Abstract

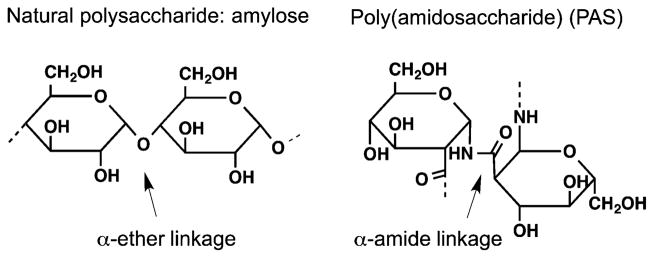

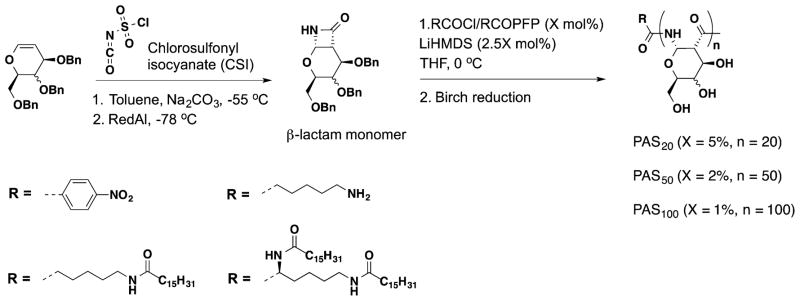

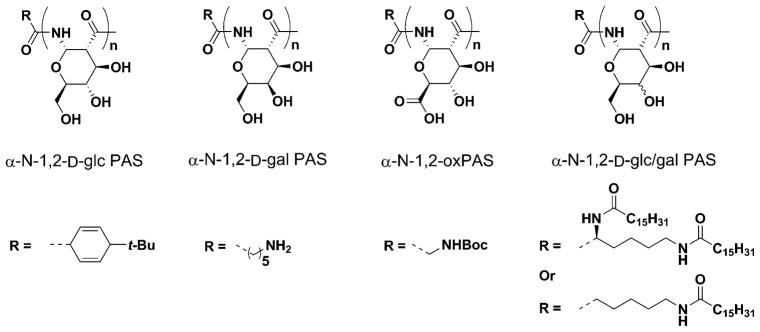

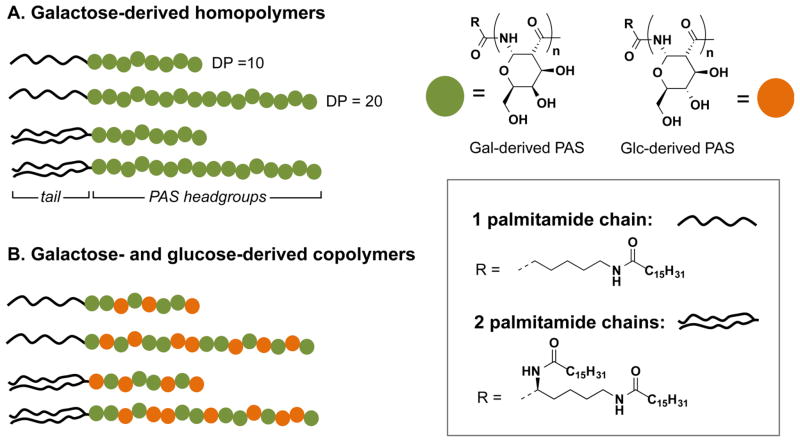

The utility of metabolic synthons as the building blocks for new biomaterials is based on the early application and success of hydroxy acid based polyesters as degradable sutures and controlled drug delivery matrices. The sheer number of potential monomers derived from the metabolome (e.g., lactic acid, dihydroxyacetone, glycerol, fumarate) gives rise to almost limitless biomaterial structural possibilities, functionality, and performance characteristics, as well as opportunities for the synthesis of new polymers. This review describes recent advances in new chemistries, as well as the inventive use of traditional chemistries, toward the design and synthesis of new polymers. Specific polymeric biomaterials can be prepared for use in varied medical applications (e.g., drug delivery, tissue engineering, wound repair, etc.) through judicious selection of the monomer and backbone linkage.

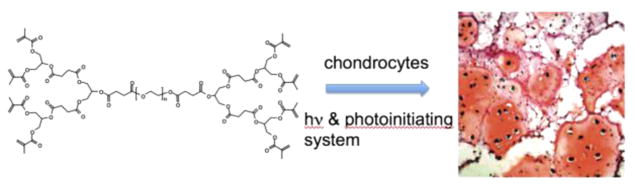

Graphical Abstract

1. INTRODUCTION

To keep pace with the rapid progress in medicine, advanced biomaterials are needed to provide the unique functionality required by the new devices, tissue scaffolds, and drug delivery systems to meet patient care needs. One approach to addressing this functional demand and to maintaining the biocompatibility necessary for new polymeric biomaterials is to synthesize new polymers derived from structures within the human metabolome. The human metabolome is made up of metabolic pathways comprised of thousands of structures needed to sustain human life. The idea is to molecularly engineer specific functions into new materials that, upon implantation, function as designed, degrade in conformance to clinical needs and are eliminated from the body via their natural metabolic pathways. This review focuses on the advances over the past decade, with some historical context included, in polymeric biomaterial design and synthesis with this specific design philosophy in mind.

Specifically, we describe the use of metabolically derived synthons to prepare unique polymers and the subsequent evaluation of these biomaterials for medical applications. We do not describe the successes in derivatization of natural polymers or un-natural poly(amino acid)s. Nor do we describe the classical condensation polymerization methods (e.g., between a diol and diacid) to prepare polymers as these topics have been extensively reviewed elsewhere and/or are outside of the scope of this article. We begin with a discussion of polymers prepared from hydroxy acids, which have been known for more than three decades. We then transition to synthons that are more compositionally complex, possessing several reactive/functional groups or stereochemical centers. We highlight the use of these biomaterials to address specific challenges observed in the clinic and note the important role that composition, structure, and physical properties play in their success. An overview of topics covered in this review, including the metabolic synthons, polymerization strategies, polymer architectures and linkages, form factors, and their applications is shown in Table 1. Finally, we conclude with a summary of the findings and the outlook for the future.

Table 1.

Summary of Polymerization Strategies, Polymers, And Applications of the Metabolic Synthons Covered in This Review

| synthon | polymerization routes | polymer architectures and linkages | form factors | applications |

|---|---|---|---|---|

| hydroxy acids | polycondensation, ring-opening polymerization, microbial synthesis, divergent dendrimer synthesis, and convergent dendrimer synthesis | linear polyesters, polyester dendrimers, and hyperbranched polyesters | microparticles, nanoparticles, hydrogels, tablets, plastics, solids, and dendrimers | biodegradable sutures, controlled drug delivery, pulmonary drug delivery, biodegradable tissue engineering scaffolds, implantable glues, packaging, medical devices, and wound repair |

| dihydroxyacetone | ring-opening polymerization, transketalization, and condensation | linear polycarbonates, linear poly(carbonate-ester)s, symmetrical lipids, poly(spiro-acetal)s, and poly(carbonate-acetal)s | microparticles, nanoparticles, hydrogels, solids, tablets, powders, and thermoplastics | seroma prevention, hemostatic agents, controlled drug delivery, tissue engineering scaffolds, and functionalizable surfaces |

| glycerol | ring-opening polymerization, epoxide/CO2 coupling, divergent dendrimer synthesis, and convergent dendrimer synthesis | linear poly(1,3-carbonate)s, linear poly(1,2-carbonate)s, poly(carbonate-ester)s, polyether and polyester dendrimers, polyether and poly(ether-ester) hyperbranched polymers, and hybrid dendritic-linear esterether copolymers | films; dendritic drug carriers, hydrogels, and anionic amphiphilic dendrons | controlled drug delivery, medical devices, tumor recurrence reduction, tissue engineering, wound repair, sealants for corneal lacerations, antibacterial agents, and cartilage tissue engineering scaffolds |

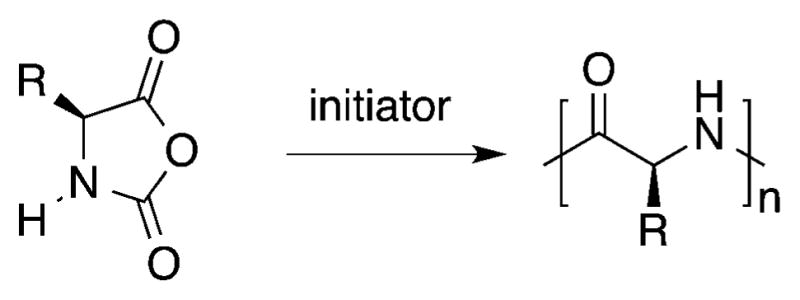

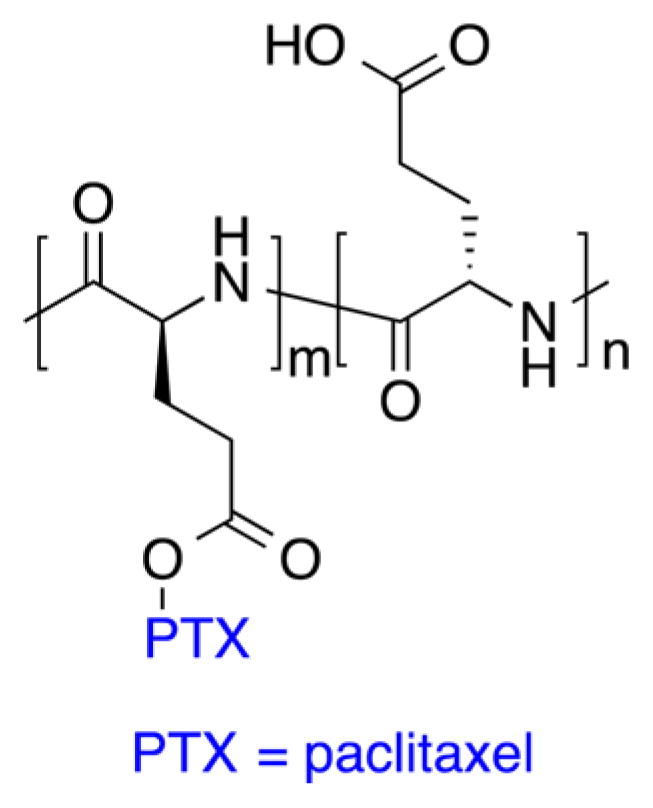

| natural amino acids | N-carboxyanhydride polymerization, genetic engineering, living systems, convergent dendrimer synthesis, divergent dendrimer synthesis, and solution or solid phase synthesis using coupling reagents (DCC, EDCI, BOP, oxalyl chloride, and pentafluoroesters) | linear poly(amino acid)s, polypeptide dendrimers, and tyrosine-based polycarbonates | hydrogels, dendrimers, and nanoparticles | drug delivery, gene delivery, surgical adhesives and sealants, and cortical neural probe carriers |

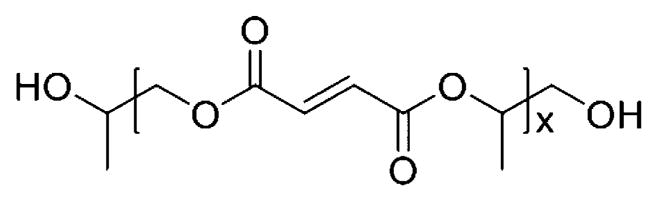

| fumarate | condensation to form a bis(hydroxypropyl) fumarate diester, followed by transesterification | poly(propylene fumarate) | viscous liquids and cross-linked networks | tissue engineering scaffolds, orthopedic implants, and drug delivery |

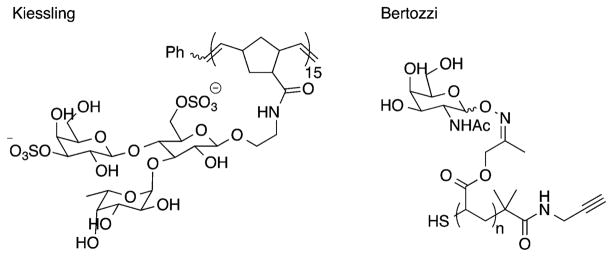

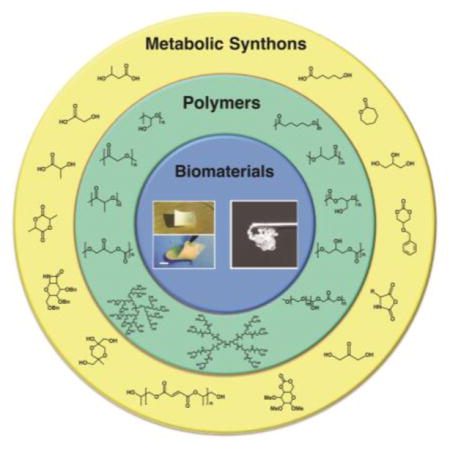

| saccharides | enzymatic catalysis, living systems, polycondensation, click-chemical polymerization (Huisen cycloaddition), organocatalyzed ring-opening polymerization, anionic ring-opening polymerization, ring-opening metathesis polymerization, and reversible addition–fragmentation chain transfer | linear polyesters, linear polyethers, poly(glycoamidoamine) s, poly(amidosaccharide)s, sugar-derived polycarbonates, and glycopolymers | micelles, nanoparticles, microparticles, and hydrogels | drug delivery, nucleic acid delivery, wound repair, tissue engineering, interactions with natural carbohydrate receptors, protein stabilizing agents, promotion/inhibition of biofilm formation, vaccine development, biosensing, and signal transduction studies |

