Abstract

Approximately one third of newly discovered drug molecules show insufficient water solubility and therefore low oral bio-availability. Self-nano-emulsifying drug-delivery systems (SNEDDSs) are one of the emerging strategies developed to tackle the issues associated with their oral delivery. SNEDDSs are composed of an oil phase, surfactant, and cosurfactant or cosolvent. SNEDDSs characteristics, their ability to dissolve a drug, and in vivo considerations are determinant factors in the choice of SNEDDSs excipients. A SNEDDS formulation can be optimized through phase diagram approach or statistical design of experiments. The characterization of SNEDDSs includes multiple orthogonal methods required to fully control SNEDDS manufacture, stability, and biological fate. Encapsulating a drug in SNEDDSs can lead to increased solubilization, stability in the gastro-intestinal tract, and absorption, resulting in enhanced bio-availability. The transformation of liquid SNEDDSs into solid dosage forms has been shown to increase the stability and patient compliance. Supersaturated, mucus-permeating, and targeted SNEDDSs can be developed to increase efficacy and patient compliance. Self-emulsification approach has been successful in oral drug delivery. The present review gives an insight of SNEDDSs for the oral administration of both lipophilic and hydrophilic compounds from the experimental bench to marketed products.

Keywords: oral bio-availability, self-nano-emulsifying drug-delivery systems (SNEDDSs), oral delivery, solubilization, food effect

1. Introduction

The oral administration route remains the best choice for drug delivery owing to its safety, patient compliance, and capacity for self-administration. In addition to being the most convenient route of administration, oral delivery has been limited owing to the numerous barriers present at the gastro-intestinal (GI) tract [1,2]. The solubilization of the drug within the GI tract is a mandatory for the drug absorption, as insufficient drug dissolution may lead to incomplete absorption, low bio-availability, and high variability following oral administration [3]. The oral delivery of drugs may also be associated with precipitation, food and drug interactions, susceptibility to degradation, and first-pass metabolism, leading to low oral bio-availability. According to the BCS (Biopharmaceutical Classification System), most of the drugs discovered thus far are classified into class II (low solubility, high permeability) and class IV (low solubility, low permeability). Following their oral administration, these compounds exhibited low oral bio-availability due to their low solubility or membrane permeability. Therefore, there is an urgent need to develop new drug carriers for their oral delivery.

The fact that the oral absorption of poor water-soluble drugs could be improved once given with food rich in lipids has brought the use of lipids-based formulations as means to improve the drug solubility and absorption following the oral administration [4]. Lipid-based formulations are considered to be a promising approach to enhance the water solubility and oral absorption of lipophilic drugs. The main goal of these formulations is to maintain the drugs in solution within the GI tract [5]. Among the wide number of lipid-based drug-delivery systems, self-nano-emulsifying drug-delivery systems (SNEDDSs) are one of the most investigated in oral drug delivery.

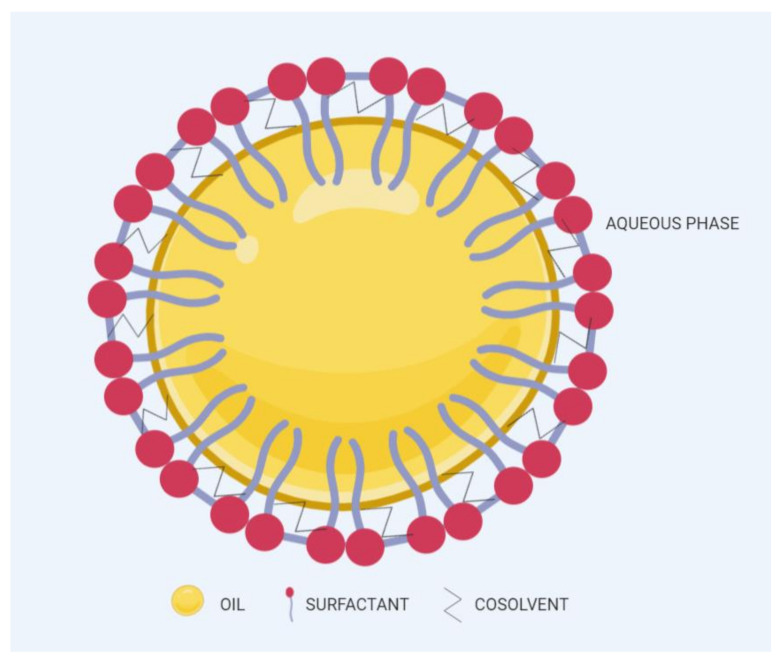

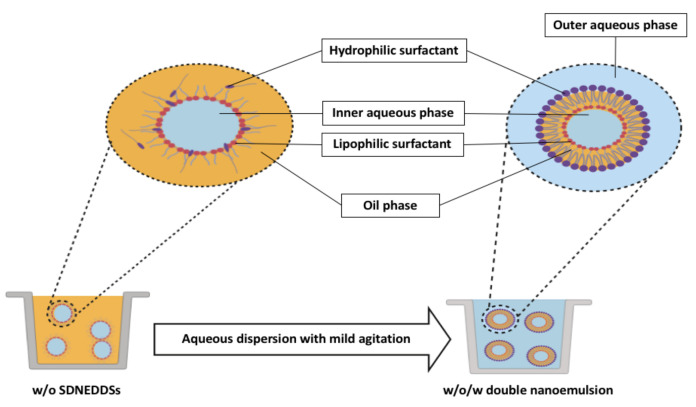

SNEDDSs have been described as a blend of oils, surfactants, and cosurfactants or cosolvents [6]. Following aqueous dispersion and mild agitation (such in GI tract), SNEDDSs spontaneously form fine oil-in-water nano-emulsions with droplet size of 200 nm or below [7], as shown in Figure 1. The spontaneous emulsification takes place when the entropy change favoring dispersion exceeds the energy required to increase the surface area of the dispersion [8,9]. SNEDDSs have shown immense potential in overcoming limitations related to the oral administration of several compounds. Such limitations include low solubility in the GI tract, inconsistent dissolution, enzymatic degradation, and erratic intestinal absorption. Surfactants and lipid components used in SNEDDSs can cooperate to enhance the GI absorption drugs. Furthermore, these components can be modified easily according to the need to make SNEDDSs feasible for both hydrophilic and hydrophobic drugs. Recent studies have shown that SNEDDSs could be effective oral drug carriers of peptides and proteins by preventing their GI degradation and improving their intestinal membrane permeability [10,11,12].

Figure 1.

Typical structure of SNEDDSs after aqueous dispersion.

In comparison to other lipid nanocarriers such as nanostructured lipid carriers (NLCs), solid lipid nanoparticles (SLNs) or liposomes or solid dispersions, SNEDDSs can be easily scaled up by mixing components with conventional equipment and then including the mixture in solid dosage form, i.e., capsule or tablet. Furthermore, drug-delivery-system-related issues such as a tendency to aggregate during the storage or to release the drug are not relevant to SNEDDSs, as fine dispersion are directly produced in the GI tract [13]. Therefore, SNEDDSs display better pharmaceutical properties for enhancing solubility and oral bio-availability [7,13]. More recently, however, the development of marketed SEDDSs formulations, such as Norvir® (ritonavir), Sandimmune® (cyclosporine), Fortavase® (saquinavir) and Neoral® (cyclosporine), has stimulated a growing interest in the use of SNEDDSs to improve the drug solubility and oral bio-availability.

To date, there are several studies that focus on SNEDDSs use for the oral delivery of lipophilic compounds, yet relatively few that introduce the potential of SNEDDSs for improving the oral delivery of hydrophilic macromolecules.

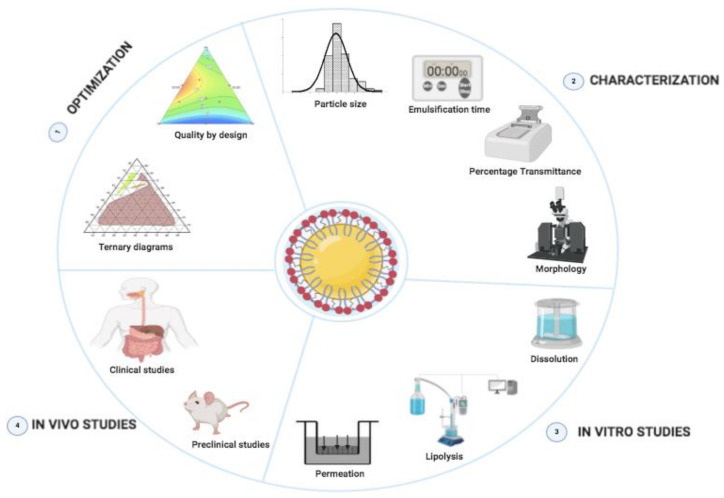

This paper offers a comprehensive overview of SNEDDSs development, characterization and in vitro/in vivo evaluation (Figure 2). We focus on SNEDDSs use for the oral delivery of both lipophilic and hydrophilic drugs, with special emphasis on the primary mechanisms by which components used to prepare SNEDDSs can improve the drug solubility, stability, and bio-availability after oral administration. Additionally, we discuss some advancements and promising techniques, such as solidification techniques for transforming liquid SNEDDSs into solid SNEDDSs formulations, as well as supersaturated SNEDDSs to enhance the drug-loading capacity. Lastly, we highlighted the most important challenges ahead related to SNEDDSs formulations.

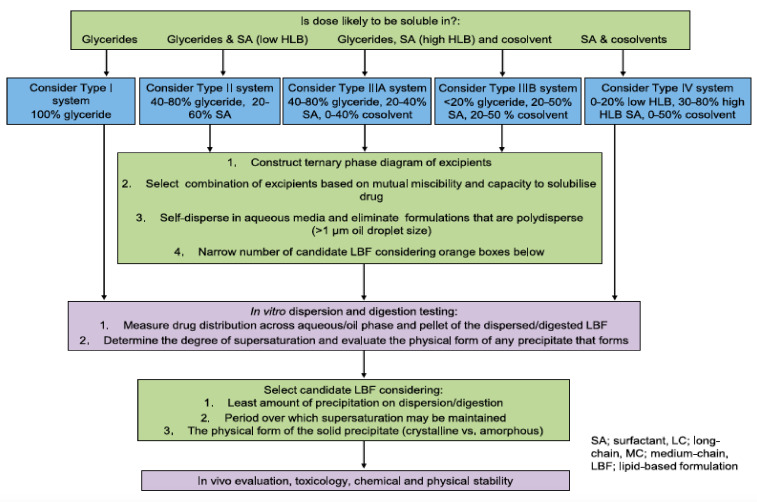

Figure 2.

Overview of the design of SNEDDSs formulations.

2. General Components of SNEDDSs and Their Role in Formulation Performance

To enable differentiation among various lipid-based carriers, Pouton et al. [7] introduced the lipid formulation classification system (LFCS). According to LFCS, SNEDDSs belong to class III compositions, which are composed of oils and water-soluble surface-active agents (surfactants and cosurfactants) and may also include cosolvents. Successful formulation of a SNEDDS requires attention when selecting formulation ingredients. Preformulation studies (e.g., solubility, emulsification efficiency) should be carried out to guide the right selection of SNEDDSs ingredients.

