Abstract

Despite tremendous advances in the field of regenerative medicine, it still remains challenging to repair the osteochondral interface and full-thickness articular cartilage defects. This inefficiency largely originates from the lack of appropriate tissue engineered artificial matrices that can replace the damaged regions and promote tissue regeneration. Hydrogels are emerging as a promising class of biomaterials for both soft and hard tissue regeneration. Many critical properties of hydrogels, such as mechanical stiffness, elasticity, water content, bioactivity, and degradation, can be rationally designed and conveniently tuned by proper selection of the material and chemistry. Particularly, advances in the development of cell-laden hydrogels have opened up new possibilities for cell therapy. In this article, we describe the problems encountered in this field and review recent progress in designing cell-hydrogel hybrid constructs for promoting the reestablishment of osteochondral/cartilage tissues. Our focus centers on the effects of hydrogel type, cell type, and growth factor delivery on achieving efficient chondrogenesis and osteogenesis. We give our perspective on developing next-generation matrices with improved physical and biological properties for osteochondral/cartilage tissue engineering. We also highlight recent advances in biomanufacturing technologies (e.g. molding, bioprinting, and assembly) for fabrication of hydrogel-based osteochondral and cartilage constructs with complex compositions and microarchitectures to mimic their native counterparts.

Graphical abstract

1. Introduction

Osteochondral interface defects commonly involve lesions of both articular (hyaline) cartilage and underlying subchondral bone that are caused by trauma, disease, or aging. Different from the vast majority of other tissues, cartilage is basically avascular and low in cellularity in nature [1]. Cartilage thus lacks the ability to self-heal due to the absence of abundant nutrients and proper progenitor cells. When a cartilage defect is left untreated, however, the joint irrevocably and progressively deteriorates, leading to osteoarthritis and eventually, disabilities [2]. Cartilage-related tissue defects and diseases are the most common cause of disability, representing around 6% of disabled people of 30 years and older [3–5]. Current treatment strategies for osteochondral interface and full-thickness cartilage defects include microfracture (marrow stimulation) [6–8], autologous chondrocyte implantation [9–12], and osteochondral autografts and allografts [13–16], among others. Despite their common uses in the clinic, notable limitations and drawbacks still exist. The microfracture treatment drills tiny holes that penetrate the cartilage and the subchondral bone to bring in blood flow and bone marrow from surrounding tissues. Induced cartilage and bone regeneration/remodeling are expected due to the introduction of stem cells and biomolecules at the defects. However, it may lead to the formation of fibrocartilage that has inferior biofunctions compared to articular cartilage [17–19]. The autologous chondrocyte implantation strategy has been used clinically to regenerate articular cartilage for two decades with satisfactory surgical outcome to certain extent. Nevertheless, there are still drawbacks including shortage of chondrocyte source, long chondrocyte harvesting time, difficulty of chondrocyte solution fixation, periosteal hypertrophy and ablation [20], as well as low effectiveness for aged patients [21]. It should also be noted that autologous chondrocyte implantation is incapable to repair osteochondral interface and full-thickness cartilage, which require simultaneous restoration of the subchondral bone. Allografts suffer from limited tissue supply, immunorejection, insufficient integration, low cell viability due to graft storage, and possibility of disease spread. Autografts not only lack integration and tissue source, but also require additional surgery and result in donor site morbidity [1, 17, 22, 23].

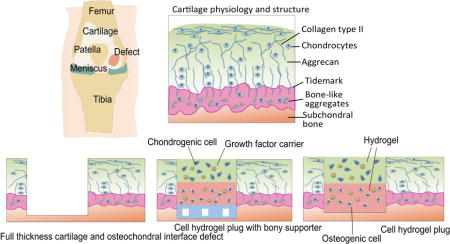

To address these limitations, osteochondral and cartilage tissue engineering (OTE and CTE) have been proposed to advance new and more effective treatments. There are two main approaches for regeneration of deficient osteochondral interface and full-thickness cartilage using tissue engineering approaches. One is to develop artificial cartilage constructs to mimic the architectural features, mechanical properties, and thus biological functions of native cartilage tissues. By combining specially designed biopolymers and advanced manufacturing technology, generation of three-dimensional (3D) tissue constructs with similar mechanical stiffness to articular cartilage has been demonstrated [24]. However, it still remains a challenge to mimic the unique biofunctions of articular cartilage and osteochondral interface tissues that are highly complex in composition and zonal structures (Fig. 1). The other tissue engineering approach emphasizes more on regenerative medicine. The essential concept is to deliver appropriate biomaterials as artificial extracellular matrix (ECM) to facilitate cell growth, proliferation, and differentiation at the sites of defects, leaving regeneration of the articular cartilage and subchondral bone to the native biological processes involving interactions among cells and biomolecules (e.g. growth factors). In these cases, the matrix material does not need to be as mechanically strong as the native tissues, since it only serves as a temporary 3D microenvironment for the chondrogenic or osteogenic progenitor cells to generate real cartilage and bone tissues. In this review, we will focus on hydrogel-based tissue engineering approaches, which have gained increasing popularity during the past few years.

Fig. 1.

Tissue engineering strategy for treatment of osteochondral interface and full-thickness cartilage defects with cell-laden hydrogel constructs.

Hydrogels are versatile and appealing biomaterials for tissue engineering and cell therapy applications, due to their unique combination of properties similar to natural ECMs, such as high water content, biodegradability, porosity, and biocompatibility [25]. The composition, structure, mechanical properties, and biochemical properties of hydrogels are conveniently tunable to suit for various desired biomedical applications [26]. As to cartilage and osteochondral engineering, hydrogels can serve as an active matrix to control cell morphology, proliferation, and differentiation [27–30]. Moreover, cell-laden hydrogels, or cell-hydrogel hybrid constructs, can be manufactured by advanced techniques with patient-customized geometries and compositions. As a result, it is widely accepted that hydrogels combining both cells and growth factors have great potentials to address the challenge of regenerating osteochondral interface and full-thickness cartilage (Fig. 1). Over the past decade, a variety of tissue-engineered cell-laden hydrogel systems have been developed for OTE and CTE applications with remarkable successes as fundamental studies [29, 30].

In this review, we will focus on the recent advances of hydrogel design, cell source selection, and growth factor delivery. We then envision further development of the next-generation engineered osteochondral/cartilage constructs composed of hydrogel/inorganic particles/stem cells with improved mechanical properties and biological functions, which promise breakthroughs in clinic practices. Finally, we highlight the development of advanced manufacturing technologies of osteochondral and cartilage constructs with complex gradient composition and zonal structure that have the potential to mimic the native tissues.

2. Designing hydrogels for reconstruction of osteochondral interface and cartilage

Hydrogels, composed of highly hydrated, ECM-mimicking polymeric networks, have attracted strong attention for applications in tissue engineering and regenerative medicine [26,31, 32]. To date, various types of hydrogels derived from different natural or synthetic polymers or their hybrids, have been used for reconstruction of deficient osteochondral interface or articular cartilage tissues [33–35] (summarized in Table 1). Hydrogels based on natural polymers, including polysaccharides (alginate, agarose, chitosan, hyaluronic acid (HA), and gellan gum) and proteins (collagen, gelatin, and fibroin), have been extensively documented [36–55]. The use of a variety of hydrogels based on synthetic polymers, e.g. poly(ethylene glycol) (PEG), polymer oligo(poly(ethylene glycol) fumarate) (OPF), polyvinyl alcohol (PVA), poly(N,N-dimethylacrylamide) (PDMAAm), and methoxy poly(ethylene glycol)-poly(ε-caprolactone) (MPEG–PCL) [53, 56–73], have also been widely reported. Hybrid hydrogels can further be fabricated from combinations of natural and synthetic polymers, providing more possibilities in selection over different compositions. In general, suitable hydrogel candidates for OTE and CTE applications should ideally be able to support cell growth/proliferation, maintain phenotypes of chondrocytes/osteoblasts, and promote chondrogenic/osteogenic differentiation of stem cells for recapitulation of osteochondral interface or cartilage tissues. Among the large variety of hydrogels reported for biomedicine applications, here we review recent progresses of investigations on hydrogels showing promise for repair of osteochondral and cartilage tissues.

Table 1.

Hydrogels, cells, and growth factors used for OTE and CTE

| Hydrogel type | Application (OTE/CTE) | Cell type | Growth factor | Crosslinking/gelation method | Stiff bone layer (Yes/No) | In vivo model | Ref. |

|---|---|---|---|---|---|---|---|

| Alginate | OTE CTE | Chondrocytes MSCs IPSCs | TGF-β3 | Physical (ionic interaction) | Yes | Rabbit medial femoral condyle | [36–40] |

| Agarose | CTE | Chondrocytes MSCs | TGF-β3 | Physical (temperature change) | No | —— | [41, 42] |

| Collagen | OTE CTE | MSCs Chondrocytes | TGF-β1-3 BMP 2-7, FGF-1 |

Chemical | Yes | Sheep medial femoral condyle | [45, 46] |

| Chitosan | CTE | Chondrocytes MSC | TGF-β1 | Chemical | No | —— | [50, 51] |

| Gellan gum | CTE | Chondrocytes | —— | Physical (ionic interaction and temperature change) | No | Mouse subcutaneous | [44] |

| Gelatin | OTE | MSCs | BMP-4 | Chemical | No | Rabbit medial femoral condyle | [52] |

| Fibroin | CTE | Chondrocytes | —— | Physical (ionic interaction) | No | —— | [48, 49] |

| Hyaluronic acid | CTE | Chondrocytes MSCs | TGF-β | Chemical (UV photo- polymerization) | No | —— | [54, 55] |

| PVA | OTE | Osteoblasts Chondrocytes | —— | Chemical (UV photo- polymerization) | No | —— | [65–70] |

| PEG | CTE OTE | MSCs Chondrocytes ESCs | TGF-β3 | Chemical (UV photo- polymerization) | Yes | Rabbit medial femoral condyle | [58–64] |

| OPF | OTE | MSCs | TGF-β1 | Chemical | No | Rabbit medial femoral condyle | [71, 72] |

| PDMAAm | OTE | Chondrocytes | —— | Chemical | No | Rabbit medial femoral condyle | [73] |

| PEG–PCL | CTE | Chondrocytes | —— | Physical (temperature change) | No | Mouse subcutaneous | [196] |

| GelMA | CTE | Chondrocytes | TGF-β1 | Chemical (UV photo- polymerization) | No | —— | [26, 213, 217] |

| —— | OTE | PBMCs | —— | —— | No | Medial femoral condyle | [197] |

(a) PEG: Poly(ethylene glycol); (b) PVA: Polyvinyl alcohol; (c) OPF: Oligo(poly(ethylene glycol) fumarate); (d) PDMAAm: Poly(N,N-dimethylacrylamide); (e) PEG–PCL: Poly(ethylene glycol)–poly(ε -caprolactone); (f) GelMA: Gelatin methacryloy; (g) BMP: Bone morphogenetic protein.