2. HYDROXY ACID SYNTHONS

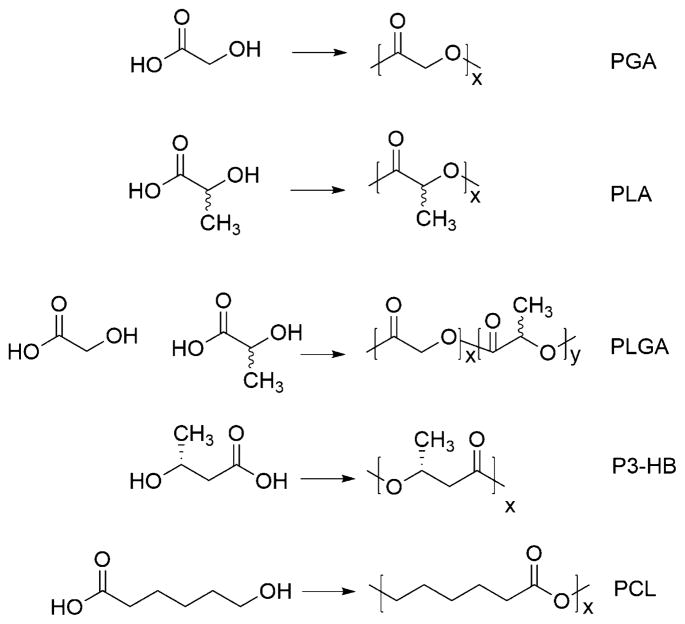

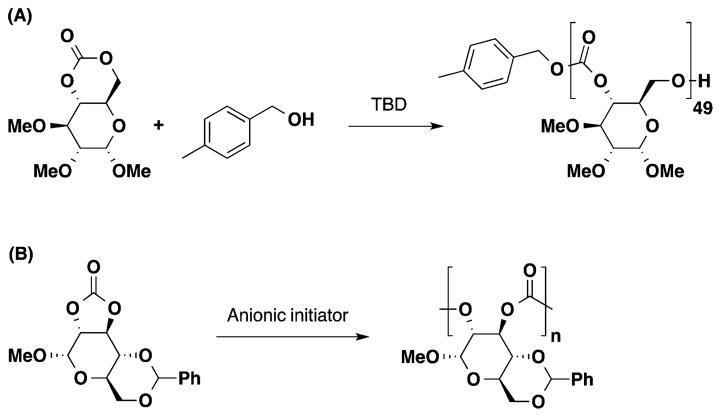

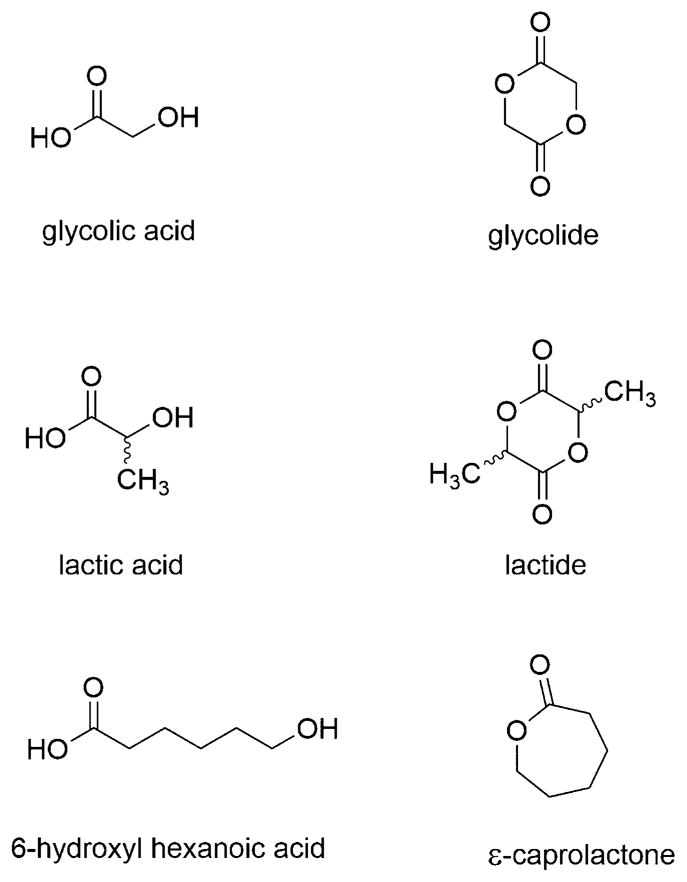

Hydroxy acids are aliphatic organic acids bearing a hydroxyl group and a carboxylic acid on each end of the molecule. Examples of common metabolic synthon hydroxy acids and their corresponding dimers or cyclized structures (in parentheses) are glycolic acid (glycolide), lactic acid (lactide), and 6-hydroxyhexanoic acid (ε-caprolactone) (Figure 1). These weak acids (pKa ranges from ~3 to ~ 5) are soluble in aqueous solution when they contain one to two methylene units separating the acid and hydroxyl functionality, and aqueous solubility decreases with an increasing number of methylene units. The first commercially available poly(hydroxy acid), poly(glycolic acid) (PGA), was developed and reported by Frazza and Schmitt at the former American Cyanamid Company in 1971,1 followed by linear polyesters of lactic acid (LA), GA:LA copolymers, and 6-hydroxyhexanoic acid, all of which are now common and widely used biomaterials. High molecular weight polymers of these hydroxy acids, in particular PGA, were introduced as biodegradable sutures in the late 1960s and early 1970s based on their safety profile, mechanical strength, and manufacturing processability.2–5 Success in sutures spurred the continued investigation of these materials for more advanced applications, such as controlled drug delivery systems,6–8 degradable tissue engineering scaffolds,9 and implantable glues.10

Figure 1.

Chemical structures of common hydroxy acids and their corresponding dimers or cyclized structures used for the synthesis of polyesters.

2.1. General

2.1.1. Hydroxy Acids in Metabolism

Cellular metabolism, a series of regulated enzymatic reactions that sustain life, is dependent on three major dietary sources of energy: carbohydrates, fats, and proteins.11 The premise of using metabolites as monomer units for the synthesis of biodegradable polymers is that the body is already equipped with pathways to eliminate downstream polymer degradation products. Therefore, the likelihood of generating a local toxic environment or initiating an inflammatory response is reduced. The representation of synthons in natural metabolic pathways is the subject of most college-level biochemistry textbooks. For example, lactic acid is an end product of glycolysis. The accumulation of lactic acid in muscle under anaerobic conditions is one cause of muscle fatigue. The transport of lactic acid to the liver feeds glyconeogenesis, thereby providing additional glucose to active muscles. This production-conversion feedback is known as the Cori cycle, and allows burden sharing of new energy source production between the muscle and liver.

GA is represented in the process of photorespiration, wherein a plant consumes oxygen and releases carbon dioxide, opposite to the more recognized photosynthesis. The process is a result of a complex interaction between the enzymes in plant chloroplasts, peroxisomes, and mitochondria. While GA is not actively involved in the metabolic pathways of humans, its consumption results in its metabolism by glycolate oxidase, and it is ultimately metabolized to oxalic acid or carbon dioxide.

The building block 6-hydroxyhexanoic acid is a substrate for alcohol dehydrogenase, wherein the primary alcohol at the 6-position is converted to an aldehyde, which is further converted by aldehyde dehydrogenase to form a diacid, a process known as ω-oxidation. The resulting 1,6-diacid (adipic acid) is conjugated to coenzyme A and ultimately enters the citric acid cycle as succinic acid or is eliminated from the body as adipic acid.

2.1.2. Structure and Reactivity

The synthesis of linear polyesters from GA, LA, and 6-hydroxyhexanoic acid by direct polycondensation is complicated by the competing formation of the 6-membered cyclic dimers, glycolide and lactide (or 7-membered ε-caprolactone), and by the difficulty in removing water. The polycondensation of these hydroxy acids creates two equilibria: dehydration to form the linear polyester and depolymerization to form the ring structures. In the absence of control over these competing equilibra, only low molecular weight polyesters (low tens of thousands) are obtained. Strategies to obtain high molecular weight polyesters with molecular weights on the order of 100 kDa by direct polymerization include, but are not limited to, melt/solid polycondensation, where a low molecular weight polymer is made by direct polycondensation, and then crystallized to the solid state, and heated to ~150 °C in the presence of a catalyst to form a large molecular weight polymer (~500 kDa) with high yield.12 Careful selection and screening of catalysts13 and azeotropic removal of water are required.14 These and other direct polycondensation routes are reviewed by Gupta and Kumar with a focus on poly(lactic acid) (PLA).15 The more common synthetic route to polyesters of this type is ring-opening polymerization (ROP), which is discussed in the following section.

2.2. Linear Polyesters

Cyclic dimers of GA and LA are produced on a manufacturing scale in a continuous process through vacuum distillation of the oligomers and purified by crystallization, although the specifics of each process vary greatly among manufacturers.16 The synthesis of ε-caprolactone (ε-CL) follows a two-step process: first, the production of a strong oxidizer, peracetic acid, followed by its use to oxidize cyclohexanone to make the final monomer.

Synthesis of these linear polyesters by ROP allows good control over the molecular weight, dispersity, and end group composition. Closed dimers of both LA and GA into 6-membered lactones, and ring closing of 6-hydroxyhexanoic acid into a 7-membered lactone, afford structures that readily polymerize in both the melt and in solution (Figure 2). The most common mechanism through which these cyclic monomers are polymerized is by coordination–insertion with tin octoate as the coordination catalyst. However, both cationic and anionic polymerization are reported, with over 100 catalysts identified for the polymerization of lactide alone.15

Figure 2.

Structures of poly(glycolic acid) [PGA], poly(D,L-lactic acid) [PLA], poly(D,L-lactic acid-co-glycolic acid) [PLGA], poly(3-hydroxybutyrate) [P3-HB], and poly(ε-caprolactone) [PCL].

Microbial routes of polyester synthesis are also reported. Of particular importance for the field of biomaterials are the poly(hydroxyalkanoate)s. These polyesters are synthesized by microbes in response to stress and starvation, generally accumulating as inclusion bodies when carbon sources exceed nitrogen sources.17 Biomass can be used as feedstock for the manufacture of poly(hydroxyalkanoate)s, and the polyesters are degradable in the environment, giving these materials a designation as “green” since they are not derived from petrochemicals, and can also be produced in plants.18 Because of their favorable stress/strain, thermal, and processing characteristics, the polymer can be used in the packaging industry.19 Medical applications of poly(hydroxyalkanoate)s are also described, and these polymers are used in tissue engineering,20 drug delivery,21 and medical devices.22 Modulation of the polyester characteristics is achieved by alteration of the feedstock, as well as by genetic manipulation of the microbe. The recent application of CRISPRi to engineer the metabolic pathways associated with poly(hydroxyalkanoate) synthesis is an exciting advance with the potential to fine-tune microbial gene expression and allow the production of tailored polyesters.23

Of particular importance for these polyesters is the ability to tune their degradation rates through engineering of their molecular architecture. Rapid degradation kinetics (i.e., days) is desirable for an application like pulmonary drug delivery;24 medium degradation kinetics (i.e., weeks) is desirable for an application like an absorbable suture, and longer degradation kinetics (i.e., years) is desirable for an application like a drug-eluting stent.25 Approaches to alter degradation rates include modulation of molecular weight, dispersity, crystallinity, monomer hydrophobicity or hydrophilicity, and end group characteristics (Table 2).

Table 2.

Design Characteristics for Modulating the Rate of Hydrolysis of Polyester Biomaterials

| parameter | increase degradation kinetics | decrease degradation kinetics |

|---|---|---|

| molecular weight | lower molecular weight broad dispersity | higher molecular weight narrow dispersity |

