Abstract

Chitin is a linear polysaccharide of N-acetylglucosamine, which is highly abundant in nature and mainly produced by marine crustaceans. Chitosan is obtained by hydrolytic deacetylation. Both polysaccharides are renewable resources, simply and cost-effectively extracted from waste material of fish industry, mainly crab and shrimp shells. Research over the past five decades has revealed that chitosan, in particular, possesses unique and useful characteristics such as chemical versatility, polyelectrolyte properties, gel- and film-forming ability, high adsorption capacity, antimicrobial and antioxidative properties, low toxicity, and biocompatibility and biodegradability features. A plethora of chemical chitosan derivatives have been synthesized yielding improved materials with suggested or effective applications in water treatment, biosensor engineering, agriculture, food processing and storage, textile additives, cosmetics fabrication, and in veterinary and human medicine. The number of studies in this research field has exploded particularly during the last two decades. Here, we review recent advances in utilizing chitosan and chitosan derivatives in different technical, agricultural, and biomedical fields.

Introduction

Chitosan, a polymer of β(1-4)-linked glucosamine (2-amino-2-deoxy-O-glucose) units, is a biopolymer with unique characteristics due to the presence of free amino groups on its backbone. It is obtained by partial deacetylation of chitin, which is found in the cell walls of unicellular and filamenous fungi and in extracellular matrices and skeletal deposits of many protozoan and metazoan organisms including algae, choanoflagellates, sponges, corals, cephalopods, and arthropods. Commercially, chitin is extracted from the waste shells of marine crustaceans such as shrimp and crab. A significant proportion is used to produce chitosan, which, in contrast to chitin, is soluble in water at a slightly acidic pH and is easy to modify chemically to increase solubility at neutral pH and to add new functionalities. Chitosan and its derivatives have many desirable properties such as antioxidative and antimicrobial effects, mucoadhesiveness, biodegradability, and biocompatibility and can be manufactured in various formulations including hydrogels, films, membranes, porous sponges, nanoparticles, and nanofibers. Moreover, chitosan is considered a harmless compound, as it has received the generally recognized as safe (GRAS) status by the US Food and Drug Administration (FDA), and it has been approved as a food additive in several Asian countries (No et al. 2007). In the European Union, chitosan is registered as a basic substance, and the use of chitosan hydrochloride is considered by the European Food Safety Authority (EFSA) as having neither harmful effects on human or animal health nor any negative effects on the environment (European Commission 2014). Therefore, chitosan-based materials have been adopted worldwide in numerous applications in water treatment; food, cosmetic, and textile industry; biosensor engineering; plant protection; pharmaceutical industry; and regenerative medicine. They are used as flocculants, ion exchangers, chelating agents, coating materials, drug carriers, and scaffolds for tissue engineering. During the past years, many companies have started to develop chitosan-based products, and some have already successfully launched them for commercial purposes. This review is intended to summarize recent developments in the use of chitosan-based materials for potential and effective applications in different technical, environmental, agricultural, and biomedical fields.

Chitosan-Based Flocculants and Hydrogels Used in Water Treatment

Pollutants in water, industrial wastewater, and reclaimed wastewater for crop irrigation have presented severe environmental and medical problems all over the world. Such contaminants include various heavy metal ions (copper, cobalt, manganese, chromium, mercury, lead, arsenic, cadmium, and nickel), dyes (mainly azo dyes like malachite green, methyl violet, or methylene blue), oil spills, and a variety of pharmaceuticals and endocrine-disrupting compounds. Among the various methods used as remedial measures to treat polluted water and wastewater, the potential of chitosan-based composites as efficient adsorbent, flocculating and chelating agents has been widely investigated.

The presence of free hydroxyls and amino groups in many structural forms of chitosan-derived composites facilitates adsorption of pollutants such as dyes, metals, and organic compounds. Chitosan derivatives like carboxymethyl chitosan and graft polymerization are a prevalent strategy to add a variety of functional groups to the composite. Magnetic particles are embedded usually as nanoparticles in the complex core to facilitate regeneration and reuse of adsorbent composites by applying external magnetic field.

Removal of Heavy Metal Ions

A large number of chitosan-based composites were investigated for removal of metal ions from aqueous solutions. They include chitosan-polymer macromolecular complexes (as cellulose, cellulosic matrix like cotton fibers, alginate, polyvinyl alcohol, polyvinyl chloride), chitosan ceramics, as well as clay and silicate composites ( bentonite, montmorillonite, perlite, and zeolite) (Wan Ngah et al. 2011). Due to the vast number of scientific publications on chitosan-based adsorption that have been published, only a representative sample is depicted for Cr(VI) and Cu(II). Cognate composites were devised as adsorbents of other metal ions (Cd, As, Fe, Pb, Co, Pb, Hg, Ni, Zn, U) that can be found in the detailed reviews of Reddy and Lee (2013), Liu and Bai (2014), Wang and Chen (2014), Kyzas and Bikiaris (2015), Salehi et al. (2016), and Wang and Wang (2016).

The mutagenic and carcinogenic Cr(VI) is considered as a dangerous pollutant for humans and marine ecosystems. Composites of chitin and chitosan nano-hydroxyapatite hybrids removed Cr(VI) from aqueous solution by electrostatic interactions and reduction to Cr(III) via electron-donating groups present in the scaffold (Kousalya et al. 2010). A nanocomposite cross-linked hybrid of chitosan-alginate was able to remove Cr(VI) from water waste (Gokila et al. 2017). A more complex scaffold resin, where chitosan was mixed with magnetic particles (Fe3O4), modified by ethylenediamine and stabilized by glutaraldehyde as cross-linker, was established as an effective adsorbent of Cr(VI) (Hu et al. 2011). Reducing toxic Cr(VI) to nontoxic Cr(III) was accomplished by zero-valent iron [Fe(0)] embedded in chitosan beads (Geng et al. 2009). The oxidized iron Fe(III) formed a precipitately complex with Cr(III), thus enabling the regeneration of the adsorbing complex. Another method used ceramic aluminum coated with chitosan to remove Cr(VI) by electrostatic attraction of the hydrogen chromate ions to the positively charged amino groups of chitosan (Boddu et al. 2003).

Copper(II) Like chromium, Cu2+ ions found particularly in industrial wastewater are hazardous to human health and the ecosystems. Ingenious absorbance methods using a variety of organic and inorganic compounds have been devised to adsorb and remove the toxic ions. Among them are promising measures based on chitosan composite supra-macromolecular structures. Chitosan-based composites with various organic and inorganic compounds were examined as Cu(II) adsorbents. A recyclable complex composed of L-arginine-chitosan-Fe3O4 for removal of Cu(II) ions (Wu et al. 2016) and magnetic cellulose-chitosan composite microspheres was capable to adsorb heavy metals like Cu(II) but also Cd(II) and Pb(II) from aqueous solutions (Peng et al. 2014). Chitosan-algal biomass composite microbeads (Sargın et al. 2016b), a binary chitosan/silk fibroin composite (Ramya and Sudha 2013), and cotton fibers functionalized by triethylenetetramine (TETA) and carboxymethyl chitosan form composites and hybrids for adsorption of Cu(II) from water (Niu et al. 2017). Microcapsules composed of phytopathogenic (Ustilago sp.) fungal spores immobilized in cross-linked chitosan matrix (Sargın et al. 2016a) and a binary complex of chitosan and emu egg shells (Anantha and Kota 2016) were shown to remove copper ions from aqueous solutions.

Chitosan complexed with clays, ceramic minerals, and carbon-based materials was used to enhance absorbance of heavy metals from aqueous solutions. A nanocomposite that consisted of chitosan-montmorillonite (Pereira et al. 2013) and silica gel/chitin and chitosan with nano-hydroxyapatite was used as adsorbents for Cu(II) (Rajiv Gandhi et al. 2011). Nanocomposites containing chitosan-poly(vinyl alcohol)-attapulgite were also used for removal of Cu(II) from aqueous solutions (Wang and Wang 2016). Furthermore, a recyclable magnetic microsphere composed of cross-linked chitosan-rectorite (a clay mineral) and Fe3O4 was studied for adsorption of Cu(II) and Cd(II) (Xie et al. 2015), and chitosan-zeolite composite hydrogel beads were examined for Cu(II) sorption (Djelad et al. 2016).

A particular interesting recyclable composite with chelating capacity consists of core magnetic (Fe3O4)-silica particles combined with cross-linked chitosan. Its porous and highly specific surface area contributed by activated carbon carrier showed an excellent adsorption capability for Cu2+ ions (Li et al. 2017). A recyclable nanocomposite with a core xanthated Fe3O4 chitosan grafted on graphene oxide introduced sulfur groups to the composite using carbon disulfide (Liu et al. 2016a).

Other sorbent composites that were prepared and studied are a recyclable composites containing chitosan grafted on a core of Fe3O4-hexadecyl trimethoxysilane (Liu et al. 2016b), a flocculant composed of poly(acrylic acid) grafted on chitosan (Saleh et al. 2017) or beads containing chitosan-poly(vinyl alcohol) and ZnO (Xu et al. 2017a). A sophisticated composite was prepared by using magnetic nanoparticles on the surface of polystyrene as core, coated with chitosan cross-linked by glutaraldehyde followed by grafting polyethylenimine on the complex surface (Xiao et al. 2017). This submicron composite is recyclable and exhibits good adsorption capacity for Cu(II) ions.

