Abstract

cis- and trans-Isomers of the platinum(II) nitrile complexes [PtCl2(NCR)2] (R = NMe2, N(C5H10), Ph, CH2Ph) were examined as catalysts for hydrosilylation cross-linking of vinyl-terminated polydimethylsiloxane and trimethylsilyl-terminated poly(dimethylsiloxane-co-ethylhydrosiloxane) producing high quality silicone rubbers. Among the tested platinum species the cis-complexes are much more active catalysts than their trans-congeners and for all studied platinum complexes cis-[PtCl2(NCCH2Ph)2] exhibits the best catalytic activity (room temperature, c = 1.0 × 10−4 mol/L, τpot-life 60 min, τcuring 6 h). Although cis-[PtCl2(NCCH2Ph)2] is less active than the widely used Karstedt’s catalyst, its application for the cross-linking can be performed not only at room temperature (c = 1.0 × 10−4 mol/L), but also, more efficiently, at 80 °C (c = 1.0 × 10−4–1.0 × 10−5 mol/L) and it prevents adherence of the formed silicone rubbers to equipment. The usage of the cis- and trans-[PtCl2(NCR)2] complexes as the hydrosilylation catalysts do not require any inhibitors and, moreover, the complexes and their mixtures with vinyl- and trimethylsilyl terminated polysiloxanes are shelf-stable in air. Tested catalysts do not form colloid platinum particles after the cross-linking.

Keywords: platinum nitrile complexes, hydrosilylation, cross-linking, catalysis, silicon rubber

1. Introduction

Catalytic hydrosilylation, viz. catalytic addition of silicon hydrides to multiple bonds, is among the most important reactions in the silicone industry, in particular, for hydrosilylation cross-linking of multifunctional silicone hydride polymers with multi-vinyl functional silicon polymers giving broad spectrum of the silicone compositions of superior practical importance [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28]. It is noteworthy that reported data on metal-catalyzed hydrosilylation cross-linking of vinyl polysiloxanes is substantially less abundant than those for monomeric dienes.

Hydrosilylation is in many respects relevant to hydrogenation, and it is not surprising that catalytic systems applied for hydrogenation are tested and successfully used for hydrosilylation reactions. Taking the analogy between two reactions into account, Pt- and Rh-based systems applied for various hydrogenations are usually considered as the most promising for hydrosilylation. Although a number of new catalysts for hydrosilylation of vinyl polysiloxanes have emerged in the past two decades [7,16,19,21,25], Karstedt’s complex (or its modified analogs) still remains the most widely used catalyst for cross-linking [7,21]. Its main disadvantage is hyperactivity that makes the cross-linking unselective even at room temperature (RT) and requires application of an inhibitor that, in many instances, impairs the strength characteristics of formed silicone formulations [29]. Moreover their use, in some circumstances, can be complicated by the colloidal platinum particles that form after reaction, which scatter light and which can render the silicone yellow.

Bearing in mind a great applied significance of hydrosilylation cross-linking for creation of silicone compositions, development of new efficient catalysts for these processes is always a challenging task. Besides general requirements to novel catalytic systems such as higher selectivity, tunable activity, and stability of the catalyst upon storage, the search for the new catalytic systems for the cross-linking includes design of catalysts that are shelf-stable at ambient temperature, but start to act at higher temperatures, as any premature curing would cause silicone polymers to adhere to equipment parts (e.g., rollers) requiring frequent shutdown for cleaning.

In the framework of our projects aimed, on the one hand, toward verification of catalytic properties of metal species in organic transformations (for recent works and for major reviews from our group on this topic, see Refs. [30,31,32,33,34]) On the other hand, on reactivity of platinum nitrile complexes (for recent work from our group, see Refs. [31]), we focused our attention on the possibility of applying platinum(II) nitrile species in hydrosilylation cross-linking of vinyl polysiloxanes. The starting point for this work was an intriguing study by Brook and coworkers [35], where the [PtCl2(NCC6H4C6H4OC3H6SiR3)2] complexes were employed as good catalysts for hydrosilylation of monomeric dienes. Although the isomeric configuration of these complexes was not elucidated, it was most likely trans as the synthetic scheme included prolonged heating (20 h) at elevated temperature (110 °C), i.e., harsh conditions typically yielding trans-configured nitrile PtII species [36,37,38], especially those featuring sterically encumbered ligands.

Our basic idea included application as catalysts for hydrosilylation cross-linking of vinyl polysiloxanes of nitrile platinum(II) species in cis- and trans-isomeric forms and bearing both conventional nitriles RCN (R = Alk, Ar) and the so-called push-pull nitriles [33] such as dialkylcyanamides (R = NAlk2). We found that the cis- and trans-isomeric platinum(II) complexes, viz. [PtCl2(RCN)2] (R = NMe2, N(C5H10), Ph, CH2Ph), behave as efficient and practical catalysts for silicone polymers cross-linking giving high-quality silicone rubbers. Accordingly, we aimed to (i) search for the most efficient catalytic system, verify its structure–reactivity relationships, and compare the catalytic activity of our complexes to that of Karstedt’s complex; (ii) optimize catalytic cross-linking of vinyl-terminated polydimethylsiloxane (PDMS) and trimethylsilyl-terminated poly(dimethylsiloxane-co-ethylhydrosiloxane) (EHDMS), and (iii) examine the properties of the obtained silicone rubbers.

