Abstract

As the market does not offer a portable and long-lasting product combining rice and beans in a single preparation, this study intends to characterize a new and alternative gluten-free biscuit, based on the most classic Brazilian staple food: rice and beans. For that, six formulations were designed to test using those ingredients as raw flours and cooked grains. One of them, formulated with wheat flour served as control. After baking, biscuits were submitted to instrumental, physicochemical, and consumer's sensory tests. Tests showed that when cooked beans substituted dried beans flour, the notes of acceptance increased and nutritional profile improved significantly (p < 0.05), which demonstrated to be an innovative use to bakery ingredients. One of the formulations even superseded the acceptance of the control formulation. At least two of the rice and beans formulations presented physicochemical profiles close to the control, with good protein (±10 g/100g) and mineral (±5 g/100g) contents, also being a food source of fibers (±8.2 g/100g), meaning they can bring potential benefits to people on gluten-restricted diets and celiac consumers, as well as to Brazilians who could consume rice and beans, now in a new versatile way.

Keywords: Snack crackers, Celiac consumers, Legumes, Sensory evaluation, Vegan consumers

snack crackers; celiac consumers; legumes; sensory evaluation; vegan consumers.

1. Introduction

Biscuits have been quite popular snacks for many centuries, precisely because they are small and long-lasting. These advantages have been noticed throughout history, as it became a mandatory food item during the transoceanic journeys of the East or West India Companies, in the 16th and 17th centuries. Records of daily rations given to sailors report the presence of biscuit portions (Richshoffer, 1897; Cavalheiro, 1945). In Portugal, close to the ports, there were biscuit ovens dedicated to provide and supply Portuguese fleets with the product that would secure survival for months onboard, when all other supplies would have ended or deteriorated (Sergio, 1941; Cascudo, 2004).

Currently, biscuit, crackers, and snacks are among the most widely available baked goods, for the same reasons of yore, combining nutrition, long shelf-life and practicality. Their shelf-life is extended due to their very low humidity content - which hinders microbial development and degradation, allowing the product to keep its optimal characteristics for longer, as long as appropriately kept dry (Manley, 2011). Combined with biscuits’ common formats, this kind of feature enhances still another advantage: its portability. The crunchy texture, the easy-to-handle and easy-to-store size, both for distribution or individual consumption, make it a trendy, versatile product, always useful in the most varied and unexpected situations.

Behind USA and China, Brazil is, beside India, the third largest biscuit market in the world (higher sales, but lower production), recording a 7.23% sales expansion in the last five years, even during an economic slowdown, while the segment of savory biscuits (including cream crackers and water biscuits) recorded a 31.24% sales increase (from 4.455 to 5.855 billion reais) in the same period (ABIMAPI, 2017). Domestic manufacturers seek an upgrading to follow global trends, offering new types and shapes, as illustrated by the first Brazilian chain of biscuit stores located in shopping centers, which annual production grew from 1.2 million in 2013 to 2.8 million in 2014, in which 10 types of biscuits accounted for 70% of the total sales (Mapa das Franquias, 2015; Oliveira, 2015).

Most of the biscuits found in the market contain gluten as the basis of their formulations (Rai et al., 2014). Gluten is a storage protein compound formed from the prolamins glutenin and gliadin present especially in wheat, being one of the most complex protein networks and having an essential function in determining the rheological behavior of bakery food products. Other gliadin similar prolamins found in cereals are secalin in rye, hordein in barley, and avenins in oats and are collectively referred to as “gluten". The gluten found in all of these grains has been identified as the component capable of triggering the immune-mediated disorders, like celiac disease (Biesiekierski, 2017), and gluten allergy, as much as those non-immune mediated like non-celiac gluten sensitive (NCGS) disorder.

Gluten is very present especially in western population diet, and there are concerns not only about dealing with associated adverse effects of its consumption, as prophylaxis and therapy, but also whether the high, cumulative and continuous exposure to gluten in modern society is involved somehow in the causes of at least some of those disorders (Lebwohl et al., 2015).

Since the only effective treatment for celiac disease is following a gluten-free diet (Midhagen and Hallert, 2003), there is a high demand for new researches of baked goods with alternative gluten-free flours with functionality and efficiency similar to traditional wheat flour. However, replacing wheat flour is a significant technological challenge due to its rheological properties (Torbica et al., 2010), as gluten has a specific role in defining the quality of both the processing and the finished good. That may be solved using other types of flour combined (Lovis, 2003; Rai & et al., 2014), added to other protein or starchy ingredients, in order to adjust the particular characteristics in the desired formulation (Mancebo et al., 2016). Replacements with rice (Chung et al., 2014), maize (Korus et al., 2017), pseudocereals such as quinoa (Alencar et al., 2017; Kahlon et al., 2016), amaranth (Alencar et al., 2015; De La Barca et al., 2010), buckwheat and millet (Brites et al., 2019), or even pulses such as beans (Sharma et al., 2017), chickpeas (Oauzib et al., 2016), lentils (Morales et al., 2015; Zucoo et al., 2011) and broad beans (Abou-Zaid et al., 2011) flours, among many others studied by the industry, have contributed to update knowledge, products and consumption patterns among people who need and desire new food options.

The addition of pulse flours has been arousing interest, especially for their nutritional properties, as their amino acid profile may complement the characteristics of cereal flour, increasing the protein biological value of the flour blend (Day, 2013; Sozer et al., 2017). Since most of the bakery products in the market rely mostly on cereals and roots/tubers, which aminoacidic profiles are not considered complementary for nutritional evaluation purposes, that approach is relevant because people can be consuming ready-to-eat products only as energy supply to a rushed modern lifestyle, possibly lacking after all, the appropriate nutritional balance in protein value. Moreover, non-wheat and no-cereal products, like legumes, have been studied for another particular advantage, by lowering glycemic index (GI) in food products they are present (Passos et al., 2014; Thompson et al., 2012). Beans have a low glycemic index (GI), and consequently, it can raise blood glucose after a meal in relatively low levels (Brand-Miller et al., 2003; Sievenpiper et al., 2009). Several non-wheat and no-cereal products are being incorporated as ingredients to new food products’ research for their power in lower GI while improving the nutritional quality to them (Galegos-Infante et al., 2010; Gomes et al., 2015; Osorio-Diaz et al., 2008), though these beneficial effects are dependant of the amount of the legume flour added in the formulation, which can sometimes compromise organoleptic and sensory characteristics of the new product obtained (Sicignano, 2015).

Researchers have studied the use of different ratios of pre-gelatinized rice and black bean flours in preparing biscuits. The finished products showed an increased B vitamin content, significantly reduced phytate content in all samples and nearly zero tannins. Sensory consumer researches showed that biscuits with lower percentages of those flours were more readily accepted (Basinello et al., 2011). Other studies showed that small additions of other flours to rice flour might increase consumers’ acceptance score for many attributes (Torbica et al., 2012) and even sprouted brown rice may replace wheat flour in biscuit preparation, with particularly good nutritional advantages (Chung et al., 2014).

The current gluten-free trend in society at large is also leveraged by top global celebrities (BBC Brasil, 2015) and many personal testimonies of gluten-free eaters show that even non-sensitive consumers perceive these products as better and healthier (PRNewswire, 2017), since they are alarmed about other possible gluten-related adverse effects (Davis, 2011). This new range of interests has been giving rise to a fast-growing market niche, by meeting the growing demand for traditionally appreciated foodstuffs, but in an innovative wheat-free version (Dewettink et al., 2008; Moroni et al., 2011; Visiongain, 2017).

This work aimed at knowing and assessing the physicochemical characteristics of a new type of gluten-free biscuit, made from rice and bean, with similar features to wheat flour-based crackers, intended mainly to celiac patients and any other person under a gluten-restricted diet, as much as assessing consumers’ sensory evaluation regarding the different studied formulations.

2. Material and methods

2.1. Ingredients and formulations

2.1.1. Ingredients ready-to-use

As ingredients to the biscuit formulations, whole wheat flour (Triticum aestivum L.) of Alkibs brand from Alkibs Ind. and Com. Ltda., Hortolândia-SP; brown rice flour and polished rice flour (Oryza sativa) of Comman brand from Maninho Commerce of Cereals Ltda., Sertão Santana-RS; white bean flour (Phaseolus vulgaris) from Reino Alimentos, São Paulo-SP, were acquired at São Paulo-SP market. Also, flaxseed, dehydrated onion flakes and xanthan gum were acquired in bulk in the same city. Other ingredients as dry carioca beans (group 1) of Camil brand from Camil Food Group, São Paulo-SP; rice (type 1, long thin, polished parboilized subgroup) of Urbano brand from Urbano Agroindustrial Ltda., Jaraguá do Sul-SC; salt (traditional, not refined), of Cisne brand from Refinaria Nacional de Sal S.A., Cabo Frio-RJ; baking soda, of Oetker brand from Dr. Oetker Brasil Ltda., São Paulo-SP; and extra virgin olive oil, of Azcoa brand from Azeites de Coa, Lda., Vila Nova de Foz Coa, Portugal, were acquired at Campinas-SP stores. Samples were kept in their original commercial package until use, or in polypropylene plastic jars after first use, and stored in a dark and dry place until the moment of preparation or analysis of biscuits.

