. There are too many examples of these types of applications to list them all here. This section will provide a sampling of non-substrate specific condensations with an emphasis on name reactions. Several reviews provide a more comprehensive overview of the subject.[132–134]

3.7.1. Henry reaction

The nitroaldol reaction, also known as Henry reaction, is a variation of the aldol reaction in which the carbonyl carbon of a ketone or an aldehyde substrate undergoes nucleophilic attack by a deprotonated nitroalkane to yield a β-nitro alcohol product (Figure 40). This reaction was first reported by M. Louis Henry in 1895 and has been used widely in organic synthesis.[135] Transglutaminase (TGase) from Streptoverticillum griseoverticillatum,[136] D-aminoacylase from Mucor javanicus,[137] D-glucoamylase from Aspergillus niger,[138] and bovine serum albumin,[139] have been shown to catalyze Henry reaction. These observations are intriguing since the physiological role of TGase is to catalyze the acyl transfer from glutamate to the ε-amino group of a lysine or another primary amine, and that of D-aminoacylase is to hydrolyze N-acyl-D-amino acids. Likewise, D-glucoamylase catalyzes the degradation of starch, and serum albumin is a protein that binds lipids circulating in blood and is not an enzyme. Since the observed activities on nitroaldol reaction of these enzymes are unrelated to their physiological functions, how they catalyze Henry reactions remains elusive. While none of the above mentioned Henry reactions are enantioselective, hydroxynitrile lyase (HNL) from Hevea brasiliensis (the rubber tree) can catalyze stereoselective nitroaldol reaction using aldehydes and nitroalkanes,[140] although the physiological role of HNL is to catalyze the degradation of cyanohydrins to the corresponding aldehyde with release of hydrogen cyanide (Figure 40).[141] The cyanide released acts as a toxin to deter predators and parasites.

Figure 40.

Henry nitroaldol reaction and hydroxylnitrile lyase-catalyzed reversible cyanohydrin formations.

3.7.2. Ugi reaction

The conventional Ugi reaction, named after Ivar Karl Ugi, is a multi-component condensation of a carboxylic acid, an isocyanide, an amine and a carbonyl compound.[142] The reaction mechanism is believed to proceed via a nitrilium ion intermediate (159), which is attacked by the nucleophilic carboxylic anion (Figure 41). The following Mumm rearrangement[143] generates the diamide compound and water as the sole by-product. Based on the mechanism, Pan and List have proposed a catalytic three-component Ugi reaction, in which the nitrilium intermediate (159) is reacted with a water molecule instead of carboxylate ion. This designed reaction was later shown to be as efficient as the classic Ugi reaction when using the acid as catalyst.[144] In addition to the chemical catalyst, Novozym 435 was found to be an effective lipase and is capable of catalyzing multi-component Ugi condensation of ethyl isocyanoacetate, isovaleric aldehyde and 2 equivalents of benzylamine (Figure 41).[145] Whether the addition of the second amine is due to the involvement of enzyme or the chemical nature of isocyanide remains unclear. However, this enzymatic Ugi reaction removes the requirement of heat in the acid-catalyzed Ugi reaction and may become useful in applied chemistry.

Figure 41.

Ugi reaction.

4. Oxidation and Reduction Reactions

4.1. Baeyer-Villiger Reaction

The Baeyer-Villiger (BV) reaction is an oxidative C-C bond cleavage reaction of an aldehyde or a ketone by insertion an oxygen atom into the C-C bond next to the carbonyl group to form the corresponding formate, lactone or ester upon treatment with suitable oxidants. The first example of BV reaction is the lactonization of menthone with potassium monopersulfate reported by Adolf von Baeyer and Victor Villiger in 1899.[146] The reaction proceeds by nucleophilic addition of peroxide on the carbonyl to form a tetrahedral intermediate (160), also known as Criegee intermediate,[147] followed by a concerted migration of one of the adjacent carbons to oxygen to afford the rearrangement product (Figure 42).[148]

Figure 42.

