Abstract

Oral administration is a pillar of the pharmaceutical industry and yet it remains challenging to administer hydrophilic therapeutics by the oral route. Smart and controlled oral drug delivery could bypass the physiological barriers that limit the oral delivery of these therapeutics. Micro- and nanoscale technologies, with an unprecedented ability to create, control, and measure micro- or nanoenvironments, have found tremendous applications in biology and medicine. In particular, significant advances have been made in using these technologies for oral drug delivery. In this review, we briefly describe biological barriers to oral drug delivery and micro and nanoscale fabrication technologies. Micro and nanoscale drug carriers fabricated using these technologies, including bioadhesives, microparticles, micropatches, and nanoparticles, are described. Other applications of micro and nanoscale technologies are discussed, including fabrication of devices and tissue engineering models to precisely control or assess oral drug delivery in vivo and in vitro, respectively. Strategies to advance translation of micro and nanotechnologies into clinical trials for oral drug delivery are mentioned. Finally, challenges and future prospects on further integration of micro and nanoscale technologies with oral drug delivery systems are highlighted.

Keywords: Drug delivery devices, Micro and nanocarriers, Micro and nanoscale technologies, Oral drug delivery, Tissue models

Graphical abstract

1. Introduction

Oral delivery has been one of the most commonly used approaches for drug administration in the body due to its high patient compliance, low cost, non-invasiveness, and ease of use [1,2]. A multitude of therapeutic compounds, including synthetic small molecules and biologics, have been administered orally. However, oral drug delivery poses significant challenges to achieving efficient therapeutic outcomes. This is primarily due to the multitude of biological barriers that are present throughout the gastrointestinal (GI) tract that a drug carrier must navigate through. Some of these biological barriers to drug delivery include harsh acidic pH environments in the stomach, degrading enzymes that render drugs ineffective, the inefficient penetration of drugs across GI tissue barriers and into systemic circulation, and the eventual clearance of drugs through the GI tract, which may occur prior to drug release. To overcome these barriers, the delivered dosage of drugs is often higher than what is needed therapeutically, as the bioavailability of the compound is often reduced due to factors like enzymatic degradation and poor permeation through the intestinal wall. However, it is important that the drug concentration should not exceed the level that can cause toxicity in the body, as has been observed with some DNA and protein based drugs above critical concentrations [3,4]. On the other hand, if a drug at a non-toxic concentration level passes the physiological barriers of the GI tract, its delivered dosage to target site may not be effective [5].

An ideal oral drug delivery system has yet to be realized, by which drugs can be delivered to a biological target at appropriate concentrations with tunable dosage windows. Several limitations of delivery of drugs through the oral cavity are due to physiochemical properties of drugs. In particular, Lipinski rules or the Rule of Five (ROF) are used for discovering new drugs and to improve the efficacy of developed drugs [6]. The ROF details four properties of drug molecules including: that the molecular weight should not exceed 500 Da, logP values should be under 5, total number of hydrogen bond donors should be 5, and number of the hydrogen acceptors should not be more than 10. The total ROF score lies between 0 and 4. Molecules with an ROF score of more than 4 are considered to be marginal drug molecules and need to have further development. However, some drug molecules do not follow the Lipinski rules, such as proteins and RNA molecules. One of the most well-studied protein therapeutics for oral administration is insulin. Currently, insulin is administered via daily injections and 45-60% of diabetic patients intentionally skip insulin doses out of dread of injections [7]. It is therefore likely that oral administration of insulin would increase patient compliance and improve therapeutic outcomes in diabetic patients. However, the bioavailability of orally administered insulin is severely limited by the physiological barriers of the GI tract, such as acidic pH, presence of proteases, and the limited transport of insulin across GI epithelial barriers into the bloodstream [8].

By incorporating drugs such as insulin into materials-based carriers, it may be possible to overcome or circumvent the physiological barriers that limit oral administration efficacies. In designing materials for oral drug delivery, the drug carrier should preserve therapeutic efficacy of the drug cargo for effective use in humans. There are two major goals for designing materials for oral drug delivery: (1) the effective targeting of drugs to a GI section of interest, and (2) the release of drugs from the GI into the bloodstream for systemic circulation. For both of these goals, the design and development of drug delivering materials need to account for the mucosal microenvironment of the GI system, intestinal physiology, and target diseases. Moreover, chemistry, size, shape, metabolism, and bioavailability of drugs play a crucial role in the design of effective oral drug delivery systems.

Micro and nanotechnologies have seen widespread use in oral drug delivery systems with the goal of improving the efficiency of delivery systems. These technologies have been used for many applications, including drug discovery via development of high throughput screening assays [[9], [10], [11]], miniaturization of therapeutic and diagnostic tools, tissue engineering and, oral drug delivery [12,13]. Some major problems in oral drug delivery have been solved by fabrication of micro and nanocarriers with precise control over their architecture and size. These efforts are a part of controlled drug delivery systems dating back to the 1950s [14,15]. In recent years, dynamic oral delivery systems have been fabricated using micro and nanofabrication technologies by which sensing, recording, and stimulating biological systems can be achieved for optimized drug delivery [16,17]. In addition, microfabrication techniques have been used to make biomimetic GI tract in vitro models in which the body’s response to drugs can be recapitulated and used for better design of drugs.

In this work, a brief review of physiological barriers to oral drug delivery is given (Fig. 1 ). We then discuss micro- and nanofabrication techniques and the subsequently fabricated drug carriers that have been used as oral drug delivery systems, with a focus on the material components, fabrication technologies, and drug loading efficiencies. We describe in detail the general chemical and physical strategies to functionalize diverse types of drug carriers for oral drug delivery applications with a focus on bioadhesion and tissue barrier remodeling. Specific examples of how engineered drug carriers have been used successfully to navigate the GI tract and improve oral drug delivery are then provided. We then discuss applications of fabrication technologies for modeling of the GI tract. Following that, clinical trials in oral drug delivery systems using fabrication technologies are mentioned. Finally, we highlight challenges and future directions in using micro- and nanofabrication technologies for oral drug delivery.

Fig. 1.

Micro- and nanoscale technologies enable fabrication of oral drug carriers as well as human tissue-on-a-chip models for precision medicine applications.

2. Physiological barriers to oral drug delivery

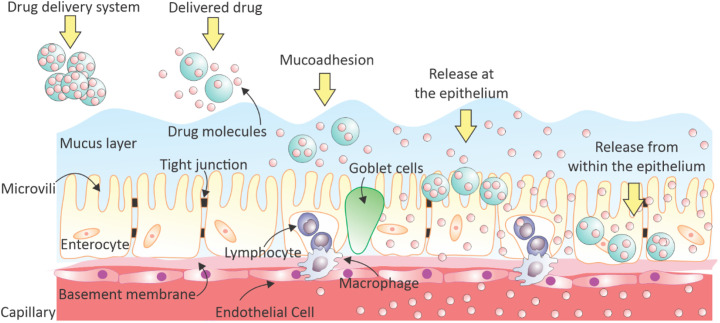

Some limitations of oral drug delivery systems are governed by GI anatomy, physiology, and biochemistry. The skin is the largest interface between the human body and the external environment [18,19]. In a healthy adult, the human skin has a surface area of approximately 2 m2. By comparison, the absorption mechanism of orally delivered drugs in the intestinal epithelium has more chemical and physical restrictions, as it has a much larger surface area (300 – 400 m2) [20]. In general, the drug is swallowed and enters the GI tract and it is released at the intestine proceeds by diffusing inside the mucus layer as shown in Fig. 2 . The mucus in the small intestine is discontinuous, whereas there are two layers in the stomach and large intestine (colon) [21]. The drug is delivered through the mucus layer and from there diffuses through pathways involving a long path through tight junctions (TJs) as well as epithelium cells. This process continues until the drug is carried all the way through the capillary layer covering the epithelium layer.

Fig. 2.

Schematic illustration of drug release and absorption mechanisms for orally delivered drugs in the large surface area of human intestinal epithelium.