2.1 Typical hydrogels of natural polymers and their chemically modified derivatives

Hydrogels fabricated from natural polymers generally possess good biocompatibility, biodegradability, low immunoresponse, and bioactive motifs encoded in their structures[37–46], and are thus promising biomaterials for OTE and CTE applications. Their derivatives have tunable biodegradability, mechanical properties, and specific biofunctions with chemical modification of functional groups, specific ligands, and macromolecules. This part reviews the recent advances in the development of representative hydrogels using natural polysaccharides (alginate, agarose, chitosan, HA, and gellan gum) and proteins (collagen, gelatin, and fibroin), and their derivatives, with emphases on their resources, properties, crosslinking mechanisms, as well as advantages and disadvantages for repair of cartilage and osteochondral tissue defects.

2.1.1 Alginate hydrogels and their derivatives

Alginate is one of naturally occurring polysaccharide polymers typically obtained from brown seaweed and various bacteria. One unique property of alginate is the ability to be physically crosslinked by divalent cations such as Ca2+ at room temperature [11, 37, 38, 74–76], which makes it very useful in various biofabrication techniques, including molding, spraying, and 3D bioprinting [77–80]. The resulting physical hydrogels have good biocompatibility, low toxicity, and relatively low cost [36–39, 81–89]. Alginate hydrogels have been shown to support growth and proliferation of encapsulated chondrocytes, as well as to maintain their chondrogenic phonotype. After in vitro culturing of chondrocytes for 21–28 days [36–38], collagen type II and aggrecan formed along with enhanced cartilage gene expressions. Alginate hydrogels were also used to deliver bone progenitor cells including mesenchymal stem cells (MSCs) for bone regeneration [84, 85]. Encapsulated MSCs could produce their own collagenous ECM that was well integrated with the host tissue.

Despite these successes, however, alginate hydrogels have some limitations for tissue engineering applications. First, physically crosslinked alginate hydrogels lack long-term stability and can gradually lose their initial mechanical strengths in physiological environment within a relatively short timeframe, which neccessitates additional crosslinking mechanisms to further stiffen the network structures [90]. Second, alginate inherently has low mammalian cell adhesiveness and cellular interaction ability; as a result, the introduction of cell adhesion peptide motifs is generally implemented to better support cell functions [76, 91].

Chemically modified alginate derivatives have been studied to improve the mechanical properties, selective solubility, and cell adhesiveness for tissue engineering purpose. By ester bond formation of long alkyl chains including dodecyl and octadecyl to the alginate backbone, amphiphilic alginate derivatives have been produced. Aqueous solutions of such alginate derivatives showed good rheological properties and could be physically crosslinked to form hydrogels, which would be useful for cartilage regeneration [74, 75]. Phenolic hydroxyl modified alginate (Alg-Ph) hydrogels have been developed through a horseradish peroxidase (HRP)-catalyzed oxidative crosslinking reaction with H2O2 as an electron acceptor [92]. The phosphorylation, cell spreading, and osteogenic differentiation of preosteoblasts encapsulated in these alginate hydrogels could be further controlled by RGD nanopatterning. Modified alginate hydrogels thus hold great potential as a cell delivery matrix for repairing bone and cartilage.

The same group also applied chemical modifications to tune the toughness and chemical stability of alginate hydrogels without compromising their excellent biocompatibility [87, 88]. Cellular adhesion on alginate hydrogels can be increased by increasing the HRP concentration during crosslinking or by chemical ligation with RGD sequences via the carbodiimide chemistry [74, 93].

2.1.2 Agarose hydrogels and their derivatives

Agarose is a type of polysaccharide composed of alternating sequences of 1,3-linked β-D-galactose and 1,4-linked 3,6-anhydro-α-L-galactose. Agarose aqueous solutions form thermally reversible physical hydrogels at 17–40 °C, which become soluble at temperatures over 65 °C [94]. At body temperature, agarose hydrogels are stable and normally deemed as an inert biomaterial, because it lacks native ligands that allow cell-material interactions. However, many studies demonstrated that agarose hydrogels promote chondrocyte phenotype maintenance for cartilage regeneration [95–99]. Importantly, the temperature-responsive gelation capability of agarose makes it possible to design injectable cell-laden hydrogels for minimally invasive treatment of cartilage and osteochondral defects [29, 100].

In addition, agarose hydrogels can support chondrogenic differentiation and in vitro cartilaginous tissue formation of encapsulated stem cells such as MSCs [42, 95, 101–103]. However, ECM generation from MSCs encapsulated in agarose hydrogels was significantly less than that from chondrocytes at day 70 under similar conditions [42]. Moreover, after in vitro chondrogenic culture and maturation for 8–10 weeks, the MSC-laden agarose hydrogel cartilage constructs had lower mechanical stiffness than those laden with chondrocytes [42, 104]. Therefore, further studies are required to optimize conditions to induce chondrogenesis of MSC-laden hydrogels for cartilage regeneration.

In addition to excellent biocompatibility to support chondrogenesis of chondrocytes and MSCs, agarose hydrogels also have good biomechanical properties (e.g., stiffness and viscoelasticity) matching those of cartilage tissues. Therefore they are deemed promising biomaterials for cartilage regeneration. However, for bone tissue engineering applications especially in load-bearing conditions, better mechanical properties of agarose hydrogels are required. Hybrid agarose hydrogels incorporated with inorganic nanomaterials might be interesting alternatives towards improvement of mechanical properties. For example, agarose hydrogels loaded with bioceramic particles not only had highly improved mechanical stiffness but also supported osteogenesis [105, 106].

Chemically modified agarose hydrogels have been studied to improve their cellular affinity and mechanical properties for extensive tissue engineering applications. For example, glycine-arginine-glycine-aspartic acid-serine (GRGDS) oligopeptide-modified 0.5 wt% agarose hydrogels were produced by immobilization of the adhesive fibronectin peptide fragment using a focused laser [41]. Such hydrogels exhibited improved cell adhesion and guided migration abilities that would be beneficial to tissue engineering applications.

Another agarose derivative was generated by carboxylation, a general method for transformation of secondary structures of helical polysaccharides [107]. Through changing the degree of carboxylation, the modulus can be tuned independent of the prepolymer concentration.

2.1.3 Chitosan hydrogels and their derivatives

Chitosan is derived from chitin, the second most abundant natural biopolymer [108] from renewable sources including shell of shellfish, crustacean shells, insect cuticles, mushrooms envelopes, and the wastes of the seafood industry [109, 110]. Chitosan has good biocompatibility and biodegradability, and is thus an attracting candidate material for tissue engineering applications. Chitosan hydrogels prepared by enzymatic crosslinking can support the proliferation of chondrocytes and MSCs, maintain the chondrogenic phenotype and morphology, and boost the deposition of cartilaginous ECM in vitro [50, 51].

Long-term in vitro culture and in vivo subcutaneous implantation of MSC-laden chitosan hydrogels have been carried out to examine the their capacity to support chondrogenesis and hypertrophy of MSCs [101]. After 8 weeks of in vitro chondrogenesis, a chondrogenic phenotype in MSCs was well maintained and robust chondrogenesis was found in chitosan hydrogel constructs with high levels of accumulated aggrecan and collagen type II deposition. The cells were found to deposit a large amount of cartilage ECM and facilitated neither vascularization nor endochondral ossification in vivo [101].

From these results, it is suggested that chitosan is a suitable and promising biomaterial for articular cartilage regeneration. However, chitosan has poor solubility in water under physiological conditions, which limits their extensive utilization in tissue engineering [111]. As a polysaccharide, chitosan also has relatively low cellular adhesiveness for adhesion, proliferation, and ECM formation of certain cell types involved in OTE and CTE such as chondrocytes [112, 113]. Allergenic reactions of chitosan may be an issue for its clinical translation. One prior study has been conducted to evaluate the safety of chitosan biomaterials [114]. Since chitosan can be derived from shellfish or shrimp, this study selected patients who were allergic to shellfish/shrimp to test the allergic responses to chitosan. No participant had a positive skin prick testing result to chitosan or experienced an adverse reaction during bandage challenges. However, more investigations are needed to further elucidate this issue.

