Abstract

Bleeding complications arising from trauma, surgery, as well as congenital, disease-associated or drug-induced blood disorders can cause significant morbidities and mortalities in civilian and military populations. Therefore, stoppage of bleeding (hemostasis) is of paramount clinical significance in prophylactic, surgical and emergency scenarios. For externally accessible injuries, a variety of natural and synthetic biomaterials have undergone robust research, leading to hemostatic technologies including glues, bandages, tamponades, tourniquets, dressings and pro-coagulant powders. In contrast, treatment of internal non-compressible hemorrhage still heavily depends on transfusion of whole blood or blood’s hemostatic components (platelets, fibrinogen and coagulation factors). Transfusion of platelets poses significant challenges of limited availability, high cost, contamination risks, short shelf-life, low portability, performance variability and immunological side-effects, while use of fibrinogen or coagulation factors provides only partial mechanisms for hemostasis. With such considerations, significant interdisciplinary research endeavors have been focused on developing materials and technologies that can be manufactured conveniently, sterilized to minimize contamination and enhance shelf-life, and administered intravenously to mimic, leverage and amplify physiological hemostatic mechanisms. Here we provide a comprehensive review regarding the various topical, intra-cavitary and intravenous hemostatic technologies in terms of materials, mechanisms and state-of-art, and discuss challenges and opportunities to help advancement of the field.

1. Introduction

Blood, a fluid connective tissue composed of red blood cells (RBCs), white blood cells (WBCs), platelets, and non-cellular liquid (plasma) containing salts, nutrients and proteins, is present at a volume of approximately 5 liters in the average human body (70 kg body weight). Blood is responsible for transport of gases and nutrients to tissues as well as providing immune surveillance and hemostatic responses as needed. Hence, loss of blood can result in a variety of pathologic scenarios that can lead to tissue morbidities and mortalities. For example, in traumatic injuries in both battlefield and civilian conditions, significant blood loss from truncal, junctional and internal non-compressible injuries can result in significant pre-hospital (and potentially preventable) mortalities stemming from hypothermia, coagulopathy, infection, acidosis and multiple organ failure [1–6]. Also, certain congenital or disease-associated conditions (e.g. coagulation factor deficiencies and platelet dysfunctions) as well as drug-induced effects (e.g. bone marrow suppression due to chemotherapy and radiotherapy in cancer patients) can put certain patient populations at high bleeding risks [7–9]. Therefore, management of various bleeding complications remains a highly significant clinical area, and substantial interdisciplinary research efforts are focused on the development of materials and technologies for efficient hemostatic management of bleeding.

The word ‘hemostasis’ was coined by ancient Greeks from the terms haíma (meaning blood) and stasis (meaning stoppage) to describe the phenomenon of blood stagnation when alum came in contact with a wound [10]. Although scattered evidences of utilizing blood products and application of coagulation/hemostasis concepts are found in ancient Greek and Roman history as well as in reports of transfusion and organ transplants around late 18th ad early 19th centuries, the modern concept of hemostatic mechanisms is credited to the seminal report written by Paul Morawitz in 1905 [11,12]. In his report, Morawitz emphasized the role of platelets, ‘thrombokinase’ (now known as tissue factor), calcium, prothrombin and fibrinogen in promoting blood coagulation. Later in the 20th century, additional coagulation factors were identified and characterized, and the concepts of coagulation being guided by a cascade of enzymes and co-factors (i.e. the intrinsic and extrinsic coagulation cascades) leading to the final output of fibrin formation (common pathway of cascades) were put forward [13,14]. As per the current (and still evolving) understanding of the process, the body’s natural mechanisms of hemostasis are rendered by a complex, spatio-temporally regulated sequence of responses involving a combination of cellular (e.g. platelets and tissue factor-bearing cells) and plasma (e.g. coagulation factors) components, as depicted in the schematic of Figure 1.

Figure 1.

Schematic of the complex mechanism of blood vessel hemostasis. Vessel injury can lead to endothelial activation and denudation resulting in secretion and deposition of von Willebrand Factor (vWF) and exposure of collagen at the injury site, as well as, exposure of tissue factor (TF) bearing cells at the site; vWF and collagen exposure allows platelet adhesion and activation, while TF exposure allows extrinsic pathway of coagulation to propagate and produce moderate amounts of thrombin (FIIa) that activates other coagulation factors in the intrinsic pathway; activated platelets aggregate via fibrinogen (Fg) mediated interaction with platelet surface integrin GPIIb-IIIa to form a platelet plug (primary hemostasis) that staunches bleeding; the surface of aggregated active platelets exposes negatively charged phospholipids that allow co-localization and further activation of coagulation factors to form the prothrombinase (FVa + FXa + FII) complex in presence of calcium (Ca++), leading to amplified generation of thrombin (FIIa) that breaks down fibrinogen (Fg) to fibrin; fibrin self-assembles and undergoes further crosslinking by action of FXIIIa to form a dense biopolymeric mesh that forms the hemostatic clot and arrests flow of blood components (secondary hemostasis).

In the absence of injury, healthy endothelial cells lining the luminal wall of blood vessels avoid blood clotting by secretion of heparin-like molecules, thrombomodulin, nitric oxide and prostacyclin, as well as, sterically hindering adsorption of clot-relevant proteins on the vessel wall due to presence of endothelial glycocalyx. Tissue injury and bleeding result in endothelial damage, leading to vasoconstriction to reduce blood flow out of the injury site and secretion/exposure of pro-coagulant proteins and factors. Platelets rapidly respond to the bleeding site by undergoing adhesion (primarily to von Willebrand Factor and sub-endothelial collagen), activation and inter-platelet aggregation at the site to form the platelet plug [15–18], a process commonly known as ‘primary hemostasis’. In tandem, exposed sub-endothelial collagen, von Willebrand factor (VWF) secreted from injured endothelium and activated platelets, and tissue factor (Coagulation Factor III, formerly known as thrombokinase or thromboplastin) on sub-endothelial matrix and localized leukocytes lead to initiation, amplification and propagation of the coagulation cascade, culminating in thrombin-catalyzed formation of fibrin from fibrinogen, a process commonly known as ‘secondary hemostasis’ [19–21]. Critical upstream steps of this process (e.g. conversion of prothrombin to thrombin) are greatly amplified by anionic lipids (phosphatidylserines) on the membrane of active platelets as well as by anionic polymers (polyphosphates or PolyP) secreted by active platelets [22–29]. Pro-hemostatic active platelets also secrete molecules adenosine di-phosphate (ADP) and platelet factor 4 (PF4) that can modulate hemostatic mechanisms. The fibrin, formed as the final product of the coagulation cascade, associates into a cross-linked biopolymeric mesh facilitated by activated coagulation factor XIII (FXIIIa) and platelet-secreted polyphosphate (PolyP) to secure the platelet plug and other blood components at the bleeding site and form the final clot [30,31]. The clot-incorporated active platelets also facilitate clot retraction and healing mechanisms [32–35]. Post-healing of the injury site, the mature fibrin clot is lysed through the action of plasmin, which is generated from the zymogen plasminogen on the surface of the fibrin, as well as, on neighboring cell surfaces by the action of tissue plasminogen activator (tPA) or urokinase (uPA) [36]. The tPA is produced from endothelial cells while uPA is produced from monocytes, macrophages and urinary epithelium. Plasmin-induced proteolysis of fibrin results in formation of soluble fibrin degradation products (FDPs), which can have some immunomodulatory and chemotactic functions relevant to healing phases. In healthy individuals the clot formation and fibrinolytic systems are highly regulated to ensure hemostatic balance, and any dysregulation can lead impaired or weak clot formation (poor hemostasis and re-bleeding) or overly strong occlusive clot growth (thrombosis). For example, the plasminogen activators (tPA and uPA) and plasmin action are regulated by local high concentration of serine protease inhibitor (serpin) molecules like plasminogen activator inhibitors-1 (PAI-1), plasminogen activator inhibitor-2 (PAI-2) and α-2 antiplasmin [37], as well as non-serpin molecules like α-2 macroglubulin and thrombin-activated fibrinolysis inhibitor (TAFI) [38,39]. Fibrin-bound tPA shows greatly enhanced catalytic efficiency of plasminogen activation compared to solution phase tPA [40]. In parallel, plasmin is protected from inhibition by α-2 antiplasmin upon binding to fibrin [41]. Thus, a combination of feedback mechanisms of fibrin formation and fibrin destruction maintains the precise spatiotemporal regulation of hemostasis.

Based on this complex concert of mechanisms in clotting, biomaterials-based approaches to render and augment hemostasis have focused on mimicking and leveraging the various mechanistic aspects, including constriction (pressure), platelet (primary hemostasis)-relevant components and coagulation (secondary hemostasis)-relevant components. The optimum requirements for a hemostatic material (and technology) is that it (i) should be applicable and adaptable to a variety of actively bleeding wounds, (ii) should act rapidly to reduce blood loss and maintain this hemostatic condition for long durations if needed, (iii) should be easily manufacturable, sterilizable and portable, (iv) should be stable under a variety of atmospheric and ambient conditions, (v) should be easily usable by non-specialized personnel if needed and (vi) should be reasonably biocompatible so as to not induce any short-term or long-term adverse effect in the body. To this end, for externally visible and accessible (often compressible) injuries, a variety of biomaterials-based technologies in the form of powders, bandages, sprays, foams, gels, tourniquets and tamponades have been developed [42–48]. In contrast, for management of internal (often non-compressible) bleeding, the clinical gold standard is the transfusion of whole blood or blood components (RBC, plasma and platelets) [49–54], and use of fibrinogen concentrate or recombinant coagulation factors in selected groups of patients (e.g. recombinant Factor VIIa used in hemophilia patients) [55–59]. However, donor-derived blood and its components often have limited availability, require meticulous type matching, pose issues of high pathologic contamination or immunogenic risks, and have limited portability and short shelf-life. These issues are particularly challenging for transfusion of platelets, which present challenges of alloimmunization and refractoriness, have a high bacterial contamination risk and have a shelf-life of only 3–7 days [60–67]. Therefore, significant research efforts are currently being focused on minimizing contamination and improving storage life of platelets [68–71] as well as on developing in vitro bioreactor technologies for production of ‘donor-independent platelets’ from cultures of precursor cells [72–74]. In parallel, robust interdisciplinary research efforts are being directed on developing biomaterials-based technologies that can be administered intravenously and can mimic, amplify and leverage various mechanistic components of hemostasis to rapidly staunch bleeding. The current article will comprehensively and critically review the various externally used and intravenously applicable hemostatic technologies in terms of materials, clotting mechanisms and current state-of-art, and discuss the challenges and opportunities associated with these technologies to help interdisciplinary advancement of the field.

