Abstract

The yeast strains IPM32-16, ISM28-8sT, and IPM46-17, isolated from plant and soil samples from Iriomote Island, Japan, were explored in terms of lipid production during growth in a mixture of glucose and xylose. Phylogenetically, the strains were most closely related to Cystobasidium slooffiae, based on the sequences of the ITS regions and the D1/D2 domain of the LSU rRNA gene. The strains were oleaginous, accumulating lipids to levels > 20% dry cell weight. Moreover, kinetic analysis of the sugar-to-lipid conversion of a 1:1 glucose/xylose mixture showed that the strains consumed the two sugars simultaneously. IPM46-17 attained the highest lipid content (33%), mostly C16 and C18 fatty acids. Thus, the yeasts efficiently converted lignocellulosic sugars to lipids, aiding in biofuel production (which benefits the environment, promotes rural jobs, and strengthens fuel security). The strains constituted a novel species of Cystobasidium, for which we propose the name Cystobasidium iriomotense (type strain ISM28-8sT = JCM 24594T = CBS 15015T).

Introduction

Recently, chemical and fuel production from lignocellulosic biomass is receiving increasing attention [1, 2]. Hydrolysates of such biomasses contain mixtures of sugars, mainly glucose and xylose in various ratios [3, 4]. Complete conversion of sugars in hydrolysates is necessary for efficient utilization of lignocellulosic biomass. The production of microbial lipids via enzymatic degradation of lignocellulosic biomass is currently a subject of intense interest. However, one major barrier to commercial application is the cost of the enzymes used to degrade cellulose to monosaccharides. The absence of a high-performance microorganism (a strain that can efficiently convert released sugars to lipid) renders practical production difficult.

Some yeasts accumulate lipids to over 20% of the cell dry weight and are thus termed oleaginous yeasts [5]. The carbon-chain lengths of the accumulated fatty acids typically range from 12 to 24, with the major components being palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1), and linoleic acid (C18:2) [6, 7]. The composition is similar to that of plant oils [8]; therefore, these lipids can be used as feedstocks for biofuels and oleochemical products. Lignocellulosic biorefineries can achieve greater reductions in CO2 emission than petroleum-based biorefineries. However, such refineries are complex and expensive to build [9]. It is anticipated that recent progress in lignocellulosic biorefinery technology will decrease production costs. High-value-added lipids, such as middle-chain fatty acids for use in health foods, are synthesized by oleaginous yeasts. Currently, such lipids are produced from animals and plants; they are expensive and not economically competitive. If lignocellulosic biomass could be used as feedstock, the cost of such lipids could be reduced, and new industries could develop.

Several groups have attempted to produce lipids by culturing oleaginous yeasts on hydrolysates derived from lignocellulosic biomass [10–13]. However, yeasts use glucose in preference to xylose, the uptake of which commences only after glucose is depleted, a phenomenon termed glucose repression [14, 15]. Such sequential utilization prolongs the conversion period and renders the process uneconomic. Efforts have been made to encourage sugar co-conversion, such that glucose and xylose are simultaneously converted to lipids. Zhao et al. [4] optimized the concentrations of sugars, nitrogen sources, and minerals, and achieved a lipid content of 61% dry weight using a medium containing 48.9 g/L glucose and 24.4 g/L xylose. It was concluded that lipid-accumulating ability was influenced by the concentrations of sugars, yeast extract, and FeSO4. Unfortunately, the sugar consumption pattern remained unclear, and rigorous preparation of the recommended medium may not be practical. Anschau et al. [16] compared batch, fed-batch, and continuous cultures. Continuous cultivation in a medium with 20 g/L glucose and 45 g/L xylose yielded a high lipid content of 49% dry weight. Both sugar were consumed simultaneously, but half remained in the broth. Glucose repression remains a significant barrier to efficient sugar conversion; optimization of conversion has not yet been achieved. Identification of oleaginous yeasts capable of simultaneous glucose and xylose conversion is thus critical when seeking to improve lipid production efficiency. Efforts have been made to find such yeast. For example, Cutaneotrichosporon cutaneum (formerly Trichosporon cutaneum) [3, 17] and Geotrichum fermentans (formerly Trichosporon fermentans) [18] engage in simultaneous glucose and xylose consumption from detoxified lignocellulosic hydrolysates. In addition, it is well-known that the oleaginous yeast Lipomyces starkeyi uses glucose and xylose simultaneously to produce lipids [16, 18].

When surveying Japanese isolates, we discovered yeasts exhibiting high-level oleaginous potential under various conditions [17, 19, 20]. In the present study, we focused on oleaginous yeasts that could utilize glucose and xylose simultaneously and selected three strains, IPM32-16, ISM28-8sT, and IPM46-17, for evaluation. These were phylogenetically close to Cystobasidium slooffiae, C. fimetarium, and C. minutum. To assess sugar assimilation patterns, we performed kinetic analyses of the lipid production using a mixture of glucose and xylose. In addition, based on both sequence analyses and phenotypic characterization, we concluded that our strains belonged to a novel species within the genus Cystobasidium, for which we propose the name Cystobasidium iriomotense f.a. sp. nov. (type strain ISM28-8sT = JCM 24594T = CBS 15015T).

