Abstract

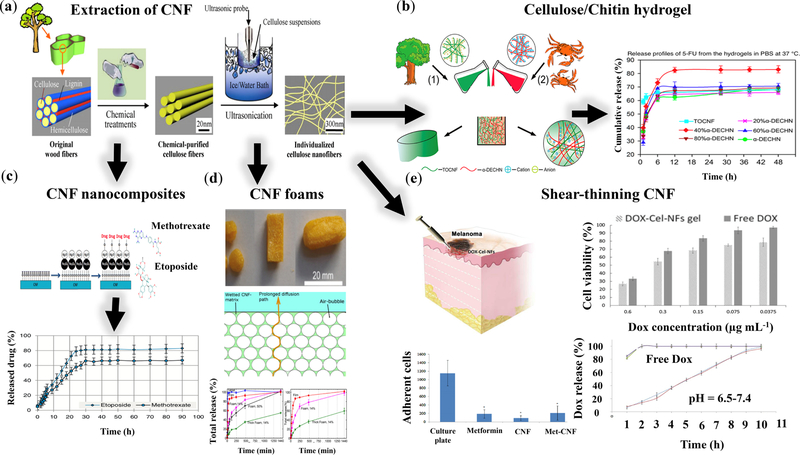

The recent decade has witnessed a growing demand to substitute synthetic materials with naturally-derived platforms for minimizing their undesirable footprints in biomedicine, environment, and ecosystems. Among the natural materials, cellulose, the most abundant biopolymer in the world with key properties, such as biocompatibility, biorenewability, and sustainability has drawn significant attention. The hierarchical structure of cellulose fibers, one of the main constituents of plant cell walls, has been nanoengineered and broken down to nanoscale building blocks, providing an infrastructure for nanomedicine. Microorganisms, such as certain types of bacteria, are another source of nanocelluloses known as bacterial nanocellulose (BNC), which benefit from high purity and crystallinity. Chemical and mechanical treatments of cellulose fibrils made up of alternating crystalline and amorphous regions have yielded cellulose nanocrystals (CNC), hairy CNC (HCNC), and cellulose nanofibrils (CNF) with dimensions spanning from a few nanometers up to several microns. Cellulose nanocrystals and nanofibrils may readily bind drugs, proteins, and nanoparticles through physical interactions or be chemically modified to covalently accommodate cargos. Engineering surface properties, such as chemical functionality, charge, area, crystallinity, and hydrophilicity, plays a pivotal role in controlling the cargo loading/releasing capacity and rate, stability, toxicity, immunogenicity, and biodegradation of nanocellulose-based delivery platforms. This review provides insights into the recent advances in nanoengineering cellulose crystals and fibrils to develop vehicles, encompassing colloidal nanoparticles, hydrogels, aerogels, films, coatings, capsules, and membranes, for the delivery of a broad range of bioactive cargos, such as chemotherapeutic drugs, anti-inflammatory agents, antibacterial compounds, and probiotics.

Keywords: Nanocellulose, cellulose nanocrystals, hairy nanocellulose, bacterial cellulose, cellulose nanofibrils, drug delivery, wound healing, cancer therapy

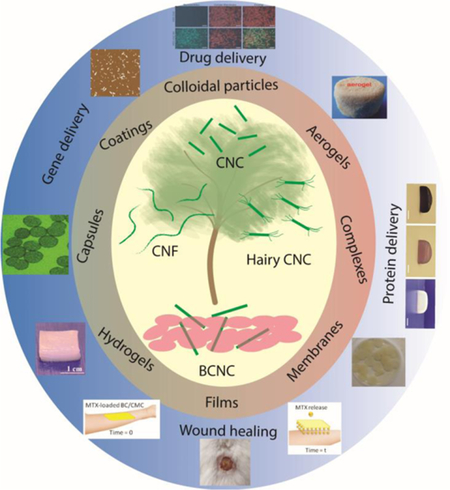

Graphical Abstract

Introduction

Cellulose is the most abundant biopolymer in the world, which is made up of linear glucose rings connected to each other through β(1 → 4) glycosidic bonds [1]. Bengt G. Rånby, whose early observations in 1951 pioneered the field of nanocelluloses [2], noted that the strong acid treatment of cellulose fibers almost always resulted in the formation of nanoscale needle-like colloidal particles (initially called micelles). The breakdown of cellulose fibers into dispersed nanowhiskers with width ~ 7 nm and varying length based on the degree of polymerization provides an indirect evidence for heterogeneity and the hierarchical structure of cellulose fibrils. This observation attests to the coexistence of regions prone to acid-mediated hydrolysis and regions resistant against the chemical modification. Later, this was attributed to the difference in crystallinity along the cellulose fibrils made up of alternating regions of crystalline and amorphous (disordered) regions [3]. The crystalline regions are difficult to penetrate; therefore, the reactants can only modify its surface, eventually resulting in the dissolution of the outer layer, whereas the amorphous layers are readily accessible [4] for facile chemical modification [5–9].

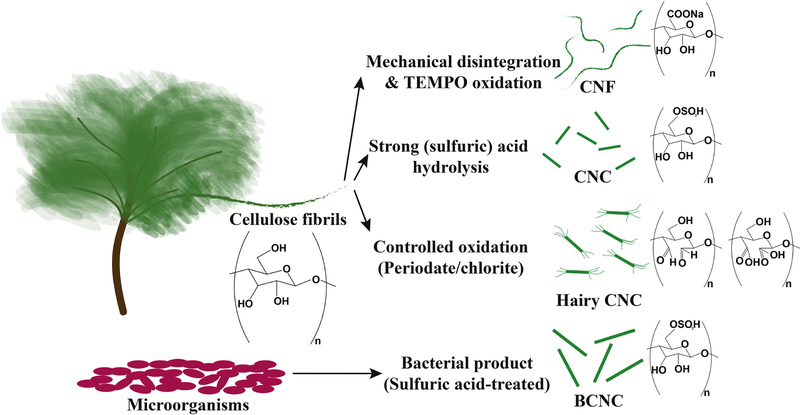

Nanocelluloses may be categorized into four main groups: cellulose nanofibrils (CNF), cellulose nanocrystals (CNC), hairy CNCs (HCNC), and bacterial CNCs (BCNC). Cellulose fibers undergoing rigorous mechanical shear experience defibrillation, yielding nanoscale fibrils with dimensions in the range of several nanometers in diameter and up to tens of microns in length, named cellulose nanofibrils [10–13]. Chemical modification of amorphous chains may be conducted through strong acid hydrolysis to remove the amorphous regions, resulting in CNC with width ~3–70 nm (typically less than 10 nm) and length ~ 25–500 nm (typically between 100200 nm) regulated by the fiber source [7]. The structure of CNF resembles spaghetti with a higher aspect ratio than rice grain-like CNCs. Recently, hairy cellulose nanocrystals have been produced by oxidizing and solubilizing the amorphous regions of fibrils. Periodate oxidation of fibers yields dialdehyde-modified cellulose fibrils, which can be heated at 50 ºC to increase the solubility of modified amorphous biopolymers. The disintegration of these fibrils into CNCs sandwiched between two layers of protruding dialdehyde cellulose chains yields neutral hairy cellulose nanocrystals, also known as sterically-stabilized cellulose nanocrystals. In another scenario, when the dialdehyde-modified cellulose fibrils are further oxidized with chlorite at room temperature, the fibrils readily fall apart in the solution, yielding CNCs attached to highly dicarboxylated protruding cellulose chains at both ends. This family of nanocelluloses has been named anionic hairy cellulose nanocrystals or electrosterically stabilized cellulose nanocrystals [8,9]. Another type of cellulose named bacterial cellulose (BC) is produced by organisms, such as bacteria [14,15]. BC is typically produced as fibers, which may chemically be treated by strong acids and disintegrated into nanocrystals known as bacterial CNC [16]. BC typically attains a high degree of crystallinity and longer crystalline body than conventional CNCs produced from wood fibers. Figure 1 summarizes nanocelluloses and their common synthesis methods.

Figure 1.

Nanocelluloses and examples of their production methods. Plants and microorganisms are two main sources of cellulose. Cellulose fibrils (often chemically pre-treated, e.g., with TEMPO) are disintegrated into nanoscale fibrils, named cellulose nanofibrils (CNF) through rigorous mechanical processing (such as microfluidization and high-pressure homogenization) [13]. When cellulose fibrils are treated with a strong acid, such as sulfuric acid, the amorphous regions of fibrils are hydrolyzed, yielding needle-shaped crystals known as cellulose nanocrystals (CNC) [17]. Moreover, instead of removing amorphous regions, when they are solubilized through oxidation, cellulose fibrils fall apart into CNCs sandwiched between two protruding layers of functionalized cellulose chains. This class of newly emerged nanocelluloses is called hairy CNCs [8,9,18]. Some microorganisms, such as bacteria Acetobacter xylinum, also produce cellulose with a high purity, which may further be processed with a strong acid to yield bacterial CNCs (BCNC) [14,16]. Note that other sources of nanocelluloses are tunicates and algae [19].

Nanocelluloses play promising roles in a broad range of applications [20,21], spanning from water treatment [22–24], environment and energy [25–27], catalysis [28], optics and photonics [29–31], sensing and biosensing [32], and biomedicine [33–38]. There was a limited literature on cellulose-based nanomedicine before 2014, which mainly focused on nanocellulose- and dissolved cellulose-base colloidal dispersions, colloidal hydrogels, and films for binding various types of molecules, such as chemotherapeutic agents to decrease their diffusion rate. Small-scale structural features of nanocelluloses have been the focus of research for developing drug delivery systems. In addition, biocompatibility and cytotoxicity [39] have sometimes been evaluated when new combinations of molecules have been added to nanocelluloses.

Here, we focus on the state-of-the-art nanocellulose-based cargo delivery systems, which have mainly emerged since 2014. The articles before 2014 are briefly summarized in each section, and relevant review papers are highlighted to provide a brief overview on the early cellulose-based nanomedicine research. We thoroughly review the recent advances in the synthesis, fabrication, and functionalization of biomaterials based on cellulose nanocrystals (non-hairy and hairy), bacterial cellulose, and cellulose nanofibrils for the delivery of a wide range of cargos, such as drugs, proteins, and antimicrobial agents and highlight various forms of nanocellulose-based delivery systems, including hydrogels, films, and aerogels. This paper provides a comprehensive review with a forward-looking approach on the nanocellulose-mediated cargo delivery platforms for nanomedicine, which have emerged in the past four years.

1. Nanocellulose properties

Physical, mechanical, chemical, and biological properties of nanocelluloses have been thoroughly reviewed in the literature. Here, we briefly explain the main characteristics of nanocelluloses to emphasize how this class of nanomaterials may be beneficial in biomedical applications, particularly for the controlled release of active substances. Depending on the cellulose source, key properties of nanocelluloses, such as shape, size, and crystallinity may vary [7,40–42]. Nanocelluloses sourced from organisms, such as bacteria and algae, are typically more pure (free from other polysaccharides, such as lignin and hemicellulose) and have a higher crystalline index (>90%) than those produced from plants (<70%) [5,43]. Accordingly, cellulose sources regulate the properties of nanocelluloses, such as density, porosity, hydrophilicity, and water absorption. An interesting example is porous Cladophora (green algae) cellulose with an extremely large surface area (> 100 m2 g−1) [44] compared to plant-derived nanocelluloses [45]. The aspect ratio (length-to-width ratio) of CNFs (which can be > 500) is noticeably higher than cellulose crystals (CNC, HCNC, or BCNC, typically < 200), while the width of all four types of nanocelluloses is typically in the order of 5–10 nm [5].