2. Results and Discussion

2.1. Monitoring of the Cross-Linking and Catalytic Studies

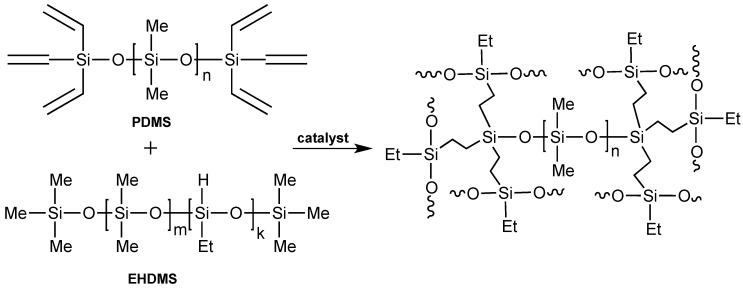

Platinum-catalyzed hydrosilylation cross-linking was studied for siloxane polymers PDMS and EHDMS (Scheme 1) at RT and at 80 °C and catalyst concentration range of 10−3−10−5 mol/L. The isomeric platinum(II) complexes featuring benzyl- and phenylcyanides and also dialkylcyanamides cis-(1−4) and trans-(1−4) (Figure 1) were examined as catalysts.

Scheme 1.

Platinum-catalyzed hydrosilylation cross-linking of siloxane polymers.

Figure 1.

Platinum complexes employed as hydrosilylation cross-linking catalysts.

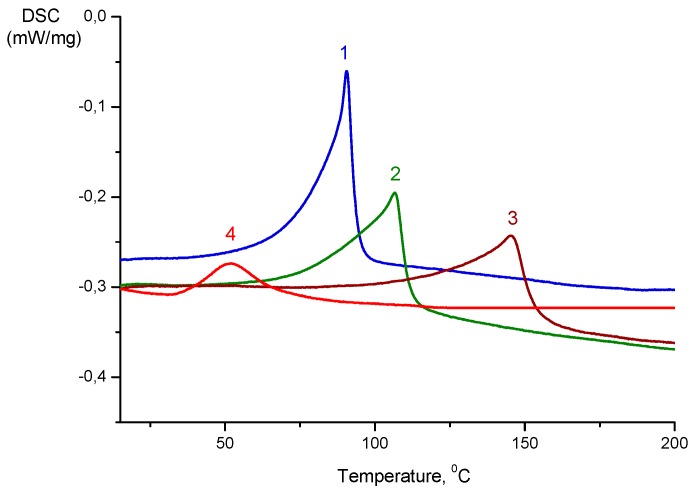

The cross-linking of PDMS and EHDMS catalyzed by any one of cis-(1−4) and trans-(1−4) was monitored by DSC and IR methods. The pot-life (τpot-life) and curing time (τcuring) determined under different experimental conditions are given in Table 1. Table 1 provides compilation of these parameters obtained under analogous conditions with variation of either concentration or temperature. All DSC curves exhibit exothermic peaks (Figure 2) indicating the reaction and/or phase transition. Temperatures onset (Tonset) and peak (Tpeak) (Table 1) are related to the beginning and the completion of the PtII-catalyzed cross-linking upon heating. In addition, EHDMS consumption was monitored by the IR method indicating gradual decrease of the ν(Si−H) band (2152 cm−1) followed by stabilization of its intensity. This stabilization corresponds well to τcuring (Table 1, Figures S1 and S2).

Table 1.

Parameters of the catalytic cross-linking of PDMS and EHDMS.

| Catalyst | сcatalyst, mol/L | τpot-life at RT, min | τcuring at RT | τcuring, min at 80 °С | DSC Data | −ΔH, J/g | ||

|---|---|---|---|---|---|---|---|---|

| Tonset, °С | Tpeak, °С | Tendset, °С | ||||||

| cis-1 | 1.0 × 10−3 | 120 | 24 h | 20 | 87.2 | 105.8 | 121.6 | 8.6 |

| cis-2 | 1.0 × 10−3 | 150 | 24 h | 10 | 82.2 | 101.8 | 118.0 | 10.1 |

| cis-3 | 1.0 × 10−3 | 120 | 20 h | 10 | 84.6 | 92.1 | 118.0 | 15.5 |

| cis-4 | 1.0 × 10−3 | 20 | 3 h | 5 | not measured | |||

| 1.0 × 10−4 | 60 | 6 h | 30 | 84.7 | 90.6 | 94.2 | 17.2 | |

| 5.0 × 10−5 | 260 | 36 h | 60 | 83.8 | 106.6 | 111.5 | 17.2 | |

| 1.0 × 10−5 | − | 30 day | 600 | 115.2 | 145.4 | 153.3 | 24.1 | |

| trans-1 | 1.0 × 10−3 | − | 30 day | 120 | 133.0 | 141.6 | 145.0 | 10.4 |

| trans-2 | 1.0 × 10−3 | − | 14 day | 80 | 126.9 | 130.3 | 133.4 | 10.7 |

| trans-3 | 1.0 × 10−3 | − | 5 day | 60 | 110.2 | 115.3 | 120.2 | 10.1 |

| trans-4 | 1.0 × 10−3 | 240 | 24 h | 15 | 98.6 | 108.8 | 115.6 | 7.6 |

| 1.0 × 10−5 | − | 20 day | 80 | 107.6 | 133.0 | 157.5 | 19.0 | |

| Karstedt’s catalyst | 1.0 × 10−4 | 0.7 | 0.1 h | − | not measured | |||

| 5.0 × 10−5 | 1.1 | 0.2 h | − | not measured | ||||

| 1.0 × 10−5 | 3 | 6 h | − | 35.4 | 51.3 | 65.9 | 4.5 | |

Figure 2.

DSC curves of the curing catalyzed by: cis-4 (1.0 × 10−4 mol/L) (1); cis-4 (5.0 × 10−5 mol/L) (2); cis-4 (1.0 × 10−5 mol/L) (3); Karstedt’s catalyst (1.0 × 10−5 mol/L) (4).

As can be inferred from inspection of the data compiled in Table 1, the most efficient catalyst among the tested platinum species is cis-4 (R = CH2Ph). When this complex is used as the catalyst at 1.0 × 10−3 mol/L, τpot-life and τcuring are 20 min and 3 h, correspondingly, whereas at 1.0 × 10−5 mol/L τcuring is 30 day. The optimized conditions for preparation of silicone rubbers is RT and c = 1.0 × 10−4 mol/L with τpot-life 60 min and τcuring 6 h. Complexes cis-1–3 as catalysts for the cross-linking at RT should be used at higher concentrations (1.0 × 10−3 mol/L) to reach reasonable values of τpot-life and τcuring.

