Abstract

Bacterial nanocellulose (BNC) has desirable properties for wound healing such as high purity, good shape retention, and high water binding capacity. Bromelain is a protease found in pineapple tissues and has been applied in several fields, it has anti-inflammatory and anticancer properties, promotes cell apoptosis, amongst others. In this work, a BNC based device for the controlled release of bromelain was developed. BNC were submersed in sterilized bromelain solution and incubated at 25 °C under 100 rpm for 24 h. Physical-chemical properties, protein concentration, antioxidant and antimicrobial activities were measured. Results demonstrate that BNC could improve bromelain antimicrobial activity 9 times. Those findings allow concluding that bromelain is a promising molecule to be incorporated into BNC’s. The BNC’s characteristics seem to represent a new promising delivery system of the loaded biomolecule, and protected from external actions.

Introduction

Current advances in biopolymer research demonstrates their potential for a wide range of applications in pharmaceutical and medical fields, including the development of drug delivery systems, wound healing, scaffolds for tissue engineering, novel vascular grafts, and dressing for skin burns and wound healing1–4. The most abundant biopolymer is cellulose, which is produced by a variety of organisms and constitutes the basic structure of cells walls of almost all plants, many fungi and some algae 5–7.

Bacterial nanocellulose (BNC) is an extracellular polysaccharide secreted mainly by Gluconacetobacter xylinus, among other bacteria of genera Gluconacetobacter, Agrobacterium Rhizobium, Pseudomonas, Sarcina, and Acetobacter 8–10. Unlike vegetable cellulose, BNC is produced in pure form, free of other polymers. In addition, it can be molded into three-dimensional structures, able to retain high water amounts, mechanically resistant and biocompatible11. BNC has a nanofibrilar structure, making it an ideal matrix for use as medical devices, either as an aid in healing skin lesions3 or in tissue engineering, assisting cell regeneration12,13.

The scope of applications of BNC can be further expanded through its association with bioactive molecules. For instance, it has been shown that the incorporation of antimicrobial agents into BNC membranes yielded an active packaging system14. Nisin-containing BNC films were effective in controlling L. monocytogenes 15, while BNC containing sorbic acid was used as a food packaging material with an ability to controlled release the antimicrobial agent16.

Proteolytic enzymes could be used as therapeutics adjuvants, due to their debridement and antimicrobial activities, facilitating tissue renewal process and accelerating ulcerated skin healing. Bromelain is a set of proteolytic enzymes found in pineapple (Ananas comosus) tissues such as stem, fruit and leaves, and has widespread applications, such as in the cosmetic and food industries, as well as in medicine17–19. In healthcare, bromelain has been used for the treatment of rheumatoid arthritis, thrombophlebitis, hematomas, oral inflammation, diabetic ulcers, rectal and perirectal inflammation, wounds, inhibition of platelet aggregation, angina pectoris, bronchitis, sinusitis, surgical traumas, and pyelonephritis, and for enhancing the absorption of drugs, particularly antibiotics18,20–22.

Dutta and Bhattacharyya23 reported that bromelain from pineapple crown leaves present nonspecific proteolytic, gelatinolytic, collagenase, fibrinolytic, acid and alkaline phosphatase, nuclease, peroxidase, with considerable anti-bacterial and anti-fungal activities. In a further study using specific cysteine proteases inhibitors, authors found that papain and bromelain antibacterial activity is not related to its proteolytic activity, and may be related to amidase and esterase activities24.

Collectively, these bromelain properties support its application in the treatment of microbial infections and also as a wound healing agent25. Thus, the incorporation of bromelain in BCN membranes could be of potential interest in different fields, mainly in pharmaceutical and medical applications, such as the development of a delivery system for healing application.

This article describes bromelain loading into BNC membranes and its release. Also presents physical-chemical properties, protein concentration, antioxidant and antimicrobial activities of developed system (Supplementary Fig. S1).

Results and Discussion

Bromelain loading and release from bacterial cellulose membrane

The many advantages of BNC including its biocompatibility, conformability, elasticity, transparency, ability to maintain a moist environment in the wound, and ability to absorb exudates during the inflammatory phase, provide great potential for applications in wound healing systems26,27. The novelty in this study is the incorporation of bromelain in BCN membranes, to improve the antimicrobial characteristics and create a potential interest in different fields, mainly in pharmaceutical and medical applications.

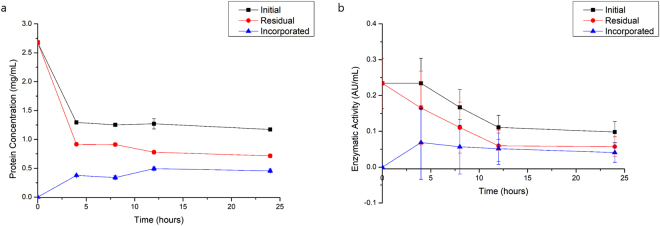

Bromelain was incorporated in BNC membranes by immerging membranes in a bromelain solution. Along with incubation time with the BNC membrane, bromelain enzymatic activity in the supernatant decayed (Fig. 1), indicating enzyme migration into the membrane. Bromelain solution was subjected to the same loading conditions, but without contact with the bacterial cellulose, and there was an enzymatic activity and protein decrease, which was considered to calculated bromelain loading into BNC membranes. These results show that bromelain migrated to the interior of BNC.

Figure 1.

Protein concentration (a) and enzymatic activity (b) of initial and residual bromelain solutions, and bacterial nanocellulose membrane, where error bars correspond to standard deviation.