Hydrogen bonding plays an important role in the mechanical properties of nanocelluloses. According to the theoretical calculations, when hydrogen bonding is taken into consideration, the longitudinal modulus of cellulose I ~ 173 GPa, whereas it reduces to ~ 71 GPa without intramolecular hydrogen bonding [46,47]. Accordingly, hydrogels and aerogels [48] prepared from nanocelluloses typically benefit from high mechanical strength. Besides mechanical properties, the rheological characteristics of nanocelluloses are important in biomedical applications. Nanocelluloses have unique rheological properties, regulated by their surface chemistry, morphology, and colloidal ordering (e.g., liquid crystalline and gel states) [40,45,49–55]. At high enough concentrations, nanocelluloses form physical hydrogels, which are typically shear-thinning at particle concentrations lower than the critical phase transition to an ordered suspension [56].

The key contributions of nanocelluloses to nanomedicine would not be possible without the chemical modification of CNCs, HCNCs, BCNCs, and CNFs to modulate their functionality and the effective binding of target compounds for controlled release. An overview of the chemical reactions of nanocelluloses has been provided in literature [57], highlighting oxidation as one of the most common modification methods. By oxidizing the hydroxyl groups, which may be followed by reductive amination and esterification reactions, bioactive compounds may be covalently attached to nanocelluloses. Self-assembly of nanocelluloses is another, often less noticed, method to bind active molecules. For example, Varjonen et al., [58] and Valo et al., [59] attached cargos such as beclomethasone dipropionate (BDP) and itraconazole (ITR) to nanocelluloses using genetically engineered binding protein HFBI-DCBD composed of hydrophobin and showed their stability for several months.

Besides chemical conjugation of cargos, some chemical treatments, such as TEMPO (2,2,6,6tetramethylpiperidine-1-oxyl)- or chlorite-mediated oxidation may alter the nanocellulose charge, promoting the physical bonding of charged molecules to the carrier. In addition, HCNCs, decorated with highly functionalized cellulose polyelectrolytes, provide nanocarriers with tunable surface charge [60], which are able to regulate the chemical responses to carried drugs. Surface charge may have negative effects on the attached cargo, e.g., degrading aspirin over time [61]. The crystalline structure of HCNCs can be preserved by controlling the oxidation reaction condition. As innovations in nanocellulose-based therapeutics advance, thorough in vitro and in vivo characterizations are required to ensure that the product is a reliable molecular carrier for clinical applications.

In vivo behavior of nanocelluloses is rarely explored. Current literature, geared towards investigating the adhesion, proliferation, spreading, viability, and differentiation of a variety of cells in nanocellulose scaffolds, has attested to the biocompatibility of nanocelluloses when their concentrations are typically less than 1 mg mL−1. CNCs are ingestible and their gastrointestinal fate is associated with acid-mediated hydrolysis and interactions with gut flora [62]. Importantly, concentration-dependent apoptotic toxicity of CNFs at 2–5 mg mL−1 has been reported [63]. Cationic nanocelluloses, e.g., trimethylammonium-CNF have been reported to be less cytotoxic than the anionic counterparts, e.g., carboxymethylated CNF [64]. Similar to nanocelluloses, BC is non-toxic against endothelial and osteoblast cells [65–67]. Toxicological studies of nanocelluloses have been conducted based on in vitro multi-trophic assays, acute lethal tests, gene mutations, and chromosomal tests, as well as oral evaluation, neurocytotoxicity, and immunoreactivity. Both CNF and BC may contain endotoxin and (1,3)-β-D-glucan contaminants, confirmed by analyzing the hot water extracts of these nanocelluloses using ELISA assays, high-performance size exclusion chromatography-multiangle laser light scattering, gas chromatography, and nuclear magnetic resonance spectroscopy [68].

2. Cellulose nanocrystals (CNC and HCNC) and their composites for cargo delivery

Here, we discuss the contributions of CNCs to the controlled release of active molecules, including a brief insight into the potentials of HCNC, a newly emerged class of nanocelluloses, in nanomedicine. CNCs, sourced from plants, are rod-like particles with length ~ 100–200 nm, width ~ 5–10 nm, and a hydroxyl-rich surface, facilitating a wide range of chemical modification [59]. These nanocelluloses are being commercially produced in large scales (hundreds of tons per year). We review the recent advances in CNC-based cargo delivery and bioimaging.

The focus of CNC research for biomedical applications before 2014 was geared towards taking advantage of the mechanically strong crystalline body of CNC for reinforcing composite biomaterials [70–72]. For example, Wang and Chen utilized cellulose nanowhiskers to improve the mechanical properties of electrospun prolamin protein fibers and create a drug delivery system that could prolong riboflavin release in phosphate buffered saline (PBS) [73]. Controlled release of water-soluble drugs, such as doxorubicin (Dox) and tetracycline from unmodified CNC as well as hydrophobic anti-cancer drugs, such as docetaxel, paclitaxel, and etoposide from cetyltrimethylammonium bromide (CTAB) modified CNC have been demonstrated [74]. Xiang et al., [75] modified CNC and demonstrated that the diffusion rate of non-ionic molecules could be controlled by adding electrospun poly(lactic acid) (PLA) to the matrix, which induced the Fickian diffusion with reduced initial (burst) release for Columbia blue dye as a model drug.

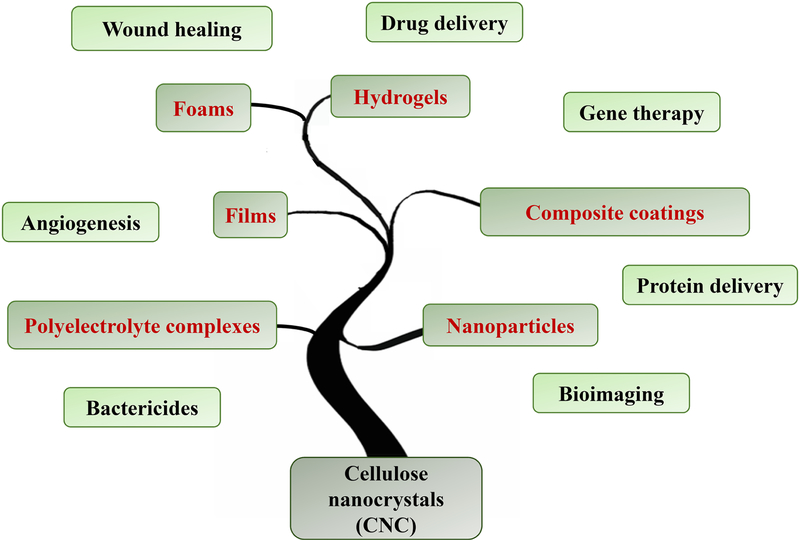

Despite the limited attempts for using CNC in biomedical engineering before 2014, the significant progress in synthesis, chemical modification, and production process optimization in the past four years has set the stage for the advanced medical applications of CNCs, in the forms of nanoparticles, hydrogels, films, and composite coatings. A summary of the main delivery applications of various forms of CNC-based biomaterials is presented in Figure 2. HCNC, however, has emerged recently, opening new horizons for producing CNCs that can accommodate ~ 1–7 mmol carboxylic acid groups on their surface [8,9], pushing the structural boundaries of conventional nanocelluloses. Applications of HCNC in the controlled release of active biomolecules has not been explored yet. The versatile chemical modality of this family of nanocelluloses may provide numerous possibilities for cargo loading and release.

Figure 2.

Various types of cellulose nanocrystal (CNC)-based biomaterials for nanomedicine and their main applications.

2.1. CNC for cargo delivery

Viable intracellular cargo delivery platforms must be nontoxic towards somatic and undifferentiated stem cells and pass through the cell membrane [76]. CNCs are currently being explored as carriers for drug delivery, because they can be inexpensively produced from widely available renewable resources [13,69,77,78] and attain large surface areas (~ 100 m2 per gram) [79] regulated by nano-morphology, particle size, and dispersity, tailored surface charge, and a high hydroxyl group content [19,42,69] for the physical and chemical binding of bioactive components. The bioactive components may be drugs for treating wounds or illnesses, or dyes to allow for visualizing the trajectory of carriers. Common drugs and contrast agents physically or chemically attached to CNCs are summarized in Table 1.

Table 1.

CNC-based cargo delivery: examples of recent cargos, carriers, applications, and loading and release mechanisms.

| Cargo | Carrier | Potential application | Loading mechanism | Release mechanism | Year [Reference] |

|---|---|---|---|---|---|

| Rhodamine B isothiocyanate (RBITC), Fluorescein-5isothiocyanate (FITC) | Colloidal CNC | Bioimaging | Covalent conjugation | NA | 2014 [80] |

| BSA-FITC | PLGA-doped PVA-CNC films | Biomacromolecule delivery to bone marrow | Physical entrapment | PLGA degradation | 2014 [81] |

| MTX | Fe3O4 nanoparticles decorated with amino-functionalized CNC | Cancer therapy | Hydrogen bonding and electrostatic interactions | pH dependent (maximum release at pH ~ 5.4) | 2016 [82] |

| 5-FU | Xanthan gum-chitosan-CNC hydrogels | Cancer therapy | Equilibrium swelling | Non-Fickian diffusion | 2017 [83] |

| Tetracycline hydrochloride (TH) | CNC-doped PLA/PEG nanofibers | Antibiotic | Hydrogen bonding and improved hydrophilicity | Composition regulated | 2017 [84] |

| Curcumin (Cur) | CNC-collagen-gelatin microspheres/porous scaffolds | Wound healing | Physical trapping | Gradual dissolution | 2017 [85] |

| Angiogenin (ANG) and Cur | PLGA/CNC/Cur/ pDNA-ANG composite nanofiber | Angiogenesis and infection prevention during wound healing | Electrostatic interactions | Expected to be pH dependent | 2017 [86] |

| siRNA | Cationic BCNC, PEI-CNC hybrids | Gene therapy | Electrostatic interactions | pH dependent (maximum release at pH ~ 4.0) | 2017 [87] |

| Bovine serum albumin (BSA), Human serum albumin (HSA) | CNC nanocomposites | Protein delivery for intracellular cholesterol efflux | Adsorption/chemical conjugation | pH dependent (maximum release at pH ~ 6.5–6.6) | 2017 [88] |

| Repaglinide | Chitosan-CNC | Oral drug | Electrostatic | pH dependent | 2018 [89] |

| (RPG) | polyelectrolyte macroion complexes (PMC) | delivery | interactions | (maximum release at acidic conditions) | |

| Chlorotoxin | Colloidal CNC | Brain tumor therapy | Covalent conjugation | NA (internalization) | 2018 [90] |

The fate of nanoparticles inside the body, regulated by protein adsorption, cellular uptake, and tissue translocation depends on numerous colloidal factors, including size, surface charge, and morphology [91,92]. Mechanisms of in vitro uptake and in vivo behavior of nanocelluloses as emerging platforms for cargo delivery have not been fully understood. Among the most important properties of nanocelluloses, surface charge plays a key role in regulating cellular uptake. Mahmoud et al., studied the effect of ζ-potential (the potential difference between the nanoparticle surface and the bulk electrolyte) on the bioactivity of CNCs conjugated with commonly used dyes, fluorescein-5-isothiocyanate (FITC) and rhodamine-B-isothiocyanate (RBITC) [93]. ζ-potential, defined as the potential difference between the nanocrystals and the surrounding fluid environment had a direct effect on cell viability and cytotoxicity. CNC-FITC uptake by human embryonic kidney 293 (HEK-293) cells and Spodoptera frugiperda (Sf9) cells was sensitive to pH, peaking at pH ~ 5 and dropping drastically at pH ~ 6.5. HEK-293 and Sf9 cells also absorbed CNC-RBITC mostly at pH ~ 5, and at the physiological pH, CNC-RBITC absorbance was much higher than CNC-FITC. ζ-potential analysis revealed that both neat and FITC-tagged CNCs have negative surface charges, −31.6 mV and −46.4 mV, respectively, while RBITC-tagged CNCs have a positive surface charge (~ +8.7 mV) at this pH range [93].