| crystallinity | highly crystalline matrix | amorphous matrix |

| monomer content | more hydrophilic | more hydrophobic |

| end group | more hydrophilic ionized | more hydrophobic end-capped |

2.3. Polyester Dendrimers

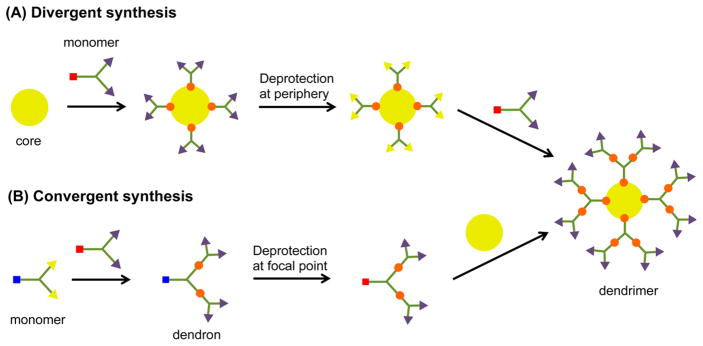

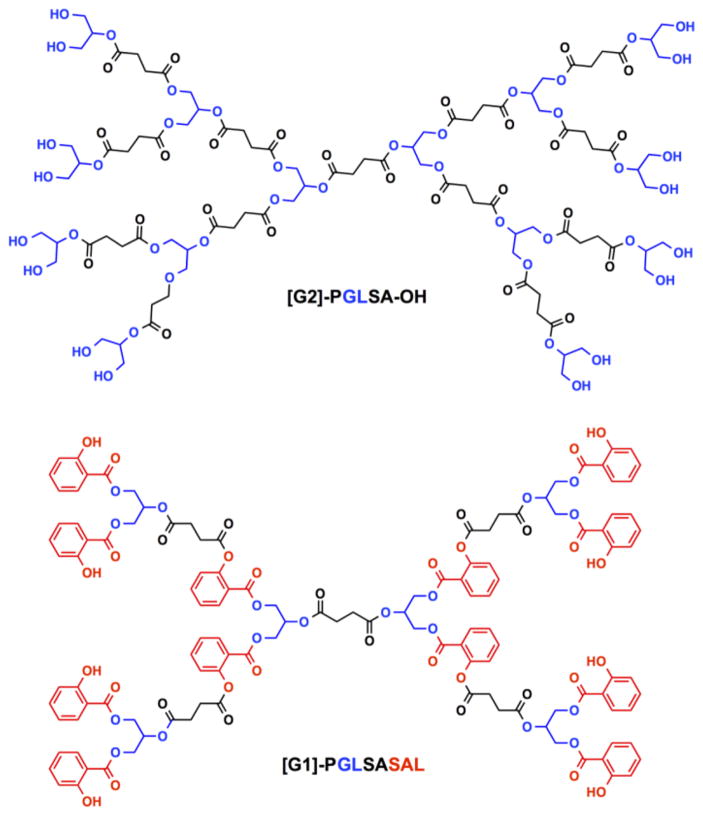

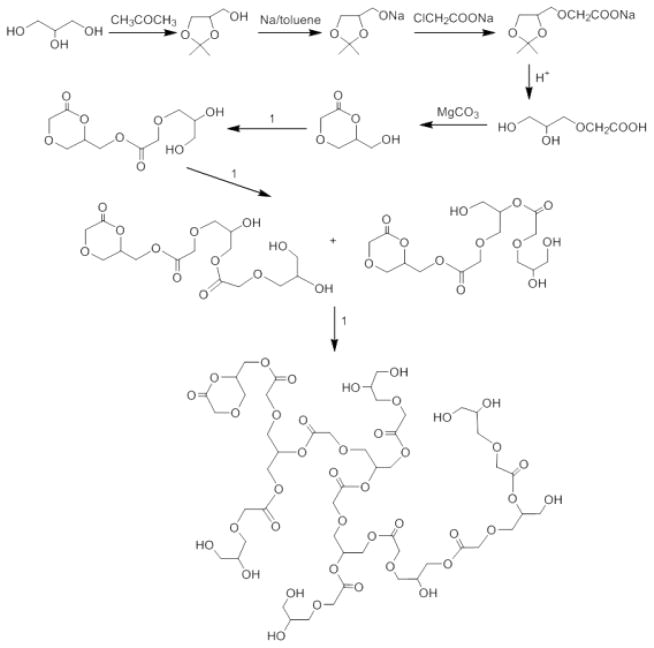

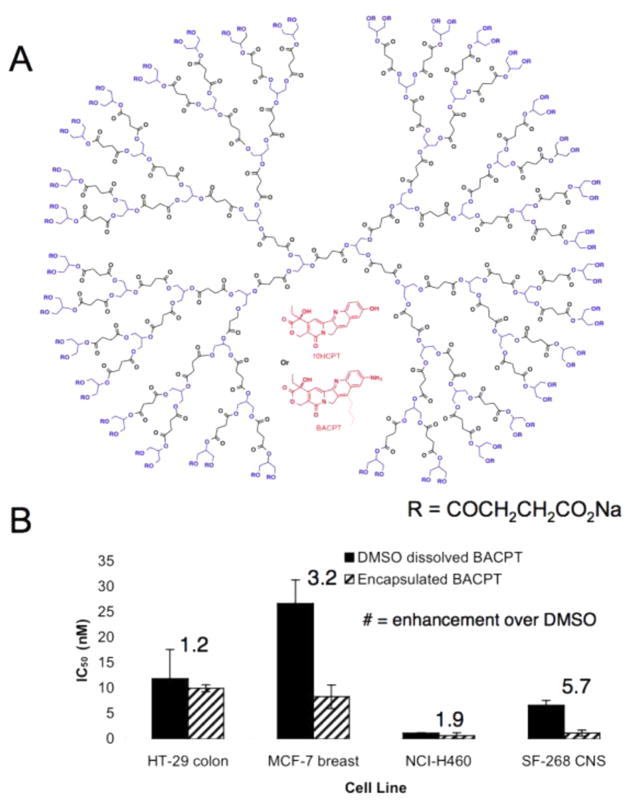

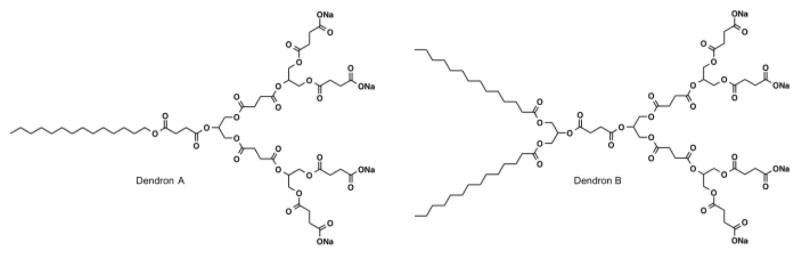

Dendrimers are three-dimensional (3D) globular nearly monodisperse macromolecules with low dispersities (Đ), composed of a central core from which are emitted branched repeating units (generations, Gn), and peripheral terminal groups that can be further functionalized for a desired application.26–30 The size, architecture, density, and surface groups of these macromolecules can be easily tuned during their synthesis, enabling a highly versatile platform for materials and biomedical research. Dendrimers are already used for a variety of applications, including drug delivery, gene transfection, tissue engineering, and molecular imaging.29 Among various dendritic structures being investigated for biomedical applications, polyester dendrimers based on metabolically derived synthons [e.g., LA and glycerol (GL), glucose, succinic acid (SA), LA and aspartic acid (AA), which are linked via ester groups] are of interest as promising biomaterials because they are biocompatible and biodegradable.31 Currently, these specific dendrimer formulations are being evaluated for drug delivery, tissue engineering, and wound repair.31–37

Dendrimers are synthesized by either a divergent (from core to surface) or a convergent (from surface to core) route, as depicted in Figure 3. Biocompatible and biodegradable polyester dendrimers based on metabolically derived synthons are one example of this class of materials, and these dendrimers are synthesized via one of the two approaches shown in Figure 3.

Figure 3.

Pictorial representation of dendrimer synthesis by (A) divergent and (B) convergent routes.

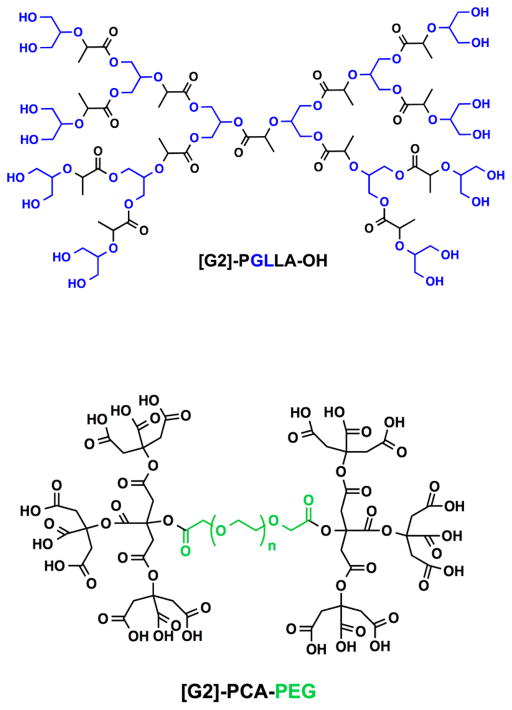

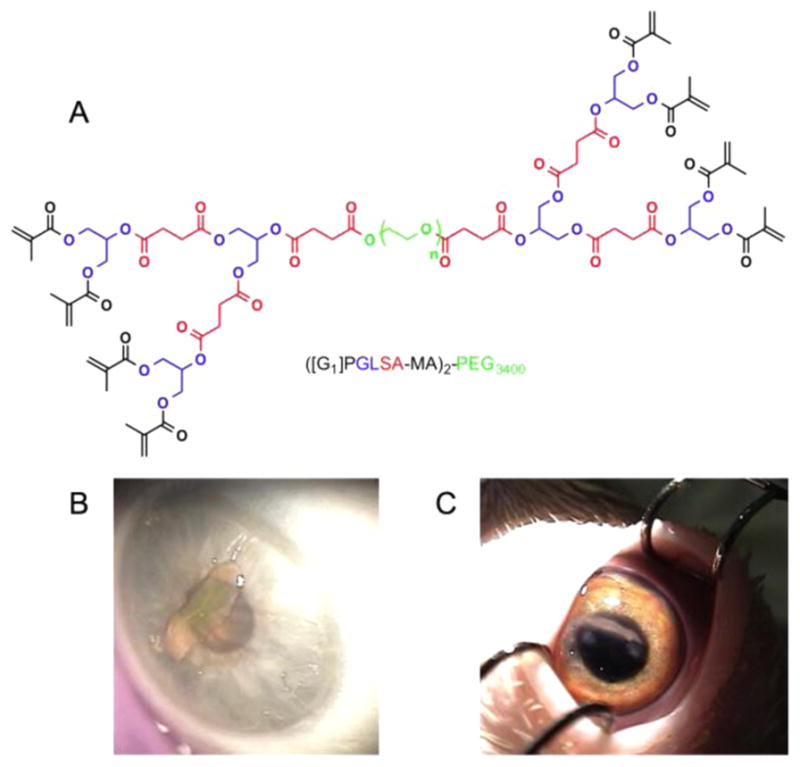

The divergent synthesis allows the growth of the dendrimer from a multifunctional core to the periphery by reacting it with a monomer unit, which possesses one reactive site and multiple protected groups, giving the first generation (G1) dendrimer (Figure 3A). Following this reaction, the protected groups on the monomer units of the G1-dendrimer are deprotected and subsequently reacted with another reactive monomer unit to generate a growing branching structure, in a stepwise fashion. Specifically, Grinstaff et al. used this strategy to synthesize GL and LA polyester Gn-dendrimers, namely Gn-PGLLAs, starting from a tetrafunctional G0-PGLLA–OH core (Figure 4).38

Figure 4.

Chemical structures of polyester dendrimers based on metabolically derived synthons from (top) lactic acid (LA, black) and glycerol (GL, blue) and (bottom) citric acid (CA, black) and poly(ethylene glycol) (PEG, green).

Each Gn is obtained in a two-step sequence: esterification of a benzylidene acetal-protected GLLA monomer with an unprotected Gn–1-PGLLA–OH dendrimer, followed by hydrogenolysis of the protecting-groups. At each sequence, the protected-dendrimers are purified by silica gel chromatography to remove unreacted monomers and coupling reagents. Nuclear magnetic resonance (NMR) spectroscopy monitored the formation of each successive generation by following the integration of the benzylidene and methyl proton groups of protected GL and LA, respectively. Fourier transform infrared (FT-IR) spectra of the deprotected dendrimers confirmed the presence of the hydroxyls via the O–H broad stretches, at around 3400 cm−1. Molecular weights of Gn dendrimers, ranging from 0.8 to 6 kDa with narrow dispersity, are described and confirmed by matrix-assisted laser desorption ionization mass spectrometry (MALDI-MS) and size exclusion chromatography (SEC) against polystyrene standards. The glass transition temperatures (Tg) of the dendrimers are generation and compositionally dependent and range from 19 to 31 °C and from −34 to −28 °C for the protected and deprotected structures, respectively.

Namazi and Adeli also used the divergent route for the synthesis of citric acid (CA)-based polyester dendrimers starting from a CA-PEG multifunctional core (Figure 4).39 The growth of the macromolecule is achieved by activating the Gn–1 dendrimer and subsequently reacting it with CA. The material is separated from the crude mixture by precipitation in diethyl ether. Gn-PCA-PEG dendrimers are purified by dialysis, and their structures were confirmed by 1H NMR and FT-IR spectroscopies. Interestingly, these dendrimers form thermoreversible hydrogels in the presence of water and viscosity measurements reveal a sol–gel transition temperature (Tsol–gel) above 37 °C (the G1 and G2-PCA-PEG dendrimers exhibited Tsol–gel of 40–45 °C and 50–55 °C at 5 wt %, respectively). The sol–gel properties and ability to synthesize various dendrimer generations allowed for facile drug encapsulation and tunable release properties from the hydrogel network.40

Another example based on the divergent synthetic approach was reported by Yeates et al. for the synthesis of aromatic polyester dendrimers based on 3,5-dihydroxybenzoic acid (3,5-DHBA).41 The DHBA synthon can be considered as an analog of the hydroxy acid synthon possessing an aromatic backbone, although the reactivity of the phenol and corresponding carboxylic acid are different than LA, for example.

Two- and three-branched initiator cores (i.e., hydroquinone, naphthalene-2,6-diol and phloroglucinol) are first coupled to either benzyl-3,5-dihydroxybenzoic acid (Bn-3,5-DHBA) monomers, using N,N′-dicyclohexylcarbodiimide (DCC) as the activating agent, or to 3,5-dibenzyloxybenzoyl chlorides (Bn-3,5-DHBCl) to obtain G1-polyester dendrimers.42,43 Next, hydrogenolysis of the benzyl groups and their subsequent reactions with the activated monomers afforded higher generation aromatic polyester dendrimers (up to G4) in good yield. 1H and 13C NMR spectroscopies and MALDI-TOF spectrometry confirmed the structures.

While the divergent route is used to synthesize a wide variety of dendrimers, incomplete reactions during the coupling step can lead to imperfect dendrimer structures. In order to limit these undesirable side reactions, the monomer units are usually added in large excess to the reaction mixtures, thus an additional purification step is necessary to remove all unwanted byproducts and reagents before any subsequent step. These limitations have led to the optimization of the divergent route, by using monomers and reagents that can be separated from the dendrimers by simple extraction or precipitation, thus avoiding the use of time-consuming flash chromatography. Moreover, the use of complementary functional groups within the monomer structures can afford high generation dendrimers in excellent yield.