Highly selective adsorption of copper ions from aqueous solutions was achieved by the ion-imprinting polymer method (Kong et al. 2017). Microspheres of magnetic cores of Fe3O4 with a shell of cross-linked chitosan and graphene oxide were used to imprint Cu2+ ions. Zarghami et al. (2014) prepared Cu(II) ion-imprinted membranes composed of cross-linked chitosan/poly(vinyl alcohol) for adsorption of the metal from aqueous solutions. A similar ion-imprinted technique was reported for selective adsorption of Pb(II) from a recycling wastewater unit (Hande et al. 2016).

Removal of Man-Made Environmental Pollutants

Industrial Dyes

Textile, leather, paper, and food industries discharge a plethora of environmental pollutants such as synthetic dyes. A variety of chitosan-based composites was examined as promising adsorbents of hard to remove industrial dyes. Chitosan per se contains functional groups for interaction with pollutants including dyes. Adding more functional groups by modifying chitosan (cross-linking of chitosan layers, direct chemical modification, or graft polymerization – see Chapter 3) improves adsorption capability. Molecular imprinting technique was devised as selective adsorbent of pollutants. Composites’ core of iron oxide magnetic nanoparticles like maghemite (γ-Fe2O3) and magnetite (Fe3O4) offers a way to recover the adsorbent scaffolds for reuse. Again, since the published articles are enormous in number, only essential parameters and basic blocks of adsorbing chitosan-based composites are included.

Methyl orange as a model anionic azo dye was adsorbed by films of cross-linked chitosan/nanonized maghemite from aqueous solution (Jiang et al. 2012). Improved adsorption of the same anionic dye was achieved by preparing a magnetic chitosan grafted with multi-walled carbon nanotubes (Zhu et al. 2010), and magnetic chitosan grafted with graphite oxide nanocomposite was able to adsorb the toxic azo dye, Reactive Black 5 (Travlou et al. 2013). Chitosan modified by ethylenediamine (Zhou et al. 2011) or polyaniline (Abbasian et al. 2017) grafting was able to adsorb other anionic azo dyes like Orange 7, Acid Orange 10 acid and red 4 and direct red 23, respectively. A magnetic complex of chitosan and zirconium oxide was a potent adsorbent of food anionic azo dyes like amaranth and tetrazine (Jiang et al. 2013a). Moreover, a complex composite adsorbent was prepared by grafting chitosan with poly[poly(ethylene glycol) methyl ether methacrylate] (Tsai et al. 2017). The functionalized groups added to chitosan contributed to improved removal of the azo dye Reactive Orange 16 from water.

Recyclable composite microspheres composed of cross-linked chitosan grafted with glutamic acid and having a core of Fe3O4 nanoparticles coated with silica adsorb cationic dyes like methylene blue, crystal violet, and light yellow 7GL (Yan et al. 2013). Similarly, an amphiphilic N-benzyl-O-carboxymethyl chitosan composite with a core of iron oxide nanoparticles was prepared for adsorption of methylene blue, crystal violet, and malachite green (Debrassi et al. 2012). The cyclic oligosaccharide β-cyclodextrin (β-CD) was added to chitosan-based composites as it provides a hydrophobic inner cavity and a hydrophilic exterior. Magnetic chitosan-β-CD with grafted graphene oxide to enlarge surface area exhibited an improved adsorption of methylene blue as a model dye from water (Fan et al. 2013). Molecular imprinting technique is of interest to selectively remove dyes from aqueous solutions. The molecule or ion used as templates will be subsequently removed, and a recognition site is generated. Alizarin red served as template molecule, and imprinted magnetic chitosan nanoparticles showed improved adsorption of the dye (Fan et al. 2012).

Removal of Micropollutants (Pharmaceuticals, Endocrine Disruptors)

Pharmaceutical, endocrine-disrupting compounds and personal care products have become a new class of hazardous environmental pollutants (Grassi et al. 2013) and have emerged as an extensive global concern. They are discharged as municipal and hospital effluents, from manufacturing industries, and found in water, reclaimed wastewater, and even in crops irrigated by reclaimed water (Paltiel et al. 2016). Pharmaceuticals, endocrine disruptors, and personal care products and their chemical transformation derivatives are characterized as stable, persistent compounds that are biologically active at very low concentrations.

The challenging goal has been to completely remove the above micropollutants from wastewater following conventional cleaning methods. Laboratory research including adsorption by chitosan-based composites has been high on the agenda (Amouzgar and Salamatinia 2015). Zhang et al. (2014) used a rather simple cross-linked magnetic chitosan-Fe3O4 composite to examine the sorption of three pharmaceutical compounds from contaminated water. The absorbance analysis showed effective sorption of diclofenac (a nonsteroidal anti-inflammatory drug) and clofibric acid (an antilipemic agent) but not of carbamazepine (an antiepileptic medication). Pharmaceuticals in water can be present as cationic, anionic, and neutral forms at different pH values. Thus, Zhang et al. (2016) in a more recent study devised an innovative, more complex three-dimensional chitosan-based scaffold. A magnetic core of chitosan-Fe3O4 was grafted with polymeric arms of either the polycation [poly(2-methyl acryoxyethyl trimethyl ammonium chloride], the polyanion poly(acrylic acid), or the neutral polymer poly(methylmethacrylate). The polycationic extension was cost-effective in removal of diclofenac from water due to charge attraction (Zhang et al. 2016). Further, magnetic composite pellets with grafted clay ( bentonite) and activated carbon were prepared to examine possible cost-effective removal of cationic and anionic pharmaceuticals (Arya and Philip 2016). The composite was effective as a sorbent for the beta-blocker ( atenolol), the antibiotic ( ciprofloxacin), and the lipid regulator ( gemfibrozil).

A variety of chitosan composites have been tested for the removal of other drugs. Cross-linked chitosan grafted with sulfonate or N-(2-carboxymethyl) groups was used as a sorbent to remove the dopamine agonist pramipexole dihydrochloride from polluted water (Kyzas et al. 2013). Chitosan-poly(acrylic acid)- graphite oxide nanocomposite showed adsorption of dorsolamide, a carbonic anhydrase inhibitor for eye treatment (Kyzas et al. 2014). Adsorption of nonsteroidal anti-inflammatory drugs ibuprofen and ketoprofen was studied using porous composite beads prepared of Chitosan-MIL 101 (Cr) (Zhuo et al. 2017). Using the antiepilectic carbamazepine as template, the magnetic molecular imprinted technique, based on chitosan-Fe3O4 nanoparticles, was applied for selective sorption of the drug (Zhang et al. 2013c).

Chlorophenols are endocrine-disrupting chemicals, used inter alia in manufacturing pharmaceuticals that are found in wastewaters (Sin et al. 2012). Excellent adsorbing capability was demonstrated using a cross-linked chitosan-salicylic acid-β-CD composite. Composites of chitosan-γ-CD were capable of adsorbing the endocrine disruptors, polychlorophenols, and bisphenol A (Duri and Tran 2013). Composite films prepared by blending microporous carbon fibers with cross-linked chitosan/polyvinyl alcohol were examined as sorbents of bisphenol A from water (Bilgin Simsek et al. 2017).

Finally, Soares et al. (2017b) proposed an interesting and unusual concept of using low-cost magnetic chitosan-based scaffold for absorbing and removing oil spills following initial skimming from water. In addition, the composite, which had a core of magnetic nanoparticles with a shell of chitosan-silica hybrid, effectively adsorbs nonpolar organic solvents.

Biosensors

Biosensors are essentially analytical devices that convert biological reactions or interactions into measurable signals. Basically, the biosensors’ constructs consist of a biological sensing element associated and intimately interfaced with a transducer that converts a signal in one form of energy to a signal of another form. Such signals should be proportional to the amount of analyte within a certain concentration range. Electrochemical biosensor devices, for example, possess advantages as being simple and relatively cheap while offering rapid detection and high sensitivity and further being amenable to miniaturization. Biosensors have been developed not only as analytical tools for medical purposes of clinical detection but also for applications in food industry and environmental monitoring.

Chitosan, and to a much lesser extent chitin, has several advantageous qualities in the design of biosensors. The polysaccharides are biocompatible, have functional groups pliable to chemical modification, and can be easily deposited on the surface of the transducer as adhesive thin films for the immobilization of recognition elements (enzymes, antibodies, DNA, whole cells, and cell organelles). Addition of carbon tubes, graphite, and graphene oxide to the composite increases electron transfer to the transducer and enhanced mechanical strength as well as water permeability and retention. Since there is a vast array of biosensors based on chitosan in their constructs, the following provide only representative devices.

Glucose detection and monitoring is of paramount importance in the medical field. A variety of biosensors, constructed with chitosan and using immobilized glucose oxidase for the detection of glucose levels, were reported. A glucose electrochemical sensor was prepared with glucose oxidase immobilized on the composite of chitosan-carbon nanotubes (Liu et al. 2005). An amperometric glucose biosensor composed of multilayered chitosan biofilms-gold nanoparticles-glucose oxidase on platinum (Pt) electrode was devised (Wu et al. 2007). The biocompatible gold nanoparticles helped in directing the transfer of electrons to the transducer. Yang et al. (2009) devised a different glucose biosensor composed of Pt electrode-glucose oxidase-Fe3O4-chitosan-nafion. Zhang et al. (2015c) prepared an electrochemical biosensor for glucose with chitosan-graphite composite and the addition of magnetic Fe3O4 nanoparticles on Pt-coated indium tin oxide (ITO) glass electrode. Shrestha et al. (2016) devised a glucose biosensor with a glassy carbon electrode on which a nanocomposite film of glucose oxidase immobilized on chitosan and on which a graft of polypyrrole-nafion and multi-walled carbon nanotubes was deposited.