Increasing CNC-FITC concentration from 30 to 300 µg/mL decreased cell viability from 59% to 29%, whereas cell viability was ~66% at 300 µg/mL of CNC-RBITC. Electric cell-substrate impedance sensing (ECIS) was conducted to study the cytotoxicity mechanism of FITC-tagged nanocrystals. Toxic compounds inhibited current flow on a gold electrode coated with Sf9 cells cultivated with varying amounts of CNC, CNC-FITC, and CNC-RBITC. CNC and CNC-FITC inhibited the current flow with half-inhibition concentrations (ECIS50) ~ 61 ± 2.4 µg/mL and 45 ± 4.6 µg/mL, respectively. ECIS50 for CNC-RBITC was 224 ± 6.3 µg/mL, indicating that CNC-RBITC inhibited cell growth less than other tested nanocrystals [93]. While cellulosic nanocrystals, often decorated with negatively-charged moieties, are potential materials for targeted drug delivery, the cytotoxicity studies suggest that functionalizing nanocelluloses with positively-charged groups may improve their uptake and reduce the toxicity, which must be well understood before these nanoparticles can serve for clinical applications.

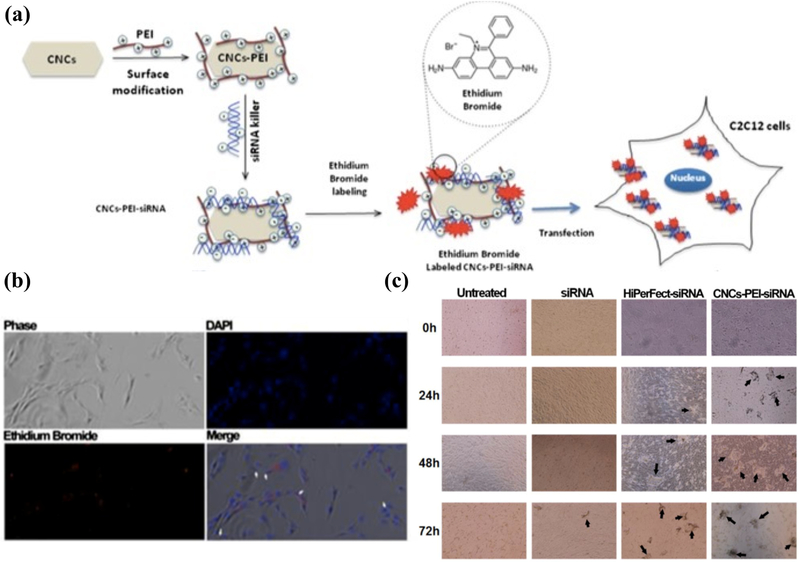

The interactions between CNCs and cargo molecules are regulated by chemical and/or physical modifications. Beside simple mixing, e.g., to produce CNC-alginate nanoparticles in honey (as a surfactant and stabilizer) for rifampicin delivery [94], a facile method to engineer the surface charge of CNCs is through the adsorption of polycations. Sulfuric acid-hydrolyzed negatively charged CNC surfaces can be coated with positively-charged polyethylenimine (PEI) to enhance small interfering RNA (siRNA) binding [87]. siRNA is a double-stranded RNA which is introduced into a cell to silence a specific gene. While siRNA serves as a potent method to alter various disease-causing agents, its susceptibility to enzymatic degradation and lack of cell target specificity are obstacles that require improvement. To this end, PEI has been used to facilitate siRNA delivery (Figure 3) via the high density of positively charged functional groups. This strategy not only enhances the electrostatic binding of siRNA to CNC but also improves the endocytosis and further enables endosomal escape as a result of the so-called “proton sponge effect” [87]. The high buffering capacity of the polycation increases the influx of counterions and water into the endosomes, disrupting the endosomal membrane due to elevated osmotic pressure, which results in releasing the cargo in the cytosol [95].

Figure 3.

(a) CNCs are readily decorated with polycations (e.g., polyethylenimine, PEI), imparting a positive charge to their surface, which promotes the electrostatic (physical) binding of siRNA killer. These self-assembled nanoparticles are internalized by C2C12 myoblasts (b), resulting in gene editing, silencing the expression of cell cycle genes, and promoting apoptosisdriven cell death [87]. (c) Within 24–72 h, cell death becomes evident by the formation of debris (shown with arrows), which is more pronounced for CNC-PEI-siRNA complexes, similar to the commercial transfection reagent (HiPerFect, Qiagen). Carbohydr. Polym., 164: 258–267, Copyright (2017), with permission from Elsevier.

The formation of CNC-PEI has been confirmed by the change in ζ-potential from ~−40 mV to ~+37 mV [87]. Subsequent siRNA adsorption decreases ζ-potential to ~ +2.5 mV. The CNC-PEI-siRNA complexes have been assayed for cytotoxicity, cellular uptake, siRNA protection, and apoptosis induction [87]. Cytotoxicity assays reported no toxic effect of CNCs-PEI on the murine C2C12 myoblast cell line for certain doses and culture conditions within 72 h. Cellular uptake was evaluated by 4′,6-diamidino-2-phenylindole (DAPI) and ethidium bromide fluorescence, which showed the localization of siRNA complexes in the cytoplasm. The degree of siRNA protection was tested by exposing the CNC-PEI-siRNA to RNase A for a limited time followed by confirming the indicative bands of siRNA in gel electrophoresis after the separation of siRNA from the complex using sodium dodecyl sulfate. The gel assay demonstrated that siRNA was protected in the presence and absence of RNase A. In addition, the presence of siRNA was not confirmed in complexed siRNA that was only exposed to RNase A, indicating that siRNA encapsulation is preserved even after the exposure to nuclease. Finally, the expression levels of extrinsic and intrinsic apoptotic genes, Casp 8 and Casp 9, respectively, were measured as indicators for apoptotic induction. Casp 8 was measured as an indicator of apoptotic induction via external stimuli (e.g., carrier attachment to the periphery of the cell) while Casp 9 was used to indicate the internal stimuli (carrier internalization). Casp 9 mRNA expression levels, measured by the quantitative analysis of cDNA produced from extracted mRNA, were significantly upregulated while Casp 8 expression was almost unchanged. This data supported that the CNC-PEI-siRNA was successfully endocytosed by the cells and delivered to the cytoplasm, followed by the siRNA-induced internal apoptosis (Figure 3) [87].

Drug delivery systems must preferably be nontoxic and stable in the circulatory system while remaining stealth against immune system. While carbon nanotubes [96] and self-assembled nanocarriers [97], such as lipid nanoparticles and vesicles [98] have been dealing with this challenge, CNCs with proper surface modifications may serve as a biocompatible biopolymer carriers for bioactive molecules. Hydroxyl groups on CNCs provide active sites for bioconjugation and promote hydrophilic interactions, decelerating phagocytosis. Needle-shaped nanoparticles, i.e., CNCs, of 50–200 nm length, may provide optimal evasion of both renal and immune system regulation [99].

Low cytotoxicity and uptake of unmodified CNCs are desirable properties for targeted drug delivery. It has been reported that CNCs are not cytotoxic against human brain microvascular endothelial cells (HBMECs) and have minimal uptake [99]. The viability of HBMECs, indicated by the formazan product of MTT assay, was not significantly different from the CNC-free control at CNC concentrations ~ 10, 25, and 50 µg/mL of media after 24, 48, or 72 h. Cellular uptake of FITC-tagged CNCs was time and dose dependent in 24 h exposure to 50 µg/mL of CNC; however, the uptake was minimal as the delivery system was non-specific. Because CNC uptake was minimal, these nanoparticles may be used as targeted drug delivery systems, which are able to minimize non-specific drug uptake.

Non-specific pharmaceutical cancer drugs (chemotherapeutic agents) typically cause damages to healthy tissues and organs. To limit these detrimental side effects, current research and development are driven towards creating specific targeting drug carriers using nontoxic materials. CNCs at optimum concentrations may not have toxic effects on the body and are not associated with specific cellular uptake. Additionally, the hydroxyl groups along the CNC body provide attachment sites for agents, such as fluorescent dyes, targeting materials, and therapeutic drugs. Typical chemical conjugation pathways rely on the facile oxidation, amination/amidation, esterification, etherification, and carbamation [100] of CNCs, enabling a broad range of surface modifications.