Bernkop-Schnürch, et al.28 used bromelain as a model in the study of incorporation and release of microparticles of poly(acrylic acid) over a period of 60 minutes at 37 °C. Additionally, the bromelain release rate could be controlled through the selection of the hydrophobicity of the polymers.

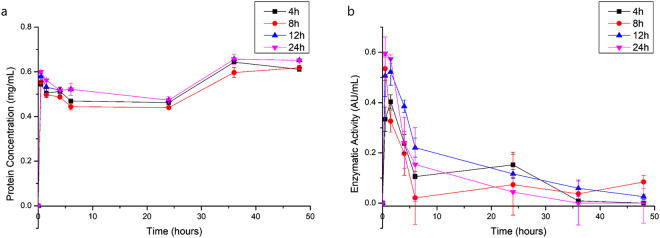

After the first 30 minutes, released bromelain amount was higher than the incorporated amount, for protein concentration and enzymatic activity (Fig. 2, Supplementary Fig. S2). The same results were observed by19, when incorporating bromelain into alginate and Arabic gum hydrogel. According with suppliers, commercial steam bromelain purity is 35%, and it contains other components with high molecular weight29, which may be not incorporated by BNC. Thus, it is possible to infer that BNC, as well as the alginate and Arabic gum based hydrogel19, selectively absorbed low molecular weight bromelain components, which present higher enzymatic activity.

Figure 2.

Protein concentration (a) and enzymatic activity (b) of released bromelain from bacterial cellulose membranes after different incorporation times at 25 °C, where error bars correspond to standard deviation.

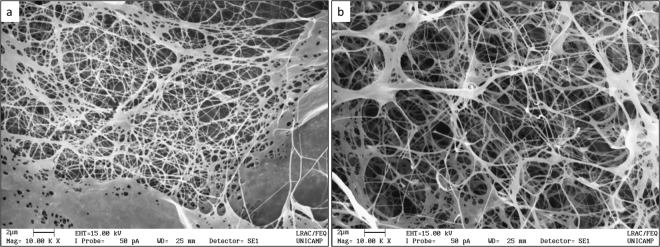

BNC structural analysis by Scanning Electron Microscopy

SEM analyses, done at 10 kx magnifications, indicated that the BC membranes presented an entangled structure, with void spaces randomly distributed throughout the membrane matrix (Fig. 3). The highly entangled thin fiber network accounts for a large surface area and the porous structure of the BNC membranes facilitates the entrapment and immobilization of proteins30. However, no relevant changes in BNC network was observed when bromelain was loaded, which was similar to previous results reported by Müller, et al.31 and Moritz, et al.32.

Figure 3.

Scanning electron microscopy of bacterial nanocellulose membranes (a) and bromelain-loaded membranes (b).

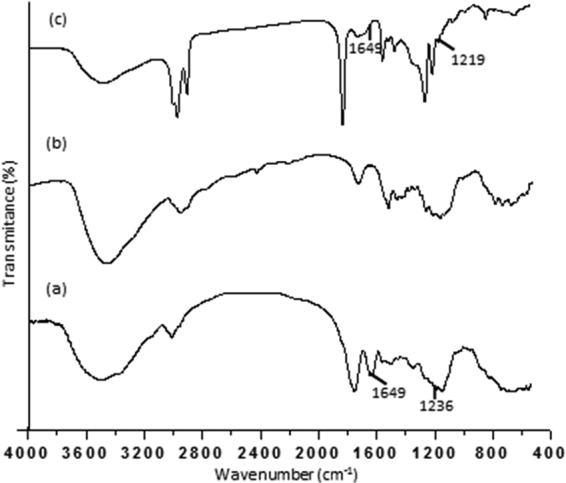

FTIR spectroscopy

Chemical cleavages characteristic of pure bromelain and bacterial cellulose membranes without and with bromelain were determined by Fourier Transform Infrared (FTIR) spectroscopy shown in Fig. 4. The bromelain-containing bacterial cellulose membrane showed a vibration displacement at 1649 cm−1, relative to the C grouping=O. The bromelain bacterial cellulose membrane showed a vibration displacement at 1649 cm−1 related to the C=O band. The C=O stretching group corresponds to the amide group from asparagine, glutamine amino acids or residual proteins of BCN membrane. The stretching in 1612 cm−1 can be attribute at N-H from amide I group of bacterial cellulose protein33. The aliphatic amine (1236 cm−1) is observed at 1219 cm−1 on the bromelain-containing bacterial cellulose membrane33. The stretching in the range of 3200–3800 nm−1 for bromelain (a), BCN membrane (b) and BCN with bromelain (c) is corresponding to -OH group. The decrease in OH stretching is related to the formation of hydrogen bonding between immobilisation of bromelain that occurs through the establishment of hydrogen bonding between -OH groups on the surface of -NH2 of BNC membrane19. Bromelain interaction with BCN membranes may also be attributed to hydrophobic interactions or Van der Waals forces, once bromelain contains hydrophobic amino acids exposed on its surface34,35.

Figure 4.

FTIR spectra of pure bromelain (a), bacterial cellulose membrane (b) and bacterial cellulose membrane with bromelain (c).

Evaluation of bromelain antimicrobial activity

For minimal inhibitory concentration (MIC), the following solutions were testes: (i) initial bromelain solution; (ii) residual bromelain solution; and (iii) bromelain solution after being released from BCNs. Table 1 present protein concentration, enzymatic activity and specific activity of those solutions.

Table 1.

