Abstract

Gas vesicles are a unique class of gas-filled protein nanostructures whose physical properties allow them to serve as highly sensitive imaging agents for ultrasound and magnetic resonance imaging (MRI), detectable at sub-nanomolar concentrations. Here we provide a protocol for isolating gas vesicles from native and heterologous host organisms, functionalizing these nanostructures with moieties for targeting and fluorescence, characterizing their biophysical properties and imaging them using ultrasound and magnetic resonance imaging. Gas vesicles can be isolated from natural cyanobacterial and haloarchaeal host organisms or from E. coli expressing a heterologous gas vesicle gene cluster, and purified using buoyancy-assisted techniques. They can then be modified by replacing surface-bound proteins with engineered, heterologously expressed variants, or through chemical conjugation, resulting in altered mechanical, surface and targeting properties. Pressurized absorbance spectroscopy is used to characterize their mechanical properties, while dynamic light scattering and transmission electron microscopy are used to determine nanoparticle size and morphology, respectively. Gas vesicles can then be imaged with ultrasound in vitro and in vivo using pulse sequences optimized for their detection versus background. They can also be imaged with hyperpolarized xenon MRI using chemical exchange saturation transfer between gas vesicle-bound and dissolved xenon – a technique currently implemented in vitro. Taking 3–8 days to prepare, these genetically encodable nanostructures enable multi-modal, noninvasive biological imaging with high sensitivity and potential for molecular targeting.

Keywords: Gas vesicles, protein nanostructures, noninvasive imaging, contrast agents, molecular reporters, ultrasound, hyperpolarized MRI, magnetic resonance imaging, acoustics

EDITORIAL SUMMARY

The physical properties of a unique class of proteins called gas vesicles allow them to be used as contrast agents for ultrasound and magnetic resonance imaging (MRI). This protocol describes how to isolate gas vesicles, functionalize them with moieties for targeting and fluorescence, and image them in vitro and in vivo.

INTRODUCTION

The study of biological function and disease and the development of clinical diagnostics require technologies for noninvasive imaging of cells and molecules in intact organisms. Ultrasound and magnetic resonance imaging (MRI) are two widely used noninvasive imaging modalities that provide high spatial and temporal resolution but are currently restricted in their molecular imaging capabilities due to limited repertoires of nanoscale contrast agents. For ultrasound, conventional imaging agents based on microbubbles – micron-sized particles of trapped gas stabilized by a lipid or protein shell – are limited by their size and physical instability to labeling the vasculature and endovascular targets1,2. Conventional MRI contrast agents based on superparamagnetic iron oxides3,4 or lanthanide chelates5 are limited by their potential toxicity and the requirement that they be present at relatively high concentrations (typically in the μM range) for detection by MRI .

Development of the Protocol

To develop biomolecular imaging agents addressing the aforementioned limitations, we recently introduced a new class of molecular imaging agents for ultrasound and MRI based on gas vesicles (GVs) – genetically encoded gas-filled protein nanostructures from buoyant photosynthetic microorganisms6,7. GVs comprise a protein shell with spatial dimensions of ~200 nm and thickness of ~2 nm enclosing a hollow gas-filled interior. Gas dissolved in the surrounding media partitions freely in and out of this nanoscale compartment, while liquid water is excluded by the shell’s hydrophobic inner surface. Microbes such as the cyanobaterium Anabaena flosaquae (Ana) and the archaeon Halobacteria salinarum (Halo) form GVs as a means to regulate cellular buoyancy for optimal access to light and nutrients. In these organisms, GVs are encoded by operons of 8–14 genes, which include the primary structural proteins GvpA and GvpC and several minor constituents and chaperones.

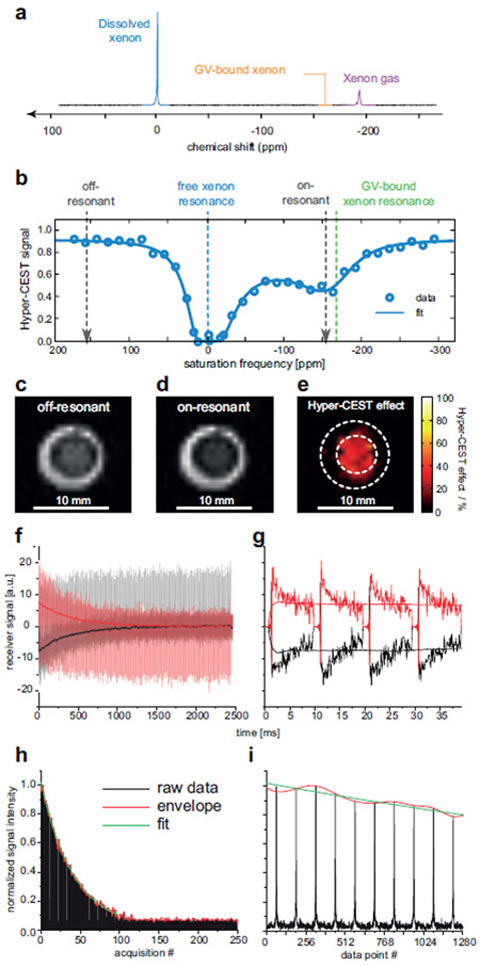

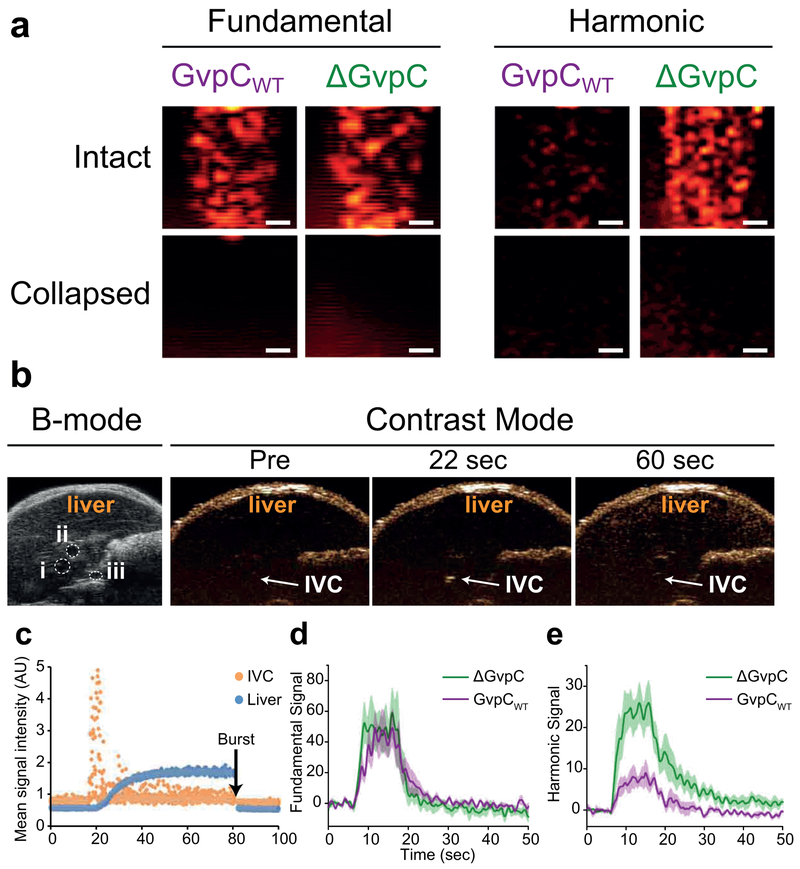

We recently discovered that GVs purified from cyanobacteria and haloarchaea scatter sound waves and thereby produce ultrasound contrast at sub-nanomolar concentrations8. Furthermore, we found that GVs’ unique physical properties enable them to produce harmonic ultrasound signals useful for contrast specificity in vitro and in vivo9,10. We also showed that GVs from different species can be imaged in multiplex based on their differential responses to acoustic pressure, and that conditional GV clustering leads to contrast enhancement, allowing them to be used as molecular sensors8. In parallel, we demonstrated that GVs produce contrast in hyperpolarized xenon MRI11, an emerging form of imaging that takes advantage of non-equilibrium spin polarization to increase molecular sensitivity by factors of up to 105. We discovered that atoms of hyperpolarized 129Xe dissolved in aqueous media exchange in and out of the GV interior, where their distinct chemical shift enables amplified MRI contrast to be produced using chemical exchange saturation transfer (CEST) pulse sequences. Using this hyperpolarized CEST (HyperCEST) technique allows GVs to be detected at picomolar concentrations11. In addition, the distinct chemical shifts of GVs in different microbial species enable multiplexed imaging. HyperCEST is currently performed in vitro, but is advancing toward in vivo use12,13.

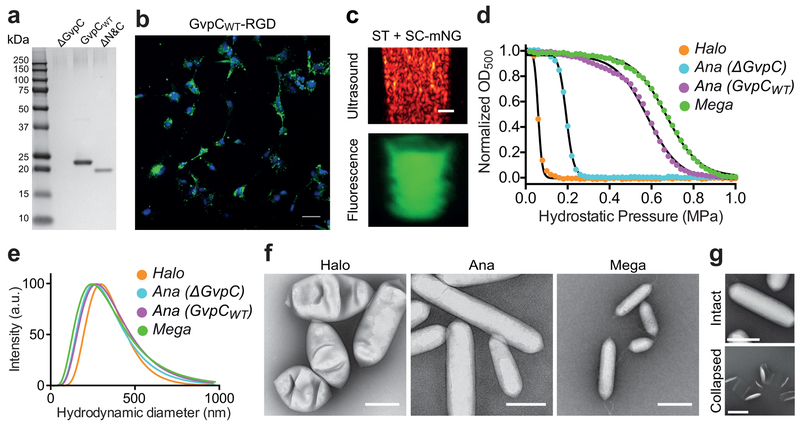

One particularly promising aspect of GVs is the possibility of engineering their physical and biochemical properties at the genetic level. To take advantage of this possibility, we recently developed a convenient genetic engineering platform, in which a single target protein, GvpC, on the surface of GVs purified from Ana cells is replaced by heterologously expressed engineered versions14. This strategy allows the modification of GV mechanical properties, including their harmonic response to sound waves and collapse under pressure for enhanced contrast and multiplexed imaging. In addition, genetic modification enables surface display of peptides such as lysine-rich protein to modify surface charge, CD47 to minimize uptake by macrophages, polyarginine for cellular internalization and RGD for targeting to integrin receptors on tumor cells14.