Electrochemical biosensors using other oxidases and various constructs were fabricated to monitor food and medically important compounds. For instance, a lactate biosensor was generated using lactate oxidase and a nanocomposite structure of chitosan-polyvinylimidazole-Os-carbon nanotubes (Cui et al. 2007). Glutamate and xanthine oxidases as recognition elements immobilized on chitosan/graphene oxide-polymerized riboflavin were constructed as glutamate and hypoxanthine biosensors (Celiesiute et al. 2017). In addition, a xanthine biosensor based on immobilization of xanthine oxidase on chitosan-polypyrrole-gold nanoparticles was fabricated by Dervisevic et al. (2017). Tkac et al. (2007) developed a selective galactose biosensor with a rather simple configuration of chitosan-single-walled carbon nanotubes and immobilized galactose oxidase. A sensitive amperometric nanocomposite biosensor for cholesterol detection was constructed using a matrix of Pt nanoparticles deposited on multi-walled chitosan-carbon nanotubes complexes with immobilized cholesterol oxidase (Tsai et al. 2008). A similar construct was proposed by Medyantseva et al. (2014) for the detection of antidepressant monoamine drugs using immobilized monoamine oxidase. Dai et al. (2010) developed an electro-chemiluminiscent biosensor to detect choline by immobilizing choline oxidase on a chitosan/titanate nanotubes composite film. Finally, a biosensor for measuring ethanol was prepared using alcohol oxidase immobilized on chitosan-eggshell film (Wen et al. 2007). The biosensor monitored the decrease in oxygen level vs ethanol concentration.

A number of electrochemical biosensors were similarly constructed to immobilize various dehydrogenase enzymes (Zhang et al. 2004). The nanocomposite scaffold film, attached predominantly to glassy carbon electrodes, consists of chitosan, multi-walled carbon nanotubes, and NAD+ as cofactor. The signal current is based essentially on electrooxidation of the formed NADH. Among the large list of enzymes suffice it to mention NAD-dependent alcohol (Lee and Tsai 2009; Zhang and Gorski 2011), lactate (Tsai et al. 2007) and glutamate (Hughes et al. 2015) dehydrogenases, and FAD-dependent glucose dehydrogenase (Monosik et al. 2012).

In contrast to the above enzyme-based biosensors, a nonenzymatic electrochemical device for monitoring glucose was formulated (Al-Mokaram et al. 2017). The construct, which was based on a nanocomposite film composed of polypyrrole-chitosan-titanium dioxide nanoparticles on ITO glass electrodes, involved redox reactions and exhibited improved glucose oxidation and high electron transfer kinetics.

Other biosensors detecting and measuring diverse compounds were formulated, for example, nitrite biosensor based on Cu-containing nitrite reductase immobilized on viologen-chitosan that catalyzes the reduction of nitrite (Quan and Shin 2010). Horseradish peroxidase immobilized on alumina nanoparticles-chitosan composite was devised to detect phenolic compounds (Liu et al. 2011). Wang et al. (2003) developed a biosensor to detect and measure glucose, galactose, and glutamate in human blood by using their corresponding oxidases immobilized on chitosan-Prussian blue composite film. The biosensor used Prussian blue as a good catalyst to form hydrogen peroxide by electroreduction. Biosensors to detect catechol as well as other phenolic compounds were based on immobilized tyrosinase on a film of chitosan-nickel nanoparticles (Yang et al. 2012a). A biosensor for detection of chlorophenol that includes immobilized laccase on ZnO-chitosan nanocomposite was prepared by Mendes et al. (2017). Nanocomposite of functionalized graphene oxide (enriched with carboxylic moieties)-polypyrrole-chitosan film was constructed to detect hydrogen peroxide using screen-printed carbon electrodes (Akhtar et al. 2017). Such a device was able to electro-catalyze the reduction of hydrogen peroxide. Teepoo et al. (2017) constructed an electrochemical biosensor to detect and monitor hydrogen peroxide by using horseradish peroxidase immobilized on a chitin-gelatin nanofiber composite. Another biosensor for hydrogen peroxide that used immobilized catalase on chitosan-β-cyclodextrin (with ferrocene in its cavity) was fabricated by Dong et al. (2017). It was based on chitosan-functionalized graphene oxide (enriched with carboxylic moieties)-polypyrrole nanocomposite able to electrocatalytically reduce hydrogen peroxide.

Detection and quantification of trace amounts of carcinogenic and toxic metallic ions are of great challenge and importance. A cross-linked chitosan-carbon nanotube sensor was developed for the determination of Cd(II) and Hg(II) (Janegitz et al. 2011). Sugunan et al. (2005) prepared a biosensor made of chitosan-gold nanoparticles to detect Cu(II) and Zn(II), and Ahmed and Fekry (2013) used a construct of chitosan-α-Fe3O4 nanoparticles sensor to detect Ni(II), As(II), and Pb(II). Biosensors were developed to detect and determine organophosphorus (OP) pesticides as well. For instance, Stoytcheva et al. (2018) prepared a device based on OP hydrolase immobilization on a chitosan-carbon-nanoparticles-hydroxyapatite nanocomposite. A nanocomposite immunosensor to monitor the OP compound, chlorpyriphos, is based on immobilized anti-chloropyriphos monoclonal antibody on multi-walled carbon nanotubes-chitosan-thionine (as electronic mediator) (Sun et al. 2012b). An intricate electrochemical immunosensor for the detection and monitoring of the fungal hepatocarcinogen, aflatoxin B1, as model antigen was developed by Masoomi et al. (2013). The construct scaffold involved chitosan-gold nanoparticles, immobilized polyclonal anti-aflatoxin B1, and a magnetite core that can enable regeneration of the immunosensor.

Biosensors based on chitosan/multi-walled carbon nanotubes hybrid films were developed largely by Babaei and colleagues to determine and quantitate drugs and neurotransmitters: acetaminophen and mefenamic acid (Babaei et al. 2010), dopamine and morphine (Babaei et al. 2011a), paracetamol (Babaei et al. 2011b), L-DOPA (Babaei and Babazadeh 2011), and 5- hydroxytryptamine and dopamine (Xu et al. 2015).

The polycationic nature of chitosan films in immunobiosensors is also exploited to immobilize polyanionic polymers such as nucleic acid sequences and proteins. Singh et al. (2013) devised an electrochemical DNA biosensor to detect typhoid which was constructed by surface immobilizing Salmonella typhi single-stranded (ss) DNA on graphene oxide/chitosan/ITO nanocomposite as a bioelectrode. The biosensor was capable of distinguishing between complementary, noncomplementary, and one base mismatch sequences. A similar electrochemical DNA biosensor was developed for the detection of 0157:H7 (Xu et al. 2017b). It was prepared with immobilized E. coli ss-DNA using a graphene oxide/chitosan hybrid nanocomposite. An electrochemical immunobiosensor to detect botulism neurotoxin A was reported by Afkhami et al. (2017). The sensor consisted of a gold nanoparticles/chitosan/graphene nanocomposite with immobilized antibodies to quantify the bound neurotoxin. To detect α-fetoprotein in human serum, an immunosensor was fabricated in which the α-fetoprotein antigen was immobilized on a film of a gold nanoparticles/ carbon nanotubes/chitosan nanocomplex to quantify protein levels using a competitive immunoassay format (Lin et al. 2009). Giannetto et al. (2017) fabricated a competitive electrochemical immunosensor to detect HIV1-related capsid protein p24 in human serum. The p24 antigen was immobilized on gold-free single-walled carbon nanotube-chitosan complex for the interaction with a mouse monoclonal anti-p24, which was used for competitive immunodetection. Liu et al. (2009) developed an immunosensor to detect carcinoembryonic antigen, which is based on corresponding antibodies immobilized on chitosan-gold nanoparticles. Finally, Qiu et al. (2009) reported an immunosensor to detect hepatitis B surface antigen, which was constructed on the basis of a gold nanoparticles/chitosan/ferrocene biofilm with immobilized hepatitis B antibodies.

Beneficial Properties of Chitosan for Possible Use in Agriculture, Food, and Textile Industry

The wide-ranging antimicrobial, antiviral, and antioxidant activities, induction of defense systems in plants, and stimulation of plant growth by chitosan, chitosan oligomers, chemically modified chitosan and their composites have indicated their potential use in agricultural practices (El Hadrami et al. 2010; Malerba and Cerana 2016). Pre- and postharvest treatment of coating seeds, fruits, and vegetables by edible chitosan-based films effectively improve germination and plant vigor and prolonged shelf life and storage quality of food products (No et al. 2007). Preservation by chitosan-based coating also expanded to include meat, eggs, dairy products, and seafood (Friedman and Juneja 2010). Other promising practices such as delivery and slow and sustained release of chitosan-based encapsulated agrochemicals ( fertilizers, micronutrients, pest control agents, and genetic materials) have been widely investigated (Malerba and Cerana 2016).

