Abstract

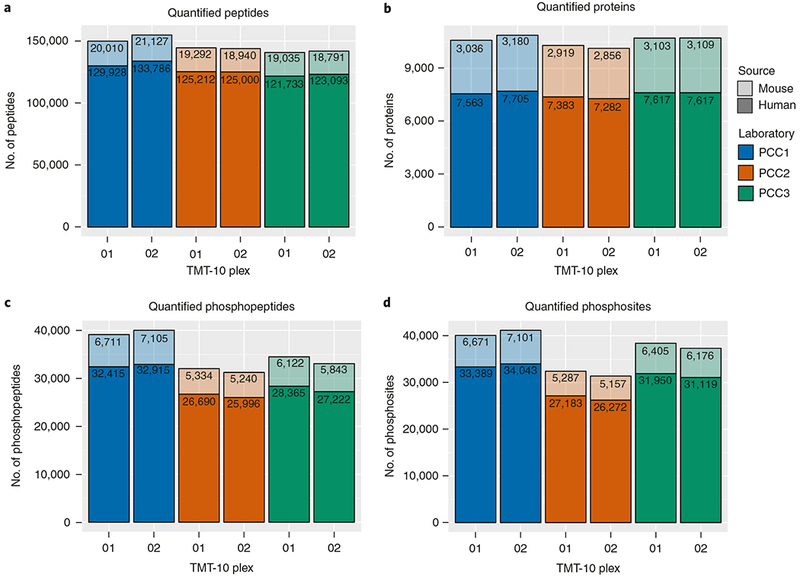

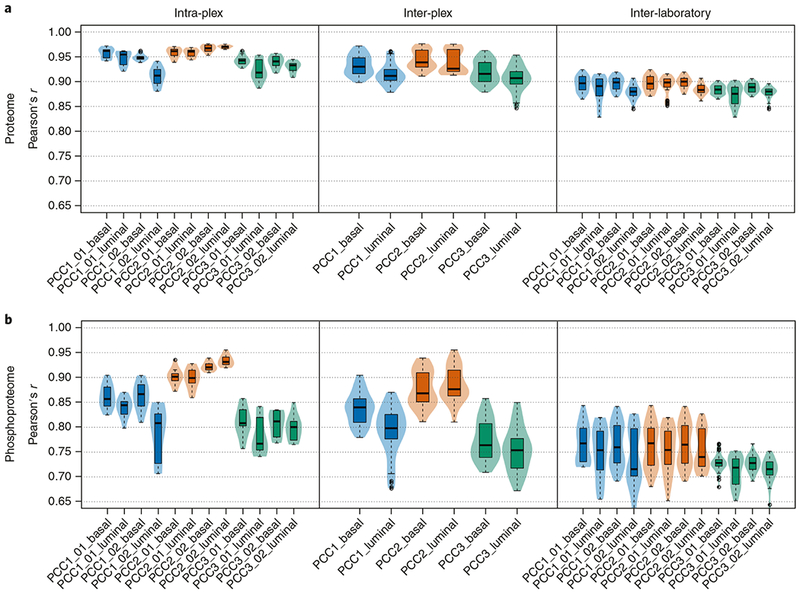

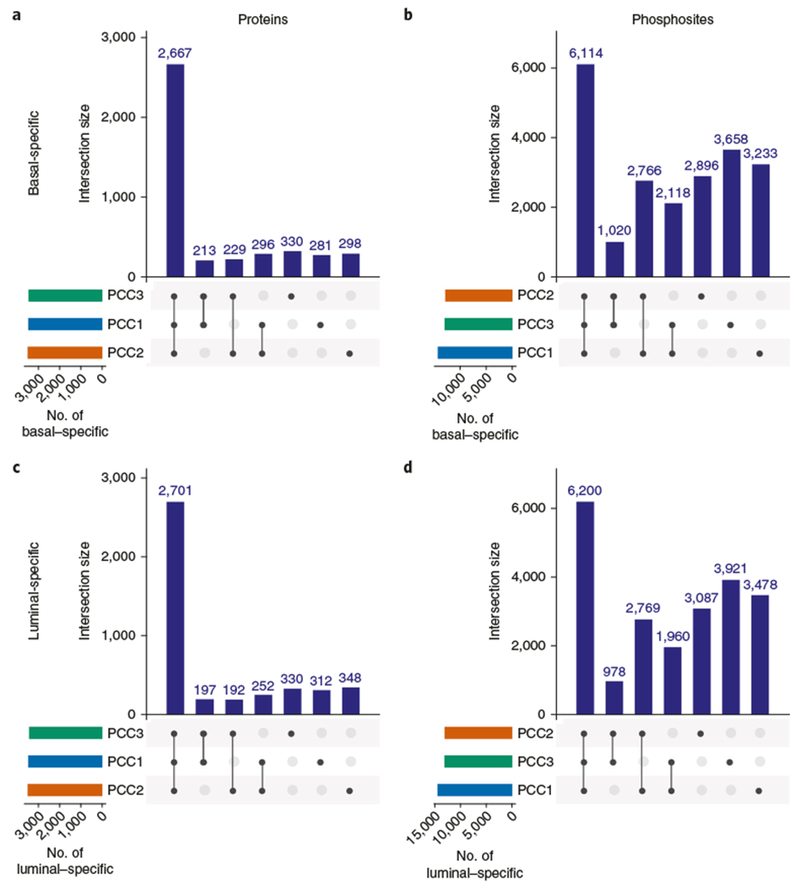

Here we present an optimized workflow for global proteome and phosphoproteome analysis of tissues or cell lines that uses isobaric tags (TMT (tandem mass tags)-10) for multiplexed analysis and relative quantification, and provides 3× higher throughput than iTRAQ (isobaric tags for absolute and relative quantification)-4-based methods with high intra- and inter-laboratory reproducibility. The workflow was systematically characterized and benchmarked across three independent laboratories using two distinct breast cancer subtypes from patient-derived xenograft models to enable assessment of proteome and phosphoproteome depth and quantitative reproducibility. Each plex consisted of ten samples, each being 300 μg of peptide derived from <50 mg of wet-weight tissue. Of the 10,000 proteins quantified per sample, we could distinguish 7,700 human proteins derived from tumor cells and 3100 mouse proteins derived from the surrounding stroma and blood. The maximum deviation across replicates and laboratories was <7%, and the inter-laboratory correlation for TMT ratio-based comparison of the two breast cancer subtypes was r > 0.88. The maximum deviation for the phosphoproteome coverage was <24% across laboratories, with an average of >37,000 quantified phosphosites per sample and differential quantification correlations of r > 0.72. The full procedure, including sample processing and data generation, can be completed within 10 d for ten tissue samples, and 100 samples can be analyzed in −4 months using a single LC-MS/MS instrument. The high quality, depth, and reproducibility of the data obtained both within and across laboratories should enable new biological insights to be obtained from mass spectrometry-based proteomics analyses of cells and tissues together with proteogenomic data integration.

Introduction

Genetic alterations in human cancer have been systematically mapped by genomic landscape studies in the past decade, but the direct consequences of these alterations on the functional proteome remain poorly understood. Deep-scale, mass spectrometry (MS)-based proteomic studies by the Clinical Proteomics Tumor Analysis Consortium (CPTAC) program have revealed that integration of proteomic and phosphoproteomic data with genomic data for human tumor samples can improve specificity for identifying cancer-relevant pathways triggered by somatic DNA variants or DNA copy-number alterations, as compared with genomic characterization alone. The proteomics results also serve to elucidate pathways activated by genomic alterations and help to narrow target selection for potential therapeutic intervention1–3.

Various proteomic methods have been developed for global proteome profiling by MS. Typically, proteins are reduced and alkylated to open disulfide bonds and block newly formed and preexisting cysteine side-chain residues. These unfolded proteins are subsequently digested to peptides using the proteolytic enzyme trypsin or LysC followed by trypsin to form tryptic peptides. This approach is referred to by various names, including ‘bottom-up’, ‘discovery’, ‘global’, and ‘shotgun’ proteomics. Methods exist that enable purified or simple mixtures of intact proteins to be analyzed (top down), but these approaches are, at present, inadequate for the comprehensive analysis of complex protein samples derived from cells or tissues4. For global profiling, proteolytic peptides are chromatographically separated in one or two dimensions to enable detection of low-abundance peptides, signals of which would otherwise be suppressed and quantification of which would be affected due to interference by co-isolated high-abundance peptides. One-dimensional or ‘single-shot’ separation methods are typically performed in a label-free manner in which one sample is analyzed at a time, usually with two to three replicate injections to achieve statistical significance for confident detection of lower-abundance proteins5. Using ultra-high-pressure separations on 75-μm inner diameter (i.d.) fused silica columns packed with sub-2 μm C18 packing material and gradient durations of up to 5 h, samples of moderate complexity, such as cancer cell lines, have been analyzed to a depth of ~6,100 proteins when using the standard, conservative metric of at least two unique peptides to identify a protein6.

Solid tumor tissues are compositionally more complex than cell lines, typically consisting of at least epithelial, stromal, and hematologic components. To detect low-abundance proteins such as oncogenes and tumor suppressors in a tumor tissue background or to reach a depth of >9,000 proteins in individual cell-line backgrounds, sample complexity must be reduced before LC-MS/MS. This is most often accomplished using a 2D separation approach involving a mode of off-line chromatography at the peptide level that is orthogonal to the final acidic reversed-phase liquid chromatography separation into the mass spectrometer. A variety of methods have been proposed to accomplish this at the peptide level, including off-gel electrophoresis7, strong cation exchange chromatography8, and high pH/basic reversed-phase chromatography (bRP9). Of these methods, bRP has proven to have the best balance of excellent chromatographic resolution, high peak capacity, reproducible retention times, and orthogonality to low-pH reversed-phase (RP) separation9,10. These properties have also been shown to extend to phosphopeptide separation11. A 2D separation method using bRP as the first dimension of separation, followed by analysis of concatenated fractions by LC-MS/MS, was developed and optimized by groups of the NCI-CPTAC consortium12,13 and others8,14. These sequential high pH/low pH RP separation approaches are equally suited for deep proteome and post-translational modification (PTM) analysis including those of phosphorylation, ubiquitination, and acetylation13. This 2D approach has been demonstrated in our previous work to provide a coverage of >10,000 proteins (at ≥2 peptides per protein) and 26,000 phosphosites per sample in cancer tissues2. Proteins and phosphosites are quantified indirectly by measuring the peptides derived from each protein by enzymatic digestion. Three methods are currently used for protein quantification15,16. In label-free quantification, the response (i.e., observed signal intensity in the mass spectrometer) of peptides or the number of peptide-to-spectrum matches (PSMs; spectral count) of peptides derived from a given protein are used to quantify that protein. In metabolic labeling, heavy isotopically labeled amino acids (typically Arg and Lys) are incorporated into proteins during cell culture (SILAC)15 or a mixture of labeled cell lines is used as an internal standard, a method referred to as ‘super SILAC’17. Up to three states can be typically achieved with SILAC, and up to five can be achieved in specialized SILAC applications18. Relative quantification is accomplished at the MS-1 level by calculating the ratios of the intensity of a given peptide between one label state and another. A limitation of the SILAC method is that humans cannot be labeled, and the multiplex level is therefore limited to two using the super SILAC approach.