In contrast to Karsted’s catalyst that is quite reactive at RT, and can be used upon heating only combined with inhibitors [7,21], any one of cis-(1–4) efficiently acts at 80 °C and does not require other additives. When 1.0 × 10−3 mol/L of cis-(1−3) is used at 80 °C, the τcuring does not exceed 10−20 min, and, in the case of most efficient cis-4, the cross-linking takes 1 h at the catalyst concentration 5.0 × 10−5 mol/L.

Complexes cis-1–4 during the cross-linking release higher energy (ΔH) than Karstedt’ catalyst and this collaterally implies that the number of vinyl groups involved in the cross-linking is higher upon usage of the nitrile platinum catalysts (Table 1). However, the difference should not be large as the swelling experiments (see later) indicated rather comparable soluble fraction and polymer volume fraction values for both rubbers.

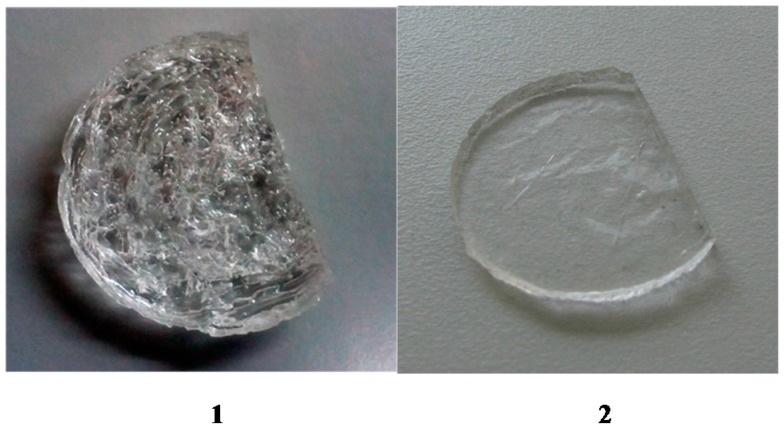

The catalytic behavior of cis-4 was compared with that of Karstedt’s catalyst (Table 1). The usage of the latter has certain disadvantages. Firstly, it must be used and stored in an inert gas atmosphere (solution in xylene, Sigma-Aldrich, St. Louis, MO, USA), without moisture, oxygen, and light. Secondly, Karstedt’s catalyst has hyperactivity that is accompanied with premature curing of vinyl-containing polysiloxanes by hydrosilylation already upon mixing the components that reflects in low values of τpot-life and τcuring. The fast cross-linking leads to the worsening in the quality of the resulting polysiloxane rubber, namely, to the formation of bubbles and other structural defects (Figure 3).

Figure 3.

Photographs of the PDMS−EHDMS rubbers obtained in the presence of Karstedt’s catalyst (1.0 × 10−5 mol/L) (1) and cis-4 (5.0 × 10−5 mol/L) (2) at RT, τcuring is 6 h and 36 h, respectively.

Thirdly, the reaction mixture persistence to early curing, as a rule, is attained by the introducing inhibitors such as, for instance, maleates, fumarates, nitriles, etc., retarding the curing [5,7,21]. However, the inhibitor introduction complicates the catalytic system. In addition, the possibilities of inhibitors are limited because, according to Ref. [29], in some cases, the strengthening properties of the obtained silicone resins are worsened. Catalyst cis-4 is free from these disadvantages as it does not require inert atmosphere and the usage of inhibitors, and it is shelf-stable.

We found that the platinum(II) nitrile complexes of the trans-configuration are much less active than their cis congeners (Table 1). Using trans-(1–4) at RT, the time of complete curing varies from 1 day to 1 month. Trans-nitrile complexes 1–4 are most effectively operate at 80 °C (Table 1, Figure S3). The curing time of PDMS and EHDMS in the presence of trans-(1–4) is 120, 80, 60, and 15 min, respectively. All studied cis-(1–4) and trans-(1–4) species are shelf-stable preserving their catalytic activity in polysiloxane solution in air for at least 30 day as confirmed by the DSC method (Figure S4).

The hydrosilylation efficiency in siloxane system in the presence of cis-(1–4) and trans-(1–4) depends on both the isomeric structure and the nature of substituents in the nitrile ligands. First of all, the catalytic activity greatly depends on the geometric structure of the complexes and, for complexes of the same composition, the cis-isomer is always more catalytically active that the trans-isomer. Among the studied cis-nitrile complexes, the catalytic activity is decreased along the following series: cis-4 (PhCH2) > cis-3 (Ph) > cis-2 (NC5H10) ≈ cis-1 (NMe2), where cis-4 exhibits substantial activity, whereas all remaining cis-species possess lower activities. It is noteworthy that the indicated consequence is approximate insofar as our bulk experiments do not take into account a possibility of the well-known cis-to-trans isomerization of the nitrile platinum(II) species [36,37,38].