2.1.2. Preparation of pre-cooked ingredients

Beans were cooked without any seasoning, in a 1:3 bean-to-water ratio in a pressure cooker for 45 min (Fernandes et al., 2011). Polished parboiled rice grains were cooked using a 1:2 rice-to-water ratio in a regular pan, for 10 min over low heat in a conventional stove. In this procedure, the water absorption index tested, showing the gravimetric flow, was 1.73 (173%) calculated by the ratio between the final weight of cooked rice and the initial weight of raw rice. The Cooking Ratio (FCy) of beans, calculated having the net weight of cooked beans in water, divided by the weight of beans before cooking, was 1.4 – close to the figure reported by Silva and Brito (2014), of 1.28 for cooked beans without soaking water. The results were used to adjust the amounts of water added to the formulations, and the balance of the portion of grains, in comparison to flours.

We chose not to soak grains that would be cooked, considering the divergences found in literature about the effect of pre-hydration in reducing cooking time (Carbonell et al., 2003; Dalla-Corte et al., 2003; Oliveira et al., 2001); and because it has been proved that “it is unlikely to standardize any of the cooking preconditions, without a more detailed description of each crop under study” (Coelho et al., 2008), which would be out of the focus of this work.

2.1.3. Formulations

Formulations were defined to verify specifically how the main ingredients would perform in the applied tests of this study. With some adjustments, a basic whole wheat biscuit formulation (B1) was set as control (Micla, 2017). For wheat-free formulations, varieties of rice: brown rice flour (BRF), polished rice flour (PRF), cooked polished long grain rice (CPR); and 2 variations in the forms of beans: white bean flour (WBF), for its commercial availability and more appealing color, and cooked carioca type beans (CB). As exposed in Table 1, the chosen blend proportion was in basic 3:1 (rice:beans) amounts, allowing a balance between nutrition/health side, contributing with a good protein complementarity among essential amino acids contained in these ingredients (Woofl et al., 2011), whilst adds health benefits (Mattei et al., 2011), and processing/sensory side, which may impact the product industrially or commercially (Sicignano, 2015).

Table 1.

Control recipe and formulations of the rice and beans biscuit.

| Ingredients: | Formulation |

|||||

|---|---|---|---|---|---|---|

| B1 |

B2 |

B3 |

B4 |

B5 |

B6 |

|

| WWF | BRF/WBF | PRF/CB | BRF/PRF/CRB | BRF/CPR/WBF | BRF/CPR/CRB | |

| Whole wheat flour (WWF) | 100 | - | - | - | - | - |

| Brown rice flour (BRF) | - | 75 | - | 37.3 | 37.3 | 37.3 |

| Polished rice flour (PRF) | - | - | 75 | 37.3 | - | - |

| Cooked polished rice (CPR) | - | - | - | - | 60.4 | 60.4 |

| White Bean flour (WBF) | - | 25 | - | - | 25.0 | - |

| Cooked beans (CRB) | - | - | 35 | 35 | - | 35 |

| Water | 51 | 51 | 41 | 41 | 33.6 | 25 |

| Flaxseed | 11 | 11 | 11 | 11 | 11 | 11 |

| Extra virgin olive oil | 3 | 3 | 3 | 3 | 3 | 3 |

| Baking Soda | 3 | 3 | 3 | 3 | 3 | 3 |

| Salt | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 |

| Xanthan gum | - | 2 | 2 | 2 | 2 | 2 |

| Dehydrated onion | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Quantities are expressed in percentages of the control flour base. Water quantity vary to balance the addition of cooked ingredients.

B1: WWF (Whole wheat flour as primary ingredient).

B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients).

B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients).

B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients).

B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients).

B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Designing for comparison on how different combinations of rice and beans could affect the consumers’ acceptance in a biscuit of cracker type, required to create pertinent variations from an original formulation. For clearness of comparisons, the formulations were built having primary ingredients (any rice, beans, wheat) somehow exchangeable, while having fixed the auxiliary/secondary ones (oil, baking powder, seasoning, etc.). The conditions of variations to rice and beans were set according to their usual processing variability, as commonly available to consumers (rice - brown/polished, grain/flour, and beans – grain/flour). Despite the eight initially rice-beans possibilities, the final selection was restricted to a maximum of five formulations to test (besides the control one), due to intrinsic limitations of time and preventing sensory overload to consumers (Pentz and Gerber, 2013). Because of that, utilizing cooked brown rice was discarded in this study, for higher granularity, affecting dough texture, and being more time consuming to prepare. So, from the six remain possibilities, the group having only primary ingredients in flour condition (for practical reasons) readily offered the next formulation (B2), which per si, defined the third formulation (B3), the glaring contrast to B2, selected from the other group having cooked beans at the base. Still, because of pre-tests showing boosted sensory performances when mixing in 50% of those rice conditions, it was considered the option of having some of the formulations representing that status. So, the last three formulations were defined: B4 and B6, unfolding B3 doubly (having fixed the whole rice portion, while switching the forms of polished rice, PRF and CPR, respectively); and B5, unfolding B2 once, respecting the limit of 6 final formulations. Here, selection preference was to add another cooked cereal portion in another formulation enabling more comparison possibilities.

2.1.4. Preparation of biscuits

Biscuits were prepared using the formulations described in Table 1, and preparation was adapted from original procedures described by Micla (2017).

The dough was processed as follows: Dry and powder ingredients: flour(s), dehydrated onion, xanthan gum, salt and baking soda were added to the bowl of a Black&Decker (China), Power Pro FP2500S food processor, processing it for 2 min at slow speed (420 rpm/min). Next, boiled filtered water was added to the dough, blending for 1 min, and then, olive oil was added, and the dough was processed for another 2 min until smooth, turning into a single compact mass. In case of formulations with cooked grains, they were added after the dry blend and before water. Next, the dough was transferred to a bowl for the incorporation of whole flax seeds, while it was kneaded by hand. Then, the dough was split into portions, and stretched using a cylindrical aluminum dough roller (greased with extra virgin olive oil) until reaching an even thickness of approximately 2 mm. The dough was finally cut into approximately 6.2 mm2 diamonds. It yielded about 180 biscuits.

The biscuits were taken to a conventional DeVille gas oven (Brastemp, São Paulo-SP), pre-heated at approximately 210 °C. Baking time was firstly preset to about 15–21 min in order to reduce the biscuit's moisture to its characteristical pattern of low moisture, close to 5% (Mamat and Hill, 2018). After baking, samples were removed from the mold and allowed to cool at room temperature (25 °C) for 45 min. Biscuits were then transferred from the molds to be stored in hermetically sealed polypropylene jars, in a dry and dark place at room temperature (Gutkowski et al., 2003).

2.2. Analyses and tests

2.2.1. Proximate composition

Base flours (wheat, brown rice, polished rice and bean), as well as the crumbs obtained from crushing baked biscuits of each formulation, were tested for their physical and chemical parameters, with regard to contents of moisture, according to the gravimetric method (AOAC, 2000); ash, according to method 08–12.01 (AACC, 2010); protein, through method 46–13.01 (AACC, 2010) with a conversion factor of 5.7 for whole wheat products, 6.25 for white bean flour, and of 5.95 for any rice products; total fat, through the Bligh and Dyer (1959) method; dietary fiber, according to method 991.43 (AOAC, 2000); and carbohydrates by difference. All those experiments were performed in triplicates for each food matrix and formulation.

2.2.2. Color measurements

The color of each flour and biscuits (crushed to flour) was assessed using the Hunterlab ColorQuest II colorimeter (Reston, Virginia, USA). The device was set at a standard Illuminant D65 (representing the typical spectral power distribution of the midday light) at 10° (field of vision) standard observer. Samples were placed in a Petri dish to measure the color in the quadruplicate surface. CIEL∗a∗b∗ scales were used and the measured color parameters were: L∗ = Lightness (0 = black, 100 = white), +a∗ = red, and -a∗ = green; +b ∗ = yellow, and -b∗ = blue (Hunterlab, 1996). This analysis was performed in triplicates for each food matrix. Calculations for Δ used subtraction between results of color results of every sample and any other sample, in all the possible paired combinations, and ΔE used the formula: ΔE∗=((ΔL∗)2+(Δa∗)2+(Δb∗)2)1/2 as described by Moritz (2011).

2.2.3. RVA

The viscoamilographic behavior of flours was assessed using ICC method 162 (1996), in RVA (Rapid Visco Analyzer) viscometer, model RVA 4500 (Warriewood, Australia) and the curves were analyzed by the software TCW 3.15.1.255. The crackers samples were previously crushed and homogenized to flour in the blender, model OBL 10/2 (OXY, Santana de Parnaíba, BRA), to 25000 rpm by 1 min. In the sequence, the flours were passed through sieves of 60 (250 μm) and 80 (177 μm) mesh to obtain a more refined flour. Four replicates for each sample was analysed, having parameters results of pasting properties including peak viscosity, trough, breakdown viscosity, final viscosity and setback, pasting temperature and peak time, registered in RVU (Rapid Viscosity Units).

2.2.4. Physical measurements

Weights of biscuits were measured with an analytical scale right before and after the baking process. The area was calculated multiplying the diagonal length by diagonal width of each biscuit sample and dividing by two. Thickness, the biscuit height, was ascertained with a caliper. All those measurements were done in triplicate.

2.2.5. Instrumental hardness measurement

Using a texture analyzer (TA-XT2i, Stable Micro Systems, Surrey, UK) with the option of measuring hardness, a force in compression registering a maximum peak, and distance, the linear distance was taken as an indication of fracturability, were measured with 12 replicates for each formulation. The test conditions were: pre-test speed at 1 mm/s, test speed at 1 mm/s and post-test speed at 10 mm/s, and the penetration distance was 3mm.

For shelf-life analysis purposes, the biscuits were stored in closed bags inside hermetically sealed polypropylene jars for the same instrumental texture measurements after about 3 h, 7, 14, 30 and 60 days, at room temperature (25 °C).