The GI tract consists of the oral cavity, esophagus, stomach, small intestine and colon, each with different properties that need to be considered when designing delivery systems and studying drug release mechanisms (Table 1 ) [22]. In general, drug uptake in the GI tract is restricted by complex physiological barriers in the different GI tract regions. The GI tract has a naturally low permeability to the bloodstream and foreign molecules, such as orally delivered drugs [22]. The bottlebrush-like architecture of mucin in the lipid-rich matrix of mucus, embedded gastric glands in the stomach with the acidic environment, residence time, microbiome, and permeability across the intestinal epithelium should be considered for the design of carriers that facilitate oral delivery of small molecules, proteins, and peptides [23]. The main obstacles that exist for oral drug delivery are the biochemical, mucus diffusional, and cellular permeability barriers of the GI tract. The site of drug absorption is determined by the type of drug, as well as local environmental conditions such as pH, enzymes, mucus barriers, drug residence time, and GI surface area [24].

Table 1.

Characteristics of different segments of the human GI tract [22].

| pH | Length (cm) | Mean Diameter (cm) | Mucus Thickness (μm) | Mucus Turnover Rate (hours) | |

|---|---|---|---|---|---|

| Stomach | 0.8 – 5 | 20 | N/A | 245 ± 200 | 24 – 48 |

| Duodenum | ~ 7 | 17 – 56 | 4 | 15.5 | 24 – 48 |

| Jejunum | ≥7 | 280 – 1000 | 2 – 2.5 | 15.5 | |

| Ileum | ≥7 | 3 | 15.5 | ||

| Colon | 7 – 8 | 80 – 313 | 4 – 4.8 | 135 ± 25 | 24 – 48 |

2.1. Biochemical barriers

Enzymatic and pH degradation act together as the major biochemical barriers for the bioavailability of orally administered therapeutics (Fig. 3a). The presence of drug-degrading enzymes and acidic pH results in an approximately 94-98% loss of ingested biologic drugs due to deamidation, oxidation, or hydrolysis [25]. The stomach’s digestive fluid is composed of hydrochloric acid, protein-digesting enzyme pepsin, and mucus secreted by gastric glands, which cause an acidic environment (pH = 1.2–3). In addition to the harsh acidic environment of the stomach, digestive enzymes such as pepsin also pose challenges for oral drug delivery. Lipases in the stomach can also contribute to the hydrolysis of drugs with hydrophobic regions. The small intestine can also account for the digestion of drugs, as digestive enzymes, such as trypsins, chymotrypsins, carboxypeptidases, and elastases are present in high concentrations [26]. Finally, the colon provides a longer residence time of up to 20 h, low concentrations of digestive enzymes, and relatively neutral pH values of 6–6.7, as well as low fluid volumes to drug ratios [27].

Fig. 3.

A schematic of physiological barriers in oral drug delivery including: (a) biochemical barriers, (b) mucus barrier, and (c) cellular barriers to oral drug delivery. Reprinted by permission from Springer Nature [26] Copyright (2019).

2.2. Mucosal diffusion barrier

In addition to the above-mentioned physiological barriers (pH and enzymes), mucus with a viscoelastic and hydrogel- like structure creates a strong barrier for the penetration of therapeutics from the lumen to the underlying epithelium (Fig. 3b). The direct interaction of therapeutics with epithelial cells is restricted by two mucus layers: the outer loosely adherent layer and the inner firmly adherent layer [26]. Mucus is secreted by goblet cells, with turnover rates of every 24–48 h, to eliminate the attachment of potentially harmful compounds and bacteria. The majority of mucus is composed of mucin glycoproteins, which form a viscous gel to entrap foreign particles [26]. Mucus is also composed of proteins, carbohydrates, nucleic acids, lipids, salts, antibodies, and other active proteins [23]. Thus, it creates a safeguard and facilitates a nutrient-rich environment for bacterial colonization and antimicrobial molecules.

2.3. Cellular permeability barrier

The intestinal epithelium is the outermost layer of cells exposed to luminal contents. It is composed of TJs and three different kinds of cells: enterocytes, goblet cells, and Microfold cells (M-cells) (Fig. 3c) [28]. Enterocytes are the most abundant cells of the epithelium layer and enhance the transportation of nutrients and water from the gut lumen to the bloodstream. Mucus-secreting goblet cells comprise 10–20% of epithelial cells, while M-cells that cover Peyer's patches represent <1%. M-cells are responsible for antigen sampling and are important drug targets since they are less shielded by mucus [26]. TJs are paracellular barriers for the transportation of drugs between intestinal epithelial cells [29].

Methods for drug absorption into the bloodstream relies on interactions between the therapeutic and epithelial cells whether the drug is transported through the cell or between the cells through TJs. The absorption pathways are: a) transcellular pathways through epithelial cells; b) paracellular pathways through the TJs between adjacent epithelial cells; c) lymphatic absorption via M-cells of Peyer’s patches; d) receptor and transcytosis-mediated endocytosis, commonly conducted by the vitamin B12 uptake pathway or by hydrogen-coupled peptide transporters, transferring receptors, and IgG neonatal receptors [26]. In the next sections we will discuss how micro and nanoscale technologies allow for the bypass of biochemical and mucosal diffusion barriers to enable successful cellular uptake.

3. Micro and nanoscale fabrication techniques

Micro-/nanoscale fabrication technologies, including lithographic techniques and microfluidics, have opened up important opportunities to further develop the fields of tissue engineering and drug delivery [1,30]. Microfabrication has been implemented for drug delivery because of its capability to combine different characteristics, including the ability to make precise shapes and sizes (e.g. needles, non-symmetrical features) that increase the contact area of the drug delivery system with the GI tract and precise sizes or reservoirs (multiple or single) to control drug release. These microfabricated devices can be further engineered to be stimuli-responsive and bioadhesive. In addition to drug delivery applications, microfabrication technologies provide great advantages in the generation of biomimetic GI tract prototypes, integrating physiological cues, flow, and biomimetic structures [1,31]. There are a variety of methods to fabricate micro- and nanoscale systems for controlled drug delivery applications, including emulsion, assembly, photolithography, mold replication, micromachining, micromilling, deposition, etching, and laser ablation [32,33].

3.1. Emulsion and self-assembling systems

Emulsion and self-assembly based systems of fabrication are some of the most widely used techniques for the development of nano and microparticles. Emulsion fabrication, as well as nano-precipitation techniques, rely on the phase separation of hydrophobic polymers in aqueous solution [[34], [35], [36]]. Such oil-in-water emulsions are frequently used with biocompatible polymers, such as poly(lactic-co-glycolic acid) (PLGA) and polycaprolactone (PCL). These emulsion techniques are compatible with drug encapsulation, either with hydrophobic drugs and single emulsion techniques, or with hydrophilic drugs and a double emulsion technique, which creates water-in-oil-in-water particles. Emulsion techniques allow for the fabrication of particles of varying sizes, ranging from tens of nanometers to hundreds of microns [37]. The size of the particles is dictated by the shear imparted during the emulsification process which is affected by the properties of solutions, as well as the concentration of polymer and surfactant in the aqueous phase. The surfactant controls the phase separation behavior during emulsification [38]. PLGA-based reverse emulsions are not able to generate hydrophilic polymer particles in oil phase. Therefore, these emulsions are less common for clinical applications in oral drug delivery where the particle needs to stably traverse aqueous environments. However, in general, some PLGA-loaded particles have been used in clinic for other drug delivery systems.

Self-assembly fabrication approaches are directed by a variety of noncovalent forces such as hydrophobic-hydrophilic and electrostatic interactions. They can offer more precise control than standard emulsion or precipitation techniques and allow for the fabrication of diverse shapes including spherical, fibrillar, and ellipsoidal particles [[39], [40], [41]]. Self-assembling systems are typically size-limited to the nanoscale, with the particles commonly reported in the tens of nanometers to low hundreds of nanometers in diameter. Similar to emulsion techniques, self-assembling systems have been used to encapsulate both hydrophobic and hydrophilic cargo for oral drug delivery applications.

3.2. Electrospinning

In electrospinning, a high voltage source is used to make micro- or nanofibers from a polymer solution or melt. An electrostatic interaction between a grounded collector and charged polymer solution is formed when the polymer is expelled from a metal needle, forming a cone at the base of the needle called a Taylor cone. A fiber jet is ejected from the Taylor cone as the electric field strength exceeds the surface tension of the liquid. By travelling the fiber jet through the air, the solvent evaporates, consequently results in the deposition of solid polymer fibers on the collector. Fibers generated by this process usually have diameters on the order of hundreds of nanometers. The capability to simply generate materials at different sizes in a rapid and simple manner has made a great interest in electrospinning for tissue engineering and drug delivery applications [42,43]. Researchers have widely used this technology in drug delivery because it is easy to modulate the release profile of drugs based on properties of polymeric materials and it is compatible with a variety of drugs and biopolymers [44].

