Abstract

Electrospinning is a versatile and viable technique for generating ultrathin fibers. Remarkable progress has been made with regard to the development of electrospinning methods and engineering of electrospun nanofibers to suit or enable various applications. We aim to provide a comprehensive overview of electrospinning, including the principle, methods, materials, and applications. We begin with a brief introduction to the early history of electrospinning, followed by discussion of its principle and typical apparatus. We then discuss its renaissance over the past two decades as a powerful technology for the production of nanofibers with diversified compositions, structures, and properties. Afterward, we discuss the applications of electrospun nanofibers, including their use as “smart” mats, filtration membranes, catalytic supports, energy harvesting/conversion/storage components, and photonic and electronic devices, as well as biomedical scaffolds. We highlight the most relevant and recent advances related to the applications of electrospun nanofibers by focusing on the most representative examples. We also offer perspectives on the challenges, opportunities, and new directions for future development. At the end, we discuss approaches to the scale-up production of electrospun nanofibers and briefly discuss various types of commercial products based on electrospun nanofibers that have found widespread use in our everyday life.

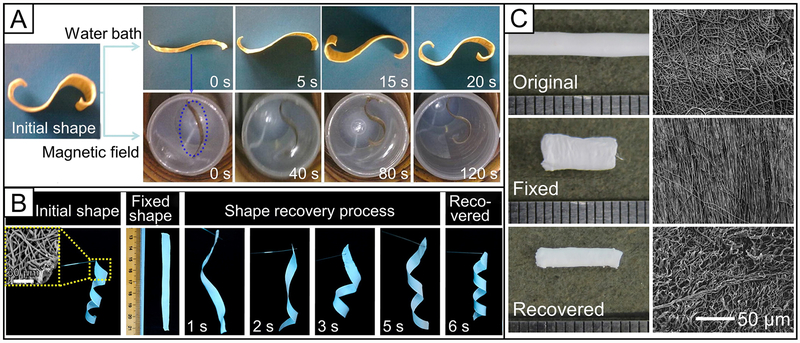

Graphical Abstract

1. INTRODUCTION

Fibers, in the form of either continuous filaments or elongated objects, are ubiquitous in nature. For more than 140 million years, spiders have relied on webs of fibers to capture prey. The webs are constructed from silk fibers with diameters ranging from 2 to 5 μm. Silkworms are also well-known for their remarkable ability to produce silk filaments for the construction of cocoons. These and many other natural systems have served as an important source of inspiration for the development of man-made fibers.1–3 As a matter of fact, fibers have been a fundamental part of human life since the dawn of civilization. The history of fiber production by mankind can be traced back to prehistoric times. Fragments of cotton articles dating back to 5000 BC have been excavated, and silkworm cultivation began in 2700 BC for the production of silk fibers and textiles. Around 1300, the spindle was invented to fabricate fibers from wool and cotton for the production of fabrics and clothes, and this practice slowly evolved into the textile industry in the 1880s. Rayon, made of cotton or wood cellulose fibers, represents the first man-made fabrics. Although it was reported in 1891, it was not commercially marketed until 1911.4 About 50 years later, synthetic fibers were produced along with the development of chemistry and polymer science. As the first commercially viable synthetic fiber, nylon was introduced by DuPont in 1938, and it immediately caught the public’s attention.5,6 Thereafter, many different types of polyesters and other synthetic polymers have been developed one after another for the manufacturing of synthetic fibers.7 The synthetic fibers significantly reduce the public’s demand for natural fibers while greatly expanding the scope of applications.

Many methods have been developed for producing fibers from synthetic polymers, most notably, those based on wet, dry, melt, and gel spinning.8,9 Wet spinning involves a spinneret submerged in a chemical bath. When a polymer solution is extruded from the spinneret into the chemical bath, the polymer is precipitated out because of the dilution effect or chemical reaction, generating fibers through solidification. For dry spinning, a polymer solution is extruded into air through a spinneret and fibers are obtained as a result of solvent evaporation from the jets aided by a stream of hot air. During melt spinning, a polymer melt is extruded from a spinneret to generate fibers upon cooling. Gel spinning is used to produce fibers with high mechanical strength or other special properties by spinning a polymer in the “gel” state, followed by drying in air and then cooling in a liquid bath. During these spinning processes, jets are mainly formed under external shearing forces and/or mechanical drawing when passing through spinnerets, and fibers are formed upon solidification of the jets as a result of precipitation or drying. The jets are only stretched to a limited extent, corresponding to the formation of fibers with diameters typically in the range of 10–100 μm.8,9 Even with further mechanical drawing during the solidification process or after complete cooling of the jets, the resultant fibers still cannot reach the sub-micrometer scale.

In 1887, Charles V. Boys reported that fibers could be drawn from a viscoelastic liquid in the presence of an external electric field.10 He used an apparatus consisting of an insulated dish connected to an electrical supply. It was demonstrated that a viscous liquid (e.g., beeswax and collodion) could be drawn into fibers when it moved to the edge of the dish. Widely known as electrospinning now, this technique opens the door to the production of ultrathin fibers with diameters down to the nanometer scale. In general, electrospinning allows for the facile production of continuous fibers with diameters ranging from tens of nanometers to several micrometers.11 Electrospun fibers with diameters down to 1 nm, and even below, have also been reported.12 In literature, electrospun fibers are often referred to as nanofibers when their diameters are thinner than roughly 500 nm.

The concept of electrospinning was conceived in an earlier study conducted by William Gilbert in 1600, in which he observed the formation of a cone-shaped water droplet in the presence of an electric field.13 About one century later, Stephen Gray observed the electrohydrodynamic atomization of a water droplet from which a very fine stream was generated.14 In 1747, Abbé Nollet performed the earliest known electrospraying experiment, demonstrating that water could be sprayed as an aerosol when passing through an electrostatically charged vessel that was placed next to the ground.15 The behaviors of charged droplets were then systematically studied by Lord Rayleigh. In 1882, he theoretically estimated the maximum amount of charges that a liquid droplet could carry before liquid jets would be ejected from the surface.16 Electrospinning can be considered a variant of the electrospraying technique,17 both of which rely on the use of a high voltage to eject liquid jets. The major differences between electrospinning and electrospraying lie in the viscosity and viscoelasticity of the liquid involved and thus the behavior of the jet. During electrospinning, the jet can be kept in a continuous form to produce fibers instead of breaking into droplets (for the formation of particles) as with electrospraying.

In 1902, two patents on electrospinning were filed by John Cooley and William Morton, respectively,18,19 describing a prototype of the setup for electrospinning. Afterward, Anton Formhals filed a couple of additional patents in 1934 and 1944 to disclose the improvement in equipment, moving toward the commercialization of electrospinning for the fabrication of textile yarns.20,21 Electrospun nanofibers were first implemented in the Soviet Union in 1938 for the development of air filters, known as “Petryanov filters”, for capturing aerosol particles. By 1939, this work had led to the establishment of a factory in Tver for the manufacturing of smoke filters with nanofiber-based mats as gas masks. During this period of time, a mechanistic understanding of electrospinning was slowly developed. Between 1964 and 1969, Geoffrey Taylor published a series of pioneering papers, showing how to mathematically describe and model the spherical to conical shape change of a polymer solution or melt droplet under the influence of a strong electric field.22–24 Specifically, as the strength of the electric field was increased beyond a critical level, the spherical droplet would gradually evolve into a cone (now commonly referred to as Taylor cone) and emanate a liquid jet. Afterward, the development of electrospinning technique experienced 20 years of stagnancy, as it did not receive much attention from academia or industry during this period of time. This stagnancy can be largely attributed to the lack of characterization tools capable of accurately measuring the sizes of fibers with diameters down to the sub-micrometer range. Nevertheless, a variety of applications were proposed for electrospun fibers during this period of time, including their potential use as wound dressing materials as described by a patent filed in 1977.25 In the early 1980s, Donaldson Co. Inc. in the U.S. began to produce and sell filters comprised of electrospun fibers for air filtration. However, the company did not disclose the makeup of their products in order to gain advantages over its competitors.

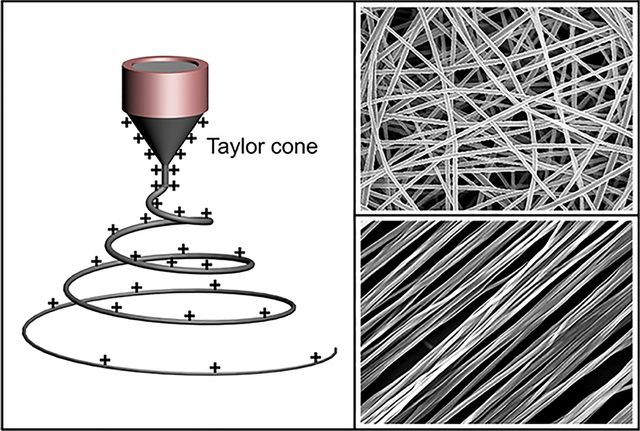

It was not until the early 1990s that several research groups, notably those led by Darrell Reneker and Gregory Rutledge, began to reinvent this technique.26–32 This was made possible by the increased accessibility of electron microscopes capable of resolving features down to the nanometer scale. These groups demonstrated that many different organic polymers could be electrospun into nanofibers. The term “electrospinning” was popularized for describing this technique. Their studies brought new life to electrospinning, and this technique eventually became the method of choice for producing long and continuous fibers with diameters down to the nanometer scale. At the beginning of this century, electrospinning started to receive increasing attention when its capability was further expanded by switching to new materials and formulations for the fabrication of composite and ceramic nanofibers.33–35 The ability to electrospin new materials quickly enabled new applications in catalysis, as well as energy harvesting, conversion, and storage, which were traditionally dominated by inorganic nanoparticles. In parallel, new strategies were also developed to control the structure and alignment of electrospun nanofibers, opening a world of opportunities in energy-related and biomedical applications. Notably, several methods for aligning the nanofibers were developed, demonstrating the feasibility to combine different properties arising from the size, structure, composition, morphology, porosity, and assembly of nanofibers.35–38 At the same time, coaxial electrospinning was developed to produce continuous core–sheath and hollow nanofibers.39 The fabrication of continuous yarns of electro-spun nanofibers was also reported.40 Figure 1 shows a brief summary of the major milestones for the development of electrospinning. These achievements make electrospinning a versatile and viable technology for the production of nanofiber-based materials to target a broad range of applications.

Figure 1.

Brief summary of the development history of electrospinning.

Today, industrial production lines have been designed and implemented by a number of companies to manufacture electrospun nanofibers in large volumes, enabling downstream commercial products. At the moment, electrospun nanofibers are widely used for water and air filtration, ranging from industrial products (e.g., car filters) to civilian goods (e.g., facial masks and water filters). With the receipt of the Conformité Européene (CE) Mark for the AVflo vascular access graft by Nicast, more and more biomedical products based on electrospun nanofibers are approved for clinical use. Meanwhile, in the laboratory setting, electrospun nanofibers have been further engineered with specific compositions and innovative structures, endowing them with special functions for advanced applications.