Chitosan derivatives have been produced through chemical modification to introduce specific functional groups, ligands, macromolecular side chains, or crosslinking sites to tune the solubility, gelation property, cell affinity, and specific biological properties for repair of cartilage and osteochondral defects [115]. Trimethyl chitosan (TMC) has been developed for an enhanced solubility over a broader range of pH via the reaction of methyl iodide with the amino groups [116]. RGD-chitosan derivatives were generated by reaction with 2-iminothiolane via disulfide bond linkage with the aid of dimethyl sulfoxide [117]. These chitosan derivatives exhibited improved ability of adhesion and proliferation for chondrocytes. Lactose-conjugated chitosan derivatives were developed by reductive N-alkylation for improved chondrocyte adhesion, aggregation and proliferation, as well as aggrecan and collagen type II formation [118–120].

2.1.4 HA hydrogels and their derivatives

HA, as a linear polysaccharide consisting of 250–25,000 repeating disaccharide units [94], is the most abundant component in the cartilage and an important aggrecan component organizing cartilage ECM into resilient structures. Therefore, HA-based hydrogels are one of the most promising naturally derived biomaterials for OTE and CTE applications. HA involves in some key cellular processes of chondrocytes, such as morphogenesis, proliferation, and inflammation [121]. And HA has stimulatory effects on chondrocyte metabolism in vitro [122]. HA could also significantly increase the synthesis of chondroitin-6-sulphate, collagen type II, glycosaminoglycan, hydroxyproline, and DNA. Due to the unique effects of HA on cellular behavior of chondrocytes, much effort has been made to develop chondrocyte-laden HA hydrogels for regeneration of cartilage tissues [55, 123–125].

HA hydrogels were demonstrated to support early differentiation of MSCs down to chondrogenic linage and enhance cartilage tissue formation in vitro and in vivo [126–133]. MSC-laden HA hydrogels were developed to generate engineered cartilage constructs with high mechanical properties by fostering chondrogenic differentiation and ECM production. After in vitro maturation for 9 weeks, HA hydrogel constructs with high-density (60 × 106/mL) of encapsulated MSC reached a compressive modulus of 1 MPa under dynamic culture conditions (compared with 0.3–0.4 MPa under static culture conditions) [127]. The dynamic culture condition (orbital shaking) ensured that optimal nutrient access was delivered, which resulted in improved formation of aggrecan and collagen in the dynamically cultured cartilage constructs based on HA hydrogels, 30% and 29% greater than the amounts of aggrecan and collagen formed in the statically cultured controls. In this case, dynamically cultured samples exhibited much higher compressive modulus. In this case, dynamically cultured samples exhibited much higher compressive modulus. In vivo studies have demonstrated that MSC-laden HA hydrogels could promote neocartilage formation with increasing collagen type II and aggrecan production [126, 131, 132].

Chemical modifications of HA can be achieved via reactions of the carboxylic groups with various hydroxyl- or amine-bearing motifs to form derivatives with improved biocompatibility and controlled biodegradability [94]. HA can also be chemically modified with photocrosslinkable functional groups such as methacrylate and glycidyl methacrylate, which enable feasible crosslinking of the resulting HA derivative via exposure to visible or low-energy ultraviolet light. The photocrosslinkable HA derivatives can be used to formulate injectable cell-laden hydrogels for repair of irregular cartilage and osteochondral tissue defects with enhanced mechanical properties [134, 135]. Compressive moduli of photocrosslinked HA-MA hydrogel could range from 3 to 146 kPa by tailoring the molecular weight and concentration [136]. Through chemical modification, a variety of HA-based hydrogels can be fabricated towards tunable biodegradability and improved mechanical properties, as well as better photocrosslinking ability.

2.1.5 Gellan Gum hydrogels and their derivatives

Gellan gum is a linear anionic polysaccharide consisting of tetrasaccharide repeating units with one carboxyl side group per four saccharide units [137]. Gellan gum shows thermally reversible gelation processes to form physical hydrogels. With temperature decreasing, gellan gum molecules perform a rapid random-coil to double-helix conformational transition with further intermolecular aggregation of the helices, leading to the formation of junction zones and therefore a three dimensional network via complexation with cations and hydrogen bonding in water [138–141]. During the gelation process, the carboxylic groups in glucuronic acid units serve as the ionic complexation sites to bind the polysaccharide chains to each other via divalent cations, resulting in much stronger interactions than monovalent binding [142]. Substantial studies have shown that gellan gum hydrogels possess good biocompatibility, biodegradability, and injectability for OTE and CTE applications, and they can be easily produced by gelation via temperature change and presence of cations without harsh chemical reagents [44, 137, 140, 143–145].

MSC-laden gellan gum hydrogels were studied for in vitro chondrogenesis. After 42-day culture in chondrogenic medium, cartilaginous ECM components of aggrecan and collagen type II were produced with the confirmation of chondrocytic gene expression [146]. Gellan gum hydrogels incorporated with bioglass/bioceramic particles or bone-forming growth factors were shown to support encapsulation, proliferation, and osteogenesis of preosteoblasts and MSCs for bone tissue regeneration [147–149]. Although gellan gum hydrogels are promising for cartilage and bone tissue regeneration, the three key problems may hinder their clinical translations. First, the gelation temperature (>42 °C) is higher than the physiological temperature, which may result in compromised cell viability during the gelation process [139, 143, 150]. Second, Young’s modulus of physically crosslinked gellan gum hydrogels is typically below 5 kPa, which is much lower compared with that of native cartilage tissues (typically over 60 kPa) [139, 151]. Third, gellan gum hydrogels are readily to get loss of their stability and mechanical properties in vivo because of the exchange of divalent cations with monovalent ions presenting in higher concentrations in physiological environment [139].

To decrease the gelation temperature and improve the initial mechanical properties and in vivo stability of gellan gum hydrogels, chemically modified gellan gum derivatives have been developed through various methods. For example, reducing the molecular weight of gellan gum via oxidation can decrease the gelling temperature. It was reported that the gelation temperature of gellan gum decreased to the range of 37 °C to 22 °C by increasing the NaIO4 oxidant dosage or oxidation period [152]. The results of 150-day in vitro culture demonstrated that the modified injectable chondrocyte-laden gellan gum hydrogel with low gelation temperature well maintained the chondrocyte phenotype with high viability and promoted cartilage ECM formation in a long-term scale. In addition to oxidation, gelation temperature can also be tuned by changing proportion of low/high acyl gellan gum and the concentration of covalent cations to optimize cell encapsulation and injectability [153].

Chemical modification of gellan gum has also been demonstrated by the incorporation of methacrylate groups for improved structural stability and mechanical properties with retaining the biocompatibility [139, 154–156]. A Young’s modulus of 148 kPa was achieved for methacrylated gellan gum hydrogels [139]. The in vitro and in vivo studies showed that such hydrogels supported cell encapsulation with good viability and cytocompatibility [155, 156]. Chemically modified gellan gum hydrogels have shown decreased gelation temperature, improved mechanical properties, and better in vivo stability that are crucial as injectable biomaterials for OTE and CTE applications.

2.1.6 Collagen hydrogels and collagen derivative hydrogels

Collagen is the most abundant structural protein component of ECM. Around 90% of the dry weight of articular cartilage is collagen type II. The crosslinked collagen network contains about 70% water and provides the mechanical strength and shape of cartilages during articulation [94]. On the other hand, collagen type I is the most abundant ECM in bone tissues [157]. Collagen hydrogels can be produced by crosslinking via photo-polymerization of UV irradiation, dehydrothermal treatment, or via chemical crosslinking by reacting with aldehydes, carbodiimides, isocyanates, genipin, and transglutaminase, among others [94]. Collagen type I hydrogels have been demonstrated to exert certain immunoisolation effects on the encapsulated chondrocytes, and thus enhance in vitro chondrogenesis and cartilage ECM formation during the culture over 28 days [46]. The isolation and protection, coming from formed ECM and hydrogel, effectively controlled the adverse immunogenicity of seeded chondrocytes and helped to reduce the immunogenicity of the engineered cartilage.

Moreover, it has been demonstrated that collagen type I hydrogels supported growth/adhesion and chondrogenic differentiation of MSCs for in vitro fabrication of engineered osteochondral constructs [158]. Collagen type I hydrogels could be combined with bioceramic scaffolds to prepare hybrid constructs for repairing osteochondral interface defects. In vivo studies indicated that collagen type I hydrogels support cartilaginous integration and cartilage formation during post-implantation of 1 year [158]. In vitro and in vivo results demonstrated that chondrocytes-laden collagen type II hydrogel constructs supported proliferation and chondrogenesis of MSCs [159, 160]. Studies have been done to compare the regulation effects of collagen type II hydrogels on the chondrogenic differentiation and in vitro chondrogenesis of MSCs with alginate and collagen type I hydrogels [161]. The results indicated that in the absence of transforming growth factor (TGF)-β1, collagen type II hydrogels were able to induce and maintain MSC chondrogenic differentiation. All cartilage-related genes were upregulated by collagen, particularly collagen type II.

Collagen hydrogels have excellent biological properties and therefore few studies have been performed on chemical modification of collagen. However, to solve the issues related to the relatively low mechanical properties, collagen hydrogels that were chemically modified with synthetic polymers have been reported [162, 163]. Collagen hydrogels modified with chitosan showed significantly increased strength and elasticity by 100% and 20%, respectively, compared to unmodified collagen hydrogels [163]. Moreover, the introduction of photocrosslinkable groups can also improve strength but retain the ability of supporting chondrocytes proliferation and new cartilage formation [164, 165]. These studies shed some light on ways to avoid the poor mechanical properties of collagen-based hydrogels that might hinder their extensive applications in tissue engineering.

