Abstract

1. INTRODUCTION

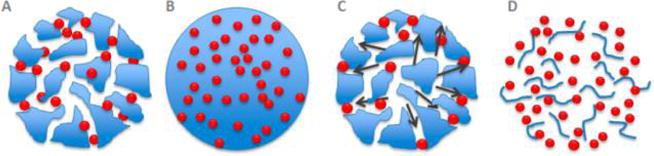

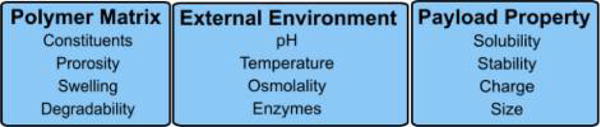

The development of biodegradable polymers represents a revolution in medicine spanning over 50 years and leading to significant biotechnological advancements in drug delivery, biomaterials, tissue engineering, and medical device development while bringing together chemists, engineers, biologists, and physicians in a unique and collaborative manner. The time frame of this revolution mirrors discoveries of more potent therapeutics in the form of peptides, proteins, nucleic acids, and other bioactive molecules. The short half-lives of many of these modern therapeutics, in addition to the nonspecific distribution and toxicity of previously identified small molecule drugs, has been a major driving force for the development of polymeric drug delivery platforms. The successful clinical translation of the earlier macro- and micro-drug-delivery systems has led to the evolution of controlled-release nanodrug delivery platforms that are capable of overcoming pharmacological limitations with substantial advantages over conventional dosage forms. Investigations and discoveries in synthetic methodologies, fabrication methods, and mathematical models for studying the mechanisms of controlled drug release have led to the ability to create tunable polymeric nanoparticle (NP) drug delivery systems capable of localized and sustained delivery, facilitating improvements in the therapeutic index of drugs. The ability to control the release of therapeutics and the extremely versatile nature of polymeric drug delivery platforms offer numerous important advantages (Figure 1).

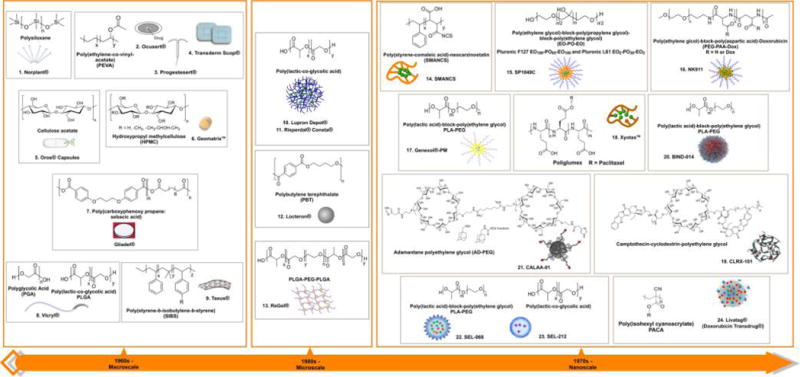

Figure 1.

Key features of polymeric drug delivery systems (DDS).

Starting for the most part in the 1960s, polymeric drug delivery has flourished since the pioneering works of notable researchers in the field, including Folkman, Langer, Higuchi, Roseman, Peppas, Heller, Ringsdorf, and Speiser.1–18 We have witnessed an evolution in drug delivery capabilities from the initial use of controlled-release polymers in macroscopic drug depots, implants, and suture materials to injectable microscale controlled drug delivery systems, such as microparticles, to nanoscale drug delivery, which may progressively represent a bigger part of the pipeline of pharmaceutical companies over the next few decades.19,20 To date we have seen the first bench-to-bedside translation of targeted and tunable controlled release polymeric NPs for small molecule drugs, from initial proof-of-concept in vitro,21,22 to successful in vivo investigations,23,24 which have laid the foundation for human testing and ongoing phase II clinical trials for multiple cancer types.25 The emergence of controlled-release polymeric NPs has fostered novel investigations of synthetic methodologies, bioconjugation techniques, and a rapid proliferation of scientific publications addressing the use of target-site activated chemical reactions that trigger changes in NP structure, shape, chemistry, and degradation rates. The ability to tune the physicochemical properties of polymeric NPs and to incorporate targeting elements into their design has allowed new generations of controlled-release polymeric NPs to navigate the complex and chemically rich in vivo environment.

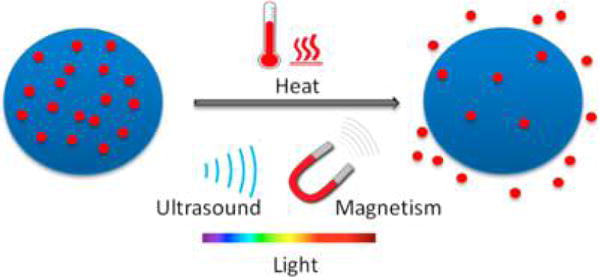

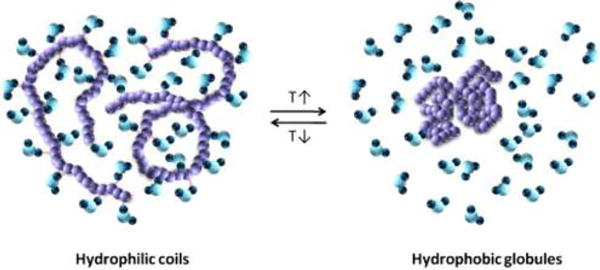

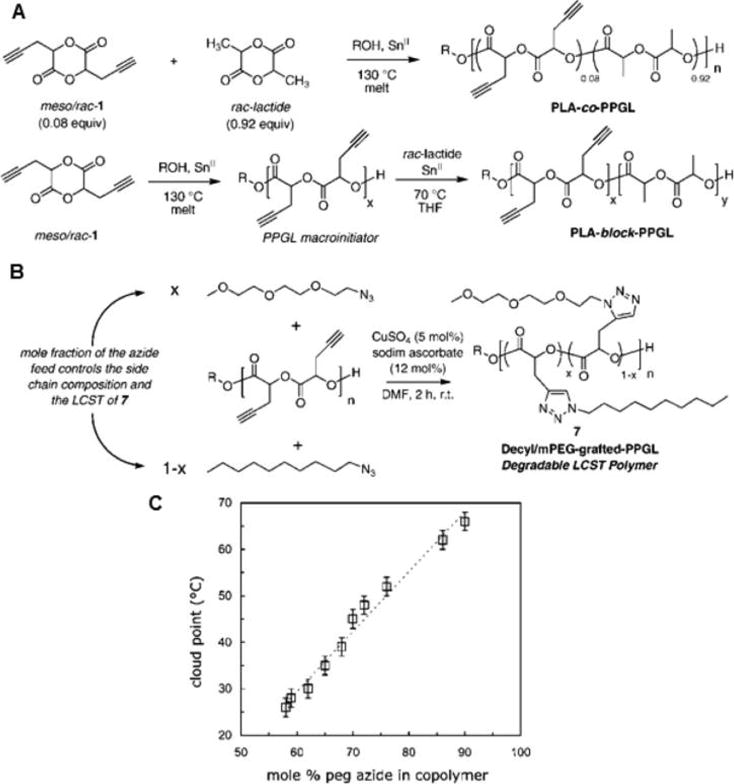

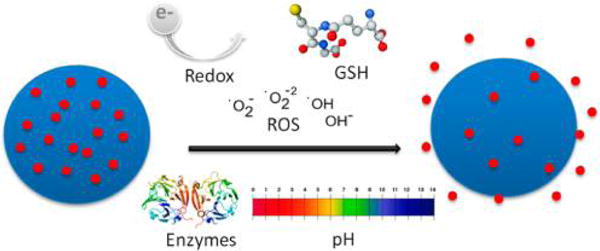

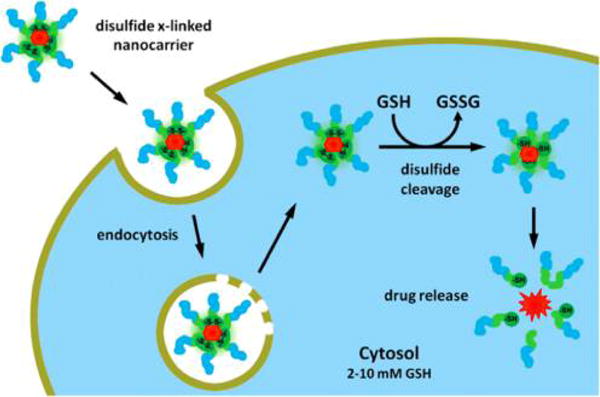

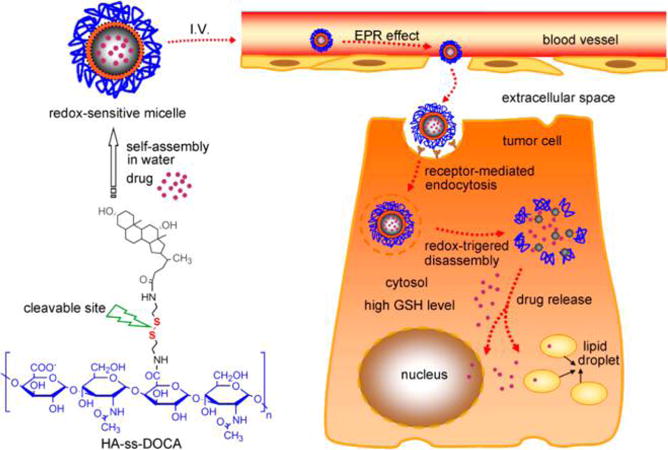

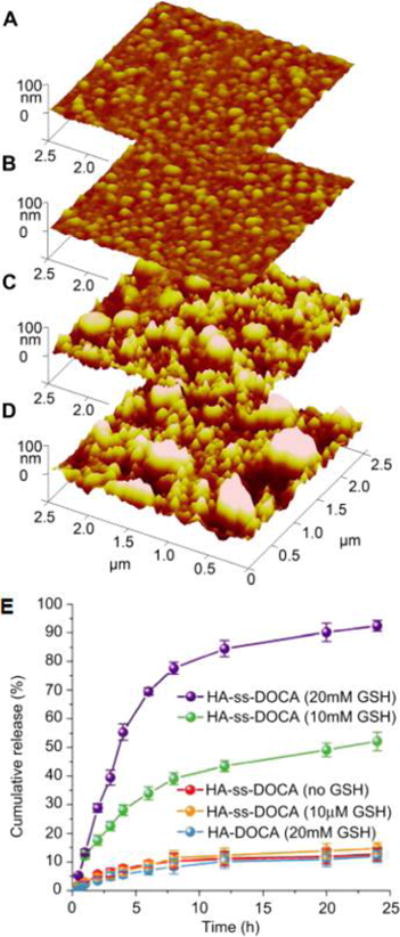

With our improved understanding of biological processes in diseased states, the design of controlled-release polymeric NP drug delivery systems has evolved from classical release mechanisms to the utilization of local biochemical changes in aberrant disease states to trigger and activate drug release. In diseases such as cancer an inevitable shift in homeostatic chemical equilibrium occurs, such as amplified or triggered enzymatic activity, a change toward acidic pH, reductive or oxidative states, or an increase in reactive oxygen species.33 These differential biochemical signatures can be exploited for the development of more precise therapies and offer ample opportunity for polymer design, rendering further control over the site-specificity and kinetics of drug release. In addition to exogenously triggered drug release, endogenously controlled physical parameters, such as local induction of thermal, electrical, ultrasound, or magnetic energy, can also be used to trigger various responsive components of drug delivery systems. As a result, to maximize the utility of degradable polymers in drug delivery, interest is growing in adding biologically responsive elements to the overall polymer design, to achieve more biologically controlled therapeutic outcomes.

The overall aim and scope of this review is to provide an informative account of physical, chemical, and biological parameters that can be harnessed to gain full spatiotemporal control of drug delivery. We will initially introduce the properties of commonly utilized degradable polymers used in drug delivery and then offer a retrospective account of the evolution of controlled-release polymers and how pioneering work in the field evolved to produce the current application of nanotechnology to medicine and healthcare (nanomedicine) as related to polymeric NPs. We will then focus on the various mechanisms for controlling drug release from polymeric NPs. We conclude by discussing the challenges of activatable controlled-release polymeric NPs and provide an outlook for these systems. Since polymers have been most widely used for controlled-release drug delivery, this review focuses on polymeric nanomedicines; however, a number of excellent reviews have also been published on different types of stimuli-responsive NPs developed using liposomes, micelles, silica NPs, and metal oxides.37–43 Furthermore, many of the concepts and parameters discussed herein can also be applied to the spatiotemporal controlled delivery of diagnostic and theranostic agents, which have been presented elsewhere.44–50

2. BIODEGRADABLE POLYMERS IN CONTROLLED RELEASE DRUG DELIVERY

Natural biodegradable materials have a long history of use in medicine, dating back over 3000 years when ancient Egyptians used plant fibers, hair, tendons, and wool fibers as suture material.51–53 The need to develop safer biodegradable sutures and to improve on commonly used catgut sutures led to investigations of synthetic biodegradable polymers.56 The earlier applications of synthetic biodegradable polymers dates back to the 1960s and 1970s, when the polyesters poly(glycolic acid) (PGA), poly(D,L-lactic acid) (PLA), and poly(D,L-lactic-co-glycolic acid) (PLGA) were developed for use as biodegradable sutures.60 Since then, the use of degradable polymers in drug delivery applications has become prominent due to their biocompatibility and degradability properties, as they can break down inside the body to produce nontoxic natural byproducts such as water and carbon dioxide, and are thereby easily eliminated.62 Although much of the pioneering work in controlled-release systems was conducted using nondegradable polymers, degradable and biodegradable polymers are the preferred choice for the development of polymeric drug delivery systems, and the terms biodegradable, bioabsorbable, bioeliminable, and bioerodible are often used interchangeably to describe polymers such as PLGA and PLA. These terms have recently been defined by the IUPAC.64 It is important to note that the term “biodegradable” has been defined according to the IUPAC as the break down of polymers due to cellular or in vivo biological actions.64 For the purposes of drug delivery, many of the degradable polymers utilized are commonly referred to as biodegradable, even though the mechanism of degradation is not biological and in most cases is hydrolysis driven. Given that the majority of degradable polymers used in drug delivery applications are based on hydrolyzable ester bonds and evidence for their biological breakdown in vivo is limited or conflicting, in this review we refer to these polymers using the correct terminology of “degradable polymers” based on the IUPAC definition (in vivo degradation resulting solely from hydrolysis by the water present in tissues and organs, referred to as hydrolysis or hydrolytic degradation).64