Total protein concentration, enzymatic and specific activity of bromelain solution in initial condition and after BCN membranes loaded and release.

| Protein Concentration (mg/mL) | Enzymatic Activity (U/mL) | Specific Activity (U/mg) | |

|---|---|---|---|

| Initial Solution | 25.57 | 8.7 | 0.34 |

| Residual Solution* | 17.63 | 6.78 | 0.38 |

| Release Solution* | 1.43 | 1.42 | 0.99 |

*Collected after 24 hours.

It is possible to note that residual bromelain solution presented a decrease in all parameters when compared with initial solution, indicating that BCN membrane was capable to absorb 7.94 mg/mL of proteins, representing 31% of total protein concentration in the initial bromelain solution. It is also possible to observe, an increase in bromelain specific activity in the release solution (3-times higher than initial solution), which may be related with BCN membrane selectively absorbing bromelain low molecular weight components with higher enzymatic activity.

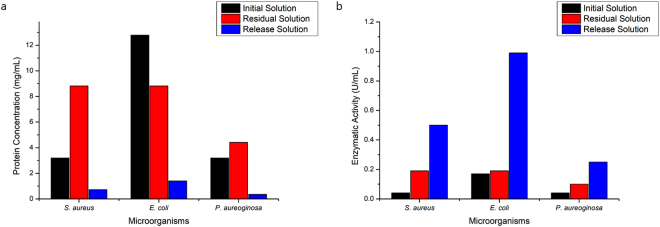

Those three solutions, were used for the minimal inhibitory concentration assay (MIC), Fig. 5 presents protein concentration (Fig. 5a) and enzymatic activity (Fig. 5b) of tested solutions when MIC was achieved.

Figure 5.

Protein concentration (a) and enzymatic activity (b) of initial and residual bromelain solution, and release solution found as MIC.

Results showed in Fig. 5b indicate the bromelain antimicrobial activity has a relation with its enzymatic activity. It is possible observe this effect for all microorganism, to E. coli, bromelain release solution MIC was 0.99 U/mL, 6 times higher than initial solution MIC. The same behavior was observed for P. aureoginosa, where MIC was achieved at 0.25 U/mL in the release solution, 6 times higher than MIC of initial solution 0.04 U/mL, and for S. aureus bromelain release solution MIC was 0.5 U/mL, 12 times higher than initial solution MIC.

According to Ali, et al.36, crude bromelain is more effective in inhibiting Gram-positive bacteria growth than Gram-negative. Our results, however, pointed in a different direction, since bromelain inhibit all tested microorganisms, especially for release solution. Dutta and Bhattacharyya23 reported bromelain antimicrobial activity against S. aureus. A bromelain solution with 1.95 mg/mL concentration inhibited S. aureus growth by 50%, however bromelain enzymatic activity was not reported. The same study showed the bromelain concentration of 1.86 and 2.11 mg/mL were responsible to inhibit E. coli XL1 blue and E coli DH5α Pet16b (Amp)r growth, respectively. Our results (Fig. 5a) showed a higher protein concentration for bromelain initial solution (3.2 mg/mL) and lower concentration for release bromelain solution (0.72 mg/mL) when compared to previous study, which also could be explained by the high specific activity of bromelain after incorporated in BNC membranes.

Crude bromelain extract (1.8 mg/mL) and standard bromelain (2 mg/mL) created a 22 mm zone of inhibition of E. coli growth at 37 °C in neutral pH. However, at alkaline pH, crude bromelain extract and standard bromelain created a zone of growth inhibition of 8.33 and 9.67 mm, respectively36. In our study, initial bromelain solution and release solution MIC was 12.79 mg/mL and 1.41 mg/mL concentration, and enzymatic activity was 0.17 AU/mL and 0.99 AU/mL, respectively. In this case, it was also observed a lower protein concentration with higher enzymatic activity for release solution.

Aggregatibacter actinomycetemcomitans, Porphyromonas gingivalis, and Streptococcus mutans have been predominantly associated with periodontal diseases. Bromelain was investigated as a potential antimicrobial agent to be used as a monotherapy and as an adjunct with mechanical debridement. Bromelain showed antibacterial efficacy against all the isolated strains of both aerobic and anaerobic microorganisms. S. mutans showed sensitivity at the lowest concentration (2 mg/mL), followed by P. gingivalis (4.15 mg/mL). While A. actinomycetemcomitans demonstrated the higher resistance and a MIC of 16.6 mg/mL37.

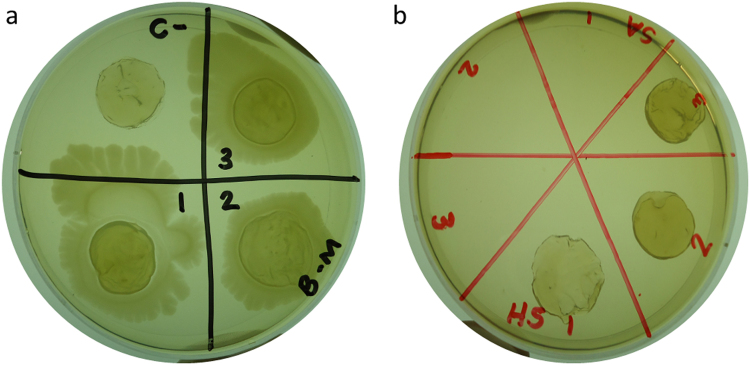

For agar diffusion modified assay, bromelain-loaded BNC membranes showed antimicrobial activity for all tested microorganisms (Fig. 6b), differently from BNC membranes without bromelain (Fig. 6a).

Figure 6.

Antimicrobial activity evaluated by modified agar diffusion method of bacterial nanocellulose membranes (a) and bromelain-loaded membranes (b) for S. aureus (1), E. coli (2) and P. aeruginosa (3).