Materials and methods

Strains and media

The new strains were isolated from plant and soil samples collected on Iriomote Island in the Iriomote Ishigaki National Park, Japan [21] (Table 1). A reference strain, C. slooffiae JCM 10954T, was obtained from the Japan Collection of Microorganisms (JCM) at the RIKEN BioResource Center (http://jcm.brc.riken.jp/en/). C. slooffiae was an appropriate control, because the strain was (1) phylogenetically most closely related to the isolates; (2) capable of glucose and xylose assimilation [22]; and (3) capable of accumulating lipids [23]. YM agar medium (Difco, Detroit, MI, USA) was used for yeast pre-culture and maintenance. The 1:1 (w/w) glucose/xylose (GX) medium was based on the medium of Gong et al. [18], and contained ammonium sulfate 1 g/L, yeast extract 0.5 g/L, potassium dihydrogen phosphate 1 g/L, magnesium sulfate heptahydrate 1 g/L, glucose 10 g/L, and xylose 10 g/L. We used a 1:1 glucose-to-xylose weight ratio to simplify our analyses.

Table 1. Yeast strains used in this study.

| Species | Strain | Source | JCM/CBS number | Sequence accession no. |

|---|---|---|---|---|

| Cystobasidium iriomotense | IPM32-16 | Dead branch of an unidentified treea | JCM 24574 | AB726384 |

| ISM28-8sT | Sandy soila | JCM 24594T, CBS 15015T | AB726571 | |

| IPM46-17 | Bark of an unidentified treea | JCM 24575 | AB726474 | |

| Cystobasidium slooffiae | - | Throat swab | JCM 10954T | - |

JCM, Japan Collection of Microorganisms; CBS, Centraalbureau voor Schimmelcultures

a Samples were collected in November 2008 on Iriomote Island in the Iriomote Ishigaki National Park, Okinawa Prefecture, Japan.

Sequencing and phylogenetic analysis

DNA fragments, including the internal transcribed spacer (ITS) regions plus the D1/D2 domain of the LSU rRNA gene, were amplified directly from yeast cells. Cells were suspended in 60-μL amounts of Prepman Ultra Sample Preparation Reagent (Applied Biosystems, Foster City, CA, USA) and template DNA prepared according to the manufacturer’s instructions. The ITS regions, including the 5.8S rRNA gene and the D1/D2 domain of the LSU rRNA gene, were amplified using the primers 5’-AACTTGGTCATTTAGAGGAA-3’ [24] and NL4 [25]. The PCR products were directly sequenced using an ABI Prism BigDye Terminator Cycle Sequencing Ready Reaction kit (Applied Biosystems) and analyzed with an Applied Biosystems sequencer model 3100, according to the manufacturer’s instructions. The sequences including the ITS regions and D1/D2 domain of the LSU rRNA gene are available from the DDBJ/GenBank/EMBL database, as shown in Table 1. Reference sequences used in the phylogenetic study were obtained from the DDBJ/GenBank/EMBL database [26]. Multiple alignment was performed using MEGA7 software [27]. A phylogenetic tree was constructed using the maximum likelihood method of MEGA7. The Tamura-Nei model [28] was used for analyses. Initial trees for the heuristic search were automatically obtained by applying the neighbor-joining and BIONJ algorithms to a matrix of pairwise distances estimated using the maximum composite likelihood (MCL) approach and then selecting the topology with the highest log likelihood value. Bootstrap analysis was performed 500 times [29].

Taxonomic characteristics

Most of the morphological, physiological, and biochemical characteristics were examined as suggested by Kurtzman et al. [30] Assimilation of nitrogen compounds was investigated on solid media using starved inocula. Sexual reproduction tests were performed on YM and cornmeal agar (individual or paired strains) at room temperature.

Kinetic analysis

Single loops of 3-day-old yeast colonies were suspended in 100 mL amounts of GX medium in Erlenmeyer flasks and incubated at 28°C, with rotary shaking at 150 rpm, for 10 d. Broth was withdrawn at various times. The levels of intracellular lipids and sugars were determined. All experiments were performed in triplicate.

Measurement of fatty acids

Total intracellular lipid contents were estimated as total fatty acids. Accumulated lipids were extracted from lyophilized cells using a hydrochloric acid-catalyzed direct methylation method [31]. In brief, after cultivation, the centrifuged cells were lyophilized and weighed, dissolved in toluene and methanol, and directly transmethylated with 8% (v/v) methanolic HCl at 100°C for 1 h. The resultant fatty acid methyl esters were extracted with n-hexane and analyzed using a gas chromatograph (GC-2010 Plus; Shimadzu, Kyoto, Japan) equipped with a flame ionization detector (FID) and an autosampler (AOC20; Shimadzu). A TC-17 capillary column (GL Science, Tokyo, Japan) was used. The elution temperature commenced at 165°C for 2 min and then increased by 5°C/min to 180°C, followed by a hold for 5 min, an increase at 5°C/min to 240°C, and an additional hold for 3 min. Helium at 2.0 mL/min served as the carrier gas, and nitrogen as the make-up gas. The injector temperature was 250°C and the detector temperature was 260°C, with a split ratio of 50:1. Major peaks were identified by their retention times using standards obtained from Sigma-Aldrich (St. Louis, MO, USA). Heptadecanoic acid (C17:0) served as an internal standard for the determination of fatty acid concentrations.

Sugar measurements

Residual glucose and xylose concentrations were determined using a high-performance liquid chromatograph (Shimadzu) equipped with an Aminex Fermentation Monitoring Column (Bio-Rad Laboratories, Hercules, CA, USA) and Micro-Guard Cation H Refill Cartridges in a Standard Cartridge Holder (Bio-Rad Laboratories). The detector was an RID 10A refractive index detector (Shimadzu). The column was held at 60°C using a CTO 20A column oven (Shimadzu). A sulfuric acid solution (5 mM) served as the mobile phase at a constant flow rate of 0.6 mL/min.