The general components used for SNEDDSs formulation are summarized below.

2.1. Oil Phase

Generally, medium- and long-chain triglycerides (TG) containing oils presenting varying degrees of saturation are used to formulate SNEDDSs. The oil with maximum ability to solubilize a specific a drug is usually selected due to its key influence in both formulation-loading capacity and drug absorption [14]. However, one exception to this general rule was reported by Larsen et al. [15], who demonstrated that SNEDDS containing an oil with the lowest solubilization capacity exhibited the highest drug absorption, indicating that the high solubilization in an oil is not always the best indicator of better in vivo performance.

Natural edible oils (i.e., castor oil, soybean oil, coconut oil, etc.) remain the logical and desired oil ingredients, but they exhibit relatively low drug-loading capacity and poor emulsification efficiency [16]. Modified medium-chain triglycerides (MCTs) and long-chain triglycerides (LCTs) are mostly employed to enhance the drug solubility in the formulation and are presented in Table 1.

Table 1.

Commonly used oils, surfactants, and cosolvents.

| General Class | Example | Molecular Structure | Commercial Name | Acceptability |

|---|---|---|---|---|

| OILS | ||||

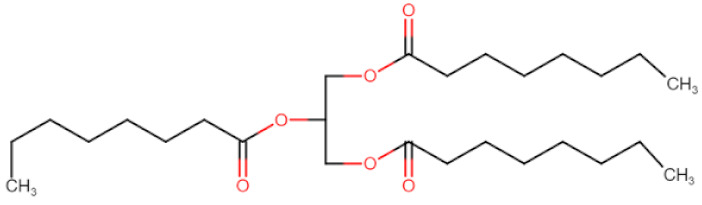

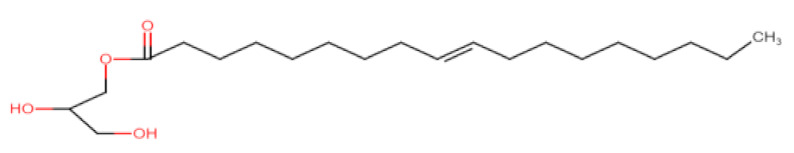

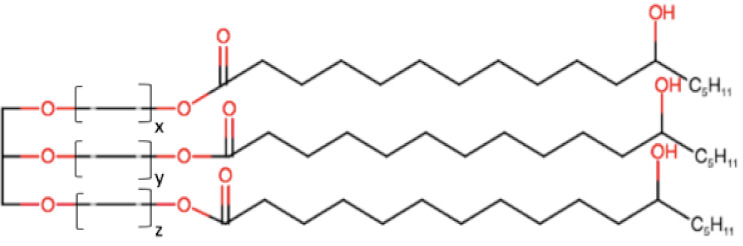

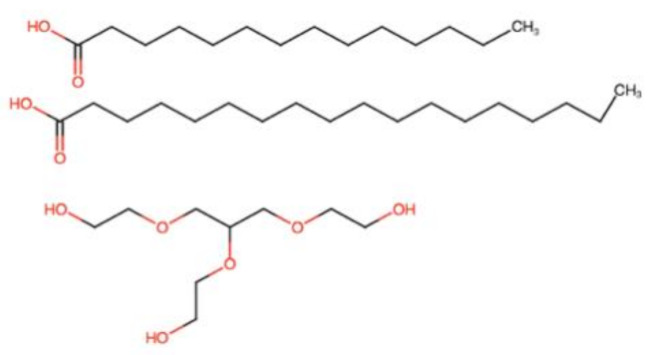

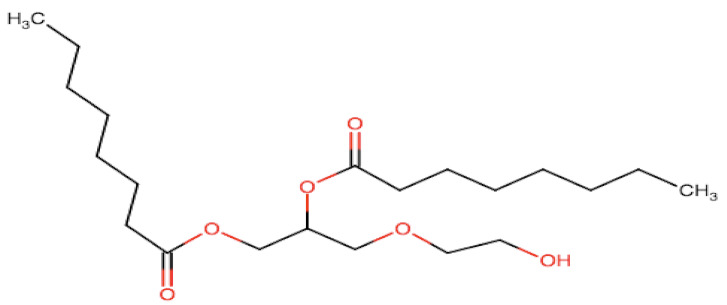

| Medium-chain | Triglycerides of capric/caprylic acids |

|

Captex® 300, 350, Labrafac® CC, Crodamol GTCC | P/O/T/Oc/M |

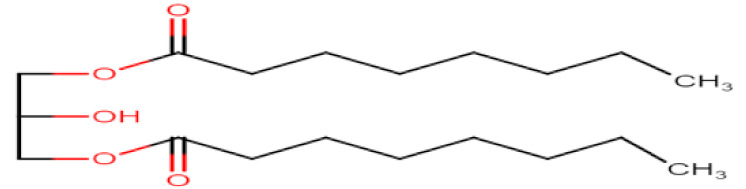

| Di-glycerides of capric/caprylic acids |

|

Capmul® MCM, Akoline® MCM | O/T | |

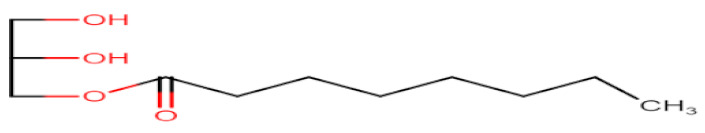

| Monoglycerides of capric/caprylic acids |

|

Capryol® 90, Capryol® PGMC, Imwitor® 742 | O/T | |

| Long-chain | Glyceryl monooleate |

|

Peceol®, Capmul®-GMO | O/T |

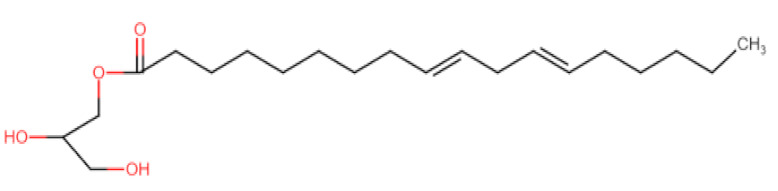

| Glyceryl monolinoleate |

|

Maisine®-35 | O/T | |

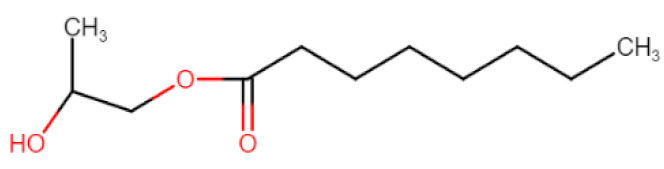

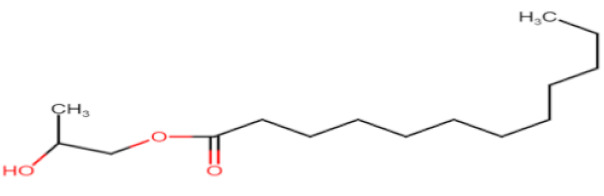

| Propylene glycol fatty acid esters | Propylene glycol monocaprylate |

|

Capmul® PG-8, Sefsol 218 | O/T |

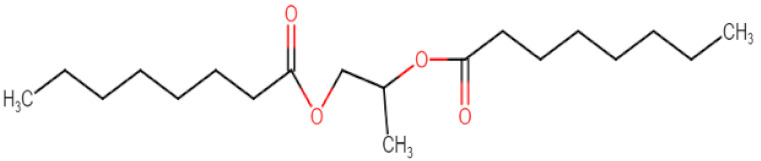

| Propylene glycol dicaprylate/caprate |

|

Miglyol® 840, Captex® 200 | O/T | |

| Propylene glycol Monolaurate |

|

Lauroglycol® 90, Capmul® PG-12, Lauroglycol® FCC | O/T | |

| SURFACTANTS | ||||

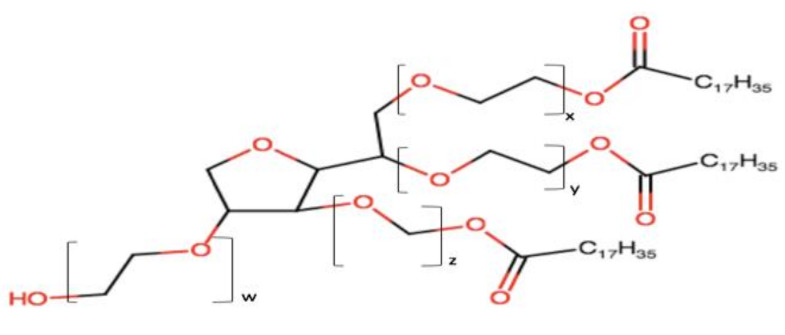

| Polysorbates | Polysorbate esters |

|

Tween® 20, Tween® 80 | P/O/T/Oc M |

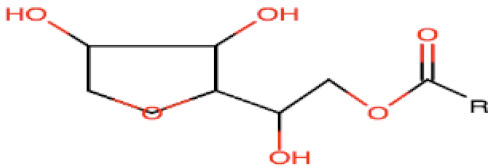

| Sorban esters | Sorban esters |

|

Span® 20,80, Crill® 4 | P/O/T/Oc M |

| Castor oil esters | Ethoxylated castor oil |

|

Cremophor®-EL, Etocas® 35 HV | O/T |

| Hydrogenated castor oil |

|

Cremophor® RH40, 60, Croduret® 40 | O/T | |

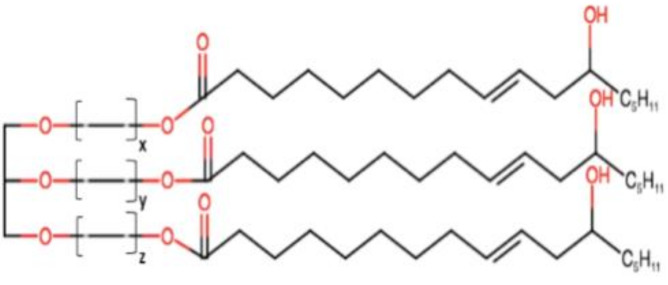

| Polyglycolyzed glycerides | Linoleoyl/Oleoyl Macrogol glycerides |

|

Labrafil® 1944, 2121 CS | O/T |

| Caprylocaproyl macrogol glycerides |

|

Labrasol® | O/T | |

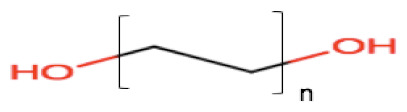

| COSOLVENTS | ||||

| Alcohols | Short chain Alcohols | R-OH | Ethanol, benzyl alcohol | P/T/Oc/M |

| Alkane diols |

|

Propylene glycol | P/T/Oc/M | |

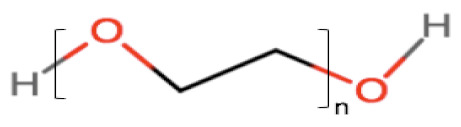

| Polyethylene glycols | Polyethylene glycols |

|

PEG 400, 600 | P/T/Oc/M |

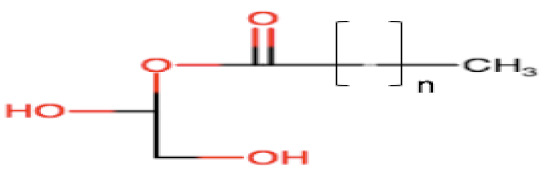

| Esters | Glycerol esters |

|

Transcutol® | O/T |

M: Mucosal; P: Parenteral; O: Oral; Oc: Ocular; T: Topical. Adapted from [17].