2.1.7 Gelatin hydrogels and their derivatives

Gelatin is a hydrolysis product from collagen, the major ECM component in most tissues. It consists of a number of arginine-glycine-aspartic acid (RGD) sequences promoting cell adhesion, and the matrix metalloproteinase (MMP) target sequences facilitating cell remodeling [26]. Gelatin solution could form physically crosslinked hydrogels through self-gelation at low temperatures (< 30 °C) [166] or chemically crosslinked hydrogels via chemical reactions [26]. Because physically crosslinked gelatin hydrogels are not stable at the temperatures used for in vitro culture of mammalian cells and in vivo implantation [166], chemical crosslinking of gelatin hydrogels is usually preferred for tissue engineering applications. Chemically crosslinked gelatin hydrogels are much more stable and strong, but the toxicity of the harsh crosslinking agents can limit their applications for encapsulating live cells. Recent studies suggested that gelatin-based hydrogels crosslinked by click chemistry (tetrazine and norbornene click pairs) were cell-friendly to support attachment and spreading of MSCs [167]. Subcutaneous implantation in mice revealed a minimal inflammatory response and sustained in vivo biodegradation after infiltration by the hosting cells. Unmodified gelatin has a gelation temperature not suitable for in vitro culture of mammalian cells or in vivo implantation, and is rarely used for OTE and CTE.

Grafting methacryloyl substituent groups is an efficient modification method to make gelatin chemically crosslinkable by photopolymerization. Such photocrosslinking polymerization can proceed at mild conditions (e.g., neutral pH, room temperature, in water-based solutions), and also allows for spatial and temporal control of the gelation process and hydrogel properties. This makes it possible to microfabricate cell-laden hydrogels based on gelatin derivatives for engineering tissue constructs. The methacryloyl-modified gelatin (GelMA) retains most of the functional amino acid motifs (e.g. RGD motifs) so that it inherits the excellent cell adhesive properties of gelatin.

GelMA hydrogels are biodegradable, biocompatible, non-immunogenic, highly tunable, and easy-to-microfabricate [168]. Therefore, GelMA has gained increasing attention as a new family of biomaterials for cell delivery and tissue engineering applications. For example, GelMA and equine chondrocytes were employed to fabricate cell-laden hydrogel constructs by 3D bioprinting [169]. Chondrocytes encapsulated in 10 wt% GelMA hydrogel exhibited a good viability of 80–90% on day 1. Cartilaginous tissue matrices of aggrecan and collagen type II were formed after a 4-week in vitro culture. Alternatively, MSC-laden GelMA hydrogels (8 wt%) were cultured in the chondrogenic medium for 6 weeks to assess the chondrogenesis ability. Abundant aggrecan and collagen type II depositions were found in the hydrogel constructs, which indicated that the GelMA hydrogels supported proliferation and chondrogenic differentiation of MSCs for OTE and CTE purposes [169–171].

In addition to GelMA, phenolic hydroxyl group-modified gelatin was also developed for improved injectability, in situ gellability, chemical stability, and crosslinkability under mild conditions [166]. This gelatin derivative was produced through the aqueous-phase carbodiimide activation chemistry and can be crosslinked via an enzymatic peroxidase-catalyzed reaction within 10 s to form stable hydrogels. Moreover, the gelation time could be further decreased by increasing the phenolic hydroxyl (Ph) groups and peroxidase concentration. The encapsulated cells showed a highly viability of about 95% and proliferated as well as those seeded on unmodified gelatin. The subcutaneous rodent injection test demonstrated successful in situ gelation and prolonged in vivo stability of this gelatin-based hydrogel. Histological studies indicated that the surrounding tissues did not have necrosis, while a layer of thin fibrous capsules were observed on implanted gel surface. [172].

Chemically modified gelatin hydrogels are biodegradable, highly tunable, and easy-to-microfabricate. However, there are some aspects to be further improved for better chondrogenesis and mimicking the functions of cartilage tissues. First, viability of chondrocytes/MSCs in modified gelatin hydrogels should be further increased to produce more connective cartilage extracellular matrix. Second, the mechanical properties should be further enhanced to be able to withstand the high-load-bearing conditions of articular cartilage. Third, the rheological properties (e.g. viscosity) of modified gelatin hydrogels prepolymer solutions should be carefully adjusted to adapt with the micro/nanofabrication process by advanced manufacturing technologies (e.g. 3D bioprinting). To achieve these goals, it would be an effective strategy to improve some key characteristics of modified gelatin hydrogels by incorporating other functional constituents (e.g. natural biopolymers, synthetic biopolymers, inorganic nanoparticles) for different applications [173].

2.1.8 Silk fibroin hydrogels and their derivatives

Natural silk, composed of silk fibroin protein core with sericin protein coating, is produced by the silkworm (Bombyx mori) cocoons. Silk fibroin has become a new biomaterial for tissue engineering applications due to its robust mechanical properties, excellent biocompatibility, slow degradability, and abundant supply source. Fibroin hydrogels can be produced through a variety of mechanisms involving a change in fibroin conformation from an amorphous random coil to organized crystalline β-sheet structures [174]. The gelation process is controlled by protein concentration, temperature, pH, and salt/ion concentration. Gelation methods for fibroin solution include sonication, lyophilization, as well as treatments by acids, dehydrating agents, and ions [175]. Because cartilage regrowth typically requires extended time, hydrogels with long-term stability and mechanical integrity would be advantageous for this purpose. Through optimization of fibrinogen concentration, calcium ion concentration, and pH value, a stable fibroin hydrogel was prepared to provide sufficient time for embedded human chondrocytes to form neocartilage [49]. In vitro culture of chondrocyte/MSC-laden fibroin hydrogels produced abundant native cartilage-like ECM of aggrecan and collagen type II, which suggested that fibroin could be a promising biomaterial for cartilage regeneration [174, 176]. Taking the advantage of fibroin for minimal invasiveness tissue engineering applications, its injectable forms have recently been developed by sodium dodecyl sulfate-induced rapid gelation and vortex-induced gelation [177, 178].

Although fibroin hydrogels have been reported to support chondrocyte proliferation and chondrogenesis for CTE [94], it is desirable to tailor the interactions between chondrocytes/MSCs and fibroin for improved chondrogenesis and osteogenesis by chemical modifications with cell binding domains and growth factors [179–181]. Arg-Gly-Asp-Ser (RGDS)-modified fibroin demonstrated the ability to enhance mRNA expression levels of integrin α5β1, and aggrecan at 12 h after seeding [181]. It also suggested that RGDS induced moderate chondrocyte adhesion to fibroin well maintained the chondrogenic phenotype and facilitated chondrogenesis. Fibroin was also modified using the diazonium-coupling chemistry to control protein structure and overall hydrophilicity to direct encapsulated MSCs towards enhanced osteogenic differentiation [179]. These results indicated that MSCs exhibited different growth rates and morphologies on hydrophobic and hydrophilic fibroin derivatives, although all the fibroin derivatives supported osteogenic differentiation and osteogenesis of seeded MSCs, as confirmed by the expression of osteogenic biomarkers when subjected to osteogenic stimuli. Such chemically modified fibroin hydrogels have the ability to effectively interact with chondrocytes and MSCs due to the immobilized cell binding domains and growth factors, so that they can maintain the chondrogenic/osteogenic phenotype without extra growth factors.

2.2 Typical synthetic (composite) polymer-based hydrogels

Although hydrogels based on naturally derived polymers show excellent biocompatibility for chondrogenic cells growth, proliferation, and phenotype maintaining, the low mechanical properties and uncontrolled degradation often limit their applications in OTE and CTE. Hydrogels based on synthetic polymers, on the other hand, exhibit highly tunable biodegradability, biocompatibility, mechanical properties, and biochemical characteristics, due to the convenience to tune their chemical structure and molecular composition. Moreover, composite hydrogels, consisting of two or more natural/synthetic biopolymers, combine the biocompatibility, biodegradability, and tunable mechanical strength, so that they are appealing for osteochondral and cartilage tissue regeneration.

PVA and modified PVA hydrogels with a modulus of 1 to 5 MPa have been developed to repair cartilage tissues [65–70]. However, PVA is non-biodegradable so that it can only be used as permanent cartilage implant. Further study is still required to improve the biofunctions of PVA hydrogels mimicking natural cartilage. PEG-based hydrogels support adhesion and proliferation of chondrocytes, MSCs, and ESCs [53, 58–64]. With addition of calcium minerals or organic growth factors, MSCs and ESCs encapsulated in PEG hydrogel could differentiate to osteogenic or chondrogenic linages [58]. It has been reported that the mechanical loading and materials stiffness regulated the differentiation of MSCs embedded in PEG hydrogels [62, 182]. Surgical options for cartilage resurfacing may be significantly improved by advances and application of biomaterials that direct tissue repair.

PEG diacrylate (PEGDA)-based hydrogels have been widely studied for cartilage regeneration. For example, the in vitro assessment, preclinical study in a caprine model and a pilot clinical study on PEGDA hydrogels were reported [183]. The results indicated that cartilage ECM was deposited in the hydrogel, adjacent cartilage tissue growth was facilitated by MSCs, and significantly more cartilage tissue formation was found compared to the control group with microfracture treatment. Another composite hydrogel based on PEGDA-fibrinogen (commercially known as GelrinC™ for cartilage repair) has been shown to support enhanced chondrogenesis of MSCs with minimizing hypertrophy [184], which suggested that composite hydrogels can be designed for improved ability to regenerate cartilage tissues.

The higher loading and stiffness resulted to osteogenic differentiation, whereas lower loading and stiffness led to chondrogenic differentiation. Layered OPF hydrogels have been prepared for controlled biodegradability and cartilage/none formation ability for osteochondral interface reconstruction [182]. In vivo results showed that hyaline cartilage formed in the cartilage layer with a zonal structure and hypertrophic cartilage formed in the bone layer (subchondral region), where bone generation was eventually observed with the hydrogel partially degraded. A PDMMAm-based double-network hydrogel was shown to promote in vivo hyaline cartilage regeneration in a large osteochondral defect model [73]. An injectable MPEG-PCL copolymer hydrogel has been fabricated and subcutaneous in vivo study indicated that such hydrogel could form an interconnected microporous structure to support chondrocytes growth and proliferation, as well as hyaline cartilage formation [35]. Hydrogels derived from synthesized polymers exhibit tunable properties and have promising potentials for OTE and OCE applications.