3.3. Lithography

Photolithography involves the transferring of a photomask’s pattern onto a photoresist by exposure to light [1,45,46]. The photoresist layer is employed to transfer the pattern to a material after development. The wavelength of light exposure is the dominant limitation of photolithography. High resolution nanostructures can be made using more advanced techniques, such as ion beam lithography and electron beam lithography [33].

Soft lithography is a complementary version of photolithography. While photolithography has worked well to deal with photoresists [47], soft lithography expands the capabilities of photolithography. Soft lithography can process a variety of elastomeric materials. Polydimethylsiloxane (PDMS) is commonly used for soft lithography applications due to its biocompatibility, low cost, chemical inertness, low toxicity, mechanical flexibility and durability, and versatile surface chemistry. Additionally, fabricating PDMS devices requires minimal equipment [48,49].

3.4. Microfluidics

Microfluidic systems are capable of handling and transporting small volumes of fluids through microchannels and they can be created with photo and soft lithography. Microfluidics have been used as a tool for designing drug delivery systems [45,50]. Drug delivery to target sites can be done in an efficient and well-controlled manner with desired rates using microfluidic platforms via implantation, localization, precise control, automation, and integration of the platform [51]. Microfluidics can fabricate materials with high precision and recapitulate in vivo conditions for drug screening [[52], [53], [54]] and drug discovery [54,55] because of its capability to provide physiologically relevant fluid flow [1]. This technology has become an essential part of cellular assays for the analysis of oral drug absorption.

Recently, different microfluidic-based platforms have been developed to produce and screen drug nanocarriers. Microfluidic drug development platforms provide high-throughput, reproducible, and low-cost methods for producing, screening, and optimizing nanocarriers. The properties of synthesized nanocarriers, such as morphology, drug loading capacity, and release kinetic parameters, can be easily and effectively be modified and optimized by adjusting the channel geometries and flow rate. Microfluidics facilitate the efficient and low cost production of various micro and nanoparticles, composed of different materials and therapeutic agents, with high loading capacity and controlled release at small scale, which minimizes the amount of required reagents, as compared to bulk mixing methods [56].

Microfluidic-based synthesizers are classified as diffusion and droplet-based methods (Fig. 4 ) [57]. Hasani-Sadrabadi et al. fabricated a microfluidic device for generating core-shell chitosan-based nanoparticles for oral delivery of hydrophobic anti-cancer drugs to treat colorectal cancer tumors [58]. The core of the nanoparticles was composed of a hydrophobic modified N-palmitoyl chitosan for efficient loading of hydrophobic drugs. The core also allowed for the formation of nanoparticles through the self-assembly of chitosan chains, without using a cross-linking agent. The self-assembly of chitosan chains occurred in the first microreactor with hydrodynamically focused flow controlling the mixing time of flow streams. A Tesla micromixer was also designed for efficient mixing and coating of nanoparticles by pH-responsive layer of Eudragit ((pH-sensitive poly(methyl methacrylate)) in a controlled manner. The Coanda effect generated in this Tesla-designed micromixer enhances mixing efficiency. It results in deflection of a part of the flow toward the narrow side of the channel and flow of other part through the curved side for an efficient mixing of two flow streams. In the latter study, the thickness of the shell in synthesized particles was controlled by the ratio of sheath flow rate to the main flow rate.

Fig. 4.

Microfluidic approaches to fabricate nanocarriers for oral drug delivery. Different diffusion- and droplet-based microfluidic platforms for preparation of nanoparticles including (a) microfluidic continuous flow, (b) microfluidic mixer, (c) microfluidic droplet generator, (d) microfluidic processor. Reprinted from [57] Copyright (2013), with permission from Elsevier.

Although the generation of particles can be controlled by tuning the flow rate in diffusion-based mixing methods, the continuous flow regime limits efficient diffusion and the reaction between materials boundaries between separate flow streams. In droplet-based techniques, each droplet serves as a microreactor for an independent reaction, resulting in higher production efficiency for drug-loaded nanocarriers. This method allows for precise control of nanocarrier size, drug loading efficiency, and total amount of nanocarrier produced. Nano-in-micro platforms can be introduced based on droplet-based methods to prepare nanoparticles encapsulated inside microparticles. Araujo et al. produced a multifunctional composite for the oral delivery of a mixture of glucagon-like peptide-1 and an enzymatic inhibitor (dipeptidyl peptidase 4) as antidiabetic drugs for synergistic therapy using droplet-based microfluidic techniques [59]. The glucagon-like peptide-1 was first loaded in different PLGA and mesoporous silicon biomaterials to limit its rapid degradation in the intestine. The resulting nanoparticles were further functionalized by mucoadhesive polymers, such as chitosan and cell penetrating peptides. Similar Nano-In-Micro platforms were utilized in several other investigations to encapsulate nanoparticles inside of microstructures, such as halloysite nanotubes-polymer, mesoporous silicon-solid lipid, and mesoporous silicon-polymer composites, for oral drug delivery applications [[60], [61], [62]].

3.5. Three-dimensional Printing

Three-dimensional (3D) printing technology is a promising fabrication technique that has received wide interest in biomedical engineering and drug delivery applications to provide complex drug release profiles, precise drug dosing, novel drug delivery devices, and 3D printed polypills [63]. 3D printing technology offers low-cost applications compared to conventional systems since it does not need several unit operations and requires minimal human intervention [[64], [65], [66], [67]]. Typically, 3D printing works through the digitally-controlled and layer-by-layer deposition of materials to make different 3D constructs and desired geometries without the need for molds or machining [[68], [69], [70]]. This technology can offer precise and personalized dosing for treatment of different patients [64,71]. However, 3D printing technology may need multiple steps and sophisticated equipment to synthesize oral delivery platforms in a commercial setting.

Spritam® [72] was approved as the first 3D printed drug tablet by the Food and Drug Administration (FDA) and this led to great interest into the implementation of 3D printed drug delivery systems. The capability to handle low volumes of fluids with spatial control facilitates the preparation of devices with interesting compositions and geometries. The flexibility of 3D printing enables the preparation of systems with multiple drugs and specific release profiles [73]. Various 3D printing technologies can be employed for the development of pharmaceutical formulations. Technologies such as digital light processing, selective laser sintering, continuous liquid interface production, stereolithography, fused deposition modelling (FDM), material jetting, inkjet deposition, and binder jetting are the most common 3D printing technologies that have been implemented in pharmaceutical research and customized drug formulation [68,74]. The most challenging part of using 3D printing for the fabrication of drug delivery systems is the development of functional inks that retain the features necessary for sustain release and bioadhesion. Some examples of such inks are commercially available (e.g., Resomer® filaments for 3D printing by Evonik). These could be potentially used for the development of oral delivery carriers.

Progress in 3D printing technology has led to innovative medical devices, as well as customized drug delivery systems. 3D printing technology offers multiple formulation options compared to conventional drug delivery systems. Moreover, it provides an opportunity to load multiple drugs into a single device and make multifunctional drug delivery systems and dimension-specific drug formulations to attain tunable drug release profiles [63]. More recently, two-photon lithography technologies were designed to offer 3D printing capabilities at nanoscale that could be interesting for oral delivery systems where a nanoparticle has to be of specific shape.

4. Micro and nanoscale carrier types

The unique physiochemical properties and high surface area to volume ratio of nanoparticles facilitate high loading of drugs through encapsulation or formation of chemical-physical bindings with their functional groups. The stability of some nanoparticles in aqueous physiological environments allows for successful loading and delivery of poorly water-soluble drugs [75]. Additionally, nanoparticles can be functionalized using different targeting or imaging agents in order to be utilized for imaging and targeted drug delivery applications [76]. Specifically, drug delivery using biocompatible nanocarriers has been introduced as an effective solution to overcome some challenges involved in oral drug administration, particularly for drugs with low stability, bioavailability, and solubility. Nanoparticles can protect drugs from the acidic environment of GI and the secretion of mucus to enhance membrane permeability, which promotes drug absorption and bioavailability. Bioadhesive properties of nanoparticles enhance the permeation of drugs by increasing residence time in the GI tract [77].

