Abstract

The development of antimicrobial drug resistance among pathogenic bacteria and fungi is one of the most significant health issues of the 21st century. Recently, advances in nanotechnology have led to the development of nanomaterials, particularly metals that exhibit antimicrobial properties. These metal nanomaterials have emerged as promising alternatives to traditional antimicrobial therapies. In this review, a broad overview of metal nanomaterials, their synthesis, properties, and interactions with pathogenic micro‐organisms is first provided. Secondly, the range of nanomaterials that demonstrate passive antimicrobial properties are outlined and in‐depth analysis and comparison of stimuli‐responsive antimicrobial nanomaterials are provided, which represent the next generation of microbiocidal nanomaterials. The stimulus applied to activate such nanomaterials includes light (including photocatalytic and photothermal) and magnetic fields, which can induce magnetic hyperthermia and kinetically driven magnetic activation. Broadly, this review aims to summarize the currently available research and provide future scope for the development of metal nanomaterial‐based antimicrobial technologies, particularly those that can be activated through externally applied stimuli.

Keywords: antimicrobial metal nanomaterials, bacteria, fungus, nanoparticles

Antimicrobial resistance remains a significant health issue. Recently, metal nanomaterials have emerged as promising antimicrobials. This review provides an overview of metal nanomaterials, detailing their synthesis, properties and antimicrobial activity. The antimicrobial mechanisms of these nanomaterials are discussed in the context of passive and stimuli‐responsive activity. The review summarizes this area of research and provides direction for future studies.

1. Introduction

Antimicrobial resistance (AMR) is one of the most significant health‐related issues of the 21st century.[ 1 , 2 , 3 ] Despite continued, thorough investigations into the development of new chemical classes of antibiotics, scientific progress has been unable to contend with the rapid rise of bacterial resistance.[ 1 , 3 , 4 ] For bacteria, several mechanisms of resistance have evolved, including decreased membrane permeability,[ 5 ] overexpression of specific efflux pumps,[ 6 ] the development of mechanisms to degrade or alter the conventional antibiotic,[ 7 ] and the biological differentiation of the antibiotic target site.[ 8 ] Bacteria possessing just one of these resistance mechanisms can be treated through an alternative class of antibiotic, however, it is becoming increasingly common for single strains of bacteria to simultaneously possess the genes for more than one of these resistance mechanisms; these bacteria are often termed “superbugs.” The rapid development of bacterial antibiotic resistance has been expedited by the life‐cycle of the micro‐organism. For example, bacteria possess fast rates of reproduction and an ability to horizontally transfer genes,[ 9 ] which is accelerated when different species are in close proximity to one another, such as those responsible for biofilm infections.[ 10 , 11 ] Biofilms refer to communities of micro‐organisms which adhere to a surface and are contained within a self‐produced protective matrix.[ 10 , 12 ] This matrix is primarily composed of extracellular polymeric substances (EPS), as well as some additional components such as proteins, nucleic acids, and environmental debris, which provides a protective barrier against factors in the surrounding environment, including antimicrobial agents, such as antibiotics.[ 10 , 11 , 12 ] As such, effective treatment of biofilms requires additional strategies which often include removal of the infected surface (i.e., medical implant) or breaking up the protective matrix.[ 13 ] Stimuli‐activated antibiofilm treatments will be a particular focus of Section 7.2 of this review. Widespread scientific consensus has concluded that the human overuse and mismanagement of antimicrobial agents has contributed to the rapid development of microbial resistance in pathogenic micro‐organisms.[ 1 , 14 ] Notably, as antibiotics become increasingly ineffective, the human population is set to lose its most successful tool, the medical “silver bullet,” returning us to a pre‐antibiotics era, where minor cuts, grazes, and other sources of infection, including routine surgeries, could potentially be fatal.

In addition, fungal infections are also of great concern, particularly in the form of hospital‐acquired infections.[ 15 ] Fungal infections can result in morbidity and mortality, most notably in immunocompromised patients such as those suffering from AIDS.[ 16 ] As with bacteria, many fungi can adhere to biotic and abiotic surfaces, presenting as a challenge for removal of the biofilm communities.[ 17 , 18 ] For example, Candida species were found to be the fourth most common pathogen causing hospital‐acquired bloodstream infection in the USA,[ 19 ] with around 400 000 cases a year worldwide, which are often associated with implanted medical devices.[ 20 ] Antifungal drugs predominately target the disruption of the biosynthesis pathways or integrity of important components of the fungal cell wall.[ 21 , 22 ] For example, echinocandins prevent the correct synthesis of β‐glucans,[ 23 ] polyenes bind to membrane sterols,[ 24 ] while azoles and allylamines inhibit the essential steps in the synthesis pathway of ergosterol.[ 25 ] Fungal resistance to drugs, however, is a major problem, which is exacerbated by the overuse of antifungal agents in medical contexts, as well as environmental settings, such as the overuse in antifouling coatings and livestock feed formulations.[ 17 , 26 , 27 ] Mechanisms of resistance against antifungal agents vary greatly between and within individual classes of antifungal agents, however these modes of resistance are not as comprehensively understood when compared to bacterial modes of resistance.[ 22 , 27 , 28 ] For example, resistance to the azole class of antifungal agents can be due to the increased activity of specific drug efflux pumps,[ 29 ] alterations to the enzyme target,[ 30 ] overexpression of the target enzyme[ 31 ] and through biosynthesis bypass pathways.[ 32 ] While resistance to antifungal agents within the polyene class is considered quite rare, resistance has been detected among Candida and Aspergillus species. The mode of resistance is believed to be caused by inducing a decrease in ergosterol production, which is typically supplemented by an overexpression of other sterols.[ 33 ] Fungal resistance to echinocandins is poorly understood, however, it is thought to be caused by point mutations in the β‐glucan synthase complex.[ 34 ] As is the case for bacterial pathogens, multidrug resistance is also an emerging issue in fungal pathogens.[ 35 ]

There is a critical need for the development of new antimicrobial technologies as alternatives to, or to work in combination with, conventional antimicrobial treatment methods.[ 2 ] There are a range of criteria to which new antimicrobial technologies must conform to in order to be effective. The key criteria include: 1) effective antimicrobial performance, 2) selectivity towards the pathogenic micro‐organism, 3) fast acting, 4) permit clinically practical methods of delivery, 5) low to zero cytotoxicity or other detrimental side effects, and 6) the ability to control the temporal and spatial delivery. The use of metal nanomaterials for their antimicrobial properties has already been shown to address many of these criteria, with varying success.[ 36 , 37 , 38 , 39 ] In particular, metal nanomaterials have been studied extensively as they possess a range of innate antimicrobial mechanisms, including the disruption of the cellular membrane, diffusion into and degradation of internal cellular components such as DNA, RNA, and enzymes, and the release of ions with antimicrobial activity.[ 40 , 41 , 42 ] Common materials include, but are not limited to: silver, gold, copper, zinc, and their corresponding oxides, with a range of shapes and sizes (typically below 100 nm).[ 37 , 43 , 44 , 45 ] While there still remains a need for systematic studies to comprehensively explain the bactericidal and fungicidal mechanisms associated with metal nanomaterials, it is clear that they often simultaneously demonstrate several antimicrobial mechanisms.[ 41 , 46 ] Therefore, for pathogenic bacteria or fungi to develop resistance they would need to acquire a suite of mutations to counteract the different mechanisms taking place, which is more unlikely than in the case of antibiotics which typically possess a single mode of action.

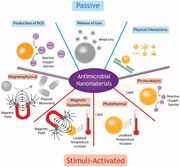

Next‐generation nanomaterials that can be activated by an external stimulus to illicit antimicrobial properties represent an exciting new step in progress towards an alternative for traditional antimicrobial drugs. Often, the antimicrobial property of the nanomaterial is also responsible for the associated side effects, such as dissolved ions.[ 47 ] Stimuli‐activated nanomaterials can, however, remain “dormant” until selectively “switched on,” reducing the possibility of detrimental side effects on human cells or beneficial micro‐organisms. Additional benefits include the improved control of the treatment temporally and/or spatially, which enables increased levels of treatment specificity toward the infection region and causative pathogenic micro‐organism. Light and magnetism are the two primary stimuli for current stimuli‐activated antimicrobial nanomaterials, with different mechanisms of action being responsible in each case. Photocatalytic and photothermal nanomaterials are stimulated by the input of energy from certain wavelengths of light to produce reactive oxygen species (ROS) and localized increases in temperature, respectively, which have been observed to be effective against pathogenic bacteria and fungi. Magnetic hyperthermia and magnetophysical nanomaterials respond to magnetic fields to kill pathogens through a localized temperature increase and physical rupture, respectively. In addition to these four stimuli‐activated antimicrobial nanomaterials, there are multiple drug delivery systems that can be activated by a wide range of stimuli,[ 39 , 48 ] such as light,[ 49 ] magnetism,[ 50 ] ultrasound,[ 51 ] pH,[ 52 ] and enzymatic activity;[ 53 ] however these are beyond the scope of this review which primarily focuses on metal nanomaterials which themselves possess antimicrobial properties as opposed to a mechanism of delivery.

This review focuses on metal nanomaterials, which demonstrate antimicrobial activity. We provide a broad overview of the properties and synthesis of nanomaterials and their passive interactions with bacteria and fungi. Furthermore, we provide an in‐depth analysis and comparison of the next‐generation approaches of stimuli‐activated antimicrobial nanomaterials, providing scope for the design of future antimicrobial treatments.

2. Structure of the Bacterial and Fungal Cell Wall

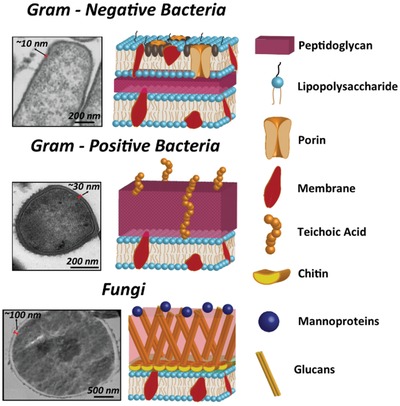

The cell wall is the protective barrier that isolates the internal components of the cell from the external environment. As such, it is immensely important to the cells' ability to survive and flourish.[ 54 ] For bacteria, the cell wall is a complex structure, composed of proteins, lipids, and carbohydrates, of which there are two primary classes: 1) Gram‐positive and 2) Gram‐negative.[ 55 ] The Gram‐positive cell wall consists of a thick peptidoglycan layer, surrounding the lipid bilayer membrane with lipoteichoic acids linking the two layers[ 56 , 57 , 58 ] (Figure 1 ). This thick peptidoglycan layer consists of chains of the alternating disaccharides N‐acetylmuramic acid and N‐acetylglucosamine, which are connected via β‐1,4 linkages, with individual layers connected by pentapeptide cross‐links to form a think, robust layer. This provides the cell with enhanced levels of protection from external chemical and physical factors.[ 54 , 59 ] Conversely, the Gram‐negative cell wall is more complex, possessing a thinner peptidoglycan layer than Gram‐positive bacterium, which is sandwiched between an inner and outer cell membrane; the latter consisting of negatively charged lipopolysaccharides[ 54 , 60 ] (Figure 1). This external membrane is unique to Gram‐negative bacterium and acts as the interface between the environment and the cell, and is largely responsible for protection as well as contributing to the cells pathogenicity, namely the presence of lipopolysaccharides.[ 61 ] Additional components in the outer membrane include porins, which allow the diffusion of molecules that would not be able to otherwise translocate through the cell membrane, lipoproteins, periplasmic space and numerous membrane‐bound proteins that serve specific functions for the cell.[ 58 ] Due to the complex nature of the bacterial cell wall and the fundamentally dynamic nature of the cell as a living organism, interactions between nanomaterials and the cell wall are still not well understood and are thought to consist of a combination of physicochemical forces such as electrostatic, hydrodynamic, hydrophobic, dispersion, and van der Waals forces.[ 56 , 62 ]

Figure 1.