The convergent strategy is another common approach for the synthesis of dendrimers and was developed to circumvent some of the problems with using the divergent strategy (Figure 3B). Defect-free dendrimers are obtained and successfully separated from byproducts using this approach. The convergent approach enables the construction of dendrons from the periphery toward the central focal point, followed by their subsequent reaction through their focal point with the polyfunctional core to generate the dendrimers. Additionally, the purification of the dendrons is simpler after each step because their structures and molecular weights differ significantly from the starting materials and reaction byproducts. Thus, a wide panel of reaction conditions can be used to generate different dendrimer structures. Despite the advantages of the convergent approach, it is still mainly used to obtain lower generation dendrimers because the synthetic coupling yields between the focal point of the large dendron and the next building block are reduced due to steric hindrance.

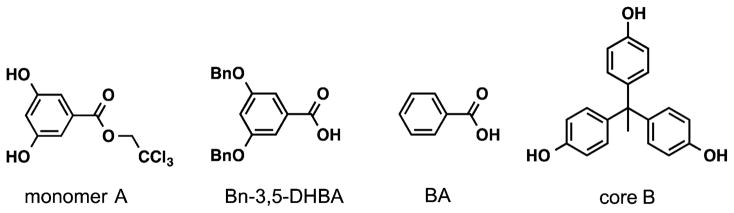

Fréchet et al. reported the first convergent synthesis of polyester aromatic dendrimers based on the naturally occurring 3,5-DHBA metabolite.42,43 The dendritic starting fragments are prepared by first coupling the monomer unit, 2,2,2-trichloroethyl-3,5-dihydroxybenzoate (A), with either activated benzoic acid (BA) or Bn-3,5-DHBA (Figure 5). The trichloroethyl ester of the G1-dendron is then activated by zinc in glacial acetic acid to afford the carboxylic acid, which is subsequently coupled with A to obtain the G2-dendron. Repetition of this two-step procedure affords higher generation dendrons, which upon reaction with the 1,l,l-tris(4′-hydroxyphenyl)ethane multifunctional core (B), generated the Gn-polyester dendrimers. Deprotection of the benzyl-protected dendrimers by catalytic hydrogenolysis generated hydroxyl groups on the surface, which can potentially be functionalized for any desired application. Flash chromatography after each step provided the dendrons and dendrimers in good isolated yields and purity. Integration of the methylene proton resonance of the dendron focal point and its comparison to other resonances in the spectrum allowed the confirmation of the dendritic structures and their generation number. Moreover, coupling of the dendrons to the polyfunctional core is easily detected by the appearance of the resonances in the NMR spectrum for the core structure. Similarly, the disappearance of the benzylresonances confirmed the complete deprotection of the dendrimers. FT-IR, MALDI-MS, elemental analysis, and SEC provided additional data that support the proposed structures and their purity. The composition of the surface functional groups affects the physical properties of the dendritic materials, and thus one can tailor the surface functionalization of the dendrimer for a given property. For example, benzyl-protected polyesters of 10.746 kDa molecular weight possess a Tg of 346 K, while the Tg is 474 K for the corresponding phenolic polyester.

Figure 5.

Chemical structures of monomer units and multifunctional core used in Fréchet et al. convergent synthesis of polyester-dendrimers.42,43

Do et al. also reported the convergent synthesis of 3,5-DHBA-polyester dendrimers, similar to the type prepared by Fréchet et al., where peripheral phenolic groups are further functionalized with chromophore units, and the materials were evaluated for their optical properties.44–46

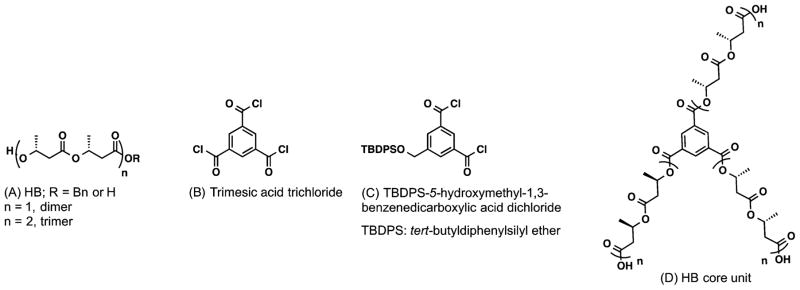

Amrein et al. described the convergent synthesis of (R)-3-hydroxy-butanoic acid (HB)- and trimesic acid (TMA)-derived polyester dendrimers, starting from the benzyl-protected dimer and tetramer of HB (A), TMA-trichloride (B), and tert-butyldiphenylsilyl ether-protected 5-hydroxymethyl-1,3-benzenedicarboxylic acid dichloride (C) (Figure 6).47 For the construction of the branching dendritic units, Bn-HB (A) is first acylated with compound C to obtain the Bn-G1 dendron. After the subsequent deprotection of benzyl-groups, activation of the carboxylic acids and their reaction with the benzyl-protected G1-dendron, the benzyl-G2 dendron is obtained. Finally, for the assembly of G1/G2 dendrimers, desilylated Bn-G1/G2-dendrons are coupled with a trifunctional HB core (D), respectively. The dendrons and dendrimers were characterized by FT-IR, 1H, and 13C NMR spectroscopies, optical rotation, MALDI-MS spectrometry, and elemental analysis. Their biodegradability, evaluated in the presence of poly(3-hydroxybutyrate) depolymerase (PHB-depolymerase) and compared to a standard substrate, the linear tetrameric HB (A; n = 2, R = H), showed that deprotected dendrimers with dimer-HB units are better candidates for the hydrolase than their respective benzyl-ones, whereas the simple dimer-HB (A; n = 1, R = H) did not decompose in the presence of the enzyme. Similar to the standard substrate, all dendrimers with tetrameric-HB units are hydrolyzed by the enzyme. In addition, other enzymes such as esterase, lipase, and protease degrade these dendrimers.

Figure 6.

Chemical structures of monomer and core units used in Amrein et al. convergent synthesis of polyester dendrimers.47

2.4. Hyperbranched Polyester Structures

Hyperbranched polymers display highly and randomly branched 3D globular architectures, which contain more defects in their structures than the previously described monodisperse and uniformly branched dendrimers. These polymers possess a branching degree (DB) (i.e., the mole fraction of fully branched monomers in the polymer structure) lower than one (generally, 0.4–0.6) and high dispersities (Đ > 3). Importantly, the advantages of dendritic structures over the linear ones, such as low molecular entanglement, high solubility, low viscosity, and highly reactive functional groups, are also exhibited in hyperbranched polymers. Moreover, hyperbranched polymers are synthesized in one-step reactions, whereas dendrimers are constructed in step-by-step sequences, which often require protection/deprotection of the monomers/dendrons before subsequent reaction with another reactive one and purification of the product after each step. Therefore, despite the irregular structures of hyperbranched polymers, their relative ease of synthesis is advantageous for applications requiring highly functionalizable globular macromolecules. Hyperbranched polymers are currently of significant interest in nanoscience and nanotechnology, as well as in biomedical research. Potential applications of these materials include their use as components for coating, blends and sensors, drug delivery, gene transfection, and bioimaging.48–51 Hyperbranched polyesters are an important subclass of hyperbranched polymers, composed of either aliphatic or aromatic monomer units, linked together by ester groups. These structures are extensively studied in the literature for their use as additives, rheology modifiers, and components for blends, coatings, and sensors.52–54 However, hyperbranched polyesters are surprisingly less explored in the biomedical field, with commercially available Boltorns Hx (x = 20, 30, and 40), based on 2,2-dimethylol propionic acid (Bis-MPA), being the most widely used hyperbranched polyesters at present.50,55 Today there are no formulations of hyperbranched polyesters, based on naturally occurring metabolites, currently in clinical use. The challenges associated with development of such a product include the reproducibility of the synthesis and control measures to ensure the quality of the hyperbranched polyester.

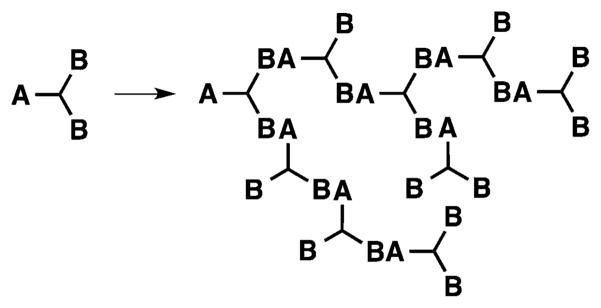

Hyperbranched polyesters are generally synthesized via one of two approaches: polymerization of an ABx monomer or polymerization of two types of monomers or a monomer pair, each method having advantages and disadvantages.48 The first approach can be divided into four subclasses, depending on the reaction mechanism: (1) polycondensation of ABx monomers, (2) self-condensing vinyl polymerization, (3) self-condensing ROP, and (4) proton-transfer polymerization. The second approach includes two main subclasses: (1) polymerization of A2 and Bx (x > 2) monomers and (2) in situ generation of one type of ABx intermediate due to the nonequal reactivity of specific functional groups in monomer pairs, leading to hyperbranched polyesters. A broad range of hyperbranched polyesters, specifically those based on naturally occurring metabolites, are reported via the polycondensation of ABx monomers, which was first theoretically described by Flory in the early 1950s. Therefore, this paragraph will solely focus on this type of polymerization. Flory predicted that ABx monomers, where A is a single functional group of one type and B is two or more of another type, can react with each other, in a single step, to form highly branched 3D polymer structures, free of cross-links (Figure 7).56 The polycondensation of the reactive monomers is activated by the presence of a catalyst or after activation of A and B monomer units via a thermal, chemical, or photochemical process and leads to polydisperse and irregular hyperbranched structures.

Figure 7.

Flory’s polycondensation of ABx monomers (where x ≥ 2) to form hyperbranched polymers. Adapted with permission from ref 56. Copyright 1952 American Chemical Society.

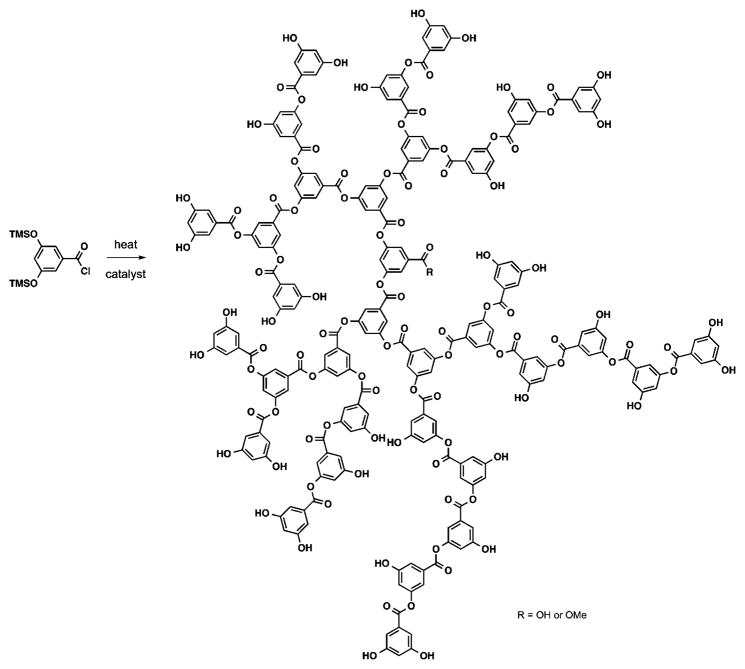

Fréchet et al. reported the first one-step synthesis of hyperbranched polyesters based on metabolically derived synthons by heating (trimethylsiloxy)benzoyl chlorides in the presence of a catalyst (Figure 8).57–59 This hyperbranched aromatic polyester is based on DHBA. This synthetic strategy afforded high mass weighted molecular weight DHBA-derived polymers (Mw = 30–65 kDa; Đ = 1.9–2.5) with irregular dendritic structures in a 60–88% yield after precipitation in methanol. Moreover, these structures possess free phenolic groups both throughout and at the periphery of the macromolecules, which can be further functionalized with various end groups to tune the physicochemical properties of the materials. The hyperbranched aromatic polyesters are soluble in most common organic solvents. 1H and 13C NMR spectroscopy confirmed their structures with determination of DB in the range of 0.55–0.60. The polymers with free phenolic groups possess a Tg of 190 °C and are stable up to 400 °C, with about 10 and 50 weight percentage (wt %) loss at 435 and 560 °C, respectively.58 These results are similar to those obtained with linear polyesters based on DHBA, demonstrating that the branching structure and the multiple functional groups at the periphery afford a minimal effect on the thermal properties of the polymers. However, further functionalization of the phenolic groups influences the thermal properties of the macromolecules, which are dependent on the nature of the side chains. For example, when flexible adipic acid chains are coupled to the phenolic hydroxyl groups, the Tg dropped to 6 °C, whereas when the phenolic hydroxyl groups are silylated with t-butyldimethyl silyl groups or esterified with acetyl chlorides, the Tg increases to 103 and 133 °C, respectively, due to the rigidity and polarity of the protecting groups.59 Additionally, the thermal decomposition temperatures (Tdecomp) of the hyperbranched aromatic polyesters also depend on the nature and composition of the side chains. Two Tdecomp are observed for the functionalized polymers, one in the range of 280–400 °C which corresponded to the wt % loss of the side chains and the second in the range of 400–545 °C, attributed to the remaining polymeric structure.59

Figure 8.

Synthesis of hyperbranched aromatic polyesters by Fréchet et al. Adapted with permission from ref 58. Copyright 1991 American Chemical Society.