In preparing this review, we aim to provide a comprehensive overview of electrospinning, including the principle, methods, materials, and applications. We begin with a discussion on the principle and typical apparatus of electrospinning to give the readers a clear picture of this remarkably simple and versatile technique. We then extensively review the methods and materials typically involved in electrospinning. Afterward, we discuss how the compositions, structures, and properties of electrospun nanofibers can be engineered to target different types of applications. All these attributes make electrospun nanofibers a class of nanomaterials well-suited for a broad spectrum of applications, including their use as “smart” mats, filtration membranes, catalytic supports, energy harvesting/conversion/storage components, and photonic and electronic devices, as well as biomedical scaffolds. We concentrate on the most relevant examples to highlight the advances related to the development of electrospun nanofibers. At the end of each section, we also offer perspectives on the challenges, opportunities, and new directions for future development. Finally, after a brief summary, we discuss approaches to the scale-up production of electrospun nanofibers and showcase typical examples of commercial products based on electrospun nanofibers. We also briefly compare electrospinning with other techniques that have been developed in recent years for producing nanofibers.

2. ELECTROSPINNING

2.1. Principle of Electrospinning

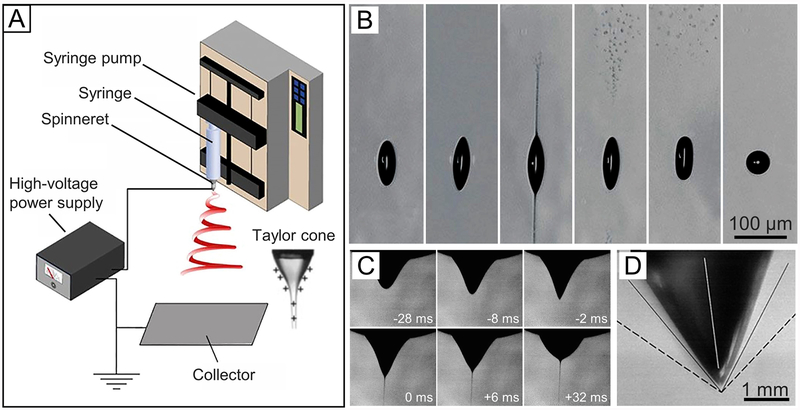

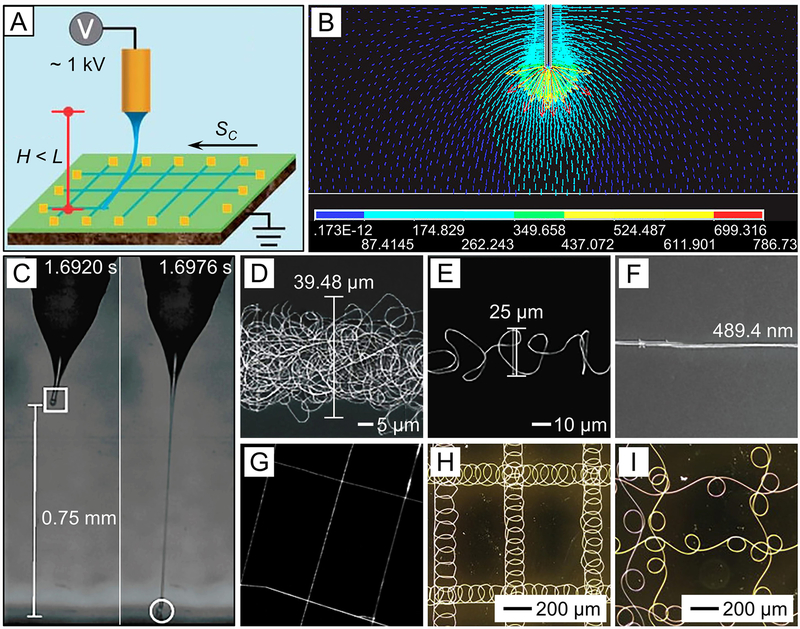

Electrospinning involves an electrohydrodynamic process, during which a liquid droplet is electrified to generate a jet, followed by stretching and elongation to generate fiber(s). As illustrated in Figure 2A, the basic setup for electrospinning is rather simple, making it accessible to almost every laboratory.41,42 The major components include a high-voltage power supply, a syringe pump, a spinneret (usually, a hypodermic needle with blunt tip), and a conductive collector. The power supply can be either direct current (DC) or alternating current (AC). During electrospinning, the liquid is extruded from the spinneret to produce a pendant droplet as a result of surface tension. Upon electrification, the electrostatic repulsion among the surface charges that feature the same sign deforms the droplet into a Taylor cone, from which a charged jet is ejected. The jet initially extends in a straight line and then undergoes vigorous whipping motions because of bending instabilities. As the jet is stretched into finer diameters, it solidifies quickly, leading to the deposition of solid fiber(s) on the grounded collector. In general, the electrospinning process can be divided into four consecutive steps: (i) charging of the liquid droplet and formation of Taylor cone or cone-shaped jet; (ii) extension of the charged jet along a straight line; (iii) thinning of the jet in the presence of an electric field and growth of electrical bending instability (also known as whipping instability); and (iv) solidification and collection of the jet as solid fiber(s) on a grounded collector.41,43,44 A more detailed discussion of these four steps is provided in the following subsections.

Figure 2.

(A) Basic setup for electrospinning. (B) High-speed photographs showing the disintegration of a levitated droplet of ethylene glycol charged to the Rayleigh limit for the ejection of two jets. (C) Photographs showing the evolution of a pendant drop of PEO in water from a spherical to a conical shape, followed by the ejection of a jet. (D) Photograph of the droplet at the critical point. (A) Reprinted with permission from ref 42. Copyright 2017 American Chemical Society. (B) Reprinted with permission from ref 45. Copyright 2003 Springer Nature. (C) Reprinted with permission from ref 50. Copyright 2008 Elsevier. (D) Reprinted with permission from ref 51. Copyright 2001 AIP Publishing.

2.1.1. Formation of Taylor Cone upon Charging a Liquid Droplet.

To understand the formation of a Taylor cone from an electrically charged liquid droplet during electrospinning, it is necessary to grasp the electrohydrodynamic principles involved. A classic example can be found in the formation of Rayleigh jets from levitated droplets of ethylene glycol in an electric field (Figure 2B).45 Upon injection into the levitator, the droplet took a spherical shape with a radius of 58 μm. The charge on the surface was about 3.3 pC. Due to the evaporation of neutral molecules, the droplet shrank in size over time, reaching the limit of Rayleigh stability at a radius of about 24 μm within 140 μs. At that point, the droplet deformed into an ellipsoidal shape, and two sharp tips were developed at the poles. Almost immediately after the formation of tips, two fine liquid jets were ejected from the tips along the opposite directions. The jets later broke into fine droplets that were repelled away from the parent droplet due to electrostatic repulsion. Upon the ejection of jets, the tips disappeared, and the barrel-shaped droplet contracted until it regained a spherical shape after about 210 μs. This experiment clearly shows the disintegration of a droplet charged to the limit of Rayleigh instability and the production of Rayleigh jets. When the ethylene glycol in the droplets was replaced by a sol–gel precursor solution, the Rayleigh jets could be fixed for characterization using electron microscopy.46

During electrospinning, the liquid is typically fed through the spinneret at a constant and controllable rate using a syringe pump. When there is a potential difference between the spinneret and the collector, positive and negative charges will undergo separation within the liquid and charges in the same sign as the spinneret’s polarity will migrate toward the surface of the droplet, producing excess charges. With the gradual increase of voltage, more charges will be accumulated, increasing the density of surface charges residing on the droplet. While the surface tension favors a spherical shape to minimize the total surface free energy of the droplet, electrostatic repulsion tends to deform the shape of the droplet, so its surface area will be increased to attenuate the repulsion.47 The droplet is assumed to take a shape that minimizes the sum of the electrostatic energy and the surface free energy.

By assuming the liquid in the droplet as a perfect conductor,22 the electrostatic pressure (pe) acting on the surface of the droplet by the external electric field can be calculated as pe = εE2/2, where ε is the dielectric constant of the medium surrounding the droplet and E is the intensity of the electric field. The capillary pressure (pc) caused by the surface tension is defined by the Young–Laplace equation in the following form: pc = 2γ/r, where γ is the surface tension and r is the mean radius of curvature of the surface, which can be represented by the inner radius of the spinneret.48,49 When the electric field reaches an adequate strength at a critical voltage of Vc, pe will surpass pc; that is, the electrostatic repulsion will be strong enough to overcome the surface tension. In consequence, the droplet will deform into a conical shape.22 In this case, Vc can be calculated using the following equation:24

| (1) |

where H is the distance between the tip of the spinneret and the collector, h is the length of the spinneret, and R is the outer radius of the spinneret. The units of H, h, and R are all in centimeters, while the unit of γ is dyn/cm and the unit of the voltage is kV. The factor 1.3 is derived from 2 cos 49.3° when considering that the cone has a semivertical angle close to a possible equilibrium value of 49.3°.22 During the electrospinning process, the critical voltage needed to generate a conical shape for the droplet is dependent on the properties of the liquid. When a viscous liquid is used, the voltage needs to reach a critical value capable of generating an electrostatic repulsion strong enough to overcome the surface tension plus the viscoelastic force of the liquid. As demonstrated by the photographs in Figure 2C, a pendent droplet of poly(ethylene oxide) (PEO) in water gradually deforms into a conical shape before a jet is ejected.50 Figure 2D shows a photograph of the droplet at the critical point.51 The conical shape can be maintained as long as an adequate amount of liquid is supplied to replace the ejected amount during an electrospinning process.

2.1.2. Stretching of the Charged Jet.

From the apex of the Taylor cone, an electrically charged jet is ejected and then accelerated by the electric field. The jet will be extended in the direction of the electric field as it moves toward the collector.52 Based on both experimental observations and electrohydrodynamic theories, different models have been developed to describe the behavior of the charged jet. In one model, the jet was treated as a string of connected, viscoelastic dumbbells.27 Using a linear Maxwell equation, the three-dimensional (3D) trajectory for the jet was calculated and the calculation results were in agreement with the experimental observations. In another model, the jet was treated as a long, slender object to account for the electrospinning phenomenon.31 In this case, the electrospinning process only involved whipping rather than splaying. This model was further extended to predict the saturation of whipping amplitude and the diameter of the resultant fiber(s).53 A third model was also proposed, in which the role of nonlinear rheology in stretching the jet was included to describe its motion in an electric field.54,55 All these models help us achieve a deep understanding of the mechanism of electrospinning. More importantly, they also greatly assist experimentalists in designing new setups and controlling the parameters of electrospinning to obtain nanofibers with desirable diameters and structures.53,56

As illustrated in Figure 3A,47 the tapered jet initially follows a nearly straight line for a certain distance away from the tip of the spinneret, and this space is known as the near-field region. The viscoelastic properties of the fluid should be able to suppress the Rayleigh instability, which otherwise causes the jet to break into droplets.45,47 The surface charges move with the jet, generating a current passing through it. The velocity, length, and diameter of the jet in the straight segment can all be readily measured.57,58 The velocity of the jet at the end of the straight segment was estimated to be 1–15 m/s. The critical length (L) of the straight segment can be estimated using the following equation:56,59

| (2) |

where R0 = (2σQ/πκρE)1/3, σ is the surface charge, Q is the flow rate, κ is the electrical conductivity of the fluid, ρ is the density of the fluid, E is the strength of the electric field, I is the current passing through the jet, and r0 is the initial radius of the jet. Under some certain conditions (e.g., at a relatively slow flow rate), the straight segment can be very short. Figure 3B shows the characteristic interference colors observed in the straight segment of a jet of aqueous PEO.47,60 The illuminating light was produced by a Xenon arc lamp, and the image was recorded using a digital video camera. The observed color had a correlation with the diameter of the jet. The straight segment was about 30 mm in length. With the decrease of voltage, the straight segment was shortened. In another study involving a poly(ε-caprolactone) (PCL) solution in acetone, the straight segment was about 3 mm in length, together with a diameter of 5–10 μm at the midpoint. The jet tended to move downward at a velocity close to 1 m/s.57

Figure 3.

