Switchgrass mitigates greenhouse gas (GHG) emissions and no-till corn is GHG neutral for bioenergy production’s agronomic phase.

Abstract

Bio-based energy is key to developing a globally sustainable low-carbon economy. Lignocellulosic feedstock production on marginally productive croplands is expected to provide substantial climate mitigation benefits, but long-term field research comparing greenhouse gas (GHG) outcomes during the production of annual versus perennial crop-based feedstocks is lacking. Here, we show that long-term (16 years) switchgrass (Panicum virgatum L.) systems mitigate GHG emissions during the feedstock production phase compared to GHG-neutral continuous corn (Zea mays L.) under conservation management on marginally productive cropland. Increased soil organic carbon was the major GHG sink in all feedstock systems, but net agronomic GHG outcomes hinged on soil nitrous oxide emissions controlled by nitrogen (N) fertilizer rate. This long-term field study is the first to demonstrate that annual crop and perennial grass systems respectively maintain or mitigate atmospheric GHG contributions during the agronomic phase of bioenergy production, providing flexibility for land-use decisions on marginally productive croplands.

INTRODUCTION

Renewable energy from biomass plays a critical role in limiting global warming (1), where management decisions are key to biofuel sustainability and climate change mitigation potential (2–4). To date, there has been a lack of long-term data on the effects of management decisions and environmental variability on bioenergy system sustainability (4–6), specifically during the agronomic phase of feedstock production. Bioenergy feedstock production is expected to require substantial land area, highlighting the importance of predicting land use and ecosystem service impacts (4, 6–9). Converting uncultivated native ecosystems to intensively managed agricultural systems leads to significant carbon losses directly through burning or microbial decomposition of soil organic matter or by triggering indirect land use changes (5, 7, 9, 10). In contrast, biofuel feedstock production on marginally productive agricultural lands (3) and targeted landscape placement (11, 12) have been identified as strategies that avoid the food-versus-fuel conflict while conferring climate mitigation and other ecosystem service benefits (6–9).

Global estimates of marginally productive land are highly variable, ranging from 0.1 billion to 1.1 billion ha (13, 14). Estimates of marginally productive land in the United States alone are similarly variable and range from 59 million to 127 million ha (13, 15), with ~20 million ha identified as suitable for perennial grasses as dedicated bioenergy feedstocks (16). While there are many different criteria for “marginal land,” here, we define cropland as “marginally productive” when historical crop yields are 25% below the regional average (17). A sufficient land base of marginally productive cropland exists in the U.S. Corn Belt to support a perennial bioenergy system with minimal impacts to productive cropland (2, 18). The U.S. Corn Belt is also a primary source for crop residues for cellulosic bioenergy and bioproduct manufacture, particularly corn (Zea mays L.) stover, which is currently used for livestock grazing, feed, and bedding (19).

In recent years, cropland expansion in the U.S. Central Plains region has occurred most rapidly on land less suitable for cultivation (20), foreshadowing increases in land-use competition between annual row crops and future bioenergy grass production on marginally productive land (3, 20). Transition of marginal lands from intensively managed annual row crop systems to dedicated perennial cellulosic production systems, however, is expected to yield greater climate benefits through fossil fuel offsets, gains in soil organic carbon (SOC), and avoided greenhouse gas (GHG) emissions (4, 6–8, 18). The lack of long-term field data, however, poses major constraints to validating modeled GHG outcomes and associated errors for both annual and perennial bioenergy production systems (6, 21).

Here, we present results for different N fertilizer management and harvest strategies on the long-term (16 years) GHG emissions during the production phase of annual and perennial bioenergy feedstocks on marginally productive croplands. This study is the longest running systems-level field experiment reporting data that compares annual and perennial bioenergy feedstock production at an operationally relevant management scale (17, 22–26). This site is representative of marginally productive croplands targeted for dedicated bioenergy grass production in the U.S. Corn Belt. Here, we report crop yields, SOC change over 16 years (0- to 30-cm depth), direct GHG emissions from soils as nitrous oxide (N2O) and methane (CH4) over 7 years, and estimated emissions from management operations (i.e., fuel use) and agrochemical manufacturing (i.e., herbicides; ammonium nitrate or urea fertilizer) to calculate GHG emissions during the agronomic phase of corn and switchgrass (Panicum virgatum L.) production.

Treatments compared included three levels of N fertilizer (0, 60, and 120 kg N ha−1 year−1) in (i) a no-tillage (hereafter “no-till”) continuous corn system with ~60% stover removal, (ii) a continuous switchgrass system (cultivar “Cave-in-Rock”) harvested post-killing frost, and (iii) a rotational switchgrass system [cultivar “Trailblazer” followed by a 2-year transition period in soybean (27) and then cultivar “Liberty” until present] harvested post-killing frost. We also evaluated stover removal impacts on no-till corn by measuring 0% stover removal at the near-optimal corn N rate at this site (120 kg N ha−1 year−1). The rotational switchgrass system represents the likely real-world management scenario where switchgrass is replaced every ~10 years as improved cultivars become available.

Previous life cycle assessments for this site using the GREET (Greenhouse Gases, Regulated Emissions, and Energy Use in the Transportation) model indicated that management practices resulted in large variation in petroleum offset potential but that both corn and switchgrass bioenergy systems resulted in near-term net GHG reductions (17). Although not a full life cycle assessment (i.e., no accounting of fossil fuel use for transportation, production of useful coproducts, and indirect land use change), here, we incorporate primary data from measured field-scale biomass yields, SOC, and direct gas emissions instead of relying on modeled data to evaluate the GHG outcomes during the production phase of these bioenergy feedstock systems.

RESULTS

Crop yields

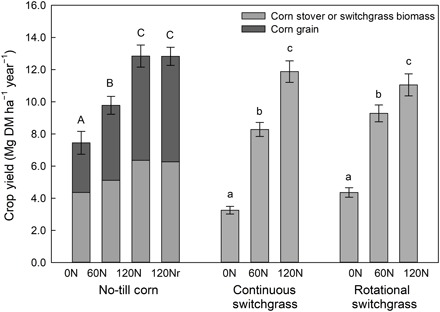

Yields of corn grain, stover (i.e., nongrain biomass before stover harvest), and total aboveground biomass were similarly affected by the main effects of year and N treatment. Specifically, the lowest yields occurred in 2002 and 2012, corresponding with severe drought years. The highest yields occurred in 2004 and 2015. Grain, stover, and total biomass yields increased with N rate, with no differences between stover retained versus removed at the highest N rate (Fig. 1). Across all N levels, stover removal rates averaged 59 ± 3% of nongrain biomass (2000–2017). Total aboveground biomass yields did not differ between continuous or rotational switchgrass systems but increased with N rate (Fig. 1). Fertilizer effects on switchgrass varied from year to year, with fertilizer addition boosting switchgrass yield by four- to fivefold in 2012 and 2013 (0 versus 60 kg N ha−1 year−1).

Fig. 1. Mean dry matter (0% moisture) yields for annual and perennial crops.

Uppercase letters indicate N rate differences in corn yields, where stover was removed except in 120Nr (stover retained). Corn SE bars are for total aboveground biomass. Lowercase letters indicate N rate differences in total aboveground biomass for switchgrass systems. DM, dry matter.

SOC changes

Both annual and perennial systems maintained or gained SOC in surface soils after 16 years (Table 1 and fig. S1). Accrual rates varied, with no statistical differences in crop type or N management (overall mean, 0.8 ± 0.1 Mg C ha−1 year−1) and were lower than rates measured after 9 years of treatment (1.3 ± 0.2 Mg C ha−1 year−1) (21). No-till corn with stover removal maintained SOC levels over time and gained SOC when no stover was removed (0.7 Mg C ha−1 year−1). All switchgrass systems, except rotational switchgrass with no fertilizer, showed significant SOC gains (0.9 to 1.3 Mg C ha−1 year−1).

Table 1. Rates of change in SOC in surface soils, 1998–2014 (mean ± SE).

| Fertilizer N* | Change in SOC stocks, 1998–2014† | ||

|

No-till continuous corn |

Continuous switchgrass |

Rotational switchgrass |

|

| kg N ha−1 year−1 | Mg C ha−1 year−1 | ||

| 0 | – | 0.9 ± 0.6‡ | 0.3 ± 0.1 |

| 60 | 0.2 ± 0.3 | 1.1 ± 0.1‡ | 1.0 ± 0.2‡ |

| 120 | 0.5 ± 0.3 | 1.1 ± 0.3‡ | 1.3 ± 0.5‡ |

| 120 + R§ | 0.7 ± 0.4|| | – | – |

| Site mean (all N, all crops) | 0.8 ± 0.1 | ||

*No stock changes were measured in continuous corn under 0 kg N ha−1 year−1.

†Equivalent soil mass approximates top 30 cm of soil (4133 Mg/ha). There were no significant differences between crop type or N rate (P > 0.10).

‡Mean rate was significantly different from zero (P ≤ 0.05).

§“+R” indicates stover retention (0% removal) in continuous corn only.

||Mean rate was marginally significant from zero (P = 0.10).

Soil GHG emissions

Soil CH4 fluxes were negligible compared to N2O emissions and not affected by year, crop, or N rate (overall mean, 0.19 ± 0.03 kg CH4-C ha−1 year−1). Soil CH4 fluxes, however, were included as total non-CO2 emissions for calculations of net GHG outcomes during the agronomic phase of feedstock production (below). For all production systems, direct emissions of N2O varied during the year (fig. S2). Total annual N2O emissions did not differ from zero for most years in the fertilizer rates of 0 and 60 kg N ha−1 year−1, but most systems released N2O in the rate of 120 kg N ha−1 year−1 (Fig. 2). Background N2O emissions (i.e., 0 kg N ha−1 year−1) were not different between cropping systems or years, with an overall site mean of 0.47 kg N2O-N ha−1 year−1. Soil N2O emissions were higher in the continuous versus rotational switchgrass system, and both systems showed significant interannual variability in N2O effluxes not apparent in no-till corn. Stover removal at the high N rate decreased mean annual N2O emissions by 23% compared to stover retention. Emission factors (EFs) for N2O over all systems increased from 1.1 ± 0.2% at 60 kg N ha−1 year−1 to 1.9 ± 0.2% at 120 kg N ha−1 year−1. Stover removal decreased EF compared to stover retained (2.2 ± 0.5% versus 3.2 ± 0.6%) at the rate of 120 kg N ha−1 year−1. The greatest cropping system differences in EFs occurred at 120 kg N ha−1 year−1, where EFs from the continuous switchgrass system (5.0 ± 0.8%) were higher than the rotational switchgrass system (1.1 ± 0.4%) for 2012 to 2016.

Fig. 2. Total annual direct emissions at annual fertilizer rates.

(A) 0, (B) 60, and (C) 120 kg N ha−1 year−1. Hatched bars indicate no significance from zero (P ≤ 0.05). In (C), different letters indicate significant differences in annual N2O emissions in switchgrass only. ND, no data.

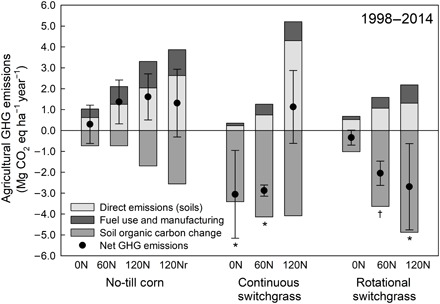

Production phase net GHG outcomes

After aggregating 16-year SOC changes, soil non-CO2 GHG emissions (i.e., N2O and CH4), and emissions from fuel use and agrochemical manufacturing (table S1), net agricultural emissions from no-till corn systems were GHG neutral (i.e., not significantly different from zero; 0.3 to 1.6 Mg CO2 eq ha−1 year−1) and higher than both switchgrass systems (−3.1 to 1.1 Mg CO2 eq ha−1 year−1) (Fig. 3 and table S2). Changes in SOC accounted for 35% of gross emissions in corn and 66 to 70% of gross emissions in switchgrass, and direct N2O emissions accounted for 40% of gross emissions from corn and 22 to 23% of gross emissions in switchgrass (table S2).

Fig. 3. Total and net GHG emissions from the agronomic production phase.

Net GHG emissions: closed symbols. Significance from zero for net GHG emissions is indicated by †P ≤ 0.10 and *P ≤ 0.05.

DISCUSSION

Our results showed that (i) perennial bioenergy systems are net GHG sinks compared to annual bioenergy systems and (ii) no-till continuous corn systems were GHG neutral over the long term on this marginally productive cropland site in the U.S. Corn Belt. Net GHG sink strength in both annual and perennial production systems was controlled by SOC gains. Soil C gains are expected when converting marginally productive croplands to bioenergy grasses (11, 12, 22, 26–29), and our long-term SOC accrual rates in switchgrass systems were consistent with regional on-farm assessment (29). Although corn stover biomass (and presumably plant input into the soil) was intermediate relative to switchgrass yields at 0 and 60 kg N ha−1 year−1, SOC accrual rates in continuous corn systems were almost half the SOC accrual rate for switchgrass grown with no N fertilizer. Retaining corn stover marginally improved SOC gains, consistent with a recent meta-analysis reporting SOC maintenance or gains in corn systems regardless of stover removal (28), which contrasted with removal-related losses in an earlier review (30). Nonetheless, the maintenance or storage of SOC at this site under continuous corn with and without stover removal, respectively, was attributed to the higher C storage capacity of these degraded soils (i.e., low initial SOC levels) plus the adoption of no-till management (22, 24, 26). For all systems studied here, plant roots were the principal inputs for building SOC stocks, with N fertilizer rate as a key determinant for maximizing belowground inputs in both crop types (26).

The mitigation outcome for agronomic phase GHGs, however, was determined by the magnitude of direct N2O emissions. Cumulative annual soil N2O emissions increased with N rate, where the mean EF (i.e., the amount of total fertilizer N lost as N2O) for the middle N rate (60 kg N ha−1 year−1) approximated to 1% across all cropping systems and matched the Intergovernmental Panel on Climate Change (IPCC) Tier 1 assumptions for N2O released from fertilizer (31). When the fertilizer rate doubled, EFs in all cropping systems increased, similar to nonlinear increases with fertilizer rate observed in other studies (32, 33) but in contrast to the linear function assumed by IPCC Tier 1. The effect of stover removal on EF compared to stover retained (2.2 ± 0.5% versus 3.2 ± 0.6%), however, did match the IPCC Tier 1 assumption that 1% of emissions are derived from crop residue N (31). The overall reduction in direct emissions with stover removal is consistent with a regional stover management study in the U.S. Corn Belt (23).

Under the high N rate, mean EFs were five times higher in the continuous switchgrass system versus the rotational system for 2012 to 2016. This was expected for 2010 to 2013 when no N was added during the transitional soybean crop and rotational switchgrass establishment years. In contrast, the continuous switchgrass system experienced long-term accrual of soil and plant N, resulting in disproportionately high emissions of N2O in 2014 to 2017 because fertilizer was applied far in excess of plant demand (26). A recent meta-analysis identified the optimum N rate for switchgrass between 30 and 60 kg N ha−1 year−1 (34), similar to observations presented above and previously (22, 26).

Our results support the view that SOC stock changes and soil N2O emissions associated with N fertilizer management dominate system GHG balances (2, 4, 5, 12). Specifically, we found that although SOC stock change was the major GHG sink in all bioenergy feedstock systems, net agricultural GHG outcomes hinged on the magnitude of direct N2O emissions. For corn, greater SOC storage with stover retention was offset by higher direct N2O emissions, resulting in similar net GHG-neutral outcomes under both residue management practices. In continuous switchgrass, disproportionate N2O emissions due to excess N application (120 kg N ha−1 year−1) completely offset SOC gains, making this perennial system net GHG neutral instead of a GHG sink. Although we used SOC changes in only the top 30 cm of soil, more than 50% of SOC storage occurs deeper than 30 cm at this site (22) and in many biofuel production systems (28). Using earlier SOC data from this site, Schmer et al. (25) demonstrated in a full biofuel life cycle comparison that system GHG emissions differed by as much as 154% between near-surface SOC versus near- plus subsurface SOC changes using the GREET model, highlighting the importance of subsurface SOC changes in system GHG outcomes (22, 28).

Although it is unclear whether increasing the carbon efficiency of landscapes will translate to reduced system GHG emissions from the bioenergy production chain as a whole (10), continued high input costs and low commodity prices for corn grain in the United States signal opportunities for returning perennials to marginally productive croplands to meet future energy challenges and help limit global warming below 2°C (1). As the lignocellulosic industry is still in developmental stages, our findings here confer greater management flexibility in the selection of crops to use on marginally productive landscapes in the U.S. Corn Belt. Using conservation practices (i.e., no-till) and rotating annual and perennial systems could provide near-term GHG-neutral options, with stronger longer-term climate mitigation possibilities when cellulosic feedstocks become a viable revenue source.

MATERIALS AND METHODS

Site description and experimental design

Experimental design, agronomic management operations, and soil sampling methods were described previously (22, 24). Briefly, the field study was established in 1998 at the University of Nebraska’s Eastern Nebraska Research and Extension Center near Ithaca, NE (41.2°N, 96.4°W). Soils at the site consisted of Yutan silty clay loams (a fine-silty, mixed, superactive, mesic Mollic Hapludalf), Tomek silt loams (a fine, smectitic, mesic Pachic Argiudoll), and Filbert silt loams (a fine, smectitic, mesic Vertic Argialboll), comprising 47, 35, and 18% of the study area, respectively (35). While these soil map units typically fall into nonirrigated land capability classes 1 (few limitations restricting cultivation) and 2 (some limitations requiring moderate conservation practices) (35), the study site itself was geologically underlain with Platte River sands (36), which appeared as shallow as ~50-cm soil depth in various site areas, contributing to this site’s historically marginal crop production (<25% of the regional average). The site was previously cropped in sorghum [Sorghum bicolor (L.) Moench] and soybean [Glycine max (L.) Merr.] under conventional disk-tillage practices.

The study was established in a randomized complete block split-split plot design (n = 3), where main plot sizes were 0.3 ha to accommodate commercial equipment use. Main plots were cropping system (no-till corn, continuous switchgrass, and rotational switchgrass), and subplots were N fertilizer rate (0, 60, and 120 kg N ha−1 year−1). Sub-sub plots were harvest treatments, which were initiated in 2001, and a subset of harvest treatments was used in the present study to best represent likely producer practices: (i) in no-till corn, stover removal at all N rates plus no stover removal at the optimal N rate of 120 kg N ha−1 year−1 and (2) in switchgrass, post-killing frost harvest. The 0 kg N ha−1 year−1 treatment in corn began in 2010 as a nested treatment within the 60 N ha−1 year−1 subplot to quantify background GHG emissions and calculate N2O EFs (31).

The no-till corn and continuous switchgrass treatments were in place since the beginning of the study. Corn stover removal treatments began in 2000. The rotational switchgrass treatment included 11-years of the Trailblazer cultivar, followed by a 2-year transition period in soybean, and then a 2-year establishment period for the bioenergy cultivar Liberty. The 2-year establishment period accounted for initial stand failure of Liberty in the first year due to severe drought in 2012, and this cultivar continues at present.

Crop yield measurement

For continuous corn, total aboveground biomass, grain and stover yields at physiological maturity, and stover removal rate measured from 2000 to 2017 (18 years) for the 60 and 120 kg N ha−1 year−1 treatments. Total aboveground biomass, grain, and stover yields were measured in the 0 kg N ha−1 year−1 from 2010 to 2017 (8 years). Stover removal rates were determined for nongrain biomass removed after grain harvest relative to stover biomass at physiological maturity (22, 24). For the continuous switchgrass system (cultivar Cave-in-Rock), total aboveground biomass was measured from 1998 to 2017 (20 years). The rotational switchgrass system included 17 years of yield data from cultivars Trailblazer (1998–2009) and Liberty (2013–2017). In this system, yields were not included for the transitional soybean crop (2010–2011), and there was no measurable yield for Liberty in 2012 because of stand failure during this establishment year when historical drought occurred. Additional management and biomass measurement description was previously reported (22, 24, 26).

SOC change measurement

Soil samples were collected in July 1998 (baseline) and sampled periodically, with only the baseline and latest collection in April 2014 presented here. SOC stocks and changes over time were calculated on an equivalent soil mass basis that approximated the top 30 cm of soil (mass, 4133 Mg ha−1) (26). No soil sampling was conducted in the 0 kg N ha−1 year−1 treatment in no-till corn. Sampled soils were 2-mm sieved, and identifiable plant materials (i.e., litter and roots) were hand-picked from the soil before total C and N analysis. Soil sampling and analysis methods were previously reported (22, 26), and the same methods were used for the April 2014 collection.

Soil GHG emission measurement

Soil GHG emissions (N2O and CH4) were measured for crop years 2011 to 2017 using static vented chambers following the U.S. Department of Agriculture–Agricultural Research Service (USDA-ARS) Greenhouse Gas Reduction through Agricultural Carbon Enhancement network (GRACEnet) protocols, as described in (37). Over 7 crop years, ~3800 individual measurements were taken in 126 sampling events. Total annual emissions for each N2O and CH4 were estimated by linear interpolation of flux rates between sampling dates, then, using the trapezoidal integration method (37). EFs for N2O in the 60 and 120 N ha−1 year−1 treatments were calculated as the percent of fertilizer N emitted as N2O minus background emissions (i.e., 0 kg N ha−1 year−1).

Production phase net GHG calculations

Although not a full life cycle assessment (i.e., no accounting of transportation fossil fuel use, useful coproducts, or indirect land use change), we approximated net GHG emissions for the agronomic phase of biofuel feedstock production (1998 to 2014) as the total non-CO2 soil GHG emissions, plus total fuel usage from agronomic operations and fertilizer manufacturing (table S1), minus total SOC stock changes (37). For crop years 1998 to 2010, when no GHG measurements occurred, annual direct emissions were estimated as the 7-year mean of measured 2011–2017 emissions. This assumption was supported by similar means and variations in growing season air temperature (May to October) and annual precipitation between the GHG measurement period (2011–2017) and nonmeasurement period (1998–2010) (table S3). Actual direct GHG values were used in calculations for crop years 2011 to 2014.

Changes in SOC from the 60 N ha−1 year−1 treatment in no-till corn was used to calculate net agricultural GHG emissions for the 0 kg N ha−1 yr−1 treatment in no-till corn. The 4 years involved in the rotational switchgrass system between cultivars (i.e., 2-year transition in unfertilized soybean plus 2 years for Liberty switchgrass establishment) were included in the calculation of net GHG emissions from the rotational switchgrass system. Sixteen-year changes in SOC stocks and net agricultural GHG emissions were divided by 16 to annualize rates (Mg CO2 eq ha−1 year−1). A positive or negative net value indicated that the system was a GHG source or sink, respectively. Relative contributions of fuel use/manufacturing, direct emissions, and SOC change were calculated as percentages of gross GHG fluxes for each cropping system.

Statistical analyses

Crop yields, annual direct GHG emissions, and EFs were analyzed as a split plot design with repeated measures using the GLIMMIX procedure of SAS (24). Data were transformed for normality when necessary. Fixed main treatment effects were year, cropping system (crop), and N(crop), where replicate and replicate*N(crop) were considered random effects, and the repeated measure was year. Changes in SOC and net agricultural GHG emissions were analyzed with the fixed main treatment effects of cropping system (crop) and N(crop), with same random effects terms defined previously. Treatment means were determined to be different from zero by LSMEANS significance. Multiple comparisons between significant treatment responses were evaluated with Bonferroni-adjusted P values in the LSMEANS statement.

Supplementary Material

Acknowledgments

We thank E. Buenger, E. Pruessner, S. Sampson-Liebig, S. Masterson, P. Callahan, K. Grams, S. Swanson, S. Siragusa-Ortman, N. Mellor, B. Fann, J. Leach, D. Walla, and the many students who contributed to data collection, analysis, and continued management of this experimental study. We acknowledge field and coordination assistance from N. Dominy, state soil scientist; D. Shurtliff, assistant state soil scientist; and P. Cowsert, resource soil scientist with the USDA-NRCS and laboratory support by the USDA-NRCS Kellogg National Soil Survey Laboratory. We also thank anonymous reviewers for constructive comments. Funding: Research was funded by the USDA-ARS including from USDA-ARS GRACEnet and in-kind support from the USDA-NRCS. Author contributions: R.B.M., G.E.V., R.F.F., J.K., and K.P.V. conceptualized the study and designed the experiment. V.L.J., C.O.W., and C.E.S. performed soil and gas sample analyses. V.L.J., M.R.S., C.E.S., and B.J.W. analyzed the data. V.L.J. and M.R.S. wrote the manuscript, with discussions and contributions from C.E.S., B.J.W., C.O.W., R.B.M., R.F.F., J.K., and K.P.V. Competing interests: The authors declare that there are no competing interests. Data and materials availability: All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials. This data and additional data related to this paper may be requested from the authors or can be accessed through the USDA-ARS’s Agricultural Collaborative Research Outcomes System (AgCROS) database (https://agcros-usdaars.opendata.arcgis.com/) in the Resilient Economic Agricultural Practices (REAP) Network (Site ID Lincoln, NE Corn-Switchgrass Bioenergy).

SUPPLEMENTARY MATERIALS

Supplementary material for this article is available at http://advances.sciencemag.org/cgi/content/full/5/12/eaav9318/DC1

Fig. S1. Total 16-year change in SOC stocks in surface soils (1998–2014).

Fig. S2. Environmental conditions and soil N2O emissions for crop years 2012–2017.

Table S1. Annual energy requirements and GHG emissions for off-site agrochemical manufacturing and field agronomic operations.

Table S2. Net GHG outcomes for the agronomic phase of biofuel feedstock production over 16 years of management.

Table S3. Mean daily air temperatures and precipitation inputs (1998–2017) for the growing season (May 1 to October 31) and for crop year (May 1 to April 30).

REFERENCES AND NOTES

- 1.Intergovernmental Panel on Climate Change, Global warming of 1.5°C, Special Report (2018); http://report.ipcc.ch/sr15/pdf/sr15_ts.pdf.

- 2.Gelfand I., Sahajpal R., Zhang X., Izaurralde R. C., Gross K. L., Robertson G. P., Sustainable bioenergy production from marginal lands in the US Midwest. Nature 493, 514–517 (2013). [DOI] [PubMed] [Google Scholar]

- 3.Mitchell R. B., Schmer M. R., Anderson W. F., Jin V., Balkcom K. S., Kiniry J., Coffin A., White P., Dedicated energy crops and crop residues for bioenergy feedstocks in the Central and Eastern USA. Bioenergy Res. 9, 384–398 (2016). [Google Scholar]

- 4.Robertson G. P., Hamilton S. K., Barham B. L., Dale B. E., Izaurralde R. C., Jackson R. D., Landis D. A., Swinton S. M., Thelen K. D., Tiedje J. M., Cellulosic biofuel contributions to a sustainable energy future: Choices and outcomes. Science 356, 1349–1357 (2017). [DOI] [PubMed] [Google Scholar]

- 5.Crutzen P. J., Mosier A. R., Smith K. A., Winiwarter W., N2O release from agro-biofuel production negates global warming reduction by replacing fossil fuels. Atmos. Chem. Phys. 8, 389–395 (2008). [Google Scholar]

- 6.Evans S. G., Ramage B. S., DiRocco T. L., Potts M. D., Greenhouse gas mitigation on marginal land: A quantitative review of the relative benefits of forest recovery versus biofuel production. Environ. Sci. Technol. 49, 2503–2511 (2015). [DOI] [PubMed] [Google Scholar]

- 7.Fargione J., Hill J., Tilman D., Polasky S., Hawthorne P., Land clearing and the biofuel carbon debt. Science 319, 1235–1238 (2008). [DOI] [PubMed] [Google Scholar]

- 8.Davis S. C., Parton W. J., Del Grosso S. J., Keough C., Marx E., Adler P. R., DeLucia E. H., Impact of second-generation biofuel agriculture on greenhouse-gas emissions in the corn-growing regions of the US. Front. Ecol. Environ. 10, 69–74 (2012). [Google Scholar]

- 9.Searchinger T. D., Heimlich R., Houghton R. A., Dong F., Elobeid A., Fabiosa J., Tokgoz S., Hayes D., Yu T., Use of U.S. croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 319, 1238–1240 (2008). [DOI] [PubMed] [Google Scholar]

- 10.Searchinger T. D., Wirsenius S., Beringer T., Dumas P., Assessing the efficiency of changes in land use for mitigating climate change. Nature 564, 249–253 (2018). [DOI] [PubMed] [Google Scholar]

- 11.Asbjornsen H., Hernandez-Santana V., Liebman M., Bayala J., Chen J., Helmers M., Ong C. K., Schulte L. A., Targeting perennial vegetation in agricultural landscapes for enhancing ecosystem services. Renewable Agric. Food Syst. 29, 101–125 (2014). [Google Scholar]

- 12.Field J. L., Evans S. G., Marx E., Easter M., Adler P. R., Dinh T., Willson B., Paustian K., High-resolution techno–ecological modelling of a bioenergy landscape to identify climate mitigation opportunities in cellulosic ethanol production. Nat. Energy 3, 211–219 (2018). [Google Scholar]

- 13.Campbell J. E., Lobell D. B., Genova R. C., Field C. B., The global potential of bioenergy on abandoned agriculture lands. Environ. Sci. Technol. 42, 5791–5794 (2008). [DOI] [PubMed] [Google Scholar]

- 14.Cai X., Zhang X., Wang D., Land availability for biofuel production. Environ. Sci. Technol. 45, 334–339 (2011). [DOI] [PubMed] [Google Scholar]

- 15.Emery I., Mueller S., Qin Z., Dunn J. B., Evaluating the potential of marginal land for cellulosic feedstock production and carbon sequestration in the United States. Environ. Sci. Technol. 51, 733–741 (2016). [DOI] [PubMed] [Google Scholar]

- 16.U.S. Department of Energy, U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry (Oak Ridge National Laboratory, 2011).

- 17.Schmer M. R., Vogel K. P., Varvel G. E., Follett R. F., Mitchell R. B., Jin V. L., Energy potential and greenhouse gas emissions from bioenergy cropping systems on marginally productive cropland. PLOS ONE 9, e89501 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Uden D. R., Mitchell R. B., Allen C. R., Guan Q., McCoy T., The feasibility of producing adequate feedstock for year-round cellulosic ethanol production in an intensive agricultural fuelshed. Bioenergy Res. 6, 930–938 (2013). [Google Scholar]

- 19.Schmer M. R., Brown R. M., Jin V. L., Mitchell R. B., Redfearn D. D., Corn residue use by livestock in the United States. Agric. Environ. Lett. 2, 160043 (2017). [Google Scholar]

- 20.Lark T. J., Salmon J. M., Gibbs H. K., Cropland expansion outpaces agricultural and biofuel policies in the United States. Environ. Res. Lett. 10, 044003 (2015). [Google Scholar]

- 21.Harris Z. M., Spake R., Taylor G., Land use change to bioenergy: A meta-analysis of soil carbon and GHG emissions. Biomass Bioenergy 82, 27–39 (2015). [Google Scholar]

- 22.Follett R. F., Vogel K. P., Varvel G. E., Mitchell R. B., Kimble J., Soil carbon sequestration by switchgrass and no-till maize grown for bioenergy. Bioenergy Res. 5, 866–875 (2012). [Google Scholar]

- 23.Jin V. L., Baker J. M., Johnson J. M.-F., Karlen D. L., Lehman R. M., Osborne S. L., Sauer T. J., Stott D. E., Varvel G. E., Venterea R. T., Schmer M. R., Wienhold B. J., Soil greenhouse gas emissions in response to corn stover removal and tillage management across the US Corn Belt. Bioenergy Res. 7, 517–527 (2014). [Google Scholar]

- 24.Jin V. L., Schmer M. R., Wienhold B. J., Stewart C. E., Varvel G. E., Sindelar A. J., Follett R. F., Mitchell R. B., Vogel K. P., Twelve years of stover removal increases soil erosion potential without impacting yield. Soil Sci. Soc. Am. J. 79, 1169–1178 (2015). [Google Scholar]

- 25.Schmer M. R., Jin V. L., Wienhold B. J., Sub-surface soil carbon changes affects biofuel greenhouse gas emissions. Biomass Bioenergy 81, 31–34 (2015). [Google Scholar]

- 26.Stewart C. E., Follett R. F., Pruessner E. G., Varvel G. E., Vogel K. P., Mitchell R. B., N fertilizer and harvest impacts on bioenergy crop contributions to SOC. Glob. Chang. Biol. 8, 1201–1211 (2016). [Google Scholar]

- 27.R. B. Mitchell, K. P. Vogel, B. E. Anderson, T. J. McAndrew, Renovating pastures with glyphosate tolerant soybeans, in Forage and Grazinglands (2005); doi: 10.1094/FG-2005-0428-01-BR. [DOI]

- 28.Qin Z., Dunn J. B., Kwon H., Mueller S., Wander M. M., Soil carbon sequestration and land use change associated with biofuel production: Empirical evidence. Glob. Change Biol. Bioenergy 8, 66–80 (2016). [Google Scholar]

- 29.Liebig M. A., Schmer M. R., Vogel K. P., Mitchell R. B., Soil carbon storage by switchgrass grown for bioenergy. Bioenergy Res. 1, 215–222 (2008). [Google Scholar]

- 30.Anderson-Teixeira K. J., Davis S. C., Masters M. D., DeLucia E. H., Changes in soil organic carbon under biofuel crops. Glob. Change Biol. Bioenergy 1, 75–96 (2009). [Google Scholar]

- 31.C. de Klein, R. S. A. Novoa, S. Ogle, N2O emissions from managed soils, and CO2 emissions from lime and urea application, in 2006 IPCC Guidelines for National Greenhouse Gas Inventories, S. Eggleston, L. Buendia, K. Miwa, T. Ngara, K. Tanabe, Eds. (IGES, 2006), vol. 4, pp. 1–54.

- 32.Shcherbak I., Millar N., Robertson G. P., Global metaanalysis of the nonlinear response of soil nitrous oxide (N2O) emissions to fertilizer nitrogen. Proc. Natl. Acad. Sci. U.S.A. 111, 9199–9204 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Ruan L., Bhardwaj A. K., Hamilton S. K., Robertson G. P., Nitrogen fertilization challenges the climate benefit of cellulosic biofuels. Environ. Res. Lett. 11, 064007 (2016). [Google Scholar]

- 34.Reichmann L. G., Collins H. P., Jin V. L., Johnson M.-V. V., Kiniry J. R., Mitchell R. B., Polley H. W., Fay P. A., Inter-annual precipitation variability decreases switchgrass productivity from arid to mesic environments. Bioenergy Res. 11, 614–622 (2018). [Google Scholar]

- 35.Soil Survey Staff 2014. Web Soil Survey. NRCS, Washington, DC, (2014); http://websoilsurvey.nrcs.usda.gov.

- 36.J. A. Elder, T. E. Beesley, W. E. McKinzie, Soil survey of Saunders County, Nebraska. USDA, Soil Conservation Service, Soil Survey Series 1959, No. 40 (1965); p. 62.

- 37.Jin V. L., Schmer M. R., Stewart C. E., Sindelar A. J., Varvel G. E., Wienhold B. J., Long-term no-till and stover retention each decrease the global warming potential of irrigated continuous corn. Glob. Chang. Biol. 23, 2848–2862 (2017). [DOI] [PubMed] [Google Scholar]

- 38.Adler P. R., Del Grosso S. J., Parton W. J., Life-cycle assessment of net greenhouse gas flux for bioenergy cropping systems. Ecol. Appl. 17, 675–691 (2007). [DOI] [PubMed] [Google Scholar]

- 39.California Air Resources Board, “Low Carbon Fuel Standard Certified Carbon Intensities” (2018); www.arb.ca.gov/fuels/lcfs/fuelpathways/pathwaytable.htm.

- 40.Johnson M. C., Palou-Rivera I., Frank E. D., Energy consumption during the manufacture of nutrients for algae cultivation. Algal Res. 2, 426–436 (2013). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material for this article is available at http://advances.sciencemag.org/cgi/content/full/5/12/eaav9318/DC1

Fig. S1. Total 16-year change in SOC stocks in surface soils (1998–2014).

Fig. S2. Environmental conditions and soil N2O emissions for crop years 2012–2017.

Table S1. Annual energy requirements and GHG emissions for off-site agrochemical manufacturing and field agronomic operations.

Table S2. Net GHG outcomes for the agronomic phase of biofuel feedstock production over 16 years of management.

Table S3. Mean daily air temperatures and precipitation inputs (1998–2017) for the growing season (May 1 to October 31) and for crop year (May 1 to April 30).