2. Hemostatic biomaterials and technologies for topical (external) applications

Externally administered hemostatic treatment of an injury or lesion is applicable to simple cuts and bruises, exposed and puncture wounds, surgical lacerations, and heterogenous blunt trauma. These scenarios result in various degrees of bleeding and tissue damage, and hence the development of appropriate hemostatic materials and technologies is driven by the need to quickly staunch bleeding, absorb shed blood, cover and protect the injury, prevent contamination and provide a suitable environment for healing. These materials and strategies include topical use of tourniquets, dressings, bandages, foams, powders and gels, as well as, administering materials intra-cavitarily. A wide variety of materials and technologies have been developed, pre-clinically evaluated and clinically translated in this area as discussed in the following sections.

2.1. Tourniquets

As described previously, a blood vessel’s first natural response to injury is spasm and construction, leading to reduction in blood flow (stypsis) and facilitating the subsequent cellular and biomolecular clotting mechanisms. Therefore, a number of hemostatic materials and technologies have focused on augmenting this process by collapsing blood vessels with application of pressure to allow platelet activity, coagulation cascade and formation of a fibrin clot. Beyond applying manual pressure with fingers and palm, a widely used technology in this category is that of tourniquets. Tourniquet is essentially a circumferentially constrictive bandage that can restrict blood supply to extremities. In ancient Roman history, Galen of Pergamon (129 – 200 AD) was known to use this method for stopping blood flow and was criticized for its use by those who feared that tourniquets would increase blood loss from a wound. In the early 16th century, famous Prussian military physician Hans von Gersdorff had described tourniquet use in amputation surgery [75]. Towards the end of the 16th century, Wilhelm Fabry of German surgical science fame, reportedly also used tourniquets in amputation surgery, utilizing mechanical tightening [76]. Historically in such uses, tourniquets have been reported to present certain negative consequences, especially in the context of denying blood supply to extremities hereby causing ischemia and infarction as well as causing mechanical nerve damage. Despite this criticism, over time tourniquets have become an adapted and accepted hemostatic technology in pre-hospital management of bleeding in the military (i.e. in combat wounds), as emphasized by documents of the Tactical Combat Casualty Care (TCCC) of the US military and reviewed recently by Lakstein et al and Kragh et al [77,78]. Before being adapted as a tactical mainstay, most tourniquets were made of an improvised stick with a cloth or a silicone elastic strip. However, due to material inferiority and risks of slippage (defective fastening), in the mid 2000s significant R&D efforts were dedicated to tourniquet design and standard-of-usage. The first result was a technology named Combat Application Tourniquet (C-A-T®, North American Rescue, USA), which is essentially a composite improvisation of the ‘cloth with turning stick for tightening’ approach (aka Spanish windlass design) that can be used with minimal effort (e.g. with one hand) [79]. Continued studies on tourniquet design, ease of usage in complex time-limiting environment, patient comfort, hemostatic efficacy and reduction of tissue morbidity and mortality have led to other tourniquet technologies such as Emergency Medical Tourniquet (EMT, Delfi Medical Innovations, Canada), Special Operations Forces Tactical Tourniquet (SOF-TT), Ratcheting Medical Tourniquet (RMT, M2 Inc, USA) etc. The EMT tourniquet is formed of circumferentially usable bladder that can go around the limb, a clamp that limits the inflated portion while holding the bladder close to the limb, and an inflator bulb equipped with a connector tube and twist cap. Hence, the design is similar to a blood pressure cuff except for the clamp component. The SOF-TT tourniquet is similar in design principle to the C-A-T system (i.e. the Spanish windlass design) with an aluminum-based stick. The RMT system requires use of a ratcheting lever instead of a windlass stick for tightening the tourniquet. The usefulness of tourniquets to reduce blood loss (and hence morbidity/mortality) by simple yet efficient application of styptic pressure is responsible for its current consideration as a standard-of-care component for emergency responders in civilian trauma [80,81].

2.2. Naturally derived biomaterials for hemostatic applications

Mother Nature has been a dependable source for a wide variety of materials like cotton, collagen, gelatin, silk, elastin, fibrin etc., that have found extensive applications in biomedical areas of device coatings, tissue adhesives and sutures, tissue repair and regeneration, cell encapsulation, drug and gene delivery etc. [82]. A variety of naturally derived materials have also found significant applications in the area of hemostasis and bleeding management. Some of these materials have only absorption and passive interaction properties, while others have active biointeractions to promote hemostatic mechanisms. Absorptive and passively interactive materials impart partial hemostasis merely by wound site coverage, absorption of blood and exudates, and subsequent protection, but do not contain any specific component that promote or augment hemostasis or biologically protect from bacterial infection. On the other hand, bioactive materials and dressings are systems that adhere to the bleeding tissue to either render hemostasis-stimulating properties by themselves or by virtue of components embedded in them that facilitate hemostatic mechanisms and prevent infection. The following sections will provide a descriptive review of absorptive, passively interactive and bioactive materials derived from natural sources that have various hemostatic applications, and at the end Table 1 will provide an ‘at-a-glance’ summary of naturally derived hemostatic materials along with representative technology names, characteristic evaluations and current application status.

Table 1.

Topical and Externally Administered Hemostatic Biomaterials from Natural Sources

| Materials and Technologies |

Mechanism of Action | Example Evaluations and Characteristic Applications |

Characteristic Findings |

|---|---|---|---|

| Cotton and cellulose-based materials, e.g., - Cotton gauze - Open weave cloth gauze soaked in paraffin, balsam and olive oil (e.g. tulle dressings) - Oxidized Cellulose (OC) - Oxidized Regenerated Cellulose (ORC) etc. - Carboxymethyl cellulose hydrogel system etc. | Provides high absorption at the wound site in addition to possibly triggering the contact pathway of coagulation; Tulle dressings maintain a moist wound bed while allowing absorption of exudate to pass into a secondary dressing and also reduces adherence of the dressing to the wound bed; Cellulose fibers initiate clotting cascade through contact activation, and can also decrease the pH at the wound site leading to platelet activation and aggregation, degradation of interleukins, antimicrobial defense and scavenging of reactive oxygen species | Cotton gauze materials have been historically evaluated and used as absorbents, dressings and packing materials in managing all forms of bleeding; Several licensed cotton-based products are approved in clinical use as dressings and bandages; Tulle gauze has been evaluated as wound dressings in partial-thickness wound models in rats; Various FDA approved products like Traumastem and Surgicel are approved in clinical use as dressings | Effectively absorbs blood and fluids but can adhere to wound bed causing discomfort and hinder wound healing; Tulle dressings were found to capture granulocytes that enhance the antimicrobial effects, but caused disturbed pattern of epithelial growth due to being embedded in the wound; OC and ORC dressings evaluated in porcine femoral artery bleeding models revealed improved hemostatic efficiency compared to cotton gauze |

| Collagen- based materials and technologies, e.g., - AviteneTM: sheet, foam or powder of partial hydrochloric acid salt of purified bovine collagen - Helistat™: Collagen sponge material - Instat™: Microfibrillar bovine collagen etc. | Collagen promotes platelet adhesion, activation and aggregation and these aggregated active platelets further release pro-coagulant molecules (e.g. ADP, Ca++ etc.), as well as, allow co-localization and activation of coagulation factors on their membrane to augment thrombin generation and fibrin formation to accelerate clotting | In vitro studies have characterized blood interactions with collagen, platelet adhesion, activation and aggregation, platelet secretions; In vivo studies have characterized bleeding time and inflammatory responses, e.g. in canine spleen incision model and porcine transectional lacerations of spleen, liver and kidney; Approved for topical and surgical hemostat applications | In vitro, collagen based hemostats show significant adhesion and activation of platelets, leading to augmentation of platelet-mediated clotting mechanisms; In vivo, collagen-based hemostats showed significant reduction of bleeding time to allow control of bleeding within 2–5 min, with minimal immune reaction |

| Composite spray consisting of bovine collagen, bovine thrombin and autologous plasma e.g. CoStasis® | Collagen can adhere to injury site and wound bed to initiate adhesion, activation and aggregation of platelets; thrombin augments platelet activation and aggregation, and also augments conversion of fibrinogen to fibrin in situ to enhance clot formation | In vitro studies have characterized platelet adhesion, activation and aggregation; In vivo studies have evaluated the material in midline laparotomy model of liver and spleen in rabbits; Phase I and Phase II clinical evaluations performed in patients undergoing cardiac, hepatic, iliac and general surgery; Approved as surgical hemostat | In vitro studies have shown increased platelet adhesion, activation and aggregation within 2–5 minutes; In vivo, complete hemostasis achieved within 2 minutes or less in rabbit models even on 50% depletion of either platelets or fibrinogen; No detectable adverse effects associated with antibody production; Clinical studies showed cessation in intraoperative bleeding within 10 min in 90% of CoStasis treated patients compared to 58% of control patients |