The third common method for protein and PTM peptide quantification involves chemical labeling at the peptide level using isobaric mass-tag reagents that react with the free N-termini of peptides, as well as the side-chain primary amine of lysine residues19,20. The two most common reagents are iTRAQ21 and TMT22. The iTRAQ reagents are available as kits with four or eight distinct labels19–21,23. The TMT reagents are available as kits with six or ten distinct labels, meaning that up to ten different samples can be labeled, mixed, fractionated, and analyzed by LC-MS/MS as a single ‘plex’22–25. The differentially labeled peptides have identical (or nearly identical) masses (i.e., they are isobaric), but their relative quantities become distinguishable after fragmentation in the mass spectrometer, which releases the mass tags from the labeled peptides, generating low-mass reporter ions in the MS/MS spectra. Quantification using either the iTRAQ or TMT reagents is based on the relative intensities or ratios of the tags to one another or to a common reference in one of the channels2,3,19–26. Isobaric mass tagging has a number of important advantages relative to either label-free or SILAC methods. First, the isobaric nature of TMT reagents leads to a summation of the abundances of peptides from individual samples. This increases the observed signals for labeled peptides and decreases the amount of any given sample required in a plex roughly by the number of channels in that plex. Second, there are few missing values in each multiplex, as each sequenced peptide can be quantified across all ten states. Third, for the analysis of PTMs, in which the majority of quantification events rely on the quantification of single peptides, isobaric tagging methods have been shown to improve the precision of quantification, whereas label-free methods suffer from high technical variation for PTM applications.

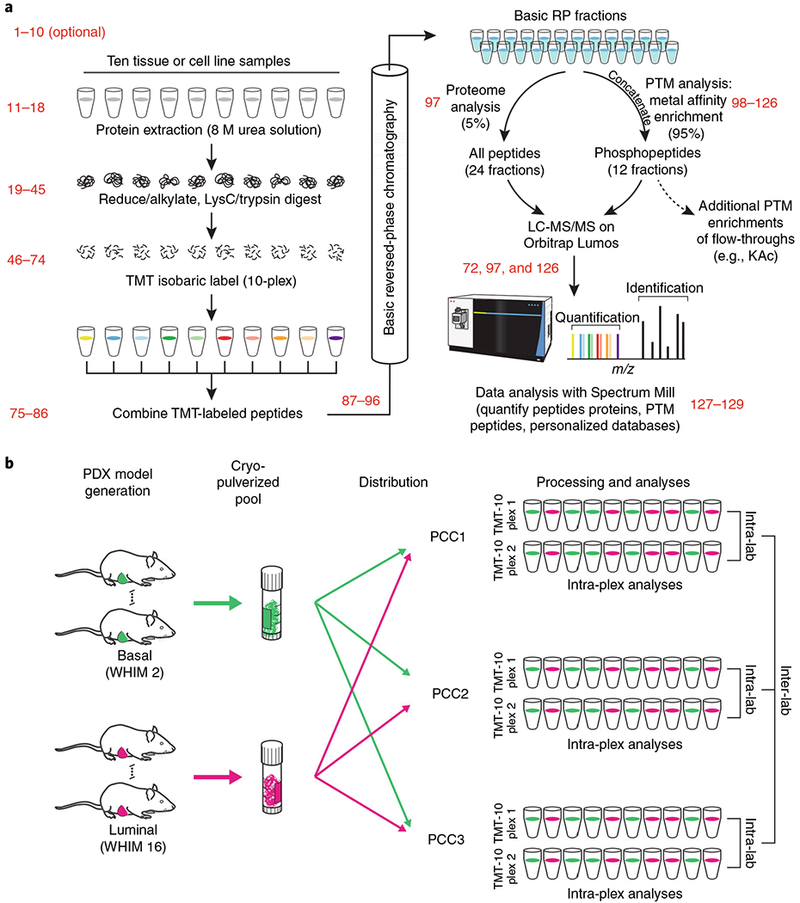

Development of the protocol

The CPTAC consortium has previously published landmark proteogenomic studies utilizing iTRAQ4-plex quantification for high-pH RP global proteome and phosphoproteome profiling that enabled a throughput for deep-scale profiling of 100 tumor samples within 9 months per laboratory2,3. In this detailed protocol, we present an improved method implementing TMT-10 quantification, which increases the throughput threefold relative to iTRAQ4, at similar proteome coverage and with high reproducibility of quantification (Fig. 1a). To study tumor patient cohorts, we typically use one isobaric channel for a common reference sample; therefore, three individual samples can be analyzed in an iTRAQ4-plex experiment and nine samples in a TMT-10-plex experiment. The procedure was developed for tumor samples that were cryo-fractured to particle sizes <100 μm using a device from Covaris (see protocol for details). Typically, a 1–3% weight-by-weight protein yield per wet-weight tissue can be expected with this protocol for breast tumor tissue, but yields can be higher depending on the type of tumor tissue analyzed. Wet weights of 50 mg per tumor sample provide sufficient amounts of total protein in the range of 0.5–1.5 mg for deep-scale proteome and phosphoproteome characterization. Proteins are extracted with an 8 M urea-based extraction buffer, reduced and alkylated, and digested first with LysC endopeptidase and subsequently with trypsin (Fig. 1a). We observed that digestion efficiencies, as measured by missed-cleavage rates, are improved by working with more-concentrated protein extracts, most likely due to the higher enzyme concentrations in these samples (see troubleshooting section). To enable multiplexing, peptide samples are labeled with TMT-10 reagents. The TMT-labeled samples are separated by high-pH reversed-phase liquid chromatography into 96 fractions that are combined in a step-wise manner, into 24 fractions for proteome analysis and 12 fractions for phosphoproteome analysis. Early-, middle-, and late-eluting peptides are combined by mixing every 24th original fraction for the proteome (e.g., combining fractions 1, 25, 49, and so on) and every 12th original fraction for the phosphoproteome analysis (e.g., combining fractions of 1, 13, 25, and so on). This step-wise concatenation strategy further improves the orthogonality of the high-pH and low-pH RP separation steps. A total of 5% by volume of the material is used for proteome analysis, and the remaining 95% of the sample is enriched for phosphopeptides by immobilized affinity chromatography (IMAC) with Fe3+-loaded nitrilotriacetic acid (NTA) beads.

Fig. 1 |. Optimized workflow and experimental design of global proteome and phosphoproteome analysis in tissues using TMT.

a, Multiple aspects of sample handling were optimized based on a preexisting workflow for global proteome and phosphoproteome analysis (Mertins et al.2). Some of the conditions tested relative to the preexisting workflow were (i) digestion at higher protein concentrations, which effectively increases the enzyme concentration during digestion, resulting in lower missed cleavage rates; (ii) reconstitution of lysyl endopeptidase in water, instead of 50 mM acetic acid, which better maintains the activity of the enzyme; (iii) quantification of peptides by BCA before isobaric labeling, which yields more accurate input amounts than BCA at the protein level; (iv) offline basic RP fractionation using either Agilent or Waters columns, which yield equivalent results; and (v) optimization of HCD energy for each individual instrument, rather than the use of a common collision energy, which improved spectral quality. The relevant steps of the Procedure are indicated in red. b, Multiple mice of basal (WHIM 2) and luminal (WHIM16) subtypes were grown, and the tumors of each subtype were pooled together. Tumors of each subtype from multiple mice were cryofractured and aliquots of the homogenized powders were distributed to the three different laboratories for global proteome and phosphoproteome analysis. Each laboratory analyzed 2× TMT-10 plexes. Intra-plex, intra-lab, and inter-lab comparisons were conducted to test depth of coverage and reproducibility. PCC1–3 indicate Protein Characterization Centers 1 (Broad Institute), 2 (Johns Hopkins University), and 3 (Pacific Northwest National Laboratory), respectively. BCA, bicinchoninic acid; HCD, higher-energy collision dissociation. a Adapted from Extended Data Fig. 1 in ref. 2, Springer Nature.

In the described protocol, off-line, high-pH RP separation is accomplished using standard HPLC equipment and columns packed with 3.5-μm C18 beads, whereas the second, online acidic RP separation uses ultra-high-performance HPLC (UHPLC) instruments and columns packed with 1.9-μm C18 beads. The datasets described in the Anticipated results section were acquired on high-performance Orbitrap Fusion Lumos instruments in three independent laboratories. All three laboratories generated highly reproducible datasets by following this procedure, with coverages of >10,000 proteins (≥2 unique peptides per protein) and >37,000 phosphorylation sites. In studies of human-only breast tumor tissue, we have achieved typical coverage depth of >8,000 proteins per experiment (≥2 unique peptides per protein) and >25,000 phosphorylation sites per experiment using the protocol described here (P.M., L.C.T., K.R.C., D.R.M., F.M. and S.A.C., unpublished data; the data are accessible at https://cptac-data-portal.georgetown.edu/cptac/s/S039?: Study name, ‘CPTAC breast cancer confirmatory study’). The optimized protocol enables deep-scale and reproducible results to be obtained within and across laboratories conducting tissue or cell-line analyses, producing high-quality data for proteogenomic data integration and facilitating proteomics-based pan-cancer studies. Information on how to identify and manage common sources of variability, such as proteolytic digest efficiency and overlabeling with TMT-10 reagents, is also provided.