Thermosensitive chitosan-pluronic (CP) hydrogels were synthesized by grafting pluronic onto chitosan. In vitro study indicated that the CP hydrogels were injectable and supported chondrocyte growth [50]. MSC-laden fibrin/PLGA hydrogels were developed for treatment of full-thickness cartilage defects [185]. The gel degraded in 12 weeks in vivo. The cell-hydrogel constructs generated cartilage-like tissue matrices of collagen type II and aggrecan. The osteochondral interface tissue was fully reconstructed in 12 weeks. Immunohistochemical and aggrecan staining results confirmed the formation of hyaline cartilage. OPF-gelatin composite hydrogels with encapsulated MSCs also showed a big promise for osteochondral tissue regeneration [71, 186, 187]. Cartilage-related gene expressions of collagen type II and aggrecan increased by 161 fold and 221 fold, respectively, after in vitro culture for 14 days. At 12 weeks of implantation, the composite hydrogels were partially degraded and cartilage/subchondral tissue formed without persistent inflammation. The cartilage showed a zonal structure and the subchondral region contained hypertrophic cartilage and bone-like tissues. Further pre-clinical and clinical studies are still required to evaluate the treatment efficiency of cell-laden composite hydrogels for functional restoration of osteochondral and cartilage tissues.

2.3 Effects of crosslinking mechanisms on the properties of hydrogels

Depending on the unique characteristics and/or the presence of specific functional groups, hydrogels made from natural polymers (including their derivatives) and synthetic polymers can be fabricated via different crosslinking mechanisms. In general, there are two main mechanisms, i.e. physical crosslinking and chemical (covalent) crosslinking, which result in hydrogels with distinct structures and properties. Physical crosslinking is normally induced by change of environmental factors including temperature, pH, force, concentration, and ions. Typical methods to induce physical crosslinking include cooling, lyophilization, and presence of acids, dehydrating agents, and cation exchange [94, 138, 166, 175]. Many naturally derived polymers can form hydrogels via physical crosslinking, which generally involves changes of molecular conformations of the polymer chains to undergo phase transition and induce intermolecular aggregation. This resulted in the formation of junction zones through bridges between polymeric chains or interactions between charged components (ions or groups) to form a reversible, semi-stable network [138–140, 188].

On the other hand, chemically modified natural polymers and synthetic polymers can be covalently crosslinked to form hydrogels via a specific reaction mechanism. The crosslinking reaction normally involves two or more functional groups presented on different polymeric chains to form new covalent chemical bonds and thus generate a permanent stable network [188]. To induce chemical crosslinking, typical methods include UV irradiation, dehydrothermal treatment, and the addition of crosslinkers [94]. In most cases, physically crosslinked hydrogels are mechanically weaker and less stable in physiological conditions compared to chemically crosslinked hydrogels. By controlling the density of chemical crosslinking sites, the mechanical properties and biodegradation rates of chemical crosslinked hydrogels are highly tunable [33, 88, 139, 140, 152, 165, 180, 188]. However, it should be careful to select proper crosslinkers and crosslinking reactions used for chemical gelation to avoid toxic effects to cells and tissues [188].

2.4 Tailoring biodegradability of hydrogels for OTE and CTE

Manipulating the biodegradability of hydrogels to match the rate of cell growth and tissue repair is an important topic for rational design of hydrogel matrices for cartilage and osteochondral tissue regeneration [189]. It is generally accepted that overly rapid degradation may lead to the reduced retention of ECM proteins, whereas hydrogels that degrade too slowly can hinder cell remodeling and thus tissue formation [190]. Previous studies have demonstrated that chondrocyte/MSC-laden hydrogels with a balanced biodegradation rate were able to promote neocartilage/bone tissue formation and achieve higher mechanical properties after long-term culture [189–195].

The importance of hydrogel degradation rate was investigated by using alginate-based hydrogels [193]. In vitro results showed that partially oxidized alginate hydrogels degraded much faster (disappeared within 9 days) than hydrogels made from pristine alginate (stable for at least 1 month), when crosslinked with calcium ions under otherwise similar conditions. Subcutaneous implantation of such hydrogels seeded with chondrocytes in the dorsal region of mice revealed that oxidized alginate samples degraded and generated abundant of connective cartilage ECM, but non-oxidized alginate samples led to small islands of cartilage ECM surrounded by significant amounts of residual alginate.

MSC-laden methacrylated caprolactone HA (MeCLHA) hydrogels were fabricated and characterized to tailor the biodegradation rate of HA to investigate the influences on in vitro neocartilage formation [190]. It was found the faster degradation of MeCLHA hydrogels increased pore sizes of the matrices and generated void spaces to allow enhanced deposition of newly formed ECM proteins. In vitro culture results after 56 days showed that the mechanical strengths were higher for hydrogels with matched degradation rates with ECM deposition than those that degraded too fast. In addition, PEG-PVA and PEG-oligo(lactic acid) (LA) composite hydrogels were developed with tuned degradation profiles [189, 194]. Their results suggested that incorporation of degradable component to PEG hydrogels facilitated generation of cartilage-like tissues.

To promote mineralized bone tissue formation, hydrogels with tailored degradation rates were synthesized by copolymerizing a degradable macromer, PEG-LA endcapped with methacrylate groups (PEG-LA-DM), with a nondegradable macromer, PEG dimethacrylate (PEGDM) [191]. It was discovered that the copolymers composed of 100:0, 83:17, 67:33, and 50:50 wt% of PEGDM and PEG-LA-DM, showed weight losses of 0, 17, 33, and 50% over the time of 25 days in osteoblast complete medium at 37 °C. Proliferation, alkaline phosphatase, and mineralized bone mineral production of encapsulated osteoblasts were facilitated by increasing PEG-LADM content and corresponding degradation.

PEG-genipin hydrogel blocks crosslinked with 8 mM, 17.6 mM, or 35.2 mM genipin were implanted into osteochondral defects made in the trochlea of mice [195]. It was found that the degradation was reduced with increasing the concentration of genipin. Almost fully degradation occurred at 8 mM, intermediate degradation at 17.6 mM, and minimal degradation at 35.2 mM over the implantation time of 5 weeks. The results showed that the higher degradation of PEG-genipin hydrogel enhanced in vivo osteochondral tissue regeneration. Overall, these results highlighted the vital significance of the degradation profile in dictating cellular behavior and tissue regeneration both in vitro and in vivo. It is necessary for future studies to optimize hydrogel formulations and achieve the best degradation rates designed for specific applications involving different targeting tissues.

3. Chondrogenesis or osteogenesis of various types of cells encapsulated in hydrogels

Tissue engineering and cell therapy have been combined to repair cartilage and osteochondral defects. Although a variety of hydrogels have been developed and used as artificial ECM for cell delivery and 3D culture, only limited cell types such as chondrocytes, preosteoblasts/osteoblasts, MSCs, induced pluripotent stem cells (iPSCs), ESCs, and peripheral blood mononuclear cells (PBMSCs), have the potential of chondrogenic and/or osteogenic differentiation to regenerate cartilage and osteochondral tissues (Table 1) [183, 196–201]. Autologous chondrocyte implantation has been successfully used as a clinical method to treat cartilage defects. However, it is very challenging for orthopedic surgeons to directly fix a chondrocyte graft in a focal cartilage site with complex shape [183]. Therefore, tissue engineers and biomaterials scientists have proposed to deliver chondrocytes with hydrogels to overcome this challenge.

3.1 Chondrogenesis of chondrocytes encapsulated in hydrogels

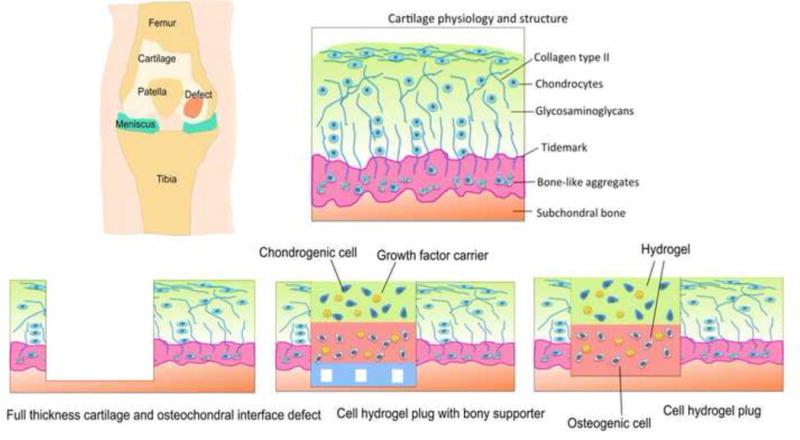

To date, chondrocytes have been embedded in a variety types of hydrogels. In vitro studies have demonstrated that chondrocytes could spread and proliferate well in 3D hydrogel matrices, showing enhanced expressions of cartilage-related proteins/genes with well-maintained cell morphology and phenotype [38, 39, 42, 45, 48, 49, 196]. However, hydrogel matrices made from different polymers behaved differently in directing chondrogenesis of chondrocytes. As discussed above, both chitosan (Fig. 2A) and agarose hydrogels were found to support long-term survival and retain morphology when cultured in vitro [50]. During in vitro maturation, chondrogenesis took place with the formation of cartilage ECM, including aggrecan and collagen type II that were homogenously distributed throughout the hydrogels. For example, abundant cartilage matrix of aggrecan and collagen type II/VI formed in chondrocyte-laden in oligo(lactic acid)-b-PEG-b-oligo(lactic acid) (PEG-LA) hydrogels cultured for 28 days (Fig. 2B) [194]. Cartilaginous ECM-modified chitosan hydrogels enhanced cellular condensation and chondrogenesis of embedded chondrocytes to promote cartilage regeneration, which was attributed to the integrin α10 binding to collagen type II and thus improvement in cell-matrix adhesion (Fig. 2C) [51]. In vivo evaluations further indicated that chondrocytes encapsulated in hydrogels could regenerate hyaline cartilage tissues with structure remodeling [44, 73, 183, 196]. Although chondrocyte-based therapy shows promising potentials in regenerating cartilage tissues, notable limitations exist. First, chondrocyte harvest involves removing healthy cartilage tissues from non-weight-bearing areas and in vitro culturing for a long time of 3 to 5 weeks [9–11]. Due to the low number of chondrocytes, cartilage defects cannot self-heal so that the donor site will become morbid. Second, autologous chondrocytes therapy is inefficient for the elderly because of the low proliferation capacity of primary chondrocytes derived from aged patients [21].