Overview of the Procedure

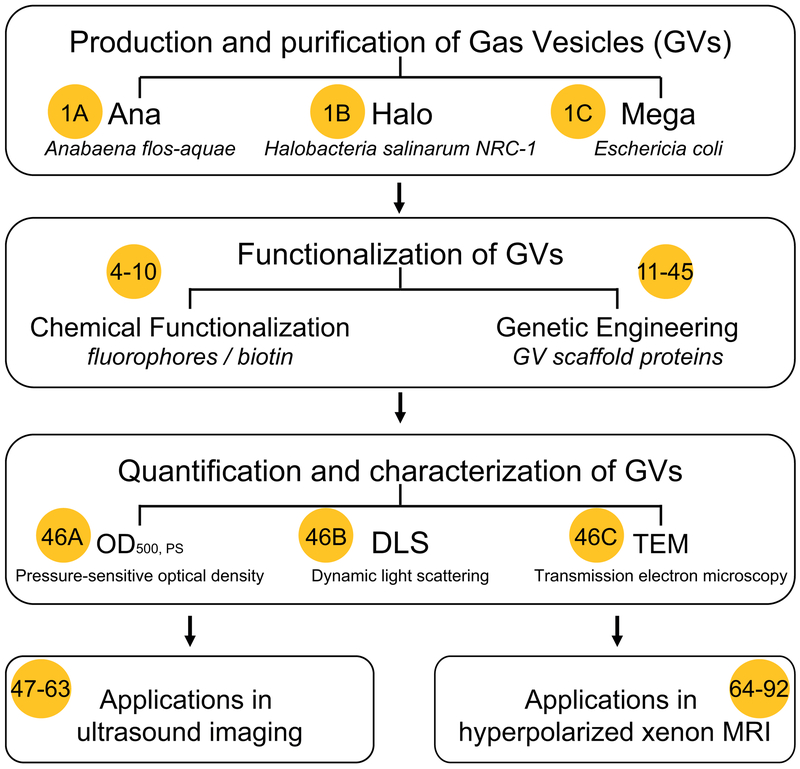

Here, we present a detailed optimized protocol to express and purify GVs (Steps 1|(A-C)) and quantify (Steps 2–3), functionalize and genetically engineer them (Steps 4–45), characterize their size and shape (Steps 46|(A-C)), and use them as contrast agents for non-invasive imaging applications (Steps 47–98). As illustrated in Figure 1, the procedure begins with isolation of GVs from cultures of Ana and Halo, or from E. coli expressing a heterologous GV gene cluster from Bacillus megaterium (Mega)15 (note that the Mega GVs were referred to as E. coli GVs in the cited paper). This results in three nanostructure populations with distinct properties (Table 1). These GVs are then quantified and characterized using pressure-dependent spectroscopy, dynamic light scattering (DLS) and transmission electron microscopy (TEM). Protocols for modification and functionalization using genetic and chemical approaches are provided as an added option based on the desired end application. Finally, the GVs are imaged in vitro and in vivo using ultrasound and in vitro using HyperCEST MRI.

Figure 1. Flowchart illustrating the experimental design and workflow for gas vesicle (GV) production, quantification, characterization, functionalization and imaging applications.

Table 1:

Characteristics of different types of GVs

| Ana GV | Halo GV | Mega GV | |

|---|---|---|---|

| Host/origin | Anabaena flosaquae | Halobacteria salinarum | Heterologous expression of a gene cluster from Bacillus megaterium in E. coli. |

| Shape | Cylindrical | Spindle | Cylindrical |

| Resistance to pressure-induced collapse | Medium (can be tuned) | Low | High |

| Ultrasound contrast | High Nonlinear after engineering |

High Nonlinear |

Low |

| Stability in Xe-MRI phantoms | High | Low | High |

| Ease of genetic modification | High | Low | Not established |

Advantages and Limitations:

Among the properties that make GVs attractive as imaging agents are their nanometer size, their fundamental physical stability, their biocompatibility as particles made entirely of protein, and their lack of requirement for metals or other inorganic cofactors to produce image contrast. In addition, as the first genetically encodable contrast agents for ultrasound and hyperpolarized xenon MRI, they offer the possibility of being developed as reporter genes16, creating new opportunities for non-invasive imaging at the molecular and cellular level.

Among the limitations of GVs in molecular imaging applications are their lower echogenicity per particle compared to conventional microbubble contrast agents for ultrasound and the specialized hyperpolarized Xe approach currently needed to take advantage of their sensitivity as reporters for MRI. In addition, the modular engineering approach presented here is done in vitro on purified GVs, and future efforts will focus on extending this platform to engineering of these nanostructures completely within cells. Furthermore, the use of GVs as dynamic molecular sensors based on conditional clustering requires ascertaining that a given molecular design does not result in non-specific aggregation, which must be done on a case-by-case basis.

EXPERIMENTAL DESIGN:

Here, we describe key experimental parameters for each stage of the protocol. One important initial consideration is the choice of GV-producing species. Although this protocol presents methods for producing three different types of GVs – Ana, Halo and Mega – one of these types may be most appropriate for a given application (see Table 1). For ultrasound, unmodified Halo GVs can be used directly in ultrasound imaging to obtain non-linear signals8,10. Ana GVs are the system of choice if one wishes to genetically tune the properties of GVs for multiplexing, multimodal imaging and targeting applications9,14. Mega GVs produce lower echogenicity under ultrasound compared to Ana and Halo GVs (Figure S1, a-d), but have a higher critical collapse pressure that may make them useful for multiplexing. Halo GVs produce non-linear ultrasound contrast immediately after purification, while Ana GVs require a chemical treatment. With regard to Xe-MRI, Ana and Mega GVs are more stable under pressure and during the bubbling of hyperpolarized xenon (as described below) compared to Halo GVs11. All three species have a unique chemical shift in Xe-MRI, allowing multiplexing.

Production and Purification of Gas Vesicles (GVs):

GVs are obtained from Ana, Halo or heterologously-expressing E. coli. Ana is a green, filamentous cyanobacterium that naturally inhabits fresh water lakes6. Halo is a pink halophilic and thermophilic archaea that grows in salt-water ponds7. Ana is cultured in low-salinity medium supplemented with trace metals and buffering agents, while Halo is cultured in high salinity medium for GV production.

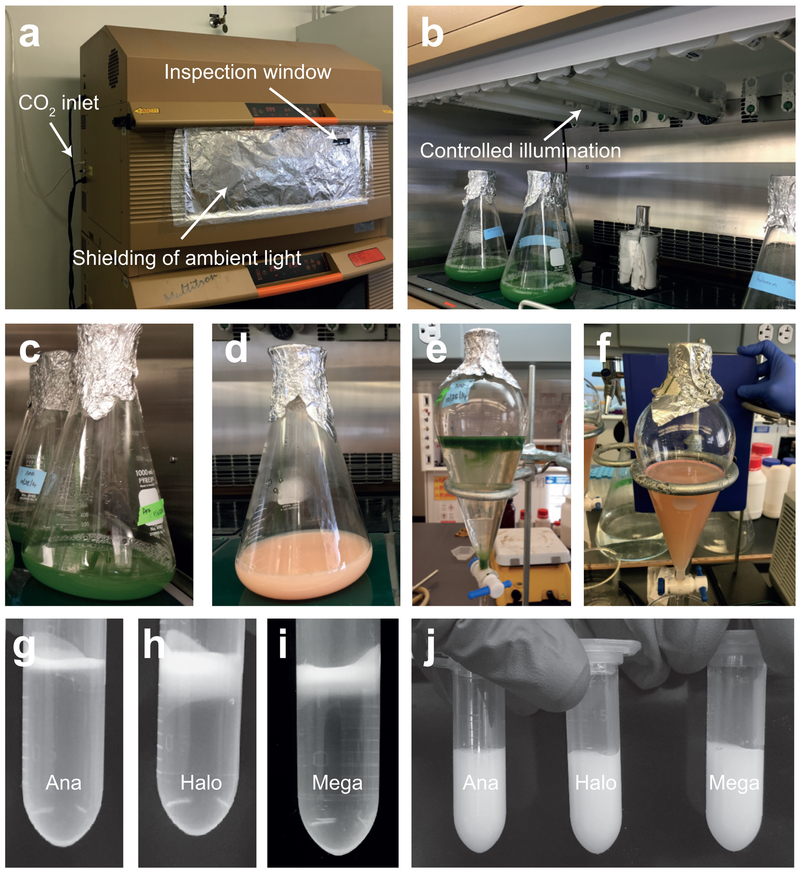

Ana and Halo cultures natively produce ample GVs after a few weeks of growth8,9,14. Ana cultures additionally require a controlled gaseous environment and illumination for optimal growth (Figure 2a-b). A freshly inoculated culture of cells may require several rounds (typically 2–3) of subculture to become strongly proliferative (Figure 2c-d). The confluent culture of microbes is then transferred to a separatory funnel that is left undisturbed for up to a week to allow the buoyant cells producing GVs to float to the top and separate from media (Figure 2e-f). Buoyant cells are then lysed using hyper-osmotic shock for Ana and hypo-osmotic shock for Halo. Subsequently, centrifugally assisted floatation is used to isolate GVs from the cell lysate to yield a concentrated, milky-white solution of GVs in the buffer of choice8,9,14 (Figure 2g-j). Heterologous production of Mega GVs in E. coli is accomplished by expression from a plasmid encoding a Mega GV gene, followed by detergent-mediated lysis11.

Figure 2. Equipment setup and expected results for native production and purification of GVs.

(a-b) Shaker-incubators adapted for the growth of cyanobacteria Anabaena flosaquae providing controlled illumination, temperature, aeration and CO2. (c-d) Confluent green and pink cultures of Anabaena flosaquae and Halobacteria salinarum respectively, just before harvesting. (e-f) Effective separation of buoyant cells from spent media in separatory funnel for isolation and harvesting of Ana and Halo cells producing GVs. Purified Halo (g) and Ana (h) and Mega (i) GVs as a dense milky-white layer post centrifugally assisted floatation. (j) Resuspended milky-white solutions of purified Ana (left), Halo (middle) and Mega (right) GVs in PBS at OD500,ps ~6 prior to use in ultrasound imaging experiments.

The procedures leading from inoculation of GV-producing microbes to harvesting and purification is summarized in the Table 2, along with important parameters that affect processing time, yield and quality.

Table 2:

Experimental Parameters for GV Production, Purification and Storage

| Procedure | Design Parameters |

|---|---|

| Inoculation of starter culture | Type of culture (suspension vs. solid), amount of inoculum, total volume of culture |

| Growth of starter culture | Temperature, rotation speed, duration, illumination |

| Sub-culturing | Number of flasks, volume of culture and media |

| Harvesting of GVs | Composition of lysis buffer and duration of lysis, concentration of cells |

| Purification | Selection of centrifugation speed, type of rotor, tube and syringe needle |

| Storage | Storage temperature, buffer and type of vial/tube |

Growth conditions are chosen to facilitate optimal proliferation of each host strain and GV expression. One unusual variable to keep track of is pressure, since GVs collapse irreversibly at hydrostatic pressures of 50 to 800 kPa, depending on species6. For example, the cultures should be grown under mild agitation, as excessive shaking may lead to GV collapse. During centrifugation steps, it is necessary to calculate the hydrostatic pressure generated for a particular g-force on the liquid column of GVs and ensure that it is well below the GV critical collapse pressure. Long-term storage of purified GV stocks should preferably be done in screw-top vials, as micro-centrifuge tubes with snap-lock caps may cause GV collapse due to pressurization of the sample while opening or closing the tube.

Quantification and Characterization of GVs:

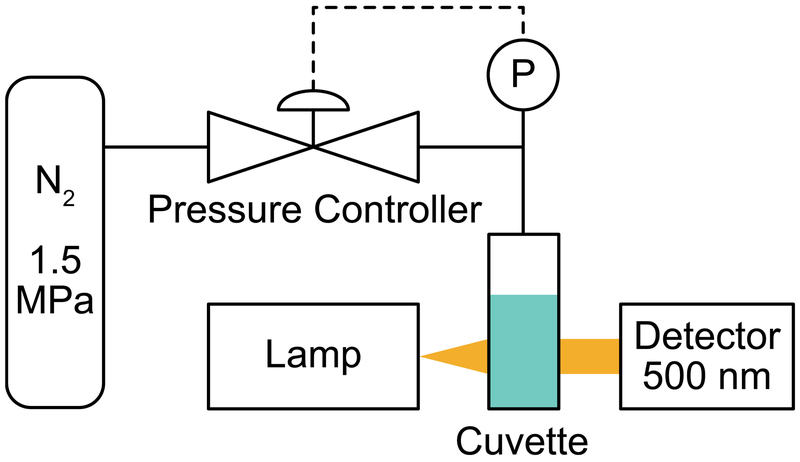

Purified GVs resuspended in the buffer of choice (e.g. phosphate buffered saline, PBS) can be quantified by measuring the optical density at 500 nm, or OD500, since GVs scatter visible light (Step 2). Collapsed GVs (in the same buffer), which do not scatter light, are typically used as the blank control for measurements, yielding a pressure-sensitive OD reading (OD500, ps). It is important to note that clustering of GVs, whether by design or due to functionalization with aggregation-prone moieties can confound OD500 measurements and contribute to errors in calculating concentration from OD500. Pressurized absorbance spectroscopy assays GV mechanical strength by measuring OD500 under increasing hydrostatic pressure using the device described in the Equipment Setup section (Figure 3) and the protocol described in Steps 46|(A)(i-ix).