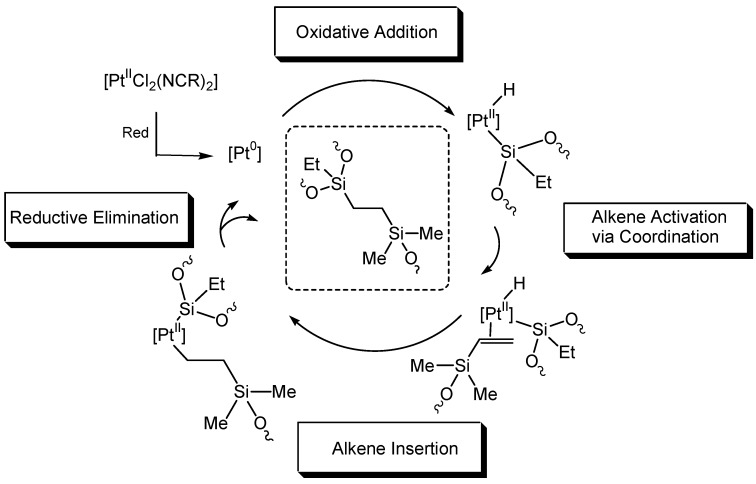

Platinum-catalyzed hydrosilylation of olefins is commonly described by the Chalk–Harrod mechanism or its modified version [7,21]. We believe that in the studied system, platinum(II) centers of the nitrile complexes are reduced by either silane- or vinyl groups to give platinum(0) species (Scheme 2) that are involved in oxidative addition with EHDMS. Vinyl groups of PDMS coordinate to the formed platinum(II) centers, undergo activation followed by their insertion into the Si–H bond. Reductive elimination with regeneration of the catalytic species terminates the process. Unfortunately, all our attempts to detect the catalytic species by high resolution electrospray ionization mass spectrometry (HRESIMS) failed due to substantial overlap of peaks from platinum species and the polymeric system.

Scheme 2.

Plausible mechanism of the cross-linking.

2.2. Properties of the Silicone Rubbers

In contrast to rubbers obtained with Karstedt’s catalyst, our PDMS-EHDMS silicone formulations bear no bubbles or other structural defects (Figure 3), and their surface is homogeneous and transparent. They can be stored in the light and in air for at least one year without visible changes. The rubbers were analyzed by DSC and TG methods, and we also performed swelling measurements. In addition, their dynamic characteristics and elastic properties were studied by the dynamic mechanical analysis DMA method and by conducting tensile tests, respectively. All our results are consistently disclosed in paragraphs that follow.

Silicone rubber obtained with cis-4 or with Karstedt’s catalyst are characterized by approximately equal melting (ca. −40 °C) and crystallization (ca. −70 °C) temperatures, and the melting (−25 J/g) and crystallization (−22 J/g) enthalpies (Figure S5). These results indicate that the nitrile platinum catalysts do not affect the phase transitions upon both heating and cooling of the obtained siloxane rubbers.

In the TG curves, the temperature of the initial weight loss of the silicone rubber obtained with cis-4 under argon and in air increases by (80−90) and (30−40) °C, respectively, to these TG data obtained for Karstedt’s catalyst (Figures S6 and S7). Final residues of the silicone rubbers obtained with cis-4 and Karstedt’s catalyst (both at 1.0 × 10−5 mol/L) remaining after heating the samples up to 800 °C are ca. 80% and 40% [under argon] or ca. 70% and 55% [in air], respectively. These TG data indicate that the usage of cis-4 improves thermal stability and flame (fire) retardancy of rubbers compared with those obtained with Karstedt’s catalyst. Weight loss shifts to a higher temperature both in argon and in air. The mechanism of thermal degradation of silicone rubbers was previously described [39,40].

Swelling measurements give information about soluble fraction (wsol) and polymer volume fraction (υ). The optimal networks formed at smaller soluble fraction and minimum swelling in good solvent (toluene is a good solvent for PDMS). As expected, there is a close correlation between the values of wsol and υ. The smaller wsol and the greater υ are for each series of networks [41,42,43]: wsol are 5.8% and 5.1% and υ are 0.21 and 0.22 in the presence of cis-4 (1.0 × 10−5 mol/L) and Karstedt’s catalyst (1.0 × 10−5 mol/L), respectively. The difference in values of the swelling experiments in the presence of cis-4 and Karstedt’s catalyst is not substantial. More complete information about cross-linking process gives ΔH of the process (see above).

Inspection of the dynamic characteristics of the siloxane rubbers obtained with cis-4 (1.0 × 10−5 mol/L) indicates that the temperature is lowered, a sharp increase in the elastic modulus E', and the passage through the highs tangent of loss angle, indicating crystallization study of siloxane rubbers [44]. Upon further cooling, the amorphous phase becomes vitrified state, but difficult fixation of this transition high crystallinity of the samples. When heated, the process is reversed. Noteworthy that the highest value of the elastic modulus are characteristic of the sample that was obtained with cis-4 (E′ 2.5 MPa at RT) and the lowest for the Karstedt’s catalyst (E′ 0.4 MPa at RT). We assume that, in the presence of cis-4, more cross-linked sample bearing less network defects is obtained.

Elastic properties of our silicon rubbers have a relatively high elongation at break (L) and tensile strength (σ), but relatively little residual elongation (Δl) compared to the rubbers obtained with Karstedt’s catalyst. The σ values are 0.25 and 0.22 MPa, L are 235% and 170%, Δl are 5% and 10% in the presence of cis-4 (1.0 × 10−5 mol/L) and Karstedt’s catalyst (1.0 × 10−5 mol/L), respectively.

3. Experimental Section

3.1. Materials and Instrumentation

Solvents were obtained from commercial sources and used as received. Complexes cis- and trans-(1–4) were prepared as previously reported [45,46,47]. The chemicals for evaluation of catalytic activity of 1–4 were obtained from the following sources, viz. 0.1 M Karstedt’s catalyst in vinyl terminated polydimethylsiloxane (Aldrich); trivinyl terminated polydimethylsiloxane (PDMS; the weight average molecular weight Mw = 80000, the number average molecular weight Mn = 33800, 0.5 wt % of CH=CH2) and trimethylsilyl terminated poly(dimethylsiloxane-co-ethylhydrosiloxane) (EHDMS; the weight average molecular weight Mw = 8150, the number average molecular weight Mn = 4600, 0.7 wt % of Si–H) from FSUE NIISK, Saint Petersburg, Russian Federation.

The progress of the cross-linking was monitored by (i) DSC method using a NETZSCH DSC 204F1 Phoenix instrument (Naperville, IL, USA). DSC conditions are as the following: cooling from 25 to −10 °C, heating from −10 to 220 °C, and then cooling from 250 to 25 °C (10 °C/min); all components were mixed before DSC studies and DSC experiments were conducted twice for each test; (ii) IR method using Shimadzu FTIR-8400S instrument (Kyoto, Japan) at RT.