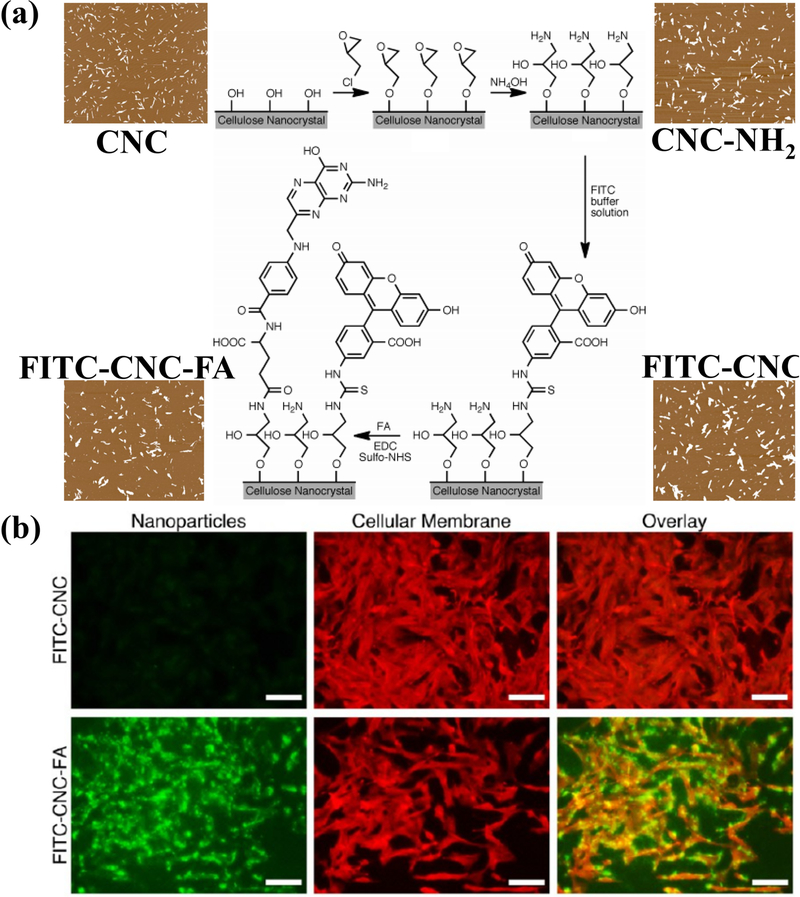

Targeted delivery may be achieved through the surface modification of CNCs with cell-specific receptors via amination. Targeting has been successful in brain tumor cells, whereby the targeting mechanism relies on folic acid (FA)/folate receptors that are overexpressed in cancer cells. Dong et al. [80] utilized these attachment sites to have CNCs bind specifically to three types of brain tumor cells: DBTRG-05MG and H4 (human brain tumor cells) and C6 (rat brain tumor cells). By adding FA to CNCs tagged with FITC, the endocytosis of FITC-CNC-FA drastically increased. X-ray diffraction and Fourier-transform infrared spectroscopy showed that the crystallinity and crystal lattice structure of CNCs were not affected by attaching FITC or FA. All three brain tumor cells endocytosed the FITC-CNC-FA, where fluorescence intensities revealed that the uptake was 1472, 975, and 46 times greater than those of FITC-CNC for DBTRG-05MG, H4, and C6 cells, respectively. Further investigation revealed that DBTRG-05MG and C6 cells, both non-neuronal cells, operate on a different uptake mechanism than H4 ganglioma cells. Genistein, an inhibitor of caveolae-mediated endocytosis, inhibited 85% and 55% of FITC-CNC-FA uptake in DBTRG-05MG and C6 cells, respectively, but had no significant effect on the H4 uptake. Conversely, chlorpromazine, an inhibitor of clathrinmediated endocytosis, inhibited 48% of FITC-CNC-FA uptake in H4 human brain tumor cells. FA-mediated cellular uptake of CNCs has also been used for enhanced tumor ablation [101], wherein the selective enhancement of the electroporation-based therapy of human breast cancer cells is achieved via defect formation on the cell membrane as a result of CNC-FA endocytosis as well as the distribution of electrically non-conductive CNCs throughout the tissue. Figure 4 presents the enhanced cellular uptake of CNC-FA for targeted delivery.

Figure 4.

(a) Chemical modification of CNC surface with FITC and folic acid (FA) for visualizing the enhanced receptor-mediated uptake of the nanocelluloses by human DBTRG05MG, which is shown in (b) the fluorescence images of stained cells [80]. Reprinted with permission from S. Dong, H.J. Cho, Y.W. Lee, M. Roman, Synthesis and cellular uptake of folic acid-conjugated CNCs for cancer targeting. Reprinted with permission from (Biomacromolecules, 15:1560–1567). Copyright (2014) American Chemical Society.

Besides cell-specific receptors, recent studies of protein functions have revealed that albumins play a critical role in cell specific drug delivery through their specificity for ligand binding [102–107], which have been used as endogenous cargo carriers [108,109]. Common ligands for albumin include fatty acids, hormones, and toxic metabolites. The degree of cholesterol production from endothelial cells in the vascular arteries is a major factor that contributes to the formation of atherosclerotic plaques. In an attempt to enhance cholesterol efflux from these endothelial cells, the effect of cellular exposure to bovine serum albumin (BSA)/human serum albumin (HSA)-conjugated CNCs on cholesterol deposition was studied. CNCs were conjugated to each type of albumin in two ways: physical adsorption and chemical conjugation. Physically adsorbed BSA/HSA CNCs were prepared by direct addition and incubation of dried CNCs in BSA and HSA solutions overnight. Chemical conjugation was conducted through the TEMPOmediated formation of carboxylic acid groups on CNCs, followed by EDC (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride)/NHS (N-hydroxysuccinimide)-mediated addition of BSA/HSA [88].

Both negatively and positively charged CNCs adsorb albumins. Binding between the cationic pyridinium-grafted CNCs and BSA is endothermic, which is driven by charge neutralization, whereas negatively charged (e.g., carboxylated and sulfated) CNCs show a weaker protein binding [110]. The efficiency of protein loading may be studied through the analysis of the supernatant after exposing CNC dispersions to BSA/HSA. Physical adsorption has yielded 40% and 36% loading efficiency while the chemical conjugation has led to 54% and 46% loading for BSA and HSA, respectively [88]. Interestingly, microscopic observations suggested that the topology of the CNC particles differed upon protein binding. Albumin-free CNCs were observed to have rod-like structures while albumin attached CNCs appeared to have more porous structures and loose arrangements so as to demonstrate a decent capacity to encapsulate various cargo. Secondary and tertiary structures along with general protein integrity were confirmed via SDS-PAGE (sodium dodecyl sulphate-polyacrylamide gel electrophoresis) and CD (circular dichroism) spectropolarimetry, suggesting that CNC does not have adverse effects on the cargo proteins before or after binding. This was also supported by quantifying the bioactivity of proteins released from the CNCs, which reached up to 90% as compared to the activity of BSA/HSA in their native states [88]. Fluorimetric cholesterol efflux assays have revealed that while cholesterol efflux is constantly high in human coronary artery endothelial cells (HCAECs) independent of the concentrations and conjugation method, human umbilical vein endothelial cells (HUVECs) experienced a gradual increase in cholesterol efflux with increasing the concentrations of both BSA- and HAS-conjugated CNCs. Notable differences were observed for chemically-conjugated CNCs as opposed to the physically-adsorbed CNCs, whereby the chemically conjugated BSA/HSA demonstrated higher efflux. Accordingly, while albumins may serve as shuttles for cholesterol efflux, CNCs are also able to perform as sinks, carrying the effluxed cholesterol to the intestinal lumen and out of circulation.

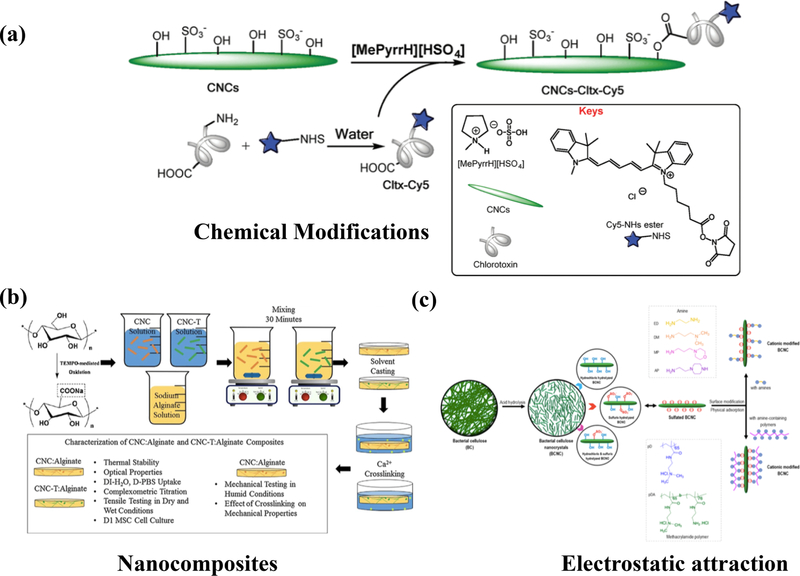

Common surface modifications of nanocelluloses involve steps that demand organic solvents, which often renders these nanomaterials less biocompatible and more difficult to produce at large scales. To address these issues, ionic liquids have been designed to replace organic solvents. Ionic liquids are a desirable alternative due to their significantly low vapor pressure and ease of separation [111]. One-step esterification using Bronsted acid ionic liquid N-methylpyrrolidinium hydrogen sulfate (MePyrrHSO4) [112] is an alternative to organic solvents. CNCs may chemically bind to chlorotoxin (Cltx) via a one-step esterification process, yielding Cltx-CNCs. Cltx is a protein that allows targeting brain tumors, such as glioblastoma multiforme (GBM) via specific binding to MMP-2/ClC3. Subsequent cellular studies using the U87MG GBM cell line shed light on the efficacy of Cltx-CNC as a target-specific drug delivery system against brain tumors [112].

Cytotoxicity of the functionalized Cltx-CNC was evaluated by an MTS assay upon the exposure of seeded cells to various concentrations of Cltx-CNC (up to 200 µg/mL) and compared to varying concentrations of non-functionalized CNCs [112], showing no significant toxicity. The internalization assay was conducted by observing the cellular uptake of Cy5-conjugated Cltx-CNC (Cy5-Cltx-CNC) via fluorescence staining. U87MG GBM, secreting high levels of MMP2 (matrix metalloproteinase 2), internalized the Cltx-CNC the most. Fluorescence staining of Cy5-Cltx-CNC indicated the nanoparticle localization in the cytoplasm and nuclei surrounding. On the other hand, MCF7 with low levels of MMP2 expression indicated no intracellular Cy5 fluorescence. The demonstrated biocompatibility and specificity for MMP2 targeting indicate the potential of Cltx-CNC as a brain tumor targeting drug delivery system.

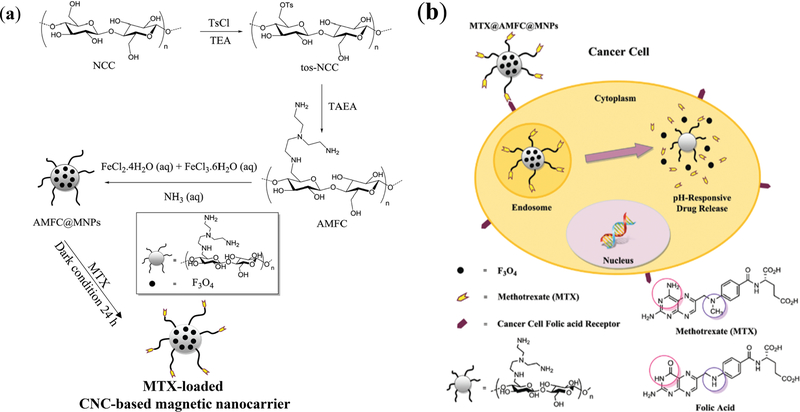

CNC may also be used as a coating material for the enhancement of colloidal stability, biocompatibility, biodegradability, and chemical functionality of nanoparticles. Modified CNCs with tris(2-aminoethyl)amine (AMFC) have been used to coat Fe3O4 magnetic nanoparticles (AMFC-MNPs) (Figure 5) [82]. The nanocellulose was treated with tosylchloride for the functionalization with tris(2-aminoethyl)amine, which was selected to provide amino groups and cationic properties. AMFC was able to effectively bind to the carboxyl groups of methotrexate (MTX, an anticancer immunosuppressive drug), overcoming the downsides of MTX by maximizing its anticancer efficacy while minimizing the off-target side effects to healthy cells. While the drug-free AMFC-MNP showed a high cell viability, the nanoparticles loaded with MTX had comparable cytotoxicity to free MTX, demonstrating that the efficacy of the bound drug is not inhibited by the nanoparticle. Hemolysis assays performed at 0–5000 µg/mL of blood showed less than 2.6% hemolytic activity for the drug-free AMFC-MNPs. The MTX-loaded nanoparticles had significantly higher cellular uptake than AMFC-MNP. This may be attributed to the chemical similarity of MTX to FA, facilitating receptor-mediated cellular internalization, which attests to the potential of MTX for enhanced cell-targeting (Figure 5) [82]. In the MTXAMFC-MNP system, drug encapsulation efficiency was ~ 91.2% along with a decent, 30.4%, drug loading efficiency. The pH-regulated controlled release is achieved based on the protonation states of MTX carboxylic groups. At physiological pH (7.4), up to 29% of the drug was released over 5 days, while up to 79% was released in acidic conditions (pH ~ 5.4). Magnetic CNCs have also been prepared using direct co-precipitation of Fe2+ and Fe3+ in CNC dispersions containing NaOH [113].