Fig. 2.

Chondrocytes cultured in various hydrogels for OTE and CTE. (A) Fluorescence microscopy images showing the chondrocyte morphology inside chitosan-based hydrogels after 3 and 14 days in culture. The upper panels show low-magnification views and lower panels display the close-ups. Scanning electron microscopy (SEM) image shows the morphology of a single chondrocyte. Reproduced with permission [50] Copyright © 2009 Elsevier B.V. (B) Cartilage matrix generation of chondrocytes encapsulated in PEG-LA hydrogels (28 days). (i) Proteoglycan deposition: Chondroitin-6-sulfate (red), aggrecan (red), link protein (red), and ell nuclei (blue). (ii) Collagen deposition: collagen II (green), collagen VI (green), decorin (red), and cell nuclei (blue). Reproduced with permission [194] Copyright © 2011 The Association of Bone and Joint Surgeons. (C) Chondrocytes encapsulated in cartilaginous ECM-modified chitosan hydrogels (MeGC = methacrylated glycol chitosan; RF = riboflavin; VBL = visible blue light). (i) Chondrocyte encapsulation and expression of cartilage-related proteins. (ii) Interior microstructure of various chitosan based hydrogels. (iii) Cell adhesion onto the hydrogels. Reproduced with permission [51] Copyright © 2014 American Chemical Society.

3.2 Osteogenesis of preosteoblasts and osteoblasts encapsulated in hydrogels

Preosteoblasts and osteoblasts, as bone progenitor cells, have stable osteogenic phenotype and have been widely studied to regenerate bone tissues [202, 203], including subchondral bones. It has been reported that preosteoblasts can differentiate to osteoblasts in vitro and enhance bone formation in vivo [83, 204]. Osteoblasts were encapsulated in PEG-based hydrogels and in vitro studies indicated that bone-related gene expression increased with gel degradation [205]. Apatite deposition and matrix mineralization increased with increasing concentration of the methacrylate groups. Osteoblasts embedded in PEG-based hydrogels modified with RGD peptides exhibited improved attachment, spreading, and cytoskeletal organization [206].

3.3 Chondrogenesis and osteogenesis of stem cells encapsulated in hydrogels

Alternatively, stem cells have the capacity to differentiate into various tissue-forming cells including chondrogenic and osteogenic lineages for cartilage and bone regeneration, respectively. Therapies combining stem cells and hydrogels are emerging for OTE and CTE. The most commonly studied stem cells include MSCs, iPSCs, ESCs, and PBMSCs. MSCs may come from a variety of sources, such as bone morrow, adipose tissue, muscle, periodontal ligament, lung, liver, spleen, thymus, amnion, placenta, umbilical cord blood, and corneal stroma [207–209]. MSCs may proliferate without differentiation for up to 40 generations [209]. Extensive studies have revealed that the therapeutic efficiency of MSCs largely replies on their capacity to work as a trophic factor generator. MSCs can also interact closely with local biochemical stimuli to generate a number of growth factors providing multiple biofunctions for tissue restoration [207]. MSCs derived from birth-associated neonatal tissues including umbilical cord, placenta, amnion, and cord blood have better proliferative capacity, higher availability, bigger life span, and higher differentiation potential compared to those obtained from distinct adult mature tissues of adipose, muscle, and bone [208]. ESCs are normally isolated from the inner tissues of early embryos so that they are pluripotent and have the potential to differentiate down to almost all cell lineages in the human body [199, 207]. However, the pluripotency makes it difficult to control the differentiation [210]. In addition, ESCs face potential immune rejection and involve ethical issues [200]. More recently, iPSCs were obtained from somatic cells including fibroblasts and exhibit similar pluripotency with ESCs in terms of multiple differentiation, thus finding increasingly widespread applications in regenerative medicine [200, 201, 211, 212].

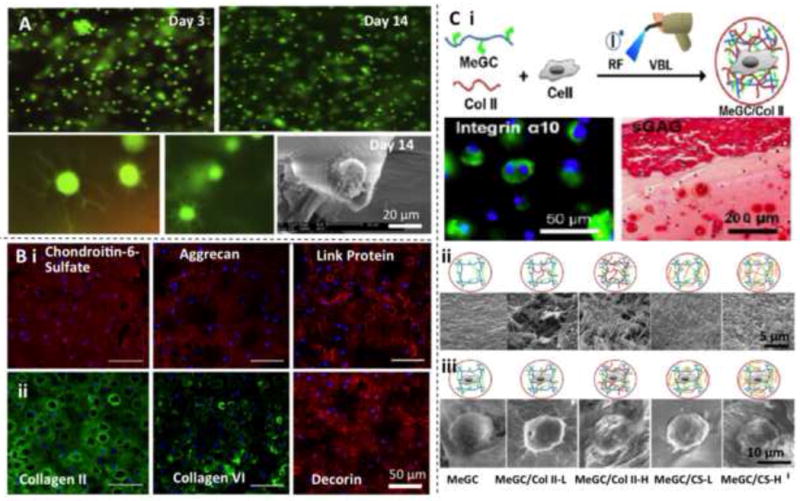

MSCs have become the most broadly used stem cells in regenerative medicine because they have abundant cell sources and low immunogenicity, no ethical concerns, and minimal teratoma risk [207]. MSCs encapsulated in various hydrogels have been tested to target reconstruction of cartilage and osteochondral tissues [34, 42, 47, 53, 54, 62, 63, 71, 182]. Similarly, it has been well documented that MSCs can spread and proliferate in hydrogels. More importantly, in the presence of chondrogenic and osteogenic cues, MSCs embedded in hydrogels can differentiate into chondrocytes and osteoblasts to produce cartilaginous/bony ECMs in vitro and form cartilage/bone tissues in vivo [52, 198, 213]. Different hydrogels exhibited different ability to support chondrogenesis and osteogenesis. The cartilaginous and osseous ECMs formed after an 8-week culture of MSCs in alginate, chitosan, and fibroin hydrogels as confirmed by histological and immunohistochemical staining (Fig. 3) [101]. Alginate and chitosan hydrogels generated more cartilage ECM than the fibroin hydrogel. MSCs encapsulated in collagen hydrogels encouraged in vitro formation of osteochondral interface tissues with a zonal structure consisting of a pure cartilage layer, a calcified cartilage layer, and a subchondral bone layer [47, 214]. The results suggested that MSC-laden hydrogels would be promising biomaterials for osteochondral interface regeneration. iPSCs had the ability to differentiate into chondrocytes in alginate hydrogels and regenerate cartilage tissues in vivo [197]. ESCs encapsulated in PEG hydrogels could differentiate into chondrogenic cells and produce neocartilage ECM [215]. In addition to the aforementioned stem cells, PBMCs were recently reported to possess similar chondrogenic differentiation and cartilage generation ability compared with MSCs [216]. PBMCs could be readily extracted from peripheral blood with minimally invasion. Their application potential requires further studies. Although stem cells have the intrinsic nature to differentiate down to chondrogenic and osteogenic lineages, growth factors are required to trigger the differentiation. In the next section we will discuss the effects of growth factors delivered by different methods on the chondrogenic/osteogenic differentiation and cartilage/bone formation of stem cells encapsulated in hydrogels.

Fig. 3.

MSCs cultured in different hydrogels for OTE and CTE. Histological and immunohistochemical staining results showing the cartilaginous and osseous ECM formation after an 8-week culture of MSCs in alginate, chitosan, and fibrin hydrogels. Constructs are stained for aggrecan (Alcian blue), collagen type II, and calcium (Alizarin red). Reproduced with the permission [101] Copyright © 2015 Elsevier.