2.1. General Polymer Properties

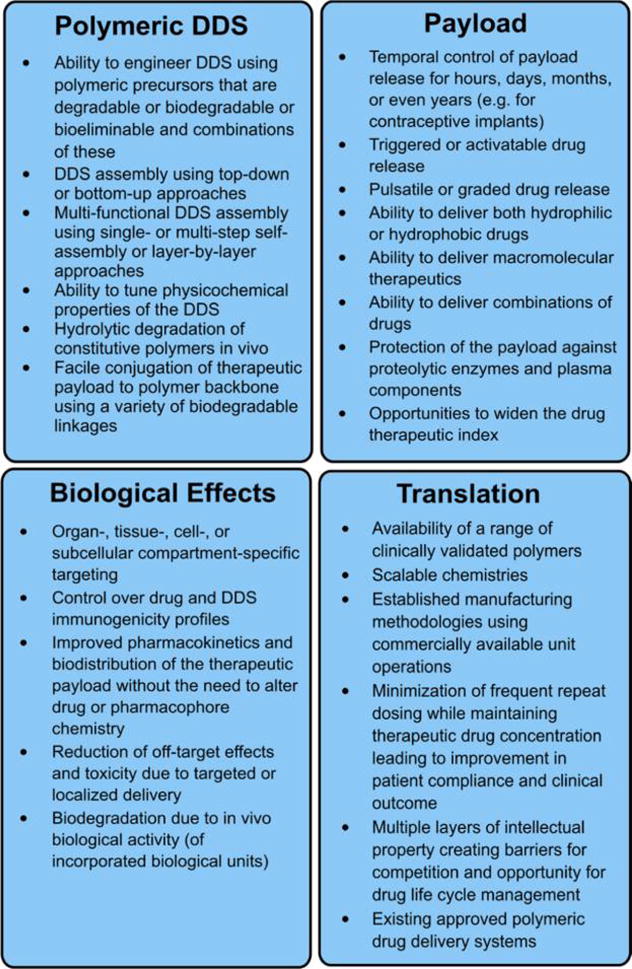

Degradable polymers can be hydrolyzed in vivo and are usually classified according to whether their source is natural or synthetic. Commonly used polymers include the α-hydroxy acids, polyanhydrides, and natural sugars such as chitosan, in addition to many other types (Figure 2). Synthetic degradable polymers are favored in tissue-engineering or drug delivery applications, as they have less batch-to-batch variability and immunogenicity as compared to degradable polymers from natural sources.79 Polymers can be rendered degradable through the inclusion of labile ester, anhydride, and amide chemical linkages, which are susceptible to common degradation mechanisms involving hydrolysis or enzymatic cleavage leading to the gradual scission (breaking of chemical bonds) of polymer chains. Drug release from degradable polymers can be governed by (1) surface erosion of the polymer matrix, (2) cleavage of polymer bonds at the surface or within the bulk of the matrix, or (3) diffusion of the physically entrapped drug. However, drug release is often a result of a simultaneous combination of all three.12

Figure 2.

Examples of common degradable and biodegradable polymers with representative monomer units used in drug delivery.

The chemical nature of the monomer is crucial to the overall design of degradable polymers, as the polymer breakdown products in the body ultimately influence the overall toxicity and biocompatibility of the polymers. The degree of polymerization describes the number of repetitive monomeric units, which is usually greater than 100 for high molecular weight (MW) polymers.80 Polymer weight can be determined according to the weight-average (Mw) or the number-average (Mn).81,82 The polydispersity index (PDI) of the system is indicated by the ratio of Mw/Mn, with values close to 1 representing monodisperse systems.82,83 Although the term PDI is widely used, this term has now been replaced by the IUPAC with “dispersity”, as denoted by Đ.84 Numerous studies have been carried out demonstrating the ramifications of these parameters on drug release from polymeric drug delivery systems.85–93 Degradable polymers (Figure 2) are attractive materials for the design of drug delivery systems, tissue-engineering scaffolds, implants, and surgical materials.94–96 PLGA is the most utilized of the degradable polymers, due its long history of clinical use and favorable controlled-release and degradation behavior.

PLGA can be used for the entrapment of most types of therapeutics with a wide range of MWs and can be fabricated into particles of various sizes and shapes.97 PLGA’s drug release capabilities can be tuned by varying properties such as MW, ratio of lactide to glycolide, and drug concentration. For example, the extra methyl group in the side chain of PLA makes this polymer more hydrophobic compared to PGA, with an increase in the PLA content leading to less water absorption and therefore slower degradation rates.98 Parameters such as crystallinity, glass transition temperature (Tg), solubility, and MW can influence the rate and release behavior of incorporated drug molecules, and an understanding of key parameters that influence polymer matrix properties is important in order to improve biodegradation and drug release behavior, and these concepts are discussed in subsequent sections.

2.1.1. Polymer Crystallinity

The partial alignment of polymer molecular chains can contribute to polymer crystallization, affecting polymer physical and chemical properties. Polymer crystallinity describes the degree of crystalline regions within a polymer sample in relation to amorphous regions and is an important concept in drug delivery, since only amorphous regions are permeable and therefore accessible to water molecules.99 Polymer mechanical strength, swelling, hydrolytic, and biodegradation rates are dependent on the degree of crystallinity, which in turn is governed by the nature of the monomers.

When the polymer chain has a stereoregular structure (regular monomer repeat units), linear polymers of high MW can rearrange into crystallites.100 Crystalline domains are separated by amorphous regions, as polymers never reach 100% crystallinity and are therefore semicrystalline. Crystallinity, which can be determined using X-ray diffraction methods, is a factor that can affect the release rate of drugs from polymeric drug delivery systems and is influenced by both the size and orientation of the polymer chains. A high degree of crystallinity causes slower drug release states when low MW polymers are used, but at high MWs (when porosity is higher), crystallinity has less impact on drug release.80

Due to the asymmetric α-carbon, PLA can be described as having D- or L- stereochemical centers (or R or S, respectively), giving rise to two enantiomeric forms of PDLA or PLLA, with PLGA being generally described as poly(D,L-lactic-co-glycolic acid) with D- and L-lactic acid equally distributed. PLLA is highly crystalline and PDLA is completely amorphous due to disordered polymer chains, while PGA is highly crystalline due to the lack of methyl groups on the side chain. In the case of copolymerization of PLA and PGA (which yields PLGA), the degree of crystallinity and amorphousness depend on the ratio of the monomers; e.g., a 50:50 ratio of lactide to glycolide results in an amorphous polymer, with increases in the lactic acid content leading to a more crystalline polymer.101 Studies have shown that the rate of drug release is higher in polyesters with a low degree of crystallinity because of higher macromolecular chain mobility.102,103

2.1.2. Polymer Glass Transition

Another factor that influences polymer physicochemical properties and is related to crystallinity is the glass transition temperature of polymers. The type of polymer and temperature dictate whether the amorphous region is in a “glasslike” or “rubberlike” state, and this depends on the polymer’s glass transition state Tg (the temperature at which the rubbery state to glassy state transition occurs) and can be determined using differential scanning calorimetry.80 Below the Tg, the polymer is in a glassy state; i.e., it has limited mobility and low diffusion rates. Above the Tg, the polymer is in a rubbery state, which facilitates higher mass transfer rates of water and drug molecules throughout the matrix.104 For effective design of degradable polymers in drug delivery applications, a balance between amorphous and crystalline states is necessary, as these parameters have direct effects on the degree of mechanical toughness and rate of drug release. For this reason, polymeric NPs are usually prepared from copolymers that contain both hydrophobic and hydrophilic segments, which make physical properties such as drug-release rates more predictable.105 The Tg of polymers such as PLGA decreases with a reduction in its lactide monomer content and MW, and several studies have investigated the effects of Tg on the rate of drug release.98,106–109

2.1.3. Polymer Hydrophilicity and Hydrophobicity

Solubility is a key concept in the design of degradable polymeric drug delivery systems and is dependent on the chemical nature, structure, and degree of crystallinity within the polymer. Polymer hydrophobicity generally increases with MW, with an increase in backbone branching resulting in more-water-soluble polymers.104 When the polymer used is hydrophobic in nature, drug release is controlled by surface erosion, and when there is a balance between hydrophobic and hydrophilic functionalities in the polymer backbone, degradation can occur from within the bulk of the polymeric system.110,111

For macro- and microscale polymeric drug delivery systems, the degree of hydrophilicity of the constituent polymers is important, although because physical properties at the nanoscale such as a very high surface-to-volume ratio render colloids of polymeric NPs stable in aqueous conditions, a wide variety of hydrophobic polymers may be utilized.111 Furthermore, the blending of hydrophilic polymers with hydrophobic polymers can increase pore formation along with an increase in the rate of polymer degradation and drug release. Polymer composition is highly important in the solubility of the polymer. For example, increasing the glycolic acid portion of PLGA, which renders the polymer more hydrophilic, can result in faster degradation rates.112,113 The solubility of the monomer is therefore a critical factor in the rate of drug release from polymeric drug delivery systems.114,115

2.1.4. Polymer Molecular Weight

The physical properties of polymers, such as Tg, solubility, viscosity, crystallinity, mechanical strength, and degradation rate, are related to the polymer’s MW, with low-MW polymers degrading more rapidly.100 The MW of degradable polymers has a significant impact on the drug-release profile from NPs and can influence the biological properties of polymeric drug delivery systems, such as elimination, phagocytosis, and biological activity.108,115–119 For example, estradiol-loaded NPs made with low-MW PLGA (14 500–45 000 Da) were found to exhibit zero-order release kinetics, compared to higher-MW (85 000–213 000 Da) PLGA, which exhibited a square root of time (Higuchi’s pattern) dependent release.120 Furthermore, drug Cmax in the plasma was shown to be polymer MW dependent (higher for the lower-MW polymers).

By using a range of PLGA MW polymers and PEG polymers, Valencia et al. were able to synthesize a library of 45 polymer NPs with varying sizes and surface hydrophilicities.117 These NPs were then screened for macrophage uptake effects on the basis of fluorescence detection of internalized NPs, confirming that NP size was a key determinant of macrophage uptake (over PEG surface density), with smaller NPs made from lower-MW PLGAs exhibiting the least amount of uptake. In general, low-MW polymers produce smaller NPs, resulting in altered drug release kinetics, enhanced blood circulation times, reduced accumulation in organs such as the liver and the spleen, and therefore enhanced biological efficacy due to longer duration of drug exposure.

The rate of drug release from polymeric drug delivery systems correlates with the mechanical properties of the polymer; high-MW polymers have a low elastic modulus, producing a relatively nondeformable matrix that limits the number of pore-forming channels. Low-MW polymers have a high elastic modulus, and the matrix is more deformable, causing pores to expand as a result of osmotic pressure.119

2.2. Poly(esters)

2.2.1. PLGA Polymers

Polyesters are polymers with ester bond linkages in the carbon backbone. The aliphatic polyesters include PGA, PLA, and PLGA and are the most extensively investigated degradable polymers to date (Figure 2).121–125 PLGA is synthesized from ring-opening polymerization (ROP) of cyclic lactide and glycolide monomers126 and degrades via hydrolysis of its ester bonds in water.127 A diverse range of monomers can be used in the synthesis of aliphatic polyesters, and polycondensation of difunctional monomers yields low-MW polymers. ROP is used for high-MW polymers.126 The simplest linear aliphatic polyester is PGA, and due to its high crystallinity (45–55%), it has poor solubility in most organic solvents.88 PGA has a Tg of 35–40 °C and therefore strong mechanical properties.88 The low solubility and fast degradation into glycolic acid makes PGA a poor choice for polymeric NP drug delivery applications;88 therefore, copolymers of PGA such as PLGA have been prepared for drug delivery applications.