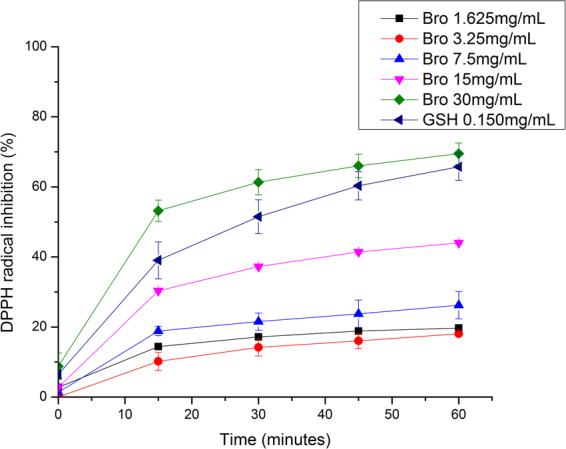

Bromelain antioxidant activity

Proteases enzymes, such as bromelain and papain, present antioxidant activity as free radical scavenging and lipid peroxidation inhibition38. Bromelain antioxidant activity was measured against 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical, which provides an easy and rapid way to evaluate antiradical activities39.

Figure 7 shows the antioxidant activity of different concentrations of bromelain initial solution over 60 minutes. According with our results, bromelain antioxidant activity was dose-dependent, and so the highest bromelain concentration (30 mg/mL) presented the highest antioxidant activity, in the lowest reaction time. At the lowest concentration (1.625 mg/ml) antioxidant activity was not significant (p > 0.05).

Figure 7.

Percent of 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical inhibition by the bromelain (Bro, in different concentrations) by the reduced glutathione (GSH), where error bars correspond to standard deviation.

Both bromelain at 30 and 15 mg/mL were statistically similar to glutathione (GSH), antioxidant standard (0.150 mg/mL), initially and after 15 minutes. However, over time, bromelain at 15 mg/mL showed a statistically lower antioxidant activity than GSH (p < 0.05) and bromelain at 30 mg/mL (p < 0.05). It is important to observe that antioxidant capacity of bromelain increased over time even in the lowest concentrations, a behavior also seen in GSH. This feature is relevant mainly when considering a formulation for topical application for example, in which the antioxidant activity remains and even increases after its application.

Several studies have been reported about bromelain and its medical use, such as inhibition of platelet aggregation and fibrinolysis40, effects on cardiovascular diseases41, modulation of inflammatory system42 and skin debridement properties43. Among them, the latter two are very convenient when associated to the antioxidant and antimicrobial capacity found in this study, once these four properties are essential in skin lesions, as a wound healing.

Mucoadhesive property

Mucoadhesive property was evaluated by a tensile test, and is a property related to the ability of a material (synthetic or biological) to adhere to a biological tissue during a certain period of time44. In this way, mucoadhesion analysis evaluates the interaction between the membrane and the surface of the mucosa at a temperature of 37 °C45,46.

Analysis of the results shows that maximum strength values significantly (p < 0.05) reduced from 0.493 ± 3.6 N to 0.112 ± 0.1 N, respectively for bacterial cellulose membrane without and with bromelain. According to Yadav, et al.44, mucoadhesion may occur by increasing the viscosity of the system or by molecular interactions, such as ionic interactions or formation of hydrogen (OH) bonds. It is worth mentioning that the immobilization of bromelain in the bacterial cellulose membrane occurs by the formation of hydrogen bonds between OH of bacterial cellulose membrane and bromelain NH2 47. In this way, one can suggest that the decrease of the mucoadhesive property occurred by the decrease of free OH groups in the membrane of bacterial cellulose containing bromelain, results evidenced in the FTIR analysis.

Conclusion

BCN membranes were able to selectively absorb and release bromelain. Bromelain itself present antimicrobial and antioxidant activities, however, after incorporated into BNC membranes, its antimicrobial activity increased. BNC membranes presented mucoadhesive properties, which decreased after bromelain loading. This can be explained by the presence of H-bonds between bromelain and BNC membrane, leading to a decrease in molecular interactions between BNC and mucin. The broad bromelain solution and BNC membrane antimicrobial spectrum and their tissue adhesion make them an alternative method for wound contamination control, since the membrane may act as platform that delivers antimicrobial gradually avoiding biofilm formation. Thus, bromelain-containing BNC membrane proved to be a promising drug delivery system to minimize healing period, reducing the risk of infection and promoting patient comfort and pain relief.

Materials and Methods

Materials

Bromelain, Folin-Ciocateau and bicinchoninic acid assay kit were purchased from Sigma-Aldrich (Brazil). Other reagents were of analytical or food grade. Assays were performed in triplicate.

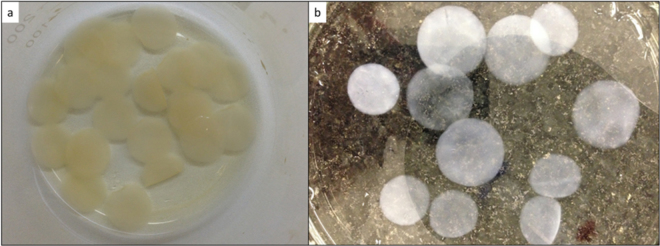

Production and purification of bacterial cellulose membranes

Bacterial nanocellulose membranes (BCN membrane) were produced through Gluconacetobacter xylinus (ATCC 53582) cultivation in Hestrin & Schramm medium (20 g/L glucose, 5 g/L bacteriological peptone, 5 g/L yeast extract, 2.7 g/L anhydrous sodium phosphate, 1.5 g/L monohydrate citric acid). Microorganism growth in 24-well cell culture plates, containing 1 mL of a 106 CFU/mL inoculum per well.