DSC of cured materials was performed at a NETZSCH DSC 204F1 Phoenix instrument: cooling from 25 to −100 °C, heating from −100 to 50 °C at 5 °C/min under argon and in air. DSC experiments were repeated twice for each test. TG measurements were performed on a NETZSCH TG 209F1 Libra instrument (Burlington, MA, USA); 2 mg of sample was taken in a platinum pan that was then heated from RT to 900 °C at 10 °C/min under a flow of argon (50 mL/min) or in air.

Dynamical mechanical analysis was performed on NETZSCH DMA 242C. Sample characteristics: length 5 mm, width 12 mm, height 2 mm. DMA conditions: cooling from 25 to −150 °C, heating from −150 to 50 °C at 5 °C/min and 1 Hz in air. Tensile tests were performed on Zwick Proline Z005 (Ulm, Germany) tensile testing machine. Tensile tests followed ISO 34, these experiments were carried out five times for each test.

3.2. Catalytic Studies

3.2.1. Catalytic Tests in Polymeric Systems

The cross-linking was studied in a system consisting of PDMS and EHDMS as cross-linking partners and a platinum catalyst, viz. any of one cis- and trans-(1−4) or Karstedt’s catalyst taken for comparison, at 23 or at 80 °C. A ratio Si‒H:CH2=CH2 is 3:1. The standard formulation had [part A]:[part B] = 1:1 ratio; concentration of 1−4 was 1.0 × 10−3−1.0 × 10−5 mol/L. [Part A]: calculated amounts of 1−4 (diluted in CH2Cl2) were added to PDMS, the mixture was carefully stirred and dried under vacuum at 30 °C overnight to remove the solvent. Karsted’s catalyst dissolved in vinyl-terminated polydimethylsiloxane was added to PDMS without drying in a vacuum. [Part B]: EHDMS (10 g) was added to PDMS (50 g) and this mixture was carefully stirred for homogenization ([−CH=CH2]/[≡Si−H] = 1:3).

3.2.2. General Procedure of Curing Time and Pot-Life Determination

The cross-linking process of the polysiloxanes mixture was performed in an aluminum vessel. The pot-life time was measured from the point of mixing equal amounts of Parts A and B before the viscosity of the initial mixture increases to an unusable level at RT [30]. Typically, the pot-life is defined as the time when viscosity of catalyzed mixture is doubled. The curing time was measured from the point of mixing equal amounts of Parts A and B at RT or from the moment of placing the aluminum vessel with equal amounts of Parts A and B mixture to a desiccator at 80 °C until liquid reaction mixture getting dry cured material.

3.2.3. Swelling Measurements

A typical sample of obtained PDMS‒EHDMS with platinum catalyst rubber (0.1 g, cylindrical disk of 10 mm diameter and 1 mm thickness) was weighted for evaluating the initial dry weight (munex), swollen by Soxhlet extractor for one day, and then plunged in toluene (50 mL) in a sealed bottle for 2 h in the dark. The sample was extracted, gently wiped to remove liquid solvent present on the sample surface and immediately weighted (ms). The sample was then dried overnight at RT and then 2 h at 60 °C under vacuum and reweighted (mex). Soluble fraction (wsol) and volume fraction of polymer in the swollen sample (υ) are calculated as follows:

| (1) |

| (2) |

where ρs and ρp are the solvent (toluene, 0.865 g/cm3) and polymer (PDMS, 0.965 g/cm3) densities, respectively. Swelling experiments were carried out five times for each test.

IR data of the cross-linking, structure-activity relationships of trans-(1–4), stability of cis-4 in polysiloxane solution in air, DSC fata for silicone rubbers, and TG measurements are given in Supplementary Materials.

4. Conclusions

The results of this work could be considered from at least three perspectives. Firstly, in the field of catalysis, we observed that isomeric platinum(II) complexes featuring benzyl- and phenylcyanides and also dialkylcyanamides, cis- and trans-(1–4), behave as efficient catalysts for the cross-linking of vinyl terminated polydimethylsiloxane and trimethylsilyl terminated poly(dimethylsiloxane-co-ethylhydrosiloxane). Among the tested platinum species, cis-complexes are much more active catalysts than their trans-congeners and, for all tested complexes, cis-[PtCl2(NCCH2Ph)2] (cis-4) exhibit the best catalytic activity.

Secondly, although cis-4 is less active than the widely used Karstedt’s catalyst, its application for the cross-linking can be performed not only at RT (c = 1.0 × 10−4 mol/L), but also, more efficiently, at 80 °C (c = 1.0 × 10−4−1.0 × 10−5 mol/L), which is crucial for some industrial applications. The cross-linking involving the nitrile PtII complexes as the catalysts can be conducted without inhibitors and, moreover, the nitrile platinum species and their mixtures with vinyl- and trimethylsilyl terminated polysiloxanes are shelf-stable in air and all these properties provide further benefits. In addition, our catalysts visually do not form colloid platinum particles after the cross-linking.

Recently, we reported that shelf-stable and moisture/air insensitive platinum(II) imino complexes—obtained by a click-type coupling between a hydroxyguanidine and (nitrile)PtII species—catalyze hydrosilylation cross-linking of vinyl terminated poly(dimethylsiloxane) and trimethylsilyl terminated poly(dimethylsiloxane-co-ethylhydrosiloxane) giving (in air and at 50 °C) high quality thermally stable silicon resins [30]. Comparison of the previous [30] and current catalytic systems indicate that the latter suggest more benefits. Indeed, in contrast to the previously reported catalysts, the current catalytic system (in particular, cis-4) operates at a substantially wider temperature range (25–80 °C) and the obtained silicone formulations are more thermally stable (by ca. 30 °C) and their dynamic characteristics are substantially better, viz. E′ is six times higher.