2.2.6. Sensory acceptability

This experimental study was approved by the Research Ethics Committee of the State University of Campinas, under CAAE No.: (65581517.8.0000.5404), and was designed in a way that 120 participants could try the acceptance of six biscuit samples (five made of rice and beans and one made of wheat).

The 120 subjects [51 men, 69 women, average age (M) = 25.08 years, standard deviation (DP) = 9.43] filed a sensory evaluation sheet, while they tried and judged each corresponding sample, using a 9-point hedonic scale (from 1-dislike extremely to 9-like extremely) to evaluate attributes such as appearance, aroma, taste, texture and overall impression (Stone and Sidel, 1993). In the same sheet, a field would question about the consumer's purchasing behavior, using a five-point purchase intent scale (Meilgaard et al., 1999) for each sample.

The test was applied in a laboratory room (see Figure 2) with 15 cabins where participants could find: 6 biscuit samples displayed in complete balanced blocks (MacFie, 1989), to be managed by the participants themselves, served at room temperature over a plate lined with white paper napkin, a glass of filtered water (200 mL), a sensory evaluation sheet, and a pen. Participants were requested to drink water between each sample to minimize the first-order carry-over effect when a sample assessment influences the evaluation of the next sample (Walkeling and MacFie, 1995). Participants took approximately 10–20 min to conclude the test, with their notes.

Figure 2.

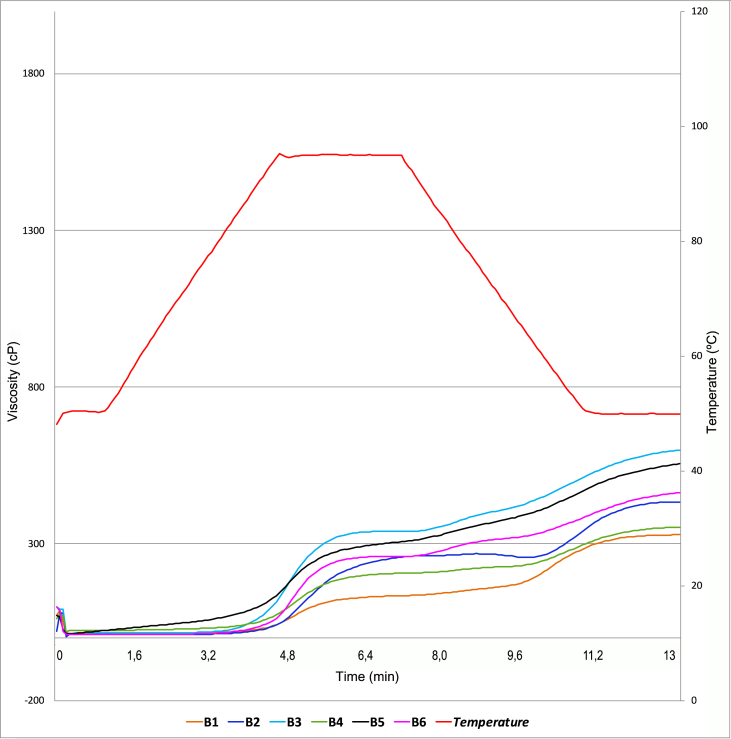

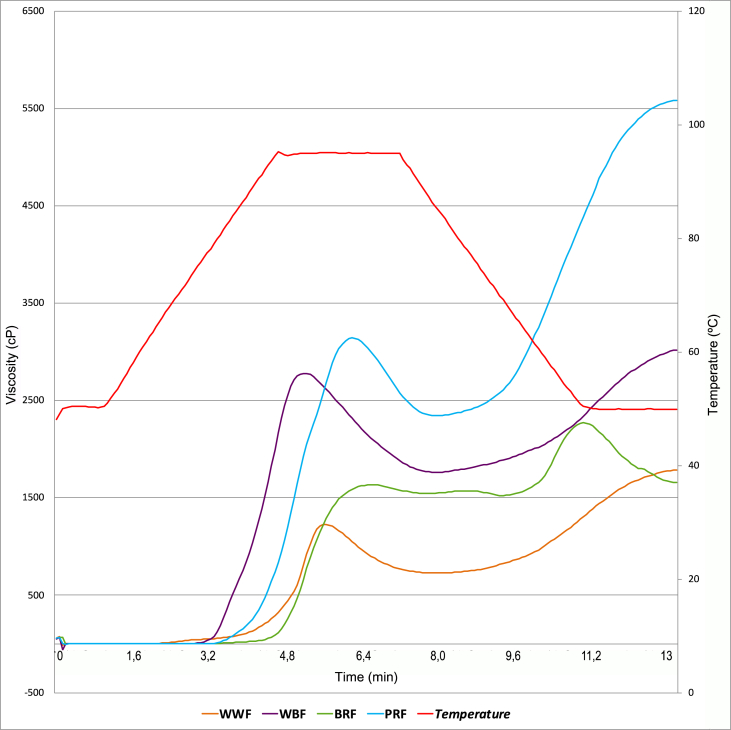

Graphic representation of the RVA analysis results for the biscuits' formulations. (cP - centipoise unit, a dynamic viscosity measure). B1: WWF (Whole wheat flour as primary ingredient). B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients). B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients). B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients). B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients). B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

2.2.7. Data analysis

The statistical analysis was carried out using the SAS software system version 9.4 (SAS Institute Inc., Cary, NC, USA). Physicochemical and sensory results were evaluated using a univariate statistical analysis – one-way variance analysis (ANOVA), to ascertain the effects of the sample and the taster; as well as Tukey's test to run multiple comparisons of the averages of the participants by attribute in each sample, in order to ascertain which samples would diverge from each other at a 5% significance level.

3. Results & discussion

3.1. Characteristics of the flours

3.1.1. Color measurements results

According to the mean notes for color instrumental analysis (Table 2), the flours used presented their different intrinsic characteristics. However, WBF and PRF presented significantly (p < 0.05) higher Lightness (L∗ value), and lower a∗ and b∗ values, showing a brighter color of a more neutral tonality than the others, probably for different reasons; PRF for its higher digestible carbohydrates, mainly starch, and WBF for its naturally bright tegument fibers. Conversely, WWF and BRF presented lower Lightness and higher a∗ and b∗ values, meaning their darker color than the former flour samples, by adding a reddish touch slightly due to their higher fibers' compounds. Red color may relate to phenolic and carotenoid compounds found in the grain structure (Colasuonno et al., 2017). Sumargo et al. (2016) found BRF with a deeper pigmentation, depending on the rice variety, in ranges of Lightness (77.6–78.4), a∗ value (0.93–2.31), and b∗ value (18.8–19.4).

Table 2.

Proximate composition (in g/100g), instrumental color, and RVA results of flours.

| Samples | WWF | WBF | BRF | PRF |

|---|---|---|---|---|

| L∗ | 80.92c ±0.08 | 89.51a ±1.91 | 85.14b ± 0.93 | 91.13a ±1.35 |

| a∗ | 2.83a ±0.03 | 0.04c ±0.03 | 0.70b ± 0.04 | -0.28d ± 0.02 |

|

b∗ |

12.31a ±0.08 |

6.58c ±0.23 |

10.59b ± 0.25 |

6.16c ±0.15 |

| Moisture | 12.05a ±1.21 | 11.33b ± 1.14 | 9.33c ±0.94 | 11.26b ± 1.13 |

| Ashes+ | 1.87b ± 0.04 | 1.92b ± 0.09 | 2.54a ±0.01 | 0.75c ±0.04 |

| Proteins+ | 12.70a ±0.39 | 10.77b ± 0.73 | 8.86c ±0.10 | 7.07d ± 0.23 |

| Lipids+ | 2.16b ± 0.22 | 1.10c ±0.11 | 3.56a ±0.36 | 1.01c ±0.10 |

| Digestible+ carbs | 72.44c ±1.71 | 80.33 bc ±1,53 | 81.24b ± 1.07 | 90.58a ±0.02 |

| Dietary fiber+ |

10.63a ±1.40 |

5.88b ± 0.94 |

3.80c ±0.61 |

0.59d ± 0.10 |

| Peak Viscosity | 1230.75d ± 23.2 | 2784.50b ± 14.4 | 1641.75c ±59.7 | 3153.00a ±20.5 |

| Through | 728.75d ± 13.3 | 1762.75b ± 28.4 | 1506.00c ±48.2 | 2344.50a ±97.9 |

| Breakdown | 502.00c ±10.2 | 1021.75a ±28.4 | 130.75d ± 26.8 | 808.50b ± 90.5 |

| Setback | 1058.75b ± 24.2 | 1255.50b ± 60.7 | 143.25c ±33.4 | 3237.75a ±266.3 |

| Final Viscosity | 1787.50c ±36.9 | 3018.25b ± 37.3 | 1654.25c ±66.0 | 5582.25a ±183.5 |

Ashes, proteins, lipids and total carbohydrates are indicated in dry basis. Averages ±standard deviation with equal superscripts in the same line do not differ significantly (p > 0.05). WWF: Whole wheat flour/WBF: White beans flour/BRF: Brow rice flour/PRF: Polished rice flour. L∗(Lightness); a∗ (greenish/reddish); b∗(bluish/yellowish). RVA: Rapid Visco Analyzer. RVA values in RVU (Rapid Visco Units).