Plates were kept for 4 days in static culture at 30 °C, yielding 2 mm thick membranes. After growth, membranes were washed in 2% sodium dodecyl sulfate (SDS) solution overnight, rinsed with distilled water until SDS removal, and immersed in 1 M NaOH solution with stirring at 60 °C for 1 and a half hours. After this period, membranes were washed again until reaching neutral pH. Then they were packaged and autoclaved at 121 °C for 15 minutes in Milli Q water, and stored at 4 °C (Fig. 8).

Figure 8.

Bacterial nanocellulose membrane (BCN membrane): appearance after production (a) and after NaOH treatment and sterilization (b).

Enzymatic activity and protein quantification

Enzymatic activity was determined by adapting the non-specific protease activity assay from Sigma® 48–50. Briefly, the method consists in casein cleavage by bromelain for 10 minutes at 37 °C and pH 7.5 and the reaction was stopped by adding trichloroacetic acid (TCA). The resulting solution was centrifuged at 4,000 g for 20 minutes, and a supernatant aliquot placed to react with Folin-Ciocalteau, in the presence of sodium carbonate. The reaction of Folin primarily with tyrosine produces free chromophore with a blue color, which is measured by absorbance analysis at 660 nm. The standard curve was drawn with L-tyrosine. Protein concentration was determined with bicinchoninic acid assay51.

Bromelain loading in bacterial cellulose membranes

In 24-well plates, BNC membranes were disposed and 1 mL of 30 mg/mL bromelain solution in citrate-phosphate buffer (pH 5.0) was poured into the plate. In the fourth well only bromelain solution was added. Plates were kept in 100 rpm orbital shaker at 25 °C for various periods ranging for 4, 8, 12 and 24 hours. After each period, supernatants were collected and bromelain activity and protein quantification were evaluated in the isolated residual solutions.

Bromelain release from bacterial cellulose membranes

This methodology was used to assess bromelain release from BNC membranes. In 24 well plates, membranes loaded with bromelain (after 24 hours loading time) were disposed in triplicate, with a negative control (membrane without bromelain) in the fourth well. In each well 1 mL of citrate-phosphate buffer (pH 5.0) was added. Plates were placed in 100 rpm orbital shaker at 25 °C. At different periods (0, 0.5, 2, 4, 6, 24, 36 and 48 hours), membranes and supernatant were collected. Bromelain activity and protein quantification were assayed in the isolated released solution.

Scanning Electron Microscopy

BNC membranes structure was observed using a Leo 440i scanning electron microscopy with 6070 X-ray dispersive energy detector (LEO Electron Microscopy, England). SEM images were obtained using an accelerating voltage of 15 kV. Before analysis, samples were lyophilized for 24 hours and coated with gold (92 A°) using SC7620 Sputter Coater POLARON (VG Microtech, England).

Fourier Transform Infrared Spectroscopy (FTIR)

The free bromelain and bacterial cellulose membrane with and without bromelain were analysed using Fourier Transform Infrared Spectroscopy (FTIR) (Shimadzu, FTIR IRAffinity-1S, Kyoto, Japan) using transmittance modes. Membranes were kept in an oven at 30 °C, after drying they were ground. Approximately 2 mg of the sample was mixed with 300 mg of KBr to form the pellet. Spectra were obtained in the 4000 to 400 cm−1 wavelength range after 64 scans, with a resolution of 4 cm−1. The spectra were normalized and the vibration bands were associated with the main chemical groups.

Evaluation of bromelain antimicrobial activity

In this assay, the microorganisms used were Escherichia coli (ATCC 25922) and Pseudomonas aeuroginosa (ATCC 9721), representing the class of gram-negative; and Staphylococcus aureus (ATCC 10390), representing the class of gram-positive.

Minimum inhibitory concentration

Minimum inhibitory concentration (MIC) classical method of successive dilution was adapted to 96-well plates, in triplicate52,53, using (i) initial bromelain solution; (ii) residual bromelain solution; and (iii) bromelain solution after being released from BCNs.

Agar diffusion assay

The agar diffusion assay was modified to verify qualitatively the antimicrobial activity in BCN membranes itself and after bromelain loading54,55. Membranes were placed in 24-well plates with 1 mL of culture medium and 100 μL of the microorganism suspension (106 CFU.mL−1), and plates incubated for 24 hours at 37 °C. After this time, the resulting membrane and solution were inoculated intro Petri dishes containing agar of the culture medium.

Bromelain antioxidant activity

Antioxidant activity was determined based on absorbance decrease at 515 nm after the reaction between radical 1,1-diphenyl-2-picrylhydrazyl (DPPH) and initial bromelain solutions, according to Brand-Williams, et al.39.

Mucoadhesive strength proprieties

Mucoadhesive strength of the bacterial cellulose membrane with and without bromelain was evaluated by the force required to remove the membrane from a mucin disc using the TAXTPlus texture analyzer (Stable Micro Systems, UK). Samples were fixed in a water bath with a temperature set at 37 °C. The mucin discs were prepared by compression (Lemaq, rotary compressor machine, Mini Express LM-D8, Diadema, BR). The surface of the mucin disc was hydrated and the disk attached to the lower end of the analytical probe. Mucin disc was compressed apical → basal on the surface of the samples, with a compression force of 0.1 N. The contact time of the disc with the surface of the samples was 200 s. Removal of the analytical probe was at the rate of 0.5 mm.s−1. The force required to separate the surfaces was determined by time versus force ratio (n = 3), and analysis parameters were described on Table 2.