Microparticles are common oral delivery systems in addition to nanoparticles, and offer the means to improve the bioavailability of pharmaceuticals through the control over shape, size, geometry, and functional characteristics of the particle [[78], [79], [80], [81]]. During the past few decades, microparticle technology has been extensively applied for various applications in therapeutic and pharmaceutical fields, such as the delivery of anti-inflammatories [82,83], antibiotics [84,85], chemotherapeutics [86,87], proteins [88], and vitamins [89,90]. Microparticle sizes range from 1 to 1000 μm and they exist in various structures [91]. Microparticles may be characterized as either homogenous or heterogeneous structures depending on the formulation and processing.

Using the techniques described above, drug carriers can be fabricated in multiple size regimes from different materials, with tunable physical and chemical properties. We will briefly describe some of the different classes of carriers, before discussing functionalization strategies and methods of targeting the GI system or systemic bloodstream circulation via oral administration of these carriers.

4.1. Lipid-based nanoparticles

Lipid-based nanoparticles, such as solid lipid nanoparticles (SLNs) and liposomes, are a group of nanoparticles used extensively for oral drug delivery due to their excellent biocompatibility, similarity with biological membranes, and drug loading capacity. Liposomes were the first nanocarriers approved by FDA for clinical use [92]. They are composed of an aqueous core, which encapsulates hydrophilic drugs, and an amphiphilic lipid bilayer, which allows for the loading of hydrophobic drugs [93] (Fig. 5a). Additionally, they can be utilized as the carrier of biomolecules like peptides, antigens or antibodies which are covalently attached to the polyethylene glycol (PEG)-coated (PEGylated) surface of liposomes (Fig. 5c). Functionalization of liposomes with PEG limits their recognition by phagocytic cells, resulting in longer circulation time and enhanced biodistribution [94]. Furthermore, different targeting agents can be conjugated to the external surface of the liposomes for the enhanced targeted delivery of therapeutic agents to specific cells. The encapsulation of hydrophilic drugs and biologics inside of liposomes significantly improves their cellular absorption [95,96]. However, the efficiency of conventional phospholipid or cholesterol-based liposomes is seriously affected by instability of their lipid vesicles and phospholipid hydrolysis or oxidation in the GI tract. Therefore, chemical and physical functionalization is employed to increase their residence time in the intestine and enhance their stability, as we will discuss in later sections.

Fig. 5.

Fabrication and characterization of nanocarriers for oral drug delivery. (a) Schematic image of possibilities for drug loading and functionalization with different targeting and therapeutics ligands in liposomes. Reprinted from [92] with permission from Elsevier. (b) A strategy for loading hydrophilic drugs in the core of solid nanoparticles (blue color) by generation of a hydrophilic viscose phase in the core. Reprinted from [101], Copyright (2016), with permission from Elsevier. (c) A two-step preparation method for insulin-loaded core-shell nanoparticles composed of a modified chitosan core coated with thiolated hyaluronic acid through electrostatic [114]. Copyright (2018) Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission. (d) Self-assembly of cationic copolymers (yellow color) with anion biomacromolecules (green color) to form polymer micelles with targeting agents can improve mucoadhesion and can generate polymeric networks of micelles. Reprinted (adapted) with permission from [115] Copyright (2005) American Chemical Society.

SLNs contain a monolayer phospholipid shell and a solid lipid core [97]. These nanoparticles can be utilized for encapsulation of lipophilic ingredients and insoluble drugs. SLNs are prepared from synthetic or natural biodegradable and biocompatible lipids, such as fatty acids, triglycerides, steroids, and phospholipids. They have shown high stability in the harsh conditions of the GI, as compared to other lipid nanoparticles, such as liposomes. Functionalizing and non-covalent coating of SLNs with carboxymethyl chitosan can further enhance their stability and drug bioavailability [98]. Several investigations reported higher oral bioavailability of hydrophobic drugs, such as nitrendipine and nimodipine, loaded in SLNs [99,100]. However, the encapsulation of hydrophilic drugs in SLNs is limited due to the particle’s hydrophobic nature. Incorporation of a SLN core with hydrophilic viscosity-enhancing polymers, such as PEG, through a water-oil-water double emulsion method is proposed for higher loading efficiency of hydrophilic drugs in the core of SLNs. In this strategy, the core of orally administered SLNs consists of a solid lipid core and a hydrogen-bonded rich aqueous phase encapsulating insulin, which is either dispersed in the lipid phase or is formed like a central core in the lipid matrix (Fig. 5b) [101]. Although surface functionalization of SLNs with PEG enhances their hydrophilicity, a reduction in muco-adhesion of SLNs is also observed.

4.2. Polymeric nano and microparticles

Natural polymers, synthetic polymers or their combinations, cellulose derivatives, polysaccharides or proteins, and waxes of plant or animal origin can be used to prepare nano or microstructural oral drug delivery materials. Polymeric particles can interact with the mucus through electrostatic, van der Waals, hydrophobic, or hydrogen-bonding interactions, which may lead to long residence time of drugs in the absorption region [102]. However, more research is required to reduce their undesired adhesion to non-target regions [103]. Several studies have demonstrated more efficient absorbance of hydrophobic polymeric nanoparticles to the Peyer's patches when compared to less hydrophobic or hydrophilic particles [104], showing the important role of hydrophobicity in polymeric nanoparticles.

Polymeric nano and microparticles made of PLGA, poly(lactic acid) (PLA), PLA-PLGA copolymer, poly(acrylic acid) (Carbopol) and poly(N-isopropylacrylamide) have been extensively explored in the pharmaceutical field as carriers for oral drug delivery due to their biocompatibility, enzymatic degradation, bioadhesion, and rapid removal in the mucus. The biodegradability and biocompatibility of these polymers have been approved for various medical and pharmaceutical applications, including drug delivery by both the FDA and the European Medicine Agency [102].

Of the polymers available, PLGA is one of the most commonly researched polymers for oral drug delivery, owing to its FDA approval [105], biocompatibility, and biodegradability. In particular, PLGA is suitable for oral delivery of water insoluble anti-cancer drugs, such as paclitaxel and curcumin, due to its hydrophobic nature [106]. The encapsulation of hydrophobic anti-cancer drugs in PLGA nanoparticles resulted in enhanced bioavailability of drugs, which is due to improved aqueous stability of loaded drugs in PLGA nanoparticles, compared to free drug, and sustained drug release by degradation of the PLGA nanoparticles [106].

In addition to nanoparticles, different microparticle, polymer-based systems have been introduced for oral drug delivery for in vivo and in vitro studies which are summarized in Table 2 . A natural polymer-based microencapsulation system was proposed by Vasiliu et al. They prepared microparticles based on polyelectrolyte complexes between two polysaccharides (xanthan gum and gellan) and an acrylic ion exchange resin to obtain a novel antibiotic delivery system. The effects of contact time, temperature, and drug concentration on the patch efficacy were optimized using batch adsorption studies [107]. Wang et al. reported a monodisperse and temperature-induced self-bursting microcapsules for encapsulating hydrophobic compounds. The proposed microcapsules had a hydrophobic core and a thermo-responsive shell comprised of poly(N-isopropyl acrylamide) and embedded superparamagnetic Fe3O4 nanoparticles [108]. Koetting et al. designed hydrogel microparticles and used them for oral delivery of therapeutic proteins [109]. More efficient surface engineering technologies, advanced bioadhesive functionalization, and combination with smart materials will result in the development of highly functional microparticle-based oral drug delivery systems.

Table 2.