| Gelatin based materials and technologies, e.g., - GelFoam: gelatin solid sponge - FloSeal: Matrix containing a mixture of crosslinked bovine gelatin granules and human thrombin - GRF Glue, GR-Dial etc.: Mixture of gelatin, resorcinol with formaldehyde and glutaraldehyde activator | Since gelatin is collagen-derived, it possibly causes activation and aggregation of platelets, accelerates clot formation and structurally supports the clot being formed; Facilitates coagulation cascade propagation via augmenting thrombin generation; Tamponande effect of swollen granular gelatin at wound site reduces bleeding and promotes formation of clotting matrix; For aldehyde-containing glue, protein crosslinking results in adherence of the glue to the wound tissue, while gelatin promotes hemostatic mechanisms and resorcinol provides bacteriostatic action | In vivo studies performed in bilateral ultrasound-guided percutaneous renal cryoablation (PRC) of swine kidney; In vivo studies performed in heparinized porcine liver abrasion model; Clinical studies performed in patients under cardiac and spinal surgeries; In vivo studies performed on bleeding control and tissue adherence in thermal injury and air-leak model on rat lung; Clinical trial carried out in patients in surgery for acute aortic dissection; GelFoam currently approved as topical hemostat, FloSeal approved for clinical use as a surgical sealant in emergency surgeries, Gelatin glues clinically approved as a surgical sealant to control intraoperative bleeding | Significantly reduced post-operative blood loss in porcine PRC kidneys; Stops bleeding within 2–3 minutes in patients undergoing cardiac, vascular, or spinal/orthopedic surgery; Glue adhered tightly to degenerated lung tissue surface and no air leaks observed 1 hr post operation at low intra-tracheal pressure; Deemed clinically safe method for acute aortic dissection surgery; In-hospital mortality in aortic surgery patients was reduced with GRF glue; Aldehyde containing materials are prone to adverse effects (dose dependence of activator) due to toxicity of formaldehyde |

| Alginate-based technologies, e.g., Algosteril | Negatively charged uronic acid chains of alginate sequester Ca++ which is a co-factor for platelet activation as well as several coagulation cascade reactions, and thus augments clotting mechanisms | Studies performed on human diabetic foot ulcer model, as well as, endo-nasal surgical procedures; Clinically approved for wound care dressing applications | Mean time to wound healing was significantly reduced compared to controls; Less severe and frequent bleeding incidents occurred compared to controls in surgical procedures |

| Chitosan-based materials and technologies, e.g., - TraumaStat: poly-ethylene fibers coated with chitosan and filled with precipitated silica - HemCon, ChitoFlex: bandages from lyophilized chitosan material - Celox: granular chitosan | High surface area to allow robust interaction with platelets and coagulation factors increasing the pace and strength of the resulting clot; Possible mobilization of Ca++ to augment platelet activation and coagulation factor activation for clot formation | Rigorous in vivo evaluation in porcine complex groin injury models, porcine femoral artery and vein transection hemorrhage model, porcine liver injury hemorrhage model etc.; Approved for bleeding management in civilian and military trauma | Significant reduction of blood loss in hemorrhagic models; Decreased post-compression blood loss and decreased fluid requirement; Improved survival rates in trauma models, compared to control treatment |

| Zeolite and kaolin powder based materials and technologies, e.g., QuikClot powder, QuikClot-modified gauze (Combat Gauze), Advanced Clotting Sponge, WoundStat etc. | Aluminosilicate inorganic powder material can rapidly absorb water from blood (hygroscopic action) to concentrate coagulation factors; The powder can release Ca++ in blood and can activate FXII to trigger the intrinsic coagulation pathway; The powder can possibly induce contact activation of platelets | Rigorous evaluation in porcine complex groin injury, porcine grade 4 and 5 liver injury, porcine partial nephrectomy, porcine femoral artery hemorrhage, rabbit complex groin injury, porcine and rabbit extremity hemorrhage models etc.; Approved for selective management of traumatic bleeding in civilian and military applications | Significant reduction in blood loss, robust clot formation, significant reduction in re-bleeding, significant improvement in survival rate compared to control treatments; Persistent issue of thermal damage to tissue due to the highly exothermic nature of hygroscopic action |

| Blood-derived or recombinant hemostatic factors and materials, e.g., Composite fibrin glues and adhesives (Tissel, Evicel, Vitagel etc.), Fibrinogen and thrombin mixture for in situ fibrin formation, Fibrin fleece (e.g. TachSeal), Fibrin fleece with aprotinin (e.g. TachoComb), Autologous plasma sealants (e.g. CryoSeal, Vivostat etc.) | Fibrin is the major physiological crosslinked biopolymer component of clot and therefore it is capable of hemostasis, platelet and other blood cells arrest, further activation and enhancement of coagulation mechanisms; Thrombin component can augment in situ conversion of fibrinogen into fibrin to enhance clot formation and clot mechanical stability; Components like aprotinin can prevent fibrinolysis and thereby maintain clot strength; Matrix can further contain other components like microfibrillar collagen etc. for added effect | Rigorous evaluation in rat femoral artery repair model, canine dura puncture and spinal surgery models, rat and pig non-cardiac thoracic surgery models, porcine liver injury model, porcine aortic injury model, etc. Clinical studies carried out for use as tissue sealant and hemostat in ophthalmology, hernia repair, non-cardiac thoracic surgery, fistula repair, orthopedic surgery, gastro-intestinal surgery, dental procedures etc.; Currently approved clinically as tissue sealant, tissue adhesive and hemostat in a variety of surgical procedures | Increased tissue adhesion, decreased blood loss, high hemostatic efficacy, reduced risks of re-bleeding; Presence of non-human sourced components (bovine, equine etc.) may result in various degrees of immunogenic effects |

2.2.1 Absorptive and passively interactive materials in hemostatic technologies

While the function of a tourniquet is to augment the vasoconstriction and stypsis at the bleeding site, the function of a bandage or dressing is to directly cover and protect the site from further contamination and tissue damage, allow exchange of gas and fluids (blood and exudate absorption and removal), potentially prevent infection and allow healing in the long term. To this end, sterile wound dressings and absorbent pads have been made of various materials including cotton gauze or cotton pad, oxidized cellulose material, nylon/rayon/polyester variants, tulle gauze, semi-permeable porous polymer membranes and foams, hydrocolloidal and hydrofiber materials, and amorphous hydrogels. Cotton is a cellulosic polymer that differs from wood cellulose by the fact that it has a much higher degree of polymerization and crystallinity than wood cellulose. Cellulose is a homopolysaccharide of glucopyranose, polymerized through β-glucosidic bonds [83,84]. Cotton contains about 90% of this cellulosic polymer along with a small amount of hydrophobic waxes and pectin, while wood contains about 40–50% cellulosic polymer. The US military standard field dressing consists of two layers of gauze wrapped over densely packed cotton, such that it can absorb a large volume of blood while the cotton strands are thought to trigger platelet activation and aggregation due to high hydrophilicity, negative surface charge and surface energy [85]. The cotton gauze or pad, when directly placed over a bleeding injury, may provide high blood absorption, partial hemostatic reaction (thrombin generation via contact pathway) and additional tamponade effect with adjunctive compression components, but they can adhere to the wound tissue which may be an issue during their subsequent removal. Nonetheless, in recent years interesting research is being focused on modulating the hemostatic characteristics of cotton dressings and gauze by modifying them with other hemostatic or strengthening materials like kaolin mineral, chitosan, viscose, rayon etc. [85,86]. Oxidized cellulose (OC) derived from cotton and oxidized regenerated cellulose (ORC) derived usually from wood pulp, refer to manipulation of the cellulose structure where primary and secondary alcohol moieties are oxidatively converted to aldehyde, ketone or carboxyl groups, which significantly changes the physico-chemical and mechanical properties of OC and ORC compared to native cellulose [87–91]. The use of OC and ORC as hemostatic dressing materials in surgery was reported around WWII [92–94], and since then its widespread application as a surgical wound dressing material has established its biocompatibility, bactericidal and hemostatic properties [84, 95–100]. The acidic pH of these oxidized cellulose materials and the negative charge are thought to impart platelet activation, aggregation and intrinsic pathway of coagulation mechanisms. These materials are also reported to be biodegradable via enzymatic (glycosidase-based) and macrophagic processes [101,102]. Recent advancement of these materials involves modification of the material matrix with other hemostatic agents like fibrin [103]. Like cotton gauze and pads, the OC and ORC materials can present the issue of adherence to the bleeding tissue, that may pose some logistical difficulties during their subsequent removal.