3.1.2. Proximate composition results

The physical-chemical analysis results of flour samples are in Table 2. Ranging from 9.33-12.05 g/100g (BRF, WWF), moisture results were in expected levels, and similar to those found in the studies of Torbica et al. (2012) and Luhovyy et al. (2017). In general, WWF presented the highest moisture, protein, and dietary fiber contents. Analyzing the contents of WWF from different crops, Gutkoski et al. (2003) recorded close protein percentages (9.10–12.45); however, the ash contents ranged lower (0.45–0.63) than that recorded in this study (1.87 g/100g).

As available in the São Paulo market, the bean flour we used presented a low profile of protein and dietary fiber contents, 10.7 and 5.88 g/100g, respectively. In analyzing the composition of white bean flour, Simons et al. (2015) and Gomes et al. (2006) reported far higher protein contents of 22 and 23.18 g/100g. When producing their beans flour at the lab, Oliveira et al. (2017) found still higher protein contents, up to 29.98 g/100g.

Compared to polished rice flour, brown rice flour presented 339% and 351% higher values of ash and lipids, respectively. These differences are related to the polishing process that removes a significant part of the bran contents, which concentrates more minerals and lipids, found mostly in the external layers of the rice grain (Storck et al., 2005). Other authors also reported similar lower profiles for polished rice flour (Rai et al., 2014; Torbica et al., 2012), which dietary fiber content is also low, due to the flour refining process (with a consequent loss of fibers and minerals, and a higher starch concentration), 84.47% lower than in brown rice. Nevertheless, the dietary fiber content of PRF in this study is at a similar level to that recorded in the Nutrition Facts, of 0.60 g/100g (TACO, 2011).

3.1.3. RVA results

The viscoamilographic analysis for the wheat, bean, brown rice, and polished rice flours shows oscillations according to the different profiles from their intrinsic characteristics (Table 2). In general, the pattern of brighter color, lower to dietary fiber, and higher to digestible carbohydrates contents, was reflected in higher values of most of the dough properties analyzed. Fiber competes with starch for water, so lower fiber contents facilitate the swelling of starch molecules under increasing temperature, influencing higher peaks of viscosity and through, but also in the setback, under water evaporation, when starch chains, particularly amylose, starts to organize a more resistant structure, with hydrogen bonds; and the higher the organization is, the higher the final viscosity will be (A. V. Carvalho et al., 2012).

Conversely, most of the significantly lower results for the dough properties happened to that darker in color, higher in fiber and protein contents, and lower in starch flour. Results increase in the sequence: WWF, BRF, WBF, PRF, as shown by the progression of letters of the test of Tukey, and better visualized in Figure 1.

Figure 1.

Graphic representation of the RVA analysis results for raw materials and formulations of the biscuit. cP (centipoise, a dynamic viscosity measure). 12 cP = 1 RVU. WWF: Whole Wheat Flour/WBF: white beans flour/BRF: Brow Rice Flour/PRF: polished rice flour.

Presented in most of the formulations, BRF is of greater interest, showing its breakdown value lower than the others', probably due to differences in its contents’ proportions in which the higher presence of non-starch components, especially lipids and minerals, interfere in the dough properties responses. Also, differences in dough results can be related to structural changes in flour granules caused by the grinding process, such as flour particle size acting as a physical barrier for heat transfer (Araki et al., 2016; Asmeda et al., 2016). Although the present work did not analyze particle sizes of the flours, Hasjim et al. (2013) relate larger particle sizes of rice flours to higher pasting temperatures requiring a longer holding time at 95 °C to reach a plateau viscosity. That effect for BRF (green line) is clearer seen in graphical profile (Figure 1).

3.2. Characteristics of the biscuits

3.2.1. Physical results

Among the physical measurements, Table 3 presents the average weight of the biscuits before baking 3.7–4.24/g; and after baking, from 2.13-2.73/g. The heating process caused the biscuits to reduce their considered weight and area; comparisons among the biscuits by the same process condition show that reductions for each formulation were not significantly different (p > 0.05). The average weight loss ranged from 34-42.6%, and except when comparing these extreme variations, most of the dehydration values were statistically similar (p > 0.05). That high dehydration rate is related to the heating and, consequently, water loss within starch granules and protein compounds from the ingredients and the shape adopted for the biscuits, which sizeable flat area and thin thickness characteristics allowed high evaporation in the molds.

Table 3.

Results of physical measurements of the biscuits.

| Samples | Weight |

De-hydration |

Area |

Thickness |

Color Parameters |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| Before baking | After baking | After baking | Before baking | After baking | Before baking | After baking | L∗ | a∗ | b∗ | |

| B1 | 4.24a ±0.36 | 2.50a ±0.24 | 40.9ab ± 0.6 | 6.53a ± 0.3 | 5.8a ±0.3 | 2.8a ±0.2 | 3.3a ±0.4 | 58.27b ± 1.69 | 10.75a ±0.40 | 25.55a ±2.08 |

| B2 | 4.10a ±0.42 | 2.58a ±0.13 | 37.0ab ± 3.7 | 6.27a ±0.3 | 5.77a ±0.3 | 2.9a ±0.4 | 2.8ab ± 0.2 | 57.69b ± 1.78 | 11.3a ±0.55 | 29.22a ±0.20 |

| B3 | 3.7a ±0.78 | 2.13a ±0.48 | 42.6a ±1.9 | 6.40a ±0.3 | 5.57a ±0.2 | 2.4a ±0.3 | 2.2b ± 0.3 | 63.83a ±2.35 | 7.38c ±1.81 | 25.22a ±2.48 |

| B4 | 3.95a ±0.35 | 2.33a ±0.16 | 41.0ab ± 1.9 | 6.13a ±0.4 | 5.47a ±0.3 | 2.8a ±0.4 | 2.7ab ± 0.4 | 60.22ab ± 3.89 | 8.04 bc ±2.19 | 26.90a ±1.67 |

| B5 | 3.88a ±0.63 | 2.40a ±0.47 | 38.2ab ± 3.6 | 6.33a ±0.6 | 5.83a ±0.6 | 2.9a ±0.3 | 2.7ab ± 0.2 | 58.39ab ± 0.80 | 10.17ab ± 0.64 | 28.41a ±0.64 |

| B6 | 4.14a ±0.48 | 2.73a ±0.33 | 34.0b ± 4.6 | 6.27a ±0.6 | 5.83a ±0.4 | 2.9a ±0.3 | 2.9ab ± 0.2 | 57.07b ± 1.48 | 7.86c ±0.40 | 25.08a ±0.76 |

Averages ±standard deviation with equal superscripts in the same column do not differ significantly (p > 0.05). Weight in grams (g)/Dehydration in % of weight/Area in squared centimeters (cm2)/Thickness in millimeters (mm)/L∗(Lightness); a∗ (greenish/reddish); b∗(bluish/yellowish).

B1: WWF (Whole wheat flour as primary ingredient).

B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients).

B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients).

B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients).

B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients).

B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Kweon et al. (2011) studied wheat flour crackers varying water proportions from 18-38% in the formulations, finding an ideal proportion of 26% to the chosen formulation. However, differences in formulations and methodologies explain those differences in results. The previous study utilized a higher temperature (about 260 °C), shorter heating time (5–6 min), and polished wheat flour as the primary ingredient compared to the present study's conditions. Concerning this ingredient, it is clear that fiber is a great competitor for water (Ronda et al., 2017), so the low content of fibers in polished wheat flours requires less water to get the dough to its ideal point. Secondly, the net gluten capacity in polished wheat flour doughs facilitates their handling and molding and less water requirement to bond the ingredients uniformly. Mostly having non-refined flours, the biscuits demanded higher water quantities to evaporate in more heating process time.

As for thickness results, no significant differences appear among the biscuit's formulations before the baking process; and after the baking, one only difference between B1 and B3 is mainly related to the distinct characteristics of their primary ingredients (WWF and PRF, respectively), which as exposed in Table 2, show the maximum contrast between their protein and fiber contents. Not by chance, the B3 dough was felt softer when rolling in the molds and, therefore, critical to controlling its dough's thickness, probably because of the lowest profile of PRF constituents offering less support and resistance to the dough when pressed.

The results of instrumental color measurements for the biscuits are in Table 3. In general, lightness values (L∗) ranged from 57.07-63.83 reduced about 30% in comparison to this same color results of the flours (Table 2), due to the Maillard reaction, typically present in the high thermal processing of seed flours, darkening the doughs under baking. For that parameter, most of the formulations did not record a significant variation (p < 0.05) excepting B3, which formulation constituted exclusively of PRF as cereal ingredient portion among all the formulations. Its brightest color resulted in the highest recorded L ∗ value differing B3 significantly from B1, B2, and B6 samples. Formulations B4 and B5 did not differ from B3 in that parameter, probably showing that the substitution of 50% of BRF for CPR (cooked polished rice) contributed to keeping higher values of lightness to them. However, the difference of L ∗ values between formulations B3 and B6 could relate to the presence of BRF (a darker ingredient) in biscuit B6 dough, and that can be positive, as health-conscious consumers are likely to relate darker colors in baked goods to the presence of more wholesome and healthy ingredients (Barros et al., 2010a, b).

As for parameter a∗, biscuits B1 and B2 achieved significantly higher results due to the typical deeper pigmentation of wholemeal flours, which were the base of both formulations. Formulations B3, B4, and B6, in turn, achieved significantly lower values than the former, which indicates that the specific pigmentation of pinto beans, in the proportion used in the formulations, did not contribute to a higher saturation of the red color. As for parameter b∗, there was not a significant variation in any of the samples. In general, combining the results of the three analyzed parameters, it might be demonstrated that the formulations' design was able to test the chromatism involved and allow color balancing among different food matrices in biscuits.

