Abstract

3D food printing sectors require comprehensive knowledge on viscoelastic and mechanical properties of diverse food materials in order to effectively utilize them in rapid and customized 3D production for supply and manufacturing chains. In this work, we present mechanical and rheological properties of Agar and Konjac based edible gels at different Agar and Konjac weight ratio and discuss their 3D printing performance. Gel samples with higher Konjac content positively contributed to the viscoelastic properties of the gel samples which in return has been found viable for extrusion-based 3D printing. By choosing appropriate printing parameters, different shapes are printed to demonstrate printing resolution. We expect, this study will add potential scope for evaluating and optimizing soft-gel materials for 3D food printing sector.

Keywords: 3D printing, Rheology, Mechanical properties, Edible gel, Food printing

3D printing, Rheology, Mechanical properties, Edible gel, Food printing

1. Introduction

In recent years, 3D printing technology has acquired significant attention because of its design freedom, low production cost, less manufacturing cycle, applicability to complex structures, customization, and fast fabrication [1, 2]. A wide variety of materials such as metals, plastics, composites, gels, biomaterials and food materials [3, 4, 5, 6] have been 3D printed for many advantageous aspects in task specific applications. Semi-solid gel materials like soft single network hydrogels, tough double network gels [7, 8], shape memory gels, ion conductive gels and composite materials are promising candidates for 3D printing field owing to their numerous applications in applied sectors of science and technology [9, 10, 11]. Recently, hydrogel materials, obtained from natural polymers have started getting attention in scientific research due to the health concerns and biodegradability [12]. Biopolymers, such as polysaccharides and proteins are popular materials due to their biocompatibility, biodegradability and renewability [13, 14]. Edible biomaterials can play useful role in not only food industries but also in developing healthcare food with imbedded information in terms of mechanical stiffness or rheological behaviours within the materials that can be used for monitoring health or sensing diseases. Consequently, 3D printing technology towards edible gel materials is getting popularity in recent years due the extended shelf life (due to touch free fabrication process), customized food design, personalized nutrition, developing edible robots for high impact area ranging from veterinary care to designing children's toys [15, 16].

In the past few years, various raw materials such as chocolate, mashed potato, dough, insects, surimi gel and cheese have been used in 3D food printing [17, 18, 19, 20, 21, 22]. Among food materials, Agar is widely used for different applications such as biological culture medium or in food decoration (Japanese desserts and sweets) which contains two components named Agarose and Agaropectin [23]. Due to the hydrogen bond in Agarose part, it is responsible for strong gelling ability while Agaropectin has weak gelling capability. This gel can hold a vast amount of water in the interior helical structure of the gel [24, 25]. The setting of the Agar gel can be occurred in the broad temperature range (from 10 °C to 40 °C) and complete melting requires high temperature (above 95 °C). This phenomenon has been linked to the aggregation of the helices formed during gelation of Agar [25].

Another food material, collected from plants named Konjac glucomannan (KGM) has plenty of application such as bio-adhesive properties improvement, cellular therapy, gel filler for prosthetic implants, coating material and so on [26, 27]. Konjac is a water-soluble polysaccharide for the abundant hydroxyl and carbonyl groups on the molecular chain and consists of (β1→4)-linked d-mannose and d-glucose with about one in 19 units being acetylated. Main component of Konjac is araceae herbaceous perennial [26, 28, 29]. Konjac is isolated from the tuber of Amorphophallus konjac k. koch plant [12] which can produce high viscous solution with water. Konjac glucomannan can interact with many other polysaccharides, such as xanthan, carrageenan and agar, and forms thermally reversible gels. Konjac powder has different application while mixed with other food powder and can produce strong gel when it is deacylated and mixed with Ca(OH)2 [28]. Previously, gel materials prepared by mixing Konjac with Agar and K-carrageenan has been reported and their mechanical properties have been investigated [30]. Rheological and synergistic properties of Konjac mixing with locust bean gum and K-carrageenan has been studied [31]. Rheological properties of Konjac-Xanthan gum-i-carragennan and Konjac-cornstarch mixed system also has been observed [32, 33]. Recently, effect of mixing of Agar with Konjac powder with different ratio (1:9, 3:7, 5:5, 7:3) for drug releasing performance have also been discussed [12]. However till to date, 3D printability of the Agar-konjac gel systems has not been reported yet. 3D printability of the Agar-konjak gel systems will add numerous new potentials in food technology and engineering aspects owing to the added advantage of moldless fabrication, customization and digitalization. Viscoelasticity is an important parameter to evaluate the extrusion parameters of the material. In this work, we used food paste made from Agar and Konjac as ink for 3D food printing. The material used in our experiment has the characteristics of gel materials i.e. between solid and fluid. This mixed material exhibited both elastic and viscous properties. Evaluation of these properties gives important information to select the printing parameters. Therefore, in this work we present a systematic study on the rheological and mechanical properties of the Agar-konjac based gel materials by varying Agar and Konjac weight ratio (Table 1) and 3D printing of the Agar: Konjac gels was carried out for the first time as far as we know. Effect of Konjac content on Agar medium has significantly altered the viscoelastic and mechanical behaviours and these results has been shown advantageous to choose samples for 3D printing of theses soft gel materials.

Table 1.