Figure 5.

(a) Synthesis of pH-responsive magnetic CNC-based nanocarrier. The nanocellulose was reacted with tosylchloride for the functionalization with tris(2-aminoethyl)amine (AMFC), providing amino groups to effectively attract the carboxyl groups of methotrexate (MTX, an anticancer drug). The magnetic CNC-based MTX delivery system, fabricated by an in situ reaction with FeCl2 and FeCl3, provides AMFC-coated magnetic nanoparticles (AMFC@MNPs), which are responsive to pH. (b) MTX-loaded magnetic CNC carriers, benefitting from the similarity of MTX to folic acid, faciliatet the folate receptor-mediated cell internalization [82]. Reproduced from [82] with permission from the Centre National de la Recherche Scientifique (CNRS) and The Royal Society of Chemistry.

2.2. CNC hydrogels, foams, and complexes

One of the main motivations for using CNCs in drug delivery scaffolds is to benefit from the stiff body of nanocrystals (elastic modulus > 100 GPa [79]) to reinforce the otherwise mechanically weak carriers. Biocompatible and biodegradable polysaccharide-based nanodrug delivery systems, such as chitosan (CS), which often lack mechanical resilience may be reinforced with CNCs [114–116]. Chitosan-based bionanocomposites reinforced with CNCs for tissue engineering and drug delivery are among the most common delivery scaffolds [117–119]. Other non-cytotoxic biopolymers, such as xanthan gum (XG), which are able to provide controlled drug release, have been used as additives in the therapeutic scaffolds loaded with chemotherapeutic drugs, such as 5-fluorouracil (5-FU) [83]. To evaluate the in vitro performance of CNC-based drug delivery hydrogels, encapsulation efficiency, cumulative release, and cytotoxicity have mainly been evaluated.

Typically, both compressive strength and stiffness increase with increasing CNC concentration. For example, XG-CS had compressive strength and stiffness ~ 36 kPa and 1432 N/m, respectively, whereas for XG-CS-CNC, they ranged from 40 kPa-58 kPa and 1525 N/m-2398 N/m for 2–10% CNC concentrations [83]. The cumulative drug (5-FU) release was regulated by the CNC: while the CNC-free system released more than 75% of the drug within the first four hours, adding 10% CNC was able to slow down the kinetics and provide ~ 60% release in ~ 30 h. This may be explained by the increased structural rigidity and enhanced physical binding between the 5-FU and hydrogel scaffold induced upon the incorporation of CNCs. Cytotoxicity assays for the hydrogels indicated that the drug delivery system was not toxic against the cells (NIH/3T3), which was concluded based on more than 95% cell viability at all concentrations of CNCs used for the preparation of hydrogels. These results suggest that CNC-reinforced biocompatible nanocomposite hydrogels may provide controlled release platforms, benefitting from decent biocompatibility and improved mechanical and chemical properties.

Besides reinforcement, CNCs may impart hydrophilicity to polymeric matrices, enabling the dispersion of hydrophobic agents, such as curcumin (Cur) in aqueous media. Cur provides antioxidant, anti-inflammatory, and antibacterial activity, which may potentially be effective for wound infection treatment; however, it is not trivial to maintain it in physiological systems due to its hydrophobicity. Porous collagen-cellulose nanocrystal (Coll-CNC) composites have been used to synthesize foam scaffolds loaded with curcumin-gelatin microspheres (GM) for prolonged Cur release [85]. This biomaterial has exhibited antibacterial activity in addition to dermis regeneration and inflammation inhibition as tested in mouse wound-infection models. The GM carriers embedded in the CNC scaffolds release Cur over a significantly longer period as compared to the GM or the CNC scaffolds alone [85], providing sustainable antimicrobial activity against various strains of bacteria. In the mouse model, the Cur/GM/Coll-CNC demonstrated accelerated dermal repair without significant wound hemorrhage or inflammation.

Increasing the dispersibility of drugs in aqueous media may not necessarily increase the circulation time in which case sudden increase in the drug concentration followed by its elimination significantly decrease the therapeutic effects and increase the side effects. Drug complex formation with nanoengineered polymeric networks may enhance the circulation time. Conventional oral drugs come into effect upon diffusion in the body fluids, such as intestinal fluid, followed by the uptake into the bloodstream. Oral drugs are known to have increased efficacy upon meeting certain criteria, among which drug residence time in the intestine is a key factor. Polyelectrolyte macroion complexes (PMC), synthesized from CNCs and chitosan have provided a long residence time in the small intestine due to the attraction between the negatively charged intestinal mucosa and positively-charged chitosan, providing an efficient platform for oral drug delivery [120].

2.3. CNC composite films

CNCs have typically been added to polymeric films to increase their Young’s modulus, elongation at break, and dissolution/release time. CNCs have been incorporated into composite electrospun nanofibers for wound care and skin regeneration. Typically, CNCs are electrospun with polymers/nanoparticles and target drugs, such as poly (D, L-lactic-co-glycolic acid) (PLGA), Cur, and polyethyleneimine (PEI)-carboxymethyl chitosan (CMCS)/plasmid DNA (pDNA)-angiogenin (ANG) [86]. ANG stimulates angiogenesis in wounded areas, facilitating skin regeneration by improving oxygen and nutrient delivery. Since ANG is highly unstable and has a short half-life in serum, drug delivery systems, such as chitosan-based nanoparticles, have been engineered to introduce ANG into cells via the transfection of pDNA. To examine the effectiveness of this nanofiber scaffold in skin regeneration, multiple tests have been conducted, including the measurement of pDNA release, ANG expression, and cell viability and proliferation, followed by in vivo evaluations using rat models [86]. PLGA/CNC/pDNA-ANG provided a significantly higher ANG expression as compared to controls with only PLGA/CNCs, recording 1.6-fold higher expression at day 3 and 2.8-fold higher expression by day 7. In vivo analyses showed that the pDNA-ANG nanocomposite-exposed rats had faster wound recovery and re-epithelialization [86].

CNCs have also been used as reinforcing agents in electrospun sheets, such as poly(3hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) [121] to increase their mechanical strength and hydrophilicity, allowing for long-term sustained release of cargos, such as tetracycline hydrochloride (TH). Similarly, PLA, a widely used nanofiber drug delivery system, has been doped with CNCs. In fact, PLA is not a suitable material for drug delivery purposes considering its hydrophobicity and subsequent poor control of hydrophilic drug release; however, CNC has been able to overcome the unfavorable properties of PLA by imparting hydrophilicity to the electrospun nanofibers while enabling sustained control of drug release as a result of drug binding [84]. Polyethylene glycol (PEG) may often be selected as an additional compatibilizer to increase biocompatibility and further enhance the hydrophilicity through its hydroxyl groups. A typical process of preparing these fibrous platforms consists of mixing the PLA solution with CNC/PEG, followed by electrospinning.

Drug release levels and cytotoxicity are two key properties of composite fibers that must be assessed before animal studies and clinical trials. Compared to additive-free PLA nanocomposites, PLA/CNC/PEG provides a two-step release profile, depending on the amount of loaded drug. When a low concertation of drug is loaded (e.g., TH concentration ~ 3%), almost all of it will be released within a few hours. On the other hand, the nanocomposites loaded with ~ 10% TH provide ~ 60% burst drug release by the first hour followed by ~ 80%−95% release after ~ 43 days. Interestingly, a biodegradability assay revealed that the drug accelerated the scaffold degradation as a result of increased hydrophilicity [84]. These drug-eluting systems have been cytocompatible against MG-63 cells (human osteosarcoma).

Hybrid spherical CNC-colloidal titania patches for the sustained delivery of antibacterial and antifungal agents, such as triclosan [122], CNC-alginate films for ampicillin delivery [123], and gold-CNC-doped guar gum and poly(vinyl alcohol) (PVA) for transdermal diltiazem hydrochloride administration [124] are among other examples of CNC-based cargo delivery films. Interestingly, the controlled release of carvacrol and Cur from TEMPO-oxidized CNC-cyclodextrin films may hold promise for antibacterial food packaging [125].

Biodegradable polymers have offered new platforms for administering proteins and other biological macromolecules that demand additional structural support. PLGA has widely been tested as a delivery polymer with tunable degradability and mechanical properties to control the administration rate of biomacromolecules. PVA, a commonly used water-soluble and biodegradable polymer, is molecularly large enough to perform as a matrix for therapeutic cargos. Nanocomposites of PVA and CNCs have a higher Young’s modulus than PVA alone, providing mechanically-robust structures [81]. PVA films doped with CNC have acquired up to 195% increase in the elongation at break at only 1% CNC. Besides mechanical reinforcement, thermal stability may also be improved by CNCs. Thermogravimetric analysis (TGA) of the polymer films has confirmed that the CNC nanocomposites have higher thermal stability than CNC-free PVA [81]. Some examples of common methods to make CNC-based cargo delivery systems are presented in Figure 6.

Figure 6.

Examples of common methods to make cellulose nanocrystal (CNC)-based cargo delivery systems. (a) Direct chemical modifications of CNC surface to conjugate Cltx via the Fisher esterification of the hydroxyl groups of CNC and the carboxylic acid groups of a drug in a Brønsted acid ionic liquid [90], reproduced from [90] with permission from the Centre National de la Recherche Scientifique (CNRS) and The Royal Society of Chemistry. (b) Solvent casting of CNC-alginate nanocomposites crosslinked using calcium ions. Carbohydr. Polym., 1:186–195, Copyright (2018), with permission from Elsevier [126]. This platform may be used to encapsulate active molecule of choice. (c) Self-assembly through the electrostatic adsorption of sulfuric acid-hydrolyzed CNC (bacterial) with amine-bearing polymers [127]. Reprinted with permission from [127]. Copyright (2018) American Chemical Society.