Baeyer-Villiger reaction and Criegee intermediate.

Enzymes catalyzing BV reaction (known as BV monooxygenases, BVMOs) are widely distributed in nature with at least 1000 putative homologs in the database.[5] The first biological example of BV reaction was discovered in the microbial degradation of steroids in 1948.[149] Later, BVMO enzymes were purified to homogeneity from Nocardia globerula CL1 and Acinetobacter sp. strain NCIB 9871 and shown to catalyze the lactonization of cyclohexanone.[150] Most BVMOs characterized thus far are flavin-dependent enzymes. They generally consume one equivalent of NAD(P)H and oxygen for each turnover and most of them can be classified into three different subsets. For type 1 BVMOs, each is a single polypeptide with FAD and NADPH bound to separate domains. Type 2 BVMOs utilize FMN and either NADPH or NADH, and are composed of two distinct polypeptides: one binds FMN and the second binds NAD(P)H.[151] Type “O” (means odd) BVMOs are evolutionarily distinct from types 1 and 2. This group of enzymes consist of a single polypeptide utilizing a surface bound FAD and either NADH or NADPH as the reducing agent.[152] BVMOs that are not flavin-dependent have also been identified. Toxoflavin lyase and AflM catalyze BV oxidation by utilizing manganese and heme-iron as cofactors, respectively.

The identification of novel BVMOs is of increasing importance, as the reactions they catalyze are generally regio-, chemo-, and enantiospecific. By using BVMOs in organic synthesis, one obviates the use of potentially dangerous oxidants and the disposal or recycling of the corresponding carboxylic acid from the peroxyacid reagent, because the only byproduct in BVMO-catalyzed reaction is water. A few selected BVMOs and the proposed catalytic mechanisms are described below. For an overview of the current state of BVMOs in organic synthesis please see the review by Leisch et al.[5]

4.1.1. The prototype of flavin-dependent BVMOs: cyclohexanone monooxygenase

BVMOs play important roles in the microbiological catabolic pathways of steroids, terpenoids, and aliphatic ketones. As the prototypical example, cyclohexanone monooxygenase (CHMO) from Acinetobacter NCIB 9871 has been extensively studied. CHMO is a type I BVMO and is the first BVMO of which the encoding gene was cloned.[153, 154] Under physiological conditions, CHMO catalyzes an oxygen insertion reaction on cyclohexanone (161) to form a seven-membered cyclic lactone (162), a key step in the degradation pathway of cyclohexanol (Figure 43).[150] Oxygen insertion catalyzed by CHMO has been proposed to proceeds through a Criegee intermediate (165) in the same manner as the non-enzymatic BV reactions.[147] Early experiments using [2,2,6,6-2H4]cyclohexanone as the substrate demonstrated that no solvent proton was incorporated into the product. Therefore, the reaction unlikely proceeds through an enolate intermediate.[155] Further spectroscopic studies on the protonation state of the oxygenated flavin intermediate revealed that, although both flavin C4a-OO– (163) and flavin C4a-OOH (164) co-exist in equilibrium (Figure 43), it is the deprotonated species (163) that reacts with the substrate.[156]

Figure 43.

Proposed mechanism of cyclohexanone monooxygenase (CHMO).