Antimicrobial and Antioxidant Activities

There are several comprehensive reviews that summarize the potential use of chitosan, its derivatives, and chitooligosaccharides in agriculture as related to their broad-spectrum antimicrobial and antioxidant activities (Aider 2010; Cota-Arriola et al. 2013; Li et al. 2013a; Xing et al. 2015; Liaqat and Eltem 2018). Such beneficial activities were demonstrated in a variety of agricultural products like preservation of vegetables, fruits, cereals, dairy products, eggs, meat, and seafood (No et al. 2007; Friedman and Juneja 2010). Chitosan per se has antimicrobial activity that depends on higher degree of deacetylation, low molecular weight (its oligosaccharides), increased protonation at low pH, and the type of microorganisms (Katiyar et al. 2014). The antimicrobial efficiency is enhanced by adding essential oils (extracted from lemon, lemon grass, cinnamon, or rosemary) (Duan and Zhang 2013; Xing et al. 2016; Yuan et al. 2016) or by adding metal ions like silver or copper (An et al. 2011; Brunel et al. 2013; Kumar-Krishnan et al. 2015; Choudhary et al. 2017a; Sharma 2017) particularly to chitosan-based nanoparticles (Friedman and Juneja 2010; Cota-Arriola et al. 2013). The mode of action is mainly attributed to electrochemical interactions between the positively charged chitosan and the negative surface charge of bacterial cells leading to membranes disruption (Xing et al. 2015). In addition, penetration and binding of nanochitosan with microbial DNA that impact mRNA and protein synthesis were proposed (Rabea et al. 2003, Malerba and Cerana 2016).

Scavenging of free radical and reactive oxygen species by chitosan and its derivatives is responsible for its antioxidative effects (Guo et al. 2005; Ngo and Kim 2014). Scavenging of superoxide and hydroxyl radicals by chitosan and its derivatives was demonstrated by several studies (Xie et al. 2001; Guo et al. 2005; Yen et al. 2008; Wan et al. 2013). Furthermore, chitosan acts as a biogenic elicitor of various enzymes that detoxify reactive oxygen species (Malerba and Cerana 2016) and induces the formation of antioxidant and fungicidal phytoalexins (Yamada et al. 1993; Hadwiger 2013; Xing et al. 2015).

Eliciting Defense Responses in Plants

Chitosan and its derivatives were shown to activate plant immunity enzymes ( catalase, peroxidase, superoxide dismutase, phenyl oxidase, phenylalanine ammonia lyase) that are capable of detoxifying reactive oxygen species (Hadwiger 2013; Xing et al. 2015; Malerba and Cerana 2016). Such activation engages different signal transduction pathways that involve a variety of second messengers. Other defense responses include pathogenesis-related proteins, phytoalexins, proteinase inhibitors, lignin synthesis, or callose formation (El Hadrami et al. 2010; Hadwiger 2013). Induction of programmed cell death and hypersensitivity-associated responses by chitosan and chitooligosaccharides was documented (Zuppini et al. 2004; Vasilêv et al. 2009; Zhang et al. 2012), as well as activation of plant defense genes via the octadecanoid pathway leading to jasmonate synthesis (Doares et al. 1995; Rakwal et al. 2002). Chitosan induces hydrolase enzymes such as chitinase and β-1,3 glucanase able to destroy chitin/glucan-containing fungal cell walls (Ma et al. 2013b; Xing et al. 2015).

Plant Protection and Food Preservation

Controlled and sustained release of chitosan-encapsulated agrochemical such as fertilizers, micronutrient, pesticides, and genetic materials was demonstrated by a plethora of investigations (Kashyap et al. 2015). Food products coating by films of edible chitosan derivatives (plus a variety of additives) prolong their shelf life with concomitant improvements in storage quality (Xing et al. 2016; Yuan et al. 2016).

Pesticides

A number of examples linked to chitosan-coated pesticides given below indicate the potential of the eco-friendly techniques in plant protection against phytopathogens, insects, and weeds: controlled release of insecticides like the botanicals azadirachtin being encapsulated in the complex carboxymethyl chitosan-ricinoleic acid (Feng and Peng 2012) and rotenone wrapped in oleoyl carboxymethyl chitosan (Kamari and Aljafree 2017); nanoparticulate chitosan-β-cyclodextrin, which encapsulated carvacrol and exhibited high acaricidal and repellency activities (Campos et al. 2018); and controlled release of avermectin conjugated to N,O-carboxymethyl chitosan (Li et al. 2016) or avermectin coated by silica cross-linked chitosan composite (He et al. 2013). Encapsulation of the neonicotinoids imidacloprid (Li et al. 2012a; Lim and Ahmad 2017) and acetamiprid (Yan et al. 2014), malathion, and spinosad (El Badawy et al. 2016) by chitosan-alginate capsules exhibited prolonged release of the insecticides. Slow release of the fungicide carbendazim against the phytopathogens Sclerotinia sclerotiorum using chitosan/β-CD-epichlorohydrin (Wang et al. 2017a) and hexaconazole encapsulated by chitosan nanoparticles against Rhizoctonia solani (Chauhan et al. 2017) was demonstrated. Ilk et al. (2017) reported the antifungal and antioxidant activities of kaempferol encapsulated in lecithin-chitosan nanoparticles against .

In addition to their slow release property, chitosan composites also protect pesticides from photodegradation. Nanoparticles of chitosan-beeswax protected deltamethrin from photodegradation (Nguyen et al. 2012), and a similar protective effect of avermectin was demonstrated for a silica/chitosan copolymer (He et al. 2013). Likewise, composites of chitosan with a variety of clays (montmorillonite, attapulgite, bentonite, and kaolinite), safe anionic dyes ( Fast Green and Naphthol Yellow S), and photo-stabilized fungal conidia of the insect biocontrol agent Aschersonia spp. were reported (Cohen et al. 2003). Chitosan composites were found to be useful carriers of herbicides facilitating soil sorption as in the case of paraquat associated with chitosan-alginate nanoparticles (Silva Mdos et al. 2011) or slow release of paraquat encapsulated in tripolyphosphate-generated chitosan nanoparticles (Grillo et al. 2014). Moreover, encapsulation of metolachlor in blended gel beads of cross-linked carboxymethyl cellulose and carboxymethyl chitosan was effective in slow release of the herbicide as a model compound (Dong et al. 2012). Finally, slow release of atrazine encapsulated in carboxymethyl chitosan/bentonite gel was demonstrated (Li et al. 2012a).

Fertilizers

The modulated release of encapsulated fertilizers is important for enhanced growth of plants while reducing environmental problems of their excessive use. Experiments were accompanied by swelling rates of composites, fertilizer loads, and kinetics of release. Examples are chitosan-xanthan tablets (Melaj and Daraio 2013) or chitosan-starch beads (Perez and Francois 2016) as carriers of potassium nitrate that serve as model fertilizer; slow release of NPK fertilizers aggregated on chitosan nanoparticles (Corradini et al. 2010) and application on leaf surfaces enables translocation via stomata into the phloem (Abdel-Aziz et al. 2016); efficient controlled slow release of water soluble NPK fertilizers coated by chitosan with an additional outer coating by poly (acrylic acid–co-acrylamide) (Wu and Liu 2008). This composite also exhibited improved water absorption and retention. Noppakundilograt et al. (2015) examined the controlled release of NPK fertilizer granules embedded in a hydrogel composed of poly(vinyl alcohol) and then chitosan and a third layer of acrylamide and acrylic acid following cross-linking of chitosan by glutaraldehyde. Controlled release of urea by a variety of chitosan-based composites was established. Urea dispersed with humic substances in chitosan (Araújo et al. 2017), urea encapsulated in chitosan-acryamide (Siafu 2017), urea release from adduct of silk fibroin-gelatin-chitosan hydrogels (Rattanamanee et al. 2015), urea smectite clay chitosan composite (Puspita et al. 2017), and urea-kaolinite mixed with chitosan (Roshanravan et al. 2015) were tested for controlled release of the fertilizer.

Chitosan-Coated Plant Materials

Preharvest

Beneficial effects of preharvest chitosan-based seed coating and foliar treatment were reported by El Hadrami et al. (2010). Chitosan-coated artichoke seeds, for example, induced better germination, stimulated root system growth, and were effective against a number of pathogenic fungi (Ziani et al. 2010). Bhaskara Reddy et al. (1999) demonstrated induced resistance to seed-borne followed by improved germination and vigor in wheat seeds coated with chitosan. Soybean seeds coated by chitosan had anti-feeding effects and protected against several insect pests (Zeng et al. 2012), and coating rice seeds increased antifungal effect, stimulated seeding growth, improved root system, and increased crop yield (Zeng and Shi 2009). Tomato seeds coated with chitosan resulted in resistance to infection by inducing plant defense mechanisms (Benhamou et al. 1994). Chickpea seeds treated with chitosan-silver nanoparticles promoted germination and increased biomass, chlorophyll, carotenoids, and protein contents as well as amylase activity and defense enzyme activities (Anusuya and Banu 2016). Similar effects were demonstrated in maize seeds coated with Cu/chitosan nanoparticles (Saharan et al. 2016; Choudhary et al. 2017b).