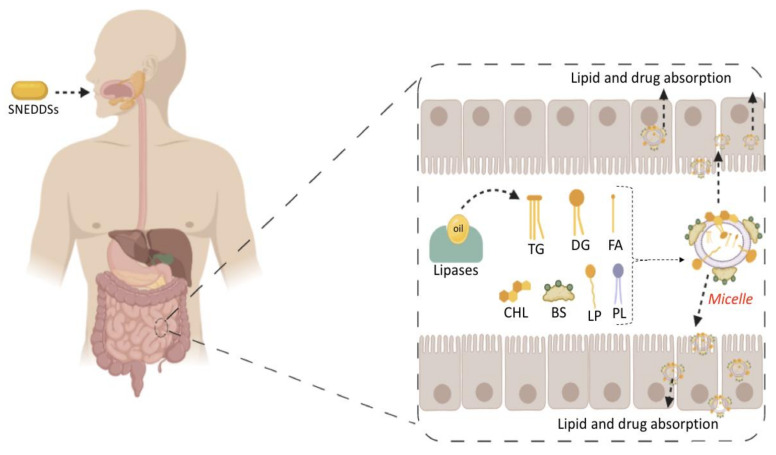

MCTs are predominantly composed of triglycerides with lipid chain lengths ranged from lipid chain lengths ranging from C8 to C10 (i.e., Capryol® 90, Captex® 300, Labrafac® CC), whereas LCTs consist of TG with lipid chain lengths greater than C10 (e.g., Maisine®-35, Lauroglycol® 90, Peceol®) [18]. After oral administration of these lipids, gastric, and pancreatic lipases break down TG into diglyceride, monoglyceride, and fatty acids. Once within the small intestine, those products stimulate the release of endogenous biliary lipids from the gall bladder, including bile salt, lipoprotein, phospholipid, and cholesterol, which enhance the solubilization and absorption ability of the intestinal tract via the formation of micelles (Figure 3) [19,20,21].

Figure 3.

Lipid digestion and drug solubilization process in the small intestine. Abbreviation: triglycerides (TG), di-glycerides (DG), monoglycerides (MG), fatty acids (FA), cholesterol (CHL), bile salts (BS), lipoproteins (LP), phospholipids (PL).

MCTs are preferred because of their better solubilizing ability and self-emulsification capacity [22]. C10 remains the only enhancer that has been used clinically in the intestine for oral drug delivery [23]. MCTs can increase the drug transport through the portal vein, but they have a limited capacity to enhance the lymphatic transport of the drugs [24,25]. Conversely, LCTs are directly encapsulated into chylomicrons, before their passage into the lymphatic system, bypassing the hepatic first-pass metabolism [4,25,26]. LCTs increase the transport of drugs through lymph vessel; however, sometimes, they are difficult to emulsify [27]. Thus, a mixture of MCTs and LCTs can be considered to meet optimum properties and improve pharmacokinetics.

2.2. Surfactants

The second obligatory components in SNEDDSs are surfactants. Due to their amphiphilic properties, surfactants are found at the oil–water interface and help in the stabilization of the nano-emulsion by reducing the surface tension. Generally, surfactants are classified based on their charge and hydrophilic-lipophilic balance (HLB) value. Regarding their charge, surfactants are categorized as ionic (anionic, cationic, and zwitterionic) and non-ionic surfactants. As compared with ionic surfactants, non-ionic surfactants are generally used because of their lower toxicity and ability to stabilize emulsion over a wider range of nano-emulsion pH and ionic strength [28]. Regarding their HLB value, surfactants can be classified as lipophilic (HLB < 10) or hydrophilic (HLB > 10) surfactants. The non-ionic surfactants with HLB > 12 are the most recommended, as they enable a spontaneous nano-emulsification with particle sizes less than 200 nm after aqueous dispersion.

The emulsification ability of a surfactant, its HLB value and the maximum solubility of the drug are three important factors to keep in mind when selecting surfactant in SNEDDSs. Furthermore, the concentration of surfactant has been demonstrated to affect the emulsion particle size. Increasing the amount of surfactant can reduce the emulsion particle size due to the surface tension lowering property of the surfactant at the oil and water interface that reduces the free energy for emulsification [14]. However, in some cases, an increase in surfactant amount results in higher particle size, due to the excess penetration of water into the lipid droplet which cause massive disruption of the oil–water interfacial and relaxation of high polydisperse nano-emulsion droplets [29,30]. Other than fine globule formation, many non-ionic surfactants, such Tween® 80 and Cremophor® EL, possess the ability to increase membrane fluidity [31] and to inhibit efflux transporters [32,33], which are contributing factors in enhancing the drug bio-availability.

The surfactant acceptability for the oral delivery and its regulatory status (e.g., GRAS—generally regarded as safe) should also be taken into consideration during the selection. Table 1 presents common non-ionic surfactants along with their acceptability. It should be noted that surfactant molecules are not always innocuous, they can exhibit structure or concentration-dependent toxicity [17]. Some of them might cause irritation the GI epithelium following oral administration. Thus, the amount of surfactant in SNEDDSs must be maintained at a low level as much as possible.

2.3. Cosurfactants/Cosolvents

A single surfactant is rarely able to provide low interfacial tension; therefore, the addition of another surfactant (cosurfactant) or cosolvent usually is necessary. They can synergically cooperate with surfactants to enhance the drug solubility and surfactant dispersibility in the oil, thus promoting nano-emulsion stability and homogeneity [34]. The use cosurfactants or cosolvents can reduce the local irritancy of the surfactant and dose variability of the formulation by improving interfacial fluidity [35]. The weight ratio of surfactant/cosurfactant or cosolvent has also been reported to have an important impact on size distribution and the extent of nano-emulsion area [36,37]. Commonly used cosolvents include propylene glycol, ethanol, poly (ethylene glycol) (PEG) and other newer cosolvents, such as Transcutol® HP [38,39], which are presented in Table 1.

However, while cosolvents can improve drug solubilization in the formulation, their amount should be kept at minimal level because of their polarity. Cosolvent readily migrate toward the water phase following aqueous dispersion, leading to drug precipitation [40]. Furthermore, alcohols and other volatile cosolvents can evaporate into shells of capsules, resulting in drug precipitation [41].

In the SNEDDS formulation, apart from previously presented components, other ingredients such antioxidants, viscosity enhancers and ingredients for modified drug release can be used [42,43,44,45].

3. Optimization of SNEDDSs Formulations

After selecting potential components of SNEDDSs, optimization studies are performed to obtain the optimum amounts of oily phase, surfactants, and cosolvents that might yield spontaneous nano-emulsion [46]. Ternary phase diagrams are largely employed to identify the emulsification area for selected components. In ternary diagrams, the ratio of one component varies while the concentrations of the other two are fixed. The emulsification area is identified visually or by measuring the particle size of the emulsion/nano-emulsion resulting after aqueous dispersion. All the SNEDDSs composition from the emulsification area yield spontaneous nano-emulsions, with globule sizes less than 200 nm after aqueous dispersion [47]. In some cases, the drugs can influence the emulsification region. Date et al. [48] demonstrated that cefpodoxime proxetil could significantly reduce the emulsification region in the ternary phase diagram.

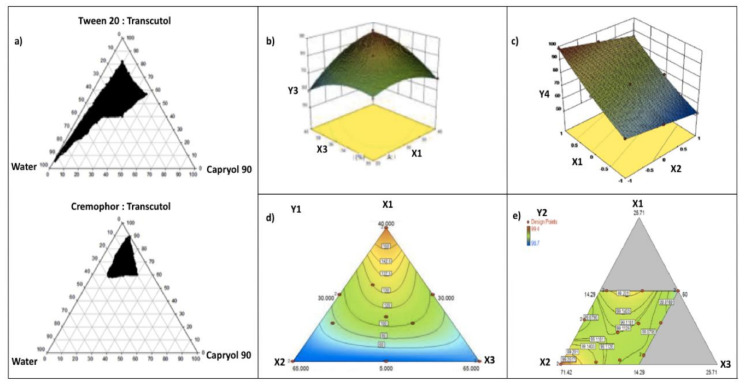

Khattab et al. [49] developed SNEDDSs to enhance aliskiren hemi-fumarate oral absorption. Capryol® 90 (oily phase), Cremophor® RH and Tween® 20 (surfactants) and Transcutol® HP (cosurfactant) were selected from the solubility study. The formulations were further optimized using a pseudo-ternary phase diagram in which an area of emulsification was identified (Figure 4a). The region of nano-emulsification was defined as the region where homogenous and clear systems were obtained after aqueous dispersion. A large nano-emulsion area indicates better emulsification efficiency of the surfactant toward oil. For Tween® 20/Transcutol® HP systems, they showed that increasing the Tween® 20 to Transcutol® HP ratio increased the nano-emulsion area, which was explained by the increase in surfactant adsorption at the emulsion interface leading to decreases in surface tension and formulation droplet sizes. For Cremophor® RH 40/Transcutol® HP systems, the opposite was noted. They observed that increasing the Cremophor® RH 40 to Transcutol® HP ratio resulted in a notable decrease in the nano-emulsion region. The fact was explained by the high viscosity of Cremophor® RH 40, preventing a rapid breakage of the oil–water interface, and thus decreasing the area of nano-emulsion. The authors concluded that Tween® 20 could better emulsify Capryol® 90 compared to Cremophor® RH 40. The final SNEDDS consisted of Capryol® 90 (oil), Tween® 20 (surfactant), Transcutol® HP (cosolvent) and improved the oral bio-availability of aliskiren hemi-fumarate in rats compared to drug solution.

Figure 4.

Optimization of SNEDDSs (a) ternary diagrams from [49], (b) Box–Benkhen design from [58]. Drug: polypeptide-k, Factors Oleoyl polyoxyl-6 glycerides (oil, X1), Tween® 80 (surfactant, X2), diethylene glycol monoethyl ether (cosolvent, X3); responses: percentage drug loading (Y3), (c) central composite design from [53]. Drug: Bosentan, Factors: Capmul® and Labrasol® (surfactants, X1), MCM (oil, X2), and PEG 600 (cosolvent, X3); responses: percentage drug release in 15 min (Y4), (d) simplex lattice design from [61]. Drug: pentagamavunon-0, Factors: oil (oleic acid, X1), surfactants (Tween® 20 and Labrasol®, X2), cosolvent (PEG 400, X3); response: particle size (Y1) (e) D-optimal design from [56]. Drug: cardamom essential oil, Factors: coconut oil (X1), Tween® 80 (X2) and PEG 400 (X3); response: transmittance percentage (Y2).

In addition to a ternary phase diagram, SNEDDSs optimization can also be done with numerous types of statistical experimental design, such as Box–Benkhen design [50,51,52], central composite design [53], simplex lattice design [54], full-factorial design [55], and D-optimal design [56].