4.1.2. BVMOs in natural products biosynthesis

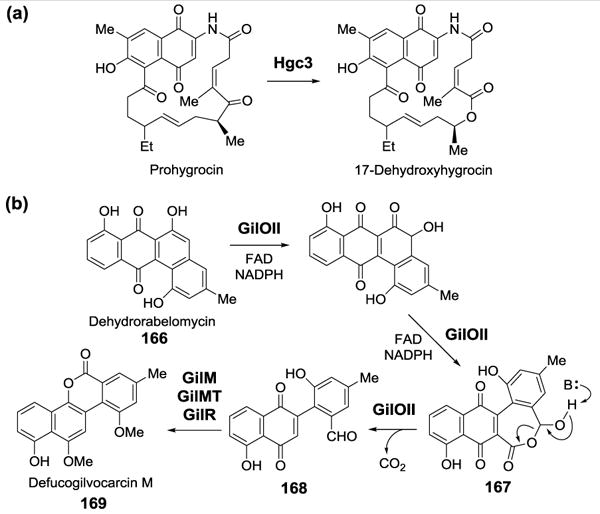

In addition to the catabolic BVMOs found in the degradation pathways, BVMOs have also been identified in the biosynthetic pathways of polyketides, aminoglycosides, cofactors and many other secondary metabolites. Knockout experiments in Streptomyces sp. LZ35 indicated that gene hgc3 encodes a flavin-dependent enzyme that catalyzes a lactonization step during the biosynthesis of hygrocin antibiotics (Figure 44a).[157] Although the catalytic activity of the purified recombinant Hgc3 has not yet been demonstrated in vitro, the Hgc3 protein is dissimilar from the categorized BVMOs known so far based on sequence alignment.

Figure 44.

(a) Proposed lactonization catalyzed by Hgc3. (b) The GilOII-catalyzed C-C bond cleavage reaction.

A BVMO involved in the biosynthesis of the gilvocarcins produced by various strains of Streptomyces was identified and its activity was confirmed by in vitro assays using purified, recombinant protein.[158] This enzyme, GilOII catalyzes the hydroxylation and the lactonization of dehydrorabelomycin (166), an intermediate in the biosynthesis of gilvocarcins (Figure 44b). The reaction only occurred in the presence of FAD, which was reduced in situ with NADPH and E. coli flavodoxin reductase. Based on sequence analysis, it is not obvious that GilOII is a flavoprotein. Rather, it displays sequence homology to the cofactor-free anthrone oxygenases, TcmH[159] and AknX,[160] which are involved in the biosynthesis of tetracinomycin C in Streptomyces glaucescens and aklavinone in Streptomyces galilaeus, respectively. The lactone product (167) is further hydrolyzed, decarboxylated, and converted to defucogilvocarcin M (169) through the actions of the downstream biosynthetic enzymes GilMT, GilM, and GilR.

The dimethylbenzimidazole (DMB, 171) is a key structural component of coenzyme B12 (170), where a nitrogen atom of DMB serves as an axial ligand to the cobalt atom. Flavin mononucleotide (FMN, 172) has been shown to be the precursor for DMB and the responsible enzyme, BluB, has recently been identified in Sinorhizobium meliloti.[161, 162] BluB is a flavin protein catalyzing the contraction of the tricyclic isoalloxazine to form DMB (Figure 45). A flavin-dependent reductase is needed to generate the reduced flavin (FMNH2, 173) in the active site of BluB before each catalytic event. The mechanism of BluB likely involves a FMN-4a-OOH intermediate (174), which undergoes an intramolecular Baeyer–Villiger reaction to yield the 7-membered lactone (175).[163] Subsequent hydrolyses occurring at both the expanded pyrimidine and the central pyrazine ring lead to the release of oxalic acid, urea and CO2. The final transformations to DMB include oxidation, retro-aldol cleavage of the ribityl side chain to liberate erythrose 4′-phosphate, cyclization and aromatization. The reaction catalyzed by BluB is unusual since the BV reaction takes place on the flavin coenzyme itself.

Figure 45.

The proposed mechanism of BluB-catalyzed reaction.