3. Bacterial cellulose (BC) and its composites for cargo delivery

Bacterial cellulose and nanocellulose (BNC) are crystalline biopolymers synthesized by specific types of bacteria, such as Gluconacetobacter xylinus [105,106]. Colloidal BNC, prepared from BC are typically negatively charged, which in concentrated BNC dispersions, form physical hydrogels with decent structural integrity, biocompatibility, and water binding capacity, providing a desirable microenvironment for selective cargo delivery [130,131]. Biocompatibility, purity, and malleability of BC make it suitable for biomedical applications [131], such as topical treatment, as it can fit the epidermal surfaces and deliver antimicrobial or dermal therapeutics. Topical products typically do not require strict sterilization processes; however, challenges associated with emulsion stability, e.g., in cream manufacturing, require careful process design. Additive selection to engineer the physical properties (e.g., rheology) of nanocellulose-based formulations is of utmost translational importance. The topical products may be in the forms of creams, sprays, drops, and patches. Biocompatibility assays of topical BC patches over 24 h have resulted in clinical scores of zero, indicating no major health risks [132]. In the past decade, BC has mostly been used for wound dressing [133].

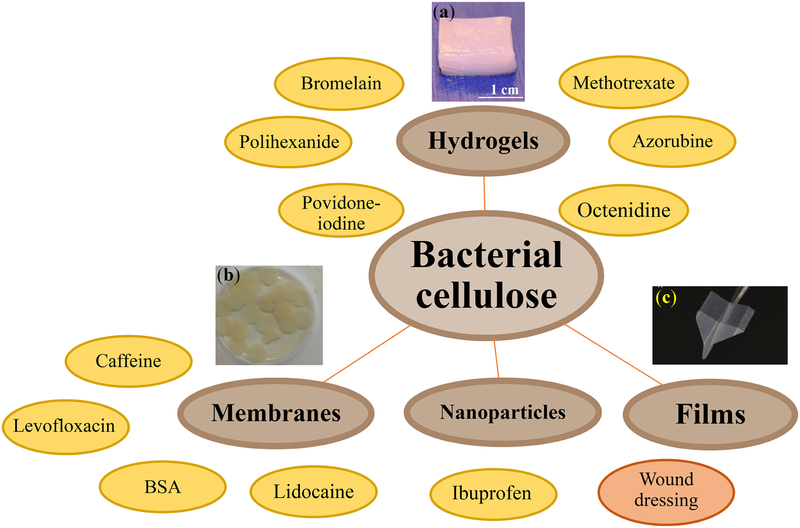

BC demonstrates desirable properties, including high tensile strength, crystallinity, and structural integrity, which are attributed to the intramolecular interactions of the hydroxyl groups on the BC surfaces [134]. BC has been integrated in various forms of medical treatment, including wound dressings, hydrogel-based oral drug delivery, and cargo scaffolds. Table 2 and Figure 7 summarize some of the most recent cargo delivery systems based on BC.

Table 2.

Cargo delivery systems based on BC: carriers, applications, and loading and release mechanisms

| Drug/bioactive agent | Carrier | Potential application | Loading mechanism | Release mechanism | Year [Reference] |

|---|---|---|---|---|---|

| Azorubine | Supplemented BC fleeces | Safe-to-store oral delivery and targeted drug delivery | Immersion in solution (absorption) | Diffusion | 2014 [135] |

| Bovine serum albumin | BNC fleece | Protein delivery | High-speed vortexing | Diffusion | 2014 [136] |

| Octenidine | BNC fleece | Wound treatment | Immersion in solution under shaking | Diffusion | 2014 [137] |

| Octenidine | BNC/poloxamer micellar hydrogels | Dermal drug delivery | Immersion under shaking | Sustained gel dissolution | 2016 [138] |

| Ibuprofen | BNC/graphene oxide composite hydrogels | Delivery of poorly watersoluble drugs | Immersion in drug solution | Non-Fickian, pH- regulated diffusion | 2017 [139] |

| Bromelain | BNC membranes | Antimicrobial wound dressing | Immersion in solution under shaking | Diffusion | 2017 [140] |

| Diclofenac sodium salt (DCF) | BNC-Poly(Nmethacryloyl glycine) membrane | Dermal and oral drug delivery | Immersion in solution | pHdependent (high release at pH ~ 7.4) | 2017 [141] |

| NA | BNC-ZnO nanocomposite films | Antimicrobial burn wound dressing | Immersion under shaking and lyophilization | Dermal application to burn as a bandage | 2017 [142] |

| Methotrexate | BC/CMC composite membrane | Topical treatment for psoriasis | Immersion in solution | Dissolution in vitro | 2018 [143] |

| Silymarin | Zein nanoparticle/BC nanofiber composite films | Antioxidant/a ntibacterial | Encapsulatio n in nanoparticles | Improved solubility | 2018 [144] |

| Cells (Keratinocytes and fibroblasts) | BC/acrylic acid hydrogels | burn wounds | encapsulation | NA | 2018 [145] |

Figure 7.

Bacterial cellulose (BC)-based biomaterials, including colloidal nanoparticles, films, membranes, and hydrogels for the delivery of a broad range of cargos. Panel (a) is reprinted with permission from [146], Copyright © 2015, Springer Nature, Springer Science Business Media New York. Panel (b) is reprinted from [140] under Creative Commons Attribution 4.0 International License for the Open Access content. Panel (c) is reprinted with permission from [147]. © 2018 WILEY- VCH Verlag GmbH & Co. KGaA, Weinheim.

3.1. BC for cargo delivery

One of the challenges in designing drug delivery systems is to control the exposure location and delivery time [148]. Engineering the spatiotemporal release profile of cargos may reduce side effects and enable targeted clinical treatments [149]. BC has been studied as an infrastructure to warrant controlled drug delivery, which benefits from stability, biocompatibility, and a large surface area decorated with hydroxyl groups that allow for attaching bioactive components. BCs attain various desirable properties that are comparable to CNCs without plant-derivative byproducts (impurities), including hemicellulose, lignin, and pectin (P) [150]. While BNCs do not possess any antimicrobial or anti-inflammatory characteristics, upon functionalization and drug loading, they may be an excellent platform for wound dressing.

Sustained release of lidocaine hydrochloride, a drug typically used for numbing, and ibuprofen (IBU, a nonsteroidal anti-inflammatory drug) are among the examples of BC-mediated drug delivery [151,152]. BC may be modified with a glycerol plasticizer [153] to increase the flexibility and swelling ratio of scaffolds, while providing the sustained release of bioactive molecules, such as caffeine for cellulite treatment. Glycerol have safely been added to the BC to soften the treated regions without any adverse effect on the biocompatibility. Another interesting cargo for BC is bromelain, a protein derived from pineapple fruit, leaves, and stem, which is a proteolytic enzyme that has antibacterial capacity for treating diabetic ulcers [154], rheumatoid arthritis [155], angina pectoris [156], and bronchitis [157]. BNC loaded with bromelain has been used for wound healing [140]. The antibacterial and antioxidant activities of bromelain-loaded BNC biomaterials attest to their applicability as a drug delivery system for treating common pathogens. Loading the cargo in the BNC hydrogels typically demands the incubation of BNC membrane in the drug (e.g., bromelain) solution for 4 to 24 h (e.g., absorbing 7.94 mg/mL of the protein). Hydrogels immersed in bromelain for 4, 8, 12, and 24 h showed identical enzymatic activity. The antibacterial properties of bromelain-attached CNC against Staphylococcus aureus, E. coli and P. aeruginosa., characterized by the agar plate method, showed that all treated colonies were eradicated. Released bromelain solution enzymatic activity was higher than initial and residual enzymatic activity, and the total protein concentration in the released solution was the lowest. The BNC successfully adsorbed and delivered the proteolytic enzyme bromelain, which exhibited high enzymatic and bactericidal activities towards gram-negative and grampositive bacteria [140].

Current BNC wound dressing technology relies on combinatorial treatments, encompassing regeneration and vascularization promoters as well as bactericidal agents. Povidone-iodine (PI)-loaded BNC wound dressing has been able to improve the currently available polyhexanide-(PHMB)-loaded BNC dressing technology [146]. Using BNC, extracted from Komagataeibacter xylinus, drug loading is readily achieved by the incubation of nanocellulose in PI or PHMB solutions. While the uptake of the PI and PHMB by BNC dressings only reached to ~ 12%, the amount of PI loaded in terms of drug mass per unit mass, surface area, and volume of the wound dressing for BNC were about 10 times higher than PHMB [146]. An initial burst drug release was observed in the first 8 h whereby the burst release for PHMB was significantly higher than that of PI, recording 67% and 46%, respectively, and the PI-loaded BNCs exhibited a more prolonged drug release than PHMB. PHMB-loaded BNCs recorded a cumulative drug release of approximately 85% after 24 h, which plateaued after 48 h. The cumulative PI release was at around 73%, which progressively increased. Drastic cytotoxicity differences were observed for the PI- and PHMB-loaded BNCs against HaCaT keratinocytes. While both PI and PHMB exhibited some degrees of cytotoxicity, the PI-loaded BNCs exhibited significantly lower toxicity, observed at concentrations ~ 15 and 20 mg/mL, whereas a pronounced toxicity was measured at 2 mg/mL of PHMB-loaded BNCs. Antimicrobial activities against S. aureus showed a log-reduction greater than 7. These tests allowed for the quantification of half maximal lethal concentrations (LC) and half maximal inhibitory concentrations (IC), whereby the LC50/IC50 of PI-loaded BNC was 4.8 while PHMB-loaded BNC recorded a ratio of 229 [146].

Recently-developed wound dressings are engineered to maintain moist conditions, attain high efficacy and selective antimicrobial effects, and promote rapid healing. In one of the attempts to design effective wound dressings, octenidine has been incorporated in BNC. Octenidine is an antiseptic drug with desirable characteristics, such as biocompatibility, skin compatibility, non-resistance-inducing bactericidal properties, and 24 h-long skin remnant. BNCs, prepared from K. xylinus, were submersed in an octenidine solution for loading [137]. An initial burst release for all BNC fleeces was desirable to achieve a therapeutically-relevant level. Equilibrium conditions were reached after 24 h, followed by a slow release. The biocompatibility of octenidine-loaded BNCs was tested against keratinocytes, a major cell type in human skin, indicating that no significant cytotoxicity was observed at 0.1–1% octenidine/BNC after 1, 24, and 48 h. However, octenidine/BNC ~ 10% drastically decreased the cell viability after 24 h. The antimicrobial activity against cultures of S. aureus, a common bacterial strain involved in wound infection, was also confirmed. Interestingly, the antimicrobial potency was preserved for BNC fleeces that were prepared and used after 6 months of storage [137]. Importantly, antimicrobial activity against the S. aureus was more pronounced than the cytotoxicity against HaCaT keratinocytes. The octenidine-loaded BNCs may serve as a powerful wound dressing with practical commercial benefits, such as potency after prolonged shelf storage [137].

BC has also been used for the delivery of nucleic acids. Singhsa et al. [127] have prepared bacterial celluloses using three different bacterial strains of K. xylinus, followed by hydrolysis using three different acids: hydrochloric acid, sulfuric acid, and a mixture of both. These BCNCs were tested for cytotoxicity and efficacy for nucleic acid delivery post-cationic (amino) functionalization. The modified cationic BCNC was simply mixed with siRNA to yield BCNC-siRNA complexes. The BCNC-siRNA complex formation was assessed using agarose gel electrophoresis, which indicated that modified BCNCs with a net negative ζ-potential failed to completely form a complex with the siRNA, while those with a net positive ζ-potential successfully yielded full complexation with siRNA. These results attest to the promising potential of surface charge modified BCNCs as cargo delivery vehicles for nucleic acids and proteins [127].