Amount of Agar and konjac for gel preparation.

| Samples Designation |

Agar (g) | Konjac (g) |

|---|---|---|

| Agar-konjac 3:1 | 15 | 5 |

| Agar-Konjac 1:1 | 10 | 10 |

| Agar-konjac 1:3 | 5 | 15 |

| Agar gel | 20 | 0 |

2. Experimental section

2.1. Materials

Agar powder was purchased from Kanto Chemical Co. Inc. that has the gel strength of 680–700 g/cm2. Konjac powder was purchased from Kitamura Sake. All the materials were used as received.

2.2. Gel preparation

Gelation of food materials classified into two categories: “Hot setting' and “Cold setting” depends on synthesizing method [34]. Agar and Konjac based food gel material follows “Cold setting” gelation method. Agar solution was prepared (1% w/v) by dissolving Agar powder in water. For the gel preparation, the Agar powder was mixed in distilled water for 10 min and the mixture was heated in a microwave oven at 600W for 50s. In the process complete dissolution of Agar powder was ensured. The Konjac powder at a specific wt% (Table 1) was mixed with hot water by stirring and then heated again at microwave oven at 600W for 20s. Then, Konjac solution was mixed with Agar solution by varying weight ratios of Agar and Konjac powder. Gels with Agar: Konjac ratio of 3:1, 1:1 and 1:3 are named as Agar-konjac 3:1, Agar-Konjac 1:1 and Agar-konjac 1:3 respectively. Agar gel without Konjac was also prepared following the same procedure.

2.3. Rheological test

The rheological properties of different hydrogels were investigated by Rotational Rheometer (MCR 302 Modular compact Rheometer) with a 25mm parallel plate (PP25/P2). Dynamic strain sweep was performed to determine Linear Viscoelastic region with a strain range from 0.01% to 100% at the frequency of 6.28 rad/s (1 Hz). Dynamic frequency sweep was performed by applying oscillation frequency of 0.1 rad/s to 100 rad/s at 1% strain at room temperature (~25 °C) under normal force condition. The gap was maintained between 0.8-1mm. Volumetric change was not observed for the Agar: Konjac gel samples. Dynamic temperature sweep was performed to check the behaviour of the material at the heating ramp from 25 °C to 95 °C at 1% strain and angular frequency of 5 rad/s.

2.4. Mechanical properties

The compression test was done to know the behaviour of the material with the constant force. For the purpose of testing the compressive strain and stress, Orientec (STA-1150) universal testing machine was used having load capacity of 500 N (maximum). For compressive test, each sample was cut into 15 mm diameter with the thickness ~2.5–3 mm from a sheet. The effect of dimension deviation was found negligible during the compression test. These gels were placed on the testing stage and compressed with a plunger (40 mm diameter) at a constant crosshead speed of 5 mm/min until the gel samples were fractured.

2.5. 3D printing

The 3D printing was performed using a customized food 3D printer. The 3D printer contains food chamber where the food paste has been kept. A heater connected with the food chamber can be heated up to 100 °C to prevent the gelation and maintain appropriate viscosity of the food gel inside the food chamber. A heat jacket in the holder prevents the heating loss to the environment. The food chambers are made of steels, so the heated holder also heats up the nozzle. The nozzle diameter during printing was 2 mm. Printing with nozzle diameter less than 2mm was not possible as Agar and Konjac mixture caused frequent clogging in the nozzle path. During printing, we kept the temperature at 70 °C in the food chamber while the temperature in the tip of the nozzle was 50–55 °C. This food printer contains two separate nozzles containing screw-based extruder for the purpose of extrusion. The temperature of the nozzle side can be controlled by setting the temperature from the interface of the Pronterface (open-source software that used as graphical user interface host for 3D printing). 3D designs were done in Solidworks and then it was converted to STL file format. Then,.stl file was transferred to open source software Slicer where all the parameters for printing was selected to generate the G-code for printing. Printing speed and extrusion multiplier were tuned to achieve the best printing results. Printing parameters are listed in Table 2.

Table 2.

3D printer and its parameter.