Box–Benkhen design is a response surface design based on three levels (−1, 0, +1) which provides an appropriate model for the quadratic behavior of factors [57]. The number of runs (N) needed to develop Box–Benkhen design is given as N = 2k(k − 1) + C0, (where k and C0 are the numbers of independent variables and central points, respectively). Garg et al. [58] formulated SNEDDSs of polypeptide-k that were optimized by Box–Benkhen design (Figure 4b). Seventeen runs were performed to study the impact of SNEDDS factors on the selected responses (dependent variables). From the study, a decrease of size (Y1) was observed at a higher level of surfactant (Tween® 80, X2), while size increased at higher levels of oil (oleoyl polyoxyl-6 glycerides, X1) and cosolvent (diethylene glycol monoethyl ether, X3). The drug loading (Y3) increased with the increases in X1, X2, and X3 ratios, as shown in Figure 4b. Furthermore, more negative values of zeta potential (Y4) were observed when the concentration of oil (oleoyl polyoxyl-6 glycerides, X1) increased. The optimized SNEDDS showed values of droplet size (Y1), 32 nm, drug loading (Y3), 73%; and zeta potential (Y4), −15.6 mV, and enhanced the oral bio-availability of polypeptide-k in rats.

Central composite designs are the most largely employed response surface designs. They are fractional factorial or factorial designs containing center points, along with a group of axial points which enable the estimations of curvature [59]. The experimental design must have at least three levels of each factor another to establish the coefficients of a polynomial with quadratic ter. A central composite design requires 2k + 2k + nc experiments, where k and nc are the numbers of factors and central points, respectively.

Panigrahi et al. [53] optimized by central composite design bosentan loaded SNEDDSs composed of Capmul® and Labrasol® (surfactants, X1), MCM (oil, X2), and PEG 600 (cosolvent, X3). Preliminary Taguchi design studies revealed surfactant and oil as important factors in SNEDDSs that were further screened and optimized by central composite design. For particle size (Y1), it was observed that at a medium to high concentration of surfactant, Y1 increased only when the amount of oil was reduced. Furthermore, particle size (Y1) was increasing with the gradient declination of surfactant amount. For emulsification time (Y2), it was observed that the gradient increase in surfactant amount reduced Y2. It also signified that an increase in oil amount will increase the Y2. In the case of percentage drug release in 15 min (Y3), it was observed that at a low level of oil, Y3 was high only when the amount of surfactant was higher. Y3 was decreasing on the gradient declination of surfactant amount (Figure 4c). The optimized SNEDDS revealed values of particle size (Y1), emulsification time (Y2) and percentage drug release in 15 min(Y3) as 62.5 nm, 12 s, and 98.5%, respectively, and improved bosentan oral bio-availability as compared to pure drug in rabbits.

Simplex lattice design is defined as a space-filling design which creates a triangular grid of experiments (runs). In this design, the fractions of excipients that make up any composition must add to unity; hence, a regular simplex represents factor space. Mixture points are evaluated in accordance with a lattice arrangement, and a simplified polynomial function is used to represent dependent variables [60]. This function represents how the components affect the response. This design offers an effective tool for investigating the properties of blends over wide ranges of composition, especially for mixtures of four or more components.

With the aim of improving the dissolution rate of pentagamavunon, Astuti et al. designed SNEDDSs formulations that were optimized using simplex lattice design. The factors were the concentrations of oil (oleic acid, X1), surfactants (Tween® 20 and Labrasol®, X2), and cosolvent (PEG 400, X3). Particle size (Y1) increased when the amounts of oil (X1), surfactants (X2), and cosolvent (X3) increased (Figure 4d). Moreover, oil concentration had the highest effect on particle size, while the effects of surfactants and cosolvent were more limited. For the drug solubility in the formulations (Y3), the main effect shows a positive coefficient, following the order: cosolvent > surfactants > oil. In addition, the authors showed that the most significant antagonistic interactive effect was X1X2X3; thus, the effect of the three factors together was less than the sum of the three factors taken independently of each other, while the most significant synergistic interaction effect was X1X2. The optimum SNEDDSs consists of 18.6% oleic acid, 51.4% Tween® 20: Labrasol® (1:1) and 30% PEG 400 and showed a size of 75 nm (Y1) and drug solubility of 31.80 mg/mL (Y3) [61].

Full-factorial design is composed of two or more independent variables interacting each other at different levels. This design is used to study the main effects and interactions of independent variables on dependent variables. The number of runs needed to study n independent variables at 2-levels is 2n. The full-factorial design is particularly useful in the early stage of the experimental work, especially when the number of independent variables is ≤4 [62].

Karamanidou et al. [63] formulated SNEDDSs for the successful oral delivery of insulin. The authors applied a 33 full-factorial design for selecting the quantities of the components (oil, surfactant and cosurfactant/cosolvent) to be used for each composition. The optimum SNEDDSs were composed of Lauroglycol® FCC as the oily phase, Cremophor® EL as the surfactant, and Transcutol® P or Labrafil® M 1944 CS as the cosurfactant. The systems were characterized by average droplet sizes of 30–45 nm and percentages of insulin loading between 0.27 and 1.12%. They demonstrated that insulin-phospholipid (dimyristoyl phosphatidylglycerol) encapsulation into SNEDDSs improved enzymatic stability of the formulations and a sustained release of insulin from the formulations was observed. The SNEDDSs were innocuous up to concentrations of 2 mg/mL and improved insulin permeability.

D-optimal design is among designs generated by a computer algorithm. This design should be applied when classical experimental designs cannot be used. Unlike classical experimental designs, D-optimal design usually contains no orthogonal matrices, and effect estimates are correlated [64]. D-optimal design is always applicable regardless of the type of mathematical model used or the specified objective of the experiment. It is a straight response surface design based on a selected optimality criterion and the best fitting model (i.e., first order plus interaction, cubic, full quadratic, etc.) [65,66].

Ujilestari et al. formulated and characterized SNEDDSs of cardamom (Amomum compactum) essential oil. The SNEDDSs formulations were optimized by D-optimal design by varying amounts of coconut oil (X1), Tween® 80 (X2) and PEG 400 (X3). Emulsification time (Y1) and transmittance percentage (Y2) were chosen as response variable for the optimization. They observed a significant (p < 0.05) relationship between the factors (X1, X2, X3) and the emulsification time (Y1), while no significant (p > 0.05) relationship was observed between the factors and the transmittance percentage (Y2) (Figure 4e). The optimized SNEDDS was composed of 10% cardamom essential oil, 10% coconut oil (X1), 65.7% Tween® 80 (X2), and 14.3% PEG 400 (X3). The SNEDDS exhibited an emulsification time of 46.38 s, 99.37% of transmittance percentage, a viscosity of 187.5 mPa, a particle size of 13.97 nm, and zeta potentials ranging from 28.8 to 45.9 mV. The studies demonstrated that the SNEDDSs had enhanced water solubility and stability of cardamom essential oil [56].

Compared with ternary phase diagrams, the key advantage of these statistical experimental designs is that they can minimize expenditure in terms of time, resources, and developmental efforts. Moreover, the simultaneous influence of factors (oil, surfactant and cosolvent) on the SNEDDS’ characteristics (i.e., droplet size, PDI, time of emulsification, etc.) can be studied.

4. Physico-Chemical Characterization of SNEDDSs Formulation

It is always important to evaluate the final SNEDDSs for several parameters. The general techniques and methods that have been employed for SNEDDSs characterization are summarized below (Table 2).

Table 2.

The general methods and models used to evaluate SNEDDSs.

| Method/Model | Information Provided | |

|---|---|---|

| DLS | Droplet size, PDI, thermodynamic stability | |

| Physico-chemical characterization | Electrophoretic velocimetry | Zeta potential |

| Spectrophotometry | Transmittance percentage, cloud point, thermodynamic stability | |

| TEM, SEM | Morphology, droplet size | |

| Viscosimeter | Viscosity, thermodynamic stability | |

| Dissolution apparatus | Drug dissolution, emulsification time | |

| Preclinical in vitro and ex vivo evaluation | pH-stat unit | Formulation digestion, drug distribution across aqueous/oil phase |

| PAMPA | Permeation across intestinal barrier | |

| SPIP | Permeation across intestinal barrier | |

| IRP | Permeation across intestinal barrier | |

| CaCO-2 | Permeation across intestinal barrier, cytotoxicity | |

| Preclinical In vivo evaluation | Animals | Pharmacokinetic, toxicity, pharmacodynamic |

| Clinical trials | Humans | Pharmacokinetic, bioequivalence toxicity, pharmacodynamic |

PAMPA: parallel artificial membrane permeability assay, SPIP: single-pass intestinal perfusion, IRP: intestinal recirculating perfusion.

4.1. Particle Size

The droplet size of a SNEDDS is often measured after aqueous dispersion via dynamic light scattering (DLS) [67]. The availability of DLS made it a popular technique for droplet size determination; however, the measure can be biased in the presence of large aggregates which scatter more than the nanoparticles, especially at low scattering angles [68,69]. To overcome this limitation, fluorescence correlation spectroscopy (FCS) and Taylor dispersion analysis (TDA) can be used as complementary techniques. In FCS, the fluorescence fluctuations from a fluorescent probe which diffuses in and out of a tiny observation volume is measured [70]. Its high sensitivity allows it to work in dilute solutions; however, FCS applications for larger-sized particles (i.e., emulsion) are still limited, probably owing to the difficulty involved in measuring particle sizes larger than 1/10th of the observation volume’s size [71,72]. Conversely, as a microcapillary-based flow method, TDA allows the characterization of particle size and the stability of small compounds in solution, even for complex composition [73]. TDA quantifies the broadening of the peaks of a specific molecule plug in a Poiseuille laminar flow to determine the molecular diffusion coefficient and subsequently, the hydrodynamic radius [74]. TDA is advantageous as it is less affected by the presence of large-particle aggregates or the sample viscosity; hence, the solutions can be run without any filtration or dilution [75]. However, it usually requires a lipophilic marker which travels in the droplet or micelle [76,77]. The Taylorgrams are plotted as optical density versus time, and the hydrodynamic radius are generated from the molecular diffusion coefficient [73,74]. Chamieh et al. [75] used TDA coupled with a fluorescence detector for the particle size characterization of Labrasol®. The particle size characterization was performed at two different temperatures (25 °C and 37 °C) and increasing concentration (from 1 to 70 g·L−1). The authors showed that when combined, DLS and TDA allowed determining the proportion and coacervates size in the dispersion as well as the PDI of the sample.

Size characterization is one of the most essential examinations for SNEDDSs development since the size of the particles can directedly affect not only the in vitro tested characteristics (i.e., dissolution, stability) but also the in vivo performance of a SNEDDS. (i.e., drug absorption) [78,79]. The literature reported that smaller particle size has a positive effect on the oral bio-availability of a drug encapsulated into SNEDDSs [80,81]. The plausible explanation for the improved oral bio-availability could be that the smaller the particle size, the larger interfacial area, which improves the drug solubilization and permeability. However, it is not a general rule that a smaller globule size of dispersion will always lead to higher oral absorption. Yap et al. [82] compared the oral bio-availability of tocotrienols from two SEDDSs, the first one yields a large emulsion that readily lipolyzed (E1), while the second produced a smaller emulsion with negligible digestion (E2).