The polycondensation of D- or L-lactic acid leads to the formation of PLA (Figure 2), which is a mixture of D,L-lactide (the natural isomer is L-lactide). PLA is hydrophobic due to the presence of the methyl side group,80 and properties of PLA can be changed by tuning D- and L-isomer racemization.88 The equivalent PLLA polymer from L-lactide is semicrystalline, whereas the PDLA polymer from D,L-lactide is amorphous. This in turn leads to changes in mechanical strength and degradation rates, with PLLA being hard and transparent with a Tg of 53 °C and PDLA having a Tg of 55 °C and low mechanical strength.88 The degradation rate of PLA is influenced by its crystallinity, and since the degradation rate of PLLA is lower than that of PGA, copolymers of lactide and glycolide began to be investigated for sutures and implant materials. This led to the development of PLGA, which can be obtained in a variety of MWs and lactide-to-glycolide ratios (L/G); hence, when the ratio of L:G monomer decreases, so does the degradation rate of PLGA.88 For example, the degradation times of PLGA polymer with 50:50, 75:25, and 85:15 (L:G) were shown to be 1–2, 4–5, and 5–6 months in aqueous conditions.88 Degradable drug delivery systems using PLGA and their precise controlled-release mechanisms will be discussed in subsequent sections. Ease of synthesis of poly(esters) by ROP or condensation polymerization and low toxicity has led to their commercial availability and popularity as degradable polymers. Radiolabeling studies of PLGA NP degradation have shown that eventually all the polymer is degraded in vivo and cleared via respiration from the lungs.128

2.2.2. PLGA Copolymers

To improve the in vivo circulation and biocompatibility of PLGA NPs, block copolymers of PLGA and PEG (PLGA–PEG) were developed.129–132 PLGA–PEG diblocks (AB) or PLGA–PEG–PLGA (ABA) copolymers are used to formulate NPs or thermogels, respectively. Due to the hydrophilicity of PEG, these chains can orient themselves toward the surface of polymeric NPs and lead to increased hydration. For in vivo applications and prolonged circulation, the surface of NPs is frequently coated with PEG, leading to neutral NP surface charges and minimization of bioadhesion and immunological response as a result of sterically inhibiting both electrostatic and hydrophobic interactions of plasma components with NPs.133–135 The solubility of PEG also allows for various targeting ligands to be conjugated to the distal end, therefore leading to targeted NPs.129,136–137 Triblock polyester ABA polymers where the A and B blocks are conjugated via ester linkages can form highly viscous gels at physiological temperatures, leading to temperature responsive degradable polymers.137 Advantages of polyester ABA and BAB type copolymers forming hydrogels have been extensively discussed elsewhere.138,139

Polyester–PEG copolymers are favorable block polymers for the generation of NPs with PEGylated surfaces, in addition to NP surface bioconjugation with various reactive PEG polymers, and PEG is currently a clinically validated polymer.19 Interestingly, a few studies to date have demonstrated anti-PEG IgG responses with immunologic memory in humans.19,140,141 However further studies are required to fully elucidate these findings.140,142

2.2.3. Polycaprolactones

Another commonly utilized degradable aliphatic polyester used in drug delivery applications is poly(caprolactone) (PCL) (Figure 2), which is made from the ROP of ε-caprolactone using tin octoate catalyst. PCL has good solubility and a very low Tg (approximately −60 °C), making it a semirigid material at room temperature. To date, PCL has found more uses in tissue engineering as scaffold matrix material than in particulate-based drug delivery.88 One reason for this is its lack of solubility and extremely slow degradation rates (2–3 years for pure PCL); however, modification of PCL with other polymers (such as block polymer synthesis or blending with PLGA and PLA) have led to improvements in its degradation and reactivity.143–145 The synthesis of PCL block copolymers leads to amphiphilic structures and different mechanical and physical properties (tuned by varying the ratio of the blocks, etc.). Hydrophilic block segments of either PEG, poly(acrylic acid) (PAA), poly(2-ethyl-2-oxazoline) (PEtOz), poly(N-isopropylacrylamide) (PNIPAAm), or poly(N,N-dimethylamino-2-ethyl methacrylate) (PDMAEMA) conjugated to the hydrophobic PCL segment have been used to formulate micelles.146 For example, RGD-functionalized PCL–PEG diblock copolymers were used to formulate doxorubicin-loaded micelles for targeting drug delivery.147 There are numerous examples of di- and triblock polymers synthesized with PCL polymers, and further examples of PCL diblock micelles used in controlled-release drug delivery applications have been reviewed.146

2.2.4. Poly(alkyl cyanoacrylates)

A class of degradable polyesters are poly(alkyl cyanoacrylates) (PACAs), which are synthesized from alkyl cyanoacrylate monomers, and their use in drug delivery applications was pioneered by Couvreur and Speiser in the late 1970s.148,149 The presence of two highly reactive electron-withdrawing groups on the alkyl cyanoacrylate monomers leads to rapid polymerization reactions.150 In general, these polymerization reactions are conducted in aqueous solutions, with the hydroxide ion acting as the initiator.150 The average MWs of these polymers are between 5 and 10 kDa to allow for full biodegradation and elimination of the monomers. Interestingly, fast anionic polymerization by biomolecules in the skin is causative of the tissue adhesive properties of liquid skin plasters and band aids that are based on alkyl cyanoacrylates.150 PACAs can be synthesized from alkyl cyanoacetate via the Knoeveagel condensation reaction leading to oligomers or via a thermal depolymerization reaction of these oligomers.151 Diblock and triblock copolymers with PEG and PACA blocks have also been synthesized using zwitterionic polymerization.151 The progression of NPs made using PACAs has been most advanced up to now, and these passively targeted NPs are currently in phase III clinical trials for the treatment of resistant liver cancer.152

2.3. Poly(ortho esters)

Developed as synthetic polymers for use as sutures in surgery in the 1970s, poly(ortho esters) (POEs) can be divided into four classes (POE I–IV, Figure 2), usually have three geminal ether bonds, and are hydrophobic surface-eroding polymers.88,153 POEs typically release drugs through diffusion mechanisms and are degradable; drug release is initiated by hydrolysis of polymer chains on the outer shell of the matrix.154 It has been shown that hydrolysis rates may be accelerated via the addition of acidic excipients.155 Furthermore, basic excipients have the ability to stabilize the bulk polymer but diffuse out of the surface region, encouraging surface erosion.156 Therefore, adjusting the acidity/basicity allows for some degree of control of temporal release. Although orthoester bonds are quite reactive in nature, polymers with these linkers are highly hydrophobic, with limited water penetrability. POE I hydrolyzes rapidly in water to produce γ-butyrolactone, which converts to γ-hydroxybutyric acid, and therefore, its use in drug delivery applications has been discontinued.157 POE II has a low degree of water sorption and a Tg of 22 °C (if based on 1,6-hexanediol) and is therefore also hydrophobic.157 POE III is a semisolid at room temperature, which provides the advantage of drug mixing without the need to use solvents or high temperatures.157 POE III is less hydrophobic than POE II. The extremely slow erosion rates of POE I–III have prevented this class from being investigated nearly as much as the POE IV class, which has been shown to have significant potential for use in bioerodible drug delivery systems when lactic and glycolic monomers are instilled in the polymer backbone.158 POE IV incorporates a mono- or diglycolide segment that is incorporated in the polymer backbone. This leads to the generation of lactic or glycolic acid monomers, which catalyze the hydrolysis of further ester linkages in the polymer. The degradation rate of POE IV is highly tunable, since it can be varied by controlling the nature of the diol R group and latent acid diols (and their relative proportions). POE IV has been used to deliver payloads such as small molecule analgesics and nucleic acids.159

2.4. Poly(anhydrides)

Poly(anhydrides) generally consist of poly(sebacic acid), poly(adipic acid), and poly(terphthalic acid), among others.160 Poly(anhydrides) undergo surface erosion, in which release kinetics is dependent on properties of the drug payload and intrinsic dissolution rates (Figure 2).161 In the case of a hydrophobic drug, the degradation of the polyanhydrides is the main factor in release, whereas in the case of a hydrophilic drug, solute transport is dependent on the concentration gradient between the delivery system and surrounding medium.161 However, the degradation of the poly(anhydride) bond also depends on the chemistry of the polymer backbone, which can be tuned by varying the nature of the monomer by up to 6 orders of magnitude.162 Both drug solubility and the dissolution rate of the polymer need to be considered when investigating poly(anhydride) drug delivery.163 Poly(anhydrides) have been fabricated into micro- or NPs for intravenous, oral, and aerosol drug delivery,164 as well as for vaccine, protein, and chemotherapeutics delivery.165–168

2.5. Poly(amides)

The most frequently utilized poly(amides) for drug delivery are poly(amino acids) (Figure 2). Their synthesis has already been extensively researched,169 which makes them an ideal mature platform to build upon. Poly(amino acids) are typically used to deliver low-MW drugs, are relatively nontoxic,170 and are typically cleaved by enzymes as they are stable to hydrolysis.171 The degradation rates of poly(amino acids) are dependent on the hydrophilicity of the amino acids that make up the polymer.172,173 Polyamides are generally semi-crystalline. Biodegradation can be accelerated by using side groups such as benzyl, hydroxyl, or methyl groups during copolymerization. Most poly(amino acids) are made up of a single type of amino acid and include the most widely used poly(amino acids): poly(γ-glutamic acid) and poly(L-lysine).174–177

Poly(γ-glutamic acid) is a water-soluble degradable poly(amide) that exists in both D- and L-optically active forms and is a highly functionalizable polymer. The carboxylate side chain can be used for covalent attachment of functional moieties and drug molecules.88 Polymeric NPs composed of poly(γ-glutamic acid) have been developed for the delivery of chemoimmunotherapies,178 chemotherapeutics,179 and therapeutic proteins.180,181

The major applications of poly(L-lysine)-based polymers has been in gene delivery, where the highly positively charged amino groups can interact with negatively charged siRNA or DNA chains.182 These peptides are also useful for facilitating endosomal escape due to their buffering capacity, although their highly cationic nature renders them toxic and further modifications are often required to mask their charge.174,183

2.6. Poly(ester amides)

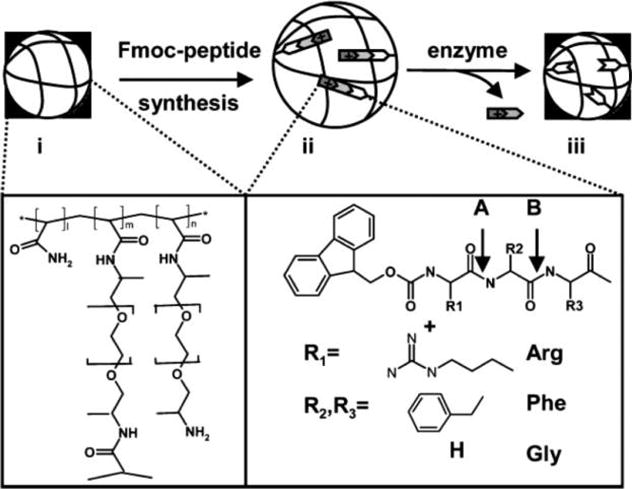

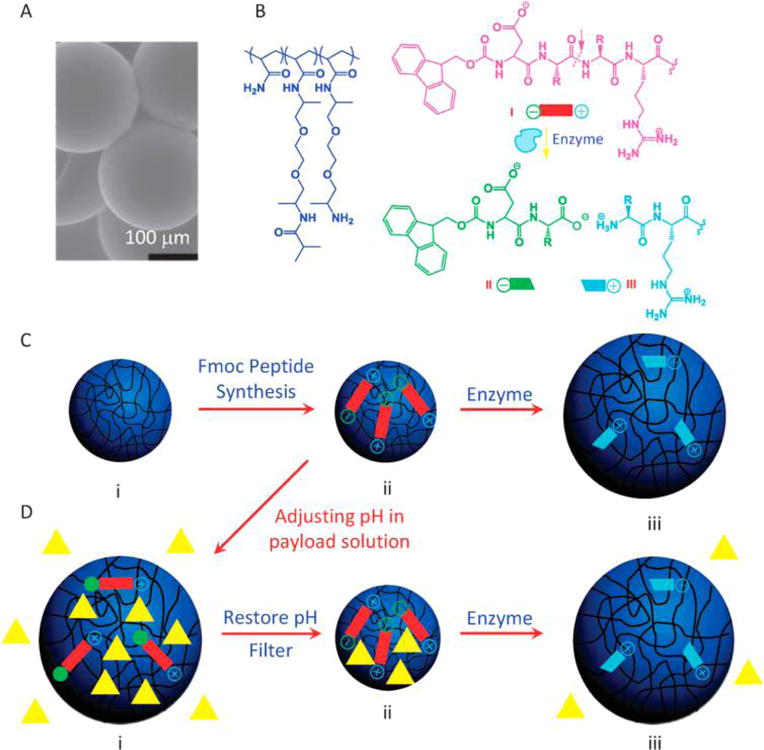

Poly(ester amides) (PEAs) are polymers that have both ester and amide linkages on their backbones (Figure 2), yielding favorable mechanical and biological properties with enzyme-catalyzed biodegradability.184–187 Invented in the late 1970s,184–187 the combination of the favorable properties of polyesters and polyamides with poly(amino acids) has produced amino acid-based PEAs with promise for biomedical and pharmaceutical applications.184–187 Typically, the PEA backbone consists of nontoxic building blocks such as α-amino acids, fatty diols, and aliphatic dicarboxylic acids.188 If hydrophobic amino acids are used (e.g., Phe, Leu), the resulting amino acid-based PEAs are hydrophobic and water insoluble.185 Due to the alternation of amide and ester bonds in this type of polymer, the rate of polymer degradation under hydrolytic mechanisms is slow, and most of the reported faster degradation rates are catalyzed by enzymes.189 These polymers are also highly crystalline, and their degradation rates can be modified by controlling the Phe:Gly ratios. The poly(β-amino esters) (PBAEs) are synthesized via the Michael addition reaction of diester diacrylates with primary and secondary amines and have led to the generation of large libraries of PBAEs with various backbones, which has facilitated the high throughput screening of polymers for gene delivery.190–193

2.7. Poly(phosphoesters)

Poly(phosphoesters) are degradable and biocompatible polymers with utility in drug delivery and tissue engineering (Figure 2).194,195 The pentavalency of the phosphorus atom allows for the conjugation of a range of side chains, such as proteins or small drugs. The conjugation of different side chains also allows for the tuning of the physicochemical properties of the polymers.196 Since poly(phosphoesters) are structurally similar to nucleic acid biopolymers, they biodegrade through hydrolysis and enzymatic digestion and are excellent classes of polymers for nucleic acid delivery due to the conjugation of charged groups to the phosphate side chain.197,198 Poly(phosphoesters) can be synthesized by ROP, condensation, and addition polymerizations,88 and their fast degradation rates produce nontoxic products. For drug delivery applications, poly(phosphoesters) can be copolymerized with polyethers and polyesters, and they are gaining attention as biomaterials.196,199–202

2.8. Naturally Occurring Biodegradable Polymers

Naturally occurring biodegradable polymers have been used in drug delivery applications, due to their abundance in nature and biocompatibility, and include protein-based polymers, such as collagen, albumin, gelatin, and polysaccharides, such as agarose, alginate, carrageenan, hyaluronic acid (HA), dextran, chitosan, and cyclodextrins.203 In particular, natural polyscaccharides have been widely used in tissue engineering and bioscaffold designs, in addition to NP fabrication for drug delivery. Although highly biodegradable in nature, a limitation of natural polymers is their batch-to-batch variability and broad MW distributions, making them less attractive than synthetic polymers that are more reproducible and versatile. Two widely used polysaccharide-based polymers for drug delivery applications are chitosan and hyaluronic acid polymers, which are further discussed below.