Microparticle systems for applications in oral drug delivery.

| Material | Model of Drug | Applications and Benefits | References |

|---|---|---|---|

| PLA | Insulin | A solvent extraction method was used to prepare different sized microcapsules and the highest insulin release profile was obtained in 7–12 h. | [116] |

| Lovastatin | PLA microspheres enhanced the bioavailability of drugs for gastroretentive drug delivery and prolonged the drug circulation time in vivo. | [117] | |

| PLGA | Amifostine | A solvent evaporation technique was used for Amifostine encapsulation and oral controlled release. It was observed that 50% of the drug was released within the first 6 h and 92% within 12 h. | [118] |

| Plasmid DNA (pDNA) | pDNA vaccine encapsulated PLGA microcapsules was synthesized via a solvent evaporation method. The pDNA was protected from degradation in the GI system. |

[119] |

|

| Insulin | Magnetic nanocrystals and insulin were encapsulated in PLGA microparticles to delay drug transition using a magnetic field. | [120] | |

| Curcumin | PLGA particles with different molecular weights were prepared by an emulsification-solvent evaporation method to encapsulate curcumin. The results showed that the bioavailability of high molecular weight PLGA particles was better than that of low molecular weight PLGA particles and curcumin. | [121] | |

| Physicochemical properties and in vivo therapeutic activities of porous and nonporous PLGA microparticles were studied. Ammonium bicarbonate was used to create the porosity and in vivo experiments showed that oral administration of porous microparticles exhibited therapeutic efficacy against Ulcerative colitis compared to nonporous microparticles. | [122] | ||

| PCL | Bovine serum albumin | PCL microparticles for use in oral vaccine applications were produced in sizes (5–10 microns) that can be taken by M cells in Peyer's patches. | [123] |

| Manidipine dihydrochloride | In order to treat high blood pressure, PCL microparticles containing Manidipine dihydrochloride with an antihypertensive effect for up to 24 h were developed. | [124] | |

| Polyvinyl alcohol (PVA) | Ornidazole | Controlled release of the drug molecule in the GI tissue was provided with PVA microparticles prepared using different ratios of PVA to starch. | [125] |

| Methylcellulose | Thymol | Methylcellulose and hydroxypropyl methylcellulose phthalate were used to produce Thymol encapsulated microspheres. In vivo pharmacokinetic studies showed that the microparticles could be used for local treatment of intestinal infections. | [126] |

| Ethylcellulose | Propranolol | Ethylcellulose microparticles containing Propranolol hydrochloride were prepared using a modified solvent evaporation method, and its use for the treatment of hypertension was studied. | [127] |

| Carboxymethyl cellulose sodium | Flurbiprofen | Chitosan-coated and uncoated sodium carboxymethyl cellulose and polyvinyl alcohol microspheres were synthesized and crosslinked with Fe3+ ions. The chitosan-coating provided a slower release and a lower burst effect. | [128] |

| Progesterone | Low methoxy amidated pectin-sodium carboxymethyl cellulose microspheres were prepared, and Zn2+ and Al3+ ions were used for crosslinking. The particles were tested in colon-targeted drug delivery. | [129] | |

| Chitosan | Ovalbumin | Porous chitosan microparticles, which can be taken up by the epithelium of the Peyer's patches, were synthesized and used as a vaccine delivery system. | [130] |

| Curcumin | A sustained release of curcumin in the intestinal tract was reported for N-trimethyl chitosan modified SLNs. | [131] | |

| Progesterone | Zn-pectinate/chitosan particles were made to increase the oral bioavailability of progesterone and to use the particles as the colon targeting system. | [132] | |

| Sodium hyaluronate | Vancomycin | Drug loading capacity of vancomycin in porous and degradable hyaluronic acid (HA) microparticles were increased by the HA porosity, and the drug release degree could be modified by the degradability of the particles. | [133] |

| Sodium alginate | Curcumin | Alginate microparticles crosslinked by ion gelation were used for controlled release curcumin solubilized in the lipid phase. | [134] |

| Insulin | The efficacy of microparticles prepared using different amounts of mucin and alginate on controlled insulin release was assessed. | [135] | |

| Gelatin | Vascular endothelial growth factor (VEGF) | Gelatin microparticles were designed for the controlled release of VEGF, and a regular controlled release was achieved by modifying the degree of microparticle crosslinking. | [136] |

| Bone morphogenetic protein-2 | Gelatin microparticles were evaluated for controlled release of bone morphogenetic protein-2, and the release profiles were compared with PLGA microparticles. | [137] | |

| Ciprofloxacin | Ciprofloxacin, a water-insoluble antimicrobial drug, was encapsulated in gelatin as a result of a one-step process by spray drying an aqueous solution. | [138] | |

| Polymethacrylic acid-polyethylene glycol-chitosan | Insulin | Surface thiolation was used to increase the drug release performance of hydrogel-based oral insulin delivery systems. | [139] |

| Chitosan-carboxymethyl starch | 5-aminosalicylic acid | Chitosan-carboxymethyl starch particles were synthesized via a casting technique with high encapsulation performance as a drug delivery system for the colon. | [140] |

| Chitosan-graft-polyacrylamide | Ibuprofen | Chitosan-graft-polyacrylamide copolymer was produced by cerium (IV) ammonium nitrate-induced free radical graft polymerization, and the release profile as a function of crosslinker amount and drug to polymer ratio was investigated. | [141] |

| Poly(butylmethacrylate-co-(2-dimethylaminoethyl) methacrylate-co-methylmethacrylate) | Micronutrients (iodine, zinc, iron, and vitamins (B2, B12, C, D, and A), biotin, folic acid, and niacin) | Poly(butylmethacrylate-co-(2-dimethylaminoethyl) methacrylate-co-methylmethacrylate) was used to encapsulate different micronutrients, and the encapsulation was shown to provide stability against a variety of factors. | [142] |

Another widely used nanocarrier for oral drug delivery is the polymer micelle, which is formed by self-assembly of amphiphilic polymers above the critical micelle concentration. This fabrication process provides a core-shell structure, which allows loading of poorly water soluble drugs in hydrophobic cores with enhanced bioavailability and stability [110,111]. For example, an amphiphilic block copolymer consisted of a micellar shell-forming PEG block and a core-forming poly(2-(4-vinylbenzyloxy)-N,N-diethylnicotinamide) block, while N,N-Diethylnicotinamide in the micellar inner core resulted in effective paclitaxel solubilization and stabilization [110]. Suitable copolymers for oral drug delivery should have self-assembling capabilities in water, biodegradability, biocompatibility, high stability, and residence time in the GI tract. Different polymeric micelles containing polyethers or polyesters have been proposed for oral drug delivery. Pluronics, composed of poly(ethylene oxide) (PEO)-poly(propylene oxide)-PEO copolymer, also known as of Poloxamer are commonly used polymers for micelle assembly. Some polymeric micelles exhibit pH-responsive disassembly with lower release rate in acidic environments, reducing initial burst release of drugs [112]. In addition to micelles, reverse micelles prepared in an oily solution with an interior hydrophilic core and exterior hydrophobic layer can be used for the encapsulation and sustained release of hydrophilic drugs [113].

4.3. Inorganic nano and microparticles

In addition to organic nano and microparticles, inorganic particles, including mesoporous silica, gold, silver, iron oxide, quantum dots, carbon nanotubes, and graphene oxide nanoparticles, have found wide applications for oral drug delivery due to their exceptional physiochemical properties [[143], [144], [145]]. High stability in aqueous conditions, along with acidic and enzymatic environments [1], feasibility of functionalization [2,3], large surface area with a high loading capacity [4,5], enhanced membrane permeability to the cells [6,7], and optical and magnetic properties [8,9] all suggest promising applications of inorganic nanoparticles not only in drug delivery, but also in bioimaging. However, their clinical applications are restricted by their poor biodegradability and biocompatibility, which requires functionalization with other biomaterials. Functionalization of inorganic nanoparticles with biocompatible ligands can be achieved during their synthesis procedure or after their preparation. Silica nanoparticles, with high porosity and surface area, possess silanol groups, which facilitate their functionalization. For example, silica nanoparticles coated with PEG slowed the release of insulin both in acidic and neutral pH [144]. PEG, chitosan, and alginate coated silicate nanoparticles have also been utilized for oral delivery of insulin to enhance their mucoadhesion and biocompatibility [144,146]. Poly(amidoamine)-functionalized multiwalled carbon nanotubes loaded with hydrophobic therapeutics were modified with a carboxylate group to increase loading capacity and drug dissolution [137]. Insulin-loaded silica nanoparticles ranging from 289 nm to 625 nm showed increased interaction with mucin when coated with chitosan [146].

4.4. Micropatches

Micropatches (also called wafers or films) can be designed as drug carriers with a typical size of 2-10 cm2 and a thickness of 20-500 μm [[147], [148], [149]]. They can be classified as melt away, rapid disintegrating, and sustained-release, referring to their different drug release rates and disintegration times as detailed by Kirsch et al. [150]. The drug release rate can be defined by the polymer used but can also be multilayered with varying disintegration times. Oral patches are usually fabricated with laminated structure, a drug-containing bioadhesive layer, and an impermeable backing layer for increased retention [151]. To improve the retention of micropatches within the intestinal lining, micropatches are designed to be thin and flat (Fig. 6a,b). This design also minimizes exposure to the constant flow of fluids from the intestine (Fig. 6c).

Fig. 6.