Both E1 and E2 showed the same oral bio-availability even though E2 yield dispersion with a smaller particle size. Thus, it appears that droplet size taken together with other SNEDDSs parameters (i.e., susceptibility to lipolysis) have direct impact on the oral absorption of a compound encapsulated into SNEDDSs. However, despite a lack of consistent correlation between emulsion droplet size and oral absorption, generating a smaller dispersion following aqueous dilution or lipolysis is generally necessary since, it is a known fact that these formulations can minimized dose variability after oral ingestion [83,84,85].

4.2. Zeta Potential

The zeta potential provides information about the colloidal stability. It is estimated by measuring the electrophoretic mobility of the droplets. The presence of a high zeta potential value (±40 mV) exhibits repulsive electrostatic forces, which reduces the possibility of particle aggregation [86]. The nanoparticle charge can affect the oral absorption of the drug encapsulated into SNEDDSs. Charge-dependent interaction with mucus and cell membrane barriers with respect to absorption enhancement has been reported [87]. The mucus thin layer protects the GI epithelium from xenobiotics and pathogens, but it also acts as a strong barrier for nanoparticles [88]. The mucus gel exhibits negatively charged substructure made of sulfonic and sialic acid, which hinders positively charged nanoparticles from diffusing into deeper mucus regions owing to electrostatic interactions. Accordingly, negatively charged nanoparticles can more easily permeate the mucus gel compared to positively charged nanoparticles. However, the apical side of the intestinal epithelial cells exhibits negative charges related to the mucosal solution in the lumen. Accordingly, nanoparticles with positive charges can interact with the negative charges of the intestinal mucosal and enhance the cellular uptake of the encapsulated molecule [89,90]. In view of this, Salimi et al. [91] developed SEDDSs that can change their zeta potential via a flip-flop mechanism. They synthesized and incorporated into SEDDSs a conjugate compound that carries both an amino group and a phosphate group. Particles exhibited both a negative value of zeta potential during the mucus transport and a positive zeta potential value after enzymatic degradation of the phosphate ester group, resulting in high cell association and uptake.

4.3. Emulsification Time Measurement

Th emulsification time can be measured on a USP II dissolution apparatus [22]. The formulation is added to a basket containing water and is maintained at 37 °C under gentle agitation (100 rpm). The emulsification time is recorded as the time required to obtain a clear dispersion [92]. The emulsification time is dependent on the oil/surfactant concentration. A spontaneous emulsification is observed with surfactant concentrations less than 60% (w/w) because of the quick release of oil droplets by water penetration into the oil–water interface. However, above the surfactant concentration of 60% (w/w), there is an increase in the time of emulsification due to the high viscosity of the surfactants [21]. A rapid emulsification can contribute to a quick drug release and a subsequently rapid onset of action [93,94].

4.4. Transmittance Percentage Measurement

The transmittance percentage is the measurement of optical clarity of the diluted SNEDDSs with water. The transmittance usually described in percentage is the measurement of how much light passes through a sample. It can be assessed by spectroscopy using water as a blank [95,96]. The increase in transmittance can be used to monitor the self-emulsification rate, and the final transmittance percentage is usually correlated with the nanoparticle droplet size [97,98].

4.5. Morphology

The morphology of the nano-emulsion droplets can be determined by scanning electron microscopy (SEM) and transmission electron microscopy (TEM)). SEM is based on back-scattered electrons, which informs the droplet morphology. In TEM, electrons are transported through the dispersion to generate the morphology of the droplets and differentiate several chemical molecules with the respect to their density. Recently, cryo-SEM and cryo-TEM have been developed to study the real morphological information of nanoparticles [74].

4.6. Viscosity Measurement

Generally liquid SNEDDSs formulations are filled into capsules. Low-viscosity formulations face leakage concerns, whereas overly viscous SNEDDSs are hardly filled into capsules due to flowability problems [99]. Generally, a viscosity ranging between 0.1–1.0 Pa at 25 °C implies that the formulated SNEDDSs can easily be filled into capsules by liquid filling equipment [100]. The viscosity of SNEDDSs is determined with viscometers.

4.7. Cloud Point Measurement

The cloud point is known as the temperature at which the nano/emulsion is broken. The cloud point is determined to investigate the stability of SNEDDSs in the Gl tract. Formulations are diluted with distilled water and placed in a water bath with gradually increasing temperature. Furthermore, spectrophotometric analyses are carried out to determine the transmittance percentage of the sample. At the cloud point, the decrease in dispersion transmittance percentage from the zero point is noted [101,102]. The cloud point of SNEDDSs should be more than 37 °C; otherwise, absorption of the drug can be interrupted, as cloudy emulsion affects the absorption by the dehydration of components used in SNEDDSs formulations [103].

4.8. Thermodynamic Stability Studies

The thermodynamic stability is an indicator of the kinetic stability of a dispersion and is generally used to study the chemical reactions occurring between the components of a dispersion. Poor stability of dispersion can lead to precipitation or phase separation, which could affect drug absorption as well as therapeutic efficacy [104,105]. Generally, centrifugation, heating-cooling, and freeze-thaw cycles are carried out for these studies. Various aspects such as phase separation, turbidity, and particle size are observed during these experiments. Subsequently, stable formulations are selected for further evaluation.

5. In Vitro Assessment of SNEDDSs Formulations

The literature reports the potential of SNEDDSs in improving the oral bio-availability of several compounds. It is a known fact that the performance of any SNEDDS depends on a complex interplay between physiological processes in the GI tract. Following oral ingestion, the digestion of SNEDDSs is initiated in the stomach, where digestible excipients (oils and surfactants) are lysed by the action of gastric lipase at the interface. Gastric digestion releases approximatively 15% of fatty acids from lipids. Within the small intestine, pancreatic lipase together with its co-lipase complete the breakdown of dietary glycerides to di-glycerides, monoglycerides, and fatty acids. The presence of exogenous lipids in the small intestine also stimulates secretion of endogenous biliary lipids, including bile salt, phospholipid, and cholesterol from the gall bladder. In the presence of an elevated bile salts concentration, lipid digestion products are subsequently incorporated into a series of colloidal structures, including multilamellar/unilamellar vesicles and bile salt phospholipid mixed micelles [19,20,21]. Together, these vesicles significantly increased the solubilization ability of the small intestine for both lipid digestion products and drugs before their absorption.

Although this knowledge is useful, the prediction of the in vivo performance of a SNEDDS remains challenging. For this purpose, a series of in vitro models or tests have been developed to simulate main processes related to the absorption of drugs. These processes are usually evaluated in various in vitro models testing dissolution, digestion, and permeation. The in vitro models employed vary depending on their physiological relevance and complexity, ranging from single unit to multi-compartmental models. More elaborate in vitro models evaluate dissolution, digestion, and permeation simultaneously [106,107]. Different in vitro models that have been used to evaluate SNEDDSs are described below.

5.1. In Vitro Dissolution

The in vitro dissolution test is routinely employed as an indicator of the likely GI drug dissolution and, consequently, as a tool to predict the rate and extent of absorption for poorly water-soluble drugs. The rate of drug dissolution relies on many factors, including the degree of wetting, the drug solubility in the intestinal contents, medium viscosity, emulsion droplet size and the volume of the intestinal contents [108]. The pH has also a key impact on drug dissolution characteristic. Generally, simulated gastric fluid without enzymes (pH 1.2) and phosphate buffer (pH 6.8–7.4) have been used to test drug dissolution. In general, the in vitro dissolution from a SNEDDS formulation is faster compared with native drug due to the reduction in particle size and the increase in surface area [93,94,109].

Eleftheriadis et al. [110] studied the dissolution behavior of SNEDDSs loaded with fenofibrate or itraconazole in comparison with the pure drugs. Dissolution studies were performed using a USP dissolution apparatus II in 900 mL of simulated intestinal fluid at 75 rpm paddle rotation and 37 °C. The results showed that the incorporation of these molecules in SNEDDSs significantly enhanced their dissolution rate. Regarding the pure drugs, only 6.6% of fenofibrate and 1.6% of itraconazole were dissolved in 45 min. Almost 100% of the active contents were dissolved from the SNEDDSs formulations in the same period (p > 0.05). At the end of the experiment, the total amounts of pure fenofibrate and itraconazole released were 11% and 4%, respectively. In another example, Abouhussein et al. [111] investigated the in vitro dissolution of rivaroxaban loaded SNEDDSs in comparison with the drug powder. The standard USP II paddle method was used at 37 ± 0.5 °C, and 900 mL of sodium lauryl sulfate (0.6%) in acetate buffer pH 4.5 was employed as the dissolution medium. From the studies, it was found that the two developed SNEDDSs provided significantly higher rates of release (100% and 78% in 5 min, respectively) compared to pure raw drug powder (15%).

However, the use of simple aqueous media to test the dissolution behaviors of poorly water-soluble drugs is often limited by two factors: (1) the poor solubility of the drug (and, therefore, the difficulty to maintain sink conditions), which, when coupled with analytical sensitivity issues such as drug binding to filters can make reproducible in vitro dissolution evaluation difficult, and (2) the lack of similarities between the simple aqueous media and the likely GI tract environment, which reduces the in vivo prediction. In attempt of improving the accuracy of in vivo prediction through in vitro dissolution test, many studies have developed and used biorelevant media that more accurately reflect the solubilization capacity of the GI tract [112,113,114,115]. The compositions of these biorelevant media have been inspired mainly by the likely concentration of endogenous phospholipids and bile salts in the stomach and the proximal part of the small intestine [116,117].

Dressman et al. [118] have studied the dissolution behavior of many lipophilic drugs using various dissolution media [119]. Consistent correlations were found for nonionizable drugs between the type of media and the dissolution profiles of the drugs. For example, the percentage release of danazol in fed state intestinal conditions (FeSSIF media) was three-fold higher compared to fasted state intestinal media (FaSSIF). For molecules with appreciable ionization over the physiological pH range, the situation is complicated by the impact of both ionization and media on the drug solubility.

It was observed for a weak base such as ketoconazole (pKa 6.5, 2.9) that the ionized species at pH 1.2 was much soluble than the unionized at pH 6.5. Furthermore, the percentage of drug dissolved in simulated fasted gastric fluid (FaSSGF) was significantly higher compared to the simulated fasted intestinal fluid (FaSSIF). However, the improved solubilizing capacity of the fed intestine is, at least in part, sufficient to overcome the poor intrinsic solubility of the unionized ketoconazole and the amount of ketoconazole dissolved under fasted gastric state is not notably different from that dissolved under simulated fed state intestinal [120,121]. Memvanga and Préat [41] developed SEDDSs composed of groundnut or sesame oil, Maisine® 35-1, Tween® 80 or Cremophor® EL, and absolute ethanol for the oral delivery of β-Arteether. The in vitro dissolution test using gastric (HCl 0.1 N) and intestinal (phosphate buffer pH 6.8) media showed an increase in drug solubilization over time (Figure 5a). Mendes et al. [122] evaluated the dissolution of hydrochlorothiazide from two SNEDDSs and pure drug. Studies were performed using USP apparatus III containing 200 mL of FaSSGF pH 1.6 or FaSSIF pH 6.5, both at 37 ± 0.5 °C as dissolution media. In the first step of the assay, the dissolution was performed in FaSSGF (20 dips/min); subsequently, the dissolution medium was replaced with FaSSIF for more 180 min (15 dips/min). They demonstrated that both SNEDDSs allowed a faster release rate of hydrochlorothiazide when compared to the free drug. An in vitro release of 27.4% was achieved after 30 min for the hydrochlorothiazide powder, while release rates of 81.9 and 75.6% were achieved by SNEDDS-1 and SNEDDS-2, respectively.