Postharvest

The antimicrobial activity of chitosan was targeted for use to improve preservation of a large variety of vegetable and fruit crops as well as of eggs, meat, and dairy products (Devlieghere et al. 2004; Friedman and Juneja 2010; Yuan et al. 2016). Chitosan with added compounds such as plant materials and animal proteins (formulations of chitosan with additions of tapioca starch, hydroxypropyl cellulose, pectin, and fish gelatin) was used to develop edible films. Such films in addition to their antimicrobial and antioxidant activities also keep food products from loss of moisture and oxygen penetration (Aider 2010; Duan and Zhang 2013). Postharvest coating of vegetables and fruits with chitosan and additional essential oils (extracts from lemon, rosemary, lemon grass, bergamont, cinnamon, oregano, and thymine), which by themselves exert antimicrobial and antioxidant activities, improved storage quality and prolonged the shelf life of products (Xing et al. 2016). Controlling postharvest decay during storage was reported also for additives such as olive oil, glacial acetic acid, green tea extract, and lactic acid (Xing et al. 2016; Yuan et al. 2016).

Technical Applications in Food Packaging

Microbial contaminations are a serious problem in food industry, because food-borne bacteria and fungi are associated with food spoilage and food poisoning leading to economic losses and human health risks. Using appropriate food packaging materials with antimicrobial properties may prevent or at least slow down bacterial and fungal growth. For this reason, a variety of biopolymers has been tested to identify alternative materials to the classical nondegradable plastic packaging materials, which have caused serious environmental issues due to their inappropriate disposal. Optimal alternative materials should be environmentally safe due to biodegradability and biocompatibility. As chitosan-based material combine antimicrobial properties with biodegradability and biocompatibility, they are the focus of research in food packaging. Moreover, chitosan-based materials have food-preserving antioxidant activity and film-forming ability, which allows the production of transparent foils and bags. Different methods have been established during the past decades to fabricate chitosan films including casting, coating, extrusion, and layer-by-layer synthesis, and the resulting materials have been evaluated for their antimicrobial and antioxidant activity and for their optical, mechanical, barrier, and thermal characteristics. Chitosan has also been combined with other functional materials resulting in composite films with tremendous preservative properties that can be utilized for the packaging of different foods such as vegetables, fruit, and meat. For a comprehensive overview on this topic, the reader is referred to an excellent review article published recently by Wang et al. (2018).

Pure chitosan films are frequently based on dispersions of chitosan nanoparticles (Ali et al. 2014), to which plasticizers, such as glycol (Leceta et al. 2013), and/or surfactants, such as Tween 80 (Martins et al. 2012), are added to modify the mechanical properties and to emulsify auxiliary compounds. In addition, chitosan nanofibers have been fabricated as a packaging material and tested for their antimicrobial activity. For instance, Arkoun et al. (2017) examined the antimicrobial activity of chitosan/polyethylene oxide nanofibers produced by an electrospinning process. They showed that the chitosan nanofibers were efficient in inhibiting growth of E. coli, Staphylococcus aureus, Lysteria innocua, and S. typhimurium, however at pH 5.8, which was below the pKa of chitosan, limiting the applicability to slightly acidic food. Importantly, the authors demonstrated that the antibacterial effects were irreversible, suggesting a bactericidal rather than bacteriostatic mechanism.

Combinations of chitosan and other natural polysaccharides have been frequently used to fabricate functional films with applications in food packaging. These biopolymers comprise of cellulose and various cellulose derivatives, alginate, cyclodextrin, glucan, mannan, pectin, starch, and xylan. Chitosan/cellulose films revealed improved mechanical properties while maintaining excellent antimicrobial properties (Xiao et al. 2013). Also chitosan/hydroxypropyl methylcellulose (HMPC) films exhibit significant antimicrobial activity. For instance, Möller et al. (2004) examined the antimicrobial effects of chitosan/HPMC films against Listeria monocytogenes and found that bacterial growth was completely inhibited on the film. Similarly, chitosan/ carboxymethyl cellulose films showed superb food preservation properties when tested on packaged cheese (Youssef et al. 2016). Antimicrobial chitosan-alginate films have a great potential for food packaging as well, particularly because they show improved gas exchange and water vapor permeability properties when prepared by a layer-by-layer electrostatic deposition approach (Poverenov et al. 2014a). Martiñon et al. (2014) studied the effectiveness of antimicrobial multilayered coatings consisting of chitosan, pectin, and trans-cinnamaldehyde at different concentrations to extend the shelf life of fresh-cut cantaloupe and found that certain compositions were effective in preventing bacterial growth and spoilage. Lorevice et al. (2016) produced chitosan nanoparticles and combined them with different methyl pectin matrices to generate nanocomposite films and tested the mechanical, thermal, and barrier properties. The results showed that the nanocomposite film improved mechanical characteristics when compared with conventionally produced pectin films, making these novel materials promising for food packaging production. Similarly, chitosan/cyclodextrin films with inclusions of essential oil have been reported to possess desirable mechanical properties for food packaging (Sun et al. 2014). Moreover, this material showed significant antimicrobial activities against a variety of pathogenic bacteria.

Chitosan films have been also combined with a variety of proteins including casein (Khwaldia et al. 2014), gelatin (Poverenov et al. 2014b; Noorbakhsh-Soltani et al. 2018), collagen (Ahmad et al. 2016), kidney bean protein (Ma et al. 2013a), lactoferrin (Brown et al. 2008), and lysozyme (Yuceer and Caner 2014), as well as with antibacterial peptides such as nisin (Wang et al. 2015). In addition, chitosan was blended with antimicrobial and antioxidant extracts from bee wax (Velickova et al. 2013) and plants, such as citrus (Iturriaga et al. 2014), thyme (Talon et al. 2017), and maqui berry (Genskowsky et al. 2015), as well as with essential oils including clove bud oil, cinnamon oil, and star anise oil (Wang et al. 2011).

Other approaches in fabricating chitosan-based films employed grafts, blends, or casts using synthetic polymers such as poly(vinyl alcohol) (Wang et al. 2015), poly(lactic acid) (Pal and Katiyar 2016), poly(ethylene) (Reesha et al. 2015), poly(ethylene oxide) (Kohsari et al. 2016), poly(styrene) (Lopez-Carballo et al. 2013), poly(propylene) (Cavallo et al. 2014), poly(caprolactone) (Alix et al. 2013), and poly(acrylonitrile-co-acrylamide) (Kumar et al. 2018) that led to improved mechanical and thermal properties. However, these synthetic polymers are not readily degraded in nature; hence concerns regarding the environmental safety have been raised. Guo et al. (2015) developed new edible antimicrobial films using microemulsions in combination with high-pressure homogenization processing. The films were made of chitosan, allyl isothiocyanide, and barley straw arabinoxylan, which were used as film-forming, antimicrobial, and emulsifying agents, respectively. The material was tested to be efficient in preventing growth of L. innocua.

To improve antibacterial activity, chitosan-based films were synthesized as composites with metals, minerals, and other inorganic compounds. Youssef et al. (2014) produced chitosan-silver and chitosan-gold (CS-Au) nanocomposites films, which showed enhanced antimicrobial activity against Gram-positive (S. aureus) and Gram-negative bacteria (Pseudomonas aerugenosa), fungi (Aspergillus niger), and yeast (Candida albicans) . In another study published by Al-Naamani et al. (2016), poly(ethylene) films were coated with zinc oxide/chitosan nanocomposite, which completely inactivated and prevented the growth of food pathogens. In an approach based on a solution cast method, Sanuja et al. (2015) fabricated a chitosan-based nanocomposite film using nano zinc oxide and neem essential oil, which improved mechanical, physical, barrier, and optical properties. Moreover, Zhang et al. (2017) prepared chitosan/titanium dioxide composite films, which were found to possess significant antimicrobial activity against E. coli, S. aureus, C. albicans, and A. niger. Xu et al. (2017c) employed a different strategy by synthesizing chitosan/ graphene oxide nanocomposites with titanium dioxide and analyzed their antimicrobial and food-preserving efficacies. They showed that the material effectively prevented and A. niger biofilm formation presumably by disrupting cellular membranes. In addition, they demonstrated that the nano-coating could be applied as a cling film, which delays loss of moisture in fruits and vegetables and inhibits polyphenol oxidase activity and thus enzymatic browning but increases superoxide dismutase activity, which protects against reactive oxygen species. Next to these materials, chitosan-montmorillonite composites, chitosan/nanosilica films, and manifold combinations of chitin, metals, and minerals have been tested. In addition, numerous chemical chitosan derivatives have been explored for their properties to screen for new films suitable in food packaging. These derivatives include carboxymethyl chitosan and quaternized chitosan such as (2-N-Hydroxypropyl-3-trimethylammonium chloride) chitosan (Hu et al. 2016).

The Use of Chitosan in the Textile Sector

Due to their versatile and unique physicochemical and biological properties, chitosan, its multiple derivatives, and their adjunct complexes (addition of functional groups) have attracted considerable attention for possible use of eco-friendly materials in the textile industry. They are relatively inexpensive, biocompatible, biodegradable, and nontoxic and readily adhere to textile fabrics and usually demonstrate antibacterial activity. Certain formulations retain moisture as well as impart thermal stability and UV protection.