Table 2.

Parameters used to evaluate the mucoadhesive property of bacterial cellulose membrane with and without bromelain.

| Parameters | |

|---|---|

| Aparate | Film Support Rigg Part Code. HDP/FSR Batch n 13085 |

| Test Mode | Compression |

| Pre-Test Speed | 0,5 mm/s |

| Test Speed | 0,5 mm/s |

| Post-Test Speed | 10 mm/s |

| Target Mode: | Distance |

| Distance | — |

| Trigger Type | Auto |

| Trigger Force | 0,049 N |

Statistical analysis

Data is presented as mean ± standard deviation. Differences among bromelain concentrations were evaluated by one-way ANOVA, followed by Tukey multiple range tests. P values < 0.05 were considered significant. Data were analyzed using Statistica®8.0 (Statsoft software, Tulsa, OK, USA).

Electronic supplementary material

Acknowledgements

Authors acknowledge Sao Paulo Research Foundation (process numbers 2011/23076-7 and 2016/05930-4) and National Council for Scientific and Technological Development (CNPq) for the financial support. Authors also acknowledge Andréa Arruda Martins Shimojo for the help with obtaining scanning electron microscopy images.

Author Contributions

J.A.A. conducted experiments and wrote the manuscript, N.M.C. conducted experiments, M.A.R. conducted experiments and analyzed results, M.V.C. analyzed results and critically reviewed manuscript, D.G. conducted experiments and analyzed results, M.G., M.R. and P.G.M. analyzed the results and critically reviewed the manuscript, A.F.J. conceived the experiments, analyzed the results and wrote the manuscript.

Competing Interests

The authors declare that they have no competing interests.

Footnotes

Electronic supplementary material

Supplementary information accompanies this paper at 10.1038/s41598-017-18271-4.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Janaína Artem Ataide, Email: janaina.a.ataide@gmail.com.

Angela Faustino Jozala, Email: angela.jozala@prof.uniso.br.

References

- 1.Jozala AF, et al. Bacterial nanocellulose production and application: a 10-year overview. Applied microbiology and biotechnology. 2016;100:2063–2072. doi: 10.1007/s00253-015-7243-4. [DOI] [PubMed] [Google Scholar]

- 2.Almeida IF, et al. Bacterial cellulose membranes as drug delivery systems: An in vivo skin compatibility study. European Journal of Pharmaceutics and Biopharmaceutics. 2014;86:332–336. doi: 10.1016/j.ejpb.2013.08.008. [DOI] [PubMed] [Google Scholar]

- 3.Czaja WK, Young DJ, Kawecki M, Brown RM. The Future Prospects of Microbial Cellulose in Biomedical Applications. Biomacromolecules. 2007;8:1–12. doi: 10.1021/bm060620d. [DOI] [PubMed] [Google Scholar]

- 4.Czaja W, Krystynowicz A, Bielecki S, Brown RM., Jr. Microbial cellulose—the natural power to heal wounds. Biomaterials. 2006;27:145–151. doi: 10.1016/j.biomaterials.2005.07.035. [DOI] [PubMed] [Google Scholar]

- 5.Czaja W, Romanovicz D, Brown R. m. Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose. 2004;11:403–411. [Google Scholar]

- 6.Jonas R, Farah LF. Production and application of microbial cellulose. Polymer Degradation and Stability. 1998;59:101–106. doi: 10.1016/S0141-3910(97)00197-3. [DOI] [Google Scholar]

- 7.Nobles DR, Romanovicz DK, Brown RM. Cellulose in Cyanobacteria. Origin of Vascular Plant Cellulose Synthase? Plant Physiology. 2001;127:529–542. doi: 10.1104/pp.010557. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Brown RM, Willison JH, Richardson CL. Cellulose biosynthesis in Acetobacter xylinum: visualization of the site of synthesis and direct measurement of the in vivo process. Proceedings of the National Academy of Sciences of the United States of America. 1976;73:4565–4569. doi: 10.1073/pnas.73.12.4565. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Li Y, et al. Improvement of bacterial cellulose production by manipulating the metabolic pathways in which ethanol and sodium citrate involved. Applied microbiology and biotechnology. 2012;96:1479–1487. doi: 10.1007/s00253-012-4242-6. [DOI] [PubMed] [Google Scholar]

- 10.Moosavi-Nasab M, Yousefi A. Biotechnological production of cellulose by Gluconacetobacter xylinus from agricultural waste. Iran J Biotechnol. 2011;9:94–101. [Google Scholar]

- 11.Lopes, R. Funcionalização de celulose bacteriana com peptídeo RGD para reparação tecidual de pele Masters thesis. Universidade Estadual Paulista (2015).