Thirdly, in the area of silicon polymer chemistry, in contrast to rubbers obtained with Karstedt’s catalyst, PDMS-EHDMS silicone formulations obtained with any one of cis-(1–4) bear no bubbles or other structural defects, and their surface is homogeneous and transparent. These rubbers can be stored in the light and in air for at least one year without visible changes. The application of cis-4 for the cross-linking largely improves thermal stability and flame (fire) retardancy of the silicone rubber compared with those generated with Karstedt’s catalyst. Our data indicate the formation of networks with significantly fewer defects (i.e., unreacted vinyl and hydride groups) and higher cross-linking density in the presence of the nitrile platinum species unlike Karstedt’s catalyst.

Acknowledgments

This project was supported by Federal Target Program (grant 14.576.21.0028). Andrey V. Vlasov and Vadim Yu. Kukushkin are much obliged to Saint Petersburg State University for a postdoctoral fellowship (12.50.1188.2014) and research grant (12.38.225.2014), correspondingly. The authors also express their gratitude to the Center of Thermal Analysis and Calorimetry (Saint Petersburg State University) for physicochemical measurements.

Supplementary Materials

Supplementary materials can be accessed at: http://www.mdpi.com/1420-3049/21/3/311/s1.

Author Contributions

Mikhail V. Dobrynin, Daniil M. Ivanov, Andrey V. Vlasov, Elena V. Kaganova, and Galina V. Grigoryan performed syntheses of the platinum complexes, conducted the catalytic studies, and studied the properties of the silicone formulations. Regina M. Islamova and Vadim Yu. Kukushkin analyzed the obtained data and wrote the manuscript. All authors read and approved the final manuscript.

Conflicts of Interest

The authors declare that they have no conflict of interests.

Footnotes

Sample Availability: Samples of cis- and trans-(1–4), as well as all silicone formulations are available from the authors.

References

- 1.Murai T., Nagaya E., Shibahara F., Maruyama T., Nakazawa H. Rhodium(I) and Iridium(I) Imidazo[1,5-a]pyridine-1-ylalkylalkoxy Complexes: Synthesis, Characterization and Application as Catalysts for Hydrosilylation of Alkynes. J. Organomet. Chem. 2015;794:76–80. doi: 10.1016/j.jorganchem.2015.05.045. [DOI] [Google Scholar]

- 2.Nakajima Y., Shimada S. Hydrosilylation Reaction of Olefins: Recent Advances and Perspectives. RSC Adv. 2015;5:20603–20616. doi: 10.1039/C4RA17281G. [DOI] [Google Scholar]

- 3.Munz D., Allolio C., Meyer D., Micksch M., Roessner L., Strassner T. Oligoether Substituted bis-NHC Palladium and Platinum Complexes for Aqueous Suzuki–Miyaura Coupling and Hydrosilylation. J. Organomet. Chem. 2015;794:330–335. doi: 10.1016/j.jorganchem.2015.03.027. [DOI] [Google Scholar]

- 4.Srinivas V., Nakajima Y., Ando W., Sato K., Shimada S. (Salicylaldiminato)Ni(II)-catalysts for Hydrosilylation of Olefins. Catal. Sci. Technol. 2015;5:2081–2084. doi: 10.1039/C5CY00270B. [DOI] [Google Scholar]

- 5.Zeng X. Recent Advances in Catalytic Sequential Reactions Involving Hydroelement Addition to Carbon–Carbon Multiple Bonds. Chem. Rev. 2013;113:6864–6900. doi: 10.1021/cr400082n. [DOI] [PubMed] [Google Scholar]

- 6.Pagliaro M., Ciriminna R., Pandarus V., Béland F. Platinum-Based Heterogeneously Catalyzed Hydrosilylation. European J. Org. Chem. 2013;2013:6227–6235. doi: 10.1002/ejoc.201300290. [DOI] [Google Scholar]

- 7.Troegel D., Stohrer J. Recent Advances and Actual Challenges in Late Transition Metal Catalyzed Hydrosilylation of Olefins from an Industrial Point of View. Coord. Chem. Rev. 2011;255:1440–1459. doi: 10.1016/j.ccr.2010.12.025. [DOI] [Google Scholar]

- 8.Roy A.K. A Review of Recent Progress in Catalyzed Homogeneous Hydrosilation (Hydrosilylation) In: Robert W., Hill A., Fink J.M., editors. Advances in Organometallic Chemistry. Volume 55. Academic Press; Cambridge, MA, USA: 2007. pp. 1–59. [Google Scholar]

- 9.Ojima I., Li Z., Zhu J. The Chemistry of Organic Silicon Compounds. Volume 2. John Wiley & Sons, Ltd.; Chichester, UK: 2003. Recent Advances in the Hydrosilylation and Related Reactions; pp. 1687–1792. [Google Scholar]

- 10.Kishi K., Ishimaru T., Ozono M., Tomita I., Endo T. Development and Application of Latent Hydrosilylation Catalyst [6]: Control of Activity of Platinum Catalyst by Isocyanide Derivatives on the Crosslinking of Silicone Resin via Hydrosilylation. Int. J. Adhes. Adhes. 2000;20:253–256. doi: 10.1016/S0143-7496(99)00050-0. [DOI] [Google Scholar]

- 11.Liu L., Li X., Dong H., Wu C. Hydrosilylation Reaction of Ethylene with Triethoxysilane Catalyzed by Ruthenium Halides and Promoted by Cuprous Halides. J. Organomet. Chem. 2013;745:454–459. doi: 10.1016/j.jorganchem.2013.07.024. [DOI] [Google Scholar]

- 12.Sakaki S., Mizoe N., Sugimoto M., Musashi Y. Pt-Catalyzed Hydrosilylation of Ethylene. A Theoretical Study of the Reaction Mechanism. Coord. Chem. Rev. 1999;190:933–960. doi: 10.1016/S0010-8545(99)00130-7. [DOI] [Google Scholar]

- 13.Brook M.A., Ketelson H.A., LaRonde F.J., Pelton R. Pt0 Compounds Bound in a Silsesquioxane Layer: Active Hydrosilation Catalysts Protected by the Gel. Inorg. Chim. Acta. 1997;264:125–135. doi: 10.1016/S0020-1693(97)05678-8. [DOI] [Google Scholar]