Applications of the method

Although this protocol was developed for tissue samples, it is also directly applicable to analysis of mammalian cell culture samples. The starting material amounts for 300 μg of peptide per sample/TMT channel described here allow for reproducible generation of deep-scale proteome and phosphoproteome datasets. In addition, the unbound material after phosphopeptide capture (Fig. 1a) can be used for deep lysine acetylation profiling, as has been described previously (refs 13,27). If sample amounts are limited, lower peptide quantities (50–100 μg of peptides per TMT channel) can be used. Reduced amounts do not affect overall proteome coverage or quantification but will reduce phosphoproteome coverage by 20–30% (P.M., L.C.T., K.R.C., D.R.M., F.M. and S.A.C., unpublished data). For proteome quantification, only 0.5–1.0 μg of peptides per bRP fraction is needed to achieve the depth of proteome coverage described here, so for a 24-fraction proteome analysis, typically, a minimum of 50 μg of peptides per TMT-10-plex or 5 μg per sample is needed. The 300-μg amount of input peptide is needed for deep-scale phosphoproteome analysis. Improvements in isobaric tagging chemistries already allow higher degrees of multiplexing, for example, by using TMT-11 reagents, which provide an 11th multiplexing channel. The higher the degree of multiplexing, the more sample fractions and MS time can be dedicated to a given multiplex experiment to increase proteome coverage at a similar time and cost.

Current limitations and future directions

Although the present protocol represents the current state of the art, advances in sample processing, chromatography, and MS technologies, as well as data analysis methods, will inevitably enable this multistep protocol to be improved, including reducing the amount of input protein per sample required to achieve the depth we report. When considering changes to any individual step, it is critical to consider the impact on the entire protocol in terms of sensitivity, dynamic range, throughput, speed, cost, time, and other relevant factors.

Not every possible sample-processing variable was examined in this study, and it is possible that further refinements resulting in additional incremental improvements can be realized. Many such process modifications will represent tradeoffs, however. For example, increasing the temperature at which enzymatic digestions are carried out could decrease the overall time required for digestion and decrease the percentage of missed cleavages observed. However, the extent of carbamylation of peptide N termini and lysines will also certainly increase at elevated temperatures, and this may have an effect on quantification. Similarly, the higher-multiplex reagents that are becoming available will further increase sample-analysis throughput, albeit at some to-be-determined cost to depth of proteome and phosphoproteome coverage23.

The described protocol benefits from the use of UHPLC in the second separation dimension, but the first dimension high-pH RP separation is performed using conventional HPLC instrumentation. Further improvements in semipreparative column technology with smaller bead sizes and the use of the latest high-flow UHPLC instrumentation may enhance the separation power and increase the uniqueness per fraction to greater than the 75% achieved here (Supplementary Fig. 1). The more unique each peptide fraction is, the more efficiently each individual fraction’s LC-MS/MS run contributes to the unique peptide count of the overall experiment.

The number of fractions collected per sample gates the overall analysis throughput, so reducing this number is highly desirable. Maintaining the sensitivity of the online LC-MS/MS analysis when analyzing fewer first-dimension high-pH RP fractions would require both increased peak capacity of the online column (e.g., through the use of smaller-dimension packing material or a longer online column) and loading of more peptide weight per fraction to maintain the same total weight of peptides used in the overall analysis. Reducing the number of fractions analyzed by LC-MS/MS would reduce the number of MS/MS spectra acquired and would thereby diminish the depth of coverage, unless the repeat peptide observation rate falls, the MS/MS interpretation rate rises, or the MS/MS scan rate increases.

TMT-labeling chemistry can result in low levels of overlabeling, whereby an additional TMT label is incorporated into peptides via O-acylation of Ser, Thr, and Tyr sites with a nearby His residue, which increases the nucleophilicity of the side-chain hydroxyl group via hydrogen bonding with the histidyl imidazole group28,29. We do not routinely allow for these variable modifications in our database searches because allowing for overlabeling substantially increases the search space (3–10×). Instead, we are working to routinely measure the extent of overlabeling present and adjust our TMT-labeling methodology to diminish the overlabeling rate. Adjustments in the labeling reaction conditions, such as use of lower pH, use of ethanol instead of acetonitrile in the labeling step, decreased TMT reagent-to-substrate ratios, and/or shorter reaction times, may lead to a decrease in the proportion of MS/MS spectra attributable to overlabeling.

Multiplexed reporter-ion quantification in MS2 mode provides many advantages, as listed above, and new chemistries enabling even higher levels of multiplexing beyond 11 plex are anticipated. However, some limitations have been noted. The reagents are expensive, but lower-cost alternatives that match the multiplex level are not currently available. The tags also increase the overall charge state of the labeled peptides, which can decrease identification rates, relative to label-free methods30. Most importantly, the accuracy of quantification is distorted by co-isolation phenomena31. Reporterion signals for a peptide of interest are contributed to by not only the primary precursor ion isolated but also background signals with similar m/z values that are co-isolated. Co-isolation correction approaches have been described32, but these need to be further improved to enhance the accuracy of TMT ratio-based quantification. Strategies to mitigate this effect include decreasing the sample and background complexity by extensive fractionation, decreasing the isolation m/z window size before MS2 scans, using MS3 fragmentation strategies33, and, very importantly, designing TMT experiments and using TMT datasets in ways that compensate for co-isolation problems.

Other foreseeable data acquisition methods may also diminish co-isolation problems. Ion mobility (IM) is a gas-phase ion separation method that separates ions on a millisecond time scale before the microsecond time scale MS analyses that occur in the mass spectrometer34. The addition of FAIMS (field asymmetric ion mobility spectrometry), which is already commercially available, to the front end of current high-performance MS instruments can improve the accuracy of quantification using isobaric labeling methods by discriminating against singly charged interferences. This and other potential advantages of FAIMS in the context of proteomics experiments have been described35. In the future, devices such as SLIM (structures for lossless ion manipulations36) may provide even higher sensitivity, resolution, and speed, as compared with current devices. Diminished co-isolation and increased sensitivity should also be achievable by increasing the chromatographic resolution of the online chromatography with longer columns, more efficient and uniform column packing, or use of smaller bead sizes to the extent the column back pressure can be handled by the LC pumping system. Narrower chromatographic peaks should increase sensitivity and decrease the spectrum acquisition rate by increasing each peptide’s effective concentration at its chromatographic peak apex.

Experimental design

One of the greatest advantages of isotopic labeling techniques in MS is that peptides in multiplexed samples are measured simultaneously, limiting the effect of detection and quantification interference by variable background signals that is observed in label-free experiments. For this reason, we primarily use TMT quantification as a relative quantification technique. Samples of interest are directly referenced to other samples or internal reference samples within the same multiplexed experiments, and intensity ratios are used for all following analyses. The use of internal reference samples is of particular use for larger sample cohorts, as has been demonstrated in our previous analysis of 80 breast tumor samples2 and 174 ovarian cancer samples3. Internal reference samples should be designed to contain the average protein concentrations of all different sample types to be investigated in a cohort of multiplexed experiments. To avoid batch effects, all different constituent sample types should be evenly distributed across multiple TMT-plex experiments. It is also important to consider the effects of isotopic impurities that lead to reporter intensity cross-contributions of up to 5% to neighboring TMT channels. Correction approaches for isotopic impurities based on the impurity factors provided by the manufacturer have been previously described37 and were adapted here for TMT-10 applications. Additional caution should be applied when samples of extremely different compositions, such as human and xenograft tumors, are placed in the same multiplexed experiments.

To resolve and accurately measure the near-isobaric N- and C-labeled reporter ions in the TMT-10 reagents, the instrument used must be able to achieve a minimum MS/MS resolution of 50,000 at m/z 150. Compatible instruments include the Thermo QE series of mass spectrometers (QE, QEplus, QE-HF, and QE-HF-X), as well as the Fusion and Lumos instruments also from Thermo. The QE series of instruments lack the linear ion trap that constitutes the ‘back-end’ of the Fusion and Lumos Tribrid mass spectrometers. As the linear trap portion of the Lumos was not used in this protocol, the less expensive QE series instruments may be used, with results differing depending on the model employed. Of the QE systems, only the QE-HF-X has what is effectively the same ion optical front end as the Lumos, and therefore results obtained when using this instrument are expected to be of similar depth and overall quality and reproducibility as those obtained when using the Lumos in the manner described in this protocol, provided that the data acquisition control feature ‘advanced peak determination’ (APD) can be turned off, to minimize the acquisition of MS/MS spectra with co-isolated precursors.

Some instrument types, such as orthogonal time-of-flight mass spectrometers, may not have sufficient mass resolution and therefore may not be compatible with the use of TMT-10 reagents. In such cases, a lower multiplex reagent such as TMT-6 that does not have as high a resolution requirement may be used, with consequent decrease in overall sample analysis throughput as well as differences in the depth of analysis.

Materials

Reagents

Cells or tissue samples. The patient-derived xenograft tumors used in this study were from previously established basal (WHIM2) and luminal (WHIM16) breast cancers2. The xenograft tumors were grown subcutaneously in 8-week-old NOD.Cg-Prkdescid Il2rgtm1Wjl/SzJ mice (Jackson Laboratories, strain code 005557). All patient-derived xenograft (PDX) models are available through the application from the Human and Mouse-Linked Evaluation of Tumor’s Core at http://digitalcommons.wustl.edu/ hamlet/. Xenograft tumors were grown in multiple animals. Tumor pieces for each subtype were cryopulverized, and the tissue powder was mixed in an aluminum weighing boat on dry ice, as previously described2. Tissue was stored at −80 °C until shipment on dry ice to each of the three participating laboratories. A sufficient amount of material was generated for all three laboratories for the duration of the project to prevent batch effects with regard to the xenograft material generation. Full proteome and phosphoproteome process replicates for each of the two xenografts were prepared as described in this study. The details for preparing bulk cryopulverized tissue in a sustained frozen state can be found in the supplementary methods of Mertins et al.2 ! CAUTION Informed consent must be in place when using patient tissues. Human material should be handled in a Biosafety Level 2 (or higher) environment and with strict attention to Biosafety Level 2 procedures. Refer to the Centers for Disease Control website (http://www.cdc.gov/biosafety/publications/bmbl5/BMBL5_sect_IV.pdf) for additional information ! CAUTION All experiments with live mice should be performed according to institutional and national regulations. The procedures in this protocol were reviewed and approved by the institutional animal care and use committee at Washington University in St. Louis.