(A) Diagram showing the path of an electrospun jet. (B) Characteristic interference colors observed in the straight segment of a jet comprised of aqueous PEO, providing live information about the jet diameter and length of straight segment as a function of the applied voltage.(C) Schematic illustration of the forces acting on a charged jet. The perturbed segment is forced by FDO downward and outward by the charges above the perturbed region. At the same time, the perturbed segment is forced by FUO upward and outward by the charges below the perturbation. The net force, FR (the lateral electrostatic force), is along a radial direction with respect to the straight jet, and it grows exponentially with time as the radial displacement of the segment increases. FR is responsible for the bending of the jet. (D) Stereographic image showing the instantaneous position of the bending jet during the different stages of bending instabilities. (A, B, and D) Adapted with permission from ref 47. Copyright 2006 American Chemical Society. (C) Reprinted with permission from ref 50. Copyright 2008 Elsevier.

2.1.3. Thinning of the Jet.

During the acceleration of the jet as a straight line, the surface tension and viscoelastic force in the jet tend to prevent it from moving forward.50 As a result, the acceleration is gradually attenuated. In the meantime, the diameter of the jet in the straight segment decreases monotonically with distance away from the tip as the jet is continuously stretched. When the acceleration drops to zero or a constant, any small perturbation is able to destroy the straight movement.56 As such, instability can easily arise as a consequence of the electrostatic repulsion among the surface charges residing on the jet, entering the far-field regime.

In the far-field region, three different types of instabilities may occur to an electrically charged jet.27–29,31,32,61 The first type is axisymmetric, also known as Rayleigh instability, which may lead to the breakup of the jet into droplets. It is dominated by surface tension and can be suppressed at a strong electric field. The second type is also axisymmetric, which occurs at a stronger electric field than the first type. The third type, also known as whipping or bending instability, is non-axisymmetric. It describes long wave perturbations to the jet as driven by the aerodynamic instability and the “lateral electrostatic force” in a radial direction relative to the jet, resulting from the electrostatic repulsion among surface charges in a strong electric field.50 As illustrated in Figure 3C, the jet is compelled to bend by the lateral force (FR) resulting from the electrostatic repulsion among the surface charges.50 The interactions among the charges residing on the jet and the external electric field coordinate these three different types of instabilities, which grow at different rates and are controlled by the physicochemical properties of the liquid and the electrospinning parameters.

To obtain ultrathin nanofibers by electrospinning, it is critical to achieve rapid growth of whipping instability and thereby bending or stretching of the jet.27 The bending perturbation creates the lateral force of FR perpendicular to the jet axis, further promoting the bending perturbation. The offaxis force generates a radial component for the velocity that is added vectorially to the downward velocity. As such, the jet quickly bends by an angle of about 90°, and the trajectory evolves into a series of loops, generating a coil with many turns around the original direction. The coil consists of one continuous, looping, spiraling, and gradually thinning jet that whips at a very high frequency. In space, the envelope of the coil takes a conical shape, known as “envelope cone”, with a well-defined half-angle at its vertex (Figure 3A). Most of the elongation takes place in the loops because of bending motion. The transverse velocity of a given loop is typically on the order of several tens m/s, whereas the downward velocity of the loop is much smaller, on the order of just 1 m/s.27,62 The jet bends, elongates, and becomes thinner in diameter to maintain continuity of the path. With further elongation, the element in the jet elongates into a thinner segment along an arc to generate a much smaller coil, triggering the formation of another stage of bending instability, the second bending instability. If the jet solidifies before the second bending instability occurs, the diameter of the loops during the first bending instability no longer increases. As a result, the envelope cone becomes an “envelope cylinder”. Several phenomena may cause the shape of the envelope to become more complicated. For example, the evaporation of solvent constantly reduces the volume and changes the viscoelastic parameters of the jet in the path, making it difficult to further stretch the jet. As such, the loops will become smaller in diameter.

Whipping instability accounts for the substantial reduction in diameter for the jet by vastly increasing the path length, over which the jet is accelerated and stretched prior to solidification or deposition on the collector. During the whipping process, the length of the jet can be elongated by up to 10,000 times within a short period of 0.05 s or less. The elongation (drawing) rate is extremely large (up to 1,000,000 s−1).63 As a result, the diameter of the jet is reduced by several orders of magnitude, ultimately leading to the formation of fibers with diameters down to the sub-micrometer and even nanometer scale.32

Figure 3D shows a stereographic picture captured using high-speed photography under the flash of an intense strobe light for 100 μs.47 The experiment was done with a solution of PEO in a mixture of water and alcohol. While the straight segment is not included, the picture clearly shows the three stages of bending instabilities. The successive loops of the coil that passed through the region during the first bending instability were observed as an envelope cone. The onset of the second bending instability was observed to develop on the loop having the largest diameter from the first bending instability. The bottom part of the picture shows small glints from the more complicated path, which can be attributed to higher order bending instability.

For a charged liquid jet with bending instabilities in an electric field, the diameter of the terminal jet can be predicted using the following equation:53

| (3) |

where dt is the terminal diameter of the jet, γ is the surface tension of the liquid, ε is the dielectric constant of the medium surrounding the jet, Q is the flow rate of the liquid, I is the electric current through the jet, and χ corresponds to the dimensionless wavelength of the bending instability, which is positively correlated with the radius of the bending perturbation divided by the radius of the jet.

In addition to bending instabilities, other characteristic instabilities such as branching and capillary instability have also been observed.26 When the number of charges per unit surface area is high enough, branches can grow outward from the primary jet.64 When the density of charges carried on the jet is reduced, capillary instability, which causes a cylindrical fluid jet to be disrupted into droplets, may occur, leading to the formation of beaded fibers.

2.1.4. Solidification of the Jet.

During the process of elongation, the jet solidifies to form fibers, which is caused by either the evaporation of solvent or the cooling of melt. When the solidification process is slow, the elongation of the charged jet can last for a longer period of time to generate fibers with a thinner diameter. In one study, it was claimed that the cross-sectional radius of a dry fiber was only 1.3 × 10−3 times of that of the initial jet as a result of stretching and solvent evaporation.28 After solidification, the charges can still be trapped on the surface of the dry fibers, but all the instabilities will cease.

2.1.5. Deposition of Fibers.

The final step in an electrospinning process is the deposition of fibers on a grounded collector. The morphologies of the fibers are mainly determined by the stage of bending instability in which the fibers are deposited. It is straightforward to collect the fibers in the loop region of the first bending instability as a nonwoven mat on a stationary or moving collector. However, the fibers in the small coiled region of the second and third bending instabilities may take a complex pattern, and the coils can be collected as fibers with a straight or wavy morphology, or even coils with many turns. After deposition, most of the charges on the fibers are quickly dissipated through the grounded collector. However, due to the low conductivity of most materials for the fibers, a measurable amount of residual charges still remain on the surface of the collected fibers.65,66 The buildup of residual charges on the collected fibers tends to repel the similarly charged jet, causing a pendulum-like motion for the electrified jet.67 As a result, the achievable thickness of a nonwoven mat of electrospun fibers is often restricted by an upper limit of about 0.5–1 mm.68

2.1.6. Control of an Electrospinning Process.

The formation of electrospun fibers and control of their diameters are largely determined by the processing parameters, including the applied voltage, the flow rate of the liquid, and the distance between the tip of the spinneret and the collector.

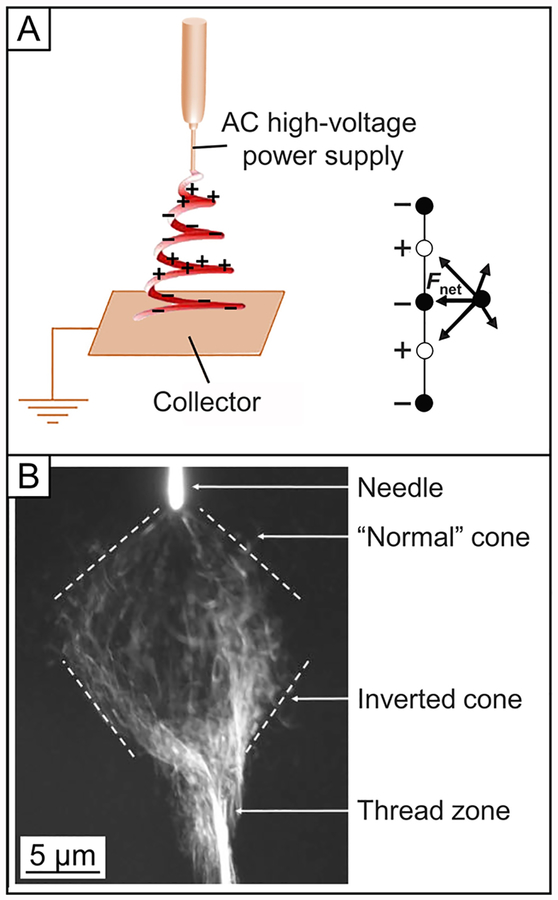

A static DC high voltage is usually applied to the spinneret to generate the electric field. The polarity of the voltage can be either positive or negative, which affects the distribution of charged molecules within the liquid and thus the type of charges accumulated on the surface of the jet. For some materials, especially electrolytes, their capacities for electrospinning are dependent on the polarity of the applied voltage.69,70 The applied voltage directly determines the amount of charges carried by the jet and the magnitude of electrostatic repulsion among the charges, as well as the strength of the interactions between the jet and the external electric field. A higher voltage usually favors the formation of thinner fibers,71 whereas it may also induce the ejection of more fluid, giving rise to fibers with thicker diameters.72 AC has also been used to electrospin fibers, but the jet shows significantly different behaviors relative to the case of DC.73–75 As illustrated in Figure 4A, the AC power supply introduces alternating segments of positive and negative charges to the jet, resulting in a decrease in electrostatic repulsion and thus the suppression of bending instability.76 The length of the charged segments is determined by the frequency of the AC potential. If the frequency is too high, the transfer of charges may not be fast enough to adequately electrify the liquid for electrospinning. When the frequency is too low, the jet may largely contain a single polarity instead of alternating segments with positive and negative charges. Only at an appropriate frequency, a whipping cloud will be formed from the spinneret, and a visible thread will emerge sometimes downstream, as shown in Figure 4B.77 The thread does not display any significant attraction toward the grounded collector and consequently can be easily deflected away. Self-bundling of the jet during AC electrospinning has also been observed due to the presence of positively and negatively charged segments.77 In addition, by applying AC high voltage, the amount of net charges on the generated fibers can be reduced, enabling long-term collection of fibers on a nonconductive substrate.78

Figure 4.

(A) Illustration of AC electrospinning, and the forces acting on a displaced segment of an electrically charged jet. (B) Photograph of the jet during AC electrospinning, which was taken at an exposure time of 0.02 s. The whipping envelope can be seen as a combination of a normal, upright cone and an inverted cone. A distinct thread zone is seen below the apex of the inverted cone. Reprinted with permission from refs 76 and 77. Copyright 2007 and 2009 Wiley-VCH, respectively.