- 14.Marciniec B., Kownacka A., Kownacki I., Hoffmann M., Taylor R. Hydrosilylation vs. Dehydrogenative Silylation of Styrene Catalysed by Iron(0) Carbonyl Complexes with Multivinylsilicon Ligands—Mechanistic Implications. J. Organomet. Chem. 2015;791:58–65. doi: 10.1016/j.jorganchem.2015.04.051. [DOI] [Google Scholar]

- 15.Szubert K., Marciniec B., Dutkiewicz M., Potrzebowski M.J., Maciejewski H. Functionalization of Spherosilicates via Hydrosilylation Catalyzed by Well-defined Rhodium Siloxide Complexes Immobilized on Silica. J. Mol. Catal. A Chem. 2014;391:150–157. doi: 10.1016/j.molcata.2014.04.014. [DOI] [Google Scholar]

- 16.Marciniec B., Kownacka A., Kownacki I., Taylor R. Hydrosilylation Cross-linking of Silicon Fluids by a Novel Class of Iron(0) Catalysts. Appl. Catal. A Gen. 2014;486:230–238. doi: 10.1016/j.apcata.2014.08.037. [DOI] [Google Scholar]

- 17.Wawrzyńczak A., Dutkiewicz M., Guliński J., Maciejewski H., Marciniec B., Fiedorow R. Hydrosilylation of n-Alkenes and Allyl Chloride Over Platinum Supported on Styrene–Divinylbenzene Copolymer. Catal. Today. 2011;169:69–74. doi: 10.1016/j.cattod.2010.11.079. [DOI] [Google Scholar]

- 18.Marciniec B., Rogalski S., Potrzebowski M.J., Pietraszuk C. Ruthenium Carbene Siloxide Complexes Immobilized on Silica: Synthesis and Catalytic Activity in Olefin Metathesis. ChemCatChem. 2011;3:904–910. doi: 10.1002/cctc.201000376. [DOI] [Google Scholar]

- 19.Kownacki I., Marciniec B., Szubert K., Kubicki M., Jankowska M., Steinberger H., Rubinsztajn S. Tris(triorganosilyl)phosphites—New Ligands Controlling Catalytic Activity of Pt(0) Complex in Curing of Silicone Rubber. Appl. Catal. A Gen. 2010;380:105–112. doi: 10.1016/j.apcata.2010.03.041. [DOI] [Google Scholar]

- 20.Marciniec B., Szubert K., Potrzebowski M.J., Kownacki I., Maciejewski H. Catalysis of Hydrosilylation by Well-Defined Surface Rhodium Siloxide Phosphine Complexes. ChemCatChem. 2009;1:304–310. doi: 10.1002/cctc.200900111. [DOI] [Google Scholar]

- 21.Marciniec B. Hydrosilylation: A Comprehensive Review on Recent Advances. Springer Science & Business Media; Dordrecht, The Netherlands: 2009. pp. 176–177. [Google Scholar]

- 22.Maciejewski H., Szubert K., Marciniec B., Pernak J. Hydrosilylation of Functionalised Olefins Catalysed by Rhodium Siloxide Complexes in Ionic Liquids. Green Chem. 2009;11:1045. doi: 10.1039/b819310j. [DOI] [Google Scholar]

- 23.Kownacki I., Marciniec B., Macina A., Rubinsztajn S., Lamb D. Catalytic Activity of Iridium Siloxide Complexes in Cross-linking of Silicones by Hydrosilylation. Appl. Catal. A Gen. 2007;317:53–57. doi: 10.1016/j.apcata.2006.09.037. [DOI] [Google Scholar]

- 24.Marciniec B., Błażejewska-Chadyniak P., Kubicki M. Synthesis, First Structures, and Catalytic Activity of the Monomeric Rhodium(I)-Siloxide Phosphine Complexes. Can. J. Chem. 2003;81:1292–1298. doi: 10.1139/v03-145. [DOI] [Google Scholar]

- 25.Marciniec B., Maciejewski H. Transition Metal-Siloxide complexes; Synthesis, Structure and Application to Catalysis. Coord. Chem. Rev. 2001;223:301–335. doi: 10.1016/S0010-8545(01)00400-3. [DOI] [Google Scholar]

- 26.Marciniec B., Krzyzanowski P., Walczuk-Gusciora E., Duczmal W. Catalytic Activity of Silyloxy-Rhodium(I) Complexes in Hydrosilylation of Alkenes. J. Mol. Catal. A Chem. 1999;144:263–271. doi: 10.1016/S1381-1169(99)00109-0. [DOI] [Google Scholar]

- 27.Marciniec B., Gulinski J., Kopylova L., Maciejewski H., Grundwald-Wyspianska M., Lewandowski M. Catalysis of Hydrosilylation: Part XXXI. Functionalization of Poly(methylhydro)siloxanes via Hydrosilylation of Allyl Derivatives. Appl. Organomet. Chem. 1997;11:843–849. doi: 10.1002/(SICI)1099-0739(199710/11)11:10/11<843::AID-AOC647>3.0.CO;2-F. [DOI] [Google Scholar]

- 28.Guliński J., James B.R., Marciniec B. The Role of Dioxygen in Hydrosilylation of Alkenes Catalyzed by Ruthenium Phosphine Complexes. J. Organomet. Chem. 1995;499:173–179. doi: 10.1016/0022-328X(95)00331-J. [DOI] [Google Scholar]

- 29.Gorshkov A.V. Vulcanization of High-molecular Weight Silicone Rubber with Polyfunctional Organosilicon Compounds. Kauchuk i Rezina. 1989;6:36–42. [Google Scholar]

- 30.Demakova M.Ya., Bolotin D.S., Bokach N.A., Islamova R.M., Starova G.L., Kukushkin V.Yu. Click-Type PtII-Mediated Hydroxyguanidine–Nitrile Coupling Provides Useful Catalysts for Hydrosilylation Cross-Linking. ChemPlusChem. 2015;80:1607–1614. doi: 10.1002/cplu.201500327. [DOI] [PubMed] [Google Scholar]