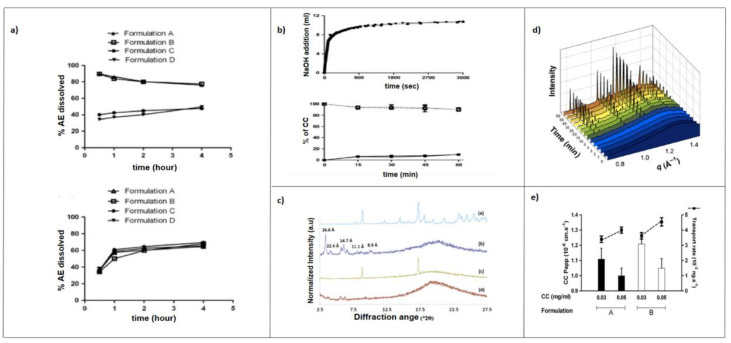

Figure 5.

(a) Solubilization and stability of beta-Arteether in 0.1 N HCl (pH = 1) (top) and in phosphate buffer (pH = 6.8) (bottom) as a function of time. Each point represents the mean ± SD (n = 3). From [41]. (b) Quantity of 0.2 M NaOH added to titrate the fatty acids that were released during lipid digestion (top) and the distribution profile of curcumin in the aqueous phase (open shapes and dotted lines) and in the pellet phase (filled shapes and lines) as a function of lipolysis time (bottom). From [40]. (c) The X-ray powder diffraction patterns of (a) crystalline, (b) CC pellet, (c) blank pellet spiked with CC and (d) blank pellet from the lipolysis of a SNEDDS formulation. The numbers over the peaks indicate d-spacings. From [40]. (d) In situ SAXS profiles during the lipolysis of the MC-SNEDDS formulation containing fenofibrate. Drug precipitation was evident at 4 min after the addition of pancreatic lipase, with the characteristic diffraction peaks for fenofibrate. From [123]. (e) Apparent permeability and transport rate of curcumin-loaded SEDDS across Caco-2 monolayers with two different drug concentrations (0.03 and 0.05 mg/mL). From [40].

5.2. In Vitro Lipolysis

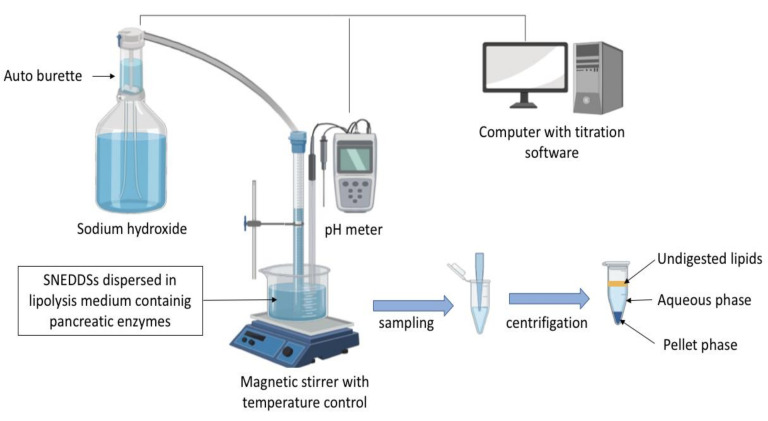

In vitro lipolysis has increasingly been used to assess the likely impact of digestion by gastric/pancreatic enzymes and the dispersion in intestinal fluids of lipid-based formulations, including SEDDSs [73,124,125]. The most frequently employed in vitro lipolysis model to evaluate SNEDDSs is the pH-stat lipolysis model [126,127,128]. The experimental setup generally consists of different equipment used to mimic the intestinal environment, as depicted in Figure 6. The in vitro lipolysis is generally carried out in a thermo-controlled reaction vessel containing a lipolysis medium representative of either fed or fasted GI fluid, formulated with an accurate pH buffer capacity along with bile salt, phospholipids, and NaCl.

Figure 6.

pH-stat lipolysis model for the in vitro assessment of lipid-based drug-delivery systems.

The digestion is triggered by addition of pancreatin extract containing lipases and other pancreatic enzymes (amylase, protease, and ribonuclease). These enzymes hydrolyze TG and other digestible SNEDDSs components (i.e., surfactants), which subsequently release free fatty acids. The fatty acids released are automatically titrated with sodium hydroxide to neutralize the drop in pH caused by the enzymatic lipolysis. The addition of calcium is important to form insoluble soaps with free fatty acids and thereby removes them from the system. Free fatty acids could migrate at the oil–water interface and inhibit enzyme activity [129]. Assuming that a high in vitro drug solubilization equals a high oral absorption, the percentage of drug dissolved in the aqueous phase during the in vitro lipolysis has been related to high oral drug absorption [106]. With this relationship, many studies have described rank-order correlation between the patterns of drug solubilization obtained on in vitro lipolysis and the plasma profiles after oral administration [130,131,132,133]. Thus, SNEDDSs that show evidence of drug precipitation during the digestion appear more likely to result in poorer in vivo drug exposure [134]. The additional solid-state characterization of the precipitates (nature/form) formed during SNEDDSs lipolysis may therefore contribute to the improvement of quality of data interpretation. A drug precipitation in amorphous form (or molecular dispersed state) might be expected to lead to rapid in vivo drug re-dissolution in comparation to the precipitation in the crystalline form [135,136,137]. Several techniques can be used to study the solid-state of the precipitates, including UV imaging, X-ray diffraction and in-line Raman spectroscopy [138,139,140,141].

Moreover, advances in synchrotron small-angle x-ray scattering (sSAXS) are providing greater details of the real-time structural configuration and colloidal phase transitions of lipolyzed formulations [142,143]. sSAXS has been used to control the structural evolution of colloidal structures on a shorter time scale and drug behaviors (solubilization and/or precipitation) on a longer time scale during lipolysis in real time [144]. This technique avoids the need for sample inhibition, time point collections, extended storage and sample retrieval for test, further improving the accuracy and efficiency of the process [74].

Memvanga et al. [40] developed SEDDSs to increase the oral bio-availability of curcumin. Results from the in vitro lipolysis showed that 90–95% of curcumin remained solubilized (Figure 5b), and X-ray powder diffraction analysis of the pellets revealed that 5–10% of the drug precipitated in amorphous form (Figure 5c). Christophersen et al. [133] evaluated the ability of a GI in vitro digestion model to predict the in vivo performance of two SNEDDSs formulations and a commercial tablet of cinnarizine, both in the fasted and fed states in dogs. A SNEDDS (sesame oil, oleic acid, Brij 97, Cremophor® RH 40, ethanol) was either filled into a gelatin capsule (SNEDDS-A) or loaded onto a porous tablet core (SNEDDS-B) and compared to a commercial tablet in an in vitro digestion model. The results in the fasted state showed that the percentage of dissolved drug decreased in the following order: SNEDDS-A > SNEDDS-B > tablet, which correlated well with the in vivo bio-availability. In the fed state in vitro digestion model, the amount of cinnarizine dissolved was similar for all formulations. The authors noted the increase in conventional tablet performance explained by food effect. The X-ray powder diffraction (XRPD) analysis of the pellets obtained at the end of the in vitro digestion showed that the drug from the commercial tablets precipitated in crystalline forms. Khan et al. [123] coupled in vitro lipolysis with sSAXS to simultaneously monitor the solid-state characteristic of precipitated fenofibrate from the lipolysis of a SNEDDS. Results showed that fenofibrate precipitates in its thermodynamically stable crystalline form upon lipolysis of the SNEDDSs, and an increase in scattering intensity over time corresponded well to an increase in concentration of precipitated fenofibrate in the pellet phase (Figure 5d).

However, while the pH-stat lipolysis model provides one means of predicting the oral absorption, it is a closed system, and many studies have since revealed a lack of in vitro–in vivo correlation (IVIVC) using the same lipolysis model [145,146,147]. Moreover, the lack of the absorption sink that is present in vivo will most likely lead to an overestimation of drug precipitation, which may produce an incorrect estimation of the in vivo performance [148,149].

In an attempt to simulate the in vivo conditions as closely as possible, recent research has developed several digestion models, including a high-throughput lipolysis model [150,151], a Permeapad® lipolysis/permeation model [136], two compartmental simultaneous setups [152,153] and the μFLUX system [107].

5.3. In Vitro Permeation Studies

The parallel artificial membrane permeability model (PAMPA) and the Caco-2 cell model are the two most often used to evaluate the drug permeation in vitro [154].

PAMPA is a high-throughput technique, based on an artificial lipidic membrane that is useful in predicting the passive oral drug absorption [155,156]. Initially, drug is placed at the donor compartment, and the apical compartment is drug-free. After the incubation time, the quantity of drug is determined in each compartment. The compartments may also contain some additional ingredients to bind the drug as it permeates [157,158]. PAMPA is especially advantageous in early drug discovery and, since it is easy to automate, cost-effective and compatible for high-amount solubilizers [159,160]. Nekkanti et al. [161] developed SNEDDSs and proliposomes for valsartan and compared their in vitro/vivo performance. SNEDDSs were developed using varying amount of Labrafil® M 2125, Capmul® MCM, and Tween® 80, while proliposomes containing soy phosphatidylcholine, hydrogenated soy phosphatidylcholine, a distearyl phosphatidylcholine were developed by a thin-film hydration technique. Results from in vitro drug permeation studies using PAMPA showed an increase in drug permeability from SNEDDSs and proliposomes over the pure drug. The effective permeability values for the pure drug, proliposomes, and SNEDDSs formulations were found to be 1.0 × 10−5, 1.7 × 10−5, and 1.8 × 10−5, respectively. However, the limitations of PAMPA are that the lipidic membrane is slightly different from the biological membrane and the presence of organic solvent in the membrane, which could result in a non-bilayer membrane structure. Furthermore, PAMPA is limited to passive permeation evaluation [159,162].

The Caco-2 cell line is routinely cultivated as monolayers on permeable filters to study intestinal drug absorption. The drug transport across the GI epithelium cells may occur by several pathways, including the passive paracellular and transcellular routes, the carrier-mediated pathways and transcytosis. Mature Caco-2 cells have been used to study transport of drugs by all these pathways [163,164,165,166]. Although Caco-2 originated from human colon carcinoma, they develop numerous features of absorptive GI cells during culture, such as microvillous structure, hydrolysis enzymes, tight junctions, and carrier-mediated transport system of fatty acids, amino acids, sugars, and many drugs [167,168,169]. Similar to in vivo conditions in intestinal cells, once in contact with lipids, they can synthetize and secrete chylomicrons [170]. Caco-2 cells can be pretreated with different inhibitors to elucidate the uptake mechanisms of drugs and lipid nanocarriers [50,171]. Several studies have shown enhanced drug permeation from SNEDDSs using Caco-2 monolayers [172,173,174,175,176]. Memvanga et al. [40] demonstrated that the transport of the curcumin-SEDDSs across Caco-2 monolayers was improved compared with that of free drug (Figure 5e).