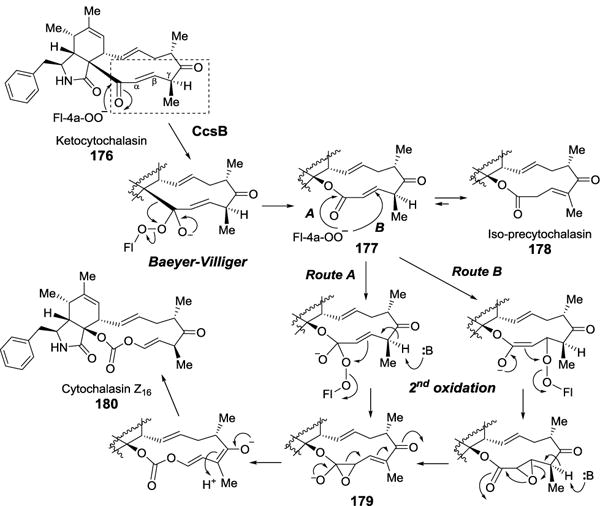

Recently, a BVMO was shown to catalyze the formation of carbonate group in the biosynthesis of cytochalasins, which are fungal natural products isolated from Aspergillus clavatus.[164] In the presence of FAD, NADPH and a flavin reductase, the recombinant CcsB converts ketocytochalasin (176) to a lactone iso-precytochalasin (178) and a carbonate-containing compound cytochalasin Z16 (180, Figure 46).[165] Iso-precytochalasin (178) is likely a side-product resulting from the rapid isomerization of the nascent product (177) from the first oxidation, which is a Baeyer-Villiger reaction. The second oxidation converting an ester to a carbonate moiety through a pseudo-BV mechanism is an intrinsically challenging transformation because the increased electron density on the ester carbonyl renders it less susceptible toward nucleophilic attack. Since the sequence analysis of CcsB reveals only moderate homology with most canonical type I BVMOs, its capability to catalyze carbonate formation has been speculated to rely on substrate activation inflicted by the functional groups adjacent to the ester carbonyl group: the vinylogous 1,5-diketo moiety, the α,β-unsaturated ester unit and the acidic proton at the γ-position (Figure 46). Such a chemical environment may allow the flavin C4a-OO– to insert through either a direct attack at the carbonyl group (Figure 46, route A) or a Michael addition to the β-carbon (Figure 46, route B). Instead of the classic BV migratory mechanism, the second oxidation reaction is proposed to form an epoxide intermediate (179), which rearranges to the carbonate product via the aid of the distal vinylogous ketone.

Figure 46.

The proposed mechanism of CcsB-catalyzed carbonate formation.

BVMO also plays a crucial role in carbamate group formation in the biosynthesis of bacterial pyrrolizidine alkaloids (PAs). It has been shown that legonmycins (181, Figure 47) biosynthetic gene cluster from Streptomyces sp.MA37 contains three NRPS genes (lgnABD) and one putative BVMO gene (lgnC).[166] The purified flavoprotein LgnC was shown to catalyze an oxygen insertion reaction of legonindolizidins (182) to form a carbamate intermediate (183), which undergoes hydrolysis followed by decarboxylative recyclization to generate 185 (Figure 47). LgnC is also expected to catalyze the second hydroxylation reaction leading to the production of legonmycins (181, Figure 47). Similar biosynthetic route has also been proposed for the formation of pyrrolizixenamides in Xenorhabdus stockiae.[167]

Figure 47.

Proposed biosynthetic pathway for legonmycins.

4.1.3. Cytochrome P450 BVMO

Although the BVMOs described above are all flavin-dependent, several cytochrome P450 enzymes catalyzing Baeyer-Villiger reactions have also been identified. For example, there exist two Bayer-Villiger lactonization reactions in the biosynthesis of aflatoxins (186), a class of environmental carcinogens produced by the fungi of the genus Aspergillus (Figure 48). Early studies of aflatoxin biosynthesis in Aspergillus parasiticus suggested that the conversion of hydroxyversicolorone (187) to versiconal acetate (188) is catalyzed by a BVMO (Figure 48).[168] Subsequent gene deletion experiments led to the identification of moxY, which encodes a cytochrome P450 monooxygenase, as the gene responsible for this reaction.[169] In separate experiments, the genes aflN and aflM, which encode a cytochrome P450 monooxygenase and an NADPH-dependent reductase, respectively, were shown to be associated with the subsequent conversion of versicolorin A (189) to demethylsterigmatocystin (191) in aflatoxin biosynthesis in Aspergillus nidulans. The gene aflN from A. nidulans is also known as stcS.[170, 171] Using chemically prepared intermediates, AflM has been verified to catalyze the reduction of the dienone intermediate (190) generated from 189 by AflN. AflN also catalyzes the following Baeyer-Villiger monooxygenation reaction leading to ring opening, re-cyclization, and decarboxylation to give 191 (Figure 48).[172, 173]

Figure 48.