Results

Phylogeny and phenotypic characteristics

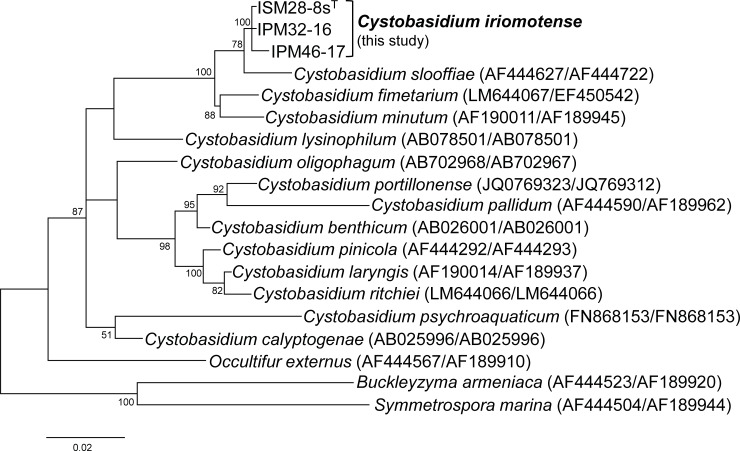

A phylogenetic tree based on the sequences of the ITS regions plus D1/D2 domain of the LSU rRNA genes showed that the three strains clustered with Cystobasidium slooffiae, C. fimetarium, and C. minutum (Fig 1). The sequence differences in the ITS region ranged from 2 bp (including one gap) to 5 bp (including one gap), and those in the D1/D2 domain ranged from 0 to 2 bp; indicating that the three strains belonged to the same species [32–34]. Of phylogenetically closely related species, the differences between our species and Cystobasidium fimetarium, and C. slooffiae and C. minutum, were 8–10 bp and 9–11 bp respectively (Fig 1), suggesting that our strains constituted a novel species [33, 35]. In addition, our species was phenotypically distinct from the phylogenetically closely related species C. fimetarium [36], C. slooffiae [22, 37] and C. minutum [22, 37] with respect to several traits: namely, galactose assimilation and the inability to use D-ribose, DL-lactate, or xylitol as the sole carbon source (Table 2). Thus, we propose the name Cystobasidium iriomotense. Our strains utilize not only xylose, but also cellobiose or L-arabinose as the sole carbon source (Table 2). We anticipate that they will be industrially useful, but we have not yet determined the lipid accumulation abilities using these sugars.

Fig 1. The phylogenetic tree of Cystobasidium iriomotense and related species based on the internal transcribed spacer (ITS) regions plus the D1/D2 domain of the LSU rRNA gene.

The evolutionary history was inferred using the maximum likelihood method based on the Tamura-Nei model [28]. The tree with the highest log likelihood (-3830.1264) is shown. The rate variation model allowed for some sites to be evolutionarily invariable ([+I], 38.4432% sites). The tree is drawn to scale; the branch lengths indicate the number of substitutions per site. All positions containing gaps and missing data were eliminated. A total of 1,047 positions were present in the final dataset. Bootstrap values < 50% are not shown.

Table 2. Salient characteristics of Cystobasidium iriomotense and phylogenetically closely related species.

| Species | C. fimetariuma |

C. minutum b |

C. slooffiaeb | C. iriomotense | ||

|---|---|---|---|---|---|---|

| IPM32-16 | ISM28-8sT | IPM46-17 | ||||

| D-Xylose | + | + | + | + | + | + |

| L-Arabinose | + | + | + | L | + | L |

| D-Arabinose | + | + | + | LW | LW | LW |

| Cellobiose | + | + | + | + | + | + |

| Galactose | - | v | - | L | L | LW |

| Melezitose | - | + | + | + | + | + |

| L-Sorbose | - | + | + | LW | LW | LW |

| D-Ribose | + | + | + | - | - | - |

| DL-Lactate | + | v | + | - | - | - |

| Xylitol | + | + | + | - | - | - |

| Growth at 35°C | - | v | - | LW | - | L |

| Growth at 37°C | - | - | - | - | - | L |

aData from Sampaio and Oberwinkler [36].

bCystobasidium minutum and C. slooffiae were formerly classified as Rhodotorula minuta and R. slooffiae, respectively, and were transferred to the genus Cystobasidium by Yurkov et al. [37]. Phenotypic data are from Sampaio [22].

+, positive; -, negative; L, latent; LW, latent and weak; v, variable.