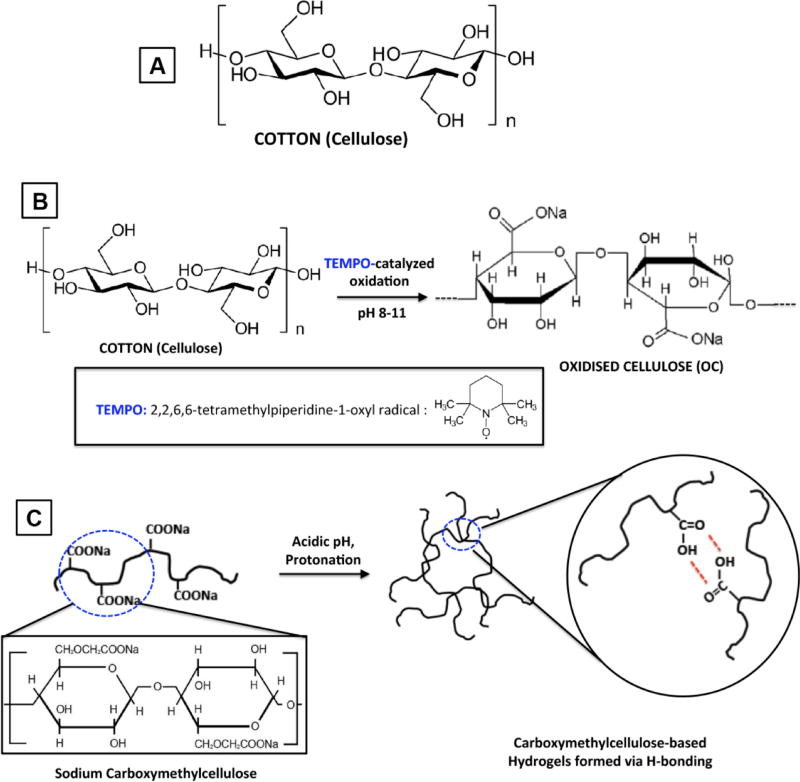

The adherence issue can be resolved by making materials non-adherent yet absorbent in dressings, e.g., paraffin-soaked tulle gauze and various polymer-based, hydrogel-based, hydrofiber-based and hydrocolloid-based dressings. Tulle dressings (Tulle Gras in French, meaning ‘oily tulle’) are essentially open weave cloth gauze soaked in paraffin (petroleum jelly), balsam and olive oil to impart hydrophobicity and non-adherence to bleeding wound site [104]. These materials are usually used for low exudate wounds and can be further modified by impregnating with anti-septic agents like chlorhexidine gluconate to impart infection-protection. The cotton pad, gauze and tulle materials are traditionally considered as ‘passive wound dressing’ materials since their primary function is to fully cover the wound for physical and mechanical protection, while allowing exudate absorption and fluid exchange. For high exudate situation, cellulose-based hydrogels have also been developed. For example, amorphous hydrogel materials consisting of mostly water with about 2–3% of a gel-forming polymer such as sodium carboxymethylcellulose, modified starch or sodium alginate, along with about 15–20% propylene glycol (a humectant and preservative), have been developed for wound dressing and hemostatic applications [105,106]. These dressings, along with synthetic polymer based hydrocolloid and hydrofiber systems (discussed later in this review), are highly suitable for burn wounds and necrotic or sloughy wound beds, since the water content can cool down the injury site to aid in comfort and healing. The gels are often used with a secondary dressing material like perforated or gas-permeable plastic film that prevents the water content of the hydrogel from evaporating outward but rather donated towards the wound. Similar hydrated water-donating property can be achieved with corboxymethylcellulose-based hydrogelic particles dispersed within polyurethane film or foam (for hydrocolloids) or carboxymethylcellulose-based fibers manufactured into non-woven pads or ribbons [107]. Both of these systems are useful for hemostatic action, protection and healing maintenance of heavily exudating deep wounds. Figure 2 shows representative chemical structures of common cellulose-based materials that are used in hemostatic wound-dressing applications. It is important to note here that although cotton and oxidized cellulose system are traditionally included in the ‘passive dressing’ group, they can be argued to possess a degree of bioactivity due to their ability to potentially stimulate primary (platelet activation and/or aggregation) and secondary (contact activation of intrinsic coagulation pathway) hemostatic mechanism components. However, a systematic study of the hemostatic mechanisms triggered by these materials is yet to be reported, and most studies report performance output in terms of extent of hemostasis, blood loss and tissue morbidity evaluation.

Figure 2.

Representative chemical structures of cotton (cellulose) biopolymers and its derivatives that have undergone extensive research in the development of hemostatic technologies like gauze and wound dressings.