Transmission electron micrographs (left) and schematic diagram (right) of the cell wall of Gram‐negative bacteria (top), Gram‐positive bacteria (middle) and fungi (bottom) cells, respectively. It should be noted that the precise composition of fungal cells can be widely variant amongst species. As such, the schematic is a generalized version of a fungal cell wall. The pictorial legend to the right of the figure provides detail of the cell wall components. Bacterial electron micrographs reproduced with permission.[ 56 ] Copyright 2019, Elsevier. The fungal electron micrograph reproduced with permission.[ 65 ] Copyright 2018, Dovepress.

Conversely, fungi are eukaryotic cells. They are nucleated and possess a distinctly different cell wall to that of bacteria. The fungal cell surface consists of a phospholipid bilayer membrane, linked with unbranched chains of polymers known as chitin, which are cross‐linked to β‐1,3‐ and β‐1‐6‐glucans, as well as additional membrane‐bound proteins, which serve a range of functions[ 63 ] (Figure 1). While this is the base structure of the fungal cell wall, many fungi have additional components such as mannan (Candida albicans), melanin (Aspergillus fumigatus), glucuronoxylomannan and galactoxylomannan (Cryptococcus), as well as other components, which can influence the properties of the cell wall and are often used for specific functions.[ 64 ]

3. Fundamental Aspects of Metal Nanomaterials

3.1. Properties

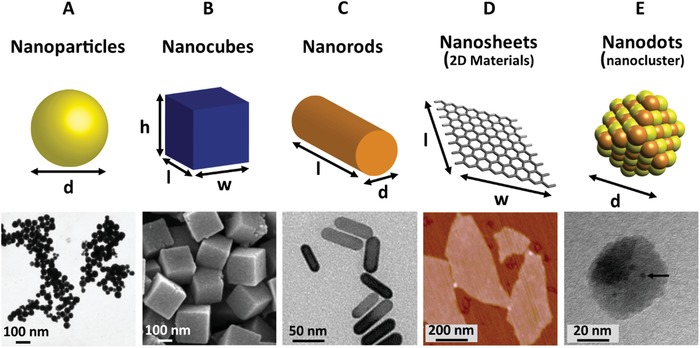

At the nanoscale, the physical and chemical properties of metals change dramatically from that of the bulk material.[ 66 ] This is primarily due to size and shape effects, as well as the high surface area to volume ratio inherent to nanomaterials.[ 66 ] Importantly, this results in changes to the fundamental properties of the nanomaterial, such as expedited ion release,[ 67 ] hardness,[ 68 ] and plasmonic and superparamagnetic properties.[ 69 ] Metal nanomaterials respond differently to external stimuli, such as light in the case of photocatalytic[ 70 ] and photothermal[ 71 ] activity and magnetism in the case of magnetically induced hyperthermia activity,[ 71 , 72 ] in contrast to their bulk‐metal counterparts. In addition to size, the shape of the nanoparticles can also influence their intrinsic properties, for example, photocatalytic properties can be affected, largely through enhanced surface area while plasmonic properties are influenced by the nanomaterials shape which affects the relative lengths along which the electron cloud can resonate and hence the specific wave function.[ 73 ] With improvements in nanotechnology and fabrication processes, a diverse array of nanoscale shapes have been constructed, such as: nanoparticles,[ 74 ] nanodots,[ 75 ] nanocubes,[ 76 , 77 ] nanorods,[ 78 , 79 ] nanoshells,[ 80 ] nanocages,[ 81 ] nanostars,[ 82 ] nanoflowers,[ 83 ] nanoeggs,[ 84 ] nanopopcorn,[ 85 ] and numerous other 2D materials.[ 86 , 87 ] Figure 2 shows a variety of commonly investigated nanomaterials, along with experimentally obtained images of example nanomaterials with the corresponding shape. The unique properties of metals at the nanoscale have led to research into the use of these nanomaterials for different applications, ranging from next‐generation electronics to numerous biomedical applications.

Figure 2.

Schematic (top) and experimental (bottom) representation of the range of different nanomaterials that possess passive antimicrobial activity. Experimental data (bottom row) shows A) TEM image of silver nanoparticles. Reproduced with permission.[ 74 ] Copyright 2006, ACS Publications. B) SEM image of ZnSn(OH)6 nanocubes. Reproduced with permission.[ 76 ] Copyright 2012, ACS Publications. C) TEM image of gold/silver hybrid nanorods. Reproduced with permission.[ 78 ] Copyright 2018, ACS Publications. D) AFM image of graphene nanosheets. Reproduced with permission.[ 86 ] Copyright 2011, ACS Publications. E) TEM image of copper nanodots (clusters). Reproduced with permission.[ 75 ] Copyright 2019, ACS Publications.

3.2. Synthesis

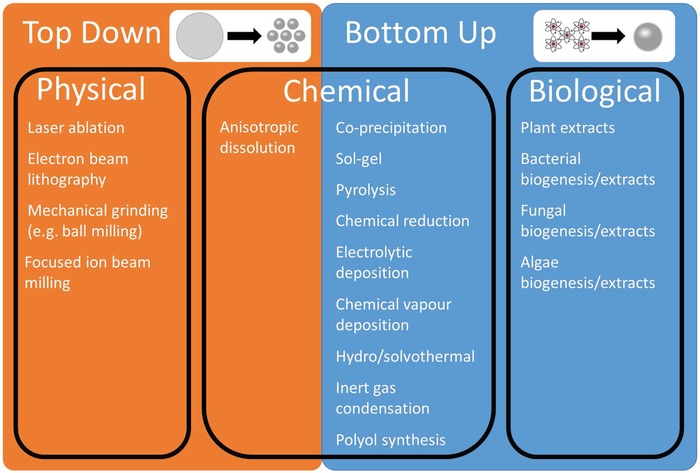

The synthesis of nanomaterials can largely be categorized into two methods: “top down”[ 88 , 89 ] or “bottom up”[ 90 , 91 ] processes (Figure 3 ). For the former, particles are generally fabricated via the breaking down of bulk materials into smaller (nano‐) fragments, typically by physical means.[ 88 , 92 ] This includes methods such as laser ablation, electron beam lithography, mechanical grinding, or focused ion beam milling. For example, Ismail et al. synthesized magnetic iron oxide nanoparticles through a process of laser ablation in solution, within the 50–110 nm range, which demonstrated antibacterial activity against Gram‐positive and Gram‐negative bacterium.[ 93 ] Whereas, for “bottom up” approaches, particles are often chemically grown from precursors, through a process of chemical reduction.[ 90 , 94 ] Typically, metal cations, in the form of salts, are combined with a reducing agent such as sodium borohydride or sodium citrate and reduced to a neutral state.[ 95 ] Following an initial nucleation step, the atoms cluster together, forming a seed of defined crystallinity, which then grows larger until the process is interrupted through the addition of a capping agent, the timing of which dramatically affects the size of the nanoparticles.[ 96 ] Often stabilizing agents, such as ligands or polymers, are added for greater control over the size of the nanomaterials.[ 97 ] Additionally, there are several other processes such as inert gas condensation,[ 98 ] sol–gel,[ 99 ] coprecipitation,[ 100 ] among others.[ 101 ] For example, Samavati and Ismail used a process of coprecipitation to synthesize copper‐substituted cobalt ferrite nanoparticles by adding CoCl2·6H2O, CuCl2·2H2O and FeCl3 together in distilled water, with the addition of citric acid as a chelating agent and NaOH to maintain a pH of 8. The precipitates were annealed at 800 °C for 10 h, forming nanoparticles in diameter within the range of 20–32 nm, which they found to have antibacterial activity against multidrug‐resistant E. coli.[ 102 ] Interestingly, there has been a push for biological methods of nanomaterial synthesis via plants and micro‐organisms,[ 103 , 104 ] which avoid using toxic or environmentally damaging chemicals unlike traditional methods. A detailed description of nanomaterial synthesis methods is beyond the scope of this review article; however, the interested reader is directed to several important methodological reviews in the field.[ 90 , 96 , 104 ] A summary of physical, chemical, and biological methods for nanoparticle synthesis is provided in Figure 3.

Figure 3.

Summary of “top down” and “bottom up” physical, chemical and biological synthesis of metal nanomaterials.

4. Passive Antimicrobial Mechanisms of Metal Nanomaterials

Metals, such as copper and silver, have been utilized for their antimicrobial properties for thousands of years for applications such as water disinfection, food preservation, and surgical bandages, and sutures.[ 46 , 105 ] While these materials were not extensively explored in early scientific studies, partly due to the discovery of antibiotics in the 1920s, there has been reinvigorated interest in the use of metal nanomaterials as antimicrobial agents. This renewed interest coincides with significant breakthroughs in the understanding, fabrication and characterization of sub‐micron‐sized materials. A wide range of nanomaterials have been demonstrated to possess antimicrobial effects, including iron (III) oxide,[ 106 ] zinc oxide,[ 107 ] magnesium oxide,[ 108 ] silver,[ 67 , 109 ] gold,[ 110 ] copper[ 45 , 77 ] and copper oxide,[ 111 ] calcium oxide,[ 41 ] titanium dioxide[ 112 ] and cadmium oxide[ 113 ] among others.[ 41 , 42 , 87 , 114 , 115 ] Successful antimicrobial activity has been demonstrated utilizing an equally wide array of shapes (Figure 2).