| Equipment used | A customized screw-type 3D printer |

|---|---|

| Temperature at food chamber | 70 °C |

| Extrusion multiplier | 8~10 |

| Infill pattern | Concentric |

| Infill percent | 100% |

| Print speed maintained | 15 mm/s |

3. Result and discussions

3.1. Characterization of Agar-Konjac

3.1.1. Rheology study: strain sweep analysis

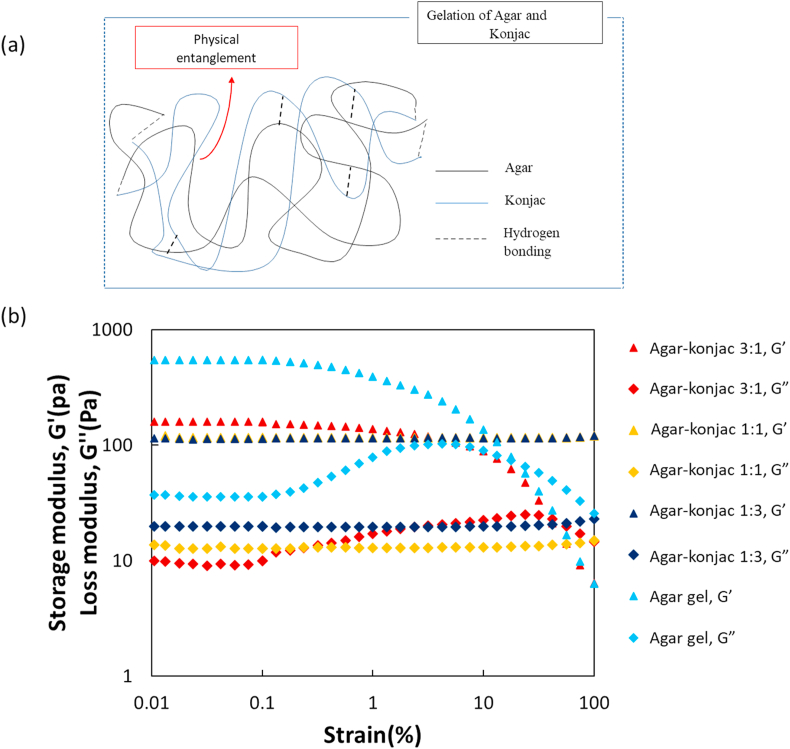

Dynamic strain sweep analysis was done on the gel samples to estimate the linear viscoelastic region (LVR) range, which can be used to evaluate the viscoelastic properties of the materials. Figure 1a and b illustrates the gel network and the storage and loss modulus of the gel samples as a function of strain sweep respectively. From Figure 1b, it was found that among all the samples, the storage modulus (G′) is highest for the Agar gel without Konjac possibly due to the better aggregation of molecules that resulted in the rigid structure. However, in case of other samples, where Konjac is mixed with Agar, the behaviour is slightly different. The value of G′ decreased with increasing Konjac concentration. That means, the network is getting less rigid with the presence of the Konjac molecules in Agar matrix. For the Agar gel and Agar-konjac 3:1 sample, where Agar concentration is higher, the value of G′ started to decrease above 0.1% strain with increasing strain indicating LVR region between 0.01%-0.1%. At 23% and 42% strain value G″ crosses G′ for Agar and Agar-konjac 3:1 respectively. This result suggests that the material loses its network strength with increasing strain. From that point forward where G’’>G′, the viscous properties become dominant. In other two samples (Agar-konjac 1:1 and Agar-konjac 1:3), G′ value remains stable with increasing strain that means the higher concentration of konjac makes the gel network more elastic by forming hydrogen bond through physical entanglement of konjac molecular chains with Agar molecules as demonstrated in Figure 1a. As no crossover occurred between G′ and G″ for Agar-konjac 1:1 and Agar-konjac 1:3 samples, these samples have dominant elastic characteristic over this range.

Figure 1.

(a) Schematic illustration of gel network (b) Strain-sweep analysis of the gel samples.

3.1.2. Rheology study: frequency sweep analysis

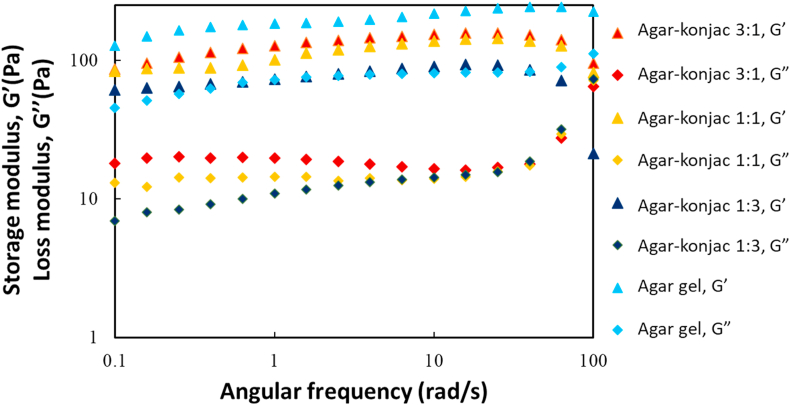

Angular frequency sweep measurements are conducted to predict the structural integrity and mechanical strength of a material (Figure 2). All of the gel samples including pure Agar, within the range exhibited greater storage modulus (G′) value than loss modulus (G″). It suggests the network integrity of molecules of Agar and Agar-based samples. The storage modulus (G′) shows slightly increasing trend with the increase of angular frequency up to 63.1 rad/s for Agar gels and 39.8 rad/s for other samples and then decreases. A crossover happened between G′ and G″ for Agar-konjac 1:3 sample (where Konjac percentage is higher) above angular frequency of 90 rad/s. That means, at 100 rad/s, Agar-konjac 1:3 sample exhibit fluid property.

Figure 2.

Frequency-sweep analysis of the gel samples.

The weak gel model has been used to describe the frequency sweep [35]. The weak gel model is

| (1) |

Where, G∗ = complex modulus, Af = gel strength, z = the degree of interaction.

In equation (1), z interprets the degree of viscoelasticity since it describes the frequency dependency of G∗ [35]. For ideal elastic behaviour, the exponent would be equal to zero so larger z values indicates that the material is viscous.

From the Table 3, Af decreases with the increased percentage of Konjac, which signifies the decrease in gel strength with the increase of Konjac percentage. Agar gel shows high Af value that indicates high network strength of the gel. We can see that the value of z is highest in case of Agar-konjac 1:3 sample. For larger z values, the material showed viscous properties.

Table 3.