Regarding the flow rate of the liquid, any increase will typically result in the formation of fibers with enlarged diameters. The working distance between the tip of the spinneret and the collector determines the stage of instability at which the jet is deposited on the collector. A relatively long enough distance is required to ensure full extension and solidification of the jet, and thereby the formation of solid fibers. In general, thinner fibers will be formed as the distance is increased. When the distance between the tip of the spinneret and the collector is beyond a certain range, the fiber will not become thinner as the distance is increased because of solidification of the jet. In general, it is the intricate interplay of all the processing parameters that controls the morphology and diameter of the fibers. For example, with the increase of flow rate, one has to increase the critical voltage for generating the fiber, as well as the working distance between the tip of the spinneret and the collector to ensure full extension and solidification of the jet. As a result, it is necessary to optimize all the processing parameters in order to control an electrospinning process.

2.2. Materials for Electrospinning

Electrospinning has been utilized to generate nanofibers from various types of materials. The most commonly used materials are organic polymers in the form of either solution or melt. Small molecules can also be directly electrospun into nanofibers if they self-assemble and generate sufficient chain entanglement. When combined with sol–gel chemistry, a variety of composite materials have been directly electrospun into nanofibers. By introducing nanoscale components with different dimensions and/or morphologies (e.g., nanoparticles, nanorods, nanowires, nanotubes, and nanosheets) into polymer solutions, the as-obtained mixtures have also been used for electrospinning. The following subsections give a brief account of all these diversified materials in the context of electrospinning or electrospun nanofibers.

2.2.1. Organic Polymers.

Most of the organic polymers can be directly applied to electrospinning as long as they can be dissolved in appropriate solvents to obtain solutions or be melted without degradation. For simplicity, we call the corresponding methods solution electrospinning and melt electrospinning, respectively.

Solution Electrospinning.

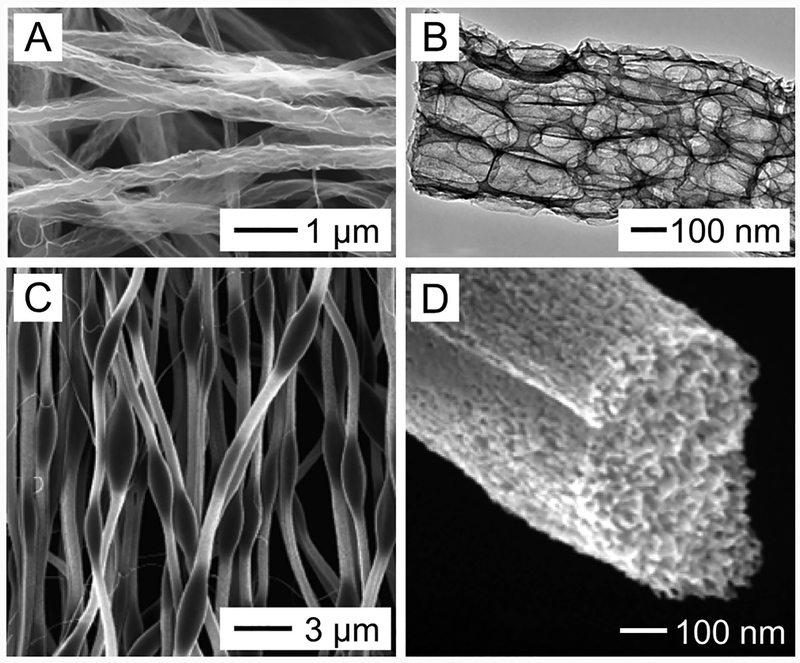

This method is more commonly used and better characterized than melt electrospinning. As the jet of a polymer solution is stretched, elongated, and thinned by whipping instability, the solvent is quickly evaporated, resulting in solidification of the jet and deposition of solid nanofibers on the collector.44 Figure 5A shows a scanning electron microscopy (SEM) image of poly(vinylpyrrolidone) (PVP) nanofibers electrospun from a 10 wt % ethanol solution of PVP with a molecular weight (Mw) of ca. 1,300,000, indicating that the nanofibers are deposited in the form of a nonwoven mat.

Figure 5.

(A) SEM image of a typical example of electrospun PVP nanofibers, indicating the formation of a nonwoven mat. (B) SEM image of nanofibers made of a blend of PEDOT and PSS electrospun from an aqueous mixture containing Mg(NO3)2. (C) Schematic diagram showing the physical cross-linking of PEDOT and PSS by Mg2+ ions for the improvement of viscoelasticity. (D) Photograph showing the formation of “standing fibers” during the electrospinning of conductive polymers. The inset shows a magnified view. (B and C) Reprinted with permission from ref 91. Copyright 2015 Elsevier. (D) Reprinted with permission from ref 92. Copyright 2006 American Chemical Society.

More than 100 different types of organic polymers, including both natural and synthetic polymers, have been successfully explored for solution electrospinning to directly produce nanofibers. Among them, synthetic polymers such as polystyrene (PS) and poly(vinyl chloride) (PVC) have been electrospun into nanofibers for commercial applications related to environmental protection. A large number of biocompatible and biodegradable synthetic polymers, such as PCL, poly(lactic acid) (PLA), and poly(lactic-co-glycolic acid) (PLGA), have been directly electrospun into nanofibers and further explored as scaffolds for biomedical applications. Natural biopolymers, such as DNA, silk fibroin, fibrinogens, dextran, chitin, chitosan, alginate, collagen, and gelatin, have also been electrospun into nanofibers from their solutions. Conductive polymers such as polyaniline (PANi) and polypyrrole (PPy) have been directly electrospun into nanofibers. Other types of functional polymers such as poly(vinylidene fluoride) (PVDF) have also been electrospun into nanofibers for piezoelectric and/or pyroelectric applications.

In general, the success of electrospinning a polymer solution, as well as the structure and morphology of the resultant polymer nanofibers, is determined by a set of parameters related to the polymer, solvent, polymer solution, processing parameters, and ambient conditions.41,42 There are two general requirements for a successful solution electrospinning: (i) sufficiently high molecular weight for the polymer and (ii) availability of a suitable solvent to dissolve the polymer. The molecular weight of a polymer has a major impact on the rheological behaviors and electrical properties of the solution. In general, lowering the molecular weight tends to generate beads rather than fibers because of the limited chain entanglement. The formation of a homogeneous polymer solution critically depends on the solubility parameter of the solvent,79,80 but the solvent with a high solubility parameter does not necessarily produce a solution suitable for electrospinning. The volatility or vapor pressure of the solvent determines its evaporation rate and thus the solidification rate of the jet. A very high volatility is not suitable for the spinning of fibers because the jet may solidify immediately upon exiting from the spinneret. If the volatility is too low, the fibers will still be wet when they are deposited on the collector. The dielectric constant of the solvent controls the magnitude of electrostatic repulsion among the surface charges residing on the jet. With increasing of the dielectric constant, the applied voltage required to achieve a stable jet will be increased.80

The commonly used solvents include alcohols, dichloromethane, chloroform, dimethylformamide (DMF), tetrahydrofuran (THF), acetone, dimethyl sulfoxide (DMSO), hexafluoroisopropanol (HFIP), and trifluoroethanol, among others. Water is not a favorable solvent for electrospinning because of its high dielectric constant and thus the attenuation of electrostatic repulsion. Sometimes, it might be necessary to use a mixture of different solvents in order to achieve the optimal formulation for electrospinning.

In addition to the molecular weight of polymer and the type of solvent, the spinnability of a polymer solution critically depends on its concentration and electrical conductivity. In order to obtain fibers, a minimum concentration is required to achieve the chain entanglement critical to the transition from electrospraying to electrospinning.81 At a concentration below this limit, the interactions between the polymer chains are too weak to overcome the Rayleigh instability, the jet will break into droplet, and thus fine particles or polymer beads instead of continuous fibers will be obtained, in a process commonly referred to as electrospray. As the concentration increases, the jet will no longer break up and the shape of the beads will change from spherical to spindle-like, eventually leading to the formation of uniform fibers owing to the increase in chain entanglement and viscosity. If the concentration is too high, however, it will be extremely difficult to overcome the viscoelastic force and no jet will be formed. Within a suitable range, reducing the concentration favors the formation of thinner fibers. The polymer concentration, however, also affects the viscosity and surface tension of the solution, and both parameters can impact the morphology and size of the resultant fibers. In general, decreasing the viscosity and surface tension favors the production of thinner fibers, but this can also be realized by adding a surfactant rather than reducing the polymer concentration.71,82 When the viscosity is too low, no fiber will be produced. If the viscosity is too high, it will become difficult to eject the solution from the spinneret. With regard to electrical conductivity, it is difficult to electrospin a solution that is perfectly insulating because such a solution is unable to conduct charges from the interior of the solution to its surface. If the solution is too conductive, however, it will be difficult to generate Taylor cone or initiate bending instability as a result of the depleted electrostatic repulsion because surface charges cannot be accumulated on a conductive droplet or jet.83–85 It is only within a proper range that increase of electrical conductivity will favor the formation of thinner fibers because of extensive bending of the jet. One efficient strategy for increasing the conductivity of a polymer solution is to introduce ionic compounds such as salts or mineral acids.86

The processing parameters (e.g., the applied voltage, flow rate of the polymer solution, and working distance between the spinneret and the collector) during solution electrospinning can affect the morphology and size of the fibers, as discussed in section 2.1.6. The ambient conditions, including relative humidity and temperature, also have an influence on solution electrospinning. The relative humidity influences the evaporation rate of the solvent and thus the solidification rate of the jet. A lower relative humidity favors the formation of thinner fibers with a more dried surface.87 However, if the relative humidity is too low, the solvent evaporates quickly, hindering the extension of the jet. On the other hand, when the relative humidity reaches a sufficiently high level, the water vapor in the air may penetrate into the jet, causing morphological changes to the nanofibers. The ambient temperature is another crucial parameter for the formation of ultrafine fibers. At an elevated temperature, both the surface tension and viscosity of the polymer solution will be reduced, favoring the formation of thinner fibers. However, the evaporation of the solvent will also be accelerated at a higher temperature, limiting the extension of the jet. Taken together, the temperature has two opposite impacts on the diameter of the fibers, and it needs to be optimized carefully.88

Some functional polymers (e.g., conductive polymers) and natural polymers may not be suitable for electrospinning from their solutions. Conductive polymers have rigid backbones with low molecular weights, resulting in poor solubility in common solvents and thus inadequate chain entanglement in the solution phase. In addition, the high solution conductivity makes it difficult to form a stable jet.83–85 So far, only a limited number of conductive polymers have been successfully electrospun into nanofibers by modifying the polymer solutions and/or the electrospinning conditions.89 In one study, PPy with an adequate molecular weight and high solubility in DMF was obtained by adding di(2-ethylhexyl) sulfosuccinate sodium salt during polymerization.90 Upon electrospinning, PPy nanofibers with an average diameter of 70 nm were fabricated. In another study, Mg(NO3)2 (10 wt % Mg2+ relative to the polymer) was introduced into an aqueous mixture of poly(3,4-ethylenedioxythiophene) (PEDOT) and poly(styrenesulfonate) (PSS).91 Upon electrospinning, conductive nanofibers with diameters in the range of 70–100 nm were obtained (Figure 5B). The formation of nanofibers can be attributed to the introduced Mg2+ ions, which served as a physical cross-linker for the polymer chains (Figure 5C).