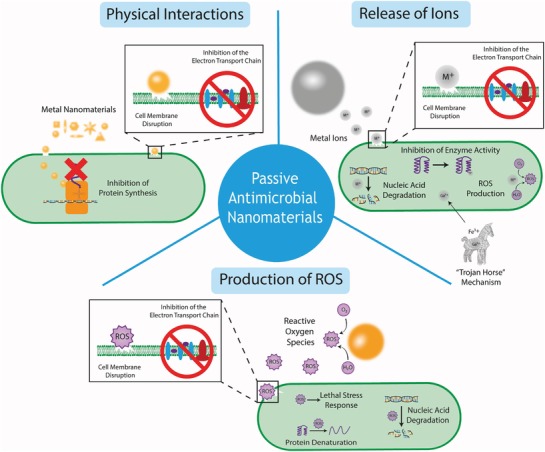

Despite several explanations for nanomaterial–microbial interactions, the mechanisms responsible for the passive antimicrobial properties of metal nanomaterials are still poorly understood. This is partly due to the multi‐factorial nature of the activity, which makes it difficult to decouple the individual mechanisms. Several different proposed mechanisms were derived from physical interactions as well as chemical interactions, such as the production of ROS and the increased dissolution of metal cations[ 37 , 41 , 43 , 116 , 117 , 118 ] (Figure 4 ). These mechanisms can have numerous target sites, such as the cell membrane, membrane‐bound proteins, inhibition of enzyme activity and nucleic acids, hence it is proposed that it is more difficult for pathogenic bacteria and fungi to develop resistance to protect all of these cellular components.[ 38 ] Due to the lack of clarity within the current literature, we have divided such proposed mechanisms into three broad categories 1) physical interactions, 2) ion leaching/dissolution, and 3) production of ROS. It is noteworthy that within these categories remains overlaps (for example metal cations can increase intracellular ROS), however broadly these cover the primary modes of passive antimicrobial activity of metal nanomaterials. Information regarding the inherent difference in bacterial and fungal cell interactions with antimicrobial nanomaterials are rarely reported in isolation. Instead, the known antibacterial mechanisms of metal nanomaterials are often directly attributed to antifungal behavior, without discussion of known differences between the microbes, such as their cell walls (Figure 1). Hence the majority of literature reporting on the antifungal activity of metal nanomaterials conflates antibacterial behavior with both antifungal and antimicrobial. Careful review of the literature, therefore, reveals no clear consensus regarding the precise mechanisms of antifungal and/or antimicrobial activity of metal nanomaterials. To this end, the authors of this review suggest that elucidating the specific antifungal mechanisms of metal nanomaterials should be the focus of future studies. For more comprehensive reviews on the passive antimicrobial activity of metal nanomaterials, readers are encouraged to read several comprehensive reviews on this topic.[ 46 , 105 , 118 ]

Figure 4.

A summary schematic diagram representing the range of passive antimicrobial mechanisms of metal nanomaterials (not to scale) including physical interactions, release of ions and production of ROS.

4.1. Physical Interactions

In this section, we summarize the direct activity of metal nanomaterials due to physical interactions (i.e., not through the generation of a subsequent chemical species such as ion release or ROS which will be summarized below). These interactions can be further divided into two primary sections: 1) interactions with the cell wall and 2) intracellular activity.

The cell wall presents as the barrier between the cell and its external environment, as well as facilitating important metabolic pathways (e.g., the electron transport chain) and hence disruption of the cell wall can be fatal for the cell. Metal nanomaterials, which are typically positively charged, can bind to the negatively charged cell wall components through electrostatic interactions, which alter the charge of the membrane, disrupting the membrane,[ 105 , 118 ] as well as forming ROS species. Damage to the membrane causes significant leakage of fluid from the cytosol as well as irreparable damage to the cell wall and ATP production, effectively inactivating the cells.[ 105 ] It is worth noting that the influence on the antimicrobial activity of nanomaterial induced cell membrane damage through physical interactions can be overreported as cell membrane damage can often be the result of another biocidal mechanism (such as an increase in intracellular ROS) rather than the primary cause of cell death. Furthermore, because membrane damage is uncomplicated to visualize, typically through electron microscopy techniques and/or the use of membrane‐permeable or membrane‐impermeable dyes and fluorescent or confocal laser scanning microscopy, it can be easily over‐attributed as the cause of cell death.

Cellular uptake of metal nanomaterials can occur when the materials are sufficiently small that they can cross the cellular membrane. In the case of mammalian cells, it has been suggested that particles below 100 nm are most efficient for cellular uptake.[ 119 ] However due to the multiple mechanisms of cellular uptake present in mammalian cells, they can also internalize larger particles. Furthermore, the surface chemistry of the particles also plays an important role in particle uptake, which can be modulated through the addition of different surface coatings.[ 120 ] While there is significant research relating to cellular uptake in mammalian cells, the cellular uptake pathways in bacteria and fungi are less well studied. One study demonstrates the internalization of ZnO and TiO2 nanoparticles of 30 and 50 nm, respectively, as measured by TEM, in Salmonella typhimurium.[ 121 ] Once internalized, metal nanomaterials can interact with important cellular components, for example, gold nanoparticles have been shown to bind to the ribosomal subunit, which inhibits successful binding of tRNA,[ 116 ] which serves an important role in successful protein synthesis.[ 122 ] However, the research is not yet clear as to the specific components that are affected and how this changes through the use of different metals, partly due to difficulties in visualizing these interactions experimentally. Future research will require carefully planned studies using a combination of high‐resolution imaging and metabolic/genomic studies to decouple the effects of the physical (such as binding to proteins/nucleic acids) and the chemical (release of ions and production of ROS) interactions of internalized metal nanomaterials, to gain a better understanding of these mechanisms.

4.2. Ion Leaching/Dissolution

Metal nanomaterials leach metal ions at a much higher rate than the bulk material, due to the significantly enhanced surface area, when compared to equivalent volumes of the bulk. These ions can detrimentally interact with various cellular components such as proteins, DNA, and the cellular membrane.[ 46 , 74 , 123 ] Ions can be taken up by bacteria and fungi through a suite of transport proteins, which control the uptake of metal species.[ 124 ] Metal ions have been shown to demonstrate multiple antimicrobial mechanisms, which often occur in a synergistic manner and researchers have faced significant challenges elucidating the individual mechanisms, however the current theories are detailed below. 1) Inhibition of enzyme activity, which can occur via metal‐catalyzed oxidation of amino acid residues in proteins.[ 46 ] 2) Generation of ROS, either directly in the case of redox‐active metals, or through damage to the Fe–S clusters within proteins, which liberate redox‐active Fe ions.[ 46 ] 3) Inhibition of nutrient uptake, for example gallium ions have recently been shown to kill bacteria through a “trojan horse” mechanism, whereby the cells mistake it for Fe3+ ions, due to the similar chemical properties[ 125 ] and the cell becomes inactivated through inhibition of metabolic activity as the bacteria are unable to reduce the Ga3+.[ 126 ] 4) Damage to the membrane can occur as the positive metal cations interact with the electronegative membrane as well as some integral proteins such as those involved in the electron transport chain.[ 46 ] Furthermore, damage to DNA has also been shown, demonstrating the genotoxic activity of metal ions, but it is not established whether this is a primary cause of cell death in vivo.[ 46 ] The most prevalent examples are silver ions, which have been shown to interact with cell membranes, nucleic acids, and the thiol and amino groups which are present in proteins, with bactericidal[ 67 , 74 , 127 ] and fungicidal[ 128 ] effects. Unfortunately, it is thought that microbial pathogens will eventually develop resistance to nanosilver.[ 129 ] Other metals, such as copper, have also been shown to leach ions which exhibit antimicrobial activity.[ 123 ] The primary drawbacks of this mechanism is the development of resistance mechanisms, such as the overexpression of efflux pumps, as well as associated side effects of ion dissolution, which have been shown to possess cytotoxic properties.[ 47 ] Ion dissolution will remain an important concept and consideration for the future designs of antimicrobial metal nanomaterials, which will ideally work in combination with an additional antimicrobial mechanism to reduce the prospect of the development of pathogen resistance.

4.3. Production of Reactive Oxide Species

Reactive oxygen species (ROS), which include singlet oxygen (1O2), superoxide anion radicals (•O2 –), hydroxyl radicals (•OH) and hydrogen peroxide (H2O2) are produced endogenously in the cell through natural processes. Under normal circumstances, the cell is able to function in the presence of low levels of ROS through repairing mechanisms for damaged cell components[ 130 ] and naturally produced ROS scavenging enzymes,[ 131 ] which protect the cells from the associated oxidative stress. In higher concentrations, however, ROS cause oxidative stress on bacterial cells, which can cause significant damage to the cell membrane,[ 132 , 133 ] degrade important proteins and nucleic acids[ 130 , 134 ] and initiate lethal stress response cascades,[ 131 ] ultimately leading to cell death. Similarly, the overproduction of ROS can have antifungal effects.[ 135 ] Metal nanomaterials can induce cells to increase the generation of ROS through metabolic responses, through the promotion or suppression of ROS‐related enzymes.[ 136 ] Furthermore, metal nanomaterials can directly participate in ROS generation, for example, Lipovsky et al. demonstrated that the antifungal effects of ZnO nanoparticles against Candida albicans were significantly reduced through the addition of histidine, a molecule which quenches hydroxyl radicals and singlet oxygen, hence concluding the primary antifungal effect was achieved through the exogenous production of ROS by the nanoparticles.[ 137 ] Further, there has been extensive screening of the antibacterial activity of ROS‐producing metal nanomaterials, including silver,[ 138 , 139 ] zinc oxide,[ 140 ] and titanium dioxide,[ 132 ] among others. The amount of ROS generated from metal nanomaterials is primarily dependent on the size[ 139 , 141 ] and chemistry[ 142 ] of the nanomaterial, while the effect of the shape of the particle is less well known.

5. Molecular Modeling to Enhance Antimicrobial Nanomaterial Development

While the exact mechanism of antimicrobial action for many nanomaterial treatments is poorly understood, molecular modeling has shown the potential to inform the development of future methods by describing the key interactions between materials and microbes. Molecular modeling techniques relevant to metal nanomaterial development utilize theoretical approaches and algorithms to relate the 3D structure of molecules and materials to their behavior and properties, and include molecular dynamics (MD) simulations, quantum mechanics (QM) calculations, and machine learning (ML) methods.