Urea (Sigma-Aldrich, cat. no. U0631–1KG; or Thermo Scientific, cat. no. 29700–1KG) ! CAUTION Urea is a health hazard level 2 compound. Avoid contact with skin and eyes, and avoid inhalation.

Tris (hydroxymethyl) aminomethane hydrochloride (Tris-HCl; Ambion, cat. no. AM9855G; or Sigma-Aldrich, cat. no. T2694–1L) ! CAUTION Tris-HCl is a health hazard level 2 compound. Avoid contact with skin and eyes, and avoid inhalation.

Sodium chloride (NaCl; Sigma-Aldrich)

Ethylenediaminetetraacetic acid (EDTA; Sigma-Aldrich, cat. no. E7889) ! CAUTION EDTA is a health hazard level 1 compound. Avoid contact with skin and eyes, and avoid inhalation.

Aprotinin (Sigma-Aldrich, cat. no. A610)

Sodium fluoride (NaF; Sigma-Aldrich, cat. no. S7920) ! CAUTION NaF is a health hazard level 3 compound. Avoid contact with skin and eyes, and avoid inhalation.

Leupeptin (Roche, cat. no. 11017101001)

PMSF (Sigma-Aldrich, cat. no. 93482)

Phosphatase inhibitor cocktail 2 (Sigma-Aldrich, cat. no. P5726)

Phosphatase inhibitor cocktail 3 (Sigma-Aldrich, cat. no. P0044)

O-(2-Acetamido-2-deoxy-D-glucopyranosylidenamino) N-phenylcarbamate (PUGNAc; Sigma-Aldrich, cat. no. A7229)

DTT (Pierce, cat. no. 20291) ! CAUTION DTT is a health hazard level 2 compound. Avoid contact with skin and eyes, and avoid inhalation.

Iodoacetamide (IAM; Sigma-Aldrich, cat. no. A3221) ! CAUTION IAM is a health hazard level 3 compound with a reactivity level of 1. Avoid contact with skin and eyes, and avoid inhalation.

Lysyl endopeptidase (LysC; Wako Chemicals, cat. no. 129–02541)

Sequencing-grade modified trypsin (500 μg per vial or 5 × 20 μg per vial; Promega, cat. no. V511X or V5113)

BCA bicinchoninic acid Protein Assay Kit (Pierce, cat. no. 23225)

Formic acid (FA; Sigma-Aldrich, cat. no. 56302) ! CAUTION FA is a health hazard level 4 compound with a flammability level of 3. Avoid contact with skin and eyes, and avoid inhalation. Use it in a well-ventilated area per MSDS recommendations. Store at room temperature (RT; 25 °C) for up to 6 months.

Trifluoroacetic acid (TFA; Sigma-Aldrich, cat. no. 91707) ! CAUTION TFA is a health hazard level 3 compound with a flammability level of 1 and reactivity of 1. Avoid contact with skin or eyes, and avoid inhalation.

Acetonitrile (MeCN; J.T. Baker, cat. no. 9829–03) ! CAUTION MeCN is a health hazard level 4 compound with a flammability level of 2. Avoid contact with skin and eyes, and avoid inhalation. Store and use it in a well-ventilated area per MSDS recommendations. Store at RT for up to 6 months. ▲ CRITICAL Requires LC/MS-grade quality.

Methanol (MeOH; Fluka, cat. no. 34966) ! CAUTION MeOH is a health hazard level 1 compound with a flammability level of 3 and an instability/reactivity level of 0. Avoid contact with skin and eyes, and avoid inhalation. Store and use it in a well-ventilated area per MSDS recommendations. Store at RT for up to 6 months.

Ammonium hydroxide solution (28% (wt/vol) NH4OH; Sigma-Aldrich, cat. no. 338818) ! CAUTION Ammonium hydroxide is a health hazard level 4 compound. Avoid contact with skin and eyes, and avoid inhalation.

HPLC-grade water (J.T. Baker, cat. no. 4218–03)

TMT-10 Reagent Kit (Thermo Fisher Scientific, cat. no. 90046)

HEPES (0.5 M buffer solution, pH 8.5, liquid; Alfa Aesar, cat. no. J63218)

50% (vol/vol) Hydroxylamine solution (Sigma-Aldrich, cat. no. 467804) ! CAUTION A 50% (vol/vol) hydroxylamine solution is a health hazard level 2 compound. Avoid contact with skin or eyes, and avoid inhalation.

Acetic acid, glacial (EMD Millipore, cat. no. AX0074–6) ! CAUTION Acetic acid is a health hazard level 3 compound with a flammability level of 2 and reactivity of 0. Avoid contact with skin or eyes, and avoid inhalation.

mColorpHast pH test strips (5–10 range; VWR, cat. no. EM1.09533.0001)

Ni-NTA superflow agarose beads (Qiagen, cat. no. 30410)

Iron (III) chloride (Sigma-Aldrich, cat. no. 451649) ! CAUTION Iron (III) chloride is a health hazard level 2 compound. May be corrosive to metals. Avoid contact with skin or eyes, and avoid inhalation/ingestion.

Potassium phosphate, dibasic (Sigma-Aldrich, cat. no. P3786)

Potassium phosphate, monobasic (Sigma-Aldrich, cat. no. P0662)

Ethanol (EtOH; Sigma-Aldrich, cat. no. 270741) ! CAUTION EtOH is a health grade level 2 compound with a flammability level of 3 and reactivity level of 0.

Synthetic peptide standards: we use an in-house set of synthetic peptides (Reagent setup), but commercial peptide standard alternatives include the Pierce Peptide Retention Time Calibration Mixture (Thermo Fisher Scientific, cat. no. 88320) or custom synthetic peptides from commercial vendors such as New England Peptide.

ReproSil-Pur (120 A, C18-AQ, 1.9-μm resin; Dr. Maisch, cat. no. r119.aq)

Equipment

Needle to make stage tips (laboratory pipetting needles with 90° blunt ends, 16-gauge, 2-inch length; Cadence Science, cat. no. 7938)

Puncher to make stage tips

Tubing (PEEK, 25 μm × 1/32 × 5 feet, natural; Idex Health & Science, cat. no. 1567)

Stage-tip C18 material (solid-phase C18 extraction disks, diam. = 47 mm, 20 pack; Empore, cat. no. 66883-U)

Adapter for stage tipping (Glygen, cat. no. CEN.24)

BCA plate (96-well microplate, flat bottom, clear; Greiner Bio-One, cat. no. 655101)

SepPak tC18 3cc Vac cartridges (200 mg of sorbent per cartridge; Waters Technologies, cat. no. WAT054925)

Offline HPLC system (Agilent, 1100 series HPLC instrument or similar)

Offline HPLC column (3.5-μm, 4.6 × 250 mm; Agilent, model no. Zorbax 300 Extend-C18)

Offline fractionation plate (96-well, 2-ml polypropylene, round-bottom; Whatman Microplate Devices Uniplate, cat. no. 7701–5200)

1-ml Autosampler vial for bRP (National Scientific, cat. no. C4010–14)

1-ml Autosampler cap for bRP (National Scientific, cat. no. C4010–55A)

LC system for online LC-MS analysis (Easy Nano liquid chromatography instrument, Thermo Fisher Scientific, model no. EASY-nLC 1200, or similar) ▲ CRITICAL We use a Proxeon Easy-nLC 1200 and operate under ultra-performance liquid chromatography (UPLC) conditions. However, any LC system that can deliver nanoflow rates and can operate up to a pressure of 1,000 bar can be used for peptide separation.

MS system for online LC-MS analysis (Thermo Fisher Scientific, Orbitrap Fusion Lumos model) ▲ CRITICAL Although we use an Orbitrap Fusion Lumos, other LC-MS/MS systems could be used, as long as they have sufficient resolution in MS/MS mode to resolve the low-mass N and C series TMT-10 reporter ions. To resolve and accurately measure the near-isobaric N- and C-labeled reporter ions in the TMT-10 reagents, the instrument used must be able to achieve a minimum MS/MS resolution of 50,000 at m/z 150. Compatible instruments include the Thermo Fisher Scientific QE series of mass spectrometers (QE, QEplus, QE-HF, and QE-HF-X), as well as the Fusion and Lumos instruments also from Thermo Fisher Scientific. If the data acquisition control feature APD is present, it should be turned off to minimize the acquisition of MS/MS spectra with co-isolated precursors.

PicoFrit column (360-μm outer diameter (o.d.) × 75-μm i.d., 10-μm i.d. tip, 50-cm length; New Objective, cat. no. PF360–75-10-N-5)

300-μl Autosampler vial for LC-MS (Waters, cat. no. 186002639)

300-μl Autosampler cap for LC-MS (Waters, cat. no. 186000305)

20-cm Nanospray column heater (Phoenix S&T, cat. no. PST-CH-20U)

Column heater controller (Phoenix S&T, cat. no. PST-CHC)

Vacuum centrifuge (Electron Savant SpeedVac Concentrator; Thermo Fisher Scientific, model no. SPD121P)

Lyophilizer (Freezone 4.5; Labconco, cat. no. 7750020)

Vortex (Scientific Industries, model no. Vortex-Genie 2)

Incubator shaker (New Brunswick, model no. 22331)

Shaker (Thermomixer; Eppendorf, model no. C1213)

Tabletop centrifuge (Galaxy Mini; VWR, model no. C1213)

Tubes (microtubes, polypropylene; 1.5 ml, 2.0 ml, and 1.5 ml with cap; Sarstedt, cat. nos. 72.607, 72.693, 72.692)

Cryopulverizer (Covaris, model no. CP02 cryoPREP Impactor)

Tissue bags (tissueTUBE TT1 and tissueTUBE TT1 plug) (Covaris, cat. nos. 520001, 520006)

Software

Spectrum Mill MS Proteomics Workbench v6.0 (Agilent Technologies, https://www.agilent.com/en/ products/software-informatics/masshunter-suite/masshunter-for-life-science-research/spectrum-mill) ▲ CRITICAL Although we used Spectrum Mill, other software packages can be used that support the identification and quantitation of high-resolution LC-MS/MS with TMT-10 reagents. Throughout the data analysis portions of the protocol, we have tried to explain the metrics, parameters, and approaches that may be somewhat different in other software packages.