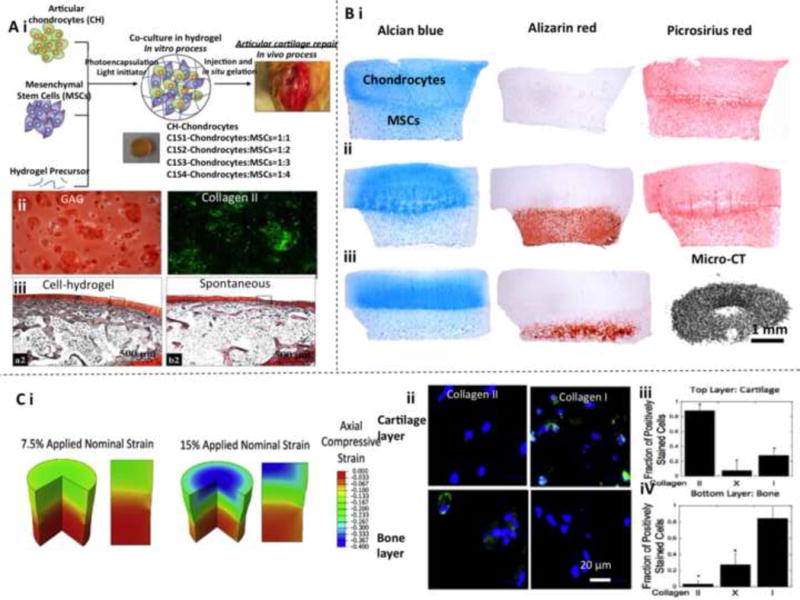

3.4 Co-culture of chondrocytes and stem cells in hydrogels and spatial control of layered constructs for chondrogenesis and osteochondrogenesis

Co-culture of chondrocytes and MSCs in hydrogels have been investigated for improved chondrogenesis and osteogenesis. Chondrocytes and MSCs were encapsulated with different population ratios (1:0, 1:1, 1:2, 1:3, and 1:4) in PCL-PEG composite hydrogels, which were cultured in chondrogenic medium and implanted in rabbits in a full-thickness articular cartilage defect model (Fig. 4A) [196]. In vitro results at 4 weeks indicated that co-culture of articular chondrocytes and MSCs facilitated expression of chondrogenic phenotype and production of cartilaginous ECM. In addition, chondrocytes promoted chondrogenesis of MSCs, while MSCs boosted cell proliferation. In vivo results at 8 weeks demonstrated that co-culture at a chondrocytes:MSCs ratio of 1:4 induced the optimal cartilage regeneration.

Fig. 4.

Chondrogenesis and osteogenesis of chondrocytes and MSCs in multi-layered hydrogel osteochondral constructs. (A) Co-culture of chondrocytes and MSCs in PCL-PEG composite hydrogels. (i) Schematic of 3D encapsulation. (ii) In vitro cartilage-related biomarker expression (aggrecan stained by Safranin O) at 4 weeks. (iii) Histological results showing in vivo cartilage formation. Reproduced with permission [196] Copyright © 2013 John Wiley & Sons, Inc. (B) A structured bilayered co-culture of chondrocytes and MSCs in agarose hydrogels for chondrogenesis and endochondral ossification. Alcian blue and Alizarin red staining are used to characterize cartilage ECM formation. Alizarin red staining and micro-computed tomography (micro-CT) scanning are employed to examine bone ECM formation. (i) After a 49-day culture in chondrogenic medium. (ii) After a 21-day culture in chondrogenic medium and a 28-day culture in hypertrophic medium with β -glycerophosphate supplement. (iii) After a 21-day culture in chondrogenic medium and a 28-day subcutaneous implantation in nude mice. Reproduced with permission [218] Copyright © 2013 Elsevier. (C) Mechanical loading regulated MSCs differentiation that were encapsulated in layered PEG hydrogel for controlled chondrogenesis and osteogenesis. (i) Finite elemental modeling results for multi-layered hydrogel constructs under compression conditions. Negative values mean compressive strain. (ii) Expression of cartilage and bone biomarkers in hydrogel layers with different mechanical loading. Green indicates collagen II or I, and blue indicates nuclei. (iii, iv) Quantitative study of chondrogenic- and osteogenic-differentiated cells induced by mechanical property change. Reproduced with permission [182] Copyright © 2015 Elsevier.

A structured bilayered co-culture of chondrocytes and MSCs in agarose hydrogels was developed for osteochondral tissue repair via chondrogenesis and endochondral ossification (Fig. 4B) [218]. In the design, the top layer of the bilayered agarose hydrogel construct was seeded with chondrocytes (termed as the cartilage layer), while the bottom layer was seeded with MSCs (termed as the bone layer). This bi-layered chondrocyte/MSC-laden hydrogel co-culture system was able to promote chondrogenesis in the cartilage layer and facilitated the chondrogenic phenotype that was lost in monolayer expansion of chondrocytes. Moreover, the bilayered co-culture was found to hinder in vitro hypertrophy and mineralization in the bone layer. However, the subcutaneous implantation results suggested that endochondral ossification took place in the bone layer to form an osteochondral tissue, which could be induced by the osteogenic molecules. Such chondrocyte/MSC-laden bi-layered hydrogel constructs hold a great potential for effective regeneration of osteochondral tissue and full-thickness cartilage defects.

A MSC-laden multi-layer PEG hydrogel system with spatial mechanical and biochemical cues was developed for OTE and CTE (Fig. 4C) [182]. This system was composed of a soft chondroitin sulfate hydrogel cartilage layer with a low RGD concentration, a stiff bone layer with a high RGD concentration, and an intermediate layer between them. The stiffness variation generated high strains, low strains, and moderate strains in the three layers, respectively. Importantly, the incorporation of biomolecules and variations in hydrogel stiffness had very limited effects on directing MSC differentiation, whereas mechanical stimulation was the critical factor. High mechanical load induced osteogenic differentiation in the bone layer and low mechanical load induced chondrogenic differentiation in the cartilage layer. This study revealed that a dynamic spatial mechanical environment was able to direct MSC differentiation for osteochondral tissue regeneration [182].

Layered hydrogels laden with multiple types of cells (e.g. chondrocytes and MSCs) have shown the ability to promote osteochondrogenesis and form osteochondral tissues with zonal structure in vivo. Therefore such functional hydrogels are promising for repair of full thickness cartilage and osteochondral tissue defects. If combined with biochemical stimulation, more effective regeneration would be possible to achieve.

3.5 Endochondral ossification of stem cells encapsulated in hydrogel for osteochondral tissue regeneration

MSCs and osteochondral progenitor cells primed by chondrogenesis have been shown to become hypertrophic and undergo endochondral ossification when implanted in vivo [218]. Modulation of this endochondral phenotype may be attractive to engineer cartilaginous and osseous phase of osteochondral constructs. Anti-angiogenic factor chondromodulin-1 has been shown to be able to stabilize the chondrocyte phenotype of osteochondral progenitor cells and support chondrogenesis, but suppress chondrocyte hypertrophy and endochondral ossification [218]. These findings indicated that chondrogenic cell-laden hydrogels were still promising for cartilage tissue repair when inhibitors of endochondral ossification were combined. On the other hand, taking advantages of endochondral ossification, MSC-laden hydrogels can be used to regenerate bone tissues or the osseous phase of osteochondral tissues [218, 219]. A bilayered osteochondral construct of agarose hydrogel seeded with MSCs was produced with the bottom layer for regenerating subchondral bone via endochondral ossification [218]. The success was confirmed by results from in vivo subcutaneous implantation in nude mice.

The three naturally derived hydrogels of alginate, chitosan, and fibroin showed various endochondral ossification of MSCs in vivo [101]. Alginate and fibroin hydrogels facilitated vascularization and endochondral ossification, while the chitosan hydrogel promoted neither vascularization nor endochondral ossification, but produced the greatest amount of cartilage ECM of aggrecan. Cells in the alginate hydrogels produced more bone mineral and supported greater bone formation in the central region. At this point, MSC-laden chitosan hydrogels appeared more appropriate for cartilage regeneration and MSC-laden alginate hydrogel seemed more suitable for endochondral bone tissue engineering applications.

4. Effects of growth factors and delivery methods on chondrogenesis and osteogenesis of cell-laden hydrogels

4.1 Common growth factors and hormones for chondrogenesis and osteogenesis

Native ECMs can sequester specific biomolecules to stimulate cell growth, proliferation, and differentiation, which are referred to as growth factors. Growth factors and hormones are also highly related to the repair of damaged tissues. The idea to use growth factors and hormones to promote chondrogenic and osteogenic tissue regeneration is thus intuitive. TGFs, insulin-like growth factors (IGFs), BMPs, and dexamethasone are among the most extensively used growth factors and hormones to stimulate chondrogenic or osteogenic differentiation of stem cells.

4.1.1 TGFs

TGFs are a family of polypeptides that can affect cell behaviors including growth, proliferation and differentiation [220–223]. There are two types of TGFs, namely, the α and β forms, which have unique amino acid sequences and different interactions with receptors [220, 224, 225]. The TGF-β family has been demonstrated to be effective to induce chondrogenic differentiation of stem cells [132, 220]. TGF-β1 and TGF-β3 have both been extensively used for chondrogenic differentiation and chondrogenic phenotype maintenance of MSCs for cartilage and osteochondral tissue regeneration, and worked well for different types of hydrogels and MSCs from various sources [47, 71, 197, 216, 226, 227]. However, their effects may be not exactly the same. It has been reported that TGF-β1 resulted in significant increases in cartilage-related gene expression in comparison of moderate effects of TGF-β3 for chondrogenic differentiation of MSCs. TGF-β1 promoted cellular adhesion molecule expression and facilitated cellular condensation, whereas TGF-β3 increased cellular proliferation. Moreover, TGF-β1 and TGF-β3 influenced different stages of chondrogenic differentiation of MSCs. As a result, the combined use of both TGF-β1 and TGF-β3 may be more effective for chondroenesis of MSCs. More studies are required to understand this possibility. Specific examples regarding the effects of TGF-β1 and TGF-β3 on chondrogenesis of MSCs will be described in section 4.2 along with introduction of delivery methods of growth factors.