Complex modulus (G∗) for different materials.

| Samples Designation |

Af | z |

|---|---|---|

| Agar-konjac 3:1 | 121.52 | 16.69449 |

| Agar-Konjac 1:1 | 103.98 | 13.5318 |

| Agar-konjac 1:3 | 73.419 | 20.20202 |

| Agar gel | 188.72 | 12.36094 |

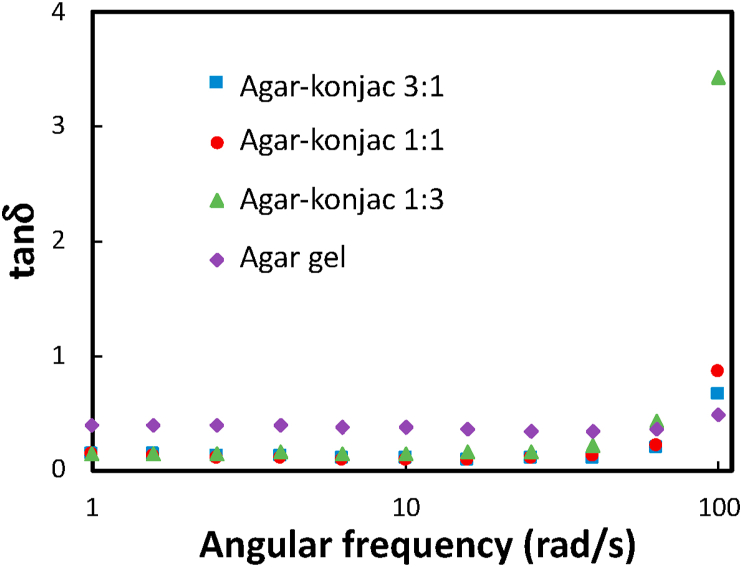

The loss factor, tanδ, reflects the dynamic viscoelastic behaviour of the samples (Figure 3). In principle when tanδ>1, G″ is dominant and mainly exhibit fluid properties and when tanδ<1, the samples exhibit elastic properties. In all cases, but Agar-konjac 1:3 sample, tanδ is less than 1. In case of Agar-konjac 1:3 sample, tanδ is greater than 1, suggesting the fluid like properties. The presence of Konjac at higher concentration (Agar-konjac 1:3) in the Agar structure provides more fluidity and flexibility to the gel network. As a result, at 100 rad/s the mixture fails to show resistant and loss factor becomes greater than 1.

Figure 3.

Loss factor as a function of angular frequency of the gel samples.

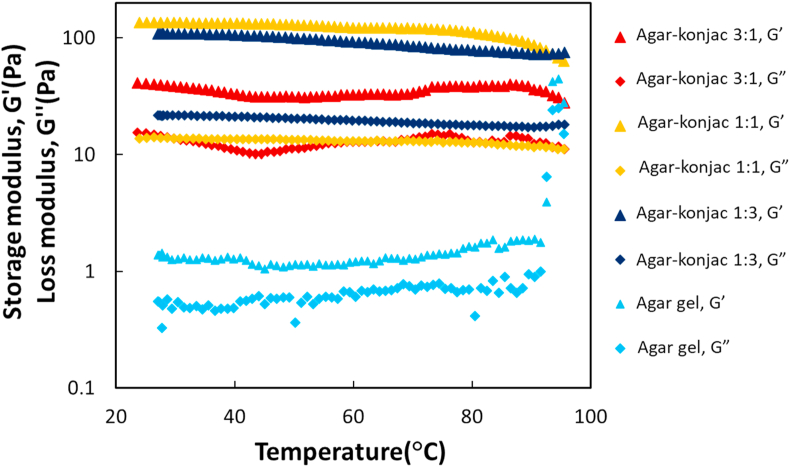

3.1.3. Rheology study: temperature sweep analysis

Temperature sweep was carried out for heating ramp on these materials. Different behaviour has been observed in the studied temperature range (Figure 4). In case of Agar-konjac 3:1, Agar-konjac 1:1 and Agar-konjac 1:3 samples no crossover happened between G′ and G″. That defines that it maintains its structure as gel. For Agar-konjac 3:1 and Agar-konjac 1:1 sample, it was observed that G′ tends to decrease monotonously when the temperature is 75 °C, which means, G’’ (loss modulus) started to become dominant from this point hence the gel network becomes weaker from this point. In case of, Agar-konjac 1:3 sample, where Konjac wt % is higher, storage modulus exhibits slow decreasing pattern as temperature rises. It implies that the addition of Konjac to the Agar molecular network makes the network softer as temperature rises. In case of Agar gel with no Konjac, G″ crosses the G'at 90 °C, suggesting that the gel becomes liquid at this temperature and cannot maintain this structure. As a result, loss modulus (G″) crosses the storage modulus (G′) signifying the phase transition of elastic region to viscous region of Agar gel.

Figure 4.

Temperature-sweep analysis of the gel samples.