Micropatches in oral drug delivery. (a) Schematic representation showing a GI patch and (b) working mechanism of the hard capsule filled with mucoadhesive patches. Reprinted from [152], Copyright (2011), with permission from Elsevier. (c) In contrast to microspheres, asymmetric and planar microdevices facilitate proximal and unidirectional drug release, while increasing residence time in the GI tract. Reprinted from [29], Copyright (2015), with permission from Elsevier.

4.5. 3D fabricated microdevices

Encapsulation of drugs in polymeric matrices can be achieved using several methods, such as injection molding, pressing, and 3D printing [[153], [154], [155], [156]]. First, a drug polymer blend can be fabricated via mixing the polymer with the desired drug and then either molded or shaped in the form of filaments for 3D printing. The release rate can be tuned by manipulating the polymer or drug concentration.

Khaled et al. utilized 3D extrusion-based printing to fabricate a polypill for patients under complex medication regiments. The polypill contained five distinct drugs with two independently well-defined and controlled release profiles. The drug formulations aimed to improve the drug usage for patients taking a variety of different drugs and to allow for the tailoring of a drug regimen with distinct release kinetics for each individual. The polypill demonstrated rapid and sustained release profiles based on the excipient/active ratio [157]. Maroni et al. proposed printed 3D capsular and multi-compartment devices. The devices were separated by a 600 or 1200 μm thickness wall, for two-pulse oral drug delivery. The devices were manufactured by FDM 3D printing, which allows for larger scale production [158]. Melocchi et al. investigated FDM 3D printing for the manufacturing of capsular devices with a shell-thickness of 600 μm using a swellable and erodible polymer (hydroxypropyl cellulose) for oral pulsatile release. This study focused on the fabrication of hollow structures via FDM and the production of hydroxypropyl cellulose filaments by hot melt extrusion. After assembly of the capsular devices, the study reported an initial slow release followed by a quantitative and rapid liberation of the drug [159].

Li et al. showed that 3D printing can be utilized to fabricate oral drug delivery devices consisting of various materials with customized designs (Fig. 7a) [160]. FDM was employed for the 3D printing of glipizide-loaded filaments, which were fabricated by melt extrusion of PVA and glipizide [154]. Then, the drug-loaded filament was 3D printed into a tablet shape. The tablet was composed of a core and shell comprised of various contents of glipizide. By this new design, both controlled and delayed release were possible as the composition of the outer layer controlled the release behavior of the core. In another study, Maroni et al. employed FDM and IM technologies to fabricate a capsular device for two pulse oral drug administration (Fig. 7b) [158]. Commercial PVA and other formulations of polymers were used for FDM and injection molding. The capsules were composed of two hollow halves with desired thicknesses with a middle partition. Varied thicknesses and compositions in each half led to faster or slower drug release in the respective halves of the capsule. FDM enabled customization of the drug delivery system and injection molding was suitable for its high throughput production. Kirtane et al. designed a novel oral dosage form for weekly and sustained drug release (Fig. 7c) [161]. The dosage form released long-acting antiretroviral for the prevention and treatment of human immunodeficiency virus (HIV). The device was composed of an elastomeric core connected to six separate polymeric arms that were flexible enough to be folded and placed into a capsule. The arms were embraced by a polymeric shell and filled with a drug-polymer composite, which was fabricated by melt mixing. Poly(adipic anhydride), poly(sebacic anhydride), and PEG polymers and three antiretrovirals, dolutegravir, cabotegravir, and rilpivirine, were selected for the drug-polymer mixtures. Various polymers for drug-polymer composites enabled different drug release rates and a modular release system.

Fig. 7.

Examples of fabricated devices for oral drug delivery. (a) Caplets fabricated by 3D printing with various designs of multiple materials showed by different colors. Reprinted with permission from [160]. Copyright (2016) American Chemical Society. (b) 3D printed multi-compartment capsular devices with two phase release profiles. Reprinted from [158] Copyright (2017), with permission from Elsevier. (c) The device consisted of an elastomeric part (core) and six drug-loaded arms. Various polymers (blue, red and yellow) released the drug at different rates. Material from [161], published 2018, Nature Springer. (d) Scanning electron microscopic (SEM) image of the microcontainer filled with polymer and impregnated with ketoprofen. Scale bar is 100μm. Reprinted from [163] Copyright (2014), with permission from Elsevier. (e) Schematic of the drug- loaded micromotor and drug delivery in stomach. Reprinted by permission from [163]. Nature, Copyright (2017).

Reservoir-based microdevices are another type of microdevices designed to protect the drug against degradation and deactivation for an efficient drug release [[162], [163], [164], [165], [166]]. Precise control over the amount of drug loaded into a device can be obtained by drop-on demand inkjet printing of the drugs. Marizza et al. developed reservoir-based microdevices for oral drug delivery of active ingredients (Fig. 7d) [163]. They employed lithography techniques to fabricate microcontainers in desired dimensions. Then, the microcontainers were filled with a precise amount of polyvinylpyrrolidone (PVP) solution via inkjet printing and ketoprofen was soaked into the PVP when supercritical carbon dioxide was used as the loading medium. The amounts of the printed polymer and loaded drug were modulated by varying printing and soaking parameters. Thus, a controlled and reproducible drug release was achieved.

4.6. Dendrimers

Dendrimers have been extensively studied for oral drug delivery. Dendrimers have complex structure, divided into three parts: core, branch, and terminal groups. Dendrimers are monodispersed, usually symmetric and their molecular weight can be controlled. Additionally, physicochemical properties of dendrimers can be tuned based on their chemical structure, surface functionalization, and core structure. Most importantly, the terminal functional group in dendrimers has a significant role as it can be conjugated to various biological active molecules, such as enzymes and antibodies. Polyamidoamine is the most commonly used dendrimer with core structure consists of alkyl diamine and tertiary amine branches. Several drugs, such as clotrimazole, sulfamethoxazole, propranolol, ketoconazole, triclosan have been conjugated to polyamidoamine dendrimer to test their efficacy through oral drug delivery [[167], [168], [169]]. The latter studies proved that the activity of the drug molecules was significantly increased in conjugation with the dendrimer compared to their pure state.

5. Strategies to improve bioadhesion of drug carriers

Over the years, many types of micro- and nanocarriers have been designed and fabricated for oral drug delivery. A combination of different materials, versatile fabrication technologies, and different sizes and shapes of carriers have been explored to develop oral drug delivery systems. The aim of fabricated micro- and nanocarriers is to obtain dynamic and accurate control over the drug delivery process. These drug carriers can be engineered to improve their interactions with biological systems, such as mucus barriers. This can be achieved either through the increased adhesion and retention of the carrier within a biological environment (termed bioadhesive), which has been shown to improve oral drug delivery to various regions of the GI tract. To improve bioadhesion, two main strategies are used to functionalize the drug carriers, i.e., chemical modification to the surface of the carriers and engineering the physical and biological properties of the carriers.

The design of carriers with bioadhesive properties is considered an important aspect in oral, transmucosal, and transdermal delivery systems. The integration of bioadhesive properties improves the oral drug delivery of fabricated carriers. A key purpose of utilizing bioadhesive materials is to delay the transit of cargos for sustainable release of drugs at target sites, prolong the residence time in order to enhance the drug absorption process, and increase material-cellular contact, thus improving bioavailability. Bioadhesive materials have also demonstrated additional properties of inducing TJ rearrangement to enhance drug transport across epithelial barriers [29]. Achieving bioadhesive properties can be classified into chemical approaches and physical approaches. In this section, we describe strategies that are used across multiple applications in oral drug delivery to further functionalize drug carriers to improve their overall bioadhesion and the interactions with tissue barriers [1,29,170].

5.1. Chemical approaches to improve bioadhesion

Chemical bioadhesion is achieved through the combination of a material’s chemical composition and structure on its surface. A common chemical approach to enhance adhesion of a material is the immobilization of target lectin and carbohydrate binding proteins onto the surface of microparticles, microdevices, or micropatches, to increase the specificity of binding receptors of intestinal epithelial cell lines. As binding to cell surface receptor results in receptor-based endocytosis of nanocarriers, this approach facilitates target delivery of carriers into cells [171].

The surface charge of carriers is another effective parameter for particle uptake in oral administration. Considering the negative charge of sugar moieties on the mucins, positively charged nanoparticles can enhance mucoadhesion through the formation of electrostatic interactions [23]. Liu et al. showed the effect of surface chemical properties of a drug carrier in the GI tract. N3-O-toluyl-fluorouracil (TFu) was loaded into cationic SLNs (TFu-SLNs) and the particles were studied to improve the uptake of TFu. They observed that cation coated TFu-SLNs elevated the oral absorption of TFu about 2-fold in comparison with TFu suspension (Fig. 8c). The plausible mechanism to enhance the ability of controlled drug release is increased bioadhesion of the carrier by electrostatic interaction between the negatively charged absorption mucosal surface and positively charged colloidal particles [172].