The proposed biosynthetic pathway of aflatoxin B1 and mechanisms of key enzymes involved.

Brassinosteroids are a class of polyhydroxylsteroids hormones important for cell expansion, cell elongation, vascular differentiation, and many other growth processes in plants.[174] Many brassinosteroids, such as brassinolide (193), contain a seven-membered lactone ring which is formed via a Baeyer-Villiger oxidation reaction from the corresponding 5-keto precursor (192, Figure 49). This reaction is catalyzed by brassinolide synthase which is a cytochrome P450 BVMO. The brassinolide synthases have been isolated from tomato and also from Arabidopsis thaliana.[175, 176]

Figure 49.

The lactonization catalyzed by brassinolide synthase.

4.1.4. Metal ion-dependent BVMO: toxoflavin lyase

Toxoflavin (194), is a plant toxin produced by several bacterial species that causes food poisoning.[177] The gene tflA, encoding an enzyme that catabolizes toxoflavin, was identified in a toxoflavin resistant strain of Paenibacillus polymyxa.[178] The activity of purified TflA was only observed in the presence of dithiothreitol (DTT) and Mn2+.[179] An X-ray crystal structure of TflA containing bound toxoflavin revealed that Mn2+ is coordinated to two glutamate residues and one histidine residue in the enzyme active site.[179] The products resulting from the degradation of toxoflavin by TflA were identified by a combination of mass spectrometry and NMR spectroscopy (Figure 50).[180] Based on the identity of these products, a Bayer-Villiger monooxygenation mechanism was proposed, in which O2 is activated for electrophilic attack on reduced toxoflavin (195) by coordination with Mn2+. In this scheme, DTT is required for the reduction of toxoflavin. The proposed mechanism has no precedent in biology.

Figure 50.

Mechanistic proposal for the degradation of toxoflavin.

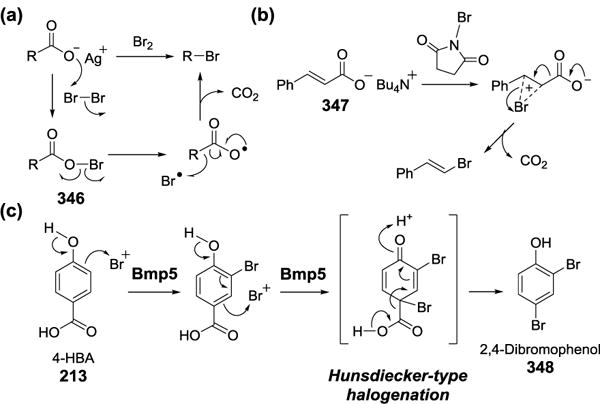

4.2. Prilezhaev Reaction

The Prilezhaev reaction is a convenient method to prepare oxiranes from alkenes using peracid (Figure 51a). The reaction is named after Nikolaus Prilezhaev who first reported this reaction in 1909.[181] Such epoxidation of olefins is a common transformation in living systems and can be catalyzed by a variety of monooxygenases including flavoproteins and P450 enzymes. While the reactive oxygen species in these enzymes, the flavin-4a-hydroperoxo (164) and ferric-peroxo (compound 0, 196), respectively, are not peracids per se, they are clearly peroxide-containing reagents (Figure 51b). Hence, their catalyzed epoxidation may be classified as pseudo-Prilezhaev reaction. Most epoxidation of double bonds in the biosynthesis of secondary metabolites are carried out by cytochrome P450 enzymes, such as PimD in the pimaricin pathway[182] and EpoK in the epothilone A pathway[183] (Figure 51c).

Figure 51.

(a) Prilezhaev reaction. (b) Biological equivalents of peracids. (c) Proposed mechanism and examples of P450 enzyme-catalyzed epoxidation.