4.1.2 Insulin-like growth factors (IGFs)

IGFs are single-chain polypeptides that have amino-acid sequences close to insulin [228]. There are two types of IGFs: IGF-1 is mainly secreted by the liver stimulated by growth hormone and regulates growth of adults. IGF-2 is deemed to play an important role in fetal growth [229]. IGF-1 has been widely studied for cartilage repair, since it has effects on cartilage homeostasis, proteoglycan synthesis balancing and breakdown. Overexpression of human IGF-1 by transplanted articular chondrocytes encapsulated in alginate hydrogels has been studied for enhancing the repair of full-thickness cartilage and osteochondral defects in rabbits [230]. The results indicated that IGF-1 improved articular cartilage regeneration and accelerated the formation of subchondral bone at both time points 14 weeks. Addition of IGF-1 in the hydrogel constructs was also able to improve chondrogenesis in vitro and in vivo [231–233]. IGFs have shown the ability to effectively facilitate cartilage regeneration by chondrocytes. More studies are required to understand the effects of TGFs on the cellular behavior and chondrogenic differentiation of stem cells.

4.1.3 BMPs

Urist first discovered that the active compound responsible for bone regeneration was a family of proteins and named these as BMPs [234, 235]. BMPs are recognized for their ability to induce ectopic bone and cartilage formation, a process that mimics embryonic endochondral bone formation [220]. Approximately 20 family members of BMPs (BMP-1-18, BMP-3b, and BMP-8b) have been identified to date [234, 236–241]. Specifically, BMP-1, 5, 9, 13 and 14 exhibit functions in cartilage formation and chondrogenic differentiation of MSCs; BMP-3, 4 and 8 play a key role in bone formation; and BMP-2, 7 induce osteogenic/chondrogenic differentiation and bone/cartilage formation. Among all, the most extensively used ones for bone and cartilage regeneration are BMP-2, 7. Implantation of 0.5–115 μg of partially purified recombinant human BMP-2 resulted in cartilage by day 7 and bone formation by day 14 [241]. Studies have shown that BMP-2 was effective for promoting osteogenic differentiation and osteogenesis of MSC-laden or cell-free hydrogels towards in vitro and in vivo, respectively [242–248]. Some studies suggested that BMP-2 had the ability to facilitate cartilage formation by chondrocytes and MSCs for treatment of cartilage and osteochondral defects [45, 249, 250]. BMP-7 was used in cell-laden hydrogel constructs for promoting chondrogenesis and cartilage ECM formation [251]. Extensive research has shown that BMPs are effective growth factors to regulate both cartilage and bone formation. Regeneration of full-thickness cartilage and osteochondral tissues is a complex process that involves biofunction restoration of zonal cartilage and subchondral bone. Further studies are required to understand how the BMPs affect chondrognesis and osteogenesis of chondrogenic and osteogenic progenitor cells under various conditions (e.g. co-culture of chondrocytes and MSCs, in the presence of other types of growth factors).

4.1.4 Dexamethasone

Dexamethasone is a type of adrenocortical hormones and has been demonstrated to promote chondrogenic and osteogenic differentiation of stem cells [252–254]. Dexamethasone has been added in culture medium or covalently bonded onto hydrogel network to induce osteogenic differentiation of MSCs into osteoblasts for improved osteogenesis [255, 256]. It has been reported that dexamethasone can also enhance chondrogenic differentiation of MSCs and ESCs as well as cartilage-related protein formation in the presence of TGF-β [257–259], whereas another study indicated that the addition of dexamethasone had suppressive effects on aggrecan synthesis and accumulation [260]. Dexamethasone is commonly used as a supplement with TGFs or BMPs to further promote cell proliferation and maximize the chondrogenic or osteogenic induction effect for optimal chondrogenesis or osteogenesis.

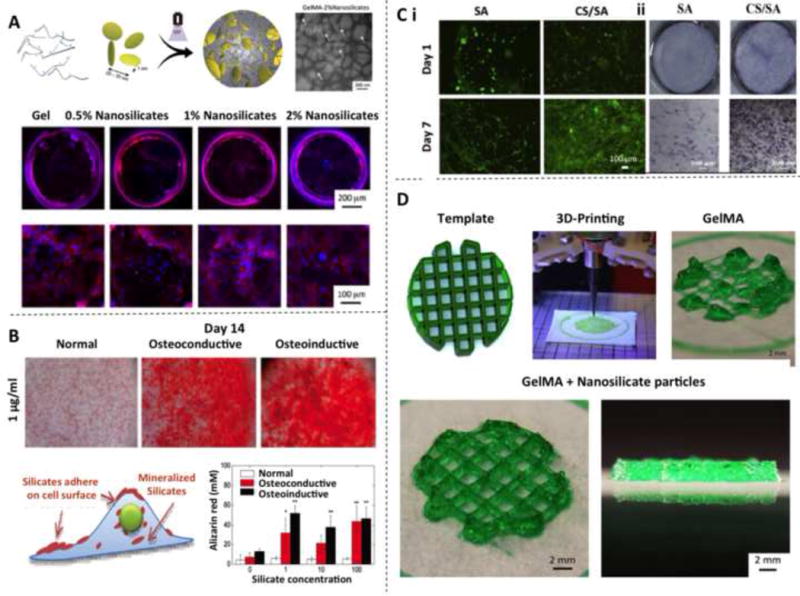

4.1.5 Newly identified growth factors and bioactive species

There are also significant on-going efforts to identify new growth factors that show enhanced stimulation effects of chondrogenic differentiation and osteogenic differentiation of stem cells. For example, it has been reported that a small molecule known as kartogenin promoted selective chondrocyte differentiation by regulating the transcription factor core-binding factor subunit (CBFb)-RUNX1 transcriptional pathway [261]. In addition, some inorganic nano-/microparticles demonstrated certain bioactivity to function as “growth factors” to trigger osteogenic differentiation of stem cells for bone regeneration [213], which will be discussed in Section 5.

4.2 Delivery methods of growth factors

In general, there are five methods for growth factor delivery: by freeform in medium, by physical blending in hydrogel, by covalent bonding to hydrogel, by microsphere carriers, and by gene delivery. Examples of each delivery methods are illustrated below.

4.2.1 Freeform in medium

The effect of TGF-β3 on chondrogenic differentiation of MSCs has been evaluated in vitro [216]. After 14 days, a larger population of MSCs cultured in TGF-β3-containing medium differentiated into chondrocytes than the control group, as indicated by increased aggrecan and collagen type II expressions. TGF-β3 and dexamethasone were applied for the chondrogenic and osteogenic pre-differentiation of MSCs to generate OPF hydrogel osteochondral constructs [216]. In vitro results indicated the cartilage layer exhibited increased expression of cartilage-related gene/protein biomarkers, while the subchondral layer presented enhanced expression of bone-related biomarkers. It was also found that MSCs that underwent 7 days of chondrogenic pre-differentiation closely resembled the phenotype of hyaline cartilage when combined with osteogenic cells in a bilayer hydrogel composite. An in vitro co-culture approach was developed to make multilayer osteochondral structures using a two-chamber well [198]. This approach can simultaneously provide chondrogenic and osteogenic stimulation with inducers of TGF-β3 and dexamethasone to MSCs encapsulated in different regions of the constructs. It can be concluded that growth factor delivery by freeform in medium is an efficient way to culture engineered cell-laden hydrogel cartilage/osteochondral constructs in vitro. However, frequent dosing is required to maintain the growth factor concentration and bioactivity in the medium, which is not optimal for long-term culture and maturation of engineered tissue constructs. Also, this delivery method is not applicable for in vivo chondrogenesis and osteogenesis.

4.2.2 Physical blending in hydrogel

Encapsulating growth factors in hydrogels was proved to be an easy and effective way to achieve release in a sustaining manner. BMP-2 was directly added in MSC-laden hydrogels composed of chitosan-lactide-fibrinogen to stimulate osteogenic differentiation [262]. Release study and characterization of bone-related biomarker expression indicated that the BMP-2 release could sustain for 4 weeks to induce osteogenic differentiation with increasing alkaline phosphate activity and mineralization. In vivo study demonstrated that BMP-2 containing hydrogels prompted neo-osteogenesis by increasing osteoprogenitor localization in the defect site [263]. Growth factor delivery by encapsulation in hydrogels does not require multi-time dosage and may be able to sustain the release for up to weeks. This is an advantage for long-term culture of engineered cartilage/osteochondral constructs. In addition, it is applicable for in vivo chondrogenesis and osteogenesis. However, the amount of growth factor released from hydrogels will significantly reduce with time, which may limit the efficiency of the chondrogenic and osteogenic induction.

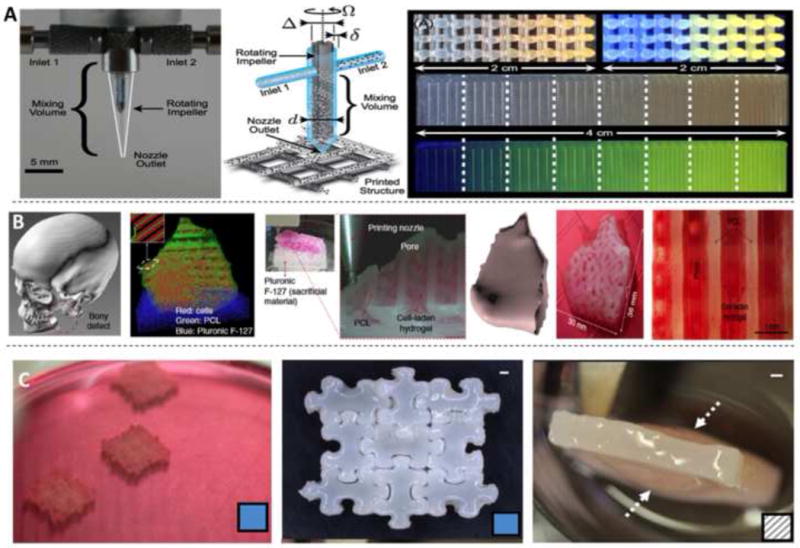

4.2.3 Covalent bonding to hydrogels