In classical atomistic MD simulations, molecules are typically represented by atomic beads with a fixed charge that are connected by bonds, angles, and dihedrals, while intermolecular interactions are described by electrostatic and van der Waals terms. While this simplistic treatment allows for simulations of up to billions of atoms[ 143 ] and up to millisecond timescales,[ 144 ] because bonds and atomic partial charges are fixed, chemical reactions, optical or electronic properties, and the effects of polarization cannot be thoroughly examined. Nevertheless, MD methods have proven useful in studying the bacterial cell wall,[ 145 ] elucidating the process of fungal biofouling[ 146 ] and providing insight into antifouling materials,[ 147 ] and by providing design principles for photoluminescent nanoparticles,[ 148 ] among others. In order to provide atomistic insight into the mechanism of membrane permeation and disruption, however, accurate models of the microbial cell membrane and cell wall are essential. Computational models of realistic cell membranes have been recently extensively reviewed,[ 149 ] and a web‐based interface for the construction of lipopolysaccharides found in Gram‐negative bacterial cell walls has been developed.[ 150 ] This can aid in the modeling of bacterial membranes even for inexperienced users. While several models of the bacterial peptidoglycan layer have been developed,[ 151 ] including the use of an atomistic reactive force field to model plasma‐induced destruction,[ 152 ] these models are often not compatible with the model of the nanomaterial of interest. For example, a 2016 review highlighted the challenges and achievements of modeling gold nanoparticles and materials at biological interfaces.[ 153 ] It is therefore critical that accurate, compatible models for relevant microbial components and models of relevant nanomaterials, ions, and ROS molecules be obtained. Once this is achieved, the effects of metal nanomaterials on bacterial and fungal cell walls and membranes, ion and ROS interactions, and passive antimicrobial activity of nanomaterials should be open avenues for investigation via MD‐based computational methods. Indeed, a recent paper describes the use of a reactive force field to model the ROS‐induced destruction of the fungal cell wall at the atomic level.[ 154 ]

QM calculations and ML methods are also available to guide the development of stimuli‐activated antimicrobial nanomaterials by providing information on bandgaps,[ 155 ] photothermal,[ 156 ] photocatalytic,[ 157 ] and magnetic[ 158 ] properties. In contrast to classical MD simulations, QM methods, or more specifically density functional theory (DFT), calculate electronic structure explicitly and thus may be used to describe chemical reactions as well as optical and electronic properties. While DFT methods provide greater chemical accuracy, they also require greater computational resources due to the increased complexity, with current upper limits of tens of thousands of atoms[ 159 ] and nanosecond timescales for ab initio MD.[ 160 ] ML methods, which require data sets of either experimental or calculated properties, can provide non‐intuitive understanding of structure–property relationships and even predict the values from computationally expensive DFT calculations[ 161 ] or use data from MD simulations to better understand microbial contamination.[ 162 ]

While a comprehensive overview of all possible computational techniques is outside the scope of this review, we point the reader to a recent review of computational modeling of magnetic nanoparticle properties for further examples.[ 163 ]

6. Light‐Activated Antimicrobial Metal Nanomaterials

6.1. Photocatalytic Antimicrobial Metal Nanomaterials

6.1.1. Antimicrobial Mechanism of Photocatalytic Metal Nanomaterials

Photocatalytic nanomaterials can be activated by light to produce free ROS, which have associated antimicrobial properties.[ 41 , 70 , 112 , 164 , 165 , 166 ] Typically these nanomaterials are made from semiconductor materials, which have a relatively small difference between the valence band and conduction band, known as the energy “bandgap.”[ 167 ] The valence band of an atom is the outer‐most orbital that electrons freely occupy when the material is in its ground state; meanwhile, the conduction band describes the higher energy orbitals into which electrons can freely transition when the material is in an excited state. When electrons are in the conduction band, they possess sufficient energy to move freely in the material, resulting in conductivity. In conducting materials, these bands are overlapped, hence the material is permanently conductive. Conversely, in insulating materials the bandgap becomes too large for the electrons to move into the conduction band (or requires an unreasonable amount of energy); hence, the material is insulating. Importantly, in some semiconductor materials, the gap between these two bands is sufficiently small that the input of energy from certain bandwidths on the electromagnetic spectrum can cause electrons to transition from the valence to conduction band (Figure 5 ).[ 168 ] The bandgap distance is dependent on the electron configuration of the material and hence the required energy input (in the form of light) is significantly influenced by the composition of the semiconductor.

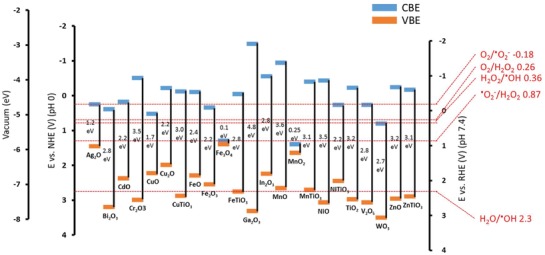

Figure 5.

Redox potentials for the generation of reactive oxygen species by semiconductors often used for photocatalytic antimicrobial activity. Includes bandgap, conduction band edge (CBE), and valence band edge (VBE) in relation to vacuum scale in electron volts (eV), normal hydrogen electrode (NHE pH 0) and reversible hydrogen electrode (RHE pH 7.4) in volts (V). Values are reproduced with permission.[ 169 ]

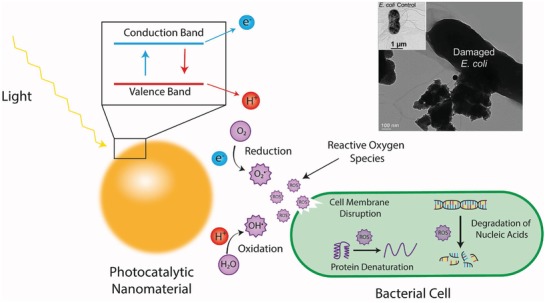

When an electron makes this transition from the valence to the conduction band, a hole is left in the valence band and the conduction band gains a free electron. This induced state leads to one of, or a combination of, two actions: 1) the electrons can instantaneously recombine, resulting in energy being released in the form of heat or radiation 2) the free electron and electron hole can react with electron acceptors and electron donors, which come into contact with the surface of the semiconductor.[ 164 , 170 ] The last case is true for photocatalytic nanomaterials with antimicrobial properties (Figure 6 ).

Figure 6.

Schematic representation of the photocatalytic effect of metal nanomaterials and subsequent antimicrobial mechanism. The energy input from light results in a free electron in the conduction band and an electron hole in the valence band which react with O2 and H2O, respectively, to form reactive oxygen species, which exhibit a number of antimicrobial mechanisms. Top right is a transmission electron micrograph of E. coli cells exposed to photocatalytic nanoparticles, which demonstrates significant membrane damage compared to the control (inset). Reproduced with permission.[ 171 ] Copyright 2013, Royal Society of Chemistry.

Typically in these cases, the electron acceptor is O2 and the electron donor is H2O. The free electron is capable of reducing O2 to the superoxide ion •O2 − which can be oxidized to form singlet oxygen 1O2 or act as a precursor for the hydroxyl radical •OH and hydrogen peroxide H2O2 which are powerful oxidizing agents. Simultaneously, the electron hole is capable of oxidizing H2O to form •OH which can dimerize to form H2O2. A summary of these reactions and the required redox potentials at physiological pH are shown in Table 1 and referenced in Figure 5.

Table 1.

Redox potentials for the generation of reactive oxygen species (ROS)

| Half‐reaction | Redox couple | Redox potential versus RHE at physiological pH 7.4 [V] a) |

|---|---|---|

| O2 + → e− + •O2 − | O2/•O2 − | −0.18 |

| •O2 − + 2H+ + e− → H2O2 | •O2 −/H2O2 | 0.87 |

| H2O2 + H+ + e− → H2O + •OH | H2O2/•OH | 0.36 |

| H2O + H+ → 2H+ + •OH | H2O/•OH | 2.30 |

| O2 + 2H+ + 2e− → H2O2 | O2/H2O2 | 0.26 |

Redox potentials were calculated using the method described in reference [ 172 ] and the Nernst Equation.

The produced •O2 −, •OH radicals, and H2O2 are the key to the antimicrobial properties of photocatalytic nanomaterials. Additionally, the production of singlet oxygen (1O2), which is a strong oxidation reagent, has also been demonstrated through photocatalysis with metal nanomaterials.[ 173 ] The antimicrobial activity of these ROS has not been conclusively determined, however, it is suggested that there are a variety of mechanisms.[ 164 ] It is hypothesized that the ROS first interact with the bacterial membrane, where they can cause oxidative damage, disrupting the cell wall, which exposes the intracellular compartment of the cell to its external environment. This action leads to an uncontrolled movement of components in and out of the cell, and eventually cell death.[ 170 , 174 ] Furthermore, ROS have been shown to damage several intracellular components of the cell, such as important nucleic acids, lipids, and proteins, which may increase the speed and efficacy of the antibacterial activity.[ 175 , 176 ] Because the generation of ROS occurs at the interface of the material and surrounding fluid, nanomaterials with smaller sizes or high aspect ratio morphologies generally possess improved antimicrobial efficacy as the specific surface area of the material is greatly increased.[ 177 , 178 ]

6.1.2. Antimicrobial Activity of Photocatalytic Metal Nanomaterials

The antimicrobial activity of photocatalytic metal nanomaterials was first demonstrated by Matsunaga et al. using a powder consisting of the semiconductor TiO2 and Pt (9:1 wt%).[ 179 ] These authors demonstrated the photochemical sterilization of the Gram‐negative bacteria Escherichia coli and Lactobacillus acidophilus, as well as Saccharomyces cerevisiae (yeast) and Chlorella vulgaris (algae). The powder was incubated with each micro‐organism in solution and the antimicrobial activity was assessed by plate counts of serially diluted solutions at different treatment time points. Following a 120 min exposure to light in the UV–vis spectrum, produced by a metal halide lamp, they observed complete sterilization of E. coli and L. acidophilus.[ 179 ] Following this initial study, there have been many significant improvements in the development of photocatalytic nanoparticles, such as greater control over the wavelength of light, which induces photocatalysis, successful conjugation of biomolecules such as antibodies and aptamers for more targeted treatments and a broadening of effective materials beyond TiO2 assessed against a broad spectrum of Gram‐negative and Gram‐positive bacteria, as well as a range of fungal species.

The photocatalytic properties of TiO2 occur under UV light, which provides sufficient energy to cause the electrons to jump from the valence to conduction band (bandgap ≈3.2 eV). The use of UV light is manageable for external use, such as sterilization of surfaces, however the use of UV is not practical in clinical situations as it poses a threat to human cells and the high energy input required is not very efficient.[ 180 ] Recently, research in the field has been focused on reducing the energy bandgap to enable catalytic activity under irradiation by visible light (≈400–700 nm) and near infrared (NIR, ≈750–2500 nm). To be effective in deep tissue infections, the excitation wavelength ideally needs to be shifted into the NIR range, which is able to penetrate through human tissue, often termed the “biological window,” which have been previously reported as occurring at 650 ≤ λ ≤ 950 nm and 1000 ≤ λ ≤ 1350 nm.[ 181 ] This can be achieved through the use of different materials, or doping TiO2 with other transition metals, providing secondary energy levels closer to the TiO2 conduction band.[ 182 , 183 , 184 ] This reduces the bandgap energy required for the electrons to jump between the two bands, and hence a lower input of energy (such as from visible or NIR light) is required for photocatalytic activity. An example of conduction and valence band edges as well as bandgaps from a variety of metal materials is provided in Figure 5. For example, Yadav et al. demonstrated the significant photocatalytic inactivation of both Gram‐positive and Gram‐negative bacteria using nickel‐doped TiO2 nanoparticles, through a sol‐gel method, under low intensity (≈0.5 mW cm−2) visible light (>400 nm) irradiation.[ 183 ] Additionally, antimicrobial activity has been observed under visible light irradiation with TiO2 nanoparticles doped with copper,[ 182 , 184 ] graphene,[ 185 ] silver,[ 186 ] silver and nitrogen,[ 187 ] sulfur[ 188 ] and cadmium sulfide.[ 189 ] Understanding these principles will provide important design parameters for next‐generation, light‐stimuli responsive antimicrobial nanomaterials.