Figure 3. Collapsometry setup.

Illustration of the collapsometry setup used for determining the critical collapse pressure of GVs.

Dynamic light scattering (DLS) is used to estimate the hydrodynamic size of GVs for routine non-destructive characterization and quality control (Steps 46|(B)(i-ii)). DLS can be used to assess GV clustering. Care should be taken in the interpretation of DLS readings of GVs due to the spherical assumption of the Einstein–Smoluchowski relation and the non-spherical shape of GVs. Negative contrast TEM is used for imaging GV size, shape, texture and integrity following production and physical or biochemical treatments (Steps 46|(C)(i-viii)). Negative staining with uranyl acetate is used to produce contrast, and use of a buffer such as HEPES is preferred over phosphate buffers that may precipitate with the uranyl acetate. The concentration of the GV solution spotted on the grid directly correlates with the density of GV particles on the grid.

Modification and Functionalization of GVs:

GVs can be modified and functionalized through genetic and chemical methods. Genetic engineering of GV mechanical and surface properties is conveniently performed via exchange of the native outer scaffolding protein GvpC (gas vesicle protein C) with recombinant GvpC variants (Steps 11–41). For example, fusing short peptides to the termini of GvpC allows for cell-specific targeting, and truncated GvpC variants enable acoustic multiplexing14. GvpC tolerates terminal fusions of peptides up to 100 residues. To covalently attach larger proteins, one can use the modular SpyTag-SpyCatcher protein assembly system17. GVs reconstituted with SpyTag-GvpC can be reacted with proteins of interest fused to SpyCatcher, forming a covalent bond (Steps 42–45).

Chemical conjugation to GVs makes use of lysine residues on their protein shells and amine-reactive crosslinkers such as sulfo-N-hydroxysuccinimide esters (Sulfo-NHS). Chemical moieties including polymers (e.g. polyethylene glycol), fluorophores and small molecules (e.g. biotin) can be conjugated using this method (Steps 4–10). Biotinylated GVs can subsequently react with streptavidin or avidinated antibodies8. The Sulfo-NHS coupling reaction can be conducted in PBS (pH 7.4) as a one-pot reaction. Depending on the application, the desired extent of labeling can be tuned by varying the molar ratio of Sulfo-NHS to GVs and by changing the incubation time. Either dialysis or buoyancy purification can be used to separate the labeled GVs from excess reactants.

Ultrasound Imaging of GVs:

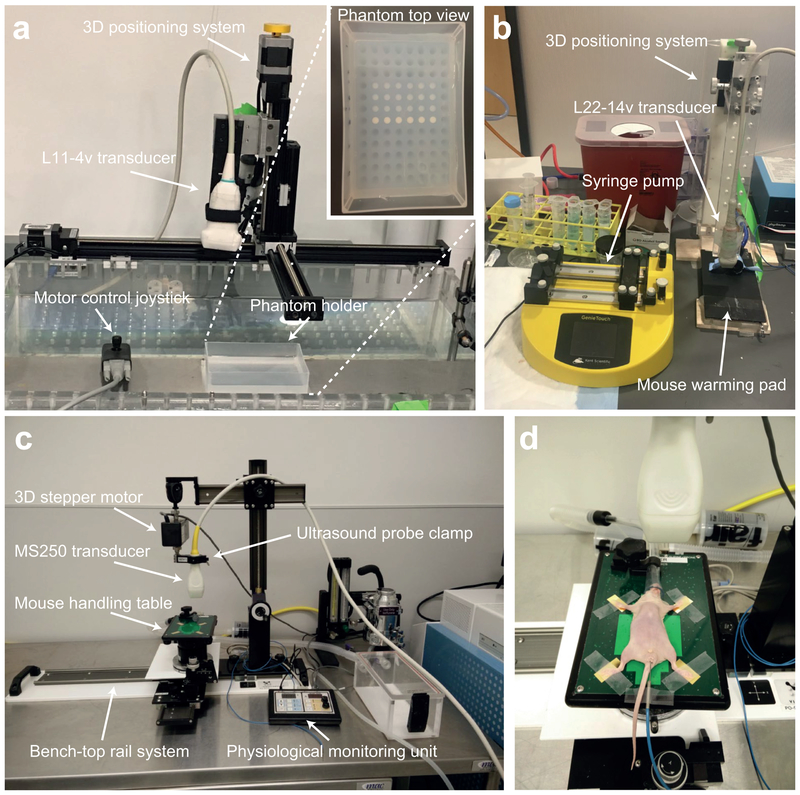

For in vitro imaging, GVs can be embedded and imaged in multi-well agarose phantoms (Figure 4a, Steps 47–62). A typical experimental setup for in vitro and in vivo ultrasound imaging is shown in Figure 4, a-d. Experimental design parameters include phantom composition, (i.e. percentage of agarose, buffer, background scattering particles), concentration and amount of GV sample loaded. Phantom molds can be made using 3-D printing to obtain defined well size, shape and spacing. Imaging parameters include plane of imaging (longitudinal versus transverse cross-section of the phantom wells), mode of ultrasound imaging (conventional or nonlinear imaging), transducer frequency range, transmit waveform characteristics such as pulse envelope shape, number of cycles, amplitude and frequency. Importantly, the amplitude used for imaging must be below the GVs’ acoustic critical collapse pressure. PBS is typically used as a negative control for ultrasound contrast and 5 μm polystyrene beads that scatter linearly at medical ultrasound frequencies are used as a reference sample. All GV samples and controls are mixed with melted agarose solution prior to loading. Solidification of the agarose after loading into the phantom wells ensures that samples are uniformly distributed throughout the well and that GVs remain suspended in the agarose matrix without floating during imaging. Typically, a final OD500 of 2.25 for Ana GVs and 0.4% (wt/vol) for polystyrene beads is used to match echogenicity. For Halo GVs, a final OD of 0.5 gives good signal without attenuation, with 0.83% (wt/vol) polystyrene beads to match echogenicity. In-situ collapse of GVs using pulses with amplitudes above the GVs’ acoustic critical collapse pressures cause GV ultrasound signals to disappear, allowing confirmation of GV-based signals and background subtraction. In addition, differential collapse at multiple pressures and spectral unmixing allow multiplexed imaging of mechanically distinct GV classes14. Quantification of signals in ultrasound images is typically performed using MATLAB or ImageJ software.

Figure 4. Ultrasound setup for in vitro and in vivo imaging.

(a) Setup of the in vitro imaging system with the Verasonics L11–4v transducer mounted on a 3-D translatable clamp (computer-controlled) and a fixed imaging phantom holder. Inset shows an agarose phantom loaded with GV and polystyrene samples prior to imaging. (b) In vivo imaging setup with the Verasonics L22–14v transducer, mounted on a 3-D positioning system (manual), an animal mounting platform with a heating pad and a syringe pump for controlled sample injections. (c) Setup of the Vevo imaging station includes the ultrasound probe clamp attached to the 3D stepper, the mouse handling table and the physiological monitoring unit. All components except the physiological monitoring unit are attached to the bench-top rail system. (d) Animal positioning with the mouse being laid down in a supine position with the nose and mouth in the nose cone and each paw extending outwards onto the electrodes and secured with surgical tape. A rectal probe is used to monitor the core temperature of the animal.

The in vivo ultrasound imaging protocol has been used to look at GV passage through the inferior vena cava (IVC) and subsequent induced contrast enhancement in the liver after intravenous injection8,14 (Step 63|(A-B)), but can be adapted for other organs or tissues. Depending on the tissue region of interest, some ultrasound imaging parameters, such as image gain and field of view may need to be adjusted accordingly. As in in vitro imaging, it is critical that the transmit power is kept at a value that provides sufficient signal without collapsing the GVs. Further adjustments can be made to GV solution concentration and volume, according to experimental needs. Functionalized GVs can also be imaged using this protocol, as long as appropriate controls are used. When planning an imaging experiment using functionalized GVs, we suggest using native GVs from the same batch as a control. It is possible to administer multiple injections of GVs in the same mouse, as long as the total injection volume does not exceed the limit stated in institutional guidelines. If required, GV solutions can be tested for bacterial endotoxins using quantitative, chromogenic endpoint LAL assays, such as the QCL-1000™ Assay (Lonza). Endotoxins can be removed using commercially available affinity resins such as the ToxinEraser™ Endotoxin Removal Resin (GenScript). Once injected, ensure GVs have cleared completely and tissue contrast signal is back to baseline before a second bolus injection.

129Xe MRI Imaging of GVs:

Hyperpolarized 129Xe-MRI is an active area of molecular imaging research, which is currently mainly performed in vitro with pure contrast agents or labeled cells18,19, while in vivo techniques are being developed12,13. This protocol describes the imaging of GVs using hyperpolarized 129Xe MRI in vitro, as previously done with purified GVs, GV-expressing cells and GV-labeled cells11. This involves preparing the hyperpolarized gas, introducing it into a liquid sample of GVs and applying a HyperCEST pulse sequence11 (Steps 64–92). This requires some specialized equipment, some of which has been described earlier in the context of xenon NMR and MRI applications. The working steps and the equipment setup in particular require people with skills in NMR/MRI and some experience in setting up custom-made electronic devices. The hyperpolarization system is available as a commercial unit (see Equipment section and Figure 5a-e) or can be built according to previous publications20. In either case, the system should be capable of delivering hyperpolarized 129Xe under very stable, continuous flow conditions 21,22.

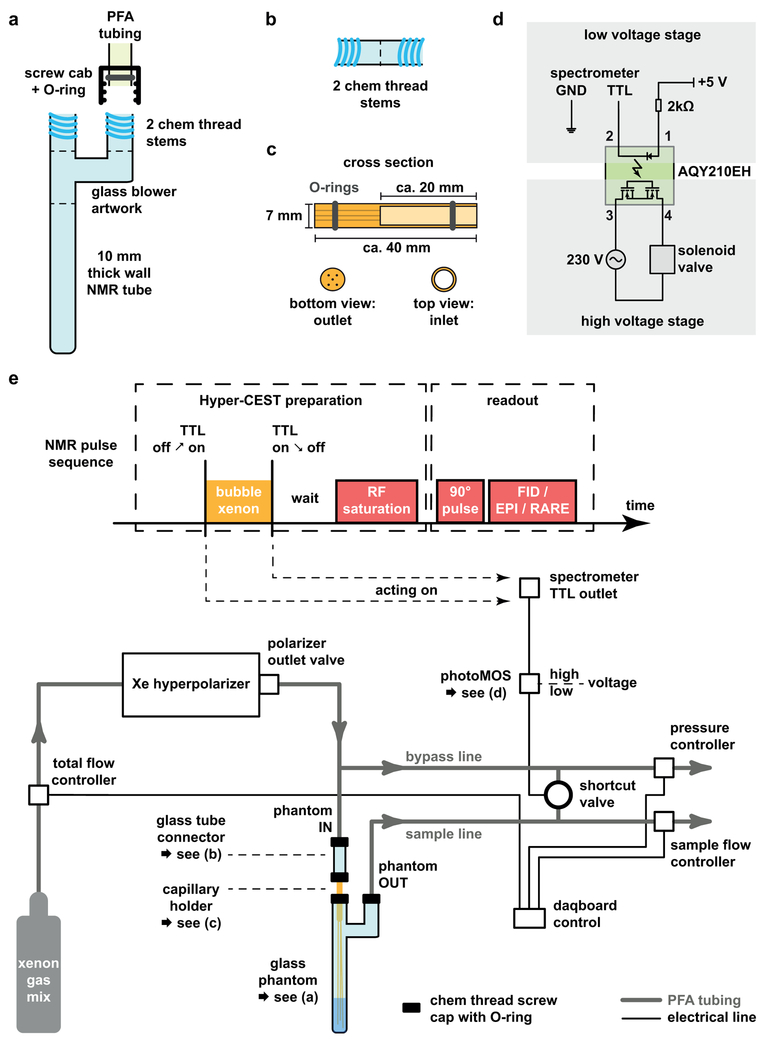

Figure 5. Required elements for assembling the gas delivery manifold for 129Xe-MRI.