At a high relative humidity, “standing fibers” that stretch vertically between the spinneret and the grounded collector can be formed during electrospinning, as shown in Figure 5D for poly(phenylenevinylene) when electrospun at a relative humidity > 45%.92 The formation of standing fibers can be attributed to the strong electrostatic attraction between the fibers and the spinneret in the presence of a significant amount of water molecules.93–95 In order to achieve continuous formation and deposition of nanofibers on the grounded collector, the relative humidity should be controlled below a critical level. In addition, blowing air vertically downward can overcome the electrostatic attraction between the nanofibers and the spinneret, promoting the deposition of more fibers. Collecting the nanofibers in a liquid bath represents another way to manipulate the electric field for the facile collection of fibers.96 For example, PANi nanofibers with an average diameter of around 139 nm were electrospun from a 20 wt % PANi solution in 98% formic acid with the use of a water bath as the collector.97

Mixing a functional polymer with another electrospinnable polymer is an efficient way to obtain a suitable solution for electrospinning. To this end, a synthetic polymer can serve as a carrier phase to greatly assist the electrospinning process for the fabrication of nanofibers containing natural biopolymers. The nanofibers made of a polymer blend can also give rise to new applications due to the integration of functions originating from individual components. It should be pointed out that the different polymer components may separate into distinct phases in the jet as a result of solvent evaporation. The separation can be mitigated by improving the compatibility between the polymers and thus the entanglement of their chains.

Melt Electrospinning.

Some polymers are difficult to dissolve in suitable solvents for solution electrospinning; notable examples include polyethylene and polypropylene (PP). In these cases, fibers can be directly electrospun from their melts instead.98 Figure 6A shows a schematic of the typical setup for melt electrospinning.99 To keep the polymer in a molten state in the spinneret, it is necessary to add a heating device, such as an electrical heating tape, circulating fluid, and laser.100,101

Figure 6.

(A) Schematic illustration of a setup for electrospinning a polymer melt onto a static collector. (B) Illustration of electrohydrodynamically driven air flow for melt electrospinning, which is capable of enhancing the heat transfer between the jet and the surrounding medium (typically, air) by 1 order of magnitude. (C) Temperature profiles showing rapid cooling of electrospun nylon-6 (N6), PP, and PLA molten jets, as well as a photograph of the PLA molten jet. (D) Photograph of a molten jet during melt electrospinning. The molten pendant droplet has one single Taylor cone that is elongated while the jet is particularly long and is visible over almost the entire distance to the collector. (E and F) SEM images showing typical examples of coiled fibers commonly observed during melt electrospinning. The coiled fibers were formed from molten jets of (E) PP and (F) a blend of poly(ethylene glycol) (PEG)-b-PCL and PCL, respectively. (A) Reprinted with permission from ref 99. Copyright 2016 Elsevier. (B and C) Reprinted with permission from ref 103. Copyright 2011 AIP Publishing. (D−F) Reprinted with permission from ref 107. Copyright 2007 Elsevier.

After ejection from the spinneret, the molten jet cools and solidifies to generate fiber(s) because of heat transfer between the jet and the surrounding medium (typically, air). The heat transfer rate can be greatly enhanced in the presence of an electric field due to the electrohydrodynamic effects.102 As shown in Figure 6B, when the tip of the spinneret and collector are applied to a positive potential separated by a dielectric component (molten jet and air in this case), the air close to the surface of the jet can be positively ionized, leading to a positive corona discharge.103 It is critical to keep the applied voltage greater than the corona onset but below the air gap breakdown voltage. The resultant corona current is able to disturb the thermal boundary layer between the jet and the air, causing the heat transfer rate to increase by 1 order of magnitude. Figure 6C shows the images captured using an infrared camera, revealing the temperature profiles of the molten jets of nylon-6, PP, and PLA, respectively.103 In all cases, the jets were thermally quenched rapidly along the ejection direction. The electrohydrodynamic quenching results in fast cooling and quick “freezing” of the jet, greatly reducing the degree of stretching for the jet.102,104–106

Different from solution electrospinning, the whipping instability of the jet is largely suppressed in melt electrospinning.100 This difference can be largely attributed to the unique properties of a polymer melt: (i) its electrical conductivity (typically less than 10−10 S/m) is much lower than that of a polymer solution, and (ii) its viscosity (typically between 40 and 200 Pa·s) is much higher than that of a polymer solution. As a result, the density of surface charges on the molten jet is lower, dampening the whipping instability. Moreover, when the temperature of the jet drops below the glass transition temperature (Tg) of the polymer, rapid solidification of the jet will further suppress the whipping instability and stronger electrostatic repulsion is required to overcome the viscoelastic force. Therefore, the electrostatic force provided by the external electric field contributes most to the thinning of the jet, and the jet usually travels in a straight line, as shown in Figure 6D.107 Upon deposition onto a stationary collector, the jet buckles under compression, and the fiber(s) coil around the midline (see Figure 6E,F). The deposited fibers do not appear to repel the incoming fibers. Due to the lack of whipping instability and solvent evaporation, melt electrospinning produces thicker fibers (typically, on the micrometer scale) than solution electrospinning.

Only a small fraction of the commercially available polymers has been successfully explored for melt electrospinning.100 As a prerequisite, the polymer must have a glass transition and melt at a temperature without involving thermal degradation. As such, melt electrospinning does not work for thermoset polymers, proteins, and thermally unstable polymers. The most commonly used polymers are thermoplastics such as PP and polyesters (e.g., polyurethane, PCL, PLA, and PLGA). Especially, polymers with low melting points (Tm), such as PCL, exhibit good thermal stability and favorable processability for melt electrospinning. Polyolefins and polyamides, which are only soluble in specific solvents, have also been processed into fibers using melt electrospinning. Other common industrial polymers that have been melt electrospun include nylon-6, polyethylene, poly(methyl methacrylate) (PMMA), and poly(ethylene terephthalate) (PET).

The electrospinnability of a polymer melt is critically dependent on its viscosity and electrical conductivity.100 By adding viscosity-reducing additives into PP melt, the diameter of the resultant fibers was significantly reduced from 35 ± 8 to 0.84 ± 0.19 μm. Increasing the electrical conductivity allows for more significant stretching of the jet, favoring the formation of thinner fibers. By adding 5 wt % NaCl, for example, the electrical conductivity of PP held at a processing temperature of 200 °C (above its Tm) could be increased from 10−12 to 10−8 S/m, leading to a substantial decrease in fiber diameter from 3.01 ± 1.07 to 0.31 ± 0.10 μm.108

The processing parameters also have impacts on melt electrospinning. Specifically, the flow rate of a polymer melt is often low (typically, <0.1 mL/h) to produce ultrathin fibers. The temperature of the melt in the spinneret is also important. By increasing the temperature to an appropriate range, both the viscosity of the melt and the cooling rate of the jet can be reduced to generate thinner fibers. An optimal combination of the applied voltage and spinneret-to-collector distance is also important to ensure adequate cooling for the jet. In addition, when a flat collector moves laterally below a stationary spinneret, the shape of the jet is greatly affected by the moving speed of the collector (SC).109 As illustrated in Figure 7A, as the ratio of SC to the jet speed (SJ) is increased, the jet gradually transforms from a “compressive heel” (SC = SJ) to a “catenary profile” (SC ≫ SJ), mainly due to the drag of the collector by the jet. Accordingly, the structure and diameter of the deposited fibers will be altered. Figure 7B shows an optical micrograph of PCL fibers produced by melt electrospinning at a flow rate of 0.05 mL/h and at 70 °C. By matching the SC and SJ (in this case, 0.5 m/min), the coiling effect disappeared, leading to the formation of a straight, continuous fiber with a diameter of approximately 19 μm.

Figure 7.

(A) Correlation between the shape of the jet and the speed of the collector (SC) relative to the speed of the jet (SJ) during melt electrospinning. (B) Photograph of PCL fibers produced by melt electrospinning. The collector was moving at constant horizontal speeds that increase from the top to the bottom as indicated on the images. (C and D) SEM images showing the assembly of PCL fibers into multilayered stacks with the orientation of fibers in adjacent layers rotated by 90° and 60°, respectively. Reprinted with permission from ref 109. Copyright 2011 Wiley-VCH.

The temperature of the surrounding air is another critical parameter. If the air is heated, the jet will be cooled at a slower rate, favoring the formation of a thinner jet. According to a modeling analysis, the heated air was able to contribute an additional 20-fold of thinning for the jet, downsizing the fibers to the nanometer scale.110,111 Through careful optimization of the aforementioned parameters, it is possible to produce nanofibers by melt electrospinning. The smallest diameter reported in literature is about 270 ± 100 nm, which involved electrospinning of a blend of PEG-b-PCL and PCL.107 Owing to its ability to precisely control the position of the deposited fiber, melt electrospinning has been explored as an additive manufacturing technique for the fabrication of 3D constructs with well-defined structures and feature sizes. For example, PCL fibers were assembled to form a multilayered construct with the orientations of fibers in adjacent layers rotated by 90° and 60°, respectively, as shown in Figure 7C,D.109

In situ polymerization of oligomers in the flying jet is another interesting strategy for producing fibers through either solution or melt electrospinning. In one study, by carefully matching the rates of photopolymerization and jet flying, continuous fibers were obtained from a solution containing hexafunctional acrylic polyester (ca. 3700 in Mw).112 Thermally induced polymerization has also been explored to produce fibers. For example, polyurethane prepolymer (1000–2000 in Mw) and PEG-400 chain extender were mixed and subjected to melt electrospinning, and the jet could be solidified quickly upon heating for the production of polyurethane fibers.113

In the case of solution electrospinning, the weight percentage of polymer in the solution is typically low and a large amount of solvent is involved, resulting in both economic and environmental concerns. The absence of solvent in melt electrospinning means no residue of toxic solvents, improving the safety and throughput of the process. In these regards, melt electrospinning has much higher productivity than solution electrospinning. Additionally, melt electrospinning enjoys the ability to precisely control the positions of fibers during their deposition. As a major limitation of melt electrospinning, it is difficult to produce fibers with diameters down to the nanometer scale. Extended heating can also lead to polymer degradation, and high processing temperatures may not be suitable for the processing of drugs or bioactive molecules. The number of polymers suitable for solution electrospinning is much greater than that for melt electrospinning. Therefore, it is necessary to fully analyze the polymer’s properties and the target applications when choosing an electrospinning method (solution versus melt) for producing fibers from an organic polymer.

2.2.2. Small Molecules.

Small molecules can be directly electrospun into fibers when the chain entanglement is significant enough to stabilize the electrified jet and thus suppress the Rayleigh instability. The key factor is the presence of suffcient intramolecular interactions among the small molecules to form self-assembled structures in their highly concentrated solutions or pure melts.

The solution-phase electrospinnability of small molecules is mainly determined by their structures and concentrations, as well as the type of solvent. The reported small molecules mainly include amphiphiles and cyclodextrin derivatives.114,115

Lecithin, a natural mixture of phospholipids and neutral lipids, is the first reported amphiphiles for electrospinning.116–118 It can self-assemble to form spherical micelles in a nonaqueous solution at a concentration above the critical micelle concentration (cmc). When the concentration is further increased, the morphology of the micelles undergoes transition from spherical to cylindrical, and eventually the cylindrical micelles can overlap and entangle to behave like polymer chains, as illustrated in Figure 8A.116 Upon electrospinning of a lecithin solution in a 70:30 (wt %) mixture of chloroform and DMF at a concentration of 43 wt % (higher than the cmc, 35 wt % in this case), continuous fibers with an average diameter of 2.8 μm were produced (Figure 8B). In comparison, particles were obtained from a solution at a concentration equal to cmc, as shown in Figure 8C. By further increasing the concentration to 50 wt %, the resultant fibers showed a thicker diameter of 5.9 μm. Similarly, gemini surfactants119,120 and bioactive peptide amphiphiles121–123 have also been directly electrospun into fibers with diameters on the micrometer scale.