In conjunction with TiO2, other semiconductor metal oxides with similarly small bandgaps have been investigated for their potential antimicrobial properties[ 114 , 189 , 190 , 191 , 192 , 193 , 194 , 195 , 196 , 197 , 198 , 199 , 200 , 201 , 202 ] (see Table 2 ). For example, Seven et al. demonstrated a significant reduction in the viability of E. coli, Pseudomonas aeruginosa and Staphylococcus aureus cells in the presence of ZnO nanoparticles under irradiation of a broad‐range UV lamp (250–400 nm).[ 195 ] Interestingly, Padmavathy and Vijayaraghavan found that antibacterial activity against E. coli was improved using smaller particles, likely due to the increased number of ROS producing particles interacting with individual E. coli cells.[ 177 ] Promising results have also been demonstrated when ZnO has been combined with other materials. For example, Zhou et al. report reductions in bacterial viability of 99.45% for S. aureus and 95.65% for E. coli, respectively using nanohydroxyapatite (n‐HA)/ZnO NP complexes under UV light irradiation.[ 196 ] Furthermore, Kavitha et al. demonstrated the antibacterial potential of ZnO–graphene composite NPs, where they suggested the 2D graphene induced physical rupture of the bacterial cell wall, providing a complimentary bactericidal mechanism to the photocatalytic activity of the ZnO.[ 203 ] Liu et al. were able to show antimicrobial photocatalytic activity against E. coli using silver phosphate (Ag3PO4) nanoparticles wrapped in graphene oxide.[ 198 ] In the visible light range, Singh and co‐workers demonstrated ROS production and associated antibacterial activity against E. coli, using CuO nanorods.[ 199 ] In a comprehensive study, Zhang et al. compared the generation of ROS and subsequent antibacterial activity of a wide range of metal nanoparticles and determined AgNPs were the most effective, followed by SiNPs, NiNPs, and AuNPs in descending order.[ 114 ] This was partially because AgNPs generate superoxide and hydroxyl free radicals, whereas the other three metal oxides only produce singlet oxygen species. More exotic metals and nanoscale shapes have also been investigated, Sharma et al. were able to demonstrate antimicrobial photocatalytic activity against E. coli under visible light irradiation using bismuth vanadate (BiVO4) nano‐octahedrals.[ 192 ] Examples of the range of nanomaterials used and associated antibacterial activity are listed in Table 2 and can be visualized in Figure 7 .

Table 2.

A comparison of photocatalytic metal nanomaterials for antimicrobial applications

| Material | Shape | Size | Concentration | Irradiation | Micro‐organisms | Antimicrobial efficacy a) | Log reduction | Treatment parameters | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| Bacteria | |||||||||

| TiO2 | Not specified | 79 nm | 100 ppm | 310 ≤ λ ≤ 400 nm | E. coli | 75% | NR | 13.6 W m−2, 6 h | [ 112 ] |

| Ni‐doped TiO2 | Sphere | 8–10 nm | 1 mg mL−1 Ni‐TiO2 in 5 mL saline water | λ > 400 nm |

S. aureus E. coli Salmonella albony B. subtilis |

>99% (4 h) >99% (5 h) >99% (6 h) >99% (4 h) |

4 3.5 3.3 4.3 |

≈0.5 mW cm−2, 0–6 h treatment |

[ 183 ] |

| Cu‐doped TiO2 | Sphere | 8–12 nm | 1 mg mL−1 Cu‐TiO2 in 5 mL saline water | λ > 400 nm |

S. aureus E. coli |

>99% (2 h) >99% (4 h) |

NR NR |

≈0.5 mW cm−2, 0–4 h treatment | [ 184 ] |

| Carbon‐doped TiO2 | Not specified | Not specified | 1 g L−1 |

λ > 385 nm λ > 455 nm |

E. coli |

>99% ≈80% |

NR NR |

1.8 W cm−2 (385 nm) 1.0 W cm−2 (455 nm), 2 h |

[ 204 ] |

| TiO2‐graphene | Sphere | 37 nm | 995 mg mL−1 | λ > 400 nm | E. coli | 64% | 0.443 |

450 W xenon lamp, ≈18 cm above sample, 440 min |

[ 185 ] |

| S‐doped TiO2 | Sphere | 10 nm | 0.2 mg mL−1 | λ > 420 nm | Micrococcus lylae | >95% | NR |

≈47 mW cm−2, 1 h |

[ 188 ] |

| Ag–TiO2 | Composites | 12.7–22.8 nm | 200 × 10−9 m | Visible light (not specified) | E. coli | >99% | NR |

Not specified 6 h |

[ 205 ] |

| CdS | Spheroids | 5–65 nm |

0.1 µg mL−1 0.5 µg mL−1 1 µg mL−1 |

λ > 420 nm |

E. coli S. aureus |

≈60 ≈80 >95% ≈55% ≈80% >90% |

NR |

300 W Xe lamp (does not specify distance from sample), 4 h |

[ 189 ] |

| ZnO | Not specified | Not specified | 0.01 mg mL−1 | 250 ≤ λ ≤ 400 nm |

E. coli P. aeruginosa S. aureus |

>99% (40 min) >99% (40 min) >99% (2 h) |

5 5 5 |

400 W sodium lamp ≈10 cm above sample, 0–4 h |

[ 195 ] |

| ZnO | Rods |

186 nm length 20 nm width |

1 g L−1 | 365 ≤ λ ≤ 750 nm | E. coli | ≈20% | 0.07 |

5.5 mW cm−2, 3 h |

[ 193 ] |

| n‐HA/ZnO | Rod |

80–90 nm length 15–30 nm diameter |

1 g mL−1 1 g mL−1 |

UV light (not specified) |

S. aureus E. coli |

99.45% 95.65% |

NR NR |

Not specified | [ 196 ] |

| nFe2O4–Ag–rGO | Particles and clusters bound to sheets | Not specified | 250 mg L−1 | λ > 400 nm | E. coli | >99% | 7.2 |

300 W Xe lamp (does not specify distance from sample), 90 min |

[ 197 ] |

|

Ag3PO4 GO‐AG3PO4 |

Rhombic Dodecahedral | 500 nm | 20 mg L−1 | 420 ≤ λ ≤ 630 nm | E. coli |

>99% >99% |

NR NR |

80 mW cm−2, 2 h |

[ 198 ] |

|

Au Ni Si Ag |

Spheres | 20–30 nm |

10 mg L−1 10 mg L−1 10 mg L−1 50 µg L−1 |

λ = 356 nm | E. coli |

≈10% ≈60% ≈80% ≈95% |

Check again |

0.78 mW cm−2, 2 h |

[ 114 ] |

| BiVO4 | Octahedral | 200–300 nm | 50 mg L−1 | Visible light (not specified) | E. coli | 88% | NR |

100 mW cm−2, 1 h |

[ 192 ] |

| CuO | Rods |

2.2 ± 0.67 µm length 70.1 ± 14.7 nm width |

5 ppm 10 ppm 20 ppm |

λ > 400 nm | E. coli |

pH 6.0 ≈40% ≈70% ≈92% pH 7.0 ≈30% ≈35% ≈45% |

NR |

pH 6.0 pH 7.0 15.6 mW cm−2, 2 h |

[ 199 ] |

| Fe‐doped CuO | Spheres | 21 nm | 100 µg mL−1 | Not specified |

S. aureus S. epidermidis |

≈20% ≈20% |

NR |

Not specified, 24 h |

[ 201 ] |

|

TiO2 |

Not specified | Not specified | 10 mg mL−1 | 315 ≤ λ ≤ 400 |

E. coli P. aeruginosa C. freundii S. aureus S. sapprophyticus |

>99% >99% >99% >99% >99% |

NR |

11 W, 20 min |

[ 200 ] |

|

ZnO |

Not specified | Not specified | 10 mg mL−1 | 315 ≤ λ ≤ 400 |

E. coli P. aeruginosa C. freundii S. aureus S. sapprophyticus |

>99% ≈97% ≈92% ≈90% ≈37% |

NR |

11 W, 20 min |

[ 200 ] |

| Fluorinated‐SnO2 | Hollow spheres |

100–200 nm (Cavity ≈50 nm) |

500 mg L−1 | λ > 365 nm | E. coli | >99% | 7.5 |

15 W, 150 min |

[ 191 ] |

| Ag–chitosan–TiO2 | Composites | ≈50 nm | 3.0 mg mL−1 | UV–vis (central wavelength 365 nm) |

E. coli S. aureus |

>99% >99% |

6 3.5 |

20 W, 2 h |

[ 206 ] |

| Fungi | |||||||||

| Ag–chitosan–TiO2 | Composites | ≈50 nm | 3.0 mg mL−1 | UV–vis (central wavelength 365 nm) | C. albicans | >99% | 4 |

20 W, 2 h |

[ 206 ] |

|

TiO2 |

Not specified | Not specified | 10 mg mL−1 | 315 ≤ λ ≤ 400 |

Aspergillus fumigatus Penicillum spp. |

>99% >99% |

NR |

11 W, 3 h |

[ 200 ] |

|

ZnO |

Not specified | Not specified | 10 mg mL−1 | 315 ≤ λ ≤ 400 |

Aspergillus fumigatus Penicillum spp. |

>99% >99% |

NR |

11 W, 3 h |

[ 200 ] |

| Carbon‐doped TiO2 | Not specified | Not specified | 1 g L−1 |

λ >385 nm λ > 455 nm |

C. albicans |

≈80% ≈20% |

NR |

1.8 W cm−2 (385 nm) 1.0 W cm−2 (455 nm), 2 h |

[ 204 ] |

| PdO‐modified N‐doped TiO2 | Nonuniform | 10–20 nm | 1 mg mL−1 | λ > 400 nm | Fusarium graminearum | >99% | 3.5 |

20 mW cm−2, 5 h |

[ 207 ] |

| TiO2 | Spheres | 30 nm | 0.1 g L−1 | λ > 340 nm |

Saccharomyces cerevisiae Botrytis cinerea Candida krusei Rhodotorula glutinis |

>99% <1% >99% ≈90% |

7 0 6.8 1 |

3.8 mW cm−2, 5 h |

[ 208 ] |

| Fe‐doped CuO | Spheres | 21 nm | 100 µg mL−1 | Not specified | C. albicans | ≈85% | NR |

Not specified, 24 h |

[ 201 ] |

| Au–methylene blue | Spheroids | 21 ± 2.5 nm | 20 µg mL−1 | λ = 660 nm | C. albicans | 82.2% | NR |

120 mW, 40 s |

[ 202 ] |

Antimicrobial efficacy may be due to combinatorial effects with other antimicrobial mechanisms in some cases. NR: Not reported.