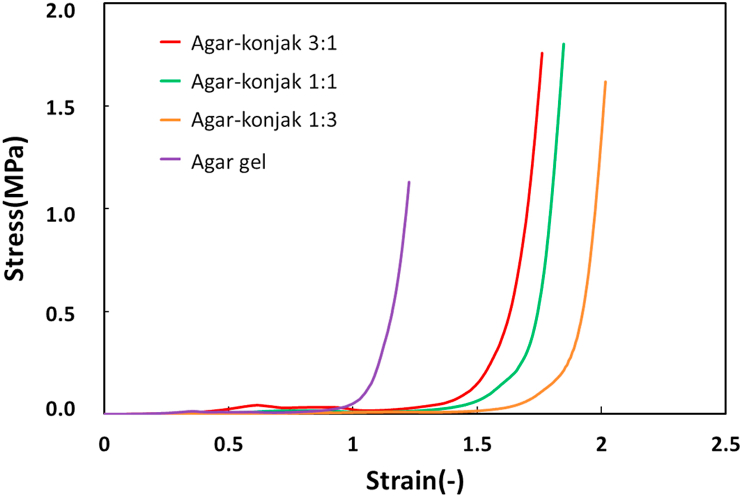

3.1.4. Mechanical property: compression test

Compression testing was done to understand the mechanical properties of the Agar gel and Agar:Konjak gel samples. A representative stress-strain curve is plotted in Figure 5 and mechanical results are listed in Table 4. Among all the gel samples, Agar-konjac 1:3 gel exhibits highest strain whereas Agar gel with no Konjac shows least flexibility. Young modulus of Agar gel shows highest and it decreases as the wt% of Konjac decreases in the gel samples. Presence of Konjac within the Agar medium makes the gel materials softer and ductile and hence the stretchability increased. The mechanical test results well justified the results obtained from the rheological studies.

Figure 5.

Representative stress-strain curve for gel samples from compression test.

Table 4.

Mechanical properties of the gel samples.

| Samples | Young's Modulus (kPa) | Maximum Stress (MPa) | Maximum strain (%) |

|---|---|---|---|

| Agar-konjac 3:1 | 121.52 ± 6.8 | 16.69449 ± 3.3 | 1.23 ± 0.22 |

| Agar-Konjac 1:1 | 103.98 ± 5.7 | 13.5318 ± 2.2 | 1.76 ± 0.25 |

| Agar-konjac 1:3 | 73.419 ± 4.5 | 20.20202 ± 4.4 | 1.85 ± 0.33 |

| Agar gel | 188.72 ± 11.4 | 12.36094 ± 3.2 | 2 ± 0.28 |

3.2. 3D printing of gels

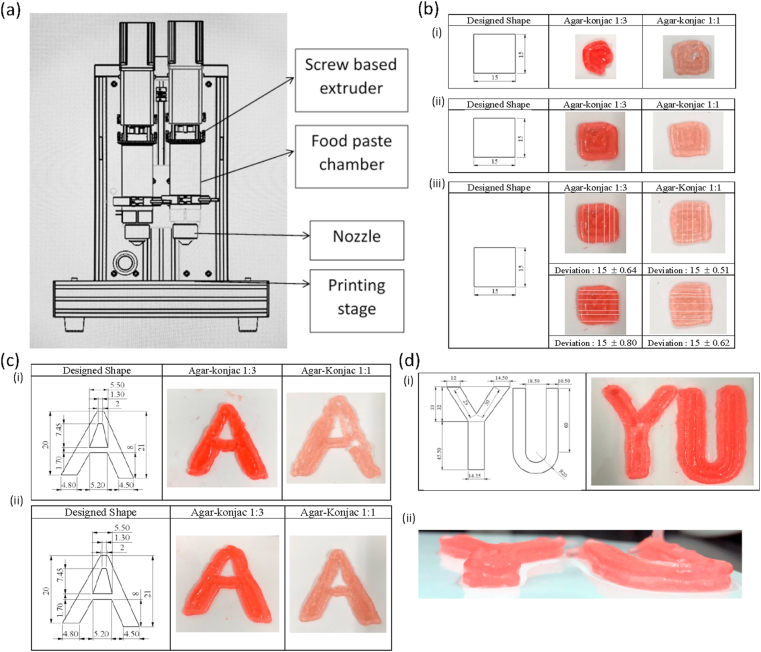

Schematic image of the food 3D printer is given in Figure 6a. For 3D printing, Agar-konjac 1:1 and Agar-konjac 1:3 samples were found suitable for printing with particular shape as demonstrated in Figure 6b-d using food 3D printer. Agar gel without Konjac was not suitable for 3D printing due to its low viscosity. Moreover, Agar gel samples showed higher tendency to gelation upon cooling in room temperature and the tip of the nozzle easily got clogged. Agar-konjac 3:1 sample showed under extrusion while trying to 3D print various shapes. It might have caused due to several reasons such as inapposite rheological properties of this composition and initiation of gelation in the food paste chamber of the 3D printer before or during extrusion. Therefore, printing performance was proceeded with Agar-konjac 1:3 and Agar-konjac 1:1 sample.

Figure 6.

(a) Schematic illustration of the customized screw-based 3D food printer, (b) Determination of printing resolution and deviation (i) printed square shape of Agar-konjac 1:1 and Agar-konjac 1:3 mixtures at extrusion multiplier 8 (ii) printed square shape of Agar-konjac 1:1 and Agar-konjac 1:3 mixtures at extrusion multiplier 10 (iii) determination of printing deviation (c) Printing pattern of shape “A” with Agar-konjac gel samples (i) printing speed is 15 mm/s and extrusion multiplier 8. (ii) printing speed is 15 mm/s extrusion multiplier 10. (d) Different printed shapes (i) Printing pattern of shape “YU” with sample C material (printing speed is 15 mm/s and extrusion multiplier 10) and (ii) Two layers clearly visible in “YU” shape.