Figure 8.

(A) Schematic showing the worm-like micelles of phospholipids entangled in a concentrated solution. (B and C) SEM images showing the morphologies of (B) lecithin fibers and (C) lecithin droplets obtained by electrospinning a lecithin solution in a 70:30 (wt %) mixture of chloroform and DMF at concentrations of 43 and 35 wt %, respectively. (D) Chemical structure of β-cyclodextrin (CD), and schematic illustration of the truncated, cone-shaped, molecular structure of CD. (E) SEM image of nanofibers produced by electrospinning a 120% (w/v) hydroxypropyl-β-CD solution in dimethylacetamide. (A−C) Reprinted with permission from ref 116. Copyright 2006 The American Association for the Advancement of Science. (D and E) Reprinted with permission from ref 124. Copyright 2012 Royal Society of Chemistry.

As another example, cyclodextrin derivatives can form aggregates via hydrogen bonding to give a solution with high viscosity and thus a viscoelastic solid-like behavior owing to the doughnut-shaped glucopyranose rings in cyclodextrin (Figure 8D).124 Upon electrospinning of a 120% (w/v) hydroxypropyl-β-cyclodextrin solution in dimethylacetamide, fibers with diameters in the range of 0.4–1.8 μm were produced, as shown in Figure 8E.

Some small molecules can also form entanglement in their melts. In these cases, continuous fibers can be readily obtained through melt electrospinning. For example, 1-palmitoyl-2-oleoyl-sn-glycero-3-phosphoethanolamine, a phospholipid with a Mw of 718 g/mol, can form large aggregates in its melt.125 Upon melt electrospinning at a temperature around 200 °C, fibers with an average diameter of 6.5 ± 2.0 μm were produced. In another demonstration, both 1,3,5-benzene and 1,3,5-cyclohexanetrisamides were found to exhibit a distinguished self-assembly behavior in their melts due to strong hydrogen bonding, supporting their electrospinning into fibers. Perylene bisimides have also been processed into fibers by melt electrospinning, thanks to the strong π−π interactions.126

2.2.3. Colloidal Particles.

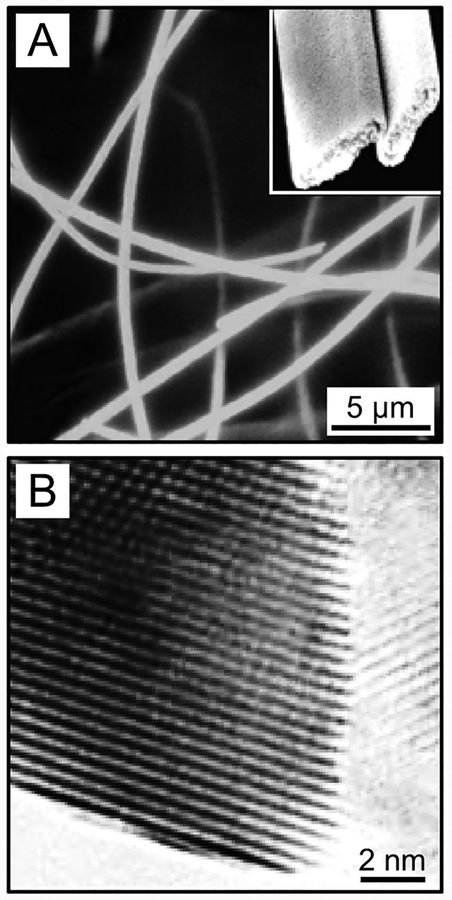

A colloid, consisting of a dispersed phase (the suspended particles) and a continuous phase (the medium of suspension), has also been adapted for electrospinning when suffcient entanglement is formed among the particles to maintain the jet as a continuous structure. A typical example can be found in the electrospinning of aged inorganic sols with spinnable viscosities arising from the hydrolysis and condensation of metal alkoxides or metal salts. The colloidal particles need to have a certain size, in addition to cross-linking among them, in order to obtain a stable electrospinning process, with the viscosity being a critical parameter in determining the fiber’s diameter. In a typical procedure, a silica sol was prepared from tetraethyl orthosilicate (TEOS), distilled water, ethanol, and HCl and then aged at 80 °C for 30 min.127 Upon electrospinning, silica fibers with diameters in the range of 0.4–1 μm were produced. Similarly, silica nanofibers thinner than 400 nm in diameter were also produced by adjusting the properties of the aged sols.128 In another study, an aged sol prepared from lithium acetate, cobalt acetate, distilled water, and citric acid was used for electrospinning.129 Upon calcination of the as-spun composite fibers, LiCoO2 fibers with diameters in the range of 0.5–2 μm (Figure 9A) were obtained. The transmission electron microscopy (TEM) image in Figure 9B indicates that the fiber was composed of uniform LiCoO2 nanoparticles of 20–35 nm in diameter. Based on the sol−gel method, ceramic fibers made of oxides such as Co3O4, NiO, and a mixture of Al2O3 and ZnO have all been produced. However, the as-obtained fibers are typically more than several micrometers in diameter. In addition, the ability to control the size and uniformity of the fibers is quite limited because of the difficulty in precisely controlling the rheological properties of a sol.130

Figure 9.

(A) SEM and (B) high-resolution TEM images of LiCoO2 fibers with diameters in the range of 0.5–2 μm, which were obtained by electrospinning an inorganic sol−gel solution prepared from lithium acetate, cobalt acetate, distilled water, and citric acid. The inset in panel A shows an enlarged view of the fibers. Reprinted with permission from ref 129. Copyright 2005 American Chemical Society.

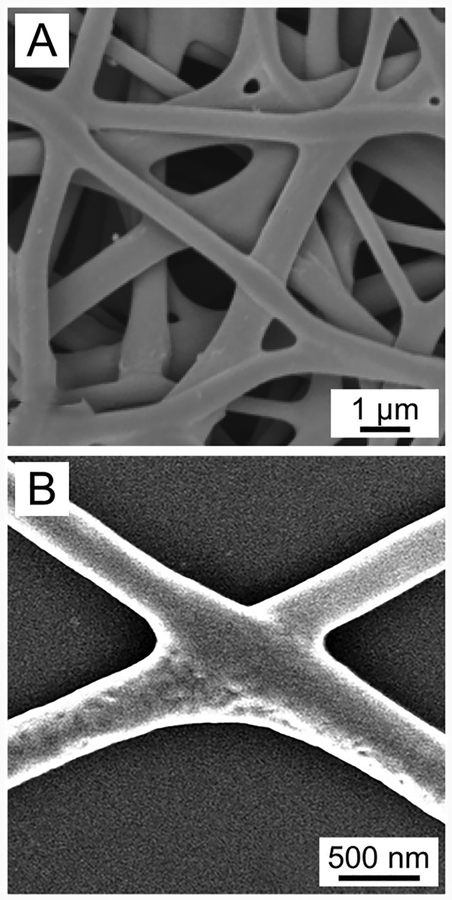

When metal nanoparticles are dispersed in a solution at a high concentration, a spinnable mixture will be obtained for electrospinning. In a recent study, Ag nanoparticles (40 ± 5 nm) were dispersed in ethylene glycol at a concentration of 50 wt %.131 Upon electrospinning, followed by thermal annealing at 150 °C in air, the Ag nanoparticles were coalesced and converted to electrically conductive Ag nanofibers with an average diameter of 338 ± 35 nm. In general, the capability of this method is limited due to the difficulty in preparing highly concentrated suspensions of metal nanoparticles.