- 12.Fontana JD, et al. Acetobacter cellulosic biofilms search for new modulators of cellulogenesis and native membrane treatments. Applied biochemistry and biotechnology. 1997;63–65:327–338. doi: 10.1007/BF02920434. [DOI] [PubMed] [Google Scholar]

- 13.Sanchavanakit N, et al. Growth of human keratinocytes and fibroblasts on bacterial cellulose film. Biotechnology progress. 2006;22:1194–1199. doi: 10.1021/bp060035o. [DOI] [PubMed] [Google Scholar]

- 14.Shahmohammadi Jebel F, Almasi H. Morphological, physical, antimicrobial and release properties of ZnO nanoparticles-loaded bacterial cellulose films. Carbohydrate Polymers. 2016;149:8–19. doi: 10.1016/j.carbpol.2016.04.089. [DOI] [PubMed] [Google Scholar]

- 15.Nguyen VT, Gidley MJ, Dykes GA. Potential of a nisin-containing bacterial cellulose film to inhibit Listeria monocytogenes on processed meats. Food microbiology. 2008;25:471–478. doi: 10.1016/j.fm.2008.01.004. [DOI] [PubMed] [Google Scholar]

- 16.Jipa IM, Stoica-Guzun A, Stroescu M. Controlled release of sorbic acid from bacterial cellulose based mono and multilayer antimicrobial films. LWT - Food Science and Technology. 2012;47:400–406. doi: 10.1016/j.lwt.2012.01.039. [DOI] [Google Scholar]

- 17.Spir LG, et al. Application of an aqueous two-phase micellar system to extract bromelain from pineapple (Ananas comosus) peel waste and analysis of bromelain stability in cosmetic formulations. Biotechnology progress. 2015;31:937–945. doi: 10.1002/btpr.2098. [DOI] [PubMed] [Google Scholar]

- 18.de Lencastre Novaes LC, et al. Stability, purification, and applications of bromelain: A review. Biotechnology progress. 2016;32:5–13. doi: 10.1002/btpr.2190. [DOI] [PubMed] [Google Scholar]

- 19.Ataide JA, et al. Bromelain Loading and Release from a Hydrogel Formulated Using Alginate and Arabic Gum. Planta medica. 2017 doi: 10.1055/s-0043-102948. [DOI] [PubMed] [Google Scholar]

- 20.Pavan R, Jain S, Shraddha, Kumar A. Properties and Therapeutic Application of Bromelain: A Review. Biotechnology Research International. 2012;2012:6. doi: 10.1155/2012/976203. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Maurer HR. Bromelain: biochemistry, pharmacology and medical use. Cellular and molecular life sciences: CMLS. 2001;58:1234–1245. doi: 10.1007/PL00000936. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Bala M, et al. Bromelain production: current trends and perspective. Archives Des Sciences. 2012;65:369–399. [Google Scholar]

- 23.Dutta S, Bhattacharyya D. Enzymatic, antimicrobial and toxicity studies of the aqueous extract of Ananas comosus (pineapple) crown leaf. Journal of Ethnopharmacology. 2013;150:451–457. doi: 10.1016/j.jep.2013.08.024. [DOI] [PubMed] [Google Scholar]

- 24.dos Anjos MM, et al. Antibacterial activity of papain and bromelain on Alicyclobacillus spp. International Journal of Food Microbiology. 2016;216:121–126. doi: 10.1016/j.ijfoodmicro.2015.10.007. [DOI] [PubMed] [Google Scholar]

- 25.Muhammad ZA, Ahmad T. Therapeutic uses of pineapple-extracted bromelain in surgical care - A review. JPMA. The Journal of the Pakistan Medical Association. 2017;67:121–125. [PubMed] [Google Scholar]

- 26.Fu L, Zhang J, Yang G. Present status and applications of bacterial cellulose-based materials for skin tissue repair. Carbohydrate Polymers. 2013;92:1432–1442. doi: 10.1016/j.carbpol.2012.10.071. [DOI] [PubMed] [Google Scholar]

- 27.Shah N, Ul-Islam M, Khattak WA, Park JK. Overview of bacterial cellulose composites: A multipurpose advanced material. Carbohydrate Polymers. 2013;98:1585–1598. doi: 10.1016/j.carbpol.2013.08.018. [DOI] [PubMed] [Google Scholar]

- 28.Bernkop-Schnürch A, Egger C, Elhassan Imam M, Krauland AH. Preparation and in vitro characterization of poly(acrylic acid)–cysteine microparticles. Journal of Controlled Release. 2003;93:29–38. doi: 10.1016/S0168-3659(03)00339-0. [DOI] [PubMed] [Google Scholar]

- 29.Bresolin IRAP, Bresolin ITL, Silveira E, Tambourgi EB, Mazzola PG. Isolation and purification of bromelain from waste peel of pineapple for therapeutic application. Brazilian Archives of Biology and Technology. 2013;56:971–979. doi: 10.1590/S1516-89132013000600012. [DOI] [Google Scholar]

- 30.Knob R, Sahore V, Sonker M, Woolley AT. Advances in monoliths and related porous materials for microfluidics. Biomicrofluidics. 2016;10:032901. doi: 10.1063/1.4948507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Müller A, et al. The Biopolymer Bacterial Nanocellulose as Drug Delivery System: Investigation of Drug Loading and Release using the Model Protein Albumin. Journal of Pharmaceutical Sciences. 2013;102:579–592. doi: 10.1002/jps.23385. [DOI] [PubMed] [Google Scholar]

- 32.Moritz S, et al. Active wound dressings based on bacterial nanocellulose as drug delivery system for octenidine. International Journal of Pharmaceutics. 2014;471:45–55. doi: 10.1016/j.ijpharm.2014.04.062. [DOI] [PubMed] [Google Scholar]

- 33.Swaroop G, Viswanathan G. Isolation and Characterization of Bromelain (BML) Proteases from Ananas cosmosus an asset to Cancer Chemotherapy. International Journal of Pharmacology and Toxicology. 2013;1:82–90. [Google Scholar]

- 34.Rowan AD, Buttle DJ, Barrett AJ. The cysteine proteinases of the pineapple plant. Biochemical Journal. 1990;266:869–875. [PMC free article] [PubMed] [Google Scholar]