2.2.2. Bioactive materials in hemostatic technologies

Thrombin, Fibrinogen and Fibrin

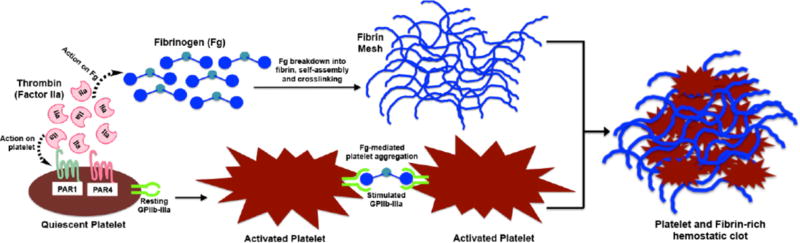

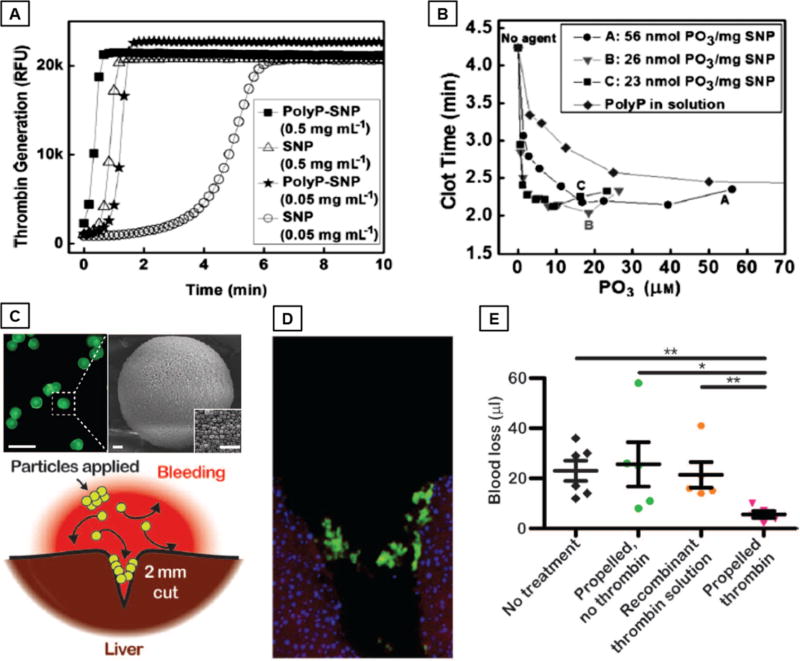

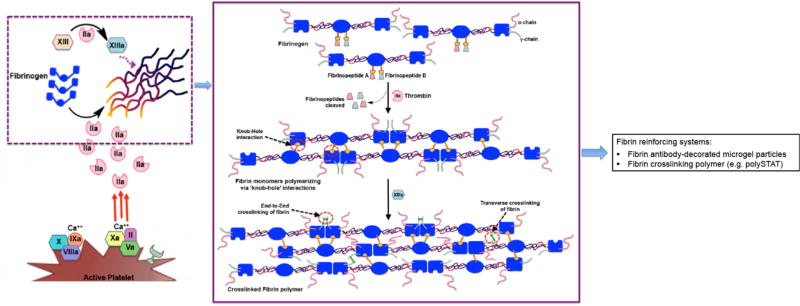

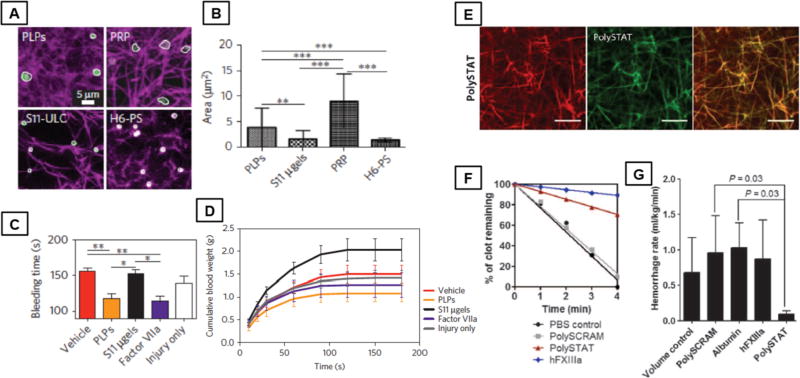

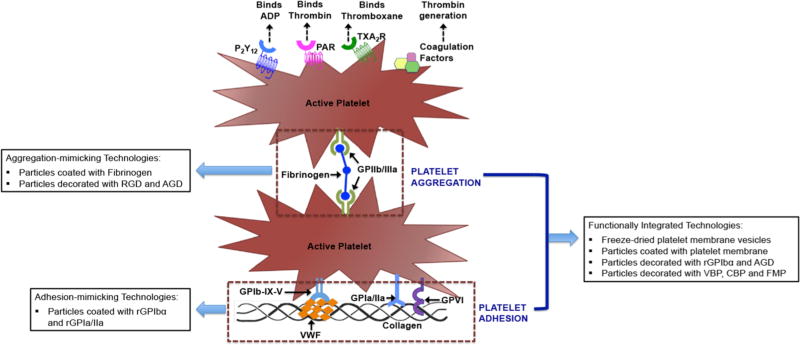

Thrombin, fibrinogen and fibrin (along with active platelets), are the critical components of the forming the hemostatic clot, as shown in Figure 3. Consequently, fibrin which is the protein formed as the end product of the coagulation cascade via reaction of thrombin on fibrinogen, has become an important bioactive material to be used in hemostatic applications. Reports from the early 20th century suggest fibrin to be superior to cotton in terms of hemostatic capacity [108–110], and since then fibrin dressings and sealants have become one of the most-studied hemostatic material, especially in the surgery field [111–115]. In early reports by Grey and Harvey, fibrin was used as pre-polymerized material processed into tamponade and plaque-like devices for treatment of bleeding in parenchymal organs [108,109]. These products demonstrated hemostatic capacity but had reduced capacities of tissue-integration since the fibrin was already pre-polymerized. Around WWII, Cronkite et al and Tedrick et al reported the usage of fibrinogen with thrombin to produce fibrin in situ in relevance to skin transplant procedures [116,117], which has led to the modern day usage of this precursor mixture for fibrin-based hemostatic products. Fibrin can be used in dry condition where animal- or human-sourced thrombin and fibrinogen are freeze-dried, processed into powder, foam, fleece, etc. and impregnated into a secondary bandage or carrier dispersant system to be applied directly onto the bleeding site [115, 118–123]. The secondary dressing can be a passive polymeric strip like silicone with an absorbent vicryl mesh backing or another bioactive but mechanically more robust material like collagen sheet [124–126]. The materials design rationale for all these systems is that upon contact with an actively bleeding site, the fibrinogen and thrombin in the dressing will interact to form fibrin in situ, leading to a hemostatic effect. In all evaluations so far, these fibrin(-generating) dressings have shown superior hemostatic performance compared to passive dressings, possibly because of their pro-coagulant bioactivity [123, 127–132]. Fibrin adhesives can also be used topically in a liquid form, where the freeze-dried fibrinogen and thrombin components are reconstituted in sterile saline immediately before administration, often through a specially manufactured dual-barrel injection device [111,112,133,134]. These liquid sealants can have high degree of tissue adherence due to physico-chemical (electrostatic, hydrogen and covalent bonding) interactions as well as mechanical integration into the tissue and can be applied to heterogenous injury sites due to their form-filling nature. The dry fibrin dressings and the liquid fibrin adhesive sealants have been reported to contain varying degrees of fibrinogen and thrombin, depending upon products from various companies and laboratories [135,136]. These compositionally different products have been tested for assessing variations in hemostatic performance, tensile strength, tissue adhesiveness etc. In some cases, no significant difference was found in the output performances, while in other cases changing the fibrinogen concentration showed some effect in mechanical strength and tissue adherence [137–140]. The fibrin-forming precursor systems (dry or liquid) can also contain other pro-coagulant materials like Factor XIII (a fibrin cross-linking transglutaminase enzyme) as well as anti-fibrinolytic agents like aprotinin and tranexamic acid (TXA, discussed in detail later in this review) to modulate clot formation speed and clot strength/stability [141–143]. Although such modifications may provide marginal benefits, the significance of such benefits have not been systematically evaluated and statistically established.

Figure 3.

Schematic of concomitant roles of thrombin and fibrin(ogen) in propagating the formation of hemostatic clots via activation of platelets and formation of fibrin mesh.

The lingering issue for a long time with such fibrinogen and thrombin based products has been the risk of immunogenicity and viral contamination, since the components are sourced from animal (bovine, porcine) or human pooled blood. Bovine thrombin preparations have been implicated in immunogenic reactions and increased risk of adverse clinical outcomes following its use in surgical procedures [144]. Fibrin based products that were mass-produced around 1944–45 to meet the needs during WWII were withdrawn in 1946 because of reports of hepatitis transmission [145]. As a progression of that, in the late 1970s many plasma-sourced fibrinogen-based products, originally clinically approved for hemostatic and surgical procedures, were recalled by the FDA. In the last decade, due to the emergence and establishment of rigorous blood screening, serological testing and pathogen (bacteria, virus) reduction/inactivation technologies, plasma-sourced products including fibrin systems have undergone a revival [110,115,145]. Through rigorous research conducted at several laboratories, including studies led by the US Army Institute of Surgical Research (USAISR), products like TachoComb and TachoSil (Nycomed, Austria) and Dry Fibrin Sealant Dressing (DFSD, developed by American Red Cross with USAISR) have become an important component in the current state-of-art toolbox for hemostatic management of traumatic and surgical bleeding [110,115,123]. Fibrin’s natural spatio-temporally regulated characteristics of biodegradation and wound healing are also responsible for its continued popularity in the milieu of hemostatic materials [146]. In recent years, there have also been reports on sourcing the fibrinogen and thrombin from salmon [147–151] as well as developing recombinant versions of such coagulation proteins [152–155]. For example, Recothrom™ (ZymoGenetic Inc, USA) is a fully recombinant human thrombin that has been clinically approved as a topical hemostatic agent to treat oozing blood and capillary bleeding and can be used in conjunction with other wound dressings. A transgenic approach has also been utilized to develop proteins like fibrinogen in the milk of other mammals for potential pharmacotherapeutic use [156]. Recombinant and transgenic versions of thrombin and fibrinogen are under pre-clinical and clinical evaluation, and can potentially resolve the availability and immunogenicity issues that are otherwise associated with human or animal plasma-resourced products. As for liquid fibrin sealants and adhesive products, although they remain a relevant material in surgery, their widespread pre-hospital use (e.g. in the battlefield) has been somewhat restricted due to time-consuming rehydration and mixing process of the lyophilized powders for in situ delivery. Furthermore, the resultant fibrin is capable of hemostasis in low volume and pressure bleeding scenarios but not heavy traumatic bleeding. In recent years, autologous fibrin generation technologies like CryoSeal (Asahi Kasei Medical Co., Tokyo, Japan) and Vivostat (Vivostat A/S, Denmark) have been reported that utilize small volumes of patient’s own plasma to generate fibrin sealant in the operating room [157]. These sealants have shown significant clinical promise as hemostatic materials during spine and sternum surgeries [158–161]. Fibrin has also be developed into ‘foam’ technologies for spray-based hemostatic use as sealants for heavy parenchymal bleeding [162–164]. Fibrin sealants have also been combined with other hemostatic materials like oxidized cellulose-based Surgicel® (Ethicon, USA) to cumulatively enhance hemostatic capability in surgical applications [165]. Due to their potential for externally injectable and space-filling properties, the liquid versions of fibrin sealant products may find use in intra-cavitary hemostatic applications.

Collagen and Gelatin

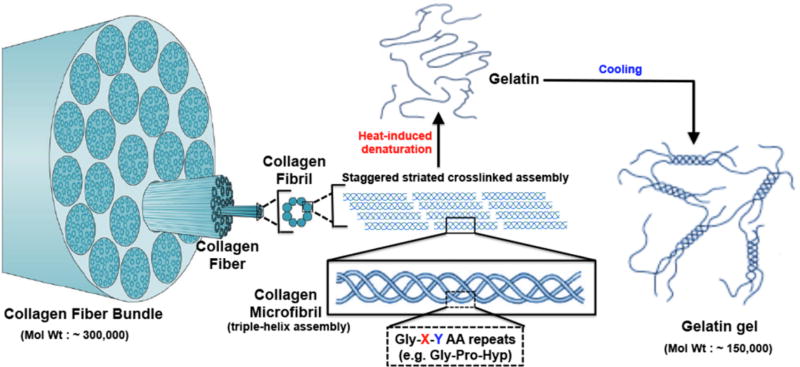

Another important bioactive material in hemostatic applications is collagen and its denatured variant, gelatin (multiscale schematic structure shown in Figure 4). Collagen is the most abundant structural protein found in the extracellular matrices of many connective tissues in mammals, making up about 25–35% of the whole-body protein content [166,167]. Fibrous collagen is present in the sub-endothelial matrix (Type III collagen mainly, with Type IV in the basement membrane) and upon injury (including endothelial disruption and denudation), collagen is exposed to circulating blood components. VWF secreted from injured endothelium and activated platelets can bind and self-associate on exposed collagen. Platelets can bind to self-associated VWF via platelet surface GPIbα receptor protein, and can also bind to collagen directly via platelet surface GPIa/IIa and GPVI receptor proteins [15,168,169]. These adhesion mechanisms of platelets at the injury site lead to further activation of localized platelets, ultimately leading to active platelet aggregation at the site (primary hemostasis) as well as augmentation of coagulation cascade events on the active platelet membrane (secondary hemostasis) [19,21]. Direct effect of collagen on coagulation factor localization and activation has also been reported, e.g. for FXII and FIX [170]. These physiological mechanisms have inspired the utilization of bio-derived collagen as a topical hemostatic material. In 1960s and 1970s, Hait et al had reported on the capability of isolated bovine collagen to adhere effectively to bleeding surfaces and promote hemostasis [171–173]. Such properties have eventually led to development of a wide variety of collagen-based products in sheet, powder, foam and fiber forms to be utilized as a topical hemostatic material, especially in surgical applications [174–179]. Representative commercially available technologies that utilize such collagen forms are Avitene™ (Davol Inc, USA), Helistat™ (Integra LifeSciences, USA), Instat™ (Ethicon, J & J, USA) etc. Collagen-based materials and technologies have also been studied for liquid form sealants. For example, a liquid composite spray consisting of microfibrillar bovine collagen, bovine thrombin and autologous plasma named CoStasis® (Cohesion Technologies, USA) was reported to render efficient hemostasis when externally administered in pre-clinical animal bleeding models (e.g. liver, spleen and kidney bleeding) and was subsequently clinically approved for surgical applications [180–183]. As with animal-sourced fibrin, animal-sourced collagen can pose immunogenic risks, and therefore research into reducing immunogenicity and infectivity has led to the popularity of a low-immunogenic collagen-derived material called gelatin [184–188]. Gelatin can be formed by thermal denaturation or irreversible hydrolysis of collagen and is extensively used in the food industry [189]. Gelatin was also been found to retain hemostatic properties like collagen [190,191]. Gelatin has been mixed into fibrin dressings to enhance the mechanical stability of the material [146]. Gelatin-based solid materials in spongy and powder form (e.g. GelFoam®, Pfizer, USA) have been evaluated for hemostatic dressings in surgical procedures but have shown limited efficacy in controlling severe bleeding [192–194]. Gelatin has also been evaluated as a material component in liquid hemostatic sealants, e.g. in products like Floseal® (Baxter, USA) where it was combined with thrombin to form a composite hemostatic sealant matrix [195]. In these composite gelatin-based sealants, the gelatin component is made up of collagen-derived gelatin cross-linked by glutaraldehyde and ground into macroscopic particles, which is mixed with bovine thrombin in a special syringe for intra-operative administration [196–199]. Another gelatin-based liquid sealant material has been reported as gelatin-resorcin-formalin glue (GRF glue), where gelatin, resorcinol, formaldehyde and glutaraldehyde are mixed in an aqueous medium for application to a bleeding site such that the aldehydes promote reaction and integration with tissue, gelatin promotes hemostatic mechanisms and resorcinol provides bacteriostatic action [200–202]. This material has been reported in extensive use in acute aortic dissection procedures but has also raised issues of formaldehyde-associated toxicity. Similar to liquid fibrin-based sealants, collagen-based and gelatin-based liquid sealants have also been evaluated for heavy hemorrhage treatment and these may also find use in intra-cavitary hemostasis applications. In recent years, there is also growing interest in recombinant collagen and gelatin materials that may potentially find application in future hemostatic technologies that pose reduced immunogenic risks [203–205].