3.2. BC composite hydrogels and membranes

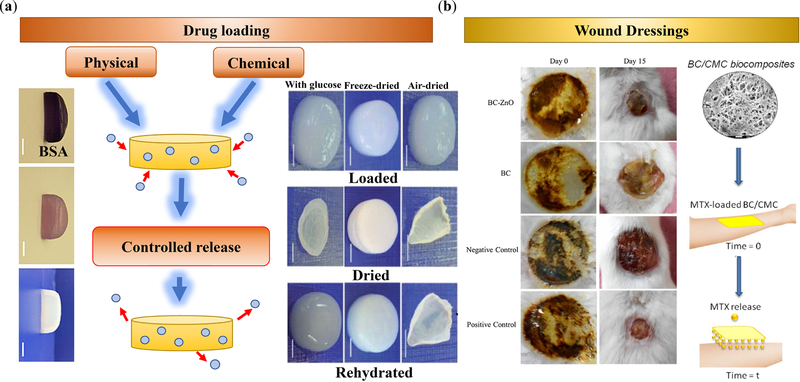

Hydrogels made up of bacterial nanocellulose have emerged as potential platforms for targeted drug delivery with remarkable biocompatibility, structural stability, water retention, and customizability. BNC hydrogels can be fabricated using as low as 1% nanocelluloses, which may benefit form a large water content. Conventional methods for loading drugs in BNC hydrogels and other BNC-integrated matrices and scaffolds involve the immersion of the BNC delivery system in the drug solution. This allows for the drugs to be loaded via diffusion and adsorption; however, the downside of this process is the prolonged loading time, which is not a practical for clinical and industrial purposes. Composite BNC/poly(N-methacryloyl glycine) membranes have been incubated with diclofenac sodium salt (DCF) for 48 h, resulting in ~ 100% drug loading (5 mg cm−2) and a pH-regulated controlled release with the highest release at the neutral pH [141]. An alternative method for drug loading involves vortexing for a few minutes, resulting in the high-speed loading of cargos, e.g., bovine serum albumin as a model protein (Figure 8a) [136]. Interestingly, the BNCs loaded through the conventional method showed a much faster BSA release as compared to the vortexing technique. Significant differences were observed after 24 h, and by 72 h, the model drug loaded with the conventional technique recorded a 91.2% release as opposed to a 62.4% release by the vortexing technique. Scanning electron microscopy (SEM) images revealed interesting outcomes that could serve as explanations for the observed drug release profile. As compared to the untreated BNC, the BNC treated with conventional drug loading methods exhibited a slight increase in fiber thickness and pore size. On the other hand, BNC treated with the vortex exhibited a significantly denser network of fibers with thicker fibers and partial pore closures [136]. Besides physical loading, drugs, such as amoxicillin may be chemically conjugated to BCs, e.g., to produce wound dressing sponges [158].

Figure 8.

(a) Mechanisms of cargo (e.g., BSA [136]) loading in BC-based carriers, including physical absorption/adsorption and chemical conjugation. The carrier may be used in hydrated or dry states. Supplementing BC with additives, such as glucose, provides remarkable shape recovery after rehydration [135]. (b) BC-based materials have been widely used for wound dressing, enabling the controlled release of bioactive (e.g., MTX) molecules [143]. BC may also be combined with antibacterial nanomaterials, such as ZnO for burn wounds [128]. Images in Panel (a, left) are reprinted from [136] Copyright (2014), with permission from Elsevier. Images in panel (a, right) are reprinted from [135] under Creative Commons Attribution 3.0 Unported Licence. Panel (b, left) is adapted from [128] Copyright (2017), with permission from Elsevier. Panel (b, right) is adapted from [143] Copyright (2018), with permission from Elsevier.

High swelling capacity is beneficial to load cargos in BCs. BC/acrylamide hydrogels may be prepared using microwave radiation under a basic condition (NaOH/urea), which demonstrate a higher theophylline (a drug for respiratory medical conditions) loading capacity than BC-free polyacrylamide scaffolds, providing controlled release in 24 h [159]. While clinical drug delivery demands hydrated hydrogels, long-term storage of hydrated materials raises issues regarding storage and the risk of bacterial contamination. Air-drying hydrogels results in microstructure collapse, which may deteriorate their bioactivity [135]. Lyophilization, supercritical carbon dioxide, ethanol drying, or hot-pressing are all expensive, resource-dependent operations that result in low-quality BNC hydrogels. To preserve the desired BNC microstructure and functionality for drug delivery, the dehydration of crystalline hydrogels may be conducted using several supplements, encompassing glucose, sucrose, lactose, trehalose, sorbitol, mannitol, PEG, magnesium chloride salt, and sodium chloride salt [135].

Supplementing 10% (w/v) magnesium chloride (MgCl2), glucose, and sucrose resulted in the highest re-swelling and drug delivery properties, which offered the best dehydration methods for preserving BNC structure and function [135]. Magnesium chloride supplement retained the largest amount of water after dehydration relative to never-dried BNC. After 168 h of rehydration, MgCl2-supplemented BNC reswelled to ~93% of its initial volume before drying and ~ 88% of its original weight. Glucose-, sucrose-, and sorbitol-treated biomaterials reswelled to above ~ 60% of their original volumes. SEM images revealed that the top and bottom surfaces as well as the cross-section of glucose-, sucrose-, and magnesium chloride-supplemented biomaterials retained their original three-dimensional structure after dehydration as compared to air-dried biomaterials that suffered from fiber aggregation and structural failure [135]. Interestingly, glucose-supplemented BNC released ~ 52% of a model drug (azorubine) in 1 h and ~ 95% in 4 h, which has a better control of the cargo release than the air-dried BNC releasing ~ 98% of the drug in the first hour (Figure 8a). Accordingly, supplementing BNC with carbohydrates or inorganic salts may facilitate the storage and transportation of BNC while maintaining the nanocrystal structure and function [135].

Interestingly, the physicochemical properties of BC have been engineered by simple drying methods. The integration of BC into single-excipient based BC matrices undergoing various drying methods, such as freeze-drying and oven-drying before and/or after drug loading (famotidine or tizanidine) has been investigated [160]. Higher drug loading was obtained for hydrated and partially hydrated BC matrices as compared to the freeze-dried ones. Hydrophilicity and porous fibrous network facilitated drug diffusion through the matrix as opposed to the freeze-dried matrix, wherein lacking these properties resulted in noticeable fiber aggregation and reduced water retention capacity. BC matrices loaded with famotidine or tizanidine had more than 80% burst drug release in the first 15 min in the simulated gastric fluid.

3.3. BC composite films

One of the main motivations to prepare BC films is their applications in wound healing, wherein functionalized substrates are required to remain on the lesion and provide healing and antibacterial effects. Traditionally, burn wounds have been covered with gauze and cotton wool; however, they adhere to the wound and are difficult to remove. Accordingly, alternative biomaterials, such as collagen, chitosan, and alginates have emerged for wound dressing [161,162]. The focus of research has been on the wound dressing biomaterials with drug releasing properties that leverage the healing process [163,164]. While various types of transdermal patches have been developed for the strategic and controlled delivery of drugs, increased microbial resistance has imposed unmet challenges to effective wound healing and wound infection prevention. To address this issue, novel approaches have been explored to achieve the dual release of proteins and antibiotics, leveraging bio-functionalities against antimicrobial resistance [165–167].

In a recent effort, the dual release of proteins and antibiotics from hybrid BC films has been investigated. BC, extracted from Komagataeibacter hansenii, was mixed with high methoxylated pectin (HMP) and modified with HSA and levofloxacin (Levo, an antibiotic agent). BC-HMP provided a lower burst drug release, enabling the controlled release of both Levo and HSA as compared to the unmodified BC. Cytotoxicity studies have suggested that this dual drug release system is biocompatible as Levo toxicity was attenuated upon loading in HMP, recording ~ 90% cell viability at 200 µg/mL (as compared to ~ 71% for free Levo) and ~ 100% cell viability at 100 µg/mL (as compared to ~ 89% for free Levo) [168]. Importantly, Levo-HSA-HMP had an antimicrobial activity against S. aureus and demonstrated promising outcomes not only for infection prevention but also for enhanced cell proliferation and tissue regeneration [168].

Another antimicrobial agent that can be delivered using BNC films is fusidic acid (FuA). FuA is a commonly used bactericidal drug, which is effective against drug-resistant bacteria. FuA can be loaded in BNC films by immersing the films in a sodium fusidate solution. The antibacterial effect of FuA-loaded BNC against S. aureus, tested using the disk diffusion method wherein the biomaterials were placed on S. aureus lawns on an agar plate and examined for the degree of clearance of the lawn surrounding the composite [169], demonstrated that the BNC films loaded with 0.4 g/L of FuA resulted in a 34 mm-diameter inhibition zone. Recorded inhibition zone diameters were 27, 30, and 32 mm for loading concentrations ~ 0.1, 0.2, and 0.3 g/L, respectively, showing the high potency of FuA-doped BNC nanocomposite films as a bactericide wound dressing.

PVA-BC hydrogels have been produced in monolayer and multilayer forms to load and release vanillin as an antimicrobial agent in a controlled manner that is regulated by the film composition [170]. Huang et al., [171] compared the release of berberine (a plant-based quaternary ammonium salt) from BC in different simulated fluids and found that the slowest berberine release occurred in simulated gastric fluid (SGF), containing sulfuric acid, and the highest release rate took place in the simulated intestinal fluid (SIF). SEM imaging confirmed that BC nanofibers became thicker in acidic solutions, resulting in smaller pore sizes that restricted the cargo diffusion rate.

Alternatively, BC may be impregnated with antimicrobial zinc oxide (ZnO) nanoparticles (Figure 8b, left panel) [172] or silver nanoparticles [173] for wound dressing. The BC-ZnO nanocomposites can be synthesized via the incubation of BC sheets in a ZnO nanoparticle dispersion [142]. These nanocomposites have antimicrobial activity against E Coli, Citrobacter freundii, Pseudomonas aeruginosa, and Staphylococcus aureus, the first three of which are Gram negative bacteria and the last Gram positive. Treatment with BC-ZnO showed a zone of inhibition that was similar in diameter to that of silver sulfadiazine (SD), a standard antimicrobial drug. Percent inhibition was calculated by dividing the BC-ZnO zone of inhibition by that of SD, all of which had approximately 90% inhibition for all four bacterial species. The effectiveness of wound healing and antibacterial activity were also confirmed in the in vivo tests conducted on burn mouse models. The average wound area was observed over 0, 5, 10, and 15 days, in which the BC-ZnO always showed significant wound healing effects (p ≤ 0.001) [142]. In fact, the recorded average wound area for the BC-ZnO-treated mice (269.3, 195.6, and 98.3 mm2 for 5, 10, and 15 days, respectively) was comparable to those of the SD-treated mice (287, 148.3, and 66.6 mm2, for 5, 10, and 15 days, respectively), supporting the potency of BC-ZnO nanocomposites.