(a) Main glass phantom made from 10 mm thick wall NMR tube and chem thread connectors; PFA tubings are connected with a chem thread srew cap and an O‐ring. (b) Glass tube connector. This is also used for step 3, but mainly for connecting the PFA tubing with the capillary holder. (c) Capillary holder. (d) PhotoMOS circuit for controlling the solenoid valve. (e) Schematics of the communication between the NMR pulse sequence and the gas delivery manifold with corresponding tube and electrical connections.

To achieve good Hyper-CEST performance with a particular GV type, it is necessary to optimize the saturation power and duration to match the exchange conditions for Xe between GVs and the surrounding media23,24. In addition, attention must be paid to GV integrity during the bubbling or inflow of xenon into the phantom, since both hydrostatic pressure and bubbles can cause irreversible GV collapse.

MATERIALS:

REAGENTS:

Anabaena flosaquae/Aphanizomenon flosaquae (Culture Collection of Algae and Protozoa, Scottish Marine Institute, cat. no. CCAP 1403/13F)

Halobacterium sp. NRC-1 as brine inclusions (Carolina Biological Supply Company, cat. no. 154777) (OR) Halobaterium sp. plate (Carolina Biological Supply Company, cat. no. 154801)

Rosetta™ 2(DE3) pLysS competent E. coli cells (EMD Millipore, cat. no.71401–3)

BL21 (DE3) competent E. coli cells (NEB, cat. no. C25271)

Cyanobacteria BG-11 Freshwater solution 50x (Sigma, cat. no. C3061)

Phosphate Buffered Saline without calcium and magnesium (PBS, Corning, cat. no. 21–040)

Sodium Nitrate, High Purity Grade (NaNO3, Amresco, cat. no. 0598)

Potassium Phosphate monobasic (KH2PO4, Sigma, cat. no. P5655)

Magnesium Chloride hexahydrate (MgCl2.6H2O, Sigma, cat. no. M9272)

Trisodium Citrate dihydrate (Sigma-Aldrich, cat. no. S1804)

Potassium Chloride (KCl, Sigma, cat. no. 746436)

Casein Hydrosylate (Sigma, cat. no. 22090)

Yeast Extract (BD, cat. no. 212750)

Magnesium sulfate heptahydrate (MgSO4.7H2O, Sigma, cat. no. 230391)

Calcium Chloride dihydrate (CaCl2.2H2O, BDH Chemicals, cat. no. BDH9224)

Sodium metasilicate nonahydrate (Na2SiO3.9H2O, Sigma, cat. no. S4392)

Sodium Carbonate (Na2CO3, Sigma, cat. no. 71345)

Sodium Bicarbonate (NaHCO3, Sigma, cat. no. S5761)

Citric Acid, 1M (BDH Chemicals, cat. no. BDH7397)

Ethylenediaminetetraacetic acid (EDTA), disodium salt dihydrate (Alfa Aesar, cat. no. A15161)

Ferric Ammonium Citrate (Amresco, cat. no. 0846)

Solulyse Bacterial Protein Extraction Reagent, in Tris.HCl Buffer, pH 7.4 (Genlantis, cat. no. L200500)

D-Sorbitol (Sigma, cat. no. S1876)

Deionized (DI) water (tap supply)

Anhydrous dimethyl sulfoxide (Life technologies, cat. no. D12345)

N-Hydroxy-Succinimidyl-Ester moiety such as Alexa-488-NHS (Thermo Fisher, cat. no. A20000)

Tris-HCl buffer (Teknova, cat. no. T1080)

HEPES (Sigma, cat. no. H3375)

Terrific broth (Sigma, cat. no. T0918)

Isopropyl β-D-1-thiogalactopyranoside (IPTG) (Anatrace, cat. no. I1003)

Kanamycin (Sigma-Aldrich, cat. no. K1377)

2% Uranyl Acetate (EMS, cat. no. 22400–2)

Urea (VWR, cat. no. 0568)

Sodium Hydroxide (NaOH, Sigma, cat. no. 221465)

Sodium Chloride (NaCl, Sigma, cat. no. 793566)

Sodium Phosphate Monobasic (NaH2PO4, Amresco, cat. no. 0823)

10X Tris/Glycine/SDS buffer (Bio-Rad, cat. no. 161–0732)

Protein standard (Bio-Rad, cat. no. 161–0375)

Laemmli sample buffer (Bio-Rad, cat. no. 161–0737)

Gel electrophoresis power supply (Bio-Rad, cat. no. 164–5050)

Gel electrophoresis cell (Bio-Rad, cat. no. 165–8004)

Any kD SDS-polyacrylamide gels (Bio-Rad, cat. no. 456–9034)

SimplyBlue™ SafeStain (Invitrogen, cat. no. LC6060)

Bradford Reagent (Sigma-Aldrich, cat no. B6916–500)

Pierce™ 660 nm protein assay reagent (Thermo-Fisher Scientific, cat. no. 22660)

Bovine serum albumin (Thermo-Fisher Scientific, cat. no. 15561020)

Ni-NTA Superflow Resin (Qiagen, cat. no. 30450)

Poly-prep chromatography columns (Bio-Rad, cat. no. 7311550)

Imidazole (Sigma, cat. no. 792527)

2-mercaptoethanol (Bio-Rad, cat. no. 1610710)

DNaseI (NEB, cat. no. M0303S)

Lysozyme (Sigma-Aldrich, cat. no. L6876)

GvpCWT, ΔN&C-GvpC and GvpC-SpyTag genes in pET28a plasmid (Addgene, ID no. 85732, 85736 and 85737 respectively)

SpyCatcher-mNeonGreen in pET26b plasmid (https://www.addgene.org/vector-database/9135 )

pST39 plasmid containing pNL29 Mega GV gene cluster (Addgene ID no. 91696)

SOC Outgrowth Medium (NEB, cat. no. B90205)

Luria-Bertani (LB) Broth base powder (Invitrogen™ by Life Technologies, cat. no.12795–084)

Ampicillin (Sigma, cat. no. A0166–25G)

Chloramphenicol (Sigma-Aldrich, cat. no. C0378)

Glucose (Sigma-Aldrich, cat. no.G8270)

Glycerol (Sigma-Aldrich, cat. no.G5516)

Phosphate buffered saline (PBS), 20x solution (Teknova, cat. no. P1225)

-

SCID Hairless Outbred (SHO) (OR) SCID Hairless Congenic (SHC) mice, female, 4–6 weeks of age (Charles River, cat. no. 474 (OR) 488)

!CAUTION All procedures involving animal use must be performed in accordance to institutional guidelines and regulations and approved by relevant Animal Care and Use Committees.

Sterile PBS (Life Technologies, cat. no.10010–023)

Isoflurane USP (Fresenius Kabi, cat. no.M60303)

-

Medical air USP cylinder (Praxair)

!CAUTION Gaseous anesthesia must be scavenged properly using a charcoal canister or house vacuum to minimize potential exposure to humans.

Charcoal canister (F-Air, Braintree, cat. no. F-AIR EA)

Eye ointment (Lacri-Lube, Refresh) (OR) Lubricating gel (Aquagel, Parker, cat. no. 57–05)

0.9% Sodium Chloride Injection, (Baxter, cat. no. JB1322 (OR) VWR, cat. no. 47729–565 )

Ultrasound gel (WavelengthCL, National Therapy Production Inc., cat. no. NTPC500X) (OR)

Aquasonic 100 ultrasound transmission gel (Parker Lab Inc. ,VWR, cat. no. 68200–712)

Electrode gel (Signa gel, Parker Lab Inc., cat. no. 15–25)

Nair™ lotion (Church & Dwight co., Inc.)

Vetbond tissue adhesive glue (Fisher Scientific, cat. no. NC9259532)

SPHERO™ polystyrene particles, 4–5-4.9 μm (Spherotech, cat. no.PP-45–10)

Agarose (Biorad, cat. no. 161–3102)

-

Xenon gas mixture: 2–5% (vol/vol) Xe (natural abundance with 26.4% (vol/vol) 129Xe is sufficient), 10% (vol/vol) N2, He balance, grade 5.0 (Praxair))

▴CRITICAL The gas tank should have a pressure regulator for adjustments around 2 bar absolute pressure. The gas amount to be used depends on the flow rate through the system. A typical value would be 0.25 L/min, i.e. 15 L per hour.

EQUIPMENT:

Shaker-Incubator with cooling, CO2 control and illumination (Infors HT, Multitron II) (Exact setup used is shown in Figure 2a-b)

Benchtop centrifuge with swinging bucket rotor (Beckman Coulter, Allegra X-15R)

Benchtop micro-centrifuge (Eppendorf 5424R)

Barnstead™ GenPure™ xCAD Plus UV/UF Water Purification System (Thermo Scientific, cat. no. 50136146)

Pyrex™ 500 mL and 1000 mL Erlenmeyer Flasks (Corning, cat. no.4980, stopper no. 9)

Pyrex™ 500 mL Separatory Funnel (Cat. no.6402–500, stopper no. 24)

Pyrex™ Culture Tubes (Corning, cat. no.9820)

Pyrex™ 250 mL, 500 mL and 1 L media storage bottles (Corning, cat. no. 1395)

4L Beaker (Thermo Scientific Nalgene, cat. no. 1201–4000)

15 and 50 mL centrifuge/falcon tubes

1.5, 1.7 and 2 mL micro-centrifuge tubes

Metal ring stand for separatory funnel

Vacuum driven disposable bottle top filter (Durapore™,0.22 μm, Millpore, cat. no. SCGVT05RE)

Adjustable volume pipets and pipet tips (100–1000 μL, 20–200 μL, 2–20 μL and 0.5–2.5 μL, Eppendorf Research Plus)

Serological pipets (1, 5, 10 mL and 25 mL, VWR)

Syringes, Luer-lok tip, 1mL, 3mL, 10 mL and 30mL (BD, cat. no.309602, 309657, 309604 and 309650)

18G and 1”/1.5” 21.5G flat bottom needles (SAI B18–100 and B21–150/B21–100)

Gel-loading pipet tips (Corning, cat. no. 4884)

Regenerated cellulose dialysis tubing, 6–8kDa cutoff (Spectrapor, cat. no. 1326650)

Formvar/Carbon 200 mesh Cu TEM grids (Ted Pella Inc., cat. no. 01801)

Ultracentrifuge (Beckman-Coulter Avanti J-30I)

Ultracentrifuge bottles (Beckman-Coulter)

PD10 desalting columns (GE Healthcare Life Sciences, cat. no. GE17–0851-01)

1 cm path-length quartz cuvette (Hellma Analytics, cat. no. 176.700-QS)

Pressure controller (Alicat Scientific, cat. no. 73907)

UV-Vis Spectrophotometer (Ocean Optics Inc., STS series microspectrometer, 350–800 nm, 50 μm slit, 400 core/1cm SMA input, cat. no. STS-VIS-L-50–400-SMA) equipped with a 400 μm fiber in the VIS/NIR range (2m, cat. no. P400–2-VIS-NIR) and a Krypton lightsource (2000 hour bulb, ECOVIS) and accompanying Oceanview spectroscopy software.