Figure 4.

Multiscale schematic representation of fibrillar collagen structure where triple-helical microfibrils formed of Gly-X-Y amino acid repeat units assemble in staggered orientation to form collagen fibrils, which in turn further assemble to form high molecular weight collagen fibers and bundles; denaturation of collagen disrupts this assembled structures to form gelatin, which can be partly reassembled into helical components to form lower molecular weight gels.

Polysaccharide derivatives

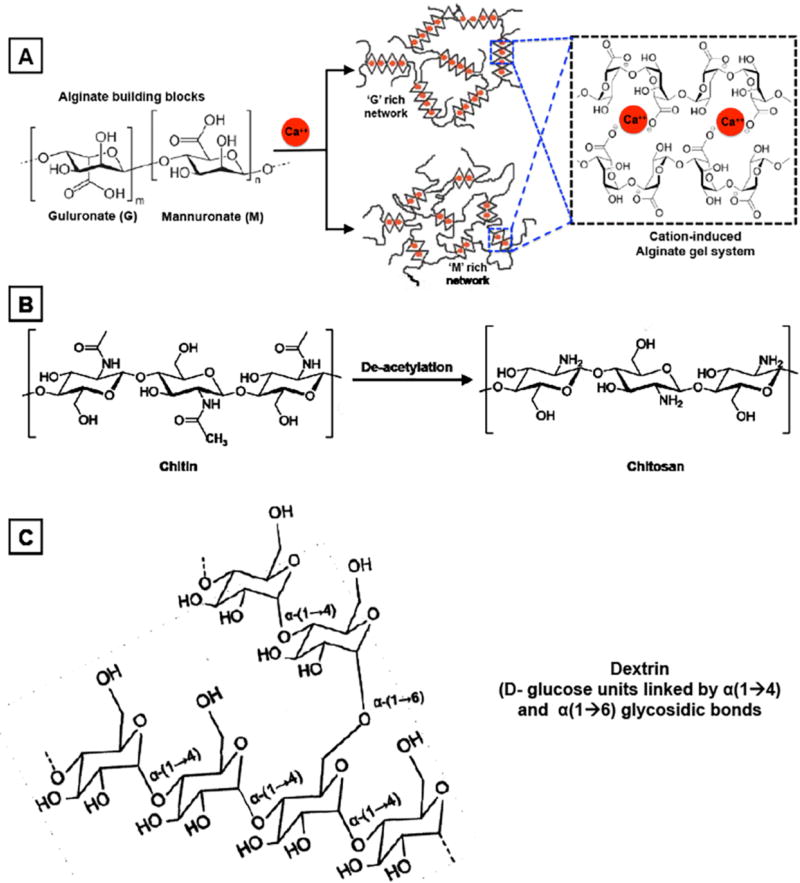

Aside from materials and technologies based on fibrin (fibrinogen + thrombin), collagen and gelatin, a third prominent category of bioactive materials in hemostatic applications is that of natural polysaccharides in native or modified forms [206]. One prominent material in this category is alginate, which is a linear polysaccharide derived from brown algae and is comprised of blocks of (1,4)-linked β-D-mannuronate (M) and α-L-guluronate (G) residues where the blocks may be consecutive G (i.e. GGGGGG), consecutive M (i.e. MMMMMM) or alternating G and M residues (i.e. GMGMGM) [207, 208]. The negatively charged uronic acid chains of alginate can gel in presence of a cation like calcium (Ca++), and this sequestration of Ca++ is thought to be responsible for the hemostatic property of these gels since Ca++ is a co-factor for platelet activation as well as several coagulation cascade reactions [209, 210]. In pre-clinical animal model studies as well as in clinical investigation, alginate-based dressings have shown superior hemostatic performance compared to traditional gauze in low-to-moderate bleeding scenarios [211–213]. The hydrogelic state of alginate dressings is suitable to keep the wound-bed moist for healing and provide comfort during dressing changes. Besides the traditional hydrogelic form, the alginate material can also be made into micro/nano particles as well as micro/nano fiber using suitable processing techniques, and these solid forms have been recently evaluated in hemostatic applications. Alginate microspheres loaded with the anti-fibrinolytic agent tranexamic acid or the pro-coagulant agent thrombin, have shown promising hemostatic capabilities in vitro and in vivo in pre-clinical models [214, 215]. Currently a large number of alginate-based wound dressings are clinically approved for surgical and hemostatic applications, e.g. Algosteril® (Johnson & Johnson, USA) and KALTOSTAT® (Conva Tec, UK). Alginate material has also been combined with other hemostatic materials (collagen, gelatin, oxidized cellulose, other polysachharides etc.) for the development of composite hemostat technologies that may provide enhanced treatment capabilities compared to mono-component systems. For example, highly absorbent collagen-alginate and gelatin-alginate dressings have shown superior wound treatment capabilities [216–218]. Alginate fibers have also been combined or co-spun with other polysachharides (e.g. chitosan) and natural polymers (e.g. gelatin), to enhance hemostatic and anti-bacterial effects [208, 219].

Along with alginate, chitosan itself has attained prominence in the area of hemostatic dressings and technologies. Chitin is a hard nitrogenous polysaccharide composed of β (1,4)-linked 2-acetamido-2-deoxy-β-D-glucose (N-acetylglucosamine), and it is the second most ubiquitous natural polysaccharide on earth (after cellulose), usually found in the exoskeleton as well as in the internal structure of invertebrates (crustaceans, shellfish etc.) [220]. Enzymatic or alkaline de-acetylation of chitin results in the linear polysaccharide chitosan, which can essentially remain as a co-polymer of N-acetylglucosamine and glucosamine depending on the degree of de-acetylation. The ability of chitosan to facilitate coagulation was reported first in the early 1980s by Malette et al [221], and this has led to extensive investigation of chitosan in various forms for hemostatic materials and technologies. The hemostatic ability of positively charged chitosan is thought to stem from its electrostatic interaction with negatively charged cell membranes of RBCs, resulting in RBC agglutination as a ‘physical’ mechanism of hemostatic plug formation [222, 223]. Chitosan has also been reported to enhance adhesion, activation and aggregation of platelets (i.e. enhancement of primary hemostatic mechanisms) as well as to be able to adsorb fibrinogen from plasma, as well as, to trigger complement activation [224–228]. The platelet stimulating effect of chitosan has been attributed to Ca++ mobilization. Chitosan is an acidic polyelectrolyte where about 50% de-acetylation of chitin results in a chitosan system with pKa of ~7.5 (i.e. soluble in water). Therefore, modulating the de-acetylation degree provides a control to modulate chitosan physico-mechanical as well as chemical properties. Chitosan can be made into films, fibers, hydrogels, lyophilized particulates and solutions, and all of these forms have demonstrated hemostatic capabilities in various studies. For example, chitosan-based layered materials with interconnected open porous structures and high specific surface area were used to develop a highly effective hemostatic dressing named HemCon® (HemCon Medical Technologies, Oregon, USA) that was extensively evaluated by USAISR investigators for management of traumatic hemorrhage, resulting in the technology being added to the metric of hemostatic strategies for US military [145, 229, 230]. This material however is rigid and inflexible, which may make it difficult to be applied over complex injuries. In further progress of this technology, the material has shown great clinical success in both military and civilian populations and a flexible version (Chitoflex®, HemCon Medical Technologies) has been developed for further evaluation [231–233]. Particulate (granulated, powder) forms of chitosan have also been utilized in developing hemostatic technologies. A prominent example is a technology named Celox® (MedTrade Products Ltd, UK), which utilizes chitosan granules and flakes to provide high contact surface area for interact with blood [234]. Upon direct administration at the wound site, blood interaction with this material is known to result in swelling of the granules for hydrogelic absorptive effect, and the chitosan contact promotes multiple mechanistic components of hemostasis. This material has been extensively evaluated for hemostatic management of heavy bleeding wounds (liver blunt trauma, arterial puncture bleeding, groin laceration etc.), showing highly effective hemostasis and reduced occurrence of re-bleeding [235–238]. Along with HemCon®, Celox® is now a prominent component of hemostatic management in pre-hospital and hospital scenarios. Chitosan has also been utilized to make hydrogel systems in situ by reacting thiol-modified chitosan with maleimide-modified ε-polylysine, and these materials have shown promising hemostatic capabilities added with tissue-adhesive properties of polylysine [239]. There are also several recent reports on developing foams with chitosan or mixture of chitosan with other materials (e.g. gelatin etc.), for potential application in hemostatic technologies [240–242]. Chitosan gauze has also been recently reported to be coated with N-(2-Hydroxypropyl)methacrylamide (HPMA) based synthetic fibrin-strengthening polymer (e.g. PolySTAT) for enhanced hemostatic action [223]. The PolySTAT material itself will be discussed in the context of fibrin-strengthening materials, later in this review. A chitosan analog, poly(-N-acetyl glucosamine), produced by a fermentation process and isolated from controlled, aseptic, microalgal cultures grown on a defined culture medium, has also gained reputation as a hemostatic material in gel form, fiber slurry and membrane form [243–245]. Thromboelastographic evaluation of this material, along with other analogous materials like chitin, chitosan etc. demonstrated reduced clot induction time when mixed with blood. The membrane form prepared by lyophilization and sheet-pressing of this material was added to a backing of standard hemostatic gauze, resulting in a hemostatic technology named Rapid Deployment Gauze (RDH, Marine Polymer Technologies USA) that was evaluated extensively for its hemostatic capability in severe traumatic bleeding [246, 247]. The hemostatic efficacy shown by this technology in pre-clinical and clinical studies has resulted in its clinical approval and its adaptation as an important component in the bleeding injury management strategies in pre-hospital scenarios. Porous polysaccharide microparticles developed from processed potato starch (dextrin) have also been studied for potential hemostatic applications, especially as a technology named TraumaDEX® (Medafor Inc., USA) that can be directly applied to bleeding wounds. When evaluated in pre-clinical bleeding models, this material and technology has demonstrated hemostatic efficacy comparable to standard gauze dressing. In similar studies, the hemostatic efficacy of TraumaDEX® was also found to have no statistical difference compared to Celox® [248, 249]. Altogether, bio-derived polysaccharides, like alginate, chitosan and dextrin, form an important materials category for hemostatic applications, and a large variety of technologies comprising of films, sheets, membranes, powders, microparticulates and liquid forms have been developed from these materials, many of which have become clinically approved systems for bleeding management in pre-hospital as well as hospital scenarios in military and civilian settings. Figure 5 shows representative chemical structures of relevant polysaccharide materials used in hemostatic dressings described above.