BC may be combined with synthetic nanomaterials to overcome their limitations. BC/graphene oxide (GO) nanocomposites overcome the non-specific binding of GO to proteins in biological systems. BC/GO nanocomposites can readily be prepared in situ by adding GO to the culture media of cellulose-producing bacteria (e.g., Komagataibacter xylinus X-2) [139], providing a higher capacity for loading drugs than neat BC. Despite increasing the surface area and improving the loading capacity, added GO may have adverse effects on cell viability. As an example, 0.48% GO was not suitable for drug delivery as it demonstrated inhibitory or cytotoxic effects. Ibuprofen delivery using BC/GO and GO-free BC was tested at near neutral pH (~ 7.4) and acidic pH (~ 1.2) at the physiological temperature (37.0 ± 0.5°C), which showed a non-Fickian diffusion-regulated release and a zero-order transport rate, respectively. For both acidic and near-neutral pH, BC/GO released IBU at a more controlled manner than neat BC over 24 h [139].

To increase the hydration capacity of BC, dissolved cellulose additives, such as carboxymethyl cellulose (CMC), have been used without significantly compromising the crystallinity and thermal stability of BC. Modifying BC with polyanions has enabled the regulation of physical and chemical interactions with target molecules, e.g., water and drugs, to design drug delivery systems with desirable swelling, loading, and release rates [174–178]. BC can be modified with solubilized celluloses in situ, for example, via adding 1% CMC to the bacteria culture medium (Figure 8b, right panel) [143]. Increasing the degree of carboxylic acid substitution (DS) of CMC had a positive effect on hydration capacity and swelling ratio; however, at high concentrations, the crystallinity index and storage modulus of BC composites decreased. BC/CMC (DS ~ 0.7) swelled more than neat BC, BC/CMC (DS ~ 0.9), and BC/CMC (DS ~ 1.2); however, the liquid intake for neat BC was 490%, and BC/CNC composites with DS ~ 0.7, 0.9, and 1.2 absorbed 958%, 86%, and 578% water, respectively [143]. Interestingly, the high porosity of BC/CMC (DS ~ 0.7) resulted in the highest swelling ratio. Hydroxyl-ester interactions in BC/CMC (DS ~ 0.9) composites increased the matrix stiffness, which decreased the liquid absorption and the swelling capacity. In all samples, 70–80% MTX was released in the first 15 min, followed by a steady drug release thereafter. BC/CMC (DS ~ 0.9) provided the lowest MTX release rate, yielding 80% release after 180 min, whereas BC/CMC (DS ~ 0.7) released 96% of MTX over the similar period [143].

4. Cellulose nanofibrils (CNF) for cargo delivery

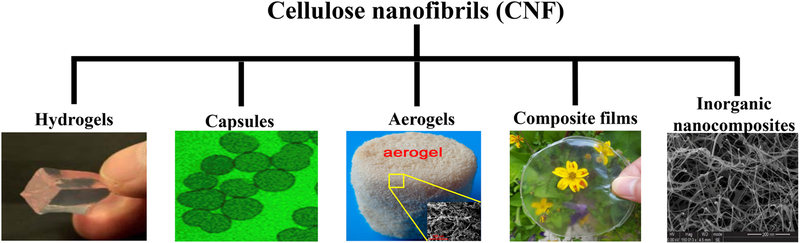

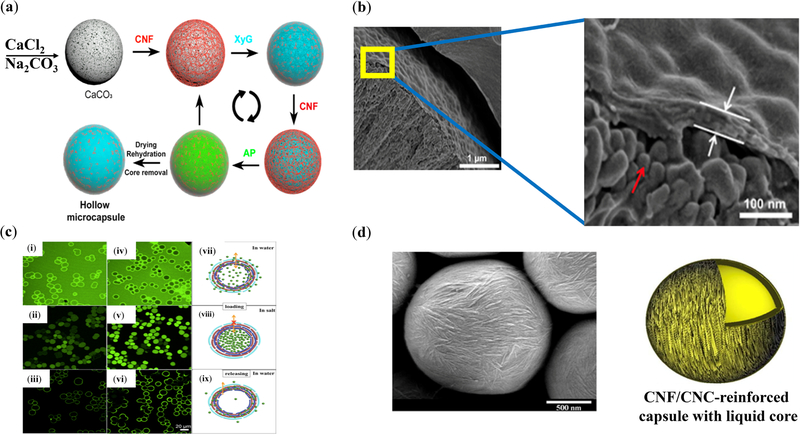

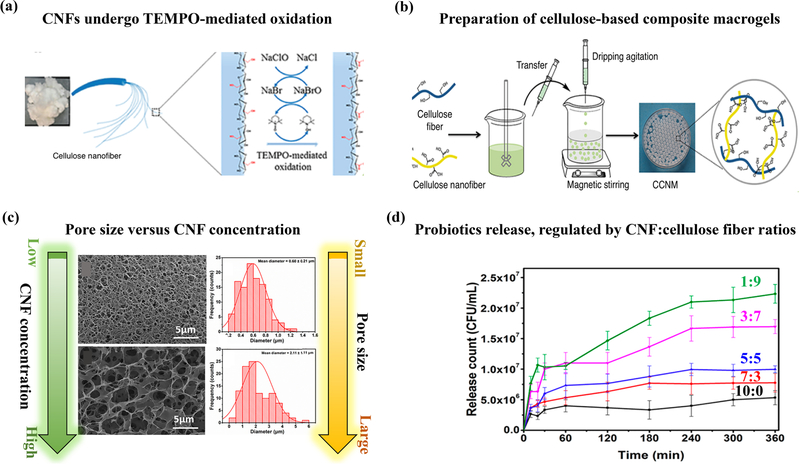

Biomedical research on CNFs has mainly revolved around studying the mechanical, chemical, thermal, and simulated loading/release properties of the nanocellulose composites. Recently, immense attention has been drawn towards biobased materials to design and produce a broad range of environmentally-benign materials with added values. The abundancy of plant biomass and the tunable mechanical and rheological properties of CNF have rendered this nanocellulose an attractive additive for a variety of polymer nanocomposites [117,179]. Different forms of CNF-based cargo delivery systems, encompassing colloidal particles, hydrogels, shells/capsules, aerogels/foams, and films are summarized in Table 3 and Figure 9.

Table 3.

Examples of recent CNF-based cargo delivery: carriers, applications, and loading and release mechanisms

| Drug/bioimaging agent | Carrier | Potential application | Loading mechanism | Release mechanism | Year [Reference] |

|---|---|---|---|---|---|

| Methotrexate | Resistant starch/pectin/CNF electrospun nanofibers | Colon inflammation | Absorption and electrostatic attraction | pH dependent, enzymatic degradation | 2016 [180] |

| Beclomethasone dipropionate, indomethacin, itraconazol | CNF microparticles and capsules | Drug delivery of poorlysoluble drugs (broad range of applications) | Mixing/filtration/drying | Diffusion | 2017 [181] |

| Cisplatin | CNF-PVA hydrogel | Cancer treatment | Mixing | pH dependent release (maximum release at 7.4) | 2017 [182] |

| Metformin | CNF gel | Anti-cancer (melanoma) drug delivery and metastasis prevention | Electrostatic adsorption | pH dependent | 2017 [183] |

| N/A | Ca2+-mediated crosslinked CNF hydrogel, kaolinCNF, and collagen-CNF | Hemostatic wound dressing | N/A | N/A | 2017 [184] |

| Etoposide, methotrexate | Fe3O4-Ag2O quantum dots decorated cellulose nanofibers | Chemotherapy for lung, breast, and skin cancer | Binding to Ag2O | Drug solubility in water | 2017 [185] |

| Bendamustine hydrochloride | CNF aerogel | Gastroretentive oral drug delivery | Absorption, electrostatic attraction | pH dependent | 2017 [186] |

| Dextran | Microcapsules of CNF, hemicellulose, and pectin | Model drug delivery | Physical encapsulation | Ion-mediated release | 2017, 2018 [187,188] |

| 5-fluorouracil | α-chitin/TEMPO-oxidized CNF hydrogel | Anti-cancer oral drug delivery | Electrostatic adsorption through swelling | pH and swelling dependent | 2018 [189] |

| L. plantarum | Cellulose fiber and nanofibril hydrogel macroparticle | Probiotic delivery | Physical encapsulatio n | pH responsive pore size | 2018 [190] |

| Doxorubicin | Injectable CNF gel | Cancer (Melanoma) treatment and metastasis prevention | Electrostatic attraction | pH dependent | 2018 [191] |

| Tetracycline hydrochloride | CNF/ polydopamine hydrogel | Wound healing | Electrostatic attraction | pH dependent, high release at low pH | 2018 [192] |

Figure 9.

Cellulose nanofibril (CNF)-based biomaterials, including hydrogels, aerogels, capsules, films, and inorganic nanocomposites for cargo delivery. Images of hydrogel, capsules, aerogel, composite films, and inorganic nanocomposites are reprinted from [193], [188], [194], [195], and [185] with permissions from The Royal Society of Chemistry, Copyright (2017) American Chemical Society, Copyright (2015) American Chemical Society, Copyright (2017) American Chemical Society, and Elsevier, respectively.

4.1. CNF for drug delivery

Formulation and development of drug delivery systems have faced several challenges in the past decade. Poor aqueous solubility of cargos remains a common obstacle in developing effective delivery systems [196,197]. To overcome the limitations of sparingly soluble drugs, CNFs have recently been noticed in the pharmaceutical industry [181,198]. Unmodified CNFs are amphiphilic nanocelluloses decorated with hydrophilic and hydrophobic surfaces, which are able to adsorb hydrophobic drug molecules and nanoparticles and increase their colloidal stability. In addition, the nanocellulose-mediated mechanical reinforcement of drug carriers, such as starch, may leverage the controlled release of active molecules [199]. These properties have been verified by multiple studies confirming the favorable molecular interactions between CNF and poorly-soluble drugs [181]. Small poorly-soluble surfactant-like drug molecules can be adsorbed by CNF and change the surface energy of nanocellulose. This can provide the Pickering stabilization of surfactant-free nanocellulose-based emulsions [200]. CNF, produced as microparticles with tight fibrillar network, has been loaded with drugs via spray drying. This strategy has resulted in the sustained release of drugs for several months, regulated by the drug solubility.

Capsules with versatile core functionality and tunable mechanical stability have been explored for potential applications in drug delivery [201,202]. Fiber-based reinforcement is inspired by the nature’s architectural solutions for building mechanically resilient constructs [203]. Mechanically-robust CNF capsules have been prepared using the layer-by-layer (LbL) technique (Figure 10) to fabricate small-scale scaffolds with on/off permeability regulated by salinity (ionic strength) for the on-demand loading/unloading of cargos, such as model fluorescent-labelled dextran [187,188]. This platform also holds promise in delivering drugs in a time-dependent manner. The modulus of wood-derived CNF is in the order of 150 GPa [204], supporting the mechanical integrity of CNF nanocomposites, such as capsules. Tunable oil core of CNF-based capsules may successfully contribute to the delivery of poorly-soluble drugs (Figure 10) [188,205].

Figure 10.