- 31.Bolotin D.S., Demakova M.Y., Novikov A.S., Avdontceva M.S., Kuznetsov M.L., Bokach N.A., Kukushkin V.Yu. Bifunctional Reactivity of Amidoximes Observed upon Nucleophilic Addition to Metal-Activated Nitriles. Inorg. Chem. 2015;54:4039–4046. doi: 10.1021/acs.inorgchem.5b00253. [DOI] [PubMed] [Google Scholar]

- 32.Boyarskiy V.P., Bokach N.A., Luzyanin K.V., Kukushkin V.Yu. Metal-Mediated and Metal-Catalyzed Reactions of Isocyanides. Chem. Rev. 2015;115:2698–2779. doi: 10.1021/cr500380d. [DOI] [PubMed] [Google Scholar]

- 33.Bokach N.A., Kukushkin V.Yu. Coordination Chemistry of Dialkylcyanamides: Binding Properties, Synthesis of Metal Complexes, and Ligand Reactivity. Coord. Chem. Rev. 2013;257:2293–2316. doi: 10.1016/j.ccr.2013.03.002. [DOI] [Google Scholar]

- 34.Islamova R.M., Monakov Y.B. Metal-complex Compounds as Components of Initiating Systems for the Controlled Radical Polymerization of Vinyl Monomers. Polym. Sci. Ser. C. 2011;53:27–34. doi: 10.1134/S1811238211060026. [DOI] [Google Scholar]

- 35.Amako M., Schinkel J., Freiburger L., Brook M.A. Siloxane-supported Organometallic Compounds and their Catalytic Activities for the Hydrosilylation of Vinylsilanes and Dienes. Dalton Trans. 2005:74–81. doi: 10.1039/b411123k. [DOI] [PubMed] [Google Scholar]

- 36.Kukushkin V.Yu. New Starting Materials in Platinum(II) Chemistry. Platin. Met. Rev. 1998;42:106–107. [Google Scholar]

- 37.Kukushkin V.Yu., Tkachuk V.M. Synthesis, Thermal Isomerization in Solution and in Solid Phase of the Complexes [Pt(RCN)2Cl2] Z. Anorg. Allg. Chem. 1992;613:123–126. doi: 10.1002/zaac.19926130122. [DOI] [Google Scholar]

- 38.Svensson P., Lövqvist K., Kukushkin V.Yu., Oskarsson Å. Thermal Cis to Trans Isomerization of [PtCl2(C2H5CN)2] and Crystal Structures of the cis- and trans-Isomers. Acta Chem. Scand. 1995;49:72–75. doi: 10.3891/acta.chem.scand.49-0072. [DOI] [Google Scholar]

- 39.Hamdani S., Longuet C., Perrin D., Lopez-Cuesta J.-M., Ganachaud F. Flame Retardancy of Silicone-based Materials. Polym. Degrad. Stab. 2009;94:465–495. doi: 10.1016/j.polymdegradstab.2008.11.019. [DOI] [Google Scholar]

- 40.Delebecq E., Hamdani-Devarennes S., Raeke J., Lopez Cuesta J.-M., Ganachaud F. High Residue Contents Indebted by Platinum and Silica Synergistic Action during the Pyrolysis of Silicone Formulations. ACS Appl. Mater. Interfaces. 2011;3:869–880. doi: 10.1021/am101216y. [DOI] [PubMed] [Google Scholar]

- 41.Takeuchi H., Cohen C. Reinforcement of Poly(dimethylsiloxane) Elastomers by Chain-End Anchoring to Clay Particles. Macromolecules. 1999;32:6792–6799. doi: 10.1021/ma990218+. [DOI] [Google Scholar]

- 42.Delebecq E., Ganachaud F. Looking over Liquid Silicone Rubbers: (1) Network Topology vs Chemical Formulations. ACS Appl. Mater. Interfaces. 2012;4:3340–3352. doi: 10.1021/am300502r. [DOI] [PubMed] [Google Scholar]

- 43.Stafie N., Stamatialis D.F., Wessling M. Effect of PDMS Cross-linking Degree on the Permeation Performance of PAN/PDMS Composite Nanofiltration Membranes. Sep. Purif. Technol. 2005;45:220–231. doi: 10.1016/j.seppur.2005.04.001. [DOI] [Google Scholar]

- 44.Delebecq E., Hermeline N., Flers A., Ganachaud F. Looking over Liquid Silicone Rubbers: (2) Mechanical Properties vs Network Topology. ACS Appl. Mater. Interfaces. 2012;4:3353–3363. doi: 10.1021/am300503j. [DOI] [PubMed] [Google Scholar]

- 45.Bokach N.A., Pakhomova T.B., Kukushkin V.Yu., Haukka M., Pombeiro A.J.L. Hydrolytic Metal-Mediated Coupling of Dialkylcyanamides at a Pt(IV) Center Giving a New Family of Diimino Ligands. Inorg. Chem. 2003;42:7560–7568. doi: 10.1021/ic034800x. [DOI] [PubMed] [Google Scholar]

- 46.Kukushkin V.Yu., Pakhomova T.B., Kukushkin Yu.N., Herrmann R., Wagner G., Pombeiro A.J.L. Iminoacylation. 1. Addition of Ketoximes or Aldoximes to Platinum(IV)-Bound Organonitriles. Inorg. Chem. 1998;37:6511–6517. doi: 10.1021/ic9807745. [DOI] [PubMed] [Google Scholar]

- 47.Uchiyama T., Toshiyasu Y., Nakamura Y., Miwa T., Kawaguchi S. The Isolation, Characterization, and Isomerization of cis- and trans-Bis(benzonitrile)dichloroplatinum(II) Bull. Chem. Soc. Jpn. 1981;54:181–185. doi: 10.1246/bcsj.54.181. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.