Figure 5.

Chemical structures of some polysaccharide polymers, namely alginate, chitosan and dextrin that have been extensively used in development of hemostatic bandages and dressings.

Minerals and zeolites

As mentioned previously, the ability of alum to facilitate hemostasis is by augmenting vasoconstriction and stypsis, which essentially is a mechanical augmentation of hemostasis. Certain microporous aluminosilicate minerals (also called zeolites) have shown the ability for bioactive augmentation of hemostatic mechanisms. The most famous material of this category is Quikclot® (Z-Medica Inc., USA), a granular zeolite technology, that has been shown to render efficient hemostasis in severe hemorrhage from arteries, liver injuries and groin injuries in multiple animal models [250–253]. The high hemostatic efficacy of this material was also demonstrated in clinical studies and this has resulted in its approval for use in combat casualties with severe bleeding [254]. The material is thought to promote rapid hemostasis via a combination of super-absorbent property (which removes aqueous volume from blood and concentrates clotting factors), platelet activation capacity and coagulation factor activation capability (contact activation of intrinsic hemostatic pathway) [255–257]. However, the interaction of this zeolite material with blood (aqueous medium) is substantially exothermic, resulting in sudden rise in local temperature, which was found to cause tissue damage and debilitation [258, 259]. In this aspect some research is being directed towards modulating the composition and structure of these zeolite minerals to retain its hemostatic property while reducing the exothermic side-effects [260–263]. In recent years, Quikclot® has been used to modify the matrix of standard gauze and sponge used in US military, resulting in a technology named Quikclot Combat Gauze (QCG) or Quikclot-Advanced Clotting Sponge (QC-ACS), that is considered to reduce the exothermic side effect of the mineral because of co-absorption by the gauze [264–266]. This new mineral-impregnated dressing material has shown similar hemostatic effect as the mineral itself and is currently an important component of tactical hemostatic strategies for the US military [267]. Another mineral based technology is WoundStat® (TraumaCare Inc., USA) that uses a smectite mineral and super-absorbent polymers [268, 269]. This technology has shown highly efficient hemostasis in topical treatment of arterial bleeding and had gained much popularity as a field hemostat in US military [270, 271]. However, further safety studies on the material revealed several systemic side effects, including vascular endothelial injury, transmural damage, systemic thrombotic and embolic risks, due to microscopic residues of WoundStat remaining in the wound and blood vessels [233, 271]. This has resulted in the military dropping the usage of this material and replacing it with the QCG technology mentioned previously.

2.3. Synthetically derived hemostatic materials

While a large volume of research has been conducted on naturally derived materials for developing bleeding management technologies, a small number of synthetically derived systems, especially certain polymers and peptides, have also been developed and evaluated for hemostatic applications. One such polymer category is that of basic poly(amino acids) like polylysine. During the 1950s DeVries et al reported that basic poly(amino acids) like polylysine, polyarginine etc. augment generation of thrombin and fibrin and also retard fibrinolysis [272–274]. It was postulated that the cationic nature of polylysine facilitates complexation and activation of certain coagulation factors [275]. This kind of report has possibly guided the use of polylysine as a cationic polyeletrolyte to be mixed with chitosan for hemostatic applications, but stand-alone polylysine based technologies have not undergone much development possibly because of biocompatibility and cytotoxicity issues of cationic polymers [276]. Poly(alkylene oxides), e.g. poly (ethylene oxide) (PEO) and poly(propylene oxide) (PPO), have been investigated as hemostatic materials since they are already well-established biocompatible synthetic polymers in biomaterials applications. For example, Wang et al and Wellisz et al have reported on the hemostatic capability of a PEO-PPO-PEO block copolymer based waxy material (now marketed as Ostene®, Baxter USA) to render hemostasis in orthopedic surgeries [277, 278]. This material acts much like natural bone wax (a mixture of beeswax with paraffin or petroleum jelly) in the context of facilitating hemostasis by a tamponade mechanical effect rather than a biochemical augmentation of coagulation mechanisms. A similar block copolymer made of poly(ethylene glycol)-b-poly(dihydroxyacetone) has also been reported recently by Spector et al. to have promising mechanical hemostatic properties [279]. A mixture of tetra-succinimidyl-derivatized and tetra-thiol-derivatized poly(ethylene glycol) has been recently evaluated as a hydrogel material for hemostatic liquid sealant [280]. In these studies, it was shown that this material can crosslink with tissues and is capable of rendering a mechanical hemostat effect by virtue of sealing a puncture hole in a rabbit artery bleed model. Several successive evaluations in pre-clinical models and in clinical trails have led to approval of this material as a surgical sealant named CoSeal® (Baxter, USA) [281, 282]. A similar material has been developed by co-polymerizing poly(ethylene glycol) with poly(α-hydroxy acid) diacrylate, and after evaluation in vitro and in vivo, this material is currently marketed as AdvaSeal® (Ethicon Inc., USA). Thus, poly(ethyelene oxide) based synthetic external hemostatic sealants have undergone considerable clinical translation, especially in surgical bleeding applications.

Another class of synthetic polymers that has gained clinical significance in tissue sealant applications is poly(cyanoacrylates). This class of polymers was reported to have excellent tissue-adhesive properties via polar interactions with the tissue and was therefore used as a sutureless tissue sealant as early as the 1940s. Synthetic cyanoacrylates (e.g. 2-octyl cyanoacrylate) under the product name Dermabond® (Ethicon Inc., New Jersey, USA), was approved in the 1990s by the FDA for skin closure. Since then, this class of tissue sealant has been widely used for surgical wound closure and hemostat applications [283–287]. Long chain poly(cyanoacrylates) sealants have shown reduced tissue toxicity and have progressed into clinically approved technologies like Histoacryl® (TissueSeal LLC, USA) and GLUture® (World Precision Instruments) for topical applications in surgeries [287, 288]. Cyanoacrylate based tissue sealants have also been combined with tourniquet-based procedures to evaluate their ability to staunch bleeding from larger hemorrhagic injuries [289]. It should be noted that cyanoacrylates technically do not possess inherent ‘hemostatic’ property in the classical sense, but rather their mode of action is through physical sealing, mechanical barrier and wound closure. Several other well-known polymeric biomaterials used in biomedical devices like sutures, contact lenses, coatings, drug delivery systems etc. have been investigated for hemostatic applications. For example, poly(glycolic acid) or PGA is an established biomaterial that is used in a variety of clinically approved bioerodible devices like sutures and implants, and this polymer has been used to develop a hemostatic felt dressing. This felt (Soft PGA Felt, Aventis Behring, Germany) was evaluated in surgical hemostatic treatment of liver resection surgeries in patients, showing promising results as a hemostatic technology option combined with fibrin glue [290]. Poly(2-hydroxyethyl methacrylate) or poly-HEMA is an established biomaterial which had originally become known for its use in contact lens devices. Porous particles made from this polymer has been reported to have the capability of reducing blood loss in endovascular occlusion surgeries [291]. Poly(acrylic acid) is another synthetic polymer biomaterial which was used to develop a hemostatic technology named Feracryl® by Russian scientists in the 1980s [292]. This material was developed by reaction of acrylic acid with Mohr’s salt in an aqueous medium and had a small percentage of iron(III) coordinated with the polymer. In evaluation in vitro and in vivo this material was found to be non-toxic with promising hemostatic ability and this has led to development of several acrylic acid based hemostatic technologies in Russia but not much has been reported elsewhere globally. Carr et al have reported on a microporous poly(acrylamide) gel in the development of a super-absorbent hemostatic technology named BioHemostat® (Hemodyne Inc., USA), which showed great promise in the treatment of heavy bleeding injuries [293]. The hemostatic ability of this material was attributed to its capacity of absorbing high amount of fluids from the wound and expanding to exert a mechanical tamponade effect on the wound. Casey et al. have recently reported on the development of a series of cationic acrylamide hydrogels that demonstrated the capability of activating coagulation factors that may aid in clot formation and hemostasis [294]. Another tissue sealant technology based on albumin-glutaraldehyde (e.g. BioGlue®, CryoLife Inc., Georgia, USA), is available in the United States for surgical adhesive applications in open surgical repair of large vessels (such as aorta, femoral and carotid arteries) [295]. In recent years, mussel-inspired biomimetic materials design approaches have led to several interesting novel classes of tissue-adhesive synthetic polymers, including citric-acid based, catechol based and hyperbranched poly(aminoester) based systems, which may find potential use as hemostats and sealants [296–298]. These studies and reports establish the promise of tissue-interactive synthetic polymeric systems for the engineering of hemostatic technologies, that can staunch bleeding through mechanical as well as biochemical mechanisms. Recently, several research groups have reported on a synthetic peptide termed RADA16-I (essentially a 4-mer repeat of Arginine-Alaninine-Aspartate-Alanine) that can self-assemble into supramolecular structures and can gel in presence of blood to arrest blood cells and promote a coagulatory effect [299–302]. The molecular mechanism of such hemostatic action of this synthetic peptide material is thought to be more due to gelation and tissue adhesion, and the presence of any additional biochemical involvement in the coagulation cascade is currently unclear. Besides being used directly as absorbent dressing, sealant or tamponade systems, synthetic polymers are also used as scaffold or backing components in many hemostat technologies. Examples of these were previously described in technologies where polyurethane films and foams were used as scaffold material for dressings. In other composite applications, polymers like polypropylene and polyurethane have been used as scaffold materials for impregnating chitosan material [303, 304]. Dressings made of polymer films, foams and amorphous hydrogels are considered to be ‘interactive wound dressings’ as they are mostly transparent to allow monitoring of wound status, while maintaining non-adherent and absorbent properties. The polymer film wound dressings are usually made of semi-permeable polyurethane membrane with an acrylic adhesive backing, while he polymer foam wound dressings are formed of soft, open cell, hydrophobic polyurethane foam sheet, approximately 6–8mm thick, with a high capacity of exudate absorption [305]. The film systems are usually used for low exudate wounds while the foam systems can be used for heavy bleeding and high exudate wounds. Polymer-based semi-permeable dressings and foams also have the advantage of preventing bacteria and fluid transfer at the injury site while allowing regulated transfer of air and moisture, such that the wound bed can be kept optimally moist to aid comfort and healing. However, if the wound site produces high amount of exudate, its build-up may negatively affect the adjoining tissue (e.g. maceration). Altogether, a variety of synthetic polymeric biomaterials have become stand-alone or integrative components of many hemostatic materials and technologies, as they provide advantages of customizing chemistry for stimulating pro-coagulant mechanisms while reducing immunogenicity risks otherwise associated with some of the bio-derived materials.