A well-known flavoprotein capable of catalyzing such epoxidation is squalene epoxidase which epoxidizes the terminal double bond of squalene (198) to yield squalene-2,3-oxide (199), the common precursor of many sterols (Figure 52a).[184] A more recent example is the FAD-dependent fungal indole epoxidase Af1206095, which converts fumiquinazoline F (FQF, 200) to an unstable epoxyindole intermediate (201) that is further processed by an alanine-activating NRPS module Af12050 to yield fumiquinazoline A (FQA, 202) (Figure 52b).[185, 186]

Figure 52.

Epoxidation reactions catalyzed by flavoproteins, (a) squalene 2,3-epoxidase (b) Af1206095.

4.3. Nef Reaction

The Nef reaction is the conversion of a primary or secondary nitroalkane (203) to the corresponding aldehyde or ketone (204) (Figure 53a).[187] This reaction was first reported in 1894 by John U. Nef and the original experiment was the acid hydrolysis of nitroethane to yield acetaldehyde and nitrous oxide. The Nef reaction can also occur under reductive condition using catalysts such as titanium trichloride, and hydrolysis of the oxime intermediate (205) leads to a carbonyl product (Figure 53b). [188] A number of enzymes related to “old yellow enzyme” (OYE) had been demonstrated to be involved in the metabolism of electrophilic, and potentially toxic, molecules such as α,β-unsaturated carbonyl compounds and aliphatic and aromatic nitro esters.[189] These enzymes utilize FMN as coenzyme with NAD(P)H as the likely physiological reductant. The following OYE-type enzymes had been shown to have the capability to catalyze the conversion of (E/Z)-1-nitro-2-phenyl-1-propene (206) to the corresponding oxime and aldehyde (Figure 53c): xenobiotic reductases A and B from Pseudomonas putida, 12-oxophytodienoic acid reductase (OPR3) from Lycopersicon esculentum, pentaerythritol teranitrate reductase (PETN-R) from Enterobacter cloacae, glycerol teranitrate reductase (NerR) from Agrobacterium radiobacter, and morphinone reductase (MorR) as well as quinone reductase (YhdA) from unnamed sources.[190] These enzyme-catalyzed degradations of nitroalkanes have been proposed to proceed via the mechanism of Nef reaction, involving the formation of an oxime intermediate.

Figure 53.

(a) Nef reaction. (b) Nef reaction via reductive methods. (c) Nef reaction catalyzed by old yellow enzymes.

4.4. Cannizzaro Reaction

The Cannizzaro reaction is a base-induced disproportionation between two aldehydes to produce an alcohol and a carboxylic acid (Figure 54a).[191] If the starting material is an α-keto aldehyde, an intramolecular Cannizzaro disproportionation can proceed as well.[192] The aldehyde used should not have an acidic α-hydrogen. This reaction was discovered by Stanislao Cannizzaro in 1853. The transformation of methylglyoxal (207), which is a toxic side product derived from the non-enzymatic breakdown of intermediates formed in several primary metabolic pathways, to lactate (210) catalyzed by the sequential actions of glyoxalases I and II was considered to be a biological equivalent of intramolecular Cannizzaro reaction (Figure 54b).[193] Glyoxalase I catalyzes the conversion of methylglyoxal to the thioester of lactate (208), utilizing glutathione (GSH) as a co-substrate. Glyoxalase II hydrolyzes this thioester intermediate to lactate (210). Unlike most other biological redox reactions, the reaction catalyzed by glyoxalase I is coenzyme-independent. When the enzymatic reaction was carried out in 3H2O, the lactate product contained less than 4% of the expected tritium. This observation supported the hypothesis that glyoxalase I operates via a Cannizzaro mechanism, which is involves a 1,2-hydride transfer step (Figure 54b, route A).[194] However, subsequent experiments using [1-2H]-fluoromethylglyoxal as the substrate led to the observation of defluorination event, which strongly supported an alternative mechanism that proceeds via an enediol intermediate (209). The fact that incorporation of solvent hydrogen was also noted in the 3-fluorolactate product lent further credence to the enediol mechanism (Figure 54b, route B).[195, 196] Thus, the reaction catalyzed by glyoxalase I may not be a Cannizzaro reaction. It is mentioned here to highlight the ambiguity surrounding enzyme mechanisms. Several of the biological name reactions described here are a matter of ongoing dispute and some have yet to be confirmed.

Figure 54.

(a) Cannizzaro reaction. (b) The conversion of methylglyoxal to lactate catalyzed by glyoxalase I and II.

4.5. Birch Reduction

4.5.1. Birch reduction in the anaerobic catabolism of aromatic compounds

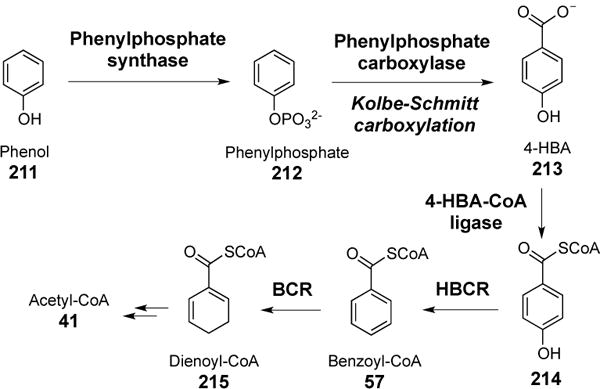

Microbes growing under anaerobic conditions utilize unique reductive pathways for the breakdown of aromatic compounds. This is in contrast to many oxidative metabolic pathways where oxygen serves as a co-substrate to facilitate the cleavage of the aromatic ring.[197] While some bacteria can degrade hydroxoquinone[198] with NADPH, and resorcinol with ferredoxin,[199] others use benzoyl-CoA (57) as a central intermediate for the reductive degradation of aromatic compounds, such as phenols, toluenes or benzoates.[200] A good example is phenol metabolism in the denitrifying bacterium Thauera aromatica, which is initiated by phosphorylation of phenol (211) to give phenylphosphate (212, Figure 55).[201] Subsequent carboxylation of 212 to generate 4-hydroxybenzoate (4-HBA, 213) is catalyzed by phenylphosphate carboxylase, which represents a biological example of Kolbe-Schmitt reaction.[202] 4-Hydroxybenzoate is then ligated with coenzyme A, followed by dehydroxylation by hydroxybenzoyl-CoA reductase (HBCR) to give benzoyl-CoA (57).[203, 204] Direct carboxylation of benzene to give benzoic acid has also been inferred in select microbial systems.[205, 206] Break down of benzoyl-CoA via the addition of two hydride equivalents by the action of benzoyl-CoA reductase (BCR) yields cyclohexa-1,5-diene-1-carboxyl-CoA (dienoyl-CoA, 215), which can then be catabolized to primary metabolites (Figure 55).[197]

Figure 55.

Bacterial anabolism of phenols.

Both HBCR and BCR operate via “Birch-like” reduction mechanisms. The Birch reaction, which was first reported by Arthur Birch in 1944, is a 1,4-reduction of aromatic compounds to their 1,4-hexadienes by alkali metals in ammonia in the presence of alcohol (Figure 56).[207] The alkali metal serves as a source of electrons and the alcohol as a source of protons. Two hydride equivalents are transferred to the reactant and the reaction proceeds via a radical anion intermediate (216). Given the harsh conditions required for the chemical Birch reaction, it is remarkable that such reduction reactions actually occur in biological systems. Although both HBCR and BCR operate via a similar mechanism, the subunit architecture and cofactor composition of these two enzymes are dissimilar. The most characterized examples of these enzymes are from the facultative anaerobe T. aromatica. The T. aromatica BCR will be described first because its mechanism necessitates prior dehydroxylation by HBCR, which will be discussed later.

Figure 56.

Birch reduction.

Benzoyl-CoA reductase (BCR) from T. aromatica