Lipid accumulation during growth on GX medium

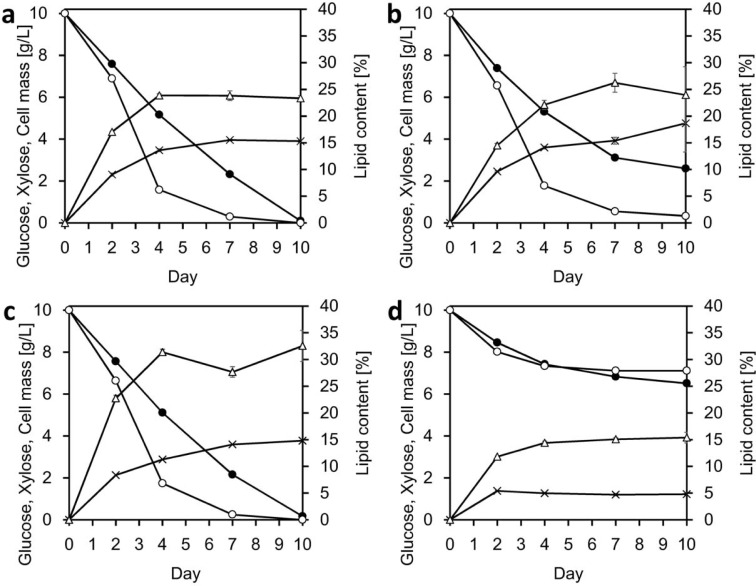

To explore the time course of conversion of sugars to lipids by IPM32-16, ISM28-8sT, IPM46-17, and C. slooffiae JCM 10954T, GX medium containing 10 g/L glucose and 10 g/L xylose as sole carbon sources was used. All strains utilized glucose and xylose simultaneously rather than sequentially (Fig 2). After cultivation, 99.5, 85.3, and 99.2% of the initial sugars were consumed by IPM32-16, ISM28-8sT, and IPM46-17, respectively. In contrast, the figure for C. slooffiae JCM 10954 was 31.9%. In addition, as shown in Fig 2, the curves were biphasic: the log phase persisted from d 0 to 4, followed by the stationary phase from d 4 to 10, except for C. slooffiae JCM 10954T. The strains were similar in terms of lipid content and cell mass (Fig 2). IPM32-16, ISM28-8sT, and IPM46-17 yielded lipids to >20% dry cell weight and were thus oleaginous species [38]. C. slooffiae JCM 10954T yielded lipids to only 15% dry cell weight. Sugar consumption was proportional to lipid production. However, the sugar-converting efficiency of C. slooffiae JCM 10954T was much lower than those of IPM32-16, ISM28-8sT, and IPM46-17. The sugar yields (g lipid per g sugar) of the three strains were 0.046 to 0.064 g/g, whereas that of C. slooffiae JCM 10954T was 0.03 g/g. Thus, it seems that the strains used different metabolic pathways for lipid production. Nutrients influence lipid production efficiencies because cells use different metabolic pathways depending on the availability of different medium components. A thorough metabolic analysis is required to define the optimal medium for lipid production.

Fig 2. Time course of lipid conversion using glucose/xylose (GX) medium (containing 10 g/L of glucose and 10 g/L of xylose) at 28°C and 150 rpm: glucose (filled circles), xylose (open circles), lipids (open triangles) and cell masses (crosses).

(a) IPM32-16; (b) ISM28-8sT; (c) IPM46-17; (d) C. slooffiae JCM 10954T. Data are means ± standard deviation (error bars) of three replicates. Some errors are very small and hidden by the symbols.

The principal fatty acid in the new strains was oleic acid (C18:1), accounting for 36.3 to 52.8% of all fatty acids in IPM32-16, ISM28-8sT, and IPM46-17, whereas the principal fatty acid of C. slooffiae JCM 10954T was linoleic acid (C18:2) (50.0%) (Table 3, S1 Table for details).

Table 3. Fatty acid compositions of IPM32-16, ISM28-8sT, IPM46-17 and C. slooffiae JCM 10954T after 10 d of culture.

| Strain | C14:0 | C16:0 | C16:1 | C18:0 | C18:1 | C18:2 | C18:3 | C22:0 | C24:0 |

|---|---|---|---|---|---|---|---|---|---|

| IPM32-16 | 0.41 | 20.36 | 0.12 | 5.96 | 52.82 | 18.25 | 0.17 | 0.28 | 1.64 |

| 8.26 | 3.49 | 8.55 | 3.72 | 4.56 | 3.66 | 72.00 | 5.72 | 5.40 | |

| ISM28-8sT | 0.28 | 17.27 | 0.03 | 25.10 | 44.37 | 10.55 | 0.12 | 0.71 | 1.57 |

| 4.14 | 4.56 | 21.73 | 2.14 | 4.02 | 1.52 | 8.51 | 0.28 | 6.00 | |

| IPM46-17 | 0.77 | 30.24 | 0.13 | 8.13 | 36.33 | 22.75 | 0.17 | 0.29 | 1.18 |

| 9.06 | 6.79 | 6.86 | 8.06 | 6.61 | 7.05 | 10.45 | 9.98 | 10.60 | |

| C. slooffiae JCM 10954T | ND | 12.12 | 0.12 | 5.67 | 28.75 | 50.00 | 1.05 | 0.28 | 2.02 |

| 5.80 | 6.70 | 6.25 | 5.79 | 2.89 | 3.49 | 19.67 | 8.47 |

Upper rows: average of three assays [%].

Lower rows: relative standard deviations [%].

ND, not detected.

Discussion

Simultaneous conversion of glucose and xylose is desirable because xylose is one of the most abundant carbohydrates in plants. Hu et al. [3] investigated the ability of Trichosporon cutaneum (present name, Cutaneotrichosporon cutaneum) AS 2.571 to produce lipids during cultivation on detoxified corn stover hydrolysate. The strain accumulated lipids to 39.2% of dry cell weight. In another study, Lipomyces starkeyi DSM 70296 produced lipids during conversion of a glucose/xylose mixture, to a final content of 27.7% [16]. Huang et al. [39] found that detoxified rice straw hydrolysate could be used for lipid production by Trichosporon fermentans (present name, Geotrichum fermentans) CICC 1368 (to a lipid content of 23%). When Trichosporon cutaneum (present name, Cutaneotrichosporon cutaneum) CX1 was cultivated with detoxified corn stover hydrolysate, the final lipid content was 23.5% [40]. The published data on lipid production during growth on a mixture of glucose and xylose are shown in Table 4. We did not observe diauxic growth during cultivation of IPM32-16, ISM28-8sT and IPM46-17 on GX medium. The ability to simultaneously utilize multiple sugars to accumulate lipids is of great importance when planning lipid production from lignocellulosic hydrolysates.