Calculations for Δ and ΔE on the three parameters confirm that the differences of instrumental colors among biscuits show that only between samples B3 and B4, ΔE∗ was 0.28, within the tolerance range of the numeric difference color of both. That means that the difference of color among them is instrumentally assured as generally unnoticeable to the consumer (according to the limit 0 < ΔE < 1, the observer cannot see the difference). As for the others, all of them presented ΔE∗ values ranging from 0.85 to 8.2, which means it was possible to notice significant color differences when comparing samples, according to the established limits (Mokrzycki and Tatol, 2011).

3.2.2. Proximate composition results

The formulations’ proximate composition (Table 4) showed that variations among samples ranged from 12.46% and 15.9% (for lipids and digestible carbohydrates) to about 70% for dietary fiber and moisture contents, having ash and protein varying about 33% and 44%, respectively.

Table 4.

Proximate composition of biscuit samples (in g/100g) in dry matter basis, except moisture.

| Samples | Moisture | Ashes∗ | Proteins∗ | Lipids∗ | Total Carbohydrates∗ |

|

|---|---|---|---|---|---|---|

| Digestible carbs∗ | Dietary fiber∗ | |||||

| B1 | 5.41c ±0.14 | 4.83a ±0.50 | 11.52a ±0.49 | 10.37a ±1.09 | 62.86b ± 1.82 | 10.42a ±1.67 |

| B2 | 6.94b ± 0.49 | 3.81b ± 0.16 | 8.27c ±0.39 | 11.32a ±0.26 | 70.30a ±0.82 | 6.30de ± 1.01 |

| B3 | 7.77b ± 0.68 | 3.89b ± 0.19 | 8.86c ±0.37 | 9.83a ±0.98 | 70.54a ±1.76 | 6.88d ± 1.10 |

| B4 | 6.16b ± 6.67 | 4.43ab ± 0.13 | 10.1b ± 0.48 | 9.77a ±0.57 | 67.89a ±1.90 | 7.81c ±1.25 |

| B5 | 7.46b ± 0.89 | 4.56ab ± 0.20 | 7.99c ±0.23 | 10.63a ±1.06 | 70.69a ±0.45 | 6.13e ±0.99 |

| B6 | 9.22a ±0.92 | 5.09a ±0.22 | 10.06b ± 0.36 | 11.61a ±1.10 | 64.62b ± 1.25 | 8.62b ± 1.38 |

B1: WWF (Whole wheat flour as primary ingredient).

B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients).

B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients).

B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients).

B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients).

B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Ashes, proteins, lipids and total carbohydrates are indicated in dry basis. Averages with equal superscripts letters in the same column does not vary significantly (p > 0.05).

The moisture contents of the biscuits reveal that all samples of the rice and beans biscuit contained significant (p < 0.05) higher levels than the control wheat biscuit (B1). Still, B6 had the highest moisture content (9.22 g/100g), differing significantly from all other formulations (p < 0.05), precisely because it is the only formulation constituted majorly by cooked ingredients (in percentages – see Table 1), which naturally increased moisture in this formulation. The substitution of polished rice flour and beans flour by cooked rice and beans grains, in this study, increased dough heterogeneity because their components, such as proteins, starches, and fibers, absorb water in the previous cooking process, contributing to the change in the final dehydration rate during baking. Also, the addition of hydrocolloids has some contribution to increasing the overall moisture in baked goods. Testing the addition of varied types of hydrocolloids in rice flour gluten-free crackers, Nammakuna et al. (2016) found that the more compact structure in those rice crackers combinedly to the higher water-holding ability of hydrocolloids allowed the higher moisture content to the end products.

In the same sense, other studies showed similar increases in the moisture content of cookies with the increase in fiber content, whether by adding navy bean flour (DeFouw et al., 1982) or from other sources (Artz et al., 1990; Chung et al., 2014; Larrea et al., 2005). For all of that, it seems that the simple reduction of water percentages in the formulation to compensate water imbalances among ingredients and their responses through the process could even be higher if allowing still proper handling of the dough. However, future research can fix those issues by studying the best relation between baking time and water quantity to pre-cooked ingredients in crackers formulations to improve the biscuit's characteristics, allowing good dough handling, without adding nutritional losses.

For ash contents, most of the formulations did not differ from the control formulation (B1). The result of sample B3 shows that adding mostly cooked beans to that formulation helped to keep mineral value close to the other samples' results, as its ash content in its primary ingredient (PRF) is low (Table 3). All the biscuit's results reached about three times or more for some formulations than the ash content in the extruded snack of rice and beans, of 1.35 g/100g (OLIVEIRA et al., 2017).

The protein contents in the biscuit's samples (7.99 and 11.52 g/100g) ranged lower than those described by Oliveira et al. (2017) when studying rice and beans extruded snack made of a blend of flours at a 3:1 ratio. They verified an average of 12.07% of the protein content in the obtained product. Since the protein contents of the PRF of both studies were close, that difference is due to the high protein content (24.67 g/100g) of the beans flour used in the extruded formulations. However, while the biscuit's ash and fat contents were very different, reflecting the formulations, the biscuit's formulation B6 result for dietary fiber was very similar to the extruded snacks (8.82 g/100g).

Constituted mostly of WWF, the biscuit B1 (control) presented the significantly (p < 0.05) highest protein and dietary fiber contents, followed by B4 and B6. Protein results of these rice and beans formulations are higher than many commercial cereal biscuits in the market, generally ranging from four to seven percent of protein contents (Rai et al., 2014); and can be set comparable to other results for cookies made of nut flours developed for celiac public, reporting 10% and 11.87% of protein content (Granato and Ellendersen, 2009). However, in Brazil, the market price of nuts is much higher than rice and beans. Han et al. (2010) also reported 10.68% of protein content in snack crackers developed with pulse flour fractions. As for the other formulations, B2 and B5 were not helped by the low protein profile of WWF in their formulation, as much as B3, with PRF's low protein content.

The rice and beans biscuit's lipid content ranged from 9.83-11.61%, which is relatively lower than those reported from commercial crackers, usually around 15%. Although the sample B2 reflected the higher lipid fraction result of BRF, which is the primary ingredient of that formulation, the standard percentage of extra-virgin olive oil in all the formulations attenuate the differences among them, so they became statistically not significant (p > 0.05).

As for the formulations' dietary fiber results, they were higher than those observed by researchers who worked with gluten-free snack crackers. Han et al. (2010) found 5.33 g/100g of dietary fiber in a snack cracker made from chickpea flour. The formulations B3, B4 and B6 were affected by the high fiber contents of CB. Dietary fibers in common carioca beans range from 8.5 (TACO, 2011) to 33.39 g/100g (Londero et al., 2008). The nutritional importance of fiber is increasingly well known, not only because it increases bowel movements but also maintains a healthy colon (Fillisetti and Lobo, 2005) also because it has a vital role in the glycemic load of foods in which it participates. Fiber intakes in sufficient quantities have a favorable impact on metabolizing glucose and insulin (Mello and Laaksonen, 2009), reducing postprandial blood sugar levels and related diseases in various ways (F. S. Carvalho et al., 2012; Hoyos-Leyva et al., 2016). To be considered a fiber-source food, the Brazilian legislation establishes a minimum of 2.5 g/portion of 30 g ration in each food portion (BRASIL, 2012), which means 8.33 g/100g. Among the biscuits of rice and beans, that requirement was reached by the B6 formulation, presenting 8.62 g/100g of dietary fiber results. Little adjustments in the B4 formulation can help it to achieve that. Also, substituting the fiber low profile WBF used in the study for another fiber high profile WBF might get formulations reaching the conditions for that nutritional claim. The high B6 fiber results are essential for consumers in general, particularly for celiac consumers, because gluten-free products usually have low fiber content, and their ingestion may lead to obesity and other associated health risks (Hager et al., 2011). All those results above showed a highly desirable nutritional profile for a favorite food, still remarkable that they are readily available at a low cost in a very accessible way throughout the country.

3.2.3. Texture and shelf-life results

Comparing the hardness performance among the biscuit formulations, as shown in Table 5, in general, most of the formulations presented no significant difference (p < 0.05) from the control, even when observing those comparisons in the succeeded weeks (please, see little letters within each column). However, B3 was the only formulation presenting a constant significantly different value (p < 0.05) in comparison to each control sample (B1) along the weeks. That effect is related to the softer dough of formulation B3 and its lighter weight among the samples, and as a consequence, lower instrumental texture values compared to the control biscuit. Results also indicate that gluten formation in the dough of the control formulation (B1) did not seem to increase hardness in B1 compared to results from other gluten-free formulations, except for B2 (partially), and B3 in full extension.

Table 5.