All mass spectra contributing to this study can be downloaded in the original instrument vendor format from: https://cptac-data-portal.georgetown.edu/cptac/s/S036 for the study name ‘reproducible workflow for multiplexed deep-scale analysis of the proteome and phosphoproteome of tumor tissues by LC-MS’.

Reagent setup

Stock solutions for lysis buffer

Stock solutions are: 1 M Tris HCl (pH 8.0), 1 M NaCl, 500 mM EDTA, 1 mg/ml aprotinin, 2 mg/ml leupeptin, 100 mM PMSF in ethanol, 1 M NaF, Phosphatase Inhibitor Cocktail 2, Phosphatase Inhibitor Cocktail 3, 14 mM PUGNAc. Stock solutions for lysis buffer can be made in advance and stored for up to 6 months, if stored properly. 1 M Tris-HCl (pH 8.0), 1 M NaCl, and 500 mM EDTA can be stored at RT for up to 12 months. 1 mg/ml aprotinin, 1 M NaF, and Phosphatase Inhibitor Cocktail 2 can be stored at 4 °C for up to 6 months. 2 mg/ml leupeptin, 100 mM PMSF in ethanol, 14 mM PUGNAc, and Phosphatase Inhibitor Cocktail 3 can be stored at −20 °C for up to 6 months.

Urea lysis buffer

Urea lysis buffer contains 8 M urea, 75 mM NaCl, 50 mM Tris (pH 8.0), 1 mM EDTA, 2 μg/ml aprotinin, 10 μg/ml leupeptin, 1 mM PMSF, 1:100 (vol/vol) Phosphatase Inhibitor Cocktail 2, 1:100 (vol/vol) Phosphatase Inhibitor Cocktail 3, 10 mM NaF, and 20 μM PUGNAc. ▲ CRITICAL Urea lysis buffer should be made fresh each time immediately before use. Make sure that the urea goes into solution before adding the additional enzymes. Add aprotinin, leupeptin, PMSF, NaF, Phosphatase Inhibitor Cocktail 2, Phosphatase Inhibitor Cocktail 3, and PUGNAc to the urea solution while it is on ice. Do not vortex after adding the additives. Swirling is sufficient. In addition, the additives should be added only immediately before use. The solution should be kept on ice once the additives are added.

BSA curve for BCA protein assay

Using the 2 mg/ml albumin stock included in the Pierce BCA Protein Assay Kit, make a serial dilution curve with HPLC-grade water. The 8-point curve we use includes albumin concentrations of 2 mg/ml, 1.5 mg/ml, 1.0 mg/ml, 0.75 mg/ml, 0.5 mg/ml, 0.25 mg/ml, 0.125 mg/ml, and 0.0625 mg/ml. The BSA curve can be made in advance and stored at 4 °C for up to a year.

Preparation of digestion enzymes

Dissolve lyophilized 10 AU Wako LysC in 20 ml of HPLC water for a final concentration of 0.5 AU/ml. Reconstituted LysC should be stored at −80 °C, can be made in advance, and is stable in storage for up to 6 months. Promega-sequencing grade modified trypsin can be purchased as 5 × 20-μg vials at 0.5 μg/μl already reconstituted in 50 mM acetic acid. To facilitate larger digestion batches and avoid pooling multiple small tubes together, we place a custom order of trypsin with Promega, in which the trypsin is in 500-μg aliquots at 0.5 μg/μl in 50 mM acetic acid solution. Reconstituted trypsin should be stored at −80 °C and is stable in storage for up to a year.

Solid-phase extraction desalting solvents

A total of 100% (vol/vol) MeCN is used for conditioning. The solvents for equilibration and washing the cartridge are 0.1% (vol/vol) TFA and 1% (vol/vol) FA. The elution solvent is 50% MeCN/0.1% (vol/vol) FA. Solid-phase extraction (SPE) desalting solvents can be made in advance and stored at RT, and are stable for up to a year.

Stage-tip desalting solvents

Solvent A for equilibration and washing is 0.1% (vol/vol) FA. Solvent B for elution is 50% (vol/vol) MeCN/0.1% (vol/vol) FA. Stage-tip desalting solvents can be made in advance and stored at RT, and are stable for up to a year.

Ammonium formate (NH4HCO2) stock solution (pH 10) for basic-pH RP solvents

To make 1 liter of 180 mM ammonium formate, add 25 ml of 28% (wt/vol) ammonium hydroxide (density 0.9 g/ml) to ~500 ml of HPLC-grade water, then add ~45 ml of 10% (vol/vol) FA to titrate the pH to 10.0, and then bring the final volume to 1 liter with HPLC-grade water. Ammonium formate stock solution is stable for up to a year at RT; check the pH before use to prepare basic-pH RP solvents.

Basic-pH RP solvent A

Basic-pH RP solvent A is 4.5 mM ammonium formate (pH 10) in 2% (vol/vol) acetonitrile. To make 1 liter, add 25 ml of ammonium formate stock solution (pH 10) and 20 ml of acetonitrile (2% (vol/vol)) to 955 ml of water. Basic RP solvents are stable at RT for up to 2 weeks.

Basic-pH RP solvent B

Basic-pH RP solvent B is 4.5 mM ammonium formate (pH 10) in 90% (vol/vol) acetonitrile. To make 1 liter, add 25 ml of ammonium formate stock solution (pH 10) and 900 ml of acetonitrile (90% (vol/vol)) to 75 ml of water. Basic RP solvents are stable at RT for up to 2 weeks. ▲ CRITICAL The ionic strength of solvents A and B, ~5 mM, is deliberately low, so that collected fractions can be readily desalted by vacuum centrifugation and are compatible with the subsequent IMAC-enrichment step of the protocol.

Synthetic peptide standards

Selection of synthetic peptides should be based on their availability as well as their chromatographic behavior, such as retention times spanning the duration of the gradient. For example, tryptic peptides of 10–15 amino acids in length with good solubility in aqueous buffer and consistent elution behavior on RP C18 are ideal. We choose peptides that are either from a different species than our sample of interest or are isotopically labeled with heavy amino acids to reduce any contamination in subsequent runs on the column. In addition, column back pressure is informative for system performance. For this scale and configuration, back pressure for the 4.6-mm i.d. columns at 1 ml/min flow is typically in the 180–220 bar range. The synthetic peptide standards can be stored dry at −80 °C indefinitely.

Solvents for conditioning and equilibrating the stage tips during IMAC

These include 100% (vol/vol) MeOH, 50% (vol/vol) MeCN/0.1% (vol/vol) FA, and 1% (vol/vol) FA. Solvent for binding and washing agarose beads is 80% (vol/vol) MeCN/0.1% (vol/vol) TFA. The stage-tip elution buffer is 50% (vol/vol) MeCN/0.1% (vol/vol) FA. The stage-tip solvents are stable for up to a year at RT.

Agarose-bead elution buffer

To make 500 ml of 500 mM potassium phosphate buffer, combine 96.25 ml of 1 M monobasic potassium phosphate with 153.75 ml of dibasic potassium phosphate in 250 ml of HPLC water. Monobasic and dibasic potassium phosphate stock solutions are stable for up to a year at RT. The 500 mM potassium phosphate buffer is stable for up to 6 months at RT.

Ten mM iron (III) chloride solution

Dissolve solid iron (III) chloride in HPLC water; this solution should be made fresh immediately before use. The agarose-bead slurry solution consists of acetonitrile, methanol, and 0.01% (vol/vol) acetic acid in a 1:1:1 ratio by volume, which can be made in advance and stored at RT for up to year.

UPLC-MS/MS solvents

Solvent A is 3% (vol/vol) MeCN/0.1% (vol/vol) FA and solvent B is 90% (vol/vol) MeCN/0.1% (vol/vol) FA. UPLC solvents are stable for up to a month at RT.

Nanoflow C18 column

The nanospray column for online UPLC-MS/MS analysis is self-packed into a 75-μm i.d. PicoFrit column with ReproSil-Pur 120 A, C18-AQ, 1.9 μm to a length of 20–24 cm using a pressure bomb set to 950 p.s.i. These columns can be stored at RT for up to 3 months without drying out.

Equipment setup

Basic RP chromatography blank gradient

A timetable summarizing the gradient used for conditioning the column before the injection of the sample at flow rate of 1 ml/min (Step 90) is given below.

| Time interval (min) | Gradient (%B) |

|---|---|

| 0 | 60 |

| 2 | 0 |

| 4 | 0 |

| 19 | 100 |

| 21 | 100 |

| 22 | 0 |

| 24 | 0 |

| 39 | 100 |

| 41 | 100 |

| 42 | 0 |

| 70 | 0 |

Basic RP chromatography label-free/iTRAQ-labeled sample gradient

A timetable summarizing the gradient used for fractionation of iTRAQ-labeled sample at a flow rate of 1 ml/min (Step 90) is given below.

| Time interval (min) | Gradient (%B) |

|---|---|

| 0 | 0 |

| 9 | 0 |

| 13 | 6 |

| 63 | 28.5 |

| 68.5 | 34 |

| 81.5 | 60 |

| 90 | 60 |

Basic RP chromatography TMT-labeled sample gradient

A timetable summarizing gradient used for fractionation of TMT-labeled sample at a flow rate of 1 ml/min (Step 94) is given below.

| Time interval (min) | Gradient (%B) |

|---|---|

| 0 | 0 |

| 7 | 0 |

| 13 | 16 |

| 73 | 40 |

| 77 | 44 |

| 82 | 60 |

| 96 | 60 |

UPLC-MS RP chromatography gradient

A timetable summarizing the gradient for LC-MS/MS analysis of label-free samples, TMT-labeled basic RP fractions, and TMT-labeled phosphorus-enriched fractions (Steps 44, 72, 97, and 126) is given below.

| Time interval (min) | Gradient (%B) | Flow rate (nl/min) |

|---|---|---|

| 0 | 2 | 200 |

| 1 | 6 | 200 |

| 85 | 30 | 200 |

| 94 | 60 | 200 |

| 95 | 90 | 200 |

| 100 | 90 | 200 |

| 101 | 50 | 500 |

| 110 | 50 | 500 |

Orbitrap Fusion Lumos MS/MS method

MS parameters used for the LC-MS/MS analysis of label-free samples (Step 44) are given below.