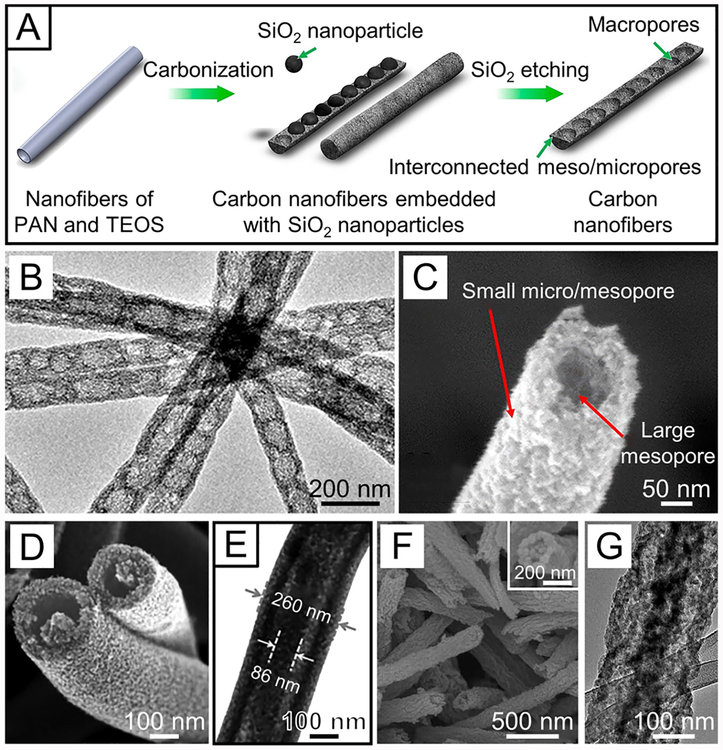

2.2.4. Composites.

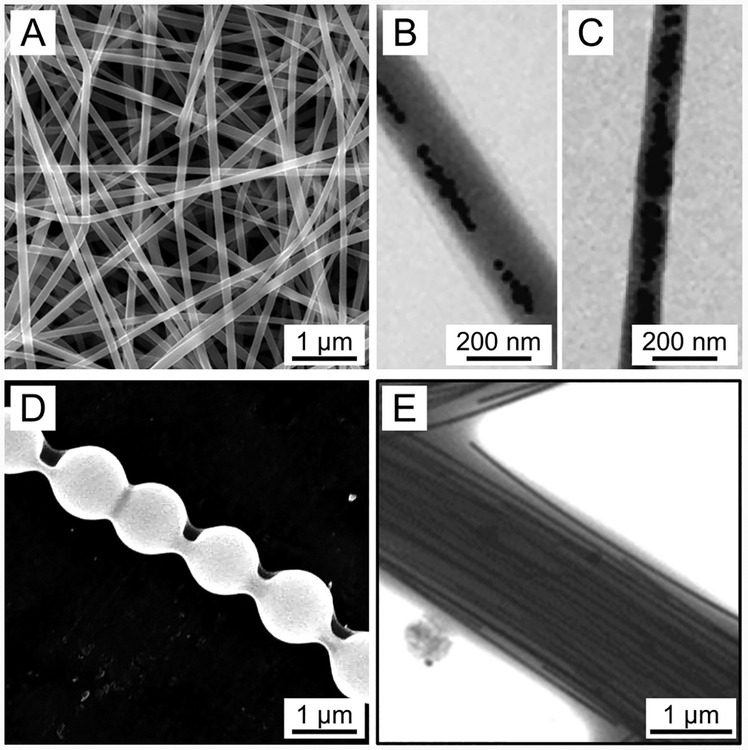

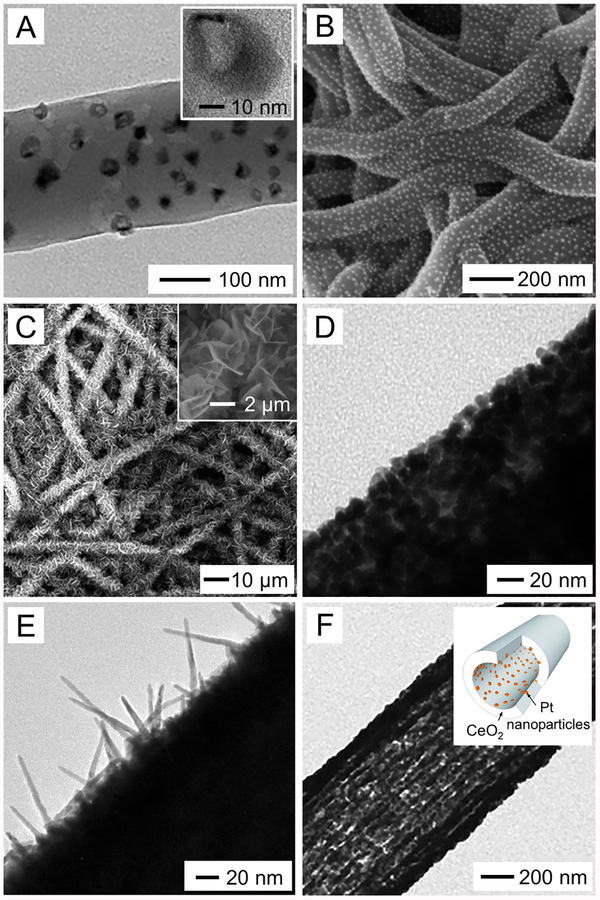

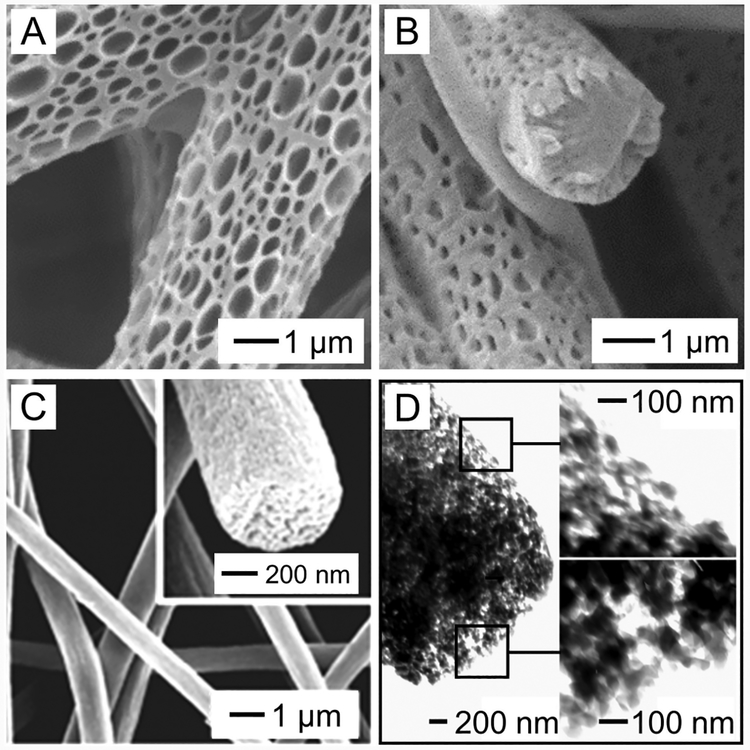

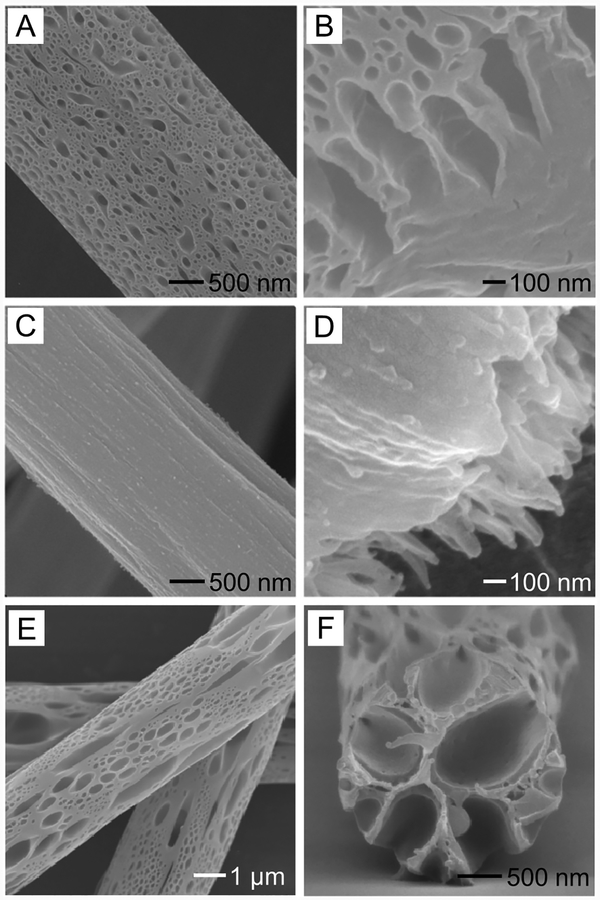

Composites, which are usually prepared by adding sol−gel precursors or nanoscale components into polymer solutions, have been extensively explored for solution electrospinning. In the case of a sol−gel precursor, one should avoid the occurrence of sol−gel reactions in the stock solution. The sol−gel reactions, including hydrolysis, condensation, and gelation of the precursor, should be initiated in the jet by contacting with the surrounding air.132,133 As such, a continuous network of the inorganic phase will be formed in the polymer matrix, leading to the formation of nanofibers made of an inorganic−polymer composite. In an early demonstration, PVP and titanium tetraisopropoxide (Ti(OiPr)4, a precursor to TiO2) were dissolved in an alcohol to obtain a spinnable solution.132 Upon electrospinning, uniform nanofibers comprised of PVP and amorphous TiO2 were produced, as shown in Figure 10A.

Figure 10.

(A) SEM image of composite nanofibers comprised of PVP and amorphous TiO2 electrospun from a PVP solution containing Ti(OiPr)4. (B and C) TEM images of representative composite nanofibers containing well-dispersed Ag nanoparticles fabricated by electrospinning an aqueous PVA solution containing Ag nanoparticles at Ag to PVA molar ratios of (B) 2:530 and (C) 4:530, respectively. (D) SEM image showing the necklace-like structure of a composite fiber comprised of PVA and 0.91 μm SiO2 particles. (E) TEM image of a composite fiber comprised of PVP and Ag nanowires. More than 10 Ag nanowires could be assembled within and aligned along a single fiber. (A) Reprinted with permission from ref 132. Copyright 2003 American Chemical Society. (B and C) Reprinted with permission from ref 141. Copyright 2009 American Chemical Society. (D) Reprinted with permission from ref 142. Copyright 2010 American Chemical Society. (E) Reprinted with permission from ref 143. Copyright 2012 Wiley-VCH.

The electrospinnability of such a solution is mainly determined by the sol−gel precursor and the nature of the carrier polymer, as well as the viscosity and electrical conductivity of the solution. The carrier polymer should be spinnable, with either a high Mw or a significant degree of chain entanglement.134 To this end, PVP represents one of the most popular carrier polymers owing to its high solubility in ethanol and water and its good compatibility with many sol−gel precursors. Other polymers, such as PEO, poly(vinyl alcohol) (PVA), and poly(acrylic acid), have also been successfully used as the carrier.132,133,135

The type of precursor greatly affects the rates of sol−gel reactions in the jet.132 A rapid hydrolysis often causes the blockage to the spinneret, whereas a rapid gelation results in a less stretchable jet and thus thicker fibers. The commonly used precursors include metal salts, such as alkoxides, nitrates, acetates, chlorides, and sulfates. Sometimes, an additive (e.g., acetic acid, hydrochloric acid, or propionic acid) is needed in order to stabilize the precursor solution by adjusting both the hydrolysis and gelation rates to ensure a stable electrospinning process.127,136

The viscosity of the solution plays a crucial role in stretching the jet, which can be controlled by varying the concentrations of the precursor and the polymer. The electrical conductivity of the solution can be increased by adding a salt (e.g., NaCl and (CH3)4NCl) to promote the formation of thinner fibers. Additionally, a well-controlled environment surrounding the jet is also of great importance. Typically, an atmosphere with a lower relative humidity and/or saturated with the solvent vapor can substantially reduce the rates of hydrolysis and gelation and therefore give rise to continuous electrospinning.130 By optimizing these parameters, the diameter of the as-spun composite fibers can be reduced to several hundred nanometers.

The composites used for solution electrospinning have also been prepared by dispersing nanoscale components in a polymer solution through extensive stirring or ultrasonication. The commonly used nanoscale components include nanoparticles made of Ag, Au, and TiO2 and even particles comprised of a metal−organic framework (MOF) compounds,137,138 one-dimensional (1D) nanostructures such as Au nanorods, Au or Ag nanowires, and carbon nanotubes, as well as two-dimensional (2D) nanostructures such as clay tablets and graphene nanosheets.139

The electrospinnability of such a formulation critically depends on the type, size, and concentration of the added nanoscale components, which will also affect the morphology of the resultant composite nanofibers. A stable dispersion of the nanoscale components in the polymer solution is instrumental to the formation of nanofibers with a homogeneous distribution of the nanoscale components, whereas it is difficult to achieve stable electrospinning and obtain uniform fibers if the nanoscale components are inclined to aggregate. The nanoscale components often need to be modified with a functional group to obtain a stable dispersion. The size and concentration of the nanoscale components also affect their dispersity and thus the morphology of resultant nanofibers.140 In one study, composite nanofibers containing well-distributed Ag nanoparticles were produced, as shown in Figure 10B, by dispersing the Ag nanoparticles in an aqueous PVA solution at a Ag to PVA molar ratio of 2:530 (Ag in terms of atom and PVA in terms of repeat unit).141 By increasing the molar ratio to 4:530, more Ag nanoparticles were incorporated into the nanofibers (Figure 10C). When SiO2 particles of 0.9 μm in diameter were used, necklace-like structures consisting of SiO2 particles linked by PVA fibers were obtained, as shown in Figure 10D.142 In this case, the large particles may be exiled from some of the fibers during the electrospinning process.

When 1D nanostructures with anisotropy are used, they can be oriented along the fibers during electrospinning. The concentration of the nanostructures has a major impact on their orientation and the distance among them in an individual fiber. In one demonstration, composite fibers consisting of Ag nanowires and PVP were fabricated using magnetic-field-assisted solution electrospinning. As shown in Figure 10E, multiple (>10) Ag nanowires could be aligned in parallel, along an individual fiber.143

2.3. Methods of Electrospinning

Electrospinning is typically conducted in the far-field mode with the use of a hollow needle as the spinneret and a piece of metal substrate (such as an aluminum foil) as the collector. This setup is mainly used for the production of nanofibers in small volumes in a laboratory setting, for evaluating the spinnability of new materials, or for optimizing the parameters for electrospinning before large-scale production. When whipping instability is involved, it will be difficult to precisely control the morphology of the deposited nanofibers. Built upon this general setup, modifications have been made to further increase the capability and versatility of electrospinning. By reducing the distance between the spinneret and the collector, for example, electrospinning can be conducted in the near field to collect fibers from the straight segment of the jet, making it possible to precisely control the position of the deposited fiber. In addition, an array of hollow needles (multiple-needle electrospinning) rather than a single needle has been used to increase the productivity of electrospinning. Instead of using a hollow needle, a 2D array of solid pins or a flat substrate with a large surface area (needleless electrospinning) has been used to increase the number of jets and thus the production volume, pushing electrospinning toward industrial production. The use of a coaxial needle further empowers electrospinning with the capability to produce nanofibers from unspinnable materials and/or to generate nanofibers with a core−sheath or other types of structures. As for the collector, it has been modified in multiple ways by combining with other techniques, such as lithography, to help organize the nanofibers into different patterns. Liquid bath has also been used as a collector, enabling the fabrication of novel fibrous structures (e.g., fiber yarns and filaments) rather than a nonwoven mat of nanofibers.