Results of instrumental texture analysis of the biscuits.

| Samples/Time | 3 h | 7 days | 14 days | 30 days | 60 days |

|---|---|---|---|---|---|

| Hardness (N) | |||||

| B1 | 26.26 (A) (a) ±8.36 | 26.38 (A) (a) ±4.64 | 27.19 (A) (a) ±4.86 | 27.81 (A) (a) ±8.55 | 26.77 (A) (a) ±5.46 |

| B2 | 20.19 (A) (ab) ±3.82 | 21.14 (A) (ab) ±4.52 | 20.17 (A) (b) ±3.74 | 18.44 (A) (b) ±6.06 | 20.89 (A) (ab) ±6.20 |

| B3 | 15.46 (A) (b) ±6.68 | 15.55 (A) (b) ±4.68 | 17.58 (A) (b) ±6.13 | 16.66 (A) (b) ±4.04 | 18.23 (A) (b) ±4.24 |

| B4 | 21.96 (A) (ab) ±6.67 | 20.02 (A) (ab) ±5.60 | 20.92 (A) (ab) ±5.84 | 22.84 (A) (ab) ±8.13 | 21.14 (A) (ab) ±1.08 |

| B5 | 21.83 (A) (ab) ±5.45 | 22.12 (A) (ab) ±4.53 | 22.30 (A) (ab) ±5.00 | 24.36 (A) (ab) ±6.12 | 25.31 (A) (a) ±4.86 |

| B6 |

19.74 (A) (ab) ±5.99 |

20.17 (A) (a) ±3.74 |

18.44 (A) (ab) ±6.06 |

25.36 (A) (ab) ±6.67 |

23.93 (A) (ab) ±4.78 |

| Distance (mm) | |||||

| B1 | 1.09 (A) (ab) ±0.45 | 1.77 (A) (a) ±0.72 | 0.71 (A) (a) ±0.23 | 0.75 (A) (b) ±0.40 | 0.97 (A) (a) ±0.52 |

| B2 | 1.82 (A) (a) ±0.93 | 1.08 (AB) (a) ±0.88 | 0.53 (B) (b) ±0.27 | 0.62 (B) (b) ±0.35 | 0.99 (B) (a) ±0.65 |

| B3 | 0.93 (AB) (ab) ±0.58 | 0.62 (B) (a) ±0.26 | 0.95 (AB) (a) ±0.40 | 1.04 (AB) (ab) ±0.52 | 1.33 (A) (a) ±0.63 |

| B4 | 0.83 (AB) (b) ±0.37 | 1.05 (B) (a) ±0.97 | 0.52 (B) (b) ±0.23 | 0.47 (B) (b) ±0.12 | 1.61 (A) (a) ±0.08 |

| B5 | 0.85 (AB) (b) ±0.64 | 0.65 (B) (a) ±0.13 | 0.67 (B) (ab) ±0.30 | 1.53 (A) (a) ±0.88 | 1.13 (AB) (a) ±0.93 |

| B6 | 1.21 (A) (ab) ±1.02 | 0.66 (A) (a) ±0.51 | 0.52 (A) (b) ±0.10 | 0.85 (A) (ab) ±0.58 | 1.27 (A) (a) ±0.77 |

Average ±standard deviation. Averages with equal uppercase letters in the same raw or equal lowercase in the same column do not vary significantly (p > 0.05). Comparisons in the same raw are about the same sample/different times. Comparisons in the same column are about different samples/same time.

B1: WWF (Whole wheat flour as primary ingredient).

B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients).

B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients).

B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients).

B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients).

B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Along with the weekly measurements, minimal differences were present, meaning that according to the instrumental texture analysis, each formulation's first hardness pattern remained stable enough in the samples at least for 60 days if properly conditioned. Those results also show that the strategy of adjusting the time for formulations with higher contents of pre-cooked ingredients proved to help those formulations getting a more similar condition of hardness comparisons among all formulations by ensuring the complete baking and consequent stability of the dough during storage.

Adding pre-cooked ingredients to the formulation brought a more significant challenge to manage dough consistency and moisture, especially for molding gluten-free doughs. Those ingredients let the dough with a more heterogenic aspect and a slight difficulty to bind ingredients because cooked grains were not milled to flour as dried ones, but chopped by the food processor into little parts remaining in the dough. The choice to have these kinds of ingredients participating in the study is justified for this study's social proposal, focused not only on industrial-scale production but also on the adequacy of homemade conditions. That can be useful in several ways, whether applying to the unique needs of specific publics whose special diets require preparing its product, whether for the typical home public giving a new food feature to leftovers, or providing the highest availability to the rice food main ingredients. In this sense, pre-cooked ingredients contributed to enlarging this study's applicability, without compromising the results.

Verifying shelf-life behavior to each formulation in Table 5 showed that the presented variations were not statistically significant (p > 0.05) for hardness parameters in any of the baked samples (comparisons of capital letters in the same row), according to the Tukey's test. That probably meant that packaging was adequate to preserve the samples' texture and that the proposed eight weeks could be insufficient to reveal significant degradations of the food regarding this specific instrumental measurement.

When looking at the instrumental measurements of distance parameter, comparisons among the formulations simultaneously show that they did not differ from the control in terms of fracturability behavior in the first two measurements. The differences from control begin after the first week, and it is related to the stabilization of the food moisture, which requires seven days. After that, some slight degradation allowing new bonds could affect formulations differently. After two months, those differences were gone back again. As for the treatment and time comparisons within the same formulation, except for B2, all formulations kept no significant differences from the first measurement (3h), meaning that the biscuits continued to present fracturability at the same levels at least for two months. For B2, this effect does not last for two weeks.

The texture is an essential and desirable attribute for biscuits, and it profoundly affects their acceptability (de Assis et al., 2009; Labuschagne et al., 1997); therefore, shelf-life assessment is beneficial to observe how time may affect the quality of the product regarding sensory, technological or microbiological aspects. Instrumental texture measurements act as a useful tool for studying how food preservation affects hardness profiles under different temporal treatments for the same sample. It contributes to rendering a specific analytical parameter result, facilitating comparisons; however, it is clear that its measurements have limits as an auxiliary tool to emulate the sample food's distinct behavior in the mouth. The human ability to perceive and evaluate texture in a sensory context is away sophisticated concerning the multi-interactions present in the samples' characteristics and the crossmodal capacity of senses in the human mind (Bolini et al., 2016). So, future studies could follow a complete shelf-life sensory evaluation of the biscuit of rice and beans to determine for industrial purposes more associated textural nuances along time on the studied attribute, still adding other textural parameters like crunchiness and freshness, among other attributes, as well as microbiological assessment along time.

3.2.4. RVA results of biscuits

The pasting properties of the biscuits are in Table 6, and though much lower, they reflect somehow the results of cereal flours (WWF, BRF, and PRF), since these are the flours used in higher proportions in the formulations. However, the biscuit results are of much lower value because their analysis occurred after processing and baking when several starch reactions have already taken place, especially gelatinization. So, peak viscosity is in significant contrast between B1 and B3 (p < 0.05) because their different major constituents, respectively WWF and PRF, respond accordingly to their characteristics within the formulations, although much more attenuated by the interactions and process they suffer.

Table 6.

Pasting properties of the different formulations of the biscuits.

| Peak Viscosity (RVU) | Through (RVU) | Breakdown (RVU) | Setback (RVU) | Final Viscosity (RVU) | |

|---|---|---|---|---|---|

| B1 | 129.75d ± 7.4 | 119.75d ± 7.8 | 9.00b ± 0 | 199.75b ± 12.5 | 319.50c ±20.2 |

| B2 | 252.25b ± 30.5 | 211.75c ±28.8 | 40.50a ±5.3 | 222.50ab ± 46.2 | 434.25b ± 72.6 |

| B3 | 340.50a ±13.7 | 328.25a ±11.1 | 12.25b ± 2.7 | 271.00a ±20.8 | 599.25a ±12.8 |

| B4 | 213.75c ±5.0 | 206.25c ±14.9 | 7.50b ± 4.1 | 238.75ab ± 12.7 | 445.00b ± 27.2 |

| B5 | 262.25b ± 10.3 | 251.75b ± 7.0 | 10.50b ± 2.1 | 213.00b ± 6.8 | 476.25b ± 13.7 |

| B6 | 260.50b ± 0.1 | 249.25b ± 8.3 | 11.25b ± 2.5 | 216.54b ± 6.4 | 462.25b ± 14.6 |

Average ± Standard deviation with equal superscripts letters in the same column do not vary significantly (p > 0.05). RVU = Rapid Visco Unit, from Rapid Visco Analyser. 1 RVU = 12 cP (centipoise).

B1: WWF (Whole wheat flour as primary ingredient).

B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients).

B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients).

B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients).

B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients).

B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Comparing Figures 1 and 2 is elementary to understand differences between flours' responses (natural products) and biscuits responses (processed products), revealing a very different behavior pattern under the same treatments of increased, stabilized, and decreased temperature, while shaken mechanically. The evenly lower and flatter curves of the formulations show that the starch was completely gelatinized during the processing and remained relatively stable, without a significant viscosity breakdown or trend to retrogradation (setback) under high temperature and stirring. As revealed by the Tukey's test (Table 6), there are little differences among the formulations, and they reflect the behavior of the predominant flours in formulations. The only highlight goes to the difference in results when comparing B1 (with the lowest values for peak viscosity, through, and final viscosity) and B3 (with the highest values for the same parameters), more related to the differences of dietary fiber contents in these formulations, precisely whole wheat flour (WWF) in B1 and polished rice flour (PRF) in B3 (Table 3). Even with the addition of fibers from cooked beans into formulation B3, results of B1 were still 53% and 30% higher for fibers and proteins, respectively. Researches have shown that lower peak viscosity values are related to higher fiber (Chen et al., 2011) and protein contents (Lifeng et al., 2020, Ocheme et al., 2018), as here more likely found in B1's profile. So, these flours' paste result depends much more on how starch behaves in the interactions with other ingredients and processing outcomes.

Although there is still insufficient understanding of the interactions between the components of rice flour (as starches-proteins or starches-lipids) concerning the thermal and rheological properties applied in rice foods production (Qian and Zghang, 2013), the RVA analysis was necessary for this study to identify how the gluten-free rice and bean biscuit responses are related to the wheat biscuit. For almost all parameters, B4 was the formulation with the closest behavior to the control. Also, because B5 and B6 did not differ (p > 0.05) in any of the parameters, it is shown that simple replacement of bean flour for a more affordable ingredient, such as cooked beans (Table 1), did not affect significantly starch interaction dynamics, as the primary difference between these formulations is precisely alternation of these ingredients.