Table 4. Conversion of sugar mixtures to lipids.

| Strain | Substrate | Mode | Initial glucose concentration [g/L] | Initial xylose concentration [g/L] | Lipid content [%] | References |

|---|---|---|---|---|---|---|

| Cutaneotrichosporon cutaneum (syn. Trichosporon cutaneum) AS 2.571 | Detoxified corn stover hydrolysate | Flask | 36 | 25 | 39.2 | [3] |

| Geotrichum fermentans (syn. Trichosporon fermentans) CICC 1368 | Detoxified rice straw hydrolysate | Flask | 15.5 | 84.3 | 23 | [39] |

| Lipomyces starkeyi DSM 70296 | Mixture of glucose and xylose | Fed-batch 2L bioreactor |

42 | 18 | 27.7 | [16] |

| Cutaneotrichosporon cutaneum (syn. Trichosporon cutaneum) CX1 | Detoxified corn stover hydrolysate | Batch 3L fermenter |

44.2 | 3.92 | 23.5 | [41] |

| Lipomyces starkeyi AS 2.1560 | Mixture of glucose and xylose | Flask | 47 | 23 | 54 | [18] |

The D1/D2 sequences of ISM28-8sT differed from those of C. fimetarium, C. minutum, and C. slooffiae by 8–9 nucleotides (Fig 1), suggesting that our isolates constituted a new species. Based on the sequence of the ITS region, C. slooffiae is more closely related to C. iriomotense ISM28-8sT than are C. fimetarium and C. minutum. Therefore, C. slooffiae JCM 10954 was used as a control strain in the conversion tests, given that the strain accumulates lipids [23] and can use xylose [22]. Indeed, C. slooffiae JCM 10954T also utilized the sugars simultaneously, but exhibited low-level sugar assimilation and poor lipid production. Interestingly, the three strains preferentially utilized xylose, not glucose (Fig 2A–2C). Generally, transport affinity for glucose is two orders of magnitude higher than that for xylose [40]. However, the sugar transporters of C. iriomotense remain unknown; further work is thus necessary.

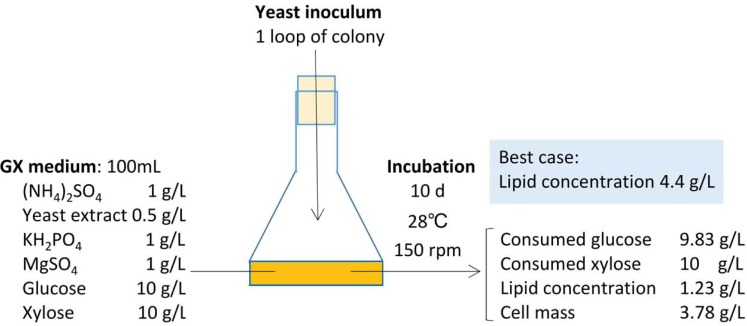

IPM32-16, ISM28-8sT and IPM46-17 accumulated lipids rapidly over the initial 4 d of conversion (Fig 2). For example, the lipid productivity of IPM32-16 (Fig 2A) on d 4 was 0.21 g/L/d, and that over the next 6 d 0.013 g/L/d. After 4 days of conversion, much more xylose than glucose was consumed; the consumption rates were 2.10 g/L/d and 1.21 g/L/d, respectively. From d 4 to d 10, the lipid concentration increased slightly as glucose consumption increased. IPM46-17 behaved similarly, indicating that xylose was efficiently used for lipid production. A similar conclusion was reached in a study on lipid production by Cutaneotrichosporon curvata (formerly Cryptococcus curvatus, Candida curvata) using five different carbon sources: glucose, sucrose, lactose, xylose and ethanol [42]. Fig 3 shows that the final lipid level was 1.23 g/L. In the best practical scenario, the lipid concentration attained 4.4 g/L [9, 43]. Our lipid yield was thus low, probably because we did not consider nitrogen limitation, although nitrogen depletion can induce lipid production. The nitrogen balance and other conditions should be optimized in future.

Fig 3. Mass balance of the conversion of glucose and xylose to lipids by C. iriomotense IPM46-17.

The fatty acid composition of C. minutum cultivated on a medium containing 10 g/L glucose was 62% oleic acid (C18:1), 18% palmitic acid (C16:0), 16% linoleic acid (C18:2), and 4% stearic acid (C18:0) [44]. The lipids contained large amounts of C16 and C18 fatty acids (97.4–97.8% of the totals); the lipid mixtures produced were suitable for biodiesel production [45]. Notably, the fatty acid compositions differed among the strains tested. In terms of stearic acid, the lowest level was 5.7% for C. slooffiae JCM 10954T, but ISM28-8sT had a stearic acid content of 25.1%.

We introduce a new yeast species facilitating efficient lipid production; the strain exhibits a unique metabolic profile. Our species may allow for engineering of xylose metabolism in other oleaginous microorganisms. Further analysis and metabolic characterization may aid in the construction of strains efficiently producing lipids from lignocellulosic biomass. Lipid production experiments using a lignocellulosic hydrolysate, such as rice straw, are required.

Nomenclature

The electronic version of this article in Portable Document Format (PDF), contained in a work with an ISSN or ISBN will represent a published work according to the International Code of Nomenclature for algae, fungi, and plants. Hence, the new names contained in the electronic version of a PLOS ONE article are effectively published under that Code from the electronic edition alone; there is no longer any need to provide printed copies.

In addition, new name contained in this work has been submitted to MycoBank, which will make it available to the Global Names Index. The unique MycoBank number and the associated information can be viewed using any standard Web browser by appending the MycoBank number contained in this publication to the prefix http://www.mycobank.org/MB/. The online version of this work is archived and available from the following digital repositories: PubMed Central, LOCKSS.

Description of Cystobasidium iriomotense Tanimura, Sugita et Takashima f.a. sp. nov.