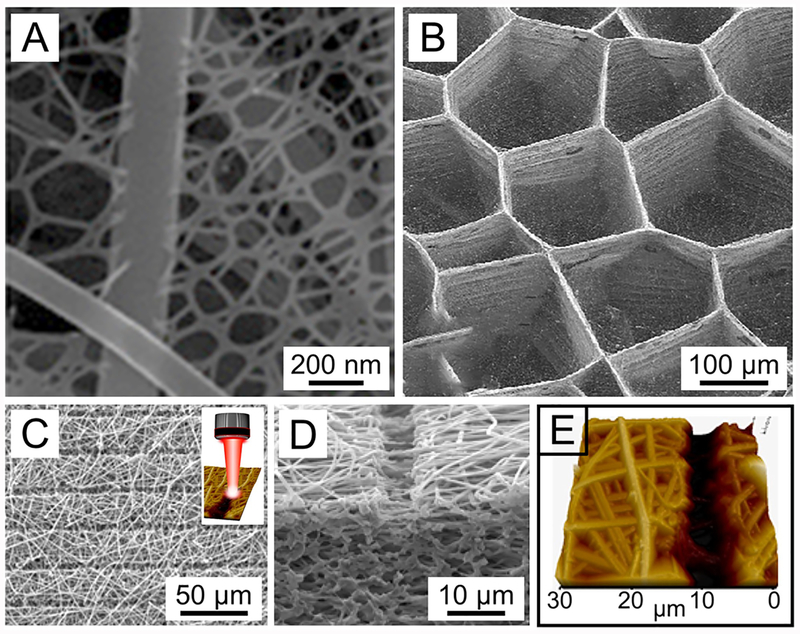

2.3.1. Far-Field versus Near-Field.

During electrospinning, the distance between the tip of the spinneret and the collector (H) determines the stages at which the fibers will be deposited on the collector. The conventional electrospinning is typically conducted in the far-field mode (H = 5− 15 cm) with the application of a high voltage (10–20 kV). As such, a nonwoven mat of nanofibers is obtained, especially for solution electrospinning, due to the difficulty in precisely controlling the positions of the deposited fibers.

When the distance is reduced to 500 μm−5 cm, near-field electrospinning will be attained (Figure 11A),144 by which the jet is impacted onto the collector within the straight segment. The distance can be predicted using the critical length (L) shown in eq 2.56,145 In this case, the electric field is highly concentrated between the spinneret and the collector (Figure 11B),146 and the applied voltage can be lowered to several hundred volts (usually 0.6–3 kV). In addition, the flow rate of the liquid must be significantly reduced to 0.01–1 mL/h in order to support a stable jet. Figure 11C shows the result of a typical example of near-field electrospinning, which involved an 18 wt % PEO solution in a mixture of water and ethanol.147 The charged jet followed a straight line for the deposition of fibers at well-defined positions on the collector when the distance and applied voltage were 1.0 mm and 1.7 kV, respectively.

Figure 11.

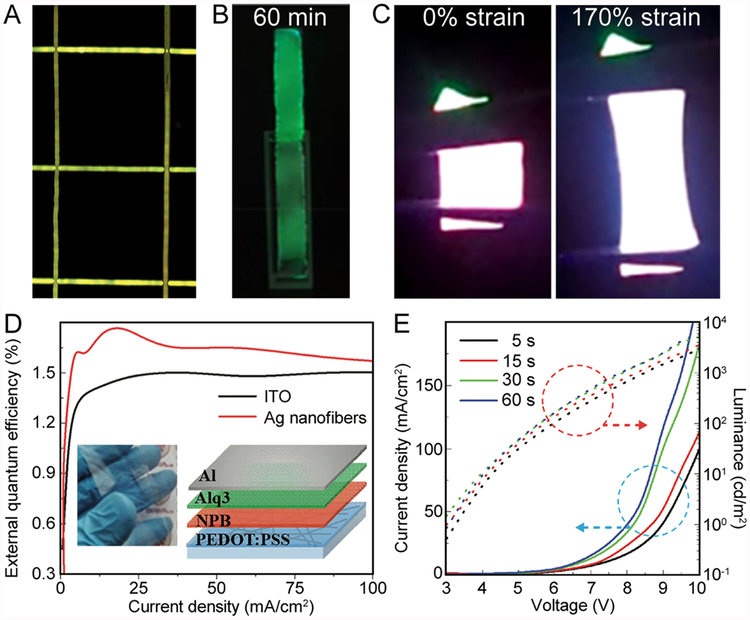

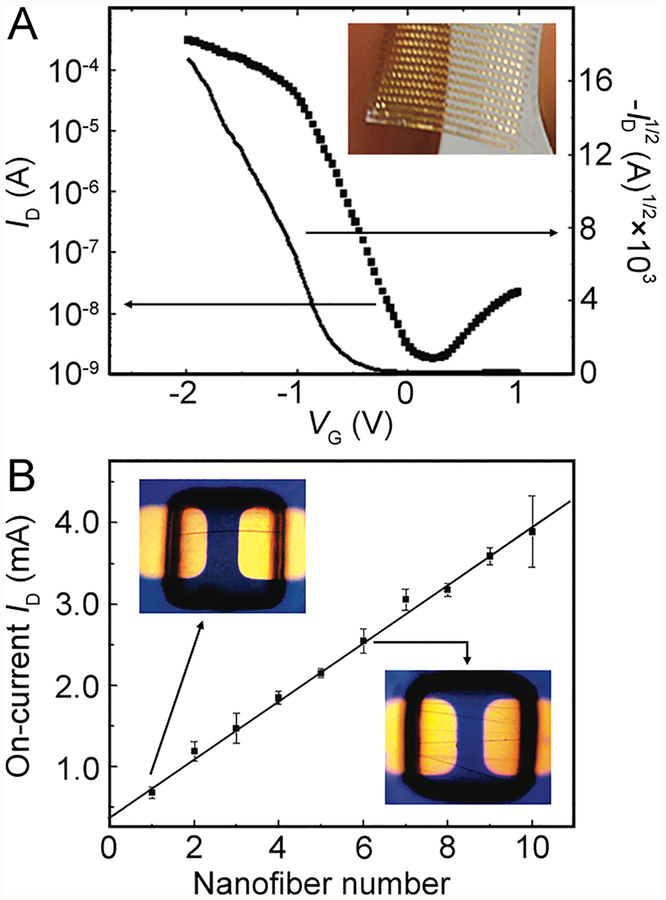

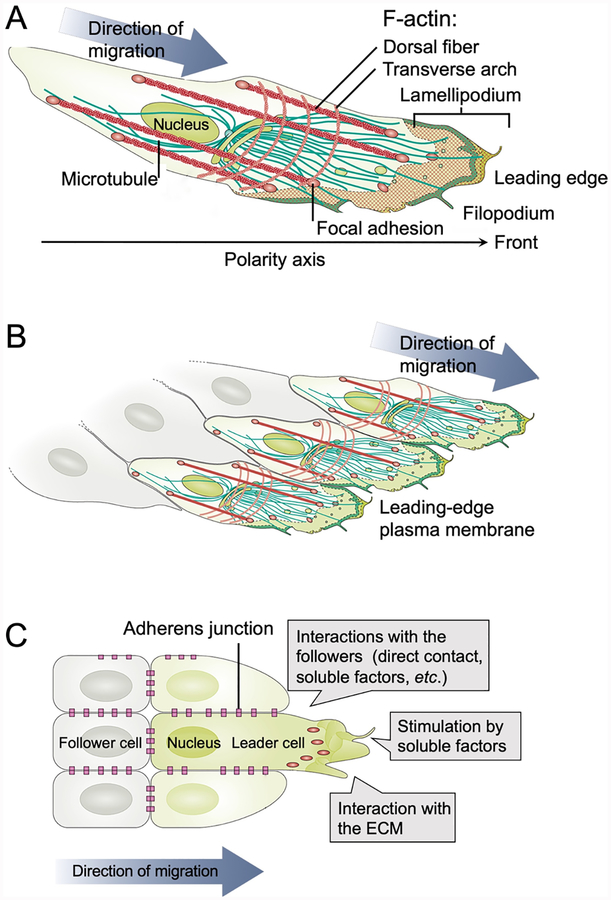

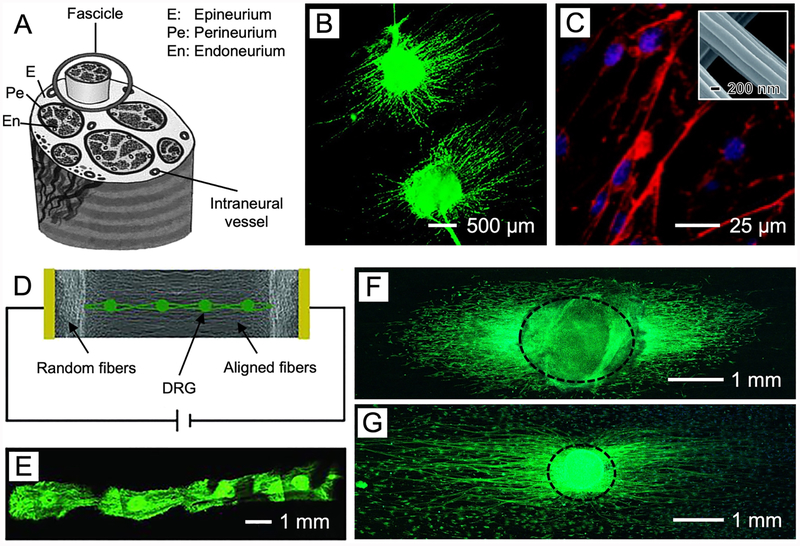

(A) Schematic illustration of the setup for near-field electrospinning to directly write fibers on a moveable collector (at a moving speed of Sc) when the distance (H) between the tip of the spinneret and the collector is kept within the straight region (the critical length is L). (B) Electric field distribution around a needle tip in the near-field electrospinning process. (C) Photographs of a straight, charged PEO jet recorded using a high-speed camera during near-field electrospinning, and (D−F) SEM images of the PEO fibers deposited on a silicon substrate when the collector moved at speeds of (D) 0.03, (E) 0.20, and (F) 0.36 m/s, respectively. (G) SEM image of PEO fibers deposited in a pattern by controlling the motion of the collector along both X and Y directions during near-field electrospinning. (H and I) Optical micrographs of patterned arrays of coiled PS fibers obtained through near-field electrospinning. (A) Reprinted with permission from ref 144. Copyright 2013 Royal Society of Chemistry. (B) Reprinted with permission from ref 146. Copyright 2015 AIP Publishing. (C−F) Reprinted with permission from ref 147. Copyright 2010 IOP Publishing. (G) Reprinted with permission from ref 150. Copyright 2011 American Chemical Society. (H and I) Reprinted with permission from ref 151. Copyright 2012 Elsevier.