Fig. 8.

Physical and chemical approaches to oral drug delivery. (a) Performance of traditional drug delivery platforms (left) compared to the developed tomato lectin-modified poly(methyl methacrylate) drug delivery microdevices. (b) SEM images of the microneedles fabricated via reactive ion etching technique (left) and insertion of needle tips into the epidermis (right). (c) Release curves of TFu-SLNs and TFu-Sol in artificial intestinal juice and artificial gastric juice. Reprinted with permission from [[172], [190], [193]].

Another important method for modifying drug carriers is through the incorporation of functional biomaterials into the design of oral drug delivery systems. Chemically modified polysaccharides, such as chitosan, alginate, pectin, gelatin, and dextran, are considered the most important natural polymers used in oral drug delivery due to their biocompatibility, bioadhesion, and enzymatic degradation. Chitosan with its positive charge enhances drug absorption and, consequently, coating nanoparticles with chitosan is an effective method to promote mucoadhesion [173]. Chitosan variants with higher molecular weight have shown better mucoadhesion [174]. Also, chemical modification of chitosan for enhanced mucoadhesion, physiological stability, permeability and bioavailability has been utilized for more efficient oral delivery of various drugs, including anti-cancer and peptide drugs [175] [176]. For instance, thiol functionalization of chitosan exhibited enhanced mucoadhesion, which is due to covalent bonds between the cysteine and thiol groups on mucus glycoproteins [177]. In a similar approach, Tian et al. introduced a two-step flash nanocomplexation process to fabricate core-shell nanoparticles coated with thiolated hyaluronic acid to be utilized for oral insulin delivery [114]. First, a positively charged insulin-loaded nanoparticle core was fabricated through electrostatic interaction between insulin and N-(2-hydroxypropyl)-3-trimethyl ammonium chloride-modified chitosan under turbulent mixing conditions. Subsequently, the prepared positively charged nanoparticle core was coated with polyanionic thiolated hyaluronic acid to synthesize the final product (Fig. 5c). A combination of chitosan with alginate and dextran have also been used for oral delivery of insulin [178].

Combining PLGA nanoparticles with chitosan has also been investigated to improve mucoadhesion of nanoparticles and facilitate their functionalization. In one example, Abd El Hady et al. studied a delivery system of diosmin in PLGA microparticles coated with chitosan and reported its effects on the gastric retention of diosmin [179]. In another study, folic acid (FA)-functionalized nanoparticles were prepared through a double emulsion method by surface coating insulin-loaded PLGA nanoparticles with chitosan-FA conjugates through electrostatic interactions to enhance their uptake and targeting abilities through FA receptors [180]. Multi-layered nanocapsules of PLGA and chitosan were prepared through layer-by-layer self-assembly of PLGA and chitosan via electrostatic interactions

Functionalization of copolymers with mucoadhesive functional groups is an efficient way to enhance the mucoadhesion of micelles as well. Dufresne et al. prepared a copolymer micelle based on PEG-poly-(2-(N,N-dimethylamino)ethyl methacrylate) and functionalized the PEG chains with thiol groups to form disulfide bonds with the mucin, leading to improved mucoadhesion of micelles [115]. In this method, thiolated copolymers with opposite charges were self-assembled in an aqueous solution to form thiolated polymer micelles with the potential for functionalization with targeting agents and improving mucoadhesion and the ability to form redox-sensitive polymer networks (Fig. 5d).

These strategies have also been applied to liposomal particles. Coating liposomes with mucoadhesive polymers, such as chitosan through non-covalent interactions increased the residence time and bioavailability of highly hydrophilic drugs with low permeability [181,182]. Modifying liposomes with thiol groups through functionalization with thiolated polymers (thiomers) imbued liposomes with desirable properties, such as mucoadhesion and enzyme inhibition [183,184]. In addition to mucoadhesive polymers, conjugation of liposomes with ligands, such as biotin, whose receptors are expressed in the intestine, can enhance the efficacy of conventional liposomes in oral drug delivery [185]. Glycans are binding sites for lectins in the membrane of cells in the GI tract; thus, functionalization of liposomes with lectin is another method to increase mucoadhesion [186].

In addition to mucoadhesive polymers, other hydrophilic polymers such as D-α-tocopheryl poly(ethylene glycol) 1000 succinate (TPGS) (a PEG-conjugated vitamin E) can be used to enhance the residence time and bioavailability of particles for oral drug delivery. TPGS can prolong the circulation time and cellular uptake of the coated nanoparticles. TPGS increases oral bioavailability by enhancing cell membrane permeability through the inhibition of P glycoproteins (P-gp) [187,188]. This is particularly important for increasing the oral bioavailability of anticancer drugs. For example, low concentrations of TPGS increased the intestinal permeability of paclitaxel, attributed to the inhibition of P-gp [189]. Therefore, TPGS stands as a potent adjuvant for orally administered chemotherapy.

5.2. Physical approaches to enhance bioadhesion

The physical properties of materials, such as mechanical properties, surface area, and surface morphology affect their adhesion properties to surfaces [29]. One of the physical methods to enhance bioadhesion is the utilization of different geometries/shapes of drug carriers. Tao and Desai made a direct comparison between conventional microspheres (multidirectional release) and their flat and thin device designed for unidirectional release, both coated with bioadhesive tomato lectin-poly(methyl methacrylate). They showed that despite the larger surface area of the microspheres compared to their device, the spheres remained less bounded to Caco-2 monolayers after consecutive washes. This was attributed to the smaller fraction of microsphere surface which is in direct contact to the cells [190]. Similarly, in nano-adhesive conditions, increasing bioadhesion of drug carriers is associated with the multivalence of adhesive elements per surface area. As the number of adhesive elements increases, Van der Waals adhesion also increases, resulting in greater absorption of the drug. The microvilli on mucosal epithelia have protrusions that increase surface area. Thus, fabricating nanostructured microdevices with multivalency could be a potential way to strengthen the bioadhesion of materials for targeting microvilli coated intestinal epithelium [191].

Microfabrication techniques are advanced technologies to design microdevice bodies with protruding microneedles and microposts. This permits the particle to interact with mucosa by strongly adhering to the mucosa surface and penetrating the mucus layer. As a result, an enhanced drug permeability occurs. Microneedle platforms were developed to increase the retention time in drug delivery systems (Fig. 8b). For instance, Guan et al. fabricated a crosslinked bilayered system made of PEG with chitosan microparticles. These fabricated systems were structured with self-folding arms. As expected, the arms anchored to the cell surface by penetrating into mucus layer. Thus, retention time of the device, as well as resistance to surface erosion of the mucus layer, increased [165][].

6. Targeting the gastrointestinal tract via oral administration with micro and nanoscale technologies

For both the gastric and intestinal tracts, innovative micro and nanoscale technologies have been developed for enhanced tissue targeting and oral drug delivery. These technologies range from polymeric nano and microparticles to 3D-printed wearables. Although many different oral drug delivery techniques have been developed so far, there are many considerations for any specific active ingredient and one delivery method does not fit all drugs. Thus, it is essential to customize the delivery technique based on the type of drugs and the patient needs. Selected examples of micro and nanotechnologies used for improving the efficacy of oral administration and drug delivery to the esophagus, stomach, intestines, and colon are described in this section.

6.1. Esophageal and stomach delivery

Delivery of drugs to the esophagus for treatment of esophageal diseases including infections, gastric reflux, and cancers is limited by the transient nature and low permeability of the esophagus. Therefore, designing an effective esophageal-targeted system with sufficient retention time during rapid transit through esophagus is of great importance. Drug-loaded nano and microparticles with prolonged contact and enhanced adhesion to the esophageal mucosa are introduced for targeting of therapeutic agents to the esophagus. Kockisch et al. developed an in vitro mucoadhesion tensile test and demonstrated efficient adhesion of polymeric microparticles, synthesized from carbopol, polycarbophil, and chitosan through water-in-oil emulsification to the porcine esophageal mucosa [194]. Additionally, magnetic systems are suggested for more efficient targeted therapy of esophageal cancer using an external magnetic force. Ito et al. prepared magnetic granules composed of ultrafine ferrite and a mixture of bioadhesive polymers containing hydroxypropyl cellulose and Carbopol 934. The granules were administered orally in rabbit models and were guided to the esophagus by applying an external magnet in less than 2 min, and results showed that almost all granules were retained in the target region for 2 h [195].