Etymology: the name iriomotense (iri.omot.en’se N.L. adj. iriomote pertaining to Iriomote) was derived from “Iriomote Island”, because the type strain of the species was isolated from soil collected on Iriomote Island.

After 3 days at 25°C in YM broth, the cells are subglobose, oval, ellipsoidal (2.5–5) × (5–10) μm, single, or in pairs. A sediment is formed. After 1 month at 17°C, an incomplete and fragile ring and a sediment are produced. After 1 month at 17°C on YM agar, the streak culture is pastel red, smooth, semi-shiny, and soft to butyrous, with fluid near the bottom, and has an entire margin. Neither mycelium nor pseudomycelium form on YM or cornmeal agar. After 4 weeks of incubation on cornmeal agar at room temperature, ballistoconidia are not produced. Sexual reproduction is not observed on YM or cornmeal agar. Does not ferment glucose. Assimilates glucose, galactose (or latent), L-sorbose (latent and weak), sucrose, cellobiose, trehalose, lactose (or latent), melezitose, ethanol (latent), D-xylose, L-arabinose (or latent), D-arabinose (latent and weak), glycerol, ribitol (latent or latent and weak), D-mannitol (latent), D-glucitol (latent), glucono-δ-lactone (or latent), salicin (variable), succinic acid (latent), D-gluconate, D-glucurono-δ-lactone (latent), propane 1,2 diol, N-acetyl-D-glucosamine, saccharic acid (latent), and xylo-oligosaccharide. Does not assimilate maltose, melibiose, raffinose, inulin, soluble starch, D-ribose, L-rhamnose, erythritol, galactitol, methyl-α-D-glucoside, DL-lactic acid, citric acid, inositol, D-glucuronic acid, D-galacturonic acid, methanol, D-glucosamine, L-arabinitol, quinic acid, xylitol, or butane 2, 3 diol. Assimilates lysine hydrochloride. Does not assimilate sodium nitrite, potassium nitrate, ethylamine hydrochloride, or cadaverine dihydrochloride. Requires p- aminobenzoic acid and thiamine for growth. Simultaneously converts glucose and xylose to lipid simultaneously. Grows at 30°C, with variable growth at 35°C and 37°C, but does not grow at 40°C. Starch-like substances are not produced. The diazonium blue B reaction is positive.

Type strain: ISM28-8sT (= JCM 24594T = CBS 15015T), isolated from soil collected in November 2008 at Iriomote Island in the Iriomote Ishigaki National Park, Okinawa, Japan, by T. Sugita. A culture from the holotype strain of this species has been deposited and preserved in a metabolically inactive state in the Japan Collection of Microorganisms (JCM), RIKEN BioResource Research Center, Tsukuba, Ibaraki Prefecture, Japan; and the Centraalbureau voor Schimmelcultures (CBS), Westerdijk Fungal Biodiversity Institute, Utrecht, the Netherlands.

The Mycobank Number is MB 819779.

Supporting information

GC data of three separate experiments with the relative standard deviation.

(PDF)

Acknowledgments

The authors are grateful to the anonymous reviewers for their constructive criticisms of this research.

Data Availability

All sequencing files are available from the GenBank database (accession numbers: AB726384, AB726571, AB726474).

Funding Statement

This work was supported in part by the Advanced Low Carbon Technology Research and Development Program (ALCA, grant no. JPMJAL1607) of the Japan Science and Technology Agency (JST). MT was partially supported by a KAKENHI (no. 26650148) from the Japan Society for the Promotion of Science (JSPS). This work was also supported in part by the RIKEN Competitive Program for Creative Science and Technology and by a grant from the Biomass Engineering Program of the RIKEN Center for Sustainable Resource Science (to MO).

References

- 1.Kim SR, Ha SJ, Wei N, Oh EJ, Jin YS. Simultaneous co-fermentation of mixed sugars: a promising strategy for producing cellulosic ethanol. Trends Biotechnol. 2012;30:274–282. 10.1016/j.tibtech.2012.01.005 [DOI] [PubMed] [Google Scholar]

- 2.Bellasio M, Mattanovich D, Sauer M, Marx H. Organic acids from lignocellulose: Candida lignohabitans as a new microbial cell factory. J Ind Microbiol Biotechnol. 2015;42:681–691. 10.1007/s10295-015-1590-0 [DOI] [PubMed] [Google Scholar]

- 3.Hu C, Wu S, Wang Q, Jin G, Shen H, Zhao ZK. Simultaneous utilization of glucose and xylose for lipid production by Trichosporon cutaneum. Biotechnol Biofuels. 2011;4:25 10.1186/1754-6834-4-25 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Zhao X, Kong X, Hua Y, Feng B, Zhao Z. Medium optimization for lipid production through co-fermentation of glucose and xylose by the oleaginous yeast Lipomyces starkeyi. Eur J Lipid Sci Technol. 2008;110:405–412. [Google Scholar]

- 5.Sitepu IR, Garay LA, Sestric R, Levin D, Block DE, Bruce German J, et al. Oleaginous yeasts for biodiesel: Current and future trends in biology and production. Biotechnol Adv. 2014;32:1336–1360. 10.1016/j.biotechadv.2014.08.003 [DOI] [PubMed] [Google Scholar]

- 6.Tapia V E, Anschau A, Coradini AL, T.Franco T, Deckmann AC. Optimization of lipid production by the oleaginous yeast Lipomyces starkeyi by random mutagenesis coupled to cerulenin screening. AMB Express. 2012;2:1–8. 10.1186/2191-0855-2-1 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Lin J, Shen H, Tan H, Zhao X, Wu S, Hu C, et al. Lipid production by Lipomyces starkeyi cells in glucose solution without auxiliary nutrients. J Biotechnol. 2011;152:184–188. 10.1016/j.jbiotec.2011.02.010 [DOI] [PubMed] [Google Scholar]