Apart from the permeability assessment, Caco-2 cells could be used to evaluate the safety of many lipid-based formulations. In these assays, Caco-2 cells are treated with increasing amounts of the formulation dispersed in a suitable buffer and left to incubate. Many cellular processes such as DNA synthesis metabolic activity and proliferation can be used to evaluate cell viability after the incubation [177,178,179]. Widely used in vitro cytotoxicity assays include 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT), 3′-[1-[(phenylamino)-carbonyl]-3,4-tetrazolium]-bis(4-methoxy-6-nitro)benzene-sulfonic acid hydrate (XTT) and 3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxyphenyl)-2-(4-sulfophenyl)-2H-tetrazolium (MTS), which give direct indications of cell viability and proliferation [180,181,182,183]. These assays are based on mitochondrial reduction of tetrazolium salts to dyed formazan-based products, providing information on cell activity and metabolism [184]. The main differences between them rely on the chemical compositions of tetrazolium salts. MTT is a positively charged compounds that easily diffuses viable cells and converts to insoluble formazan products, whereas MTS and XTT are negatively charged compounds that are readily transformed into soluble formazan products [154].

Lactate dehydrogenase (LDH) assay is commonly used to access cell membrane damage [177]. The activity of LDH released in the cell culture medium after nanoparticle treatment is spectrophotometrically measured. Released LDH converts pyruvate into lactate resulting in the chemical reduction of NADH into NAD+. A drop in NADH absorption peak correlates to an increase in extracellular concentration of LDH [154].

Desai et al. [185] compared the cytotoxicity of MCT- and LCT-containing SEDDSs on Caco-2 cells of varying maturity (1-, 5-, and 21-day cultures). The cell viability was determined using MTT assy. They demonstrated that the oil-surfactant mixtures had greater tolerance than surfactants alone, and LCT-SEDDSs were well-tolerated at almost 10-fold higher concentrations than the corresponding MCT-SEDDSs. Moreover, the LCT-SEDDSs showed better tolerance compared to MCT-SEDDSs after lipolysis. The authors concluded that MCT and LCT lipids are well-tolerated at normal human dose, and LCT lipids were less toxic than MCT lipids in a Caco-2 cell model.

6. Ex Vivo Permeation Studies

Intestinal absorption has been recognized as a crucial factor affecting the plasma concentration of compounds loaded in SNEDDSs. Several isolated systems have been used to determine the GI absorptive ability of a drug and the mechanism behind this process. These systems contribute to the reduction of live animal in experimentation. Frequently used systems are single-pass intestinal perfusion (SPIP) and intestinal recirculating perfusion that provide conditions closer to what is faced after oral ingestion [185,186,187]. The SPIP is based on the principle that the amount drug in perfusion nano-emulsion decreases over time due to the drug permeation [188]. It allows the determination of the rate and extent of permeation through the intestinal segment (i.e., duodenum, jejunum) after cannulating at both ends. The SPIP is advantageous for compounds that are rapidly absorbed [46,189]. In the intestinal recirculating perfusion (IRP), the process is repeated many times with the same perfusate. Due to the longer retention time within the intestine, the probability of drug absorption is considerably increased. Then, it is dedicated to drugs that are absorbed slowly to amplify the concentration change [190,191].

Kazi et al. [192] investigated the in vitro and in vivo performance of SNEDDSs loaded with talinolol. The in vitro dissolution revealed a significantly higher drug dissolution rate from SNEDDSs (>92% in 2 h) compared to pure drug. The data from in vitro lipolysis showed that SNEDDSs presented comparably higher amounts of drug in aqueous phase under both fed and fasted (60% and 67%, respectively) conditions. The ex vivo permeability by SPIP showed a 4-fold increase in permeability from SNEDDSs compared to pure drug. In another study, Beg et al. [193] used the quality-by-design (QbD) approach to design and optimize SNEDDSs of paclitaxel with improved biopharmaceutical attributes. Following appropriate mathematical models, the optimized SNEDDSs were earmarked by QbD optimization. Next, cationic SNEDDSs were formulated for both LCT- and MCT-containing SNEDDSs and were subjected to in vitro testing. The in vitro dissolution study indicated a 2.7-fold enhancement in dissolution rate from optimum cationic SNEDDSs over free drug. Ex vivo SPIP study exhibited nearly 6- to 8-fold enhancement in absorption and absorption parameters of the drug from the optimized cationic SNEDDSs as compared to the pure drug.

7. In Vivo Pharmacokinetics Studies

In addition to primary in vitro studies, animal pharmacokinetics studies play a major role in predicting the oral bio-availability in humans during drug development [194]. Generally, an oral dose of the drug loaded in SNEDDSs are given to animals (preconcentrate or dispersed in water). To analyze the absorbed drug in the plasma, various analytical techniques such as liquid chromatography-UV and liquid chromatography-mass spectrometry are commonly used [137,195]. The pharmacokinetic parameters (i.e., t1/2, Cmax, Tmax, AUC0-t) from animals are extrapolated to humans to select a suitable dose to use during the first trials in humans. When compared to dogs, rabbits, or pigs, rats are an economical, convenient, and relatively high-throughput animal model. Another advantage of rats is the potential of inhibition of efflux pumps, transporters, and enzymes, allowing the evaluation of their impact on drug absorption [85]. However, it should be noted that one of the major issues of extrapolating bio-availability from animals to humans is the fact that the anatomy and physiology of animals vary largely; therefore, the oral absorption of a drug dose varies across species.

There are hundreds of published articles on pharmacokinetics studies with SNEDDSs in animals such as rats, dogs, or rabbits. Diverse SNEDDSs have been formulated and have shown superior in vitro/in vivo performance compared with native drugs. Some preclinical studies reporting enhanced bio-availability from SNEDDSs formulations are presented in Table 3, with a brief description that gives an overview of this field.

Table 3.

Examples of preclinical studies reporting enhanced dissolution and bio-availability of drugs upon their incorporation into SNEDDSs.

| Class | Drug | Components | In Vitro/Vivo Observation | References |

|---|---|---|---|---|

| ANTI-CANCER | Docetaxel | Capryol® 90, Labrasol®, Transcutol® HP | AUC0-t and Cmax increased 6.4 and 6.5-fold, respectively compared to docetaxel aqueous solution. | [196] |

| Erlotinib | Labrafil® M2125 CS, Labrasol®, Transcutol® HP, Aerosil® 200, Dextran 40 | AUC0–t and Cmax increased 2.1 and 2.4-fold, respectively in case of dextran-based solid SEDDS compared to erlotinib powder. | [197] | |

| Paclitaxel | Sesame oil, Labrasol®, Sodium deoxycholate | AUC0–t and Cmax increased to 2.7 and 3.99-fold, respectively compared to drug suspension. | [194] | |

| Lycopene | LCT, Tween® 85, Cremophor® RH, Gelucire® | AUC0–t and Cmax increased 2.3 and 2.85-fold, respectively compared to Lycovit®. | [198] | |

| Methotrexate | Ethyl oleate, Tween® 80, Propylene glycol | AUC0–24 and Cmax increased 1.57 and 1.68-fold, respectively compared to native drug. | [199] | |

| Irinotecan | Capmul® CM-C8, Cremophor® EL, Pluronic L-121 | AUC0–t and Cmax increased 4.2 and 1.7-fold, respectively compared to drug suspension. | [200] | |

| CARDIOVASCULAR AND ANTI-HYPERTENSIVE | Carvedilol | Labrafil® M1944CS, Tween® 80, Transcutol® | Relative bio-availability enhanced by 4.1 times compared with tablet. | [201] |

| Felodipine | Miglyol® 812, Cremophor® RH 40, Tween® 80, Transcutol® HP, Silicon dioxide | AUC0–t increased 2-fold compared to conventional tablets. | [202] | |

| Clinidipine | Capryol® 90, Tween® 80, Transcutol® | The absorption of the drug was enhanced from liquid-SEDDS as 99 % of the drug was transported from mucosal to serosal side of the rat intestine within 90 min from SEDDS in comparison to only 42.2% from that of the pure drug suspension. | [203] | |

| Valsartan | Triacetin or Castor oil, Tween® 80, PEG 600 | For triacetin-SNEDDS 5 and 2.4-fold increase in Cmax and AUC, respectively; for castor oil SNEDDS 8 and 3.6-fold increase in Cmax and AUC, respectively. | [204] | |

| Rosuvastatin | Peceol®, Tween® 80, Transcutol® HP | In vivo pharmacokinetic studies revealed 1.8 and 5.7-fold enhancement in AUC0-t and Cmax, respectively, and 0.33-fold reduction in Tmax of drug from the SNEDDS vis-à-vis the pure drug suspension. | [173] | |

| Atenolol | Tartaric acid, Captex®, Span® 80, Oleic acid | Ex vivo intestinal permeability studies revealed that atenolol SDEDDS exhibited better drug permeation compared to atenolol or atenolol-tartaric acid suspension. | [205] | |

| Ramipril | Sefsol, Tween® 80, Carbitol | 2.29-fold improvement in oral bio-availability compared with free drug suspension. | [104] | |

| ANTI-DIABETIC | Insulin | Miglyol®, Cremophor® RH40, MCM C-10, Ethanol | AUC0–t increased 2.7-fold compared to insulin solution. | [206] |

| Glibenclamide | Cotton oil, Tween® 80, Propylene glycol | AUC0–t increased 1.4-fold compared to free drug. | [207] | |

| Trans-cinnamic acid | Isopropyl myristate, Cremophor® EL, PEG 400 | The efficacy of trans-cinnamic acid in both hyperglycemia and glucolipid metabolic disorder was enhanced in SNEDDS compared to the drug suspension. | [208] | |

| Gliclazide | Capryol® 90, Cremophor® EL, Akoline® MCM | Enhancement in oral bio-availability as compared to the free drug. | [209] | |

| Exenatide | Cremophor® EL, Labrafil® 1944, Capmul®-PG 8, propylene glycol | 14.6-fold higher relative bio-availability versus subcutaneous exenatide solution. | [210] | |

| ANTIOXIDANT | Quercetin | Capmul®, Tween® 20, Ethanol | 23.7-fold increase in the cell uptake of quercetin when incorporated in SEDDS compared to free drug. | [211] |

| Resveratrol | Miglyol® 812, Montanox, Labrasol®, Gelucire®, Ethanol | The absorptive fluxes through the intestinal epithelium from the nano-emulsions were significantly increased compared to an ethanolic control solution. | [212] | |

| Genistein | Labrafac® lipophile 1349, Maisine®-35, Cremophor® EL, Labrasol®, Transcutol® | 95% of drug release in 5 min. | [213] | |

| Retinol acetate | Soybean oil, Capmul®, Cremophor® EL | Improved in dissolution rate. | [214] | |

| Coenzyme Q10 | Lauroglycol® FCC, Witepsol® H335, Solutol® HS 15 | 5-fold improvement in oral bio-availability compared to free drug. | [39] | |

|

ANTI-VIRAL,

ANTI-BACTERIAL, ANTI-FUNGAL, AND ANTIPROTOZOAL |

Darunavir | Lauroglycol® 90, Tween® 80, Transcutol® HP | Enhancement in AUC0-t, oral bio-availability and Cmax, 1.45,5.8 and 7.5-fold, respectively compared to free drug. | [215] |

| Nelfinavir mesylate | Maisine® 35-1, Tween® 80, Transcutol® HP | 4.5-fold improvement in permeability and 3.6-fold improvement in bio-availability. | [113] | |

| Lopinavir | Maisine®, Tween®-80, Transcutol® HP | Enhanced oral bio-availability (3.9-fold) compared to the pure drug. | [216] | |

| Acyclovir | Sunflower oil, Tween® 60, Glycerol | 3.5-fold increase in oral bio-availability compared to the pure drug suspension. | [217] | |

| Rifampicin | Capmul® MCM C, Cremophor®-EL, Labrasol® | 3.72 and 5.22-fold improvement in AUC0–t and Cmax, respectively compared to drug suspension. | [218] | |

| Amphotericin B | Peceol®, PEG-200, Distearoylphos-phatidylethanolamine | Amphotericin B-SEDD treatment significantly decreases total fungal colony forming unit concentrations compared to non-treated controls without significant changes in plasma creatinine levels in the A. fumigatus infected rats. | [219] | |

| Satranidazole | Oleic acid, Tween® 20, PEG 400 | SNEDDSs formulations showed a drug release of greater than 70% in 45 minutes whereas marketed preparation showed more than 70% of drug release in 90 min. | [220] |