-

Compressed Nitrogen cylinder with pressure regulator (Air Liquide)

!CAUTION Proper safety techniques should be followed when opening and handling the compressed gas cylinder. Make sure the cylinder is secured to a wall and properly connected to pressure regulator before opening.

ZetaPALS dynamic light scattering instrument (Brookhaven Instruments)

Disposable cuvette (Eppendorf, cat. no. Z605050)

Plate-reader spectrophotometer (Molecular Devices SpectraMax M5)

Gel imaging system (BioRad Chemidoc MP, model no. 170–8280)

Water bath (various sources, e.g. Fisher Scientific, cat. no.15–462-6Q)

Disposable culture tube, 16 × 100mm (VWR, cat. no. 47729–576)

Dialysis clips, weighted/unweighted closures, 55 mm sealing width (Spectrum Labs Inc., cat. no. 132745/132737)

Transmission electron microscope (FEI Tecnai T12 LaB6 120 kV) equipped with a Gatan Ultrascan 2k X 2k CCD and Leginon automated data collection software suite

Glow Discharging System (Emitek K100X)

PELCO reverse, anti-capillary tweezers (TedPella, 5378-NM)

Glass slides (VWR Microslides, cat. no. 48382–171)

Filter paper (Whatman™, cat. no. 1001–090)

Pipet-Aid (Drummond Scientific Co.)

Magnetic Stirring Bars (VWR)

Rotatory Shaker (Rotamix, Appropriate Technical Resources, model RKVS)

Microvolume Spectrophotometer (NanoDrop™ 2000C series, Thermo Scientific, cat. no. ND-2000C)

Tail vein catheter (SAI Infusion Technologies, cat. no. BF-27–01)

Syringe with tip cap, 12 mL (Luer Lock Kendall Monoject, cat. no.1181200777)

Needle, 27G x 1/2 (PrecisionGlide, BD, cat. no. 305109)

Tuberculin Syringe, 1/2cc (BD, cat. no. 305620)

Surgical tape (Transpore, 3M, cat. no. 1527–1)

Alcohol wipes (Webcol, Covidien, cat. no. 63001) (OR) (BD, cat. no. BD326895)

Cotton swabs

Syringe pump (New Era Pump System, cat. no. NE-1000 (OR) Kent Scientific Corporation, model. GenieTouch) (Typical setup shown in Figure 4b).

Heatlamp (Home Hardware)

Ultrasound imaging system (Vevo®2100, VisualSonics, Fujifilm (OR) Verasonics Vantage 256™, Verasonics. Inc.) (Typical setup shown in Figure 4a-d).

Ultrasound transducer (L11–4v Verasonics Inc., (OR) L22–14v Verasonics, Inc., (OR) MS250, VisualSonics, Fujifilm)

Acoustic absorber sheet, 300mm x 300 mm (Precision Acoustics Ltd., cat. no. F28-SMALL)

Multi-well phantom mold (3-D printed)

Plastic reservoir for phantom preparation (Nalgene™ flat-bottom polypropylene robotic reservoirs , cat. no. 1200–1300)

Computer-controlled translation stage (X-Slide, Velmex, Inc.).

MATLAB (Licensed Software, Mathworks, Inc.)

Animal heat pad (Braintree Scientific, Inc. cat. no. HP 1M)

Temperature controller (Braintree Scientific, Inc. cat. no. TCAT 2DF)

Rectal probe for mice (Braintree Scientific, Inc. cat. no. RET 3)

Vevo® Imaging Station (VisualSonics, Fujifilm)

PE10 plastic tubing (Becton Dickinson, cat. no. 427400)

30G needles (Becton Dickinson, cat. no. 305106)

Rodent anesthesia machine (Patterson Veterinary, cat. no. 07–870-3592 (OR) VetEquip, cat. no. 901806)

Weighing Balance (sensitive in the g and mg range)

-

MR imaging system (Bruker); preferably a vertical NMR spectrometer at field strength of 7 T or higher with micro-imaging capability for 1H and 129Xe; a variable temperature unit (VTU) is desirable to keep the sample temperature stable either at room temperature or at physiological body temperature.

▴CRITICAL The operating console needs at least one available trigger signal output (TTL) to be connected to a photoMOS relay for regulating the gas flow

Dual-tuned 1H/129Xe NMR coil with 10 mm inner diameter (Bruker)

Non-selective NMR pulse sequence for acquiring a direct Xe NMR spectrum after fresh Xe delivery. This is implemented by using a simple (pulse – acquire) sequence; the sequence starts with two trigger signals to communicate with the gas delivery manifold and then a block excitation pulse of adjustable amplitude, followed by an FID acquisition

Multi-echo acquisition MRI pulse sequence (echo planar imaging [EPI] or rapid acquisition with relaxation enhancement [RARE], Bruker) with activatable magnetization transfer module (alternative: fat suppression or saturation transfer module) and two triggers.

-

Hyperpolarization system for producing spin-hyperpolarized 129Xe(commercial systems are available through www.xemed.com, www.polarean.com or as an open source design)

! CAUTION The hyperpolarization system contains ~1 g of a highly reactive alkali metal such as Rb. Make sure to be familiar with the procedures for handling the system as provided by the manufacturer

▴CRITICAL The system must be capable of producing hyperpolarized Xe in continuous flow mode for repeated re-delivery into the sample solution.

-

Gas flow controller with a maximum flow rate of100 standard mL/min (SMLM) (Omega Engineering Inc., model no. FMA 5408) and second one of 500 SMLM flow (Omega Engineering Inc., model FMA5412)

▴CRITICAL Such gas flow controllers are typically calibrated for N2 gas; the correction factors for systems based on heat flux measurements applied to the Xe gas mix are: 1.44 for the Xe fraction, 1.454 for the He fraction. Hence the correction factor for a 5% Xe mix is 0.05×1.44 + 0.1×1 + 0.85×1.454 = 1.408.

Pressure controller for up to 6 bar and 1 standard liter per minute flow (Bronkhorst, model no. P-702CV-6K0A-AAD-22-V)

Direct solenoid actuated poppet “shortcut” valve (Norgren, model no. 9502310,)

PhotoMOS relay (Panasonic, model no. AQY210EH,)

PC-operated control interface for the hyperpolarization system and the gas flow controllers based on a data acquisition board (Daq/Board3000, Omega Engineering Inc.) and a graphic user interface (e.g., DASYLab or LabView, National Instruments)

Glass phantom (made from thick wall NMR tube of 10 mm outer diameter, Wilmad) with inlet and outlet adapter with size 7 chem threads (pieces CG-350–01 from ChemGlass Life Sciences), see Figure 5a

5 mm standard NMR tube to be inserted into the glass phantom to create a second compartment inside the 10 mm NMR tube

-

¼ inch PFA flexible tubing (Swagelok)

▴CRITICAL Ensure that the PFA tubing directing the Xe flow from the hyperpolarizer into the sample does not go through any zero-field crossings in the fringe field of the superconducting magnet because this might cause loss of hyperpolarization.

Fused silica glass capillaries for Xe dispersion (e.g five pieces of ca. 15 cm length each and 350 μm outer diameter, e.g. material no. 106815–0030, Polymicro)

Glass connecting tube with size 7 chem threads on either end (Figure 5b)

Home-made capillary holder; ca. 40 mm long, on the inlet side a 20 mm deep, 5mm diameter bore, on the outlet side 5 clear bores matching the outer diameter of the capillaries (like in Figure 5c; Teflon or Delrin material)

pH meter

Magnetic Stir Plate (Thermo Scientific, cat. no. S194925)

Autoclave

Bunsen Burner

Spark Lighter

REAGENT SETUP:

G625 growth medium for Anabaena flos-aquae (Ana) (4 L):

5.84 mM NaNO3, 224 μM KH2PO4, 304 μM MgSO4.7H2O, 208 μM Na2SiO3.9H2O, 189 μM Na2CO3, 10 mM NaHCO3, 245 μM CaCl2, 31 μM citric acid and 3 μM EDTA. Separately, add 24 mg of ferric ammonium citrate to 1 mL of ultrapure water (in a 1.5 mL micro-centrifuge tube). Heat in a 42°C water-bath for 10–15 min to dissolve before adding to the media in the Nalgene 4L beaker. Adjust to pH 8.0 with HCl. Filter sterilize using a 0.22 μm bottle-top filter. G625 growth media prepared using this method is stable for at least 6 months if stored in a cool, dry place at room temperature under sterile conditions. Since the iron sediments, make sure that the bottle is swirled each time before use.

Carolina growth medium for Halobacteria salinarum-NRC1 (Halo) (1 L):

4.278 M NaCl, 81 mM MgSO4.7H2O, 10 mM Trisodium citrate dihydrate, 27 mM KCl, 5g/L casein hydrolysate and 3g/L yeast extract. Adjust pH to 7.2 with NaOH and autoclave at 121˚C and 18 psi for 30 minutes. Autoclaved media can be stored for at least 6 months under sterile conditions at room temperature.

TMC lysis buffer for Halo GVs:

10 mM Tris-HCl, 2.5 mM MgCl2 and 2mM CaCl2, pH 7.5. Store indefinitely.

Sorbitol lysis buffer for Ana GVs:

1M D-Sorbitol in distilled water. Store indefinitely.

Terrific Broth (TB):

Add 47.6 g of TB powder and 8 mL glycerol to 1L of distilled water. Autoclave at 121°C for 15 m. Autoclaved media can be stored for at least 6 months under sterile conditions at room temperature.

Luria-Bertani (LB) Broth:

Add 25 g of LB powder to 1 L of distilled water. Autoclave at 121°C for 15 m. Autoclaved media can be stored for at least 6 months under sterile conditions at room temperature.

Kanamycin stock solution:

50 mg/mL in distilled water.

Ampicillin stock solution:

100 mg/mL in distilled water.

Chloramphenicol stock solution:

25 mg/mL in ethanol.

IPTG inducer stock solution:

1M IPTG in distilled water.

GV stripping buffer (Round 1):

10M urea, 100mM Tris-HCl, pH 8.0–8.5.

GV stripping buffer (Round 2):

6M urea, 60mM Tris-HCl, pH 8.0–8.5.

TGS buffer:

1:9 (v/v) dilution of 10X TGS stock in DI H2O.

Inclusion body solubilization buffer:

6M urea, 20mM Tris-HCl, 500mM NaCl, pH 8.0.

Inclusion body wash buffer:

6M urea, 20mM Tris-HCl, 500mM NaCl, 20mM imidazole, pH 8.0.

Inclusion body elution buffer:

6M urea, 20mM Tris-HCl, 500mM NaCl, 250mM imidazole, pH 8.0.

Soluble protein wash buffer:

50mM NaH2PO4, 300mM NaCl, 20mM imidazole, 1mM 2-mercaptoethanol, pH 8.0.