- 8.Liu Y, Meng Z, Zhang F, Shan L, Wang X. Influence of lipid composition, crystallization behavior and microstructure on hardness of palm oil-based margarines. Eur Food Res Technol. 2010;230:759–767. [Google Scholar]

- 9.Jin MJ, Slininger PJ, Dien BS, Waghmode S, Moser BR, Orjuela A, et al. Microbial lipid-based lignocellulosic biorefinery: feasibility and challenges. Trends Biotechnol. 2015;33:43–54. 10.1016/j.tibtech.2014.11.005 [DOI] [PubMed] [Google Scholar]

- 10.Sitepu I, Jin M, Fernandez JE, da Costa Sousa L, Balan V, Boundy-Mills K. Identification of oleaginous yeast strains able to accumulate high intracellular lipids when cultivated in alkaline pretreated corn stover. Appl Microbiol Biotechnol. 2014;98:7645–7657. 10.1007/s00253-014-5944-8 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Huang C, Li YY, Liu LP, Wu H, Zong MH, Lou WY. Kinetics and mechanism analysis on microbial oil production by Trichosporon fermentans in rice straw hydrolysate. Ind Eng Chem Res. 2014;53:19034–19043. [Google Scholar]

- 12.Chang YH, Chang KS, Hsu CL, Chuang LT, Chen CY, Huang FY, et al. A comparative study on batch and fed-batch cultures of oleaginous yeast Cryptococcus sp in glucose-based media and corncob hydrolysate for microbial oil production. Fuel. 2013;105:711–717. [Google Scholar]

- 13.Liang Y, Tang T, Siddaramu T, Choudhary R, Umagiliyage AL. Lipid production from sweet sorghum bagasse through yeast fermentation. Renew Energ. 2012;40:130–136. [Google Scholar]

- 14.Nichols NN, Dien BS, Bothast RJ. Use of catabolite repression mutants for fermentation of sugar mixtures to ethanol. Appl Microbiol Biotechnol. 2001;56:120–125. [DOI] [PubMed] [Google Scholar]

- 15.Kim J-H, Block DE, Mills DA. Simultaneous consumption of pentose and hexose sugars: an optimal microbial phenotype for efficient fermentation of lignocellulosic biomass. Appl Microbiol Biotechnol. 2010;88:1077–1085. 10.1007/s00253-010-2839-1 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Anschau A, Xavier MCA, Hernalsteens S, Franco TT. Effect of feeding strategies on lipid production by Lipomyces starkeyi. Bioresour Technol. 2014;157:214–222. 10.1016/j.biortech.2014.01.104 [DOI] [PubMed] [Google Scholar]

- 17.Tanimura A, Takashima M, Sugita T, Endoh R, Kikukawa M, Yamaguchi S, et al. Selection of oleaginous yeasts with high lipid productivity for practical biodiesel production. Bioresour Technol. 2014;153:230–235. 10.1016/j.biortech.2013.11.086 [DOI] [PubMed] [Google Scholar]

- 18.Gong Z, Wang Q, Shen H, Hu C, Jin G, Zhao ZK. Co-fermentation of cellobiose and xylose by Lipomyces starkeyi for lipid production. Bioresour Technol. 2012;117:20–24. 10.1016/j.biortech.2012.04.063 [DOI] [PubMed] [Google Scholar]

- 19.Tanimura A, Takashima M, Sugita T, Endoh R, Kikukawa M, Yamaguchi S, et al. Cryptococcus terricola is a promising oleaginous yeast for biodiesel production from starch through consolidated bioprocessing. Sci Rep. 2014;4:4776 10.1038/srep04776 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Tanimura A, Takashima M, Sugita T, Endoh R, Ohkuma M, Kishino S, et al. Lipid production through simultaneous utilization of glucose, xylose, and L-arabinose by Pseudozyma hubeiensis: a comparative screening study. AMB Express. 2016;6:1–9. 10.1186/s13568-015-0169-5 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Takashima M, Sugita T, Van BH, Nakamura M, Endoh R, Ohkuma M. Taxonomic richness of yeasts in Japan within subtropical and cool temperate areas. PLoS One. 2012;7:e50784 10.1371/journal.pone.0050784 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Sampaio JP. Rhodotorula Harrison (1928) Yeasts: A Taxonomic Study, Vols 1–3, 5th Edition 2011:1873–1927. [Google Scholar]

- 23.Capus A, Monnerat M, Ribeiro LC, de Souza W, Martins JL, Sant'Anna C. Application of high-content image analysis for quantitatively estimating lipid accumulation in oleaginous yeasts with potential for use in biodiesel production. Bioresour Technol. 2016;203:309–317. 10.1016/j.biortech.2015.12.067 [DOI] [PubMed] [Google Scholar]

- 24.Sugita T, Ikeda R, Shinoda T. Diversity among strains of Cryptococcus neoformans var. gattii as revealed by a sequence analysis of multiple genes and a chemotype analysis of capsular polysaccharide. Microbiol Immunol. 2001;45:757–768. [DOI] [PubMed] [Google Scholar]