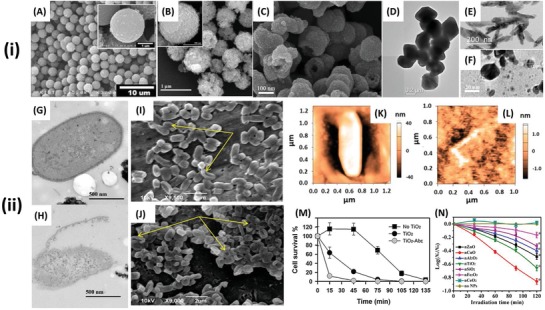

Figure 7.

i‐A–C) SEM and D–F) TEM images of antibacterial, photocatalytic nanomaterials A) TiO2 conjugated with an E. coli specific antibody. Reproduced with permission.[ 176 ] Copyright 2012, ACS Publications. B) CdIn2S4 microspheres. Reproduced with permission.[ 190 ] Copyright 2013, Elsevier. C) Porous fluorinated SnO2 hollow nanospheres. Reproduced with permission.[ 191 ] Copyright 2014, ACS Publications. D) BiVO4 nano‐octahedrals. Reproduced with permission.[ 192 ] Copyright 2016, Elsevier. E) ZnO nanorods. Reproduced with permission.[ 193 ] Copyright 2018, MDPI. F) CdS spheroids. Reproduced with permission.[ 189 ] Copyright 2014, Elsevier. ii) Visualization and quantification of the antibacterial activity of photocatalytic nanomaterials. TEM images of G) E. coli before and H) after 6 h treatment with CdIn2S4 microspheres under visible light irradiation. Reproduced with permission.[ 190 ] Copyright 2013, Elsevier. SEM images of E. coli following 3 h treatment with ZnO nanorods, I) in the dark and J) under light irradiation. The arrows indicate some of the most visibly summarized in Table damaged cells, which are more abundant in the cells exposed to light. Reproduced with permission.[ 193 ] Copyright 2018, MDPI. AFM images of E. coli K) before and L) after 3 h exposure to photocatalytic ZnO nanorods under light irradiation. Reproduced with permission.[ 193 ] Copyright 2018, MDPI. M) Inactivation of E. coli with TiO2, TiO2 conjugated with an E. coli specific antibody (TiO2‐AbE) and control under UV irradiation. Reproduced with permission.[ 194 ] Copyright 2014, Elsevier. N) Kinetics of E. coli inactivation by different types of metal‐oxide NPs under UV irradiation. Asterisks (*) denote a significant difference from the control at the 95% confidence level. Reproduced with permission.[ 176 ] Copyright 2012, ACS Publications.

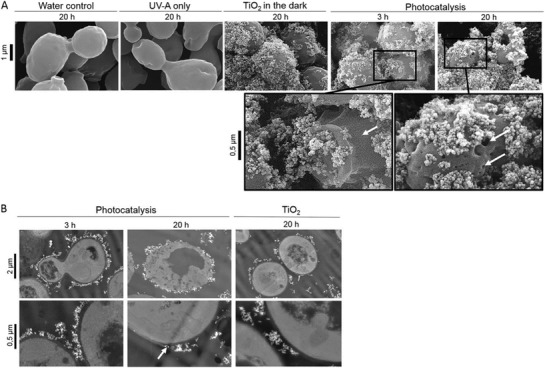

Research into the use of photocatalytic metal nanomaterials against fungi has not been as extensive as that performed for bacteria and while some studies have shown some very promising results, the differences between fungal species have been shown to significantly influence the extent of antimicrobial efficacy. Early studies assessing the antifungal potential of photocatalytic metal nanomaterials were focused on the important fungal species involved in the process of food spoilage.[ 209 ] In the context of medically relevant, pathogenic fungi, a milestone study was performed by Mitoraj et al. who doped TiO2 with carbon and tested the antimicrobial activity against the human pathogen C. albicans under irradiation with UV–vis (>385 nm) and visible (>455 nm) light. These authors found contrasting responses, with only ≈20% inactivation under visible light, while this rose to ≈80% under UV–vis irradiation.[ 204 ] In a more comprehensive study, Thabet et al. measured the photocatalytic effect on a range of fungi, incubating Saccharomyces cerevisiae, Botrytis cinerea, Candida krusei, and Rhodotorula glutinis with commercially purchased TiO2 nanospheres for 20 h, taking measurements every 5 h and calculating the viable colony forming units of the solution through dilution series and plate counts.[ 208 ] After 5 h, they demonstrated >99% inactivation of S. cerevisiae and C. krusei and ≈90% inactivation of R. glutinis, which rose to >99% following a 20 h incubation; the antifungal activity can be visualized by electron microscopy, as shown in Figure 8 . Contrastingly, B. cinerea appeared relatively unaffected by this light exposure, which the authors suggested was due to a combination of factors such as: the presence of a thick cell wall consisting of polysaccharides, the protective role of melanins and carotenoid pigment, the inability for nanoparticles to adsorb to the fungal cell wall (unexplained) and the accumulation of polyols, which may serve an antioxidative function (e.g., mannitol).[ 208 ] Alternate materials to TiO2 have also been investigated for their photocatalytic antifungal efficacy such as ZnO, which has been shown to almost completely inactivate Aspergillus fumigatus and Penicillum spp.[ 200 ] as well as Fe‐doped CuO, which was used against C. albicans with an observed >99% decrease in cell viability.[ 201 ] A summary of studies observing the antifungal activity of photocatalytic metal nanomaterials can be found in Table 2. While the use of photocatalytic metal nanomaterials against fungi has been shown to be promising, natural resistance mechanisms possessed by fungi may limit the efficacy of this treatment against a broad spectrum of pathogenic fungal species. To this end, future antifungal photocatalytic nanomaterial designs should focus on developing broad‐spectrum antifungal agents, either through increasing the efficacy of the photocatalytic effect, or more rationally, combining this activity with a secondary antifungal mechanism to enable synergistic effects.

Figure 8.

Fungal cell membrane damage as a result of photocatalytic TiO2 nanoparticles. A) Scanning electron micrographs of S. cerevisiae cells exposed to controls (20 h in water, UV‐A, or TiO2 in the dark) or treatment (3 and 20 h) under light irradiation with photocatalytic nanoparticles. B) Transmission electron micrographs of S. cerevisiae cells after 3 and 20 h of photocatalytic treatment as well as after 20 h of exposure to nonilluminated TiO2. White arrows indicate cell wall cracks and holes. Reproduced with permission.[ 208 ] Copyright 2014, American Society of Microbiology.

6.1.3. Bioconjugation for Targeted Activity

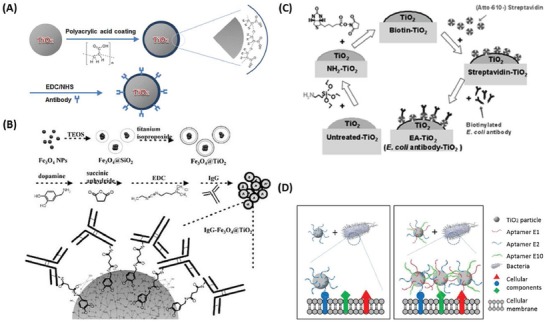

An important criterion for new antimicrobial treatment methods is their capacity to selectively target the pathogenic micro‐organism of interest. The rationale for this design is to reduce cytotoxic side effects, while simultaneously decreasing the widespread development of antimicrobial resistance; as was the case for traditional antibiotics. Additionally, following the recent paradigm shift in thinking about health as a combination of the human body and the microbiome that inhabits it, off‐targeted antimicrobial effects can often have more negative outcomes than the primary infection.[ 210 ] The main strategy for developing targeted metal nanomaterials is through bioconjugation of molecules, such as antibodies or aptamers, which selectively bind to a particular pathogenic species or strain of interest. For example, Ye et al. demonstrated a decrease of viable E. coli on the order of 104 cells from the control group after 120 min treatment using TiO2 nanoparticles bound to E. coli antibodies.[ 211 ] TiO2 nanoparticles were first treated with 3‐aminopropyltriethoxysilane, followed by N‐hydroxysuccinimidobiotin to create biotinylated TiO2 nanoparticles, which were mixed with a streptavidin solution. Biotinylated E. coli antibody solution was added, which bound to the streptavidin TiO2 nanoparticles through a sequential process of addition, ultrasonication and centrifugation (Figure 9C). They found that the E. coli antibody‐bound TiO2 nanoparticles caused flocculation of the bacterial cells and a significant reduction in concentration of E. coli following irradiation with light in the UV range, assessed through coliform specific plate counts. Importantly, they found no significant reduction in the concentration of Pseudomonas putida, which was added to the solution as a representative “non‐targeted species.”[ 211 ] In addition to the advantage of selective targeting of bioconjugated nanoparticles, these authors also found them to be more effective overall than nonconjugated particles. This is likely a result of the close proximity of the bound nanoparticles with the bacteria allowing a higher proportion of the generated ROS species to act on the cellular membrane, which would otherwise be lost to the surrounding medium.

Figure 9.

Schematic representations of the synthesis methods for bioconjugating antibodies to antimicrobial metal nanomaterials and aptamer–cell interactions. A) Schematic illustration of the preparation of bacterial target‐specific TiO2 particles, where TiO2 particles are surface‐coated with polyacrylic acid (PAA), followed by conjugation of a polyclonal antibody via an EDC/NHS coupling reaction. Reproduced with permission.[ 194 ] Copyright 2014, Elsevier. B) Preparation steps for fabricating IgG‐Fe3O4@TiO2 magnetic nanoparticles. A thin layer of silicate is first immobilized on the bare iron oxide nanoparticles followed by coating with another layer of titania. The particles are then suspended in a dopamine solution, allowing dopamine molecules to attach. The dopamine‐immobilized Fe3O4@TiO2 nanoparticles are reacted with succinic anhydride. After carboxylate terminals are generated on the surfaces of the magnetic nanoparticles, IgG molecules can be readily bound to the nanoparticles through amide bonding. Reproduced with permission.[ 212 ] Copyright 2008, Wiley‐VCH. C) Preparation of TiO2 nanoparticles with E. coli antibodies, through streptavidin–biotin interactions. Reproduced with permission.[ 211 ] Copyright 2013, ACS Publications. D) Schematic representation of TiO2 particles conjugated with a single aptamer (left) or an aptamer cocktail (right), and their binding difference on the cellular surface. Reproduced with permission.[ 213 ] Copyright 2016, Elsevier.