Similarly, Mourey et al. reported the synthesis of DHBA-derived hyperbranched polyesters starting from 3,5-diacetoxybenzoic acid (3,5-DABA).60 The melt polymerization proceeded without any catalyst, at T < 250 °C, and afforded high Mw (30–500 kDa) amorphous polymers, with high Đ (6.3–30.2), and Tg in the range of 147–160 °C. Mild acidic hydrolysis of the dendrimer removes 89% of the acetate groups to afford a phenolic-hyperbranched aromatic polyesters with Tg around 200 °C, and allowed the measurement of DB, which equaled 0.5. Additionally, copolymerization of DABA with either a nonbranching AB or a monofunctional A monomer, proceeded successfully and afforded hyperbranched aromatic polyesters with characteristics almost similar to those of the homopolymers; however, the determination of DB was not possible by 1H NMR spectroscopy for this sample. Other variants of hyperbranched aromatic polyesters based on DHBA monomers and possessing different physicochemical properties are also described by Luebbers et al.,61 Hill et al.,62 and Ramakrishnan et al.63

Due to their highly compact and branched structures, hyperbranched aromatic polyesters often exhibit extremely low viscosities, high solubilities in most organic solvents, and interesting rheological properties as compared to the linear aromatic polyesters. However, relatively few synthetic routes are reported for the formation of these structures, and most of the generated polyesters are insoluble in aqueous solutions and/or require additional steps of modification/functionalization to control their solubility and biocompatibility,50,55 limiting their use in vivo. Additionally, their complete characterization, which is critical for understanding their physicochemical properties and for identifying potential applications, is challenging. Hyperbranched polyesters, which can be easily metabolized into degradable components due to the hydrolysis of ester backbones within their structures, are less explored.50

2.5. Hydroxy Acid Synthon Summary

Since the first synthesis of high molecular weight poly(hydroxy acid)s [e.g., poly(glycolic acid)s] and their translation to the market place as sutures for use in the clinic, these polymers continue to be widely used and investigated. However, linear poly(glycolic acid), poly(lactic acid), and poly(caproic acid) possess several limitations such as control of molecular weight, chemical modification or derivatization potential, alteration of their thermal properties, and limited solubility. Consequently, significant research efforts toward new copolymers with other metabolite or nonmetabolite synthons [e.g., glycerol and poly(ethylene glycol] and polymer architectures (e.g., linear vs dendrimer) are underway, with several notable successes reported to date. Moreover, the development of new polymerization routes, starting from a variety of functionalized monomeric structures, will allow the preparation of new biocompatible and biodegradable hyperbranched aromatic or aliphatic polyesters based on hydroxy acids and enable the understanding of how their structural features impact the thermal, mechanical, degradation, and solution properties of these materials. These advances will expand their use in a variety of biological applications such as drug delivery, bioimaging, and tissue repair.

3. DIHYDROXYACETONE SYNTHONS

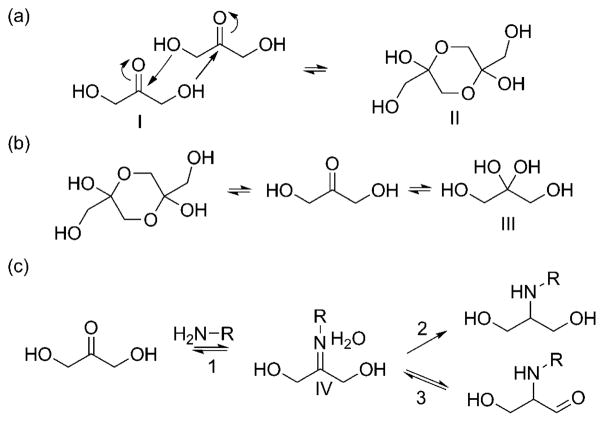

Dihydroxyacetone (DHA, I, Figure 9a), a three-carbon sugar, is an important metabolite in humans, yeast, bacteria, and plants. The awareness of DHA, sometimes called “dioxyacetone,” in carbohydrate metabolism dates back to the early 1900s.64,65 One of the first proposed therapeutic applications of DHA was for the treatment of diabetes. Rabinowitch published reports on the ability of DHA to reduce the dosage of insulin needed by diabetics.64,66–68 It was not until the late 1950s, however, that DHA gained interest for its first major commercial use: sunless tanning lotions. Eva Wittgenstein noticed that when children accidentally “spit up” an orally administered solution of DHA onto their skin, pigmentation occurred.69 While it had been previously known that sugars react with primary amines to form brown pigments known as melanoidins, a reaction discovered by Maillard in 1912,70 and more mechanistically detailed by Hodge in 1953,71 it was Wittgenstein and Berry who drew a connection between the browning in foods and the browning of skin from DHA.72 They suggested that the mechanism through which DHA functions as an artificial tanning lotion is a reaction between the carbonyl group of DHA and the basic groups of amino acids in proteins present on the surface of the skin.72,73 To date, DHA-based artificial tanning lotions are FDA approved for topical use and remain a popular selling item. Although, some controversy has arisen over the unknown long-term health effects of the inhalation of spray tan products, as well as postapplication UV exposure and the generation of harmful reactive oxygen species,74–76 DHA-based artificial tanning lotions continue to be accepted as a safe alternative to UV-based tanning.77–79 A brief review on the safety concerns of DHA-based sunless tanners is covered by Pagoto.77

Figure 9.

(a) DHA dimerization mechanism.89 (b) Dissociation of DHA dimer in aqueous solutions. (c) (1) Reversible reaction of DHA with a primary amine to form a Schiff base, (2) reductive amination to a secondary amine, and (3) Heyns rearrangement. Nomenclature: I, DHA; II, DHA dimer; III, gem-diol (DHA hydrate).

DHA’s reactive ketone functionality, two α-hydroxy groups, and metabolic involvement are key reasons why this synthon is of continued interest. From a topical standpoint, DHA shows potential as a treatment for proliferative skin diseases such as psoriasis and eczema, a cosmetic solution to the masking of vitiligo, and as an ingredient for controlled release mosquito-repellent formulations.80–84 DHA has been studied for internal use in diet formulations as a method to prolong muscle endurance (oral LD50 in rats is >16,000 mg/kg) and also as a preventative for cyanide poisoning.79,85–87 In this section, we will cover macromolecules that are synthesized from DHA and their intended applications.

3.1. General

3.1.1. Dihydroxyacetone Phosphate in Metabolism

As mentioned above, the premise of using metabolites as monomer units for synthesis of biodegradable polymers is that the body is already equipped with pathways to eliminate downstream polymer degradation products. The natural form of DHA in metabolism is dihydroxyacetone phosphate (DHAP). Once DHA enters the bloodstream, it can be phosphorylated by DHA kinases and entered into a metabolic pathway if not otherwise eliminated through natural disposal of excess or foreign material.88

Glycolysis, the breakdown of glucose for energy, is the most well-known source of DHAP in the body. DHAP, as well as the structural isomer glyceraldehyde-3-phosphate, are generated during the initial “energy consumption” stages of glycolysis, which is followed by a series of reactions resulting in pyruvate and a net positive production of ATP: the cellular “energy currency.” DHAP is also an intermediate in the breakdown of other common dietary sugars including fructose, mannose, and galactose. During times of starvation, when sugar supply is low, the liver will perform gluconeogenesis, a pathway in which glucose is synthesized so that it can be released into the bloodstream and sent to necessary organs such as the brain. DHAP plays an important role in gluconeogenesis as the pathway operates much like a reverse glycolysis cycle, requiring several of the same intermediates.11

In addition to carbohydrate metabolism, DHAP is often involved in the storage of lipids. DHAP is a precursor to the glycerol backbone of triglycerides, the major method of energy storage in the body. DHAP is first generated through glycolysis before use in triacylglycerol synthesis, thus being one of the many molecules that make metabolic processes interdependent. 11

3.1.2. Structure and Reactivity

Pentose and hexose sugars, such as fructose and glucose, exist as 5- or 6-membered rings due to intramolecular nucleophilic addition reactions between their carbonyl and hydroxyl groups. As a triose, DHA cannot react intramolecularly to form an energetically favorable ring. DHA instead reacts intermolecularly to form a hemiacetal dimer, the commercially available form of DHA, as shown in Figure 9a.89 Davis observed that in aqueous solutions the dimer dissociates into ketone and gem-diol forms (Figure 9b).90 Lyophilization of a stirred aqueous solution of dimer can be used to obtain a solid form of the keto-monomer.90,91 Davis also discovered that in solution, the ketone and hydrate exist in a 4:1 ratio, respectively, at room temperature.90 Infrared and nuclear magnetic resonance studies on DHAP indicate that the ketone:hydrate ratio is temperature dependent with a trend for increasing ketone content with increasing temperature.92

A key feature of DHA is the carbonyl group, which can react with primary and secondary amines. Reactions of DHA with amino compounds are of interest in several diverse fields including biomedical materials, enzyme mechanism determination, and cosmetics.93–96 When a primary amine reacts with the ketone, an imine is formed, commonly known as a Schiff base (IV, Figure 9c). The reaction is reversible (1, Figure 9c) but can be made irreversible through reductive amination with a reducing agent such as sodium cyanoborohydride (2, Figure 9c).93,97 A third possible outcome following imine formation is a Heyn’s rearrangement (3, Figure 9c): a presumed step in a series of rearrangements and reactions leading to Maillard-type products and browning.98,99 Precise reaction mechanisms leading to melanoidins are difficult to confirm as the Maillard reaction is known to be highly dependent on the specific amine reagent, pH of solution, temperature, and various other reaction conditions.100,101

The high chemical reactivity of the carbonyl group in combination with the ability of DHA to possess multiple forms in solution limits the number of polymerization conditions and catalysts that can be applied to DHA. In this next section, we cover several synthetic procedures used to successfully synthesize polycarbonates and poly(carbonate-esters) of DHA.

3.2. Linear Polycarbonates

3.2.1. Ring-Opening Polymerization

Ring-opening polymerization (ROP) is a highly effective and widely used technique to generate polyesters, polycarbonates, polyamides, polyethers, and others.102 Fine tuning of the ratio between cyclic monomers, catalysts, and initiators affords controlled syntheses of high molecular weight polymers with low PDIs, as well as reproducible thermal and mechanical properties. Polycarbonates, in particular, are of interest in biomedical applications due to their strength, biodegradability, and versatility. For example, various polycarbonate materials are receiving considerable attention for the development of controlled drug delivery systems103–107 and regenerative medicine.108–110 ROP is among the most widely used techniques for generating polycarbonates. Song et al. and Zhang et al. recently reviewed a number of cyclic carbonates used in the ROP of aliphatic polycarbonates as well as their biomedical applications.111,112

Cyclic ketone-protected carbonate derivatives of DHA are used to synthesize homopolymers, random copolymers, and diblock copolymers via ROP with a variety of catalyst/initiator combinations. This discussion focuses on the synthesis of cyclic DHA derivatives, catalysts used in the ROP of DHA-based polymers, postpolymerization modification, polymers synthesized through these methods, and applications of the reported polymers.

3.2.2. Ketone Protection

DHA is commercially available as a dimer, which is transformed into a stable monomeric form for subsequent polymerization. The most common methods to generate DHA-based macromolecules involve protection of the reactive ketone group. Ketone protection poses two major advantages: (1) dimerization is no longer feasible, enabling a pure monomeric derivative of DHA to be obtained and (2) the likelihood of unwanted side reactions decreases, offering a greater number of plausible starting materials and catalysts.

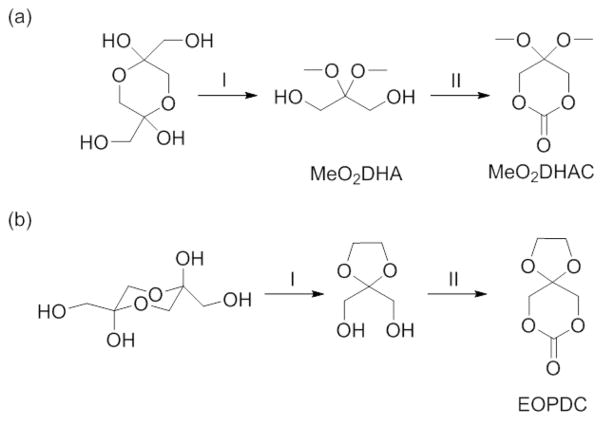

Two cyclic ketone-protected DHA derivatives are used for ROP: 2,2-dimethoxypropylene carbonate (MeO2DHAC, Figure 10a)93 and 2,2-ethylenedioxypropane-1,3-diol carbonate (EOPDC, Figure 10b).113,114 MeO2DHAC possesses a dimethoxy-acetal protecting group, whereas EOPDC contains a cyclic acetal. The synthesis of MeO2DHAC occurs in two stages as shown in Figure 10a. In the first stage, dimethoxy-protected DHA monomer, 2,2-dimethoxy-propane-1,3-diol (MeO2DHA, Figure 10a), is synthesized by combining the DHA dimer with trimethylorthoformate and p-toluenesulfonic acid in methanol. Following treatment with sodium carbonate, the product is isolated via a number of different purification procedures from column chromatography,115 to distillation,116 or recrystallization from diethyl ether.93 We found that purification by crystallization is easily amendable to large batches, generating significant quantities of material, but also has lower overall yield and can be difficult to coax into the solid state from the oil. The second stage in MeO2DHAC synthesis is the cyclization of MeO2DHA. Three different methods are presented in the literature to prepare the cyclic carbonate. Putnam et al. reported the successful use of the common reagent triphosgene, which involves addition of the reagent to a stirring solution of MeO2DHA, pyridine, and dichloromethane at −70 °C, followed by reaction at room temperature.93 Zhuo et al. showed that the reaction could be successfully carried out entirely at room temperature.117 Putnam et al. also reported a second synthetic method that is attractive, owing to the increased simplicity in the purification procedures. The reaction utilizes an alternative organochloride, ethyl chloroformate, in tetrahydrofuran solvent with triethylamine as the organic base. Purification is accomplished through paper filtration and recrystallization in diethyl ether as opposed to aqueous/organic extraction and flash chromatography.93 Waymouth et al. demonstrated that oxidative carbonylation is also an effective method to generate the cyclic carbonate. Their method uses the palladium-based reagent (neocuproine)Pd(OAc)2 and offers increased safety compared to a phosgene-type reagent.118 In the procedure, MeO2DHA is added to a stirring solution of (neocuproine)Pd(OAc)2 and sodium dichloroisocyanuric acid in acetonitrile. The reaction occurs at 35 °C inside a vessel that is vented and pressurized with carbon monoxide, both before and after diol addition.118 All three methods are adequate synthetic techniques that generate MeO2DHAC in satisfactory yields.