2.8.1. Chitosan

Biodegradable polysaccharides have shown potential in drug delivery applications. One major polysaccharide with broad utility is chitosan (Figure 2), which is derived from the chitin found naturally in crustacean exoskeleton.204 Deacetylation of chitin produces randomly repeating units of D-glucosamine and N-acetylglucosamine, with the degree of deacetylation being related to chitosan’s crystallinity and degradation rates.205 Chitosan is highly insoluble in water (due to its crystalline nature) and must be solubilized in dilute acid solutions prior to use. Chitosan has been extensively used for the development of oral drug delivery systems.206,207 It is broken down by lysozyme and chitosan polymers with low degrees of acetylation and can remain in vivo for several months.88 Chitosan’s degradation can be accelerated by disrupting the significant network of hydrogen bonding, through the inclusion of bulky side groups. Major applications of chitosan involve wound dressing and healing (where it has also demonstrated anti-inflammatory and antibacterial properties),208,209 gene delivery due to its highly positive charge,210 oral delivery,211 and pulmonary drug delivery due to its mucoadhesive properties.212,213 Additionally, chitosan has been fabricated into numerous NPs for drug delivery applications.214,215 The ease with which the side groups can be modified and deacetylated and its blending with a variety of other polymers make chitosan a versatile and bioactive polymer.216 The utility of chitosan for the development of a range of polymeric NPs for drug delivery applications (and in particular for oral delivery) has been previously extensively discussed.215–219

2.8.2. Hyaluronic Acid-Based Polymers

HA is a naturally occurring linear polysaccharide polymer composed of D-glucuronic acid and N-acetyl-D-glucosamine disaccharide.220 HA has been utilized for a wide range of applications, since it has highly favorable properties, including being biodegradable, biocompatible, nontoxic, and nonimmunogenic. It has been used in various surgical, tissue engineering, and drug delivery applications.221 Since the past decade HA has been used to develop numerous HA drug or biologic conjugates and hydrogel depot drug delivery systems. Bioconjugation of HA to therapeutics improves drug solubility, PK (pharmacokinetics), and clearance.222 The pKa of HA carboxyl groups is between 3 and 4, rendering the polymer anionically charged at neutral pH.223 Therefore, HA is highly hydrophilic, and due to its ability to absorb water, it can expand up to 1000 times its solid volume, leading to a loose, hydrated network.224 This property makes HA an attractive material for hydrogel-based drug delivery. HA also has intrinsic targeting ability, since it can selectively interact with the CD44 receptor, termed the hyaluronan receptors for endocytosis (HARE), and this has been used as an active targeting strategy for delivery of anticancer drugs.225,226 The conjugation of HA to various drugs, peptides, and proteins has been the prominent application of HA polymers to date.223

3. EVOLUTION OF CONTROLLED-RELEASE POLYMERS

Controlled release of drugs from polymeric drug delivery systems is typically achieved by regulation of the rates of polymer biodegradation and drug diffusion out of the polymer matrix. Starting from the pioneering work led by Judah Folkman on the use of silicone rubber as a controlled-release matrix, whereby anesthetic gases encapsulated in a reservoir were shown to diffuse through the porous silicon membrane,227 the controlled drug delivery field can be chronicled in evolving phases, where we have seen the implementation of macroscopic controlled drug delivery devices and implants evolve into microscopic degradable polymer depot drug delivery systems pioneered by Robert Langer, leading to the current nanoscopic era of NP-based controlled drug release.6 Ultimately, each drug delivery scale has inherent advantages and disadvantages and the choice of scale relies highly on the biological end points required. Table 1 summarizes the main differences between macro-, micro-, and nanoscaled drug delivery systems, and these concepts are further described in the following sections.

Table 1.

Comparison of Macro-, Micro-, and Nanosized Drug Delivery Systems (DDS)

| Polymeric DDS | Advantages | Disadvantages |

|---|---|---|

| Macroscale | • Highly tuneable and controlled drug release achievable (over days, weeks, months and years) | • Original DDS are non-biodegradable (in particular the earlier silicone based contraceptive depots) |

| • Large size allows comprehensive mathematical and empirical modelling of drug release (with wide body of literature available being the earliest established polymeric DDS) | • Majority of approved devices require insertion and removal procedures by trained personnel therefore creating patient compliance issues | |

| • Large size facilitates higher payloads and continuous controlled release of therapeutics | • In some cases surgical procedures are required | |

| • Reliable DDS for many critical applications including contraceptives and drug eluting stents with numerous marketed products | • Possibility of foreign body reactions | |

| • Prolonged release eliminates or reduces the need for repeat dosing | • Possibility of fibrosis encapsulation of DDS | |

| • Pulsatile or constant or zero-kinetics rate of drug release achievable | • Tissue scarring | |

| • For certain applications it can eliminate the need for injections | • Limited biological applications due to lack of systemic circulation and transport of DDS | |

| • Drug reservoir can be achieved at desired anatomic site | • Difficult to reach consensus on how to benchmark and clinically assess macroscale DDS | |

| Microscale | • Tuneable controlled release of drugs (hours, days, months) | • Large size limits in vivo circulation time and biodistribution leading to rapid clearance post systemic administration |

| • Large utility for local depot-release drug delivery applications | • Can lead to agglomeration and clotting | |

| • Wide range of payloads possible (proteins, peptides, small drugs) | • Applications mostly limited to subcutaneous and intramuscular injections due to rapid systemic clearance | |

| • Sustained and controlled release of small and macromolecules up to months (after local injection) | • DDS cannot traverse biological barriers due to large size and remains at local site of injections | |

| • Targeting of DDS to specific organs, tissues and cells possible | • Limited cellular uptake and subcellular applications due to large size | |

| • Biodegradable and in vivo degradable | ||

| • Standardized and facile fabrication of polymeric microparticles | ||

| • Higher drug loading and more control over drug release achievable (compared to nanoscale DDS) | ||

| Nanoscale | • High surface-to-volume ratios, allowing for maximal surface binding to targets and the inclusion of high number of ligands or other molecules on the surface of nanoparticles | • For oncology applications, reliance focused on the EPR effect in patients, which is variable and remains unpredictable among patients and tumors |

| • Small size facilitates long systemic circulation times and higher tissue penetration | • Smaller nanoparticles prone to renal clearance (<10 nm) | |

| • Colloidal nature facilitates accumulation in tumors and inflamed tissues through enhanced permeation and retention (EPR) effects | • Larger nanoparticles prone to increased uptake by key organs such as liver, lung and spleen | |

| • Highly tunable and decoupled nanoparticle pharmacokinetics and drug pharmacokinetics | • Small size can lead to off-target effects as nanoparticles can easily accumulate in other locations | |

| • Can be optimized to bypass the reticuloendothelial and blood brain barrier systems more effectively | • Size dependent toxicity of nanocarriers can limit dosing amounts | |

| • Amenable to cellular uptake mechanisms due to small size | • Consensus on size related biological outcomes often difficult to reach due to the variety of nanomaterials investigated across numerous laboratories | |

| • Effective for subcellular targeting and drug delivery applications | ||

| • Small size of NPs allows for facile sterilization via filtration, removing the need for complete aseptic manufacturing processes and therefore facilitating ease of fabrication | ||

| • Nanoscale phenomena enabled triggered control of drug release via directed exogenous stimuli (see section 5) |

3.1. Evolution of Macroscale Polymeric Drug Delivery Systems

Drug incorporation into solid polymers began in the 1950s for agricultural research, with extensions of this work for medicine beginning in the mid-1960s.12 Macroscale polymeric drug delivery devices were originally developed to achieve spatiotemporal control of drug delivery from a local drug depot device. This allowed for a range of payloads (such as small molecule drugs, proteins, and bioactive agents) to be delivered in a controlled manner at the site of treatment. Drugs are generally released from macroscale polymeric DDS via one of three mechanisms: (1) diffusion-controlled release, (2) drug-carrier affinity, or (3) degradation of the matrix material. Though the release rate of the therapeutic payload can be driven by any one of these mechanisms, it usually involves all three.228

Earlier drug delivery devices were mostly made of non-degradable polymers, including polyurethanes, silicone rubber, and poly(ethylene-co-vinyl acetate) (PEVA). Drug transport in these nondegradable systems was primarily driven by diffusion; thus, these polymers were used to devise reservoir or drug depot devices.127 Release rates from reservoir-based devices can be controlled by changing the thickness and degree of permeability of the rate-controlling membrane (RCM).229 For matrix-based systems, drug release is diffusion driven and can be affected by concentration gradients, diffusion distance, and amount of matrix swelling.

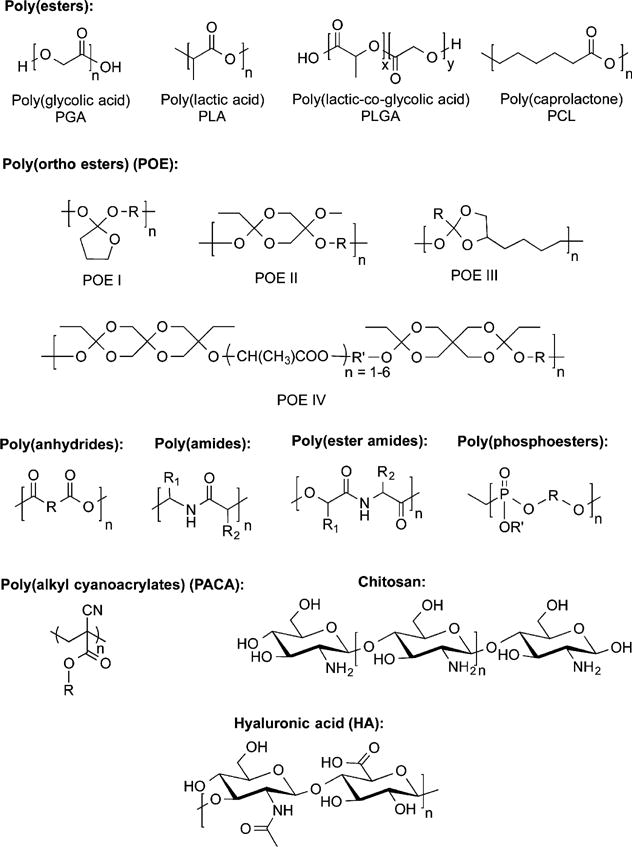

Following the demonstration of controlled release with silicone polymers, several macroscale drug delivery products were developed for contraceptive purposes, treatment of glaucoma, and drug eluting skin patches.4 In fact, delivery of steroids and their derivatives for contraception has been one of the most widely studied applications of controlled-release polymers, and among the first such systems was Norplant, approved by the FDA in 1990 (Figure 3–1).1 Norplant is an upper-arm-implanted contraceptive formed of six silicone tube capsules, each 2.4 mm × 34 mm long and containing 36 mg of the progestin levonorgestrel.2 The hormone is released at 3.8 pg/cm length/day, and the implant is effective for 5 years after implantation. This product has since been replaced by an improved version (Norplant II), which was approved by the FDA in 1996.232 This implant uses polysiloxanes consisting of a backbone of inorganic Si–O–Si units, and drug release was controlled mainly by diffusion at a constant linear rate. Another example of an implantable contraceptive controlled-release device is Implanon.233 However, one limitation of these DDS is that since the silicone capsules are nondegradable, they must be removed after drug release is complete.

Figure 3.

Evolution of polymeric drug delivery systems spanning over 50 years. 1960s: the macroscopic era of polymeric drug delivery. (1) Norplant is an upper-arm-implantable polymeric drug delivery depot for contraceptive use [active pharmaceutical ingredient (API): progestin levonorgestrel];1 (2) Ocusert is a drug-eluting polymeric eye implant for the treatment of glaucoma or ocular hypertension (API: pilocarpine);2 (3) Progestesert is a T-shaped polymeric IUD for contraceptive use (API: progesterone);3 (4) Transderm Scop is a polymer-based skin-patch drug delivery system for the treatment of motion sickness (API: scopolamine);26 (5) OROS is a polymeric capsule system for oral delivery (numerous APIs, including salbutamol, nifedipine, hydromorphone, verapamil, paliperidone, nifedipine);2,27,28 (6) Geomatrix is a polymeric tablet system for oral delivery (API: diclofenac, molsidomine, zileuton, nisoldipine, alfuzosin hydrochloride, ropinirole, paroxetine, levodopa, and benserazide);29,30 (7) Gliadel is an implantable polymeric disk for the treatment of glioblastoma multiforme [API: bis(2-chloroethyl)nitrosourea (BCNU)];31,32 (8) Vicryl is a degradable surgical suture;34 Taxus is a polymer-coated metal drug-eluting stent for prevention of restenosis (API: antiproliferative drugs such as paclitaxel).35,36 1980s: the microscopic era of polymeric drug delivery. (10) Lupron Depot is a polymeric microparticle for the treatment of prostate, breast, ovarian and endometrial cancers and also for endometriosis, infertility and benign prostatic hypertrophy (API: leuprolide acetate; a luteinizing hormone releasing hormone (LHRH) agonist);55 (11) Risperdal Consta is an antipsychotic, PLGA based polymeric microsphere, which is a long-acting injectable approved for the treatment of schizophrenia and the maintenance treatment of Bipolar I Disorder (API: risperidone);230,231 (12) Locteron is a polymeric microparticle for the treatment of hepatitis C (API: interferon-α2b);57 (13) ReGel is a polymeric drug depot delivery system for the treatment of various diseases (API: small molecules, peptides, and proteins).58,59 1970s: the nanoscopic era of polymer drug delivery. (14) Neocarzinostatin conjugated to styrene-maleic anhydride for cancer therapy (API: neocarzinostatin);61 (15) SP1049C is a polymeric micelle for the treatment of advanced adenocarcinoma of the esophagus and esophageal junction (API: doxorubicin);63 (16) NK911 is a polymeric micelle for the treatment of a range of cancers (API: doxorubicin);126 b (17) Genexol-PM (or Cynviloq) is a polymeric micelle formulation for the treatment of a range of cancers (API: paclitaxel);65 (18) Xyotax is a polymeric NP for the treatment of advanced non-small-cell lung cancer (API: paclitaxel);66,67 (19) CRL-101 is a polymeric NP for renal cell carcinoma and ovarian and rectal cancer (API: camptothecin);68–73 (20) BIND-014 is a polymeric NP targeted to prostate-specific membrane antigen (PSMA) for the treatment of castration-resistant prostate cancer, non-small cell lung cancer, cervical, bladder, and head and neck cancers (API: doxetaxel);74,75 (21) CALAA-01 is a targeted polymeric NP for cancer treatment (API: siRNA);121,76 (22) SEL-068 is a targeted polymeric NP, which is an antismoking vaccine (API: nicotine antigen, T-helper-cell peptide, and adjuvant);121,77,78 (23) SEL-212 is a polymeric NP, is designed to be the first non‑immunogenic biologic therapy for the treatment of refractory and tophaceous gout (API: rapamycin co-administered with pegsiticase, clinical trials identifier: NCT02648269); (24) Livatag is a polymeric NP for the treatment of liver cancer (API: doxorubicin).152