Aside from improved oral absorption, SNEDDSs have been reported to minimize the impact of food effect and bile secretion on the oral drug absorption [84,113]. Perlman et al. developed SEDDSs that provided considerably higher fasted exposures of torcetrapib than the formulation containing Miglyol® 812, previously employed in the clinic. SEDDSs composed of 30% Capmul® MCM, 20% MCT, 30% Triacetin, and 20% Polysorbate 80 enhanced fasted exposure and thus decreased the effect of food from 5- to 3-fold in dogs at a dose of 90 mg [221]. Moreover, reduced intra- and inter-subject variabilities by SNEDDSs were reported [84,222].

In contrast, a literature review revealed fewer clinical studies in which the absorptions of drugs were enhanced by administration in the form of SNEDDSs. Some examples are given here, and Table 4 summarizes them.

Table 4.

Pharmacokinetics data reporting enhanced bio-availability from Self-Emulsifying Drug Delivery Systems (SEDDS) in human subjects.

| Drug | Components | In Vivo Observation | References |

|---|---|---|---|

| Vitamin E | Palm oil, Tween® 80, Span® 80 | 3-fold higher oral bio-availability from SEDDSs. | [223] |

| Cyclosporin | Corn oil glycerides, Cremophor® RH40, PG, DL-α-tocopherol and ethanol | AUC0–t and Cmax increased 1.18 and 1.17-fold, respectively from SEDDSs. | [224] |

| Tocotrienols | Tocomin, Soybean oil Tween® 80 Labrasol® |

2 to 3-fold higher oral bio-availability from SEDDSs. | [82] |

| Saquinavir (Fortovase®) | Medium-chain mono- and di-glycerides | Increased oral bio-availability up to 331% from Fortovase® compared to Invirase®. | [198] |

| Simvastatin | Labrafil®, Tween® 80, Transcutol® HP | 1.55 and 1.5 increased in Cmax and AUC0–t, respectively from SNEDDSs. | [225] |

| Vitamin K | Vitamin K, Labrasol®, Transcutol® HP | Enhancement in vitamin K relative bio-availability from SNEDDSs. | [222] |

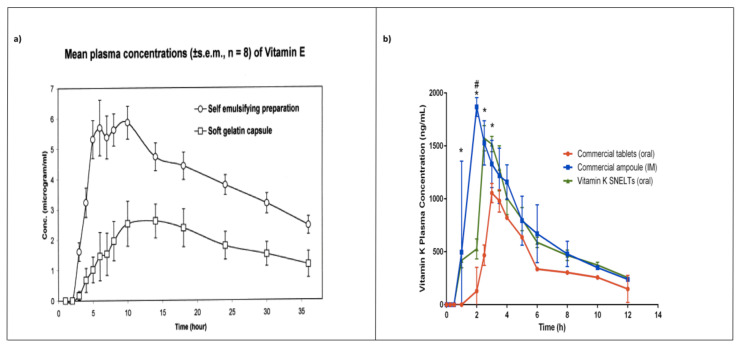

Julianto and colleagues [223] conducted a single-dose study to evaluate the oral bio-availability of a ∝-tocopherol SEDDS in comparison with that of a commercial product, Natopherol®, available as soft gelatin capsules. The SEDDS contained 40% palm oil, 20% Span® 80, 40% Tween® 80, and alpha-tocopherol (333.3 IU/mL), whereas the commercial formulation contained alpha-tocopherol (400 IU) dissolved in soybean oil. They demonstrated that SEDDS formulation enhanced the oral bio-availability of alpha -tocopherol between 210 and 410% compared with the commercial formulation in healthy male volunteers (Figure 7a).

Figure 7.

(a) Mean plasma concentration (±SEM, n = 8) of a-tocopherol as a function of time following oral administration of vitamin E (400 IU) in the form of a self-emulsifying preparation and soft gelatin capsule after subtraction of endogenous vitamin E from each subject. From [223]. (b) Plasma concentration-time profiles of vitamin K after intramuscular and oral administration of commercial vitamin K products and oral administration of vitamin K SNELTs to human volunteers. Each value represents the mean ± SD (n = 6). * p < 0.05 compared to the commercial vitamin K tablet (oral); # p < 0.05 compared to the commercial vitamin K ampoule (IM). From [222].

Postolache et al. [224] compared the oral bio-availability of cyclosporine SEDDSs with a marketed semi-solid oily solution cyclosporine on 24 human healthy volunteers. The results showed that both the AUC0-∞ and Cmax values of the SEDDSs were higher than those of the oily solution. The authors concluded that the oily solution was not bioequivalent with the SEDDSs formulations owing to the lower absorption rate.

A comparative pharmacokinetic study was conducted to evaluate the oral bio-availability of tocotrienols from SEDDSs and an oily solution. Liquid formulations loaded with 200 mg mixed tocotrienols administrated in healthy adults as SEDDSs or simple solution of soybean oil stated that SEDDSs showed a rapid onset of absorption, with a marked increase in the extent of the drug bio-availability by almost three-fold compared to the soybean oily solution under fasted condition [82].

Roche Laboratories enrolled human subjects to compare the bio-availability of Fortovase® and Invirase®, both available in the market as soft and hard gelatin capsules, respectively. Fortovase® was a SEDDS containing saquinavir (200 mg) dissolved in medium-chain mono and di-glycerides, povidone and ∝-tocopherol, whereas Invirase® contained saquinavir (500 mg), microcrystalline lactose, sodium starch glycolate, povidone, magnesium stearate, and talc. The study demonstrated a significant improvement of the oral bio-availability up to 331% from Fortovase® compared with Invirase® [226]. Due to pill burden and GI tolerability issues, Fortovase® was later discontinued from the market [226].

The pharmacokinetic parameters of vitamin K self-nano-emulsifying lyophilized tablets (SNELTs) were evaluated and compared with marketed tablets and ampoules on human volunteers [222]. SNELTs enhanced vitamin K’s relative bio-availability (170%) in comparison with the marketed tablets. Moreover, promisingly, SNELTs showed no statistically significant difference in the AUC compared with the marketed IM injectable ampoules (Figure 7b).

8. Advancements in SNEDDSs

8.1. Supersaturated SNEDDSs

Drug solubility in lipidic components is the key factor that determines the dose of a drug to be administered in a SNEDDS formulation [227,228]. As the oil content is reduced during the dispersion or digestion, the solubilizing capacity of SNEDDSs declines in vivo, leading to drug precipitation [229]. Therefore, most SNEDDSs contain drugs below their equilibrium solubility, typically between 50% and 90%, limiting the access of many drugs to this promising technology, especially drugs that should be given at a high dose [230,231,232].

To overcome this drawback, supersaturated SNEDDSs (s-SNEDDSs) containing precipitation inhibitors have been suggested [228]. s-SNEDDSs are thermodynamically stable SNEDDSs containing a polymer (such as poly vinyl pyrrolidone (PVP) or hydroxypropylmethylcellulose) that should inhibit the nucleation process and subsequent drug precipitation, thus temporarily maintaining a supersaturated solution of the drug in the GI tract [233,234,235]. Supersaturation enhances the thermodynamic stability of the drug above its solubility limit, thus improving both the extent and rate of drug absorption [3]. Moreover, the higher drug loading in the formulation increases the flux over the GI epithelium [236]. Bannow et al. studied the impact of the polymeric precipitation inhibitor (polyvinylpyrrolidone-co-vinyl acetate) PVP/VA-64 on the in vitro performance and physical stability of s-SNEDDS containing simvastatin. They demonstrated that s-SNEDDSs containing 20% (w/w) of PVP/VA-64 and a simvastatin load of 200% enhanced formulation performance during in vitro digestion, achieving a 2.5-fold higher degree of drug supersaturation after 15 min of lipolysis in comparison with PVP/VA-64-free s-SNEDDSs of the same simvastatin load [237].

As per the literature, many researchers have indicated that the bio-availability of a drug in s-SNEDDSs is enhanced and is greater than that in the traditional SNEDDSs [232,238]. s-SNEDDSs have also been employed to reduce the oil/surfactant content in the conventional SNEDDSs formulations. The high concentrations of these surfactants typically present in SNEDDSs can lead to GI side effects. It has been noted that the significantly reduced amount of oil/surfactant in s-SNEDDSs offers an improved safety/toxicity profile than the classical SNEDDSs [231].

8.2. Mucus-Permeating SNEDDSs

Due to faster clearance rates and rapid secretion, the mucus barrier sets a challenge for conventional drug-delivery systems to reach the GI epithelial cell surface and remain there for a sufficient amount of time [239,240]. It has been reported that SNEDDSs composition and resulting nano-emulsion droplet size are the most important factors influencing the mucus-permeating ability of a SNEDDS formulation [241,242]. Most SEDDSs formulations contain surfactants made of PEGylated groups to ensure self-emulsification process, so their relatively high mucus-permeating abilities can be explained by those PEGylated groups located at the surface of the oil droplets, making SNEDDSs highly muco-inert [243].

Friedl et al. observed the permeation of different droplet-sized SNEDDSs across mucus membranes and demonstrated that SNEDDS with a particle size of 12 nm had greater diffusion potential (70%) compared to the diffusion (8%) of the large SNEDDS (450 nm) [244].

Currently, several strategies are used to improve mucus permeation of SNEDDSs, including surface charge modification [245,246,247,248], mucoadhesive polymer incorporation [249,250] and the inclusion of mucolytic agents [251,252].

SNEDDSs that can change their zeta potential from negative to positive were formulated. Those SNEDDSs containing highly phosphorylated molecules have a negative zeta potential and change their zeta potential to positive once coming into contact with intestinal alkaline phosphatase, an enzyme presents in the GI mucus gel layer [91,246]. The advantages of this approach are that negatively charged SNEDDSs formulation can diffuse more quickly across the mucus gel layer, and zeta potential are shifted to positive once in contact with GI epithelium, allowing improved cellular uptake.