3.3. Sensory results

3.3.1. Acceptance test results

The results of the consumers' sensory evaluation in the acceptance test follow in Table 7. The Acceptance tests remain one of the most used assessments of the end product by the food industry to test new ingredients and formulations, as they reflect the degrees of preference of consumers regarding the product (Cavalheiro et al., 2001). That table shows that only in the Appearance attribute, none of the samples distinguished from the control formulation (B1) (p > 0.05). For the Aroma results, B4, B5, and B6 were better assessed, while B2 had the lowest result. This result appears refined in the Flavor assessment, showing B4 standing out alone with the highest average among all, while B5 and B6 fell to the intermediate level, where is the control biscuit. B2 remained at the lowest level, now close to being rejected by consumers. B2 was downgraded more likely because of its primary ingredients: raw bean flour, adding a more robust astringent flavor and tannin characteristics to the biscuit, and brown rice flour, with the highest lipid content.

Table 7.

Average scores of attributes assessed by sample in the acceptance test.

| Samples | Attributes |

||||

|---|---|---|---|---|---|

| Appearance | Aroma | Flavor | Texture | Overall Impression | |

| B1 | 6.67ab ± 1.84 | 5.97b ± 1.90 | 5.68b ± 1.92 | 5.86ab ± 2.14 | 5.91b ± 1.91 |

| B2 | 6.17b ± 2.06 | 5.36c ±2.02 | 4.82c ±2.45 | 4.92c ±2.17 | 5.12c ±2.13 |

| B3 | 6.63ab ± 1.59 | 5.96b ± 2.00 | 6.04b ± 2.39 | 5.91ab ± 2.19 | 6.07b ± 2.21 |

| B4 | 6.95a ±1.71 | 6.83a ±1.83 | 6.78a ±2.02 | 6.07a ±2.23 | 6.69a ±1.84 |

| B5 | 6.83a ±1.93 | 6.41ab ± 1.96 | 5.93b ± 2.29 | 5.27 bc ±2.31 | 6.07b ± 1.98 |

| B6 |

6.54ab ± 2.11 |

6.25b ± 1.81 |

6.24b ± 2.07 |

5.98a ±2.05 |

6.30ab ± 1.83 |

| MDS | 0.52 | 0.54 | 0.67 | 0.64 | 0.56 |

Averages with equal superscripts in the same column do not vary significantly (p > 0.05). MDS: Minimum significant difference, from Tukey's test at 5% (p < 0. 05).

B1: WWF (Whole wheat flour as primary ingredient).

B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients).

B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients).

B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients).

B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients).

B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Many compounds present in legumes can contribute to a characteristic off-flavor in that food; among the more dominants are those resulting from fatty acids oxidation, saponins, tannins, and other phenolic compounds. However, there is no focused study identifying which elements in beans affect sensory perception (Wibke et al., 2017). Buttery et al. (1976) reported that Geosmin, an oxygenated hydrocarbon was responsible for the "earth" flavor among other undesirable off-flavors in white navy beans. Lipoxygenase is also responsible for undesirable bitter flavor in cereal and legume food products. Lipoxygenase converts lipids to lipohydroperoxides, and their subsequent degradation form volatile and nonvolatile constituents responsible for off-flavors. Practically all of the Leguminosae present lipid-oxidizing activity (Sessa, 1978). According to Rackis et al. (1979), the production of off-flavors (as "beany-earthy-grassy") is a particular problem with raw legumes and can be associated with enzymatic and non-enzymatic reactions (i.e., light, heat). However, some minor changes in physical parameters such as temperature, pressure, and pH may be enough to eliminate those off-flavors. So, having their bean portion previously processed, formulations B3, B4, and B6 were not affected by the enzymatic lipid-oxidative reactions to the point of reducing their flavor acceptance. The fact that B5 had not its flavor average downgraded like B2's may mean that the substitution of BRF for CPR may have contributed to dilute the charge of those undesirable attributes in that samples' formulation.

As for the texture preference, although B4 remained in the highest place, it did not differ significantly from B3, B6, and the control (p > 0.05), while B2 especially did not seem to please the consumer. As for the Overall Impression (OI) averages, its averages generally reflect the profile of the Flavor's, and this effect happened here as well, leading Flavor's impression to become the most influential attribute in the OI final results.

In general, formulation B4 was the most accepted and was the only one always to obtain the best averages, which were significantly higher than the control biscuit's average in the Flavor, Aroma, and OI attributes. Moreover, among the formulations compounded of a mix of primary ingredients (B3, B4, and B6), B4 is the most practical formulation, since it does not need a pre-cooking process preparation. On the other hand, B2 was always the most rejected, always differing negatively from the others in all attributes, except Appearance. Among all formulations, B6 was the one that resembled most the profile of the biscuit B4, without differences concerning Appearance, texture, and overall impression (p > 0.05). Still, for recycling rice and beans surplus to avoid food waste, the B6 formulation can be convenient and beneficial in changing them into a new desirable food product.

Finally, because the formulations B4 and B6 differed basically in half of the sources of primary ingredients, it was demonstrated that the substitution of PRF for CPR interfered only in aroma and flavor acceptance, which could be better adjusted in a future study also focused on seasonings. Conversely, comparisons between B5 and B6, which differed precisely about the beans process (milling to flour or cooking), showed B5 having less acceptance in Flavor and Texture attributes than B6. Though studying the dough's rheological characteristics was not a concern of this study, there were perceived some differences among their doughs in the moment of molding the biscuit. So, because B5 had combined CPR and WBF, which have characteristics of less protein and fiber content than CB (in B6), and significantly more carbohydrates than expected for this kind of flour, this combination contributed to a higher water absorbance in the starch granules, as the RVA results for WBF indicate (Table 6). The higher capacity of starch gelatinization of WBF in the context of the B5 formulation may have contributed to more gumminess in the dough by slightly overpassing the optimal limit to which xanthan gum already worked in the formulation. A slightly stickier dough presumably affected the consumer's preference for the texture attribute. That can be readjusted studying reductions in water, gum, or exchanging this kind of WBF for another with higher protein and fiber contents.

The exclusive use of PRF in B3 did not contribute to outperform any sensory or nutritional result of other formulations, but rather to diminish protein, ash, and fiber results in the formulations. Brown rice flour remained the vector of most formulations, acting as the biscuit's central blender element, adding nutritional advantages and ensuring more even and less disparate results.

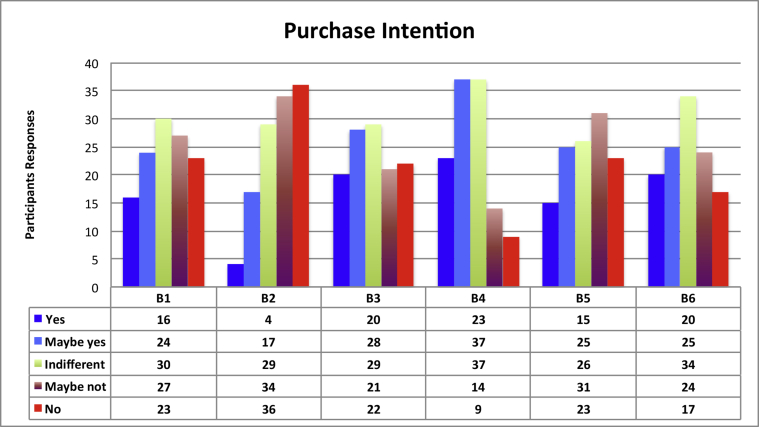

3.3.2. Purchase intention results

Answers of the 120 participants to the acceptance test on the biscuits' purchase intent from the six formulations are in the histogram of Figure 3. Combining answers from the positive range (categories "yes" and "maybe yes"), the samples B3, B4, and B6 received higher scores in the positive than in the negative range, reflecting scores profiles proportionally to the acceptance test results. The formulations B4 and B2 represented best the opposite fields. While the B4 sample attracted 50% of its consumers' positive responses, and the lowest frequency (21%) in the negative range, the sample B2 attracted only 17,5% into the positive range of buying intentions and the greatest (58,3%) frequency in the rejection field. Compared to mid-level results of the control biscuit (B1), the sample B5 registered the closest results.

Figure 3.

Purchase intention of each biscuit, per sample (N = 120 participants). BRF: Brown Rice Flour/PRF: polished rice flour/WBF: white navy beans flour/WWF: Whole Wheat Flour. B1: WWF (Whole wheat flour as primary ingredient). B2: WBF + BRF (White beans flour + Brown rice flour as primary ingredients). B3: CB + PRF (Cooked beans + Polished rice flour as primary ingredients). B4: CB + BRF + PRF (Cooked beans + Brown rice flour + Polished rice flour, as primary ingredients). B5: WBF + BRF + CPR (White beans flour + Brown rice flour + Cooked polished rice, as primary ingredients). B6: CB + BRF + CPR (Cooked beans + Brown rice flour + Cooked polished rice, as primary ingredients).

Finally, since there are no biscuits combining rice and beans in a single product in the Brazilian market, there was expectation around a genuinely new and innovative product. Thus, comparing the results of all the analyses, it was observed that 2 out of 5 rice and beans formulations (B2 and B5) had generally lower performance among all comparisons, mainly related to the specific characteristic of the WBF used in this study. However, other two of the studied formulations (B4 and B6) had gathered together successful physical and chemical performances resembling those of the control's, even by outstanding in several aspects the sensory results of the control formulation to the consumers' opinions (especially B4), which means these formulations may be used and further adjusted for industrial and commercial production.