| Parameter | Value |

|---|---|

| Polarity | Positive |

| Full MS | |

| Microscans | 1 |

| Orbitrap resolution | 60,000 m/Δ(m) at 200 m/z |

| Automatic Gain Control (AGC) target | 4 × 105 ion counts |

| Maximum ion time | 50 ms |

| Scan range | 350–1,800 m/z |

| Data-dependent dd-MS2 | |

| Microscans | 1 |

| Detector type | Orbitrap |

| Orbitrap resolution | 15,000 m/delta(m) at 200 m/z |

| AGC target | 5 × 104 ion counts |

| Maximum ion time | 50 ms |

| Number of dependent scans | 20 |

| Isolation window | 0.7 m/z |

| Fixed first mass | 110 m/z |

| Activation type | Higher-energy collision dissociation (HCD) |

| HCD energy (%) dd settings | 34 |

| Charge exclusion | Include 2–6 charge states |

| Peptide match | Preferred |

| Exclude isotopes | On |

| Dynamic exclusion | 45 s |

Orbitrap Fusion Lumos MS/MS method

MS parameters used for the LC-MS/MS analysis of TMT-labeled fractionated and phospho-enriched samples (Steps 72, 97, and 126) are given below.

| Parameter | Value |

|---|---|

| Polarity | Positive |

| Full MS | |

| Microscans | 1 |

| Orbitrap resolution | 60,000 |

| AGC Automatic Gain Control target | 4 × 105 ion counts |

| Maximum ion time | 50 ms |

| Scan range | 350–1,800 m/z |

| dd-MS2 | |

| Microscans | 1 |

| Detector type | Orbitrap |

| Orbitrap resolution | 50,000 (TMT-10) |

| AGC target | 1 × 105 ion counts |

| Maximum ion time | 105 ms |

| Cycle time: time between master scans | 2 s |

| Isolation window | 0.7 m/z |

| Fixed first mass | 110 m/z |

| Activation type | Higher-energy collision dissociation (HCD) |

| HCD energy (%) dd settings | 38 (TMT) |

| Monoisotopic peak determination | Peptide |

| Charge exclusion | Include 2–6 charge states |

| Exclude isotopes | On |

| Dynamic exclusion | 20 s |

▲ CRITICAL The performance of the combined LC-MS/MS system must be evaluated before the analysis of any precious biological materials such as tissue samples. It is difficult to be prescriptive, as each laboratory will have its own metrics for optimal instrument performance. System performance is typically evaluated relative to the maximum obtainable system performance previously established, using a highly complex sample such as a cell-line digest that can be repeatedly produced or purchased. System performance is typically evaluated using single-shot analyses and a set gradient duration (e.g., 60–90 min). The number of peptides obtained under these conditions is compared to prior ‘best performance’ to ascertain if the system is usable. A decrease on the order of 15–20% in the number of peptides identified indicates that either the column, LC, or MS is underperforming and probably needs adjustment or maintenance. The overall appearance of the chromatogram, including start and end times for eluting peptides and chromatographic peak width, as compared with that obtained when the system is operating well, can help to determine if the problem is with chromatography (LC or column) or the mass spectrometer. ▲ CRITICAL To resolve C and N series reporter ions for the TMT-10-labeling strategy, 50,000 at 200 m/z resolution is used for MS2. ▲ CRITICAL To minimize the acquisition of MS/MS spectra with co-isolated precursors, the data acquisition control feature, APD, should be turned off. ▲ CRITICAL Each center optimized the collision energy for its own instrument. The listed collision energy is one center’s value and can be used as a benchmark to further optimize individual instruments. To achieve optimal fragmentation of TMT-labeled peptides, collision energy should be optimized on the instrument used for analyses of those samples.

Procedure

(Optional) Cryopulverization of tissue blocks ● Timing 2.5 h for ten non-OCT tissue blocks; 3.5 h for ten OCT tissue blocks.

! CAUTION We recommend that Steps 1–10 be performed in a chemical hood to protect against unintended exposure to tissue fragments.

▲ CRITICAL If working with frozen cell pellets or already-cryopulverized tissue, Steps 1–10 can be skipped. If the frozen tissue blocks are not embedded in optimal-cutting temperature compound (OCT), skip Steps 1–4.

Precool a sterile, unopened Petri dish on dry ice.

Starting with a tissue block embedded in OCT, unwrap the packaging and place the block on the Petri dish. Do not open the Petri dish until immediately before starting this procedure.

-

Dip a clean, sterile scalpel into liquid nitrogen for 10 s and then use it to shave-off slices of OCT away from the tissue block. Dip a pair of tweezers into liquid nitrogen for 10 s every few minutes to use to hold the tissue block down while cutting away the OCT slices. Before freezing the tweezers each time, first clean them with 70% (vol/vol) EtOH.

▲ CRITICAL STEP The first few slices will be difficult to make because the OCT block may be too frozen. Sometimes it is helpful to wait for 15 s for the outer layers of OCT to become softer before proceeding to cut. Attempting to make cuts while the OCT block is still rock-solid frozen may lead to sample losses and could possibly introduce contamination because the tissue block may flip out of the Petri dish.

Slice the OCT away until the OCT constitutes <10% of the sample by volume. Any more than that risks the loss of too much tissue material. Use a new, freshly cooled scalpel every few cuts to ensure that the scalpel itself is not unnecessarily warming the sample.

-

Once a satisfactory amount of OCT has been cut away from the tissue block, clean and refreeze the tweezers, then use them to put the tissue block into a precooled Covaris cryopulverization bag. If the tissue block is too big, first cut the tissue block in half or thirds so that the tissue blocks fit through the mouth of the bag.

▲ CRITICAL STEP If the frozen tissue blocks are not embedded in OCT, a frozen 300-mg tissue piece can be directly placed in the tissue bag.

Once the tissue blocks are in the cryopulverization bag and the bag is capped, redip the entire bag in liquid nitrogen. Keep the tissue on dry ice until one is ready for the next step.

For the actual cryofractionation procedure, prepare dry ice, liquid nitrogen, and tweezers to prepare, store, and handle the sample bag.

-

The impact level should be adjusted depending on the amount of tissue in the tissue bag. For a tissue piece that is between 200 and 400 mg wet weight (approximated by eye), the impact level should be ~3. Smaller tissue blocks should use less impact and larger tissue blocks should use high impact. Tissue of ~300 mg wet weight is ~10 × 10 × 3 mm. This approximation can vary depending on tissue type. For example, breast cancer is less dense than lung cancer because it has higher proportions of fat.

▲ CRITICAL STEP In this protocol, we recommend a minimum of 50–100 mg of wet-weight tissue starting material because the protein yield of breast cancer tissue is ~1–3%, and the peptide yield from protein is ~40–50%. Note, however, that different tissue types will have different protein yields from wet-weight tissue, which should be taken into consideration when determining the amount of starting material needed.

▲ CRITICAL STEP To achieve best cryofracture results, the bagged tissue sample must be transferred from dry ice to liquid nitrogen for 5 s and then immediately cryofractured.

▲ CRITICAL STEP Do not hammer a tissue piece more than once, or else the bag will be pierced, and the tissue will fall out. If the impact level is too low and the tissue is not cryopulverized properly, either transfer the sample to a new bag or perform manual pulverizing with a frozen spatula. If the impact is too high, the cryofracture bag will burst on the first hammer hit and the tissue will fall out. It may be helpful to use practice tissue samples to familiarize oneself with the relative impact levels. Note that the lid of the cryofracture bag must be screwed on loosely to allow air to move out of the bag when it is hit by the metal plates; otherwise the bag may rupture.

To transfer the cryopulverized tissue from the cryofracture bag to a 1.5-ml tube, dip a capped 1.5-ml tube in liquid nitrogen for 10 s or until the boiling stops. Keep the uncapped tube on dry ice. Dip a new or clean spatula into liquid nitrogen for 10 s and then transfer the tissue from the bag to a weighing boat kept on dry ice. Transfer the sample to the cooled tube after weighing. Change spatulas between different patient samples. Clean the spatula with 70% EtOH before using and after every two to three scoops.

-

Cap the tube once the cryofracture bag is emptied into the tube and store the tube at −80 °C until ready for lysis.

■ PAUSE POINT Frozen tissue samples should be stored at −80 °C until ready for lysis. We recommend that the length of storage not exceed 1 year.

Tissue lysis ● Timing 90 min

-

11

Keep the cryopulverized tissue on ice and add 200 μl of chilled urea lysis buffer (4 °C) for each ~50-mg portion of wet-weight tissue.

▲ CRITICAL STEP Keep excess urea lysis buffer on ice to be used in later steps.

-

12

Vortex the tissue-lysis buffer mixture on the highest setting for 5–10 s.

-

13

Lyse the cells at 4 °C for 15 min by letting the tissue-lysis buffer mixture sit on ice.

-

14

Vortex the tissue-lysis buffer mixture on the highest setting for 5–10 s.

-

15

Incubate the sample for an additional 15 min on ice.

-

16

If the cryopulverized tissue was originally in a cryovial that is not compatible with the centrifuge, transfer the contents of the cryovial to a 2-ml screw-cap vial.

-

17

Centrifuge the tissue-lysis buffer solution at 20,000g at 4 °C for 10 min to clear the lysate.

▲ CRITICAL STEP When this protocol was used on human breast cancer patient material, the fat would rise to the top at this step. It is largely at the lysis step that we eliminate excess amounts of lipid, if present.

-

18

Transfer the supernatant to a 2-ml conical tube, measuring the volume of the supernatant when transferring.

! CAUTION When removing the supernatant, slide the pipette tip down the side of the tube to avoid a potential fat layer that will float above the supernatant and not pellet out with the other cellular debris.

▲ CRITICAL STEP Keep the insoluble pellet that collected at the bottom of the original tube on ice and store it at −80 °C. This pellet can be used for whole-exome sequencing at a quality comparable to that of the original samples2.

■ PAUSE POINT The cell pellets can be stored at −80 °C for up to 1 year.

Estimation of the protein yield using a Pierce BCA Kit ● Timing 60 min

-

19

Dilute the samples in water at a 1:19 (vol/vol) ratio, by removing 2 μl of sample and putting it in a 1.5-ml conical tube containing 38 μl of HPLC water. Plate 10 μl of the diluted sample in triplicate per sample in a clear, flat-bottom 96-well microplate.