Figure 10.

(a) Synthetic scheme to MeO2DHAC. I. Trimethyl orthoformate, p-toluenesulfonic acid, and methanol, followed by sodium carbonate. II. Performed through three different methods involving trisphosgene,93 ethyl chloroformate,93 or oxidative carbonylation. 121 (b) Synthetic scheme to EOPDC. I. p-toluenesulfonic acid, glycol, and benzene. II. triphosgene, pyridine, and dichloromethane.113 Figure 10b is adapted from ref 113, with permission from the Chinese Chemical Society.

Finally, Zhuo et al. introduced a cyclic-acetal protecting group to the field of DHA-based polymers as shown in compound EOPDC (Figure 10b). Both a two- and four-step process are reported for generating EOPDC.113,114 The more simplistic two-step process is described in Figure 10b. It should be noted that unlike polymers of MeO2DHAC, which are deprotected and studied in their ketone-containing form, the focus of polymers derived from EOPDC in the current literature is on their ketone-protected form.

3.2.3. Catalysts

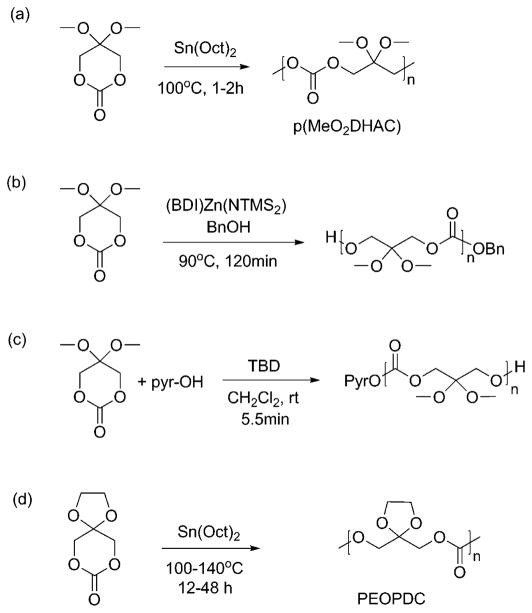

Several catalysts are employed for the polymerization of MeO2DHAC. The first reported synthesis of p(MeO2DHAC) (Figure 11a) is described by Putnam et al. using the catalyst stannous octoate, which afforded molecular weights of approximately 8–37.5 kDa, as determined by gel permeation chromotography.93 Zhuo et al. studied variations on reaction temperature, time, and monomer:catalyst ratios to identify conditions that give molecular weights up to 138.2 kDa.117

Figure 11.

Example syntheses of protected-DHA homopolymers performed by: (a) Putnam et al.,93 (b) Guillaume et al.,119 (c) Waymouth et al.,121 and (d) Zhuo et al.114

A drawback of the method reported by Putnam et al. is its reliance on trace atmospheric moisture as a polymer initiator. Guillaume and co-workers investigated alternative catalyst systems, which would yield more control over polymer molecular weight. Guillaume et al. found that dimethoxyacetal-protected DHA homopolymers can be synthesized with molecular weights as high as 70.2 kDa via an “immortal” ROP with the zinc complex [(BDI)Zn(NTMS2)] using an alcohol initiator (Figure 11b).119 Guillaume et al. additionally tested several organocatalysts to promote the use of “green” catalytic systems where concerns over trace toxic metals in final products could be eliminated.119,120 Catalysts 2-tert-butylimino-2-diethylamino-1,3-dimethylperhydro-1,3,2-diazaphosphorine (BEMP), 4-N,N-dimethylaminopyridine (DMAP), and 1,5,7-triazabicyclo-[4.4.0]dec-5-ene (TBD) were all shown to be active in the synthesis of dimethoxy protected DHA polymers.119,120 Waymouth et al. further investigated the use of organocatalysts in ROP of MeO2DHAC by evaluating 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), 1-(3,5-Bis-(trifluoromethyl)phenyl)-3-cyclohexyl-2-thiourea (TU), and (−)-sparteine as well as TBD.121 TBD is the most efficient organocatalyst reported in their study, as concluded by a monomer conversion of 95% during only 5.5 min of reaction time (Figure 11c).121 A summary of catalysts, reaction conditions, and results from syntheses of MeO2DHAC homopolymers are shown in Table 3. Copolymerizations of MeO2DHAC with poly(ethylene glycol) (PEG),122 lactide,123 ε-CL,121 and trimethylene carbonate (TMC)124 are also reported using the catalysts listed in Table 3, thus broadening the compositions and properties attained with DHA-based polymers.

Table 3.

Catalysts Used in Polymerization of MeO2DHAC

| catalyst | T (°C) | t (h) | molecular weight (kDa) | Đ | ref |

|---|---|---|---|---|---|

| metal-based catalysts | |||||

| Sn(Oct)2 | 100 | 1–2 | 8–37.5a,d | 1.35–1.5 | 93 |

| Sn(Oct)2 | 110–140 | 24 | 14.3–138.2b,e | 1.31–1.91 | 117 |

| (BDI)Zn(NTMS2) | 60, 90 | 1–2 | 3–70.2a,e | 1.12–1.79 | 119 |

| organocatalysts | |||||

| BEMP | 90 | 3 | 14–14.3a,e | 1.53, 1.66 | 119,120 |

| DMAP | 90 | 5.5 | 6.8a,e | 1.23 | 119 |

| TBD | 90 | 3 | 14.1a,e | 1.71 | 119 |

| TBD | RT | 5.5 (min) | 6.3c,e | 1.55a | 121 |

| DBU+TU | RT | 0.55, 1.17 | 7.5 and 31c,e | 1.20, 1.24a | 121 |

| (−)-sparteine + TU | RT | 7–25 | 5.8–28c,e | 1.11–1.18a | 121 |

GPC, THF, and polystyrene standards.

GPC, chloroform; no standards listed.

NMR.

Mw.

Mn.

Zhuo and co-workers first reported polymers of the cylicketone-protected DHA (Figure 11d).114 The polymer, poly-(2,2-ethylenedioxy-propane-1,3-diol carbonate) (PEOPDC), can be synthesized using two separate catalysts: stannous octoate [Sn(Oct)2] and aluminum isobutanoxide [Al(OiBu)3]. The use of stannous octoate resulted in higher molecular weights and percent yields with a reported range of 31.9–55 kDa and 79.3–92.6%, respectively.114 Copolymerizations of EOPDC with lactide,125 caprolactone,126 and 1,4-dioxane-2-one127 are also reported using stannous octoate as a catalyst.

3.2.4. Ketone Deprotection

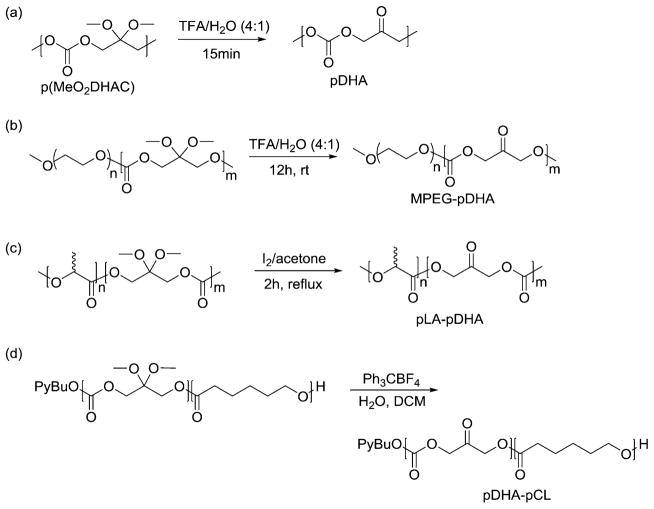

To date, three methods are established for the deprotection of dimethoxy-acetal protected dihydroxyacetone macromolecules. Putnam et al. demonstrated that the ketone functionality could be recovered after treatment with a trifluoroacetic acid (TFA)/water solution (Figure 12a).93 Deprotection >95% is possible; however, the authors targeted 85% to maintain polymer solubility for structural characterization. 93 Putnam et al. showed that this method is also effective for diblock copolymers of DHA and PEG (Figure 12b) and that the acidic nature of the protocol does not result in degradation of the polymer backbone.122

Figure 12.

Synthetic methods of dimethoxy-acetal deprotection in various DHA-based polymers demonstrated by: (a) Putnam et al.,93 (b) Putnam et al.,122 (c) Putnam et al.,123 and (d) Waymouth et al.121 Figure 4d was reprinted from ref 121. Copyright 2012 American Chemical Society.

While polymer degradation is not observed in these specific cases, Putnam et al. investigated an anhydrous deprotection protocol to reduce concern for DHA-based polymers containing additional acid-hydrolyzable bonds.123 They found that a deprotection procedure developed by Hu et al. in which ketal containing compounds are refluxed in an iodine/acetone solution successfully afforded poly(carbonate-esters) of DHA and lactic acid (pLA-pDHA, Figure 12c).123,128 The extent of deprotection to afford the ketone polymer influences polymer solubility. Increased ketone content (i.e., DHA content) decreases solubility in organic solvents like acetone, and therefore, polymers high in DHA content precipitate from solution prior to reaction completion. Despite this challenge, ≥80% deprotection is possible for all of the polymers tested, encompassing a range of 15–100% DHA content.123

Waymouth et al. demonstrated the success of triphenylcar-benium tetrafluoroborate in the deprotection of poly-(carbonate-ester) copolymers of DHA and ε-CL (pDHA-pCL, Figure 12d).121 Similar to pLA-pDHA, polymers high in DHA content precipitated from solution during reaction; however, complete deprotection was still observed and reported. Also, the procedure requires only a small quantity of water (one equivalent to each MeO2DHAC unit) compared to the TFA-based method reported by Putnam et al., thereby offering a second route by which DHA-based polymers can be deprotected with decreased probability for hydrolytic degradation. 93,121

3.2.5. Direct Esterification

While ROP affords a large number of possibilities to synthesize DHA-based polymeric materials, protection of DHA is time-consuming. Ketone protection generally takes several days depending on the desired level of purity of the final product and generates low yields. In 1969, Schrek et al. and Lasslo et al. showed that esters of DHA which retain the ketone functional group can be synthesized using acyl chloride compounds, such as undecanoyl chloride, in the presence of pyridine.84,129,130 The goal of their studies was to develop sustained release mosquito repellent technologies in which DHA would anchor the compound to the skin, then degradation would lead to release of the active repellent molecule.130 The ability to esterify DHA without first protecting the ketone is an attractive feature for the future of DHA-based macromolecules. In 2010, Putnam and Yazdi showed that lipid diesters of DHA synthesized through these methods can be formulated into microparticles and are promising controlled release drug delivery vehicles.131

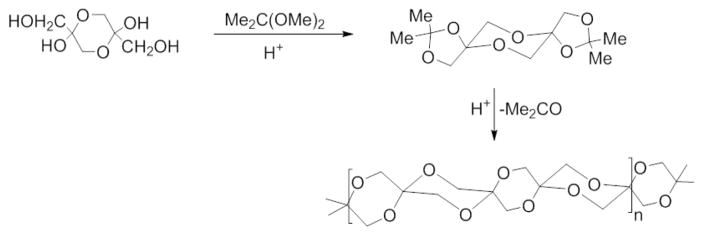

3.2.6. Cyclic Macromolecules of DHA

Few reports describe the polymerization of the DHA dimer. In 1934, based on a series of X-ray diffraction patterns, Strain and Dore suggested that when the DHA monomer is left in dry form at room temperature for 25–30 days, the molecules would dimerize, and when left for several months, DHA would polymerize further.132 In 1989, Akar and Talinli reported that the DHA dimer polymerizes into poly(spiro-acetals) by mixing DHA dimer in ethanol with heat and an acid catalyst.89 The resulting polymers are insoluble in most organic solvents but slightly soluble in dimethyl sulfoxide (DMSO). Several years later, Alder and Reddy reported a transketalization method to synthesize the poly(spiro-acetals) as shown in Figure 13.133

Figure 13.

Transketalization route to poly(spiro-acetals) of DHA as reported by Alder and Reddy. Reprinted with permission from ref 133. Copyright 1994 Elsevier Ltd.