4. Conclusion

Among the formulations of rice and bean biscuits we studied, the replacement of bean flour by cooked bean produced higher acceptance scores. Formulation B4, with cooked beans and a blend of brown rice and polished rice flours, was the formulation that obtained a moisture content and viscoamilographic behavior profile closer to the control (containing wheat flour), the highest acceptance scores in all attributes, and the highest purchase intent by consumers. We observed that flavor was the most certain attribute for the results. Among the rice and beans formulations, B6 had the closest performance to B4 and carries still a social and nutritional appeal, being its formulation constituted primarily of cooked rice and beans resembling the typical daily dish at Brazilian's homes. It can be a food source of fibers for its high contents of this essential compound. In general, the rice and beans biscuits characterized in this study proved to be an innovative gluten-free food product, as they can be even homemade with inexpensive and abundant raw material, with an essential nutritional profile, easily portable and long-lasting, potentially well accepted among all people, and mainly available and recommended to celiac consumers.

Declarations

Author contribution statement

David Wesley Silva: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Helena M. A. Bolini, Maria T. S. Clerici: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Funding statement

This work was support by the Brazilian government program Coordination for the Improvement of Higher Education Personnel (CAPES).

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- AACC (AMERICAN ASSOCIATION OF CEREAL CHEMISTS) Approved methods. 11th. St. Paul; 2010. [Google Scholar]

- ABIMAPI . 2017. Associação Brasileira das Indústrias de Biscoitos, Massas Alimentícias e Pães & Bolos Industrializados. Relatório Estatísticas/Biscoito.http://www.abimapi.com.br/estatistica-biscoito.php Avaiable in: Acessed in May 25, 2018. [Google Scholar]

- Abou-Zaid A.A.M., Ramadan M.T., Al-Asklany S.A. Utilization of faba bean and cowpea flours in gluten free cake production. Australian Journal of Basic and Applied Sciences. 2011;5:2665–2672. [Google Scholar]

- Alencar N.M.M., Steel C.J., Alvim I.D., Morais E.C., Bolini H.M.A. Addition of quinoa and amaranth flour in gluten-free breads: temporal profile and instrumental analysis. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2015;62(2):1011–1018. [Google Scholar]

- Alencar N.M.M., Steel C.J., Alvim I.D., Morais E.C., Bolini H.M.A. Sensory characterisation of gluten-free bread with addition of quinoa, amaranth flour and sweeteners as an alternative for coeliac patients. International Journal of Foof Science and Technology. 2017;52(4):872–879. [Google Scholar]

- Araki E., Ashida K., Aoki N., Takahashi M., Hamada S. Characteristics of rice flour suitable for the production of rice flour bread containing gluten and methods of reducing the cost of producing rice flour. Jpn. Agric. Res. Q. 2016;50(1):23–31. [Google Scholar]

- Artz W.E., Warren C.C., Mohring A.E., Villota R. Incorporation of corn fiber into sugar snap cookies. Cereal Chem. 1990;67:303–305. [Google Scholar]

- Asmeda R., Noorlaila A., Norziah M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 2016;191:45–51. doi: 10.1016/j.foodchem.2015.05.095. [DOI] [PubMed] [Google Scholar]

- Association of Official Analytical Chemists . seventeenth ed. AOAC International; Gaithersburg: 2000. Official Methods of Analysis of AOAC International. [Google Scholar]

- Barros F., Alviola J.N., Rooney L.W. Comparison of quality of refined and whole wheat tortillas. J. Cereal. Sci. 2010;51:50–56. [Google Scholar]

- Barros R.M., Garcia P.P.C., Almeida S.G. Análise e elaboração dos fatores de correção e cocção de alimentos. Anuário da produção de iniciação científica discente. 2010;13(16):103–113. [Google Scholar]

- Bassinello P.Z., Freitas D., Ascheri J.L., Takeiti C., Carvalho R.N., Koakuzu S.N., Carvalho A.V. Characterization of cookies formulated with rice and black bean extruded flours. Procedia Food Science. 2011;1:1645–1652. [Google Scholar]

- BBC BRASIL . 2015. Dieta Sem Glúten: Necessidade Médica Ou Moda Injustificada? Published in July 27, 2015.http://www.bbc.com/portuguese/noticias/2015/07/150727_gluten_moda_doenca_mdb Available from: Acessed in Oct 09, 2017. [Google Scholar]

- Biesiekierski J.R. What is gluten? J. Gastroenterol. Hepatol. 2017;(1):78–81. doi: 10.1111/jgh.13703. [DOI] [PubMed] [Google Scholar]

- Bligh E.G., Dyer W.J.A. A rapid method of total lipid extration and purification. Can. J. Biochem. Physiol. 1959;37:911–917. doi: 10.1139/o59-099. [DOI] [PubMed] [Google Scholar]

- Bolini H.M.A., Moskowitz H., Porreta S. Vol. 16. 2016. Breve storia dela ricerca sul consumatore dei prodotti alimentari; pp. 371–403. (L’evoluzione Dell’industria Alimentare. Pinerolo, Italy: Chiriotti Editori). [Google Scholar]

- Brand-Miller J., Hayne S., Petocz P., Colagiuri S. Low-glycemic index diets in the management of diabetes: a meta-analysis of randomized controlled trials. Diabetes Care. 2003;26:2261–2267. doi: 10.2337/diacare.26.8.2261. [DOI] [PubMed] [Google Scholar]

- BRASIL . 2012. ANVISA - Agência Nacional de Vigilância Sanitária, Ministerio da Saúde. RDC. Nº 54 de 12 de novembro de 2012. Dispõe sobre o regulamento técnico sobre informação nutricional complementar. Diário oficial da Republica Federativa do Brasil, Brasilia DF. [Google Scholar]

- Brites L.T.G.F. Gluten-free cookies elaborated with buckwheat flour, millet flour and chia seeds. Food Sci. Technol. 2019;39(2):458–466. [Google Scholar]

- Buttery R.G., Guadagni D.G., Ling L.C. Geosmin, a musty off-flavor of dry beans. J. Agric. Food Chem. 1976;24:419–420. [Google Scholar]

- Carbonell S.A.M., Carvalho C.R.L., Filho Azevedo, A J., De Sartori J.A. Bragantia; Campinas: 2003. Qualidade tecnológica de grãos de genótipos de feijoeiro cultivados em diferentes ambientes; pp. 369–379. 62(3) [Google Scholar]

- Carvalho A.V., Rios A.O., Bassinello P.Z., Ferreira T.F. Effect of the thermoplastic extrusion parameters on the technological properties of pre-cooked ours prepared with rice and beans. Braz. J. Food Technol. 2012;15(4):333–342. [Google Scholar]

- Carvalho F.S., Netto A.P., Zach P., Sachs A., Zanella M.T. Importancia da orientação nutricional e do teor de fibras da dieta no controle glicemico de pacientes diabéticos tipo 2 sob intervenção educacional intensiva. Arq. Bras. Endocrinol. Metabol. 2012;56(2):110–119. doi: 10.1590/s0004-27302012000200004. [DOI] [PubMed] [Google Scholar]

- Cascudo L.C. Editora Global; São Paulo: 2004. História da Alimentação no Brasil. 2004. [Google Scholar]

- Cavalheiro E.D.R. 1945. Memórias de forasteiros. Aquém e Além-mar, Portugal, África e Índia, séculos XII-XVI. Livraria Clássica Editora: Lisboa, s. D., 1945. [Google Scholar]

- Chen M.J. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 2011;53(2):217–224. [Google Scholar]

- Chung H.-J., Cho A., Lim S.-T. Utilization of germinated and heat-moisture treated brown rices in sugar-snap cookies, in. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2014;57(1):260–266. [Google Scholar]

- Coelho C.M.M., Souza C.A., Danelli A.L.D., Pereira T., Santos J.C.P., Piazzoli D. Capacidade de cocção de grãos de feijão em função do genótipo e da temperatura da água de hidratação. Ciência e Agrotecnologia. Lavras. 2008;32(4):1080–1086. [Google Scholar]

- Colasuonno P., Marcotuli I., Lozito M.L., Simeone R., Blanco A., Gadaleta A. Characterization of aldehyde oxidase (AO) genes involved in the accumulation of carotenoid pigments in wheat grain. Front. Plant Sci. 2017;8:863. doi: 10.3389/fpls.2017.00863. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dalla-Corte A., Moda-Cirino V., Scholz M.B.D.S., Destro D. Environment effect on grain quality in early common bean cultivars and lines. Crop Breeding and Applied Biotechnology. 2003;3(3):193–202. [Google Scholar]

- Davis W. Rodale Books; New York, NY: 2011. Wheat Belly: Lose the Wheat, Lose the Weight, and Find Your Path Back to Health; p. 228. [Google Scholar]

- Day L. Proteins from land plants - potential resources for human nutrition and food security. Trends Food Sci. Technol. 2013;32:25–42. [Google Scholar]

- De La Barca A.M.C., Martínez M.E.R., Islas-Rubio A.R., Cabrera-Chavez F. Gluten-Free Breads and Cookies of Raw and Popped Amaranth Flours with Attractive Technological and Nutritional Qualities. Plant Foods Hum. Nutr. 2010;65:241–246. doi: 10.1007/s11130-010-0187-z. [DOI] [PubMed] [Google Scholar]

- DeFouw C., Zabik M.E., Uebersax M.A., Aguilera J.M., Lusas E. Effects of heat treatment and level of navy bean hulls in sugar-snap cookies. Cereal Chem. 1982;59:245–248. [Google Scholar]