- 35.Ritonja A, et al. Stem bromelain: Amino acid sequence and implications for weak binding of cystatin. FEBS Letters. 1989;247:419–424. doi: 10.1016/0014-5793(89)81383-3. [DOI] [PubMed] [Google Scholar]

- 36.Ali AA, Milala MA, Gulani IA. Antimicrobial Effects of Crude Bromelain Extracted from Pineapple Fruit (Ananas comosus (Linn.) Merr. Advances in Biochemistry. 2015;3:4. [Google Scholar]

- 37.Praveen NC, et al. In vitro Evaluation of Antibacterial Efficacy of Pineapple Extract (Bromelain) on Periodontal Pathogens. Journal of International Oral Health: JIOH. 2014;6:96–98. [PMC free article] [PubMed] [Google Scholar]

- 38.Manosroi A, Chankhampan C, Pattamapun K, Manosroi W, Manosroi J. Antioxidant and gelatinolytic activities of papain from papaya latex and bromelain from pineapple fruits. Chiang Mai Journal Of Science. 2014;41:635–648. [Google Scholar]

- 39.Brand-Williams W, Cuvelier ME, Berset C. Use of a free radical method to evaluate antioxidant activity. LWT - Food Science and Technology. 1995;28:25–30. doi: 10.1016/S0023-6438(95)80008-5. [DOI] [Google Scholar]

- 40.Livio M, Bertoni M, DeGaetano G. Effect of bromelain on fibrinogen level, prothrombin complex factors and platelet aggregation in the rat: A preliminary report. Drugs Exp. Clin. Res. 1978;4:49. [Google Scholar]

- 41.Neumayer C, et al. Combined Enzymatic and Antioxidative Treatment Reduces Ischemia-Reperfusion Injury in Rabbit Skeletal Muscle. Journal of Surgical Research. 2006;133:150–158. doi: 10.1016/j.jss.2005.12.005. [DOI] [PubMed] [Google Scholar]

- 42.Bhui K, Prasad S, George J, Shukla Y. Bromelain inhibits COX-2 expression by blocking the activation of MAPK regulated NF-kappa B against skin tumor-initiation triggering mitochondrial death pathway. Cancer Letters. 2009;282:167–176. doi: 10.1016/j.canlet.2009.03.003. [DOI] [PubMed] [Google Scholar]

- 43.Hu W, et al. Debriding effect of bromelain on firearm wounds in pigs. The Journal of trauma. 2011;71:966–972. doi: 10.1097/TA.0b013e3182028929. [DOI] [PubMed] [Google Scholar]

- 44.Yadav VK, Gupta A, Kumar R, Yadav JS, Kumar B. Mucoadhesive polymers: means of improving the mucoadhesive properties of drug delivery system. J chem pharm Res. 2010;2:418–432. [Google Scholar]

- 45.Peppas NA, Buri PA. Surface, interfacial and molecular aspects of polymer bioadhesion on soft tissues. Journal of Controlled Release. 1985;2:257–275. doi: 10.1016/0168-3659(85)90050-1. [DOI] [Google Scholar]

- 46.Duchěne D, Touchard F, Peppas NA. Pharmaceutical and Medical Aspects of Bioadhesive Systems for Drug Administration. Drug development and industrial pharmacy. 1988;14:283–318. doi: 10.3109/03639048809151972. [DOI] [Google Scholar]

- 47.Shi W, Wei M, Jin L, Li C. Calcined layered double hydroxides as a “biomolecular vessel” for bromelain: Immobilization, storage and release. Journal of Molecular Catalysis B: Enzymatic. 2007;47:58–65. doi: 10.1016/j.molcatb.2007.04.001. [DOI] [Google Scholar]

- 48.Cupp-Enyard, C. Sigma’s Non-specific Protease Activity Assay - Casein as a Substrate. Journal of Visualized Experiments: JoVE 899, 10.3791/899 (2008). [DOI] [PMC free article] [PubMed]

- 49.Folin O, Ciocalteu V. On Tyrosine And Tryptophane Determinations In Proteins. The Journal of Biological Chemistry. 1927;73:627–650. [Google Scholar]

- 50.Anson ML. Theestimation Of Pepsin, Trypsin, Papain, And Cathepsin With Hemoglobin. The Journal of General Physiology. 1938;22:79–89. doi: 10.1085/jgp.22.1.79. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Smith PK, et al. Measurement of protein using bicinchoninic acid. Analytical biochemistry. 1985;150:76–85. doi: 10.1016/0003-2697(85)90442-7. [DOI] [PubMed] [Google Scholar]

- 52.Mazzola PG, Jozala AF, Novaes LCDL, Moriel P, Penna TCV. Minimal inhibitory concentration (MIC) determination of disinfectant and/or sterilizing agents. Brazilian Journal of Pharmaceutical Sciences. 2009;45:241–248. doi: 10.1590/S1984-82502009000200008. [DOI] [Google Scholar]

- 53.Mazzola PG, Penna TCV, da S Martins AM. Determination of decimal reduction time (D value) of chemical agents used in hospitals for disinfection purposes. BMC infectious diseases. 2003;3:1. doi: 10.1186/1471-2334-3-24. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Jozala AF, et al. Processing of byproducts to improve nisin production by Lactococcus lactis. African Journal of Biotechnology. 2011;10:14920–14925. doi: 10.5897/AJB11.979. [DOI] [Google Scholar]

- 55.Tankhiwale R, Bajpai SK. Graft copolymerization onto cellulose-based filter paper and its further development as silver nanoparticles loaded antibacterial food-packaging material. Colloids and Surfaces B: Biointerfaces. 2009;69:164–168. doi: 10.1016/j.colsurfb.2008.11.004. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.