Among other macro-DDS marketed by the pioneering drug delivery company ALZA are Ocusert (releasing the antiglaucoma drug pilocarpine) and Progestesert (an intrauterine device for the release of progesterone).3,234 These macroscale controlled drug delivery devices are composed of PEVA, which allows drugs to be released at a constant rate with zero-order kinetics.235 PEVA shows a slow release over a long period of time and good biocompatibility.236,237 Polymer permeability (and thus release rates) can be altered by varying the copolymer ratios.238 The diffusivity of the polymer matrix is dependent on the crystallinity of the polymer, and it has been shown that increasing the crystallinity reduces the diffusivity.238 Ocusert was the first controlled-release polymer drug delivery system to be used in the clinic (Figure 3–2).2 Placed in the lower eyelid, this implant delivered the active ingredient pilocarpine at a steady rate over a one-week period, which led to an improvement over daily eye drop administration of pilocarpine and resulted in fewer side effects.239 Progestesert was a T-shaped intrauterine (IUD) macroscale drug delivery device also composed of PEVA, capable of delivering 65 pg/day of progesterone for 1 year (Figure 3–3).3 Transderm Scop (Figure 3–4) was the first skin-patch drug delivery system that also used PEVA as the RCM to deliver 1 mg of scopolamine over 3 days for the treatment of motion sickness.26

In addition to the aforementioned in situ macroscale drug delivery devices, controlled-release polymeric systems for oral drug delivery to the gastrointestinal (GI) tract were also developed beginning in the 1980s.4 For example, OROS (osmotic controlled-release oral delivery system, Figure 3–5) is a pulsatile-release oral delivery capsule that has a permeable outer shell with small laser-drilled holes, which allows water to enter via osmotic pressure during its trafficking through the GI tract.2,27,28 This action in turn pushes the active drug through the opening with controlled zero-order and flat PK. This system can be further tuned to release the drug within certain regions of the GI tract. The RCM in these systems consists of cellulose acetate, which maintains a constant rate of water diffusion into the capsule while an equal volume of the drug liquid or suspension is forced out.240 A small amount of low-MW PEG may also be used to initiate water diffusion.

Another controlled-release drug delivery platform uses hydroxylpropyl methylcellulose (HPMC) as a highly swellable hydrophilic polymer to modulate drug release and is marketed as the Geomatrix system (Figure 3–6).29 The combination of polymer layers with different swelling, gelling, and erosion rates results in a controlled rate of drug release, and this system is tunable toward a range of drug payloads and release properties.241

Controlled-release polymers have also been used to develop wafer DDS. Poly(carboxyphenoxy propane: sebacic acid) was used to develop Gliadel, a degradable polymeric disklike implant, secreting carmustine for the treatment of glioblastoma multiforme (brain cancer) (Figure 3–7). The polymer and drug are formulated into polymeric disks, which are placed into the brain after surgery and tumor removal.31,32

As discussed earlier, during the 1960s and 1970s the most widely used class of degradable polymers, the poly(hydroxyl acids), were originally developed to make sutures. PGA was first synthesized as a degradable suture. This polymer was then further optimized through the addition of lactic acid to produce PLGA and was marketed as Vicryl suture by Ethicon Inc. (Figure 3–8).34 Poly(alkyl cyanoacrylates) have also been used as surgical glue (Superglue) for over 40 years.148 Controlled-release polymers have also found use as coatings on bare metal stents for the controlled-release of antirestenotic drugs. Taxus, one such device approved in both Europe and the United States in 2004, uses poly(styrene-b-isobutylene-b-styrene) (SIBS) to control paclitaxel elution from a metal stent (Figure 3–9). These devices are currently being developed to incorporate degradable polymer coatings such as PLGA and PLA to minimize side effects.

Controlled polymeric drug release evolved with macroscale DDS, and we have seen the successful translation of numerous products to the clinic.228 Although some early products incorporating controlled-release drug delivery are still on the market in the form of drug-eluting depots, stents, and implants, the successful translation of these systems is not without its challenges (Table 1). Regulatory approval, the high cost of preclinical to clinical translation of these systems (in particular for biologics delivery), and patient compliance are hurdles that still need to be more effectively addressed. The need to remove drug depot implants and improve patient compliance led to the investigation of microscale DDS.

3.2. Evolution of Microscale Polymeric Drug Delivery Systems

In the 1970s the pioneering work of Langer and Folkman demonstrated the capability of polymers to release macromolecular therapeutic proteins in a controlled manner.6 The need for pulsatile release of hormones to resemble physiological levels was one motivation for developing tunable controlled-release systems, and the realization of the therapeutic potency of biologic drugs alongside their short half-lives in vivo spurred the investigation of microscale controlled-release DDS for systemic administration.

In the late 1970s and early 1980s, a PLGA microparticle system was developed that was capable of controlled release of luteinizing hormone-releasing hormone (LHRH) for up to 1 month for the treatment of prostate cancer.86,242 The plasma half-life of LHRH is 2.9 h; however, as the polymer slowly degrades, therapeutic levels of this antitumor peptide can be maintained for up to 3 months.243 Later, Decapentyl LP, a version of this microparticle, was subsequently developed for the treatment of prostate cancer and approved for clinical use in Europe in 1986.54 This was the first degradable microparticle drug delivery system approved for human use and is still available today as Lupron Depot (Figure 3–10).55

A highly successful long acting PLGA microsphere is Risperdal Consta (Figure 3–11). This PLGA based microsphere contains the antipsychotic drug risperidone and is an intramuscular formulation, with improved efficacy in the treatment of patients with schizophrenia.230 In the 1990s, the development of the ProLease process for the fabrication of homogeneous batches of drug-loaded PLGA microparticles using a low-temperature ultrasonic spraying technique facilitated the development of numerous drug-loaded PLGA microparticles.244 Further microparticles were developed using poly(butylene terephthalate) (PBT) for the delivery of interferon-α2b (Locteron, Figure 3–12).57

The first thermally responsive, degradable, controlled-release polymeric drug depot delivery systems were developed by Kim and co-workers using diblock and triblock copolymers of PLGA–PEG, which were termed ReGel (Figure 3–13).58 A major advantage of PLGA as the controlled-release polymer of choice is that its physicochemical properties have been widely studied and its release profiles can be easily tuned on the basis of MW and the lactide:glycolide monomer ratios.62 Drug release can be controlled from hours to months, and the blending of other polymers in the formulation can further control drug release. The versatility of PLGA allows for a wide range of payloads—from small-molecule drugs to peptides and proteins—to be encapsulated. The in vivo degradation of polymers such as PLGA therefore facilitated sustained release with tunable dosing without the need for surgical procedures.

3.3. Evolution of Nanoscale Polymeric Drug Delivery Systems

The ability to manufacture and control the assembly of polymers to nanoscale dimensions, combined with growing interest in applying nanotechnology to medicine, drove the further downsizing of controlled-release DDS from macro- or microscale products to the nanoscale.245 Indeed, the clinical success of the initially developed microparticles validated the concept of controlled release from polymers and set the stage for the era of polymeric controlled-release NPs. Driven by the fast pace of innovation and emerging successes of NP-based drug delivery, the phenomenal interest and investment in nanomedicine research and development is set to progressively improve the landscape of controlled-release drug delivery applications.246–248

Beginning with pioneering discoveries with the earlier nanomedicines (liposomes and polymer–drug conjugates)249–254 we have seen how the ability to modify the surface of these particles using the inert hydrophilic polymer PEG (a process termed PEGylation) facilitated the widespread use of these nanoscale DDS in vivo and led to the current astonishing pace of preclinical NP development.132 Prior to these events, the development of antibody technologies and bioconjugation techniques facilitated the creation of NPs specifically targeted toward disease antigens.253,255 In addition to antibodies, antibody fragments, peptides, aptamers (Apts), sugars, and small molecules have also been used to create targeted NPs.253,255–257 Specific targeting of polymeric NPs allows for their differential spatial localization within the body, minimizing the drug payload’s off-target adverse effects. Among the different approaches to NP targeting are “passive” and “active” targeting.258 Passive targeting refers to the preferential accumulation of NPs (bearing no affinity ligands) at active sites and is directly related to the inherent biophysicochemical properties of the NP (size, shape, charge, flexibility, etc.).19 Active targeting describes the mode of action of NPs with surface modification to incorporate affinity ligands with specificity to disease cells and tissues.19

Initially, nanoscale polymeric drug release systems involved the covalent conjugation of drugs to pendant groups on the polymer backbone, such as conjugation to poly(hydroxypropyl methacrylamide) (PHPMA) polymers.259,260 Here the drugs were bonded to the polymer via tetrapeptide linkages that were degradable by cathepsin B.259 These drug–polymer conjugates were then further targeted using ligands such as sugar molecules.259 Conjugation of the anticancer peptide neocarzinostatin to styrene-maleic anhydride (SMANCS, Figure 3–14) in 1984 by Maeda et al. led to the establishment of the enhanced permeation and retention (EPR) effect theory by Maeda, who observed that these colloidal macromolecular drug conjugates accumulated in tumors due to “leaky” vasculature.61 As a result of these breakthrough findings, passive targeting of NPs to tumors has been widely exploited in oncology applications.61

Another important development in the field was the synthesis of PEGylated block copolymers to formulate polymer micelle NPs.261 Cabral and Kataoka synthesized A–B block copolymers of PEG block polymers conjugated to hydrophobic amino acid blocks.262 These block copolymers could self-assemble into PEGylated polymeric micelles at very low critical micelle concentrations (cmc), with their hydrophobic cores loaded with small-molecule hydrophobic drugs.263 The drugs could be loaded either physically or by direct conjugation to the amino acid pendant groups of the polymer backbone. The terminal distal ends of the PEG polymers were also conjugated to targeting ligands, creating targeted NPs.263,264 Around the same period, Pluronic triblock polymers were also developed.265 Together these developments led to the clinical translation of a number of passively targeted polymer micelle NPs, including SP1049C (Figure 3–15), NK911 (Figure 3–16), Genexol-PM (Figure 3–17), and others, which are currently in clinical trials for cancer treatment.63,266,267

SP1049C is a Pluronic polymeric micelle NP composed of a doxorubicin (DOX)-entrapping hydrophobic core and a hydrophilic tail and is currently undergoing phase II studies in patients with metastatic cancer of the esophagus and esophageal junction who have been found refractive to standard chemotherapy treatments.63 SP1049C was shown to be efficacious in bypassing p-glycoprotein-mediated drug resistance.268 Patients were treated with a single dose of SP1049C (75 mg/m2 DOX) given as an intravenous infusion every 3 weeks.63 The results of this study and preclinical studies demonstrated superior antitumor efficacy for SP1049C when compared to free DOX.63 In a similar manner, we have seen the development of NK911, a micellar NP comprising PEG, DOX, and poly(aspartic acid), and Genexol-PM, a paclitaxel (Ptxl)-encapsulated PEG–PLA micelle formulation currently in clinical development for various cancers in USA and Europe, and clinically approved in South Korea in 2007.267,269–271 Genexol-PM does not require the use of the toxic Cremphor EL excipient for drug solubility and has therefore led to decreased toxicity and an increase in Ptxl maximum tolerated dose (MTD) for breast cancer therapy.272,273 Genexol-PM administration demonstrated increased treatment–response rates when given to patients who were not responsive to standard taxane therapy with Ptxl/carboplatin therapies, further suggesting improved outcomes for multidrug resistant (MDR) cases. Xyotax (Ptxl–poliglumex, Figure 3–18), also a passively targeted polymeric NP in which Ptxl is conjugated to poly(L-glutamic acid), was shown to preferentially target ovarian tumors.66,67 Another example of a passively targeted polymeric NP undergoing phase trials is CRLX-101 (previously known as IT-101, Figure 3–19), a camptothecin–cyclodextrin polymer conjugate that has shown prolonged circulation times and slow drug release kinetics in vivo, in preclinical and clinical studies.68–72,274 This NP formulation is being investigated as both a monotherapy and in combination with other clinically approved therapeutics for antiangiogenic and drug-resistance therapy.70,73 By encapsulating camptothecin within these polymeric NPs, the systemic toxicity of the drug is improved. In this manner, many promising drugs that do not meet toxicity, stability, or solubility requirements can be revisited once entrapped within polymeric NPs.