Soluble protein elution buffer:

50mM NaH2PO4, 300mM NaCl, 250mM imidazole, pH 8.0.

▴CRITICAL Antibiotic stocks and IPTG solution are at 1000x concentration and should be filter-sterilized after preparation and stored at −20°C. IPTG is light-sensitive and should be stored in the dark at −20°C. Lysis buffers and stock solutions for media preparation should be filtered (0.22 μm filter) and stored at room temperature. All protein purification buffers (wash and elution buffers) should be filter-sterilized and stored at 4°C.It is not advisable to use urea buffers more than a week old for protein purification. GV stripping buffers should be freshly prepared before each use.

Ultrasound gel preparation for imaging experiments:

Take a 30 mL luer-lok syringe, remove the piston and place the syringe with the tip facing down in a 50 mL falcon tube. Fill the syringe with ultrasound gel before loading the falcon tube into a table top centrifuge. Spin at 2500g for 30 minutes to ensure that there are no air bubbles in the gel and keep at room temperature. It is advisable to prepare the gel on the same day of the experiment, as longer storage may lead to drying if the syringe is not sealed tightly.

EQUIPMENT SETUP:

Cleaning and sterilization of glassware:

Clean and sterilize all glassware by autoclaving and fully dry them before use.

Setting up the apparatus for pressurized absorbance spectroscopy:

The setup used to conduct pressurized absorbance spectroscopy is illustrated in Figure 3 and includes the following components: (i) computer equipped with MATLAB to run the collapse pressure scripts, (ii) compressed N2 tank with control valves and a regulator, (iii) pressure controller, (iv) flow-through quartz cuvette, (v) UV-Vis spectrometer equipped with a light source and cuvette holder.

Couple the pressure controller to the gas tank via a stainless steel gas connector, to the computer via a USB port, and to the flow-through cuvette via plastic cannulae. Connect the Ecovis Krypton light source of the UV-Vis spectrometer to a power supply, allowing light to pass through the sample in the quartz cuvette. The transmitted light then passes through an optical fiber connector into the OceanOptics STS microspectrometer. The spectrometer is connected to the computer and controlled by a MATLAB script, which also interfaces with the pressure controller. These scripts can be downloaded from http://shapirolab.caltech.edu/?page_id=525. An equilibration time of 7 seconds at each pressure step and a final collapse pressure of 1400 kPa (for blanking) is hard-coded into the script and kept constant for all measurements. Before acquiring sample measurements, the system is calibrated by recording the spectra for full transmission (using the cuvette loaded with PBS or buffer of choice) and zero transmission (by turning the cuvette 90° so that no light passes through).

!CAUTION Ensure that the compressed nitrogen tank is transported and stored safely. Cylinders should be secured and stored upright in a cool dry area protected from combustible materials. The gas valve seal must always be in place. When not in use, keep all the cylinder and regulator valves shut and the pressure controller and spectrometer powered off.

Setting up the Verasonics imaging station and imaging parameters:

The Verasonics imaging system and setup for in vitro and in vivo experiments is shown in Figure 4a-b and comprises the following components: (i) computer, (ii) ultrasound probe, (iii) translatable probe clamp equipped with three independent motors that move in the x, y and z directions with μm-level precision (iv) fixed phantom holder and (v) Verasonics scripts running on MATLAB software. Adapt the setup for in vivo imaging by replacing the phantom holder with a mouse mounting platform equipped with a heating pad, anesthesia equipment and nose-cone for the animal and a manually translatable probe clamp.

CRITICAL Make sure that the probe is well coupled to the sample and that the transducer array of the probe is immersed in liquid or covered with ultrasound gel before transmitting ultrasound.

GVs can be imaged using the Ray-lines Verasonics example script. Imaging is typically performed at around 18 MHz using the L22–14v transducer with an F-number of 2 or 3, focal depth of 8 mm (matching the natural focus of the transducer) and 6 cycle pulses. For these parameters, nondestructive imaging of GVs can be performed at voltages of or below 3V. The onset of GV collapse usually takes place at around 5V. For efficient GV destruction, a 25V pulse is applied for a few seconds.

GVs are imaged at lower frequencies around 6.25 MHz using the L11–4v transducer and the corresponding Ray-lines script. The F-number is set to 2, transmit focus to 20 mm and transmit voltage to 1.6V. Images are saved from the Verasonics graphical user interface.

Setting up the Vevo imaging station and imaging parameters:

The imaging station setup is depicted in Figure 4c-d, and encompasses the following components: (i) bench-top rail system; (ii) 3D stepper motor; (iii) ultrasound probe clamp; (iv) mouse handling table; and (v) physiological monitoring unit. Make sure that the 3D motor is connected to the Vevo®2100 ultrasound system to allow for 3D image acquisition. Also connect the physiological monitoring unit to the Vevo®2100 system to allow on screen tracking of physiological parameters, such as heart rate, respiratory rate and body temperature.

Halo gas vesicles are imaged under the following imaging settings using the Vevo®2100 system: (i) frequency - 21MHz and 18MHz for B-mode and contrast mode respectively; (ii) transmit power - 2%; and (iii) gain - 16dB and 32dB for B-mode and contrast mode respectively. The imaging field of view can be adjusted accordingly to fit the tissue region of interest, by increasing or decreasing the image width and depth.

▴CRITICAL It is crucial to keep the transmit power on the Vevo®2100 system to 2%, to allow for stable imaging of Halo gas vesicles. Higher transmit power will collapse exposed GVs.

Setting up the syringe pump:

Gas vesicle injections are administered as a bolus using a syringe pump (shown in Figure 4b). The following settings are used for each injection: (i) syringe diameter - 3.55 mm (inner diameter of a BD 1/2cc Tuberculin Syringe); (ii) injection rate - 300 μL/min to 500 μL/min; and (iii) injection volume – 50 μL.

Installing the control electronics for the 129Xe MRI:

Set up the TTL output of the spectrometer with the photoMOS relay such that the latter one controls the status of the shortcut valve (see Figure 5d for the circuit). This is used to alternatingly force gas flow through the sample or to bypass the sample. From the Daq/board, use one analog output to operate the set points of the flow and pressure controllers. Connect one analog input each to read the process values of the controllers. Display the corresponding parameters through appropriate elements in the DASYLab/LabView software.

Preparation of the Xe gas delivery manifold:

The timing of Xe bubbling is controlled by the pulse sequence and achieved through a proper gas delivery system by connecting the PFA tubing and controllers according to Figure 5e. Prior to each experiment, insert the (five) capillaries into the capillary holder. The end tips should reach close to the bottom of the glass phantom.

▴CRITICAL This design of the flow and pressure controllers prevents Xe gas from passing through any needle valves or (electro-) magnetic units during its transfer from the hyperpolarizer to the sample, thus minimizing the depolarization of Xe.

▴CRITICAL Gas bubbles can cause serious image artifacts if persistent during image acquisition. Therefore, the bubbling has to be stopped and the sample has to settle down prior to acquisition. Fresh hyperpolarized xenon has to be re-delivered for each subsequent acquisition.

MRI pulse sequence setup:

The non-selective NMR sequence for acquiring direct Xe NMR spectra is adapted from an existing simple FID sequence by implementing the TTL trigger pulses and bubble/wait delays prior to the 90° block pulse (Figure 5e). The FID sampling window is typically 1000 ms and the spectral width to cover is ca. 350 ppm. For Xe MRI imaging sequence, single-shot pulse sequences should be used to make the most efficient use of the non-renewable Xe polarization. A single-shot EPI pulse sequence can be used when long T2* values are expected. Alternatively, a single-shot RARE pulse sequence can be used and is limited by T2. To set up the imaging sequence, take a standard sequence with image encoding of your choice (EPI or RARE) and implement a magnetization transfer or saturation module (Bruker ParaVision terminology) after the TTL trigger pulse for xenon delivery and prior to the k-space encoding. The saturation offsets are defined through a saturation frequency list. This list can be accessed by providing in the ParaVision graphical user interface a menu to enter a fixed number of saturation pulse frequency offsets. Point these entries to the saturation frequency list. Finally, loop the entire xenon delivery, wait time, the saturation pulse and the imaging sequence multiple times to walk through the entire saturation frequency list. Some general parameters when implementing the sequence are: a field-of-view of 20 × 20 mm2; matrix size 32 × 32 (in-plane spatial resolution: 625 μm2); slice thickness: 20 mm; repetition time including saturation time and xenon delivery: ca. 18 s.

Detailed parameters for RARE sequence: 90° Hermite excitation pulse: length = 3.375 ms, bandwidth = 1,600 Hz; 180° Mao refocusing pulse: length = 3.105 ms, bandwidth = 2,000 Hz; short echo time of ca. 10 ms (this is also the effective echo time as centric encoding is used here), echo readout time of 2.66 ms; ensure the RARE factor is set to give a single-shot acquisition, i.e., a RARE factor of 32 is used when the image matrix size is 322.

Detailed parameters for EPI sequence: 90° Gaussian-shaped excitation pulse: length = 1.0 ms, bandwidth = 2,740 Hz; encoding: partial Fourier-acceleration factor = 1.68 (i.e. 19 out of 32 k-space lines) and double sampling; short echo time of ca. 6 ms; echo train readout time of 6.01 ms for 19 k-space lines.

PROCEDURE:

Production and purification of gas vesicles (GVs):

1| Gas vesicles can be produced natively in cyanobacterial (Ana GVs) or haloarchaeal (Halo GVs) hosts. In addition, they can be heterologously expressed in E. coli (Mega GVs). To produce and purify Ana, Halo or Mega GVs, follow steps in Option A, B, or C respectively.

(A). Producing and purifying Ana GVs ● TIMING 4.5 weeks

-

(i)

Making Ana starter cultures (Steps i-iv: ● TIMING 2 wks) Open the seal of the primary culture tube of Anabaena flosaquae (as received from CCAP, UK), and loosen the screw cap to allow aeration of the culture. Let the tube stand upright and undisturbed for 2 days in a cool (room temperature i.e. (18–25 °C)), dry place with access to ambient light. Viable Ana cells producing GVs will float to the top of the tube, forming a dark green layer.

-

(ii)

Take a pre-sterilized Pyrex glass culture tube. Aliquot 9 mL of G625 growth media into the tube in the presence of a flame to ensure sterility. Add 0.2 mL of 50x BG-11 cyanobacteria freshwater solution. Swirl a few times to ensure complete mixing.

-

(iii)

Gently transfer 0.8 mL of the floating green cells from the primary culture to the G625 media in the culture tube to make a total volume of 10 mL. Swirl gently to disperse the cells. The culture should have just a hint of green at this stage.

-

(iv)

Transfer the starter culture to the shaker incubator (shown in Figure 2b) and allow it to grow at 25°C, 100 rpm and 1% CO2 with cycles of 14 hours of light illumination and 10 hours in the dark until the cells form a dense, floating green layer that is clearly visible at the top of the liquid phase. This growth typically takes around 1–2 weeks. Note that the doubling time of Anabaena flosaquae during exponential phase is ~ 56.5 hours25, so depending on the number of viable cells in the starter culture, it will take 1–2 weeks to produce enough floating green cells that have the ability to produce GVs. Viable cells typically form the dense layer at the top and dead cells sink to the bottom of the tube.

?TROUBLESHOOTING

-

(v)

Sub-culturing Ana for GV production (Steps v-vi: ● TIMING 2 wk) Aliquot 200–250 mL of G625 media into an autoclaved 1L Erlenmeyer flask (use a bunsen burner flame or a laminar hood to provide a sterile environment to avoid contamination). Add 1x final concentration of BG-11 freshwater solution (4–5 mL of the 50x stock) just before inoculation with Ana starter culture. Swirl to mix components.