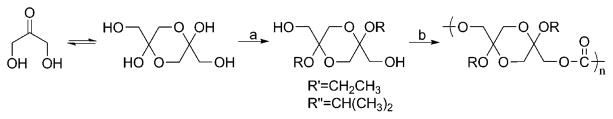

Putnam et al. reported additional polymers that retain the cyclic nature of the DHA dimer134,135 (Figure 14). In order to prevent dissociation during polymerization, modified forms of the dimer are synthesized, as shown in Figure 14. The ethyl derivative, 2,5-diethoxy-1,4-dioxane-2,5-dimethanol (Figure 14, R=CH2CH3), is used, previously described by Wong et al., as an intermediate in a method for synthesizing DHAP.136 The molecular weight of the resulting polymers ranged from 28 to 48.4 kDa with dispersities of 1.7 to 2.2. The materials exhibited comparable mechanical properties to that of cancellous bone, with compressive yield strengths of 45 ± 5 MPa and Young’s moduli of 0.8 ± 0.01 GPa.134,137,138 The mechanical properties in combination with confirmed NIH-3T3 cell growth on polymer films suggests that polymers generated from the dimeric form of DHA may have applications in tissue engineering.

Figure 14.

Synthetic route to poly(carbonate-acetals) from DHA dimer. (a) R′: triethyl orthoformate, EtOH, p-TsOH, RT, and R″: triisopropyl orthoformate, 2-propanol, p-TsOH, and RT and (b) triphosgene, pyridine, and CH2Cl2. Adapted with permission from ref 134. Copyright 2005 American Chemical Society.

3.3. Applications

3.3.1. Functionalizable Surfaces

Surfaces bearing reactive functional groups are of widespread interest for uses including, but not limited to cell adhesion,139 modifying degradation rates,140 protein immobilization,141 drug attachments, 142,143 and layer-by-layer assembly of nanostructures.144 As previously discussed, DHA reacts with primary amines to form an imine or Schiff base (Figure 9c). Therefore, a number of surface modifications of DHA-based materials are possible.

The Schiff base itself is a powerful tool with applications in drug delivery,143,145,146 bioreactor design,147,148 biosensors,149 protein microarrays,150,151 preparation of nano152/microstructures, 153 etc. The imine possesses several unique properties which enable its widespread use including: (1) pH sensitivity, (2) autofluorescence, (3) formation under mild conditions without added reagents, (4) occurrence in both aqueous and organic solvents, and (5) reversibility (with the option of irreversibility through reductive amination).97 In most biomedical applications, Schiff bases are formed by reactions with aldehydes as opposed to ketones due to the increased reactivity of the carbonyl group. For example, as a tool to prevent infection from medical implants over a prolonged period of time, Meier et al. synthesized polymersomes with outer aldehyde groups that permanently attach to amine-coated silicon surfaces via reductive amination of imine linkages and sustain local release of antibiotics.154 Li et al. synthesized biodegradable and biocompatible microcapsules containing covalently assembled layers of chitosan (amine-containing polysaccharide) and derivatized alginate (oxidized to contain aldehyde groups). The Schiff base linkages between layers resulted in autofluoroescence of the microcapsules and pH dependent permeability, indicating their potential use in drug delivery applications with improved in vivo tracking capabilities. 155 An extensive review of Schiff base forming technologies based on aldehyde-amine reactions, and their applications, is recently covered by Jia and Li.97

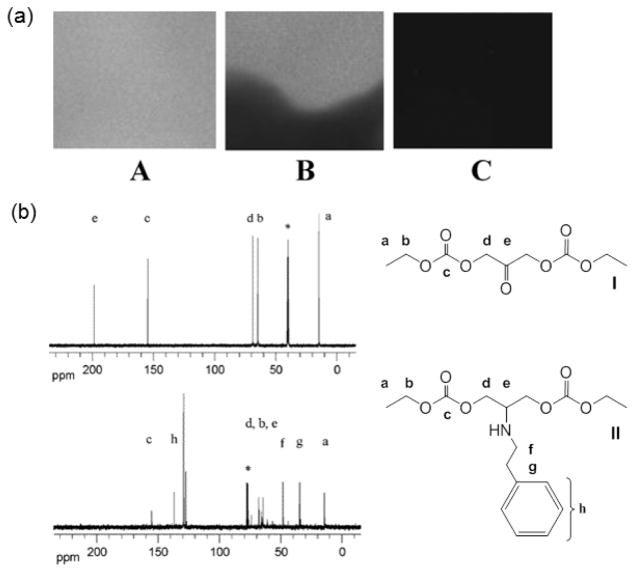

Putnam et al. performed several studies to show that the ketone functionality of DHA-based polymers does not lose reactivity upon polymerization of the alpha hydroxyl groups.93 They spin-coated ketone-protected DHA polymer [p-(MeO2DHAC)] onto glass slides and spotted a TFA/water solution in specified regions to generate areas of deprotected (i.e., ketone-containing) polymer. Subsequent incubation with fluorescently tagged poly(lysine) showed immobilization only in regions containing deprotected polymer, indicating that the ketone is essential to the immobilization mechanism (Figure 15a). Similar results are obtained for studies with fluorescently tagged albumin, demonstrating that pDHA is also reactive with proteins. To further verify that Schiff base formation is feasible postpolymerization, Putnam et al. synthesized a small molecular weight analog (I, Figure 15b) of pDHA and studied its reaction with phenylethylamine in the presence of a reducing agent. 13C NMR data showed the expected product from reductive amination of a Schiff base formed between the analog and amine compounds (II, Figure 15b).93 The results of Putnam et al. indicate that pDHA, and copolymers thereof, are promising functional biomaterials. In addition, pDHA is reported to possess high strength, similar to that of cancellous bone, and a Tg above physiological temperature (~60 °C). These properties further support the potential for DHA-based materials in medical devices, drug delivery, tissue engineering, and more.93

Figure 15.

(a) Fluorescent imaging of poly(lysine) surface conjugation onto glass microscope slides coated with A, pDHA; B, p-(MeO2DHAC) and pDHA; and C, p(MeO2DHAC). (b)13C NMR spectra of a small molecular weight analog of pDHA both (I) before and (II) after reaction with phenylethylamine and a reducing agent. Reprinted with permission from ref 93. Copyright 2006 American Chemical Society.

3.3.2. Hydrogels

Hydrogels are cross-linked polymer networks that swell in aqueous solutions and have varied applications in tissue engineering,156–158 wound healing,159–163 and drug delivery.164–167 Hydrogels are prepared using naturally occurring polymers [cellulose,168 hyaluronan,169 alginate,170 etc.), synthetic materials (poly(vinyl alcohol),171 poly(ethylene glycol),172,173 poly(2-hydroxyethyl methacrylate), 174,175 etc.] and genetically engineered protein-based materials created using recombinant DNA technology.176–178

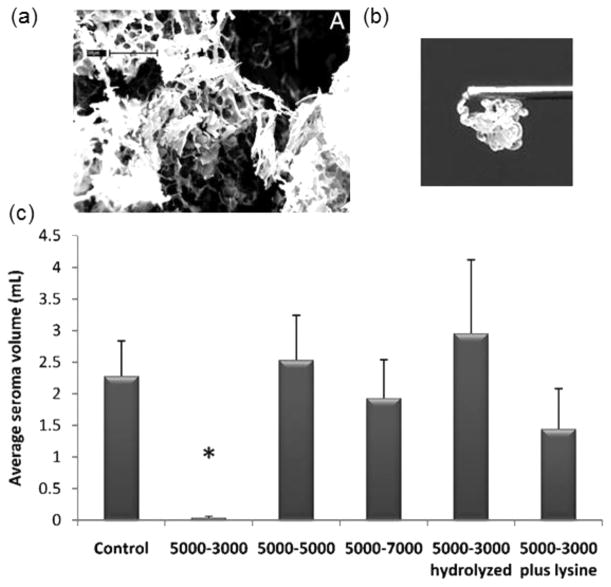

Putnam et al. reported a new class of synthetic hydrogels using DHA-based polymers.122,179 They found that diblock copolymers comprised of pDHA, a water-insoluble polymer, and the highly hydrophilic polymer PEG afford biocompatible hydrogels with tunable properties (MPEG-pDHA, Figure 16a). Studies performed on diblock copolymers with fixed-length MPEG segments (5 kDa) and variable pDHA segments showed that as the pDHA chain increases, hydrogel pore size, swelling, and hydrolytic degradation rates decrease, whereas entanglement density and viscosity increases. Physical cross-linking in MPEG-pDHA hydrogels is hypothesized to occur due to charge interactions arising from the dipole moment of the carbonyl groups on dihydroxyacetone. It is hypothesized that the transient nature of such attractions contribute to the ability to extrude MPEG-pDHA through a 26-gauge needle (Figure 16b).179

Figure 16.

(a) SEM image of lyophilized MPEG-pDHA (5000–3000) hydrogel. (b) MPEG-pDHA (5000–5000) hydrogel extrusion through a 26-gauge needle. (c) Seroma volumes measured using a rat mastectomy model following treatment with various MPEG-pDHA formulations and a saline control. Figures are reprinted from ref 179 with permission. Copyright 2010 National Academy of Sciences, USA.

A unique property of DHA-based hydrogels is the relatively rapid degradation rate compared to other polycarbonates [e.g., poly(trimethylene carbonate), (PTMC)]. In vitro, under conditions mimicking the physiological media, MPEG-DHA hydrogels degrade within a 24 h period.179 The rapid degradation rate of DHA hydrogels, in combination with the ease of extrusion through a needle, is advantageous in the prevention of seromas, accumulation of serous fluid resulting from surgical complications. In an in vivo rat model of lymphandenctomy, the polymers with molecular weights ~3 kDa in pDHA and ~5 kDa in MPEG are highly effective at preventing seroma formation (Figure 16c).179 Three days after treatment, no polymer is observed at the surgical site, indicating that MPEG-pDHA hydrogels are capable of serving a transient distinct function before being eliminated from the body.

The rapid degradation of MPEG-pDHA polymers along with the ability to prevent seroma provides a rationale for investigation of other potential uses, including one as a biodegradable hemostatic agent.180 With use of an in vivo liver resection rat model, application of the MPEG-pDHA reduced the bleeding time to 97 s compared to a saline control (464 s) and Instat, an industry standard (165 s).180 The total blood loss is not statistically different between MPEG-pDHA and Instat trials, indicating that MPEG-pDHA hydrogels are adequate hemostatic agents with the added bonus of a rapid in vivo resorption rate. Histological studies performed 3 weeks postoperation showed a similar inflammatory response of MPEG-pDHA samples to saline controls.180 The combination of biocompatibility, reduced bleeding time, synthetic origin of the material, and rapid degradation of MPEG-pDHA hydrogels suggest that MPEG-pDHA hemostatic agents would lead to minimized risk of infection and long-term inflammation.

The reactive carbonyl functionality present within DHA hydrogels provides opportunities for chemical cross-linking, drug attachments, or surface modifications, thereby opening doors to additional applications. Furthermore, chemical alterations, such as the introduction of small hydrophobic regions or the use of urethane polymer linkages, may lead to enhanced control in hydrogel swelling and degradation, expanding the potential for DHA-based hydrogels in biomedical applications.

3.3.3. Controlled Drug Delivery

Polymeric materials are of significant interest in the field of controlled drug delivery owing to the vast opportunities in synthetic design leading to various tunable features as well as their ability to form macro, micro, or nanostructures. Several review articles cover polymers used for controlled drug delivery that describe their unique advantages and specific applications in detail, and the reader is referred to these articles.181–185 DHA-based polymers contain several desirable characteristics for controlled drug release systems. First, the degradation of DHA-based polymers into biocompatible compounds reduces risks of inflammation and toxicity while also eliminating concerns over invasive post-treatment device removal. Second, through ROP, DHA can be easily copolymerized in a controlled manner with other biocompatible materials such as lactide123 and caprolactone.121 By altering initial monomer, comonomer, initiator, and catalyst ratios, the final product composition can be predicted, creating a reliable parameter by which drug release rates are controlled. Overall, there is a large realm of possibilities for DHA-based polymers with regard to hydrophilicity, rigidity, glass-transition temperatures, melting temperatures, rheological properties, and pH sensitivity, depending on the chosen comonomer and reaction conditions. Furthermore, variations in these properties yield opportunities for different 3D structures. Diblock copolymers of DHA and MPEG afford hydrogels179 and nanoparticles,122 whereas random copolymers of DHA and LA give powders that can be compressed into solid tablets.123 Putnam and Yazdi showed that DHA-based microparticles are also feasible; however, these materials employ a separate synthetic technique, as previously discussed.131 A third attractive feature of DHA-based materials is the reactive ketone functionality. Although this has yet to be specifically explored, it is an extension of the research and opens up possibilities for the attachment of active agents or affinity-ligands.

Putnam et al. showed that random copolymers of DHA and LA, synthesized via ROP with stannous octoate catalysts, are promising candidates for controlled release of protein therapeutics.186 Cylindrical tablets, for subsequent drug release studies, are prepared by mixing the powdered polymers containing approximately 50 to 85% DHA with dry powders of model proteins, bovine serum albumin (BSA) or lysozyme, and compressed. Copolymers containing less than 50% DHA are too tough to process into tablets and therefore were not investigated. Thermal studies revealed that for all LA:DHA ratios, glass transition temperature (53–68 °C) and degradation temperatures (Td, 50 wt %: 230–330 °C) are above physiological temperature, indicating that the tablets will retain structural integrity when subject to in vivo temperatures.123,186

In vitro controlled release experiments showed a first-order release of BSA and lysozyme over 2.5–70 days, depending on the percent drug loading and percent DHA in the polymer backbone.186 Lysozyme activity tests following release indicated that the protein retained significant activity throughout release and was not highly inactivated due to the environment of the delivery device. For any copolymer composition, at least 50% of the protein activity is retained after one month of release. Protein release rates increased with increasing pDHA content.186 This result is not surprising given the results of in vitro degradation studies, which showed that polymer erosion occurs more rapidly with increasing DHA content within the polymer backbone. In addition to tablet erosion studies visualized by scanning electron microscopy, degradation of the polymer backbone can be tracked utilizing the bicinchoninic acid assay, which Putnam et al. discovered to be a valuable tool in quantitatively measuring α-hydroxy ketones, such as DHA, in solution.187 Zhuo et al. report that upon deprotection of the pDHA homopolymer, hydrolytic degradation of the associated carbonate bonds drastically increases.117 The results suggest that percent deprotection of pDHA in DHA-based materials is a potential control parameter in drug release technologies.