Additional examples of the bioconjugation of photocatalytic nanomaterials include Song et al. who used polyacrylic acid, as opposed to streptavidin‐biotin, to bind E. coli antibodies to TiO2 nanoparticles (Figure 9A); demonstrating 90% inactivity following a 15 min treatment period.[ 194 ] Interestingly, Chen et al. were able to utilize Fe3O4/TiO2 core/shell magnetic nanoparticles, bound with bacterial antibodies for selective antibacterial targeting (Figure 9B), while the magnetic properties allowed selective control of the movement of the particles in vivo.[ 212 ] In addition to antibodies, aptamers, which are specialized oligonucleotides or peptides, can be utilized to selectively bind to the target pathogenic bacteria. For example, Song et al. demonstrated that TiO2 nanoparticles bound with aptamers were more effective at reducing the concentration of E. coli than unbound nanoparticles (Figure 9D). Interestingly, they found that TiO2 nanoparticles bound with multiple aptamers demonstrated increased levels of inactivation of E. coli cells than nanoparticles bound with single aptamers, likely due to the increased selectivity generated by the multiple different aptamers, which can simultaneously target different bacterial molecules present in the same bacteria.[ 213 ] Such selectivity is important in vivo where the pathogenic species may be in a mixed culture environment.

6.1.4. Challenges and Future Outlooks for Antimicrobial Photocatalytic Metal Nanomaterials

Photocatalytic nanomaterials demonstrate considerable promise as candidates for antimicrobial applications. Since the first proof of principle study investigating the use of photocatalytic nanomaterials for their antimicrobial activity in 1985, researchers have developed antimicrobial photocatalytic nanomaterials from a wide variety of materials with high antimicrobial efficacy against a broad spectrum of pathogenic micro‐organisms, as summarized in Table 2. Targeted methods of delivery have also found success through bioconjugation of the nanomaterials with pathogen‐specific antibodies and aptamers.

While the use of photocatalytic metal nanomaterials against fungi has shown promise, natural resistance mechanisms possessed by fungi may limit the efficacy of this treatment against a broad spectrum of pathogenic fungal species. Additionally, despite successful targeting of specific bacterial species in vitro through bioconjugation, the oxygen free radicals produced by these photocatalytic nanomaterials may cause damage to the mammalian cell membrane and hence the proposition of cytotoxicity is still a prominent issue.

For this technology to be clinically successful, future strategies require the incorporation of well‐thought‐out design principles and analytical approaches, before testing the antimicrobial activity. Importantly, materials and combinations of materials that possess conduction and valence band edges above and below (respectively) the required redox potentials of relevant ROS reactions should be explored (illustrated in Figure 5). Concurrently, careful consideration of the total bandgap required to initiate the reaction is required. This should ideally remain within the energy levels equivalent to light in the NIR wavelengths, which are biomedically relevant. This can be simply calculated by utilizing Planck's constant (h)

| (1) |

where c is the speed of light and λ is the wavelength of the photon. For example, the wavelengths which are thought to be able to penetrate into deep tissue (650 ≤ λ ≤ 950 and 1000 ≤ λ ≤ 1350) are equivalent to ≈1.9–1.3 and 1.2–0.9 eV, respectively. For this reason, it is not possible to develop photocatalytic nanomaterials that can drive all the ROS reactions described in Table 1, as the total bandgap required would be too large. A simple strategy would be to utilize separate nanomaterials that have similarly small bandgaps, but different conduction and valence band edges, which can cover the entire range of ROS redox reactions. Furthermore, the development of Janus nanoparticles, composed of two or more semiconducting materials, may enable such activity to occur within a single particle, with enhanced photocatalytic activity.[ 214 ] Thorough assessments of bioconjugated nanomaterials to improve targeting of specific bacteria and fungi are necessary, as well as comprehensive in vivo experiments to determine the cytotoxic, or other potential, side effects of photocatalytic nanomaterials.

6.2. Photothermal Antimicrobial Metal Nanomaterials

6.2.1. Antimicrobial Mechanism of Photothermal Metal Nanomaterials

In addition to photocatalysis, the absorbance of light by metal nanomaterials can be utilized to induce rapid and considerable localized temperature increases through photothermal effects. Photothermal therapy was traditionally developed as a targeted treatment method for tumor cells, which used specific light‐absorbing dyes;[ 215 ] however, recent advances in nanotechnology have allowed the development of nanomaterials that can convert light to heat.[ 216 ] Photothermal activity generated from nanomaterials is highly efficient and the photothermal activity can be readily tuned to specific wavelengths by altering their size and/or shape.[ 71 , 217 ] As such, photothermal nanomaterials have been proposed as a promising solution as a targeted treatment of pathogenic micro‐organisms as they are controllable and can be localized to the immediate area surrounding the nanomaterial.[ 71 , 166 , 218 , 219 ]

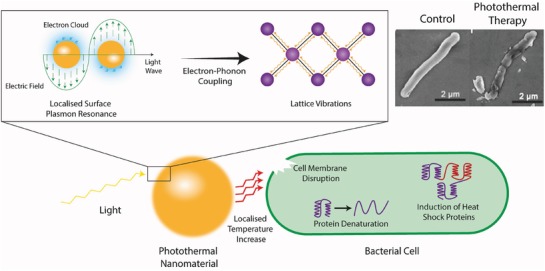

Nanomaterials composed of certain metals possess the phenomena of localized surface plasmon resonance (LSPR) when exposed to light at specific wavelengths. In short, at a wavelength close to the size of the metal nanomaterial, the electromagnetic field causes electrons in the conduction band at the surface of the metal nanomaterials to oscillate, creating a rapidly moving electron cloud.[ 71 , 220 , 221 ] This absorbed energy can be dissipated either by re‐emitting a photon, or via heat through electron–electron interactions and then electron–phonon relaxation, which induces vibrations in the metal lattice structures, these lattice vibrations are transferred into thermal energy causing localized heat around the nanomaterial[ 44 , 71 , 220 ] (Figure 10 ). This phenomenon has been predominately studied using gold; however silver,[ 222 ] copper,[ 223 ] and other materials[ 224 ] have also been investigated. By conjugating specific attachments to the nanomaterials, such as antibodies, they can specifically target the pathogen of interest, where the localized increase in temperature causes cell death through a suite of actions including denaturation of essential proteins/enzymes, induction of heat shock proteins, disruption of metabolic signaling and rupture of the cell membrane[ 71 , 85 , 218 , 219 , 225 , 226 , 227 ] (Figure 10).

Figure 10.

Schematic representation of the photothermal conversion of light to heat and the subsequent antimicrobial mechanism taking place. The electromagnetic field causes electrons in the conduction band at the surface of the metal nanomaterials to rapidly oscillate. This absorbed energy induces vibrations in the metallic lattice, via electron–phonon coupling, which is subsequently transferred into thermal energy resulting in a localized increase in temperature which is responsible for the antimicrobial activity. Top right are scanning electron micrographs of E. coli cells before (left) and after (right) treatment with photothermal nanomaterials. Reproduced with permission.[ 232 ] Copyright 2018, Wiley‐VCH.

LSPR is determined by the electron charge density at the surface of the nanomaterial, which is affected by the size, shape, and composition of the nanomaterial and hence can be altered and controlled.[ 228 ] For example, nonspherical nanomaterials can possess multiple excitation peaks as the shape allows different ways in which the electron clouds can be polarized. Furthermore, increased edges and/or aspect ratio of the nanomaterial typically results in a shift toward longer excitation wavelengths due to charge separation, while increasing the size of the nanomaterial also increases the excitation wavelength.[ 229 ] Additionally, the composition can also shift the excitation wavelength, for example, when assessing the LSPR of similar sized nanocubes on identical substrates, it was found that gold excites at longer wavelengths.[ 230 ] Advances in nanomaterial synthesis have allowed the design of customized nanomaterials such as gold nanorods,[ 231 ] nanoshells,[ 80 ] nanocages,[ 81 ] nanostars,[ 82 ] nanopopcorn,[ 85 ] and a variety of other unique shapes and similarly unique names.[ 219 ] The advantage of these shapes is that the specific SPR wavelength can be shifted into the biological NIR windows, which largely passes through human cells and tissues making in vivo applications of this technology very promising.

6.2.2. Antimicrobial Activity of Photothermal Metal Nanomaterials

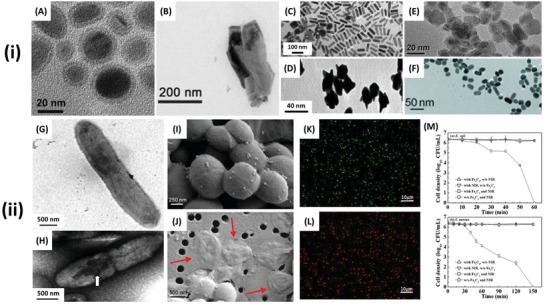

A landmark study for the use of antimicrobial photothermal nanomaterials was compiled by Zharov et al. using antibody conjugated, spherical gold nanoparticles with diameters ≈10, 20, and 40 nm, against S. aureus. They observed significant decreases in their viability following the addition of the 40 nm conjugated gold nanoparticles and laser irradiation at 532 nm, when compared to control samples which were exposed to only either the nanoparticles or the laser. A dual function bactericidal mechanism was proposed, in which the bacterial cell wall is disrupted through a combination of localized heating and bubble formation by the gold nanoparticles attached to the bacterial cell wall.[ 233 ] Since then, there have been numerous studies investigating the antimicrobial activity of photothermal metal nanomaterials such as Huang et al. who were able to successfully attach vancomycin, which binds to specific peptides on the cell wall, to polyglonal gold nanoparticles which demonstrated the prospects of targeted antibacterial activity of photothermal nanomaterials.[ 218 ] Conjugation of antibodies is also possible, for example, Norman et al. were able to covalently bind P. aeruginosa antibodies to gold nanorods and selectively target and inactivate ≈75% of P. aeruginosa cells following exposure to NIR radiation (λ = 785 nm) for only 5 min;[ 226 ] among others.[ 225 ] Similarly, Wang et al. were able to bind anti‐salmonella antibodies onto oval‐shaped gold nanoparticles, where they found ≈90% inactivation following a 10 min exposure to 785 nm laser irradiation.[ 234 ] To bind the antibodies onto the gold nanoparticles, first they capped the nanoparticle in a bilayer of positively charged CTAB. Following this, the nanoparticle surface was modified with amine groups using cystamine dihydrochloride and the antibody was covalently bound using a glutaraldehyde spacer method.[ 234 ] The successful bioconjugation of photothermal nanomaterials shows promise toward the selectivity of this treatment method. The range of metal nanomaterials used for antibacterial photothermal activity can be visualized in Figure 11 .