Rapid degradation, low stability, and poor absorption of drugs in the GI tract can be solved using stable drug delivery capsules to deliver drugs to the stomach, which is dominated by the gastric emptying time of 1-4 hours [196]. In one approach, Jiang et al. studied oral delivery of mussel-inspired and protein-functionalized electrospun nanofibers for treating gastric cancer [197]. Through the incorporation of a pH-responsive release mechanism, the authors demonstrated doxorubicin release from PCL nanofibers in acidic conditions of the stomach over neutral medium. In addition to the acidic stomach environment, there are a number of other challenges for the delivery of oral peptides, including low permeation through the intestinal epithelium, inactivation, and proteolytic degradation in the GI tract [198].

The incorporation of microneedles into pills that push into the GI lining (intra-enteral injection) to bypass these challenges can improve the bioavailability of a biologically active macromolecule [199]. An illustration of the working mechanism of such microneedle pills is represented in Fig. 9 . Recent studies suggest that macromolecule drug delivery may be possible via ingestible self-orienting millimeter-scale applicator (SOMA) capsules, which contain a tiny needle to autonomously position the capsule to engage the GI lining of the stomach in a safe manner to increase retention and enable the escape of insulin cargo from the GI into the bloodstream [196] (Fig. 10 ). The use of these methods is an alternative to injectable delivery of biologics medications, such as insulin and peptides, and enhances patient convenience, as well as increases safety and efficacy.

Fig. 9.

A microneedle approach for the delivery of biologics via oral administration. Delivery of biologics via the GI tract using a luminal unfolding microneedle injector (LUMI). Reprinted by permission from [199]. Nature, Copyright (2019).

Fig. 10.

(a) A schematic illustrating SOMA capsules for oral drug delivery. SOMA capsules reach a stable point of orientation and deliver biologics through the GI lining and into systemic circulation, (b) scale of fabricated SOMA, (c) the shape of SOMA capsules were inspired by the leopard tortoise shell, (d) mechanism of drug release after needle injection to the mucus through the spring ejection in caramelized sucrose. Reprinted from [196]. Reprinted with permission from AAAS.

Microneedle capsules can deliver not only small molecules but also proteins, peptides, vaccines, hormones, and other macromolecules. Traverso et al. successfully deployed a microneedle-containing device, modeled after current FDA-approved ingestible devices [200], and monitored the administration of insulin in the stomach [198].

Recently, some novel self-propelled microdevices, known as microrockets or micromotors, have been developed for delivery of drugs to target locations of organs. Microrockets should be biocompatible and be degraded in the gastric acid. Zhou et al. developed a self-propelled microdevice for target-based delivery of doxorubicin [202]. The microdevice consisted of a core of Zinc (Zn) surrounded by a thin layer of iron (Fe) and poly(aspartic acid) (PASP) microtube layer. Doxorubicin was adsorbed on the PASP surface by electrostatic interaction. The Zn particles electrodeposited onto the PASP/Fe layers could propel the microdevice by creating hydrogen bubbles in an acidic environment and prevent the oxidation of Fe. The microdevice was magnetically controlled due to presence of an Fe layer and navigated to the target site of the stomach by locating a strong magnet near it. The microdevice was trapped into gastric layer and started releasing the drug in an acidic environment. In another work, Ávila et al. proposed a magnesium (Mg)-based micromotor for active delivery of antibiotics for treatment of gastric bacterial infections [203]. The in vivo treatment of H. pylori infection using Mg-based micromotor loaded with clarithromycin was demonstrated in a mouse model. The micromotor consisted of a core of Mg microparticles coated with a thin layer of titanium oxide (TiO2) and then with a film of PLGA loaded with clarithromycin, while a small opening for the contact with acid was left. Then, the micromotor was coated with a thin layer of chitosan to enable electrostatic adhesion of the micromotor to the mucus of the stomach. In the acidic environment of stomach, Mg core reacted with acid and Mg gradually dissolved, while created hydrogen gas that led to self-propulsion of the micromotor in the gastric fluid and delivery of the drug. The in vivo studies illustrated high efficiency in delivery of antibiotics when using Mg-based micromotors compared to the passive drug delivery approaches.

6.2. Intestines and colon delivery

Enhancing intestinal drug delivery is primarily driven through the increased adhesion of materials to the intestinal lining and mucosal barriers, both to facilitate local release of drugs to intestinal drug targets, and to increase the release of drugs into the bloodstream for systemic circulation. Thus, the majority of oral drug delivery research is focused on delivery to this region of the GI tract. We will discuss significant examples of successful intestinal delivery of therapeutics, first discussing tissue-targeting strategies to achieve controlled drug release, and then discussing approaches focused at the cellular level of targeted intestinal drug delivery.

One of the most widely used drugs in oral drug delivery studies is insulin, with the goal of increasing insulin bioavailability via oral administration so that regular insulin injections are no longer required. One of the key goals with biologic delivery in the intestine is to protect the drug cargo from the harsh environment of the stomach prior to improving bioadhesion and controlled release of insulin within the intestines. Recently, Nemeth et al. reported on the loading of Eudragit® microwell devices via picoliter inkjet 3D printing for oral drug delivery applications [204]. This method provides a high throughput and reproducible means of loading biologics such as insulin into flat devices to increase tissue retention and improve oral drug delivery. In another study, Fox et al. employed a multi-step lithography process to develop a microdevice including a drug reservoir sealed by a nanostraw membrane [205]. The proposed device could facilitate drug loading and enable tunable release by manipulating the nanostraw inner diameter and density. The proposed microdevice could adhere to the GI tissue due to the presence of nanostructural topology (i.e., nanostraws) on the surface of the device. Thus, the drugs could be locally released over an adjustable time period, while the drugs were not exposed to drug-degrading biomolecules and digestive enzymes. The proposed microdevice can improve the oral absorption, which is of great importance for drugs with poor bioavailability such as insulin.

To increase the release of biomolecules from the intestine into the bloodstream, Abramson et al. developed a capsule named LUMI for the oral administration of various biomacromolecule drugs, using insulin as the potential target drug [206]. The device consisted of three degradable arms with drug-loaded microneedles packed into a capsule that was 9 mm in diameter and 30 mm in length. The microneedles were generated at the end of each arm and were composed of PVP with insulin powder at the tip. After taking the capsule, the poly(methacrylic acid-co-ethyl acrylate) coating was dissolved at pH levels above 5.5 and then the PEG coating embracing the compressed spring actuator was dissolved and the device was pushed out of the capsule when the arms were in a random direction to the intestinal wall. Then, the drug was delivered, and the rest of device was dissolved. The actuation time of the capsule could be tuned by varying the molecular weight of the PEG in an environment with the proper pH condition. After actuation, the capsule broke apart and was transported through GI tract. The LUMI device showed consistent release of drugs into the small intestinal mucosa during the in vivo studies. However, one limitation of this devices is that the LUMI delivery method may cause discomfort for patients due to scratching the intestine after activation of the device.

In another work, oral administration of insulin-loaded liposomes, containing three kinds of bile salts including sodium glycocholate, sodium taurocholate, and sodium deoxycholate, resulted in enhanced bioavailability and an increase in blood insulin for 20 h [207,208]. Liposomes containing ergosterol as the stabilizer, instead of cholesterol, have also shown a significant improvement in stability [209].

Recently, Lamson et al. reported on the development of anionic silica nanoparticles for the enhanced oral delivery of insulin [210]. The researchers found that both the size and charge of the silica nanoparticles influenced not only their interactions with the mucus barriers, but also the permeabilization of the epithelial barriers for enhanced insulin release into the bloodstream. Interestingly, 50 nm silica nanoparticles in juxtaposition to 20 nm or 100 nm particles, provided an optimal balance between increased mucus penetration and integrin-mediated TJ relaxation. Thus, 50 nm silica nanoparticles loaded with insulin displayed enhanced insulin bioavailability over what would normally be possible with oral drug delivery. This study lends support to other research that demonstrated nanostructural cues can influence TJ remodeling [29,205], and provides an example of the combined strengths of chemical and physical engineering of nanoscale drug carriers.