Zhuo and co-workers performed release studies on polymers containing EOPDC (Figure 10b), a cyclic-acetal protected form of DHA, using the chemotherapeutic agent Tegafur.125–127 Results from EOPDC:1,4-dioxane-2-one copolymers and EOPDC:caprolactone copolymers show a decreased drug release rate with increasing EOPDC content, resulting in release of less than 4% in 350 h in any formulation.126,127

Diblock copolymers of pDHA and MPEG (Figure 12b) are also proposed for controlled release applications; however, no formal testing is reported. Putnam et al. showed that in addition to hydrogels, MPEG-pDHA polymers can be formulated into nanoparticles that take on a micellar shape with a pDHA core and PEG corona.122 Nanoparticles, prepared by control precipitation (via stirring) from DMSO/polymer solutions in water, ethanol, or dichloromethane, afforded average particle diameters of 45 ± 1 nm, 70 ± 1 nm, and 94 ± 1 nm, respectively, from polymers with molecular weights of 1.8 kDa for pDHA and 4.5 kDa PEG.

3.3.4. Green Thermoplastics

Today, concerns over landfill sizes, depletion of scarce resources, and greenhouse gas production are significant given the increasing world population. These issues spurred the investigation, development, and use of biodegradable plastics from renewable resources, as opposed to traditional petroleum-based materials such as polyethylene or polypropylene. Examples of “green” plastics include those composed of starch, soy protein, cellulose, PLA, and poly(hydroxyalkanoate)s.188–192 Waymouth et al. noticed that the structure of pDHA is similar to Carilon, a polyketone thermoplastic derived from ethylene (E) and carbon monoxide (CO).121 Since DHA can be synthesized from glycerol,193,194 a byproduct in the production of bio-diesel, the authors investigated the potential use of DHA-based polymers in the field of renewable and biodegradable thermoplastic materials.121 Similar to E/CO polymers, pDHA possesses a melting temperature, Tm of 246 °C, close to the thermal degradation temperature, Td = 273 °C, which is difficult for processing due the high Tm and close Tm and Td values.121 As a solution, Waymouth et al. copolymerized DHA with ε-CL, which lowered the Tm of the polymer, with the extent of Tm lowering depending on the percent of caprolactone added to the composition.121 These results indicate that pDHA-CL copolymers are thermoplastic materials with tunable thermal properties.

Guillaume et al., also interested in creating thermoplastic materials from biorenewable resources, synthesized diblock and triblock copolymers of dimethoxy-acetal protected DHA with the well-known polycarbonate PTMC.124 It was found that much like PLA, a popular “green” choice for polymers, segments of protected DHA added rigidity to PTMC polymers which is a control parameter for the generation of well-performing thermoplastic materials. The results from the Guillaume and Waymouth laboratories, show that DHA-based polymers are not limited to biomedical applications. The features that make these polymers appeal to biomedical research, their biocompatibility and biodegradability, also open doors to the possibility of producing materials with improved environmental preservation capabilities.

3.4. Dihydroxyacetone Synthon Summary

Dihydroxyacetone is a natural metabolite used in the synthesis of several polymeric biomaterials including hydrogels, nanoparticles, microparticles, powders, and thermoplastics. The resulting DHA-based macromolecules successfully demonstrated their use in controlled drug delivery, seroma prevention, hemostasis, and tissue engineering applications. ROP is the primary synthetic route to DHA-based polymers, offering facile copolymerization with additional monomers and various control parameters. ROP, however, requires timely protection/deprotection of the active ketone. The use of acyl chloride reactions provides an alternative synthetic route that avoids ketone modification procedures.

While a diverse set of DHA-based materials are known and useful in several applications, a number of opportunities remain. First, the carbonyl group present on DHA-based polymers offers unique capabilities for drug attachments, chemical cross-linking, and surface modifications via Schiff base formation, which are yet to be reported. Second, the α-hydroxy groups present on dihydroxyacetone offer the possibility of polymerization into urethane bonds, which is not extensively studied. Lastly, 2,2-dimethoxy-propane-1,3-diol (MeO2DHA, Figure 10a), the intermediate product in the synthesis of MeO2DHAC, is a promising candidate for synthesis of future DHA-based polymers.

Similarly to other metabolic synthons that have gained widespread attention for use in polymeric biomaterials, such as lactic acid, dihydroxyacetone offers a diverse set of synthetic opportunities that can yield adjustable mechanical and thermal properties for a broad range of applications, both inside and outside the realm of biomedical engineering.

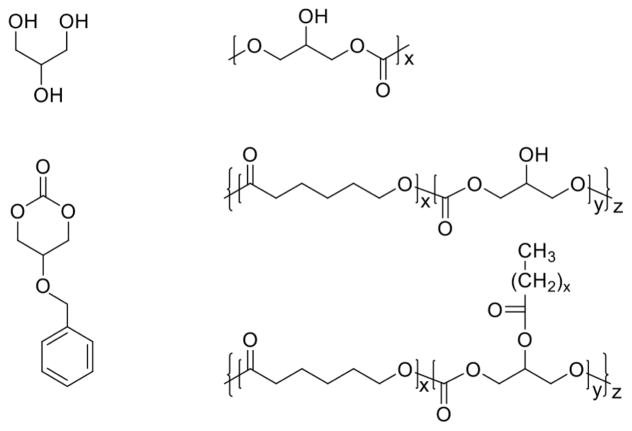

4. GLYCEROL SYNTHONS

Glycerol, like DHA, is a three-carbon polyol and contains two primary and one secondary hydroxyl groups. Oxidation of the secondary hydroxyl to a ketone in glycerol affords DHA, discussed in the previous section. GL (also known as glycerin or glycerine) is generally considered to be nontoxic and has an oral LD50 of 12600 mg/kg in rats.195 GL is widely used in cosmetic and pharmaceutical products as a thickener, plasticizer, emollient, bodying agent, humectant, and lubricant. Its use as a synthon for the preparation of copolymers with other monomers is well-established via thermal condensation polymerization approaches; however, the preparation and subsequent use of cyclic derivatives for more controlled polymerization reactions is only recently described. As discussed below, these newer approaches afford polymers with specific molecular weights and lower dispersities, as well as opportunities to synthesize chiral polymers and copolymers with other monomers.

4.1. General

4.1.1. Glycerol Metabolism

GL is a well-known natural metabolite with many roles, including serving as the backbone unit of triglycerides and phospholipids. For example, GL phospholipids, the most abundant lipids in cell membranes, can possess a variety of different head groups. Thus, GL (and more accurately, GL 3-phosphate) is a key intermediate in the biosynthesis of these important lipids. GL is also a precursor for the biosynthesis of glucose. Catabolism of triacylglycerols to give GL, which is then phosphorylated at the C3 position, enables entry into gluconeogenesis (discussed above) and subsequent glucose production.

4.1.2. Structure and Reactivity

Although GL only possesses two primary and one secondary hydroxyl groups, it is amenable to a large number of chemical transformations (e.g., dehydration, selective oxidation, and hydrogenolysis),196 providing a means to prepare GL-derived synthons for subsequent polymerization. For example, with primary alcohols at the C1 and C3 positions and a protected secondary alcohol at the C2 position, 6-membered cyclic carbonates are obtained upon treatment with triphosgene or ethyl chloroformate. This cyclic structure is the monomer for the synthesis of linear poly(1,3-glycerol carbonates) [P(1,3-GLCs)] described next.

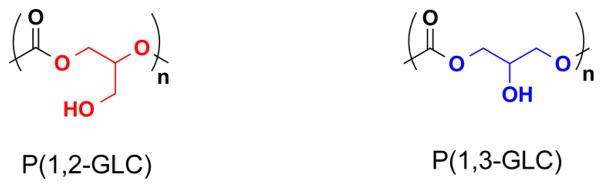

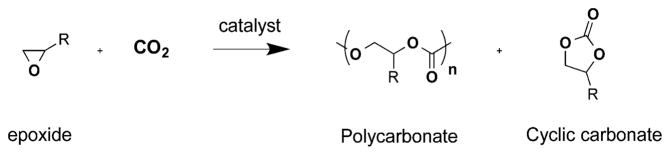

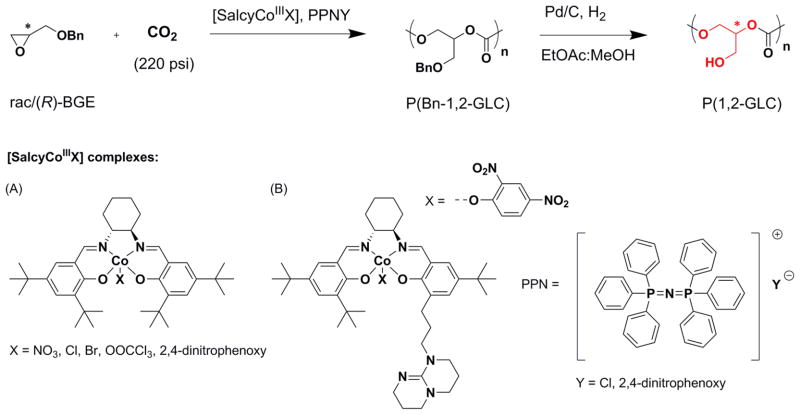

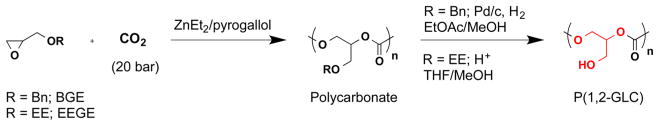

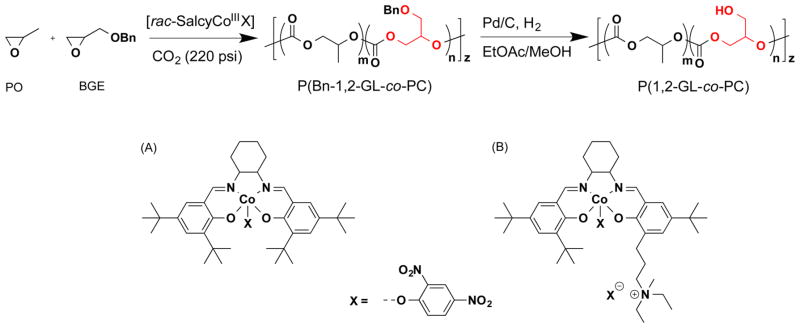

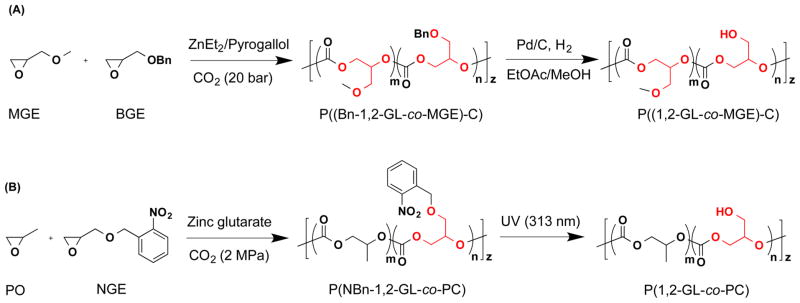

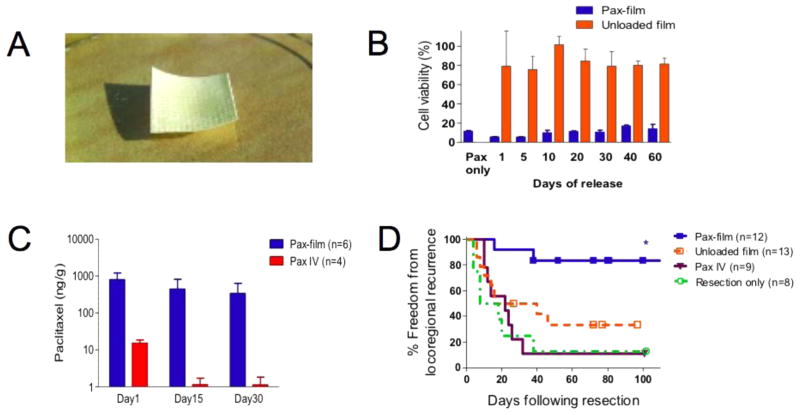

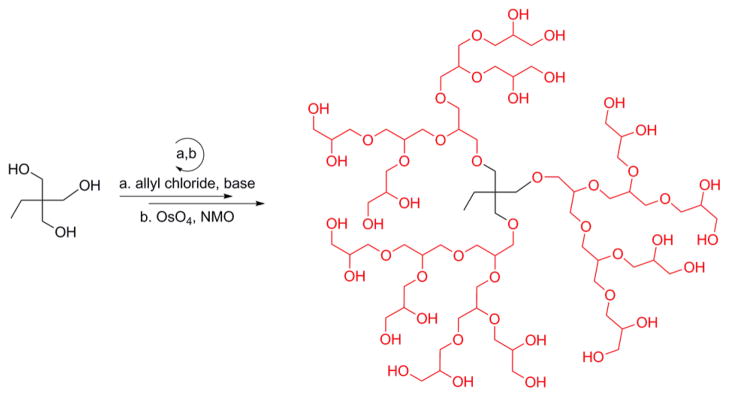

4.2. Linear Poly(1,3-glycerol Carbonates)