Figure 11.

i) TEM images of antibacterial, photothermal nanomaterials. A) Fe5C2 spheroids. Reproduced with permission.[ 235 ] Copyright 2015, Royal Society of Chemistry. B) In2Se3 nanosheets. Reproduced with permission.[ 232 ] Copyright 2018, Wiley‐VCH. C) Gold nanorods. Reproduced with permission.[ 226 ] Copyright 2008, ACS Publications. D) Monoclonal M3038 antibody‐conjugated popcorn shaped gold nanoparticles. Reproduced with permission.[ 85 ] Copyright 2011, Royal Society of Chemistry. E) BSA–CuS platelike particles. Reproduced with permission.[ 223 ] Copyright 2017, ACS Publications. F) Anti‐salmonella‐antibody‐conjugated oval‐shaped gold nanoparticles. Reproduced with permission.[ 234 ] Copyright 2010, Wiley‐VCH. ii) Visualization and quantification of the antibacterial activity of photothermal nanomaterials. TEM images of P. aeruginosa bound by antibody conjugated nanorods G) before and H) after 10 min NIR irradiation. The white arrow indicates an area of the bacterial cell surface that has suffered irreparable damage. Reproduced with permission.[ 226 ] Copyright 2008, ACS Publications. SEM images showing S. aureus treated with functionalized gold nanoparticles I) control and J) exposed to pulsed laser irradiation at 532 nm. Red arrows indicate damaged bacterial cells. Reproduced with permission.[ 225 ] Copyright 2015, Dove Press. Confocal laser scanning microscopy (CLSM) images of E. coli exposed to BSA–CuS nanoparticles K) before and L) after NIR irradiation. Bacterial viability determined through live/dead staining where green indicates live bacteria and red indicates bacteria with significant membrane damage. Reproduced with permission.[ 223 ] Copyright 2017, ACS Publications. M) Inactivation effects of Fe5C2 nanoparticles (50 mg L−1, pH 6) and NIR irradiation for E. coli (top) and S. aureus (bottom). Error bars represent standard deviations from triplicate experiments (n = 3) . Reproduced with permission.[ 235 ] Copyright 2015, Royal Society of Chemistry.

While gold is the most commonly used material for photothermal therapy, researchers have also found success with other metal nanomaterials, highlighting the versatility of this treatment method. For example, Huang et al. used copper–sulfide (CuS) nanocomposites, bioconjugated with bovine serum albumin (BSA) to improve the biocompatibility of the nanocomposites. They demonstrated over 80% cell death of both the Gram‐positive S. aureus and Gram‐negative E. coli following the addition of 50 ppm of the BSA–CuS nanocomposites and irradiation to a NIR laser at 980 nm for 45 min.[ 223 ] Additionally, D'Agostino et al. utilized triangular silver nanoplates, with sides approximately 200 nm, which demonstrated inactivation of S. aureus (97%) and E. coli (>99%) cells respectively, following irradiation at 808 nm (260 mW cm−2), for 15 min.[ 222 ] Interestingly, they were able to affix the nanoplates to glass surfaces to demonstrate the effectiveness of photothermal nanomaterials as a stimuli‐activated surface coating, for purposes such as biomedical implants.[ 222 ] Furthermore, they explored the relationship between the nanoscale dimensions of the triangular nanoplates and the specific excitation wavelength to initiate the photothermal response, highlighting the controllability of this technique, which will logically become easier to manipulate as synthesis processes of metal nanomaterials continue to rapidly improve. Additional materials have also been utilized, such as vancomycin‐modified polyelectrolyte‐cypate coated silica nanoparticles (SiO2‐Cy‐Van), which were found to possess successful activity against methicillin‐resistant S. aureus both in vitro and in vivo following 5 min irradiation at 808 nm.[ 224 ] Further studies and materials used for antimicrobial photothermal nanomaterials can be found in Table 3 .

Table 3.

A comparison of photothermal metal nanomaterials for antimicrobial applications

| Material | Shape | Size | Concentration | Irradiation | Micro‐organisms | Antimicrobial efficacy a) | Log reduction | Treatment parameters | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| Bacteria | |||||||||

| Au | Sphere |

10 nm 20 nm 40 nm |

NR | λ = 525 nm | S. aureus |

≈20% ≈60% ≈90% |

NR | 100 laser pulses. Pulse width, 8 ns; and pulse energy, 1 µJ (0.2 J cm−2) | [ 233 ] |

| Au | Star | 50–100 nm | 1.1–1.4 × 1014 cm−2 (surface coverage) | λ = 808 nm | S. aureus | ≈96% | 1.5 |

90 mW cm−2, 30 min |

[ 82 ] |

| Au | Rod |

18 nm width 68 nm length |

NR | λ = 785 nm | P. aeruginosa | 75% | NR |

≈50 mW, 10 min |

[ 226 ] |

| Au | Oval |

≈10–30 nm width ≈20–40 nm length |

NR | λ = 670 nm | Salmonella typhimurium | 90% | NR |

40 mW, 10 min |

[ 234 ] |

| Au | Popcorn |

Not specified (≈15–40 nm) |

NR | λ = 670 nm | Salmonella typhimurium | >99% | NR |

200 mW cm−2, 20 min |

[ 85 ] |

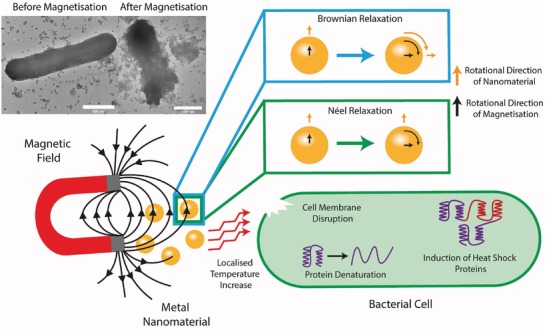

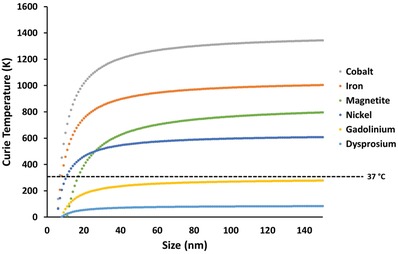

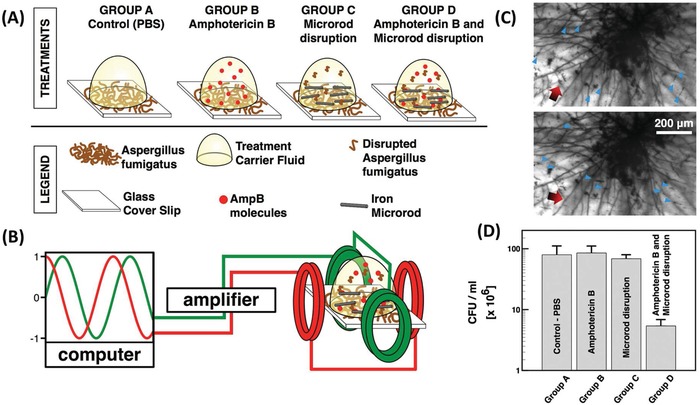

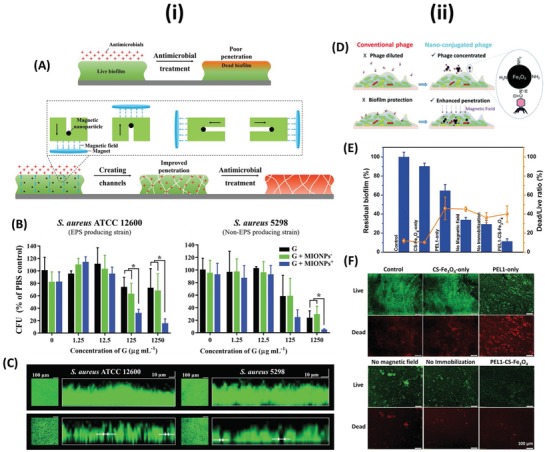

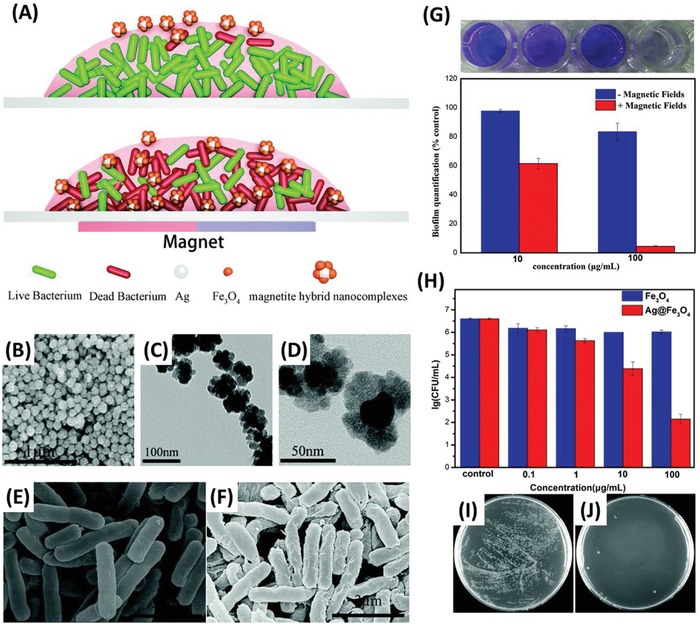

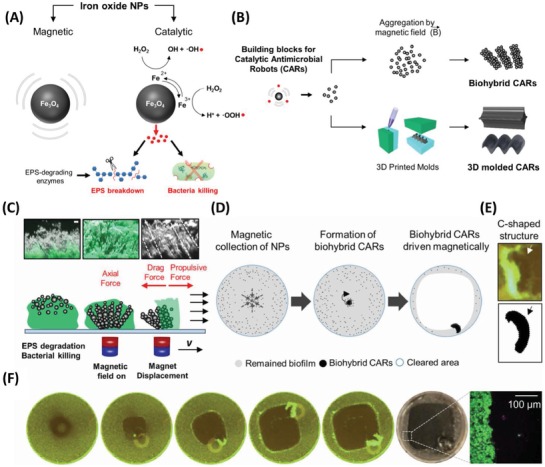

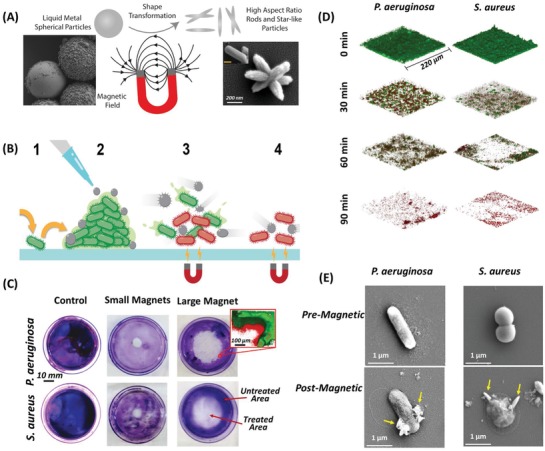

| Van‐Fe3O4–Au | Eggs | 50–100 nm | 168.75 µg mL−1 | λ = 808 nm |