To understand printing resolution and accuracy, a rectangle box of 15 mm by 15 mm was designed in Solidworks (CAD software) and this design was printed by the 3D printer. Extrusion multiplier was varied between 8 and 10 while printing speed was set at 15 mm/s Figure 6(b)(i)-(ii) shows images of printed square shape of Agar-konjac 1:1 and Agar-konjac 1:3 mixtures at different extrusion multiplier. It was observed that when extrusion multiplier was 8, it showed under-extrusion of the materials (Figure 6(b)-i). Layer height was set at 1 mm and infill was kept at 100% with concentric pattern while printing. In the next approach, we set the extrusion multiplier at 10 and fixed all other parameters (e.g. speed, layer height, infill patter) and found that both Agar-konjak 1:3 and Agar-konjak 1:1 mixture maintained a decent shape, after 3D printing. Therefore, these conditions were found favourable to use the Agar-konjak 1:3 and Agar-konjak 1:1 mixture in 3D printing to make different shapes.

To determine the printing accuracy, we used the images with extrusion ratio 10 to measure how accurately the printer is printing rectangle. For this purpose, we used open source image analysis software “ImageJ”. This software is used for analysing, measuring scientific image. We first set the scale by drawing one line in the image and then after the calibration for each image we draw seven horizontal line and six vertical line to measure the deviation from the known value. As given in Figure 6(b)-iii it was found that the deviation value was less than 1. Considering the nozzle diameter and deviation, it can be said that the Agar-Konjak mixtures at the studied compositions are not suitable for printing small objects but can be suitable for printing medium sized objects (<10mm). Our work is underway to enhance the printing resolution and make food printing suitable in the microscale dimension.

Figure 6c shows printed “A” shape using the 3D food printer. After designing the shape in Solidworks followed by setting printing parameters in Slicer, G-code is exported to the Pronterface for printing. Figure 6c(i) shows the image of printed shape of Agar-konjac 1:3 and Agar-konjac 1:3 samples at extrusion multiplier 8. We find that with this extrusion multiplier setting, Agar-konjac 1:3 gel gives the best printing result, whereas the Agar-konjac 1:1 sample exhibited under-extrusion, thus, the printing quality is not as expected.

The extrusion multiplier was increased to 10 and the printing speed was maintained at 15 mm/s. Layer height was maintained at 1 mm and infill pattern was selected as 100% and concentric respectively. In case of Agar-konjac 1:3 sample, it shows little bit over extrusion. While Agar-konjac 1:1 gives the perfect printed shape (Figure 6c(ii)). Another shape “YU” was also printed using Agar-konjac 1:3 sample as demonstrated in Figure 6d(i). We have found that the Agar-konjac 1:3 sample, which contains higher percentage of Konjac showed good result during 3D printing using the 3D food printer. Figure 6d(ii) shows two layers printed “YU” shape. That clearly defines that Agar-konjac 1:3 sample can be used for bigger height printing.

Rheology plays important role to regulate the extrusion of food samples during printing and maintaining the printed structure on the printing bed. Low viscous solution will ensure good flow but the structure will collapse after printing if not solidified properly. Again, in case of high viscous solution, due to its high viscosity it will clog the nozzle resulting in discontinues printing with poor resolution. Therefore, both rheology and viscosity play important role to decide the properties of 3D printed material for 3D food printing. The extrusion process followed in our experiment is cold extrusion or room temperature extrusion that relies on the inks' rheology for printing. However, to avoid gelation of Agar at room temperature, we kept the food paste in slightly heated chamber. Temperature dependent rheology study provided the information that temperature has negligible effect on the storage and loss moduli of the samples at higher temperature. From the printing point of view the rheological and mechanical properties of the Agar: Konjac 1:3 sample has been found suitable for 3D printing owing to the better flow property and enhanced flexibility respectively at this composition. From the frequency sweep analysis and loss factor data it was found that Agar: Konjac 1:3 sample shows dominant elastic behaviour and flow properties compared to all the samples. Both rheological and printing data suggests that Konjac plays important in modifying the rheological properties of the samples in favour to 3D printing.

According to the printing result, it can be said that the final product printed with Agar: Konjac 1:3 sample showed promising result with good printing resolution. The printed structures maintained stable shape as per the design. However, extrusion multiplier and printing speed showed significant dependency on the quality of the printing. Also, the preparation of the food paste plays a crucial role to enable the smooth flow of the material while printing. Therefore, the printing parameters and sample preparation should be done properly to produce good quality printed 3D food samples.

4. Conclusions

In the present study, we systematically analysed the rheological and mechanical properties of Agar and Agar-konjac gel samples and 3D printing was done successfully. From the rheological studies, we find that the addition of Konjac powder affects the network structure of Agar as it decreases the breaking strength of the gel. Mechanical test results also validated that with the increase in Konjac concentration in the Agar gel network, the elasticity improves. Furthermore, it has been found that addition of Konjac is advantageous for 3D printing of the gel samples as Konjac makes the extrusion smooth owing to improving viscoelastic properties of the gel samples. Thus, both rheology and mechanical has offered useful information to evaluate the applicability of Agar-Konjak based soft materials for extrusion-based 3D printing. We hope this work on 3D printability of Agar-based gel materials will open new aspect in food-based materials for making touch free printable foods, edible sensor for health monitoring and numerous features for future food industries.