Chitosan per se or blends of chitosan-based composites deposited onto textiles fabrics were mostly tested for durable antibacterial activity (nearly all antibacterial studies include E. coli and S. aureus that represent correspondingly Gram-negative and Gram-positive bacteria). Coated Thai silk fabric with chitosan using radio frequencies plasma treatment exhibited antibacterial effects (Wongsawaeng et al. 2017), and polyester/cotton fabric treated with chitosan can be used as an alternative to the antibacterial triclosan (Ranganath and Sarkar 2014). Chitosan grafted on cotton (Ferrero et al. 2015) or on wool (Periolatto and Ferrero 2013) fabrics using UV irradiation bestowed antibacterial activity after many washing cycles. Chitosan reduced to nanoparticles and applied onto wool fabric imparted durable antibacterial and bestowed shrink proofing (Yang et al. 2010). Nanonized chitosan applied onto cotton exhibited, in addition to antibacterial activity, also thermal stability, UV protection, as well as improved dye-binding ability (Hebeish et al. 2013). Periolatto et al. (2012) demonstrated antibacterial effects and laundry durability of cotton and silk fabrics by UV curing with 2-hydroxy-2-methylpropylpropane-1-one as photoinitiator of the photochemical reaction.

Chitosan possesses abundant potential, in particular, for use in medical textiles and sportswear. For example, a blend of chitosan (short fibers) with cotton (long fibers) yarn by spinning technology is desirable for medical applications (Lam et al. 2017). Gauze bandages for wound dressing were prepared by electrospinning of chitosan nanofibers and cotton fabric (Nawalakhe et al. 2015). Plasma treatment was applied to improve adhesion by increased cross-linking between the two fiber systems imparting subsequent durability (Nawalakhe et al. 2015). Pure chitosan microfibers produced by wet spinning process was aimed for possible stable 3-D scaffold woven or nonwoven textile fabrics to be used in regenerative medicine such as bone and cartilage engineering (Toskas et al. 2013). Lam et al. (2018) examined a blend of chitin fibrils with cotton jersey fabric and showed reduced rigidity that may provide comfort to patients with epidermolysis bullosa skin disease. Likewise, chitosan-coated textile fabrics improved atopic dermatitis disease by restraining skin microbiome (Lopes et al. 2015). Sonochemical deposition was used by Petkova et al. (2014) to coat cotton fabrics with a hybrid of chitosan and ZnO nanoparticles. This complex showed improved antibacterial activity, slow release of the metal and washing stability, and postulated as effective treatment for hospital textiles to prevent transfer of pathogens. Similarly, the hybrid of chitosan and silver nanoparticles deposited onto cotton fabric demonstrated antibacterial effects and laundry durability befitting their possible use for medical textiles and sportswear (Xu et al. 2016). Ali et al. (2011) proposed to use chitosan nanoparticles that are able to pick and retain silver ions in medical textile applications. A polyester fabric coated with this complex hybrid imparted enhanced antibacterial activity. Nanonized chitosan applied onto cotton exhibited in addition to antibacterial activity, also thermal stability, UV protection as well as improved dye-ability (Hebeish et al. 2013).

A large number of publications signified and reported beneficial properties of chitosan and chitosan-based formulations with possibly great potential to treat textile fabrics. Such valuable features include protecting a variety of fabrics with emphasis on medical textiles, production of aromatic and flame-retarding fabrics, as well as dye removal and treatment of textile wastewater. Table 14.1 summarizes inter alia nanochitosan, chitosan nanometal complexes, or chitosan derivative composites with metals and other substances, which were treated onto textile fabrics (notably cotton), and depicts their conceivable potential for the textile industry.

Table 14.1.

Possible applications of chitosan and chitosan-based composites in the textile industry

| Textile fabric | Chitosan-based composite | Property | Reference |

|---|---|---|---|

| Chitosan derivatives | |||

| Cotton, silk | CS- 2-hydroxy-2-methylpropylpropane-1-onea | AB, laundry durability | Periolatto et al. (2012) |

| Cotton | CS nanoparticles-copper | AB, thermal stability, UV protection | Hebeish et al. (2013) |

| Polyester | CS nanoparticles-silver | AB, sustained release of silver | Ali et al. (2011) |

| Cotton | CS-silver nanoparticles | AB, laundry durability | Xu et al. (2016) |

| Cotton | CS-ZnO | AB, slow release of metal, washing stability | Petkova et al. (2014) |

| Cotton | CS-ZnO nanoparticles | AB, UV blocking | Raza et al. (2016) |

| Cotton | CS-CuO nanoparticles | AB | Dhineshbabu and Rajendran (2016) |

| Cotton/polyester | CS-ZnO, RiO2, SiO2 (nanoparticles) | AB, UV protection, self-cleaning, washing durability | Ibrahim et al. (2017b) |

| Cotton | CS-silver nanoparticles, montmorillonite | AB, thermal stability, flame-retarding activity, UV protection, water retention | Rehan et al. (2018) |

| Cotton | CS-poly(N-isopropylacrylamide) –silver nanoparticles | AB, controlled release of silver | Štular et al. (2017) |

| Cotton | CS-silver-zeolite film | Antimicrobial | Scacchetti et al. (2017) |

| Cotton | LBL CS and graphene oxide | UV protection, laundering durability | Tian et al. (2016) |

| Cotton | CS-poly(2-acrylamide-2-methylpropane sulfonic acid salt). LBL film | AB | Cheng et al. (2016) |

| Cotton | CS-(N,N,N-three methyloxirane methylammonium chloride) | Antimicrobial wound dressing, moisture retention | Yin et al. (2018) |

| Cotton | CS-poly(N-isopropylacrylamide) | AB, thermosensitivity | Wang et al. (2016a) |

| Cotton | CS-N-benzyl-N,N diethyl quaternary ammonium salt | AB | Feng et al. (2016) |

| Wool | CS-poly(propylene) imine | AB, durable washings | Sadeghi-Kiakhani et al. (2013) |

| Silk (Antheraea pernyi) | CS-(N-[(2-hydroxy-3-trimethylammonium) propyl] chloride nanoparticles | AB, durable wrinkle and shrinkage resistant, laundry durability | Lu et al. (2014) |

| Polyester (polylactic acid) | CS-poly(vinyl alcohol) | Thermally stable blend | Grande et al. (2018) |

| Cotton | CS-coating pyrazole compounds | AB | Nada et al. (2018) |

| Wool | CS-cyanuric acid | AB, improved dyeing performance | Zargarkazemi et al. (2015) |

| Polyester | CS covered by nanonized polyaniline | Electrical conductivity, water repellency, stable laundry | Tang et al. (2014) |

| Plant extracts and aromatic textiles | |||

| Cotton | CS-neem seed extract | AB, antiviral | Revathi and Thambidurai (2017) |

| Cotton | CS-beeswax are impregnated with essential oils (Eucalyptus, tea tree, sage) | AB, slow release of fragrant | Cerempei et al. (2015) |

| Cotton | CS microcapsules containing essential oils (Eucalyptus, sandal wood) | AB | Javid et al. (2014) |

| Cotton | CS-β-CD, inclusion of cinnamon oil | AB, slow release of fragrant | Bashari et al. (2017) |

| Cotton | CS β-CD, inclusion of lavender oil | AB, slow release of fragrant | Singh et al. (2017) |

| Cotton | CS-vanillin microcapsules | AB, slow release and retained fragrant after wash cycles | Yang et al. (2014) |

| Flame retardation | |||

| Cotton | CS-diammonium hydrogen phosphate | Durable flame retardation | El-Tahlawy (2008) |

| Cotton | LBL CS and ammonium polyphosphate | Itumescent flame effect | Fang et al. (2015) |

| Cotton | CS phosphate-TiO2 nanoparticles-1,2,3,4-butane tetracarboxylic acid, hypophosphite | AB, flame retardation | El-Shafei et al. (2015) |

| Cotton/polyester | LBL CS and melamine polyphosphate | Flame retardation | Leistner et al. (2015) |

| Cotton | LBL CS and ammonium polyphosphate | Flame retardation | Jimenez et al. (2016) |

| Polyamide 66 fabric | CS-phytic acid, oxidized sodium alginate | Flame retardation | Kundu et al. (2017) |

| Acrylic fabric | LBL CS and montmorillonite | Flame retardant | Carosio and Alongi (2018) |

| Textile wastewater and dye removal | |||

| Cotton | UV-grafted CS | Absorbance and removal of excess dyes | Periolatto and Ferrero (2013) |

| Textile fabrics | CS beads impregnated with ZnO | Photodecolorization of Rhodamine B & Methylene Blue dyes | Farzana and Meenakshi (2015) |

| Textile fabrics | Laccase immobilized on CS-cerium (VI) dioxide microspheres | Decolorization of methyl red and orange II reactive dyes | Lin et al. (2015) |

| Textile fabrics | CS plus ferrous sulfate | Decolorization | Kos (2016) |

| Textile fabrics | CS-coating ZnO nanoparticles-Fe3O4 nanoparticles | Removal of azo dye (reactive blue 198), recyclable composite | Nguyen et al. (2015) |

| Textile fabrics | CS-coating Fe3O4 nanoparticles | Removal of azo dye (Acid Red 2) | Kadam and Lee (2015) |

| Textile fabrics | Acrylic acid grafted on Jute fibers followed by immobilization of CS | Desorption of anthraquinone dye | Hassan (2015) |

| Textile fabrics | Manganese peroxidase immobilized on CS beads | Degradation and detoxification of dyes | Bilal et al. (2016) |

| Textile fabrics | Manganese doped in CS-ZnO | Photocatalytic degradation of azo dye | Nguyen et al. (2016) |

| Textile fabrics | CS-poly(methacrylic acid)-TiO2 microparticles | Removal and degradation of anionic azo dyes | Škorić et al. (2016) |

AB antibacterial effects, CS chitosan, LBL layer by layer deposition, β-CD β-cyclodextrin

aPhotochemical reaction by UV generating cross-linked polymers

Utilization of Chitosan in Cosmetics

Chitin and, in particular, chitosan and its derivatives provide advantageous properties in the cosmetic area. They are biocompatible and adhere to surface components of the skin and hair, forming elastic films with moisturizing and water retention capabilities. They can serve as vehicles for encapsulated cosmetic ingredients and their controlled delivery and release and formation of gels in mixtures with water and alcohol and have some antimicrobial, antioxidant, and anti-inflammatory activities, with the additional important benefit of low cytotoxicity (Lee et al. 2013; Jimtaisong and Saewan 2014; Aranaz et al. 2018).