- 25.Kurtzman CP, Robnett CJ. Identification of clinically important ascomycetous yeasts based on nucleotide divergence in the 5' end of the large-subunit (26S) ribosomal DNA gene. J Clin Microbiol. 1997;35:1216–1223. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Wang QM, Yurkov AM, Goker M, Lumbsch HT, Leavitt SD, Groenewald M, et al. Phylogenetic classification of yeasts and related taxa within Pucciniomycotina. Stud Mycol. 2015:149–189. 10.1016/j.simyco.2015.12.002 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Kumar S, Stecher G, Tamura K. MEGA7: Molecular Evolutionary Genetics Analysis Version 7.0 for Bigger Datasets. Mol Biol Evol. 2016;33:1870–1874. 10.1093/molbev/msw054 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Tamura K, Nei M. Estimation of the number of nucleotide substitutions in the control region of mitochondrial DNA in humans and chimpanzees. Mol Biol Evol. 1993;10:512–526. 10.1093/oxfordjournals.molbev.a040023 [DOI] [PubMed] [Google Scholar]

- 29.Felsenstein J. Confidence limits on phylogenies—An approach using the bootstrap. Evolution. 1985;39:783–791. 10.1111/j.1558-5646.1985.tb00420.x [DOI] [PubMed] [Google Scholar]

- 30.Kurtzman CP, Fell JW, Boekhout T, Robert V. Chapter 7—Methods for Isolation, Phenotypic Characterization and Maintenance of Yeasts The Yeasts (Fifth Edition). London: Elsevier; 2011. p. 87–110. [Google Scholar]

- 31.Ichihara K, Fukubayashi Y. Preparation of fatty acid methyl esters for gas-liquid chromatography. J Lipid Res. 2010;51:635–640. 10.1194/jlr.D001065 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Sugita T, Nishikawa A, Ikeda R, Shinoda T. Identification of medically relevant Trichosporon species based on sequences of internal transcribed spacer regions and construction of a database for Trichosporon identification. J Clin Microbiol. 1999;37:1985–1993. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Kurtzman CP, Robnett CJ. Identification and phylogeny of ascomycetous yeasts from analysis of nuclear large subunit (26S) ribosomal DNA partial sequences. Anton Leeuw. 1998;73:331–371. [DOI] [PubMed] [Google Scholar]

- 34.Fell JW, Boekhout T, Fonseca A, Scorzetti G, Statzell-Tallman A. Biodiversity and systematics of basidiomycetous yeasts as determined by large-subunit rDNA D1/D2 domain sequence analysis. Int J Syst Evol Microbiol. 2000;50:1351–1371. 10.1099/00207713-50-3-1351 [DOI] [PubMed] [Google Scholar]

- 35.Scorzetti G, Fell JW, Fonseca A, Statzell-Tallman A. Systematics of basidiomycetous yeasts: a comparison of large subunit D1/D2 and internal transcribed spacer rDNA regions. FEMS Yeast Res. 2002;2:495–517. [DOI] [PubMed] [Google Scholar]

- 36.Sampaio JP, Oberwinkler F. Cystobasidium (Lagerheim) Neuhoff (1924) Yeasts: A Taxonomic Study, Vols 1–3, 5th Edition 2011:1419–1422. [Google Scholar]

- 37.Yurkov AM, Kachalkin AV, Daniel HM, Groenewald M, Libkind D, de Garcia V, et al. Two yeast species Cystobasidium psychroaquaticum f.a. sp nov and Cystobasidium rietchieii f.a. sp nov isolated from natural environments, and the transfer of Rhodotorula minuta clade members to the genus Cystobasidium. Anton Leeuw Int J G. 2015;107:173–185. [DOI] [PubMed] [Google Scholar]

- 38.Meng X, Yang J, Xu X, Zhang L, Nie Q, Xian M. Biodiesel production from oleaginous microorganisms. Renew Energ. 2009;34:1–5. [Google Scholar]

- 39.Huang C, Zong M-h, Wu H, Liu Q-p. Microbial oil production from rice straw hydrolysate by Trichosporon fermentans. Bioresour Technol. 2009;100:4535–4538. 10.1016/j.biortech.2009.04.022 [DOI] [PubMed] [Google Scholar]

- 40.Farwick A, Bruder S, Schadeweg V, Oreb M, Boles E. Engineering of yeast hexose transporters to transport D-xylose without inhibition by D-glucose. Proc Natl Acad Sci USA. 2014;111:5159–5164. 10.1073/pnas.1323464111 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Huang X, Wang YM, Liu W, Bao J. Biological removal of inhibitors leads to the improved lipid production in the lipid fermentation of corn stover hydrolysate by Trichosporon cutaneum. Bioresour Technol. 2011;102:9705–9709. 10.1016/j.biortech.2011.08.024 [DOI] [PubMed] [Google Scholar]

- 42.Evans CT, Ratledge C. A comparison of the oleaginous yeast, Candida curvata, grown on different carbon sources in continuous and batch culture. Lipids. 1983;18:623–629. [DOI] [PubMed] [Google Scholar]

- 43.Bommareddy RR, Sabra W, Maheshwari G, Zeng AP. Metabolic network analysis and experimental study of lipid production in Rhodosporidium toruloides grown on single and mixed substrates. Microb Cell Fact. 2015;14 10.1186/s12934-015-0197-5 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Sargeant LA, Mardell M, Saad-Allah KM, Hussein AH, Whiffin F, Santomauro F, et al. Production of lipid from depolymerised lignocellulose using the biocontrol yeast, Rhodotorula minuta: The fatty acid profile remains stable irrespective of environmental conditions. Eur J Lipid Sci Tech. 2016;118:777–787. [Google Scholar]

- 45.Knothe G. Improving biodiesel fuel properties by modifying fatty ester composition. Energ Environ Sci. 2009;2:759–766. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

GC data of three separate experiments with the relative standard deviation.

(PDF)

Data Availability Statement

All sequencing files are available from the GenBank database (accession numbers: AB726384, AB726571, AB726474).