Declarations

Author contribution statement

Julkarnyne M. Habibur Rahman: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Md Nahin Islam Shiblee: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Kumkum Ahmed: Analyzed and interpreted the data; Wrote the paper.

Ajit Khosla: Analyzed and interpreted the data.

Masaru Kawakami, Hidemitsu Furukawa: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Funding statement

This work was supported by the Japan Society for the Promotion of Science (JP17H01224, JP18H0547, and JP19H01122), the Center of Innovation Program (JPMJCE1314), the Program on Open Innovation Platform with Enterprises, Research Institute and Academia (JPMJOP1844 and JPMJOP1614), and the New Energy and Industrial Technology Development Organization.

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Contributor Information

MD Nahin Islam Shiblee, Email: nahin@yz.yamagata-u.ac.jp.

Hidemitsu Furukawa, Email: furukawa@yz.yamagata-u.ac.jp.

References

- 1.Li S. Structure, processing and properties of 3D printable metallic materials. Mater. Technol. 2016;31(2):65. 65. [Google Scholar]

- 2.Ning F., Cong W., Qiu J., Wei J., Wang S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. B Eng. 2015;80:369–378. [Google Scholar]

- 3.(a) Shiblee M.N.I., Ahmed K., Khosla A., Kawakami M., Furukawa H. 3D printing of shape memory hydrogels with tunable mechanical properties. Soft Matter. 2018;14(38):7809–7817. doi: 10.1039/c8sm01156g. [DOI] [PubMed] [Google Scholar]; (b) Long H., Wu Z., Dong Q., Shen Y., Zhou W., Luo Y., Zhang C., Dong X. Mechanical and thermal properties of bamboo fiber reinforced polypropylene/polylactic acid composites for 3D printing. Polym. Eng. Sci. 2019;59:E247–E260. [Google Scholar]; (c) Ambone T., Torris A., Shanmuganathan K. Enhancing the mechanical properties of 3D printed polylactic acid using nanocellulose. Polym. Eng. Sci. 2020;1–14 [Google Scholar]

- 4.Cui J., Zhuang A.H., Olch A.J., Wong K., Ragab O.M., Jennelle R. Evaluating 3D-printed bronze-plastic hybrid material as a new tissue compensator for photon beams. Int. J. Radiat. Oncol. Biol. Phys. 2017;99(2):E653. [Google Scholar]

- 5.Murphy S.V., Atala A. Multi-material food printing with complex internal structure suitable for conventional post-processing. Nat. Biotechnol. 2014;32(8):773. [Google Scholar]

- 6.Lipton J., Arnold D., Nigl F., Lopez N., Cohen D.L., Norén N., Lipson H. Multi-material food printing with complex internal structure suitable for conventional post-processing. Solid Freeform Fabr. Symp. Proc. 2010:809–815. [Google Scholar]

- 7.Maitra J., Shukla V.K. Necking phenomenon of double-network gels. Am. J. Polym. Sci. 2014;4(2):25–31. [Google Scholar]

- 8.Na Y.H., Tanaka Y., Kawauchi Y., Furukawa H., Sumiyoshi T., Gong J.P., Osada Y. Necking phenomenon of double-network gels. Macromolecules. 2006;39(14):4641–4645. [Google Scholar]

- 9.(a) Ahmed K., Kawakami M., Khosla A., Furukawa H. Soft, conductive nanocomposites based on ionic liquids/carbon nanotubes for 3D printing of flexible electronic devices. Polym. J. 2019;51(5):511–521. [Google Scholar]; (b) Shiblee M.N.I., Ahmed K., Kawakami M., Furukawa H. 4D printing of shape-memory hydrogels for soft-robotic functions. Adv. Mater. Technol. 2019;4:1900071. [Google Scholar]; (c) Ahmed K., Naga N., Kawakami M., Furukawa H. Extremely soft, conductive, and transparent ionic gels by 3D optical printing. Macromol. Chem. Phys. 2019;219:1800216. [Google Scholar]; (d) Ahmed K., Shiblee M.N.I., Khosla A., Nagahara L., Thundat T., Furukawa H. Review—recent progresses in 4D printing of gel materials. J. Electrochem. Soc. 2020;167 [Google Scholar]; (e) Rahman M.S., Shiblee M.N.I., Ahmed K., Khosla A., Ogawa J., Kawakami M., Furukawa H. Flexible and conductive 3D printable polyvinylidene fluoride and poly(N,N-dimethylacrylamide) based gel polymer electrolytes. Macromol. Mater. Eng. 2020:2000262. [Google Scholar]

- 10.Bahram M., Mohseni N., Moghtader M. An introduction to hydrogels and some recent applications. IntechOpen. 2016 [Google Scholar]

- 11.Wang C.C., Huang W.M., Ding Z., Zhao Y., Purnawali H. Effects of konjac glucomannan on the structure, properties, and drug release characteristics of agarose hydrogels. Compos. Sci. Technol. 2012;72(10):1178–1182. [Google Scholar]

- 12.Yuan Y., Wang L., Mu R.J., Gong J., Wang Y., Li Y., Ma J., Pang J., Wu C. Effects of konjac glucomannan on the structure, properties, and drug release characteristics of agarose hydrogels. Carbohydr. Polym. 2018;190:196–203. doi: 10.1016/j.carbpol.2018.02.049. [DOI] [PubMed] [Google Scholar]