Chitosan and its derivatives are included in cosmetic formulations and products for mainly care and protection of the skin and hair but inter alia in tooth enamel and tooth lacquer, nail lacquer, lipsticks, cleansing and bath materials, toothpaste, mouthwash, chewing gum, deodorants, and breath refresheners (Dutta et al. 2004). Aging of the skin, viewed as wrinkling, dryness, loss of elasticity, dehydration, and hyperpigmentation, is the result of long-term exposure to sunlight UV, which mainly forms reactive oxygen species. Protection from photoaging is a major drive in the cosmetic industry. For example, chitooligosaccharides per se were able to protect UV-irradiated hairless mouse skin from photoaging damage (Kong et al. 2018). Gel formulation of chitosan microparticles served as a delivery system for the sustained release of the hydrophilic sunscreen, phenylbenzimidazole sulphonic acid (Gomaa et al. 2010). The cosmetic gel formulation of blended chitosan, collagen, and , with antibacterial and antioxidant effects, proved useful in the regeneration and rejuvenation of the skin using cultured mouse fibroblast (Rajashree and Rose 2017). Microspheres composed of carboxymethyl chitosan/collagen peptides-calcium chloride protected mice skin and thymus lymphocytes from UV-B radiation damage (Liu et al. 2015b). A cosmetic cream formulation composed of quaternized carboxymethyl chitosan-montmorillonite nanocomposite bestowed good UV protection and additional moisturizing and water retention effects (Chen et al. 2017). There is a possible cosmetic use of neutralized chitosan in citrate buffer film for skin exfoliation (Libio et al. 2016).

Chitosan and various chitosan derivatives, as active ingredients, were examined in cosmetic hair care products like shampoos, permanent wave agents, hair conditioner, styling lotions, rinses, hair colorant, hair sprays, and hair tonics (Dutta et al. 2004; Aranaz et al. 2018). They can adhere to the negatively charged hair keratin forming a transparent elastic film that covers hair fibers endowing smoothness, softness, and also mechanical strength (Dutta et al. 2004). A blend of chitosan and two other biopolymers like collagen and hyaluronic acid that forms a thin film over hair surface provides enhanced mechanical strength and improved conditioning of the treated hair (Sionkowska et al. 2017). Chitosan as a targeting vehicle to hair follicles in the skin was demonstrated with entrapped minoxidil, a medication to treat hair loss (Gelfuso et al. 2011; Matos et al. 2015). Microparticles and nanoparticles of chitosan-encapsulating minoxidil enabled its controlled release.

A large number of possible applications of cosmetic formulations containing chitosan and its derivatives have been patented. It is noteworthy that formulations containing chitosan are already in the busy cosmetic market.

Biomedical Applications of Chitosan Derivatives

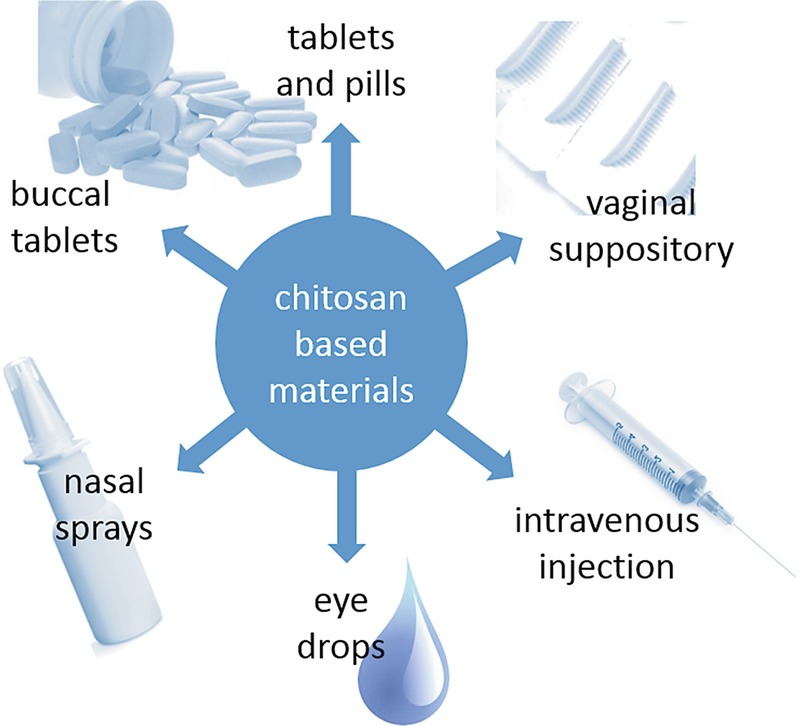

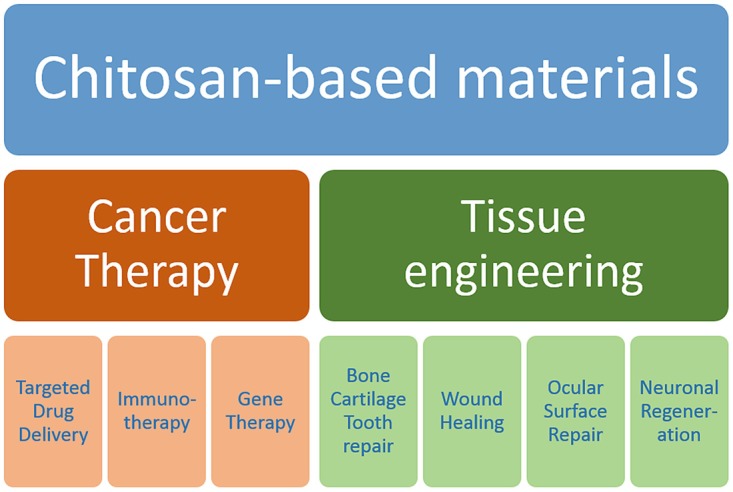

Because chitosan and many of its derivatives are nontoxic, biocompatible, biodegradable, and highly versatile polymers, a large assortment of possible biomedical applications have been explored, of which some were implemented into therapeutic strategies by the pharmaceutical industry. To obtain optimal materials for the delivery of drugs, several factors have to be considered including the stability of the bioactive agents, absorption properties and mucoadhesiveness, gelling properties, particle sizes, permeation and transfection-enhancing properties, efflux pump inhibition, tissue targeting, residual toxicity of the final products, as well as release kinetic profiles. Chitosan derivatives have been developed into different kinds of pharmaceutical excipients used for the production of tablets and capsules (Illum 1998; Werle and Bernkop-Schnurch 2008), suppositories (Caramella et al. 2015), sprays (Osman et al. 2013), ointments (Kang et al. 2016), eye drops (Basaran and Yazan 2012), and wound dressings (Bano et al. 2017). The drugs are usually encapsulated by ionotropic gelation, spray drying, emulsion solvent evaporation, and coacervation (Panos et al. 2008). Chitosan-based excipients have been found useful in tablet disintegration and drug dissolution (Illum 1998) and in enhancing penetration and absorption properties (Thanou et al. 2001; van der Merwe et al. 2004; Sahni et al. 2008). Most importantly, certain dosage forms allow the controlled release of drugs (Jennings et al. 2015; Fonseca-Santos and Chorilli 2017). These include chitosan-based hydrogels (Knapczyk 1993; Kristl et al. 1993; Berger et al. 2004; Ishihara et al. 2006; Elviri et al. 2017) and micro-/nanoparticles for drug delivery (Hamman 2010). Here, we will focus on the applications of chitosan-based matrices in drug delivery for cancer, immune, and gene therapy, and we will summarize some recent advances in tissue engineering (Fig. 14.1).

Fig. 14.1.

Overview on biomedical applications of chitosan-based materials in cancer therapy and tissue engineering

Chitosan-Based Drug Carrier Systems

Chitosan-based materials can be used in various forms as drug delivery system (Fig. 14.2). Tablets are probably the most favorable and accurate dosage form, which are moreover easy to fabricate and handle. A simple method for their production is homogenization of the drug and chitosan and compressing the resulting mixture to tablets. However, it has to be considered that due to the alkaline conditions in the distal intestine, drug absorption is restricted to the more proximal regions of the gastrointestinal tract when pure chitosan is used which precipitates at an alkaline pH (Sakkinen et al. 2004; Dhaliwal et al. 2008). Therefore, more pH-insensitive formulations using higher-charged chitosan derivatives such as trimethylated chitosans or thiolated chitosan conjugates have improved absorption properties along the gastrointestinal tract. Although there is still a lack of robust data in human volunteers, some studies indicate that tablet formulations using higher-charged chitosan derivatives increase bioavailability due to improved mucoadhesiveness and better protection of the drug from degrading enzymes (van der Merwe et al. 2004). Chitosan-based tablets have been also examined for their use in vaginal drug delivery, mainly as carriers for antiviral and antifungal therapeutics (El-Kamel et al. 2002; Senyigit et al. 2014; Frank et al. 2017). However, the antimicrobial properties of chitosan may negatively affect the vaginal microflora, and hence long-term treatment should be critically evaluated (Raafat and Sahl 2009).