2.4. Compression bandage technologies

The aspect of applying pressure to cause ‘stypsis’ and the aspect of applying bandages and dressings (made from natural or synthetic biomaterials) to allow absorptive and interactive mechanisms at the bleeding site, have been integrated to result in compression bandage technologies. The simplest versions of such technologies consist of cotton gauze pads placed with manual pressure over the bleeding wound, but this material as well as procedure is unreliable due to variations in severity of injuries and external manual pressure needed for efficient hemostatic compression [48, 306]. A marginal improvement of this technology is found in the Army Field Bandage where a thick pad of cotton is contained within layers of gauze and tying straps are attached to this material to help fastening and tightening of pressure [307]. A further improvement is found in the emergency field bandage (aka ‘the Israeli bandage’, First Care Products) originally designed and developed by Israeli military serviceman Ben Bar-Natan, which consists of an elastic bandage sewn over a sterile non-adherent absorbent pad material. The bandage is equipped with a pressure bar through which the wrapping material may be inserted, reversed in direction and tightened over the bleeding site to apply tourniquet-like compression [308]. Unlike the direct placement of gauze or gauze-wrapped cotton pad on the bleeding injury, which can make removal of the bandage material cumbersome and risky, the utilization of non-adherent material along with the compression bar made this bandage design a welcome improvement in management of traumatic wounds in the military. Another military-tested compression bandage is the CinchTight bandage system (H&H Medical Corporation, USA), which is available in a variety of sizes and consists of long elastic wrapping sewn over a sterile non-adherent absorbent pad and equipped with a metal hook (instead of the pressure bar found in the Israeli bandage) through which the elastic wrap can be manipulated to wrap-around and tighten for compressive force on the wound site. Another relatively recent technology in the mix of compression bandages is the Elastic Adhesive (ELAD) bandage developed by Dr. Sody Naimer in Israel [309]. In this design, the non-adherent sterile absorbent pad is laminated over by a long self-adherent polyethylene strip that allows for flexible wrapping around various tissue/organ morphologies while the transparency of the strip allows for direct observation of the dressing-covered wound site to ensure that bleeding has been reduced. In all the above designs, the main purpose is to provide a combination of compression plus sterile coverage of the wound that can reduce bleeding to some extent, and this reduction may be sufficient to reduce the tissue morbidity or mortality risk until the patient can be attended to in a medical facility. The elastic wrap-around materials in many cases are proprietary in composition, but it is apparent that most of these materials are possibly latex or nylon or Coban™ (3M, USA) type non-woven elastic composites or polyethylene-based stretchable polymers. Table 2 provides an ‘at-a-glance’ summary of synthetically derived hemostatic biomaterials along with representative technology names, characteristic evaluations and current application status.

Table 2.

Topical and Externally Administered Hemostatic Biomaterials from Synthetic Sources

| Materials and Technologies | Mechanism of Action | Example Evaluations and Characteristic Applications |

Characteristic Findings |

|---|---|---|---|

| Polyurethane-based systems, e.g., - semi-permeable polyurethane membrane with an acrylic adhesive backing in wound dressings (e.g. Bioclusive, Mefilm, OpSite, Flexigrid, Tegaderm etc.) - soft, open cell, hydrophobic, polyurethane foam sheet for wound dressings (e.g. Allevyn, Lyofoam, Tielle etc.) | Polyurethane material can create a moist wound environment owing to their permeability to air and water vapor and impermeability to fluids and bacteria; Moisture and Oxygen are transmitted in addition to providing thermal insulation to the wound; Promote autolytic debridement; Many polyurethane dressings are highly absorbent due to the presence of hydrophilic contact surface and microporous foam combined with hydrophobic backing | Polyurethane film dressings evaluated clinically for split-thickness skin grafting; Polyurethane foam based dressings evaluated clinically for management of leg ulcers and other exudative wounds; Comparative clinical data are under-reported and randomized clinical trials across the various technologies are lacking, but several polyurethane-based dressings remain currently clinically approved | Protects wound from bacteria, foreign debris and shearing injuries; High absorptive capacity of microporous polyurethane foams allow for significant removal of exudate; Polyurethane dressings are easy to remove, allowing convenient changing of wound dressings without injury; |

| Polylysine based systems, e.g., - poly(amino acid) polymer of lysine - Hydrogels composed of ε-polylysine grafted unto functionalized chitosan - Hydrogels of ε-polylysine grafted polyethylene glycol | Cationic polylysine can complex and activate coagulation factors, increase thrombin and fibrin generation, and retards fibrinolysis | In vitro fibrinolytic activity tested on human plasma, coagulation factor activation, Cytotoxicity (MTT, LDH); In vivo hemostatic ability assays was evaluated by assessing total blood loss in a rat liver injury model; Polylysine materials also tested for evaluation of wound closure on the back of male Sprague-Dawley rats; No stand-alone polylysine technology for externally administered hemostatic application exists, but the material has been investigated as a co-polymer component (e.g. with alginate). | Polylysine has shown conflicting results of resisting fibrinolysis, but also acting as a co-factor to activate plasminogen that can cause fibrinolysis; Polylysine-based materials have shown significantly reduced blood loss compared to untreated liver injury; Polylysine materials showed greater capabilities for wound closure compared to suture, fibrin glue and cytotoxic cyanoacrylate treatment after 7 and 14 days post treatment; Evidence exists for polylysine-induced activation of FVII for increased thrombin and fibrin generation; Polylysine may impart cytotoxic effects dependent on polymer concentration, incubation times and charge density |

| Water soluble Polyethylene oxide and polypropylene oxide (PEO-PPO-PEO) block copolymer for bone hemostasis, e.g. Ostene | Facilitate hemostasis by tamponade mechanical effect | Evaluated for soft tissue response in paravertebral muscles incision in rabbits; Evaluated in Femur defect model hemostasis in rabbits; Clinically approved for orthopedic application | Ostene showed no fibrous response at the bone defect site 2 weeks after implantation in animal models; No adverse effects of Ostene after 4 and 8 weeks with evidence of new bone formation in animal models |

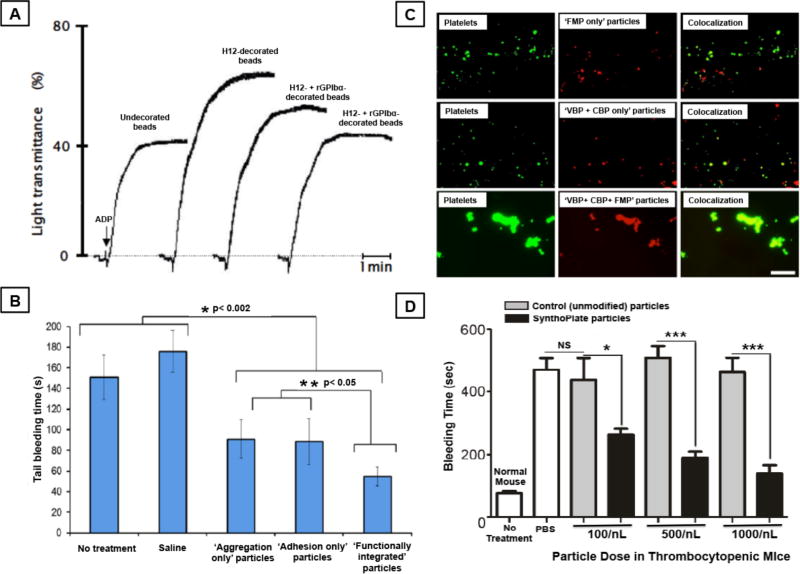

| Poly(ethylene glycol)-b-poly(dihydroxyacetone) MPEG-pDHA block copolymer | Facilitate hemostasis by tamponade mechanical effect; Can be resorbed and metabolized in the body | In vivo evaluation for blood loss and bleeding time from partial and survival hepatectomy in rodent models; Only pre-clinical evaluation reported | Significantly reduced bleeding time and blood loss compared to saline treatment; No abnormal inflammatory response was detected for MPEG-pDHA compared to saline control |