- 13.Chen H., Hu X., Chen E., Wu S., McClements D.J., Liu S., Bin L., Li Y. Hydrophobicity and physicochemical properties of agarose film as affected by chitosan addition. Food Hydrocolloids. 2016;61:662–671. [Google Scholar]

- 14.Cao Q., Zhang Y., Chen W., Meng X., Liu B. Hydrophobicity and physicochemical properties of agarose film as affected by chitosan addition. Int. J. Biol. Macromol. 2018;106:1307–1313. doi: 10.1016/j.ijbiomac.2017.08.134. [DOI] [PubMed] [Google Scholar]

- 15.Dille M.J., Draget K.I., Hattrem M.N. The effect of filler particles on the texture of food gels. Modifying Food Texture. 2015:183–200. [Google Scholar]

- 16.Holland S., Foster T., MacNaughtan W., Tuck C. 3D printing complex chocolate objects: platform design, optimization and evaluation. J. Food Eng. 2018;220:12–19. [Google Scholar]

- 17.Lanaro M., Forrestal D.P., Scheurer S., Slinger D.J., Liao S., Powell S.K., Woodruff M.A. 3D printing complex chocolate objects: platform design, optimization and evaluation. J. Food Eng. 2017;215:13–22. [Google Scholar]

- 18.Liu Z., Zhang M., Bhandari B., Wang Y. Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. Trends Food Sci. Technol. 2017;69:83–94. [Google Scholar]

- 19.Yang F., Zhang M., Bhandari B. Recent development in 3D food printing. Crit. Rev. Food Sci. Nutr. 2017;57(14):3145–3153. doi: 10.1080/10408398.2015.1094732. [DOI] [PubMed] [Google Scholar]

- 20.Severini C., Derossi A., Ricci I., Caporizzi R., Fiore A. Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. J. Food Eng. 2018;220:89–100. [Google Scholar]

- 21.Wang L., Zhang M., Bhandari B., Yang C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018;220:101–108. [Google Scholar]

- 22.Le Tohic C., O’Sullivan J.J., Drapala K.P., Chartrin V., Chan T., Morrison A.P., Kerry J.P., Kelly A.L. Hydrocolloids as thickening and gelling agents in food: a critical review. J. Food Eng. 2018;220:56–64. [Google Scholar]

- 23.Saha D., Bhattacharya S. Hydrocolloids as thickening and gelling agents in food: a critical review. J. Food Sci. Technol. 2010;47(6):587–597. doi: 10.1007/s13197-010-0162-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Montaño N.E., Villanueva R.D., Romero J.B. Chemical characteristics and gelling properties of agar from two Philippine Gracilaria spp. (Gracilariales, Rhodophyta) J. Appl. Phycol. 1999;11:27. [Google Scholar]

- 25.Lahaye M., Rochas C. Chemical structure and physico-chemical properties of agar. Hydrobiologia. 1991;221:137–148. [Google Scholar]

- 26.Wang C., Xu M., Lv W.P., Qiu P., Gong Y.Y., Li D.S. Study on rheological behavior of konjac glucomannan. Phys. Procedia. 2012;33:25–30. [Google Scholar]

- 27.Zhang Y.Q., Xie B.J., Gan X. Advance in the applications of konjac glucomannan and its derivatives. Carbohydr. Polym. 2005;60(1):27–31. [Google Scholar]

- 28.Yang D., Yuan Y., Wang L., Wang X., Mu R., Pang J., Xiao J., Zheng Y. A review on konjac glucomannan gels: microstructure and application. Int. J. Mol. Sci. 2017;18:2250. doi: 10.3390/ijms18112250. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Smith F., Srivastava H.C. Constitutional studies on the glucomannan of konjak flour. J. Am. Chem. Soc. 1959;81(7):1715–1718. [Google Scholar]

- 30.Rhim J.W., Wang L.F. Rheology and synergy of κ-carrageenan/locust bean gum/konjac glucomannan gels. Carbohydr. Polym. 2013;96(1):71–81. [Google Scholar]

- 31.Brenner T., Wang Z., Achayuthakan P., Nakajima T., Nishinari K. Rheology and synergy of κ-carrageenan/locust bean gum/konjac glucomannan gels. Carbohydr. Polym. 2013;98(1):754–760. doi: 10.1016/j.carbpol.2013.04.020. [DOI] [PubMed] [Google Scholar]

- 32.Brenner T., Tuvikene R., Fang Y., Matsukawa S., Nishinari K. Rheology of highly elastic iota-carrageenan/kappa-carrageenan/xanthan/konjac glucomannan gels. Food Hydrocolloids. 2015;44:136–144. [Google Scholar]

- 33.Yoshimura M., Takaya T., Nishinari K. Rheological studies on mixtures of corn starch and konjac-glucomannan. Carbohydr. Polym. 1998;35(1–2):71–79. [Google Scholar]

- 34.Basu S., Shivhare U.S., Chakraborty P. Influence of sugar substitute in rheology of fruit gel. Adv. Food Rheol. Appl. 2017:355–376. [Google Scholar]

- 35.Murekatete N., Hua Y., Chamba M.V.M., Djakpo O., Zhang C. Gelation behavior and rheological properties of salt-or acid-induced soy proteins soft tofu-type gels. J. Texture Stud. 2014;45(1):62–73. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.