Fig. 14.2.

Chitosan-based drug delivery systems

As chitosan-based hydrogels facilitate equal distribution and increase mucoadhesiveness, permeation, and bioavailability, they are effective formulations for eye drops to administer therapeutic drugs in ophthalmology (Krishnaswami et al. 2018). Chitosan-based formulations used in eye care include hydrogels, nanoparticles, and liposomal and colloidal systems (De Campos et al. 2001; De Campos et al. 2003; Diebold et al. 2007; Gupta et al. 2010). For similar reasons, they are also in use for nasal drug delivery, which is impaired by high turnover and secretion rates (Illum 2003). Notably, chitosan-coated lipid micro- and nanoparticles have been developed for nose-to-brain delivery of a variety of therapeutic drugs (Casettari and Illum 2014; Sarvaiya and Agrawal 2015). Chitosan-based nanoparticles are also a promising carrier for buccal drug delivery, which has the advantage of avoiding the hepatic first-pass metabolism and degradation in the gastrointestinal system (Sandri et al. 2005). Polymeric carriers generally have the potential advantage of prolonged release times of low-molecular-weight drugs. Because chitosan is additionally susceptible to hydrolysis by lysozyme in the blood serum, which facilitates drug release, and exhibits no toxic or hemolytic effects when applied parenteral (Nordtveit et al. 1994; Richardson et al. 1999), chitosan-based formulations are also suitable carriers for controlled drug release when administered by intravenous injection (Thanoo et al. 1992).

Chitosan-Based Drug Delivery Systems in Chemotherapy

Conventional chemotherapeutics are frequently not very effective in reaching the tumor cells, as solid tumors are not well supplied with blood, and lack lymphatic vessels, which results in and decreased convective flow in the interstitial fluid. To overcome these problems, novel drug delivery systems have been designed. These carriers are capable of encapsulating high concentrations of the cytotoxic compound within a macromolecular matrix that specifically targets the cargo to the tumor cells where the drugs are finally released in a controlled manner. This concept profits from the EPR (enhanced permeability and retention) effect, the phenomenon that macromolecules preferentially accumulate in solid tumors, probably because they have a defective vasculature and lack effective lymphatic drainage (Matsumura and Maeda 1986). Chitosan-based nanoparticles have many properties that make them suitable carriers for anticancer drugs. Next to their great chemical flexibility, allowing the design of selective carriers, chitosan-based materials evidently exhibit also the EPR effect depending on the tumor microenvironment (Yhee et al. 2017). Moreover, they are degraded inside the body into fragments which can be cleared by the kidney (Kean and Thanou 2010), and several studies suggested that chitosan itself has antitumor effects (Qi and Xu 2006; Yao et al. 2013a), making this polymer a highly suitable supplementary antitumor drug and drug carrier. Indeed, chitosan-based nanocomposites can be used to deliver hydrophilic and hydrophobic drugs such as doxorubicin hydrochloride and paclitaxel, respectively (Kim et al. 2006; Yousefpour et al. 2011). Studies analyzing chitosan-based drug delivery systems for cancer treatment are summarized in Table 14.2.

Table 14.2.

In vitro and in vivo studies using chitosan-based nanoparticles in various cancer treatments

| Drug/targeting | Chitosan-based composite | Experimental system, effects | Reference |

|---|---|---|---|

| Chemotherapeutic drug delivery | |||

| Doxorubicin | CS-dextrane conjugate | Mice, AT, prolonged circulation | Mitra et al. (2001) |

| Doxorubicin/trastuzumab | CS cross-linked by succinic anhydrate, Lys thiolation | SKOV-3 cells, AT, targets HER2+ receptors, enhanced uptake | Hebeish et al. (2013) |

| Doxorubicin | CS-pluronic F127 micelles | MCF7 cells, AT, high drug loading capacity | Naruphontjirakul and Viravaidya-Pasuwat (2011) |

| Doxorubicin/luteinizing hormone RH | CS-/poly(methyl vinyl ether maleic acid, magnetic nanoparticles | MCF7 cells, AT, increased cytotoxicity, targeting LHRH receptors | Varshosaz et al. (2016) |

| Doxorubicin/folate | CS-coated magnetic nanoparticles | U87 cells in athymic mice, AT, guide by magnetic field, decreased tumor growth | Yang et al. (2017) |

| Doxorubicin | Aluminosilicate zeolite (ZSM-5) CS core-shell nanodisks | Mice, AT, pH-dependent drug release, reduced Tu growth and increased apoptosis | Yang et al. (2018) |

| Doxorubicin | CS-cobalt-ferrite-titanium oxide nanofibers | B16F10 cells, AT, fast drug release at low pH and alternating magnetic field | Radmansouri et al. (2018) |

| Doxorubicin, verapamil/cRGD | Magnetic CS-poly(lactic acid-co-glycolic acid) nanoparticles | HepG2 and S-180 cells, Tu-bearing mice, AT, accumulation in tumor tissue | Shen et al. (2013a) |

| Paclitaxel | Glycol-CS-β-cholanic acid nanoparticles | Tu-bearing mice, AT, impaired tumor growth after injection | Kim et al. (2006) |

| Paclitaxel | CS-glyceryl monooleate core-shell nanopoparticles | MDA-MB-231cells, AT, 1000-fold reduction in IC50 | Trickler et al. (2008) |

| Glycol-CS-β-cholanic acid nanoparticles | Tu-bearing mice, AT, impaired tumor growth after injection, EPR | Kim et al. (2008) | |

| CS-polyaspartic acid sodium salt | Mice, sustained drug release in vitro and in vivo | Zheng et al. (2007) | |

| 5-Fluorouracil/hyaluronidase | CS-polyethylenglycol-gelatin copolymer | COLO-205 and HT-29 cells, AT, increased cytotoxicity by uptake and controlled drug release | Rajan et al. (2013) |

| 5-Fluorouracil | N-succinyl-CS-g-poly(acrylamide-co-acrylic acid) | Simulated gastric and intestinal fluids, efficient drug loading pH-dependent drug release | Bashir et al. (2017) |

| 5-Fluorouracil/ | cystamine conjugated CS- methoxy poly(ethylene glycol) | MCF7 cells, AT, improved hemocompatibility, high cytotoxicity to cancer cells | Antoniraj et al. (2018) |

| TNF-α/anti-EGFR-2 | CS-silica hollow nanospheres | MCF-7 cells, AT, pH-dependent TNF-α release inside tumor | Deng et al. (2011b) |

| Oxaliplatin/hyaluronic acid | CS nanoparticles encapsulated in Eudragit S100 coated pellets | Mice, HT-29 cells, AT, specific drug delivery in the colon | Jain et al. (2010) |

| Trans-resveratrol/ , | CS nanoparticles | HepG2 cells, cytotoxicity highest when both, avidin and biotin, were coupled | Bu et al. (2013) |

| /anti-EGFR, anti-chitosan | Glycol-CS nanobioconjugate | SW1990 cells, effective inhibition of cell proliferation, colony formation, migration, and invasion | Xiao and Yu (2017) |

| Cancer gene therapy | |||

| Survivin-siRNA/ | N-trimethyl CS-TPP developed for pulmonary delivery | A549 cells, bronchoalveolar lavage fluid, effective gene silencing of the survivin gene resulting in apoptosis | Ni et al. (2018) |

| Midkine-siRNA | CS combined with 2-chloroethylamine and N,N-dimethyl-2-chloroethylamine hydrochloride | HepG2 cells, efficient transfection, significant decrease of cell proliferation | Zhong et al. (2015) |

| psiRNA-hBCL2/dendrimeric RGD | Polyethyleneimine-g-CS | Tu-bearing mice, AT, efficient and specific transfection of tumor cells and silencing of anti-apoptotic hBcl2 | Kim et al. (2017) |

| Ovalbumin | CS nanoparticles | Mice, AT, increased cytokine levels and stimulation of natural killer cells, deacreased tumor growth, detection of ovalalbumin specific cytotoxic T cells | Wen et al. (2011), Highton et al. (2016) |

| IL-12 | CS nanoparticles | Mice, AT, activcation of cytotoxic T cells and natural killer cells, tumor regression, nor recurrence | Zaharoff et al. (2009) |

| GRP | Mannosylated CS nanoparticles | Mice, intranasal application, AT, enhanced tumor regression paralleled by anti-GRP antibody production | Yao et al. (2013b) |

| IP-10 plasmid/folate | CS nanoparticles | Mice, AT, inhibition of cell proliferation, induction of apoptosis, suppression of angiogenesis, and inactivation of regulatory T cells | Lai et al. (2014) |

AT anti-tumor effects, CS chitosan, Tu tumor