-

20

Plate 10 μl of HPLC water as a blank and plate a urea lysis buffer dilution sample (1:19 (vol/vol), urea lysis buffer to water), each in triplicate.

-

21

Plate eight wells of 10 μl each of an 8-point BSA curve, ranging in concentration from 50 μg/ml to 2 mg/ml.

-

22

Prepare the BCA reagent by mixing reagent B and reagent A in a 1:49 (vol/vol) ratio.

▲ CRITICAL STEP This solution must be made fresh right before use.

-

23

Add 200 μl of freshly prepared BCA reagent to each well containing 10 μl of sample.

-

24

Incubate the microplate at 37 °C for 30 min.

-

25

Read the plate at 562 nm and determine the protein concentrations of the samples.

-

26

Adjust each sample concentration to 8 μg/μl with urea lysis buffer. If the sample concentration does not reach 8 μg/μl, record the maximum concentration achieved and adjust subsequent amounts of reducing reagents accordingly.

-

27

Prepare 1-mg aliquots per sample for reduction, alkylation, and digestion.

■ PAUSE POINT Samples can be frozen and stored at −80 °C for several weeks. Thawing of previously frozen samples is performed gently on ice.

Reduction and alkylation ● Timing 2 h

-

28

Reduce the disulfide bonds in the denatured proteins by adding DTT to 1 mg of sample (one of the aliquots prepared in Step 27) at a final concentration of 5 mM DTT, followed by incubation for 1 h at 37 °C in a Thermomixer.

-

29

Alkylate the reduced cysteine residues by adding IAM to a final concentration of 10 mM IAM, followed by incubation for 45 min in the dark at 25 °C.

In-solution digestion ● Timing 2 h + overnight digestion + 30 min

-

30

Dilute the samples 1:3 (vol/vol) with 50 mM Tris-HCl (pH 8.0) to decrease the urea concentration to <2 M.

-

31

Add LysC in an enzyme/substrate ratio of 1 mAU LysC per 50 μg of total protein, followed by incubation for 2 h at 25 °C in the incubator shaker.

▲ CRITICAL STEP The manufacturer of the LysC (Wako) provides quantities only in milli-Anson units and not in micrograms. It is impossible for us to know exactly how much LysC we are adding when measured in micrograms. Our general rule is that for each milli-Anson unit of LysC, we use 1 μg of enzyme. A sequencing-grade version of the enzyme is also available at substantially higher cost from the same vendor, and it is indicated as being packaged at 20 μg/vial. However, we have not used this version of the product.

-

32

Add trypsin in an enzyme/substrate ratio of 1:49 (wt/wt) for overnight digestion at 25 °C in the incubator shaker.

▲ CRITICAL STEP Use of higher temperatures will increase the extent of carbamylation of peptide N termini and lysines, and may have an unfavorable effect on quantification.

-

33

Quench the digestion reaction by acidifying the digestion mixture to a final concentration of 1% (vol/vol) FA using 100% (vol/vol) FA.

▲ CRITICAL STEP Using pH paper, check that the pH of the final solution is at pH 3. If not, add 100% (vol/vol) FA until a pH = 3 is reached.

-

34

Dilute the samples with 0.1% (vol/vol) FA to a 1.5-ml volume for ease of handling in subsequent steps.

-

35

Centrifuge the solution at 1,500g at RT for 15 min. The supernatant containing the peptides to be analyzed is subsequently desalted (Step 41). The pellet is generally discarded but can be saved for possible additional processing.

Peptide desalting of the digest by SPE ● Timing 90–120 min per set of ten samples

-

36

Use a 200-mg tC18 SepPak cartridge with a vacuum manifold to desalt the peptide samples.

▲ CRITICAL STEP Do not let the cartridges run dry during washing or loading, as this can increase sample loss during desalting from 5 to >20%.

-

37

Condition the cartridge with 3 ml of 100% (vol/vol) MeCN.

-

38

Condition the cartridge with 3 ml of 50% (vol/vol) MeCN/0.1% (vol/vol) FA.

-

39

Equilibrate the cartridge with 4 × 3 ml of 0.1% (vol/vol) TFA.

-

40

Load the sample supernatant from after centrifugation (from Step 35).

-

41

Desalt the sample with 3 × 3 ml of 0.1% (vol/vol) TFA.

-

42

Wash the cartridge with 1 × 3 ml of 1% (vol/vol) FA to remove the TFA.

-

43

Elute the sample from the tC18 cartridge with 2 × 1.5 ml of 50% (vol/vol) MeCN/0.1% (vol/vol) FA.

-

44

(Optional) To check for digestion success of individual samples by metrics such as missed cleavage rates and peptide counts, as read by LC-MS/MS, prepare a single-shot quality control (QC) per sample. This QC sample can also be used to detect the amount of OCT contamination in each sample. To generate the QC sample, remove 15 μg of the 3 ml eluate and dry it in an HPLC vial using a vacuum centrifuge. Reconstitute the sample in 30 μl of 3% (vol/vol) MeCN/0.1% (vol/vol) FA and analyze by LC-MS/MS, injecting 1 μg onto the column. Run QC on the sample and digestion by checking parameters such as missed-cleavage rates (Supplementary Fig. 2). Skip this step if instrument time on an LC-MS/MS system is limited.

? TROUBLESHOOTING

-

45

Freeze the eluate in liquid nitrogen or in a −80 °C freezer space before drying down with a vacuum centrifuge.

■ PAUSE POINT Dried peptides can be stored in a −80 °C freezer space.

Estimation of the peptide amount using a Pierce BCA Kit ● Timing 60 min

-

46

Reconstitute the sample in 500 μl of 50 mM HEPES (pH 8.5) by mixing well.

-

47

Remove a 25-μl aliquot for the peptide-level BCA estimation.

-

48

Dilute the 25-μl aliquot of sample 1:1 (vol/vol) with 25 μl of 50 mM HEPES (pH 8.5).

-

49

Plate 10 μl of the diluted sample in triplicate per sample in a clear, flat-bottom 96-well microplate.

-

50

Plate a 10-μl HPLC water blank and a 50 mM HEPES, pH 8.5, blank, each in triplicate.

-

51

Plate eight wells of 10 μl each of an 8-point BSA curve, ranging from 50 μg/ml to 2 mg/ml.

-

52

Prepare the BCA reagent by mixing reagent B and reagent A in a 1:49 (vol/vol) ratio.

▲ CRITICAL STEP This solution must be made fresh immediately before use.

-

53

Add 200 μl of freshly prepared BCA reagent to each well containing 10 μl of sample.

-

54

Incubate the microplate at 37 °C for 30 min.

-

55

Read the plate at 562 nm. We usually recover 40–50% of the starting material at this step. When using 1 mg of protein starting material, we usually recover 400–500 μg of tryptic peptides.

-

56

On the basis of the BCA results at the peptide level, dilute the samples with 50 mM HEPES (pH 8.5) for a concentration of 1 μg/μl. Vortex the well to mix.

■ PAUSE POINT Peptides in 50 mM HEPES (pH 8.5) can be stored in a −80 °C freezer space for up to 1 week.

TMT labeling of 300 μg of peptide per channel ● Timing 90 min

-

57

Remove 300 μg of peptides, as measured by peptide-level BCA, which should be in 300 μl of 50 mM HEPES (pH 8.5) at this point, and transfer it to a 2-ml screw-cap tube.

-

58

Reconstitute each 5-mg TMT reagent vial in 256 μl of anhydrous acetonitrile. Allow it to sit for 5 min.

-

59

Vortex the reagent tubes briefly and spin down on a benchtop centrifuge at 1,000g at RT for 30 s.

-

60

Add 123 μl of each reagent to the corresponding aliquot of peptides. Mix well and incubate at RT for 1 h with shaking on a tabletop shaker set at 1,000 r.p.m.

-

61

After 1 h, remove 2-μg aliquots from each sample and combine these to create a mixing QC test sample. Using a vacuum centrifuge, dry down this mixture of the ten channels and desalt these QC samples as described in Steps 63–72.

-

62

Freeze the rest of the samples at −80 °C until the mixing QC test is analyzed.

▲ CRITICAL STEP Do not quench the labeling reaction until after assessment of the label incorporation test results.

■ PAUSE POINT Peptides in 50 mM HEPES (pH 8.5) with TMT-labeling reagent can be stored in a −80 °C freezer space for up to 2 weeks.

Desalting of the mixing QC test sample ● Timing 30 min

-

63

Prepare C18 stage tips by using Empore C18 extraction disks, as described in ref. 38. Pack two plugs of C18 material into the tip of each stage tip (200-μl pipette tip) for a total binding capacity of ~40 μg. Create extraction disks using a 16-gauge blunt-end metal needle to hole-punch the ~1-mm disks. We recommend using adapters to hold the stage-tip pipette tip at the orifice of each 2 ml microcentrifuge tube.

-

64

Condition the stage tip with 100 μl of MeOH. Centrifuge at 3,000–3,500g for 3 min at RT and discard the liquid from the collection vial. All subsequent centrifugation steps are for the same duration or until all the solvent has passed through the stage tip at the same speed and at RT.

▲ CRITICAL STEP Do not centrifuge the stage tips at speeds above 3,500g or else the C18 material will dry out.

-

65

Wash the stage tips with 100 μl of 50% (vol/vol) MeCN in 0.1% (vol/vol) FA (stage-tip desalting solvent B). Centrifuge the stage tip at 3,000–3,500g for 3 min at RT. Discard the liquid.

-

66

Equilibrate the stage tips twice with 100 μl of 0.1% (vol/vol) FA (stage-tip desalting solvent A). Centrifuge the stage tip at 3,000–3,500g for 3 min at RT after each solvent loading. Discard the liquid.

-

67

Reconstitute the sample in 100 μl of 3% (vol/vol) MeCN/0.1% (vol/vol) FA and add the samples to the stage tip. Centrifuge the stage tip at 3,000–3,500g for 3 min at RT and discard the liquid from the collection vial.

-

68

Wash the samples twice with 100 μl of stage-tip desalting solvent A. Centrifuge the stage tip at 3,000–3,500g for 3 min at RT. Discard the liquid.

-

69

Replace the collection vial with a new 1.5 ml screw-cap vial for the collection of the eluate.

-

70

Elute the sample with 60 μl of stage-tip desalting solvent B. Centrifuge the stage tip at 3,000–3,500g for 3 min at RT.