Work led by Farokhzad and co-workers established single step self-assembly techniques for-the-first in human clinical translation of targeted polymeric nanoparticles. Initial proof-of-concept in vitro demonstrated the effective nanoengineering of targeted Apt NPs for the first time, and subsequent targeting of prostate cancer cells over-expressing the prostate-specific membrane antigen (PSMA) receptor with up to 77-fold increase in binding compared to non-targeted controls.21 The efficacy of these NPs was further investigated in preclinical models where tumor growth was monitored up to 109 days and results revealed that a single administration of Apt NPs containing docetaxel (Dtxl) was significantly effective at tumor size reduction compared to controls, showing almost complete tumor reduction and 100% survival (compared to 57% for non-targeted NPs and 14% for Dtxl alone).23 This study presented improvements in the therapeutic index of Dtxl, in addition to that of Ptxl,24 and paved the path for clinical translation of this polymeric platform in humans. Next, employing a modular self-assembly approach using pre-functionalized polymeric materials, libraries of targeted NPs that varied narrowly from each other in their biophysicochemical properties were developed by BIND Therapeutics, which led to the translation of the most optimal hit; BIND-014-the first targeted and controlled release polymeric NP for cancer chemotherapy to reach clinical development.25 BIND-014, is a PSMA-targeted Dtxl-encapsulated polymeric NP composed of PLA-PEG (Figure 3–20). PSMA is a transmembrane protein overexpressed on the surface of prostate cancer cells and tumor-associated neovasculature of virtually all solid tumours.275,276 BIND-014 is capable of delivering up to 10 times more Dtxl to tumors compared to an equivalent dose of free Dtxl in multiple animal models,74 and is currently undergoing clinical trials for castration-resistant prostate cancer, non-small cell lung cancer, cervical, bladder, and head and neck cancers.75 However, up to now as evidenced by initial clinical trial results, these first-generation targeted polymeric NPs have in some cases demonstrated activity against tumors that is not materially differentiated from their parent drug, underscoring the need for patient selection (i.e. those with high EPR). Ascertaining EPR in patients is no trivial task, however research efforts towards investigating companion diagnostics is helping to shed light on this complex problem. For example, we have recently shown that magnetic resonance imaging (MRI) could be a useful tool to identify patients susceptible to higher NP accumulation in tumors.277 We investigated the use of a clinically established 30 nm magnetic NP contrast agent for its potential to predict colocalization of PLGA-PEG NPs to tumors in mice using MRI. The magnetic MRI contrast agent was able to predict the colocalization of the polymeric NPs with >85% accuracy and circulation within the microvasculature with >95% accuracy, despite their markedly different sizes and compositions. Computational analysis of NP transport enabled predictive modeling of polymeric NP distribution based on imaging data and identified key parameters governing intratumoral NP accumulation and macrophage uptake. Using MRI we could accurately predict initial treatment response and drug accumulation in a preclinical efficacy study using a paclitaxel-encapsulated NP in tumor-bearing mice. These approaches yielded valuable insight into the in vivo kinetics of NP distribution and suggested that clinically relevant imaging modalities and agents, can be used to select patients with high EPR for treatment with therapeutic polymeric NPs (or similar agents).277

CALAA-01 is the first targeted polymeric NP to enter the clinic for siRNA delivery (Figure 3–21).279 The CALAA-01 NP consists of siRNA that reduces the expression of the M2 subunit of ribonucleotide reductase (R2), cyclodextrin containing polymer (CDP) for siRNA condensation, adamantine-PEG (AD-PEG) for steric stabilization, and adamantine-PEG conjugated to human Tf (AD-PEG–Tf) to target the TfR overexpressed on the surface of most cancer cells.19,280 CALAA-01 employs a unique two-vial formulation strategy, which allows for the rapid self-assembly of the NP (50–70 nm) delivery system components (CDP, AD-PEG, AD-PEG–Tf) with siRNA at the point of care.279,121 This formulation is also capable of high siRNA payload delivery and endosomal pH-triggered (<6.0) release of siRNA once NPs are endocytosed.121,76

SEL-068 is a first-in-class synthetic and integrative targeted polymeric NP vaccine to reach clinical development for the treatment of chronic conditions, such as smoking addiction (Figure 3–22). SEL-068 is fabricated using degradable PLGA and PLA–PEG polymers and contains nicotine as antigen, T-helper-cell peptides, and TLR agonists as adjuvants and is currently under development for smoking cessation and relapse prevention.121,77 The encapsulation and controlled release of the synthetic TLR agonist by the polymeric NP matrix minimizes systemic inflammatory cytokine response, leading to an improvement in the overall safety of this novel adjuvant-containing vaccine. The administration of SEL-068, which is based on modular self-assembly NP technology,24 results in high antinicotine antibody concentrations and high antinicotine antibody affinity. This leads to the sequestration of nicotine molecules in the circulation and largely blocks central nervous system exposure, thereby diminishing the addictive effects of nicotine.121 SEL-068 is the first targeted, controlled-release polymeric vaccine delivery NP to enter the clinic and is based on the synthetic vaccine particle (SVPs) technology developed by Selecta Biosciences. These SVPs can effectively coencapsulate both antigen and adjuvants capable of cellular immunity and robust humoral responses.78

Currently, a passively targeted poly(isohexyl cyanoacrylate) polymeric NP termed Livatag (doxorubicin Transdrug) is undergoing phase III clinical trials for hepatocellular carcinoma (Figure 3–23).152 This degradable polymeric NP developed by BioAlliance Pharma encapsulates doxorubicin and demonstrated high antitumor activity against MDR protein-overexpressing hepatocellular carcinomas in vitro and in vivo.152 In one phase II trial, Livatag led to 88.9% survival rate after 18 months of treatment, whereas 54.5% survival rate was observed in patients with the current transarterial chemoembolization treatment.152 Currently, this polymeric nanoscale DDS has progressed the furthest in phase trials (currently undergoing phase III investigation).152

Numerous targeted polymeric NPs are currently under investigation for various drug delivery applications; in particular, polymeric NPs are attractive platforms for the targeted and controlled release of antigens and adjuvants in nanoimmunotherapy applications as well as for the delivery of anti-inflammatory agents.281–284 Targeted polymeric NPs engineered to deliver inflammation resolving biological therapeutics have also been recently developed that can target inflammatory sites in a spatiotemporal manner, facilitating the tempering of inflammation using controlled-release proresolving mediators.285–287

3.4. The EPR Effect

Many of the polymeric NPs discussed in this section exploit the so-called EPR effect mentioned previously for tumor penetration and accumulation. In the context of controlled-release drug behavior within the intratumoral environment, important variables include NP design, the nature of the drug, and the diffusivity of both the NP and encapsulated drug throughout the vasculature, in addition to patient tumor heterogeneity and the lack of or predisposition to the EPR effect. As more patient data from clinical trials using both active and passively targeted NPs accumulates, the issues of tumor heterogeneity and patient response variability become more significant. It is therefore important to acknowledge not only that the EPR effect is a complex phenomenon, shaped by many biological variables in the tumor microenvironment, but also that our understanding of this effect is constantly evolving.

Preclinical research has begun to address EPR limitations by investigating normalization of tumor vessels prior to NP administration, in addition to utilizing companion diagnostics using approved NP imaging contrast agents to assess EPR beforehand.258,289 Tumor hallmarks, such as hypoxic gradients, increased interstitial pressure, and patient tumor heterogeneity, and lack of or predisposition to the EPR effect point to major gaps in this theory, and these concepts are discussed in detail elsewhere.258,289 We have also previously investigated the benefits of companion diagnostics as an EPR effect indicator and also showed the influence of tumor-associated macrophages on polymeric NP accumulation within tumors.277,278

3.5. Fabrication Techniques of Polymeric Nanoparticles

The progression from macro- to micropolymeric DDS was facilitated due to new fabrication methodologies that were able to produce uniformly sized drug-loaded polymeric microparticles using low temperature casting techniques, which established the ProLease process.290 This in turn facilitated the development of injectable controlled-release polymeric systems for the delivery of a wide range of therapeutics, including macromolecular biologics.228

The ability to increase the half-life of protein drugs by conjugating the inert and lipophilic polymer PEG to their surface led to the further miniaturization of controlled-release polymeric systems to the nanoscale, whereby the same PEGylation principles were applied to the development of polymeric NPs for in vivo use.19 Initially, this progress was motivated by the transition from macro- and depot-based drug delivery systems to injectable microparticle drug delivery systems, including albumin or galactose microspheres that were injected systemically for imaging studies.132 However, due to their large micrometer sizes, these particles were cleared from circulation rapidly, significantly hindering their use.132 Therefore, in order to facilitate longer circulation times in vivo, nanospheres with PEGylated surfaces were developed.132

Numerous methods have been developed for the encapsulation of therapeutics into polymeric NPs, the choice of which depends on the polymer and drug properties. Either bottom-up or top-down techniques have been employed; bottom-up methods include emulsion, interfacial polymerization, and precipitation polymerization. These polymerization methods employ a monomer as the initiator, and although highly defined NPs with precise size and shapes are obtainable, this technique is limited by the fact that the polymeric materials are not biodegradable and synthetic reagents may be retained as residues. One way around this is to use presynthesized and characterized polymers with added functionalities of PEG or targeting moieties; these are top-down preparations, a commonly used method for preparing NPs via the self-assembly of block copolymers, which can occur during nanoprecipitation (also referred to as solvent displacement), emulsification/solvent evaporation, and salting-out methods.149,291,292 The NP fabrication route is often dependent on the physicochemical properties of the drug molecules, along with NP size and loading requirements.19 Nanoprecipitation, oil-in-water (O/W) emulsification–solvent evaporation (single emulsion), and water-in-oil-in-water (W/O/W) emulsification–solvent evaporation (double emulsion) are three of the most commonly utilized methods for preparing a variety of polymeric NPs.19,293 In general, a number of considerations should be taken into account for the preparation of polymeric NPs and these include solvent choice, the solubility of the drugs (e.g., log Po/w), the mixing time of the aqueous and organic solvents, the type of surfactant used, the concentration of polymer in the organic solution, and the ratio of organic to aqueous solution, in addition to other factors.293–295 Newer approaches, such as supercritical technology, electrospraying, premix membrane emulsification, and aerosol flow reactor methods, have also been developed and are discussed elsewhere.293 The most common methods of preparing polymeric NPs for drug delivery applications are described in more detail in subsequent sections.

3.5.1. Prolease Technique

The ProLease technique is a process whereby microspheres are produced at very cold temperatures with bioactive polymers entrapped, which in turn facilitates high retention of biological activity. After the polymer and payload mixture is atomized into a vessel, cold liquefied gas or liquid causes the polymer droplets to immediately freeze, and the solvent in the droplets is extracted, leading to hardened spherical microparticles.290 The need to maintain the integrity of biological drugs, such as proteins, led to the development of this technique, which was initially utilized for the entrapment of recombinant human growth hormone (rhGH).244 The goal was to create slow-releasing polymeric microspheres that could be injected once a month instead of daily or triweekly. The ProLease method is suitable for microsphere fabrication, since it uses low temperatures to preserve the protein integrity and nonaqueous based (the protein is not subjected to oil–water interface where it can denature) entrapment, which leads to high protein encapsulation efficiencies. This microsphere formulation was composed of PGA (50:50) and termed Nutropin Depot, and it was approved by the FDA in 1999 for growth hormone deficiencies.296 This technique has limitations in that it is not easily applicable to other types of proteins, the use of liquid nitrogen on a large-scale may not be feasible, and organic solvents are still required during the process.

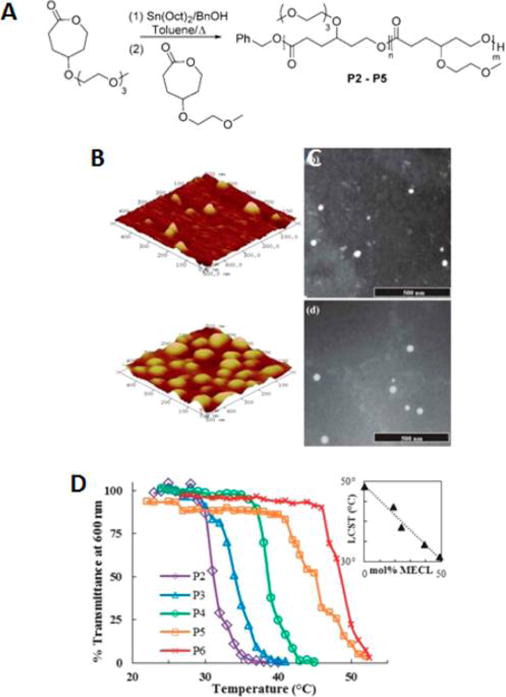

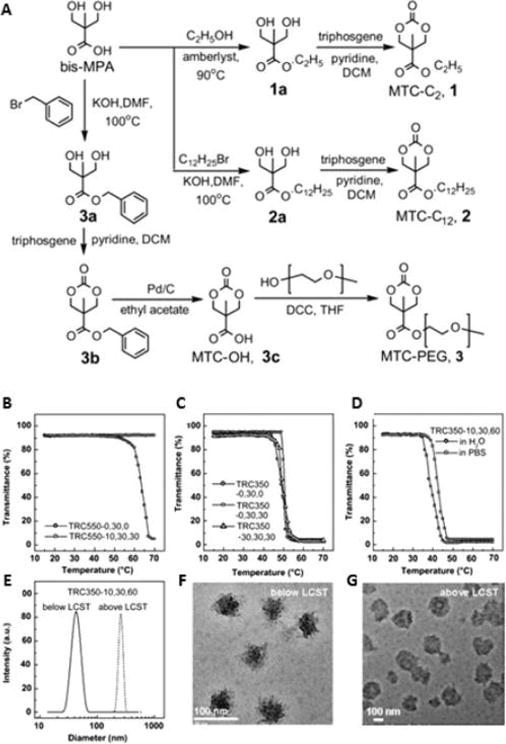

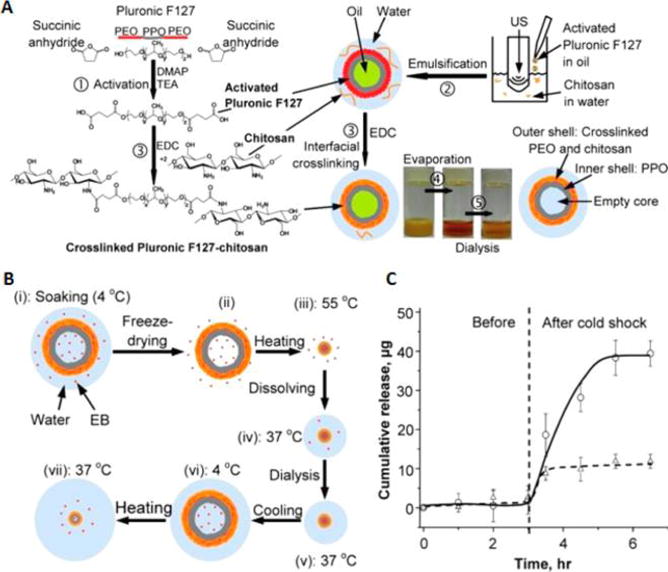

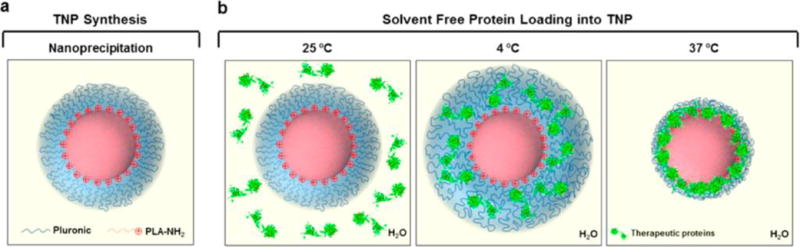

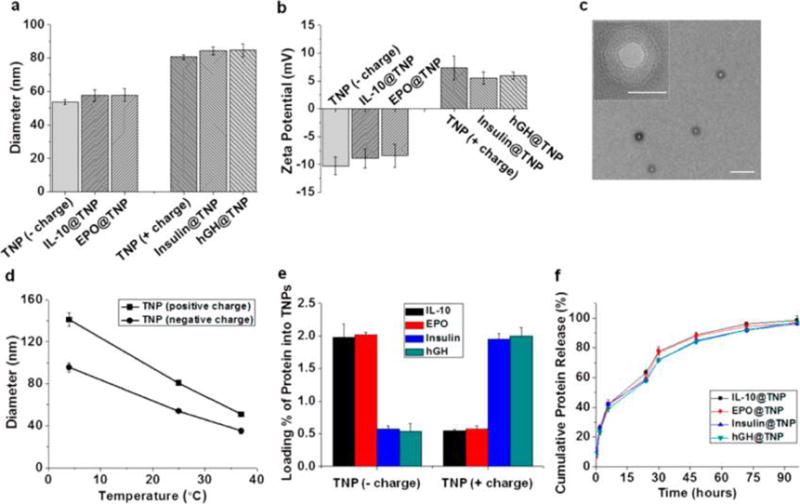

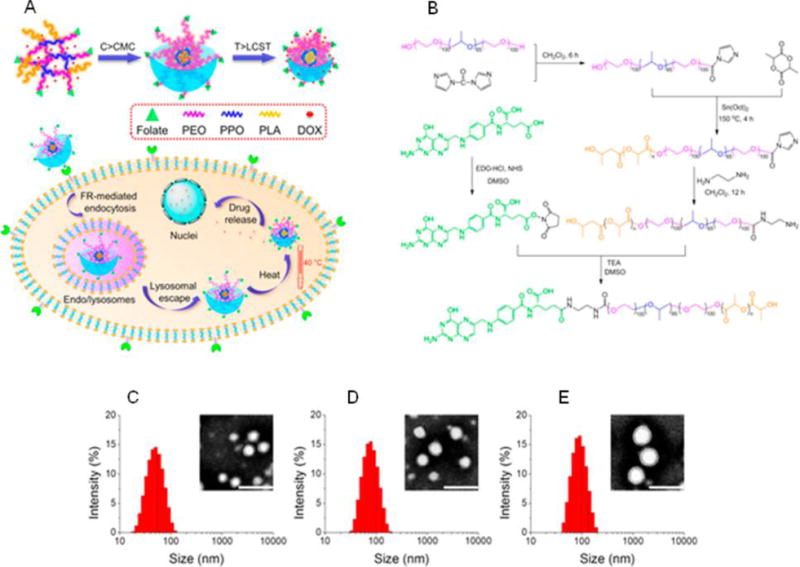

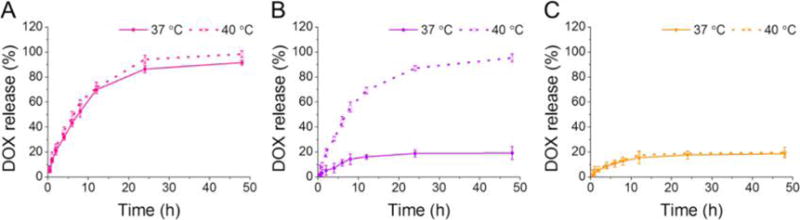

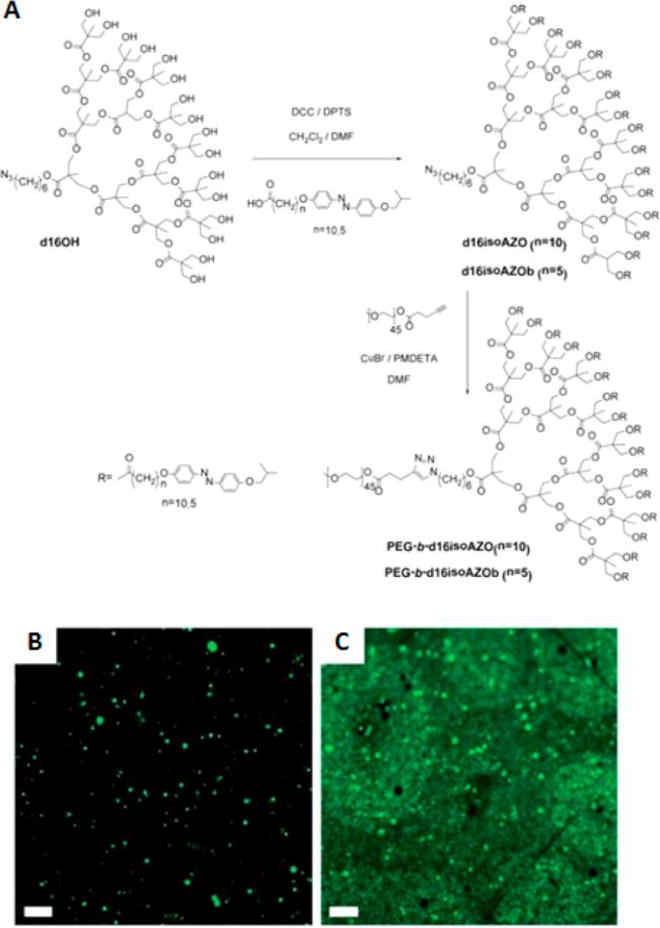

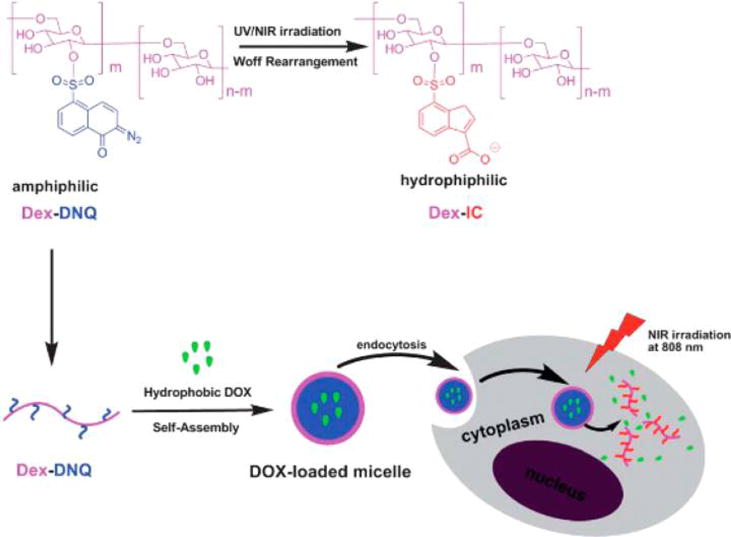

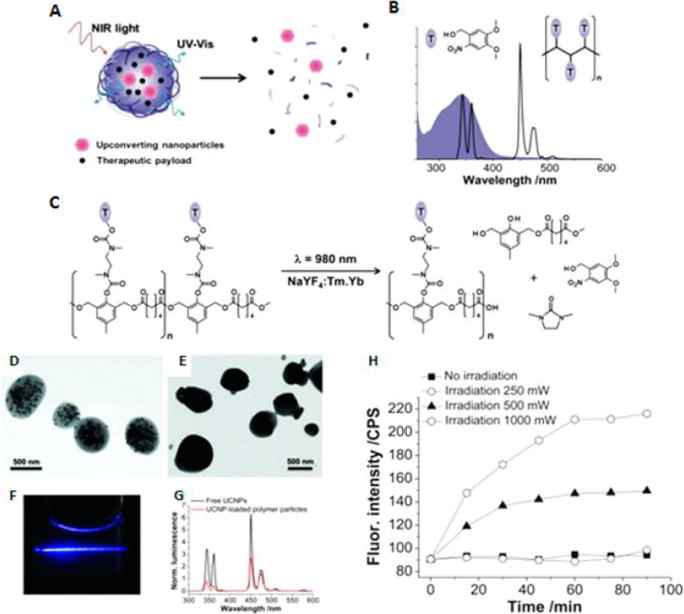

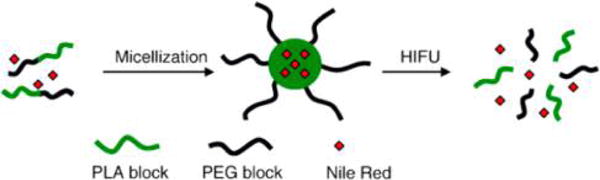

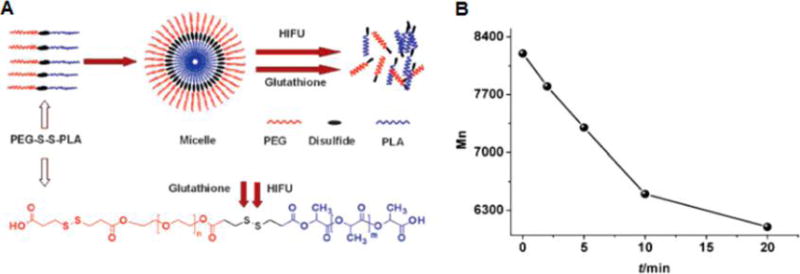

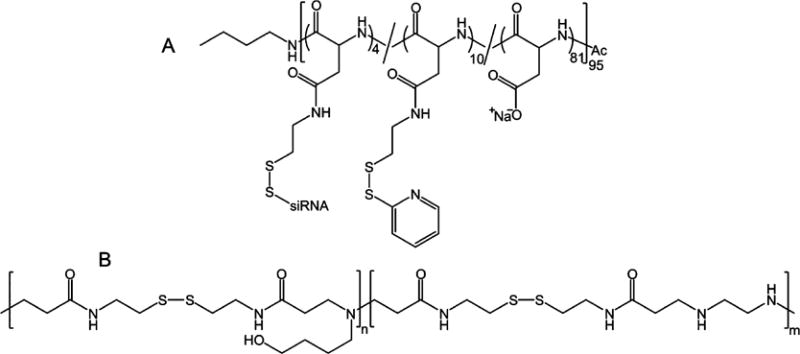

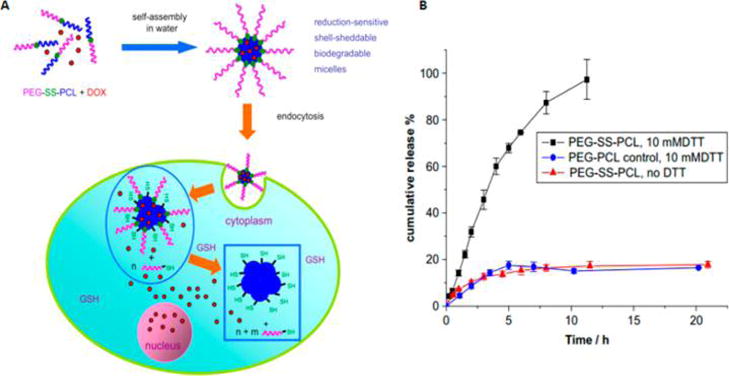

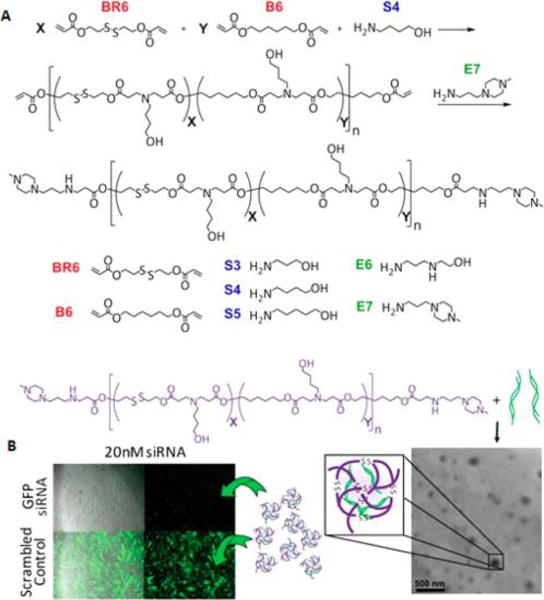

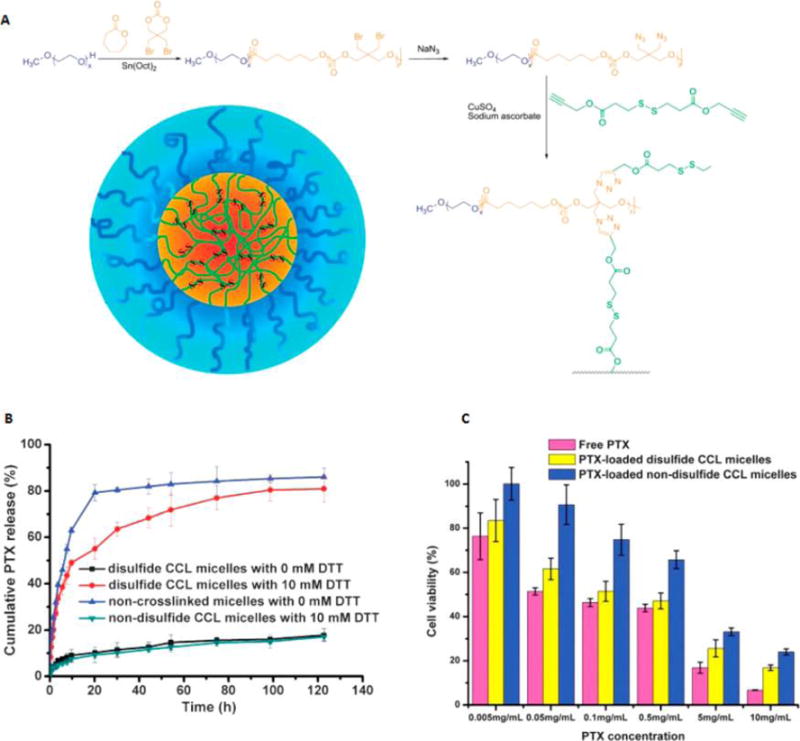

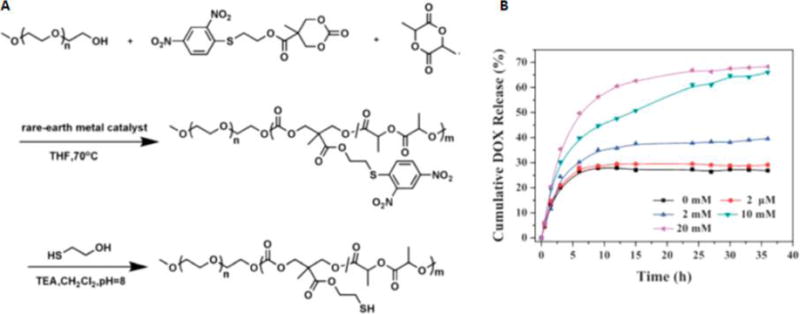

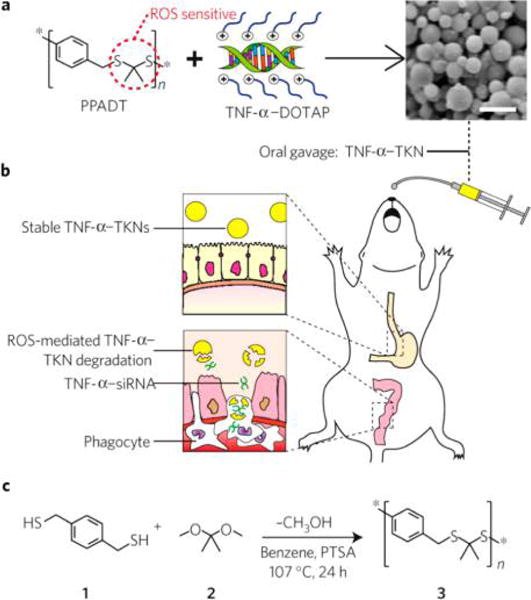

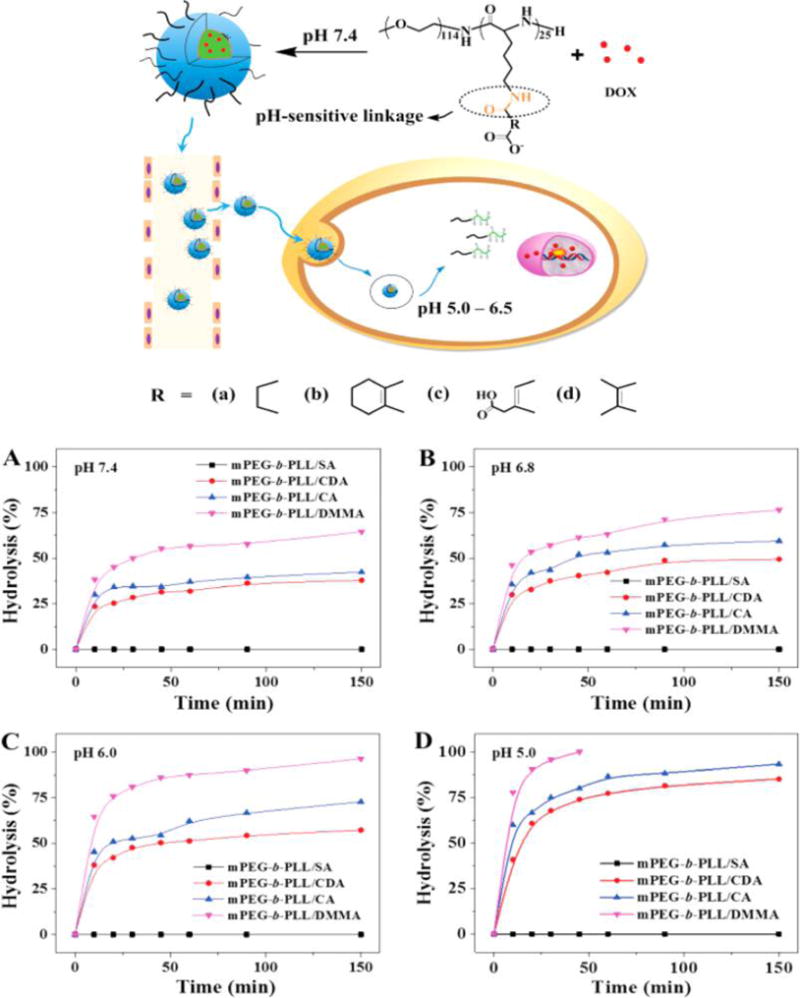

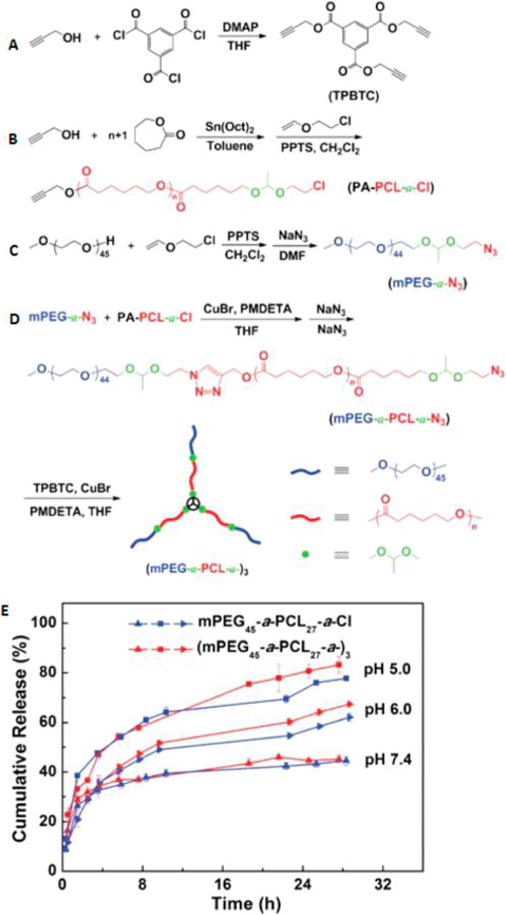

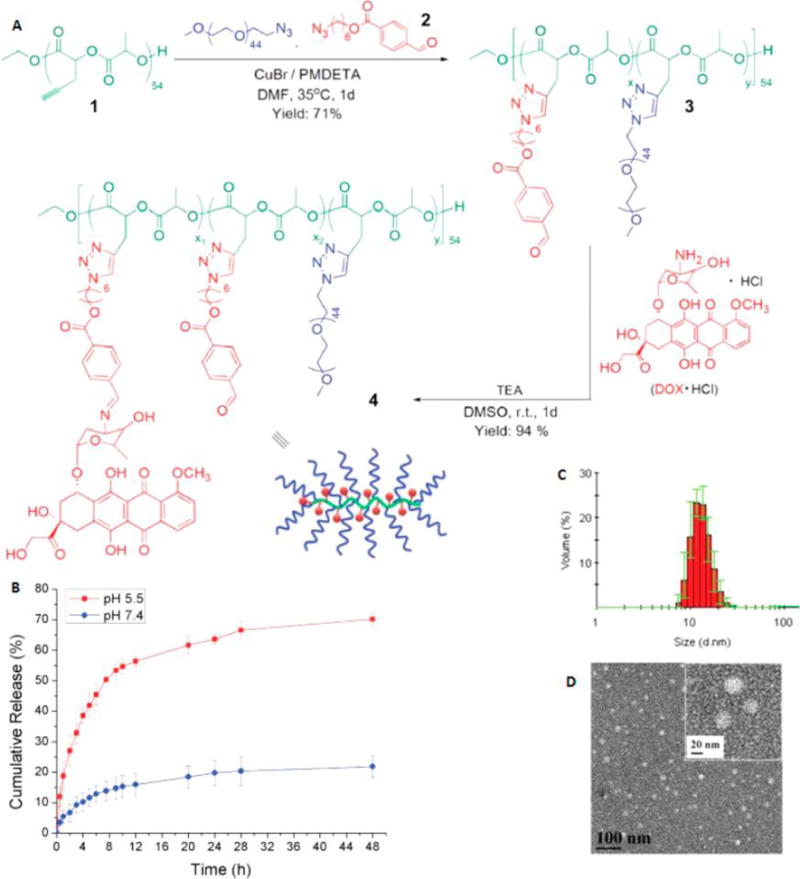

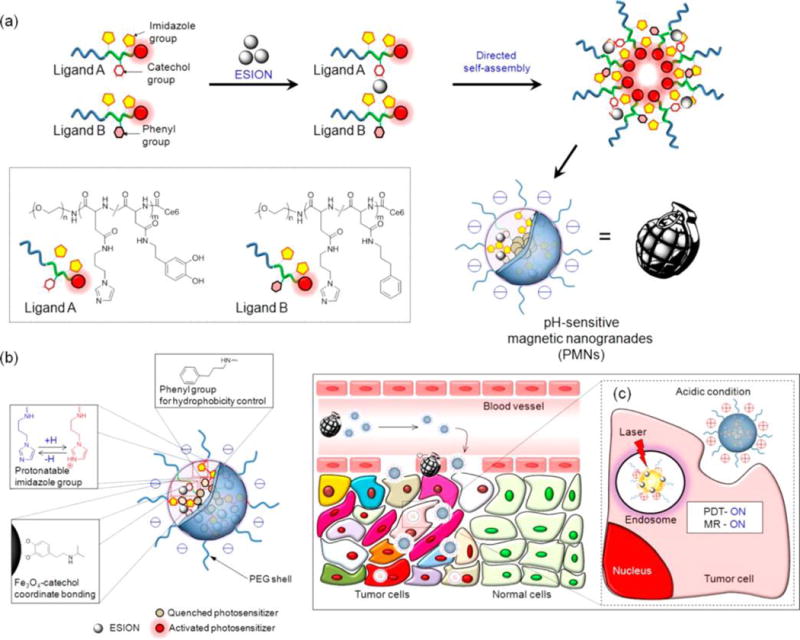

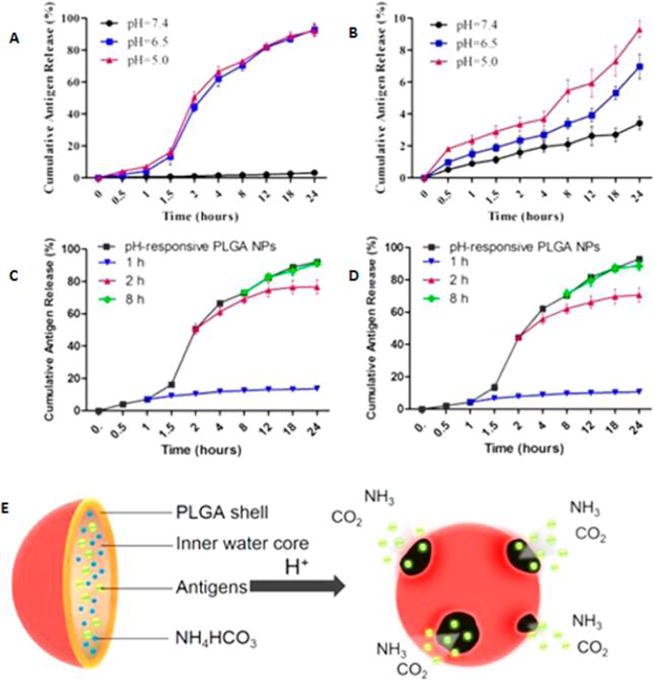

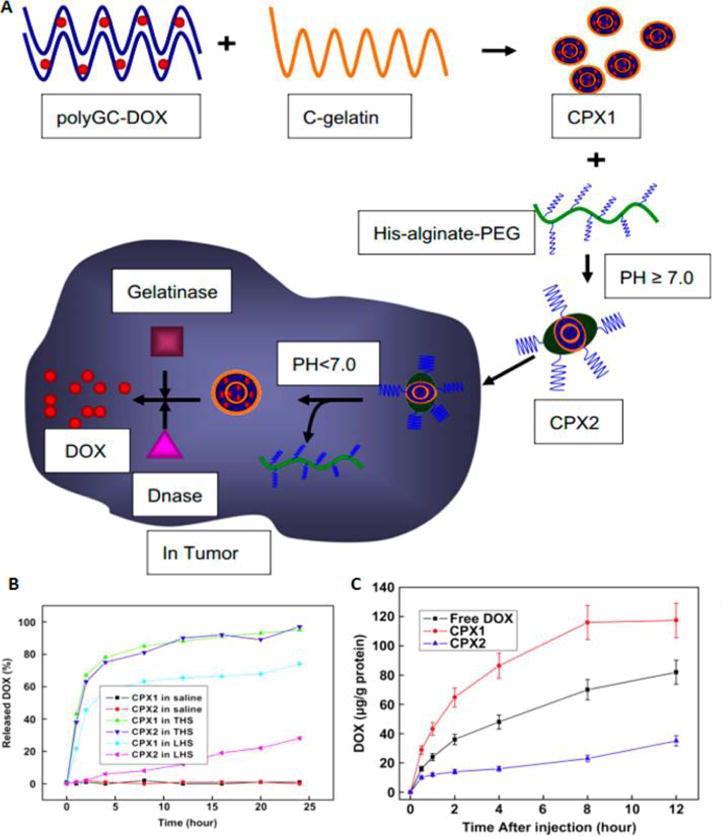

3.5.2. Nanoprecipitation/Solvent Displacement