-

(vi)

Inoculate 2 mL of the green, floating layer of the starter culture per flask and grow cells in the incubator at 25°C, 100 rpm, 1% CO2, 14 h light and 10 h dark cycle until they become confluent (as shown in Figure 2b-c). This should take ~ 2 weeks, with the exact time depending on the number of viable cells inoculated.

?TROUBLESHOOTING

-

(vii)

Harvesting Ana GVs (Steps vii-xi: ● TIMING 1 d) Pour the confluent culture from the flask into a separatory funnel (pre-sterilized with stopcork in place), allowing it to stand undisturbed on a metal ring stand for 12–16 hours until the GV-producing Ana cells separate from the spent media to form a compact green layer at the top (Figure 2e).

-

(viii)

Carefully remove most of the spent media by opening the stopcork at the bottom of the funnel and retain only the green fraction at the top along with ~30 ml of media.

-

(ix)

Using a 25 mL serological pipet, gently resuspend the cells and transfer to a 50 mL tube.

-

(x)

Use 10 mL of fresh G625 growth media to collect cells sticking to the walls of the funnel. Each flask should be reconstituted to ~ 50 mL of concentrated cell suspension.

-

(xi)

plit the suspension into two falcon tubes and add equal volume of 1M sorbitol (final concentration is 500 mM) and 10% (vol/vol) of Solulyse (i.e. 5.5 mL in 55 mL) to achieve hypertonic lysis. Place the tubes in a rotatory shaker at 4°C for 6–8 hours. Green lysates will have a milky tinge post-lysis due to the presence of GVs.

CRITICAL STEP We have observed that GVs become structurally compromised by certain detergents and surfactants used routinely for cell lysis such as BugBuster (EMD Millipore), Triton-X and sodium dodecyl sulfate. It is therefore advisable to thoroughly characterize the effect of any new detergent on GV structure and integrity using techniques such as TEM and pressure absorbance spectroscopy before using them for ultrasound and MRI.

?TROUBLESHOOTING

-

(xii)

Isolation and purification of Ana GVs from lysate (Steps xii-xvii: ● TIMING 2–3 d) Transfer 35 mL of cell lysate to a 50 mL tube and centrifuge at 350g, 8°C for ~24 hours in a table-top centrifuge, preferably equipped with a swinging bucket rotor.

?TROUBLESHOOTING

-

(xiii)

Slowly remove as much as possible of the green subnatant liquid and cell pellet using a 25 mL serological pipet, without disturbing the white GV layer on top.

-

(xiv)

For the second and third round of centrifugation (350g, 8°C), resuspend the white supernatant layer containing GVs in 25 mL of sterile 1x PBS (Corning). During each resuspension step, gently wash the inner walls of the falcon tube with fresh PBS to recover GVs sticking to the sides. The green subnatant should progressively become clearer with each spin. The second and third rounds of centrifugation are shorter than the first, with the endpoint being when all the GVs rise to the top of the tube.

-

(xv)

For the final spin, resuspend GVs in 10–12 mL of PBS (total volume can be varied depending on GV yield) and aliquot them into 2 mL tubes. Spin in a microcentrifuge at 350g for 4 hrs at 4–8°C.

CRITICAL STEP Do not fill the tube to the brim as GVs will get stuck to the lid of the tube when they float to the top during centrifugation

?TROUBLESHOOTING

-

(xvi)

Using a 21.5 G flat needle attached to a 3 mL syringe, maintain the angle of the microcentrifuge tube and slowly insert the needle through the GV film to the bottom. Collect most of the subnatant and slowly take out the needle. Some GV loss will occur at this step. This is OK as long as most of the GVs do not get sucked up into the syringe.

-

(xvii)

Resuspend the purified GVs in ~ 6–8 mL of PBS (exact volume of added PBS can be varied and is determined by how concentrated the GV solution needs to be for the end application) and aliquot the milky white GV solution (Figure 2j) into screw-top vials or microcentrifuge tubes.

▪ PAUSE POINT The Ana GVs aliquoted into tubes can be stored for up to a year at 4°C.

CRITICAL STEP Avoid freezing and subjecting the tube to shocks, such as dropping to the ground or snapping the cap, as this may collapse the GVs.

(B). Producing and purifying Halo GVs ● TIMING 3.5 weeks

-

(i)

Growing Halo cultures for GV production (Steps i-iii: ● TIMING 2 wks) Aliquot 250 mL of Carolina growth medium in to an autoclaved 1L Erlenmeyer flask under sterile conditions.

-

(ii)

Inoculate Halo cultures using one of the following methods. (1) Using a sterile pipette tip or toothpick, scrape a small amount of pink culture from the agar plate to add to the flask as inoculum. (2) Use one to two brine crystals containing Halo for inoculation. (3) Inoculate 2.5 mL from a healthy pink liquid starter culture into 250 mL of fresh growth medium (1:100).

-

(iii)

Grow the culture in an incubator at 42˚C with 100 rpm shaking. Depending on the health of the parent culture, it may take ~ 2 weeks for the inoculated culture to become confluent . Confluency is determined by the color and turbidity of cultures as shown in Figure 2d.

?TROUBLESHOOTING

-

(iv)

Harvesting Halo GVs (Steps iv-vi: ● TIMING 1 wk) Gently pour the culture from the flask into a separatory funnel (pre-sterilized with stopcork in place). Allow the culture to remain undisturbed until a visible ring is formed at the top (Figure 2f). This typically takes 4–6 days.

-

(v)

Remove as much of the spent media as possible by opening the stopcork, retaining only the buoyant layer of milky-pink cells for lysis. The retained volume is~10–20 mL , and a lot of cells stick to the sides of the funnel.

-

(vi)

Using equal volume (10–20 mL) of TMC lysis buffer (pH 7.5), gently wash the cells stuck on the sides of the funnel and retrieve as many cells as possible. The volume of TMC buffer used might be varied depending on the cell density to achieve efficient hypo-osmotic lysis. However, note that if too much buffer is used in this step, the number of 2 mL aliquots will proportionately increase for the next step, thus increasing sample processing time.

?TROUBLESHOOTING

-

(vii)

Isolation and purification of Halo GVs from lysate (Steps vii-xi: ● TIMING 2 d) Aliquot ~1.6 mL of cells in 2 mL tubes and spin in a microcentrifuge at 300g for 4 hours at 8˚C.

▴CRITICAL STEP Close the tubes gently; the pressure wave caused from snapping the lid will collapse a large number of Halo GVs.

?TROUBLESHOOTING

-

(viii)

At the top of the tube, a mixed layer of Halo GVs (white) and unlysed Halo cells (milky-pink) will be visible. Using a blunt end 18.5 or 21.5G needle, aspirate the pellet at the bottom of the tubes as well as the pink cell lysate. CRITICAL STEP Take care to limit the amount of floating Halo cells and Halo GVs (white) that are aspirated in to the syringe.

-

(ix)

Transfer the GVs and unlysed Halo cells to fresh tubes and bring to 1.6 mL with 1x PBS. Centrifuge tubes at 300 g for 4 hours at 8˚C.

-

(x)

Repeat steps viii and ix. After each step, the amount of milky-pink buoyant cells will reduce and white Halo GVs will increase. Continue with centrifugally-assisted floatation until all the cells have lysed and there is no evidence of pink cell lysate in the subnatant.

-

(xi)

Resuspend the purified GVs in PBS and aliquot the milky white GV solution (Figure 2j) into screw top vials or microcentrifuge tubes.

▪ PAUSE POINT The aliquoted Halo GVs can be stored for up to one year at 4°C.

CRITICAL STEP Avoid freezing and subjecting the tube to mechanical shocks, such as dropping to the ground or snapping the cap, as this may collapse the GVs.

(C). Producing and purifying Mega GVs ● TIMING 4 d

-

(i)

Heterologous expression of Mega GVs in E. coli (Steps i-iv: ● TIMING 2 d) Transform 50 μL chemically competent Rosetta™ 2(DE3) pLysS cells using > 1 ng of pST39 plasmid containing the pNL29 Mega GV gene cluster11 by mixing the two components in a 1.5 mL tube and incubating on ice for 30 minutes. Heat shock the tube in a 42 °C water bath for 45 seconds, and put the tube back on ice for a minute. Add 500μL of SOC outgrowth medium and incubate in a shaker at 37°C and 250 rpm for 1 hour.

-

(ii)

Prepare 3 mL of LB broth containing 1x Ampicillin (100 μg/mL), 1x Chloramphenicol (25 μg/mL) and 1% (wt/vol) glucose in a glass culture tube. Resuspend 300 μL of the transformed E. coli in the broth. Grow the culture in a shaker-incubator at 37°C and 250 rpm until OD600 reaches 0.4 – 0.6. Make 100 μL aliquots of the culture in sterile tubes, and mix with 100 μL of 50% sterile glycerol. Freeze the tubes at −80°C as E. coli glycerol stocks.

▪ PAUSE POINT The glycerol stocks can be stored at –80°C and used for up to 3 months. Note that while using glycerol stocks is convenient, the GV yield is reduced when using frozen stocks, so we recommend fresh overnight transformations for best results.

-

(iii)

Resuspend a tube of the aliquoted glycerol stock in 3 mL LB broth containing 1x Ampicillin, 1x Chloramphenicol and 1% (wt/vol) glucose. Grow the E. coli culture to saturation (OD600 > 4). For fresh transformations, aliquot 500 uL of the transformed E.Coli from Step (i) into 5 mL of LB broth containing 1x Ampicillin, 1x Chloramphenicol and 1% (wt/vol) glucose. Allow it to grow overnight until the culture reaches saturation (~ 16 hours).

-

(iv)

Prepare 100 mL LB broth containing 1x Ampicillin, 1x Chloramphenicol and 0.2% (wt/vol) glucose, and inoculate 1 mL of the saturated E. coli culture into the broth. Grow at 37°C for ~ 2 hours until OD600 reaches 0.4 to 0.6. Induce the culture by adding 20 μM IPTG (final concentration), and grow at 30°C for an additional 16–24 hours.

-

(v)

Harvesting and purifying Mega GVs from E. coli cultures (Steps v-x: ● TIMING 2 d) Split the culture equally into three 50 ml Falcon tubes and spin for 1 hour at 500g and 25°C.

CRITICAL STEP Avoid higher speeds because they may cause collapse of GVs.

? TROUBLESHOOTING

-

(vi)

Insert a 10mL syringe with needle to > 1 cm below the surface of the solution and withdraw the clear liquid component of the solution. Withdraw the liquid slowly to preserve the thin layer of cells floating at the top of the solution, as well as the pellet at the bottom, both of which contain Mega GVs.

-

(vii)

To lyse the cells, add 4 ml SoluLyse-Tris reagent per 50 ml of E. coli culture, 250 μg/ml lysozyme and 10 μg/ml DNAseI. Rotate the tubes for 10 minutes at room temperature and then aliquot 1.5 mL of the solution to 2 mL tubes. Spin samples for 4 hours at 800 g and 8°C. Mix the floating GV layer gently with supernatant and transfer to a clean tube.

-

(viii)

Spin the samples for 4 h at 800g. Use a 3 mL syringe to remove the bottom fraction, which sometimes includes a small pellet. Gently resuspend GVs in 1 mL of PBS. Repeat the spin and wash steps 3 times.

CRITICAL STEP Be aware that GVs are susceptible to desiccation and resuspend GVs immediately after withdrawing the liquid.