-

71

Transfer the eluate to an HPLC vial, freeze it, and completely dry it by vacuum centrifugation.

-

72

Reconstitute the dried sample in 40 μl of 3% (vol/vol) MeCN/0.1% (vol/vol) FA and analyze the sample by LC-MS/MS (using the parameters described in the ‘Equipment setup’ section) to check the label incorporation and relative channel abundance. For the LC-MS/MS analysis, inject 2 μl onto the column.

▲ CRITICAL STEP As it can take a considerable amount of instrument time to analyze each of the individual label-incorporation test samples, particularly for TMT-10, one can consider analyzing the mixing QC test sample for both labeling efficiency and mixing consistency, and only analyzing the individual label-incorporation test samples for troubleshooting purposes if the labeling efficiency is suspect in the mixing test sample.

Data analysis for assessment of labeling efficiency and mixing ● Timing 1 h

-

73

To evaluate the completeness of free-amine labeling, database searches should be configured to allow for both peptide N termini and lysine side chains to be present in either labeled or unlabeled form. With Spectrum Mill, accounting for partial labeling is accomplished with a fixed/mix search cycle strategy that runs a search four consecutive times with different sets of modifications in each round and then produces a single integrated output. The four cycles are as follows: all unmodified, both peptide N termini and lysines labeled, only lysines labeled, and only peptide N termini labeled. As the primary amine groups of lysine side chains (pKa ~10) are more reactive than peptide N-terminal amines (pKa ~7.5), incomplete labeling tends to be observed predominantly in the form of unlabeled peptide N termini. Furthermore, so long as a peptide includes at least 1 label, reporter-ion quantitation is viable. After running a four-cycle partial-labeling database search configuration with a suitable (1%) PSM-level false-discovery rate (FDR) threshold on a label-check aliquot, labeling efficiency percentage metrics are calculated in the Spectrum Mill Quality Metrics module: full label % = 100 × fully labeled PSMs/total PSMs and label % = 100 × 1 or more labeled PSMs/total PSMs.

▲ CRITICAL STEP We typically apply a threshold for minimal labeling efficiency of >99% labeling by PSM identifications. If the threshold is not met, then the samples will be relabeled (see Troubleshooting section for relabeling procedure) before proceeding with further peptide-level fractionation. In our experience, TMT labeling is more robust and less likely to require relabeling than iTRAQ labeling.

? TROUBLESHOOTING

-

74

Analyze the resulting MS data from the mixing test sample to check if the total protein amount from each sample is the same. The Spectrum Mill Quality Metrics module does this by summing the reporter-ion intensity (after applying isotopic correction) for each channel across all the confidently identified PSMs in the dataset. Then, per-sample mixing percentages are calculated using the most abundant reporter-ion channel sum as a common denominator and each of the other channels as a numerator.

▲ CRITICAL STEP Unless particular samples are available in limited quantity, we require each sample to have a reporter-ion intensity sum for all identified PSMs in the mixing test sample LC-MS/MS run that deviates <25% from the reporter-ion intensity sum of the reference channel, if present, or from the average reporter-ion intensity sum of all channels.

? TROUBLESHOOTING

Quenching of the TMT-labeling reaction ● Timing 20 min

-

75

Quench all individual TMT-labeling reactions by adding 32 μl of 5% (vol/vol) hydroxylamine, followed by incubation at RT for 15 min with shaking at 1,000 r.p.m.

-

76

Combine the volumes of each of the ten TMT-labeled samples in a 15-ml conical tube before freezing in liquid nitrogen or by placing into a −80 °C freezer space. Dry down the combined sample.

■ PAUSE POINT Dried peptides can be stored in a −80 °C freezer space for up to 1 month.

Peptide desalting of labeled peptides by SPE ● Timing 30 min

-

77

Use a 200-mg tC18 SepPak cartridge with a vacuum manifold to desalt the peptide samples.

▲ CRITICAL STEP Do not let the cartridges run dry during washing or loading, as this can increase sample losses during desalting from 5% to >20%.

-

78

Reconstitute the combined sample of TMT-labeled peptides in 3 ml of 3% (vol/vol) MeCN/0.1% (vol/vol) FA.

▲ CRITICAL STEP Measure the pH with pH-indicator paper and adjust the pH to 3 with 100% (vol/vol) FA if necessary.

-

79

Condition the cartridge with 3 ml of 100% (vol/vol) MeCN.

-

80

Condition the cartridge with 3 ml of 50% (vol/vol) MeCN/0.1% (vol/vol) FA.

-

81

Equilibrate the cartridge with 4 × 3 ml of 0.1% (vol/vol) TFA.

-

82

Load the sample onto the cartridge.

-

83

Desalt the sample with 3 × 3 ml of 0.1% (vol/vol) TFA.

-

84

Wash the cartridge with 1 × 3 ml of 1% (vol/vol) FA to remove the TFA.

-

85

Elute the sample from the tC18 cartridge with 2 × 1.5 ml of 50% (vol/vol) MeCN/0.1% (vol/vol) FA.

-

86

Freeze the eluate in liquid nitrogen or in a −80 °C freezer space before drying down with a vacuum centrifuge.

■ PAUSE POINT Dried peptides can be stored in a −80 °C freezer space for up to 1 year.

Offline HPLC fractionation ● Timing 60 min + overnight QC + 5 h

-

87

Prepare the HPLC system by purging solvent lines A and B of air. Equilibrate the bRP fractionation column with 100% (vol/vol) solvent B, then 100% (vol/vol) solvent A, and finally with 50% (vol/vol) solvent A/50% (vol/vol) solvent B. Equilibrate with each of these conditions for 30 min, for a total of 1.5 h. The flow rate for equilibration is that of the method, which in our method is 1 ml/min.

-

88

Perform a QC of the HPLC system before fractionation. We typically accomplish this by injecting peptide standards in duplicate before running the actual sample. For this scale of bRP, 200 pmol of a mixture of ten in-house synthetic peptide standards (Reagent setup) is injected and evaluated for retention time reproducibility, signal intensity, and peak resolution (Supplementary Fig. 3a).

-

89

Prepare the LC system for QC sample injection: the composition of a single sample separation is a sequence of two methods: a blank gradient, used to condition the column, followed by the sample gradient. For the QC run, we typically use a method that is meant for label-free peptides for better separation and resolution peaks for the peptides.

-

90

Once the QC of the peptide standards indicates the system is running properly, run a blank gradient to condition the column for the TMT-labeled sample (Equipment setup). This is achieved by injecting 50 μl of bRP solvent A (refer to ‘Reagent setup’ for basic-pH RP solvents) from an HPLC vial with the gradient outlined in the ‘Equipment setup’ as a blank gradient.

-

91

Upon completion of the blank run, reconstitute the sample in 900 μl of bRP solvent A (see ‘Reagent setup’ for basic-pH RP solvents). Vortex until the sample is in solution.

▲ CRITICAL STEP Do not pipette up and down to bring the sample into solution, as this will result in the formation of bubbles.

-

92

Transfer the sample to a 1.5-ml screw-cap vial and centrifuge at 20,000g at RT for 5 min to remove any material that did not go into solution.

-

93

Transfer the sample, avoiding the pelleted insoluble peptides, to an HPLC vial. Inject 850 μl of the sample into the sample loop of the HPLC system.

▲ CRITICAL STEP The sample volume is brought to 900 μl, but only 850 μl is injected, because extra volume is needed to avoid injecting air bubbles into the system during sample injection.

-

94

For separation of the TMT-labeled samples, use the corresponding gradient and flow rate settings outlined in the tables in the ‘Equipment setup’ section. For an example chromatogram, see Supplementary Fig. 3b. In the bRP separation, 96 fractions are collected into a Whatman 2-ml 96-well plate at a flow rate of 1 ml/min.

▲ CRITICAL STEP To store the HPLC column after separation, flow water through the column at 1 ml/min and then flow methanol through the column, also at 1 ml/min. Do not store or maintain the column in basic solvent when samples are not being run, as this will substantially speed up the aging of the column and cause premature widening of peaks.

-

95

After separation, pool the bRP fractions (as described in Table 1) in 15-ml conical vials to generate 24 final fractions and fraction A. Fraction A does not contain many peptides, acts as a negative control, and contains multiply phosphorylated peptides that do not bind well to the RP column. The plate layout describes the recombination of wells in which B10 is combined with D10 and F10 as fraction 1, B9 is combined with D9 and F9 as fraction 2, and so on (Table 1).

▲ CRITICAL STEP In our method of pooling, we have factored in the fact that our sample is eluted in a serpentine manner. For methods that do not eluate in a serpentine method, please correct the pooling scheme to still allow pooling of the fractions from the beginning, middle, and end of the gradient in an even and recurring manner. Our method reduces 96 individual wells into 23 final fractions (three wells with disparate hydrophobicity) plus two fractions from the early and late portions of the chromatogram that are sparser in peptide content.

-

96

Acidify each pooled fraction using 10% (vol/vol) FA to achieve a final concentration of 0.1% (vol/vol) FA and a pH of 3.

-

97

From each pooled fraction, collect 5% of each fraction into an HPLC vial for proteome analysis by LC-MS/MS. Vacuum-centrifuge each HPLC vial with the proteome analysis fraction. For analysis, bring the sample up in 3% (vol/vol) MeCN/0.1% (vol/vol) FA to a final concentration of 0.5 μg/μl and inject 1 μl onto the column. In practice, we assume there is 6.25 μg in each of the 24 fractions and we bring the sample up in 12.5 μl of 3% (vol/vol) MeCN/0.1% (vol/vol) FA. We have previously found that the columns can accommodate 1 μg without overloading when samples are measured on the protein level. In our current protocol, we are quantifying the amounts on the peptide level. Peptide yields are approximately half of protein yields. Therefore, by loading 0.5 μg (peptide-level BCA), we are effectively reproducing our previous 1 μg on the column (protein-level BCA). Experience from one of the three labs indicates that results with 0.5- and 1-μg loads (by peptide BCA) are very similar. In general, it should be noted that the higher the peptide load, the greater the possibility of the chromatographic separation decreasing because of overloading.

? TROUBLESHOOTING

-

98

Combine the remaining 95% of each fraction into 12 fractions + fraction A for enrichment of phosphopeptides as follows: