Abstract

Eggplant (Solanum melongena L.) is the third solanaceous of horticultural importance in the world, after potato and tomato. In the agricultural production of this vegetable, there are post-harvest losses and waste generation. Reduction of these inconveniences can be avoided by obtaining ingredients with high nutritional value for food processing, as breadmaking. Changes in wheat dough and bread quality due to the incorporation of eggplant flour were studied. Different levels (5, 7.5, 10%) of replacement with flour from Large eggplant were analysed. The optimum level of eggplant flour (7.5%) was used for comparison technological performance of eggplant–wheat breads elaborated with flour from eggplants of different size: small size eggplant (Baby, BE) and large size eggplant (Large, LE). Dough was characterized through farinographic (water absorption, development time, stability, softening degree) and fermentation parameters (maximum volume of fermented dough, fermentation time). Technological quality (specific volume, hardness, elasticity, number of crumb alveolus, colour of crust and crumb) and sensory analysis of breads were evaluated. Proximal composition and antioxidant activity of flour and breads were studied. Water absorption, development time and softening degree increased, while bread volume, elasticity and the area occupied by alveoli decreased with the presence of eggplant flour. Breads also became darker. Breads with 7.5% of BE, presented a harder crumb with lower luminosity than those with LE. Both type of breads were well accepted by consumers; nevertheless, BE was the bread that contains higher amount of compounds with antioxidant activity and therefore it is recommended for formulation of functional breads.

Electronic supplementary material

The online version of this article (10.1007/s13197-019-04046-4) contains supplementary material, which is available to authorized users.

Keywords: Eggplant, Dough optimization, Eggplant–wheat, Bread quality, Bread composition

Introduction

Eggplant (Solanum melongena L.) is the third horticultural crop of importance in the world within solanaceous after potato and tomato (Sękara et al. 2007) and is one of the fruits of main production in our region (La Plata, Argentina) according to the National Agricultural Census (2002). In addition, the production rate of eggplant in this area is high; for this reason, there is a special interest in finding uses of the waste derived from their agricultural production, to avoid environmental contamination. Other target is the reduction of post-harvest losses and also obtaining from them ingredients with high nutritional value. The inclusion of bioactive components through the incorporation of this fruit in the form of flour to wheat bread is a way to increase the consumption of vegetables and also to add value to commodities of our agricultural production.

In the last years eggplant became more important due to its nutritional characteristics, mainly for being a source of fibre (Jenkins et al. 2003; Makrogianni et al. 2017) and antioxidant compounds (Scalzo et al. 2016). Consumption of dietary fibre was associated to a lower risk of several diseases such as cardiovascular, diabetes, hypertension, obesity and gastrointestinal disorder (Anderson et al. 2009). Ingestion of phenolic compounds is also related to benefits for health due to anti-inflammatory, antiviral and anti-mutagenic properties (Yao et al. 2004). Eggplant is harvested according to their length or size and usually when they achieved the 80% of their final size, to maximize quality and yield, and before the complete development of seeds (Gajewski and Arasimowicz 2004; Mohammed and Brecht 2002). Although eggplants can be consumed in all stages of growth or size, fruits of small size or Baby have begun to be commercialized generating an added value product, which in turn has a higher content of antioxidants compared to larger fruits (Zaro et al. 2014). The development of functional foods through the incorporation of bioactive compounds of natural origin has been increasing in recent years. Given that the current consumption of vegetables is below the recommended intake and the increasingly high incidence of deaths due to non-transmissible diseases (WHO 2003), a possible promotion for increasing their consumption could be the incorporation of vegetables to another food matrix (Oliviero and Fogliano 2016). Being bread a basic product of massive consumption and highly accepted by consumers of all ages, it could be a highly convenient matrix for the incorporation of vegetables into the diet.

There are some research works in which bread were enriched with different functional components such as soluble fibres like inulin extracted from artichoke or chicory (Blanco Canalis et al. 2017; Linlaud et al. 2009; Salinas and Puppo 2013; Sirbu and Arghire 2017). The effect of replacement of wheat flour with flour from other cereals in the hydration and rheological properties of dough were also studied (Bigne 2016; Doxastakis et al. 2002). In the area of fruit and vegetables there are works where fruits were incorporated into bread, such as grapes, grapefruit and papaya (Peng et al. 2010; Reshmi et al. 2017; dos Santos et al. 2018); while not many studies on vegetables–wheat bread properties were found, some studies focuses mainly on the acceptance of the product. Hobbs et al. (2014) evaluated the acceptance of breads with added tomato, beet and pepper in the form of puree and cubes with the aim of increasing the consumption of vegetables and achieve a widely accepted product; but they did not evaluate the optimization process variables, as well as the nutritional quality of the obtained product. Ranawana et al. (2016) studied the antioxidant potential, storage life, shelf stability, textural changes and macronutrient oxidation of breads fortified with carrot, tomato, beetroot and broccoli, but they did not study the variables for process optimization. Considering that no studies were previously performed on the characterization of quality of wheat breads with eggplant flour, the first objective of the present work was to determine the optimum level of replacement of wheat flour with eggplant flour for obtaining breads of high technological quality. After that, with the optimum level of eggplant flour previously defined, the second objective was to determine chemical composition, quality and sensory acceptability of eggplant–wheat breads formulated with flour obtained from Baby and Large-size eggplant fruits.

Materials and methods

Materials

Wheat flour for bread making was used (type 0000, Molino Campodónico Ltda., Argentina). Purple eggplants (Solanum melongena L.) cv. Monarca were harvested in La Plata, Argentina, in two lengths or size (distance from calix to bottom of the fruit) and classified as Baby eggplant or BE (length: 0.09 m) and Large eggplant or LE (length: 0.17 m), and frozen in liquid nitrogen till use. The eggplant was cut, freeze-dried (RIFICOR, Argentina) and subsequent milled in a domestic mill used for coffee (Peabody, PE-MC9100, China) for obtaining the flour. The flour was sieved in a 500 µm mesh in which larger particles containing skin were retained. Finally, the fine fraction of the eggplant flour presented approximately 10% skin and a granulometry less or equal than 500 µm.

Methods

Effect of the level of eggplant flour The first part of this study was performed employing flour obtained from large-size eggplants. The wheat flour was partially replaced at three levels: 5%, 7.5% and 10% (kg eggplant flour/100 kg wet total flour basis, w.t.f.b.); and parameters for optimization the bread dough (farinographic and fermentation assays) determined. Quality sensory properties of eggplant–wheat breads were also analysed.

Effect of the eggplant size In this second part of the study the effect of the eggplant size, Baby (length: 0.09 m) and Large (length: 0.17 m), on different dough properties were evaluated; also quality, sensory attributes, proximal composition and antioxidant capacity of wheat–eggplant breads, were determined. For both size of eggplant, flour from Baby (BE) and Large (LE) fruits, the optimum concentration of replacement selected was 7.5%.

Bread–dough optimization parameters

Farinographic assays

Aptitude of flour blend for dough development was followed by farinographic assays. A Brabender farinograph (0.3 kg capacity) (Brabender, Duigsburg, Germany) was utilized for measuring water absorption, development time, stability and softening degree of dough AACC 54-21.02 method (AACC 2000). Flour blend consisted of mixing wheat flour, NaCl (2 kg/100 kg w.t.f.b.) and eggplant flour at levels of 5, 7.5 and 10% (kg flour/100 kg w.t.f.b.) for the level selection assay. For the second assay, the level of 7.5% of Baby and Large eggplant (kg flour/100 kg w.t.f.b.) flour was selected. Assays were performed by duplicate.

Fermentation curves

Each bread dough consisted of wheat flour, NaCl (2 kg/100 kg w.t.f.b.), dry yeast (2.5 kg/100 kg w.t.f.b.), malt extract (2 kg/100 kg w.t.f.b.), margarine (8 kg/100 kg w.t.f.b.), and eggplant flour at level of 5%, 7.5% and 10% (kg eggplant flour/100 kg w.t.f.b.) for the level selection assay; and 7.5% of Baby and Large eggplant (kg flour/100 kg w.t.f.b.) for the second assay. The amount of water added was selected from the farinographic assay. Bread dough (0.050 kg, n = 3) was placed in a 500 mL graduated cylinder with a mobile plunger and inserted in a fermentation cabinet (Brito Hnos, Argentina) at 30 °C for 4 h. Dough volume (mL) was registered in a graduated glass test tube every 5 min for the first hour and every 20 min for the ulterior 3 h. Measurements were performed in duplicate for each dough. The increase in volume was registered as a function of time and curves were adjusted by the Chapman model (Eq. 1) using the Origin 9 program: where V is the volume increment, t is the time and Vmax correspond to the maximum volume increment achieved; b and c are constants. Fermentation time (tf) is the time required for achieving 3/4 of Vmax, because during the beginning of the baking process the fermentation continues until the structure is established.

| 1 |

Bread and dough preparation

The flour/s and salt were premixed for 1 min, then the dry yeast, malt extract, margarine and water were added and mixed for 1 min more and finally the dough was mixed at 90 rpm for the remaining development time in planetary kneader (Kenwood, Treviso, Italy). The amount of water and development time were determined by farinographic assay. The dough obtained was separated in pieces (0.05 kg), allowed to rest for 15 min at room temperature and covered with a polyethylene film to prevent dehydration. Then, the buns were manually formed and put in a fermentation cabinet (Brito Hnos., Los Polvorines, Argentina) at 30 °C during the optimal fermentation time for each formulation. After fermentation process, the leavened dough was baked for 20 min at 200 °C in an oven (White-Westinghouse W-CG18), obtaining fully baked breads.

Bread quality

Specific volume

The volume of breads was determined according to Sciammaro et al. (2018) with the rapeseed displacement method, using a graduated cylinder to record the change in volume. The measure was performed in triplicate using 10 breads for each determination. The breads were weighed in a digital balance (Kern 572, Argentina). The specific volume was calculated as the ratio of the volume and mass in cm3/g.

Texture profile analysis (TPA)

Texture Profile Analysis was performed on bread according to Sciammaro et al. (2018) using a TA.XT2i Texture Analyzer (STABLE MICRO SYSTEMS, Surrey, U.K.) with a load cell of 25 kg. Centre pieces (3 cm of diameter and 2 cm of thickness) of ten breads were assayed for each formulation. Breads underwent a cycle of double compression that reproduces in an empiric form a two-bite texture profile. Samples were compressed up to 40% of deformation according to the original height of the bread with a cylindrical probe of 75 mm diameter (SMSP/75) at a crosshead speed of 0.5 mm/s. A curve of compression force vs time was obtained. Hardness was calculated as the force of the first peak and elasticity was calculated as the d2/d1 ratio, being d2 the distance between the beginning and the maximum of the second compression peak and d1 is the same distance for the first peak.

Crust and crumb colour

Crust and crumb colour measurements were performed on 10 bread for each formulation using a colorimeter Minolta CR-400 (Minolta, Osaka, Japan). Measurements were performed in triplicate. Parameter L* of the CIELAB colour space was determined.

Area of alevoli

Slices from the middle part of breads were scanned (Epson Stylus Tx115) (Figure S1a), and each image was converted to a grey scale (Figure S1b), alveolus areas stained as the resulting region of interest mask (Figure S1c) and then converted to binary (Figure S1d) and the area occupied by alveoli was measurement according to Sciammaro et al. (2018) using the ImageJ 1.37q software (National Institutes of Health, Bethesda, USA). For these measurements, a lower limit was fixed for alveolus size (0.1 mm2). At least 10 bread slices were analysed for each formulation.

Sensory analysis

For the second assay, a panel with consumers (non-trained people) between 25 and 60 years old (80 people) was used to evaluate the acceptability of breads added with 7.5% of Baby and Large eggplant. Each panellist received two samples of bread codified and sorted randomly. They were asked to indicate the level of satisfaction using hedonic scales of 9 points (1 = dislikes much, 9 = likes much) for the following parameters: taste, texture, crumb colour and global acceptability. They were also asked if they would buy this bread.

Proximal composition

Proximal composition of flour and breads was performed according to AOAC (1998). Moisture of samples was determined by triplicate after drying in oven at 105 °C until constant weight. Protein content was determined according to Kjeldahl method; the factor utilized for conversion nitrogen to protein was 6.25. Lipid content was determined using Soxhlet method; samples were extracted during 3 h with petroleum ether (35–60 °C fraction). The ash content was determined using the direct method according to AACC 08-01.01. Carbohydrate content was determined by difference. Total dietary fibre (TDF) and insoluble dietary fibre (IDF) were assayed by enzymatic hydrolysis (Megazyme kit, K-TDRF, Megazyme, Wicklow, Ireland) according to the official AOAC method. Soluble dietary fibre (SDF) was calculated by difference between total and insoluble fibre. Assays were performed by duplicate.

Antioxidant capacity

Samples of flour (0.5 g of wheat flour and 0.1 g of eggplant flour) and breads (2 g of eggplant–wheat bread) were extracted with 5 mL of 70% methanol and sonicated for 20 min. The suspension was centrifuged at 13,000×g for 15 min at 3 °C (Thermo Scientific Sorval ST 16R). The supernatant was collected and the pellet re-extracted in similar conditions. The extractions were performed in duplicate. The antioxidant capacity was determined by ABTS and FRAP methods.

ABTS assay The antioxidant capacity was estimated in terms of radical scavenging activity according to Arnao et al. (2001). Fifty microlitres of extracts were added to 1 mL of ABTS·+ working solution (absorbance of 0.700 ± 0.03 at 734 nm), incubated for 6 min and the absorbance at 734 nm was measured. A Trolox solution was used as standard. Samples were measured in triplicate. Results were expressed as Trolox Equivalent Antioxidant Capacity (TEAC) in mg/kg of dry sample.

FRAP assay The ferric reducing ability was determined according to Benzie and Strain (1996). Freshly prepared FRAP reagent (0.9 mL) was mixed with 0.1 mL of the extract. After 6 min, the sample absorbance was measured at 593 nm. A Trolox solution was used as standard. Samples were measured in triplicate. Results were expressed as Ferric Reducing Capacity Equivalent to Trolox (TEFRC) in mg of Trolox/kg of dry sample.

Statistical analysis

The experiments were carried out in a completely randomized design. Results were subjected to analysis by ANOVA and means were compared by a Fisher test at P < 0.05 performed in InfoStat software (Di Rienzo et al. 2008).

Results and discussion

Effect of the eggplant flour level on dough and bread quality

The incorporation of eggplant flour to wheat bread dough produce changes in the proportion and type of components that would alter the physicochemical properties of dough and therefore those of the final product, the bread. Due to these variations, the optimization of bread dough is necessary to find the optimum level of eggplant flour that ensures a bread of high quality. In this sense, optimization of parameters of quality of wheat dough like development and fermentation times and water absorption must be previously determined.

The amount of farinographic water absorption (Wabs) and development time (td) increased with the presence of eggplant flour (Table 1). Water absorption increased approximately 6%, in other works, the incorporation of chickpea, soybean, lupine and triticale flour also produced the increase of Wabs and this parameter did not significantly change with the level of the flour (Doxastakis et al. 2002; Mohammed et al. 2012). Development time significantly increased with eggplant flour up to a level of 7.5%, therefore with 10% considerably decreased, achieving td a half value of that observed for wheat flour (Table 1). Both, Wabs and td are important parameters for reaching the adequate hydration of flour components and the gluten network development in dough (Weiser 2012).

Table 1.

Bread–dough optimization and quality parameters for wheat flour (W) and blend of wheat flour with 5% (E-5%), 7.5% (E-7.5%) and 10% (E-10%) eggplant flour

| W | E-5% | E-7.5% | E-10% | |

|---|---|---|---|---|

| Farinographic parameters | ||||

| Wabs (%) | 57.7 ± 0.3c | 61.0 ± 0.0b | 61.7 ± 0.1a | 61.7 ± 0.1a |

| td (min) | 9.0 ± 0.0c | 10.4 ± 0.2b | 14.5 ± 0.7a | 5.5 ± 0.0d |

| Stability (min) | 36.3 ± 0.7a | 8.8 ± 0.3b | 13.3 ± 0.4b | 11.9 ± 4.5b |

| Degree of softening (FU) | 18.5 ± 6.4c | 105.0 ± 0.0a | 59.0 ± 8.5b | 47.0 ± 8.5b |

| Fermentation parameters | ||||

| Vmax (mL) | 97.6 ± 1.6a | 81.8 ± 0.0b | 59.5 ± 2.1c | 47.5 ± 2.0d |

| tf (min) | 52.0 ± 0.5b | 113. 7 ± 9.4a | 58.6 ± 0.9b | 63.7 ± 1.4b |

| Quality parameters | ||||

| Vsp (cm3/g) | 3.59 ± 0.19a | 2.40 ± 0.03b | 2.18 ± 0.21c | 1.59 ± 0.11d |

| Hardness (N) | 0.96 ± 0.07d | 4.26 ± 0.43c | 6.87 ± 0.61b | 8.12 ± 0.53a |

| Elasticity | 0.97 ± 0.01a | 0.87 ± 0.02b | 0.77 ± 0.03bc | 0.75 ± 0.03c |

| Cohesiveness | 0.69 ± 0.01a | 0.61 ± 0.01b | 0.53 ± 0.02c | 0.52 ± 0.01c |

| Chewiness (N) | 0.65 ± 0.04d | 2.24 ± 0.21c | 2.81 ± 0.26b | 3.15 ± 0.25a |

| L* bread crust | 65.65 ± 3.16a | 63.09 ± 1.70b | 61.45 ± 2.15c | 57.85 ± 1.48d |

| L* bread crumb | 68.10 ± 1.30a | 55.82 ± 1.50b | 56.36 ± 1.06b | 53.54 ± 0.92c |

| Area of alveolus (%) | 34.15 ± 2.63a | 32.26 ± 1.85b | 25.99 ± 3.91c | 25.61 ± 1.20c |

Wabs, water absorption; td, development time; Vmax, maximum volume; tf, fermentation time; Vsp, specific volume

Different letters in the same row indicate significant differences at p < 0.05

Dough stability is related with the dough force, low values of this parameter are related to more weak dough with less tolerance to kneading. The stability of eggplant bread dough decreased respect to the value observed for the wheat dough, in a proportion between 24 and 37%; nevertheless no significant changes were observed between the different levels of eggplant flour utilized. On the other hand, softening degree increased with eggplant, presenting E-5% a maximum value (Table 1). Similar results were obtained by Bigne (2016) with the replacement of wheat flour with Prosopis alba flour, attributing the decrease in dough stability to the gluten protein dilution; nevertheless, at the highest level of this flour these authors observed values similar to that of wheat dough.

The maximum volume of dough (Vmax) during fermentation decreased with the increase of the level of eggplant flour, being for E-10% a 50% lower than the volume of wheat dough (Table 1). For fermentation time (tf) an increase of 100% was observed for E-5%, while no significant differences were observed for E-7.5% and E-10% respect to W. Although the incorporation of 5% of eggplant flour considerably increased softening of dough, it was able to maintain the volume of the dough during fermentation with yeast, but at the expense of a long time (114 min) for the development of the optimum mass.

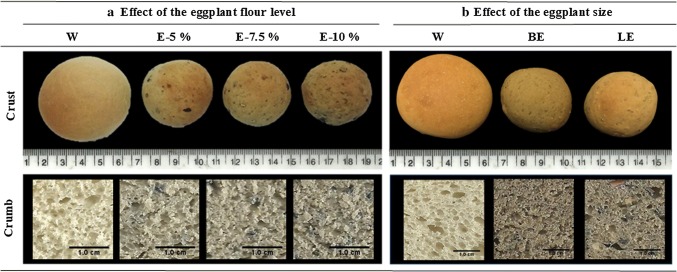

Bread with eggplant flour presented a different aspect to that of the wheat bread, and differences in crust and crumb were detected for the highest level of addition (Fig. 1). These results were supported by parameters obtained from different quality assays. The incorporation of eggplant flour to wheat flour reduced almost to a half value the specific volume (Vsp) of bread, the E-10% bread were eight times harder than wheat bread, lower elasticity and cohesiveness and presented also the highest chewiness. In addition, darker crust and crumb were obtained represented by a significant decrease in L* value respect to W with lower number of alveoli in the crumb structure (Table 1). In conclusion, changes in quality parameters of bread decreased in a progressive form with the increase in eggplant flour content (Table 1 and Fig. 1a). A ranking test of sensory evaluation of bread formulated with the three levels of eggplant (5, 7.5 and 10%) with 40 non-trained persons was performed. No significant differences in sensory acceptability between the three types of bread were observed (data not shown). All levels affected the technological bread quality but in a lesser amount those of 5 and 7.5%. In addition, the replacement of wheat flour with 7.5% of eggplant flour contribute to fibre in a greater proportion than the 5% level; therefore the 7.5% level was selected to examine the effect of eggplant size in bread making.

Fig. 1.

Appearance of bread crust and bread crumb. a Bread with wheat (W) and 5% (E-5%), 7.5% (E-7.5%) and 10% (E-10%) Large eggplant flour. b Breads with wheat (W) and 7.5% of Baby (BE) and Large (LE) eggplant flours

Effect of eggplant size on dough and bread quality

Baby eggplant (BE) is the same vegetable as the Large fruit, but in a previous stage of growing; it was harvested before the fruit reached the standard Large size (LE). Diverse studies (Glew et al. 2003; Kulkarni and Aradhya 2005) proved that composition and nutritional value depend on the state of fruit development, so that it is necessary to perform their comparative characterization.

All farinographic parameters were affected in the same manner as described in “Effect of the eggplant flour level on dough and bread quality” section with the addition of eggplant flour, and no significant differences were observed between BE or LE sample (Table 2), with the exception of Wabs.

Table 2.

Bread–dough optimization and quality parameters for wheat flour (W) and blend of wheat flour with 7.5% baby (BE) and Large (LE) eggplant flours

| W | BE | LE | |

|---|---|---|---|

| Farinographic parameters | |||

| Wabs (%) | 57.7 ± 0.3c | 62.6 ± 0.1a | 61.5 ± 0.4b |

| td (min) | 9.0 ± 0.0b | 13.7 ± 0.1a | 14.5 ± 0.8a |

| Stability (min) | 36.3 ± 0.7a | 13.4 ± 0.2b | 12.8 ± 0.4b |

| Degree of softening (FU) | 18.5 ± 6.4b | 52.5 ± 3.5a | 65.0 ± 7.1a |

| Fermentation parameters | |||

| Vmax (mL) | 97.6 ± 1.6a | 34.4 ± 0.6c | 59.5 ± 2.1b |

| tf (min) | 52.0 ± 0.5a | 50.7 ± 7.5a | 58.6 ± 0.9a |

| Quality parameters | |||

| Vsp (cm3/g) | 2.66 ± 0.21a | 1.80 ± 0.16b | 1.82 ± 0.02b |

| Hardness (N) | 1.77 ± 0.16c | 11.11 ± 1.06a | 9.30 ± 0.99b |

| Elasticity | 0.96 ± 0.01a | 0.77 ± 0.03b | 0.79 ± 0.07b |

| Cohesiveness (–) | 0.66 ± 0.01a | 0.53 ± 0.02b | 0.52 ± 0.02b |

| Chewiness (N) | 1.12 ± 0.11c | 4.41 ± 0.58a | 3.88 ± 0.43b |

| L* bread crust | 67.44 ± 2.01a | 46.09 ± 0.64c | 52.82 ± 0.82b |

| L* bread crumb | 67.93 ± 1.20a | 42.39 ± 0.92c | 46.83 ± 0.64b |

| Area of alveolus (%) | 36.20 ± 3.98a | 25.56 ± 1.61b | 25.15 ± 1.68b |

Wabs, water absorption; td, development time; Vmax, maximum volume; tf, fermentation time; Vsp, specific volume

Different letters in the same row indicate significant differences at p < 0.05

For fermentation parameters, a significant decrease in Vmax was also observed with the inclusion of eggplant flour, being for BE significantly lower than for LE; while no significant differences in fermentation times were observed between both samples (Table 2).

The addition of BE and LE eggplant flour to wheat flour, both at 7.5%, produced the same variation previously observed in “Effect of the eggplant flour level on dough and bread quality” section in bread quality respect to control sample (W): a decrease in Vsp, crumb elasticity and cohesiveness, and alveolar density with significant increase in hardness and in the chewiness (Table 2). It was observed that Vsp, elasticity, cohesiveness and area occupied by alveoli did not present significant differences between BE and LE, but hardness, chewiness and colour (crust and crumb) differed; bread with BE were harder, more chewiness and presented brownish crust and crumb (Table 2, Fig. 1b). Considering that the amount of fibre in Baby and in Large eggplants was not significantly different (see Table 3), this last difference could be due to the nature of fibre present in each type of eggplant. Baby eggplant presented higher bread hardness and a more intense brownish colour (lower L*) in the crust and crumb, because Baby present higher content of insoluble fibre, due to its greater amount of skin surface (higher ratio skin area/volume) in the fruit, compared to the Large eggplant. The insoluble fibre is in skin, while inside the fruit there is a higher proportion of soluble fibre (Sagar et al. 2018). In addition, the presence of higher amounts of dark skin due to the presence of higher contents of coloured compounds like polyphenols with antioxidant activity (see Table 3), conduct to darker bread like those observed for BE sample.

Table 3.

Proximal composition (kg/100 kg of dry sample) and antioxidant capacity (mg/kg of dry sample) of flours (a) and breads (b) of the wheat (W), Baby (BE) and Large (LE) eggplant samples

| a-Flour | b-Bread | |||||

|---|---|---|---|---|---|---|

| W | BE | LE | W | BE | LE | |

| Moisture* (kg/100 kg) | 13.61 ± 0.13b | 13.58 ± 0.26b | 16.70 ± 0.65a | 37.76 ± 1.15a | 37.25 ± 2.98a | 38.23 ± 1.02a |

| Proteins (kg/100 kg) | 13.20 ± 0.03a | 12.99 ± 0.02a | 11.01 ± 0.29b | 14.17 ± 0.17a | 14.36 ± 0.01a | 14.36 ± 0.27a |

| Lipids (kg/100 kg) | 1.53 ± 0.06a | 1.98 ± 0.07a | 1.79 ± 0.34a | 5.51 ± 0.09a | 4.97 ± 0.00b | 4.79 ± 0.28b |

| Ash (kg/100 kg) | 0.84 ± 0.03b | 9.16 ± 0.46a | 8.72 ± 0.47a | 2.51 ± 0.04b | 3.17 ± 0.10a | 3.08 ± 0.21a |

| TDF (kg/100 kg) | 6.13 ± 0.25b | 47.56 ± 2.67a | 51.14 ± 2.16a | 5.63 ± 0.09b | 8.35 ± 0.07a | 8.40 ± 0.07a |

| Carbohydrates (non-fibre)** (kg/100 kg) | 78.30 | 28.31 | 27.34 | 72.18 | 69.15 | 69.73 |

| TEAC (mg/kg) | 481.77 ± 44.25c | 23,408.53 ± 1138.41a | 16,015.15 ± 547.19b | 333.87 ± 22.04c | 806.38 ± 53.63a | 537.32 ± 34.40b |

| TEFRC (mg/kg) | 149 ± 8c | 20,110 ± 1108a | 11,905 ± 430b | 162 ± 7c | 576 ± 13a | 337 ± 10b |

TDF total dietary fibre, TEAC antioxidant capacity equivalent to Trolox, TEFRC ferric reducing capacity equivalent to Trolox

*kg/100 kg of wet sample

**Total Carbohydrates different from fibre = 100 − Proteins − Lipids − Ash − TDF

Different letters in the same row indicate significant differences at p < 0.05

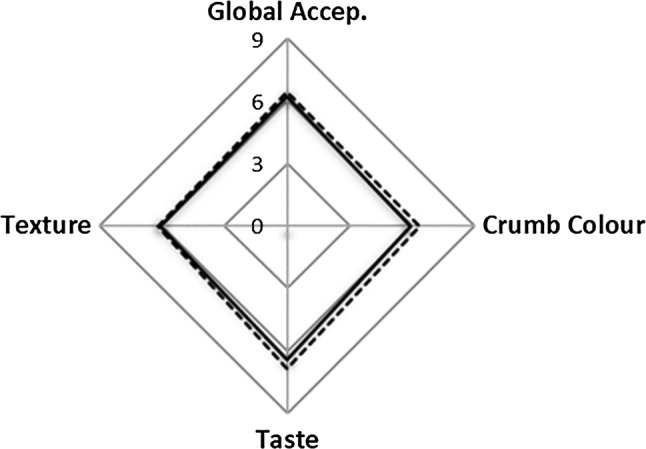

Sensory analysis of eggplant bread

Figure 2 shows that consumers did not perceived significant differences in sensory texture nor in crumb colour and taste, in spite of BE bread were harder and darker than LE bread. In addition, both products presented the same global acceptability. For all parameters evaluated, the average score was 6 points. In several works, a score of 5 is considered as an intermediate point (“neither liked nor disliked”), where above this value the product is accepted (Bower 2009). All attributes presented this score; therefore, it can be supposed that bread with eggplant were well accepted in each attributed evaluated.

Fig. 2.

Scores obtained from the sensory analysis for bread with 7.5% of Baby (-) and Large (- -) eggplant flour

Proximal composition and antioxidant capacity of flour and bread

Eggplant flour presented, in comparison with wheat flour, approximately more than 9 times of ash content, 80% less content of carbohydrates different from fibre and a significantly higher proportion of total dietary fibre (TDF) (Table 3a). While BE presented lower moisture and higher content of proteins and non-fibre carbohydrates respect to LE, the size of eggplant did not affect the amount of the other components. On the other hand, bread with eggplant, as it was expected, presented higher amounts of ash and dietary fibre (Table 3b). In this case, it should be considered that variations in composition of bread from wheat–eggplant blends were more tenuous than in pure flour, due to bread were mainly composed by wheat flour. In addition, in eggplant-wheat bread a lower content of lipids respect to W was observed, behaviour that could be due to the different levels of components in bread.

Antioxidant capacity (AC), measured by capture of free radicals (TEAC) and by reduction capacity of iron (TEFRC), was significantly higher for flour and bread from eggplants respect to W, presenting in both cases, BE a double value than in LE (Table 3a, b). Zaro et al. (2014) determined that AC of pulp of eggplant decreased with the increase in the fruit size, at the same time, it is well known that the major content of antioxidant polyphenols are placed in the skin (Valerga et al. 2017). The higher AC found in BE respect to LE in flour and in bread can be explain with the fact that BE present a high amount of antioxidant compounds in the pulp, is a smaller fruit and therefore present a high surface-to-volume ratio, contributing to a high proportion of the external tegument of the fruit (skin) per unit of fruit. While differences in values observed for TEAC and TEFRC in both flour and bread, are due to the differences in the mechanism of reaction of each assay, the observation of the same tendency in both AC experiments suggest that AC responds to both reaction mechanisms.

Therefore, flour and bread from eggplants presented a higher nutritional quality than wheat bread, due to eggplant contribute with minerals and fibre. From the bioactive point of view, also contribute to diet with antioxidant components and to lesser amount of available carbohydrates, considering that eggplant do not contain starch, only soluble sugars as glucose, fructose and mainly sucrose (Valerga et al. 2019). On the other hand, wheat flour contains a great proportion of non-fibre and available carbohydrates as starch.

Conclusion

Wheat dough and bread significantly changed with the addition of eggplant flour. Water absorption increased and did not change with the level of eggplant flour, nevertheless, softening degree, dough development and fermentation times highly increased with 5% of this flour, and with higher amounts (7.5 and 10%), these parameters considerably decreased. Consequently, bread presented a lower volume with a higher crumb hardness; tendency that was intensified with the increase of eggplant flour proportion. Hence, a crumb with low elasticity and with low amounts of alveoli per area was obtained. The eggplant size did not influence dough optimization parameters at a flour level of 7.5%. Bread with BE were smaller, hardener and presented less luminosity than bread with LE; nevertheless, bread with BE presented higher proportion of minerals and compounds with antioxidant activity and in addition, similar proportion of fibre and acceptance level by consumers than bread with LE. These results suggest that the inclusion of eggplant to wheat bread would contribute to the development of functional breads enriched in bioactive compounds.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

We want to acknowledge to University of La Plata (UNLP), Scientific Research Council (CONICET) and Science and Technology Minister (MINCYT) of Argentina for the financial support (PICT2016-3047). We also want to thank Molino Campodónico S.A, Molino Rio de la Plata S.A and AE María Emilia Dosantos.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC (2000) Approved Methods of the American Association of Cereal Chemists. vol v. 1-2, 10th edn. AACC, USA

- Anderson JW, et al. Health benefits of dietary fiber. Nutr Rev. 2009;67:188–205. doi: 10.1111/j.1753-4887.2009.00189.x. [DOI] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis. 16. Gaithersburg: AOAC International; 1998. [Google Scholar]

- Arnao MB, Cano A, Acosta M. The hydrophilic and lipophilic contribution to total antioxidant activity. Food Chem. 2001;73:239–244. doi: 10.1016/S0308-8146(00)00324-1. [DOI] [Google Scholar]

- Benzie IFF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem. 1996;239:70–76. doi: 10.1006/abio.1996.0292. [DOI] [PubMed] [Google Scholar]

- Bigne F. Rheological and microstructure characterization of composite dough with wheat and mesquite (Prosopis spp.) flours. Int J Food Prop. 2016;19:243–256. doi: 10.1080/10942912.2015.1020435. [DOI] [Google Scholar]

- Blanco Canalis MS, Steffolani ME, León AE, Ribotta PD. Effect of different fibers on dough properties and biscuit quality. J Sci Food Agric. 2017;97:1607–1615. doi: 10.1002/jsfa.7909. [DOI] [PubMed] [Google Scholar]

- Bower J. Statistical methods for food science. 1. Edinburgh: Wiley; 2009. [Google Scholar]

- Di Rienzo J, Casanoves F, Balzarini M, Gonzalez L, Tablada M, Robledo C (2008) InfoStat Versión 2011

- dos Santos CM, Rocha DA, Madeira RAV, de Rezende Queiroz E, Mendez Mendonça M, Pereira J, Patto de Abreu CM. Preparation, characterization and sensory analysis of whole wheat bread enriched with flour of papaya byproducts. Braz J Food Technol. 2018;21:1–9. doi: 10.1590/1981-6723.12017. [DOI] [Google Scholar]

- Doxastakis G, Zafiriadis I, Irakli M, Marlani H, Tananaki C. Lupin, soya and triticale addition to wheat flour doughs and their effect on rheological properties. Food Chem. 2002;77:219–227. doi: 10.1016/S0308-8146(01)00362-4. [DOI] [Google Scholar]

- Gajewski M, Arasimowicz D. Sensory quality of eggplant fruits (Solanum Melongena L.) as effected by cultivar and maturity stage. Pol J Food Nutr Sci. 2004;54:249–254. [Google Scholar]

- Glew RH, Ayaz FA, Sanz C, VanderJagt DJ, Huang HS, Chuang LT, Strnad M. Changes in sugars, organic acids and amino acids in medlar (Mespilus germanica L.) during fruit development and maturation. Food Chem. 2003;83:363–369. doi: 10.1016/S0308-8146(03)00097-9. [DOI] [Google Scholar]

- Hobbs DA, Ashouri A, George TW, Lovegrove JA, Methven L. The consumer acceptance of novel vegetable-enriched bread products as a potential vehicle to increase vegetable consumption. Food Res Int. 2014;58:15–22. doi: 10.1016/j.foodres.2014.01.038. [DOI] [Google Scholar]

- Jenkins DJA, et al. Effects of a dietary portfolio of cholesterol-lowering foods vs lovastatin on serum lipids and C-reactive protein. JAMA. 2003;290:502–510. doi: 10.1001/jama.290.4.502. [DOI] [PubMed] [Google Scholar]

- Kulkarni AP, Aradhya SM. Chemical changes and antioxidant activity in pomegranate arils during fruit development. Food Chem. 2005;93:319–324. doi: 10.1016/j.foodchem.2004.09.029. [DOI] [Google Scholar]

- Linlaud NE, Puppo MC, Ferrero C. Effect of hydrocolloids on water absorption of wheat flour and farinograph and textural characteristics of dough. Cereal Chem. 2009;86:376–382. doi: 10.1094/cchem-86-4-0376. [DOI] [Google Scholar]

- Makrogianni DI, Tsistraki A, Karapanos IC, Passam HC. Nutritional value and antioxidant content of seed-containing and seedless eggplant fruits of two cultivars grown under protected cultivation during autumn–winter and spring–summer. J Sci Food Agric. 2017;97:3752–3760. doi: 10.1002/jsfa.8238. [DOI] [PubMed] [Google Scholar]

- Mohammed Majeed, Brecht Jeffrey. Postharvest Physiology and Pathology of Vegetables. 2002. Immature Fruit Vegetables. [Google Scholar]

- Mohammed I, Ahmed AR, Senge B. Dough rheology and bread quality of wheat–chickpea flour blends. Ind Crops Prod. 2012;36:196–202. doi: 10.1016/j.indcrop.2011.09.006. [DOI] [Google Scholar]

- National Agricultural Census . Secretaria de Agricultura Ganadería y Pesca (SAGPYA) Argentina: Buenos Aires; 2002. [Google Scholar]

- Oliviero T, Fogliano V. Food design strategies to increase vegetable intake: the case of vegetable enriched pasta. Trends Food Sci Technol. 2016;51:58–64. doi: 10.1016/j.tifs.2016.03.008. [DOI] [Google Scholar]

- Peng X, Ma J, Cheng K-W, Jiang Y, Chen F, Wang M. The effects of grape seed extract fortification on the antioxidant activity and quality attributes of bread. Food Chem. 2010;119:49–53. doi: 10.1016/j.foodchem.2009.05.083. [DOI] [Google Scholar]

- Ranawana V, Raikos V, Campbell F, Bestwick C, Nicol P, Milne L, Duthie G. Breads fortified with freeze-dried vegetables: quality and nutritional attributes. Part 1: breads containing oil as an ingredient. Foods. 2016;5:19. doi: 10.3390/foods5010019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reshmi S, Sudha M, Shashirekha M. Starch digestibility and predicted glycemic index in the bread fortified with pomelo (Citrus maxima) fruit segments. Food Chem. 2017;237:957–965. doi: 10.1016/j.foodchem.2017.05.138. [DOI] [PubMed] [Google Scholar]

- Sagar NA, Pareek S, Sharma S, Yahia EM, Lobo MG. Fruit and vegetable waste: bioactive compounds, their extraction, and possible utilization. Compr Rev Food Sci Food Saf. 2018;17:512–531. doi: 10.1111/1541-4337.12330. [DOI] [PubMed] [Google Scholar]

- Salinas MV, Puppo MC. Effect of organic calcium salts–inulin systems on hydration and thermal properties of wheat flour. Food Res Int. 2013;50:298–306. doi: 10.1016/j.foodres.2012.10.036. [DOI] [Google Scholar]

- Scalzo RL, Fibiani M, Francese G, D’Alessandro A, Rotino GL, Conte P, Mennella G. Cooking influence on physico-chemical fruit characteristics of eggplant (Solanum melongena L.) Food Chem. 2016;194:835–842. doi: 10.1016/j.foodchem.2015.08.063. [DOI] [PubMed] [Google Scholar]

- Sciammaro LP, Ferrero C, Puppo MC. Gluten-free baked muffins developed with Prosopis alba flour. LWT. 2018;98:568–576. doi: 10.1016/j.lwt.2018.09.045. [DOI] [Google Scholar]

- Sękara A, Cebula S, Kunicki E. Cultivated eggplants–origin, breeding objectives and genetic resources: a review. Folia Horticulturae. 2007;19:97–114. [Google Scholar]

- Sirbu A, Arghire C. Functional bread: effect of inulin-type products addition on dough rheology and bread quality. J Cereal Sci. 2017;75:220–227. doi: 10.1016/j.jcs.2017.03.029. [DOI] [Google Scholar]

- Valerga L, Darré M, Zaro MJ, Lemoine ML, Concellón A (2017) Influencia de la estación de cosecha sobre los antioxidantes de berenjena en distintos estados de desarrollo. Full paperpresentedto: XVI Congreso Argentino de Ciencia y Tecnología de Alimentos, Buenos Aires, Argentina. ISBN 978-987-22165-8-0

- Valerga L, Quintero-Ruiz NA, Concellón A, Puppo MC (2019) Artichoke, eggplant and tomato flours as nutritional ingredients for wheat dough: Hydration properties. Food Sci Nutr (under evaluation) [DOI] [PMC free article] [PubMed]

- WHO . Diet, nutrition, and the prevention of chronic diseases: report of a joint WHO/FAO expert consultation. Geneva: World Health Organization; 2003. [Google Scholar]

- Wieser H. 18—the use of redox agents in breadmaking. In: Cauvain SP, editor. Breadmaking. 2. Sawston: Woodhead Publishing; 2012. pp. 447–469. [Google Scholar]

- Yao LH, Jiang Y, Shi J, Tomas-Barberan F, Datta N, Singanusong R, Chen S. Flavonoids in food and their health benefits. Plant Foods Hum Nutr. 2004;59:113–122. doi: 10.1007/s11130-004-0049-7. [DOI] [PubMed] [Google Scholar]

- Zaro MJ, Keunchkarian S, Chaves AR, Vicente AR, Concellón A. Changes in bioactive compounds and response to postharvest storage conditions in purple eggplants as affected by fruit developmental stage. Postharvest Biol Technol. 2014;96:110–117. doi: 10.1016/j.postharvbio.2014.05.012. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.