-

(ix)

Mega GVs are natively clustered. To uncluster them, GV-containing solution is mixed with 10 M urea in a 2:3 ratio to achieve 6 M final urea concentration, and the resulting solution is gently rotated for 30 min.

-

(x)

Dialyze GVs overnight in 6–8 kDa MWCO tubing against 4L of PBS. This step can be omitted for experiments with no stringent requirements for buffer conditions. The white layer of unclustered GVs at the top of the liquid phase after buoyancy purification, as well as the re-suspended milky-white solution of Mega GVs in PBS is shown in Figure 2i-j.

▪ PAUSE POINT Mega GVs can be stored for up to one year at 4°C .

CRITICAL STEP Avoid freezing and subjecting the tube to mechanical shocks, such as dropping to the ground or snapping the cap, as this may collapse the GVs.

Quantification of GVs by measuring pressure-sensitive optical density ● TIMING 15 m

2| Determine the concentration of a solution of gas vesicles by measuring its pressure-sensitive optical density at 500 nm (OD500,ps) using a NanoDrop 2000 Spectrophotometer. Load 2 μL of sample on the pedestal for each measurement. Collapsed gas vesicles in the same buffer are used as a blank for measurements. Prepare collapsed GVs by sonication in a water bath until the solution turns completely clear or by manual collapse in a capped syringe. For manual collapse, remove the plunger from a 12 mL Luer-Lock syringe closed with a tip cap and place 5–10 μL of gas vesicle solution at the bottom of the syringe. Making sure that the tip cap is screwed on tight, replace the plunger and push down until there is significant resistance. The increase in pressure will collapse the gas vesicles, turning the milky white solution clear. A shortcut for quick measurements of GV concentration is to blank with the GV resuspension buffer. For most samples, this will give an OD reading that is very close to that measured when using collapsed GVs as a blank. However, for some samples containing GVs that are fluorescent, it is necessary to use the collapsed GVs as the blank.

! CAUTION Before doing manual collapse, ensure that the tip-cap on the syringe is facing away from you and securely fastened, as pressurization of the syringe may cause ejection of the cap, resulting in potential injury to the user. Wear protective eyewear and clothing.

▴CRITICAL STEP It is important to ensure that the GVs are homogenously re-suspended in solution just before measurements. For each sample, take the average OD500,ps value after multiple measurements (n>=3) to ensure precision and accuracy.

Quantification of GV protein concentration ● TIMING 15 m

3| Measure the protein concentrations using the Pierce 660nm protein assay to obtain relationships between optical density and protein content for the GV solutions. We have established the protein concentrations to OD relationships of our three types of GVs, and the results are as shown in Table 3 below (N = 4, 5, 3 for Mega, Ana and Halo GVs respectively and the errors are in SEM). The molecular weight is derived from the TEM data summarized in Table 4, assuming a spindle shape for Halo GVs, a cylindrical shape for Mega and Ana GVs, a wall thickness of 18 Å and a protein density of 1.4 g/mL.

Table 3.

Quantification and calculation of GV molecular weight and molar concentration.

| Ana | Halo | Mega | |

|---|---|---|---|

| Protein concentration to OD500 ratio ([μg/mL] / OD) | 36.6 ± 2.6 | 13.4 ± 2.2 | 145.5 ± 6.4 |

| Estimated molecular weight (MDa) | 320 | 282 | 71.7 |

| Estimated molar protein concentration to OD500 ratio (pM / OD) | 114 | 47.3 | 2,030 |

| Estimated gas fraction to OD500 ratio (v/v/OD) | 0.000417 | 0.000178 | 0.000794 |

Table 4:

GV Dimensions

| Spatial Dimension | Ana GV | Halo GV | Mega GV |

|---|---|---|---|

| Length (nm) | 519 ± 160 | 400 ± 113 | 249 ± 99 |

| Width (nm) | 136.3 ± 21.0 | 250.8 ± 51.4 | 72.5 ± 13.6 |

Chemical functionalization of GVs ● TIMING 2 d

CRITICAL Purified Ana, Halo and Mega GVs contain lysine residues on the surface that can be used to chemically conjugate a variety of moieties such as polyethylene glycol, fluorophores and biotin using an amine-reactive coupling group such as N-hydroxysuccinimide ester.

4| Measure the concentration of purified GVs using the OD relationships in Table 2.

5| Aliquot the NHS-moiety in anhydrous DMSO at 100x of the required molar concentration for the amine-NHS reaction. For Alexa-488-NHS conjugation to Ana GVs, aliquot 5 μl of the 10 mM stock solution of the dye pre-prepared in anhydrous-DMSO.

▴CRITICAL STEP Ensure that the NHS-moiety solution does not contain detergents or surfactants that might affect the integrity and properties of GVs.

6| Adjust the concentration and volume of GVs to the desired amount and ensure that the buffer is free of amines (avoid Tris buffer). For Alexa-488-NHS conjugation to Ana GVs, bring Ana GVs to OD1 in 1 mL of PBS at pH 7.4.

▴CRITICAL STEP If GVs were previously in a buffer containing free amines or PBS with pH less than 7, ensure complete buffer exchange with PBS at pH 7 – 9 before proceeding with the amine-NHS reaction.

7|Add 105 molar excess of the NHS-moiety to GVs, keeping the DMSO concentration at 0.5% or less of the total reaction volume. For Alexa-488-NHS conjugation to Ana GVs, add 5 μl of the 10 mM Alexa-488-NHS in DMSO to 1 mL of Ana GV solution. Based on the average number of gvpA and gvpC protein monomers that make up Ana GVs, approximately 50,000 lysine residues are present for every Ana GV. One can tune the molar ratio of the two reactants (NHS-moiety:GV) to achieve the desired reaction efficiency.

8| Allow the reaction to proceed for 4 hours at room temperature under gentle rotation.

?TROUBLESHOOTING

9| Quench the unreacted NHS-moieties using Tris-HCl buffer at pH 8 to a final concentration of 10 mM for 20 minutes at room temperature under gentle rotation

10| Add the whole reaction to dialysis tubes (6–8 kDa cutoff) and dialyze against a 4000x volume excess of PBS at 4˚C for 8 hours. Replace the buffer and allow dialysis to continue for an additional 8 hours.

CRITICAL STEP If NHS-moiety is not amenable to dialysis, repeated rounds of centrifugally-assisted purification is an alternative method to remove excess reactants and/or for buffer exchange.

?TROUBLESHOOTING

▪ PAUSE POINT Chemically functionalized GVs can be stored in PBS buffer for up to one year at 4˚C −.

Optional: Genetic modification and functionalization of Ana GVs ● TIMING 3 days

CRITICAL The outer scaffold protein of Ana GVs, gas vesicle protein C (GvpC), can be removed and replaced with genetically modified recombinant versions as a molecular handle for GV mechanical modification and functionalization. This procedure comprises stripping native GvpC off Ana GVs (Steps 11–19), preparing recombinant GvpC (Steps 20–38) and re-adding this GvpC onto ∆GvpC Ana GVs via dialysis (Steps 39–41). In addition, GVs functionalized with GvpC fused to the SpyTag peptide enable convenient downstream covalent functionalization with proteins fused to the SpyCatcher moiety (Steps 42–45).

11| Preparation of ∆GvpC GVs (Steps 11-19: ● TIMING 12 h) Dilute purified Ana GVs in PBS such that OD500,ps <10.

12| Prepare 3:2 (vol/vol) mix of GV stripping buffer (10M urea in 100mM Tris buffer) and GV solution in PBS. Pipet 1.7 mL into 2 mL microcentrifuge tubes.

13| Centrifuge at 300g for 4 hours, or until the subnatant is completely clear. Remove the clear subnatant with a syringe using a 21G flat needle. Retain the milky white supernatant in the tube. Resuspend the GV-containing supernatant in GV stripping Buffer (Round 2 i.e. 6M urea, 60mM Tris-HCl). Repeat this step 1 time.

14| Confirm GvpC removal by performing SDS-PAGE. Incubate a 1:1 (vol/vol) mix of GVs in 2x Laemmli buffer (containing 5% (vol/vol) 2-mercaptoethanol) at 95°C for 5 m. Centrifuge briefly to collect condensate.

15| Assemble the electrophoresis cell with the comb and tape removed from the polyacrylamide gels. Fill the inner chamber completely with 200 mL 1x TGS buffer. Ensure that the cell is not leaking fluid. Fill the outer chamber up to mark with 600 mL 1x TGS buffer.

16| Load the protein ladder and samples in the gel using gel-loading tips. GVs should be at OD500 > 3 prior to the 1:1 dilution. If purified proteins are being run on the same gel for comparison, load > 100 ng.

CRITICAL STEP In order to prevent contamination between wells, do not exceed the maximum recommended volume per well.

17| Connect electrophoresis cell to power supply and run the gel for 55 m at 120V.

18| Recover the gel by disassembling the electrophoresis cell and the gel cassette. Incubate the gel in a holder with DI H2O for 10 m, then stain for 1 h with 10 mL SimplyBlue™ SafeStain. De-stain the gel for at least 1 h with 10 mL DI H2O.

19| Image the gel using a Coomassie imaging protocol using the gel imaging system to visualize protein bands. The GvpC band at approximately 25 kDa should be missing.

▪ PAUSE POINT Store the ΔGvpC GVs in urea buffer at 4°C for no more than 1 week. When preparing ΔGvpC GVs for long term storage without any further genetic functionalization or recombinant GvpC addition (steps 39–45), we recommend dialyzing the GV solution against PBS in order to completely remove the urea.

?TROUBLESHOOTING

20| Preparation of recombinant GvpC (Steps 20-38) :● TIMING 1 d) Transform > 1 ng pure plasmid encoding recombinant GvpC with a C-terminal hexahistidine tag into BL21 (DE3) competent cells and grow culture in terrific broth with 50 μg/ml kanamycin overnight.

21| Dilute 500 μL of the starter culture 1:1 with 50% glycerol in water and store at −80°C. Future starter cultures can be grown from aliquots of this glycerol stock instead of fresh transformations.

22| Dilute starter culture 1:250 in terrific broth with 50 μg/ml kanamycin and grow to OD600~0.4–0.7 with shaking (250 rpm) at 37ºC. Induce at a final concentration of 1mM IPTG. Grow culture for 6–12 h at 30ºC with shaking.

CRITICAL STEP Frozen IPTG stocks should be thawed fully and vortexed to mix contents before use.

23| Pellet the cells in ultracentrifuge tubes at 5,500g for 15 min at 4°C and discard the supernatant.

▪ PAUSE POINT Cell pellets can be stored at −20°C. Protein extraction is typically more effective with frozen cells.

24| Resuspend the pellets in 10 mL Solulyse with 10 μg/mL DNAse. Rotate at room temperature for 10 min.

25| Centrifuge at 20,000g for 15 m at 4°C to clear the lysate and discard the supernatant.

26| Resuspend the pellet in 10mL Solulyse and lysozyme (0.25 mg/mL). Rotate at room temperature for 10 m.

27| Add 5mL Solulyse and vortex. Centrifuge at 20,000g for 20 m at 4°C and discard the supernatant.

28| Thoroughly resuspend the pellet in 5 mL of inclusion body solubilization buffer.

29| Centrifuge at 20,000g for 20 m at 4°C.

30| Add 1.5mL Ni-NTA slurry to the supernatant, incubate at 4°C with shaking (60 rpm) for 2 h or more.

31| Pour into a polyprep column and collect all the flow-through, wash and elutions in the next steps. Collecting all fractions is good practice for troubleshooting and analyzing purification steps using SDS-PAGE.

32| Wash with 10 column volumes of inclusion body wash buffer.

33| Elute with 2 column volumes of inclusion body elution buffer.